Coupled power generating system using solar thermal collector assisted coal-fired unit

A solar collector and power generation system technology, applied in the direction of solar thermal power generation, the use of solar energy to generate mechanical power, solar thermal devices, etc. Conducive to sustainable development, ensuring power supply stability and optimizing energy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

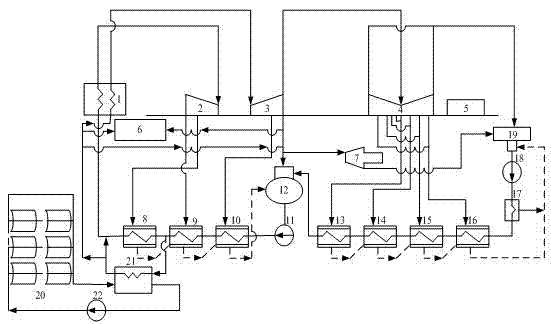

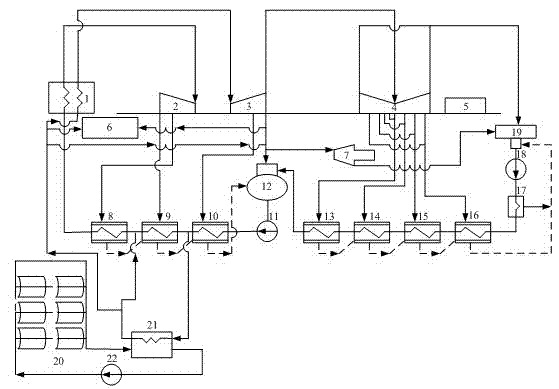

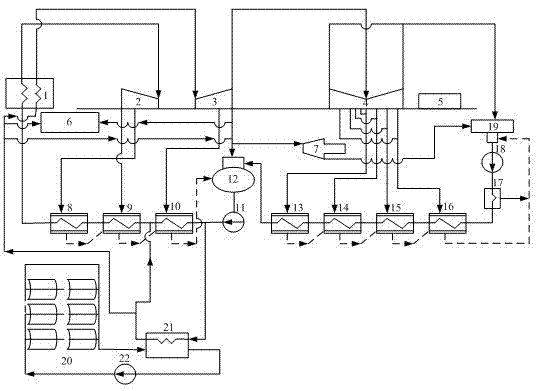

[0018] figure 1 As the first embodiment of the present invention, the coupled power generation system consists of a coal-fired boiler 1, a steam turbine, a generator 5, a heater, a solar collector field (20), a thermal oil heat exchanger 21, an auxiliary steam header 6, Feedwater pump 11, deaerator 12, condenser 19, condensate pump 18, etc., among which the solar heat collector field (20) 20 is formed by connecting glass-covered vacuum trough solar heat collectors in series and parallel. The system flow is: the condensed water flowing out from the condenser 19 passes through the condensed water pump 18 and the series-connected shaft seal heater 17, the first stage low pressure heater 16, the second stage low pressure heater 15, and the third stage low pressure heater 14 1. After the fourth-stage low-pressure heater 13 carries out the initial temperature and pressure increase, it enters the deaerator 12 to remove oxygen, and then passes through the feed water pump 11 to increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com