Method for improving sensory quality of tobacco leaves by using compound enzymic preparation

A compound enzyme preparation and sensory quality technology, which is applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of mildew of tobacco leaves, inactivation of enzyme preparations, and uneven distribution of water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

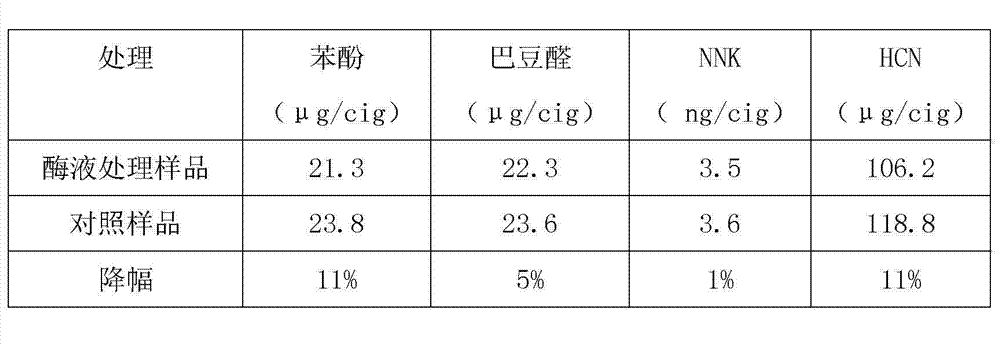

Embodiment 1

[0015] A method for improving the sensory quality of tobacco leaves by using a compound enzyme preparation, the relevant process steps are as follows:

[0016] (1) The cellulase, pectinase and protease required for the production of relevant strains are used for fermentation. After the enzyme preparation is obtained, it is prepared into a treatment solution. Add 5‰ trisodium citrate, 5‰ citric acid, 10‰ cellulase, 8‰ pectinase, 6‰ protease, 3‰ biacetyl, 3‰ FeSO in the pure water frozen to 4℃ 4 .

[0017] (2) Spray treatment solution: Spray the prepared treatment solution evenly on the surface of tobacco leaves with 50% mass (1000g tobacco leaves sprayed with 500ml compound enzyme preparation), and turn the tobacco leaves when spraying to make the spray even and keep the tobacco leaves loose.

[0018] (3) Constant temperature and humidity reaction: Put the tobacco leaves sprayed with the treatment liquid in a sealed container, adjust the reaction temperature to 48°C, and the...

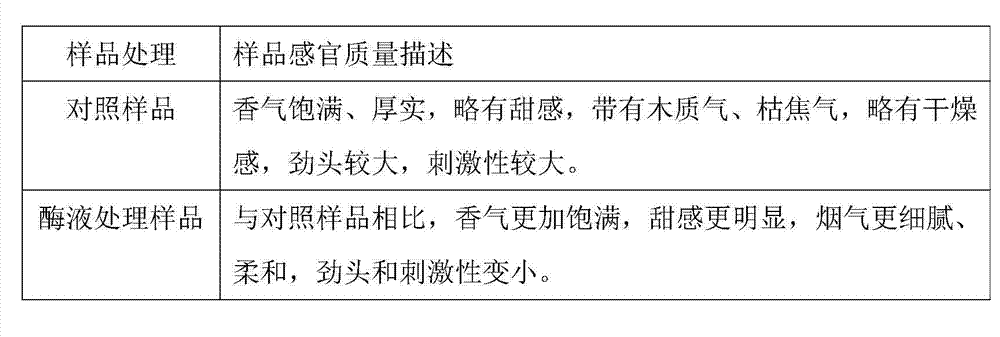

Embodiment 2

[0028] To treat shredded tobacco with compound enzyme preparation, the relevant process steps are as follows:

[0029] (1) Obtain biological enzymes and prepare treatment solutions: For a small amount of research and treatment, you can directly purchase relevant biological enzymes, and for industrialization, you can build large-scale fermentation facilities by yourself, and use relevant strains to ferment and produce the required cellulase, pectinase and protease. After the enzyme preparation is obtained, it is prepared into a treatment solution. Add 4‰ trisodium citrate, 4‰ citric acid, 8‰ cellulase, 5‰ pectinase, 4‰ protease, 2‰ biacetyl, 2‰ FeSO in the pure water frozen to 4℃ 4 .

[0030] (2) Spray treatment solution: Spray the prepared treatment solution with 28% mass (1000g tobacco leaves sprayed with 280ml compound enzyme preparation) evenly on the surface of tobacco leaves, and turn the tobacco leaves when spraying to make the spray even and keep the tobacco leaves lo...

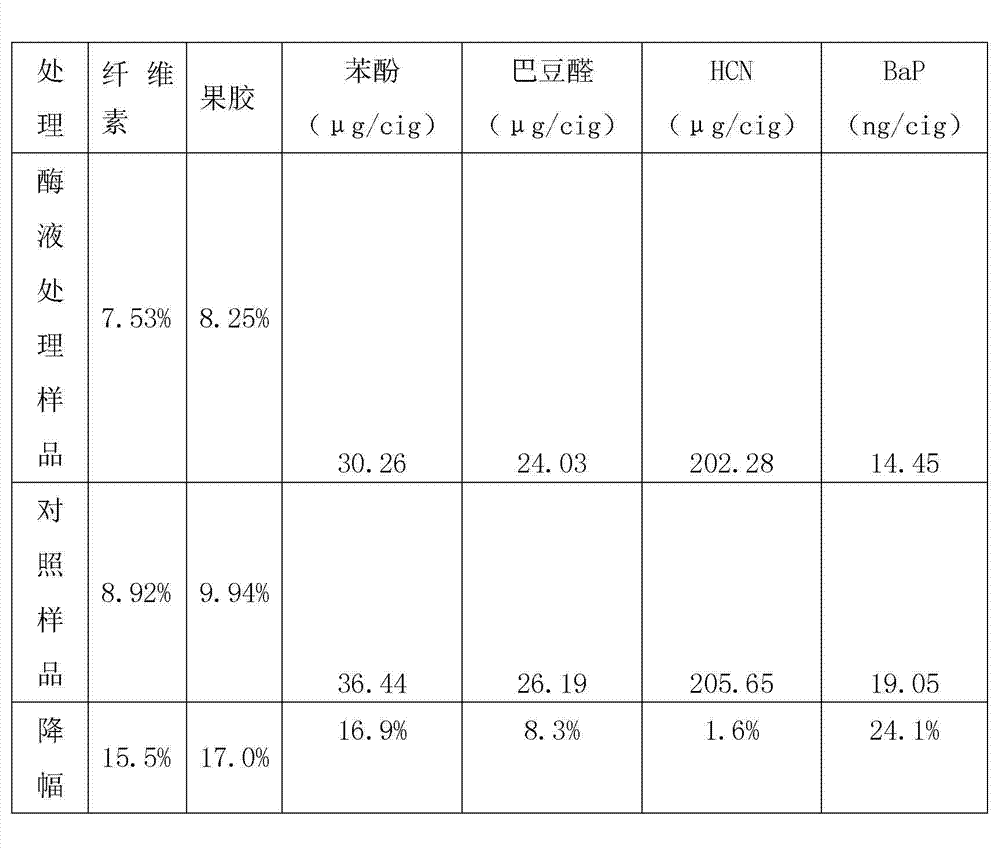

Embodiment 3

[0039] To treat shredded tobacco with compound enzyme preparation, the relevant process steps are as follows:

[0040] (1) The cellulase, pectinase and protease required for the production of relevant strains are used for fermentation. After the enzyme preparation is obtained, it is prepared into a treatment solution. Add 1‰ trisodium citrate, 1‰ citric acid, 4‰ cellulase, 3‰ pectinase, 2‰ protease, 1‰ biacetyl, 1‰ FeSO in the pure water frozen to 4℃ 4 .

[0041] (2) Spray treatment liquid: Spray the prepared treatment liquid evenly on the surface of tobacco leaves with 8% mass (1000g cut tobacco sprayed with 80ml compound enzyme preparation), and turn the tobacco leaves when spraying to make the spray even and keep the tobacco leaves loose.

[0042] (3) Constant temperature and humidity reaction: Put the tobacco leaves sprayed with the treatment liquid in a sealed container, adjust the reaction temperature to 30°C, the ambient humidity to 50%, and the reaction time to be 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com