Removing tool and removing method of indoor ultrahigh assembly-type steel structure support system

A support system and demolition tool technology, applied in the track system, transportation and packaging, building construction, etc., can solve the problems of inability to use large-scale mechanical lifting equipment, limited operating space, etc., and achieve the effect of efficient demolition and lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

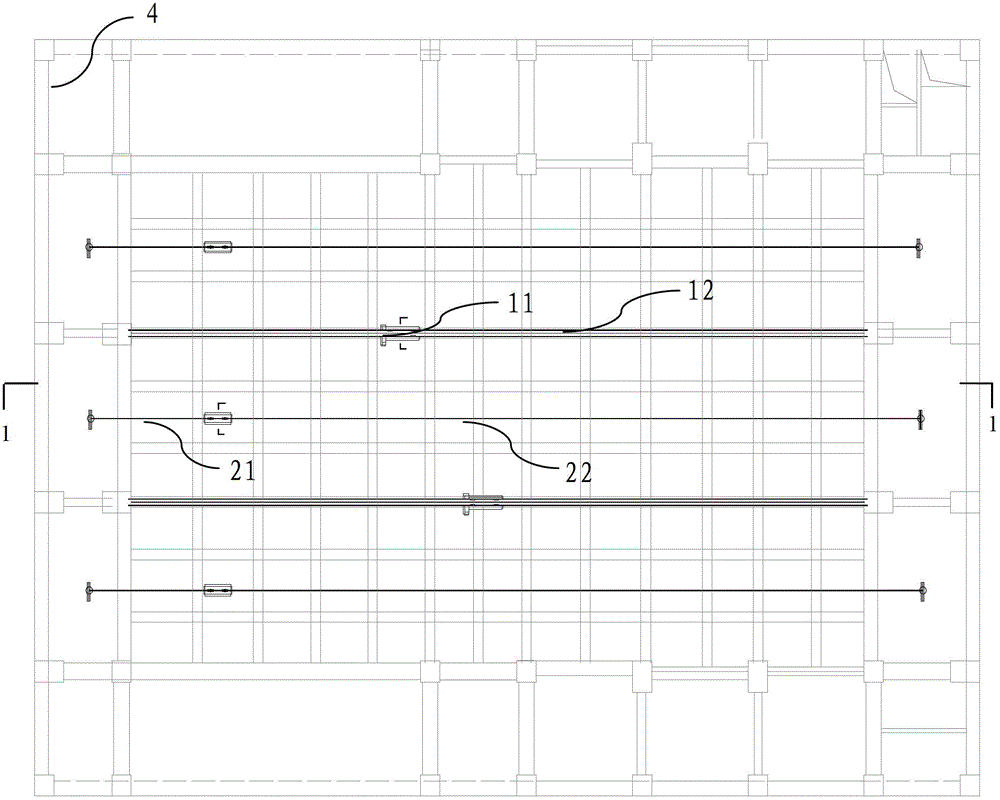

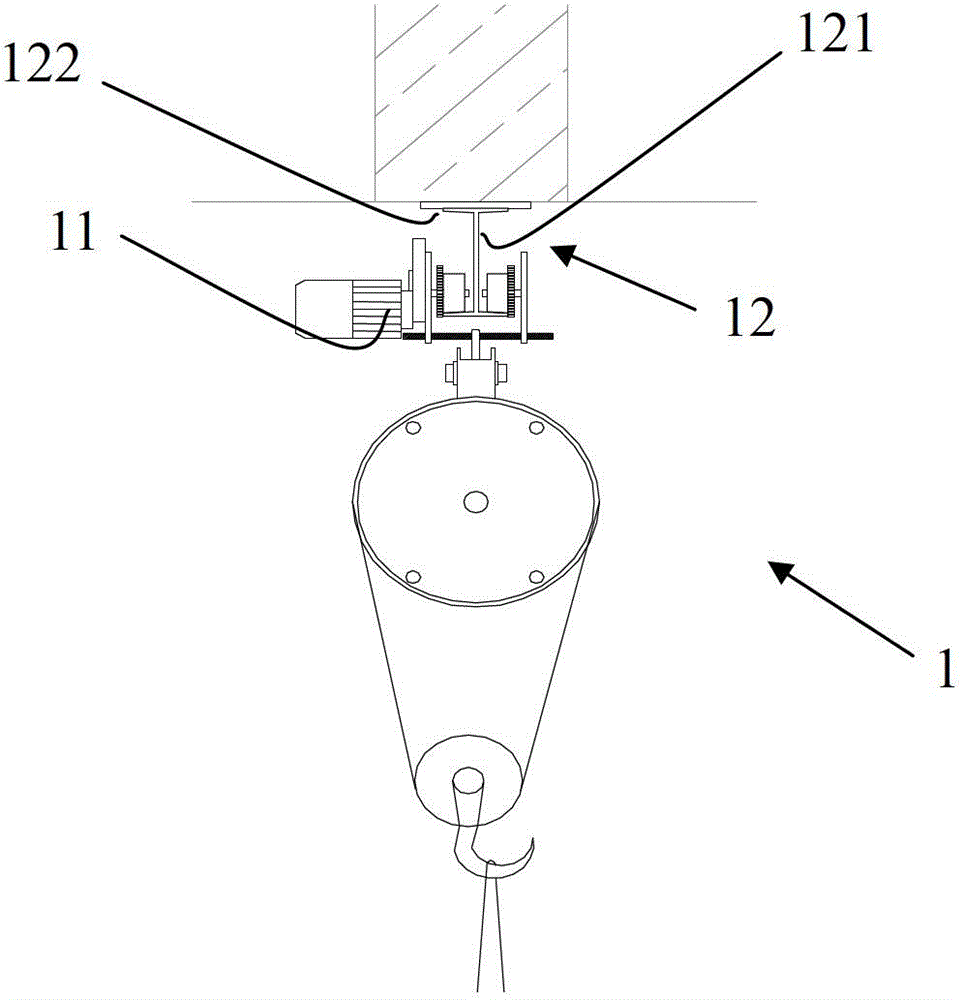

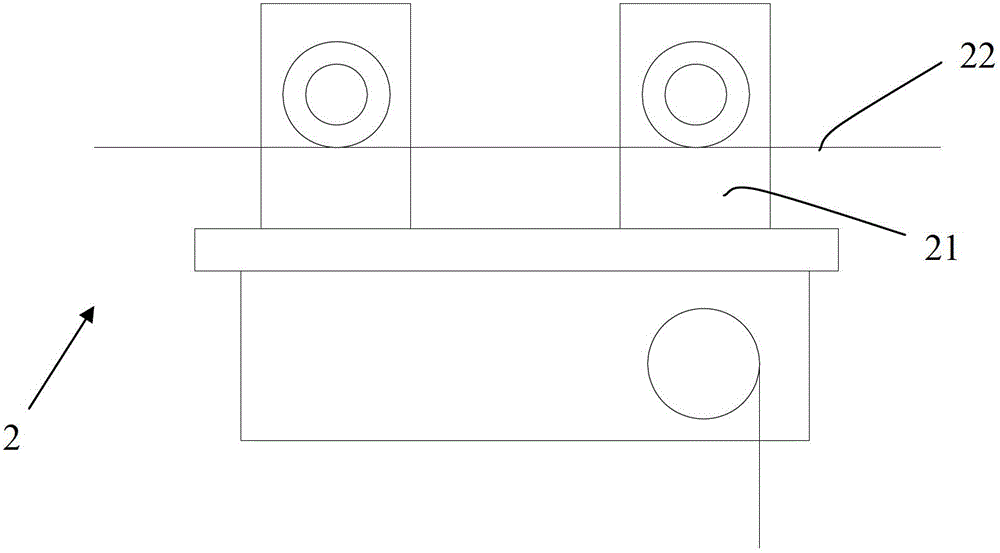

[0033] to combine Figure 1 to Figure 4 As shown, a demolition tool for an indoor ultra-high and large-scale assembled steel structure formwork support system of the present invention includes a first demolition unit 1 and a second demolition unit 2 arranged at intervals between the roof top plate and the bottom of the beam, and the first demolition unit 1 includes a non-standard electric hoist 11 and a pre-embedded rigid rail 12, the rigid rail 12 is formed by welding the I-beam 121 and the pre-embedded plate 122, and the non-standard electric hoist 11 is slid on the rigid rail 12, the second removal unit 2 Including hoist 21 and flexible track 22, the flexible track 22 is formed by tying the steel wire rope 221 and the manual hoist 222, the flexibility of the steel wire rope 221 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com