Preparation method of fruit concentrate Maillard reaction product, and application of product in tobacco perfuming

A technology of Maillard reaction and concentrate, which is applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of unsuitable fragrance style of cigarettes, improve the comfort of smoking, reduce miscellaneous gas, and highlight the flavor of fragrance effect of style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After testing, every 10g of strawberry concentrate contains 2.48 grams of fructose and 3.27 grams of glucose.

[0025] Add strawberry concentrate (30.0g), glutamic acid (14.12g), alanine (8.54g), glycerol (250mL, water content 12% ), mechanically stirred at room temperature. 10% NaOH aqueous solution was added dropwise to adjust the pH value, and the solid gradually dissolved. The temperature of the water bath was raised to 100°C within 30 minutes, and its pH value (pH meter) was measured to be 7.0 at this time. When the internal temperature of the reaction solution rose to 100°C, the reaction system began to brown, and as the reaction time increased, the color of the reaction system became darker and darker.

[0026] After reacting at 100° C. for 1.0 h, the reaction was stopped to obtain a brown-red reaction product.

[0027] (Molar ratio sugar:amino acid=1:2)

Embodiment 2

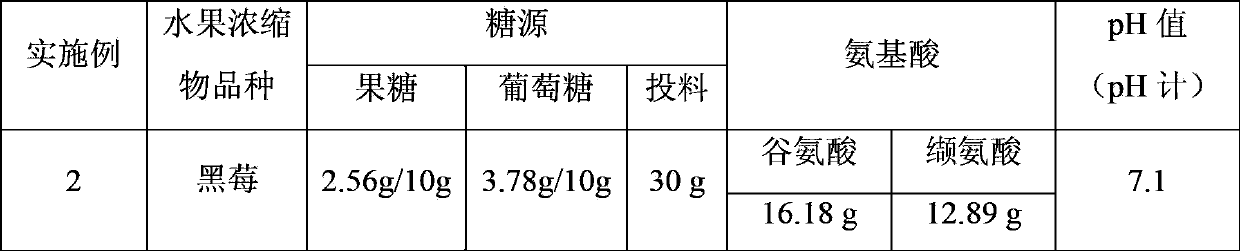

[0029] The reaction conditions and operations of Example 2 are the same as in Example 1, that is, the reaction solvent is glycerol (250 mL, 12% water content), and mechanically stirred at room temperature. Add 10% NaOH aqueous solution dropwise to adjust the pH value, raise the temperature of the water bath to 100°C within 30min, and react at 100°C for 1.0h, then stop the reaction to obtain a brown-red reaction product. The different specific feeding quantity and pH value control are shown in Table 2.

[0030] Table 1 Example 2

[0031]

Embodiment 3

[0033] After testing, every 10 grams of dark plum concentrate contains 2.28 grams of fructose and 2.99 grams of glucose.

[0034]In a 500mL three-necked flask equipped with a thermometer, a reflux tube, and a stirring paddle, sequentially add a 500mL three-necked flask, ebony concentrate (10.0g), fructose (10.4g), valine (4.69g), alanine (4.19g) , propylene glycol (150 mL), mechanically stirred at room temperature. Add 10% NaOH aqueous solution drop by drop to adjust the pH value, and the temperature of the water bath was raised to 95°C within 60 minutes. At this time, the pH value (pH meter) was measured to be 8.9. When the internal temperature of the reaction solution rose to 95°C, the reaction system began to brown, and as the reaction time increased, the color of the reaction system became darker.

[0035] After reacting at 95°C for 1.0h, stop the reaction to obtain the product.

[0036] (Molar ratio sugar:amino acid=1:1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com