Odorless ultraviolet-curing wood lacquer and preparation method thereof

A wood coating and ultraviolet light technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of polluting the environment, failing to achieve clean smell, benzene health and the impact of the surrounding environment, achieving smooth board surface and short construction period , the effect of excellent leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: net odor UV photocuring coating

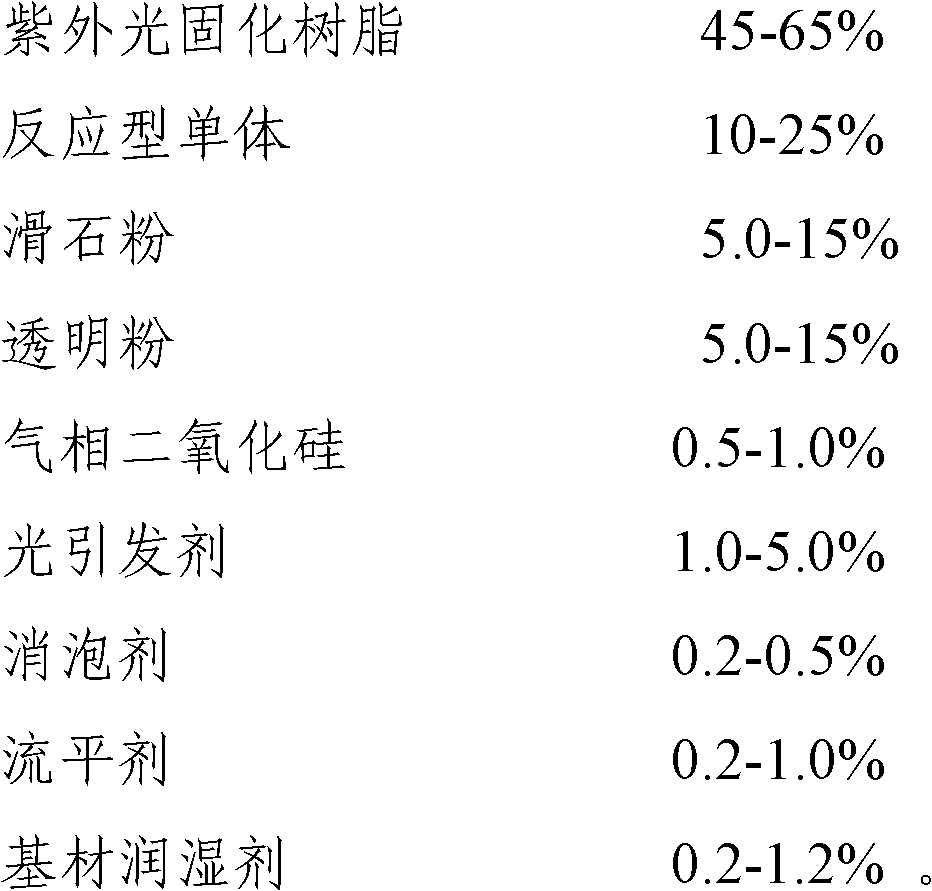

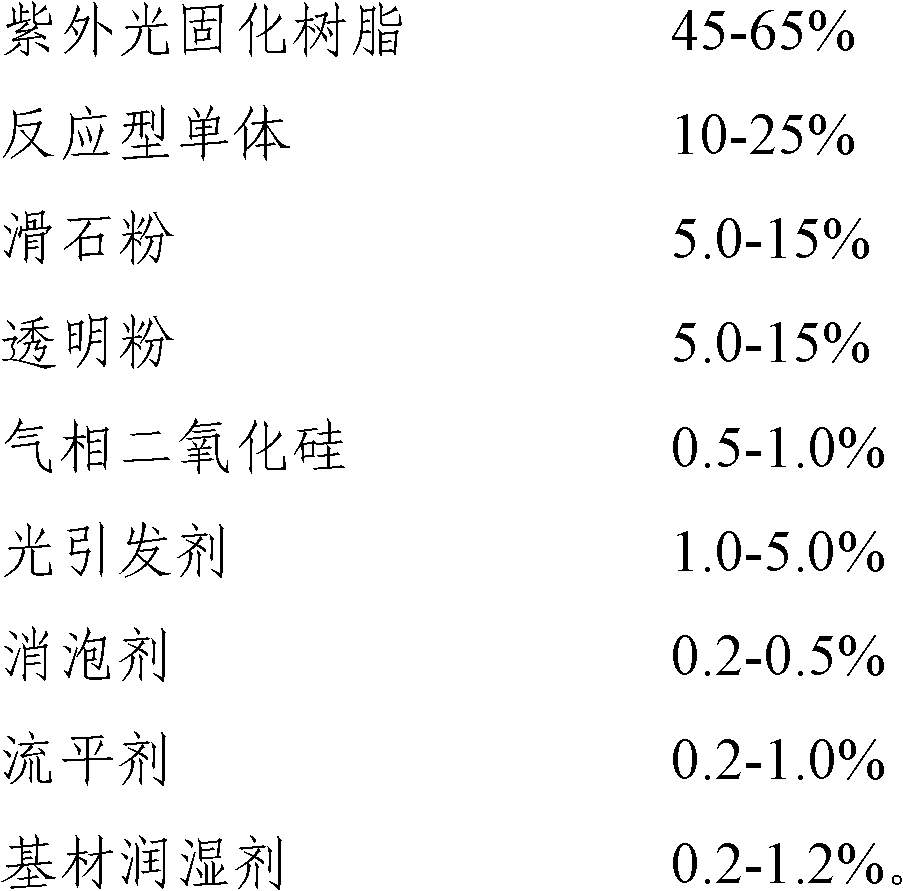

[0044] Raw material weight percentages are as follows:

[0045] composition

Weight percentage (%)

621-100 UV curable resin

32

188 UV curable resin

19

EM2382

9

ACMO

9

CX-2

6

11.5

Transparent powder TM2500

9

0.5

6022 Photoinitiator

3.0

Defoamer BYK-390

0.4

Leveling agent TEGO-410

0.3

Wetting and dispersing agent BYK333

0.3

total

100

[0046] 2. Preparation method:

[0047] 1) First add 621-100, 188, EO-TMPTA, ACMO, and CX-2 into the tank, then add TP1250, TM2500, and A200 under stirring, and disperse at high speed for 10 minutes after stirring evenly;

[0048] 2) Add BYK-333, BYK-390, TEGO410 and disperse at medium speed for 10 minutes;

[0049] 3) Add 6022 photoinitiator, stir evenly, and adjust the viscosi...

Embodiment 2

[0053] Embodiment 2: net odor UV photocuring coating

[0054] 1. The weight percentage of raw materials is as follows:

[0055] composition

Weight percentage (%)

621-100 UV curable resin

26.8

188 UV curable resin

28

EM2382

8

ACMO

6

CX-2

7

Talc powder TP1250

8

Transparent powder TM2500

12

0.5

PBZ photoinitiator

3.0

Defoamer BYK-390

0.2

Leveling agent TEGO-410

0.2

Wetting and dispersing agent BYK333

0.3

total

100

[0056] 2. Preparation method:

[0057] 1) First add 621-100, 188, EO-TMPTA, ACMO, and CX-2 into the tank, then add TP1250, TM2500, and A200 under stirring, and disperse at high speed for 10 minutes after stirring evenly;

[0058] 2) Add BYK-333, TEGO410, BYK-390 and disperse at medium speed for 10 minutes;

[0059] 3) Add PBZ photoinitiator, stir evenly, and adjust ...

Embodiment 3

[0063] Embodiment 3: pure odor UV photocuring coating

[0064] Raw material weight percentages are as follows:

[0065] composition

Weight percentage (%)

621-100 UV curable resin

38

EM-2382

23

ACMO

5

CX-2

9

Talc powder TP1250

11.5

Transparent powder TM2500

9.0

0.5

BP photoinitiator

3.0

leveling agent

0.3

0.2

wetting and dispersing agent

0.5

total

100

[0066] 2. Preparation method:

[0067] 1) First add 621-100, EM-2382, ACMO, and CX-2 into the tank, then add TP1250, TM2500, and A200 under stirring, and disperse at high speed for 10 minutes after stirring evenly;

[0068] 2) Add BYK-333 and BYK-390 and disperse at medium speed for 10 minutes;

[0069] 3) Add BP photoinitiator, stir evenly, and adjust the viscosity to 40-60KU / 25°C to obtain the product.

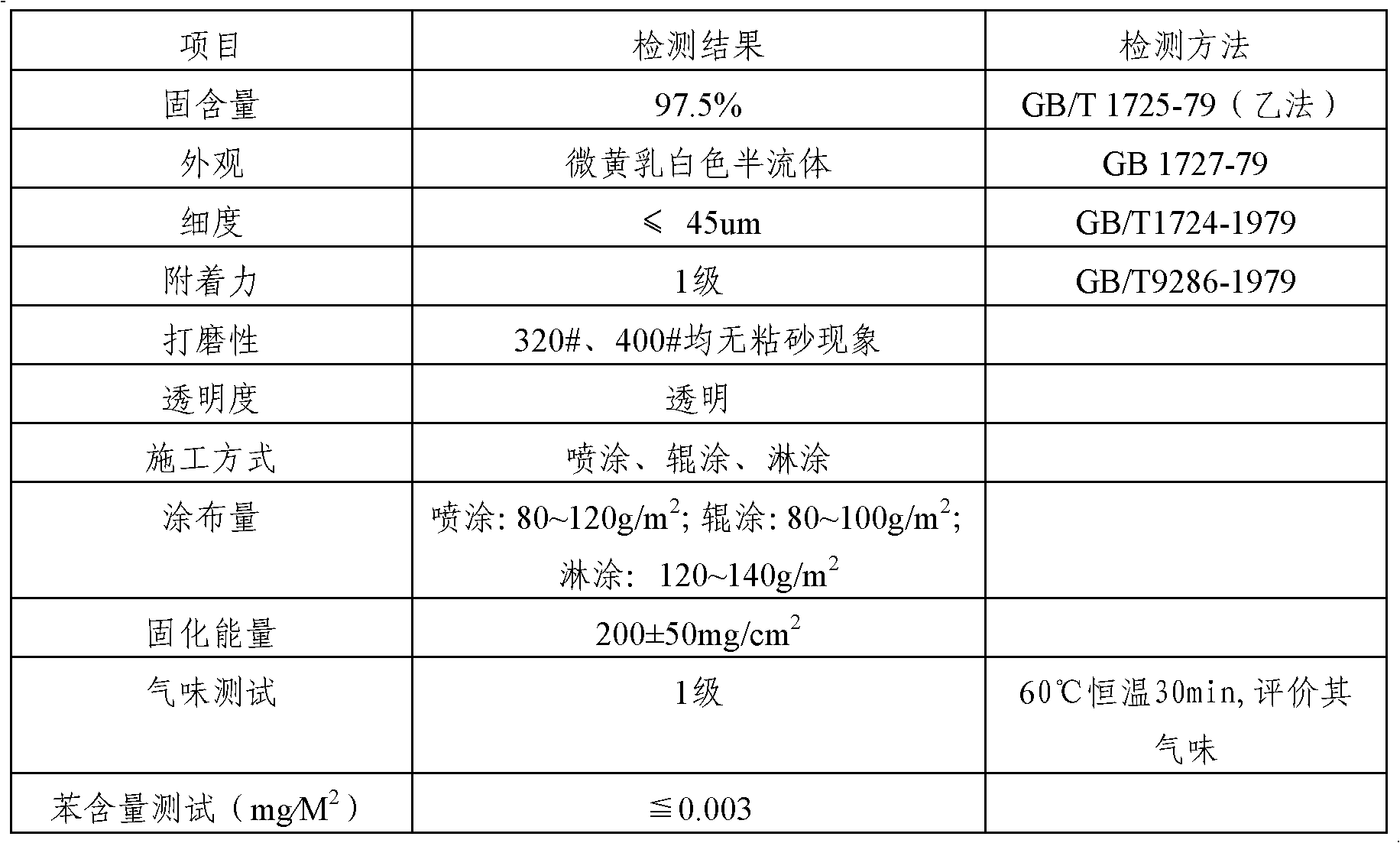

[0070] 3. The detection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com