Patents

Literature

90results about How to "Low content of harmful ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

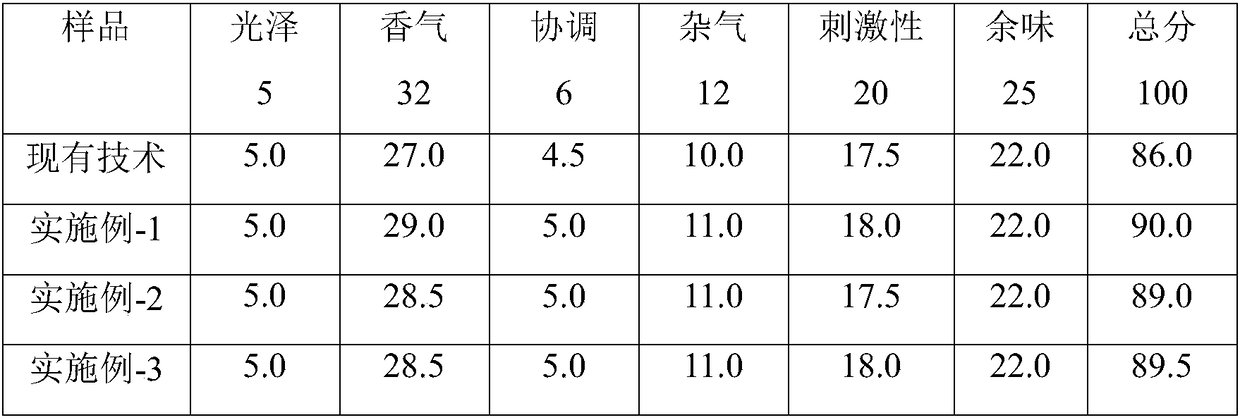

Method for improving sensory quality of tobacco leaves by using compound enzymic preparation

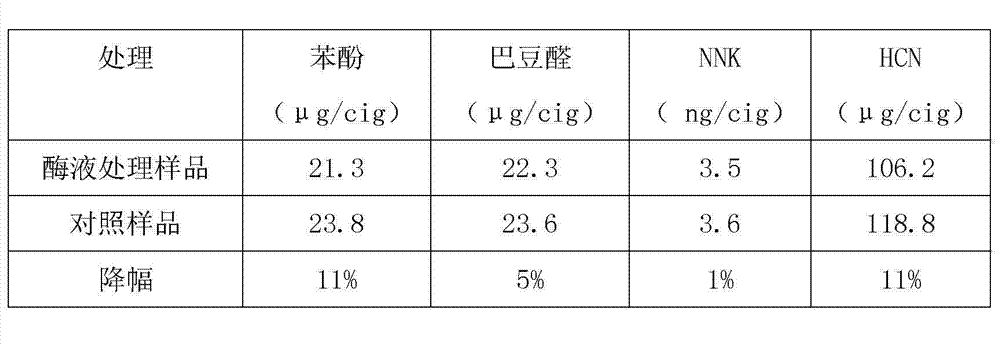

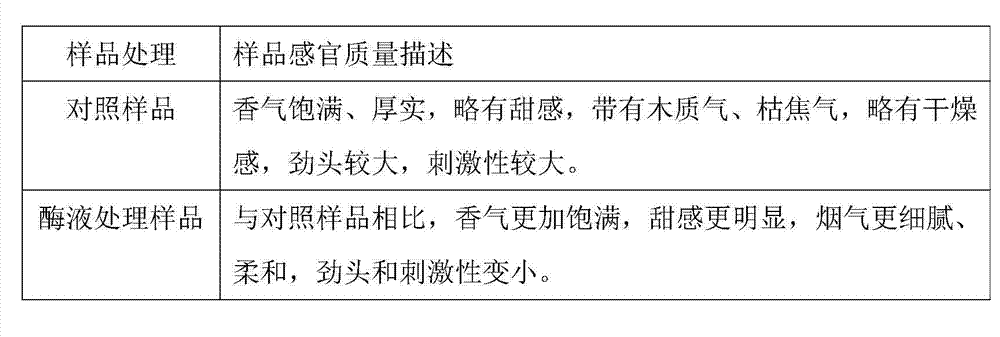

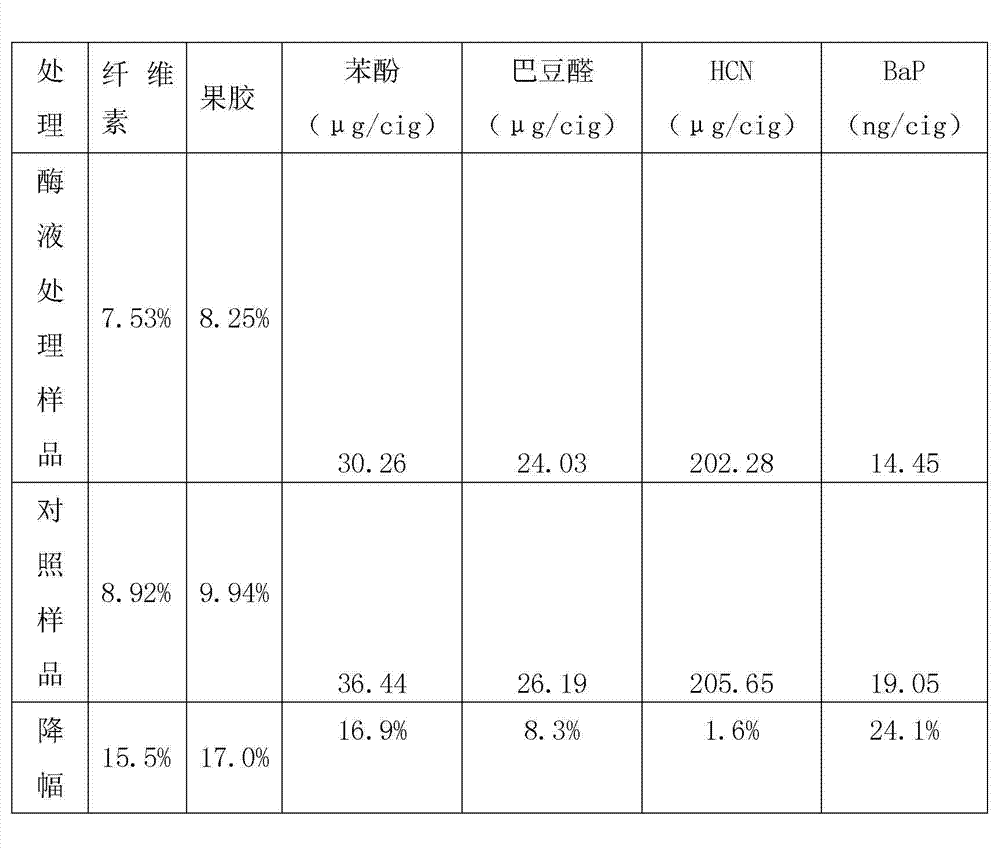

The invention relates to a method for improving sensory quality of tobacco leaves by using a compound enzymic preparation. According to the method, the compound enzymic preparation containing cellulose, pectinase, protease, FeSO4, biacetyl, citric acid, trisodium citrate and water is used to degrade celluloses and pectin in tobacco leaves. The compound enzymic preparation has the advantages of reducing the content of harmful ingredients in cigarette smoke such as phenol, HCN, BaP and NNK, reducing the irritability and strength of the cigarette smoke, enriching fragrance, and lightening miscellaneous gas, so that the cigarette smoke is relatively fine, and the sensory quality of the tobacco leaves is improved.

Owner:CHINA TOBACCO FUJIAN IND +2

Application of Chinese yam extractives in cigarettes

ActiveCN103315387AImprove suction qualityLow content of harmful ingredientsTobacco preparationTobacco treatmentBiotechnologyAlcohol ethyl

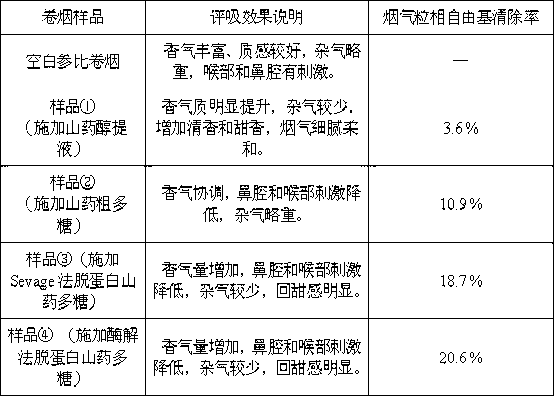

The invention discloses an application of Chinese yam extractives in cigarettes. The Chinese yam extractives are prepared according to the method that a. a fresh Chinese yam is washed, cut into slices, dried and smashed; b. the Chinese yam is extracted and condensed through ethyl alcohol with the certain concentration to obtain Chinese yam alcohol extraction liquid; c. material residues after alcohol extraction are further extracted through water; d. after water extraction liquid is filtered and condensed, ethyl alcohol is added to the water extraction liquid, precipitating, standing and filtering are conducted, and precipitates are dried to obtain Chinese yam crude polysaccharide; e. deproteinization and purification are conducted. When being applied in a cigarette perfuming link, Chinese yam alcohol extraction liquid can improve perfuming quality, cover sundry flavors, increase clean aroma and sweet aroma, ensure that smoke is more delicate, and improve cigarette smoking and absorbing comfort. After being dissolved in water and used as cigarette material liquid, the Chinese yam crude polysaccharide plays a role in thickening smoke, reducing stimulation and improving mouthfeel, and can reduce the amount of harmful ingredients such as cigarette smoke free radicals. The application of the Chinese yam extractives in the cigarettes does not change the previous performance and the previous processing processes of the cigarettes, improves perfume quality of the cigarettes and sense organ comfort of cigarette smoking, and also has practical production significance and value.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

Processing method of secondary hemp fibers

ActiveCN102828254AHigh economic valueSoft touchVegetable materialMechanical fibre separationChemical treatmentWastewater

The invention provides a processing method of secondary hemp fibers, and relates to a method for processing the secondary hemp fibers which are the materials separated from hemp stalk bark. The method adopts the combination of bio-enzyme and chemical and mechanical degumming. The method comprises the following technical steps of: mechanical opening and impurity removing, bio-enzyme degumming and preprocessing, chemical degumming processing, mechanical dehydrating and degumming processing, and post-degumming processing. According to the method, the secondary hemp fibers are processed through the way in the combination of bio-enzyme and chemical and mechanical degumming. The method is simple in technology and easy to carry out. Over 95% of pectin, lignin and waxiness in the fibers can be removed via the method. The processed fibers have soft handfeel and the separation degree over 2000Nm, and the fiber main body is 33 to 40mm in length, thus, the spinnability and the stainability of the fibers can be greatly improved. The processing method effectively increases the economic value of the secondary hemp fibers; and moreover, as the bio-enzyme preprocessing is firstly adopted in the production, the harmful components in the waste water produced by the chemical processing have low contents and can be easily purified. The method is an ideal processing method of the secondary hemp fibers.

Owner:YINGKOU XINYI TEXTILE

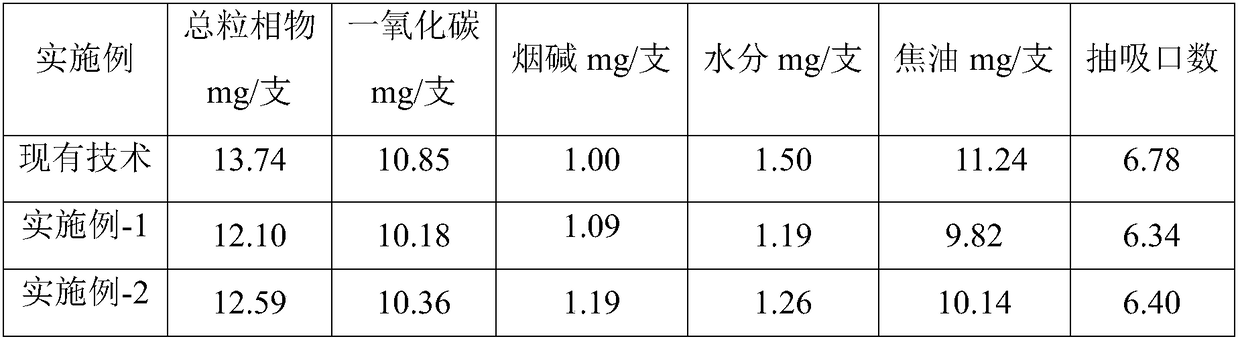

Shredded peduncle dipping type material feeding process

The invention relates to a cabo processing method in the tobacco industry, which comprises the steps of cabo steeping, steam heating, cabo storing, chopping, fountain feeding, drying and swelling, wherein the fountain charging is replaced by impregnated charging, the cabo is fully immersed into the steeping liquor added by feed liquid, dewatering the steeped cabo to next stage (drying and swelling).

Owner:蚌埠卷烟厂

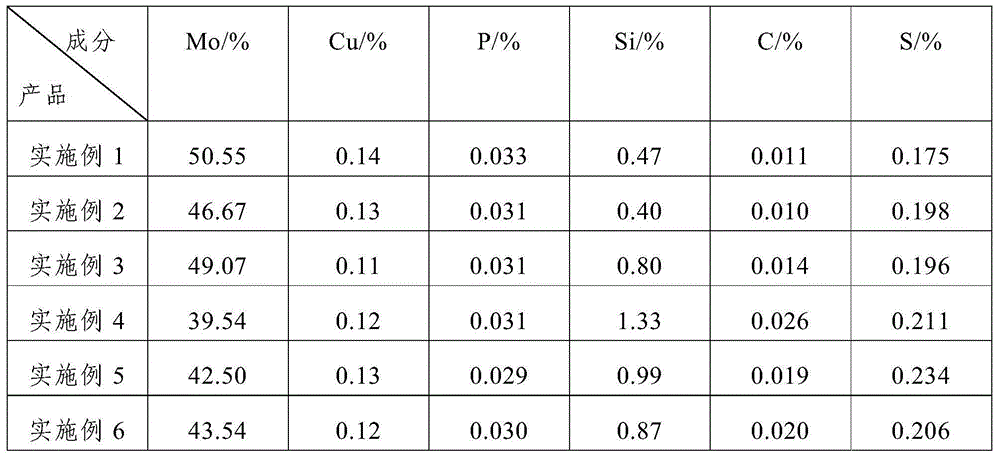

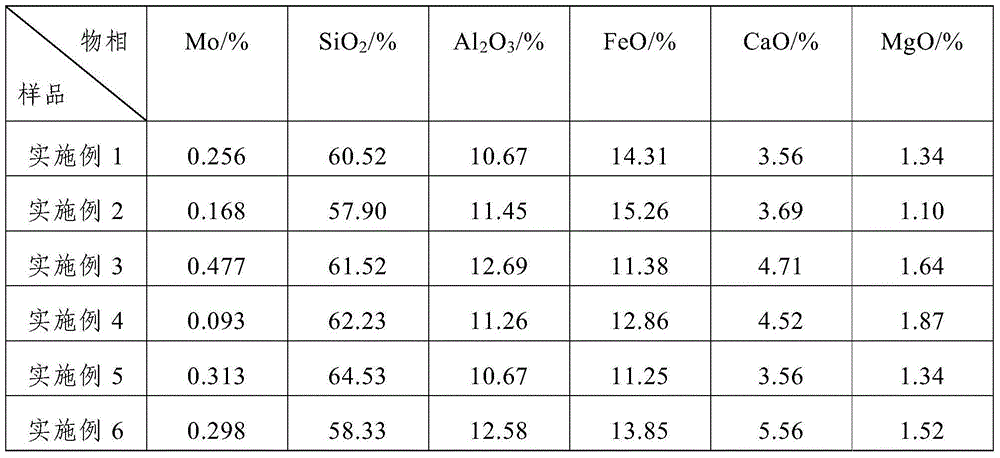

Method for smelting ferro-molybdenum from ammonia leaching residue to recover molybdenum

ActiveCN104152707AImprove resource utilizationReduce consumptionProcess efficiency improvementAluminiumResource utilization

The invention discloses a method for smelting ferro-molybdenum from ammonia leaching residue to recover molybdenum. The method comprises the following steps: 1, the ammonia leaching residue and an auxiliary material are added into a mixer to be mixed uniformly to obtain a mixture, wherein the auxiliary material comprises ferro-silicon, ferro-phosphorus, aluminum particles, sodium nitrate and a fluxing agent, and the fluxing agent adopts calcium oxide or fluorite; 2, the mixture is loaded in a smelting furnace, the surface of the mixture is covered with a layer of firelighter, and a reaction product is obtained after ignition for smelting; the reaction product stands still so that iron is precipitated to form smelting residue and a ferro-molybdenum ingot, the smelting residue is removed, the ferro-molybdenum ingot cools naturally to be solidified, and the purpose of smelting ferro-molybdenum from the ammonia leaching residue to recover molybdenum is achieved. According to the method provided by the invention, the ammonia leaching residue is mixed with the smelting auxiliary material on the basis of a silicon-aluminium thermal reduction method, and the smelting residue and the ferro-molybdenum ingot are produced by a ferro-alloy self-heating reaction technique, so that the effect of recycling molybdenum metal is achieved; when used for smelting ferro-molybdenum to recover molybdenum in ammonia leaching residue, the method has the advantages of high resource utilization rate, low smelting auxiliary material consumption, small environmental pollution and high metal recovery rate.

Owner:JINDUICHENG MOLYBDENUM CO LTD

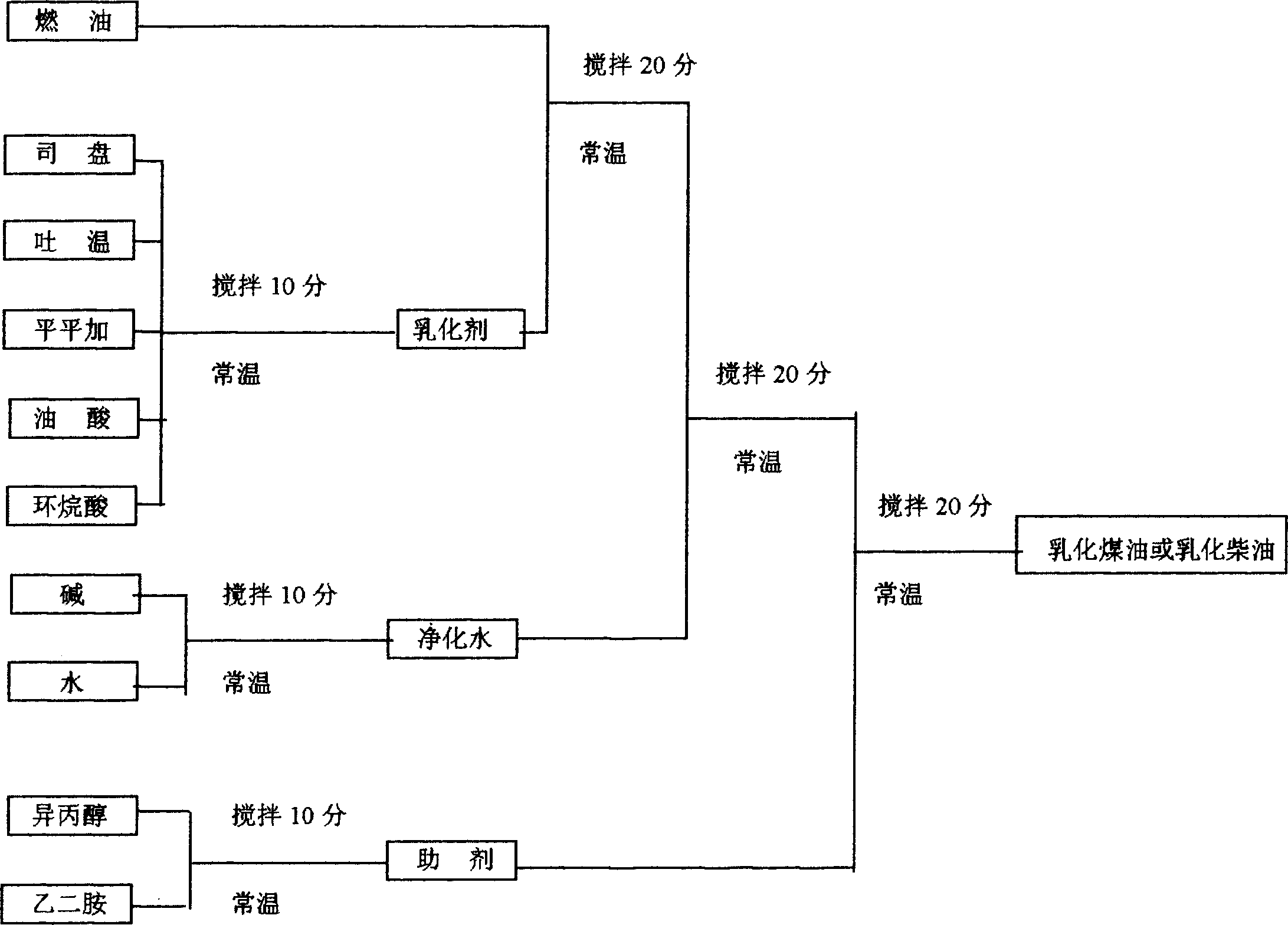

Micro emulsion fuel production process and formula

InactiveCN1422934ALow content of harmful ingredientsReduce odorRefining by water treatmentEngineeringEmulsified fuel

The invention is a producing technique of micro-emulsified fuel and the formula. Its character: according to the weight percentage, emulsifying agent 6-9%, fuel 70-80%, purified water 15-20% and assistant 0.4-0.7%, mix them and fully stir to make the micro-emulsifier fuel. It adopts the micro-emulsifier techinque. It can alone be used and also mixed with similar fuel for use.

Owner:徐涛

Method using fennel straw as raw material to make tobacco sheets

InactiveCN107647468AFacilitate dissociationHigh yieldTobacco preparationTobacco treatmentFiberIrritation

The invention discloses a method using fennel straw as raw material to make tobacco sheets. The method comprises the steps that fennel straw cut to have the length of 2-4 cm is adopted, steam explosion treatment is performed after impurity and dust removal, the exploded fennel straw raw material is subjected to impurity and core removal treatment again and then is uniformly mixed with natural non-tobacco plant fiber pulp and water, finished pulp is obtained after low-concentration pulping treatment, papermaking and drying are performed to obtain base sheets after impurities and coarse and large fiber of the finished pulp are removed, a tobacco extract is sprayed on double faces of each base sheet, and finally drying and splitting are performed to obtain tobacco sheet products with the moisture of about 10%. The made fennel straw tobacco sheets have the advantages of having high fragrance content, low tar convent and low harm, the fennel straw tobacco sheets are added to cigarettes andhave the effects of decreasing offensive odor, making fragrance fine and smooth, decreasing irritation and making the compatibility with the natural fragrance of tobaccos good.

Owner:ZHEJIANG ZEYUAN PLANT SCI & TECH

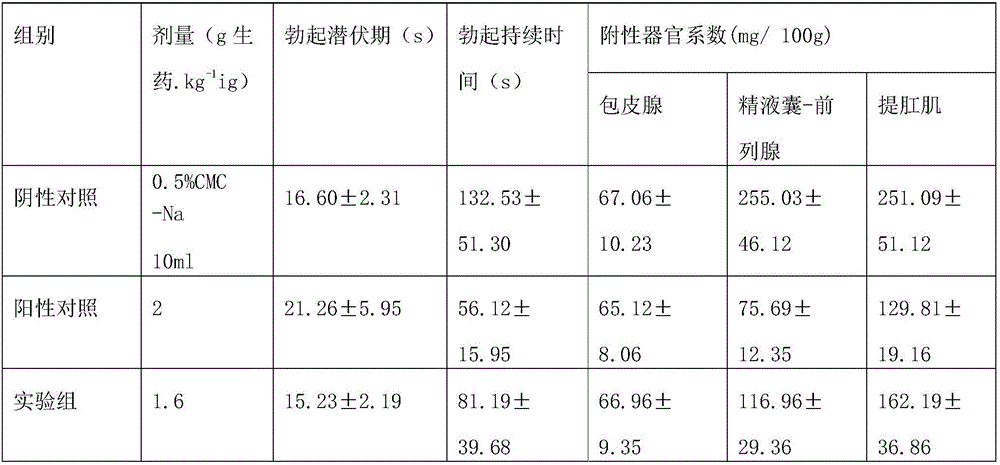

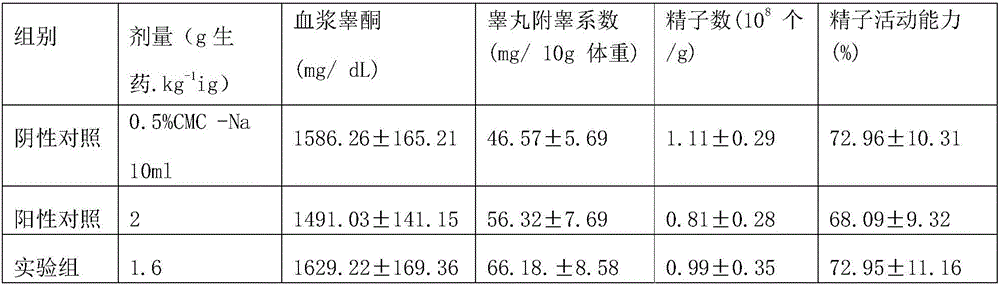

Traditional Chinese medicine composition for treating impotence

InactiveCN103611113AEasy to obtainEasy to makeHeavy metal active ingredientsFish material medical ingredientsMedicinal herbsMonkshoods

The invention provides a traditional Chinese medicine composition for treating impotence, relating to the technical field of Chinese medicinal herbs. The composition is composed of the following active pharmaceutical ingredients: 80-100g of gerba pyrolae, 50-70g of black monkshood piece, 25-25g of cinnamon, 15-25g of baked ginger, 25-35g of Morinda officinalis, 9-11g of sea dragon, 25-35g of actinolite, 25-35g of epimedium, 25-35g of dodder, 50-70g of Allium tuberosum, 25-35g of radix rehmanniae preparata, 15-25g of glossy privet fruit, 15-25g of angelica, 25-35g of Chinese wolfberry, 25-35g of Desertliving Cistanche, 25-35g of fructus psoraleae, 10-15g of teasel root, 9-11g of eucommia, 10-20g of Chinese date, 10-20g of radix astragali, 10-20g of cumin, 8-12g of gastrodia elata, 7-10g of motherwort, 7-12g of rhizoma alismatis, 10-20g of dangshen and 10-20g of Chinese yam. The composition has the characteristics of accessible materials, simple manufacturing process, low cost, reasonable formula, small dosage, low content of harmful ingredients, no toxic or side effect, obvious curative effect and the like.

Owner:ANHUI BAOZHITANG PHARMA

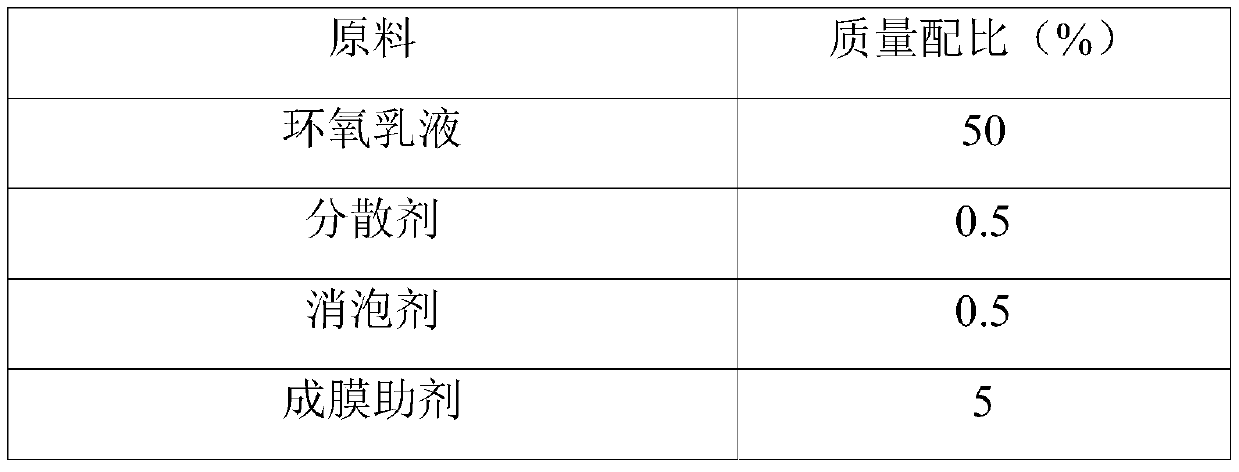

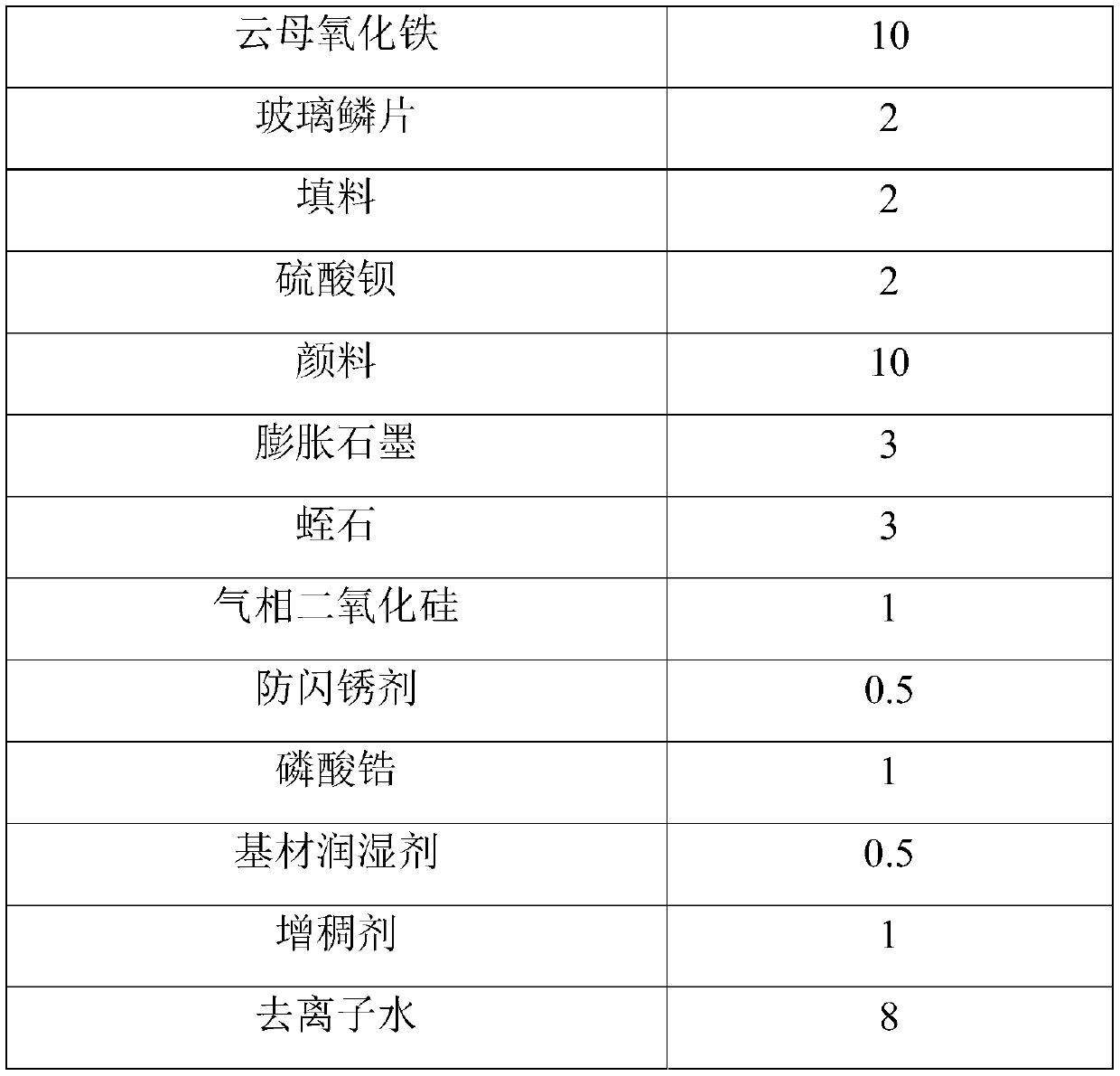

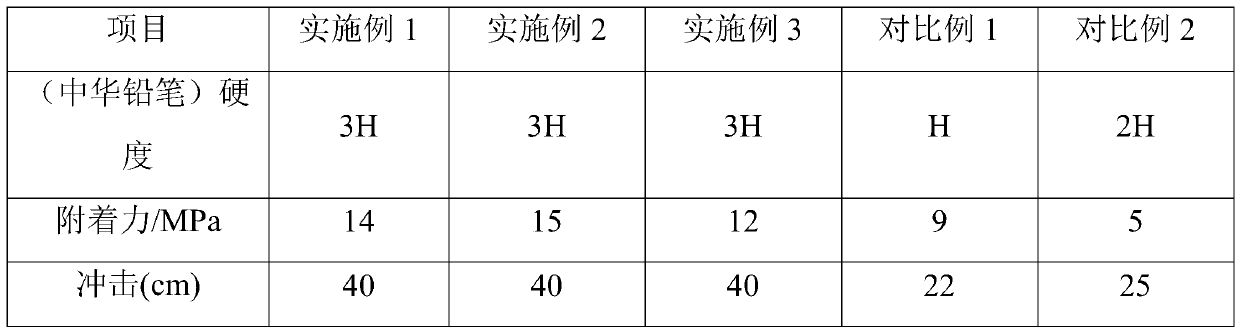

Waterborne intermediate paint coating and preparation method thereof

InactiveCN110373086AGood storage stabilityImprove sag resistanceFireproof paintsAnti-corrosive paintsEpoxySilicon dioxide

The invention relates to the technical field of coatings, and discloses a waterborne intermediate paint coating and a preparation method thereof. The waterborne intermediate paint coating is preparedfrom the component A and the component B; the component A is prepared from the following components in percentage by mass: epoxy emulsion, a dispersant, a defoamer, a coalescing agent, mica iron oxide, glass flake, fillers, barium sulfate, pigments, expanded graphite, vermiculite, silicon dioxide, an anti flash rust agent, zirconium phosphate, a base material wetting agent, a thickener and the balance of deionized water; the component B is prepared from the following components in percentage by mass: a curing agent and the balance of a coalescing agent; the mass ratio of the component A to thecomponent B is (4-8) to 1. The waterborne intermediate paint coating is good in flow resistance, stable in storage performance and anticorrosion performance, and good in adhesion, impact resistance,flame retardancy and flexibility performance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Traditional Chinese medicinal composition for treating prostatoplasia

InactiveCN103599472AEasy to obtainEasy to makeUrinary disorderPlant ingredientsSide effectAgrimonia eupatoria

The invention discloses a traditional Chinese medicinal composition for treating prostatoplasia, and relates to the technical field of Chinese herbal medicines. The composition comprises, by weight, 25-35 parts of Sargentodoxa cuneata, 5-10 parts of dragon's blood, 5-15 parts of Panax Notoginseng, 45-55 parts of coix seed, 5-10 parts of Manis pentadactyla, 25-35 parts of Vaccaria segetalis, 25-35 parts of Rhizoma Sparganii, 25-35 parts of Rhizoma Curcumae, 10-20 parts of Agrimonia eupatoria, 5-15 parts of Rhizoma Cyperi, 5-15 parts of Combined Spicebush Root, 25-35 parts of Radix Astragali, 5-15 parts of Chinese angelica and 10-20 parts of Amur Corktree Bark. The composition has the characteristics of easily available materials, simple preparation, low cost, good practicality, small dosage, low content of harmful components, no toxic side effects and substantial curative effect.

Owner:甘肃白海螺藏医药生物科技发展有限公司

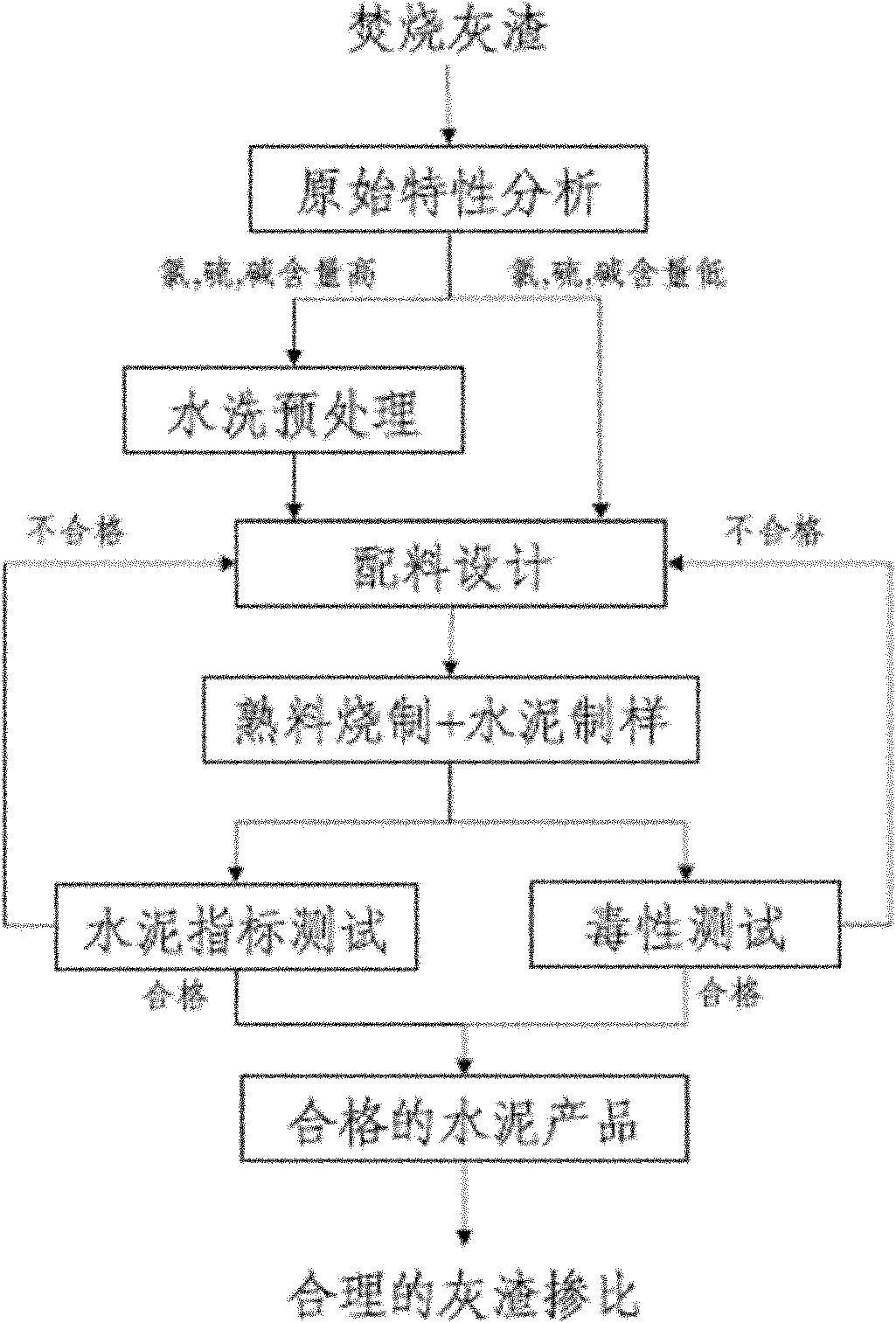

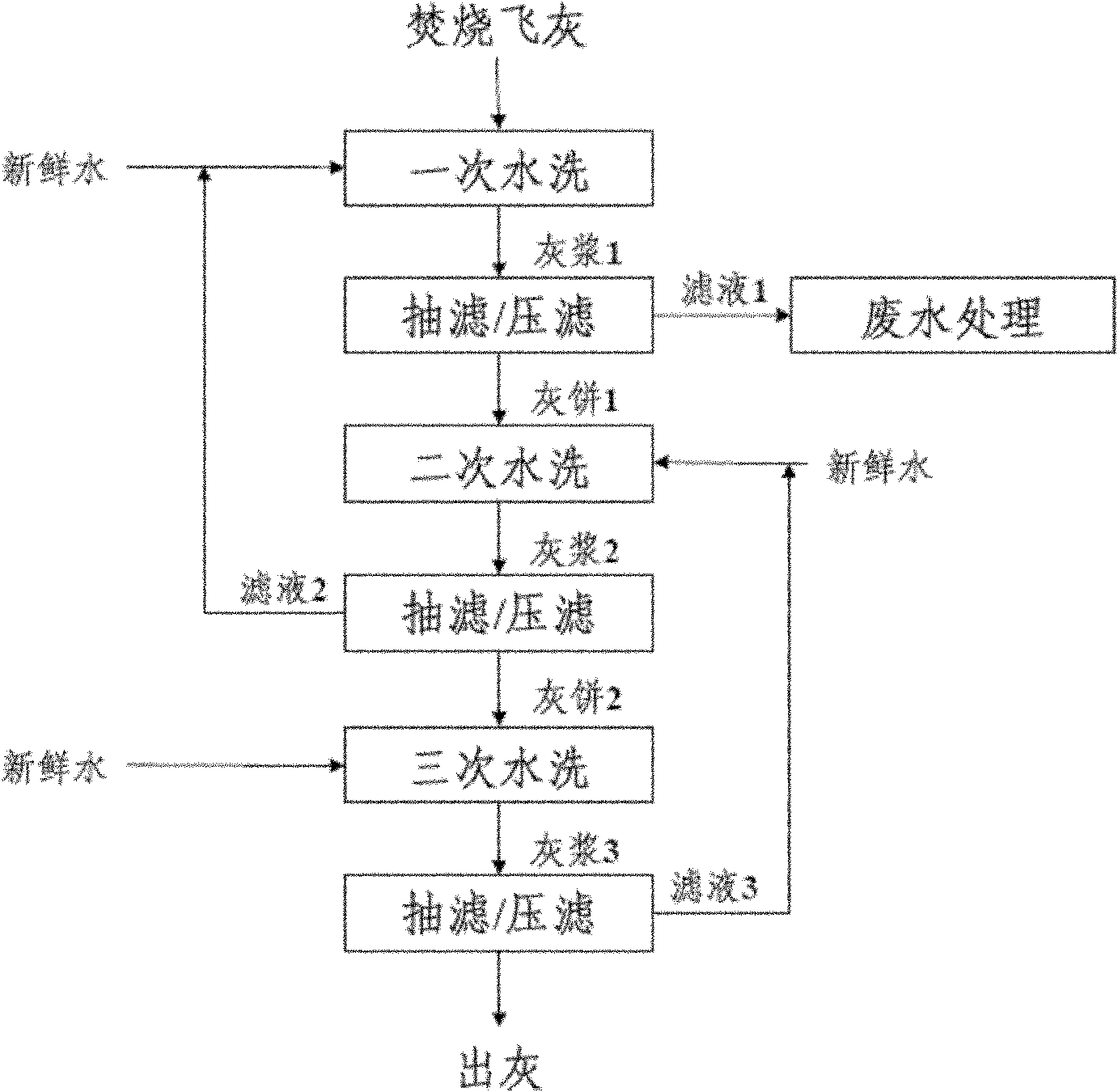

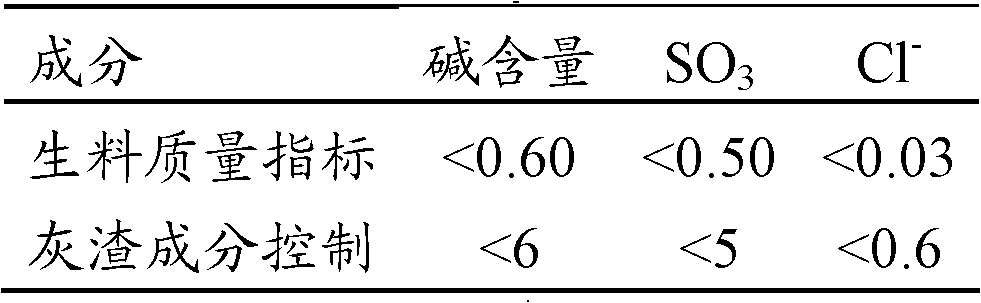

Method for improving mixing ratio of burning ash in cement raw materials

ActiveCN101935174ALow content of harmful ingredientsIncrease the blending ratioCement productionCement factoryMixing ratio

The invention provides a test method capable of effectively improving the mixing ratio of burning ash in cement raw materials. The method comprises the following steps of: analyzing original characteristics; performing washing pretreatment; firing ingredients to form clinker; and testing index and toxicity of the cement. The test method is designed completely aiming at a practical project, the raw materials are all the actual raw materials of a cement factory and the mixing ratio is also the actual production control ratio of the cement factory; the test method is well instructive to the project application; and on the premise of realizing stable operation of cement production and guaranteeing production quality, the test method greatly improves the mixing ratio of the burning ash in the cement raw materials. The whole test has the advantages of relatively a few involved large instruments, convenient operation, low cost and high test reproducibility.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Preparation method of drug for treating acute lumbar sprain

InactiveCN103494842AEasy to obtainEasy to makeAnthropod material medical ingredientsAntipyreticWarm waterPharmaceutical drug

A preparation method of a drug for treating acute lumbar sprain relates to the technical field of Chinese herbal medicines. The method is as follows: taking 8-15 fresh woodlouses, first, cleaning the woodlouses with warm water, mashing in a bowl, wringing juice and removing dregs, and taking the drug juice. The drug is taken after mixing with wine, the drug is taken for 1-2 times in one day, and one bag of the drug is taken in one day. The drug has the characteristics of easily obtained raw materials, simple production, low cost, good practicability and the like, and has low content of harmful ingredients, no side effect, and obvious curative effects.

Owner:孔令刚

Wuzi yanzong pills and preparation method thereof

InactiveCN105998371AImprove utilizationTaste close to the peoplePill deliverySexual disorderTreatment effectSide effect

The invention discloses Wuzi yanzong pills and a preparation method thereof and belongs to the field of traditional Chinese medicine preparations. The preparation method includes: weighing raw materials; pretreating and smashing; adopting a GT circulating extraction method for extraction; adopting a film concentration method for concentration; depressurizing for secondary concentration; pilling. Type and content of active ingredients are remarkably increased, content of inactive and harmful ingredients is remarkably increased, and the pills are better in treatment effect, less in side effect and safer for long-time administration; administration amount is further reduced, so that the pills are more convenient to carry and stable and reliable in quality after being stored for a long time.

Owner:TAIJI GROUP SICHUAN MIANYANG PHARMA

Preparation method of rex rabbit fur, rex rabbit fur and fur product

ActiveCN108374062ASlow down the speed of bindingMild tanning and fillingTanning treatmentPre-tanning chemical treatmentChemistryChromium

The invention provides a preparation method of rex rabbit fur, the rex rabbit fur and a fur product and belongs to the field of fine processing of fur. The preparation method comprises the following steps: pre-tanning rex rabbit fur, which is treated before tanning, by utilizing a synthetic tanning agent; carrying out oil tanning on the pre-tanned rex rabbit fur by utilizing an oil tanning agent.The rex rabbit fur is prepared through the preparation method. The fur product comprises the rex rabbit fur. In a preparation process, the pre-tanning of the synthetic tanning agent and the oil tanning of the oil tanning agent are combined; advantages of two tanning methods are complementary to generate positive synergistic benefits, so that the problem that formaldehyde and chromium exceed the standard is solved; the content of harmful components is low and the fur is soft and has rich elasticity and high tensile strength.

Owner:宁夏西部皮草有限公司

Paper cigarette filter stick containing collagen fibers and preparation method thereof

ActiveCN109403129AFair pricePromote degradationMonocomponent protein artificial filamentOrganic non-cellulose fibresFiberTar

The invention discloses a paper cigarette filter stick containing collagen fibers and a preparation method thereof. The paper cigarette filter stick is prepared from the following raw materials in percentage by weight: 1-90% of the collagen fibers and 10-99% of fibers used for papermaking. The preparation method of the paper cigarette filter stick containing the collagen fibers comprises the following steps that collagen fiber paper is prepared; the collagen fiber paper is subjected to roll-in, rolling and wrapping shaping by adopting a paper filter stick conventional shaping technology, so that the paper cigarette filter stick containing the collagen fibers is prepared. According to the paper filter stick prepared through the method, tar and other harmful components in cigarette smoke canbe effectively reduced, and meanwhile, effects of a common paper filter stick on absorbing a cigarette smoke flavor are improved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Preserved meat and preparation method of same

InactiveCN107495165AGreat tasteGood colorFood ingredient as mouthfeel improving agentSlurryChemistry

The invention relates to the technical field of production of preserved meat, and especially relates to preserved meat and a preparation method of same. In the preparation method, pork is cut into strips, wherein the weight of each pork strip is controlled; by controlling amount of salt and Chinese prickly ash, the preserved pork strips have excellent quality; through turning treatment, the salt, Chinese prickly ash and other components, which are adsorbed on the surfaces of the pork strips, enter water; and by pouring a sabia parviflora leaf slurry to soak the pork strips, contents of harmful components on the pork strips are greatly reduced; by air-blowing and smoking the pork, wherein the smoke is generated by combusting roots, stalks and leaves of sugarcane and rudraksha, the content of harmful residues in the prepared preserved meat is greatly reduced. The method, compared with conventional production methods of preserved meat, the harmful residual substance during smoking is reduced by more than 87%, so that the quality of the preserved meat is greatly improved. The method also avoids cost of filtering smoke, and is reduced in preparation cost.

Owner:望谟县桑郎镇奔康腊肉豆腐制品有限公司

Semi-coke powder, molding sand containing semi-coke powder and application in casting

InactiveCN108339926AReduce the amount addedLess materialFoundry mouldsFoundry coresAdditive ingredientWater content

The invention relates to semi-coke powder, molding sand containing the semi-coke powder and application in casting and belongs to the field of material science, in particular to casting materials andcasting processes. The water content of the semi-coke powder is 1(wt)%-10(wt)%, and the particle size of the semi-coke powder is 180-200 meshes. The molding sand is fabricated by mixing reuse sand, new sand, bentonite and the semi-coke powder and can be used for casting. By means of the semi-coke powder or the molding sand provided by the invention for casting, the used materials are less, the cost is low, ash content and sulphur content are low, the problems that ash ingredients block molding sand gaps and absorb large amounts of water to form casting air holes or casting sand holes and the like do not exist, the quality of castings is made to be improved, and meanwhile, the workshop environment is improved to a great extent and the environmental pollution is reduced at the same time.

Owner:哈尔滨市易合铸造材料有限公司

Pig fodder

InactiveCN108125035AMobilizable disease resistance factorReduce the chance of getting sickAnimal feeding stuffWorking-up animal fodderBiotechnologyPollen

The invention provides a pig fodder, belonging to the technical field of fodder processing. The pig fodder is prepared through the following steps: heating, stirring and mixing paris polyphylla root,Chinese lobelia herb, peristrophe japonica herb, herba bidentis bipinnatae, rhizoma arisaematis and water, filtering, decompressing and concentrating to obtain a traditional Chinese medicine extracting solution; mixing, standing and swelling agar powder and water in a mass ratio of (1:50)-(1:100), then heating, stirring and mixing to obtain agar liquid; mixing soybean curb residue, soya bean meal,wine residue, the traditional Chinese medicine extracting solution, vitamin, shell powder, plant essential oil, the agar liquid, sepiolite, pollen, lotus root starch, caffeine, biogas slurry and a glucose solution, fermenting, decompressing and concentrating, squeezing to granulate, and drying to obtain the pig fodder. According to the technical scheme, the prepared pig fodder has the characteristics of improving reproductive performance and increasing yield, not only is the yield of piglets improved, but also the pork quality is obviously improved, secondly, anti-venom factors exist in pork,after eaten by a person, the anti-venom factors in the pork enter a human body, and the anti-venom capacity of the human body is enhanced.

Owner:石磊

Health capsule as well as preparation method and identification method thereof

ActiveCN104383261AQuality assuranceKeep intactSenses disorderNervous disorderAmnesiaLiver and kidney

The invention relates to the technical field of health capsules, and in particular relates to a health capsule as well as a preparation method and an identification method thereof. According to the invention, through an appropriate ratio of the raw materials such as polygonum multiflorum, rhizoma polygonati, glossy privet fruits and yerbadetajo herbs combined with process steps such as raw material treatment, filtrate mixing and powder addition, nutritional ingredients in raw materials are sufficiently maintained, the nutritional efficacies of the prepared health capsule are improved, the quality of the health capsule is improved, and the soothing of the health capsule on the diseases such as insomnia and dreaminess, tinnitus and amnesia, epilation and premature graying of hair is enhanced, and thus the efficacies of tonifying liver and kidney and benefiting life essence and nourishing blood are achieved. Through the specific identification method provided for the health capsule prepared by the technical scheme provided by the invention, the quality of the health capsule is further ensured.

Owner:GUIZHOU MAQIKA PHARMA

Traditional Chinese medicine composition for relieving severe pain caused by renal calculus

The invention relates to a traditional Chinese medicine composition for relieving severe pain caused by renal calculus, belonging to the technical field of Chinese medicinal herbs. The composition is composed of the following active pharmaceutical ingredients in parts by weight: 25-35 parts of deer's horn deglued, 10-20 parts of cassia twig, 95-105 parts of Herba Lysimachiae, 15-25 parts of radix astragali, 15-25 parts of radix clematidis, 15-25 parts of chickens gizzard-skin, 5-15 parts of Reed Rhizome, 5-10 parts of dried ginger, 5-15 parts of rhubarb and 25-25 parts of malva seed. The composition has the characteristics of accessible materials, simple manufacturing process, low cost, high practicality, small dosage, low content of harmful ingredients, no toxic or side effect, obvious curative effect and the like.

Owner:陈丙动

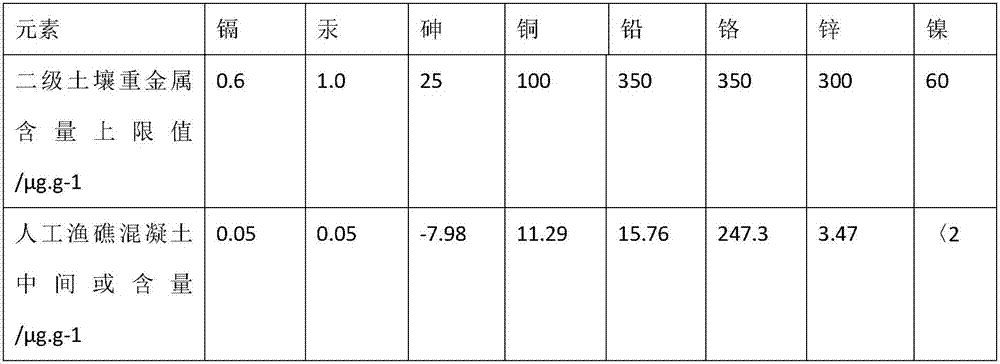

Method of manufacturing artificial fish reef with residence frame to be disassembled

ActiveCN107125181AEfficient manufacturingReduce pollutionClimate change adaptationPisciculture and aquariaRebarPollution

The invention discloses a method of manufacturing an artificial fish reef with a residence frame to be disassembled. The method includes the preparing steps of cutting reinforced concrete of the residence frame to be disassembled, processing notches and processing the surface of the reinforced concrete. In the notch processing step, organosilicon emulsion is used as a waterproof coating for the fracture face of the reinforced concrete, surface coating is conducted, the coating permeates into the surface layer of the concrete by 2-3 mm to form a waterproof layer, and consequently sea water is prevented from entering; cured type fluorocarbon resin paint is used for forming a finishing coating, and then the finishing coating is dried. The method has the advantages of being low in manufacturing cost, capable of effectively using the residence frame to be disassembled and reducing environment pollution, low in heavy metal content and beneficial for fish shoal elusion or survival and achieving resource recycling.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Traditional Chinese medicinal composition for treating cardiac asthma

A traditional Chinese medicinal composition for treating cardiac asthma relates to the technical field of Chinese herbal medicines. The traditional Chinese medicinal composition comprises the following bulk drugs: by weight, 15-25 parts of Radix Codonopsis, 10-20 parts of prepared pinellia tuber, 25-35 parts of roasted malt, 25-35 parts of roasted rice sprout, 10-15 parts of red sage root, 5-10 parts of safflower, 5-10 parts of Chinese magnoliavine, 45-55 parts of Radix Astragali, 5-15 parts of Chinese angelica, 15-25 parts of Draba nemorosa, 25-35 parts of perilla, 5-15 parts of cassia twig, 10-20 parts of trichosanthes root, 15-25 parts of Cornus officinalis, 25-35 parts of root of kudzu vine and 5-15 parts of ephedra stem. The traditional Chinese medicinal composition has characteristics of easily-obtained materials, simple production, low cost, good practicality, small use dosage, low content of harmful components, no toxic or side effect and remarkable curative effect.

Owner:四川恒康源药业有限公司

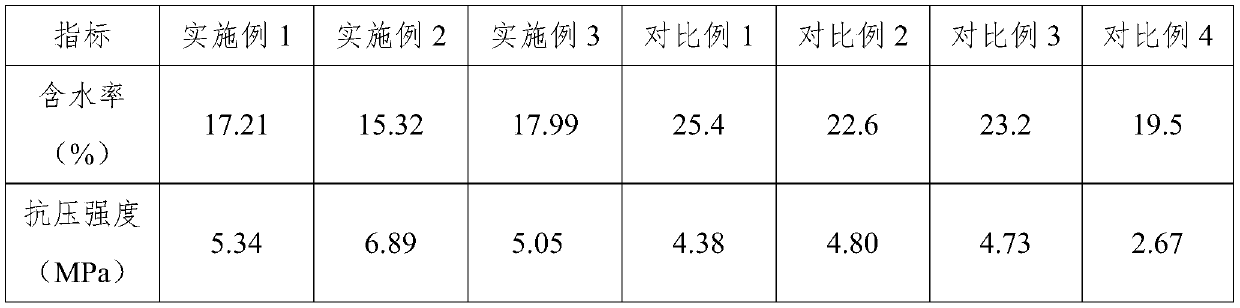

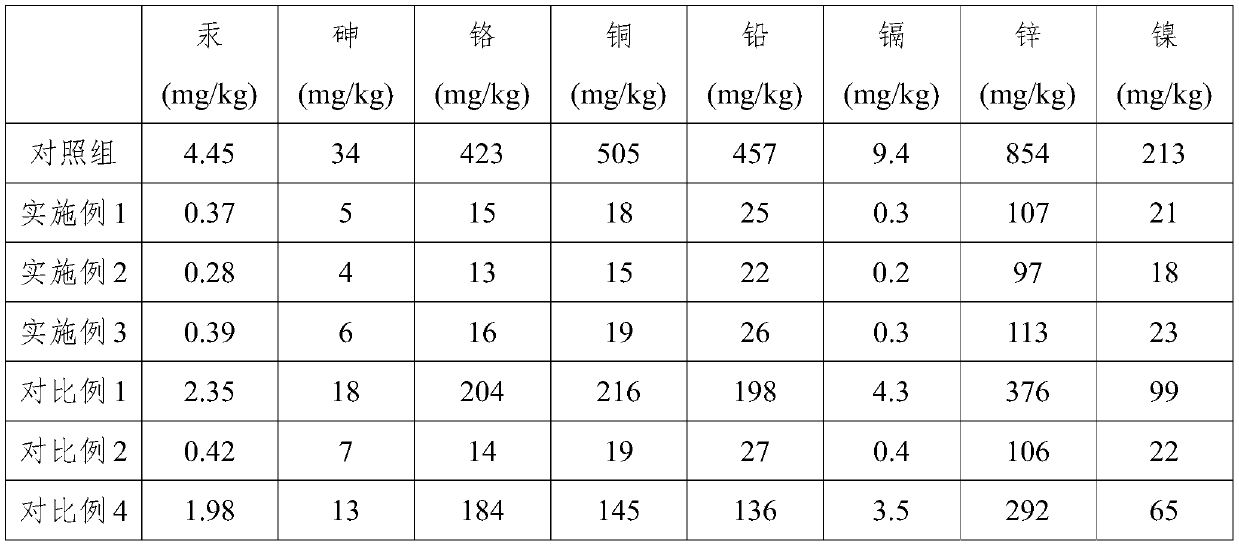

Urban river sludge treatment method

ActiveCN111559849AMeet the process requirementsImprove dehydration effectWater contaminantsFixation/solidifcation sludge treatmentCelluloseO-Phosphoric Acid

The invention belongs to the technical field of sludge treatment, and particularly relates to an urban river sludge treatment method. The urban river sludge treatment method provided by the inventioncomprises the following steps: firstly adding hydroxypropyl methyl cellulose to treat slurry, then adding phosphoric acid and potassium permanganate, then adding hydroxyethyl ethylenediamine, and finally adding a self-made curing agent for treatment. The sludge treated by the urban river sludge treatment method provided by the invention has the advantages of low water content, high compressive strength and low organic matter content and heavy metal content. Meanwhile, the treatment method can greatly reduce turbidity, absorbance, suspended solid content and particle size of the sludge filtrate, and can effectively improve the water quality of the sludge filtrate, reduce environmental pollution, and achieve the effect of environmental protection.

Owner:广州粤水建设有限公司

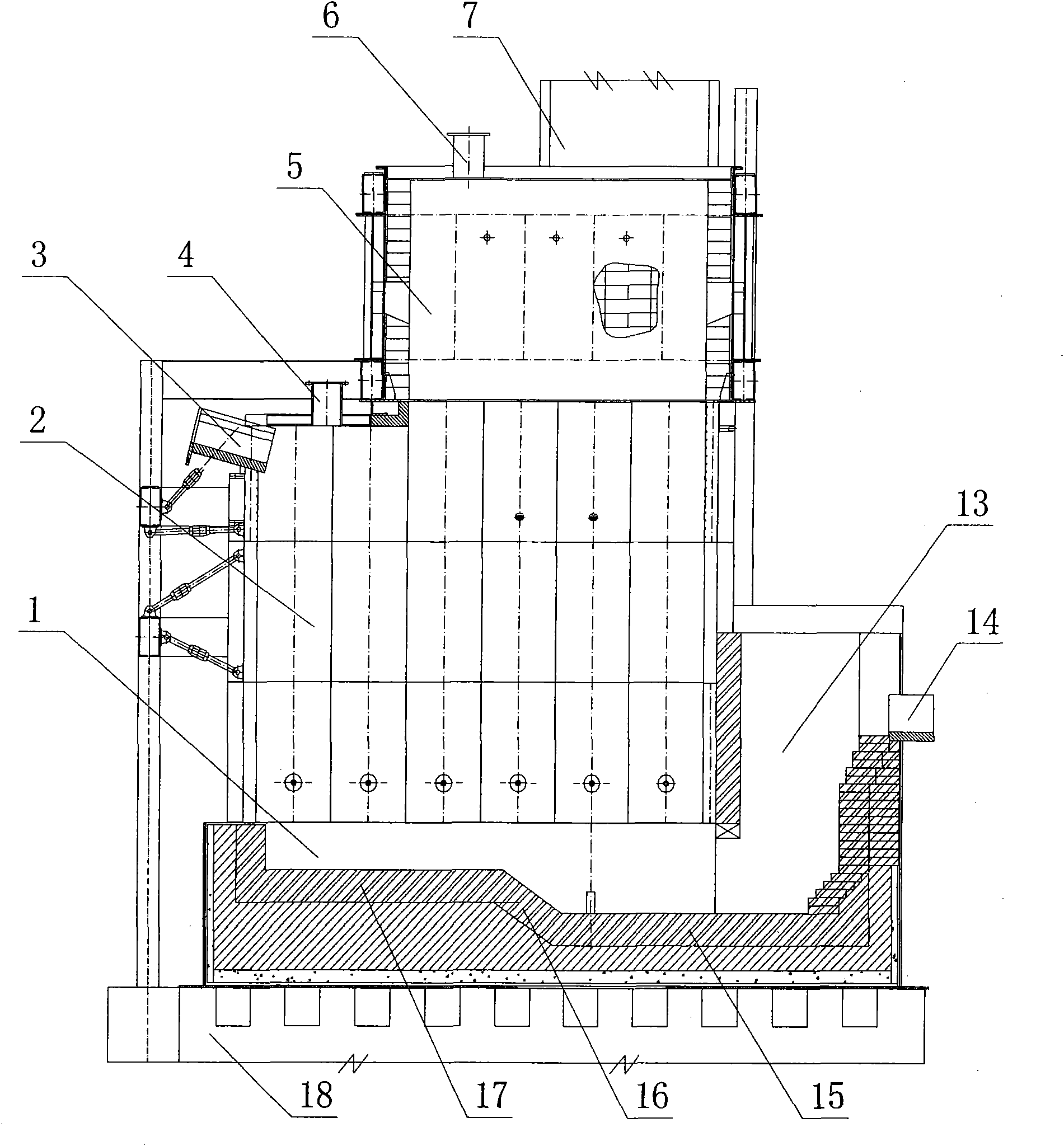

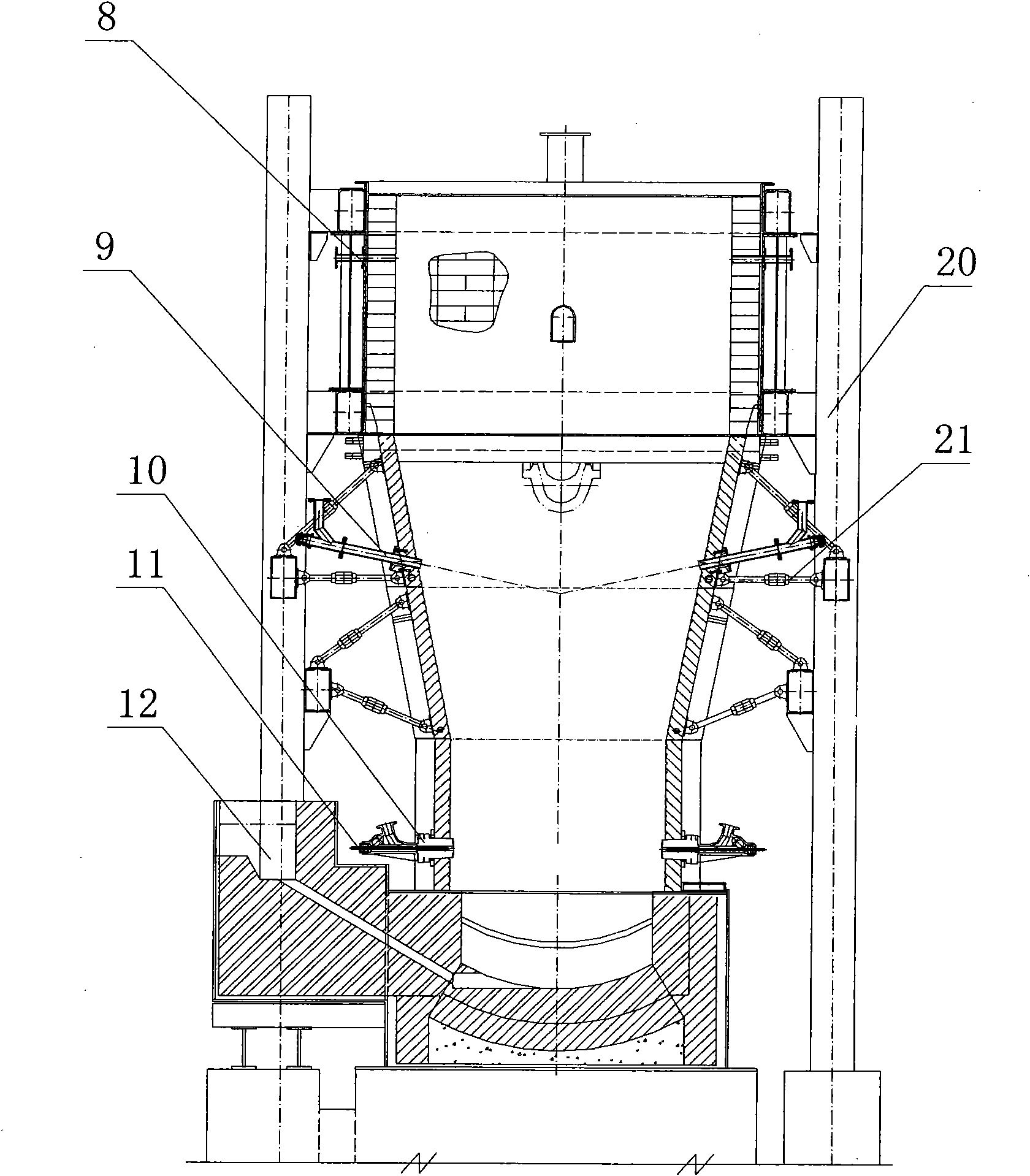

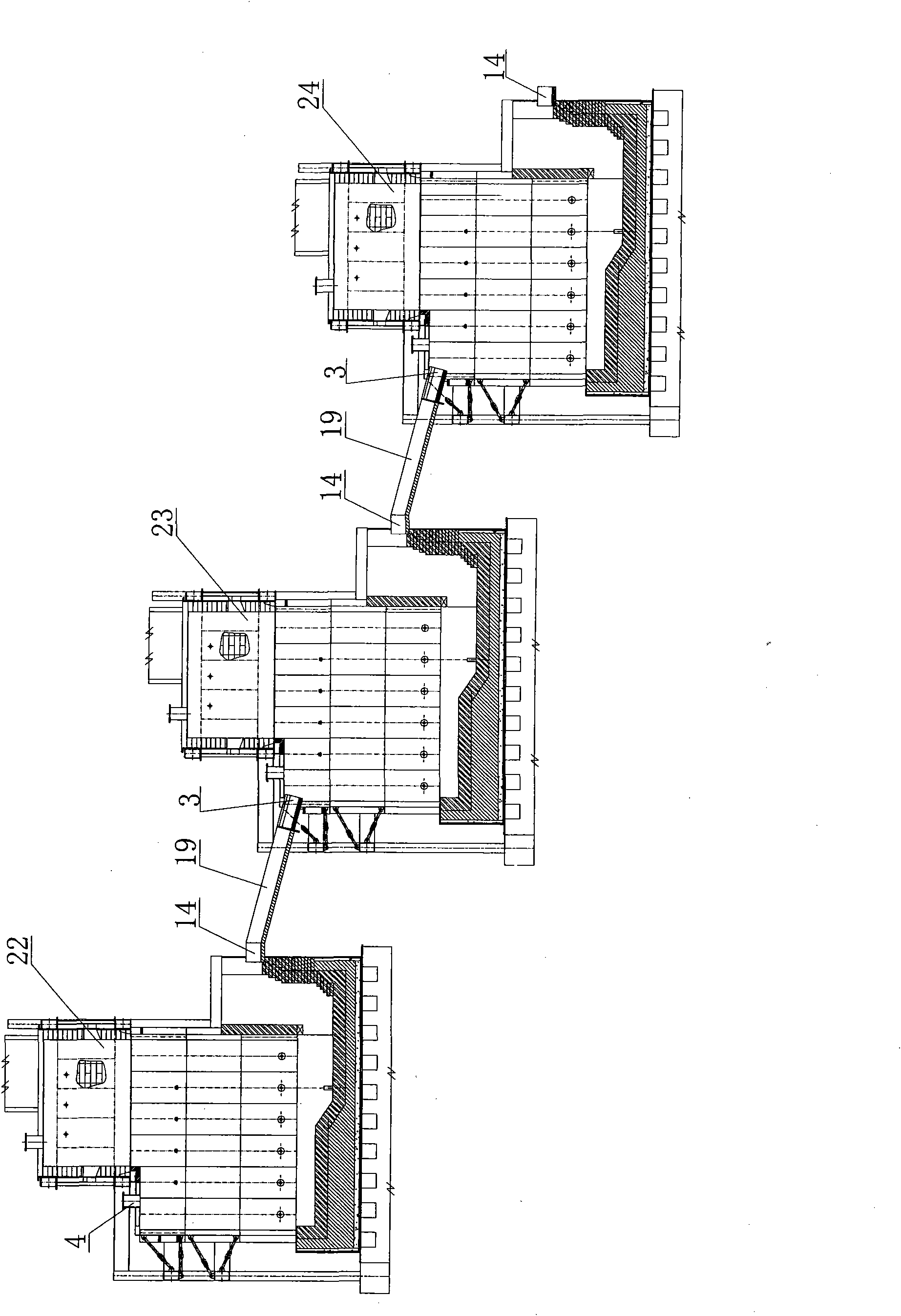

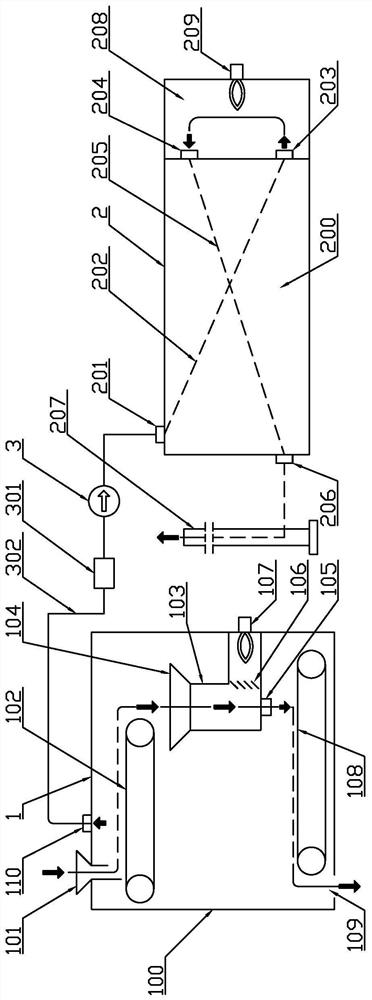

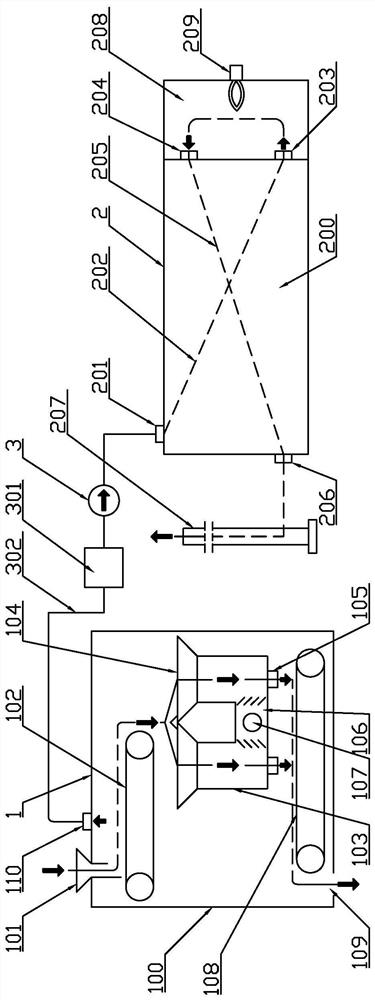

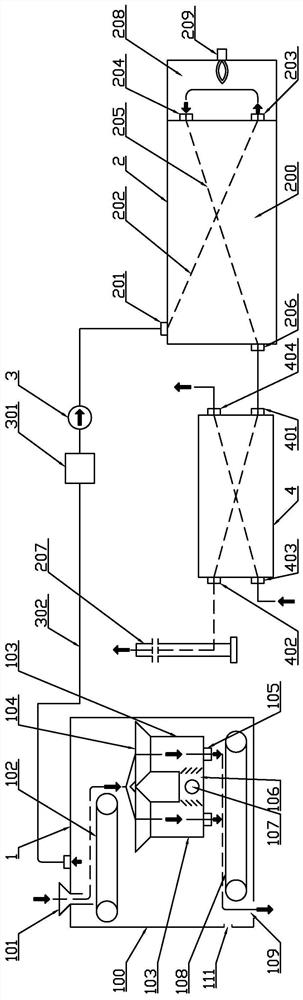

Direct lead-smelting comprehensive metallurgical device and smelting process

The invention relates to an energy-saving high-efficient direct lead-smelting comprehensive metallurgical device, which is formed by serially joining three melting bath smelting furnaces: a first furnace, a second furnace and a third furnace; and the second furnace consists of a furnace cylinder and a furnace body which is arranged on the furnace cylinder. The top part of the upper furnace body is provided with a smoke exhaust port and a standby feeding port; a charge feeding port and a slag feeding port are arranged above the lower furnace body; and the bottom part of the lower furnace body is provided with a slag siphonic water-collecting well. The furnace body is provided with three rows of supply-air outlets. The bottom part of the furnace cylinder is provided with a metal siphonic outlet. Due to the adoption of the direct lead-smelting comprehensive metallurgical device, the heat loss is small, the heat utilization rate is high, sulfuric dioxide smoke with high concentration can be produced, and the requirement for producing the acid can be more favorably satisfied; and molten high-lead thermal slag which is produced through oxidation and smelting directly flows into a reducing furnace, so the heat of the thermal molten slag can be adequately utilized. The land occupied area is small, the investment can be saved, the heat loss is less, the heat utilization rate is high, the heat energy can be adequately utilized, a great amount of energy consumption can be saved, output of smoke is small, the content of harmful ingredients in smoke is low, and the environmental pollution problem can be more effectively solved.

Owner:JIYUAN WANYANG SMELTING GROUP +2

Semi-coke powder combination, molding sand containing combination and application to casting

InactiveCN108339925AReduce the amount addedLess materialFoundry mouldsFoundry coresSodium BentoniteMetallurgy

The invention relates to a semi-coke powder combination, molding sand containing the combination and application to casting, belongs to the field of materialogy, and in particular, relates to a casting material and a casting process. The combination contains one or a mixture of two of semi-coke powder, starch or flour. Reused sand, new sand, bentonite and the semi-coke powder combination are mixedto prepare the molding sand for casting. The semi-coke powder combination or the molding sand is used for casting, so that used materials are few, the cost is low, the ash content and the sulfur content are low, such problems as blockage of molding sand holes by ash and casting air holes or casting sand holes formed by absorption of a lot of water are not generated, the casting quality is improved, and meanwhile, the environmental pollution is reduced when the workshop environment is greatly improved.

Solid waste pyrolysis and related gas combustion device

The invention discloses a solid waste pyrolysis and related gas combustion device. The device comprises a solid processor, a gas combustor and a draught fan; the solid processor comprises a shell, a raw material conveying mechanism, a pyrolyzing furnace and a slag conveying mechanism; the gas combustor comprises a heat exchanger and a combustion chamber, wherein the heat exchanger is provided withan air inlet channel and an air outlet channel which are isolated from each other and can exchange heat with each other, wherein the air inlet channel is provided with a waste gas inlet and a waste gas outlet, and the air outlet channel is provided with a flue gas inlet and a flue gas outlet; and the waste gas outlet and the flue gas inlet communicate with the combustion chamber, the waste gas inlet communicates with an air extraction port through a pipeline and the draught fan, and the flue gas outlet communicates with a chimney. According to the device, the problem that combustible gas generated by pyrolysis is difficult to combust after being diluted due to the fact that a large amount of fresh air is sucked in due to air extraction conducted on the solid processor is solved; and the technological process is simplified, and the equipment investment can be reduced.

Owner:FOSHAN HUAJIEYUAN THERMAL ENERGY & ENVIRONMENTAL ENG TECH CO

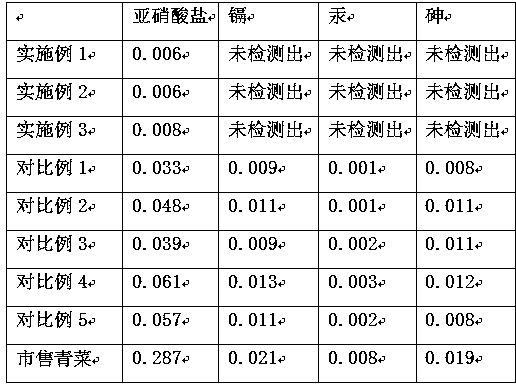

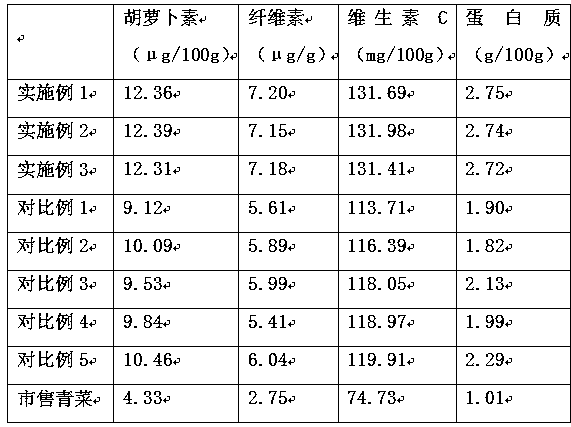

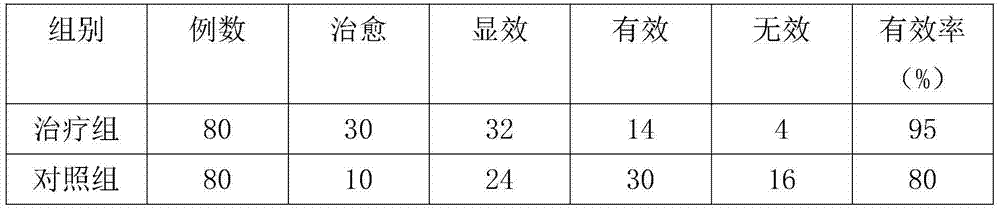

Planting method for improving nutritional quality of summer green vegetables

InactiveCN109287404AImprove water retentionImprove biological enzyme activityPlant growth regulatorsBiocideCelluloseVitamin C

The invention belongs to the technical field of green vegetable planting, and particularly relates to a planting method for improving the nutritional quality of summer green vegetables. Themethod comprises the steps that (1) at the beginning of July, a planting place with a fore-rotating crop of rapeseed is selected,bio-organic fertilizers of cow dung and grape skin are applied, shallow ploughingis conducted, and farmlands are made; (2) in mid-July, the seeds of the full-bodied green vegetables are irradiated with 60Co-gamma rays,immersed in a soaking agent, and irradiated with the 60Co-gammarays to obtain seeds of the green vegetables to be sown; (3)the seeds of the green vegetables to be sown are sown in the planting area, two micro-spraying treatment is conducted after emergence, first foliar application of a nutrient solution is conducted after the growth of 1-2 true leavesof the green vegetable seedlings, and second foliar application of the nutrient solution is conducted after13-15 days;the emergence rate and emergence index are effectively improved,the content of nutrients such as carotene, cellulose, vitamin C, protein and the like in the green vegetables is improved, the content of harmful components such as nitrite, cadmium, mercury, arsenic and the like is reduced, and the green vegetables are green, hygiene, nutritious and healthy.

Owner:安徽双圆农业科技有限公司

Traditional Chinese medicinal composition for treating prostatitis with insomnia and dreaminess

ActiveCN103599407AEasy to obtainEasy to makeNervous disorderInanimate material medical ingredientsPolygonum aviculareSide effect

The invention discloses a traditional Chinese medicinal composition for treating prostatitis with insomnia and dreaminess, and relates to the technical field of Chinese herbal medicines. The composition comprises, by weight, 25-35 parts of Cogongrass rhizome, 45-55 parts of Gracilaria verrucosa, 5-15 parts of amber, 5-15 parts of licorice root, 5-15 parts of Poria cocos, 45-55 parts of Radix Astragali, 10-20 parts of Radix Polygalae, 10-20 parts of pawpaw, 10-20 parts of Amur Corktree Bark, 15-25 parts of spine date seed, 25-35 parts of Polygonum aviculare L. and 10-20 parts of Corydalis tuber. The composition has the characteristics of easily available materials, simple preparation, low cost, good practicality, small dosage, low content of harmful components, no toxic side effects and substantial curative effect.

Owner:四川省十尚科技有限公司

Medicine for treating infantile hernia

InactiveCN104771630AEasy to obtainEasy to makeDrug compositionsPlant ingredientsHerniarinWater Chestnuts

The invention provides a medicine for treating infantile hernia. The medicine is prepared from the following medicines by weight: 1-3g of fennel fruit, 1-3g of clove, 1-3g of oyster shell, 4-6g of snail meat, 1-3g of lychee seed, 1-3g of sorghum root, 1-3g of akebia stem, 1-3g of hull of water chestnut, 1-3g of celery leaves and 1-3g of lily. The medicine has the characteristics of easiness in material obtainment, simplicity in preparation and low cost, is convenient to use, has low content of harmful components, does not have toxic or side effect, has obvious curative effects and enables sick children not to suffer from pain caused by operative treatment.

Owner:陆开云

Traditional Chinese medicine composition for treating oral ulcer

InactiveCN104274688AEasy to obtainEasy to makeDigestive systemPharmaceutical delivery mechanismSide effectOral ulcers

The invention relates to a traditional Chinese medicine composition for treating oral ulcer. The traditional Chinese medicine composition is prepared from the following ingredients by weight: 5-7g of prepared liquorice root, 6-8g of honeysuckle stem, 4-6g of radix paeoniae alba, 4-6g of fried atractylodes macrocephala, 4-6g of wild chrysanthemum flower, 4-6g of codonopsis pilosula, 4-6g of verbena, 4-6g of hairy-vein agrimony, 4-6g of capillary artemisia, 4-6g of flavescent sophora root, 4-6g of tripterygium wilfordii, 4-6g of rhizome alismatis, 4-6g of lotus leaf, 4-6g of Chuanxiong rhizome, 4-6g of spatholobus stem, 4-6g of trachelospermum jasminoides, 4-6g of cnidium monnieri, 4-6g of fructus sophorae, 4-6g of tree peony bark, 4-6g of ophiopogon root, 4-6g of radix scrophulariae and 4-6g of honeysuckle flower. The traditional Chinese medicine composition has the characteristics of easiness in material obtaining, simplicity in preparation and low cost, is convenient in use, low in content of harmful ingredients and remarkable in curative effect and is free from toxic or side effects.

Owner:吴传明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com