Patents

Literature

596results about How to "Reduce mist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

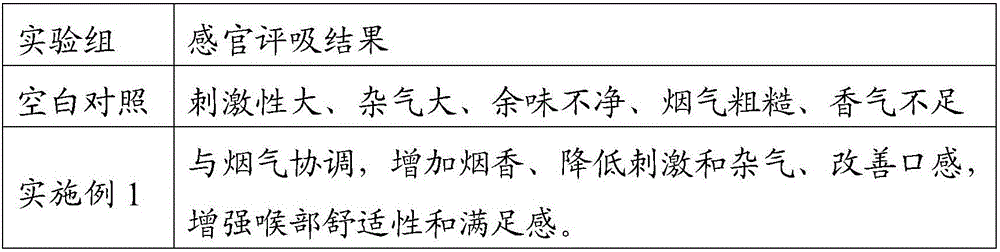

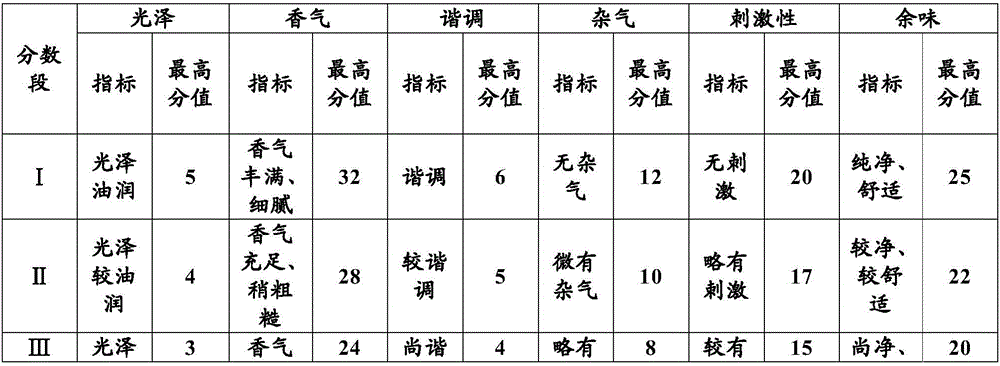

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

Essential oil of tobaccos as well as preparation method and application thereof to cigarettes

InactiveCN102559388ANo residueImprove extraction yieldTobacco treatmentEssential-oils/perfumesOrganic solventWater vapor

The invention relates to the essential oil of tobaccos as well as a preparation method and application thereof to cigarettes. The essential oil of the tobaccos is prepared by the following method of: taking discarded / defective tobacco wastes, extracting by an organic solvent, taking the crude extract of the essential oil, introducing water vapor, condensing and separating oil and water so as to obtain the essential oil of the tobaccos. By adding the essential oil of the tobaccos, which is disclosed by the invention and is used as a flavoring agent, into the tobacco shreds of cigarettes, the self fragrance of the tobaccos can be increased, the quality of the fragrance of the cigarettes is enhanced, the excitation and the miscellaneous gas of the tobaccos are reduced, and smoke is softened. The essential oil of the tobaccos as well as the preparation method and the application thereof to the cigarettes have the advantages that the advantage of higher extracting yield of a solvent extracting method and the characteristic of refinement of a water-vapor distillation extracting method are combined, the yield of the essential oil of the tobaccos is obviously higher than that of a traditional water-vapor distillation method, and extracting equipment and a solvent are simple and convenient and are easy to obtain; and moreover, no solvent residue exists in a final product of the essential oil of the tobaccos, and the safety of the product is high.

Owner:CHINA TOBACCO ZHEJIANG IND

Technology for manufacturing snuff

InactiveCN101084798AReduce irritation and fumesIncrease aftertaste and comfortTobacco preparationTobacco treatmentFlavorEngineering

The invention discloses a technology for processing snuff which comprises dampening the tobacco bag, unpackaging, removing residues, defoliating, removing stems, dampening again, preparing, slicing, oven drying, pulverizing, subpackaging, and packaging. Compared with the present technology and on the foundation of the traditional formulation, the invention make use of soil-cured tobacco alcoholized more than three years, flue-cured tobacco, burley tobacco, and oriental tobacco to prepare snuff, thereby reducing miscellaneous flavor and stimulation, simplifying technology, reducing cost, improving comfortablility of the snuff, broadening application. The invention can also adjust the smell, concentration, miscellaneous gas, strength, and stimulation according to different users through adding different kinds of additives.

Owner:黄宣正

Technique for preparing thin slice of tobacco and prepared thin slice of tobacco

InactiveCN101438852ARich aromaImprove combustion qualityTobacco preparationTobacco treatmentPectinaseChemistry

The invention provides a technique for preparing tobacco sheets and the tobacco sheets. The technique comprises the following steps: soaking tobacco materials in water to obtain extract liquid and a water-insoluble solid; carry out enzymatic hydrolysis on the extract liquid by pectinase and / or protease so as to obtain a first water-soluble extract; degrading the protein in the water-insoluble solid by the protease so as to obtain an enzyme-hydrolyzed water-insoluble solid and a second water-soluble extract; placing the enzyme-hydrolyzed water-insoluble solid in acidic alcohol solution so as to acid-degrade lignose, then preparing the separated solid into tobacco sheet bases; and carrying out vacuum concentration on the first and the second water-soluble extracts and applying the first and the second water-soluble extracts to the tobacco sheet bases to prepare the tobacco sheets. The technique can effectively reduce the content of water-soluble pectin and water-insoluble protease, and reduce the unique lignin flavor in the tobacco sheets by the chemical degradation of the lignose.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD +1

Technique for preparing tobacco sheet through paper making method

ActiveCN1600183AImprove the quality of delicious tasteImprove qualityTobacco treatmentWater solubleEnzyme

A process for preparing the tobacco sheet by paper-making method includes preparing the concentrated liquid for the water-soluble components in tobacco, adding enzyme and / or microbe, biodegradating for generating micro-molecular compounds to be changed into flavouring substance in post-treatment, spraying it on substrate, drying, and cutting by defined sizes.

Owner:SHENZHEN BOTON FLAVORS & FRAGRANCES

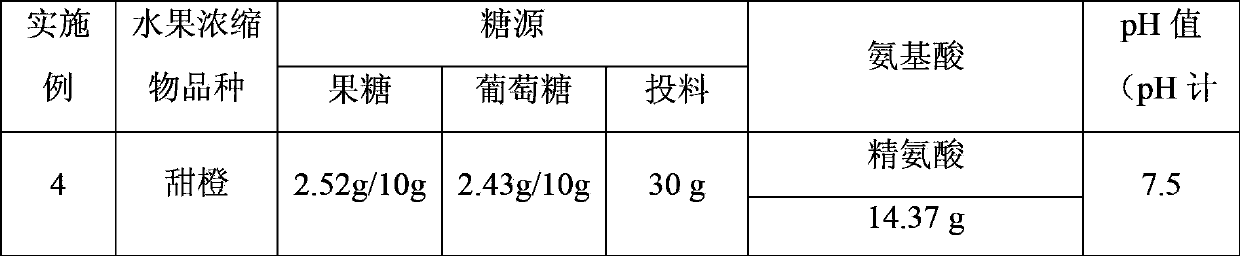

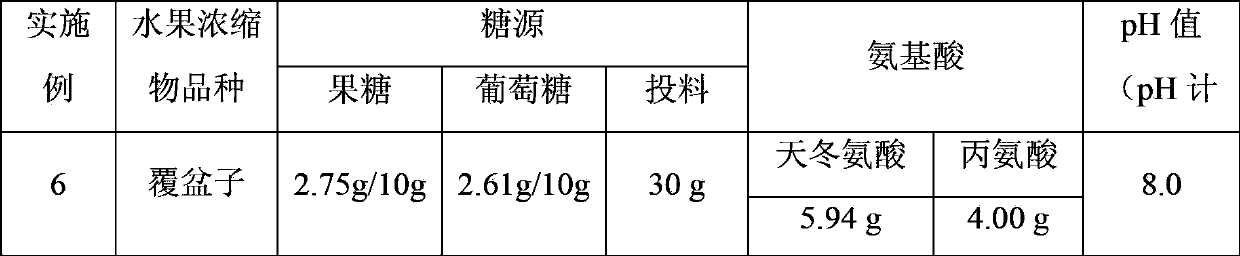

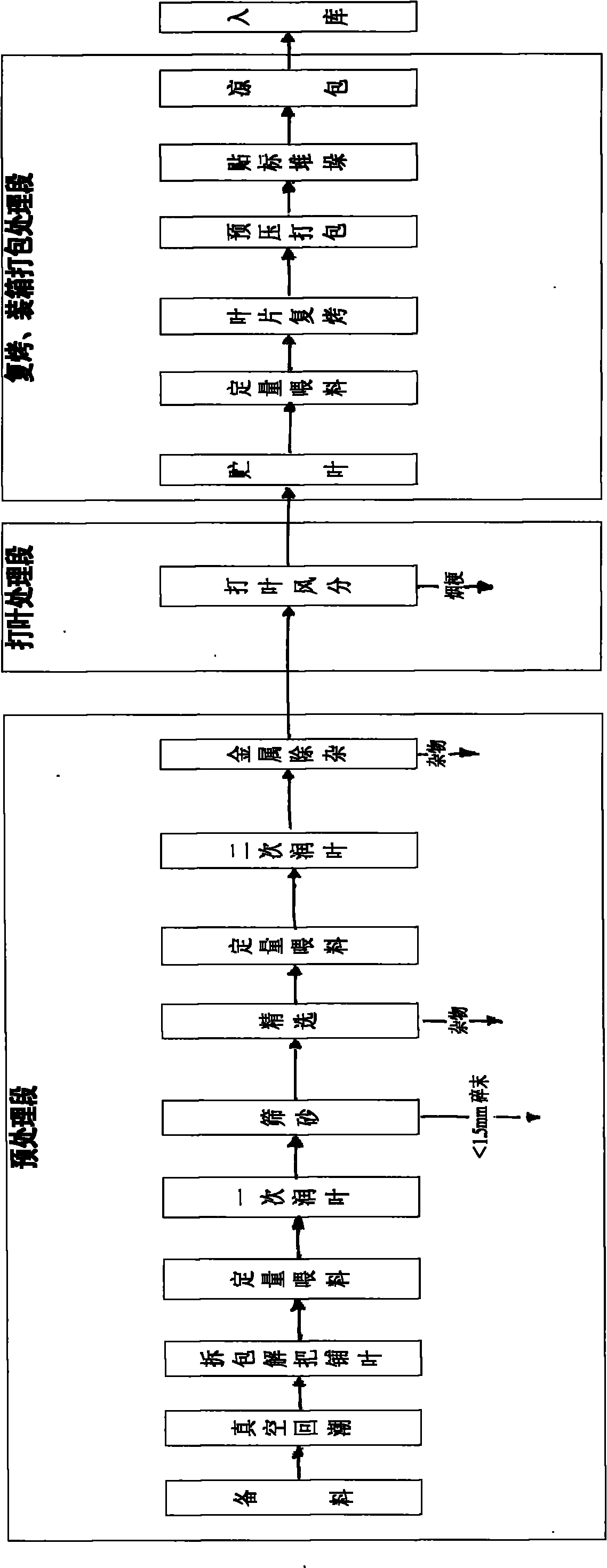

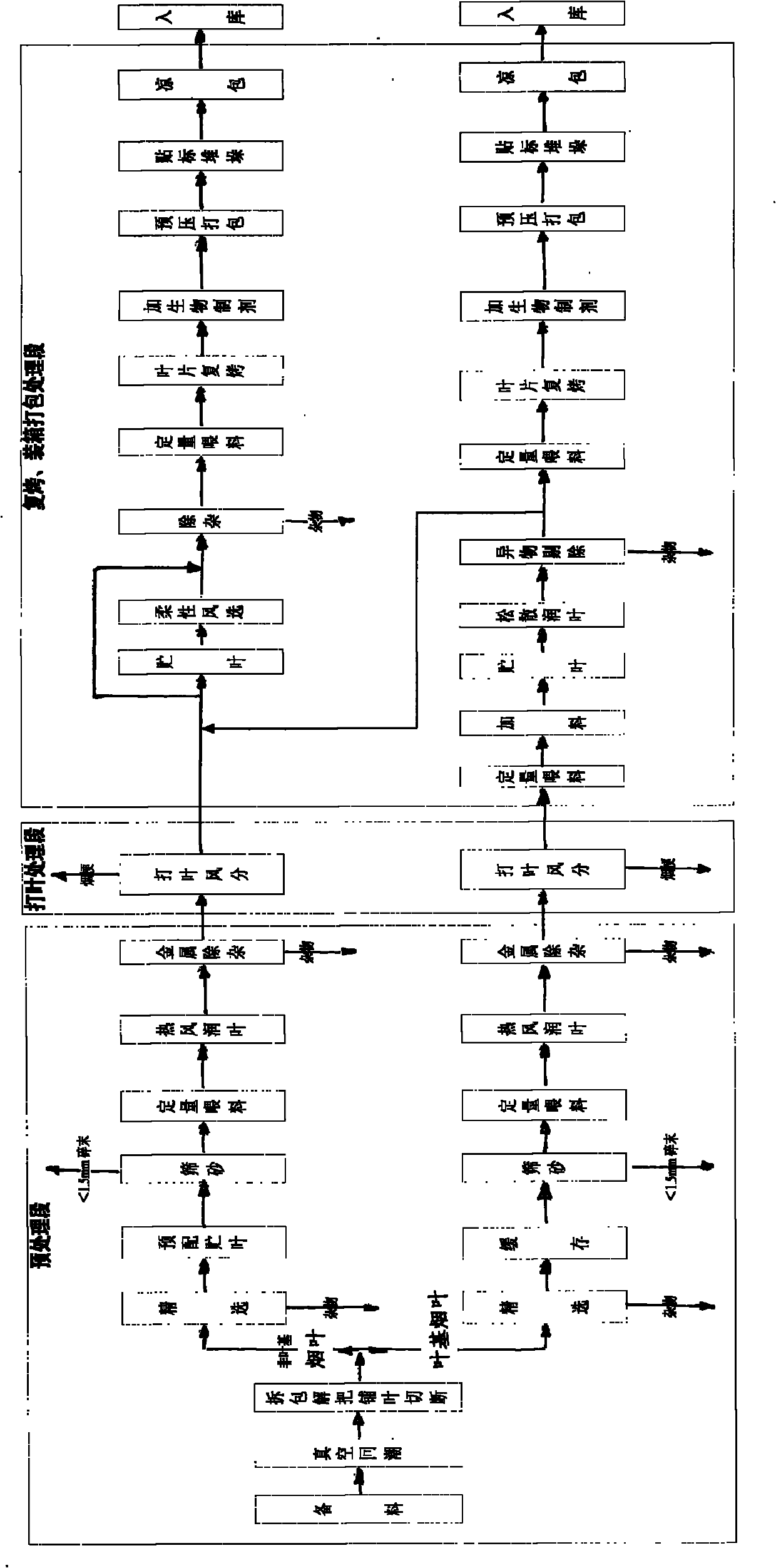

Preparation method of fruit concentrate Maillard reaction product, and application of product in tobacco perfuming

ActiveCN103865645AHigh fullnessMild reaction conditionsTobacco preparationEssential-oils/perfumesMaillard reactionFlavor

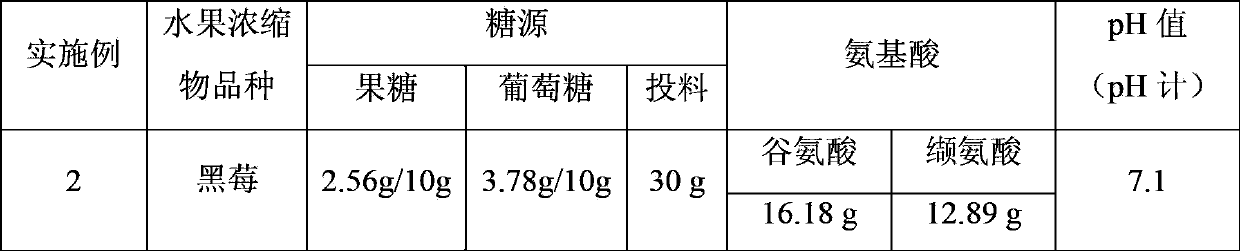

The invention relates to a preparation method of a fruit concentrate Maillard reaction product, and an application of the product in tobacco perfuming. The preparation method comprises the following steps: mixing a fruit concentrate or the fruit concentrate containing reducing monosaccharide with amino acids and a reaction solvent, using an aqueous solution of sodium hydroxide to adjust the pH value of a reaction system to 6-9, heating to 80-100DEG C within 20-90min, continuously reacting for 0.5-1.5h, and cooling to obtain the corresponding reaction product. The Maillard reaction product generated after reacting the fruit concentrate with the amino acids is rich in the natural perfume of fruits, can be naturally coordinates with the original perfume of tobacco, and is safe and reliable. The above reactive perfume prepared in the invention is used to process cut tobacco under certain conditions, and is added to tobacco according to different proportions, so the smoking quality of the the prepared cut tobacco is substantially improved. The fruit concentrate Maillard reaction product can improve the fullness and the softness of the smoke of cigarette, improves the smoking smell comfortableness, and highlights the delicate perfume style of the cigarette.

Owner:APPLE FLAVOR & FRAGRANCE GRP +1

Method for slitting, striking and redrying tobacco

The invention relates to a method for slitting, striking and redrying tobacco, which is technically characterized by comprising the following step of: cutting tobacco lead bases with minimum tensile strength, poorest physical processing resistance and poorer perception smoke panel test quality and appearance quality in the tobacco for singly cutting, striking and redrying. The method has the mainadvantages that remained non leaf base tobacco leaves are crushed to be smaller when leaves and stems are separated singly after the tobacco leaf bases are cut for being singly processed, the leaf structures are more uniform after the leaves are separated from the stems, the green and impurity content in the tobacco is reduced, thus the large-medium leaf ratio after the striking is improved, the crushing generated when the leaves are separated from the stems is reduced, the leaf yield is improved, and the purity of the tobacco is increased. After the tobacco is processed by using a slitting, striking and redrying method of the invention, the leaf base smoking quality is better, the fragrance quantity is improved, the smoke explosive force is increased, the smoking comfort is enhanced, andthe impurity gases are reduced, thus the use value of the tobacco can be improved.

Owner:HONGTA TOBACCO GRP

Method for improving quality of cut stems

ActiveCN103704867AImprove qualityIncrease vitalityTobacco preparationTobacco treatmentPulp and paper industryMoisture regain

The invention provides a method for improving the quality of cut stems. The method comprises the following steps that (1) tobacco stems are washed and degraded; (2) moisture regain is conducted on the tobacco stems and the tobacco stems are stored; (3) the tobacco stems are expanded and pressed; (4) stem pieces are degraded and stored; (5) material adding is conducted on the stem pieces; (6) the stem pieces are dried; (7) the dried stem pieces are stored; (8) moisture regain is conducted on the dried stem pieces and the dried stem pieces are expanded and pressed; (9) the stem pieces are cut into shreds and materials are added; (10) the cut stems are expanded and dried. Cigarettes with the cut stems prepared through the method are clear in fragrance characteristic, the fragrance quality is good, the smoke state is improved, the fine and smooth performance is improved, the harmony is better, miscellaneous gases are reduced, the dry sensation is reduced, and taste is more comfortable.

Owner:CHINA TOBACCO FUJIAN IND

Preparation method for aired tobacco extracts and essential oil

InactiveCN102488318ASimple production process and equipmentImprove controllabilityTobacco preparationTobacco treatmentWaxAlcohol

The invention discloses a preparation method for aired tobacco extracts and essential oil. The preparation method includes extracting aroma components such as ester, wax compounds and the like in aired tobaccos by the aid of carbon dioxide supercritical fluid; adopting water as eluent to dynamically wash supercritical fluid extracts in a primary separating kettle so as to extract water soluble components; eluting the supercritical fluid extracts via ethanol in a secondary separating kettle to obtain alcohol soluble aired tobacco essential oil; and utilizing alcohol insoluble substances as cigarette aroma additives by an emulsion dispersion method. The preparation method can remarkably increase aired tobacco aroma component extracting efficiency and selectivity, aired tobacco aromatic characteristics of the extracts are remarkable, offensive and irritancy can be reduced, and sensory comfort can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

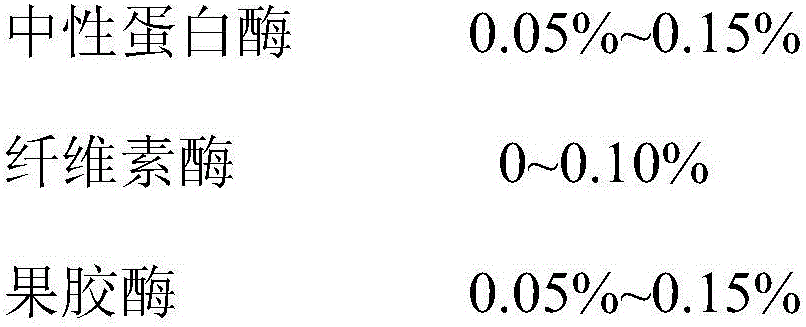

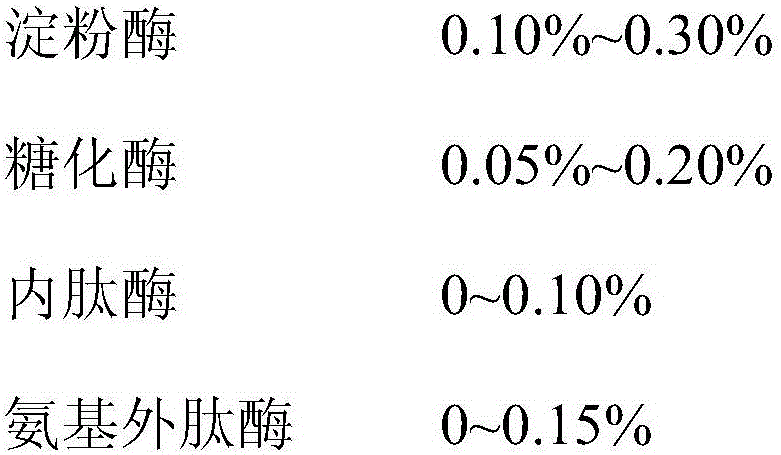

Biological treatment method of papermaking-method reconstituted tobacco raw materials and pulp

ActiveCN104957752AImprove inner qualityReduce mistTobacco preparationMacromolecular SubstancesChemistry

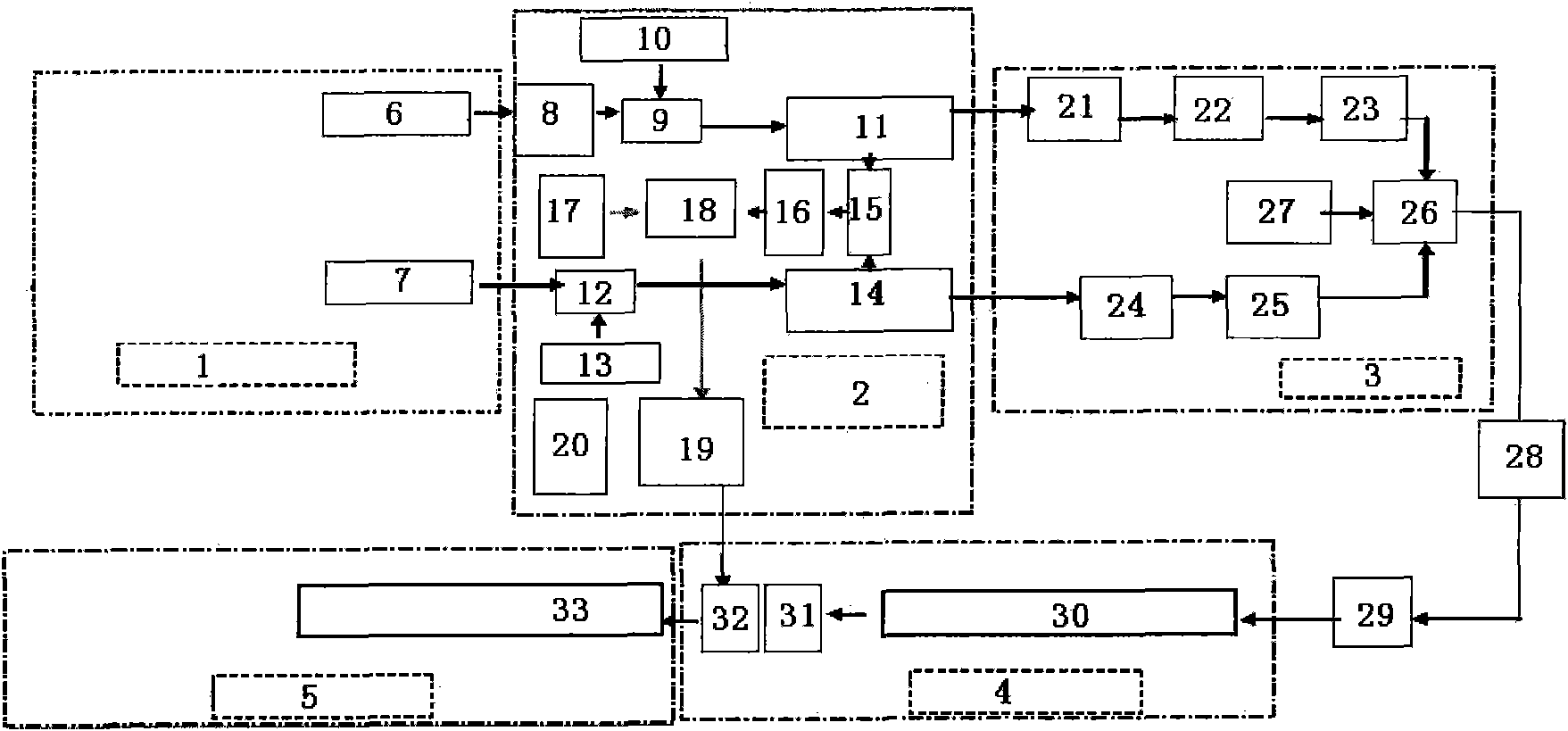

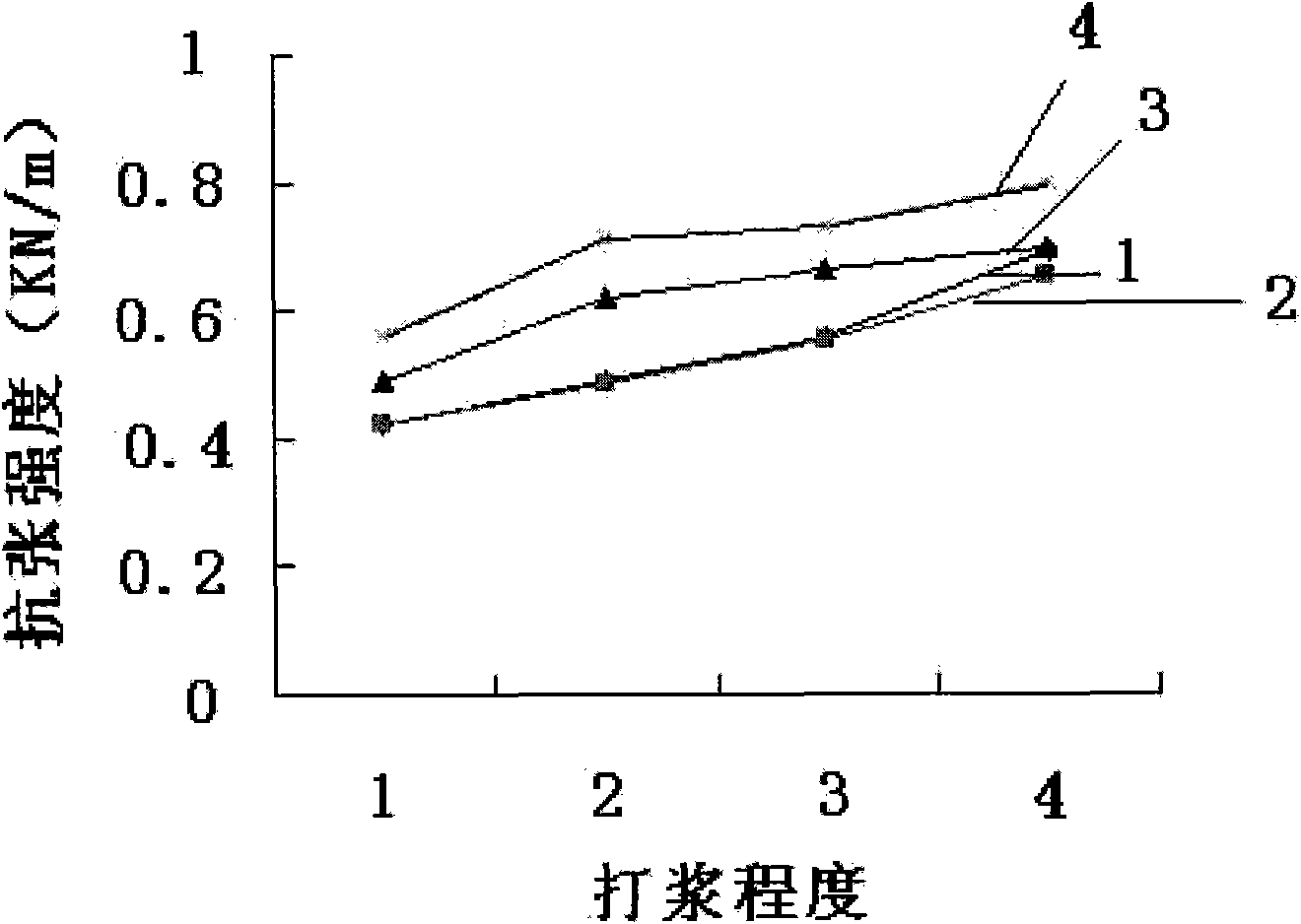

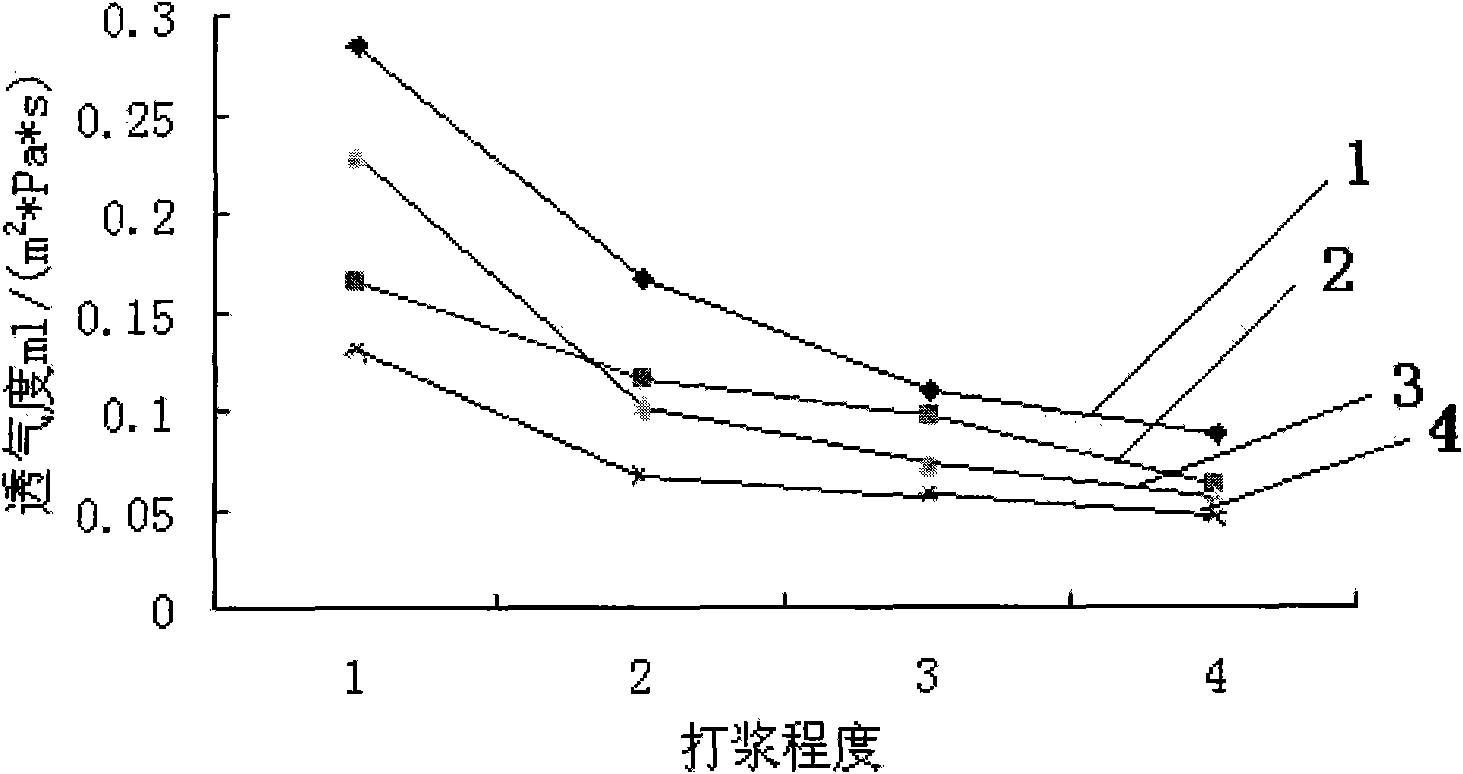

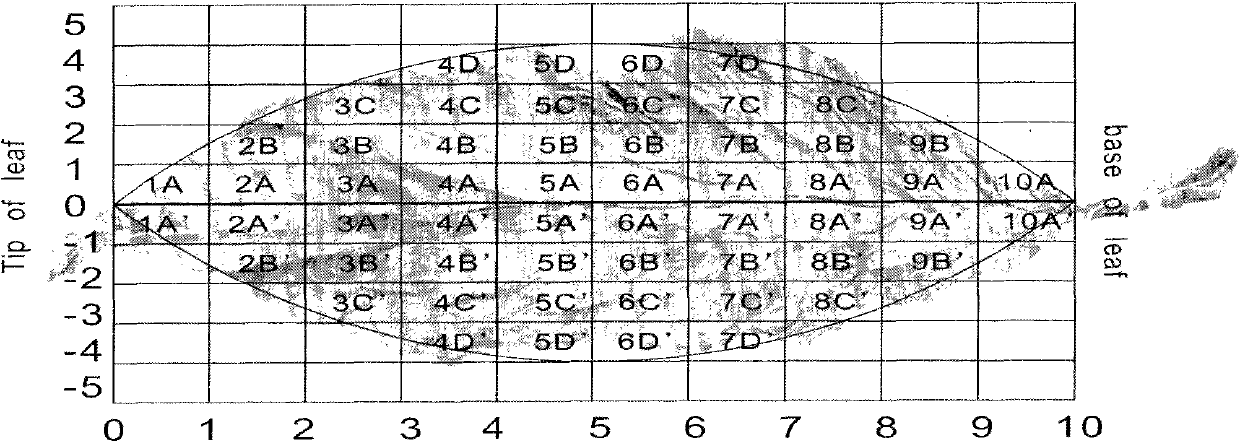

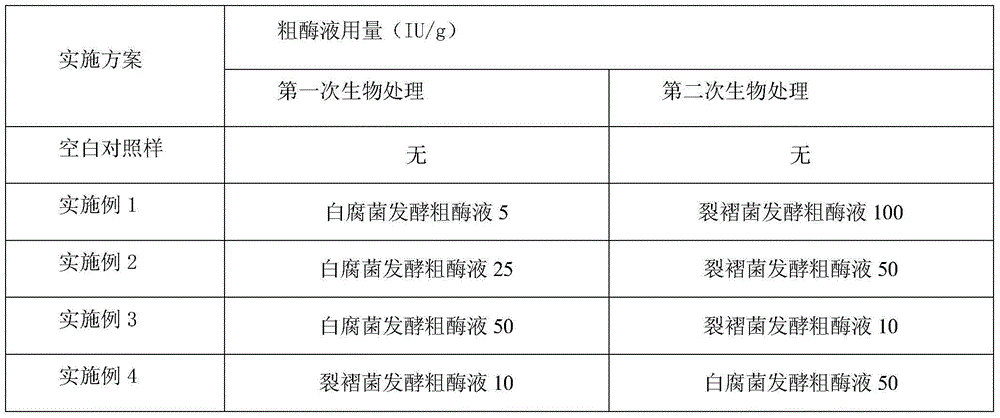

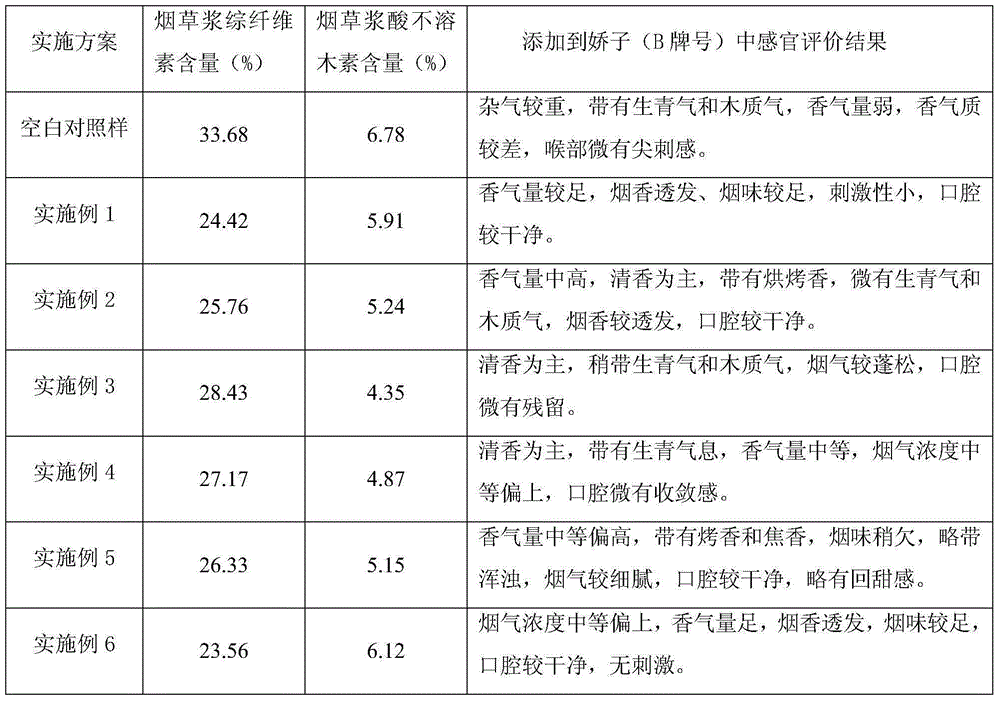

The invention discloses a biological treatment method of papermaking-method reconstituted tobacco raw materials and pulp, biological treatment is conducted twice on the papermaking-method reconstituted tobacco raw materials and pulp by means of the crude enzymes obtained through microbial fermentation, the object for the first biological treatment is materials which are extracted and tread rolled, and biological enzymes degrade cell wall substances and plays a role of enzymatic pulping; the second biological treatment is conducted in the potential elimination process after high consistency pulping is conducted and before low consistency beating is conducted, and the biological enzymes are acted on pulp fibers, further efficiently degrades macromolecular substances such as lignin, cellulose, hemicellulose, pectin and protein, conducts decoration or modification on the fiber surfaces, and plays the role of enzymatic beating. After the biological treatment is conducted twice, the cell wall substances in the materials and the pulp and undissolved macromolecular substances are degraded effectively, and the sensory quality of papermaking-method reconstituted tobaccos is promoted obviously.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +2

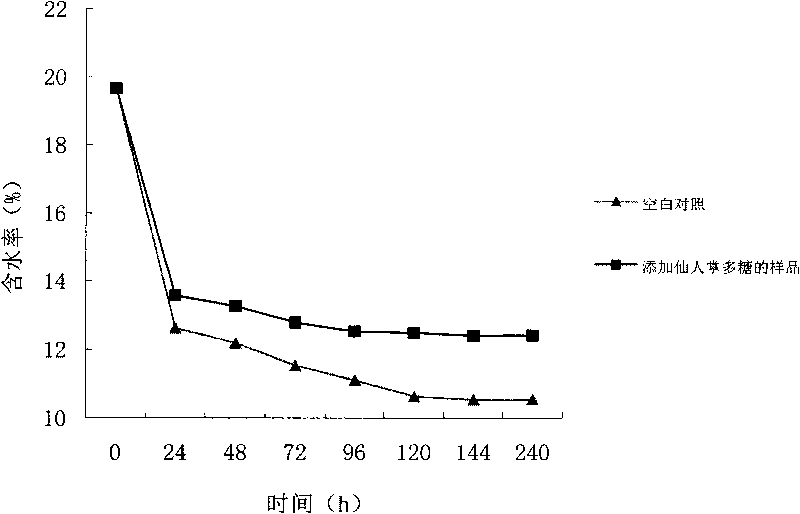

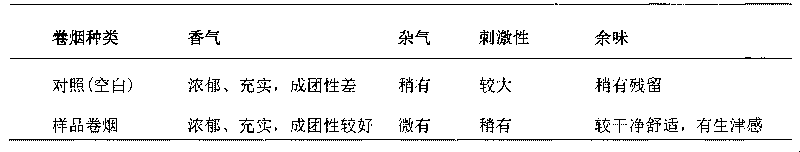

Extraction method of cactus polysaccharide and application thereof in cigarettes

ActiveCN101704900AImproves moisture retentionMoisturizing effect is obviousTobacco treatmentIrritationFiltration

The invention discloses an extraction method of cactus polysaccharide, which is characterized by comprising the following steps: high temperature enzyme inactivation; drying and crushing; extraction, centrifugal separation and filtration; filtrate concentration, adding into alcohol, precipitation, and crude cactus polysaccharide collection; dissolving of the crude cactus polysaccharide and purification; and obtaining of the cactus polysaccharide after collecting, washing and vacuum drying the precipitation. The cactus polysaccharide is applied to tobacco threads along with feed liquid after being dissolved with water, therefore, the smoke has no peculiar smell when a person smokes, the cactus polysaccharide can improve quality of aroma, mellow degree and sweet taste, improve oral comfort, reduce unpleasant smell and irritation, improve the dry sensation to a certain degree and obviously improve the moisturizing performance. The cactus polysaccharide does not change the original properties and the original processing technology of cigarettes, and does not change or influence the smoking quality of the cigarettes, thus having practical production significance and value.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation method and application of natural tobacco aroma enhancer

ActiveCN102936535AReduce mistLess irritatingTobacco preparationEssential-oils/perfumesIrritationSolvent

The invention relates to a preparation method of a natural tobacco aroma enhancer. The preparation method is characterized in that the natural tobacco aroma enhancer is obtained by taking albizia flowers as raw materials, extracting the albizia flowers by virtue of a solvent and concentrating the extract. Smoke irritation can be reduced after the natural tobacco aroma enhancer is added into cigarette cut tobacco, offensive odor can be masked, the aroma quality and amount of smoke can be improved, and cigarette smoke is endowed with elegant faint scent. The novel natural tobacco aroma enhancer prepared by the method has a prominent characteristic that a novel application is provided for albizia flower.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

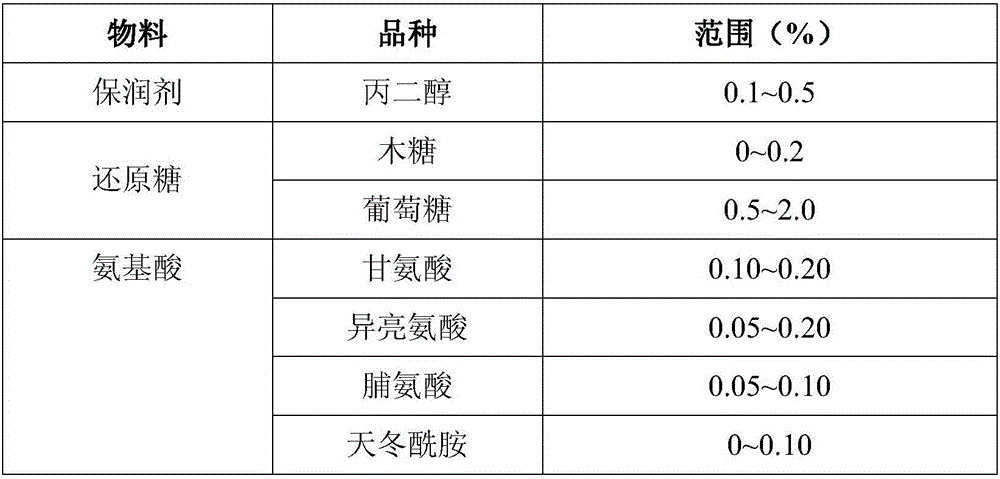

Method for preparing coffee reaction flavor through Maillard reaction and application of coffee reaction flavor

ActiveCN102228121ASolve the cost-prohibitive problemSimple preparation processCoffee flavouringBiotechnologyMaillard reaction

The invention discloses a method for preparing coffee reaction flavor through Maillard reaction. The method is characterized by comprising the following steps: taking baked coffee powder, reducing sugar and complex amino acids as raw materials and water and propylene glycol as solvents to carry out Maillard reaction under heating condition to prepare the coffee reaction flavor, wherein the complex amino acids are at least four of lysine, arginine, glutamic acid, histidine, glycine and leucine. The method has the following beneficial effects: the gaps in preparation and application of the coffee reaction flavor at home and abroad are filled in and the problem of too high cost caused by only adding coffee extracts to the food and cigarettes is effectively solved at the same time.

Owner:上海龙殷生物科技有限公司

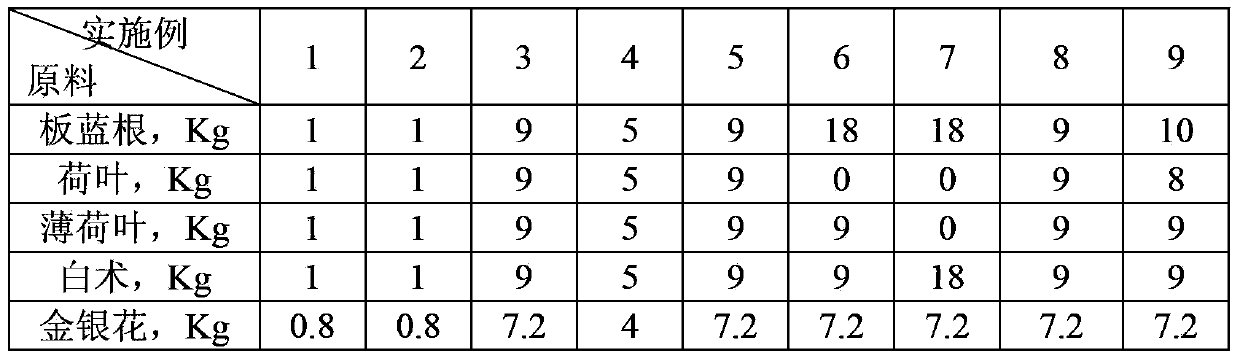

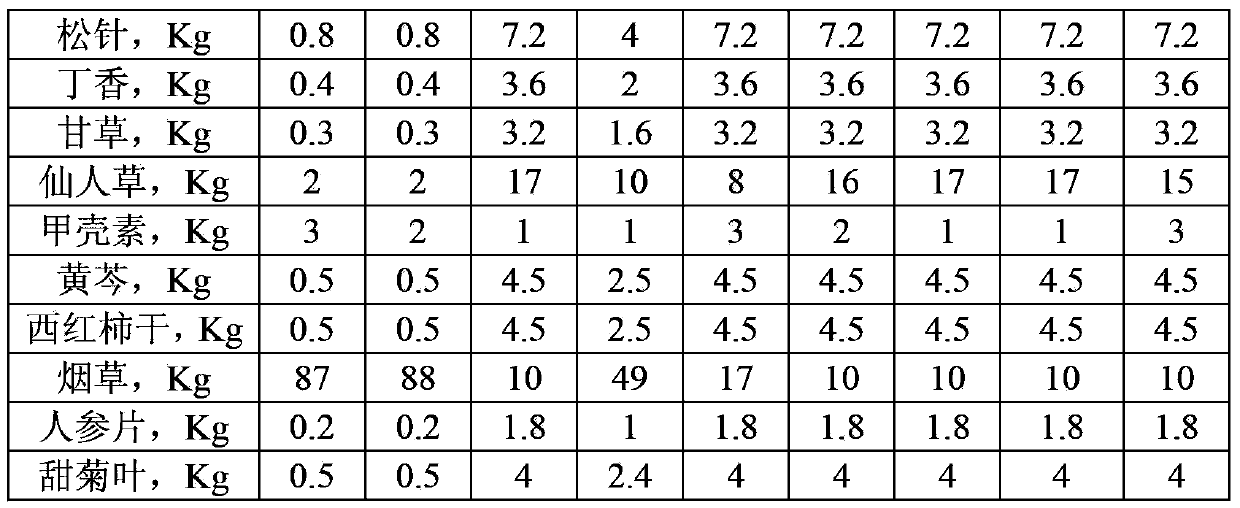

Chinese herbal medicine healthcare cigarette

InactiveCN103431516ASolve the disadvantages of containing a large amount of tar and other harmful substancesChange the status quo that is highly irritating and easy to dry outTobacco treatmentAntiinfectivesTraditional originLiquorices

The invention discloses a Chinese herbal medicine healthcare cigarette which comprises a cigarette rod and a filter tip connected with the cigarette rod, wherein tobacco shreds are wrapped in the cigarette rod and prepared by mixing the following raw materials by weight percent: 10%-89% of Chinese herbal medicines, 10%-89% of tobaccos and 1%-3% of chitin; the Chinese herbal medicines comprise one or more of radix isatidis, bighead atractylodes rhizome, honeysuckle, pine needles, clove, liquorice, scutellaria baicalensis, mesona chinensis benth, ginseng tablets and stevia rebaudian leaves. The Chinese herbal medicine healthcare cigarette adopts the chitin instead of a traditional tobacco shred bonder containing harmful substances such as a great amount of tar, combines the properties of the Chinese herbal medicines and the chitin, ensures that a smoker inhales Chinese herbal medicine essences while enjoying a traditional smoking feel, has an effect of keeping fitness, guarantees that the smoker unconsciously and completely quits smoking, and avoids a huge pain in a smoking cessation process.

Owner:QIAI GROUP CO LTD

Processing method for improving cut stem quality

The invention belongs to the field of tobacco processing, in particular to a processing method for improving cut stem quality. The processing method for improving the cut stem quality is characterized in that tobacco stems and stem pieces are extracted by using an alcoholic solution, and then the alcoholic solution is added back into the produced cut stems made from the tobacco stems or the stem pieces. Compared with the prior art, the processing method for improving the cut stem quality has the advantages that substances with active functions on tobacco smoking smell such as sugar, nicotine, pigment ingredients and the like of the tobacco stems are extracted by using the alcoholic solution and are added back into the cut stems later, compounds harmful to the tobacco smoking smell such as macromolecules (like pectin, protein and the like) in the tobacco stems are removed by combining water washing with acidolysis and enzymolysis, and therefore improvement of sensory quality of the cut stems is achieved, and smoke panel tests demonstrate that the cut stems prepared have the advantages that the offensive odors are reduced, the irritation is lowered, and the flavor remaining smell is improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation and application of cigarette paper filter material containing Chinese herbal components

ActiveCN101736654ALess irritatingReduce mistTobacco smoke filtersFiltration separationMedicineLicorice roots

The invention discloses preparation and application of cigarette paper filter material containing Chinese herbal components, which belongs to the technical field of cigarette preparation. The preparation and the application comprise: crushing one or more of common coltsfoot flowers, aster, fineleaf schizonepeta herbs, ballonflower, reed rhizome, Japanese ardisia herbs, sessile stemona roots, cynanchum stauntoni, mint, licorice roots and the like and then performing beating and papermaking on the obtained product together with wood pulp, cotton pulp or bamboo pulp for papermaking; or extracting raw materials through water or ethanol and then smearing or spraying extract on cigarette paper filter material; embossing and cutting the cigarette paper filter material; molding the obtained product to be cigarette filter rods; and preparing cigarettes from the filter rods separately or preparing the filter rods into composite filter rod rolls and then preparing the cigarettes. The method has the advantages of significantly reducing the irritation and mixed smell of the cigarettes with paper filter tips, improving the smoking odor of the cigarettes and improving the applicability of paper filter material in the cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Preparation method of natural tobacco texture cigarette paper

InactiveCN103469691AIncrease the fragranceReduce mistSpecial paperPaper coatingCombustionSolid matter

The invention discloses a preparation method of natural tobacco texture cigarette paper. The method comprises the following steps: firstly weighing 5-60% of tobacco raw material and 40-95% of wood pulp by weight percentage; extracting the tobacco raw material, and separating to get a tobacco solid matter and an extraction solution; mixing the tobacco solid matter and the wood pulp to obtain mixed pulp; and preparing a cigarette paper base from the mixed pulp; concentrating the extraction solution to prepare a tobacco extract; adding 1-4% of a combustion-supporting agent, 0-4% of a natural pigment extract and 0-3% of a moisture retention agent relative to the weight of the tobacco extract into the tobacco extract to prepare a coating solution, coating the cigarette paper base with the coating solution, and directly performing embossing treatment by utilizing an embossing roller carved with tobacco textures after coating and drying to prepare the cigarette paper with the tobacco vein textures. According to the preparation method disclosed by the invention, the natural tobacco fragrance of the cigarette paper is increased, and the cigarette paper is also endowed with the tobacco characteristic appearance; the cigarette grade is upgraded; the cigarette paper miscellaneous gas during combustion is reduced, and the smoking quality is upgraded; the natural tobacco texture cigarette paper can further serve as wrappers of hand-rolled cigars.

Owner:HUBEI CHINA TOBACCO IND +1

Method of improving cabo quality

ActiveCN101228967AIncrease irritationReduce woody smellTobacco preparationTobacco treatmentFlavorCellulose

The invention discloses a method for improving the quality of cabo, comprising the following steps: dissolving microbial enzymes in a citric acid solution, uniformly spraying the completely dissolved enzyme solution on the cabo, treating the cabo sprayed with enzyme solution under constant temperature and humidity, and drying, etc. The invention uses the microbial enzyme technique to strengthen the fermentation treatment of the cabo, which reduces the wood flavor of the cabo, improves the irritation caused by undesirable substances such as cellulose. The improved cabo facilitates the process of the subsequent procedures and is added into the group prescription of the tobacco leaves, which increases the comfort of the oral cavity, decreases miscellaneous gases, softens the smoking gas, reduces the content of harmful substances in the cigarette and improves the safety of smoking. The invention has the advantages of simple and easy practice and strong practicality, which is beneficial to reducing the consumption of tobacco leaves and save tobacco leaf resources.

Owner:CHINA TOBACCO GUANGDONG IND

Method for treating American burley tobacco

InactiveCN102058147AFull Maillard reactionElegant qualityTobacco preparationMaillard reactionEngineering

The invention discloses a method for treating American burley tobacco, comprising the steps of: adding internal materials to burley tobacco leaves in twice in a loosening and moisturizing step and a charging step respectively, carrying out dry treatment on the tobacco leaves in a burley tobacco dryer, and adding external materials and then directly mixing with flue-cured tobacco and aromatic tobacco in a formulation of a product; wherein, in the loosening and moisturizing step, reducing sugar, humectant, Maillard reaction intermediate and plant extracting liquid are added to internal material liquid, the moisture content of the moisturized tobacco leaves is 24-28%, the tobacco leaves are stored in a storage tank for 2-4h and discharged, then liquorice paste liquid and cocoa powder liquid are added on line in the charging step, and after charging, the moisture content of the tobacco leaves is 32-38%. The method ensures that Maillard reaction can be fully carried out on a burley tobacco sheet, improves aromatic characteristics and aromatic amount of the treated burley tobacco and effectively reduces pungency and miscellaneous gas at the same time.

Owner:CHINA TOBACCO ANHUI IND CO LTD

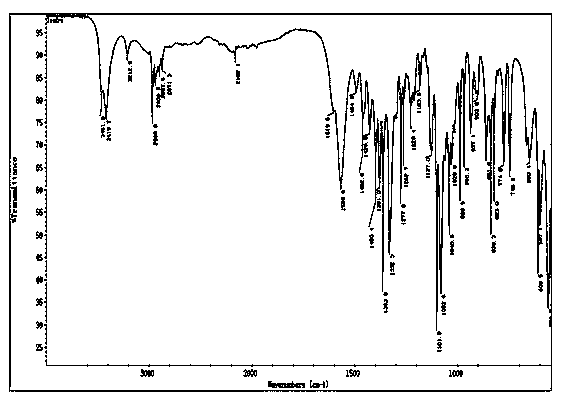

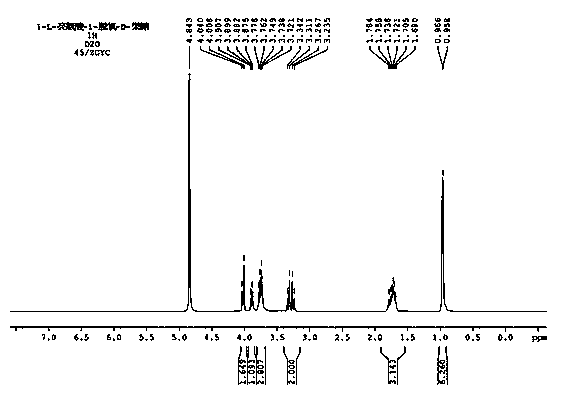

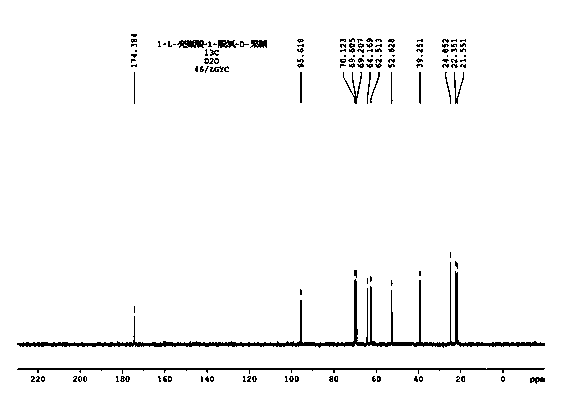

Cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose and preparation method thereof

ActiveCN103349356AReasonable synthetic routeGood physical moisturizing effectSugar derivativesTobacco treatmentFructoseBiochemical engineering

The invention discloses cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose. The structural formula of the cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose is as follows. The invention further discloses a preparation method of the compound. D-mannose is taken as a raw material, and the cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose is successfully synthesized through simple reaction processing. Physical humectant performance tests and inherent sensory quality evaluations show that the humectant has a good physical humectant effect on cigarettes, and can reduce irritation and blended gases of the cigarettes and improve the smoke mellow sense and comfort of the cigarettes.

Owner:CHINA TOBACCO HENAN IND +1

Extraction method of the tobacco thin slice production of paper process

InactiveCN101766327AObvious sweetnessImprove taste qualityTobacco preparationTobacco treatmentFlavorCellulose

The present invention discloses an extraction method of the tobacco thin slice production of a paper process, which belongs to a thin slice production technology in the technical field of cigarettes. The following matters are also put into extraction liquid, and the weight percentage accounted by the extraction liquid is: 0.02 to 0.1 % of acid protease, 0.01 to 0.1% of cellulose, 0.01 to 0.1 % of pectase, and 0.1 to 1% of accelerant. The acid protease is made in liquid subsurface fermentation and rear processing, and meanwhile, self-made enzyme activity accelerant is used. The extraction method is used for the production of tobacco thin slices of the paper process. The eating flavor quality of the tobacco thin slices is improved; the miscellaneous QI is reduced; the thrill is reduced, and meanwhile, the sour flavor formed in a process of manufacture paper with pulp of part of thin slices; and the natural tobacco sweet feeling is obvious.

Owner:HUBEI CHINA TOBACCO IND

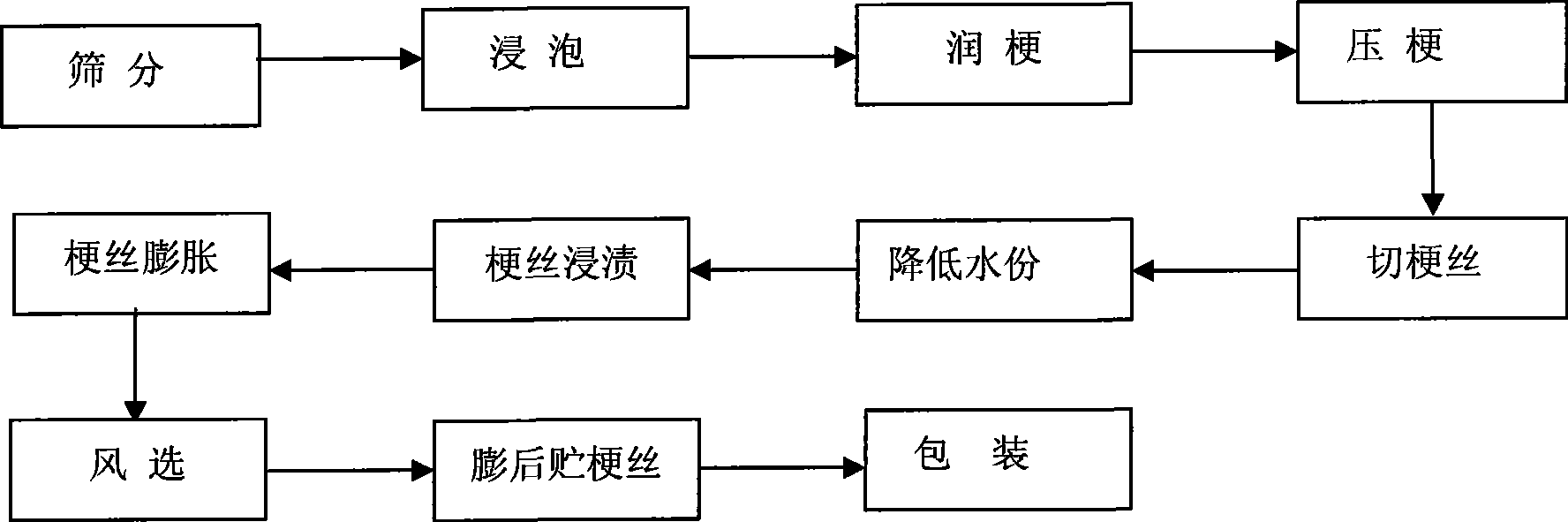

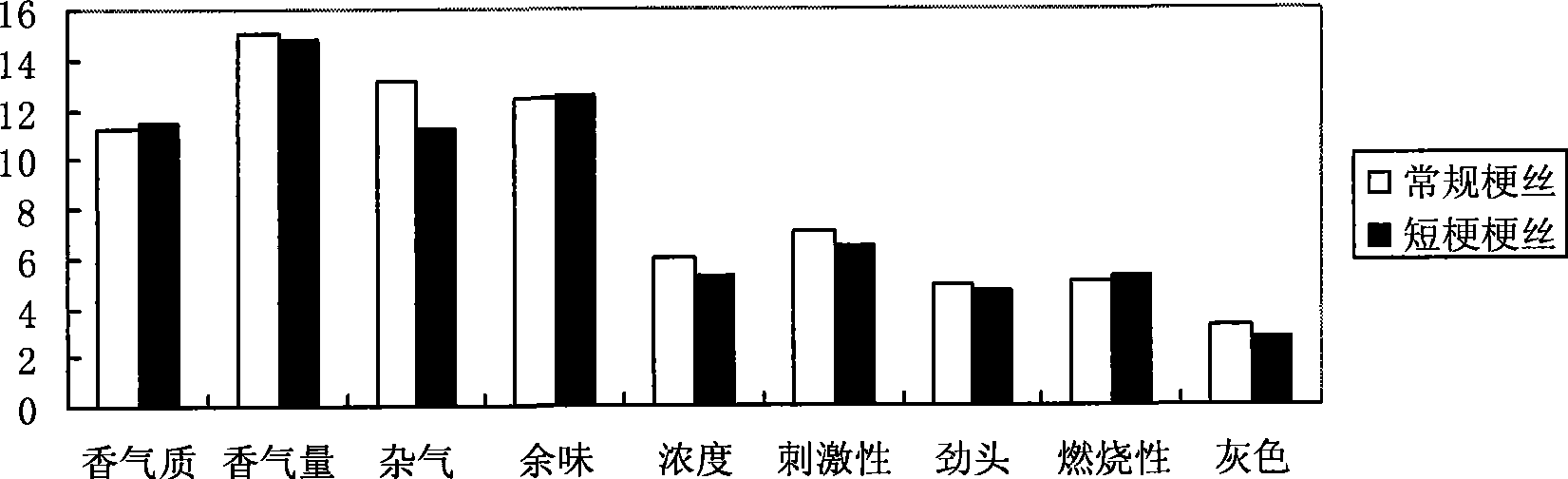

Method for processing short cabo less than 20mm into expanded cut stem

InactiveCN101371719AWell formedIncrease elasticityTobacco preparationTobacco treatmentEvaluation resultDry ice

The invention discloses a method for making short tobacco stalks which are shorter than 20mm into expanded cut stalks and relates to a production method of tobacco industry. The method adopts a processing technology of flattening stalks after fully soaking, and then the stalks are cut into threads, and dry ice expanding is carried out. The temperature of the water for soaking is 45 plus or minus 5 DEG C, while the soaking time is 10-15 minutes; the optimal stalk flattening gap is 0.50mm plus or minus 0.02mm, and the optimal cutting width is 0.16mm plus or minus 0.02mm. According to the evaluation results of all aspects, short tobacco stalk that is shorter than 20mm can be made into expanded cut tobacco with preferable appearance and good smoking quality; and a great amount of the resource of the short stalks discarded can be effectively used by adopting the technique of the invention, the smoking quality of the cigarette products can be obviously improved when the technique is applied to the cigarette products, and the method changes waste into valuable.

Owner:WUHAN TOBACCO GROUP

Method for manufacturing reconstituted tobacco suited to flue-cured tobacco flavor from sun-cured tobacco

The invention provides a method for manufacturing reconstituted tobacco suited to flue-cured tobacco flavor from sun-cured tobacco. The method for manufacturing reconstituted tobacco suited to flue-cured tobacco flavor from sun-cured tobacco comprises the steps as follows: a water extracting solution of a sun-cured tobacco material and a water extracting solution of flue-cured tobacco stems are mixed and concentrated to form a coating solution, and slices are prepared from water extraction filter residues of the sun-cured tobacco material and water extraction filter residues of the flue-cured tobacco stems through mixing with a papermaking method, and are then coated with the coating solution; a special complex enzyme preparation and aids are added during water extraction, concentration and pulping respectively. Excessive macromolecular substances such as protein, pectin, starch and the like in the sun-cured tobacco material are degraded through a special enzyme group, and a large number of small-molecule substances and precursors of flavoring substances are produced; meanwhile, the extraction efficiency is improved, and offensive odor and irritation produced by the reconstituted tobacco after combustion are reduced; various aroma producing and aroma increasing reactions are performed in the concentration process, and accordingly, the aroma quality of the reconstituted tobacco is improved, and the satisfaction and the coordination of smoke are increased.

Owner:HUBEI CHINA TOBACCO IND

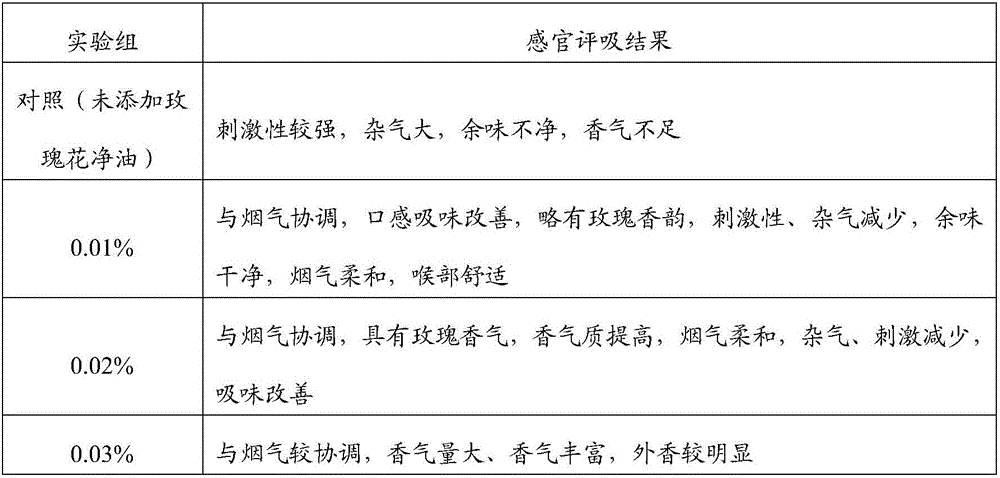

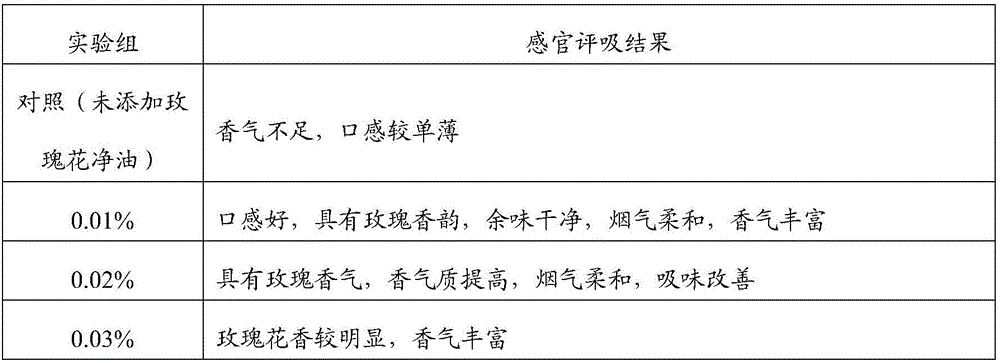

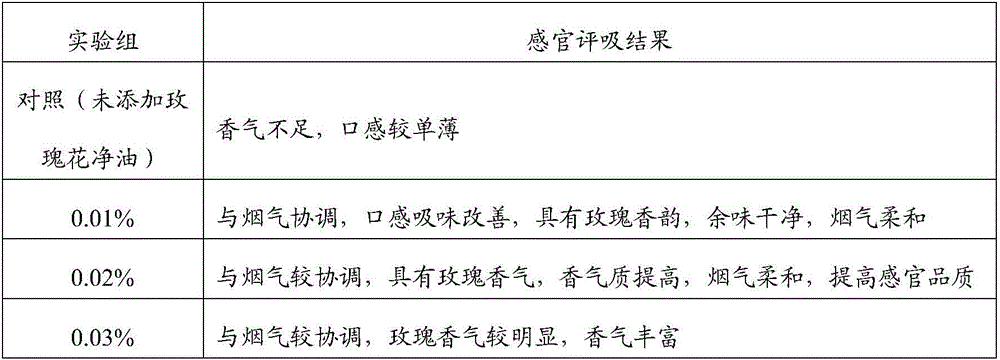

Biochemical joint preparation method and application of absolute rose oil

ActiveCN106418663ARich aromaGood effectTobacco treatmentEssential-oils/perfumesAmylaseMaillard reaction

The invention provides a biochemical joint preparation method and application of absolute rose oil. The preparation method comprises the steps that coarse rose powder is prefermented by beta-glucosidase, amylase and cellulase to generate aroma, reflux extraction is conducted for 3-5 h with an aqueous solution the pH value is regulated to be 9-14, a Maillard reaction is conducted for 3-5 h, suction filtration is conducted, filtrate is retained, an ethanol solution is added into filter residues for secondary reflux extraction, suction filtration is conducted, filtrate is retained, the filtrates obtained in two times of suction filtration are mixed, concentration and alcohol precipitation are sequentially conducted, and a rose extract is obtained; the rose extract is purified through molecular distillation, light components are retained, heavy components are purified through molecular distillation again, the light components are mixed, and the purified absolute rose oil is obtained. The absolute rose oil has purer and richer aroma and fewer impurities, and the irritation is reduced. When the absolute rose oil is applied to reconstituted tobaccos, the color and luster of the reconstituted tobaccos is more natural and uniform, the aroma can be enriched, irritation and offensive odor can be reduced, and the sensory quality can be improved; when the absolute rose oil is applied to a novel tobacco product atomizing agent, the aroma is enriched, the noble rose note is improved, and the tobacco aroma is increased.

Owner:HUBEI CHINA TOBACCO IND

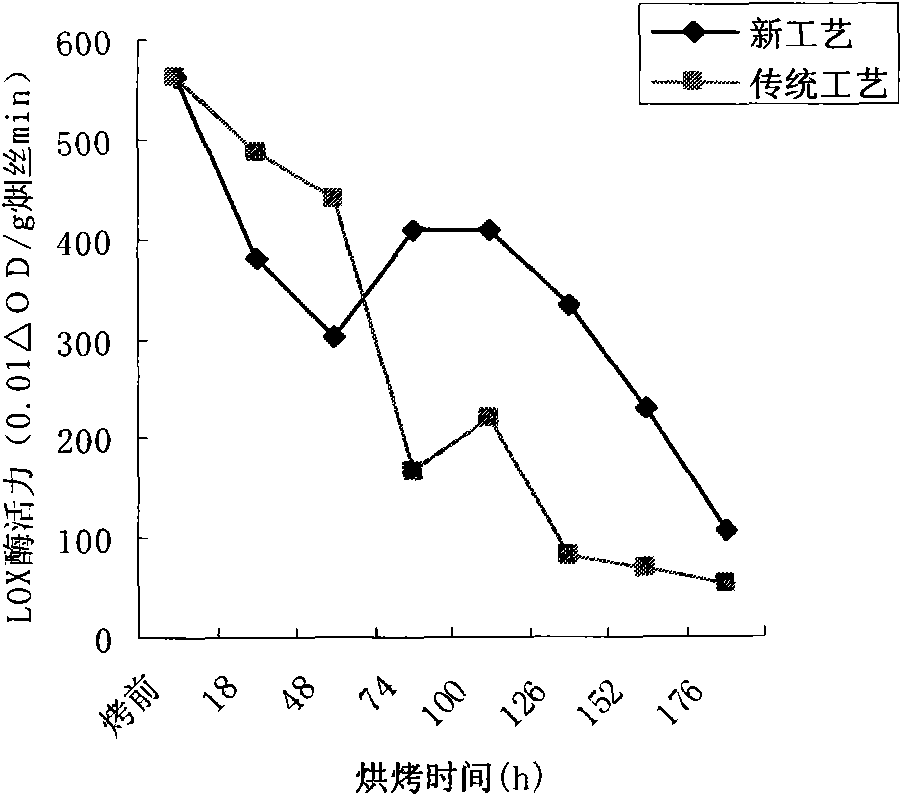

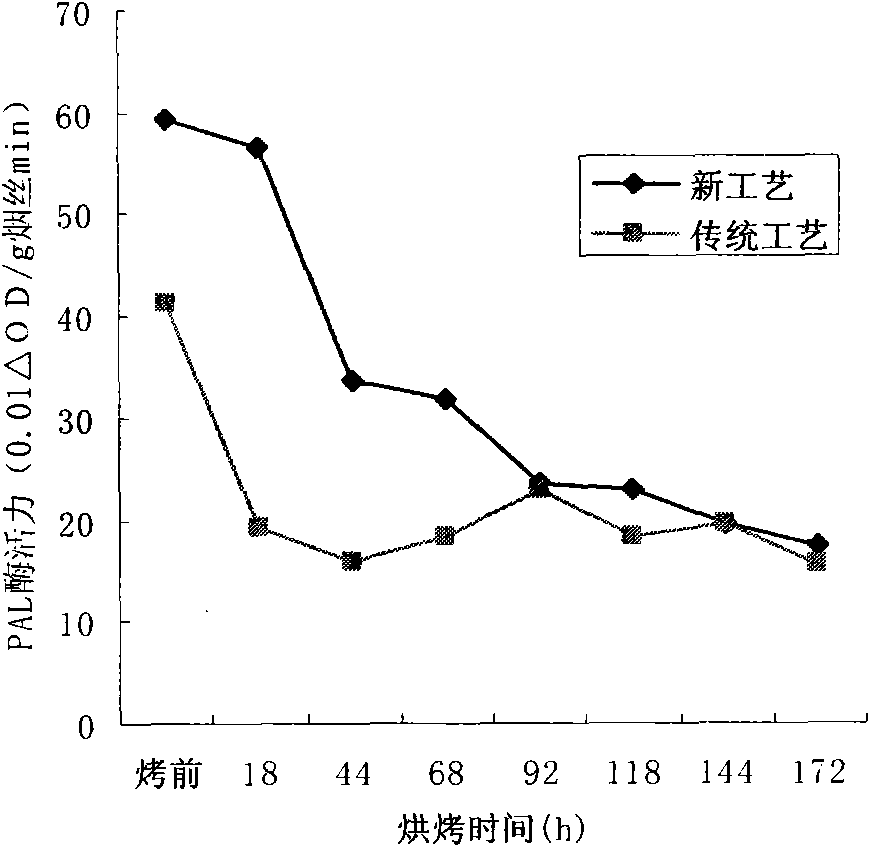

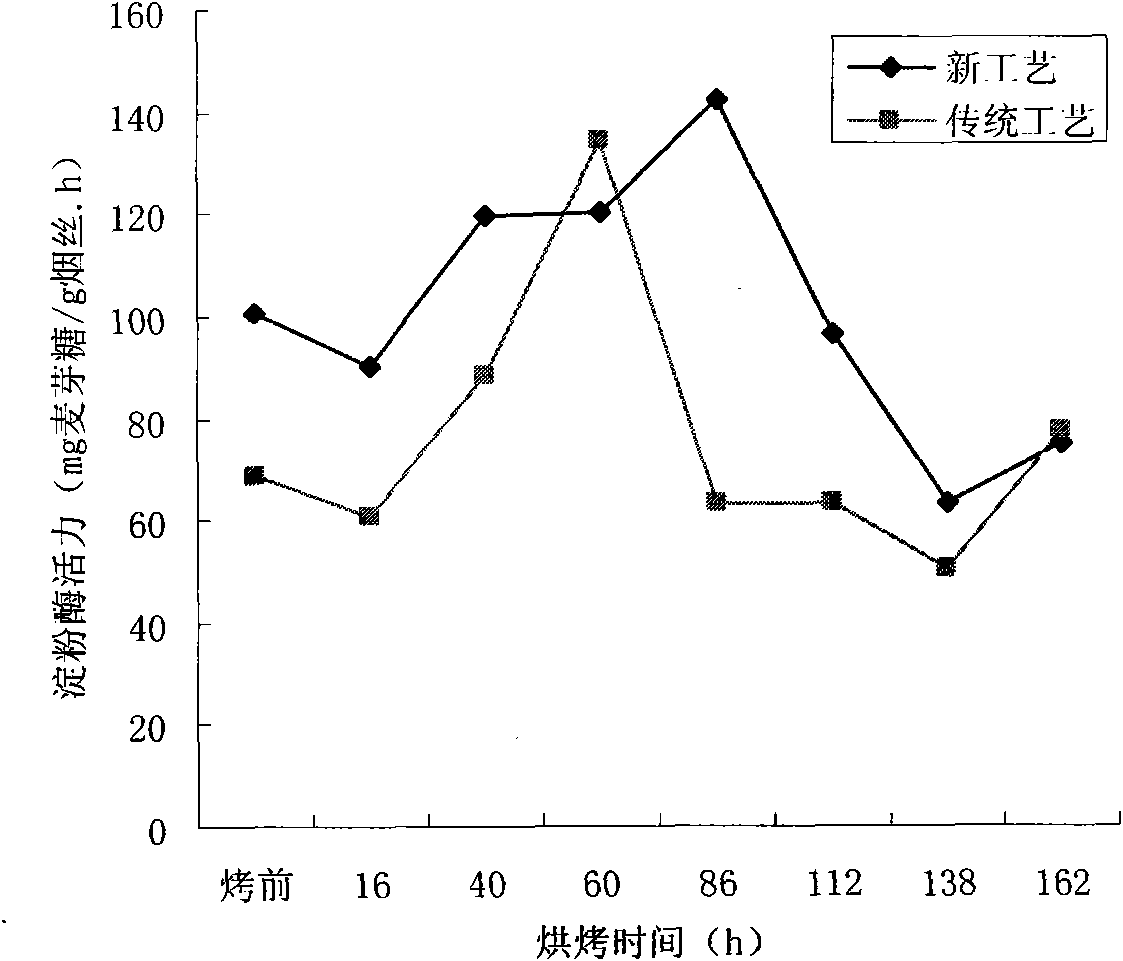

Process for baking Hongda tobacco leaves

The invention relates to a process for baking Hongda tobacco leaves, which belongs to the technical field of tobacco application. The method is an improvement of the traditional baking process and has the main improving points that the total baking time of the tobacco leaves grown at the lower part is shortened to 156 hours from original 168 hours; the total baking time of the tobacco leaves grown at the middle part is shortened to 168 hours from original 180 hours; and the total baking time of the tobacco leaves grown at the upper part is shortened to 170 hours from original 178 hours. The baking temperatures are adjusted by increasing the braking temperature in a yellowing stage to 31-32 DEG C from original 27-29 DEG C, increasing the braking temperature in a withering stage to 40-41 DEG C from original 38-39 DEG C, increasing the braking temperature in a leaf drying stage to 47-49 DEG C from original 43-45 DEG C, and increasing the braking temperature in a leaf ribbing stage to 66-67 DEG C from original 63-65 DEG C. The process for baking Hongda tobacco leaves is favorable for the conversion of chemical substances and the activity of enzymes by improving the baking time and thebaking temperature, the quality of the tobacco leaves is improved obviously, and the Hongda tobacco leaves with the optimum braking quality can be obtained.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH +1

Prepn. contg. composite enzyme for improving quality of tobacco

InactiveCN1692846AAccelerates the natural aging processShorten the natural aging cycleTobacco treatmentAmylaseYeast

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Preparation method of maillard reaction flavor for cigarette

InactiveCN104194938ATemperament improvementReduce mistTobacco treatmentEssential-oils/perfumesSpray driedBiotechnology

The invention relates to the field of additives for cigarettes, in particular to a preparation method of a maillard reaction flavor for a cigarette. The preparation method is characterized by comprising the steps of mixing glucose and phenylalanine at a mole ratio of (0.2-5):1 in an alcohol solution, adjust pH (potential of hydrogen) of a system to 5-10, heating for reaction for a certain time, rapidly cooling a reaction product to room temperature after the reaction, obtaining an ingredient with molecular weight distributed within 2-6kD by an ultrafiltration technology, and obtaining the maillard reaction flavor for the cigarette after concentration and spray drying. The method has the greatest characteristic of providing the novel maillard reaction flavor for the cigarette, the flavor is applied into the cigarette and can endow the cigarette with a sweet and elegant style, and aesthetic quality is improved. In addition, the flavor is simple in preparation technology and easy for industrial production, has a good tobacco perfuming effect, can effectively improve the organoleptic quality of the cigarette and has practical production significance and values.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation method and application of discarded tobacco leaf fermentation extract

InactiveCN106047481AIncrease aromaIncrease concentrationTobacco preparationEssential-oils/perfumesMaillard reactionNicotiana tabacum

The invention provides a preparation method and an application of a discarded tobacco leaf fermentation extract. Discarded tobacco leaves are fermented with beta-glucosidase, a tobacco biotransformation liquid containing various increased small-molecular aroma substances is obtained through enzymatic curing, then amino acid and reducing sugar in certain proportion are added for a high-temperature Maillard reaction under an alkaline condition, a natural tobacco Maillard reaction liquid is obtained and subjected to pumping filtration, a filtrate and filter residues are obtained, the filtrate is concentrated and mixed with propylene glycol and the like, further separation and purification are performed through molecular distillation, and light components are collected and taken as the discarded tobacco leaf fermentation extract. Reconstituted tobacco substrates with low irritation, low miscellaneous gas, low nicotine content and low harm are prepared from the filter residues with a paper-making process, the quality of the thin discarded tobacco leaf substrates is improved, the use effect of the discarded tobacco leaves on cigarette products is improved, the adding quantity of the extract is increased, the extract can be applied to an atomization filler material for novel carbon heating tobacco, and the quality of the atomization filler material is improved.

Owner:HUBEI CHINA TOBACCO IND

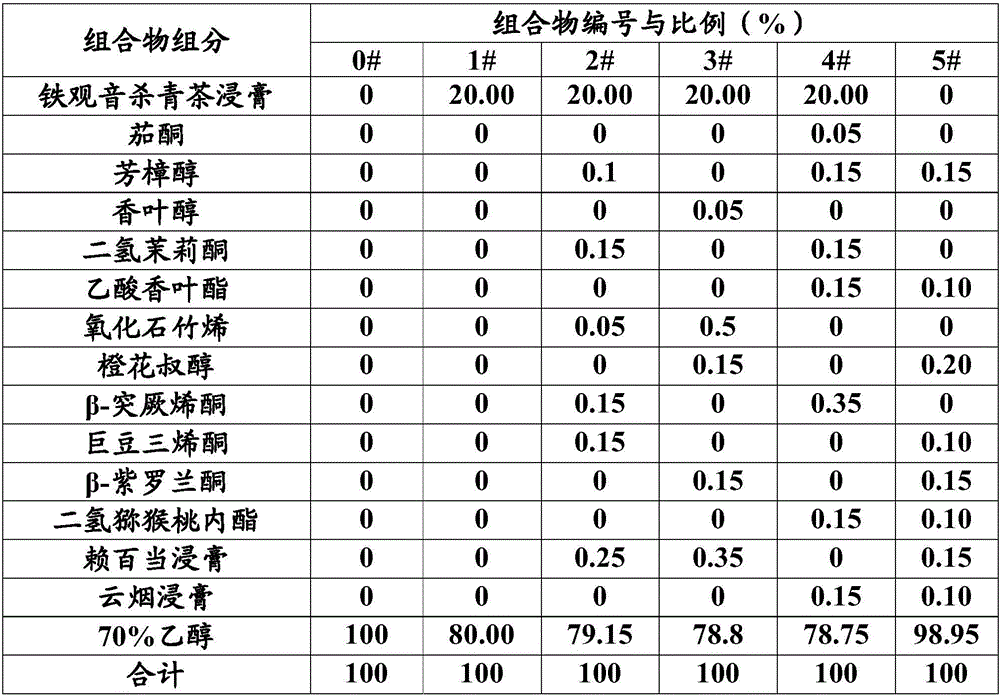

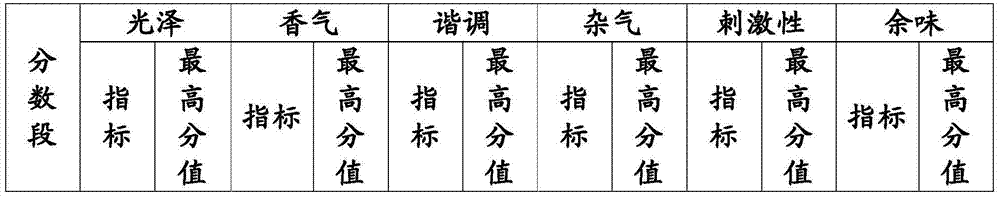

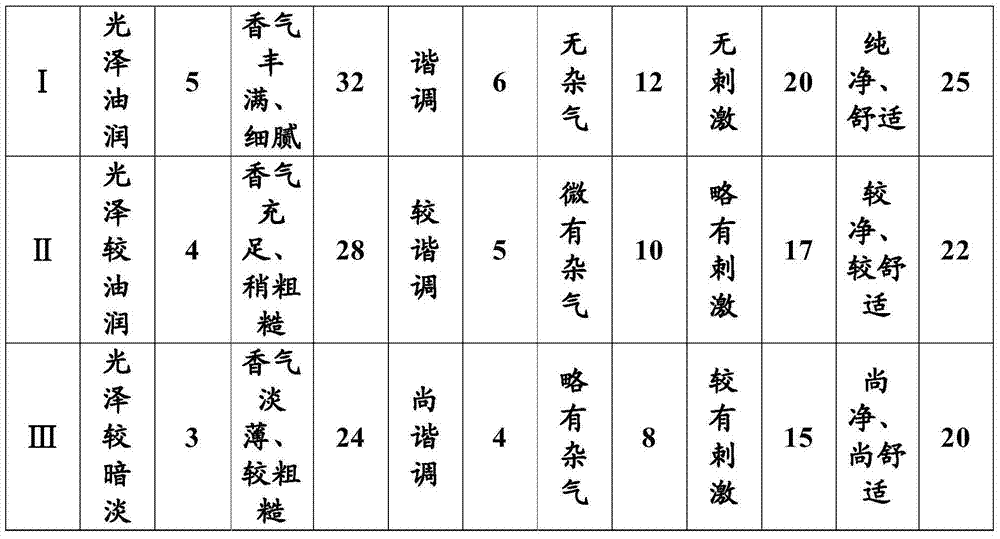

Composition and application of composition in cigarettes

InactiveCN105969524AElegant aromaDelicate and elegant aromaTobacco preparationEssential-oils/perfumesNerolidolBeta-damascenone

The invention provides a composition and application of the composition in cigarettes and particularly provides a composition. The composition contains a main flavor enhancer, a coordination agent, a modifier and a fixative, wherein the main flavor enhancer is an extract of a preliminary tea product, the coordination agent is tomato ketone, linalool, geraniol, dihydrogen jasmone, geranyl acetate or any combination thereof, the modifier is caryophyllene oxide, nerolidol, beta-damascenone, megastigmatrienone, beta-ionone, dihydro kiwifruit lactone or any combination thereof, and the fixative is a ladanum extract, a Yunyan tobacco extract or a combination thereof. The composition has an elegant and natural aroma, is fresh and fragrant, has a sweet, fragrant and graceful smell and can be widely used in the fields of tobaccos, foods and daily chemicals and the like.

Owner:CHINA TOBACCO FUJIAN IND

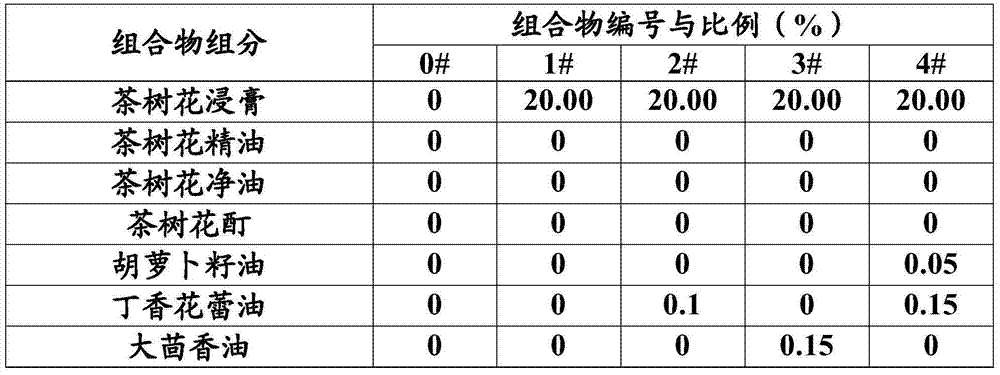

Camellia extract composition with spicy fragrance and application of same to cigarettes

ActiveCN103478894AElegant aromaIncrease diversityTobacco preparationTobacco treatmentFlavorAroma aroma

The invention relates to a camellia extract composition with spicy fragrance and application of the composition serving as a cigarette additive to cigarettes. The camellia extract composition is prepared from camellia extract and spice. After the camellia extract composition with the spicy fragrance is added into the cigarettes, fragrance of the cigarettes is harmonious, unique fragrance of the cigarettes is enhanced, the spicy fragrance is enhanced, cigarette flavor is enabled to be richer and more natural, richness, sense of thickness and mellowness of the cigarette fragrance are improved, smokers smoking the cigarettes can feel nature and relaxed, offensive odor and stimulation are reduced, and overall smoking quality is improved.

Owner:CHINA TOBACCO FUJIAN IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com