Patents

Literature

744 results about "Condensate pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A condensate pump is a specific type of pump used to pump the condensate (water) produced in an HVAC (heating or cooling), refrigeration, condensing boiler furnace, or steam system.

Condensate Pump

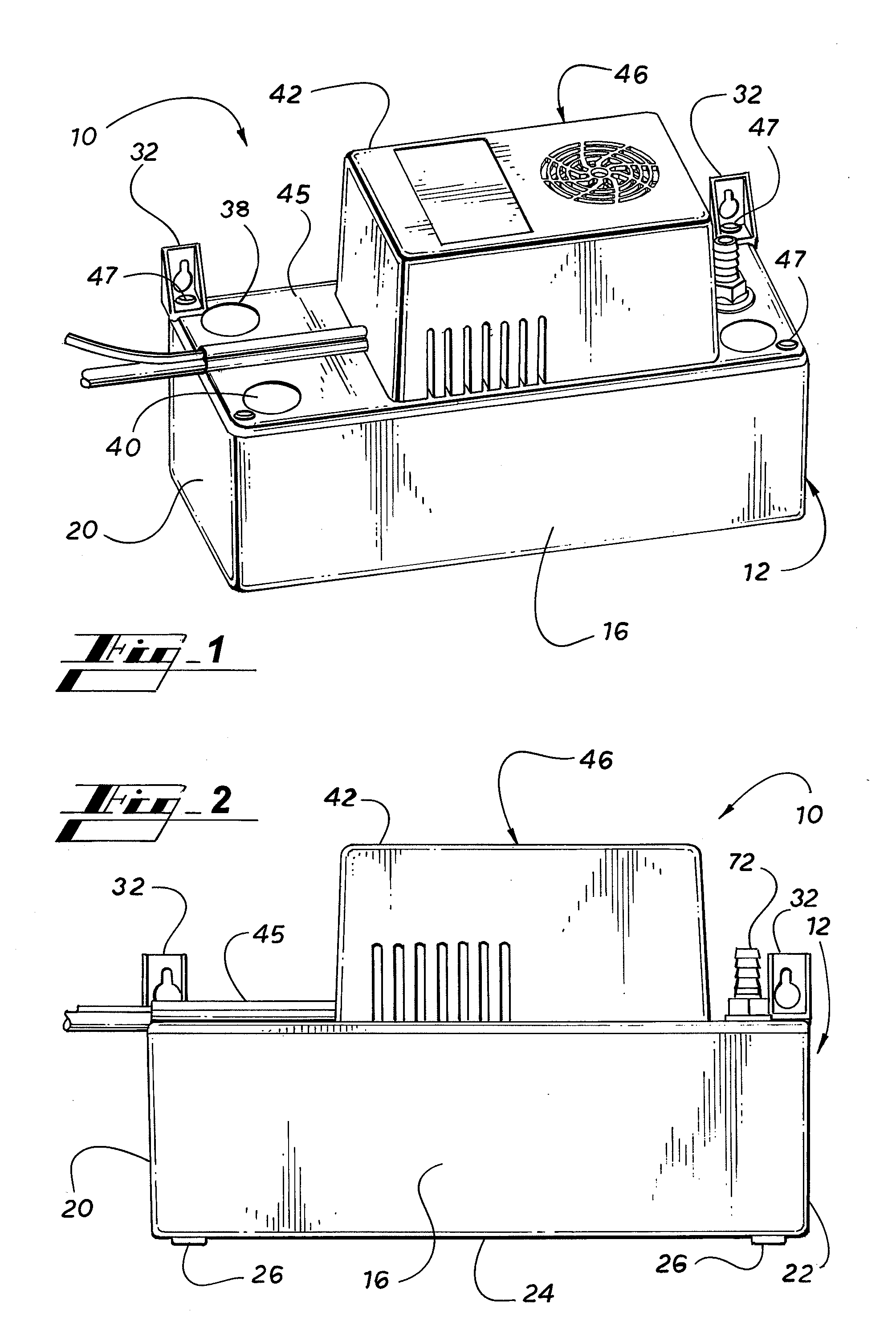

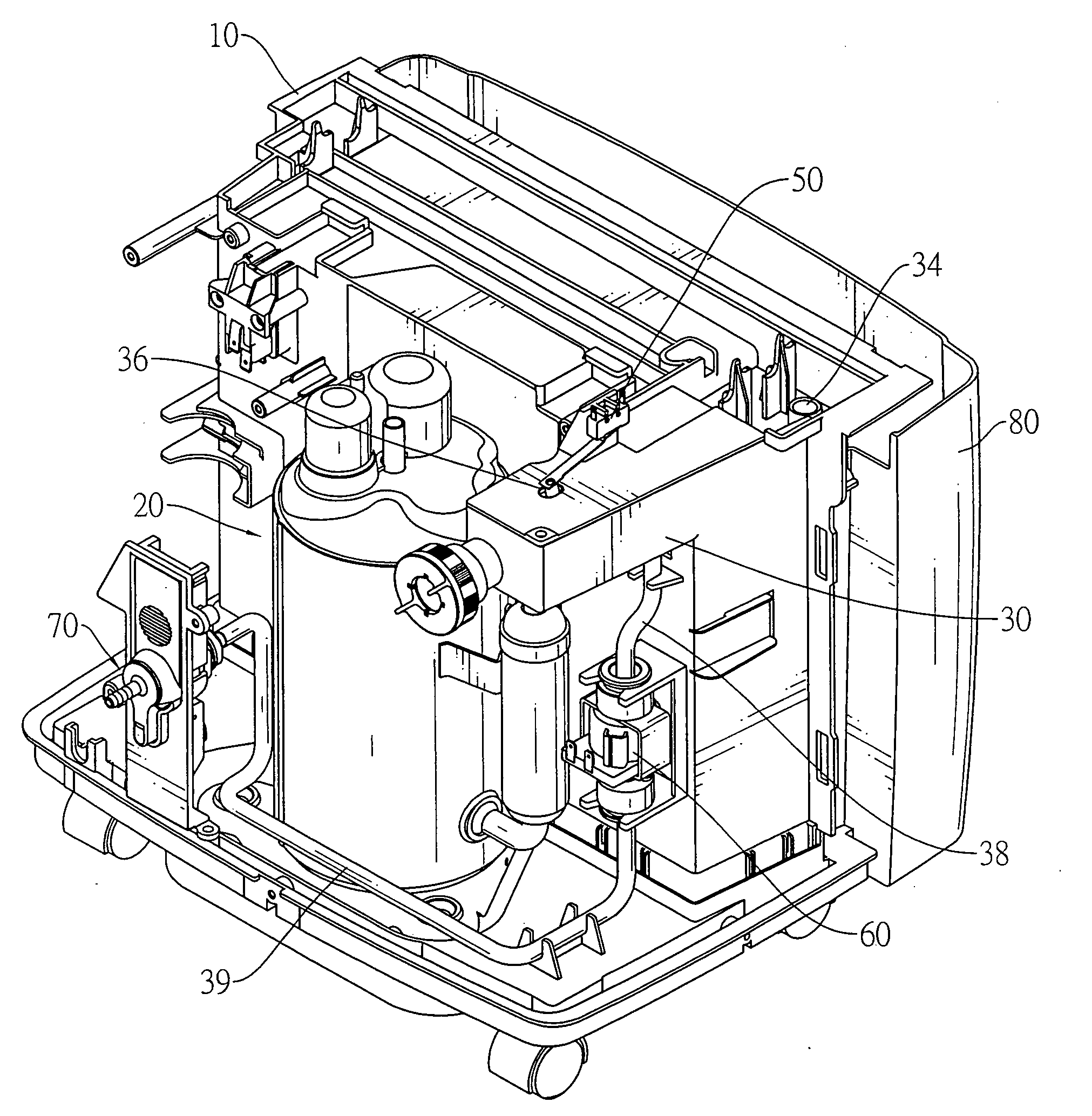

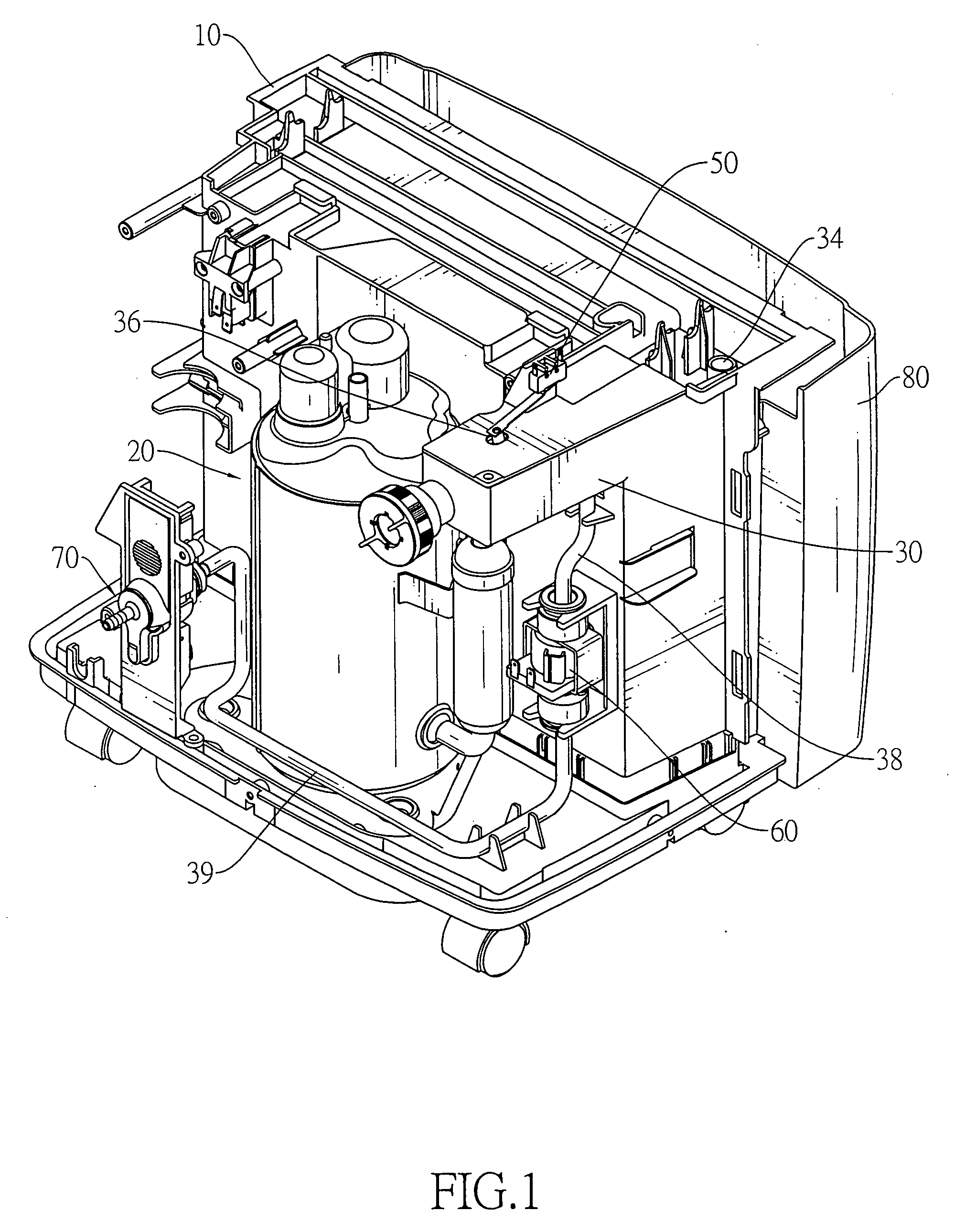

ActiveUS20110061415A1Reliable and quiet in operationLow costCondensate preventionLighting and heating apparatusWater useMicrocontroller

A condensate pump for an HVAC system includes a reservoir for collecting condensate water, a pump motor connected to an impeller pump for pumping the condensate water out of the reservoir, and a floatless pump control module. The floatless pump's microcontroller detects the water level in the reservoir and, based on the water level in the reservoir, controls the operation of the pump motor, and if necessary, sounds an alarm and shuts down the HVAC system. The floatless pump microcontroller may employ an ultrasonic transducer or capacitance sensors to detect the level of condensate water in the reservoir. The microcontroller implements a variable water lift feature to pump the water using the lowest possible speed for the pump. The microcontroller implements a self-cleaning feature to pump stagnant water out of the reservoir and to pulse water in the drain line and the agitation of the water in the reservoir. The microcontroller implements an anti-clog feature to clear a clogged drain line when an overflow condition is detected.

Owner:DIVERSITECH

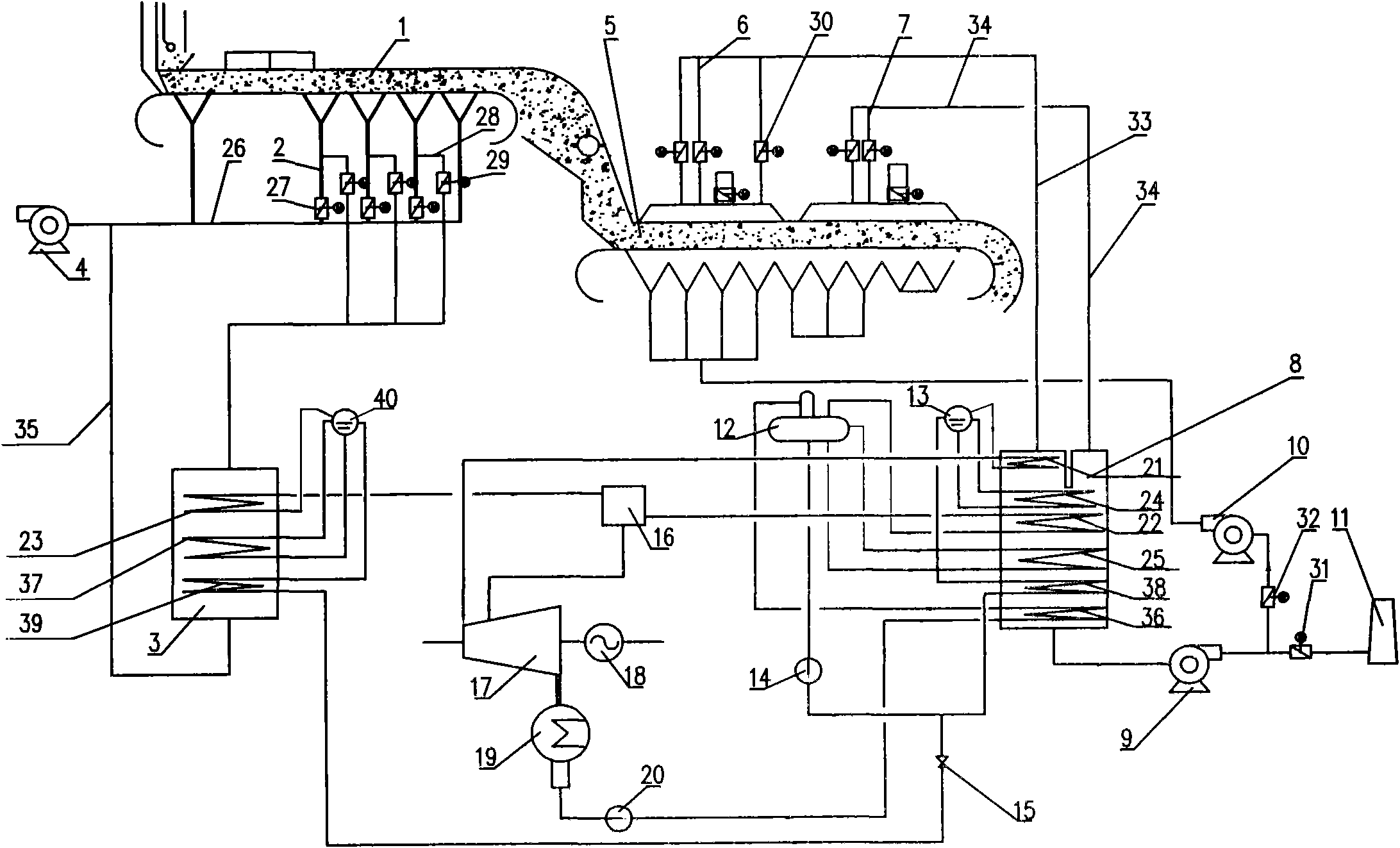

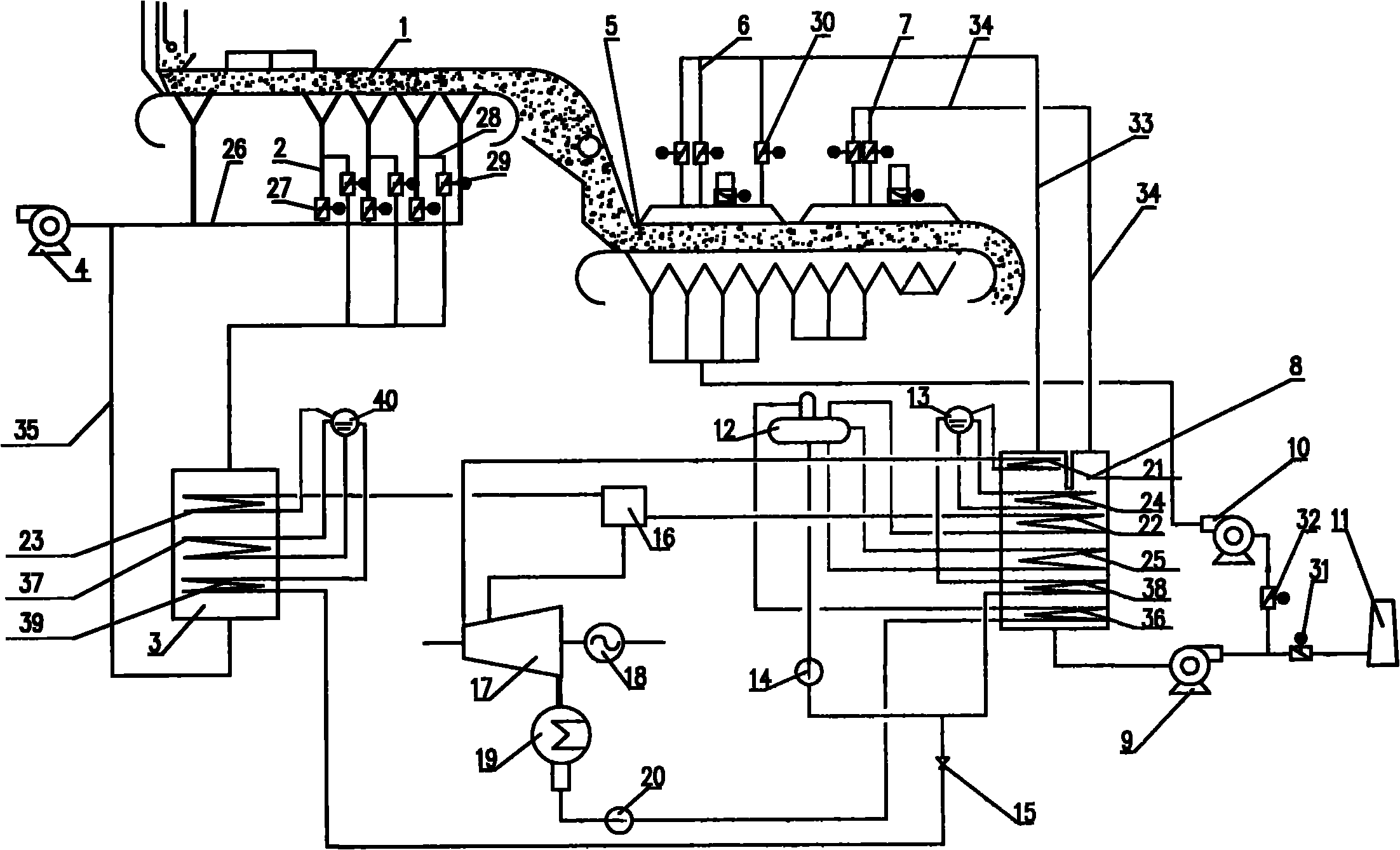

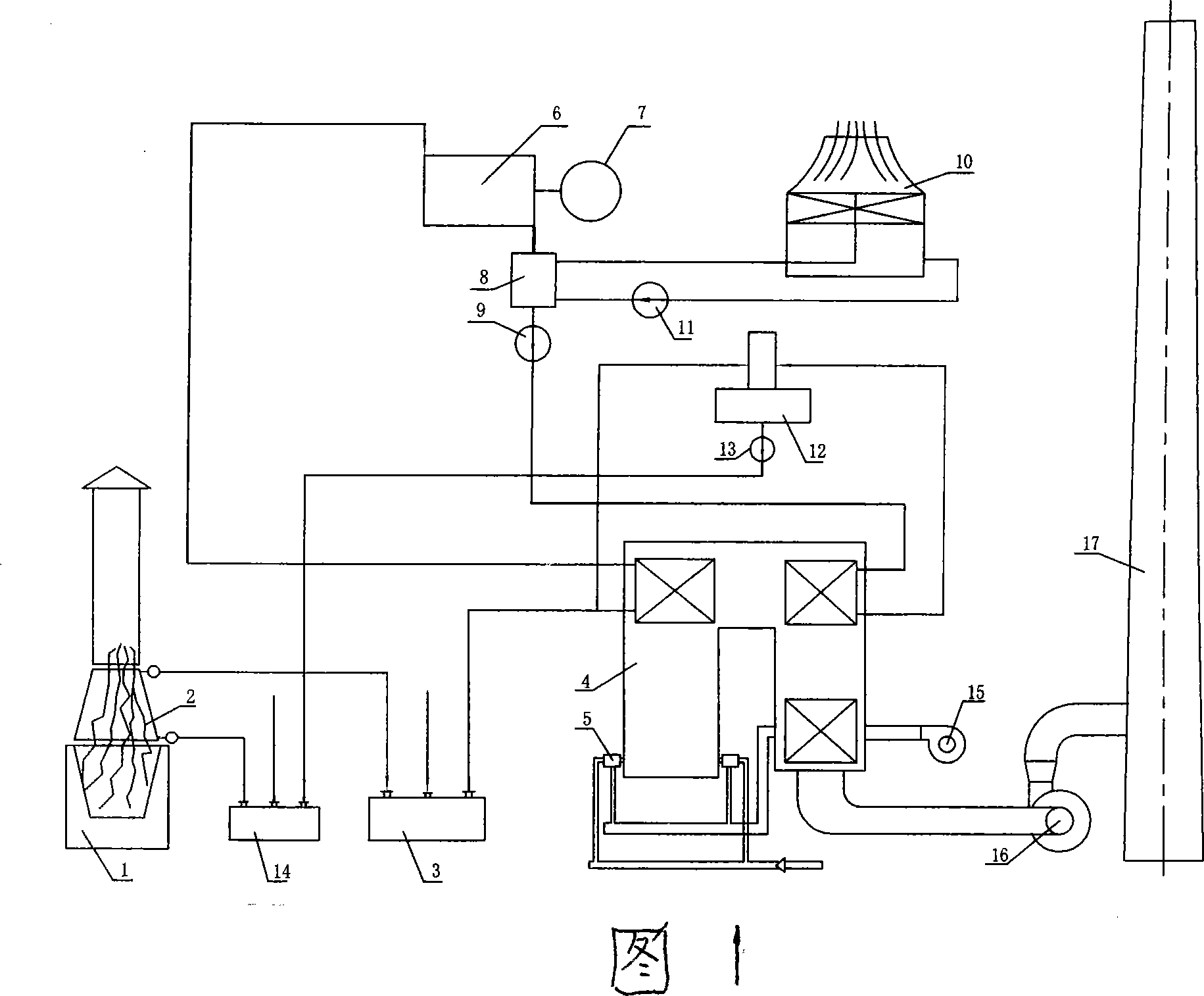

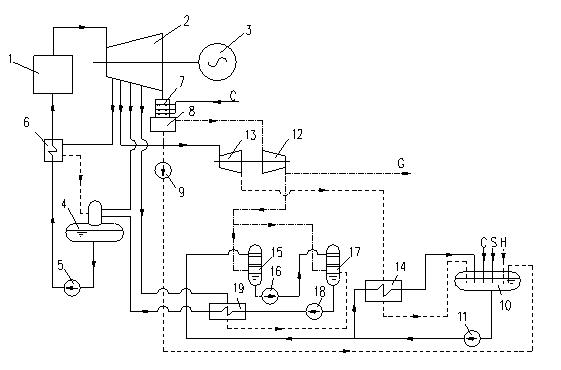

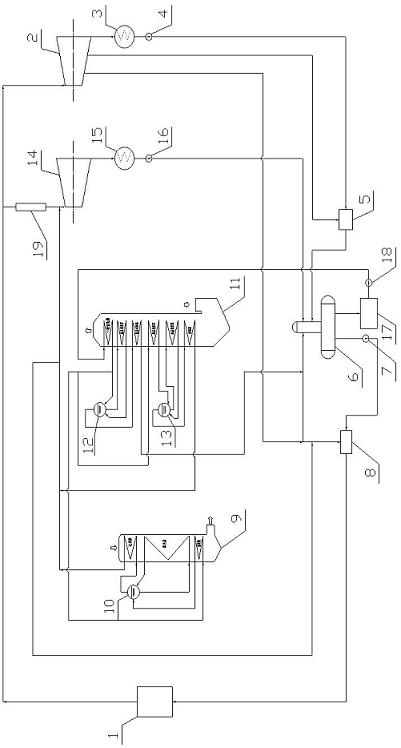

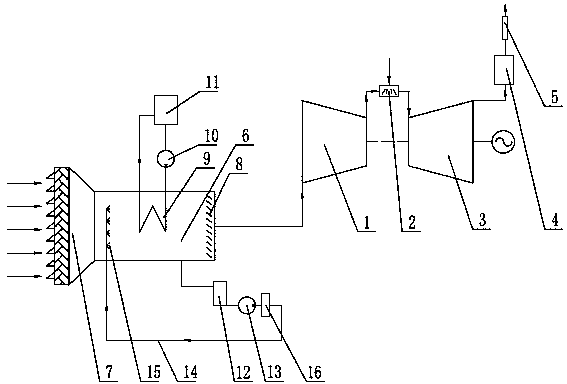

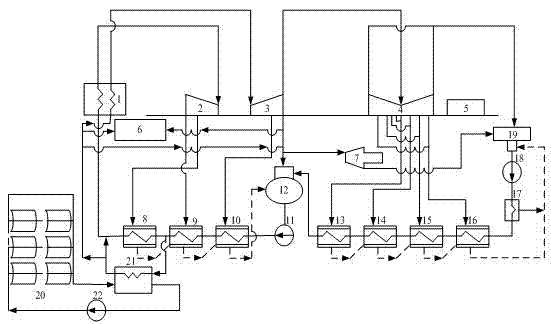

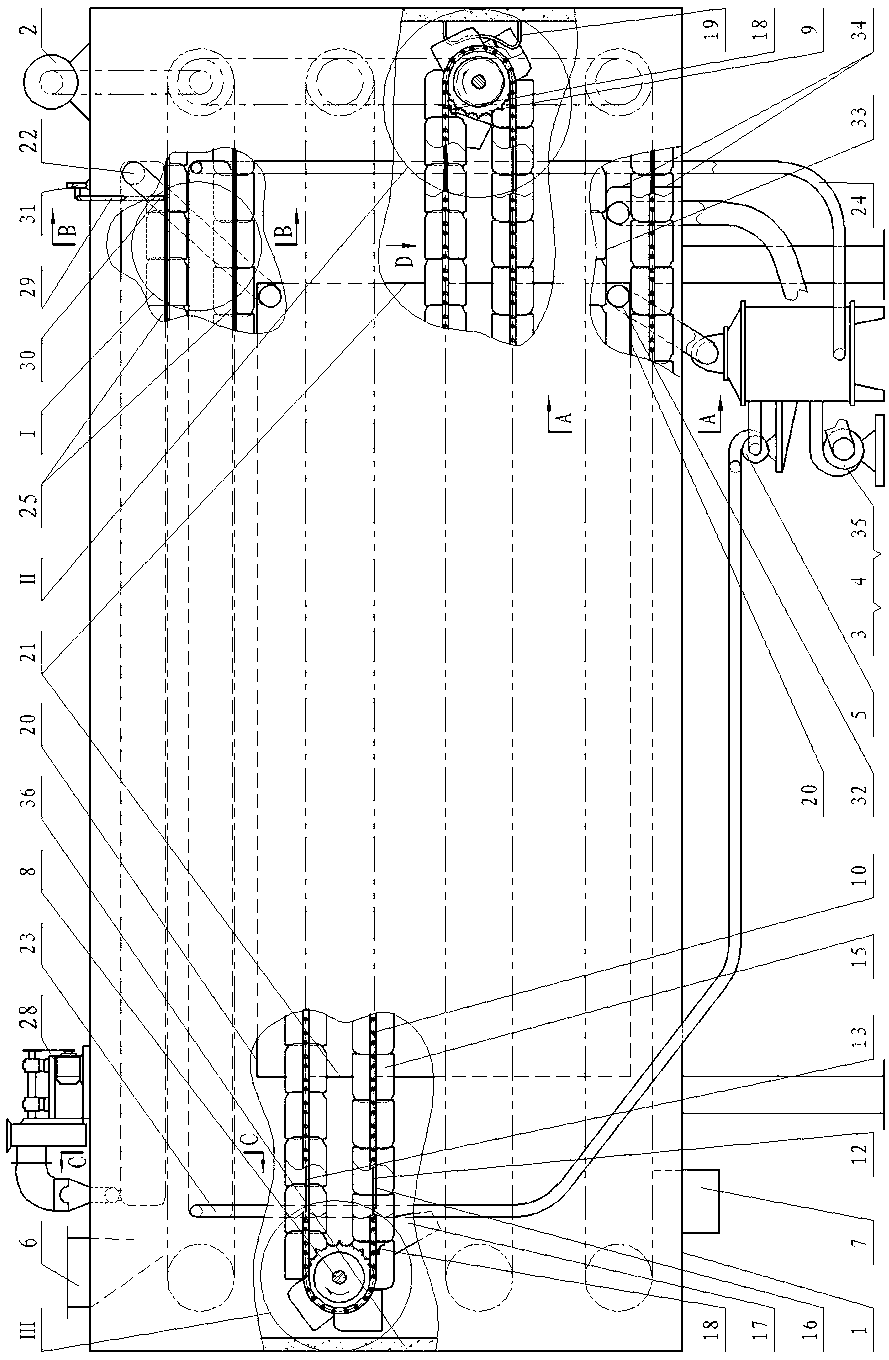

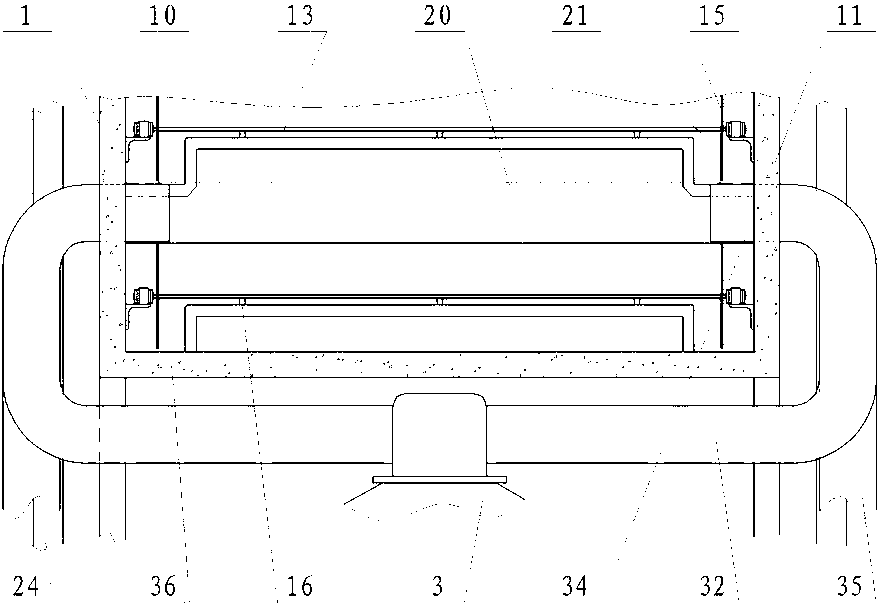

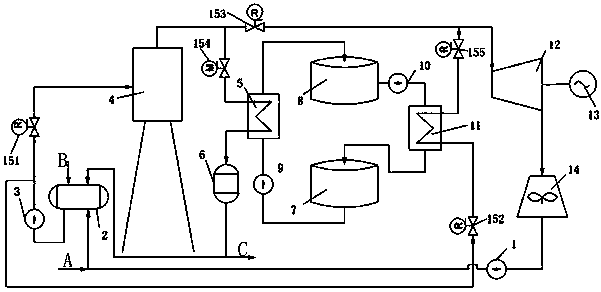

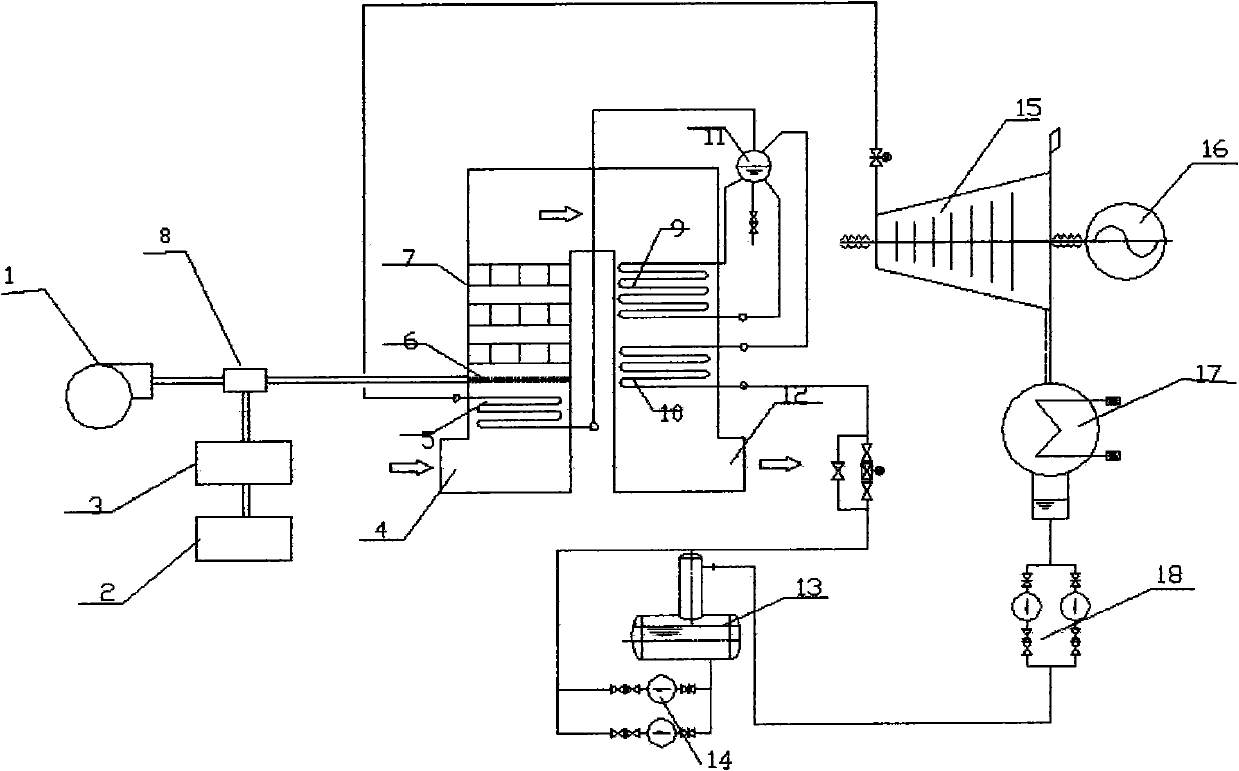

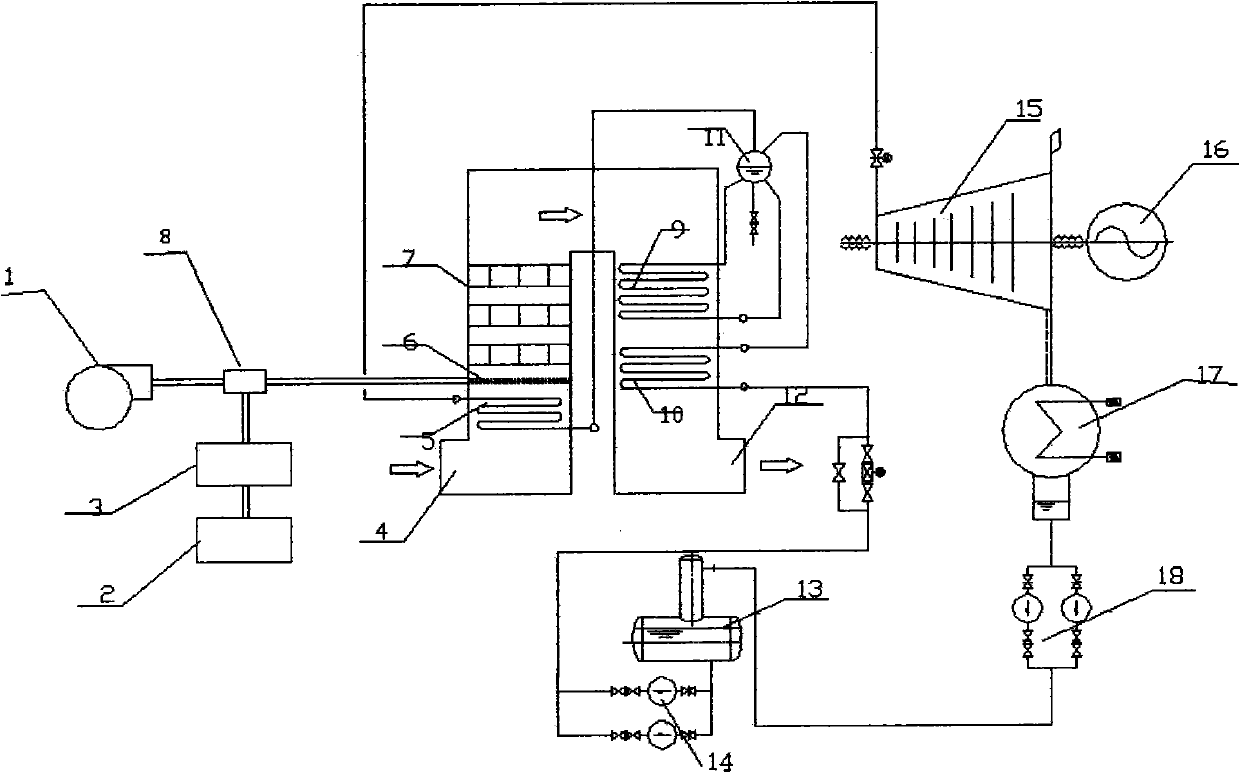

System and method for using sintering waste heat to generate electricity

InactiveCN101806230AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityExhaust fumes

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of the ring cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

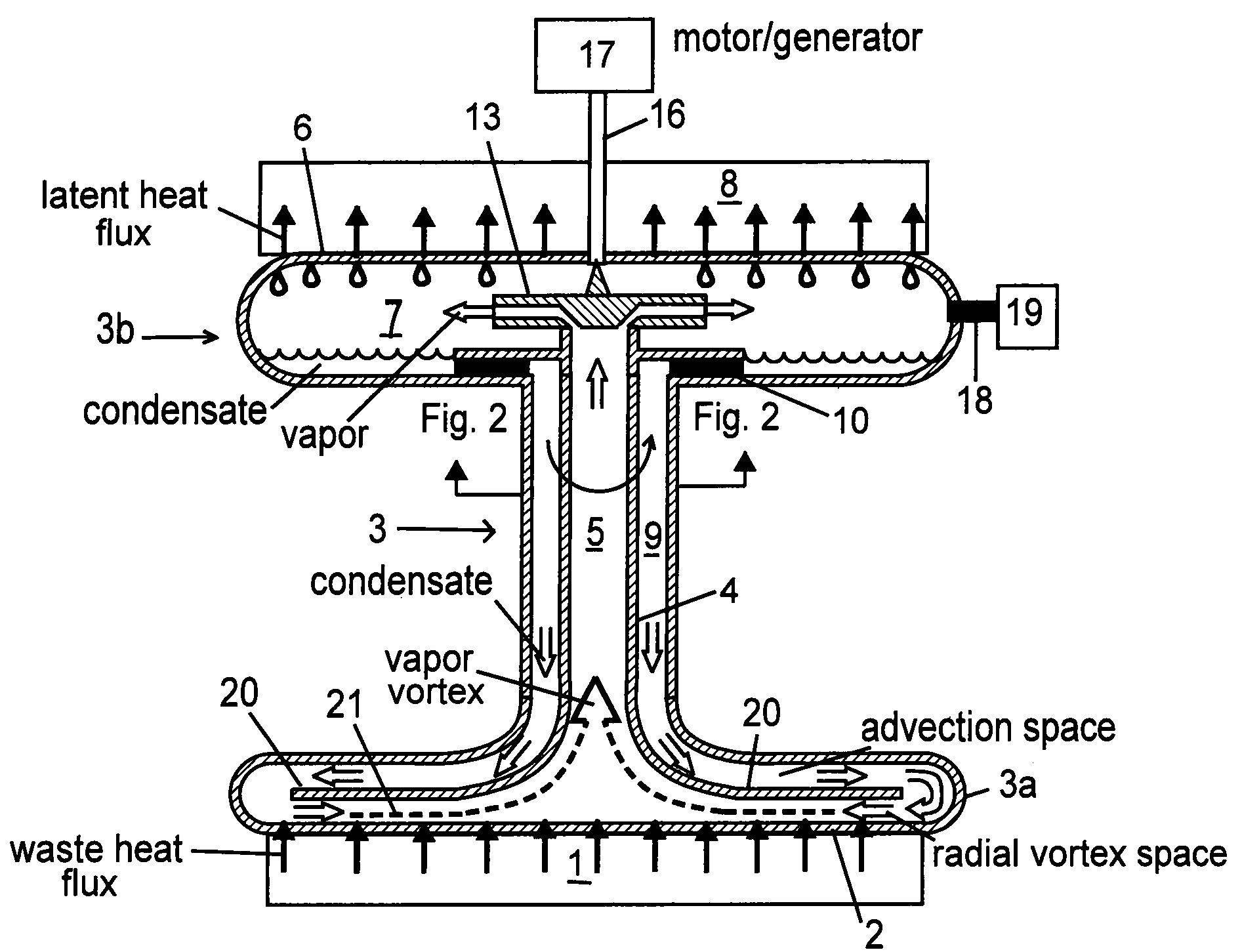

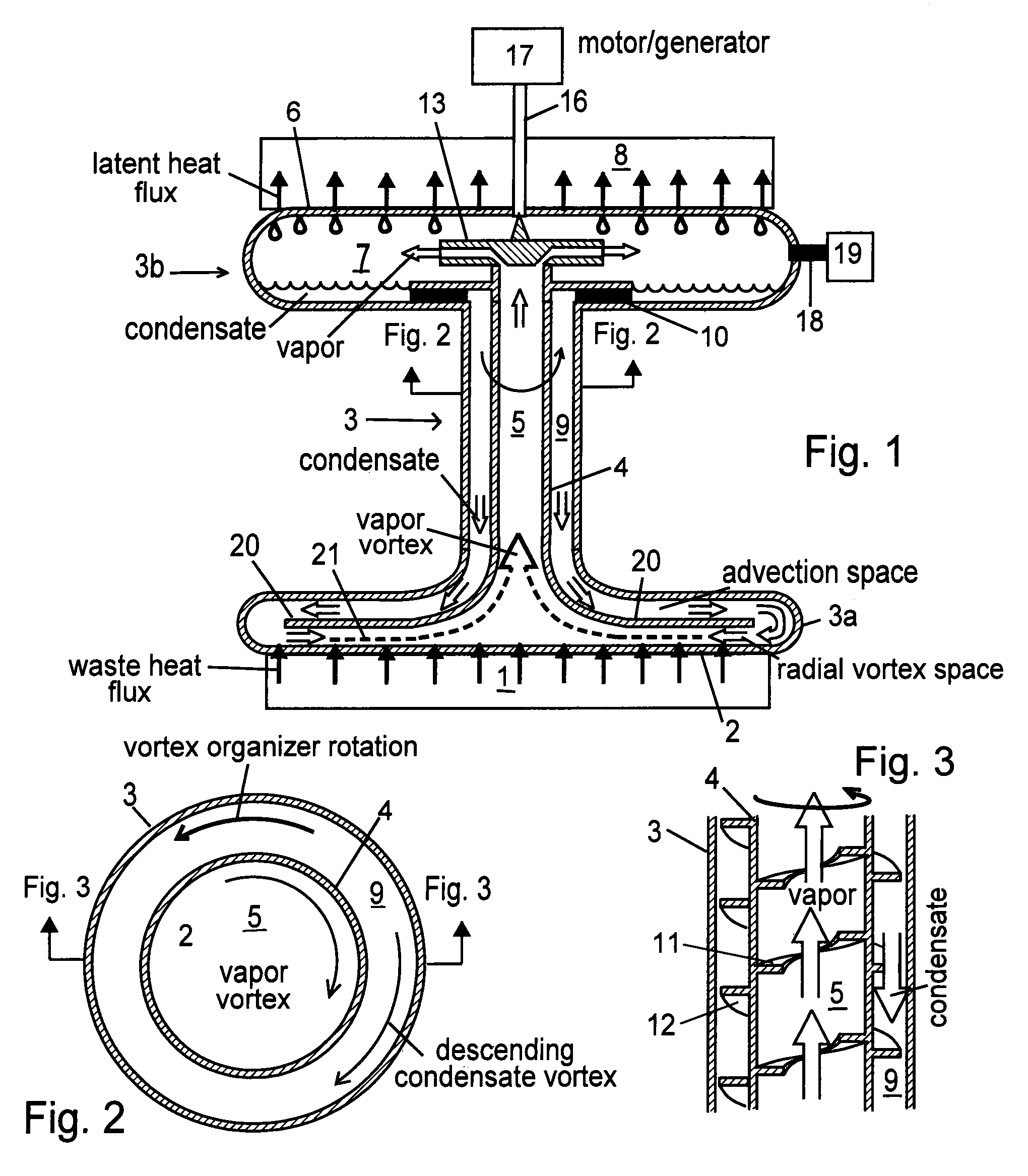

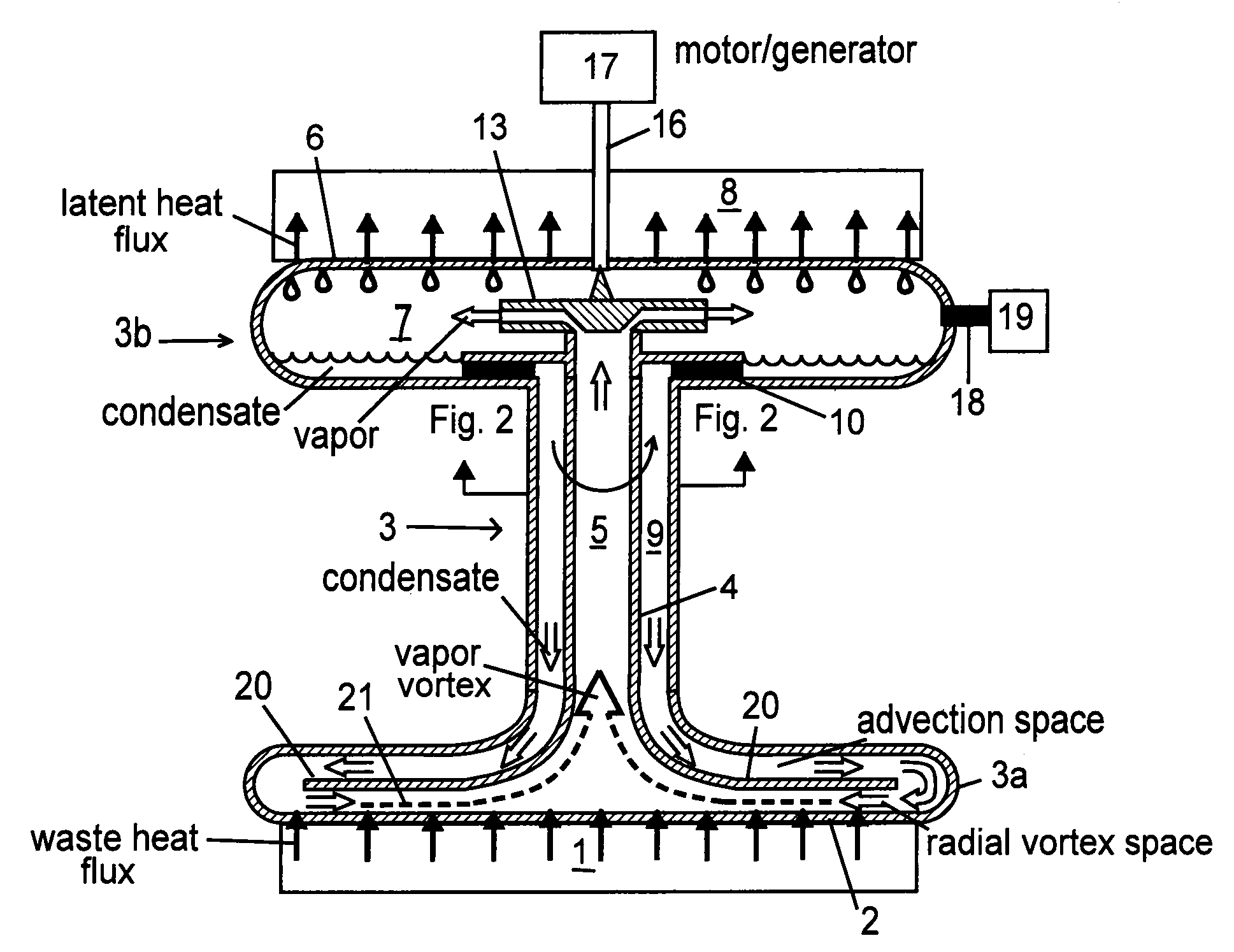

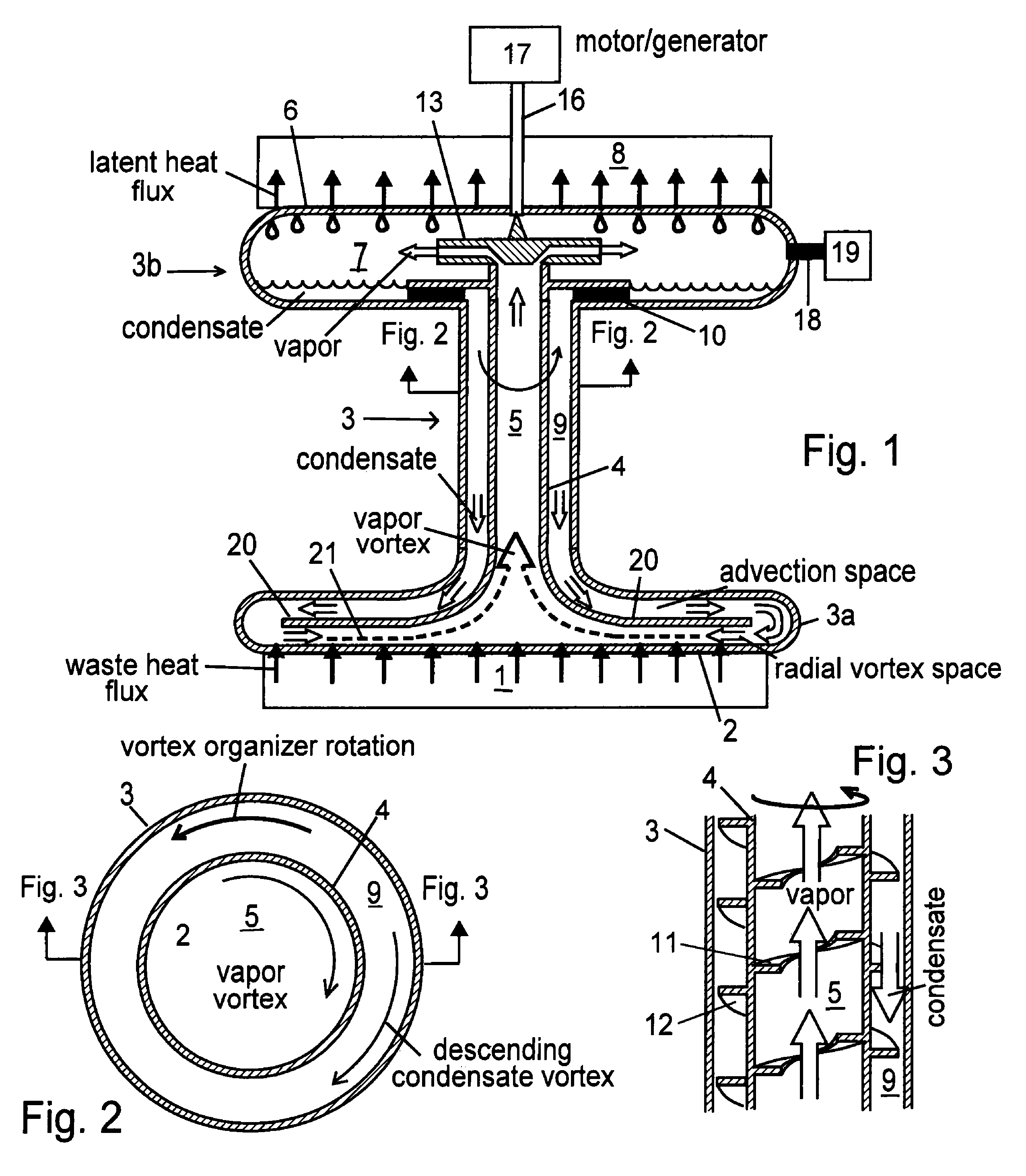

Vapor vortex heat sink

ActiveUS20090242174A1Powerful power generationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat flux

A hermetic Rankine cycle in a sealed casing powers an internal centrifugal condensate pump with an internal vapor turbine during forced convective heat transfer between a heat source and a heat sink. No work is imported into the cycle during operation. A centrifugal pumping disk shears the working fluid against a heating surface, sweeping evolving vapor into radial vortices which provide sink flow conduits to a vapor space at the center of the cylindrical turbine. Convective mass flow through the vapor space to the condensing end of the casing spins the turbine and the centrifugal pumping disk which is connected to it. Vapor is continuously swept from the heating surface, so bubbles do not form and superheat while blocking heat flux into liquid working fluid. Vapor is sucked through the radial vortices into the central vapor space and into the condensing end of the casing along the low pressure gradients in vortex cores established by cooling power. A high heat flux surface is thereby thermally connected to a conventional heat sink having high cooling power, for maximal heat extraction at data centers or other heat sources. Vapor vortices organize counterflow of vapor and condensate in a continuous mass flow cycle, and extract work from heat. Organic working fluids can be used in the casing to make even low temperature waste heat a power source.

Owner:MCCUTCHEN CO

Vapor vortex heat sink

InactiveUS7980078B2Semiconductor/solid-state device detailsSolid-state devicesHeat fluxWorking fluid

A hermetic Rankine cycle in a sealed casing powers an internal centrifugal condensate pump with an internal vapor turbine during forced convective heat transfer between a heat source and a heat sink. No work is imported into the cycle during operation. A centrifugal pumping disk shears the working fluid against a heating surface, sweeping evolving vapor into radial vortices which provide sink flow conduits to a vapor space at the center of the cylindrical turbine. Convective mass flow through the vapor space to the condensing end of the casing spins the turbine and the centrifugal pumping disk which is connected to it. Vapor is continuously swept from the heating surface, so bubbles do not form and superheat while blocking heat flux into liquid working fluid. Vapor is sucked through the radial vortices into the central vapor space and into the condensing end of the casing along the low pressure gradients in vortex cores established by cooling power. A high heat flux surface is thereby thermally connected to a conventional heat sink having high cooling power, for maximal heat extraction at data centers or other heat sources. Vapor vortices organize counterflow of vapor and condensate in a continuous mass flow cycle, and extract work from heat. Organic working fluids can be used in the casing to make even low temperature waste heat a power source.

Owner:MCCUTCHEN CO

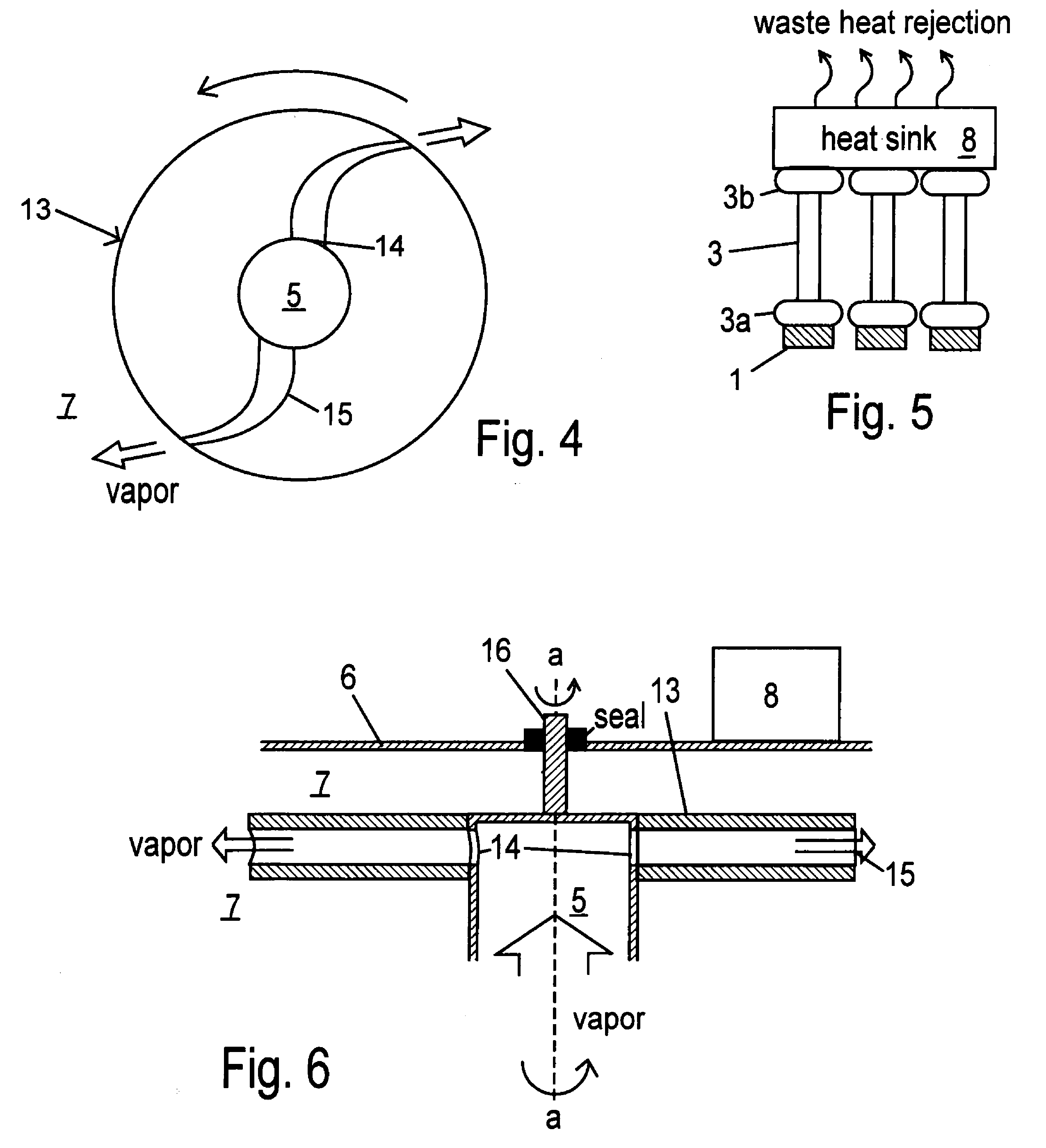

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

Method for recycling and regenerating steel plant residual heat boiler saturated steam

InactiveCN101178017AIncrease profitEfficient use ofSteam engine plantsSteam superheatersCooling towerDeaerator

The invention relates to a method to recycle saturated steam from waste heat boiler in steel plant to generate. The method is characterized in that the invention comprises a converter, a converter heat recovery boiler, a steam filtering pressure stabilizer, a saturated steam heating furnace, a heating furnace burner, a low pressure turbine, a motor, a condenser, a condensate pump, a cooling tower, a circulating water pump, a deaerator, a water supply pump, a water supply distributor, a blower, an induced draft fan and a chimney. The invention has the advantages of making full use of the current waste heat boiler of the steel plant, adopting the steam filtering pressure stabilizer and the saturated steam heating furnace, improving efficiency by 140 percent compared with the traditional small-sized medium temperature and medium pressure unit and efficiency being 20 percent up higher than that of the most efficient gas turbine in the world.

Owner:中冶集团华冶资源开发有限责任公司

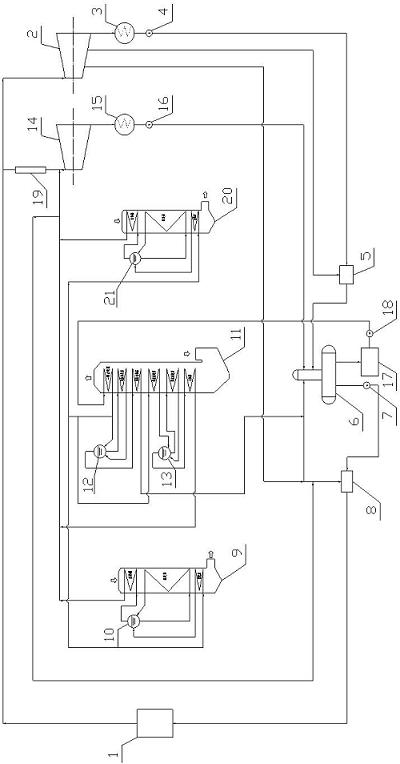

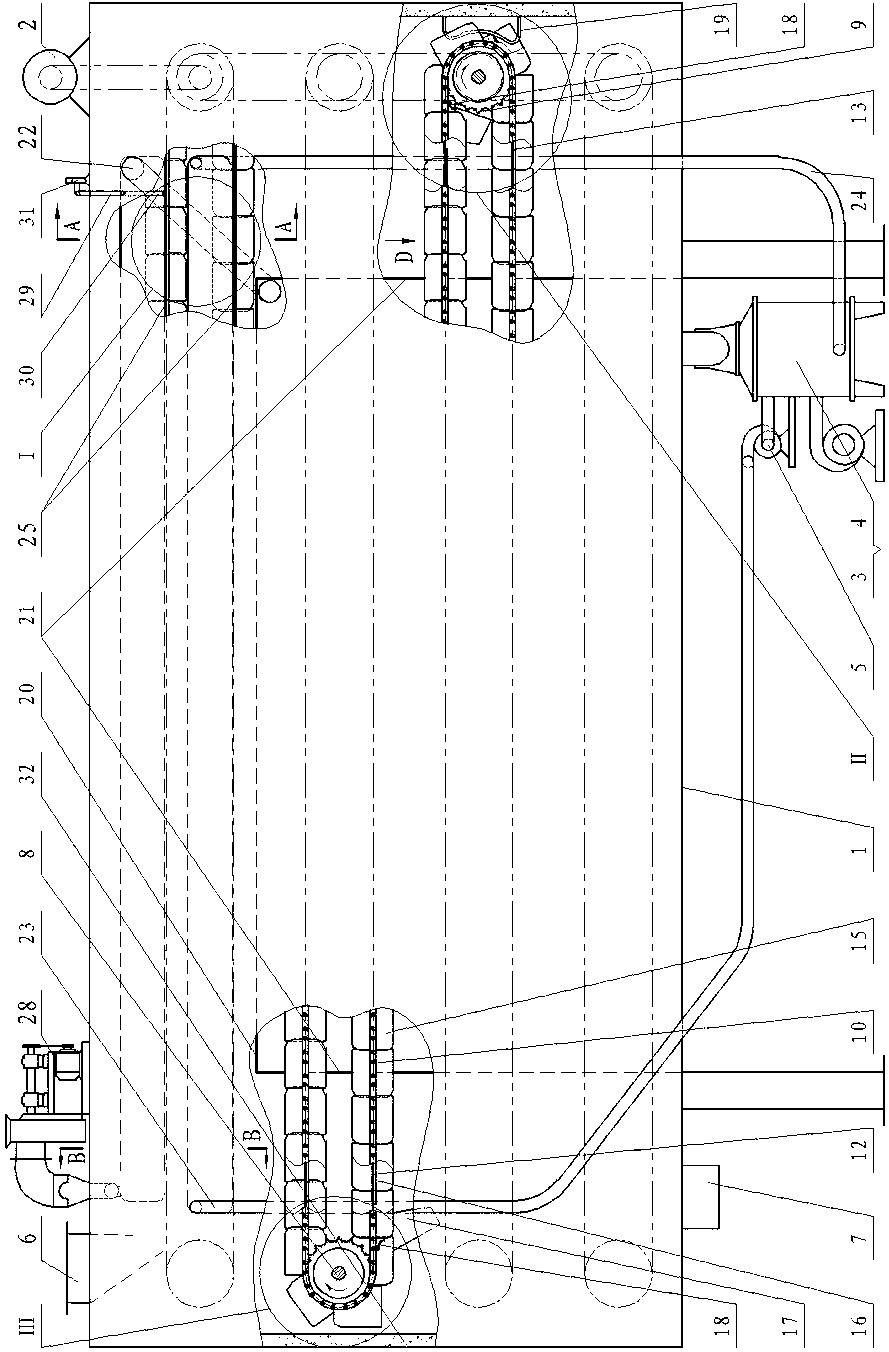

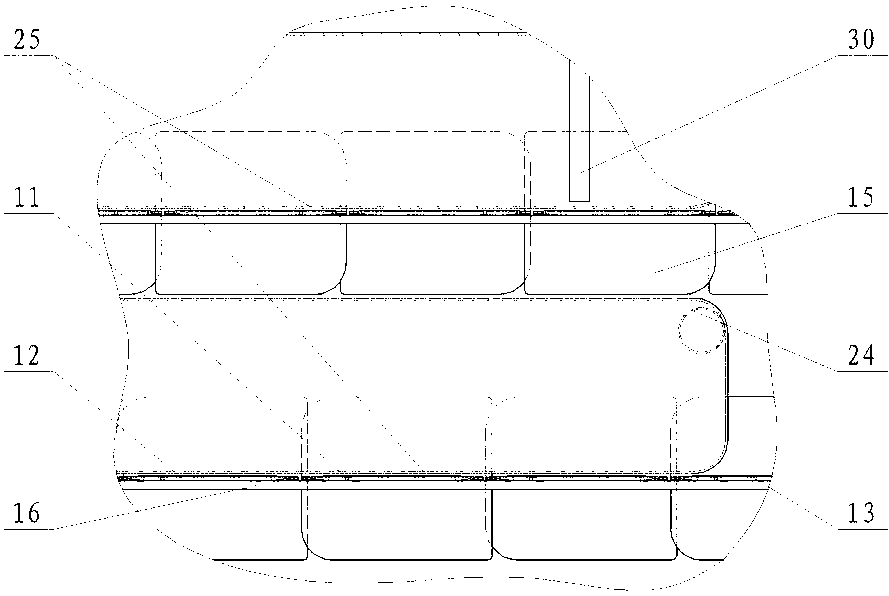

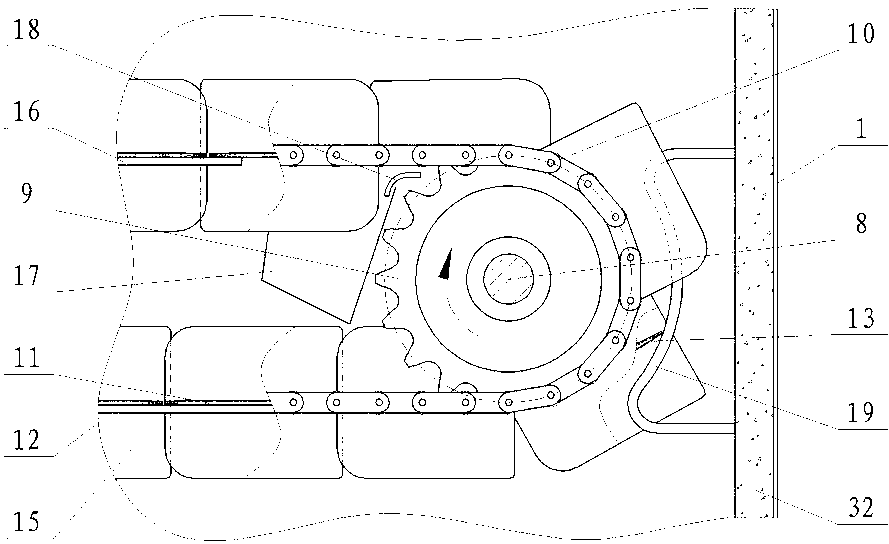

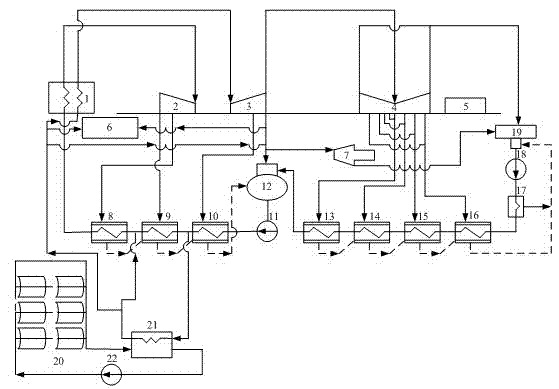

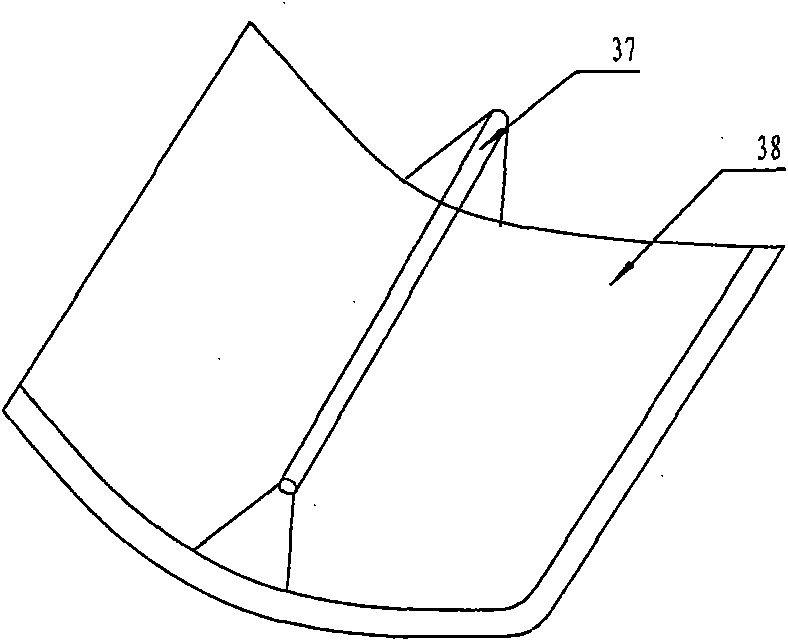

Sintered ring cold exhaust heat stepped recovery power generation system and technique

ActiveCN101344359AGuaranteed cycleImprove parametersFurnace typesIncreasing energy efficiencyAir volumeCooling effect

A sintering circulating cooling waste heat cascade recovery power generation system and a process thereof belong to the sintering waste heat utilization technology field. The system comprises a sintering circulating cooling machine, a windward chamber, a leeward chamber, a heat exchanger, a fan, a waste heat boiler, a steam bag, a superheater, an evaporator, an oxygen remover, a steam turbine, a generator, a condenser, a condensate pump and a water supply pump. The totally closed system is adopted to carry out subsection cooling and cascade recovery of waste heat of sinter, thereby recovering the sensible heat of the sinter to the maximum extent; the gradual increase of the temperature of cooling air can reduce the heat exchange temperature difference with the sinter; in order to not affect the cooling effect of the sinter, the system adopts the combined mode of the sub-cycle of the cooling air and the major cycle to absorb the sensible heat of the sinter, thereby improving the waste heat recovery efficiency. Compared with the prior art, the system and the process can extremely recover the waste heat of the sinter, improve the temperature of steam which is used for power generation under the premise of not increasing the total circulating air volume, increase the waste heat power generation amount and have great economic effects.

Owner:SHOUGANG CORPORATION +1

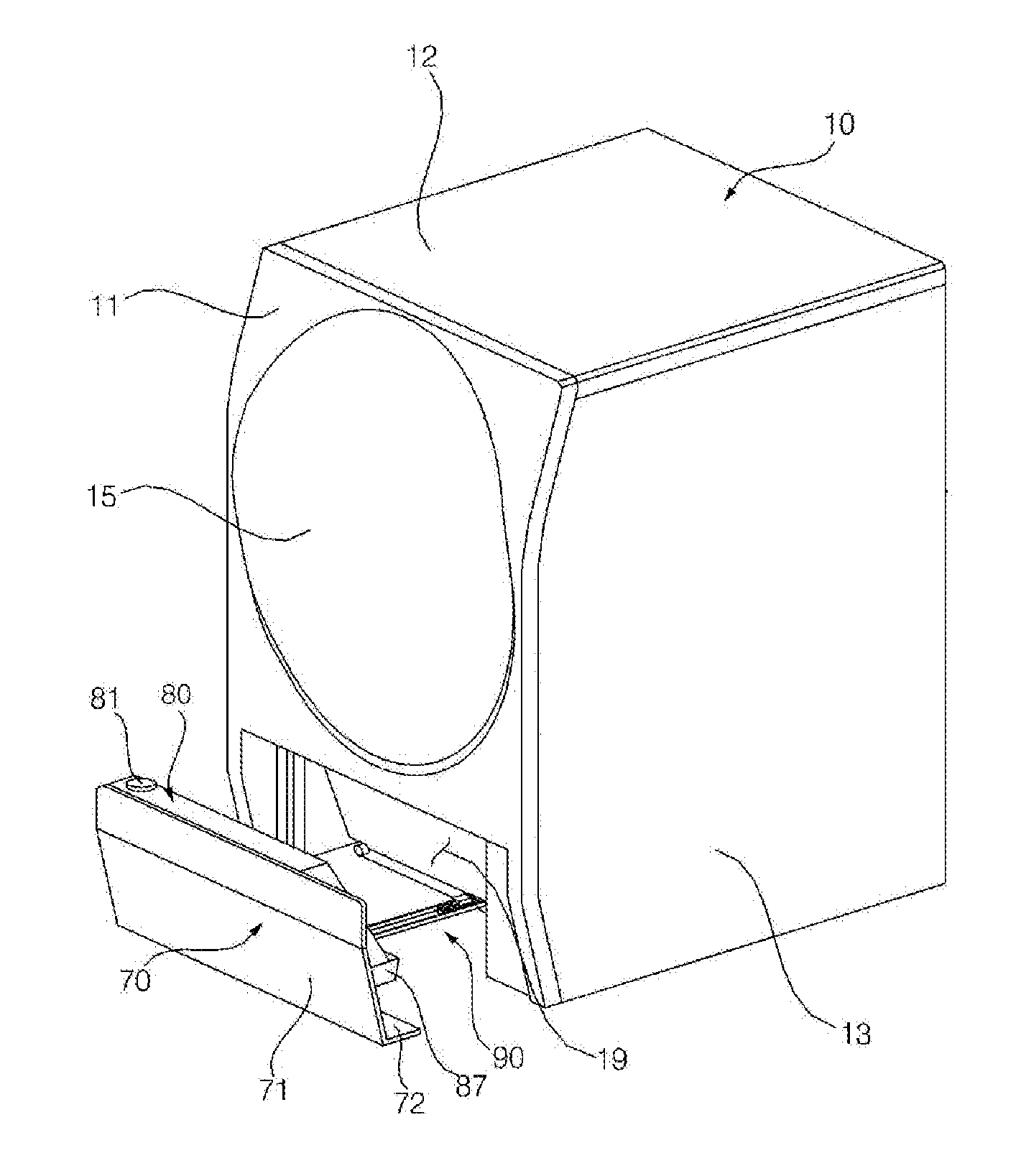

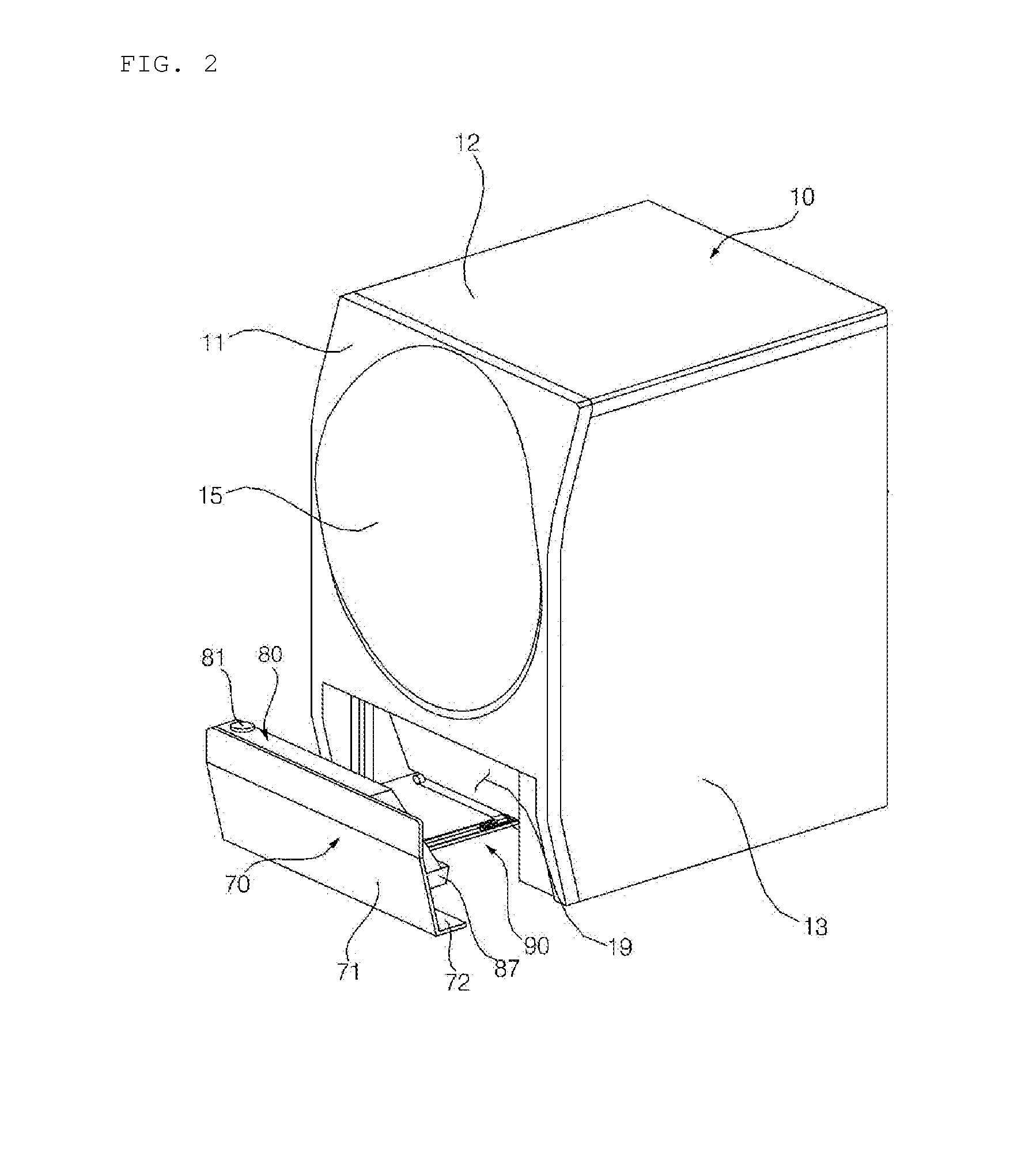

Clothes dryer

A clothes dryer including a cabinet, a drum, a condenser, a sump, a drawer, a hose, a condensate pump, and a condensed water container. The drawer includes a bucket for receiving condensed water which overflows from the condensed water container, and a condensate discharge pipe formed at the bucket to discharge condensed water collected in the bucket. When the drawer is stored in the cabinet, the sump is connected to the condensate discharge pipe such that condensed water introduced through the condensate discharge pipe is returned to the sump. When the drawer is withdrawn from the cabinet, the sump includes a sump connection pipe separated from the condensate discharge pipe.

Owner:LG ELECTRONICS INC

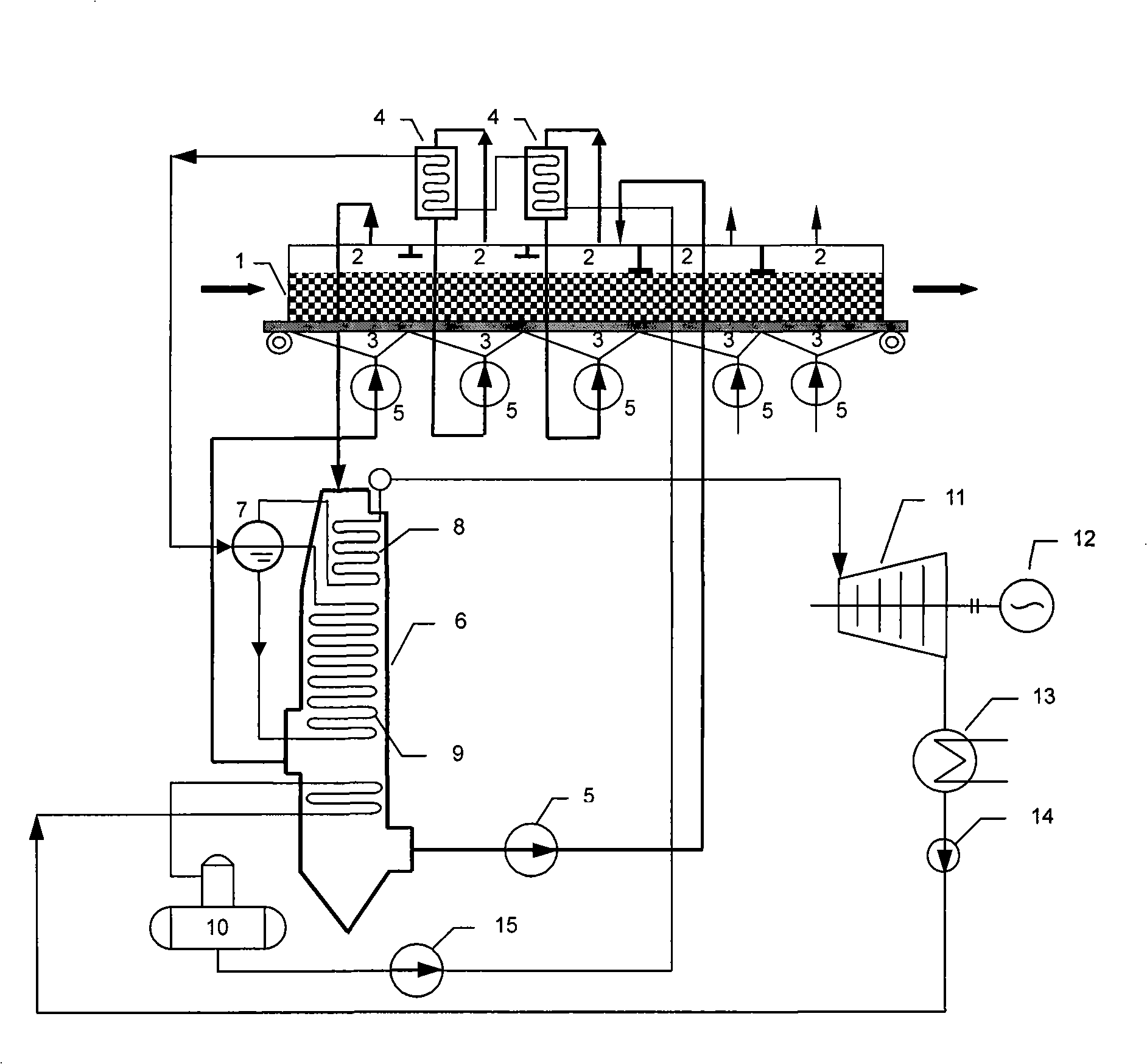

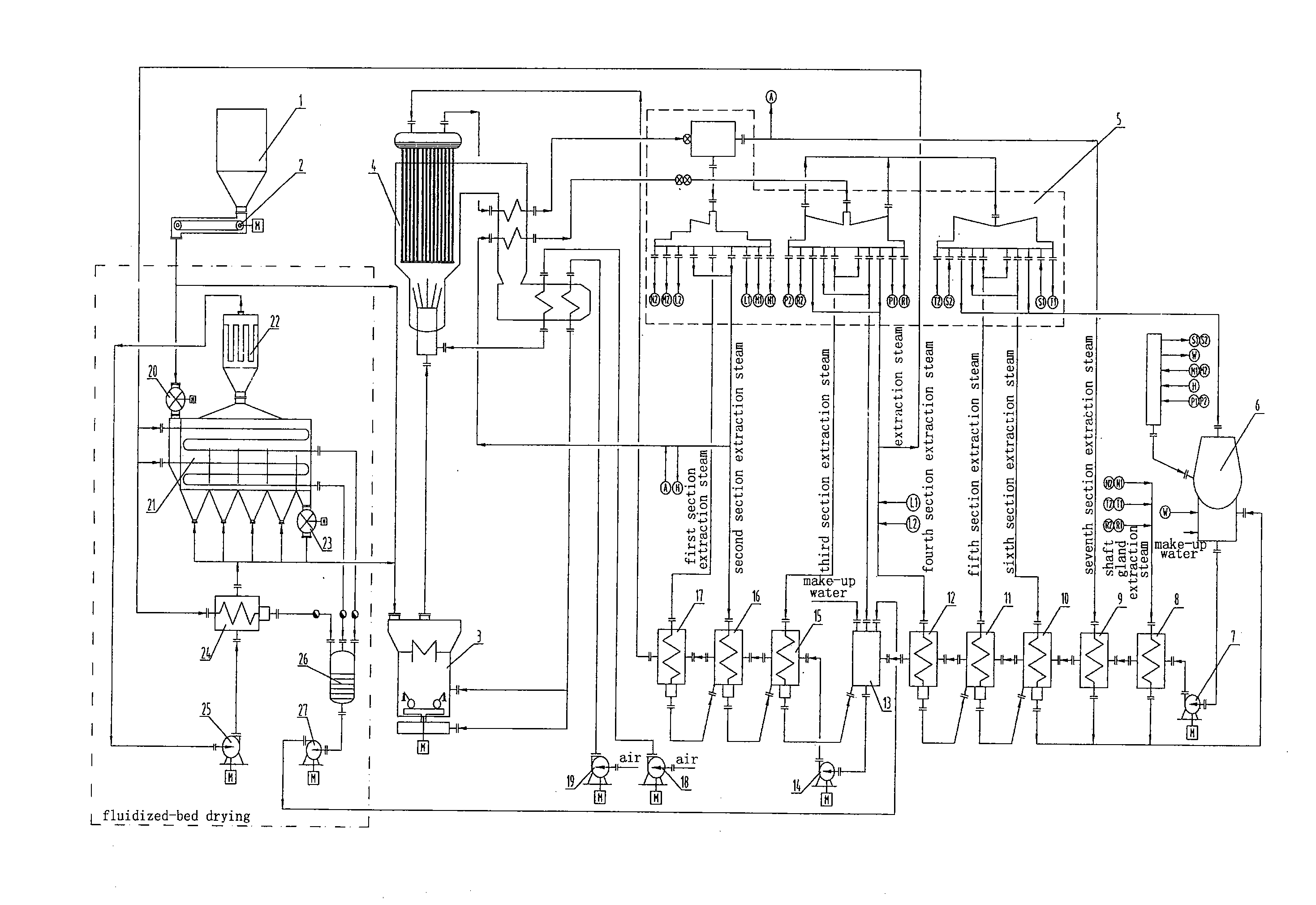

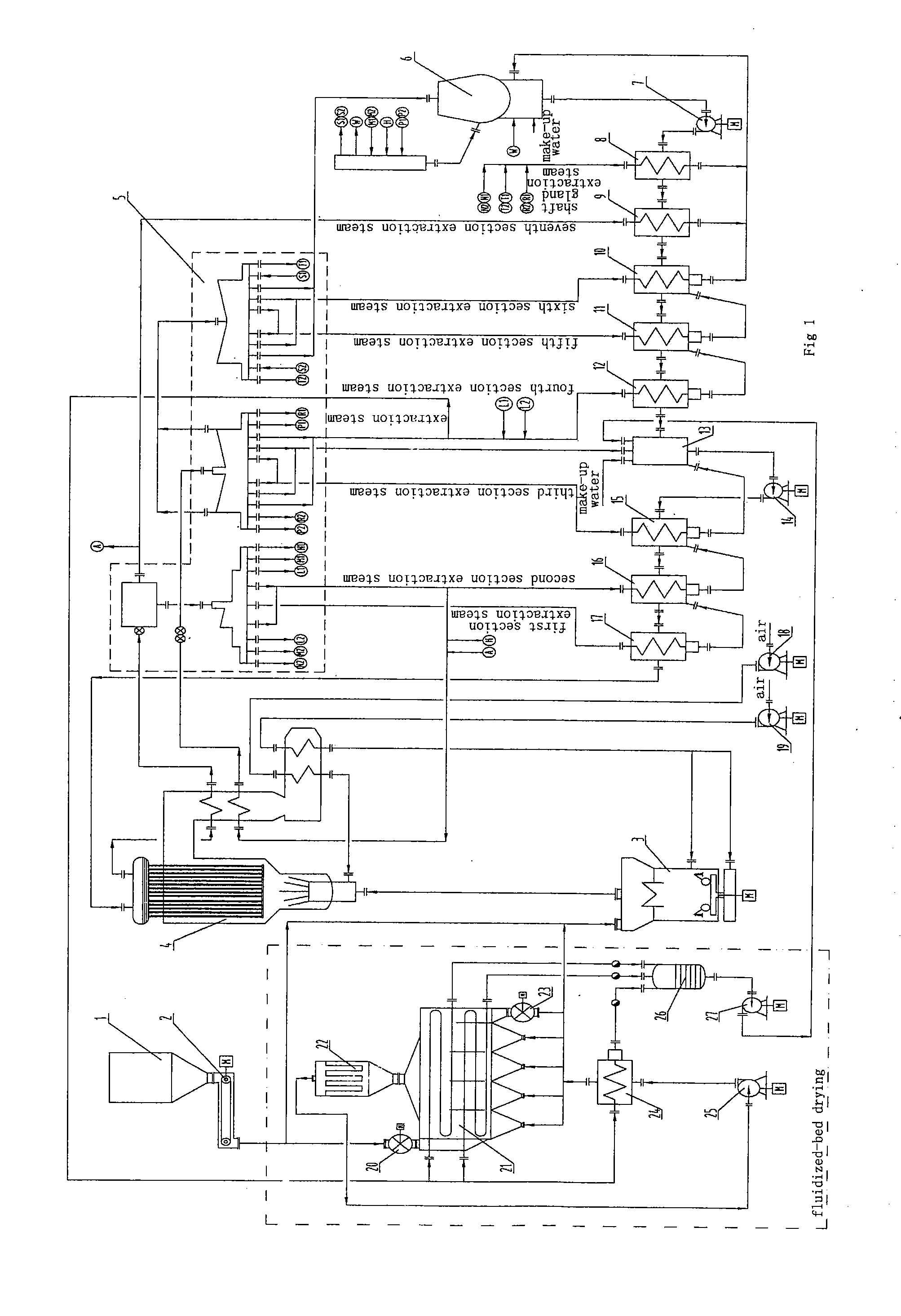

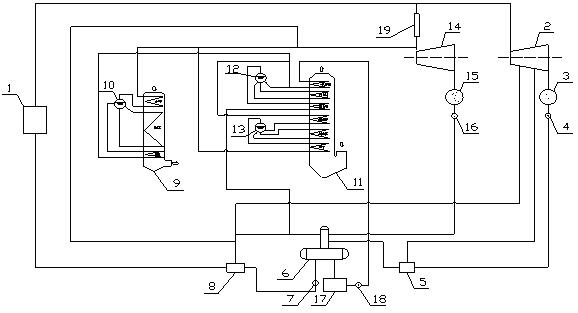

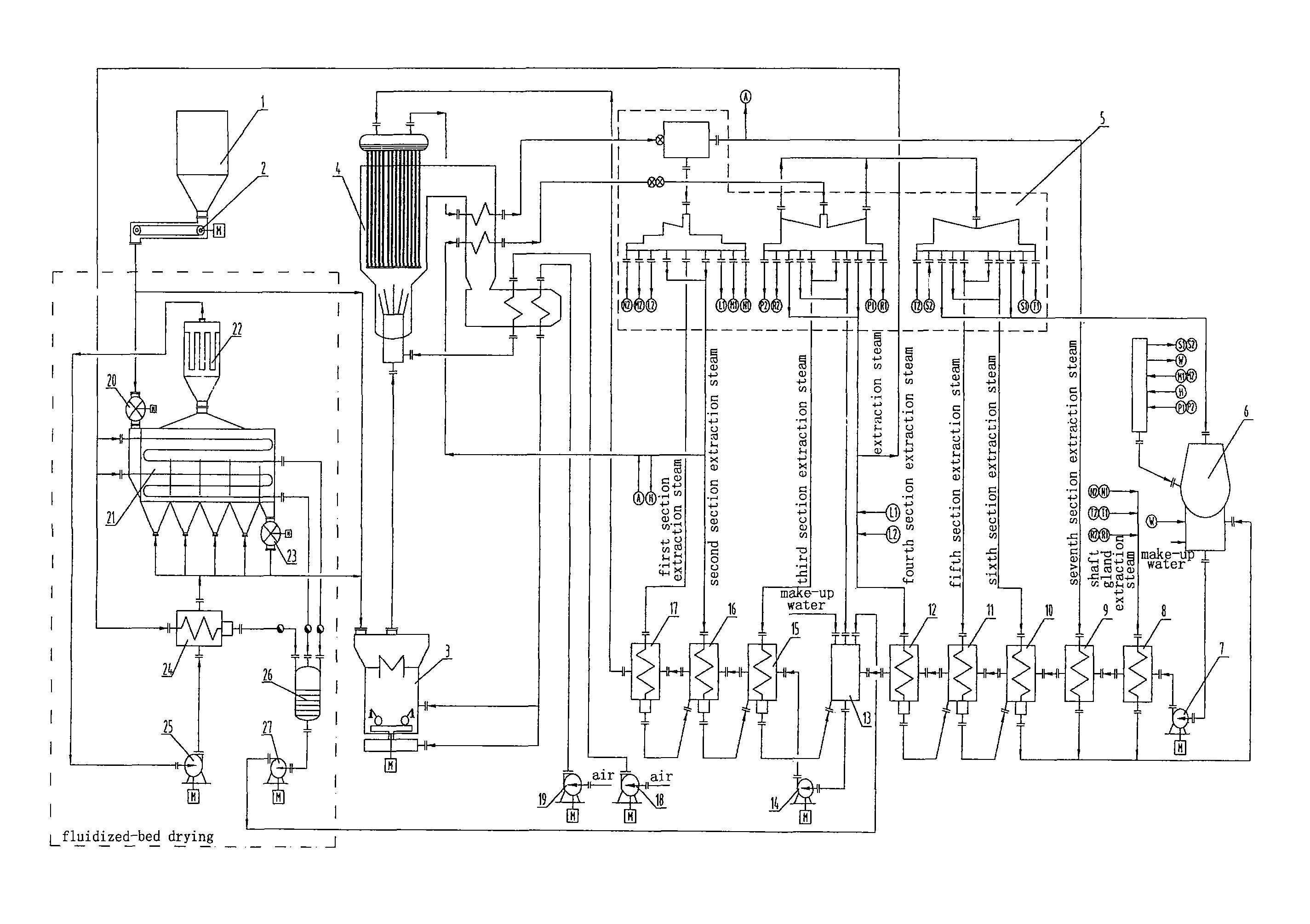

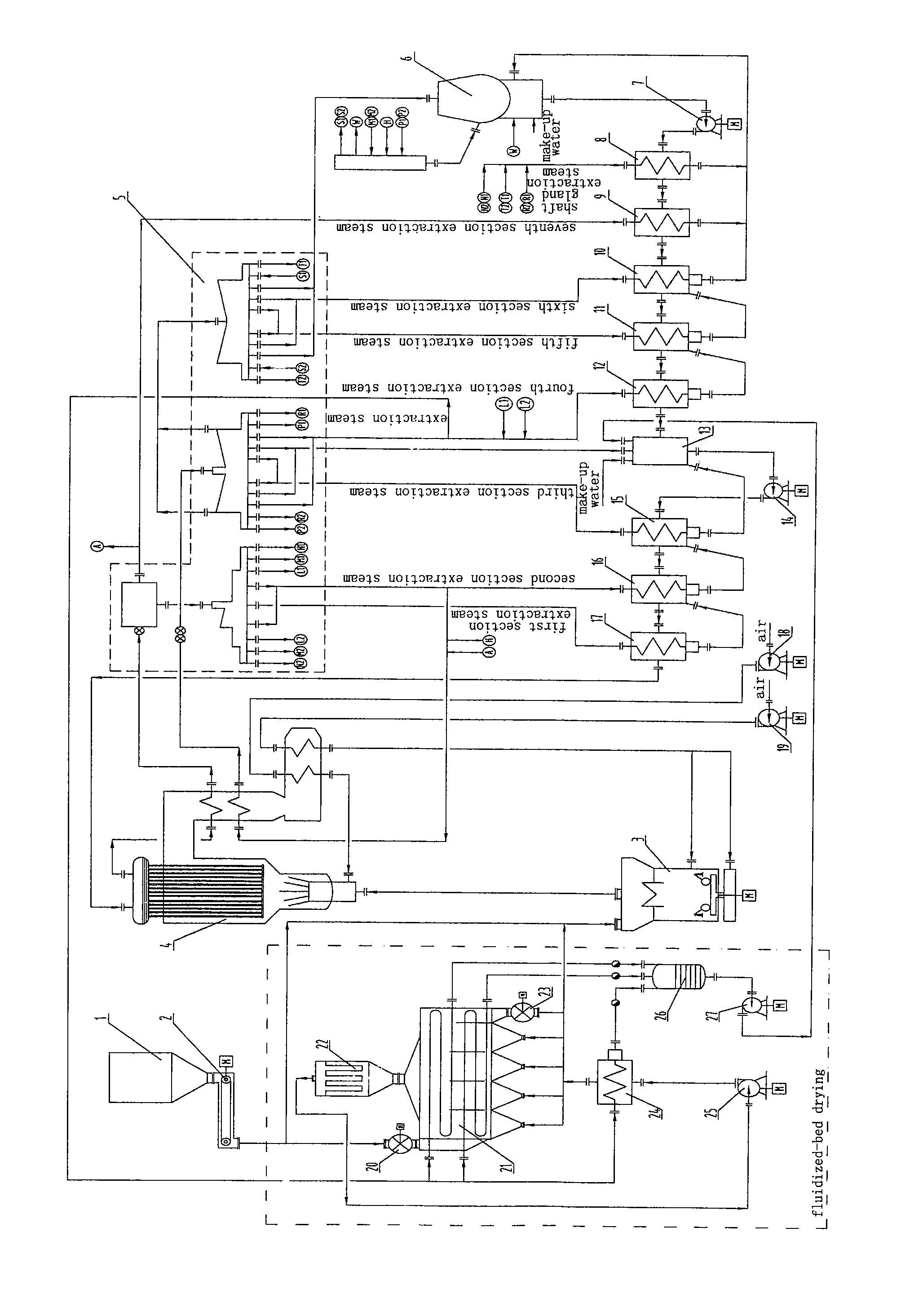

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS20110220744A1Reduce coal consumptionRemarkable effectFuel feeding arrangementsDrying solid materials with heatFluidized bed dryingProcess engineering

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

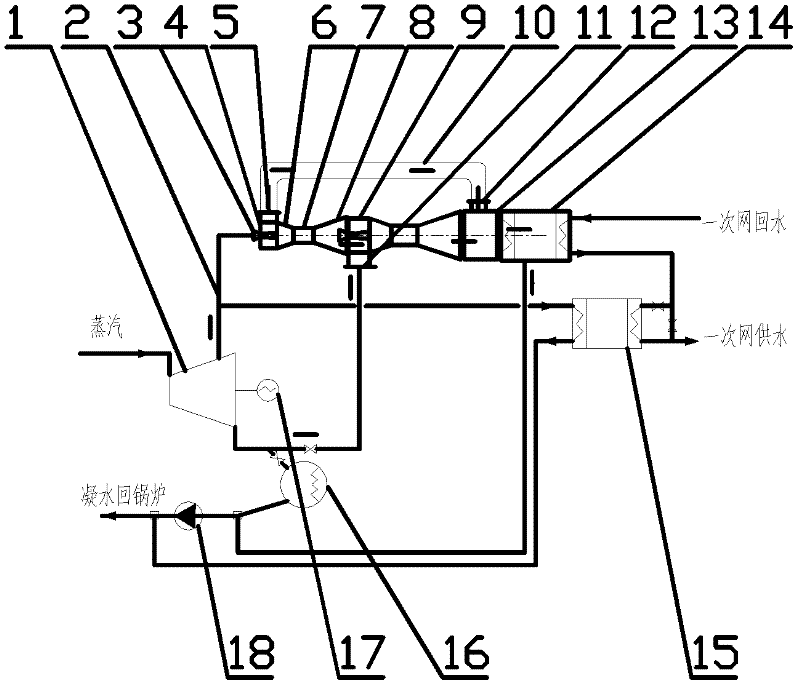

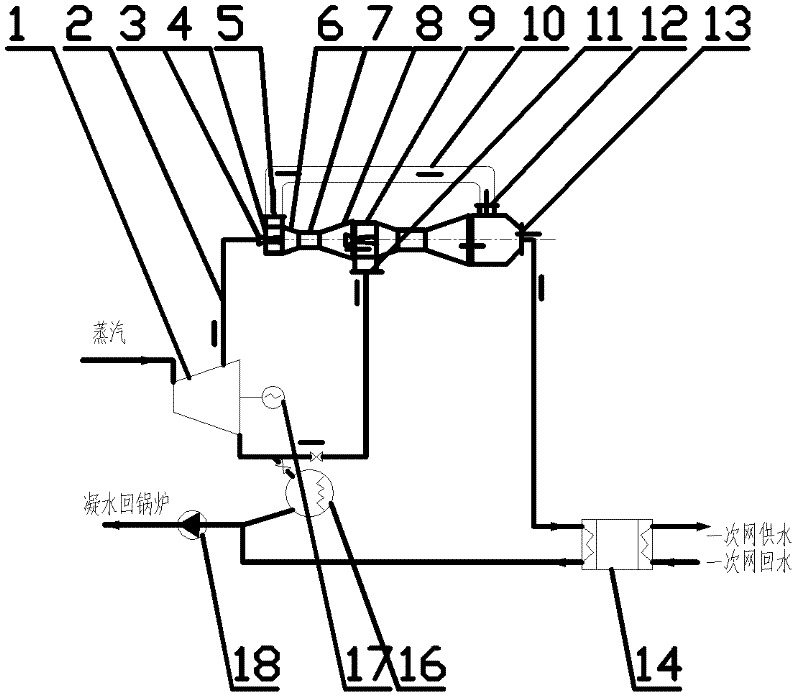

Thermal power generation system with function of exhaust steam recovery

InactiveCN102022144AReduce loadGuaranteed and stable vacuumSteam useEnergy industryThermal energyCooling tower

The invention discloses a thermal power generation system with the function of exhaust steam recovery, which belongs to the technical field of thermal power generation. The thermal power generation system comprises a boiler, a steam turbine, a generator, an exhaust-steam hot well, a closed pressure condensation tank, a centrifugal vapor compression machine and a membrane steam-water mix heater, wherein the boiler, the steam turbine and the generator are sequentially connected, and an exhaust steam outlet of the steam turbine is connected with the exhaust-steam hot well in which a water-spray cooling device is arranged; the condensed water discharged from the exhaust-steam hot well after sequentially passing through a hot-well condensate pump, the closed pressure condensation tank, a main condensate pump, the membrane steam-water mix heater, a water booster pump, a deaerator and a feed pump is fed into the boiler; and the exhaust steam discharged from the exhaust-steam hot well is divided into two parts after being pressurized by the centrifugal vapor compression machine, one part of exhaust steam is used for supplying heats for the outside, and the other part of exhaust steam is connected to the membrane steam-water mix heater to heat the condensed water. The thermal power generation system disclosed by the invention can recover huge amounts of thermal energies, and also can guarantee and stabilize the vacuum degree required by the steam turbine; and meanwhile, the problem of heat pollution caused by the exhaust steam of a cooling tower can be solved by using the thermal power generation system, and the water resource can be saved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

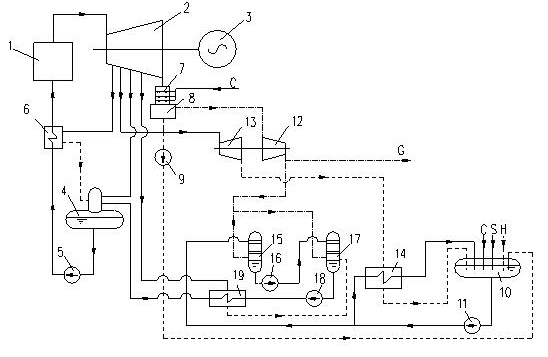

Multi-effect cascade jet type heat exchange based exhaust steam waste heat recovering and heat and power jointly producing system

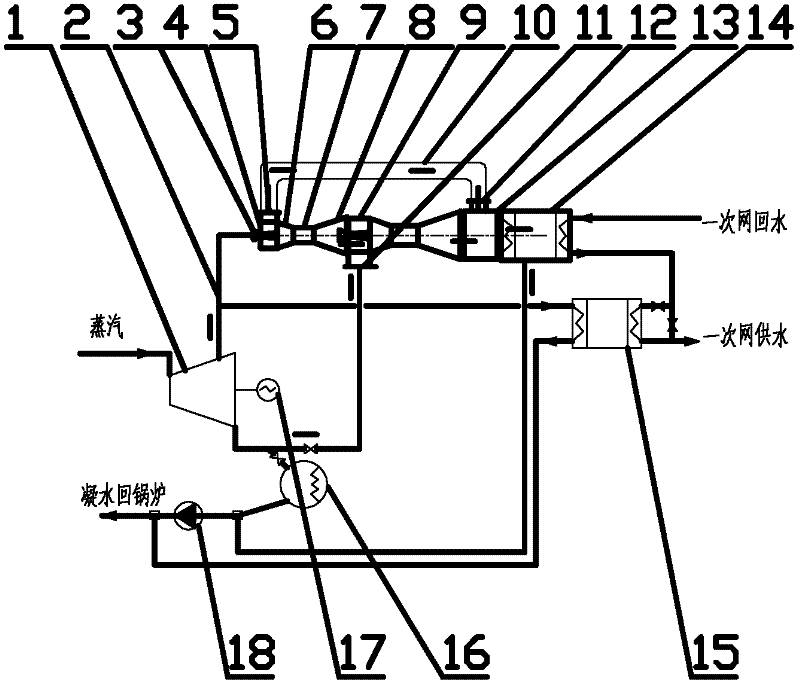

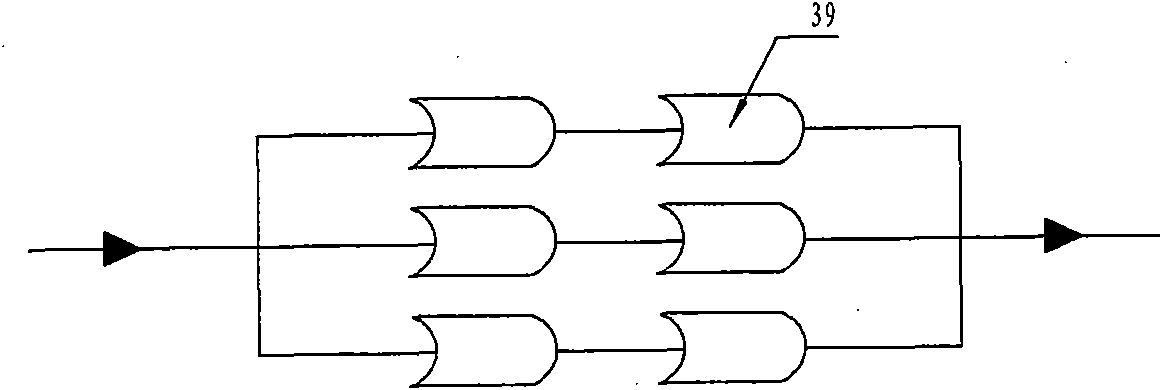

InactiveCN102519069AIncrease heating rateImprove energy efficiencyHeat recovery systemsLighting and heating apparatusWhole bodyCogeneration

The invention relates to a multi-effect cascade jet type heat exchange based exhaust steam waste heat recovering and heat and electrical jointly producing system, belonging to the field of exhaust steam waste heat recovering and heat and power joint producing. The system comprises a steam turbine, a multi-effect cascade jet heat pump, a heating network last-stage heater, a low-pressure steam-water heater, a high-temperature heating network heater, a steam condenser, a power generator and a condensate pump. The multi-effect cascade jet heat pump comprises a cascade first-stage mixing section, a cascade first-stage throat part, a cascade first-stage diffusing section, a cascade last-stage diffusing section, and a cascade last-stage distributor which are connected into a whole body in sequence, wherein the cascade first-stage mixing section is provided with a cascade first-stage jet opening. The system adopts the multi-effect cascade workflow, thereby the irreversible loss of the jet heat pump is greatly reduced, a large proportion of the exhaust steam is mixed with the medium-pressure extraction steam used as the driving steam, and the pressure is increased greatly. The primary heating network returns water, the technical problems of recovering the exhaust steam waste heat efficiently by adopting the jet heat pump and supplying heat by using the recovered exhaust steam waste heat are solved, and the waste heat recovering capacity is improved by several times.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

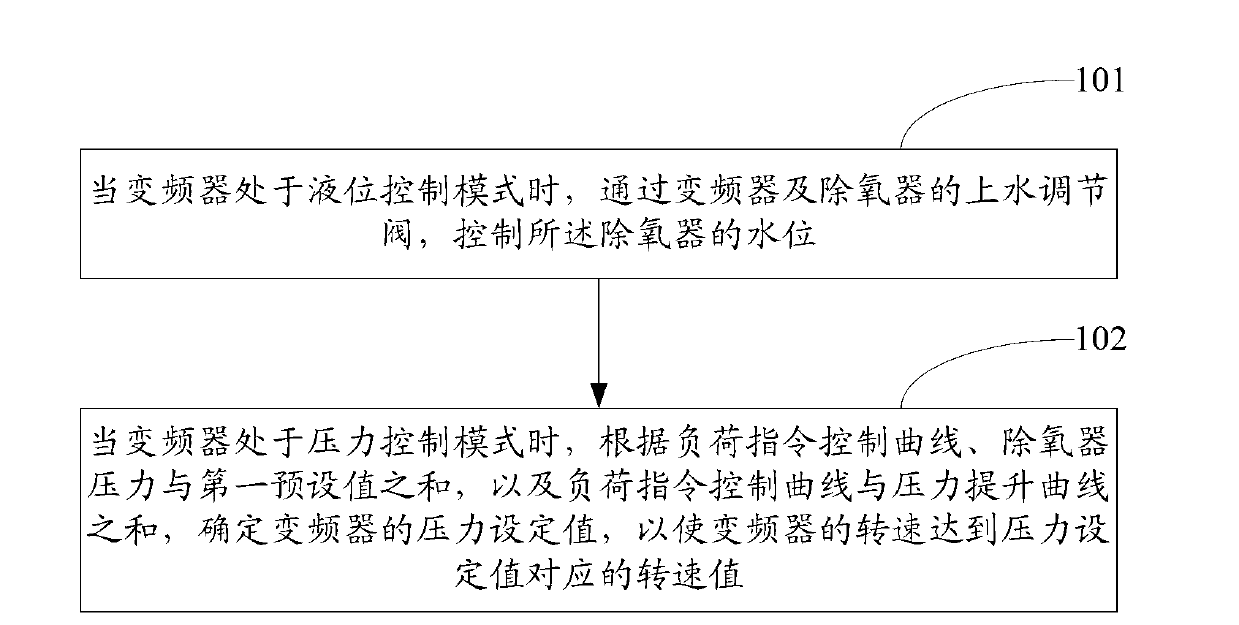

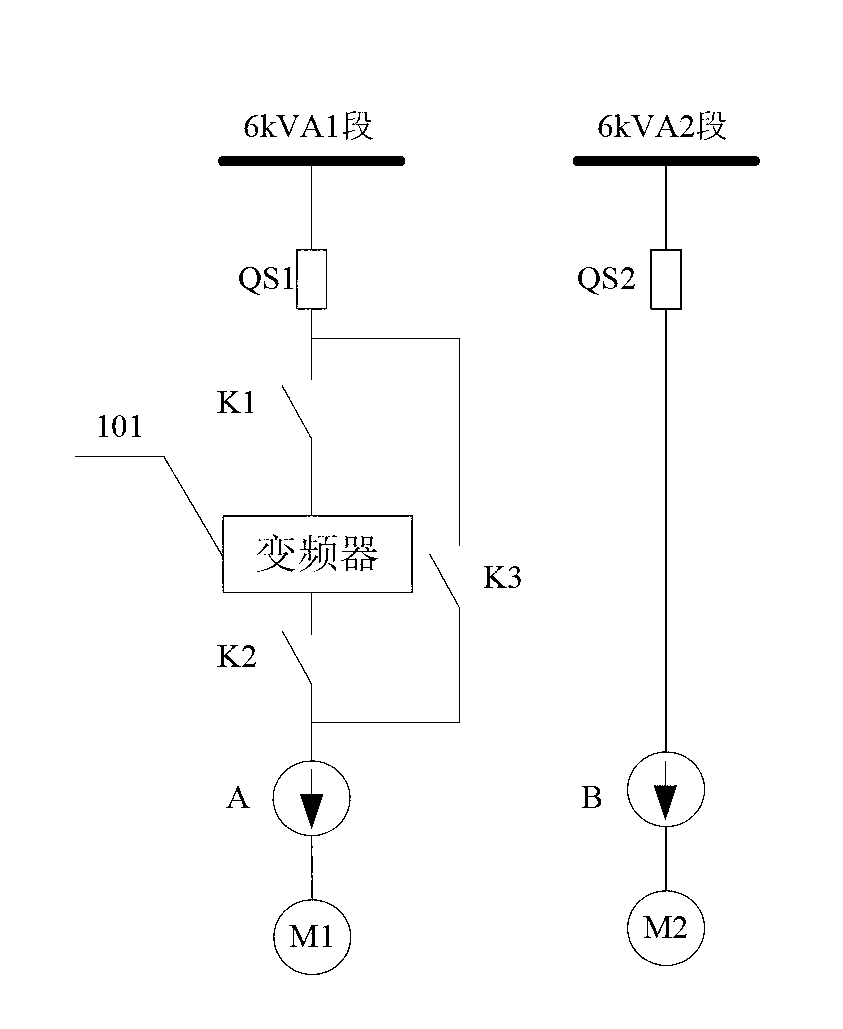

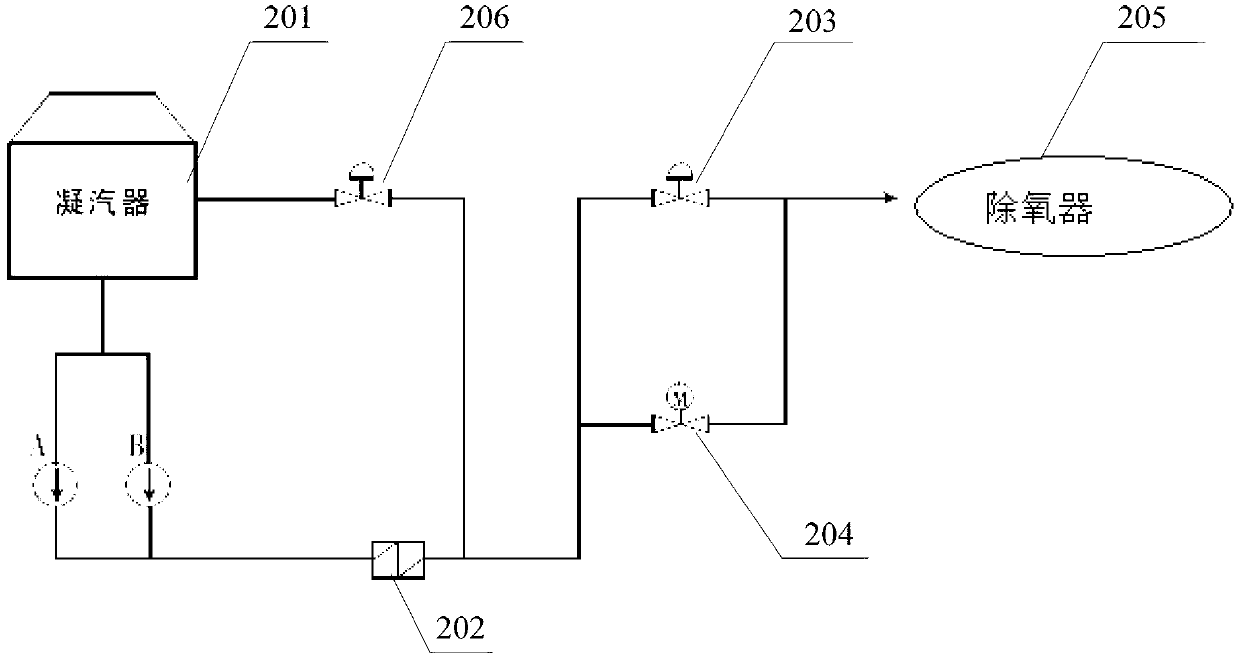

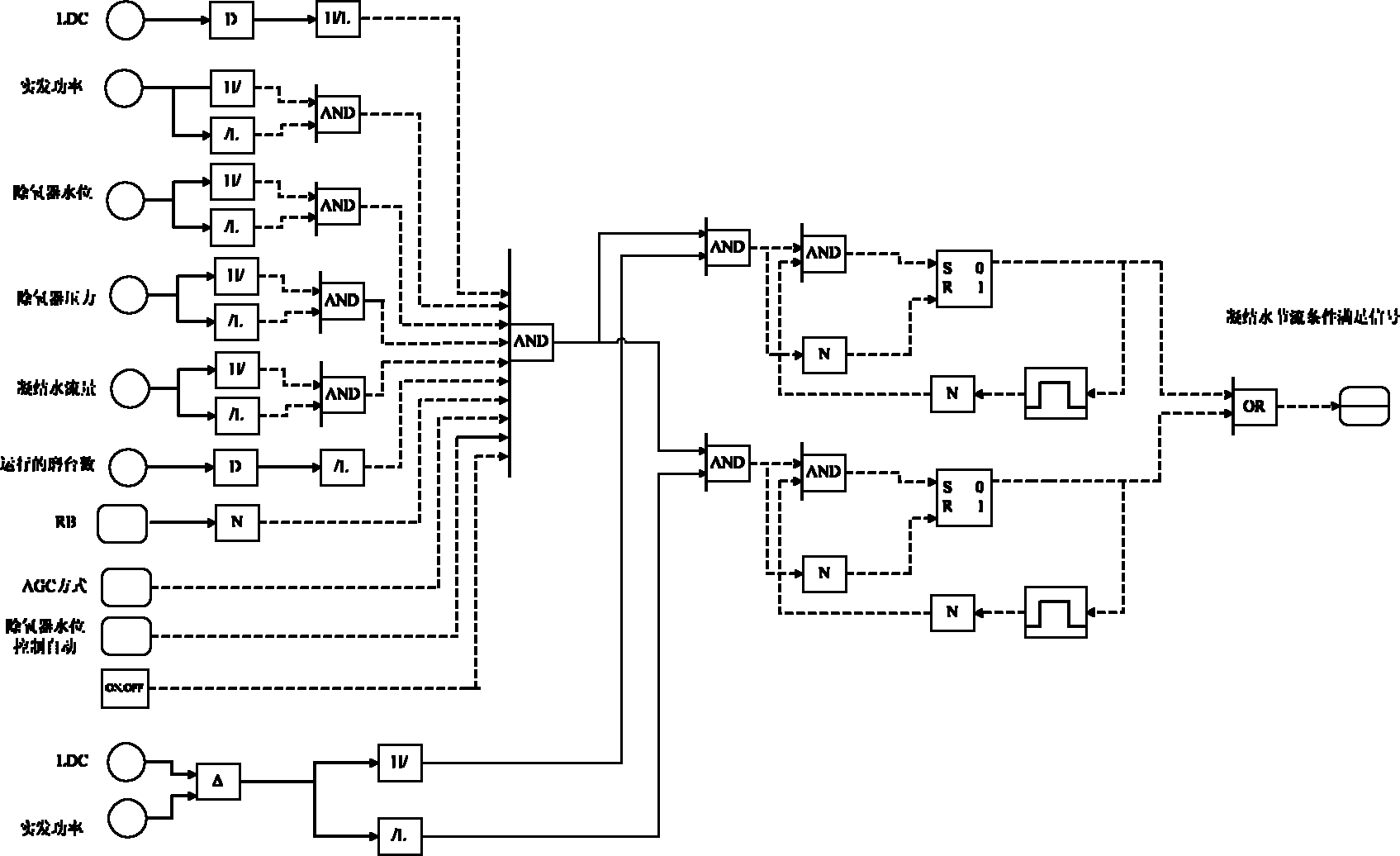

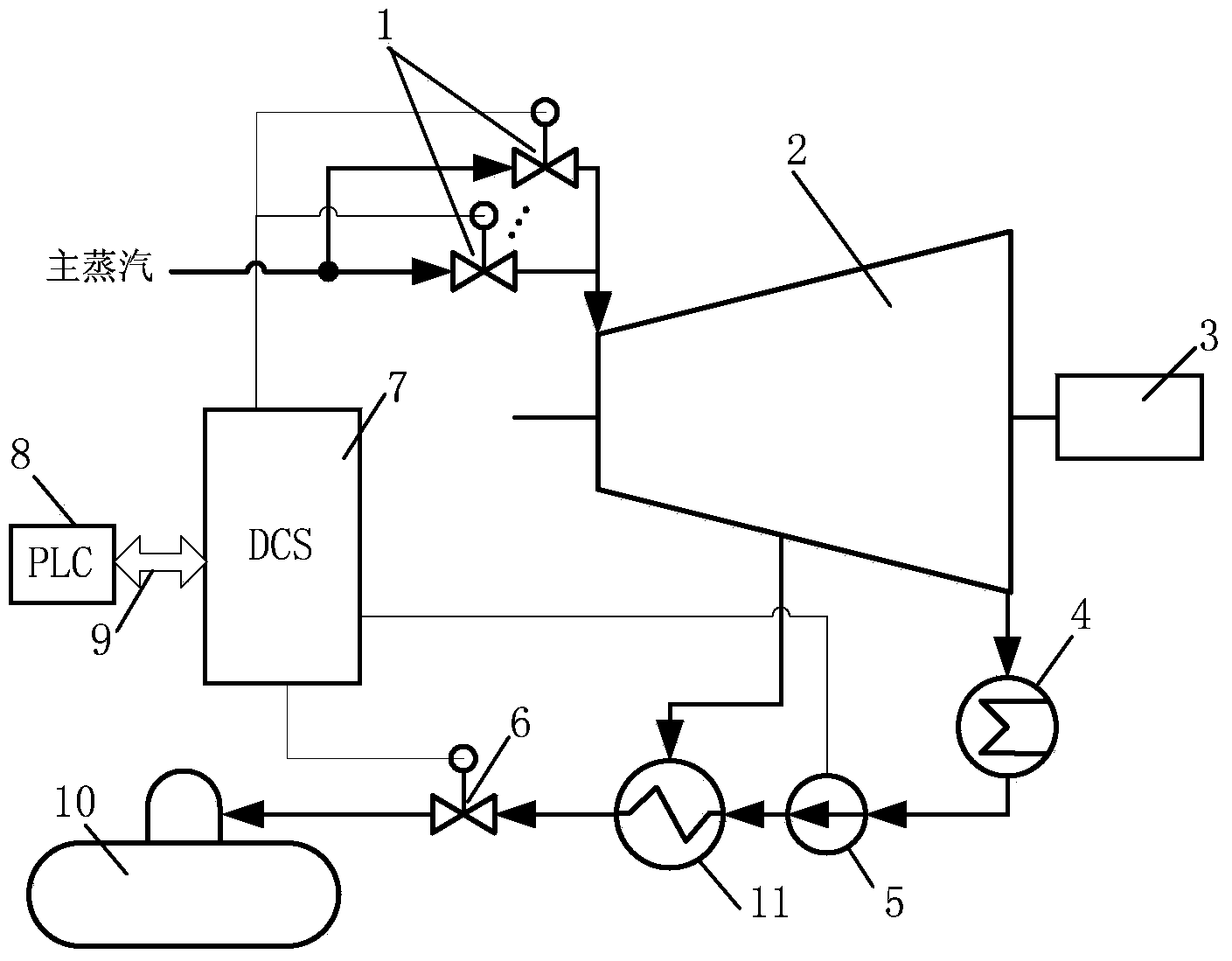

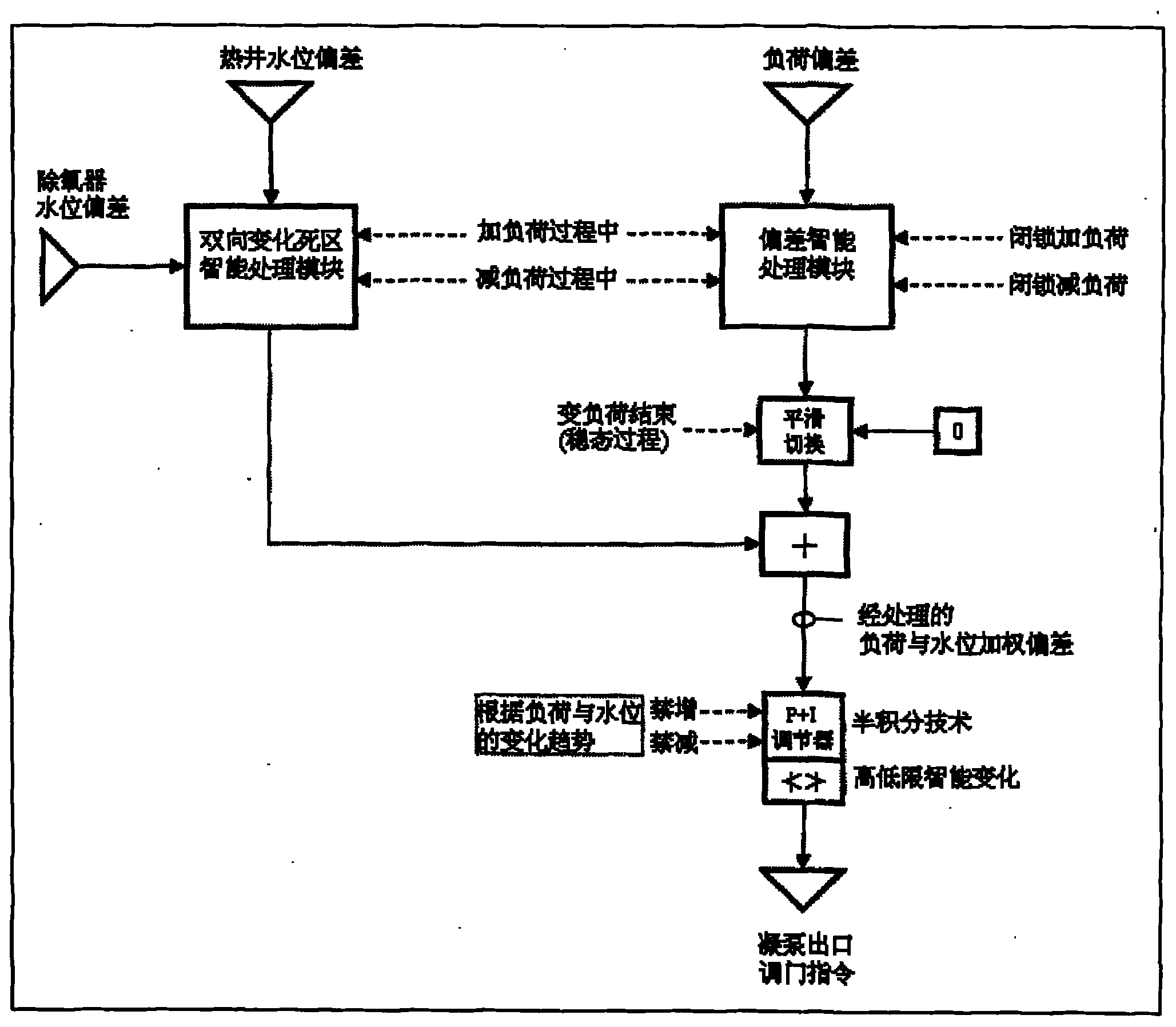

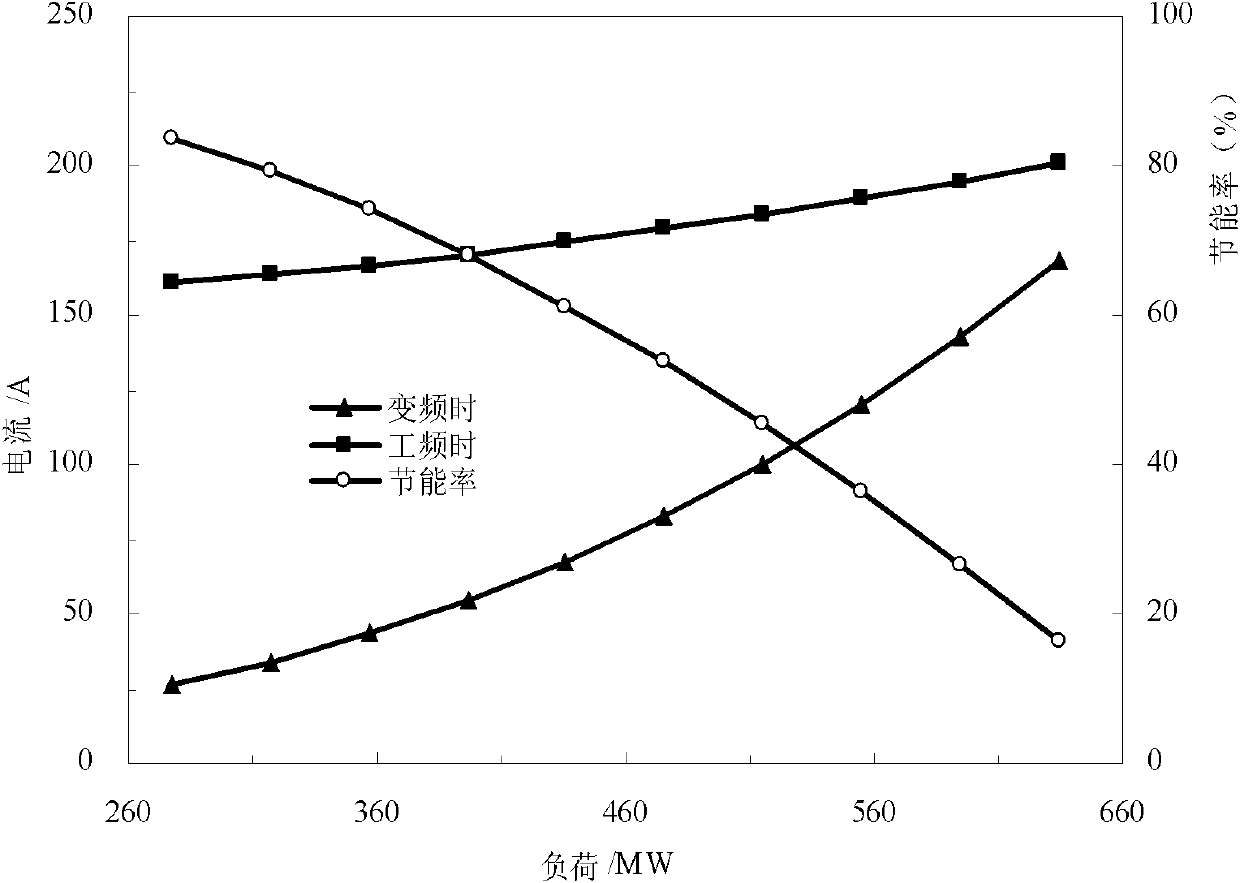

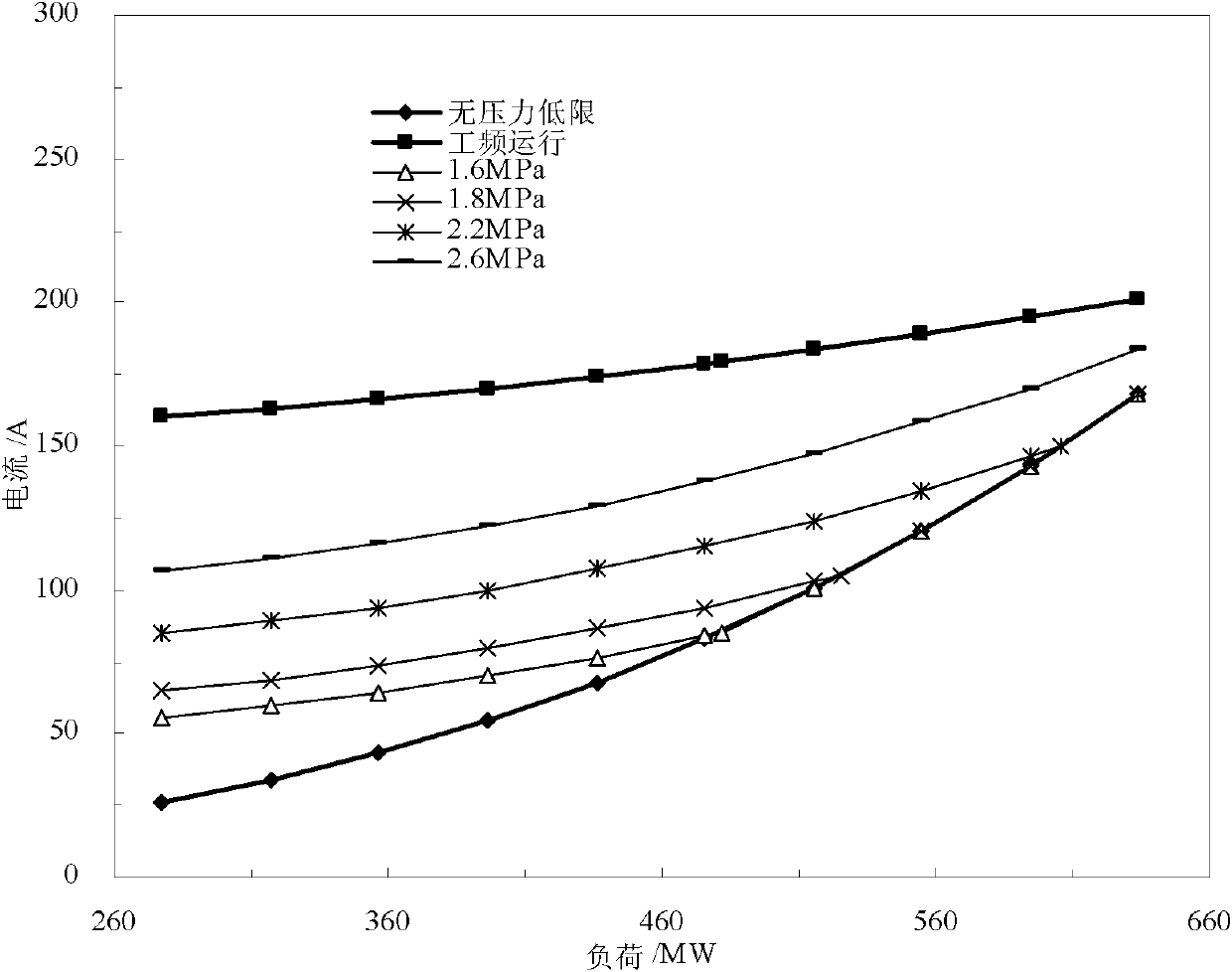

Frequency converting control method and system of condensate pump of condensed steam generator set

ActiveCN103133319AReduce speedOutput frequency adjustablePump controlPositive-displacement liquid enginesFrequency changerDeaerator

The invention discloses a frequency converting control method and system of a condensate pump of a condensed steam generator set. When a frequency converter is in a liquid control mode, the water level of a deaerator is controlled by the frequency converter and a water adjusting valve on the deaerator, and the frequency converter controls the water level of the deaerator by adjusting the rotating speed. A water feeding main adjusting valve on the deaerator is maintained at certain aperture according to the load of a machine unit; and under the same load, when the machine unit is in a load up stage, the aperture of the water feeding main adjusting valve is maintained to be small, and when the machine unit is in a load down stage, the aperture of the water feeding main adjusting valve is maintained to be large. Simultaneously certain load space can be generated by control of two clamped curves during load up and load down, and frequent aperture changing of the water feeding adjusting valve caused by small load fluctuation can be avoided. The rotating speed of the frequency converter can be lower, the current is small, the output frequency of the frequency converter is in the adjustable and economical range, and energy consumption of the frequency converter is reduced.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Coal-fired power generation and waste heat power generation coupling system for private station of cement kiln

ActiveCN102080582AReduce non-adjusted steam extractionImprove stabilityEnergy industryIncreasing energy efficiencyEngineeringDeaerator

The invention discloses a coal-fired power generation and waste heat power generation coupling system for a private station of a cement kiln, comprising a coal-fired boiler, a kiln head waste heat boiler, a kiln tail waste heat boiler, a kiln head steam pocket, a kiln tail steam pocket, a condensing steam turbine, a condensate pump, a heater, a deaerator, a water feeding pump and related auxiliary devices, wherein the kiln head waste heat boiler utilizes a dual-pressure system; a primary economizer of the low-pressure system is used as a public economizer for the waste heat power generation; the high-pressure steam and the steam generated by the kiln tail waste heat boiler are collected to the main steam pipeline of the waste heat power generation system; one path of the main steam pipeline is connected with a steam turbine of the waste heat power generation system while the other path thereof is connected with non-adjustable extraction steam of a coal-fired steam turbine; one path ofthe main steam pipeline of the coal-fired unit is connected with the coal-fired steam turbine while the other path thereof is connected with the waste heat steam turbine. In the invention, the coal-fired power generation is rationally coupled with waste heat power generation system so that the problem that the stability of the waste heat power generation system of the cement kiln is low is solved, and the whole thermal circulating efficiency of the private station can be largely increased.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

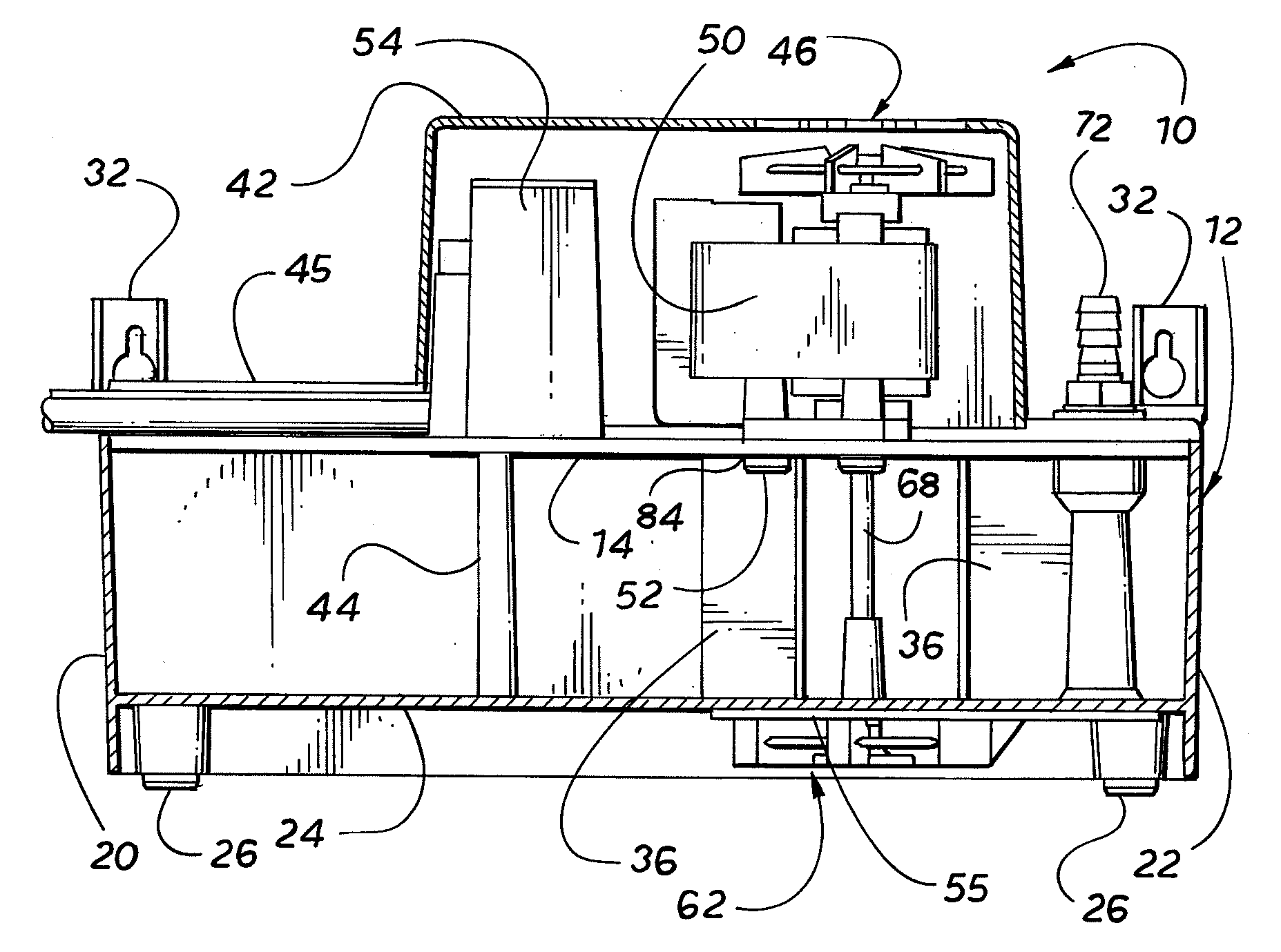

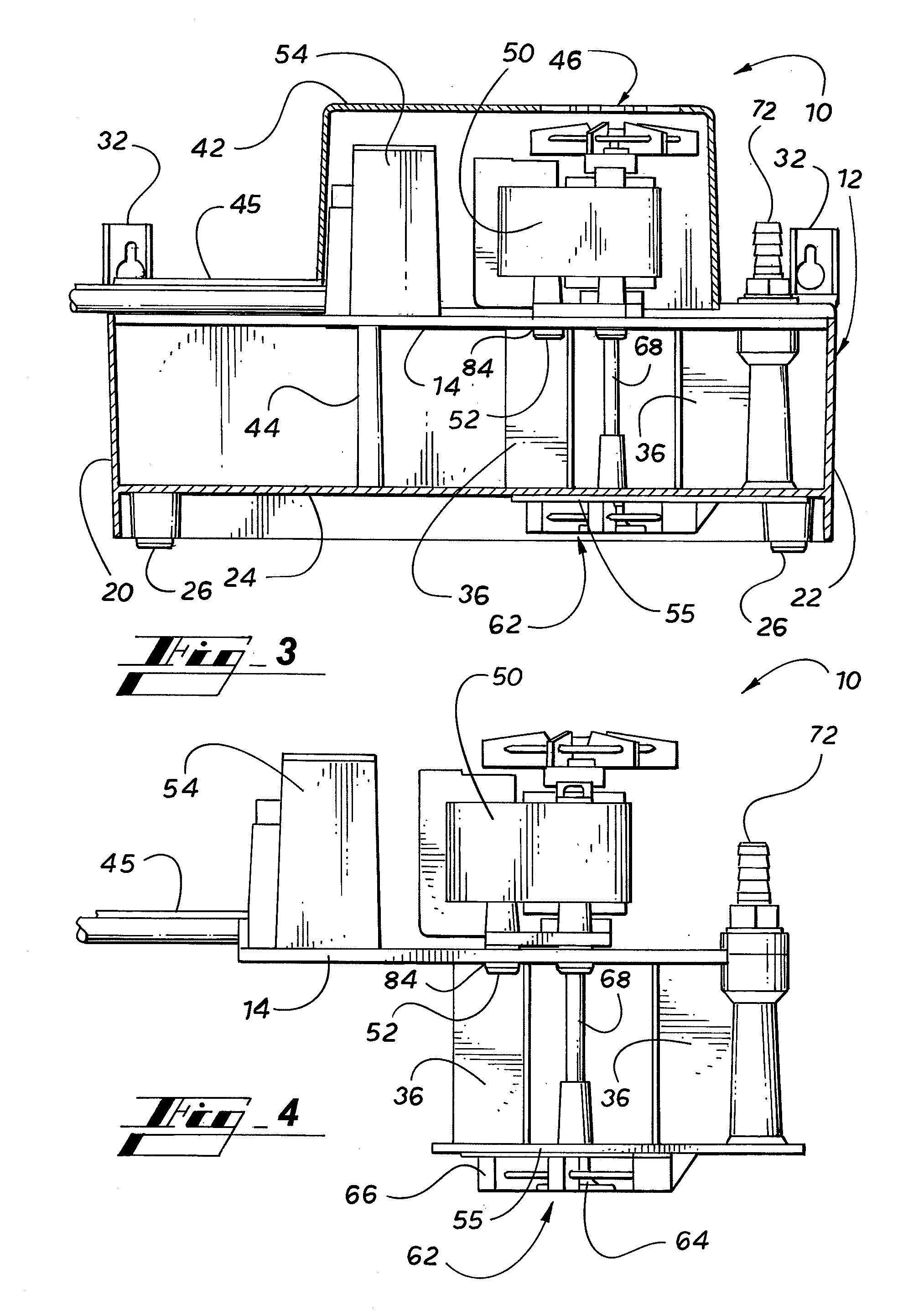

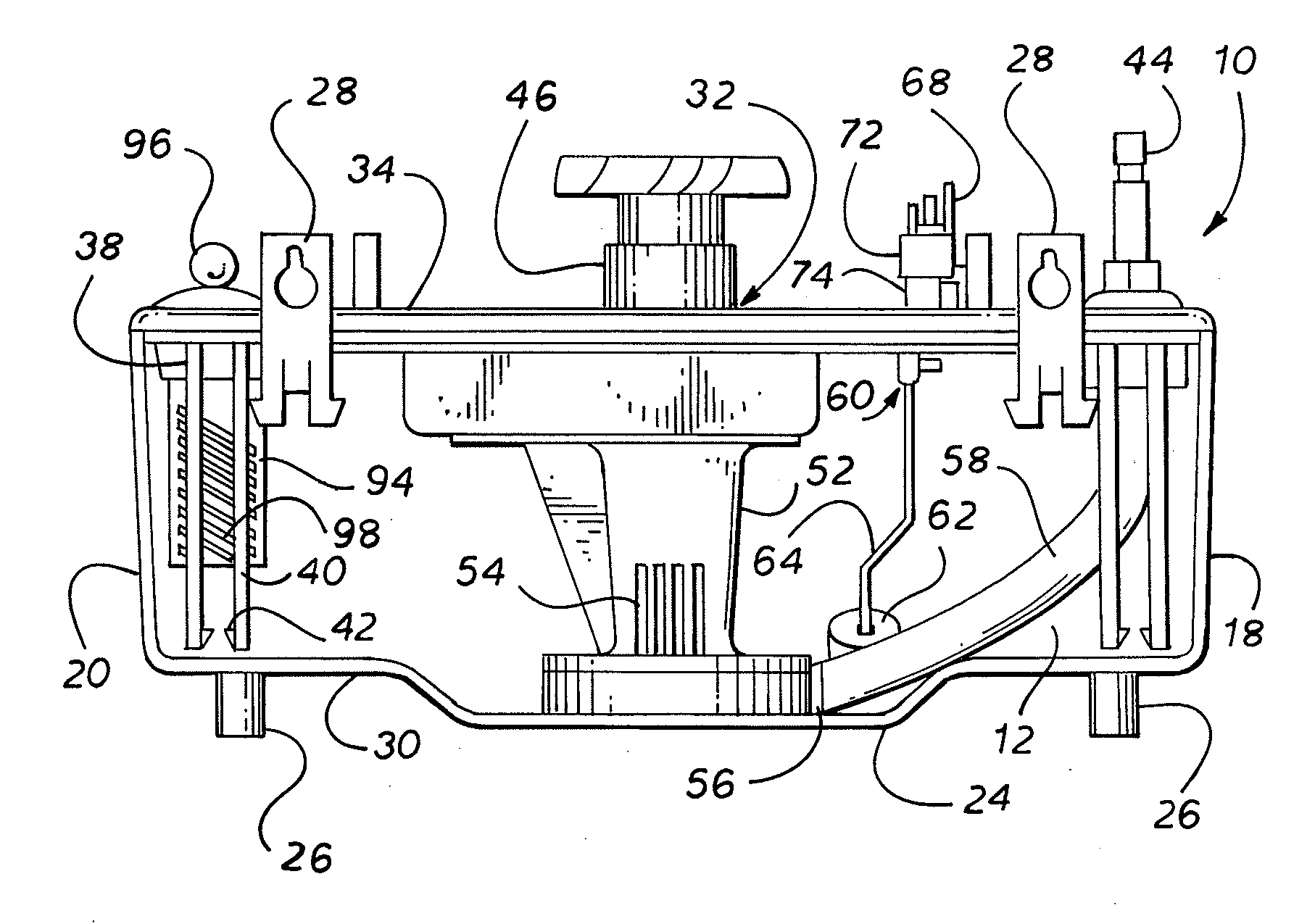

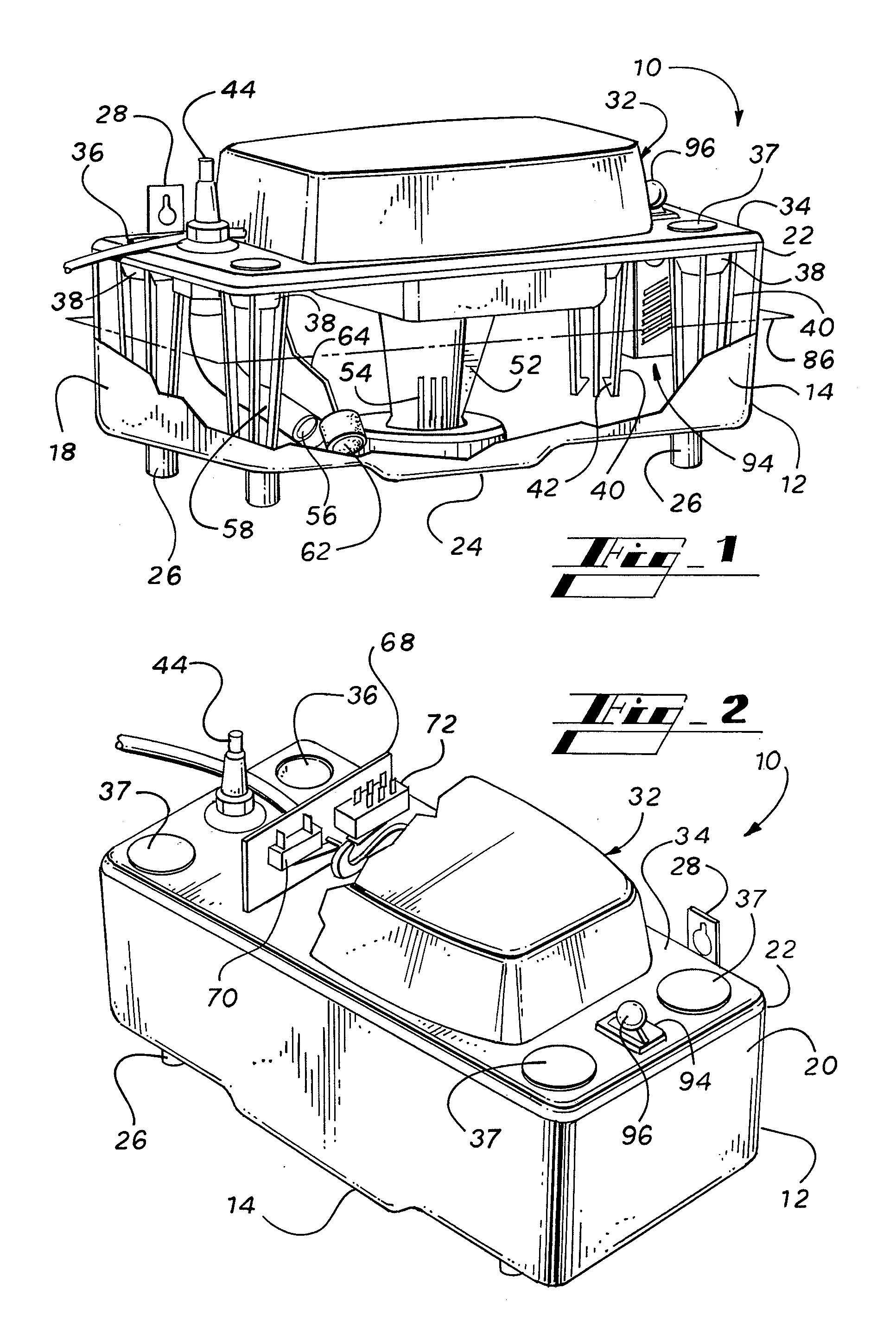

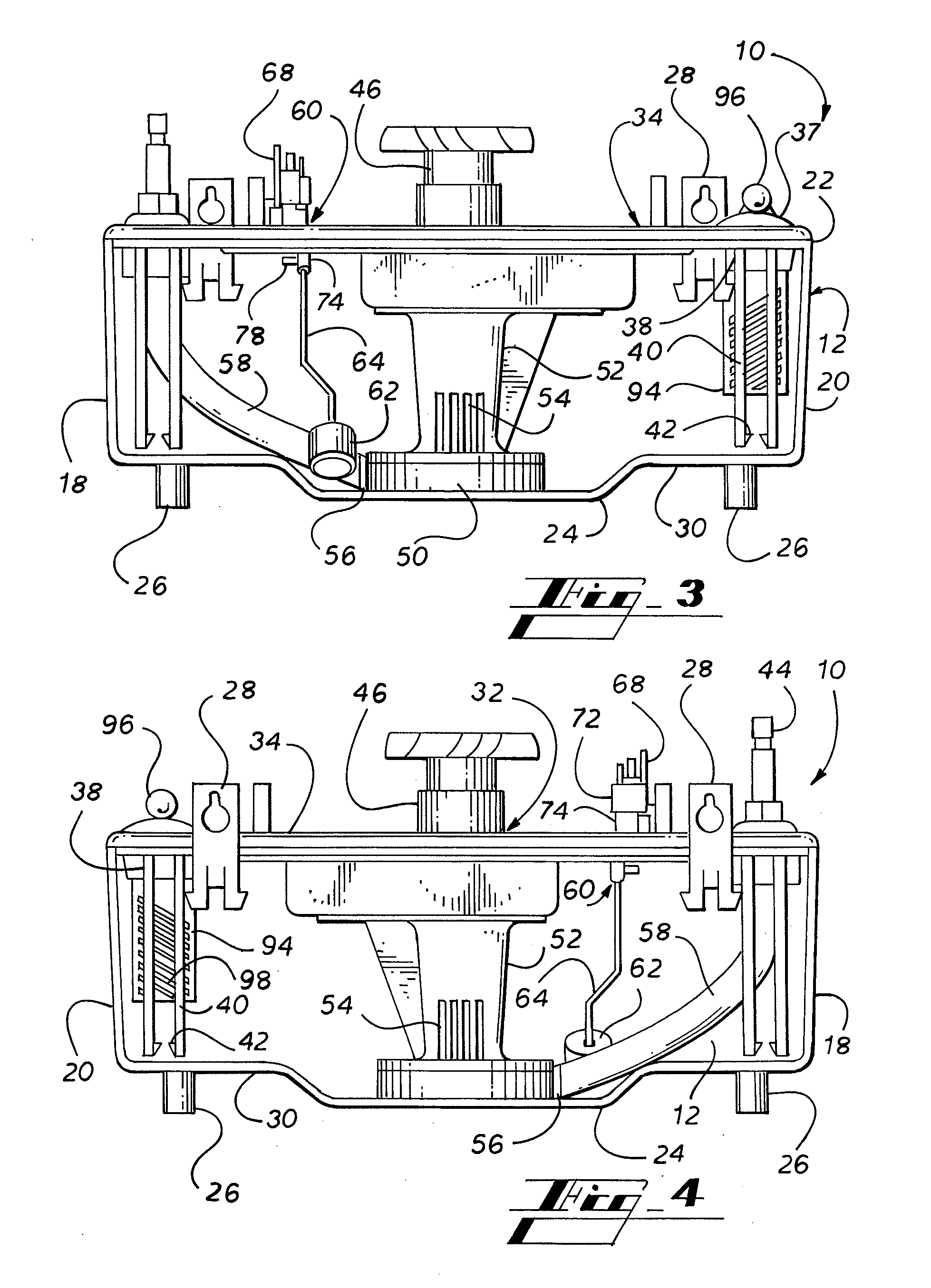

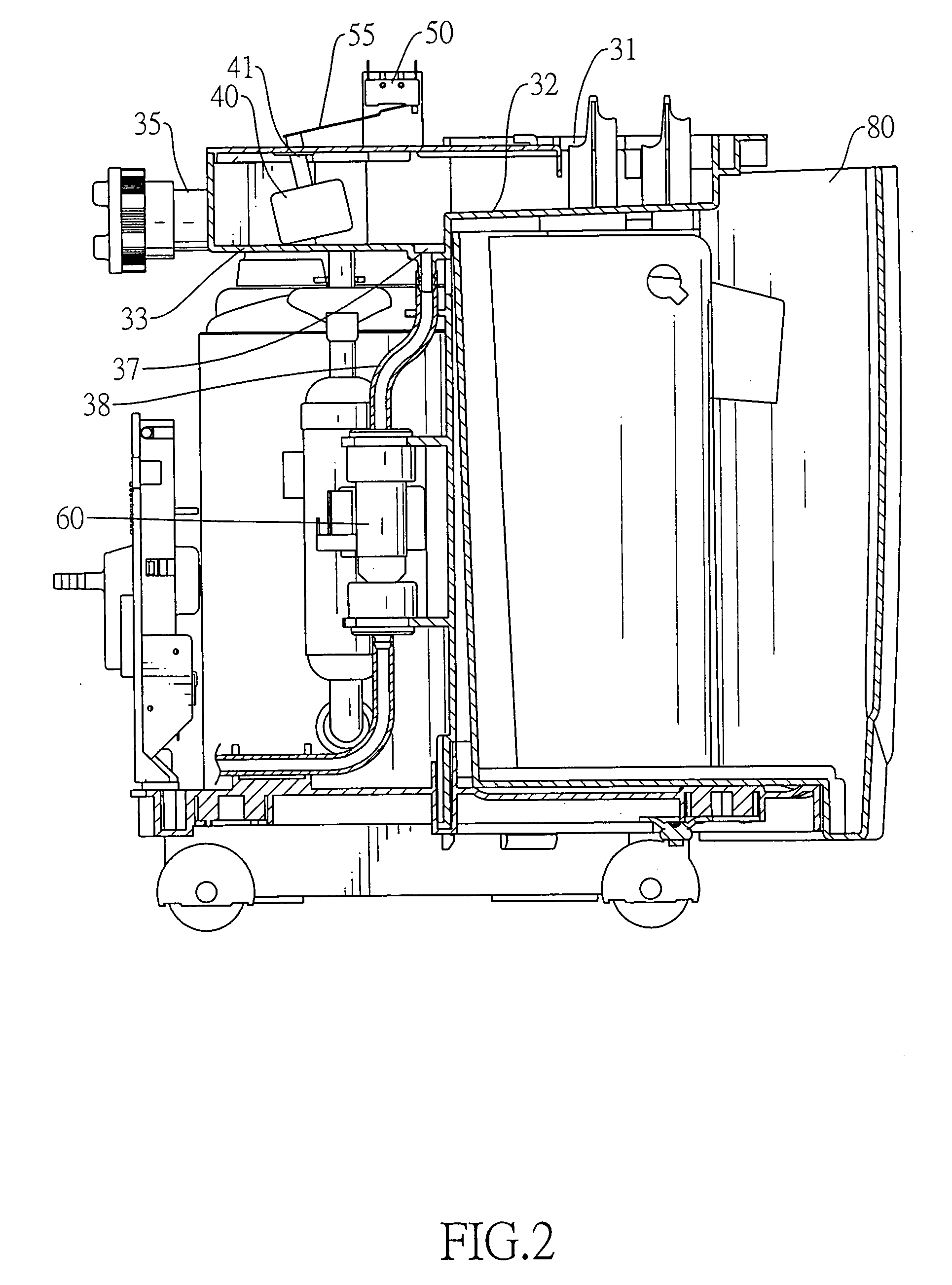

Condensate pump

InactiveUS20070224050A1Reduce maintenanceEasy to observeLighting and heating apparatusSpace heating and ventilation detailsImpellerControl electronics

A condensate pump for an HVAC system includes a reservoir with a top assembly, which includes control electronics, a pump motor, and a pump impeller, mounted on top of the reservoir. The condensate pump includes wall hangers. The top assembly has a top cover with four inlet openings, and the top cover is reversible to accommodate placement of the electric service and the evaporator tube. The top cover has tube holders that extend into the reservoir so that the evaporator tube does not bottom out in the reservoir. The reservoir is made of clear plastic so that the water level can be readily observed. The condensate pump has control circuitry that can shut off the HVAC system or sound an alarm when the pump fails. The condensate pump has a drawer for biostat tablets. The drawer passes through the top assembly and extends into reservoir.

Owner:DIVERSITECH

Dehumidifier with multistage draining

InactiveUS20100000242A1Operating means/releasing devices for valvesLighting and heating apparatusEngineeringCondensate pump

A dehumidifier with multistage draining has a container that collects and stores condensed water from a dehumidifying assembly, a float mounted in the container, a float actuator connected to the float and a drain motor connected to the float actuator and an attachment actuator having a switch. When an external pipe is connected to the attachment connector to switch on the switch and the condensed water in the container gradually raises the float to switch on the float actuator, the drain motor is switched on to pump the condensed water out of the container. The dehumidifier automatically drains condensed water in the container according to the quantity of the condensed water, does not have to be cleared frequently and is convenient.

Owner:NEW WIDETECH IND

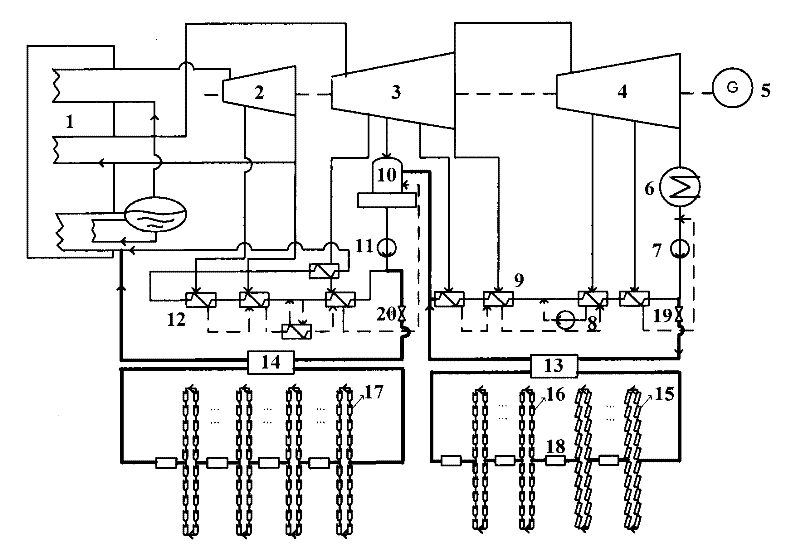

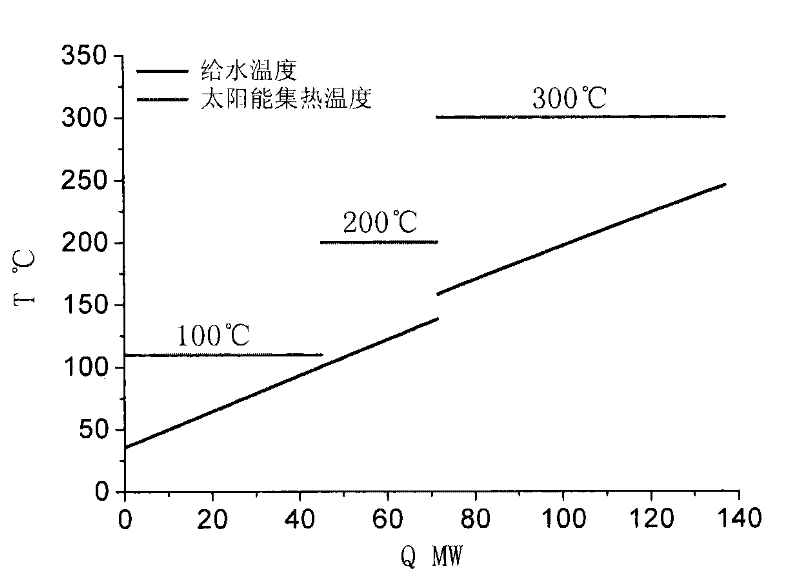

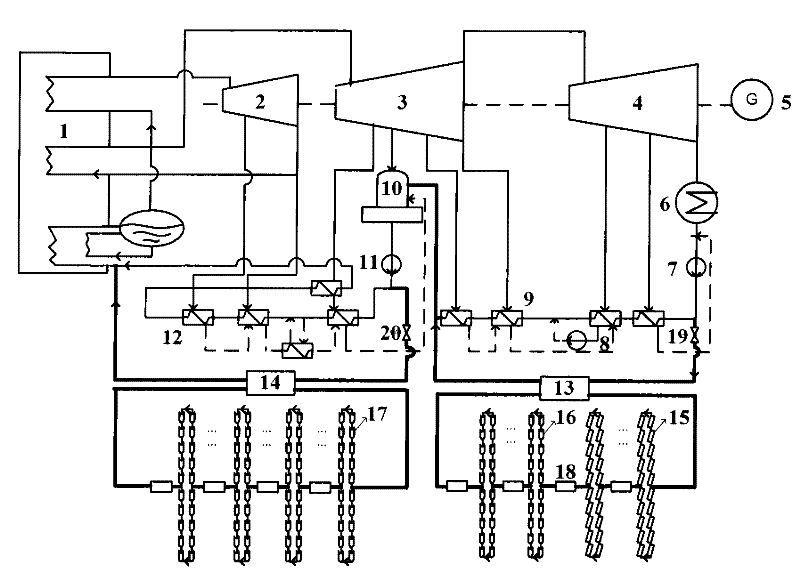

Board slot combined solar energy and thermal power station complementary generating system

ActiveCN102454440AReduce irreversibilityHigh thermal efficiencySteam generation heating methodsSolar heat devicesWater vaporDeaerator

The invention discloses a board slot combined solar energy and thermal power station complementary generating system which comprises a coal-fired boiler, a steam turbine, a generator, a condenser, a condensate pump, an oil-water heat exchanger of a low-pressure solar feed water heater, a flat-plate solar collector, a first parabolic trough type solar collector, a deaerator, a high-pressure water pump, an oil-water heat exchanger of a high-pressure solar feed water heater and a second parabolic trough type solar collector, wherein the steam turbine comprises a high-pressure cylinder, an intermediate-pressure cylinder and a low-pressure cylinder; high-temperature and high-pressure steam generated in the coal-fired boiler does work by expansion in the high-pressure cylinder, the intermediate-pressure cylinder and the low-pressure cylinder of the steam turbine to drive a generator to rotate and output an electrical load externally. The generating system can be used for realizing the capacity expansion and consumption reduction of thermal power stations and solving the problem that the solar energy is unstable and discontinuous, and is beneficial to low-cost transformation of the thermal power stations and large-scale application and popularization of a solar energy technology.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

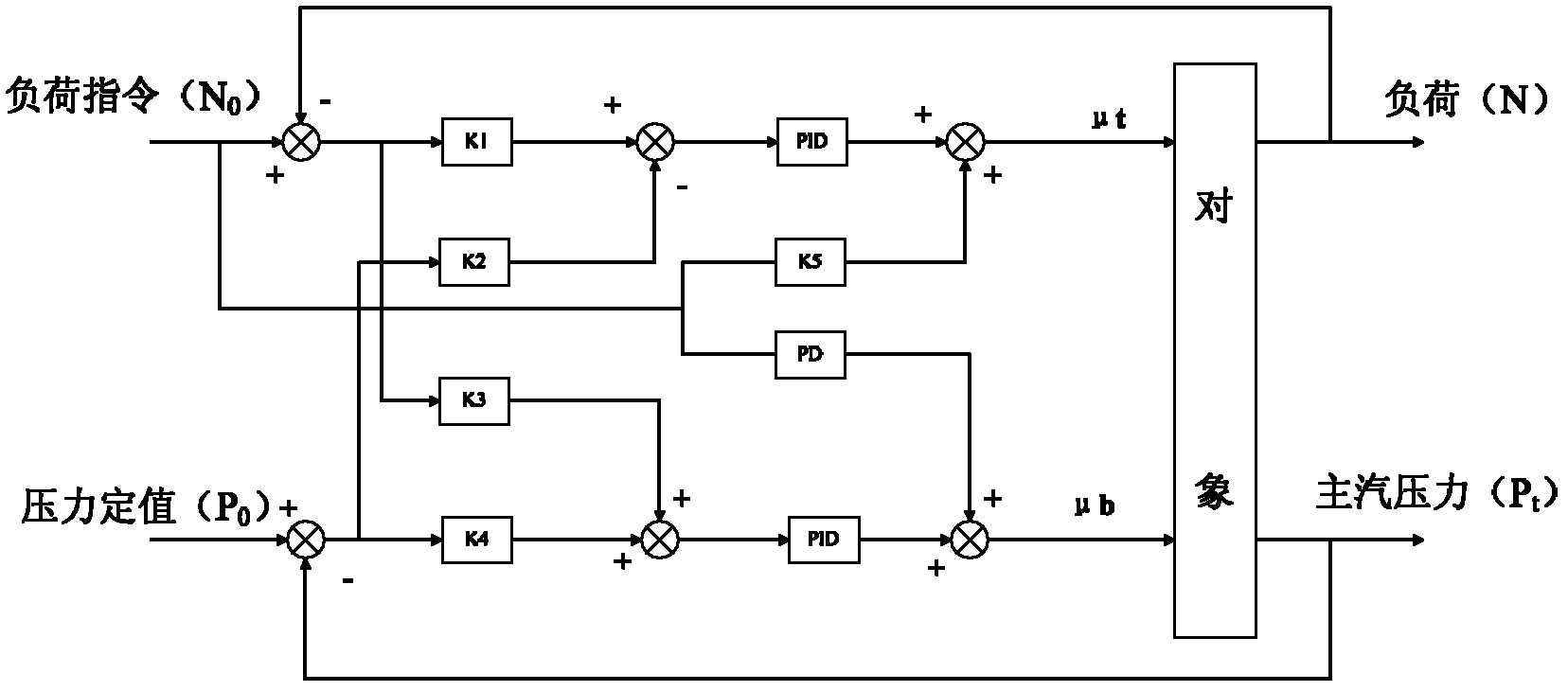

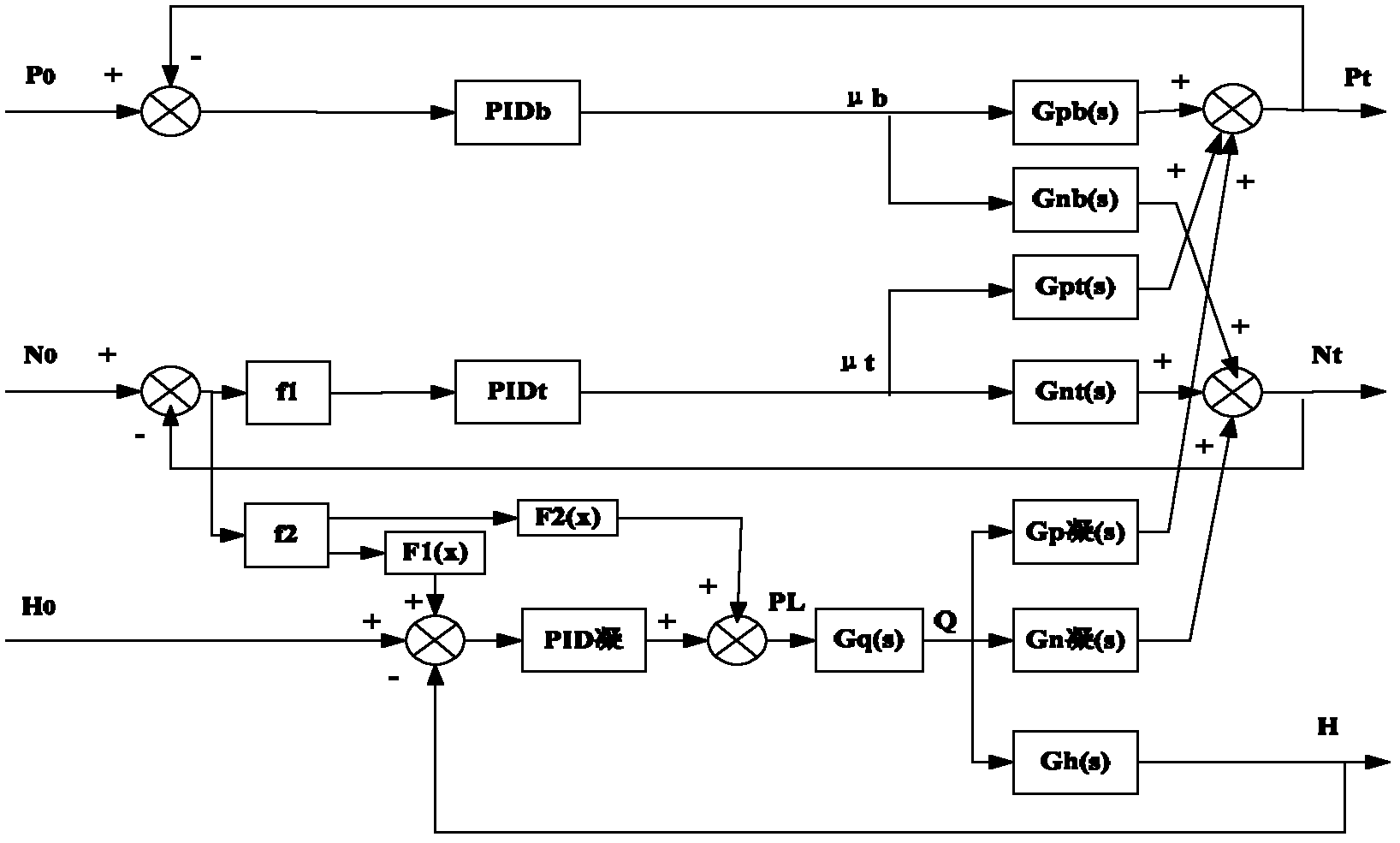

Coordinative control method for pulse-mode regulation of condensate flow to participate in frequency modulation

InactiveCN102629131AImprove control economyReduce the frequency of movementsTotal factory controlProgramme total factory controlControl mannerCondensate pump

The invention discloses a coordinative control method for the pulse-mode regulation of condensate flow to participate in frequency modulation, which comprises four steps: 1: several control forms in a traditional coordinative control mode are defined, i.e. three control modes including boiler following mode (BF), turbine following mode (TF) and coordinative control (CC); 2: a transfer function schematic diagram of the traditional coordinative control mode are given; 3: compared with the traditional coordinative control, the new coordinative control system for unit additionally adopts the frequency of a condensate pump frequency converter as regulating amount and the water level of a deaerator as regulated amount, so this system is changed into a 3x3 coupling system; and 4: the purpose of changing unit load is achieved by means of pulse-mode regulation for condensate flow. Aiming at the load-pressure control object in a thermal power unit boiler-turbine system, a new control method for the pulse-mode regulation of condensate flow to partially replace main steam valve and participate in modulation for power grid frequency is designed, and this method has good reference and practical values in the technical field of industrial control for thermal power generation procedures.

Owner:GUODIAN SCI & TECH RES INST

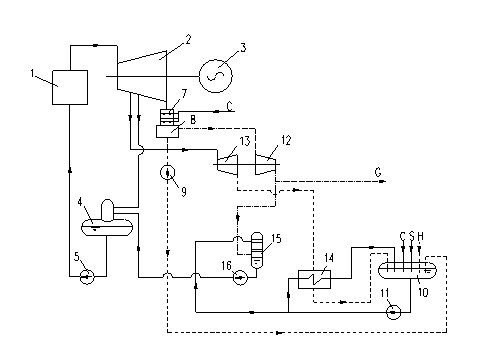

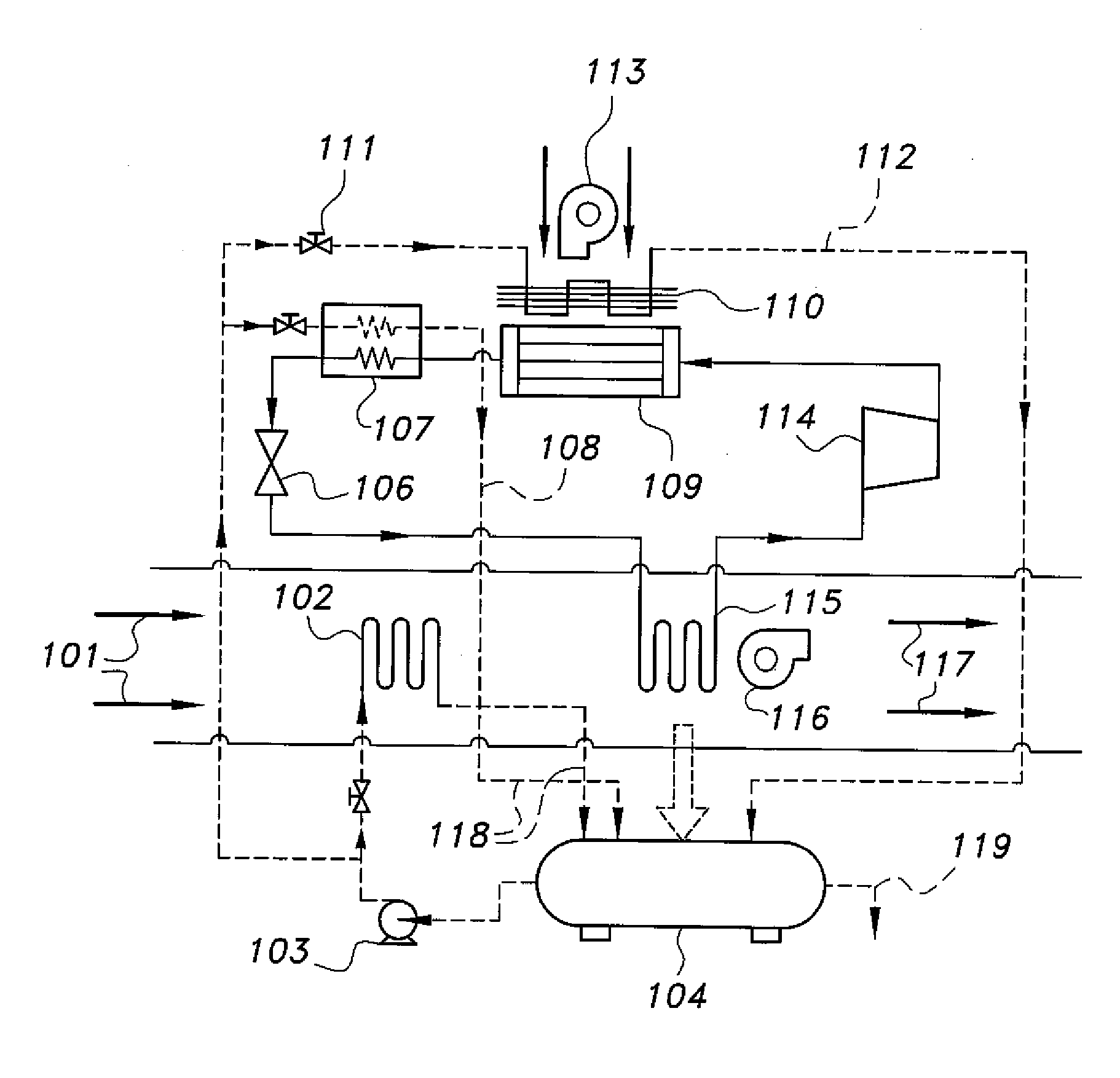

Air conditioning system with pre-cooler

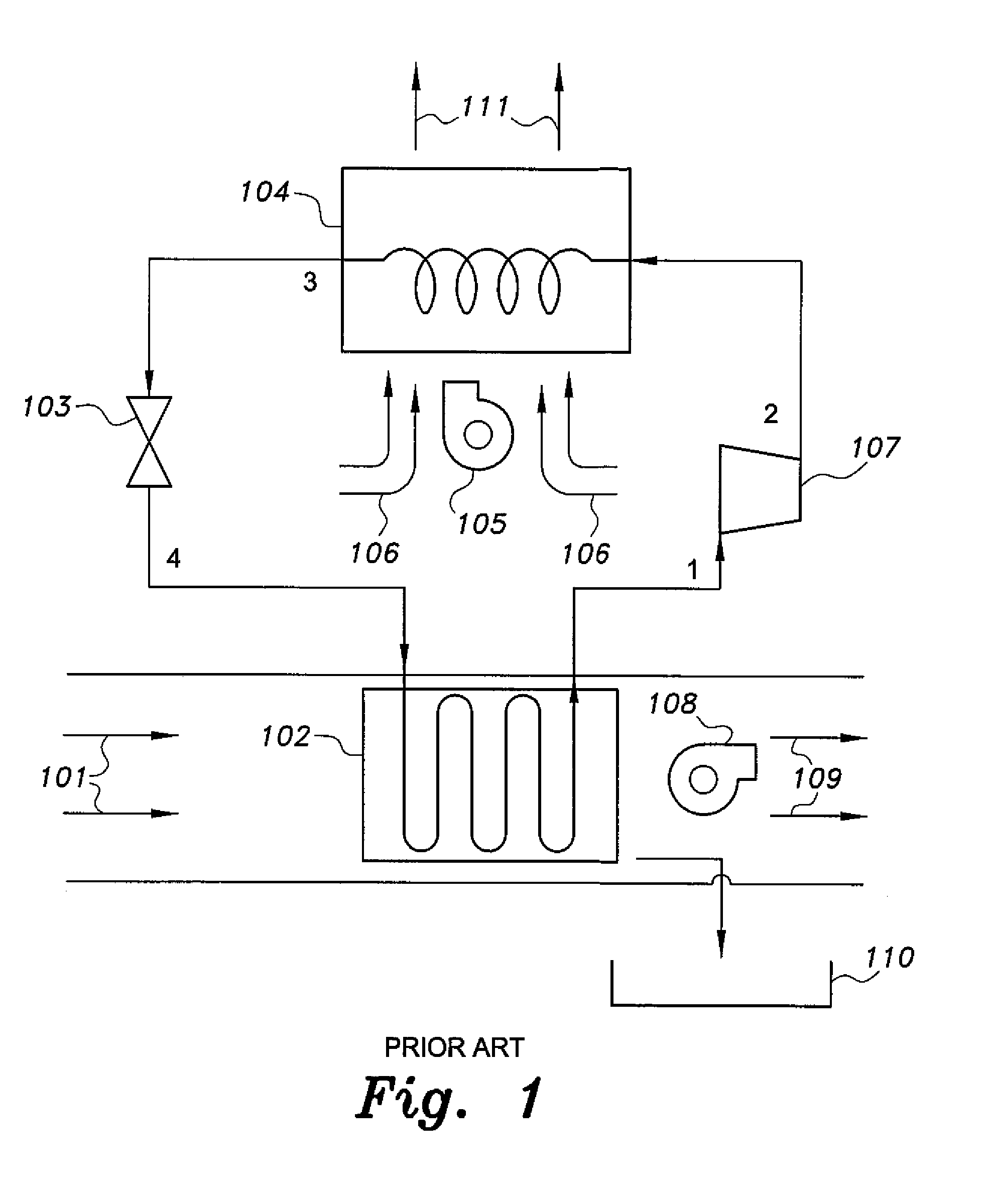

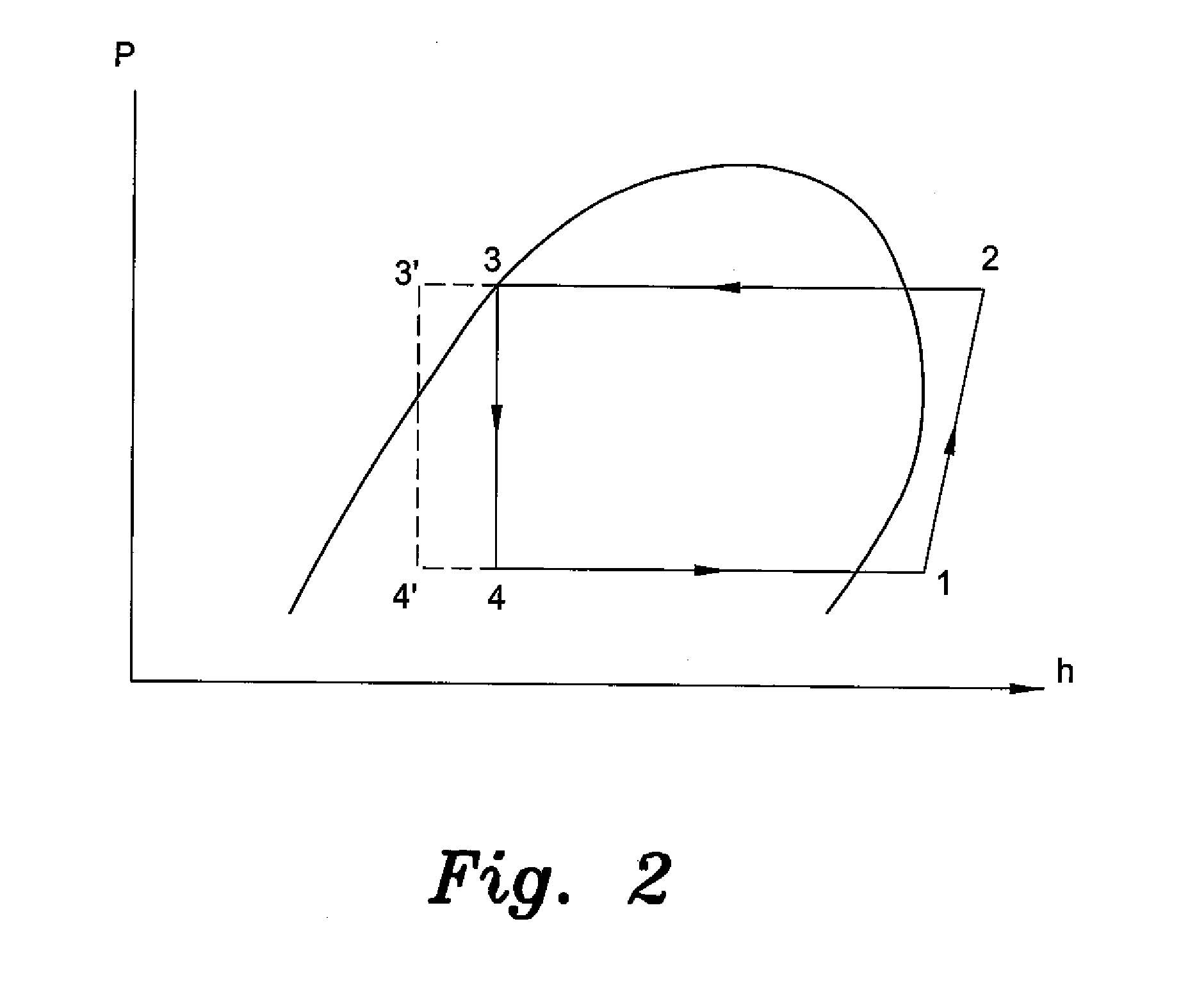

InactiveUS20150362230A1Readily apparentEvaporators/condensersSubcoolersAir conditioningCondensate pump

The air conditioning system with pre-cooler includes a compressor; a condenser; an evaporator; a condensate reservoir to collect condensed water discharged from the evaporator; and a condensate pump associated with the condensate reservoir. In one embodiment, the system includes a single pre-cooler that uses condensate to precool air before it reaches the evaporator. In a second embodiment, the system includes a sub-cooler between the condenser and an expansion valve that uses the condensate to pre-cool the refrigerant before it reaches the evaporator. In a third embodiment, the system includes a first pre-cooler that uses condensate to precool air before it reaches the evaporator; a sub-cooler between the condenser and an expansion valve that uses the condensate to pre-cool the refrigerant before it reaches the evaporator; and a second pre-cooler that uses the condensate to pre-cool air before it reaches the condenser.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

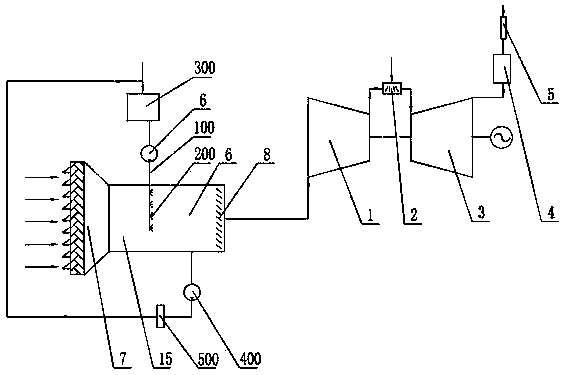

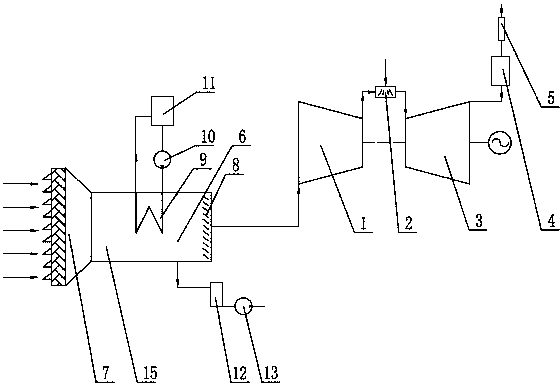

Combined type energy-saving gas turbine inlet air cooling system

ActiveCN103470379AReduce installed capacityIncrease output powerGas turbine plantsJet propulsion plantsCombustion chamberAir filter

The invention relates to a combined type energy-saving gas turbine inlet air cooling system which comprises an air compressor, a combustion chamber and a gas turbine, wherein the air compressor is connected with an air outlet pipeline of a cooler, the air inlet of the cooler is connected with an air filter, a demister is arranged in the cooler, a first surface heat exchanger is arranged in the air cooler, the water inlet of the first surface heat exchanger is connected with the water outlet of a first chilled water circulating pump, the water inlet of the first chilled water circulating pump is connected with the chilled water outlet of a main refrigerator, the water outlet of the first surface heat exchanger is connected with the chilled water inlet of the main refrigerator, the water outlet of the cooler is connected with a water inlet of a condensed water tank, condensed water returns to the cooler via a high pressure pipe, an atomizing nozzle is arranged on the high pressure pipe stretching into the cooler, and the high pressure pipe outside the cooler is provided with a condensed water pump and a condensed water filtering device. According to the invention, indirect heat exchange cooling and direct evaporative cooling are adopted by the combination, so that the energy consumption is reduced, the installing capacity of the main refrigerator is reduced, and the system is suitable for use in areas with high temperature and high humidity.

Owner:无锡金龙石化冶金设备制造有限公司

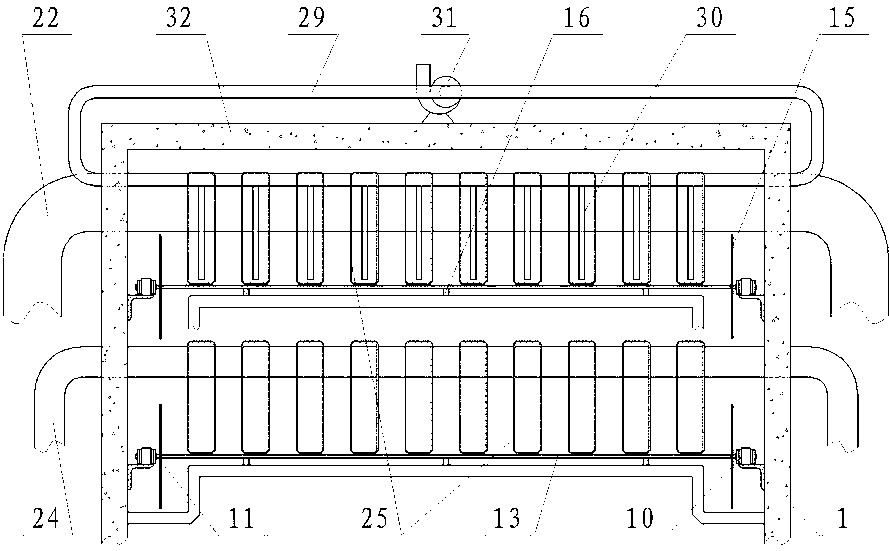

Water circulation pre-heating type corncob drier

InactiveCN103070235AKeep dryImprove uniformitySeed preservation by dryingWater circulationEngineering

The invention provides a water circulation pre-heating type corncob drier. The water circulation pre-heating type corncob drier is characterized in that a box is partitioned into an upper region and a lower region by a partition plate I; the lower region is partitioned into three parts by partition plates II; a water gas heater is arranged at the bottom of the middle of the box; one end of a heat exchange box above a first conveying device is communicated with the middle of the box, and the other end of the heat exchange box is connected with an induced draft fan which is arranged on the top of the box; two ends of each heat exchange box between upper and lower groove-shaped material channels of the first conveying device are connected with the water gas heater through a circulating water pump; a condensing water pump which is arranged on the top of the box is connected with a straight water pipe which is inserted into each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device to rotate are arranged in the box; a first moulding chain plate and a second moulding chain plate are suspended on a pin shaft of a chain extending inwards at intervals and supported on a guide rail to form a groove-shaped material channel; a material guide groove is formed below the tail end of the channel; a charging hole is formed on the top of the box; and a discharging hole is formed at the bottom of the box. The water circulation pre-heating type corncob drier is good in preheating and drying effect, and reliable in operation.

Owner:SHANDONG UNIV OF TECH

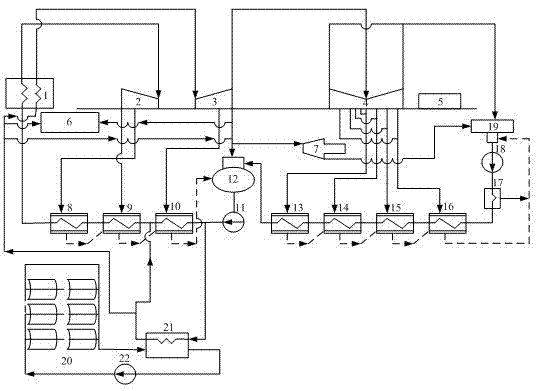

Coupled power generating system using solar thermal collector assisted coal-fired unit

InactiveCN102758746AReduce coal consumptionReduce pollutionFrom solar energySolar heat devicesEngineeringDeaerator

The invention provides a coupled power generating system using a solar thermal collector assisted coal-fired unit. The system comprises a coal-fired boiler power generating system, a solar thermal collector field, a circulating pump and a hot oil heat exchanger, wherein the coal-fired boiler power generating system comprises a generator and a condenser, a condensate pump, multiple stages of low-pressure heaters, a deaerator, a feed pump, multiple stages of high-pressure heaters, a coal-fired boiler and a steam turbine, which are connected in series in sequence; the steam turbine drives the generator and the steam exhausted by the steam turbine enters the condenser; the solar thermal collector field, the circulating pump and an oil chamber of the heat exchanger are connected to form a circulation loop; and a part of feed water from the inlet end of the high-pressure heater at one stage is sent to the high-pressure heater at the next stage, the cold reheat steam inlet or the feed pump steam turbine inlet after being heated by the heat exchanger. The system has the following beneficial effects: as the solar thermal collector field and the traditional coal-fired boiler power generating system are organically bonded, the coal consumption of the power plants is greatly reduced and the environmental pollution of the power generating system is reduced while the power supply stability is ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Cogeneration system by firing coil assisted by biomass and solar energy

InactiveCN101906996ADoes not affect normal operationReduce coal consumptionSolar heating energySolar heat devicesLow voltageCogeneration

The invention relates to a cogeneration system by firing coil assisted by biomass and solar energy, which comprises a coal-fired boiler generation system and a series assistance system, wherein the coal-fired boiler generation system comprises a generator and a condenser, a condensate pump, a multi-stage low-voltage heaters, a deaerator, a feed water pump, a multi-stage high-voltage heaters, a coal-fired boiler and a steam turbine orderly connected in series, wherein a steam inlet of the condenser is connected with exhaust steam of the steam turbine, and the multi-stage low-voltage heaters, the deaerator and the multi-stage high-voltage heaters are all connected with extracted steam of the steam turbine, and the steam turbine drives the generator; and the series assistance system comprises a biomass gasification device and a paraboloid channel type solar energy heat collector array, and the biomass gasification device and the paraboloid channel type solar energy heat collector array are connected in series and then connected between an outlet of the feed water pump and an extracted steam inlet of one of the multi-stage high-voltage heaters. The invention reduces the coal consumption, optimizes the energy utilization structures, solves the problem of high pollution of the traditional generation system by firing coal to a great extent and is beneficial to ecological protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Cooling discharge type corncob drying machine

InactiveCN103070236AReduce the temperatureGuaranteed temperatureSeed preservation by dryingWater pipeCondensate pump

The invention provides a cooling discharge type corncob drying machine. The cooling discharge type corncob drying machine is characterized in that the inner part of a box is divided into an upper region and a lower region by a separator plate I; the lower region is divided into three parts by a separator plate II; the separator plate I and separator plates III and IV located at the lower part of the box form a cooling region; a water heater is arranged at the bottom of the middle box; the cooling region is connected with the air inlet of the water heater by a blower; the air outlet of the water heater is connected with the middle part of the box; one end of each heat exchange box at the uppermost part in the box is communicated with the middle part of the box, and the other end of the heat exchange box is connected with an induced draft fan; two ends of each heat exchange box in the lower place are connected with the water heater by a circulating water pump; a condensate water pump is connected with straight water pipes in each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device are arranged in the box; each forming chain plate is supported on a guide rail to form a groove-shaped material channel; a guide chute is arranged under the tail end of the channel; a feed port is formed in the top part of the box; and a discharge port is formed in the bottom of the box. The cooling discharge type corncob drying machine is good in drying effect and low in energy consumption, and corncobs can be packaged directly after being dried by the drying machine.

Owner:SHANDONG UNIV OF TECH

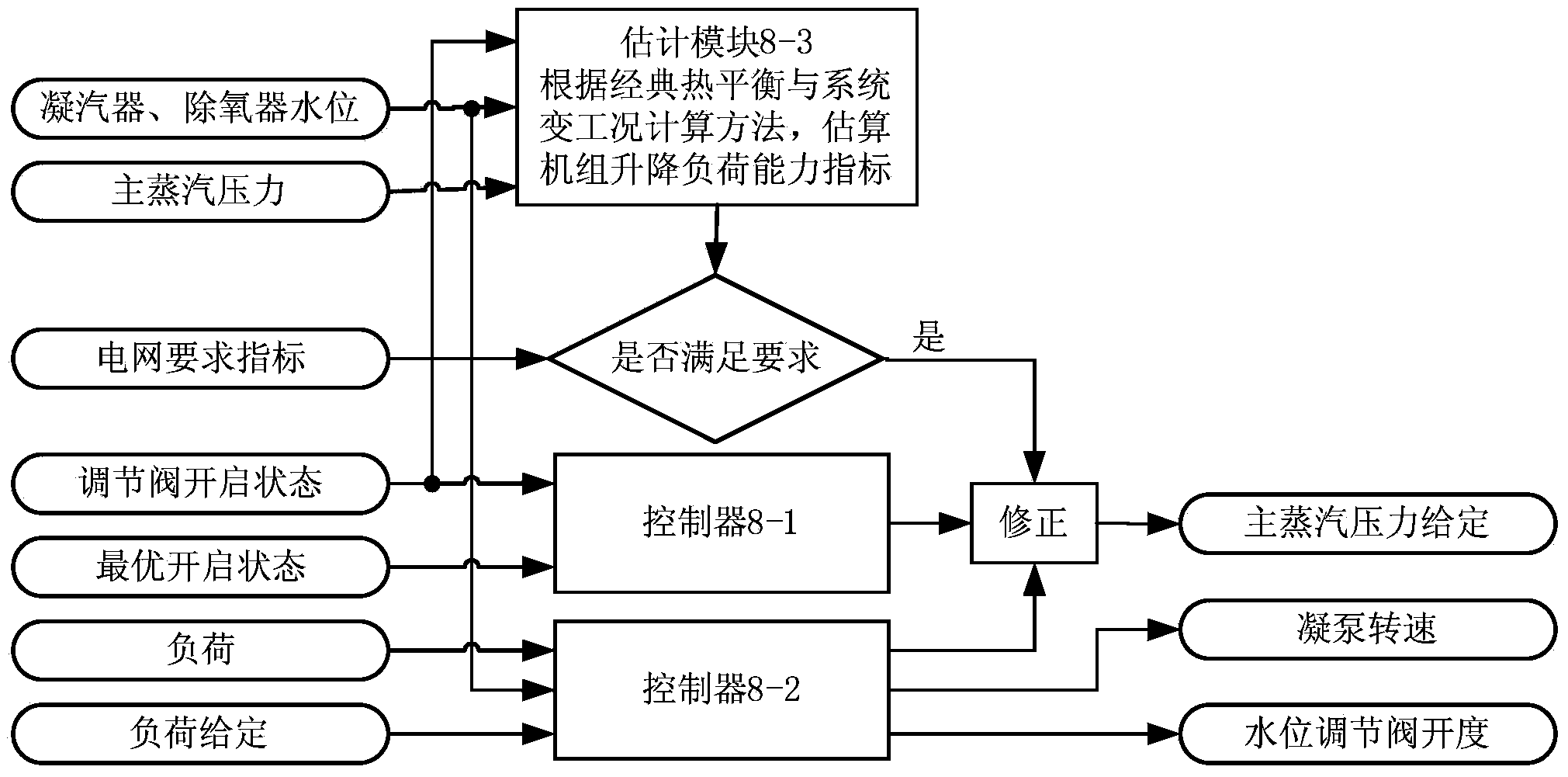

Thermal power unit sliding pressure optimizing and regulating system and method

ActiveCN103713569AWide adaptabilityOptimizing sliding pressure operating pressureProgramme control in sequence/logic controllersSteam pressureUnit operation

The invention discloses a thermal power unit sliding pressure optimizing and regulating system and method. The system comprises a PLC control unit, a distributed control system, a plurality of steam turbine septum valves, a variable-frequency condensate pump and a deaerator level control valve, wherein the distributed control system is connected with the PLC control unit through a two-way interface, the steam turbine septum valves are connected with the distributed control system, and the PLC control unit is used for achieving system parameter and signal reading through the distributed control system and achieving control over main steam pressure, the variable-frequency condensate pump and the deaerator level control valve. By means of the thermal power unit sliding pressure optimizing and regulating system and method, time-consuming and labor-consuming unit operation optimizing experiments and calculation are avoided, a set target of the main steam pressure can be dynamically optimized in real time according to environment changes, contradiction between main steam pressure optimizing capacity and load regulating capacity is avoided through the energy storage and regulation function of a condensate system, and the maximization of operating economy of a generator unit is dynamically achieved in real time under the premise that requirements of a power grid are met.

Owner:XIAN TPRI THERMAL CONTROL TECH +1

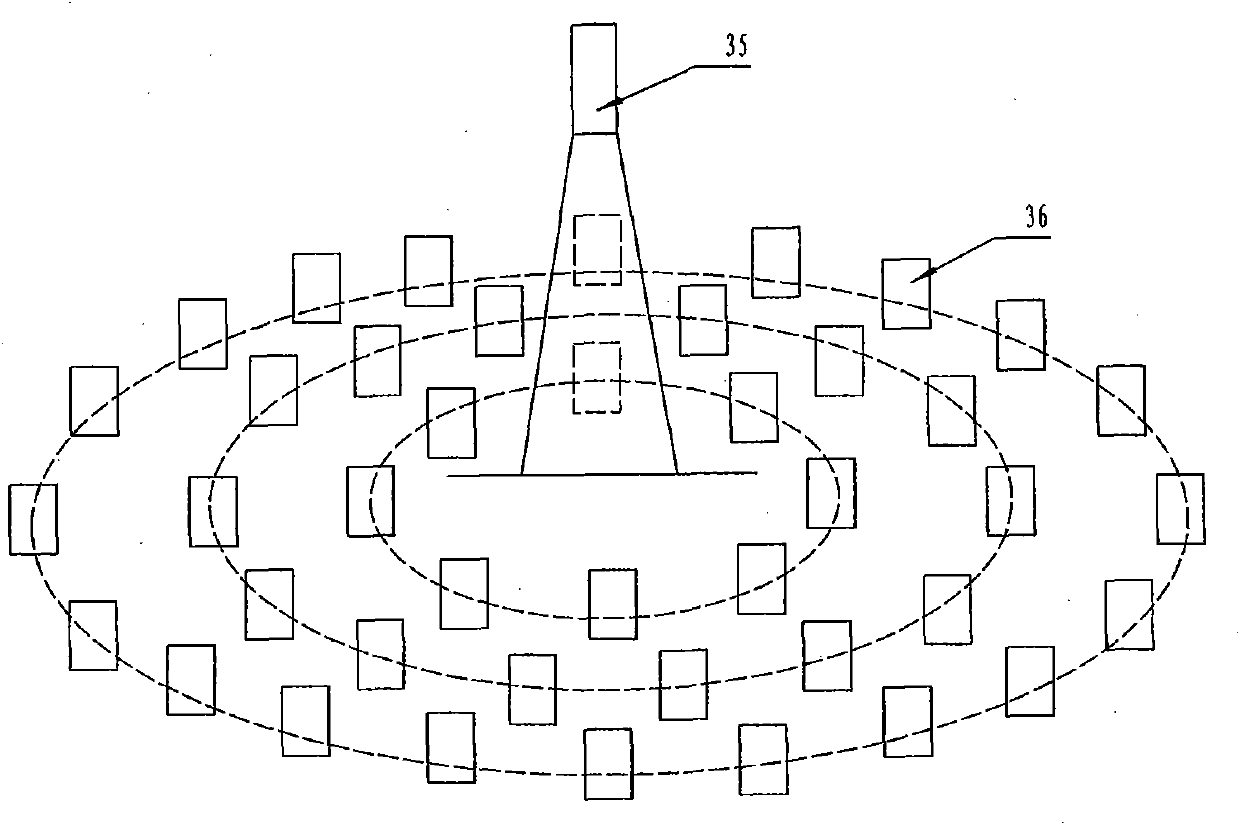

Tower solar thermal power plant utilizing supercritical water heat absorber and molten salt heat storage

ActiveCN103742373AImprove photoelectric conversion efficiencyGuaranteed power generationFrom solar energyMachines/enginesEngineeringDeaerator

The invention provides a tower solar thermal power plant utilizing a supercritical water heat absorber and molten salt heat storage. The tower solar thermal power plant comprises a condensate pump, a deaerator, a water supply pump, the supercritical water heat absorber, a molten salt heat storage system, a steam turbine, a power generator and a condenser; the molten salt heat storage system comprises a water and molten salt heat exchanger, an expanding device, a cold salt tank, a hot salt tank, a cold salt pump, a hot salt pump and a molten salt and water heat exchanger; the condensate water is heated through the deaerator and input into the supercritical water heat absorber through the water supply pump, the solar radiation is absorbed, and the deaerated water is converted into the supercritical water to enter into the steam turbine to for work applying and power generation. The tower solar thermal power plant is combined with the work applying and power generation of the supercritical water and the molten salt heat storage and accordingly the tower solar thermal power plant can be suitable for various solar radiation conditions and the thermoelectric conversion efficiency is high; the work applying of the supercritical water is high in efficiency and free of phase change and accordingly the high thermoelectric efficiency can be guaranteed through a simple single-stage heat storage system; meanwhile the risk that the molten salt is solidified in the upper tower process is voided in comparison with a molten salt heat absorber.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

Energy-saving ammonia-nitrogen wastewater treatment method and device

ActiveCN104860464ASimple processEasy to operateMultistage water/sewage treatmentReboilerWater quality

The invention discloses an energy-saving ammonia-nitrogen wastewater treatment method. According to the method, firstly, the pH (potential of hydrogen) value of ammonia-nitrogen wastewater is adjusted firstly, compounded ammonia in the ammonia-nitrogen wastewater is decomposed to free ammonia through mixed heat exchange and heating, free ammonia is conveyed to the upper part of an ammonia removal tower and flows into the lower part, meanwhile, high-temperature steam is conveyed from the lower part of the ammonia removal tower through a reboiler, ammonia-nitrogen wastewater and the high-temperature steam have steam-liquid contact in a medium in the ammonia removal tower, ammonia and nitrogen in the ammonia-nitrogen wastewater and the steam form ammonia-containing steam in an ammonia and nitrogen removal tower, the ammonia-containing steam is discharged from the top of the tower, and wastewater without ammonia is discharged from the bottom of the tower; the general concentration of the ammonia-containing steam discharged from the top of the ammonia removal tower is higher than 30%, the ammonia-containing steam is firstly condensed through cooling and collected in a condensate buffer tank, accordingly, ammonia water condensate is formed, the ammonia water condensate is conveyed into an ammonia water circulating tank intermittently through an ammonia water condensate pump, and ammonia water is prepared. By means of the method and the device, the removal rate of ammonia and nitrogen is higher than 99.9%, the operation is convenient, the working stability is good, the occupation area is small, and the operation cost is low; the content of ammonia and nitrogen is not higher than 100 mg / L, and the quality of discharged water is good.

Owner:JIANGXI NAIKE CHEM IND EQUIP PACKINGCO

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS8661821B2Remarkable effectEasy to operateDrying solid materials with heatFuel feeding arrangementsFluidized bed dryingProcess engineering

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

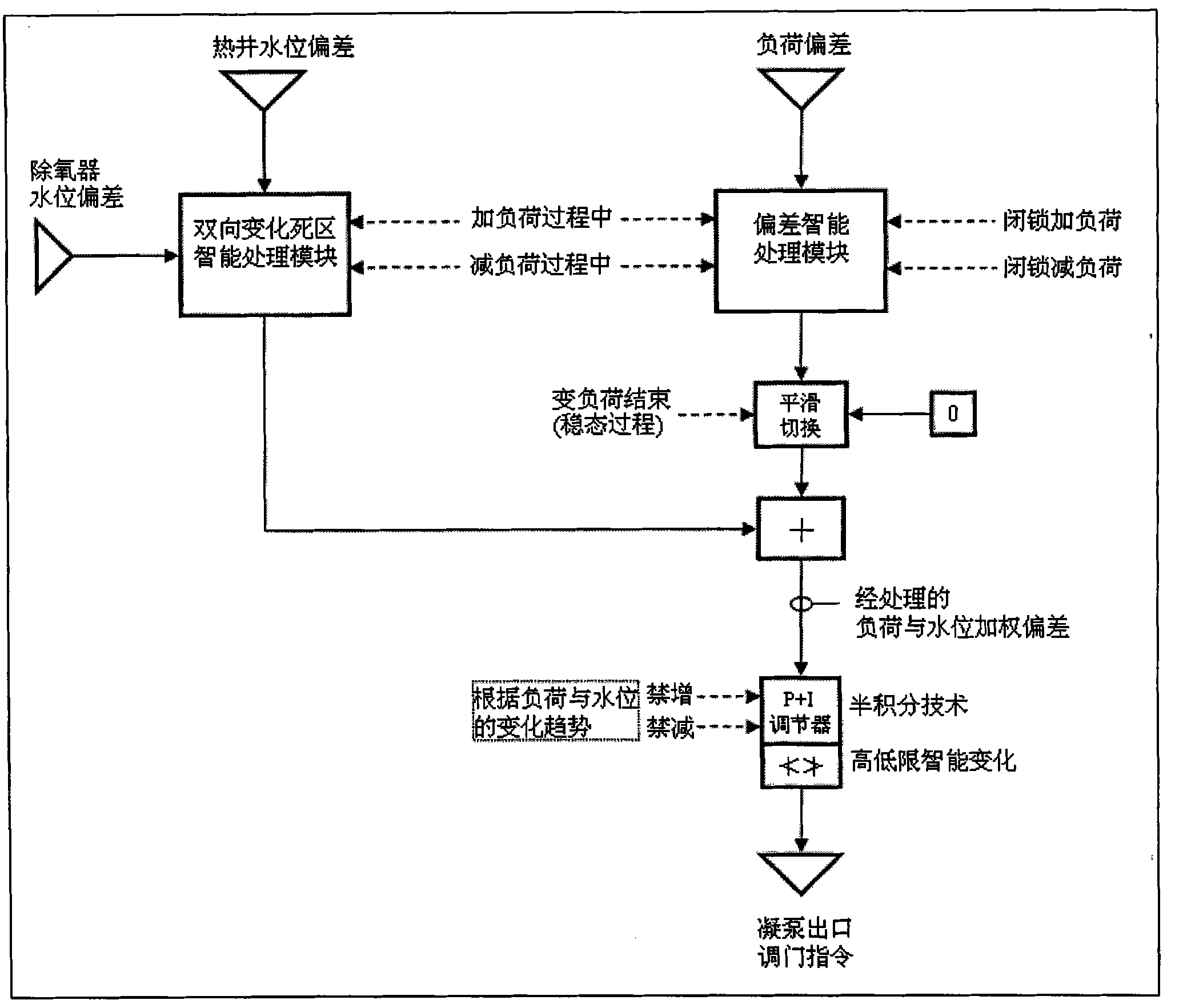

Thermal power unit cooperative load change control method

The invention provides a thermal power unit cooperative load change control method, including that: load deviation, thermal well water level deviation and deaerator water level deviation are acquired; steady state, loading or unloading process is carried out on the load deviation, thermal well water level deviation and deaerator water level deviation; according to different working conditions, the load deviation and the water level deviation are subject to weighting; the result is subject to half integral and high-low limit intelligent change; a condensate pump outlet door adjustment instruction is obtained; and control at the boiler side is reasonably combined, and performance requirement of thermal power unit load change is met. The thermal power unit cooperative load change control method provided by the invention is a new method utilizing unit energy storage, the control at the boiler side is reasonably combined, and the requirement of peak shaping can be met while greatly reducing steam engine door adjustment throttle loss, thus improving economy of unit operation.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST +1

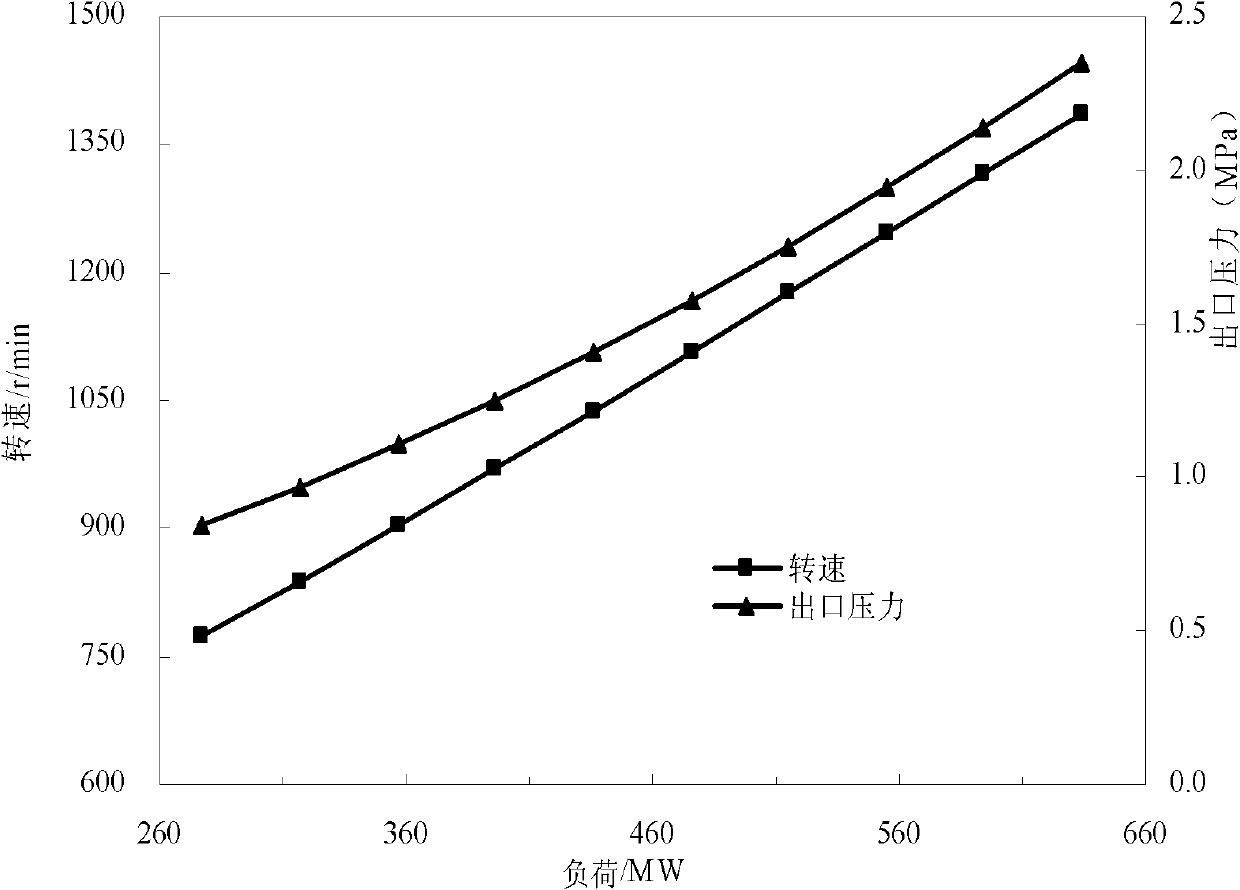

Precomputation method of frequency conversion transformation working condition points of condensate pump for thermoelectric generating set

InactiveCN102200120ARealize the pre-evaluation of energy saving effectPump controlPositive-displacement liquid enginesFrequency conversionPrecomputation

The invention discloses a precomputation method of frequency conversion transformation working condition points of a condensate pump for a thermoelectric generating set. Before frequency conversion transformation is carried out on the condensate pump, evaluation of economy after frequency conversion transformation is necessary, and the working condition precomputation after frequency conversion transformation for the condensate pump is a chief premise of the work. The method provided by the invention is characterized by comprising the following steps: analyzing the variable speed operation working condition of the condensate pump by combining a variable speed operation balanced point computation method, and combining the related experiment under a working frequency state from the characteristics of a water level regulating valve of a deaerator to compute so as to obtain each coefficient of the balanced point computation method; and then combining the law of proportionality of a water pump to realize the quantitative computation of variable speed operation working condition point parameters of the condensate pump. On the basis, the energy conservation effect of the frequency conversion of the condensate pump can be evaluated, and a basis is provided for the transformation.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

Glass kiln denitration generating system

ActiveCN101947413AMeet the requirements of denitrification processLow investment costDispersed particle separationIncreasing energy efficiencyEngineeringSuperheater

The invention relates to a glass kiln denitration generating device. The system comprises an ammonia spraying device, a reactor, a boiler evaporimeter, a superheater and a boiler economizer, wherein the ammonia spraying device comprises an ammonia storing tank, a heater, an ammonia spraying fence, a fan and a heat exchanger; the reactor is arranged inside a denitration exhaust-heat boiler and on the upper part of the heat exchanger; the boiler evaporimeter is arranged inside the denitration exhaust-heat boiler and is connected with a turbine outside the denitration exhaust-heat boiler through a pipeline, and the turbine is successively connected with a generator, a condenser, a condensate pump, a deaerator, a boiler feed pump outside the denitration exhaust-heat boiler through the pipeline; the superheater is arranged inside the denitration exhaust-heat boiler and at the bottom of the ammonia spraying fence and on the upper part of a smoke inlet, wherein one end of the superheater is connected to the evaporimeter through the pipeline, and the other end thereof is connected to the turbine through the pipeline; and the boiler economizer is arranged inside the denitration exhaust-heat boiler and at the bottom of the boiler evaporimeter.

Owner:SINOMA ENERGY CONSERVATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com