Beam bottom formwork detaching mechanism and beam bottom formwork detaching method

The technology of bottom formwork and steel formwork is applied in the field of beam bottom formwork dismantling mechanism, which can solve problems such as poor construction quality, and achieve the effects of fast construction speed, improvement of removal efficiency and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

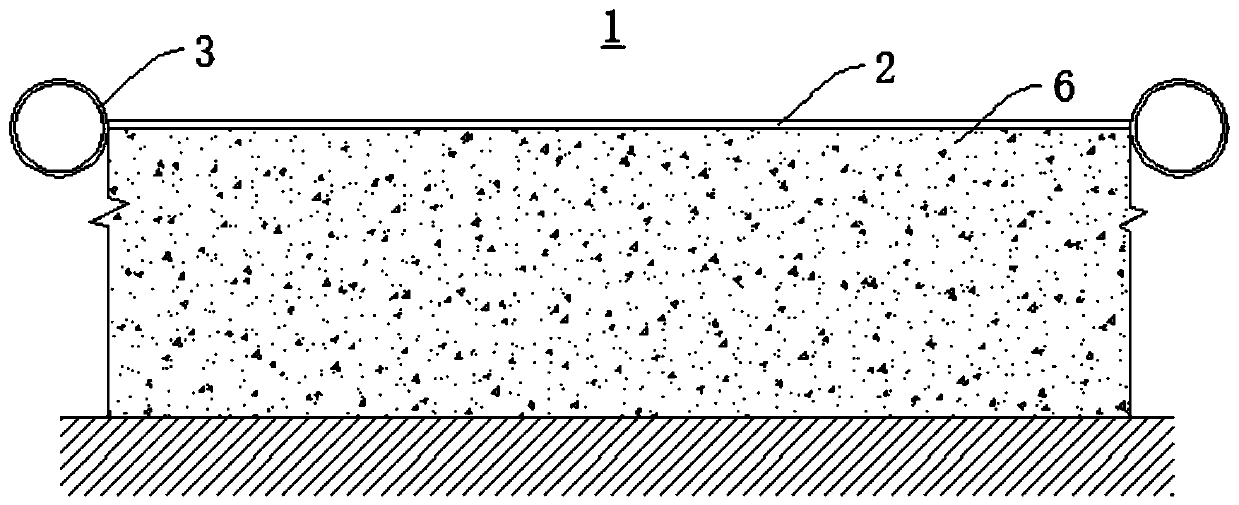

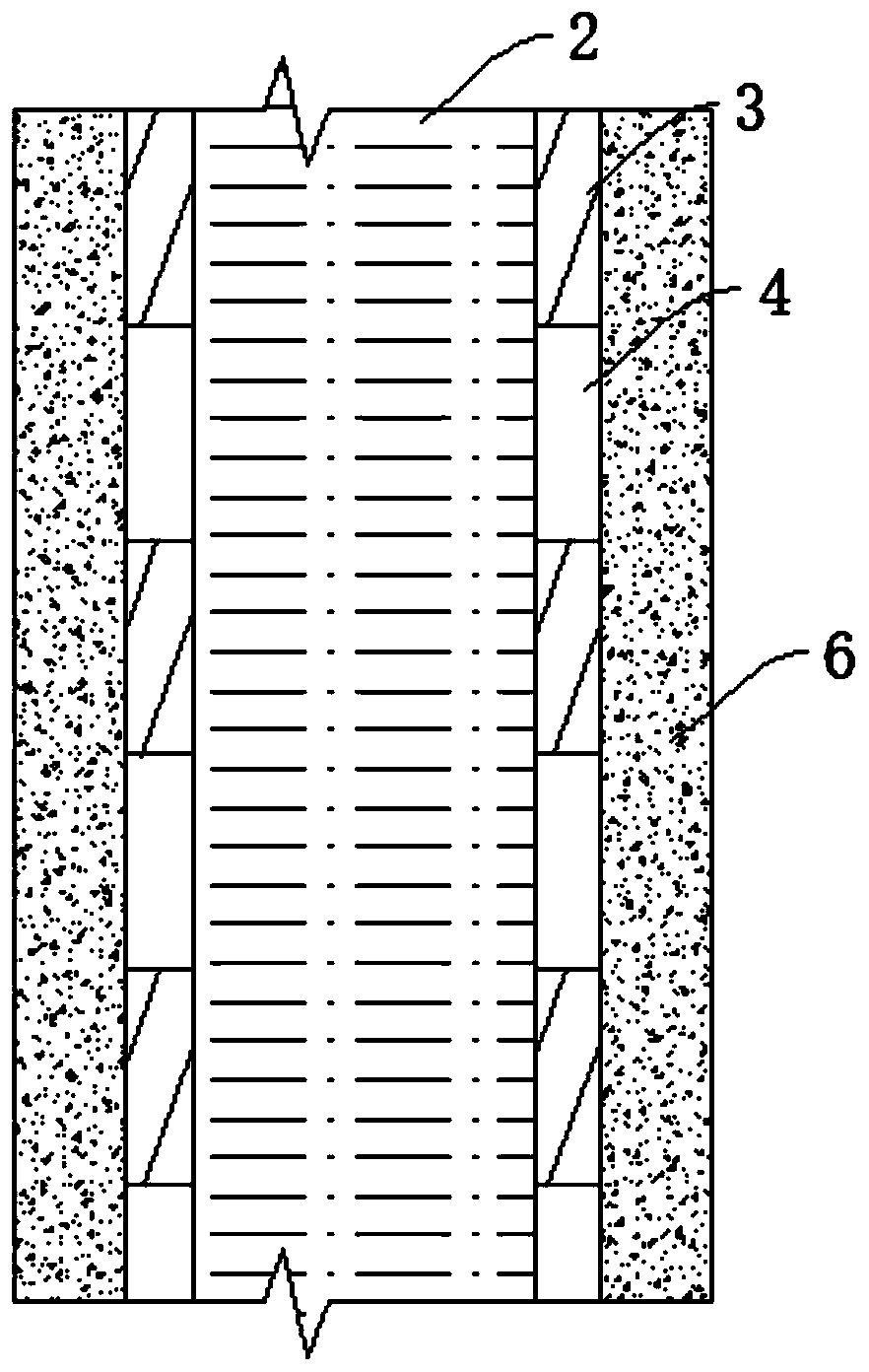

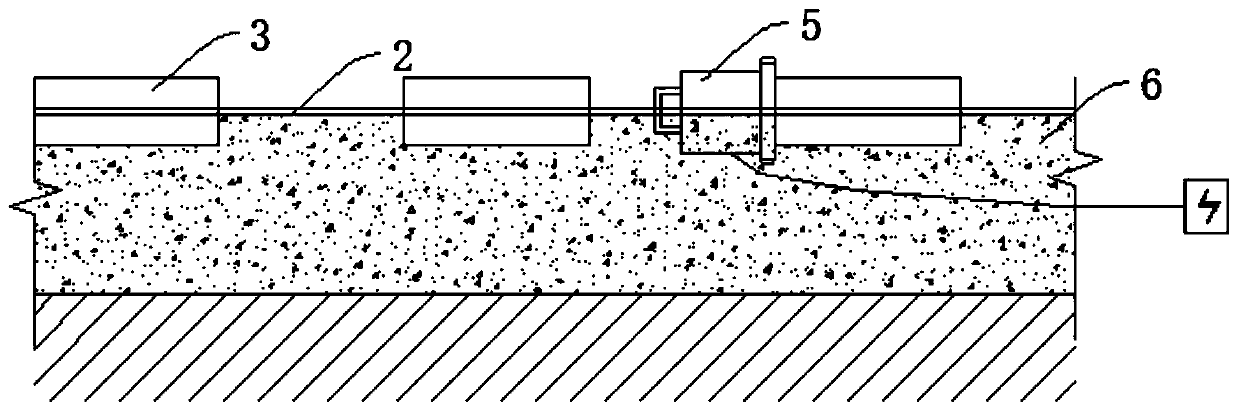

[0037] Please refer to figure 1 , with reference to figure 2 and image 3 , the present application provides a beam bottom formwork removal mechanism 1, which includes a beam lower steel formwork 2 arranged on a concrete cushion 6, a plurality of vibration steel sleeves 3 and a plurality of vibration assemblies 5, and the opposite two sides of the beam lower steel formwork 2 A plurality of vibrating steel sleeves 3 arranged at intervals are respectively installed on the sides, and there is a static space 4 between adjacent vibrating steel sleeves 3; The connection is vibrated correspondingly, so that the concrete cushion 6 near the position of the steel formwork 2 under the beam falls off and is removed.

[0038] It should be noted that, in this embodiment, a plurality of vibrating steel sleeves 3 are sequentially arranged at intervals along the length direction of the steel formwork 2 under the beam.

[0039]It should be noted that, in this embodiment, the intervals betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com