Lifting repair method for ballastless track with settled curved section

A ballastless track and repair method technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of increased track structure offset and excessive track structure offset, and achieves good environmental performance and high economy. , the effect of efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

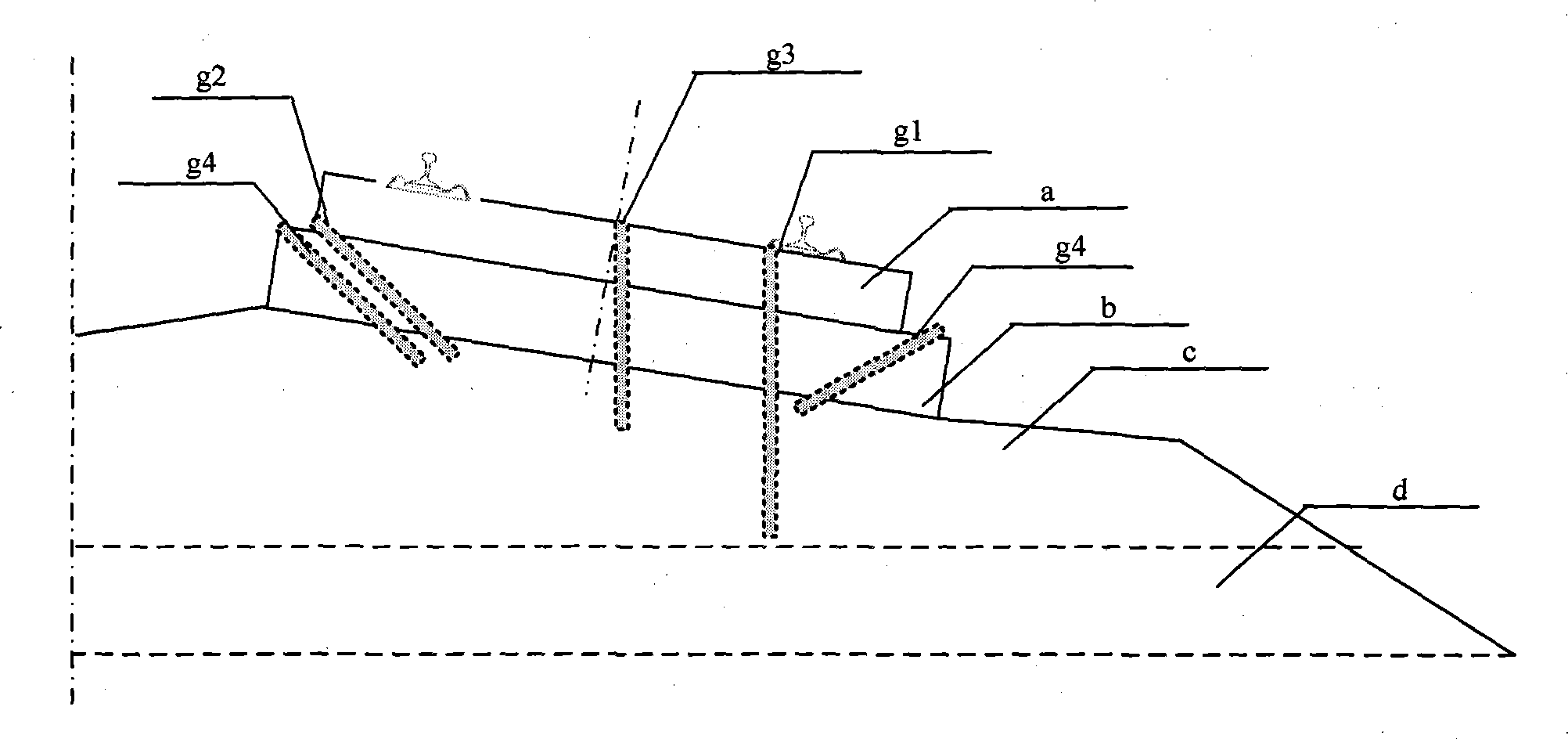

[0036] The embodiment of the present invention provides a grouting and lifting quick repair method and a complete set of construction technology used for the settlement of a curve section of a ballastless track railway.

[0037] (1) Use electronic level and total station to measure the elevation of a line's subsidence ballastless track structure, calculate the required elevation to be 5.5cm, and establish the elevation point monitoring network, and formulate the following elevation plan: use special grouting equipment and The special polyurethane foam material raises the track structure three times, the first two times are designed to raise 2cm, and the third time is 1.5cm. During the lifting process, electronic level and total station are used to monitor the elevation of the track structure in real time.

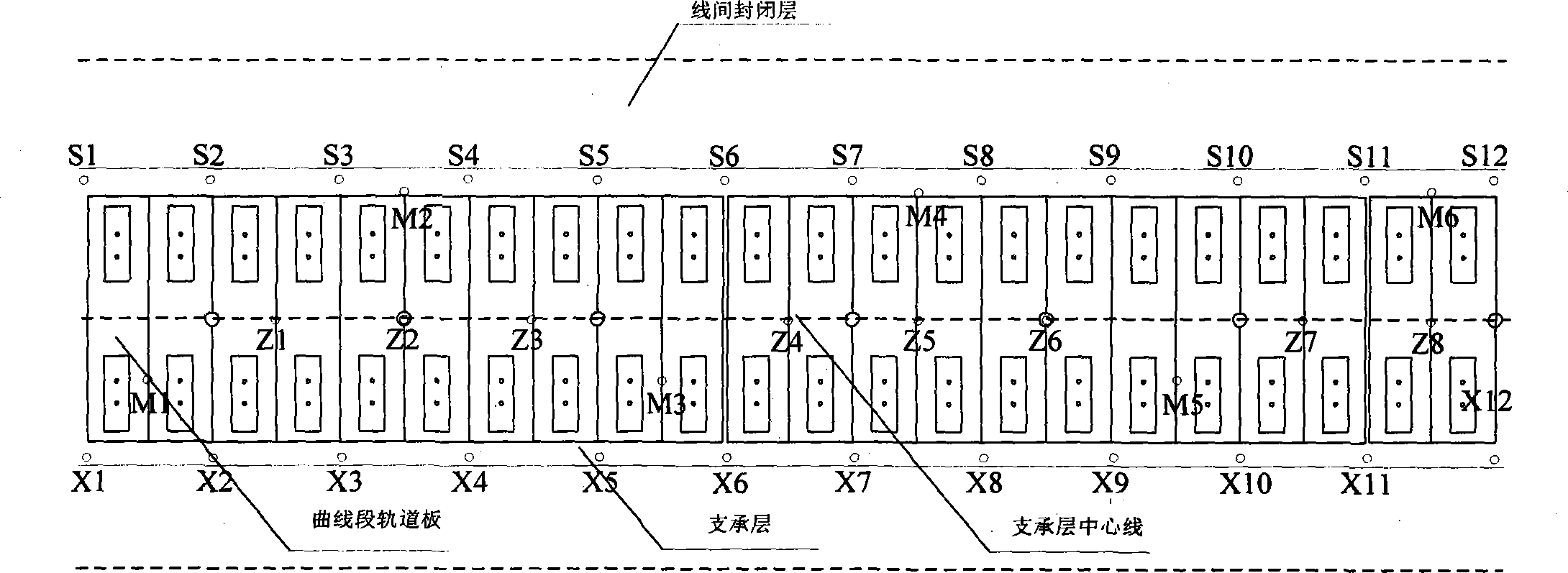

[0038] (2) According to the characteristics of the on-site ballastless track and the survey results, the lifting unit is divided and the grouting hole is arranged. The layout of...

Embodiment 2

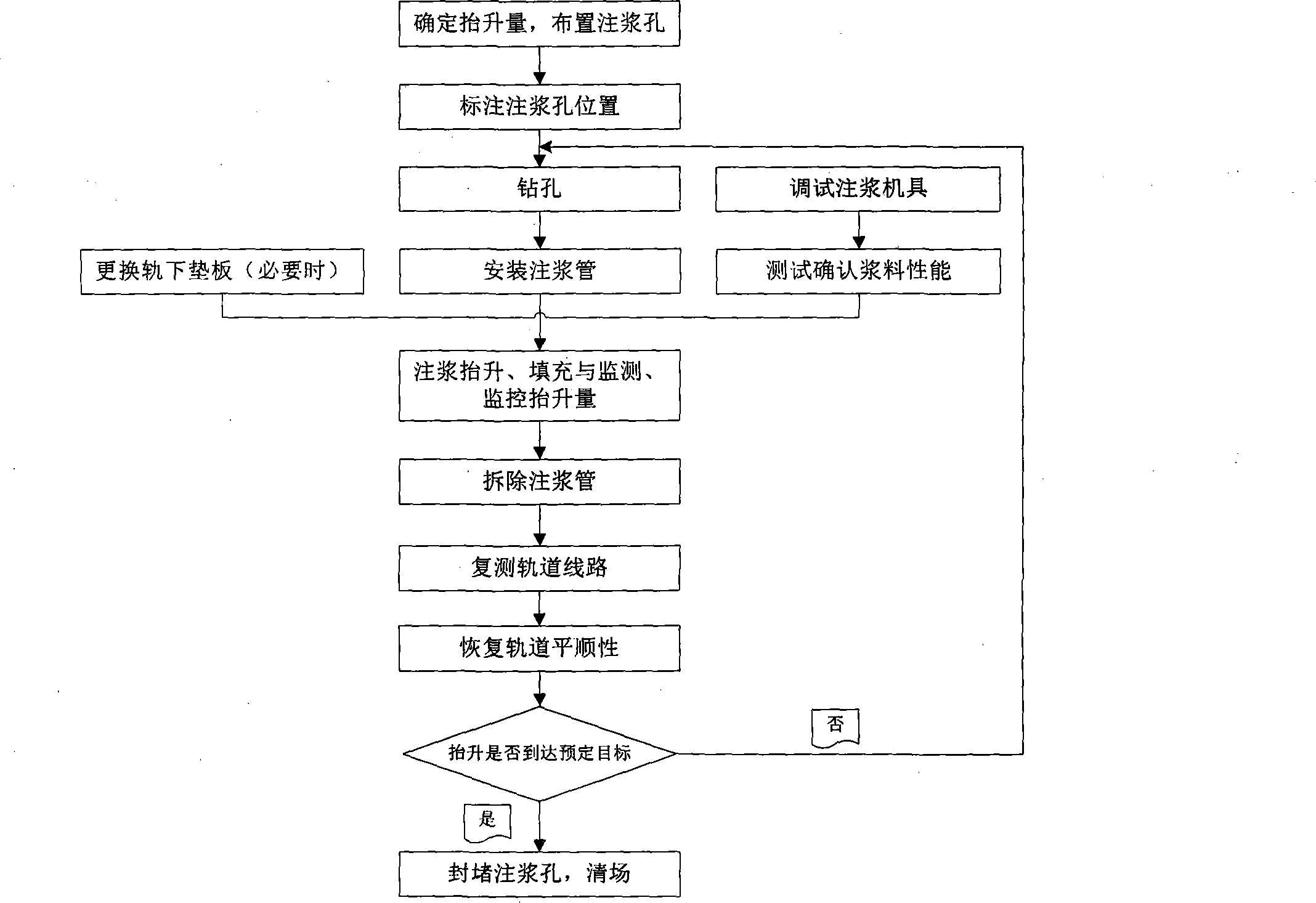

[0048] Such as image 3 As shown, when this embodiment describes grouting and lifting, the construction steps specifically include the following aspects:

[0049] A. Before lifting, use measuring devices such as total station and electronic level to measure the ballastless track structure in the settlement area, and work out the lifting plan of the track structure;

[0050] B. Mark the position of the grouting hole according to the lifting plan, and then implement the drilling. The diameter of the hole is 25mm. After the drilling is completed, the grouting hole is sealed with a plugging piece;

[0051] C. The grouting equipment is installed in place, and the parameters of the grouting equipment are adjusted in time to obtain suitable grouting material performance;

[0052] D. Remove the plugging parts on the upper part of the grouting hole, use a special wrench to quickly install the grouting pipe, and arrange for someone to check the tightness and installation depth of the grouting p...

Embodiment 3

[0058] This embodiment describes that when the grouting material is cement-water glass grouting material, the construction process and corresponding grouting process parameters are specifically as follows.

[0059] The grouting material is a cement-water glass quick-setting and fast-hardening material, with a working time of 30s, and the compressive strength within 1 hour of over 85% of the design strength. The grouting holes are also arranged in the form of plum blossoms, but the spacing of the grouting holes is smaller than that of organic material quick-setting and fast-hardening materials. The lifting hole spacing of the grouting hole is 6.5m, the filling hole spacing is 0.9m, the grouting hole diameter is 4cm, the inner diameter of the grouting pipe is 3cm, and the lower part of the grouting pipe goes deep into the lower part of the ballastless track bed. 5cm below the surface of graded gravel.

[0060] The grouting process parameters of the grouting equipment are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com