Method for improving mixing ratio of burning ash in cement raw materials

A technology for incinerating ash and cement raw materials, applied in cement production, etc., to achieve the effects of reducing the content of harmful components, good experimental reproducibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

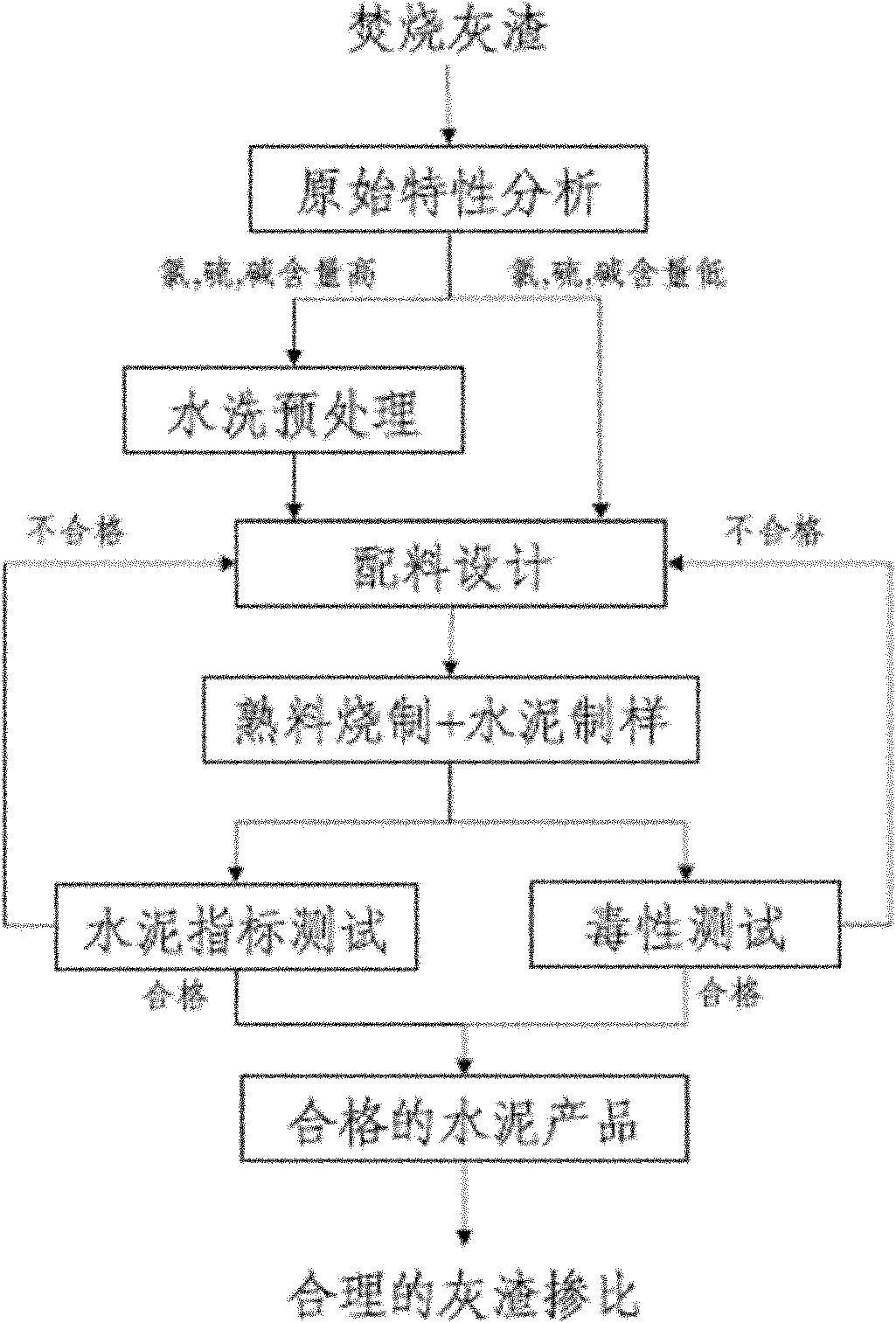

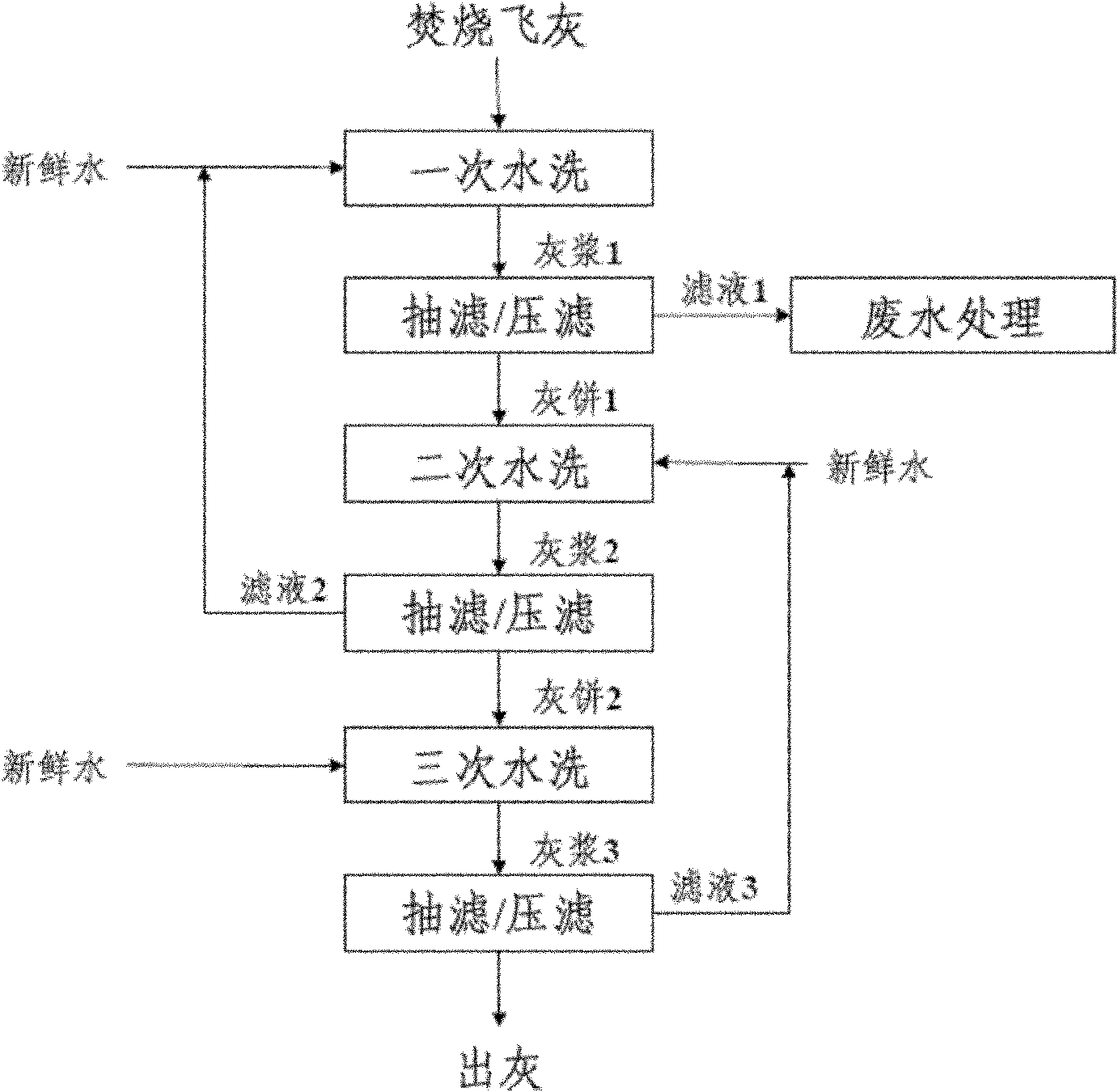

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Original Feature Analysis

[0037] A household waste incineration fly ash was taken from a place in Zhejiang Province, hereinafter referred to as fly ash 1#.

[0038] Fly ash from an industrial hazardous waste incineration was taken from a place in Zhejiang Province, hereinafter referred to as fly ash 2#.

[0039] A cement factory actually selects the following cement raw materials: limestone for calcareous raw materials, shale for clayey raw materials, copper slag for iron correction raw materials, and quartz sand for silicon correction raw materials.

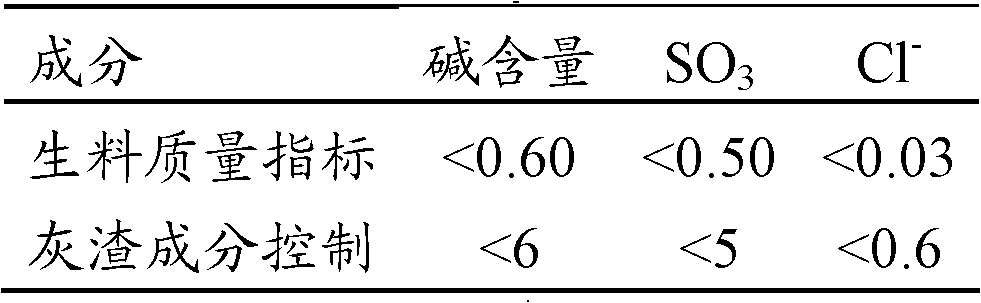

[0040] The main components of the above-mentioned fly ash 1#, fly ash 2# and several cement raw materials are as follows:

[0041] Table 1 The main chemical components of incineration fly ash and cement raw materials

[0042]

[0043] Note 1 Alkali content according to Na 2 O+0.658K 2 O Calculated value representation;

[0044] It can be seen that the main components of fly ash 1# and 2# are both CaO-SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com