System and method for improving efficiency of combined cycle electric power plant

A technology of combined cycle and high efficiency, which is applied in the direction of charging system, combined combustion mitigation, turbine/propellant fuel delivery system, etc., and can solve the problems of heat waste, large exhaust gas flow of waste heat boiler, and exhaust waste heat that is not recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

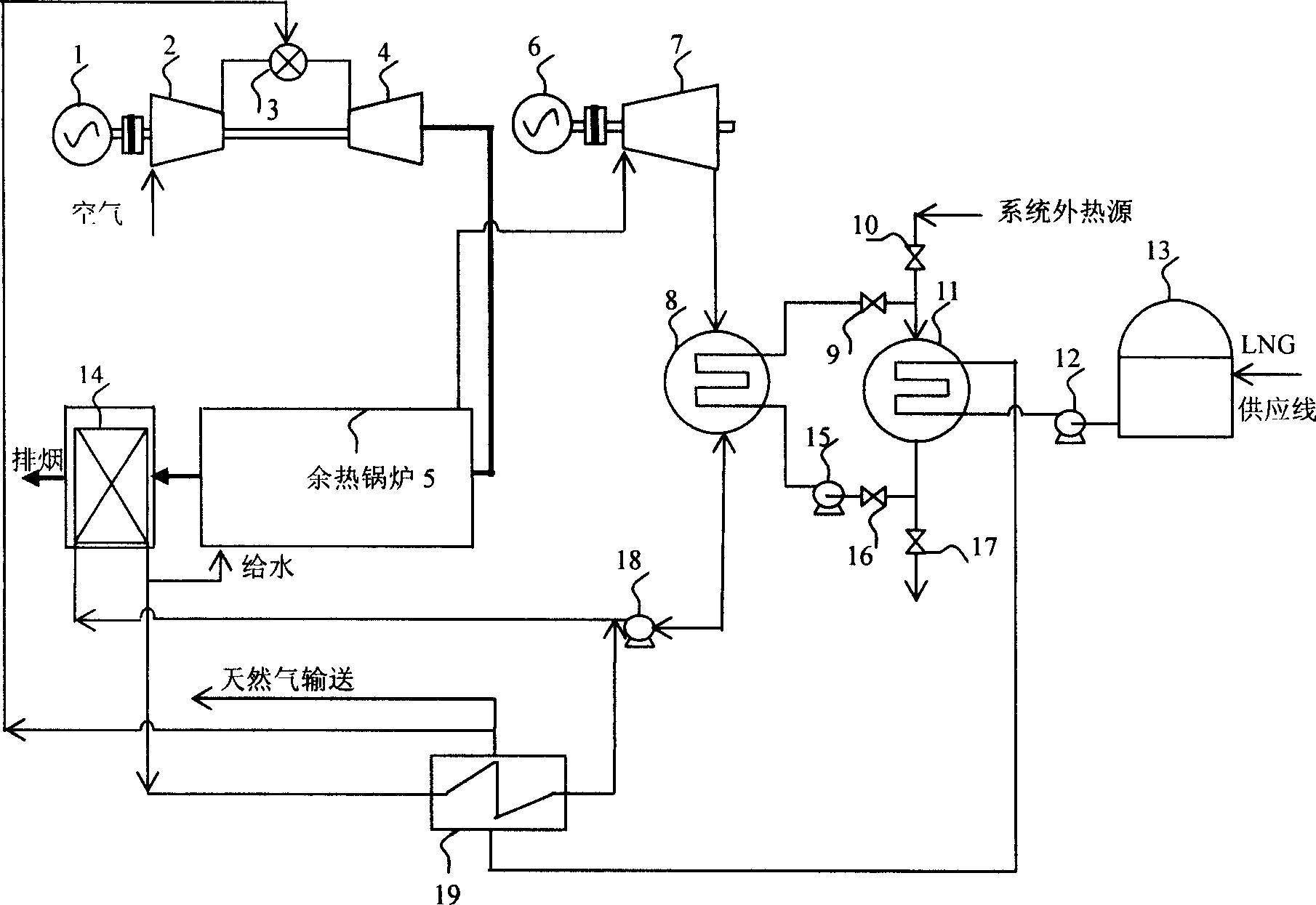

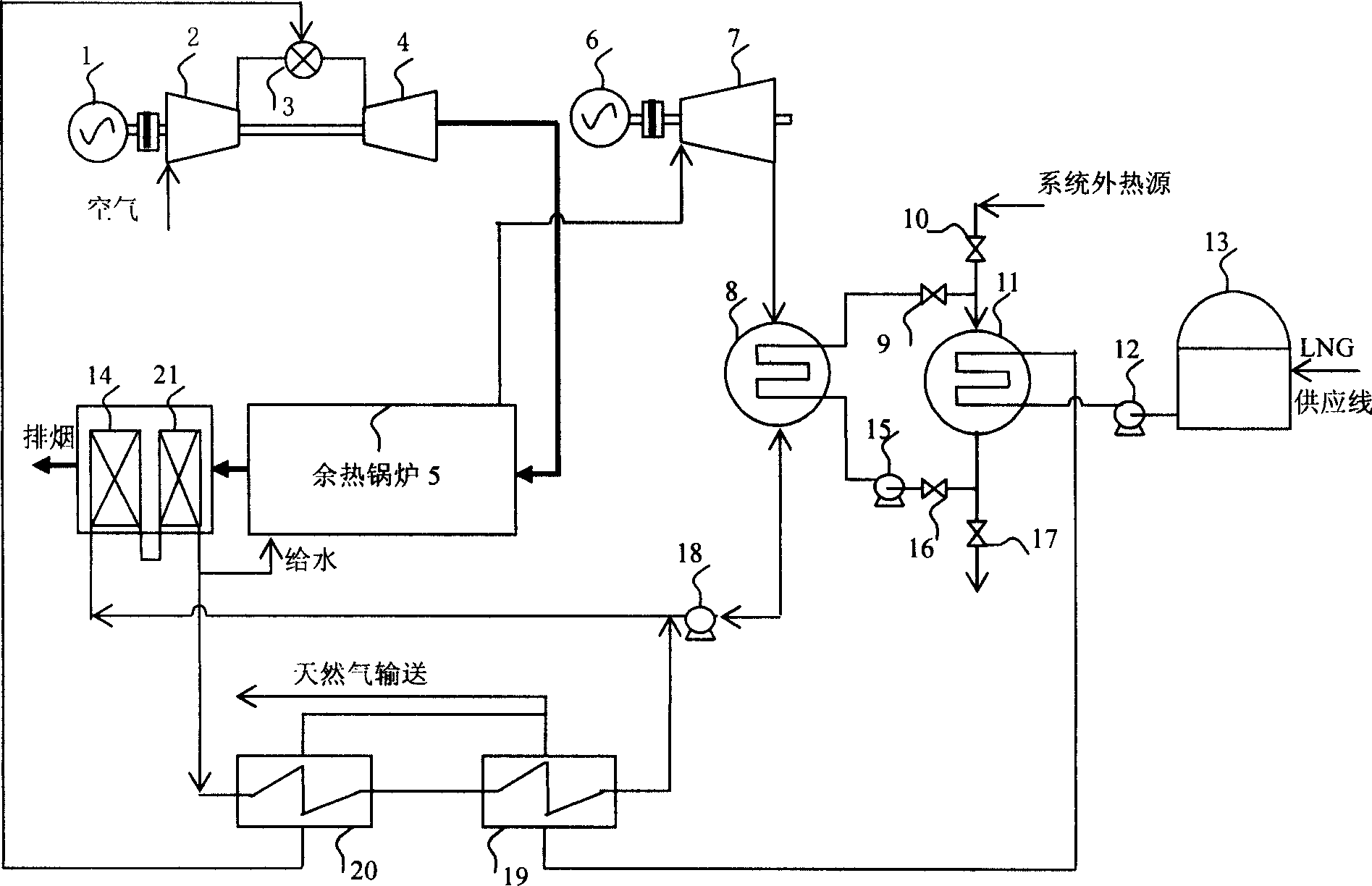

[0026] Such as figure 1 As shown, its system mainly includes:

[0027] LNG supply line, storage tank 13, booster pump 12, gasifier 11, preheater 19, condensate pump 18, condenser 8, steam turbine 7, second generator 6, waste heat boiler 5, gas turbine 4, Combustion chamber 3, compressor 2, first generator 1, condensing heat exchanger 14, heat exchange fluid pump 15;

[0028] Wherein the first generator 1, the compressor 2, the combustion chamber 3 and the gas turbine 4 and the second generator 6, the waste heat boiler 5, the condenser 8 and the steam turbine 7 constitute the power output;

[0029] A booster pump 12 is connected downstream of the storage tank 13 connected to the liquefied natural gas supply line, and the booster pump 12 communicates with the vaporizer 11 that is in a heat exchange relationship with the condenser 8, and the heat exchange fluid flows between the vaporizer 11 and the condensing steam There is a heat exchange fluid pump 15 between the tanks 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com