Patents

Literature

72results about How to "Increase the blending ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

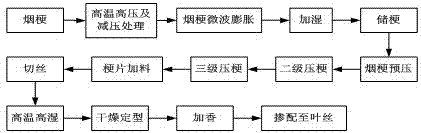

Technology for processing tobacco stalk into shreds

ActiveCN102631016AUniform expansionSimilar expansion rateTobacco preparationTobacco treatmentMicrowaveTar

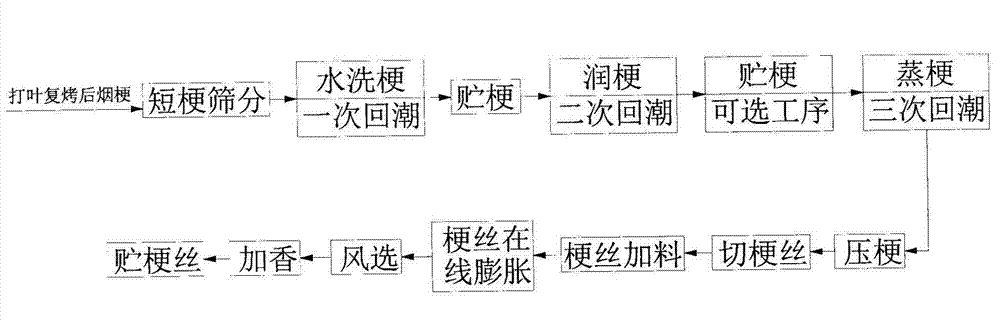

The invention provides a technology for processing tobacco stalk into shreds, and belongs to the technical field of tobacco processing. The technology disclosed by the invention has the following steps of: pretreating tobacco stalk, expanding the tobacco stalk with microwave, washing the tobacco with water, storing the tobacco stalk, straightening out the tobacco stalk, slicing the tobacco stalk, charging and storing stalk slices, shredding the stalk slices, drying and shaping the stalk shreds, and perfuming the stalk shreds and storing the stalk shreds. Equipment used in the technology is purchased from the market, wherein the equipment which is purchased from the market, adopts a low-frequency (915MHz) high-power (more than 10kW) microwave magnetron, and transports the tobacco stalk by a belt is improved into equipment which adopts an ultrahigh-frequency (2450MHz) single-pipe low-power (1.5kW) microwave magnetron, performs group control on the microwave magnetron and transports tobacco stalk by a drum. The technology has the characteristics that the tobacco stalk shreds are good in quality consistency and more similar to tobacco leaf shreds in the physical property, and have high sensory quality and filling value; and uniformity, stability and mixing proportion of the tobacco stalk shreds are improved when the tobacco stalk shreds are mixed with the tobacco leaf shreds, the quality of cigarette is improved, the application range and use ratio of the tobacco stalk shreds in the cigarette are improved, and the aims of tar reducing, harm reducing, cost reducing and efficacy enhancing are achieved.

Owner:YUNNAN RES INST OF TOBACCO SCI

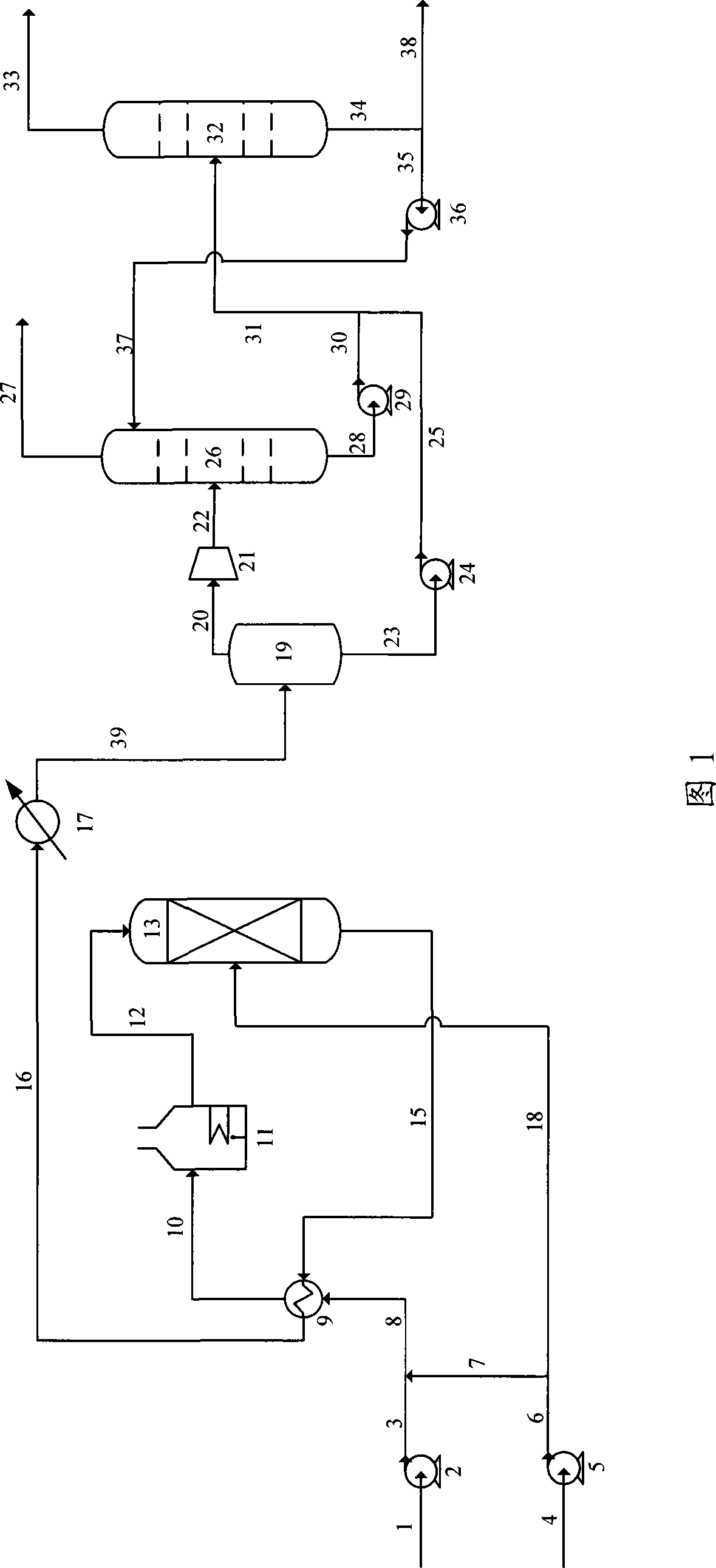

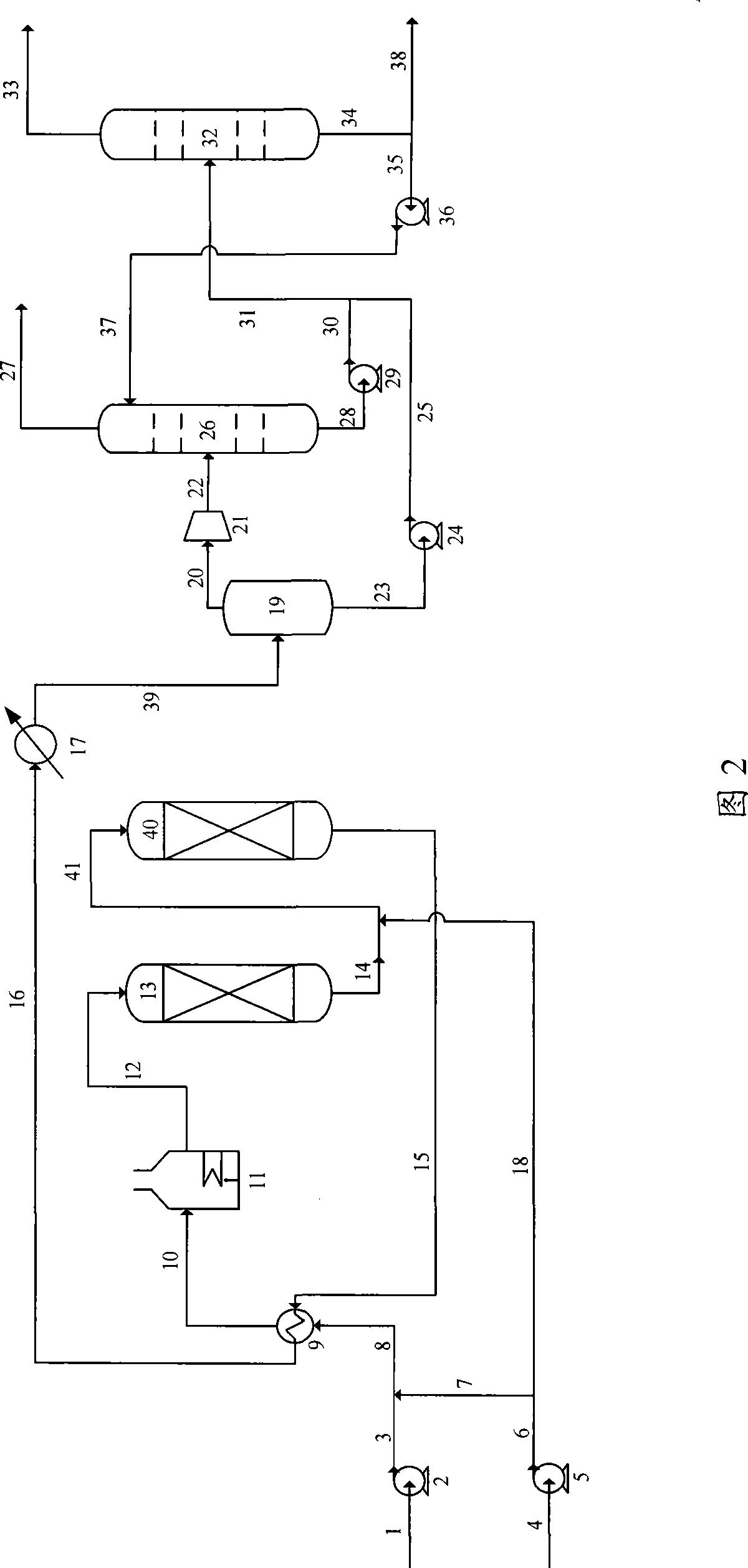

Inferior gasoline upgrading method

ActiveCN101397510AIncrease the blending ratioBalanced Operating SeverityCatalytic naphtha reformingProduction rateHydrogen

A modification method of inferior gasoline includes the following steps: the inferior gasoline is mixed with C4 fraction and introduced into a reactor as raw materials of reaction, and the mixture contacts and reacts with catalyst under the conditions without hydrogen; and the C4 fraction is divided into two strands at least and enters the reactor from different positions. The method is used for the modification reaction of the inferior gasoline, and can increase the doping amount of the C4 fraction, improve the production rate of gasoline, and prolong the serve life of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

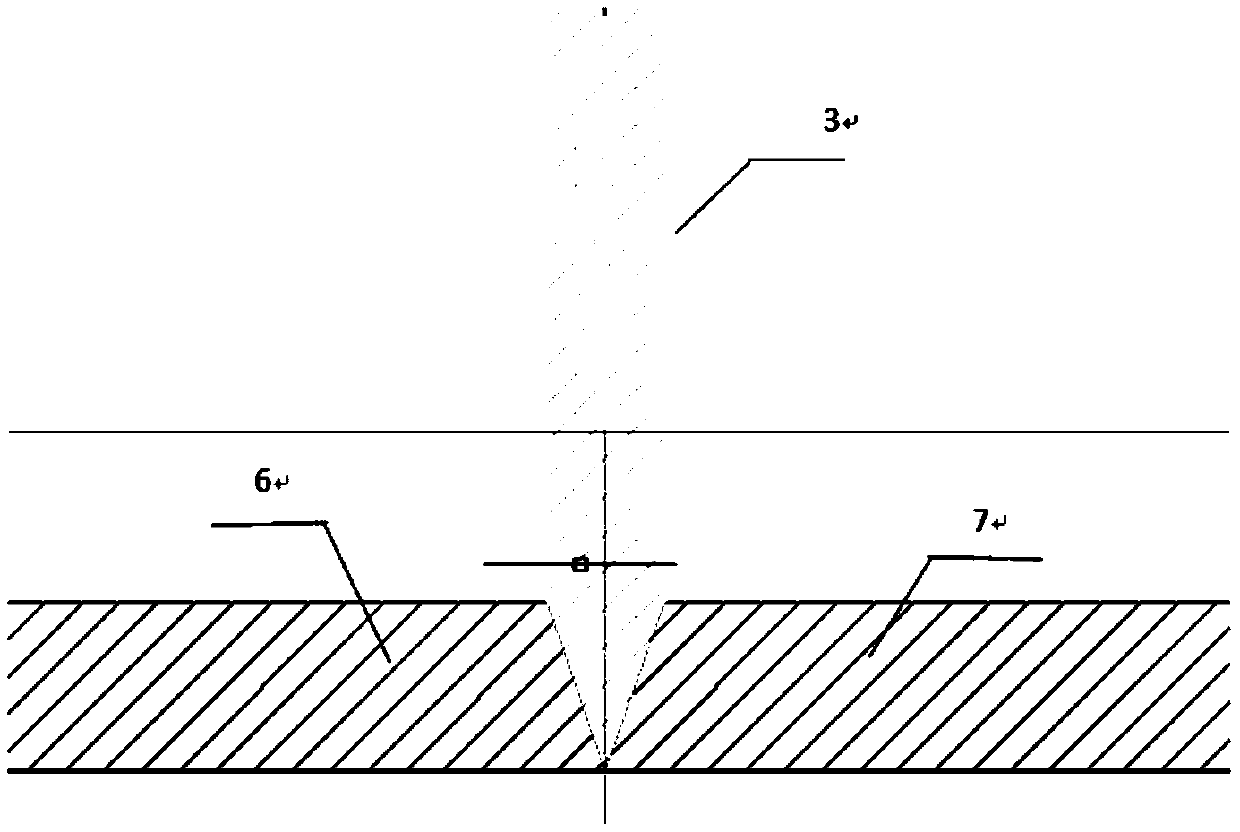

Tobacco stem pressing and shredding technology

The invention discloses a tobacco stem pressing and shredding technology and belongs to the technical field of tobacco processing. The technology comprises the steps of conducting high-temperature high-pressure and decompression preprocessing on tobacco stems, conducting microwave expansion on tobacco stems, humidifying and storing tobacco stems, heating and humidifying tobacco stems, pre-pressing tobacco stems, conducting secondary stem pressing, conducting ternary stem pressing, feeding stems, shredding stems, shaping and drying stem shreds, and perfuming and storing stem shreds. The technology has the advantages that the quality consistency of stem shreds is good, the physical property of stem shreds is closer to that of leaf shreds, organoleptic quality and padding value are high, the uniformity, stability and blending ratio of stem shreds blended with leaf shreds are improved, cigarette quality is improved, the application range and utilization rate of stem shreds in cigarettes are increased, and tar reduction, harm reduction, cost reduction and benefit increasing are realized.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

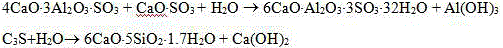

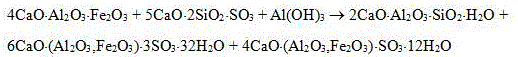

Preparation method and application method of low-carbon cement clinker

InactiveCN106220008ALower sintering temperatureIncrease the blending ratioCement productionSiliconGypsum

The invention relates to a preparation method and an application method of low-carbon cement clinker. The low-carbon cement clinker is prepared by the steps: uniformly mixing raw materials of silicon-aluminum containing material, limestone and gypsum according to a certain ratio; grinding the mixture to form a raw material, wherein the grain size of the ground raw material requires that residue on a 0.08-mm square hole sieve is less than 10%; calcining the ground raw material for 20 to 40 minutes at the calcining temperature of 1200 to 1300 DEG C; cooling to obtain the low-carbon cement clinker. The low-carbon cement clinker provided by the invention comprises 10 to 25 percent of beta-dicalcium silicate, 5 to 15 percent of calcium sulphosilicate, 15 to 45 percent of tricalcium silicate and 15 to 45 percent of calcium sulphoaluminate. 0.01 to 15 percent of gypsum and 0.01 to 15 percent of limestone are added into the low-carbon cement clinker and then are ground to obtain a cement finished product. The preparation method and the application method of the low-carbon cement clinker have the advantages of low calcining temperature, short coagulation time, high hardening speed, high early strength and continuously enhanced later strength.

Owner:郑州市王楼水泥工业有限公司

Application of astragalus extract in stem strings or reproduced tobaccos

The invention discloses application of an astragalus extract in stem strings or reproduced tobaccos. The application is characterized in that the astragalus extract is added into the stem strings or the reproduced tobaccos, so that the wood gas and the irritation of the stem strings or the reproduced tobaccos can be obviously reduced, the doping rate of the stem strings or the reproduced tobaccos in a medium-grade and high-grade cigarette formula is increased, and the smoke quality of cigarettes is not influenced; and the astragalus extract is prepared from astragalus by the process of solvent soaking, extraction and concentration. The application has the outstanding characteristics that new astragalus application is developed by the conventional solvent and the common extraction method; and a new natural stem flavoring agent is provided.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Additive for improving Zhundong coal combustion and coking characteristics and use method thereof

The invention relates to a Zhundong coal additive and provides an additive for improving Zhundong coal combustion and coking characteristics and a use method thereof. The additive comprises, by mass, 20-36% of SiO2, 8-18% of Al2O3, 12-28% of MnO2, 6-23% of Fe2O3, 4-10% of KMnO4, 5-15% of Fe(NO3)3, 1-5% of TiO2 and 2-4% of a waterproof adhesive. The additive of Zhundong coal can be prepared by simple processes, has a low cost, can be transported, stored and used conveniently, can well improve Zhundong coal combustion, coking, slag-bonding and dust deposition characteristics, can effectively improve a blending combustion ratio of Zhundong coal, and has no side effect on fire coal equipment, no damage on the human body and no pollution on the environment.

Owner:浙江百能科技有限公司 +1

Diesel-alternative fuel hybrid combustion engine control method

ActiveCN102220916AReduce injection volumeReduce output torqueElectrical controlInternal combustion piston enginesInjectorHigh pressure

The invention provides a diesel-alternative fuel hybrid combustion engine control method without an electric oil pump rack actuating mechanism, belonging to the field of engine control. According to the invention, an exhaust temperature sensor, a wide-range oxygen sensor, a mixedly burning ratio information display screen, an alternative fuel injection controller, a high pressure diesel pump rack displacement sensor and an alternative fuel injector are additionally arranged on an original diesel engine with a mechanical high pressure fuel pump; a high pressure diesel pump rack is mechanically connected with a vehicle accelerator pedal; and according to the position of the high pressure oil pump rack of the diesel engine, the alternative fuel injection controller determines the injection quantity of alternative fuel in combination with estimation on the excess air coefficient of an engine and the operation intention of the driver and sends a control command to drive an alternative fuel injection valve to inject corresponding alternative fuel to an engine intake pipe. The method has the beneficial effects of lowering the cost and overcoming the adverse factors caused by the adoption of an electric oil pump rack actuator and can be widely applied to the diesel-alternative fuel hybrid combustion engines.

Owner:NANTONG YATAI ENG TECH

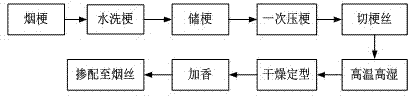

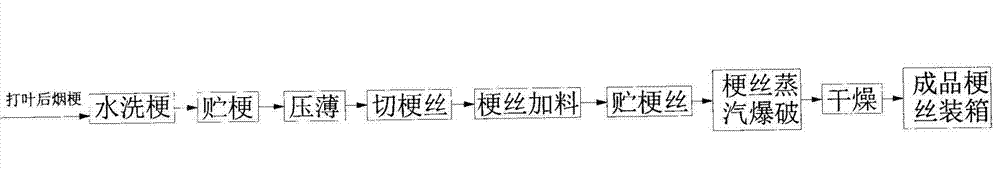

Tobacco stem cutting process by threshed tobacco stems

InactiveCN102783705AImprove qualityImprove blending uniformityTobacco treatmentIndustrial engineeringCigarette smoke

The invention discloses a tobacco stem cutting process by threshed tobacco stems. The process is characterized in comprising the following technical steps: washing stem, storing stem, thinning, cutting stem, carrying out steam explosion for cut stem, drying and so on. The process has the advantages that color and shape of the cut stem processed by the technical method are close to that of the cut tobacco; the breakage rate in the cut stem process is low; the blending uniformity is improved; when smoked, the tobacco is free from harmful wood flavor; the cigarette smoke is harmonized; the comfort of the tobacco is improved; the cut stem is strong in filling capability; and the internal quality of the cigarette is further improved. The power consumption of the corresponding tobacco stem processing enterprise can be reduced. At present, a threshing redrying factory usually stores a lot of tobacco stems, so that the direct stem cutting process provides a new method for comprehensive utilization of the tobacco stems for the redrying factory, and provides a technical economic scheme for forward leading the stem cutting process of a cigarette factory to the redrying factory.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Application of codonopsis pilosula extract in cut stems or reconstituted tobaccos

InactiveCN105901760AReduce mistLess irritatingTobacco preparationTobacco treatmentBiotechnologyCodonopsis pilosula

The invention discloses application of a codonopsis pilosula extract in cut stems or reconstituted tobaccos. The application is characterized in that the codonopsis pilosula extract is added into the cut tobacco stems or the reconstituted tobaccos, so that wood gas (miscellaneous gas) and the irritation in the cut stems or the reconstituted tobaccos can be obviously reduced, the blending rate of the cut stems or the reconstituted tobaccos in the formula of medium- and high-grade cigarettes is increased, the smoke tar in the cigarettes is reduced, the cigarette production cost is reduced, and the smoke quality of the cigarette cannot be affected; the codonopsis pilosula extract is prepared by performing solvent soaking, extraction, refining and concentration on codonopsis pilosula serving as a raw material. The application disclosed by the invention has the outstanding characteristics that new application of the codonopsis pilosula is developed by a conventional solvent and a common extraction method, so that a novel natural flavoring agent for the cigarettes is prepared.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

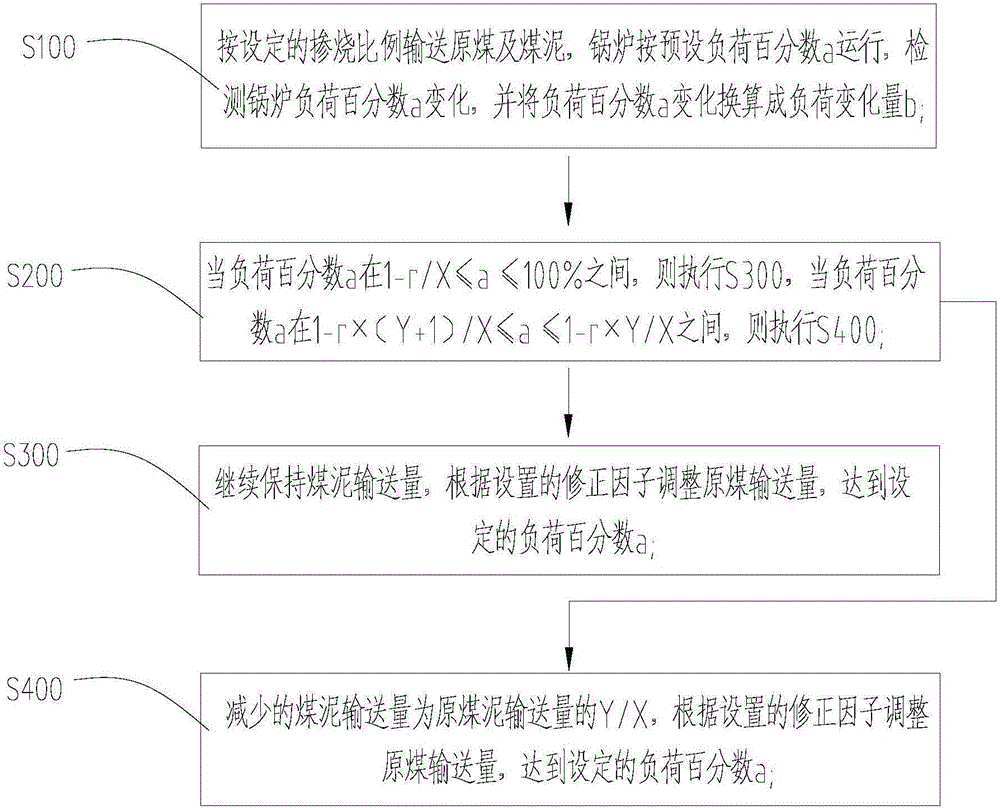

Method of adjusting boiler load of circulating fluidized bed

ActiveCN105114948AIncrease the blending ratioIncrease profitFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

The invention relates to a method of adjusting boiler load of a circulating fluidized bed. The method includes the steps of 1, conveying raw coal and coal slime according to a set mixed burning ratio, allowing a boiler to function according to a preset load percentage a, detecting changes in the boiler load percentage a, and converting the load percentage a into a load variation b; 2, when the load percentage a meets 1-r / X< / =a< / =100%, executing a step 3, and when the load percentage a meets 1-r*(Y+1) / X< / =a< / =1-r*Y / X, and executing a step 4; 3, continuing to keep a coal slime conveying amount, and adjusting a raw coal conveying amount according to set correction factors so as to obtain the set load percentage a; and 4, decreasing the coal slime conveying amount to Y / X, and adjusting the raw coal conveying amount according to the set correction factors to obtain the set load percentage a. stepwise adjustment of the coal slime is used in the method, mixed burning ratio of the coal slime is increased, and quick response to load adjusting commands is provided.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

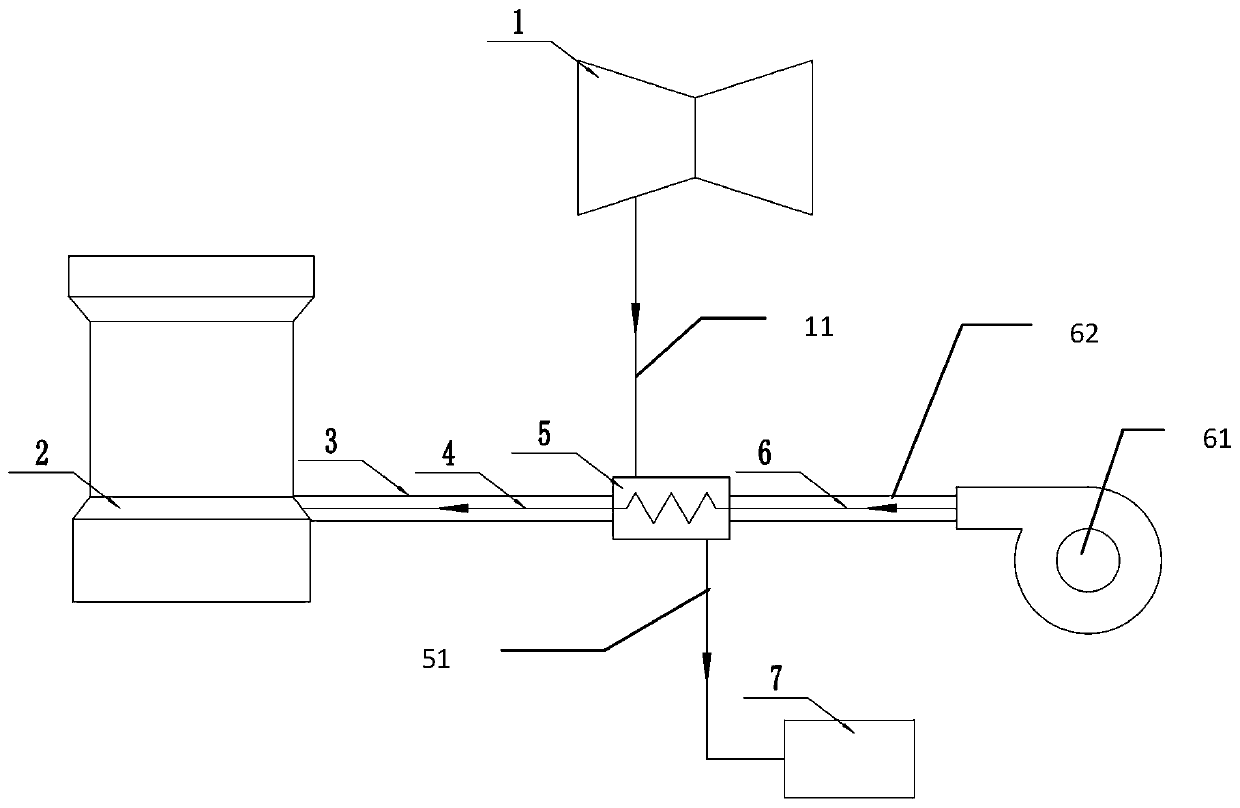

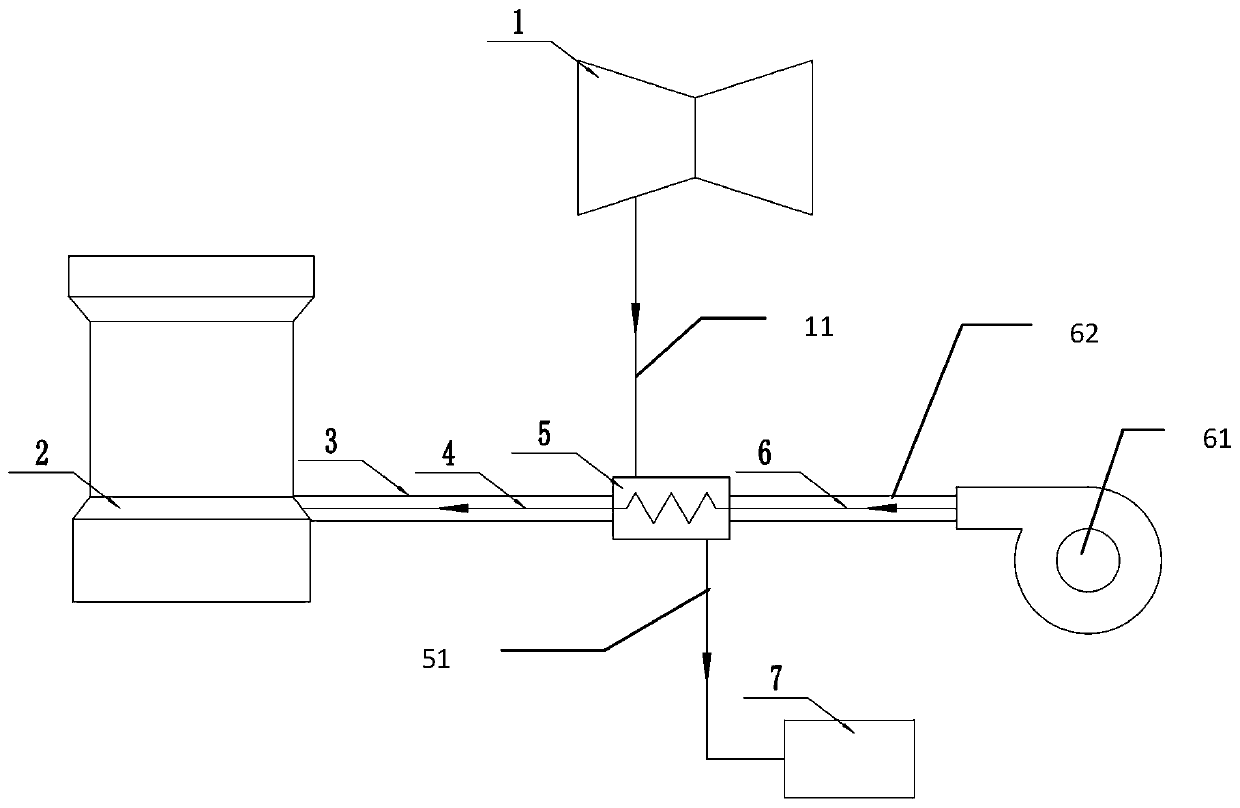

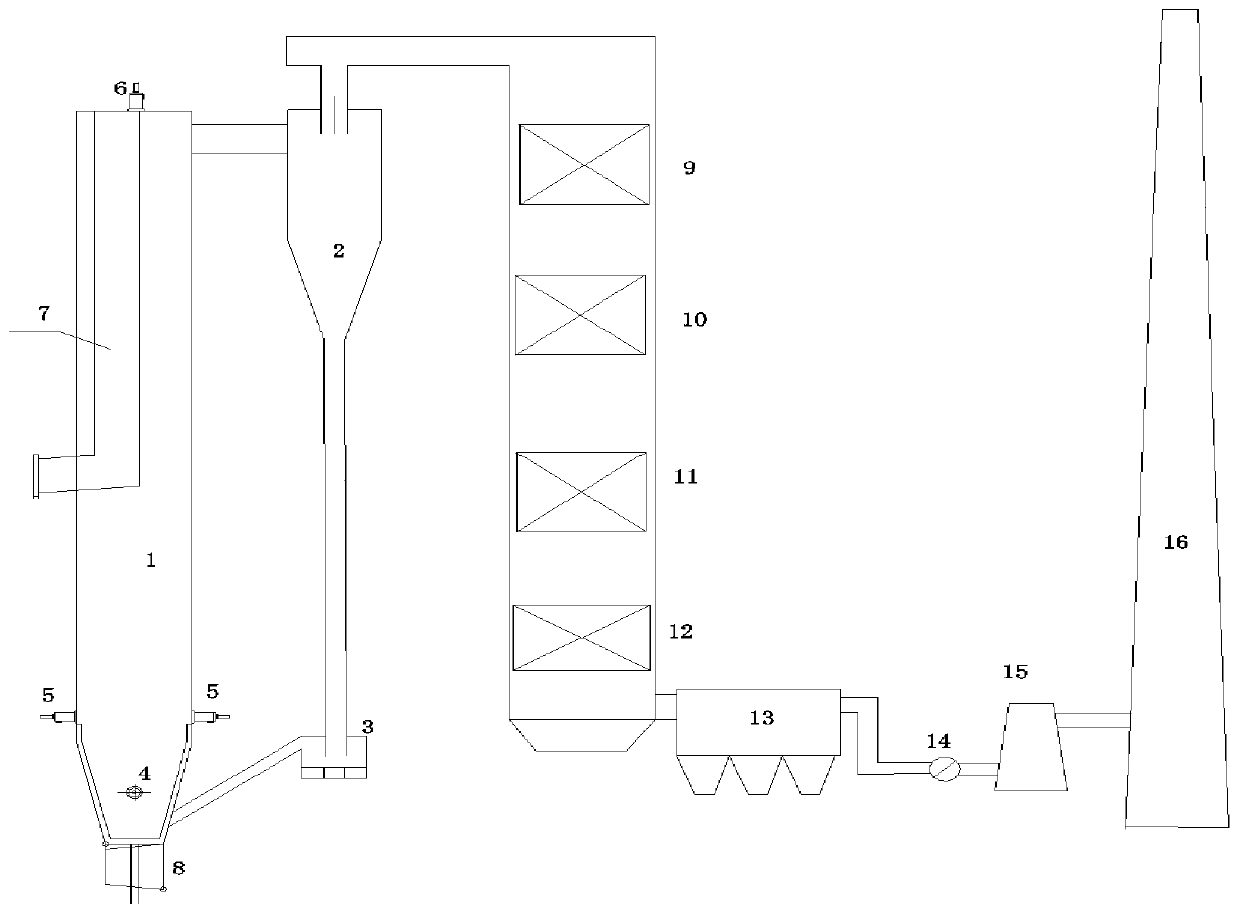

Pulverized coal and ammonia mixed fuel pre-pyrolysis combustion system and method

PendingCN113154369ALow costStable sourceNon-combustible gases/liquids supplyLump/pulverulent fuel preparationCombustion systemNitrogen oxides

The invention discloses a pulverized coal and ammonia mixed fuel pre-pyrolysis combustion system and method. The system comprises a boiler, each layer of combustor of the boiler communicates with a pyrolysis furnace through a transition flue, pulverized coal and primary air are mixed and then communicate with an inlet of each pyrolysis furnace in multiple paths, and secondary air tangentially communicates with each pyrolysis furnace. An outlet of a liquid ammonia storage tank communicates with a liquid ammonia inlet of an evaporator, ammonia gas at an ammonia gas outlet of the evaporator is divided into a plurality of ammonia gas branches to communicate with ammonia nozzles of transition flues after passing through an ammonia gas main pipeline, a main regulating valve is arranged on the ammonia gas main pipeline, and a regulating valve is arranged on each ammonia gas branch. The invention further discloses a working method of the system. The pulverized coal and ammonia mixed fuel pre-pyrolysis combustion system and method have the advantages of large-proportion ammonia blending combustion and low nitrogen oxide emission.

Owner:XIAN THERMAL POWER RES INST CO LTD

Preparation method for mixed desulfurizing agent for circulating fluidized bed boiler

InactiveCN104208989ASimple crafting systemLess investmentDispersed particle separationFluidized bedEngineering

The invention discloses a preparation method for a mixed desulfurizing agent for a circulating fluidized bed boiler, and relates to a desulfurizing technology in the circulating fluidized bed boiler. The preparation method solves the problems of low utilization rate of conventional limestone flour serving as a desulfurizing agent, high equipment loss and high power consumption. The preparation method comprises the technical steps of (1) conveying limestone fine-powder materials into a limestone powder bin; (2) stirring the limestone fine-powder materials by a star wheel feeder and a differential turbine so as to enable the limestone fine-powder materials to fall to a coal slime conveying belt; (3) adding coal slime into the conveying belt so as to be mixed with the limestone fine-powder materials; (4) stirring the coal slime and the limestone fine-powder material mixture in a double-shaft stirring machine, and then conveying to a briquette forming machine; (5) pressing the stirred coal slime and limestone fine-powder material mixture to form the spherical mixed desulfurizing agent; and (6) conveying the spherical mixed desulfurizing agent into a finished product bin for later use through a mixed desulfurizing agent conveying belt. The mixed desulfurizing agent prepared by the preparation method is used for realizing desulfurization in the circulating fluidized bed boiler and has the advantages of simple system, low investment, high desulfurizing agent utilization rate, low equipment loss and low power consumption.

Owner:山西平朔煤矸石发电有限责任公司

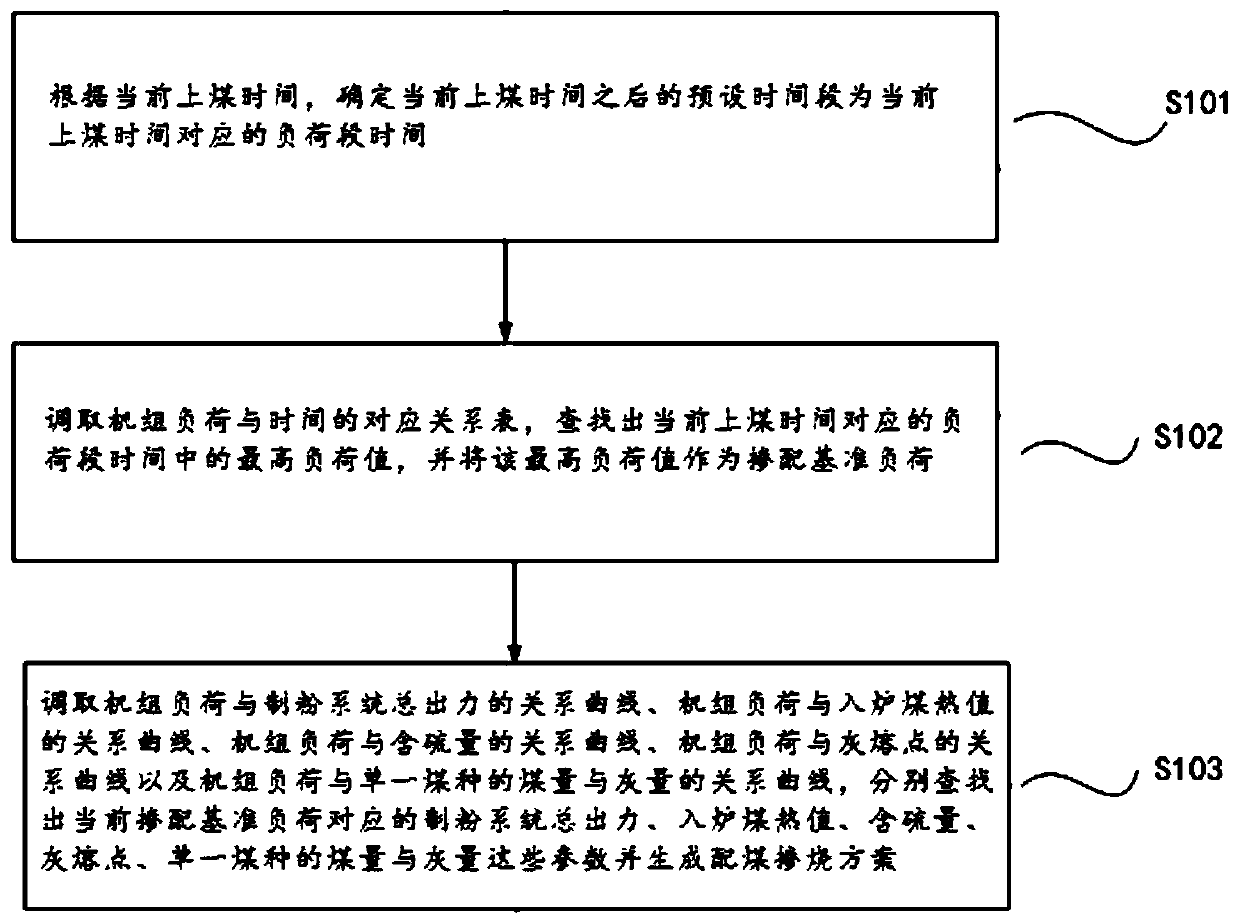

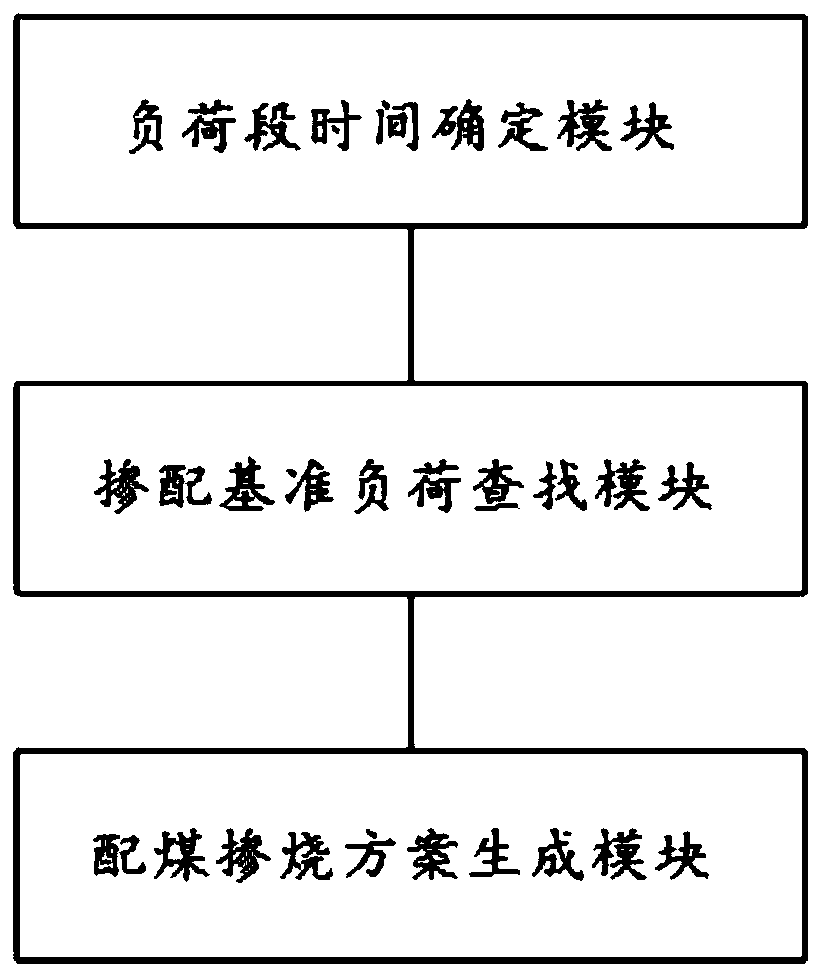

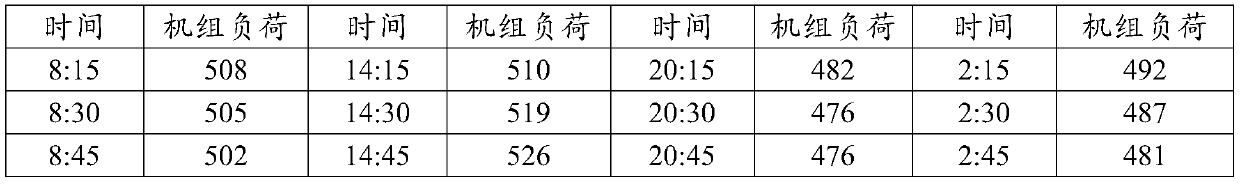

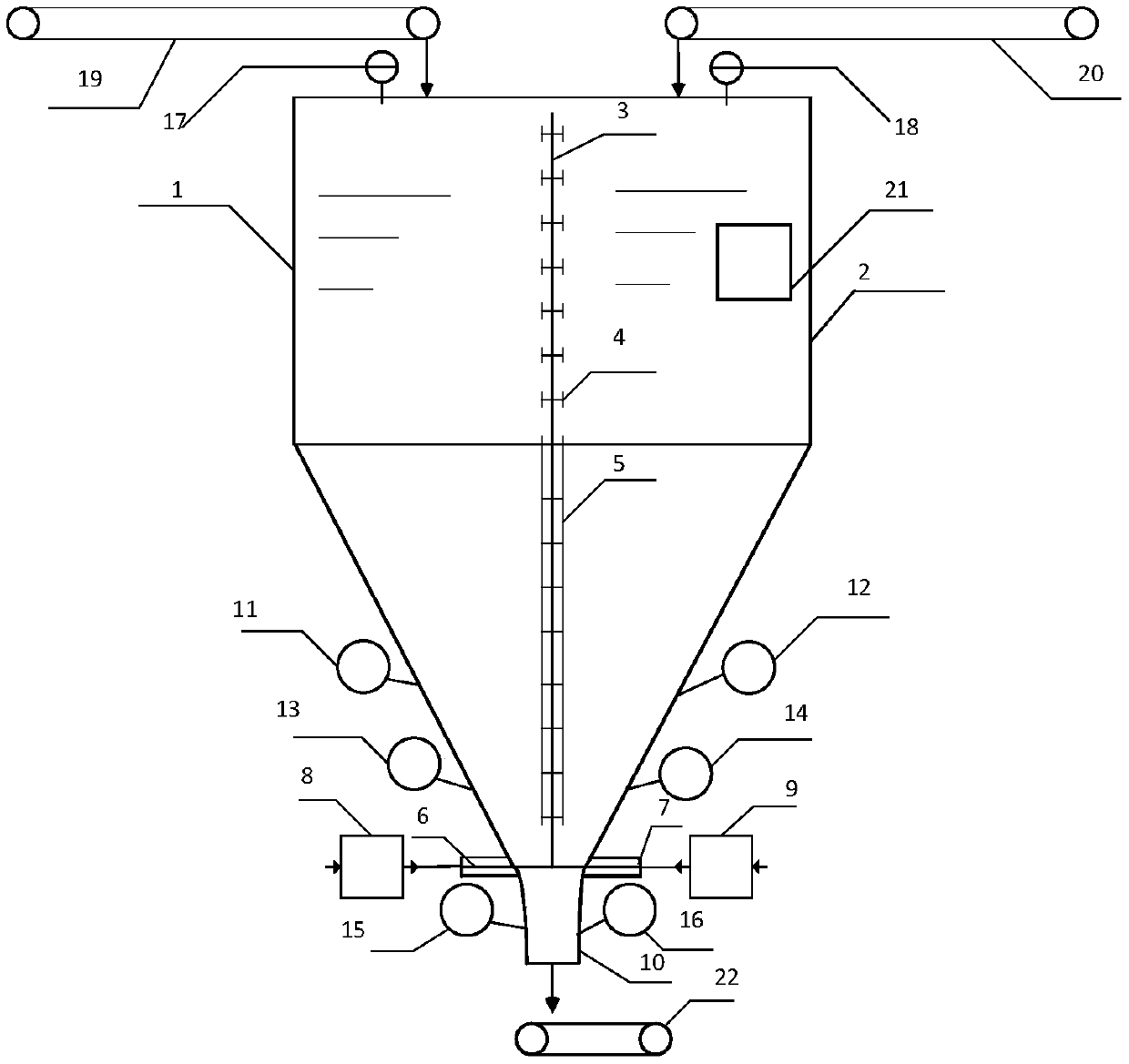

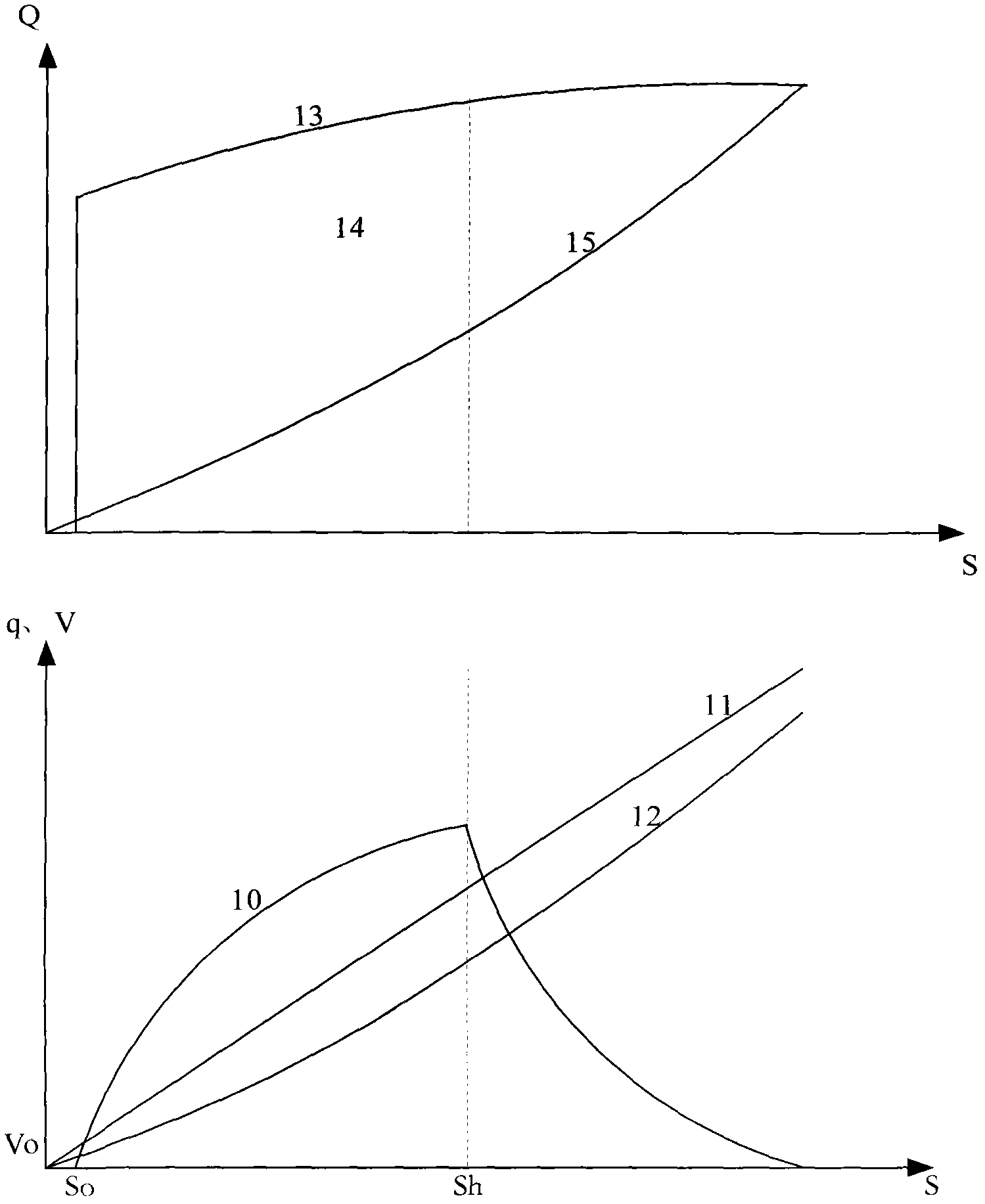

Method and system for generating coal blending and blending combustion scheme of load section coal-fired boiler

The invention provides a method and a system for generating a coal blending and blending combustion scheme of a load section coal-fired boiler. The method for generating the coal blending and blendingcombustion scheme of the load section coal-fired boiler comprises the steps: according to current coal feeding time, determining a preset time period after the current coal feeding time as load section time corresponding to the current coal feeding time; calling a corresponding relation table of the unit load and the time, finding out the highest load value in the load section time correspondingto the current coaling time, and taking the highest load value as a blending reference load; calling a relation curve between the unit load and the total output of the coal pulverizing system, a relation curve between the unit load and the heat value of the coal as fired, a relation curve between the unit load and the sulfur content, a relation curve between the unit load and the ash melting point, and a relation curve between the unit load and the coal quantity and ash quantity of a single coal type; and respectively searching parameters such as the total output of the coal pulverizing system, the calorific value of coal as fired, the sulfur content, the ash melting point, the coal amount of a single coal type and the ash amount corresponding to the current blending reference load, and generating a coal blending combustion scheme.

Owner:DATANG HUANGDAO POWER GENERATION

Raw coal bin system and operation method adapting to flexible blending of fuel of coal-fired boiler

PendingCN110282274AIncrease flexibilityLow costLarge containersConveyor partsUnit operationProcess engineering

The invention discloses a raw coal bin system and operation method adapting to flexible blending of fuel of a coal-fired boiler and belongs to the field of coal conveying and feeding system equipment of the coal-fired boiler. The system comprises a left side coal bin, a right side coal bin, a wear-resisting middle partition plate, a hydraulic inserting plate valve, a hydraulic station, a hyperbolical coal falling opening, an air cannon, a coal bin guided wave radar level gauge, coal conveying belts, a manhole door, a coal feeder, a coal falling opening and the like. According to the system, the wear-resisting middle partition plate divides the raw coal bin into two coal bins, the middle partition plate is provided with an H-shaped support plate, a stainless steel lining plate and the like, by means of the two coal conveying belts, different kinds of fuel are conveyed into two different coal bins, individual inserting doors are arranged for the two coal bins correspondingly, the hydraulic station is controlled remotely to drive the hydraulic inserting plate valve to be opened and closed, two kinds of fuel can be conveyed to the coal feeder flexibly, and flexible switching of the fuel of the boiler is achieved. According to the system and the method, accurate blending of multiple kinds of coal can be achieved, and safety and economy of unit operation are improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

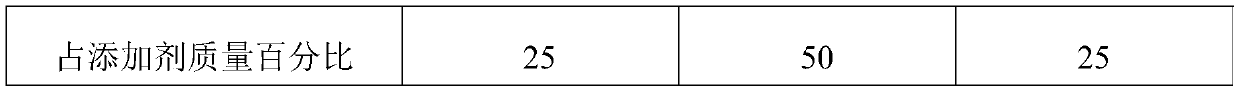

Additive for improving slagging feature of high-iron Zhundong coal and application method thereof

ActiveCN110360587AImprove slagging characteristicsSimple ingredientsSolid fuel pretreatmentSolid fuelsIndustrial wasteMagnesium

The invention discloses an additive for improving the slagging feature of high-iron Zhundong coal and an application method of the additive. The additive is composed of, by mass, 15%-65% of aluminum ash, 25%-50% of magnesium oxide and the balance dolomite. According to the application method of the additive, mixed coal is prepared according to the mass ratio of (3-8):100 between the additive and the high-iron Zhundong coal, wherein the aluminum ash accounts for 1%-6% of the mass of the high-iron Zhundong coal, the magnesium oxide accounts for 1%-5% of the mass of the high-iron Zhundong coal, and the dolomite accounts for 1%-5% of the mass of the high-iron Zhundong coal. The application method comprises the implementation steps that firstly, according to the mass of the high-iron Zhundong coal, the mass of each ingredient of the additive is determined; the additive and the high-iron Zhundong coal are crushed and mixed in a coal mill or undergo flowing mixing in a primary air pipeline, and finally the mixture is fed into a hearth to be combusted. The additive is composed of natural minerals and industrial waste, the ingredients are simple, the cost of the additive is low, and the additive has the effects of fixing sodium, improving an ash fusion point and fixing sulphur, can significantly improve the features of ash deposition, coking and slagging of the high-iron Zhundong coal and improve the blending combustion ratio of the high-iron Zhundong coal.

Owner:XI AN JIAOTONG UNIV

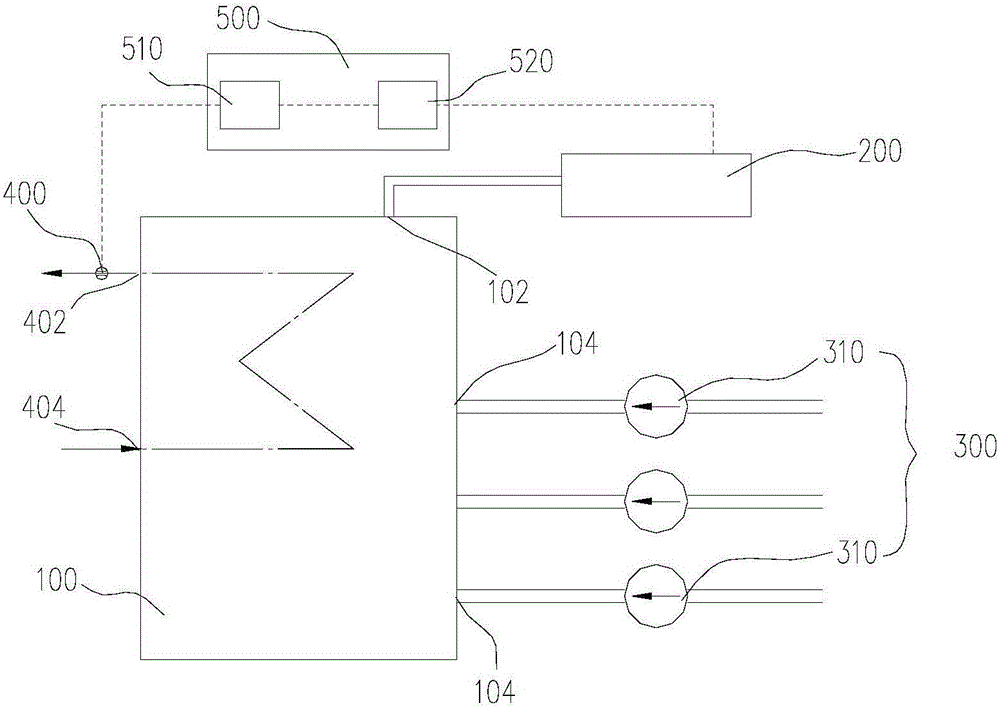

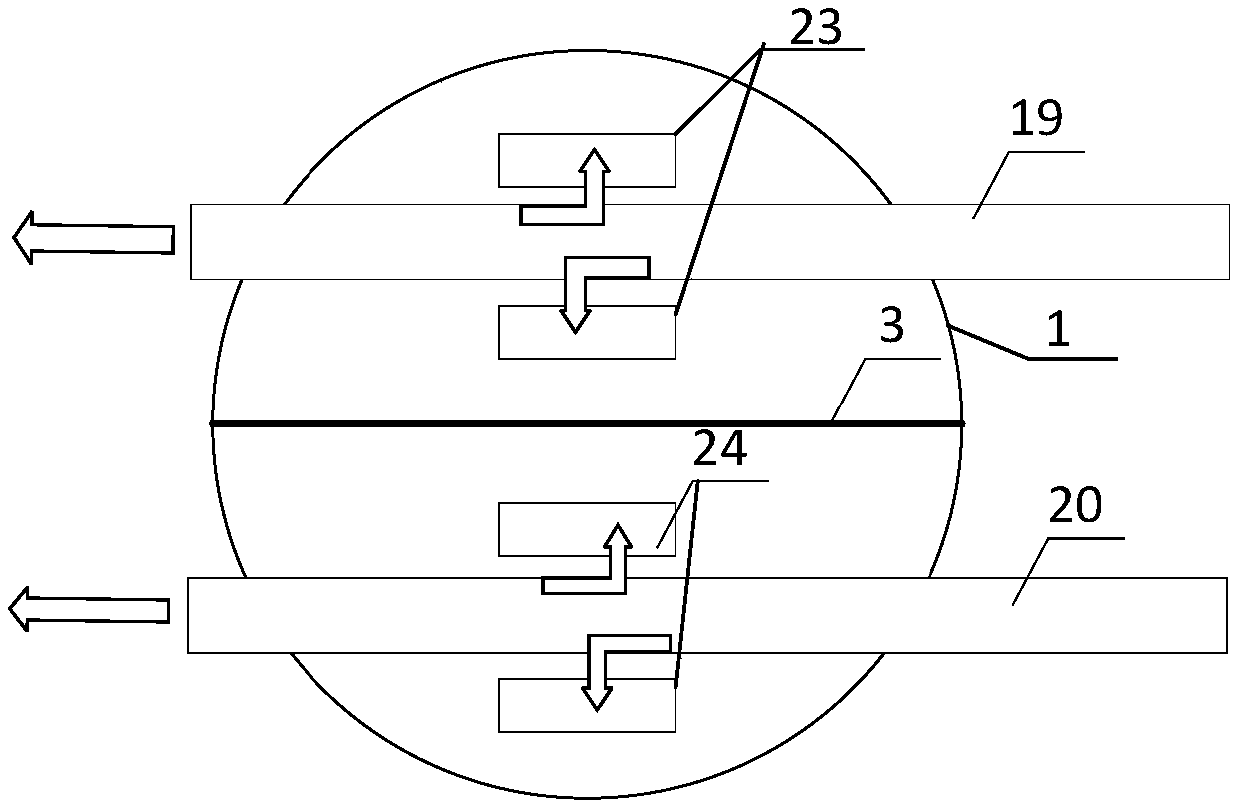

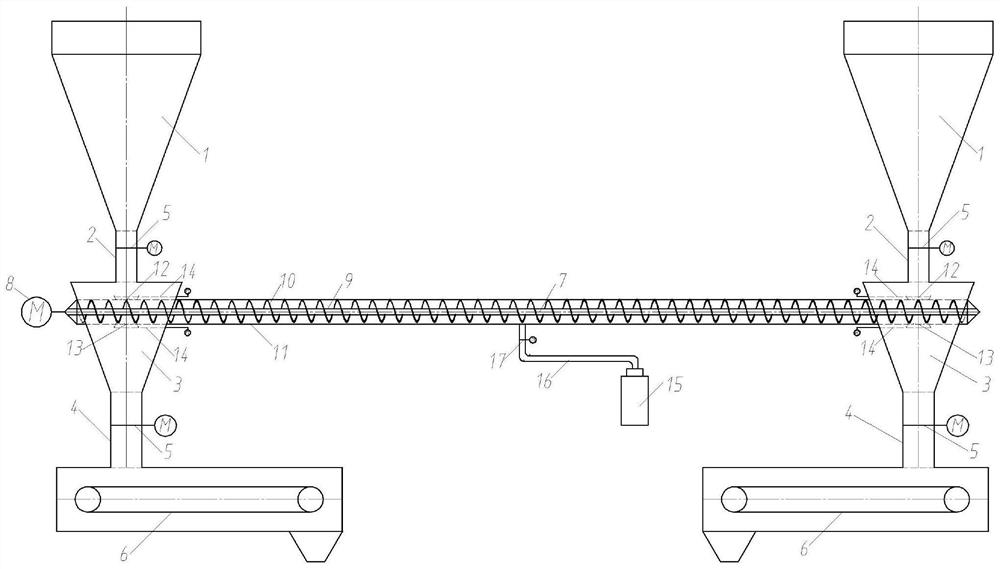

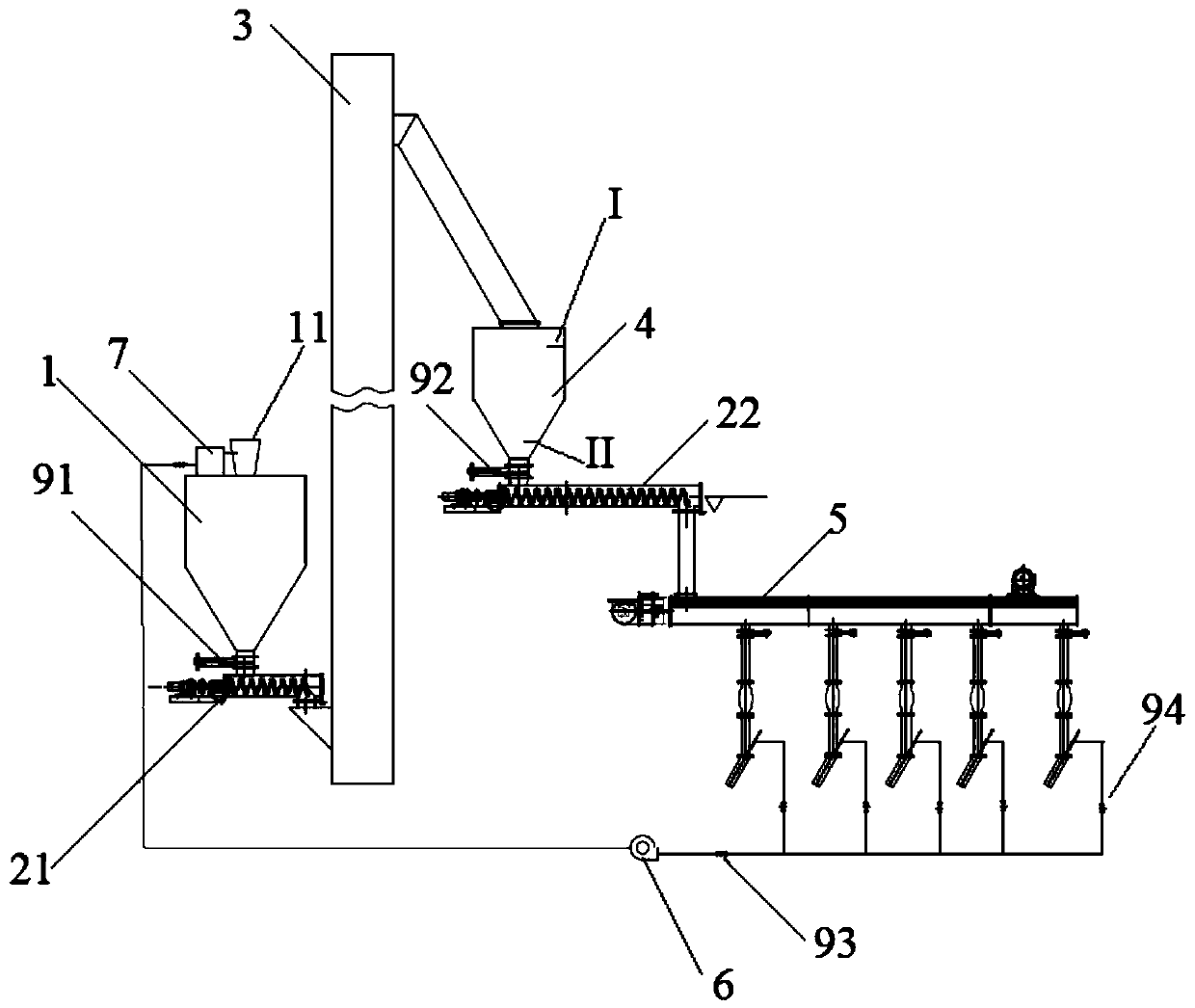

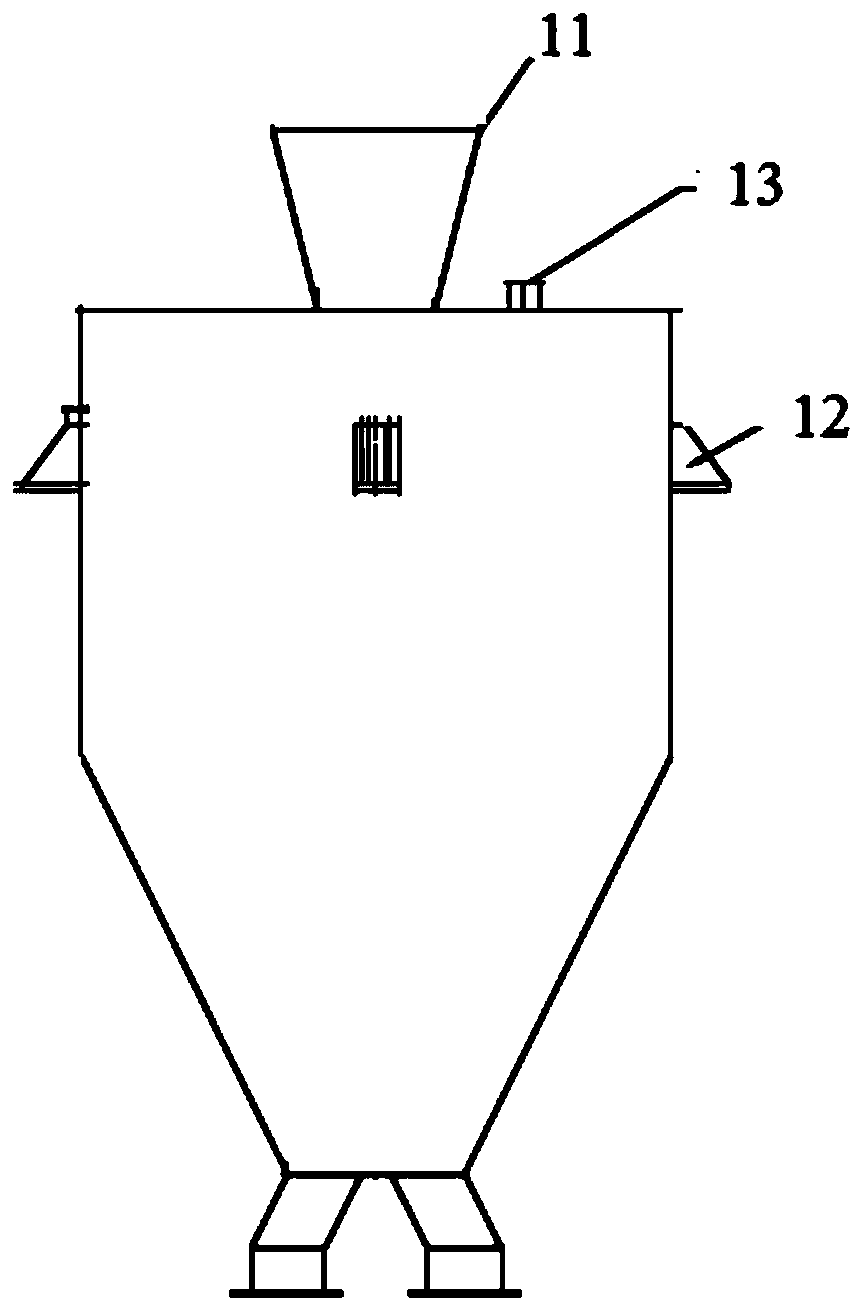

Mixed feeding device capable of automatically adjusting blending combustion amount of stale garbage

PendingCN112728554AIncrease the blending ratioSlow down the feed rateIncinerator apparatusThermodynamicsMixed feeding

The invention discloses a mixed feeding device capable of automatically adjusting the blending combustion amount of stale garbage. The mixed feeding device comprises a mechanical grate furnace, a mixed garbage conveying device, a raw garbage feeding device, a stale garbage feeding device, a mixed garbage crushing device and a control center. The raw garbage feeding device, the stale garbage feeding device and the mixed garbage conveying device are all connected with the control center. The stale garbage feeding device is used for transporting stale garbage to the raw garbage feeding device. The raw garbage feeding device is located between the stale garbage feeding device and the mixed garbage conveying device. The mixed garbage crushing device is used for chopping garbage and inputting the chopped garbage into the mechanical grate furnace. Multiple temperature sensors are arranged in the mechanical grate furnace, the multiple temperature sensors are connected with the control center, the multiple temperature sensors collect working parameters of the mechanical grate furnace and transmit the working parameters back to the control center, the control center transmits feedback signals to each device, and therefore the blending combustion ratio is controlled and adjusted.

Owner:SOUTH CHINA UNIV OF TECH

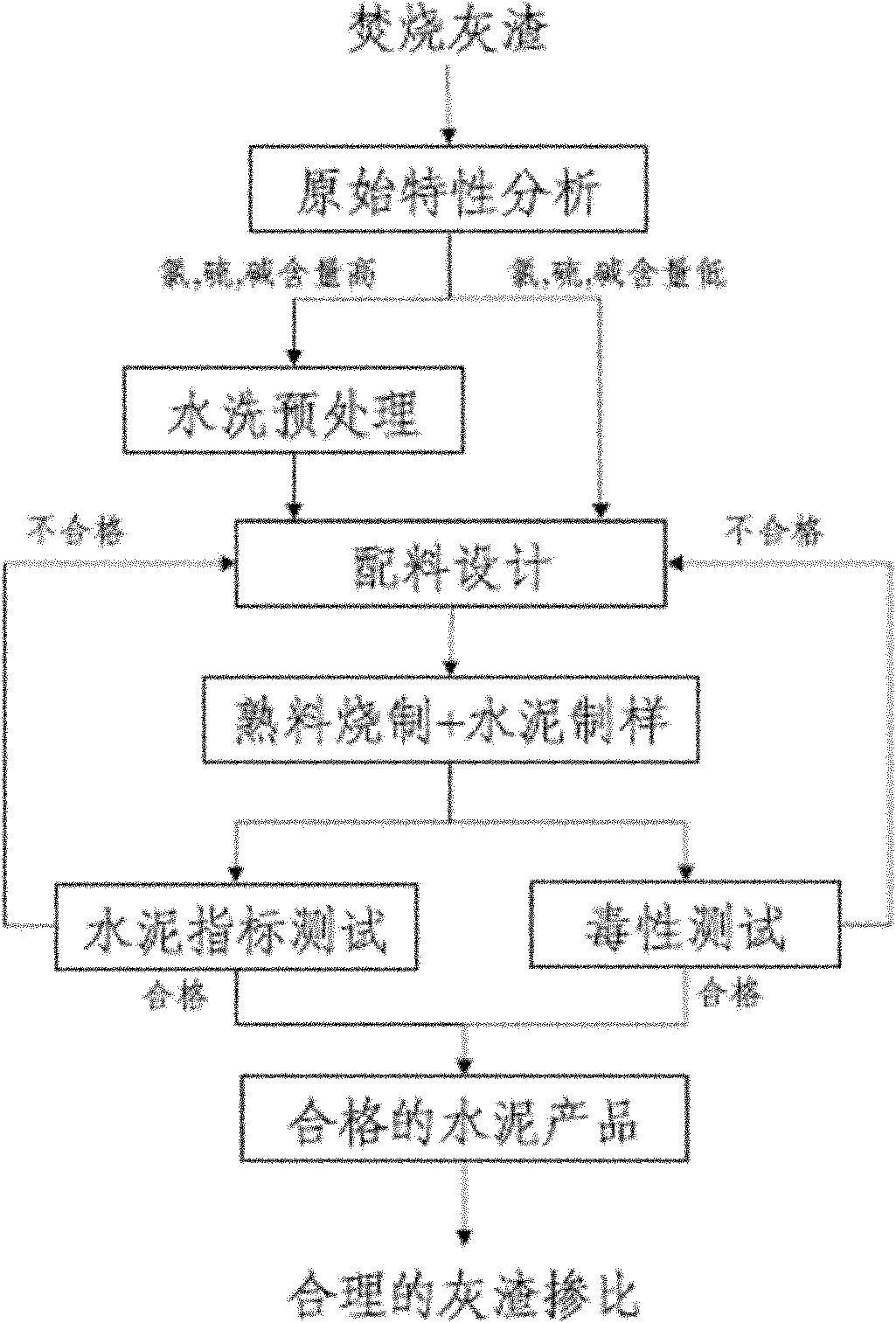

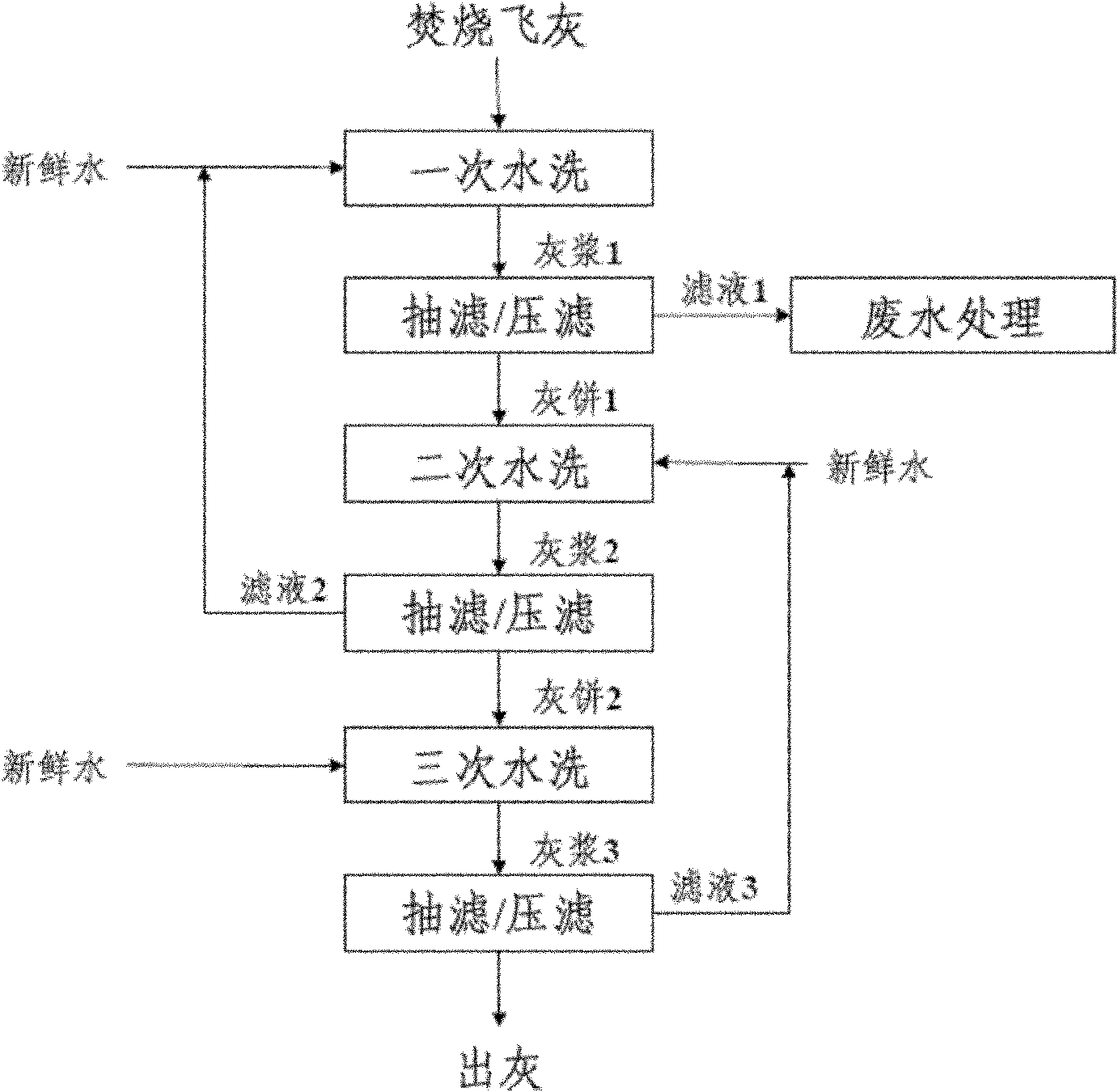

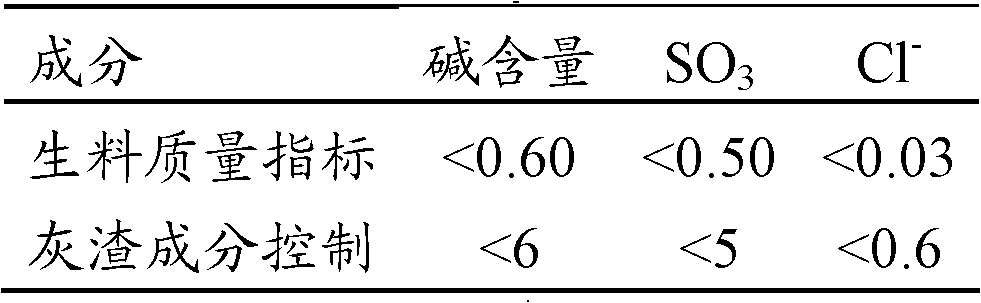

Method for improving mixing ratio of burning ash in cement raw materials

ActiveCN101935174ALow content of harmful ingredientsIncrease the blending ratioCement productionCement factoryMixing ratio

The invention provides a test method capable of effectively improving the mixing ratio of burning ash in cement raw materials. The method comprises the following steps of: analyzing original characteristics; performing washing pretreatment; firing ingredients to form clinker; and testing index and toxicity of the cement. The test method is designed completely aiming at a practical project, the raw materials are all the actual raw materials of a cement factory and the mixing ratio is also the actual production control ratio of the cement factory; the test method is well instructive to the project application; and on the premise of realizing stable operation of cement production and guaranteeing production quality, the test method greatly improves the mixing ratio of the burning ash in the cement raw materials. The whole test has the advantages of relatively a few involved large instruments, convenient operation, low cost and high test reproducibility.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

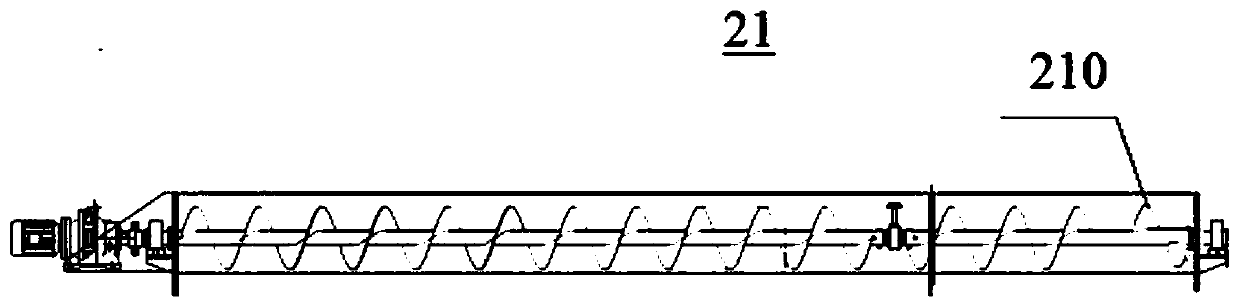

Raw coal bunker structure of direct-fired pulverizing system and deep peak regulation method

PendingCN112268295AImprove flexibility and peak shaving capabilitiesRapid deploymentFuel supply regulationLarge containersCombustionScrew conveyor

The invention discloses a raw coal bunker structure of a direct-fired pulverizing system and a deep peak regulation method. The structure comprises multiple groups of raw coal bunker units; coal typeswith different levels of volatile components and heat values are stored in the different raw coal bunker units; each raw coal bunker unit comprises a storage bunker, the storage bunker is connected with a coal feeder through a blending bunker, the storage bunker communicates with the blending bunker through a coal discharging pipe, the blending bunker communicates with the coal feeder through a coal falling pipe, and coal gates are arranged on the coal discharging pipe and the coal falling pipe; and the blending bunkers among the different raw coal bunker units communicate through screw conveyor devices. According to the deep peak regulation method for the raw coal bunker structure of the direct-fired pulverizing system, coal quality can be rapidly and flexibly allocated according to changes of unit loads and combustion conditions, and thus the flexible peak regulation capacity of the unit is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

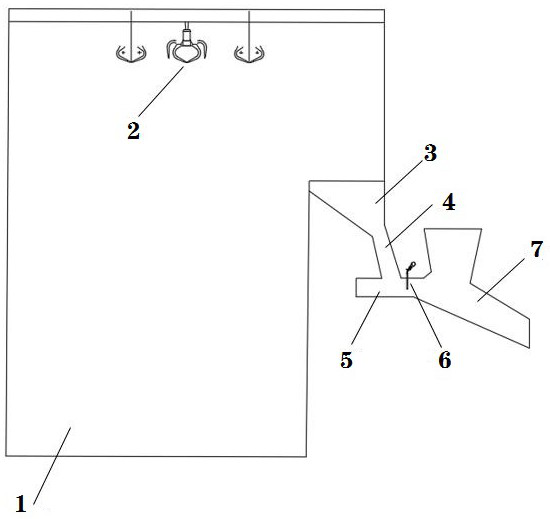

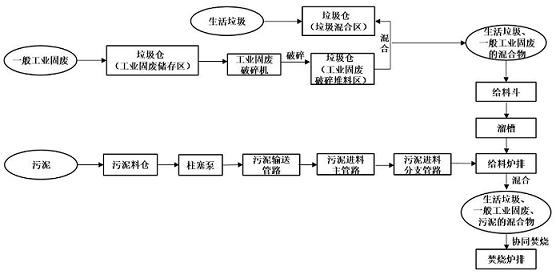

Feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge

PendingCN113339809AWell mixedAvoid uneven calorific valueIncinerator apparatusSludgeRefuse Disposals

The invention discloses a feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge, and belongs to the technical field of garbage treatment. The feeding system comprises a garbage bin, a garbage grab bucket, a feeding hopper, a chute, a feeding fire grate, a sludge feeding pipeline and an incinerator fire grate, wherein the garbage grab bucket is arranged at the top of the garbage bin; the top of the feeding hopper is communicated with the garbage bin; the bottom of the feeding hopper is communicated with the chute; the feeding fire grate is arranged at the bottom of the chute; the sludge feeding pipeline is arranged above the feeding fire grate; an inlet of the incinerator fire grate is communicated with an outlet of the feeding fire grate; an industrial solid waste storage area, an industrial solid waste crushing area, an industrial solid waste crushing and stacking area and a garbage mixing area are sequentially arranged in the garbage bin; an industrial solid waste crusher is arranged in the industrial solid waste crushing area; and a sliding way is arranged at the bottom of the industrial solid waste crusher and used for conveying crushed general industrial solid waste to the industrial solid waste crushing and stacking area. According to the feeding system, the three wastes can be uniformly mixed, and stable combustion is promoted.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD +2

Device and method for increasing capacity and improving efficiency of coal mill based on lignite

InactiveCN111167590ANo change in flammabilityHigh outputSteam useDrying gas arrangementsBrown coalPower station

The invention relates to the technical field of coal pulverizing by a coal mill for co-firing of lignite in a thermal power plant, in particular to a device and method for increasing capacity and improving efficiency of a coal mill based on lignite. According to the device for increasing the capacity and improving the efficiency of the coal mill, a high temperature superheated steam pipeline led from a steam turbine is connected with a steam heat exchanger; the steam heat exchanger is connected with a coal mill primary air chamber through an inlet primary air duct; the steam heat exchanger isconnected with a high pressure heater III through a pipeline; and a primary draught fan is connected with the steam heat exchanger through a hot primary air pipeline. According to the device and method for increasing the capacity and improving the efficiency of the coal mill based on the lignite, the adaptability to coal types and output of the coal mill are improved, the proportion of lignite mixed combustion is effectively increased, and the combustion performance of a boiler basically keeps unchanged. The technical scheme of adding hot primary air at an inlet of the coal mill solves the technical problems of insufficient output of the coal mill and low combustion efficiency of the boiler. According to the device and method for increasing the capacity and improving the efficiency of thecoal mill based on the lignite, the application scope of the lignite is expanded, thus any power plant can have the ability of burning the lignite, and the operation cost of an enterprise is greatly reduced.

Owner:北京蓝爱迪电力技术有限公司

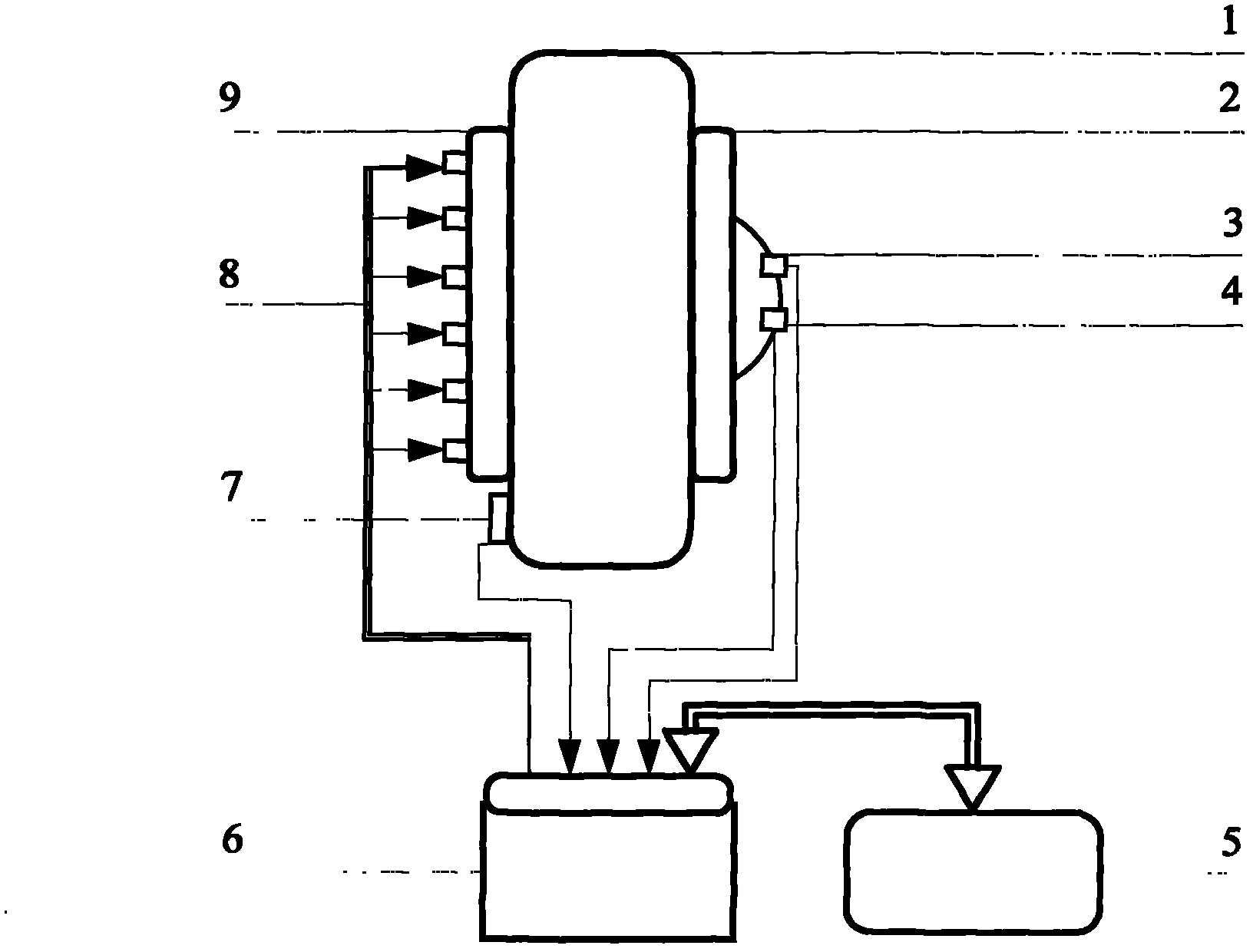

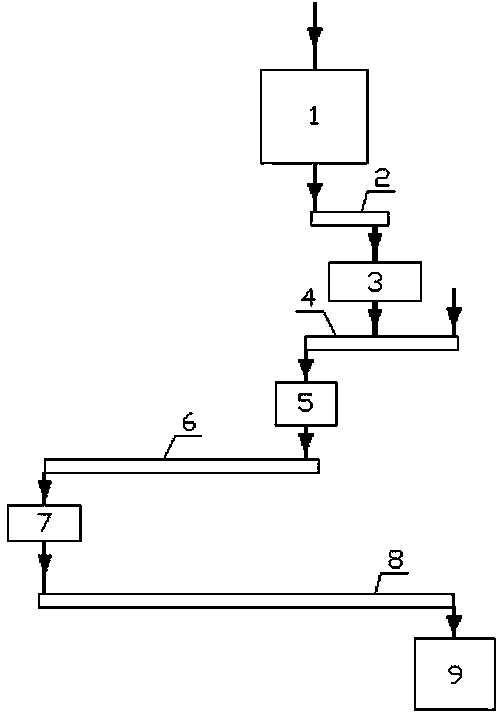

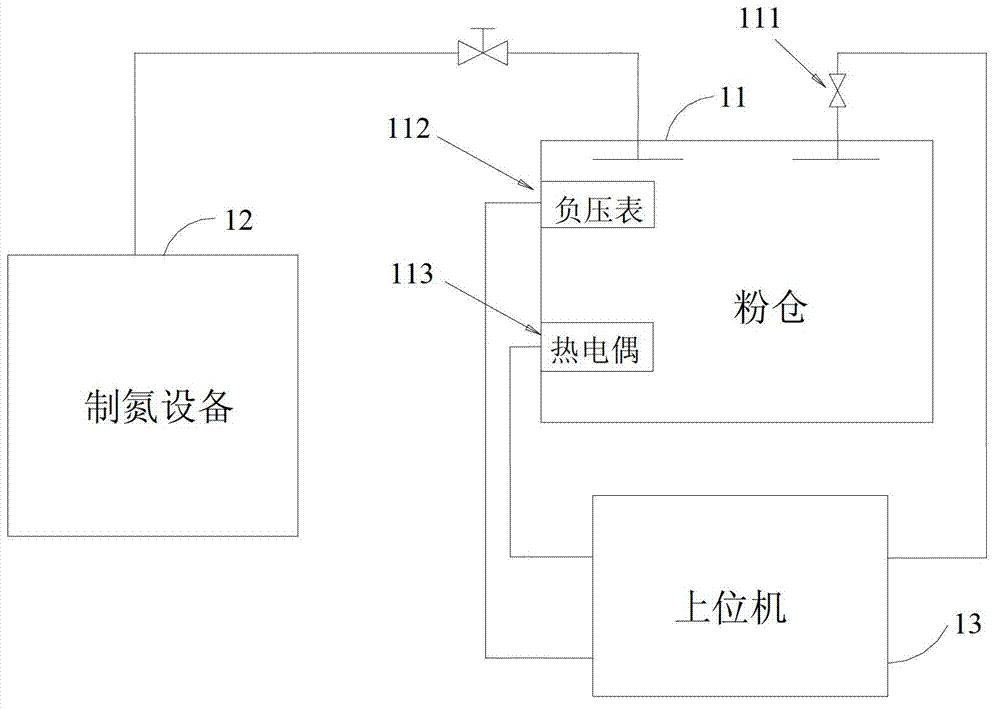

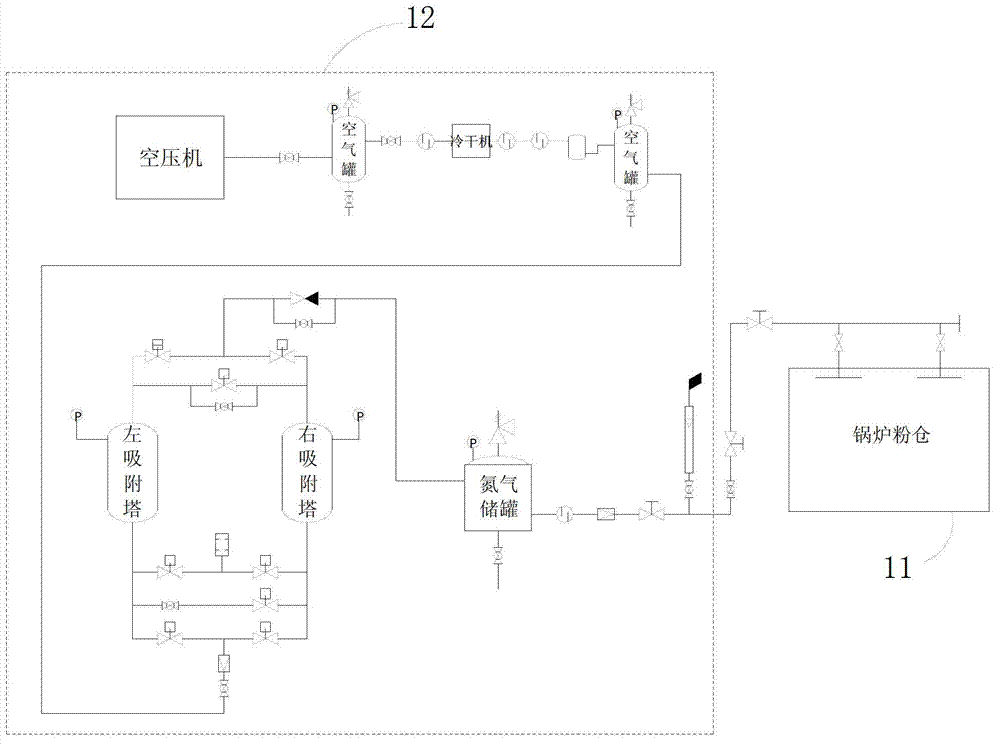

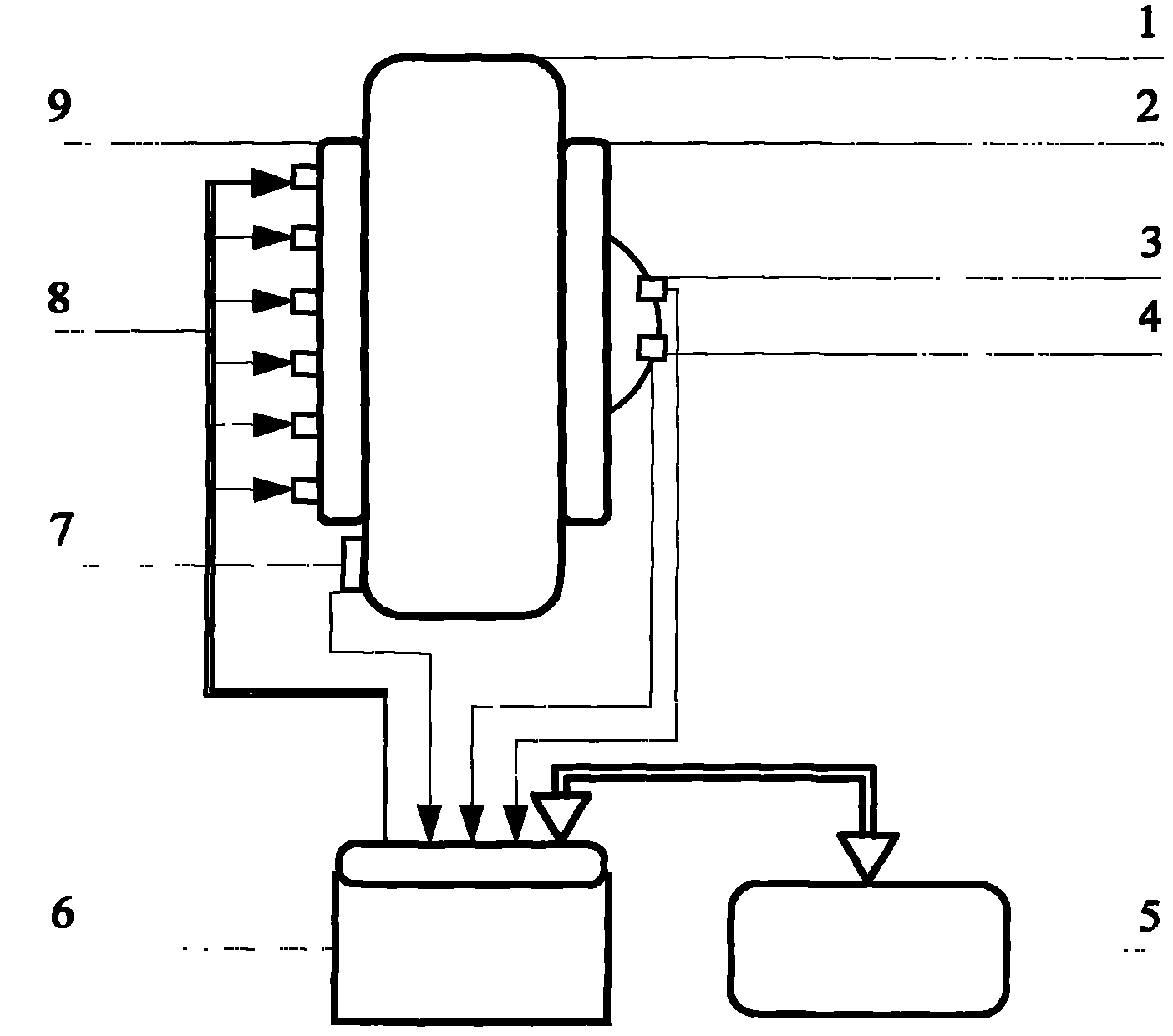

Coal pulverizing system

ActiveCN102927579AImprove securityImprove reliabilityDispersed particle separationLump/pulverulent fuel preparationEngineeringNitrogen source

The invention discloses a coal pulverizing system which comprises a coal powder cabin. The coal powder cabin comprises an upper cover, wherein further comprises nitrogen generating equipment. A nitrogen charging inlet is arranged on the upper cover of the coal powder cabin, and the outlet of the nitrogen generating equipment is connected with the nitrogen charging inlet of the coal powder cabin through pipe lines. The coal pulverizing system uses the nitrogen generating equipment as a flame protection device, and continuous nitrogen sources can be provided for the coal powder cabin of a pulverized coal boiler. Nitrogen can be produced under normal temperature, process is simple, energy consumption is small and cost is low. The nitrogen enters the coal powder cabin through pipe lines, and can reduce oxygen content, plays a role of oxygen isolation and carries out inerting to the internal portion of the coal powder cabin, and forms a good nitrogen protection layer; and meanwhile coal powder can be prevented from low temperature clotting, and has no smoldering danger. The safety performance and the reliability of the coal pulverizing system are greatly improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

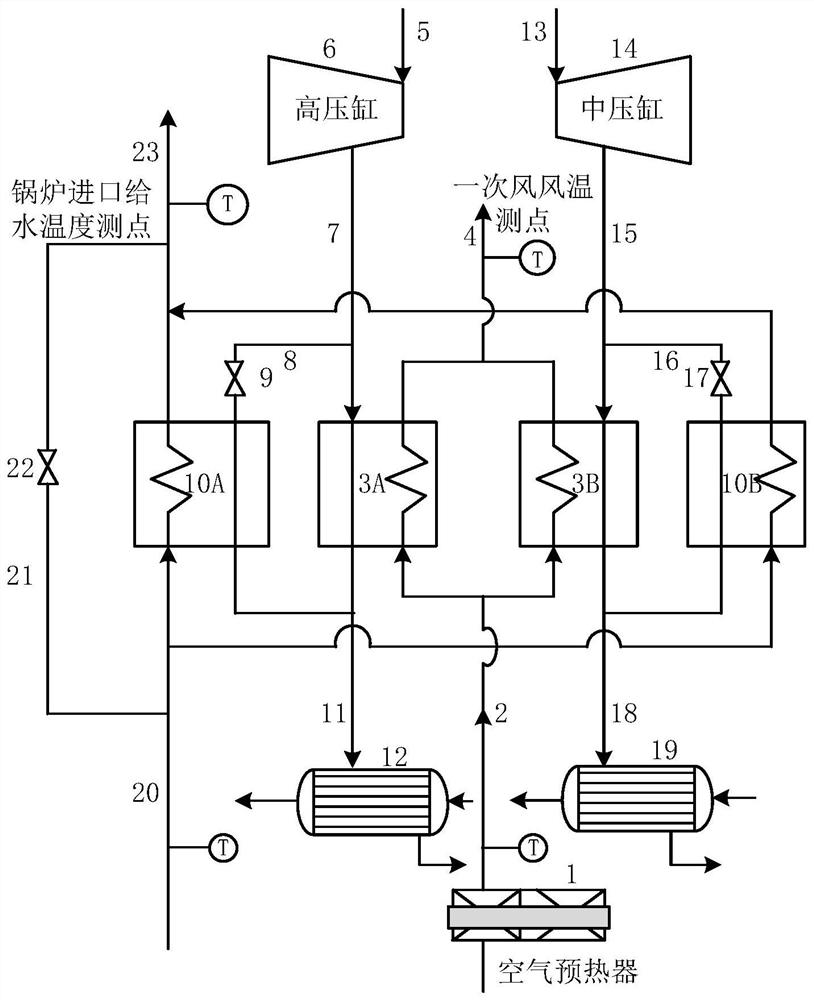

Primary hot air heating system of secondary reheated fired coal power generation set

PendingCN111749744AIncrease the blending ratioExpand the scope of coal adaptationSteam useEngine componentsHeating systemProcess engineering

The invention relates to a primary hot air heating system of a secondary reheated fired coal power generation set. The system comprises a second-stage extraction steam system of a steam turbine, wherein the second-stage extraction steam system of the steam turbine is connected to an external steam cooler and a primary hot air heater, separately, and extracted steam through the external steam cooler and the primary hot air heater is in joint connection to a second high pressure heater; four-stage extracted steam of the steam turbine is connected to the external steam cooler and the primary hotair heater, separately, and is in joint connection to a fourth high pressure heater through the external steam cooler and the primary hot air heater; a primary hot air inlet air duct is connected to an air pre-heater, and the primary hot air inlet air duct is connected to a primary hot air outlet air duct through two primary hot air heaters arranged in parallel; and a flow regulating valve on a water supply bypass of the external steam cooler can adjust the flow of water flowing through the external steam cooler. The system can improve the blending combustion proportion of a secondary reheatedfired coal boiler on high water and low heating value coal types, so that the variable load operating performance of the secondary reheating boiler is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

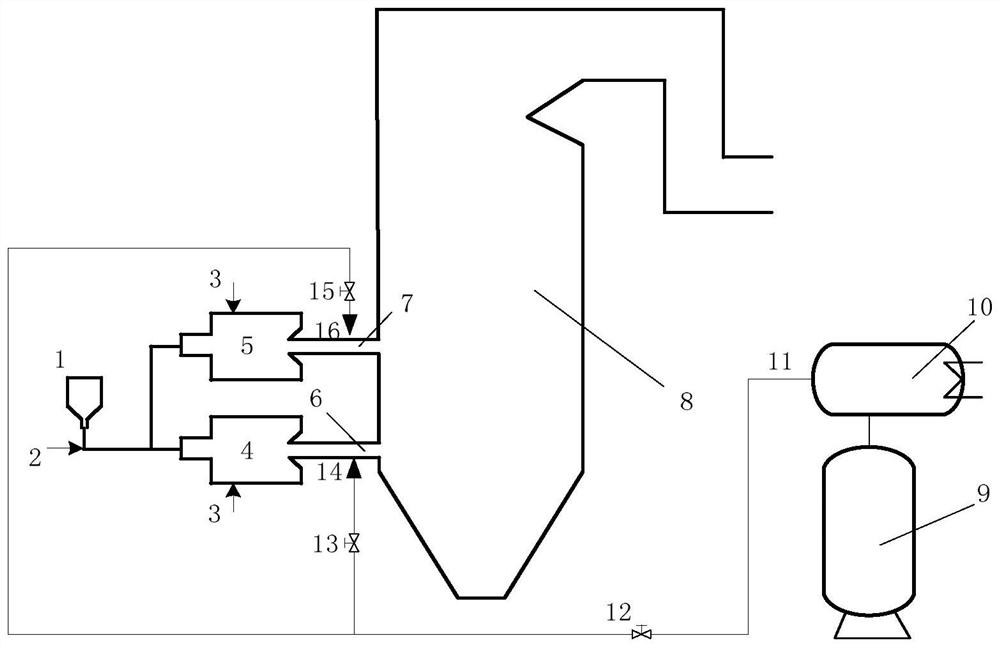

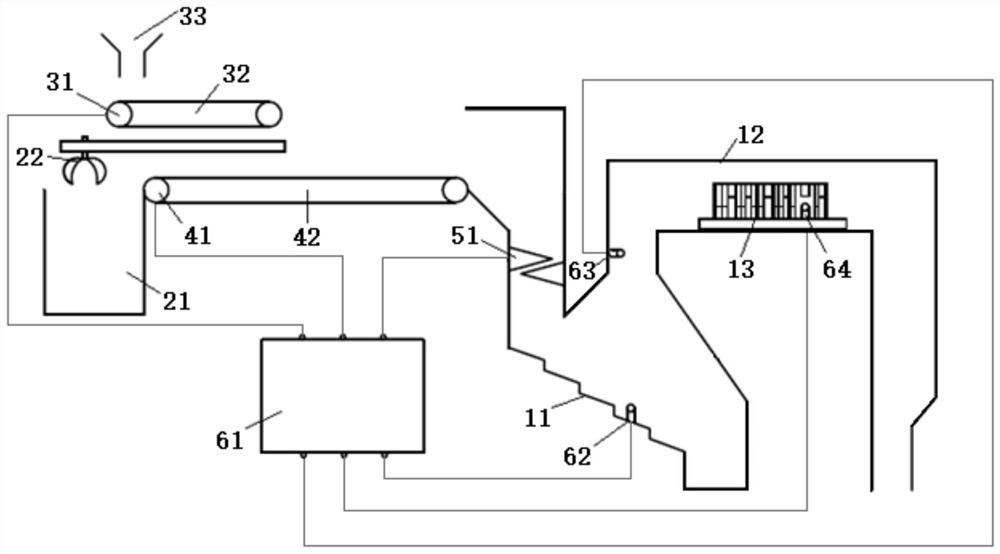

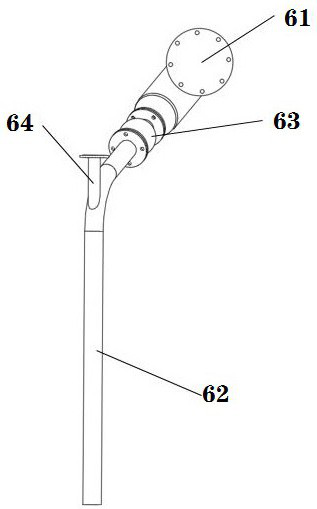

Household waste incinerator for co-processing dry sludge and disposal method adopting household waste incinerator

ActiveCN111412478ABest feeding pointIncrease the blending ratioIncinerator apparatusSludgeDomestic waste

The invention discloses a household waste incinerator for co-processing dry sludge. The household waste incinerator comprises an incinerator body and a dry sludge treatment system. Sludge particles are put into the incinerator body through the dry sludge treatment system, so that the sludge particles and waste in the incinerator body are incinerated and treated together; and the dry sludge treatment system comprises a control device, and the control device controls the in-incinerator amount of sludge when the dry sludge treatment system puts the sludge particles into the incinerator body. In addition, the invention discloses a disposal method adopting the household waste incinerator. According to the household waste incinerator, the in-incinerator amount of the sludge can be controlled when the sludge particles enter the incinerator body, and it is ensured that the sludge particles have enough combustion temperature and burn-out time in the incinerator, so that good incineration characteristics are achieved.

Owner:上海东石塘再生能源有限公司

Diesel-alternative fuel hybrid combustion engine control method

ActiveCN102220916BReduce injection volumeReduce output torqueElectrical controlInternal combustion piston enginesAlternative fuelsDriver/operator

The invention provides a diesel-alternative fuel hybrid combustion engine control method without an electric oil pump rack actuating mechanism, belonging to the field of engine control. According to the invention, an exhaust temperature sensor, a wide-range oxygen sensor, a mixedly burning ratio information display screen, an alternative fuel injection controller, a high pressure diesel pump rack displacement sensor and an alternative fuel injector are additionally arranged on an original diesel engine with a mechanical high pressure fuel pump; a high pressure diesel pump rack is mechanically connected with a vehicle accelerator pedal; and according to the position of the high pressure oil pump rack of the diesel engine, the alternative fuel injection controller determines the injection quantity of alternative fuel in combination with estimation on the excess air coefficient of an engine and the operation intention of the driver and sends a control command to drive an alternative fuel injection valve to inject corresponding alternative fuel to an engine intake pipe. The method has the beneficial effects of lowering the cost and overcoming the adverse factors caused by the adoption of an electric oil pump rack actuator and can be widely applied to the diesel-alternative fuel hybrid combustion engines.

Owner:NANTONG YATAI ENG TECH

Application of radix adenophorae extract to cut stems or reconstituted tobacco leaves

An application of Nansha ginseng extract in shredded stems or reconstituted tobacco leaves, characterized in that adding the extract of Nansha ginseng to shredded tobacco stems or reconstituted tobacco leaves can significantly reduce the woody gas (miscellaneous gas) of shredded stems or reconstituted tobacco leaves and irritation, increase the blending ratio of shredded stems or reconstituted tobacco leaves in middle and high-grade cigarette formulas, reduce the amount of tar in cigarette smoke, and reduce the production cost of cigarettes without affecting the smoke quality of cigarettes. The extract of Nansha ginseng is based on Nansha ginseng is used as raw material, and it is prepared through solvent immersion, extraction, refining, and concentration processes. The outstanding feature of the invention is that: a new application of Nansha ginseng is developed by using common solvents and common extraction methods, and a new natural flavoring agent for tobacco is introduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

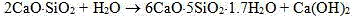

A method for preparing low-carbon cement clinker from iron tailings

ActiveCN103373826BIncrease the blending ratioEmission reductionCement productionCement mortarMaterials science

The invention provides a method for preparing low-carbon cement clinker by utilizing iron tailings. The method for preparing the low-carbon cement clinker comprises the step of firing the iron tailings and limestone as main raw materials at the temperature lower than 1400 DEG C. The low-carbon cement clinker comprises the following mineral compositions: 70-85% of dicalcium silicate, 5-15% of tricalcium silicate, 0-5% of tricalcium aluminate and 4-15% of tetra calcium aluminoferrite. The method has the advantages that the proportion of iron tailings in the raw materials can be up to 32%; in addition, compared with the firing temperature 1450 DEG C of traditional portland cement clinker, the firing temperature is reduced by 50-150 DEG C; compared with the emission of the greenhouse gases in traditional cement production, the emission of CO2 and other NOx-based greenhouse gases is reduced by about 20%. The cement prepared by utilizing the low-carbon cement clinker has the advantages that the 28-day strength can be up to 65-75 MPa; the strength grade is up to 62.5; the cement mortar dispersion degree can be up to 135-200mm; the cement is low in the hydration heat, good in safety and excellent in working performance.

Owner:承德金隅水泥有限责任公司

CFB boiler system capable of combusting waste gas and waste liquid in blending manner

InactiveCN110486717AImprove combustion intensityIncreased burning intensity and speedFluidized bed combustionIncinerator apparatusFlueExhaust fumes

The invention discloses a CFB boiler system capable of combusting waste gas and waste liquid in a blending manner. The CFB boiler system comprises a CFB boiler chamber, a boiler tail flue and a separator, wherein first combustors are respectively arranged on two side walls of a dense phase region of the CFB boiler chamber, second combustors are respectively arranged in secondary air nozzle regionson the front wall and rear wall of the CFB boiler chamber, and a third combustor is arranged at the top of the boiler; a flue gas outlet of the CFB boiler chamber communicates with an inlet of the separator; a flue gas outlet of the separator communicates with the boiler tail flue; an outlet in the bottom of the separator communicates with an inlet of a material returning machine; an outlet of the material returning machine communicates with an inlet of the CFB boiler chamber; and a wind distributing device is arranged at the bottom of the CFB boiler chamber. Through the adoption of the CFB boiler system disclosed by the invention, elimination treatment of the waste gas and the waste liquid can be better realized.

Owner:HUANENG CLEAN ENERGY RES INST

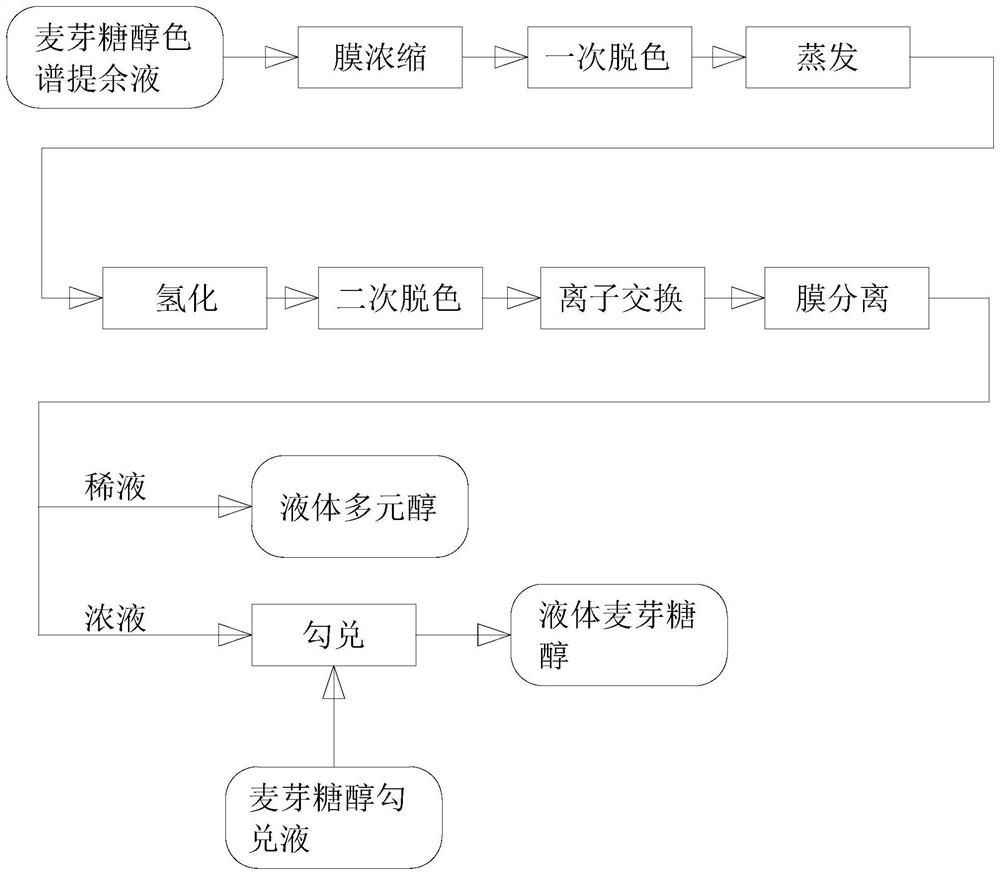

Method for preparing liquid maltitol and liquid polyol from maltitol chromatography raffinate

ActiveCN114249780AIncrease valueIncrease the blending ratioSugar derivativesOrganic compound preparationPolyolAlcohol

The invention relates to a method for preparing liquid maltitol and liquid polyhydric alcohol by using maltitol chromatographic raffinate, which comprises the following steps: hydrotreating the pretreated maltitol chromatographic raffinate to obtain hydrogenated liquid, and then post-treating the hydrogenated liquid to remove impurities to obtain post-treated liquid, the post-treatment liquid is subjected to membrane separation treatment to obtain thin liquid and enriched maltitol concentrated liquid, the thin liquid is directly used as liquid polyhydric alcohol, and the enriched maltitol concentrated liquid is blended with existing maltitol blending liquid with the maltitol content higher than 50%; the content of the maltitol is greater than or equal to 50%, and the liquid maltitol meets the national standard. Before the membrane separation treatment is adopted, the reducing sugar component in the sugar liquid is reduced by utilizing a hydrogenation method, the risk that the color turns yellow in the process is reduced, and the quality of the final product is improved. The method is simple to operate and short in production cycle, by-products are comprehensively utilized, and good economic benefits are achieved.

Owner:ZHEJIANG HUAKANG PHARMA

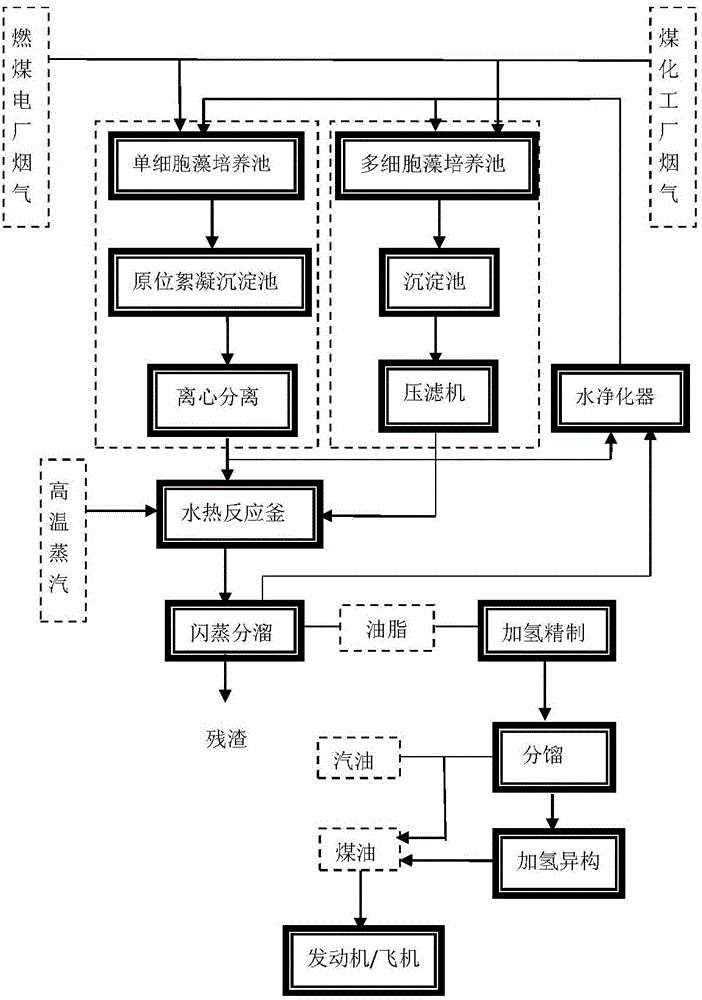

Preparation method and system of low-carbon biological aviation fuel based on full life cycle

PendingCN107523423AEfficient CO2 fixationHigh fatty acid productionFatty acid hydrogenationBioreactor/fermenter combinationsKeroseneChemistry

The invention provides a preparation method of a low-carbon biological aviation fuel based on full life cycle. The preparation method includes the steps: S1 screening micro-algae coupled with carbon spectrum characteristics of the aviation fuel; S2 cultivating the micro-algae to obtain oil-producing micro-algae with an efficient carbon dioxide fixation function and high fatty acid yield; S3 extracting grease from the oil-producing micro-algae by a hydrothermal method to obtain raw oil containing the grease; S4 sequentially performing impurity removal and hydrorefining treatment on the raw oil to obtain a hydrogenated product; S5 fractionating the hydrogenated product to obtain a kerosene component and a gasoline component, wherein the gasoline component is the biological aviation fuel. The prepared biological aviation fuel can be applied to six types of engines-aircrafts, and full life cycle greenhouse gas emission reduction proportion can reach 50-80% by the aid of the biological aviation fuel.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com