Patents

Literature

271results about How to "Improve construction conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-proof acid resistant heat resistant light heat insulating casting material and its manufacturing method

InactiveCN1537821AReduce intensityGood impermeability and antifreeze performanceSolid waste managementCeramic shaping apparatusHigh resistancePolymer science

A water-proof light-weight insulating casting material resisting acid and high temp for the liner of chimney is prepared from the inorganic light aggregate particles resisting acid and high temp, the acid and high temp resistant powder, the acid and high temp resistant adhesive and additive through proportional mixing, stirring, casting in mould for 1-5 days, demoulding, and natural drying and curing. Its advantages are high volume density and strength, light weight and high resistance to water, acid and high temp.

Owner:张东辉 +1

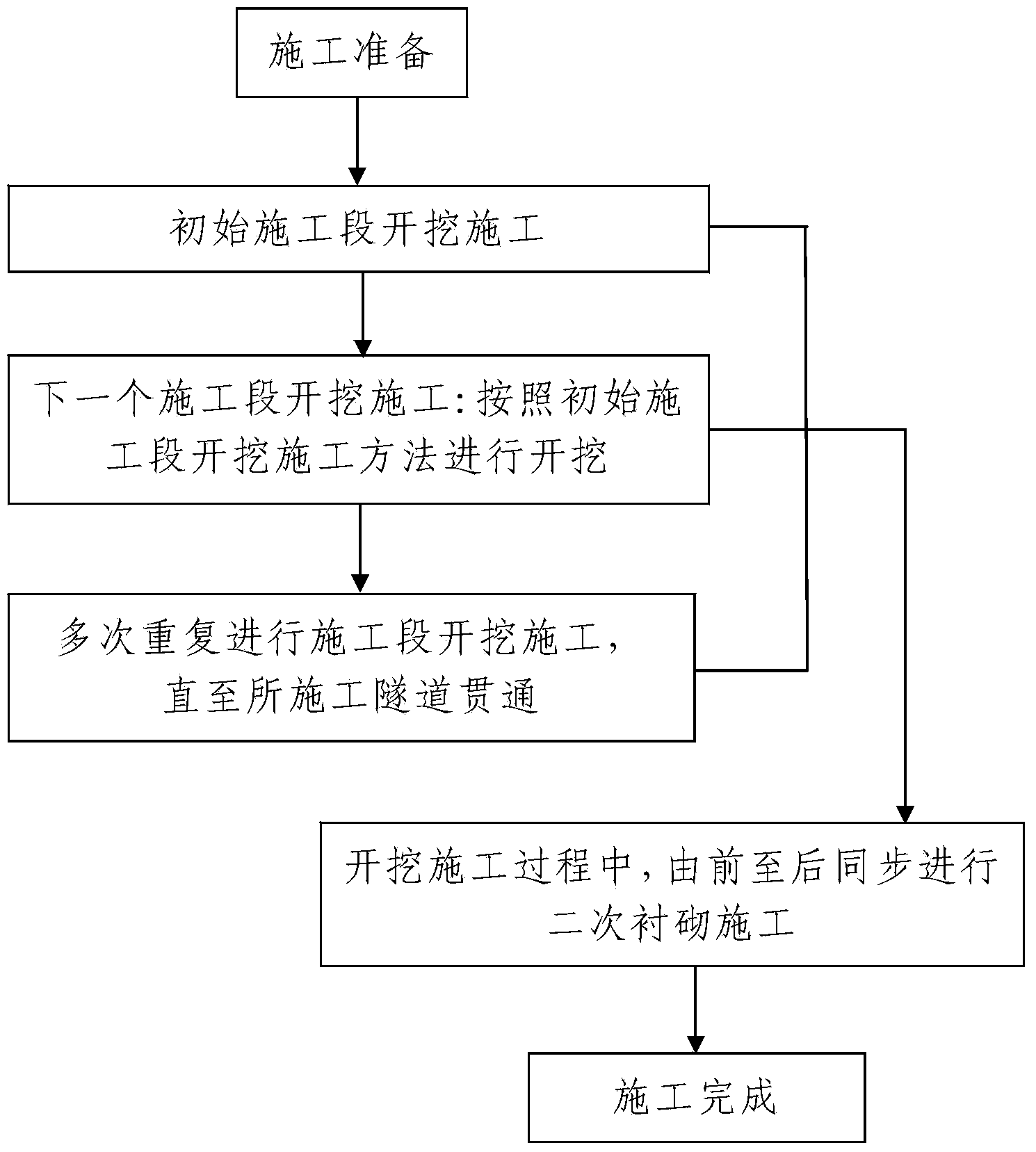

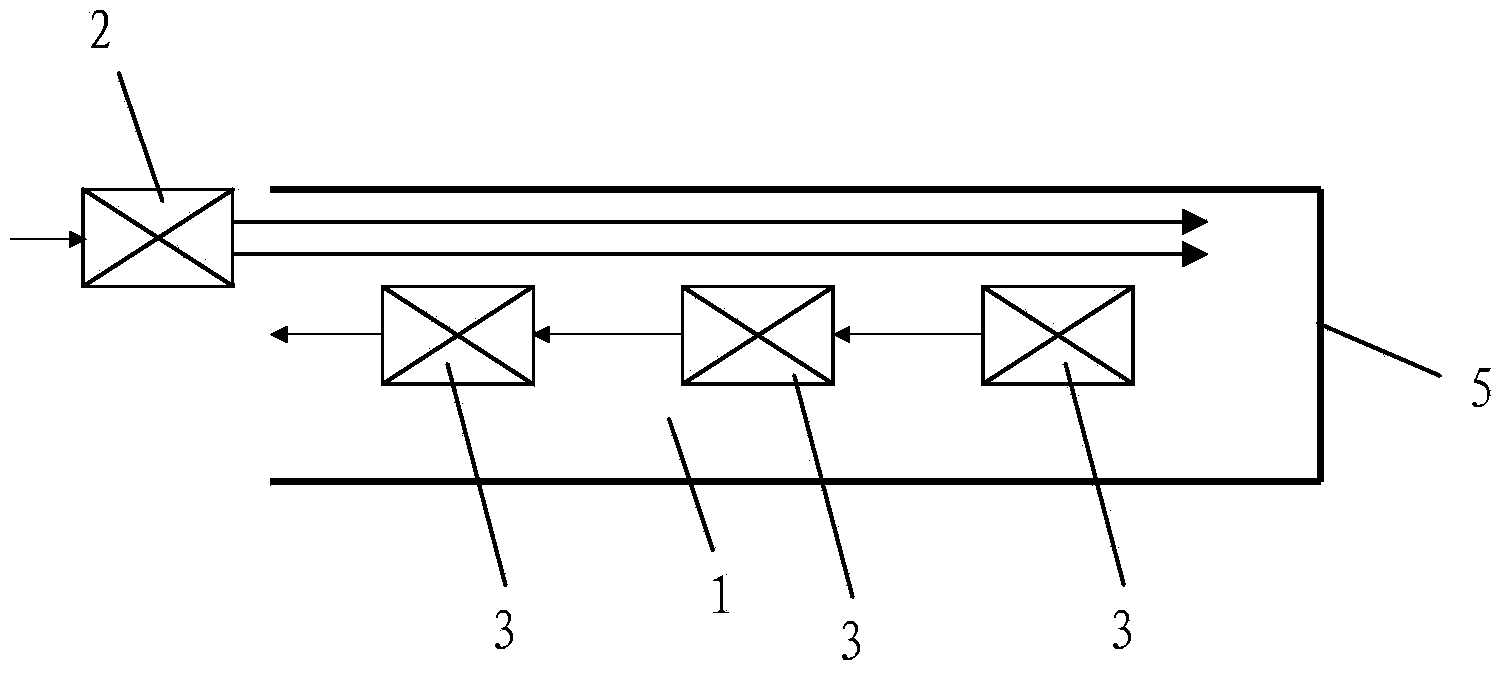

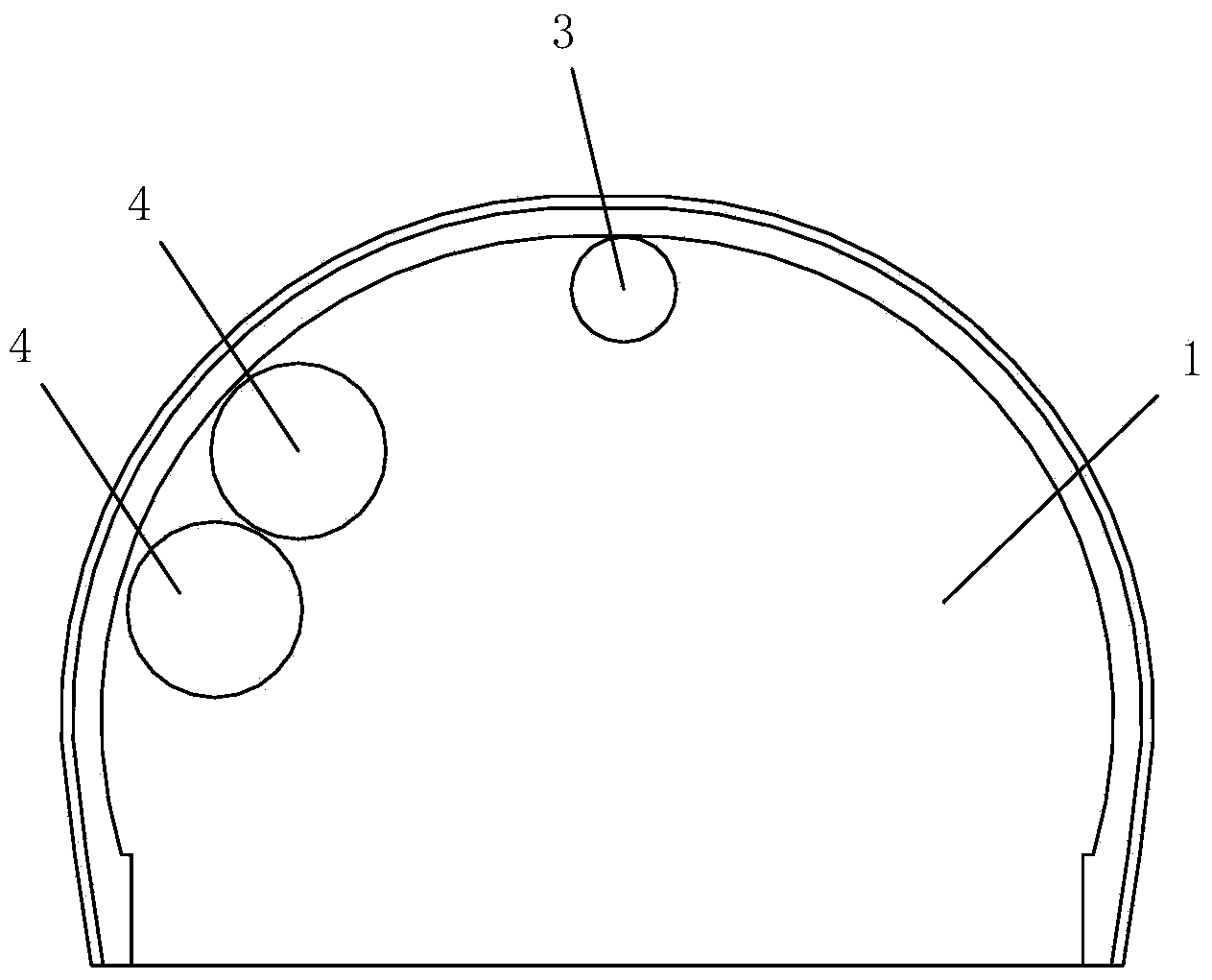

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

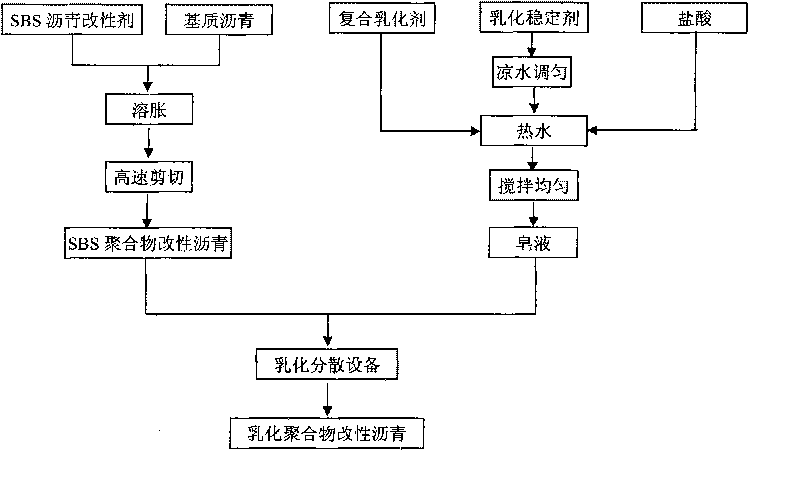

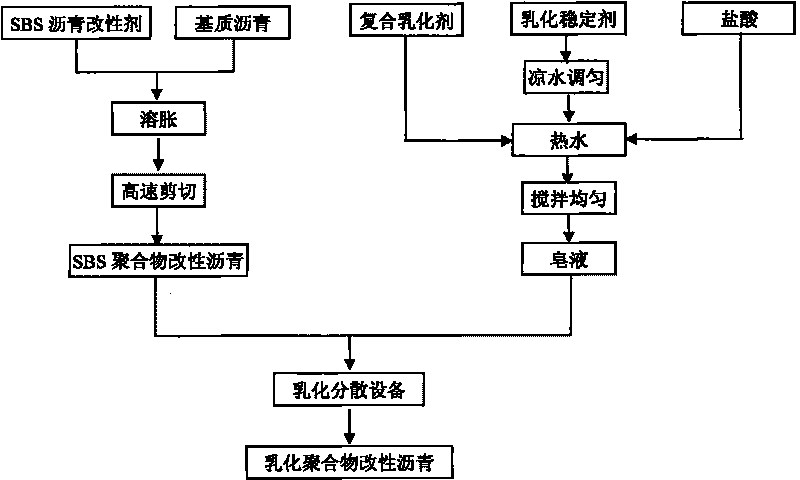

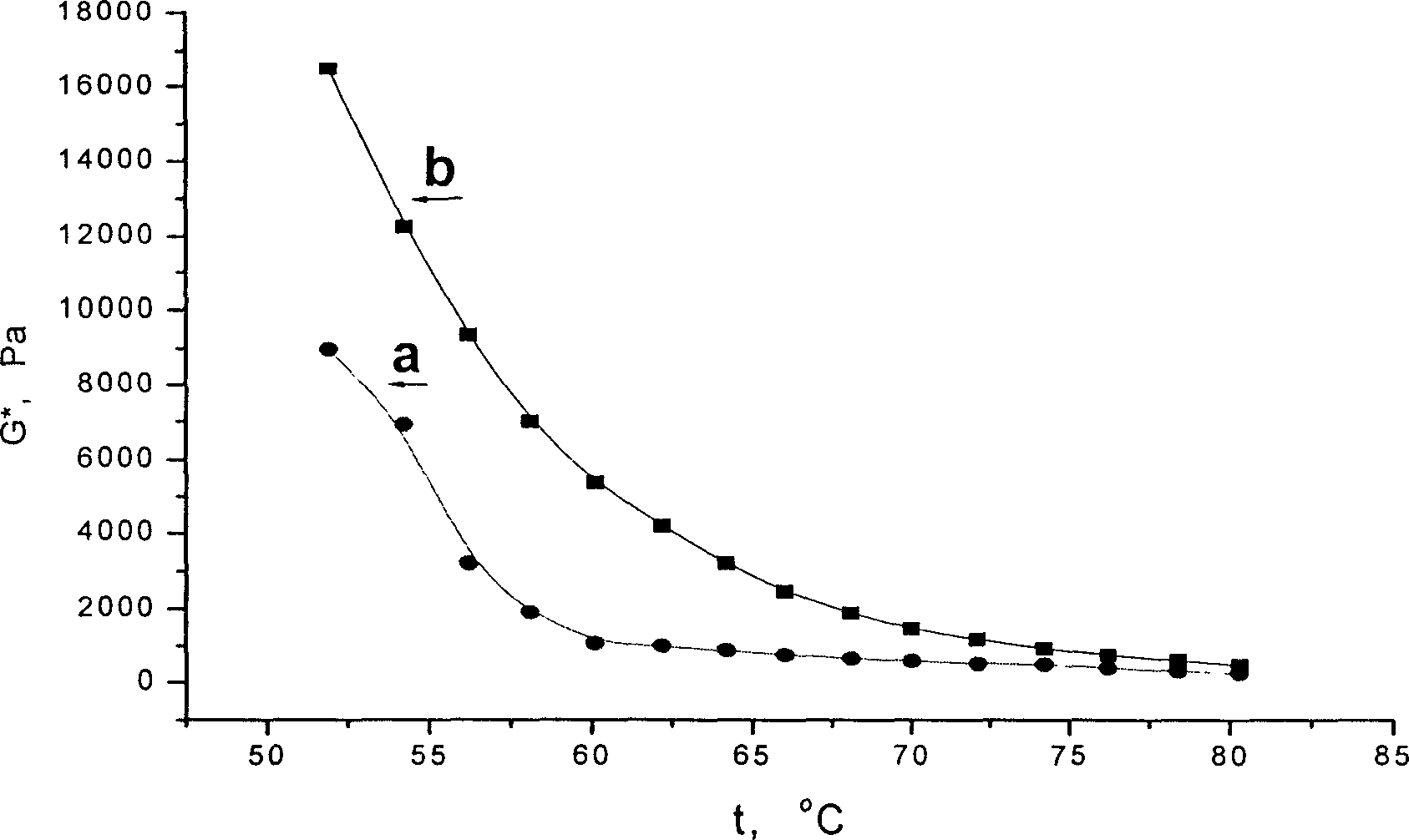

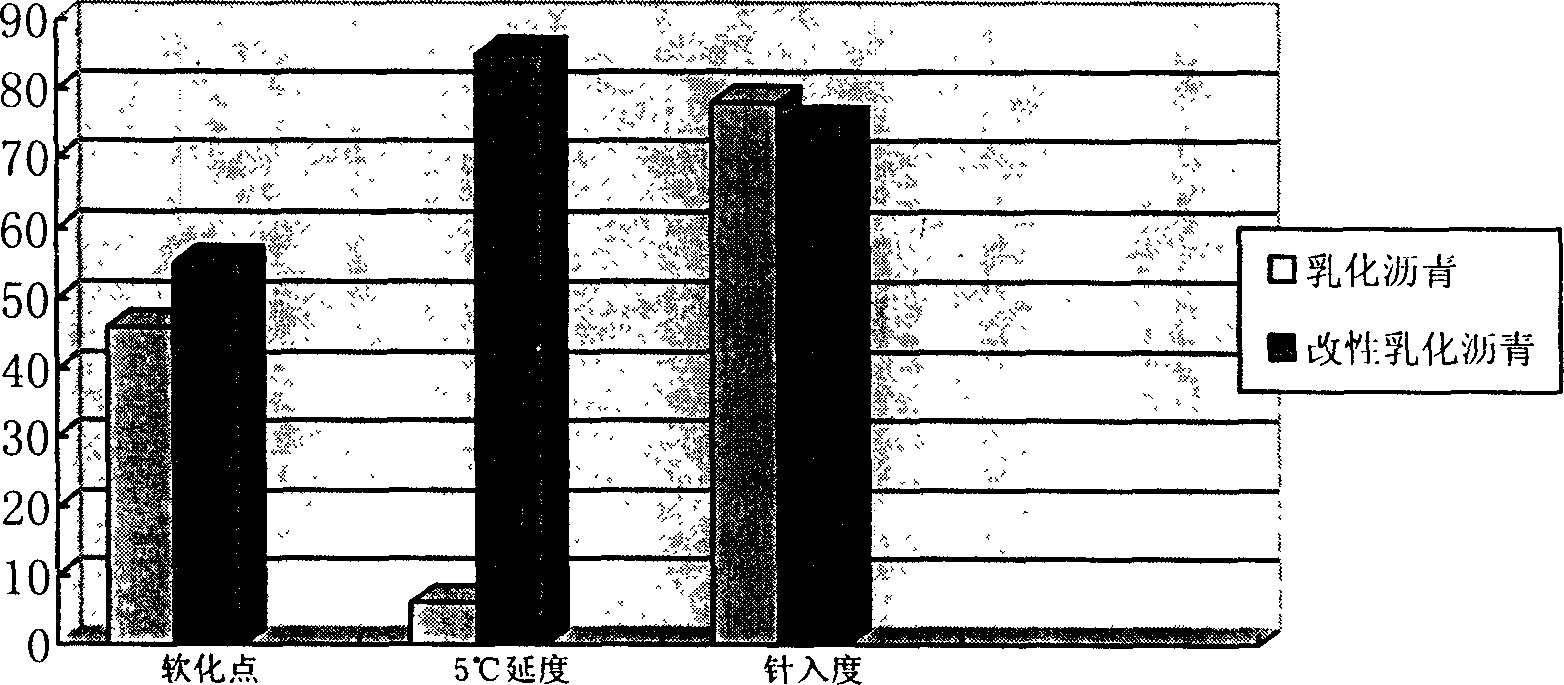

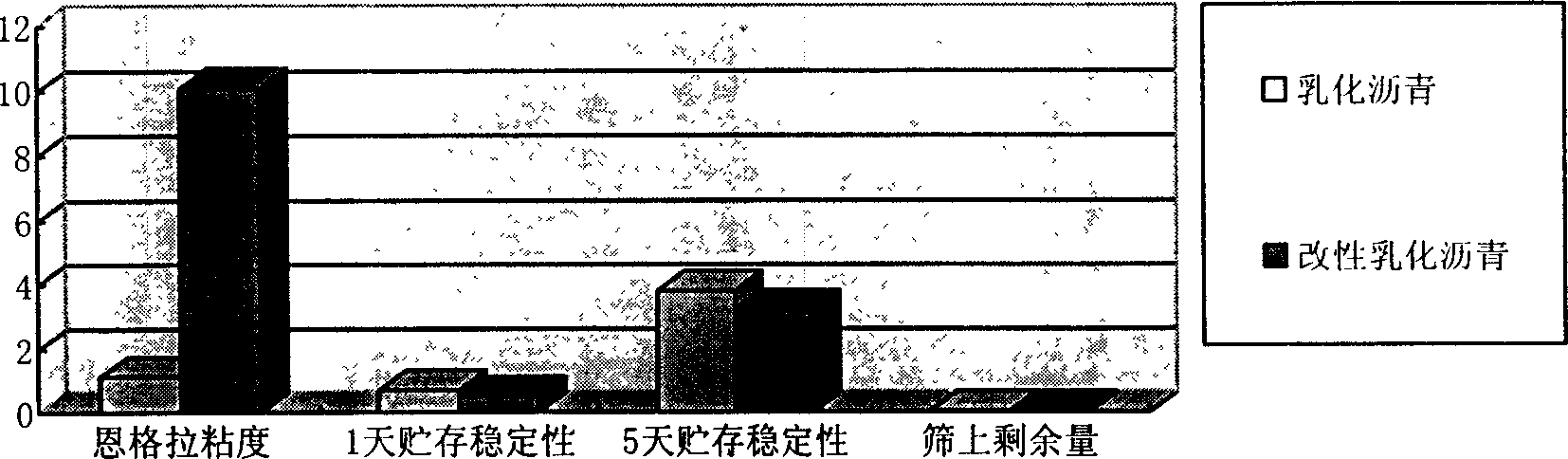

Emulsified SBS polymer modified asphalt and preparation method thereof

InactiveCN101717585AImprove performanceReduce the difficulty of productionClimate change adaptationBuilding insulationsPolymer scienceHigh-speed grinding

The invention relates to an emulsified SBS polymer modified asphalt and preparation method thereof. At present, emulsification and emulsified modified asphalt applied to surfacing is hard to produce and not stable in quality, high temperature performance improvement is not obvious. The raw materials of the invention are matrix asphalt, water, SBS asphalt modifier, compound asphalt emulsifier, emulsification stabilizer and hydrochloric acid; firstly the matrix asphalt is heated, added with SBS asphalt modifier and then stirred to be swelled, high speed grinding by colloid grinder and full dispersion are carried out, and heat preservation growth is carried out to obtain SBS modified asphalt; compound asphalt emulsifier is added into water, emulsification stabilizer smoothened by water in advance is added, and appropriate hydrochloric acid is added to adjust pH value, so as to obtain liquid soap; and finally the SBS modified asphalt is subject to temperature reduction and then mixed with the liquid soap and emulsification dispersion is carried out, thus obtaining emulsified SBS polymer modified asphalt. The invention is applicable to coat tacking, coat sealing, surface treatment, slurry sealing and asphalt pavement recycling, asphalt wet-mixing of road construction and cerement asphalt mortar layer of passenger special line plate type unballasted track.

Owner:深圳路安特沥青高新技术有限公司

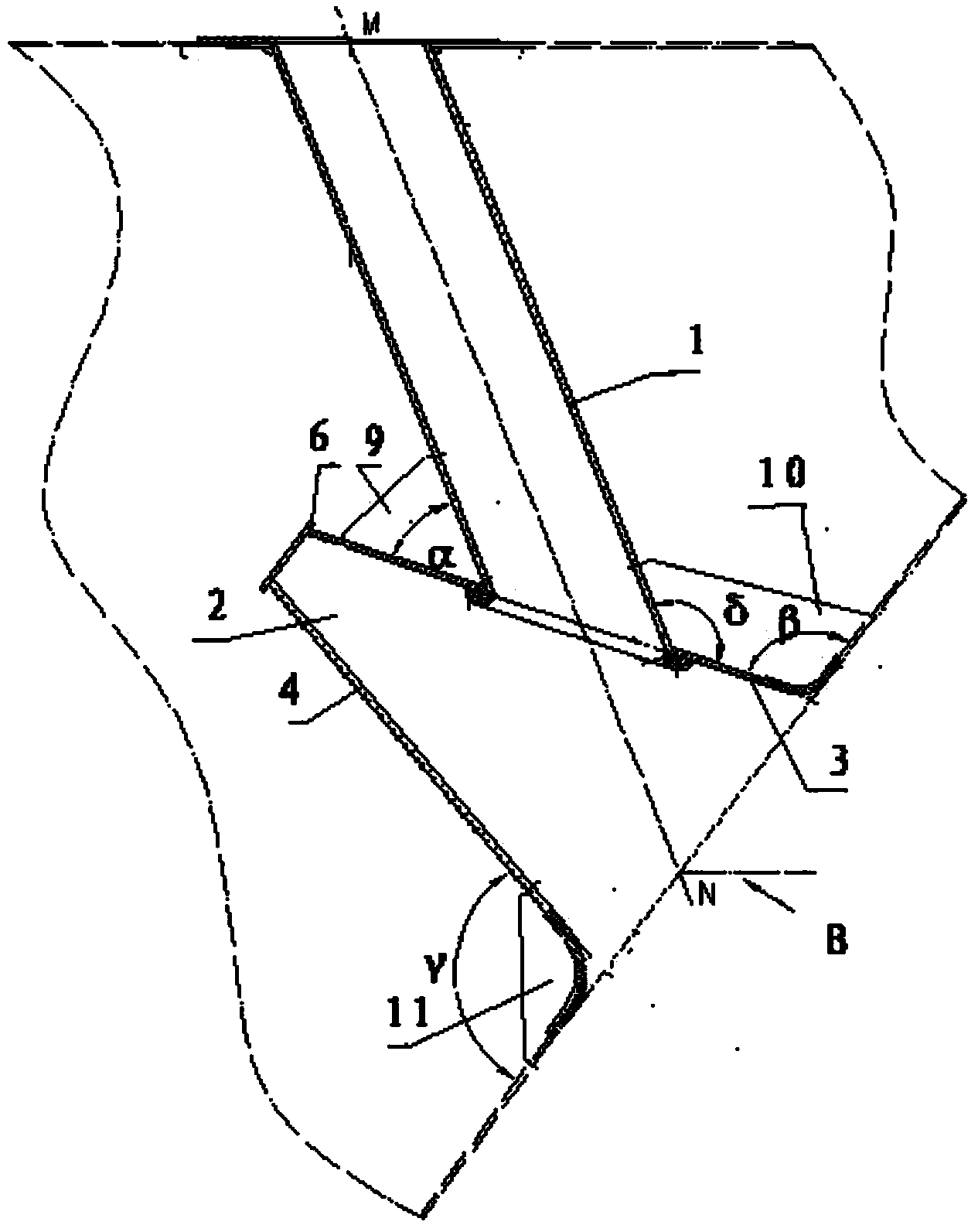

High precision welding method for rudder horn, propeller shaft bracket and intermediate shaft bracket of long shaft ship

InactiveCN102059461AImprove construction conditionsGuaranteed installation accuracyVessel partsWelding apparatusPropellerControl theory

The invention discloses a high precision welding method for a rudder horn, a propeller shaft bracket and an intermediate shaft bracket of a long shaft ship, belonging to the field of ship welding. In the high precision welding method, a shaft center line of the ship is firstly pulled out according to design requirements when the ship is assembled and installed; after the shaft center line is examined, the following three steps are synchronously carried out: firstly, welding of the rudder horn; secondly, the welding of the propeller shaft bracket; and thirdly, the welding of the intermediate shaft bracket. Compared with the prior art, because installation phases of the propeller shaft bracket and the intermediate shaft bracket are advanced to the assembling phase, the construction condition is improved, and the installation precision is ensured; and because the complete cross section of a ship body is horizontally assembled (the complete cross section is the propeller shaft bracket which is reversely placed, and the intermediate shaft bracket is over the intermediate shaft bracket), the installation position can be adjusted by fully utilizing a crane when the ship body is installed, the working efficiency is improved, and the utilization time of a dock is greatly reduced.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

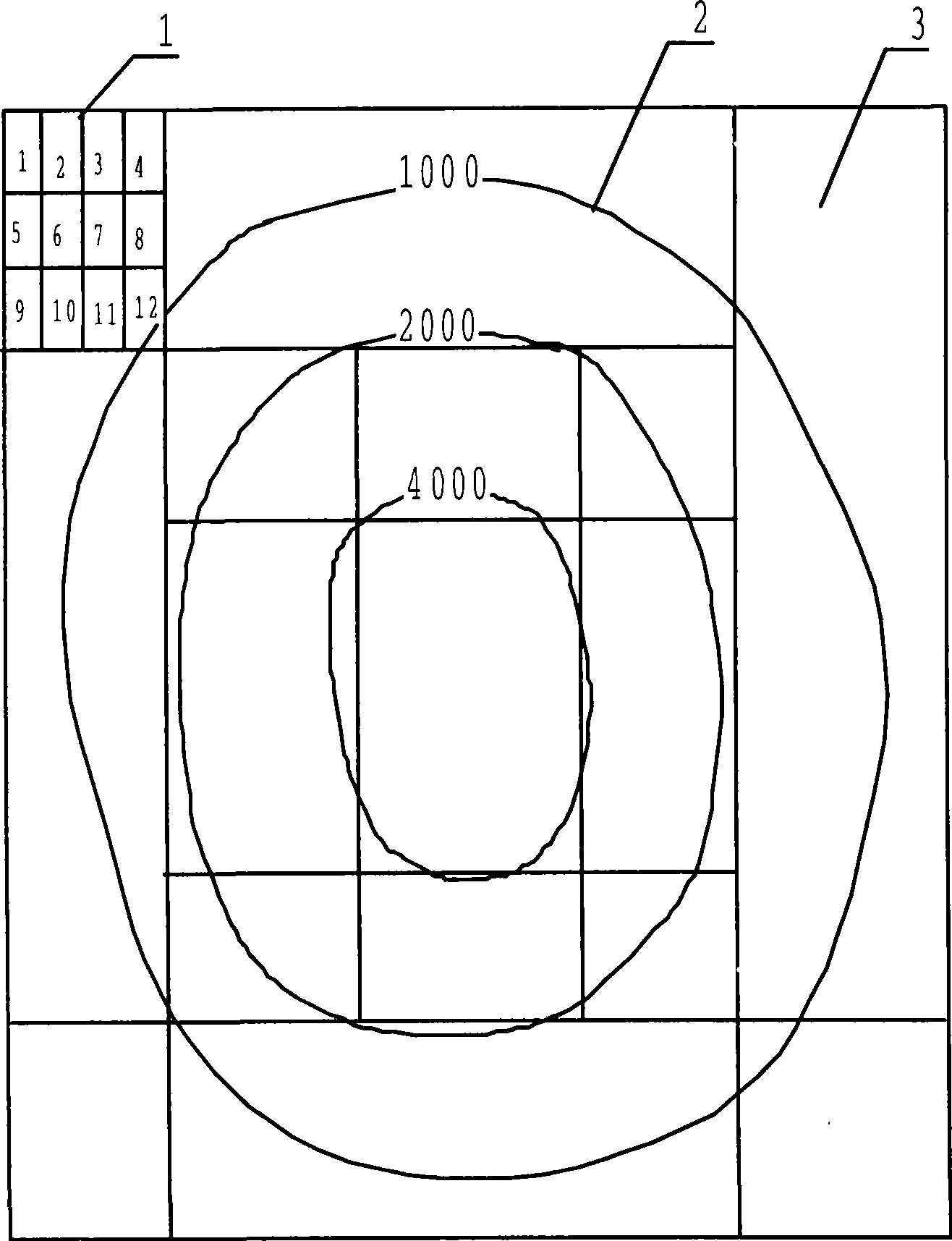

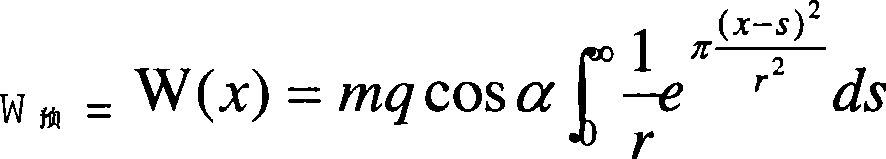

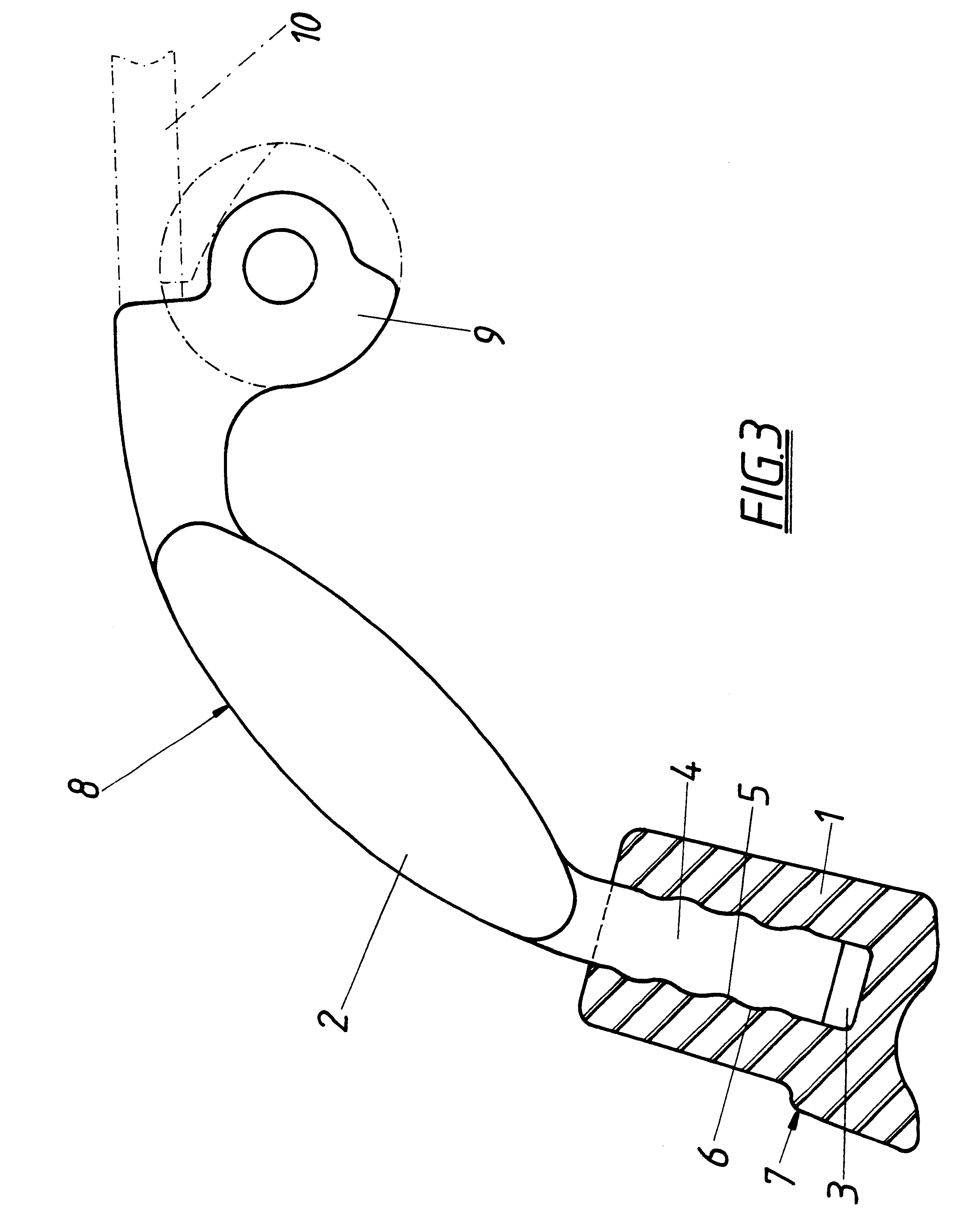

Thick-bed mining subsidence-land dynamic pre-reclamation method at plane mining-area

InactiveCN101422094AAchieve sustainable developmentConducive to sustainable useClimate change adaptationSoil-working methodsVegetationLand resources

The invention discloses a dynamic pre-reclamation method for subsided land caused by exploiting a high seam in a plane mining area, which belongs to the technical field of mining and is used for solving the land reclamation problem of the subsided land caused by unstable subsidence mining. The dynamic pre-reclamation method is carried out when a mining subside is not complete and seeper is not formed; the dynamic pre-reclamation method consists of two stages: engineering design calculation and engineering implementation according to the scale, range and target needed to be reclaimed. The stage of engineering design calculation comprises the steps of: calculating a predicated subsidence, dividing the construction field pieces, confirming the construction parameters and the like. Compared with the prior art of 'first destroying and then controlling', the dynamic pre-reclamation method has the following advantages that the dynamic pre-reclamation realizes the full and effective combination of miming and reclamation, can reduce the reclamation investment, shorten the reclamation period, increase the reclamation benefit, and can promote the sustainable utilization of land resources in a mining area and the sustainable development of the mining area, can effectively ease the deterioration of the ecological environment in the mining area caused by the vegetation deterioration due to the mining subsidence and water and soil loss and most extensively protect the land resources.

Owner:TANGSHAN BRANCH COAL SCI ACAD

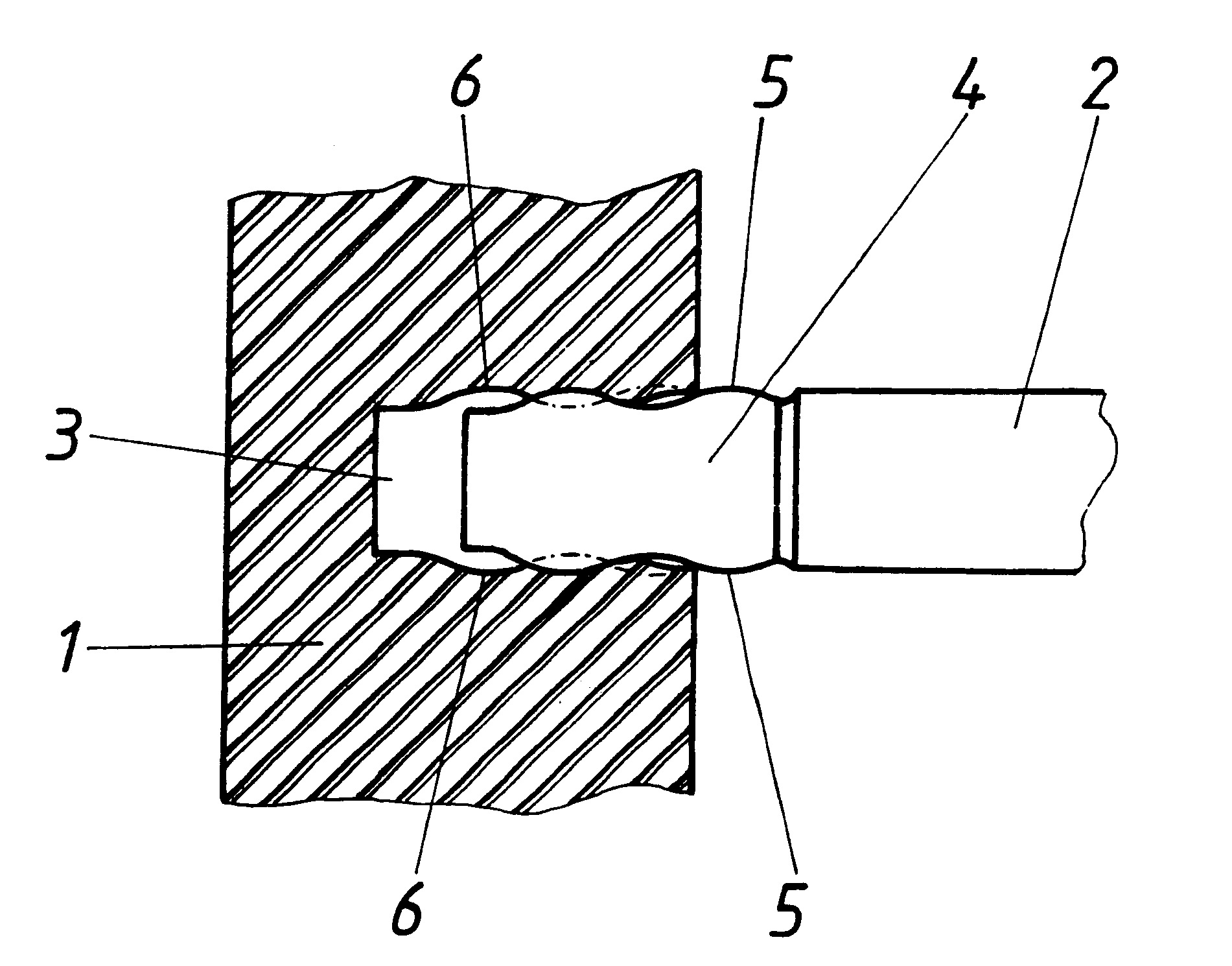

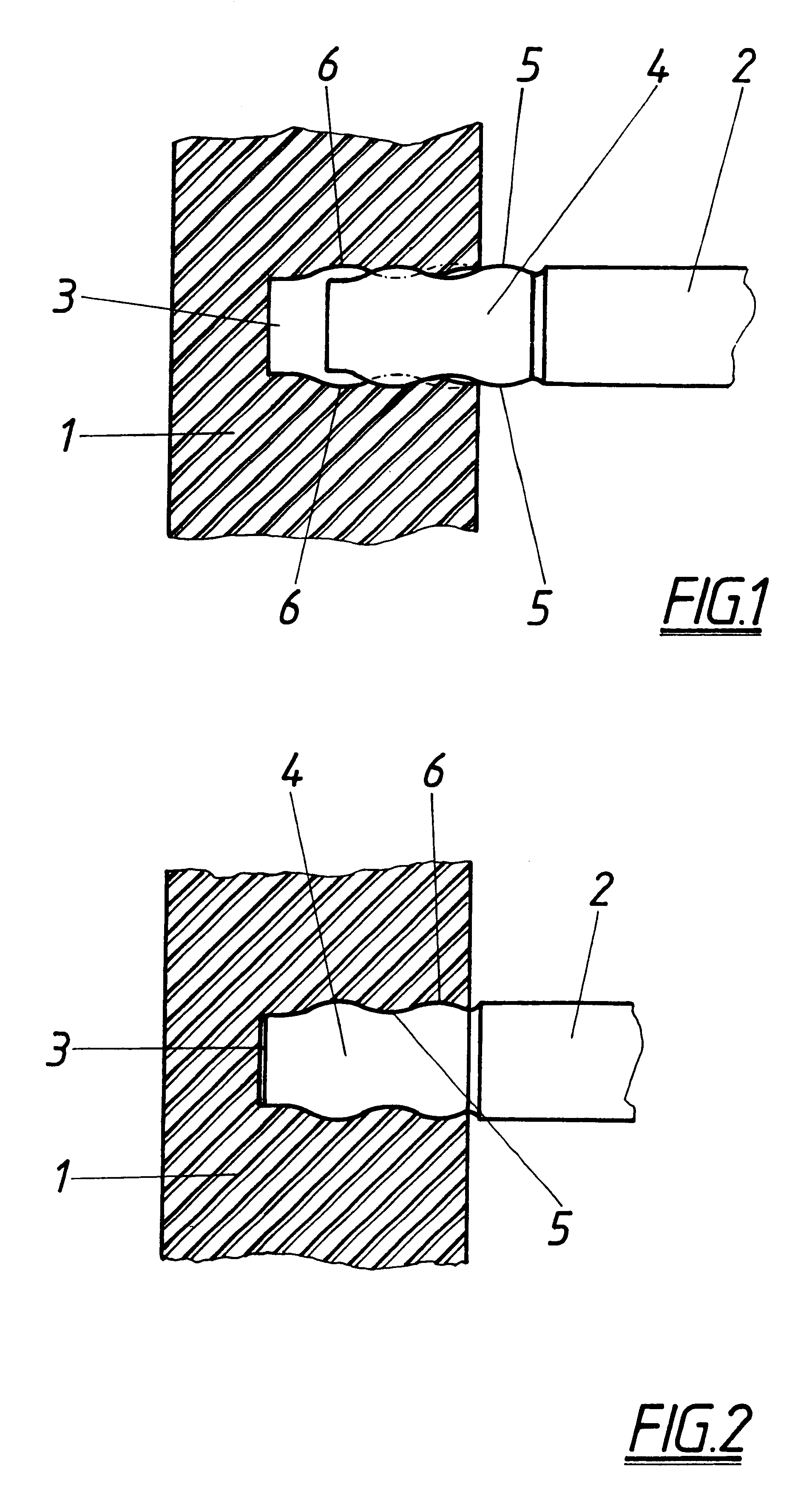

Positive-fit connection between a metallic link and an injection-moulded plastic part notably for spectacles

InactiveUS6357873B1Advantageously producedEfficient retentionShrinkage connectionsNon-optical partsMating connectionEngineering

Owner:SILHOUETTE INT SCHMIED

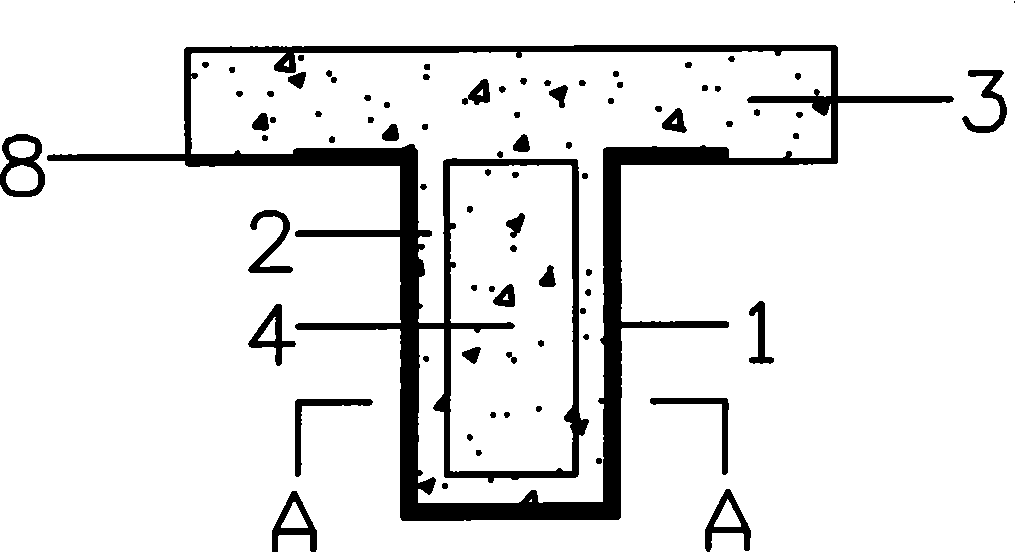

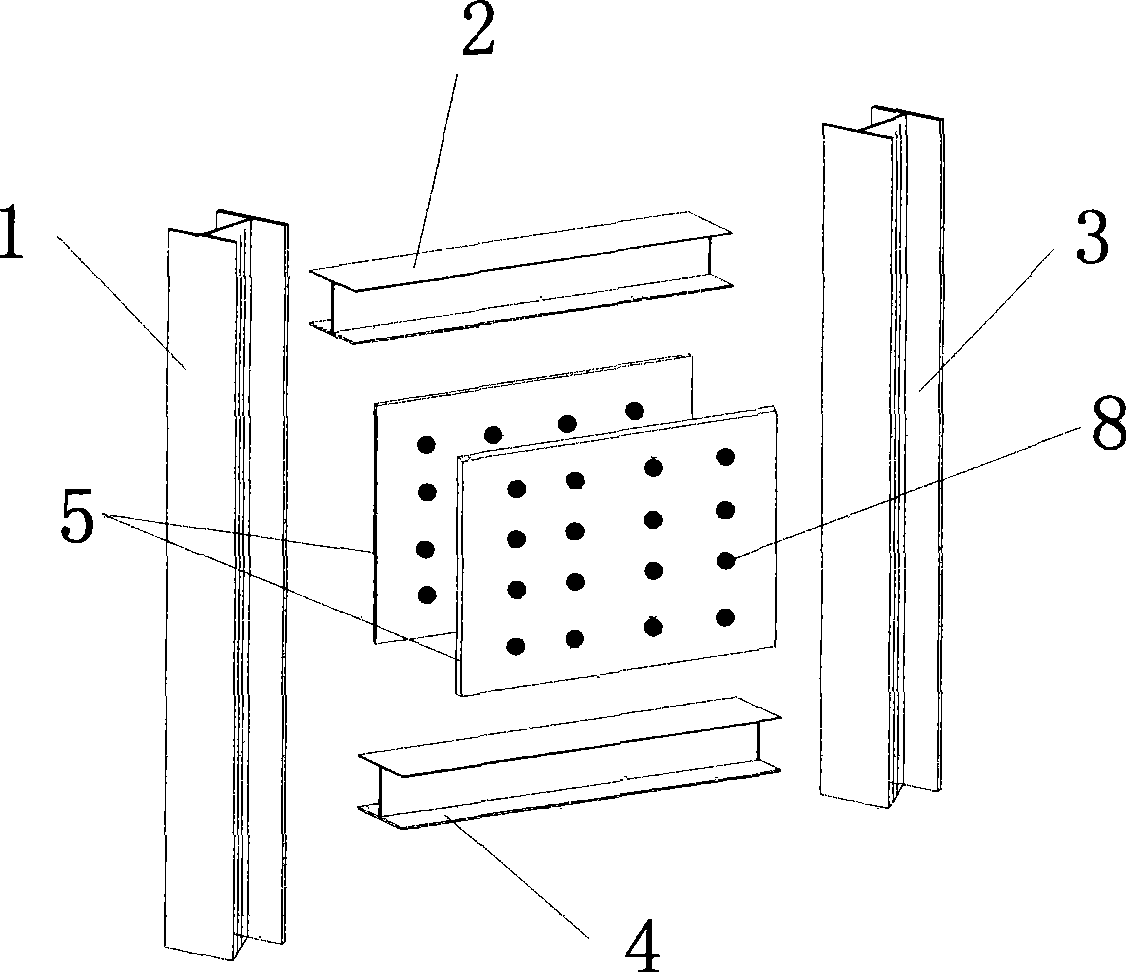

U-shaped steel-coated Regenerated composite beam of and construction method thereof

InactiveCN101418631AIncrease stiffnessImprove ductilityFloorsLoad-supporting elementsFloor slabRebar

The invention discloses a U-shaped steel-encased regenerated composite beam and a construction method thereof. The U-shaped steel-encased regenerated composite beam comprises one or more disused concrete blocks, new concrete, and U-shaped encased steel, the disused concrete blocks are arranged inside the U-shaped encased steel, and the gap between the disused concrete block and the U-shaped encased steel is filled with the new concrete. The method includes the following steps: the U-shaped encased steel is made as the formwork of a beam and is integrated with the formwork of the floor slab or roof slab; a layer of new concrete is first poured into the U-shaped encased steel, then the disused concrete blocks and new concrete are alternately put into the U-shaped encased steel, tamping is utilized then to distributed the disused concrete blocks into the new concrete; steel bars of the floor slab or the roof slab are put into the formwork of the floor slab or the roof slab, and the new concrete is poured into the formwork of the floor slab or the roof slab. The invention can save a great amount of energy consumed in the processes of breaking, screening, purifying and the like for the concrete waste.

Owner:SOUTH CHINA UNIV OF TECH

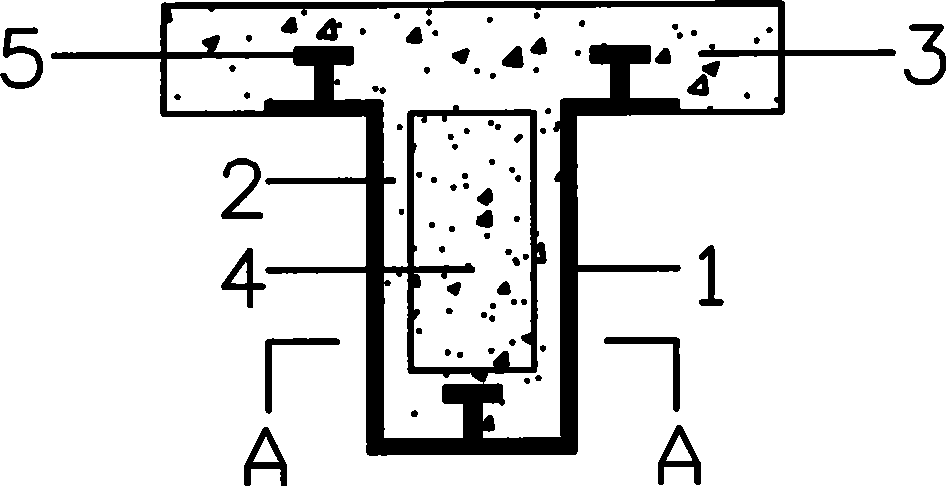

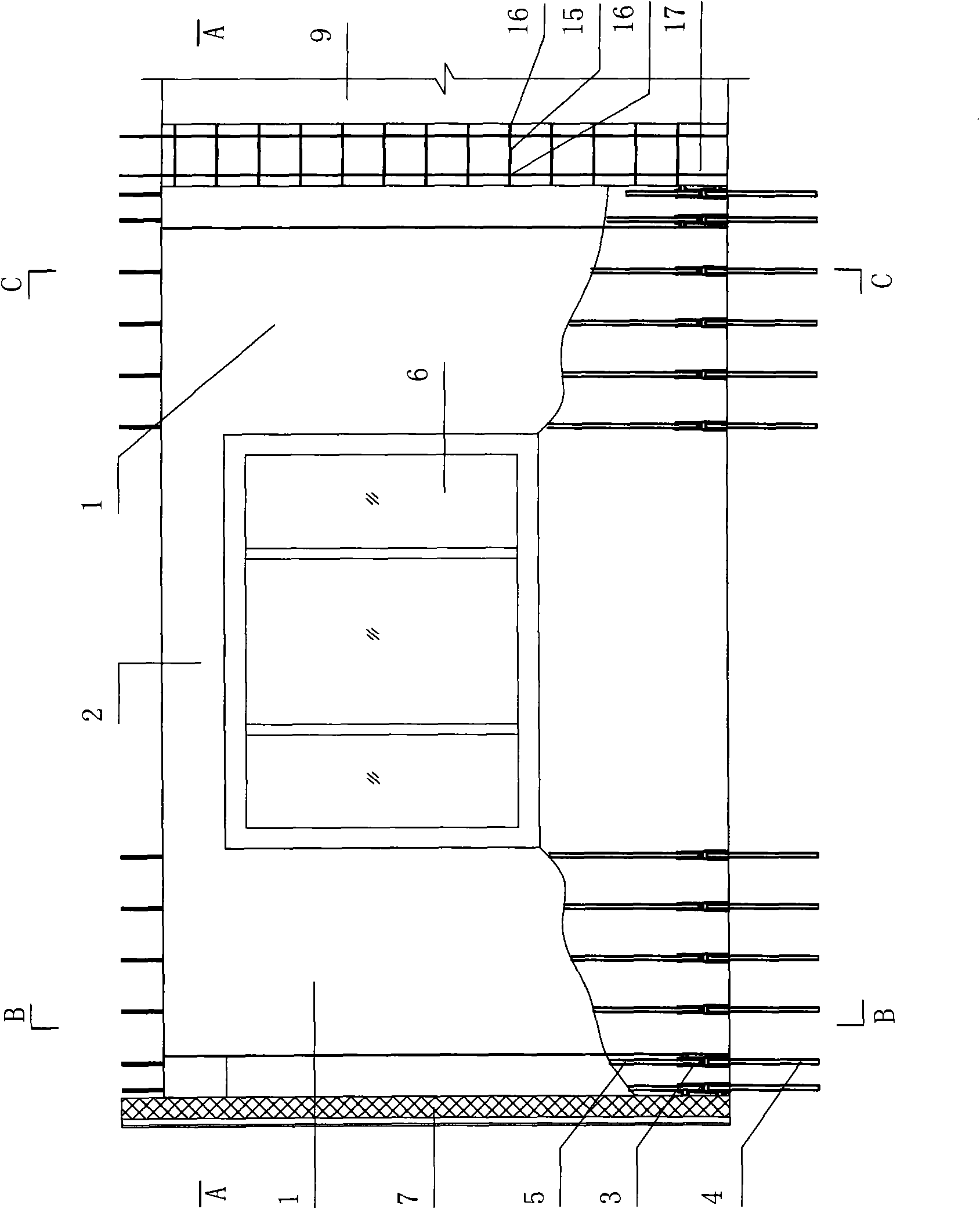

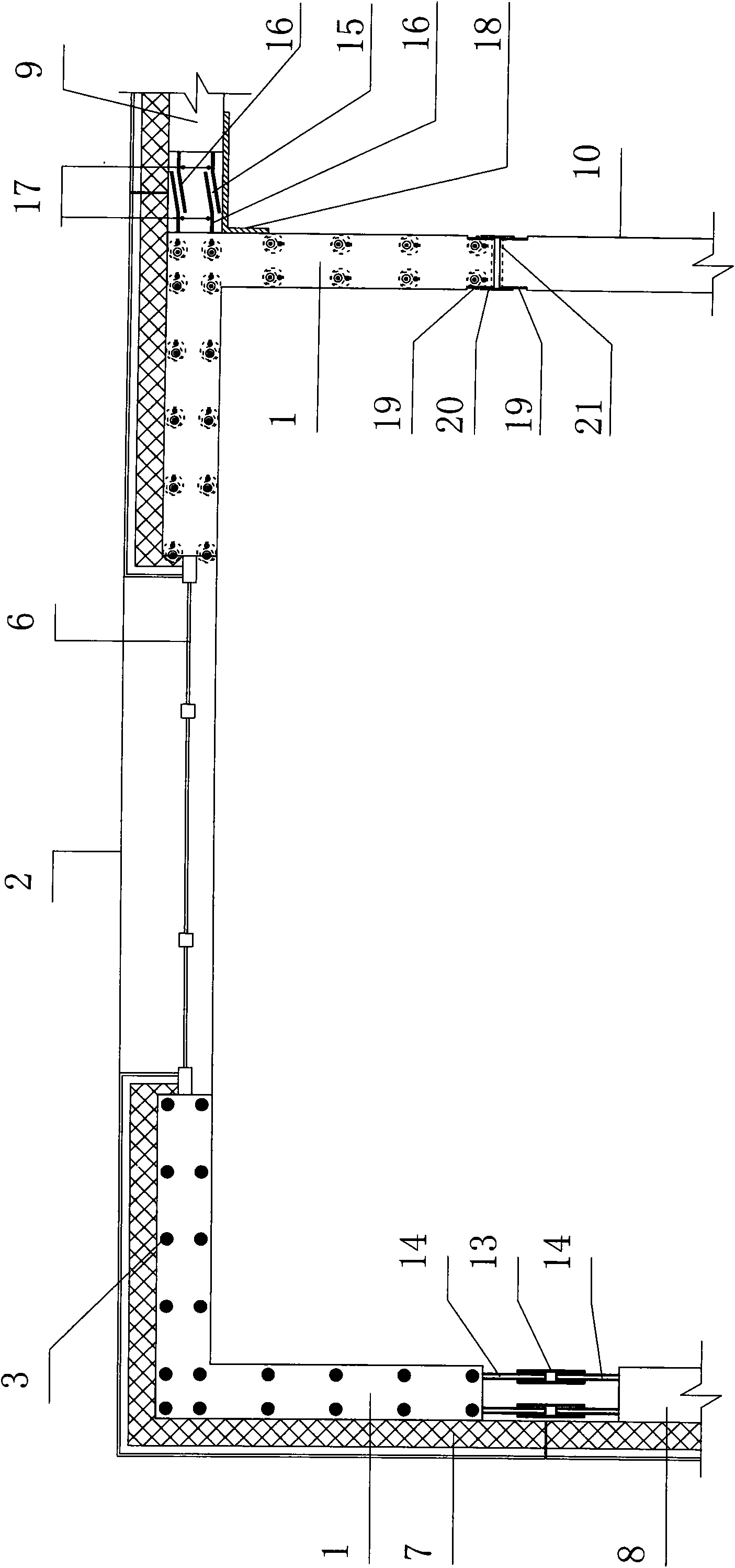

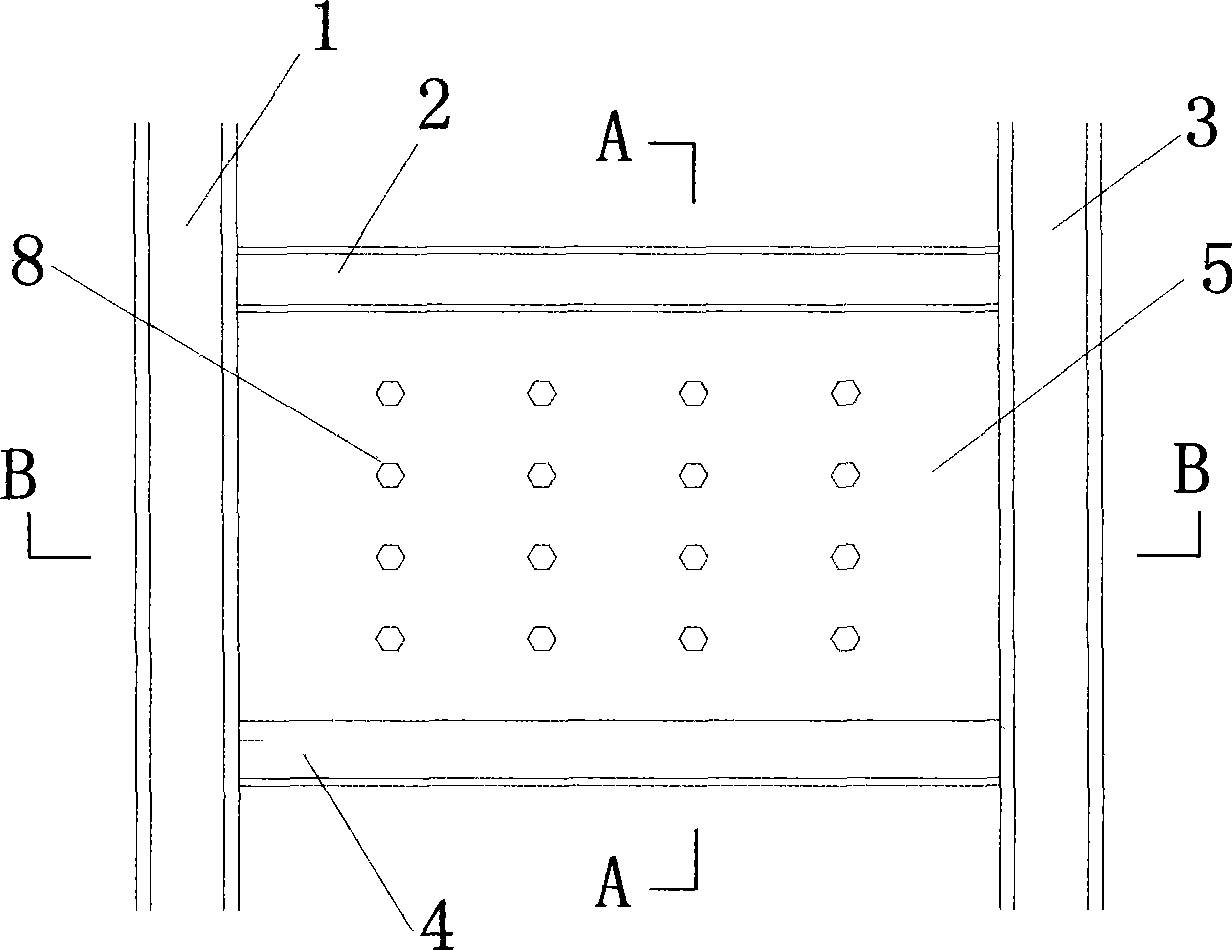

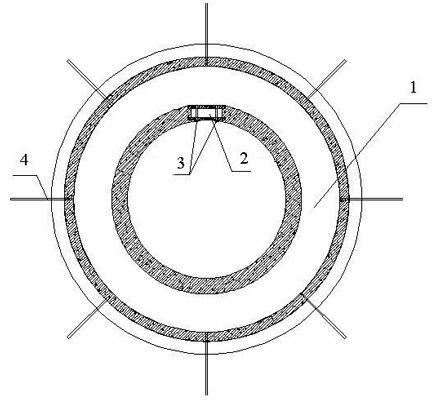

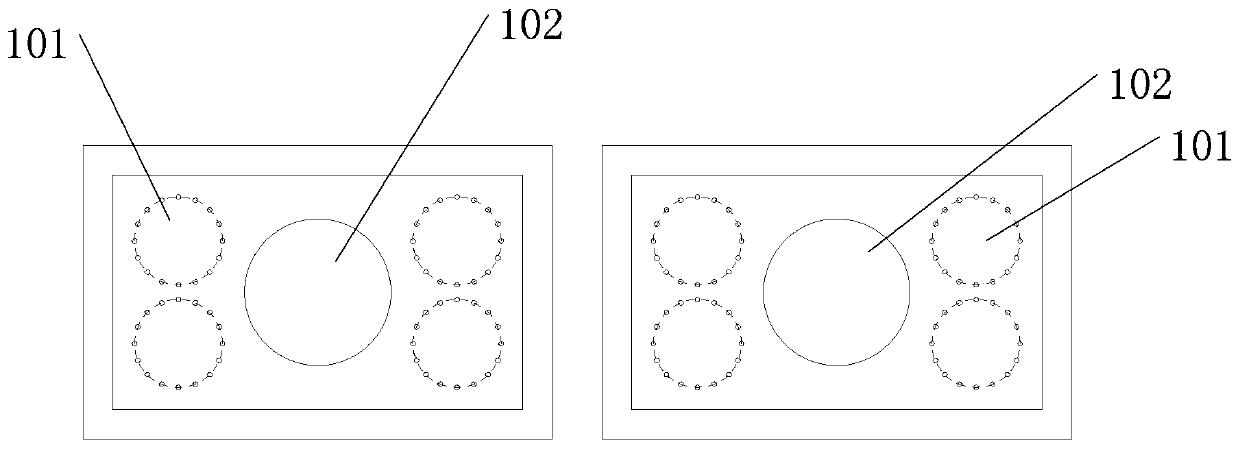

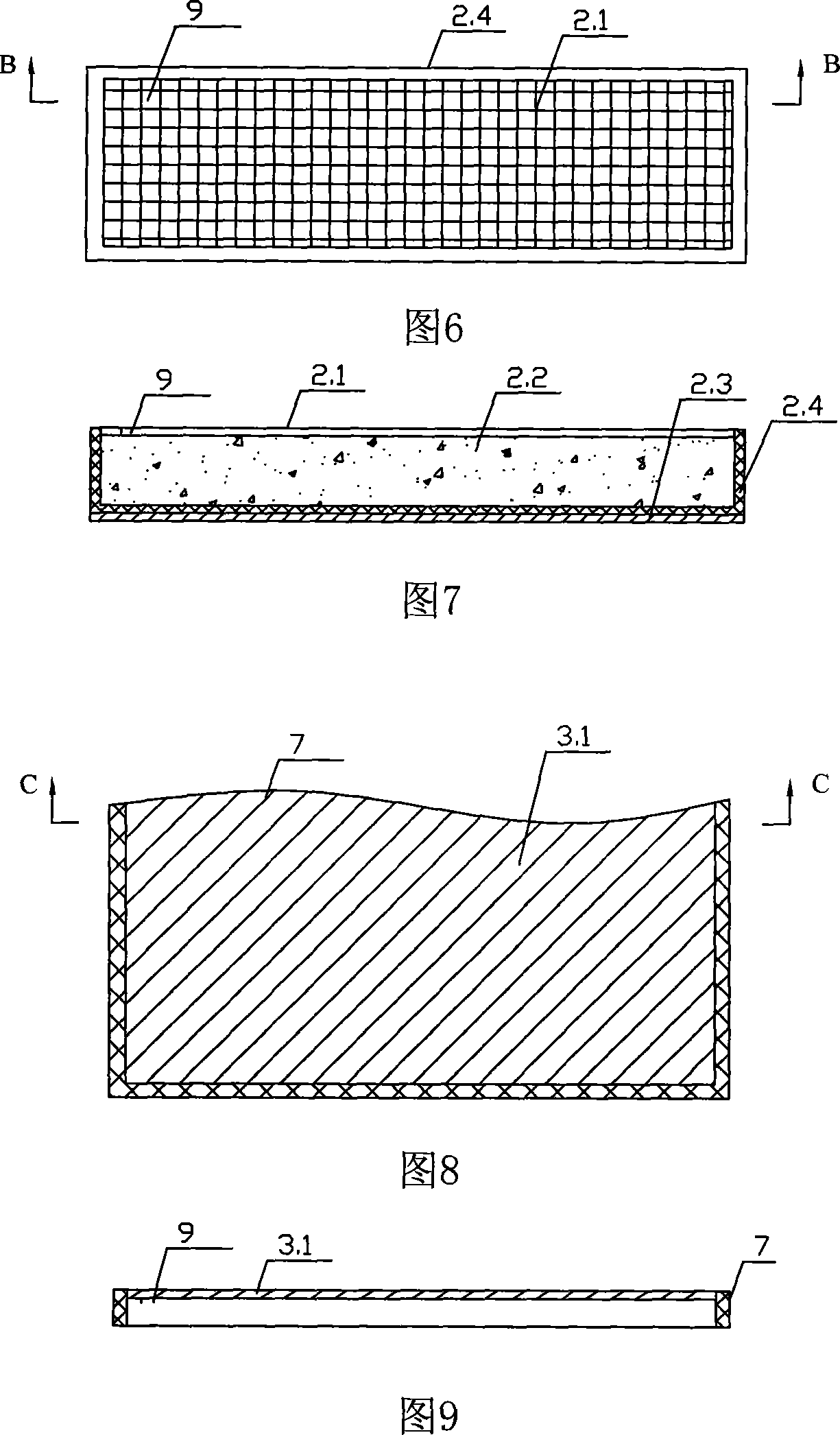

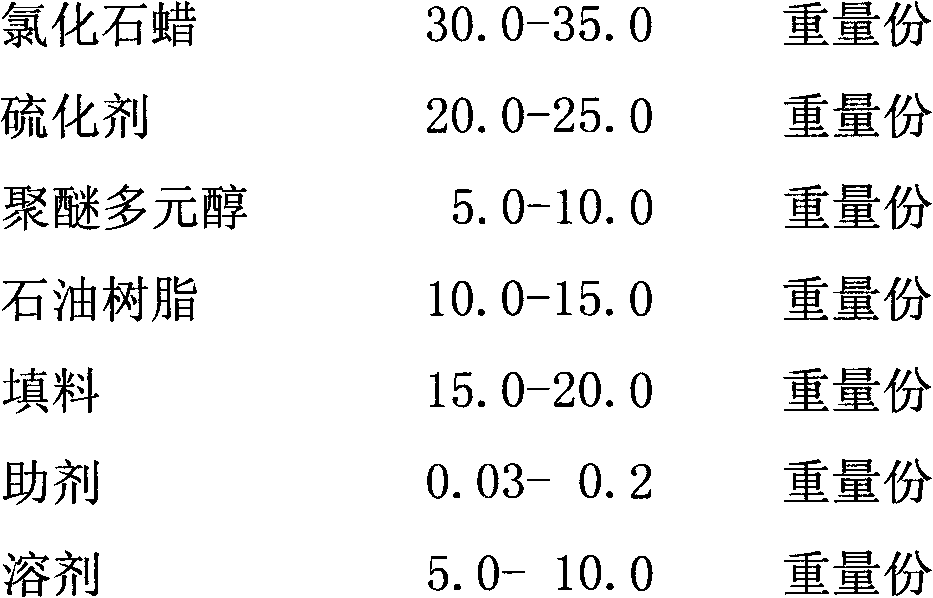

Precast concrete short-limb shear wall provided with door windows and manufacturing method thereof

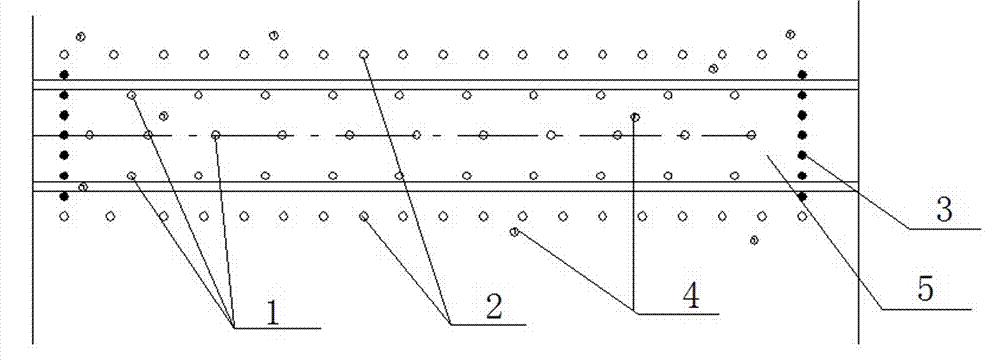

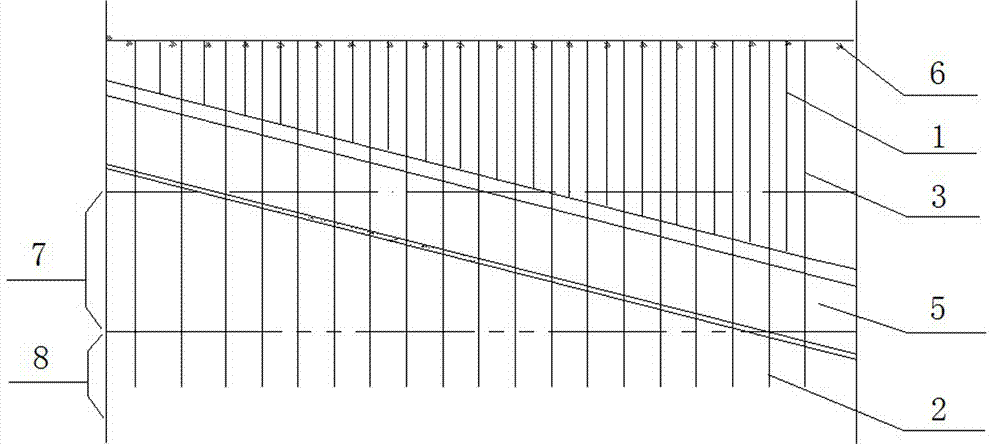

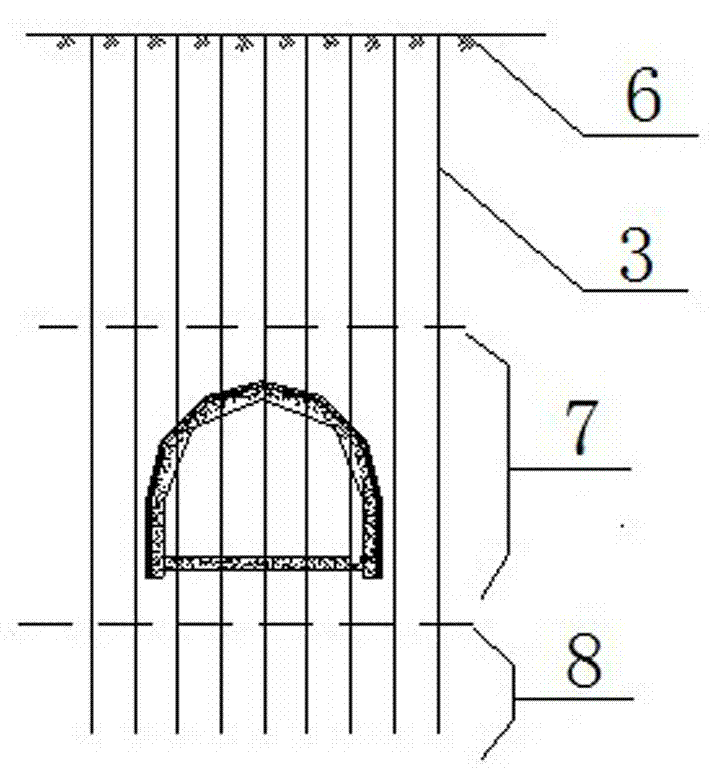

The invention relates to a precast concrete short-limb shear wall provided with door windows and a manufacturing method thereof. The concrete short-limb shear wall refers to a shock-resistant wall of which the ratio of the wall limb cross section height to the thickness is between 5 and 8, and according to the active code requirement in China, the cross section thickness of a wall body is not less than 200 millimeters, and the stress performance of the structure of the concrete short-limb shear wall is between a specially-shaped column and a common shear wall structure. Because of the good performances in various aspects of construction, structure, construction cost, energy conservation and environmental protection and the like, the structural system becomes the structural form which is most suitable for residential constructions. The precast concrete short-limb shear wall comprises precast concrete wall limbs (1), wherein the wall limbs (1) are connected with connecting beams (2), are provided with door windows (6), and are connected with an external wall heat insulation layer and an architectural surface (7), and the wall limbs are connected with each other by assembling steel bars. The precast concrete short-limb shear wall is applied to industrialized fully-assembled shear walls for residential buildings.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

Method for preparing modified asphalt

The invention discloses a preparation method of modified asphalt. The modified asphalt is produced by asphalt and an undersaturation double bond compound which are reacted under the action of an evocating agent; the method comprises the following steps: firstly, the asphalt is put into a reaction kettle; the evocating agent is added into the reaction kettle; the weight of the evocating agent is 0.05-1 percent of the weight of the asphalt; the undersaturation double bond compound with the weight of 1-10 percent of that of the asphalt and 0.1-1 percent of N-phenyl maleimide are added into the reaction kettle at the temperature of 80-160 DEG C; and the pressure remains 0.1-0.4 MPa. The reaction is carried out for 3-6 hours; the reaction product is deaerated and filtered, and then the modified asphalt is obtained. The chemically modified asphalt provided by the method has good performance, which greatly improves the shortcomings that the common asphalt has strong temperature sensibility, low viscosity, poor flexility and the like. The modified asphalt can meet the use performance of roads and prolong the service life of roads; when the modified asphalt is used in road maintaining, maintenance, the time of traffic closing is shortened, the construction condition is improved and the construction efficiency is increased.

Owner:JURONG NINGWU SCI & TECH DEV

Method for herbaceous plants to cope with global climate change

InactiveCN108370881AHigh energy storageReduce the greenhouse effectAgriculture gas emission reductionPlant cultivationCoastal erosionSoil horizon

The invention provides a method for herbaceous plants to cope with global climate change. The method comprises the steps of 1, with herbaceous plants being the main body, managing stony desertification and desertification, controlling coastal erosion and water and soil loss and preventing an earth ecological system from collapsing and breaking down; 2, planting the herbaceous plants in regions with the stony desertification, the desertification, the coastal erosion and the water and soil loss, fixing the surface soil layer, recovering or rebuilding vegetation and controlling emission of carbonin lithosphere to atmosphere and hydrosphere; 3, utilizing the characteristics that the fast-growing herbaceous plants are fast in growth and development, high in carbon capturing efficiency and hugein biomass, convert movable carbon in the atmosphere into fixed carbon, develop new climate economy, further promote the increase of the amount of the fixed carbon in the industries of agriculture, forestry, animal husbandry, side-line production and fishery and achieving a world zero carbon development mode. Ecological development is the best carbon emission reduction mode, and carbon dioxide isprecious wealth of the human. Respecting the nature, conforming to the nature, protecting the nature and guiding the nature solve the problem of ecology, environment, resources, economy and global climate warming.

Owner:雷学军

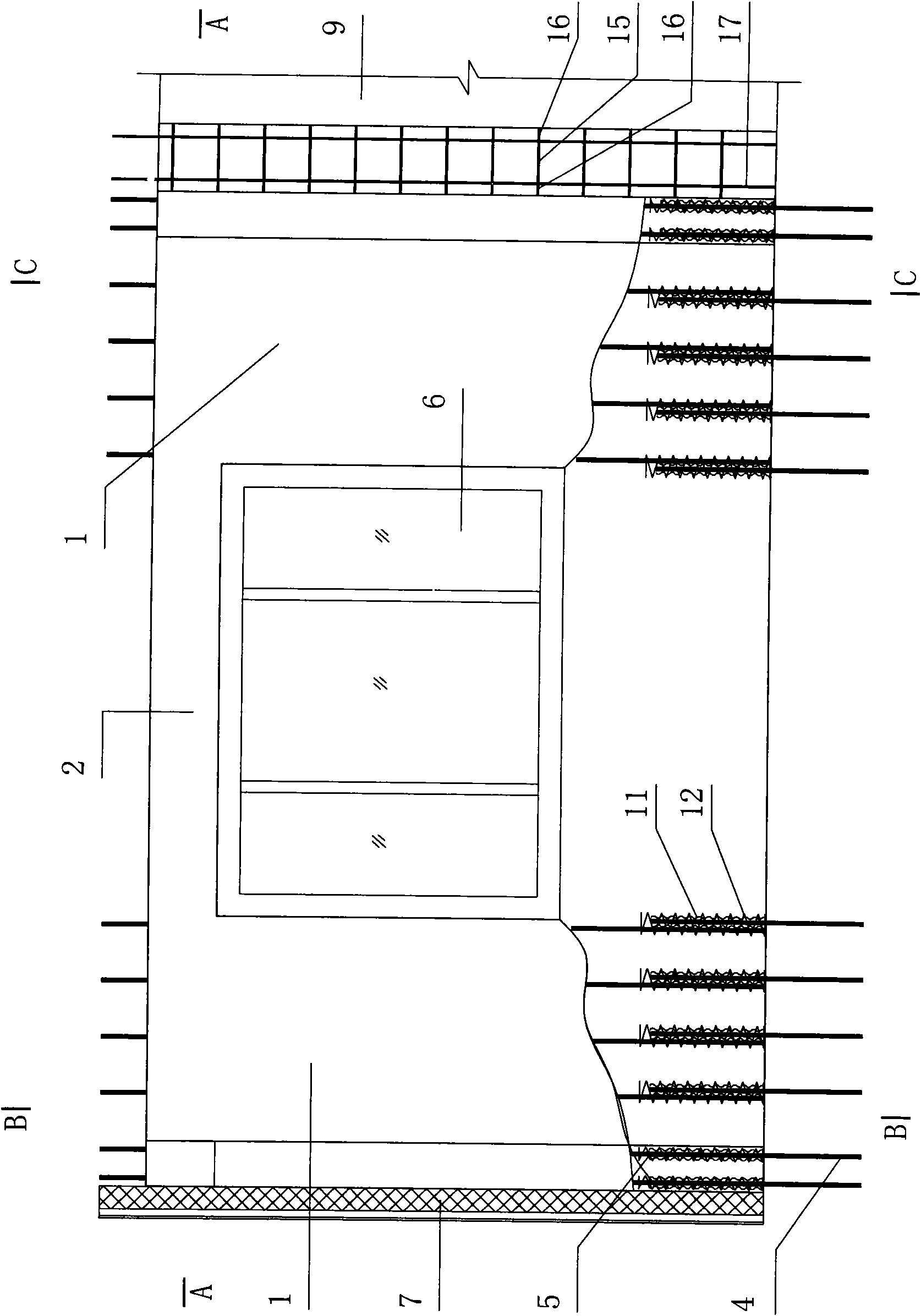

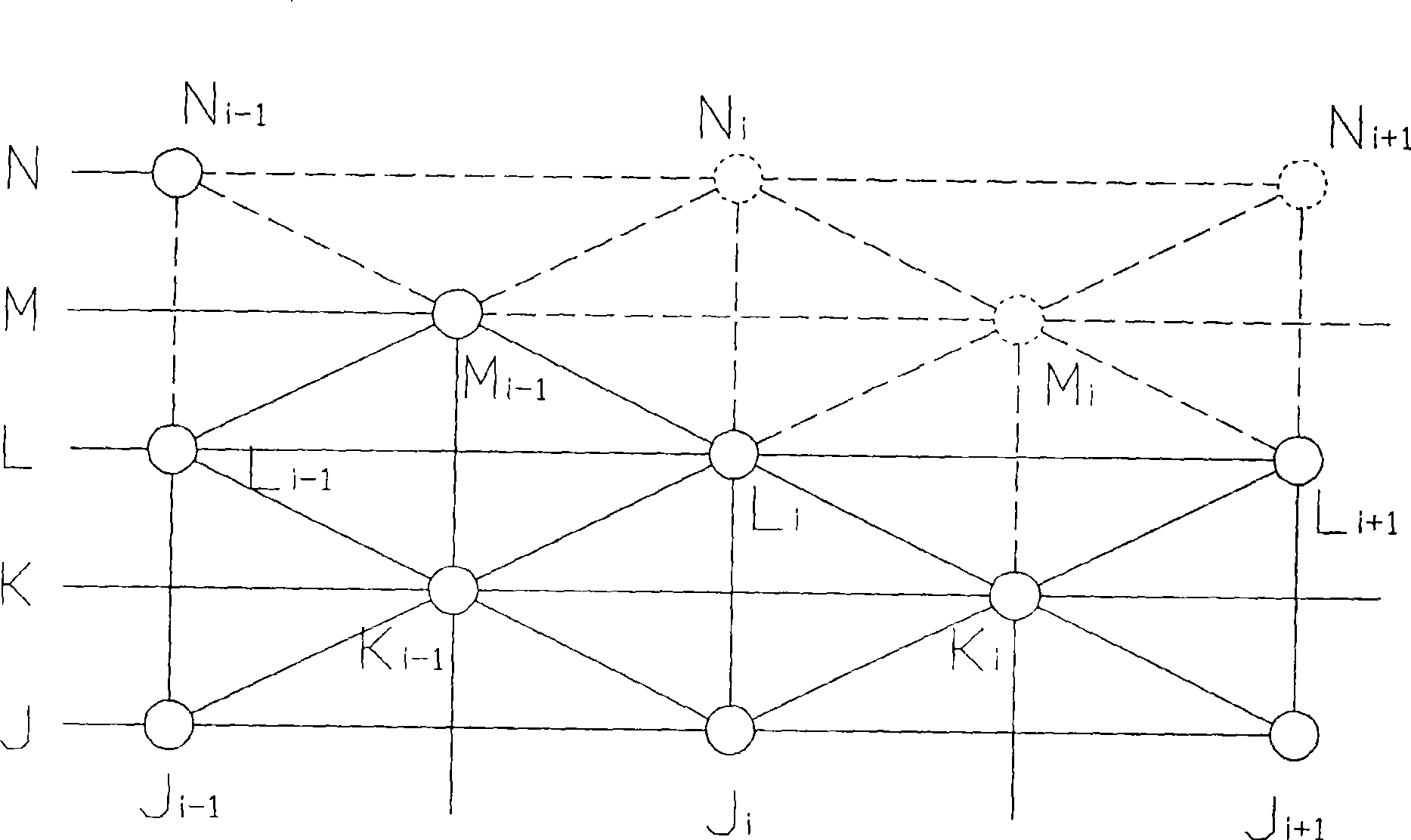

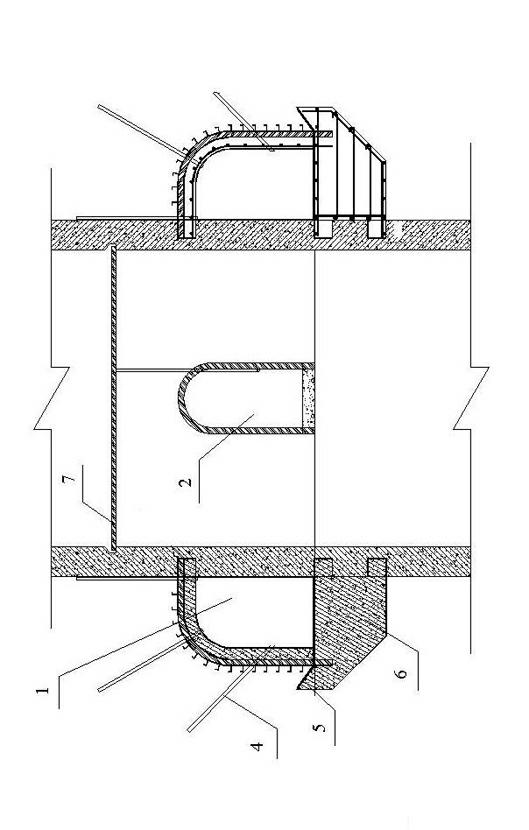

High altitude suspension selecting bulk construction method of barrel shell type bolt ball node network frame

InactiveCN101435224AImprove construction flexibilityImprove installation efficiencyBuilding constructionsSUSPENDING VEHICLESupport condition

The invention relates to a small assembling unit high suspending construction method for cylinder casing type bolt ball node grid. The cylinder casing type bolt ball node grid is divided into a plurality annuluses in longitudinal direction according to the support condition, a steel pipe scaffold is arranged in any one annulus, an upper net casing of the annulus is assemble on the annulus by a bulk method, and the scaffold is dismounted after the assembly is qualified; a second annulus is constructed by the small assembling unit high suspending method from the assembled first annulus, and the annulus is assembled one by one along the longitudinal direction, after the bolt balls on the lower boom loop wire in the annuluses are mounted in order, the bolt balls on adjacent upper boom loop wire are mounted in order, each bolt ball and a longitudinal boom, an annular boom and two web members are put together to form a one-ball-four-rod member on the ground before assembly, and then the formed members are suspended by crane to proper positions in the air to be connected to the bolt balls mounted on the periphery. The method of the invention is safe, flexible, convenient, fast, and has low cost.

Owner:河南中美铝业有限公司

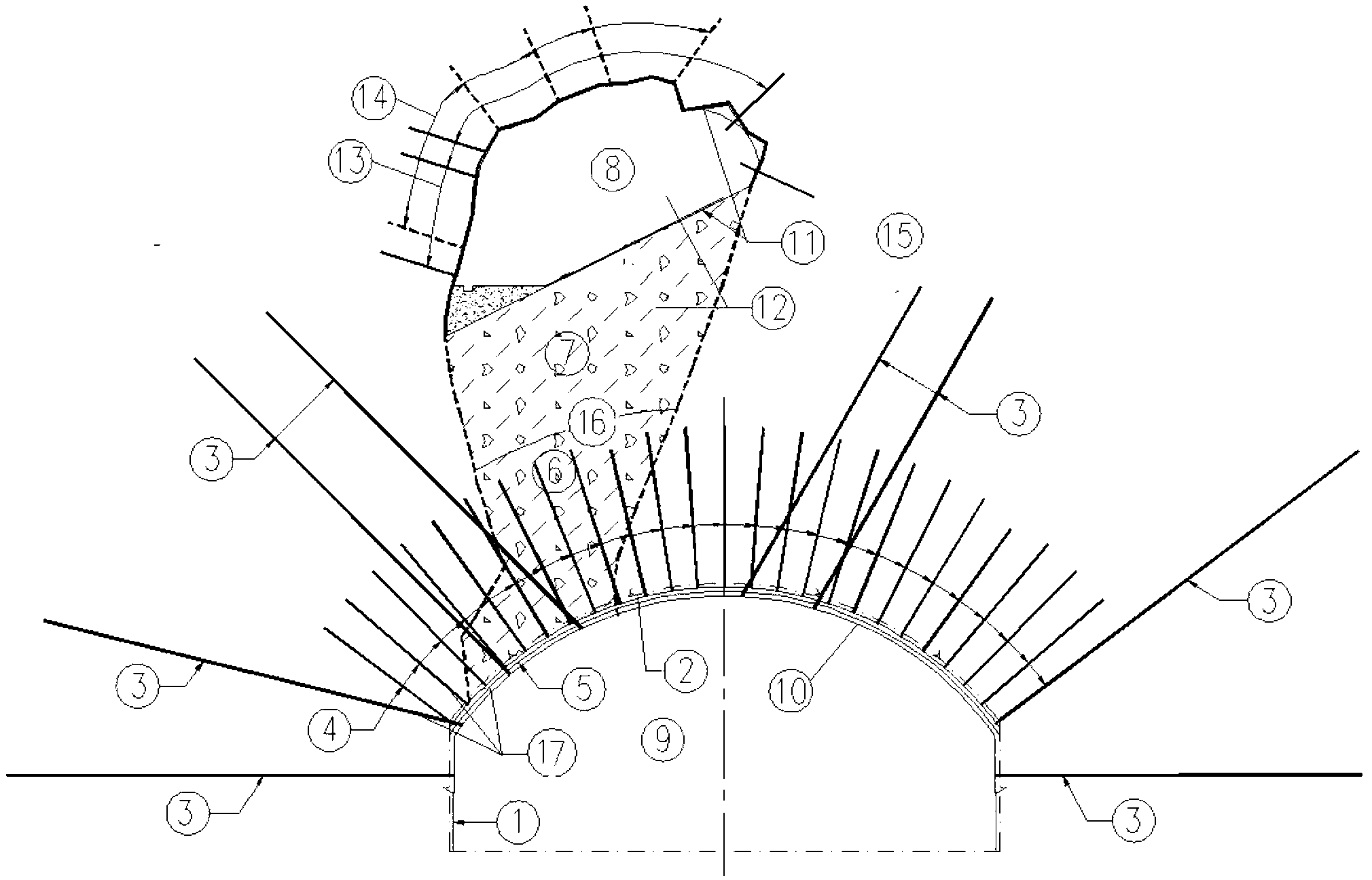

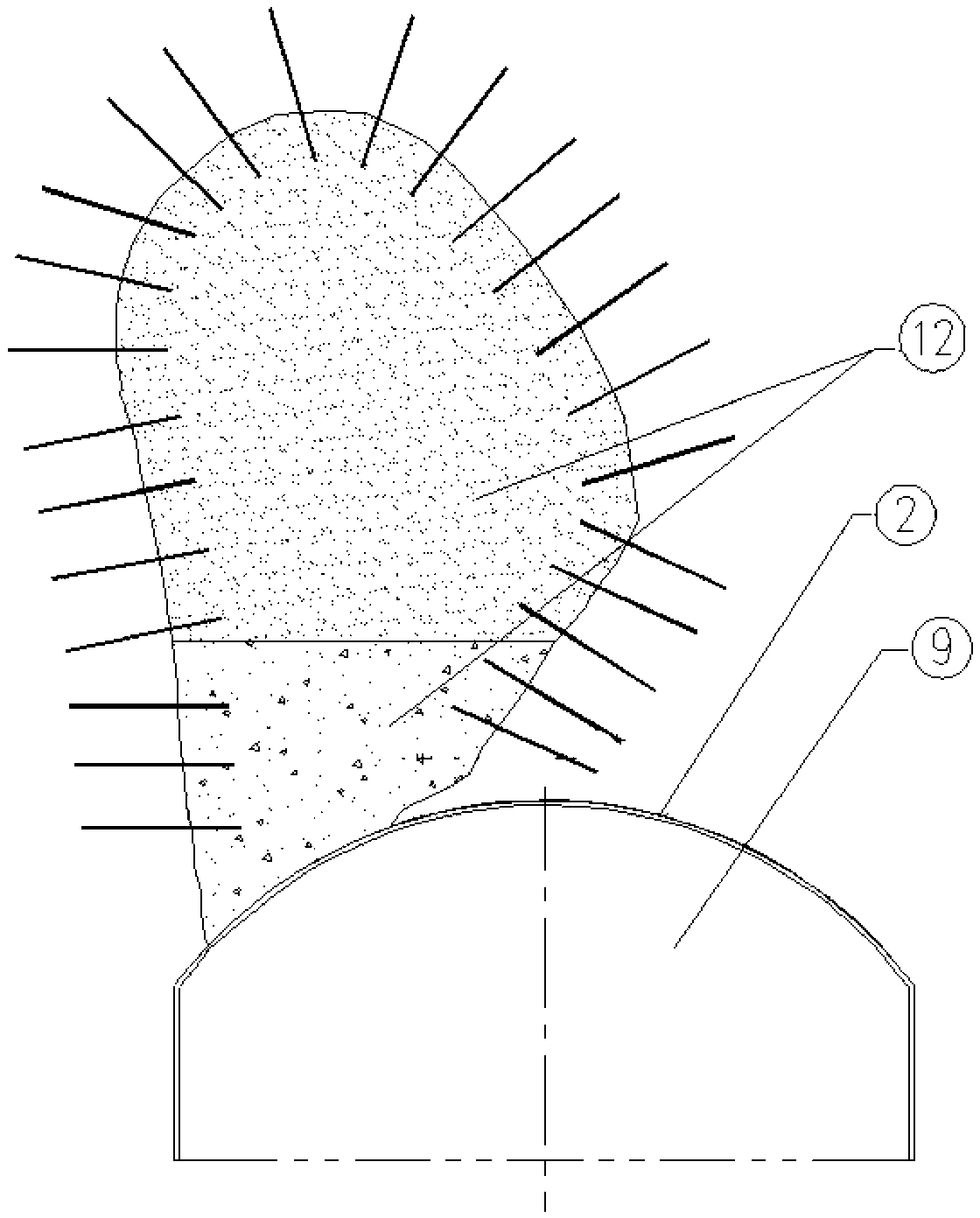

Method of treating lining after collapse of underground cavern crown

ActiveCN103321653ASave engineering investmentShorten the construction periodUnderground chambersTunnel liningUnderground cavernBeam matching

The invention discloses a method of treating a lining after collapse of an underground cavern crown, relates to the field of underground cavern construction, and provides a method of treating the lining after collapse of the underground cavern crown, with low workload, low cost and effective collapse prevention. The method includes the steps of a, clearing collapse waste in the cavern; b, inserting at least one reinforcing anchor bar into the residual collapse waste and surrounding rock on two sides of the residual collapse waste, and allowing one end of each reinforcing anchor bar, close to the cavern, to be located in the same cross section; c, connecting an arch beam matching with the cross section of the cavern crown in shape to all reinforcing anchor bars, and attaching the arch beam to the cavern crown; d, subjecting the residual collapse waste to systematic consolidation grouting; and e, repeating the steps from a to d until the collapse waste in the cavern is fully cleared. The method is applicable to repairing collapsed underground caverns.

Owner:POWERCHINA CHENGDU ENG

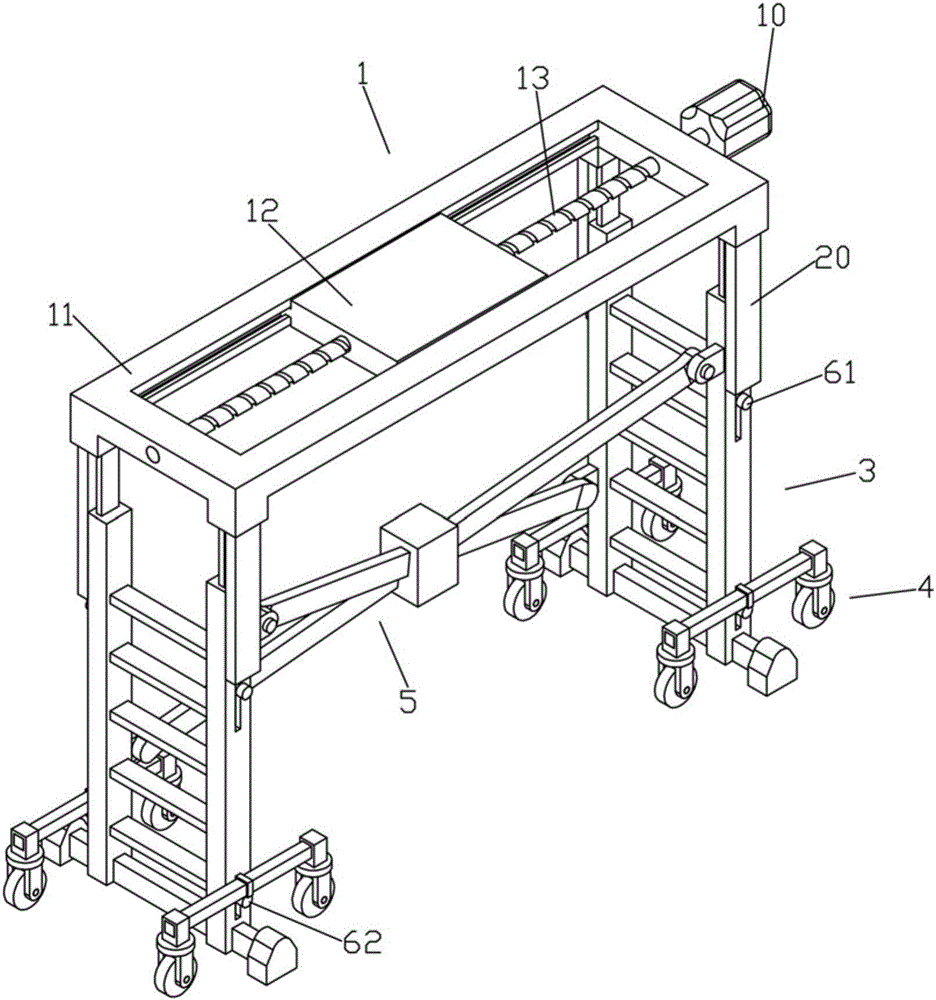

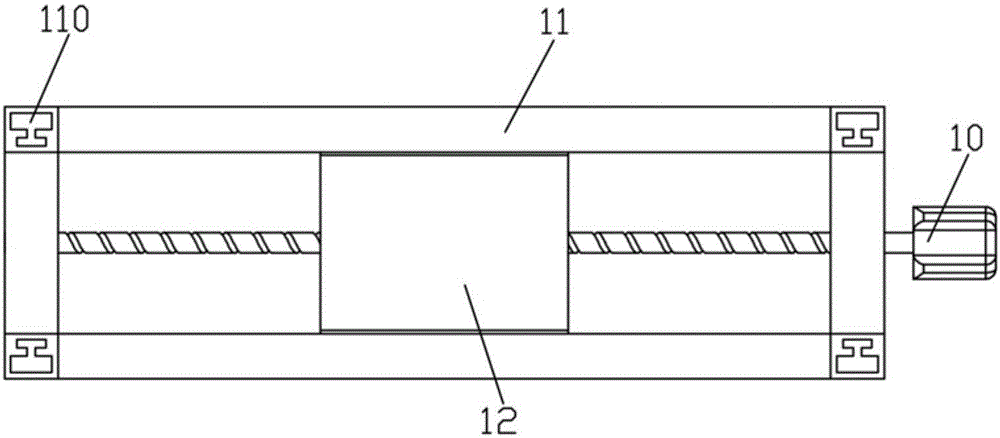

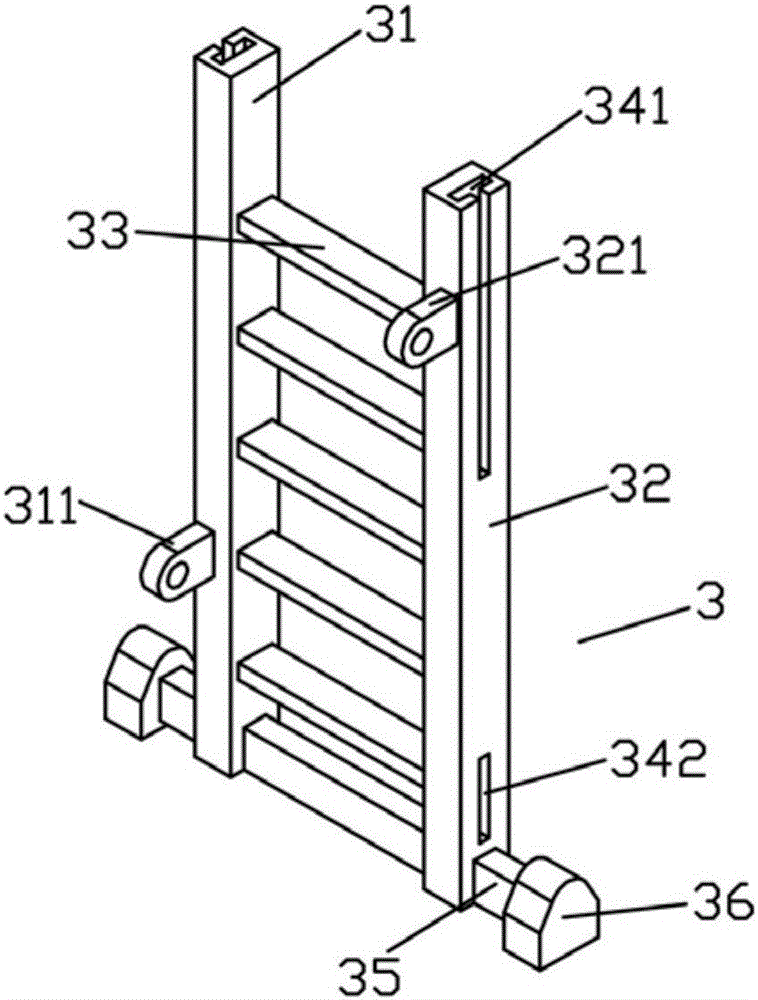

Movable lifting scaffold

ActiveCN105756332AAvoid pitfalls of support strength requirementsImprove construction conditionsBuilding scaffoldsFalseworkBuilding construction

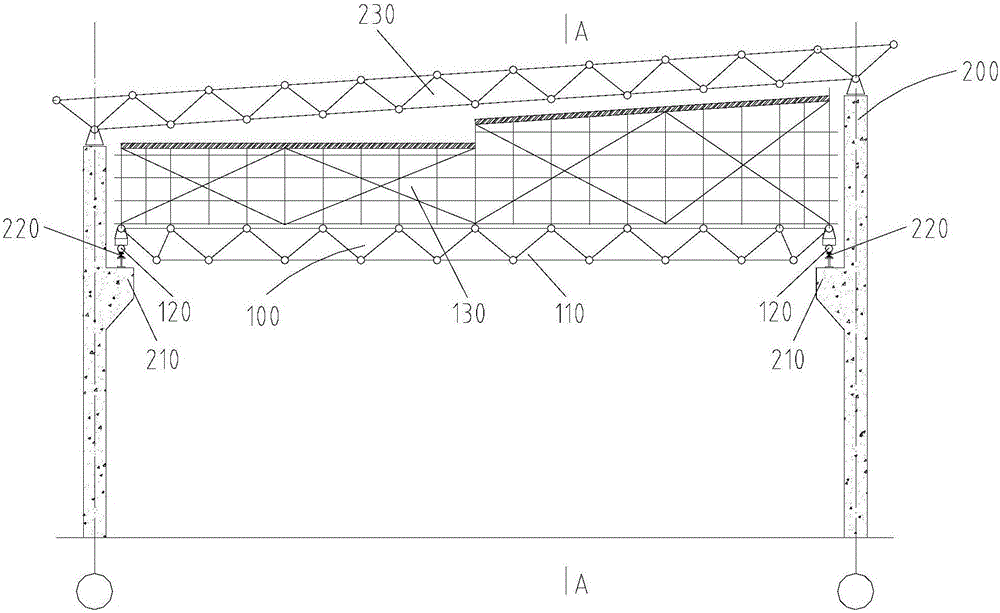

The invention discloses a movable lifting scaffold. The movable lifting scaffold comprises a support plate, two lower scaffold bodies, two upper scaffold bodies, a fixing reinforcing mechanism and a walk unit, wherein the upper scaffold bodies are arranged above the lower scaffold bodies; the lower scaffold bodies and the upper scaffold bodies are in sliding lifting connection; the support plate is arranged at the upper parts of the upper scaffold bodies and detachably connected with the upper scaffold bodies to form an integral structure; the walk unit is arranged at the lower parts of the lower scaffold bodies; one end of the fixing reinforcing mechanism is connected with one lower scaffold body; and the other end of the fixing reinforcing mechanism is connected with the other lower scaffold body. The support plate on the movable lifting scaffold can be adjusted along with the construction positions of workers, so that the defects that the support plate is laid on the whole surface and the support strength requirement of the scaffold is increased are avoided; and in the meantime, the scaffold can be moved and lifted, so that the construction condition of the workers is improved and a wider working range is provided.

Owner:安徽东锋齿轮有限公司

Construction method of installing and fixing equipment basic pre-buried iron elements

InactiveCN101787706APrecise positioningAccurate installation and molding positionFoundation engineeringBuilding constructionsEngineeringBuilding construction

Thee invention relates to a construction method of installing and fixing equipment basic pre-buried iron elements, which comprises the following steps: processing and manufacturing the pre-buried iron elements according to a design drawing; processing fixing holes on the pre-buried iron elements; welding pre-buried iron element anchoring ribs; installing the pre-buried iron elements in correct positions after the formwork completion of a basic template; drilling holes on a template sleeve; fixing the pre-buried iron elements to the template through fixing screw bolts; casting concrete; after completion, releasing the fixing screw bolts of the pre-buried iron elements; cutting exposed screw bolts; and grinding the screw bolts to obtain the smooth appearance. The invention changes the traditional pre-buried iron element fixing method on the basis of summarizing the defects of the existing pre-buried iron element fixing method, and the screw bolts are adopted for positioning and fixing, so the installation positions of the pre-buried iron elements are accurate. When the method of the invention is adopted, the positioning accuracy of the installation positions of the pre-buried iron elements is greatly improved, the rework and repair loss is reduced, good construction conditions are created for the subsequent work, and the effect is obvious.

Owner:MCC SHIJIU CONSTR

Hidden anchor recess and manufacturing installation technology

InactiveCN103523174ABreakthrough installation accuracy is not highHigh precisionVessel partsMarine engineeringReturned Amount

The invention relates to a hidden anchor recess. Sides of a first elbow plate and a second elbow plate are symmetrically welded at the two sides of an anchor recess side plate. Bottom plates of the first elbow plate and the second elbow plate are welded to an outer plate respectively. One side of a third elbow plate is welded to an anchor recess top plate and the other side of the third elbow plate is welded to the inner side of an anchor chain tube. The first side of a fourth elbow plate is welded to the outer side of the anchor chain tube, the second side of the fourth elbow plate is welded to the anchor recess top plate and the third side of the fourth elbow plate is welded to the outer plate. One side of a fifth elbow plate is welded to an anchor recess bottom plate and the other side of the fifth elbow plate is welded to the outer plate. In an inner field stage, all parts of the hidden anchor recess and the five elbow plates are welded and assembled and the hidden anchor recess is welded to the outer plate at one time in a slipway stage. According to the hidden anchor recess, a plurality of elbow plates are added on the outer side of the anchor recess and the included angles between the anchor recess and other devices are fixed, the sizes of parts are determined at one time and precision of manufacturing the parts is improved. Work of the anchor recess is completed in the inner field in advance instead of being performed in the slipway. Work loads and the waste and return amount of the slipway are reduced, the period of shipbuilding is shortened and shipbuilding cost is reduced.

Owner:WUCHANG SHIPBUILDING IND

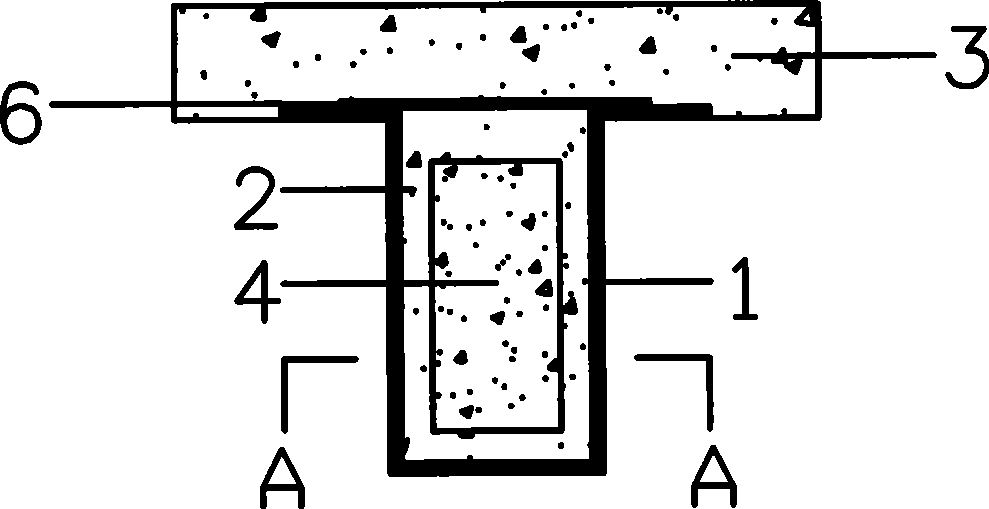

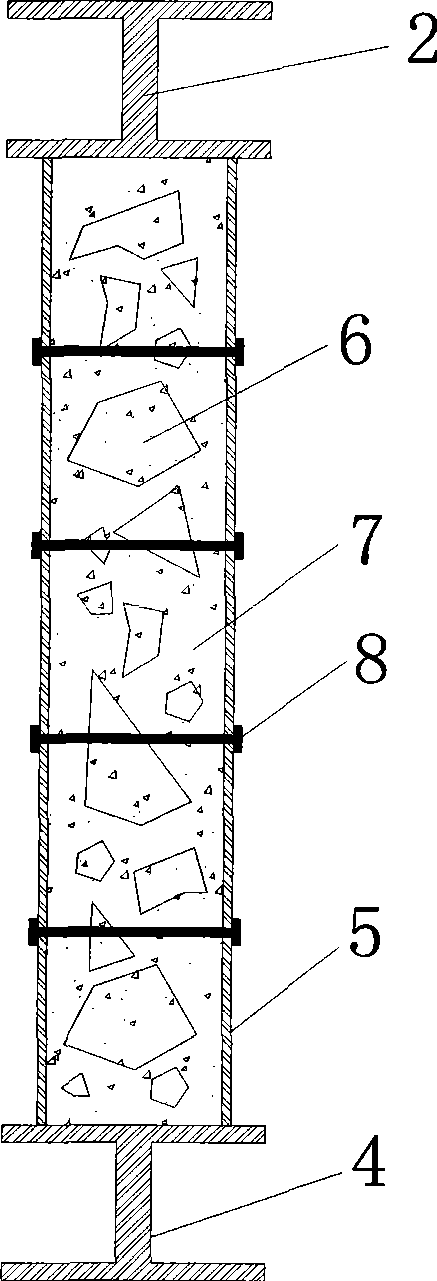

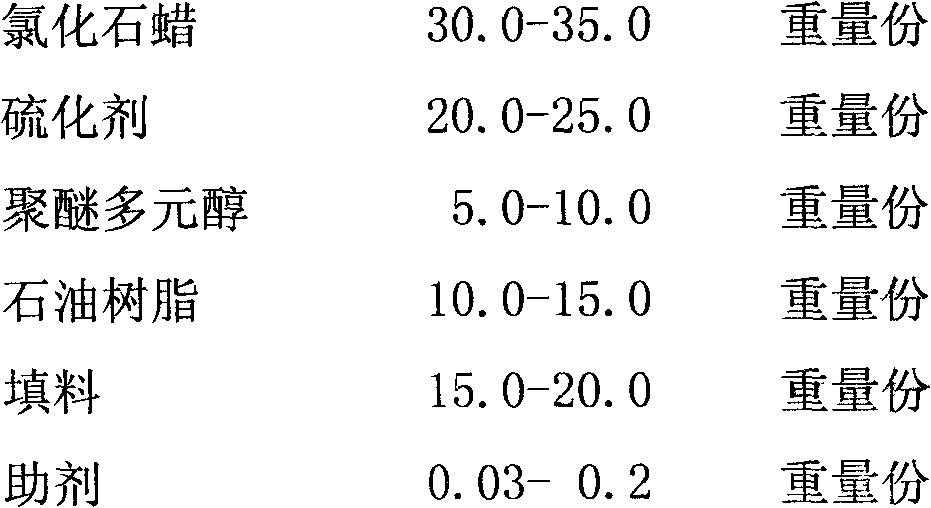

Steel sheet regeneration mixed wall and construction method thereof

The invention discloses a steel plate regenerative composite wall and a construction method thereof. Holes are reserved on front and back corresponding positions of a front steel plate and a back steel plate of the steel plate regenerative composite wall, bolts pass through the reserved holes to connect the two steel plates, concrete is filled between the two steel plates, the concrete comprises new concrete and one or more waste concrete blocks, and the new concrete is filled among the waste concrete blocks and between the waste concrete blocks and the steel plates; the mass ratio of the waste concrete blocks to the new concrete is 1.4 to 1.1; and the diameter of the waste concrete block is more than 50 millimeters. The steel plate regenerative composite wall is suitable for a building structure, has the characteristics of large side rigidity resistance, good ductility, high bearing capacity and the like, has stable hysteresis performance and large absorbed energy in destructive process, can reduce large usage amount of templates, and can use the waste concrete to reach the aim of environmental protection, energy saving and discharge reduction.

Owner:SOUTH CHINA UNIV OF TECH

Novel water control method suitable for mine shafts

ActiveCN102425421AImprove construction conditionsProtection securityDrainageShaft liningEngineeringWater layer

The invention relates to a novel water control method suitable for mine shafts, which is characterized by firstly adopting grouting for water plugging at a water-bearing layer at the upper part of the shaft; arranging a wall seat at the boundary of the water-bearing layer and a water-resisting layer and arranging a bypass for water interception after the wall on the upper surface of the wall seat; arranging a dewatering orifice in the bypass and arranging a water guide pipe in the orifice, wherein the wall seat is wider than the bypass and the wide part of the wall seat is upwarped for water blocking; arranging a water collecting ring in the shaft at the upper part of an access road and draining water collected by the water collecting ring into the bypass after the wall, wherein a baseplate of the access road is 200-300mm higher than the bypass; and pre-burying a drainage pipe and enabling gushing water collected at the upper part of the bypass to self-flow into a water sump and be further drained to the ground through a drainage device. By adopting the novel water control method, the construction conditions of the mine shaft can be improved, the construction quality can be improved and the progress can be accelerated; furthermore, water damages can be effectively prevented during the production period of a mine, the safety of the mine shaft is protected, the drainage cost is reduced and the service life of the mine shaft is prolonged.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

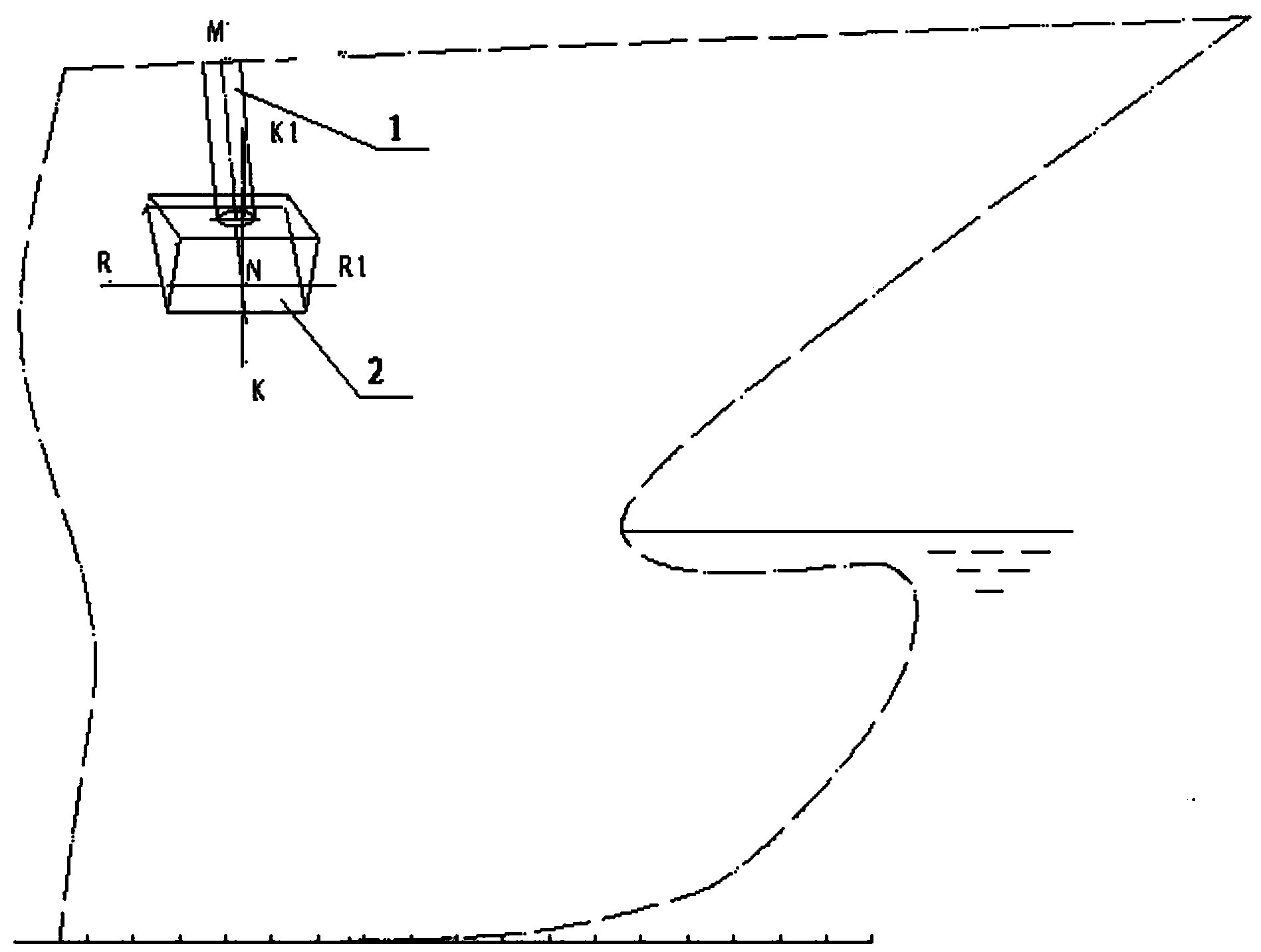

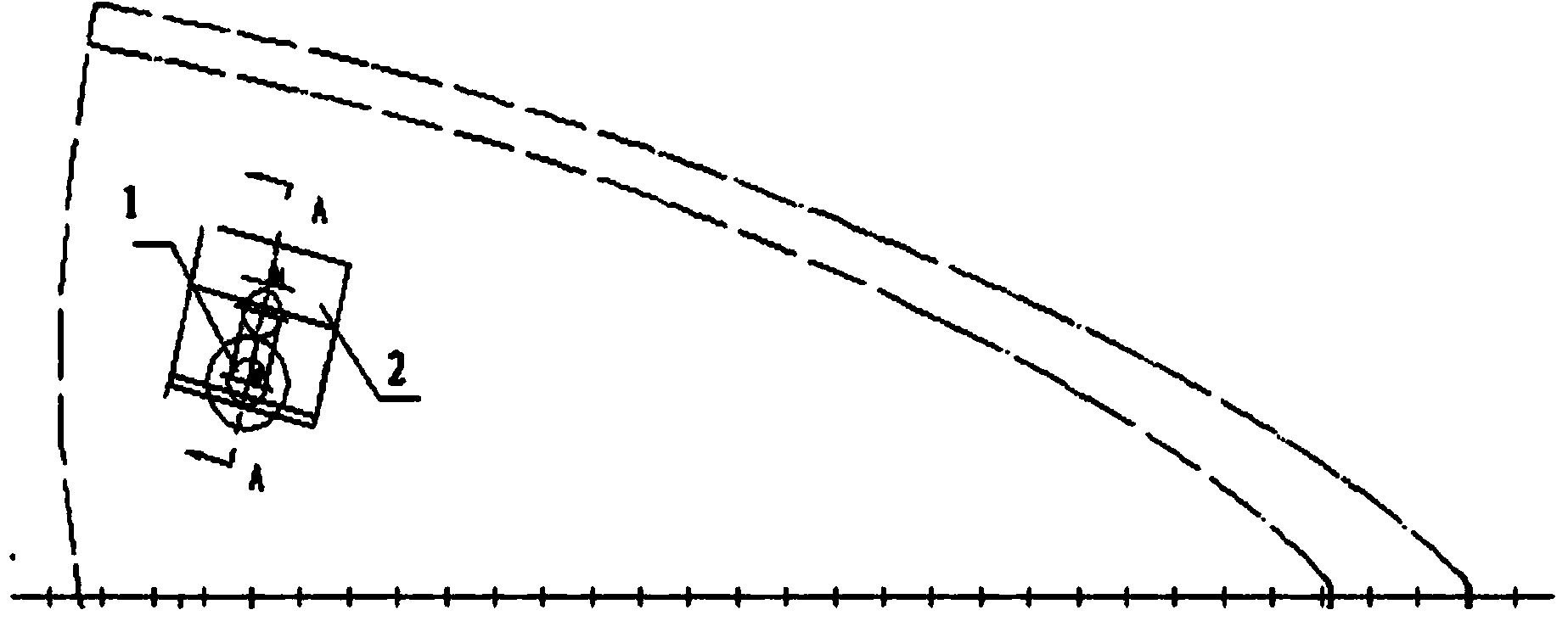

Method for installing rudder horn

ActiveCN102336250AImprove construction conditions and construction qualityEasy constructionVessel partsStructural engineeringRudder

The invention discloses a method for installing a rudder horn. The method comprises the following steps: a, preparing an inverted-manufactured rudder horn-steering gear room platform subsection combined member; b, completing the welding operation of a main stern section, and after the main stern section is turned over, erecting and positioning the main stern section, and determining a subsection baseline surface; c, arranging a strengthening structure between a main deck and a steering gear room platform, then arranging an opening on the main deck; d, arranging an opening on a part (at which the rudder horn is arranged) of a hull baseplate, and carrying out rounded corner and surrounding structure strengthening on the opening of the baseplate; e, hoisting the erected rudder horn-steering gear room platform subsection combined member from the main deck, so that the rudder horn-steering gear room platform subsection combined member is hoisted from the main deck to the the composite member is below the rudder horn, then enabling the composite member to get out the opening of the baseplate; and f, welding the subsections of the steering gear room platform with other subsections. In the invention, through performing a rudder horn installation process in advance, the shipbuilding period is shortened, the accurate installation of the rudder horn is realized, the cost is reduced, and the efficiency is improved.

Owner:WUCHANG SHIPBUILDING IND

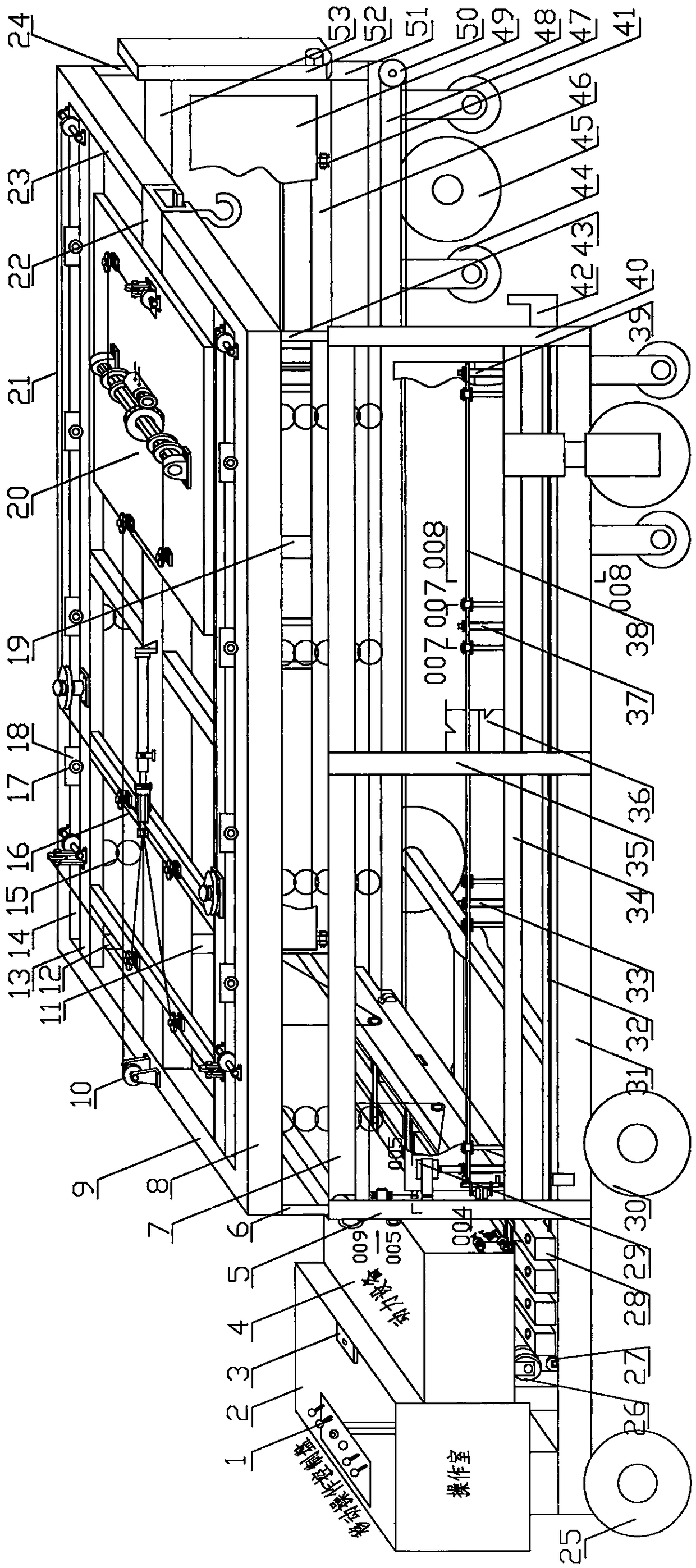

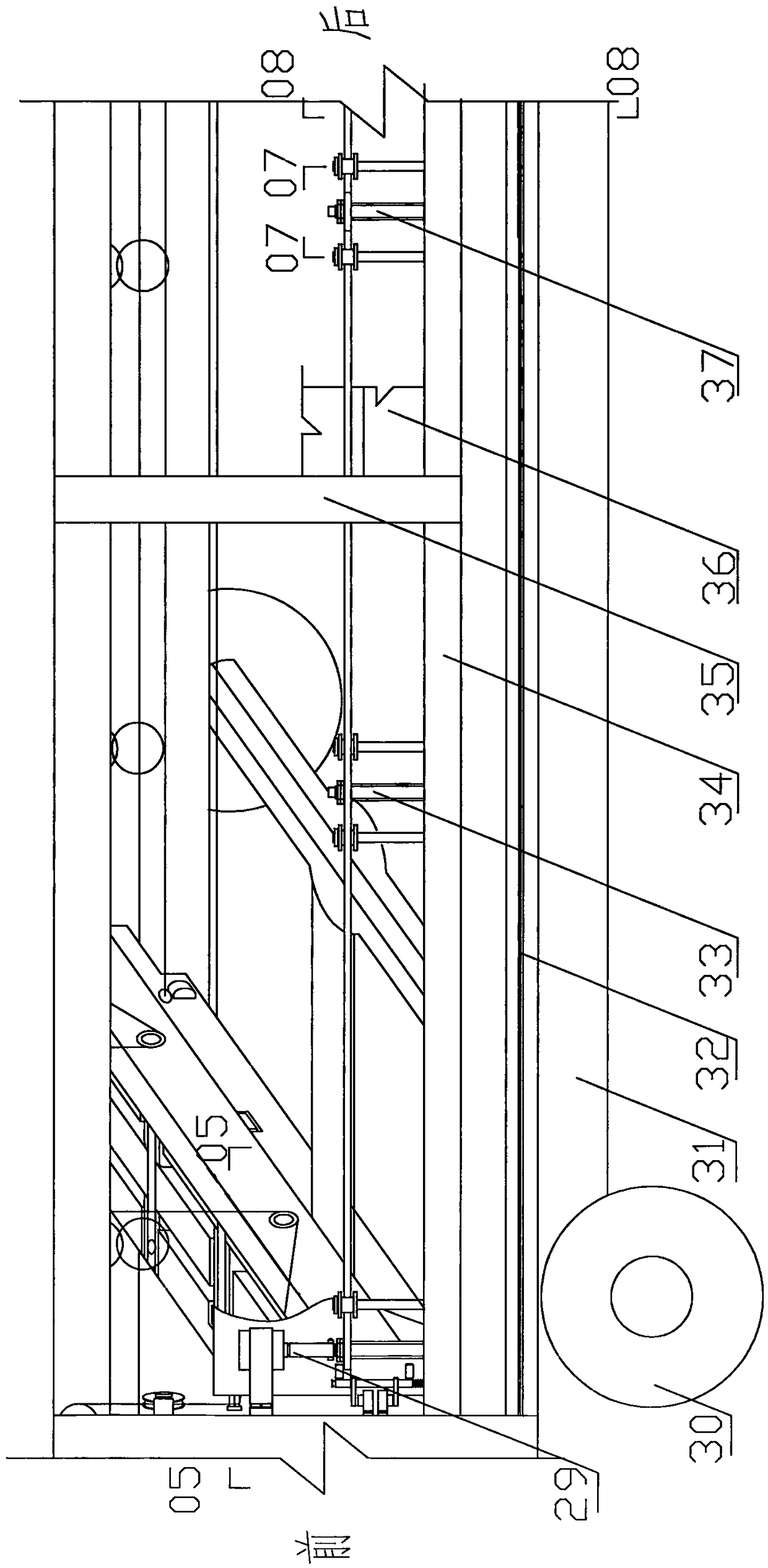

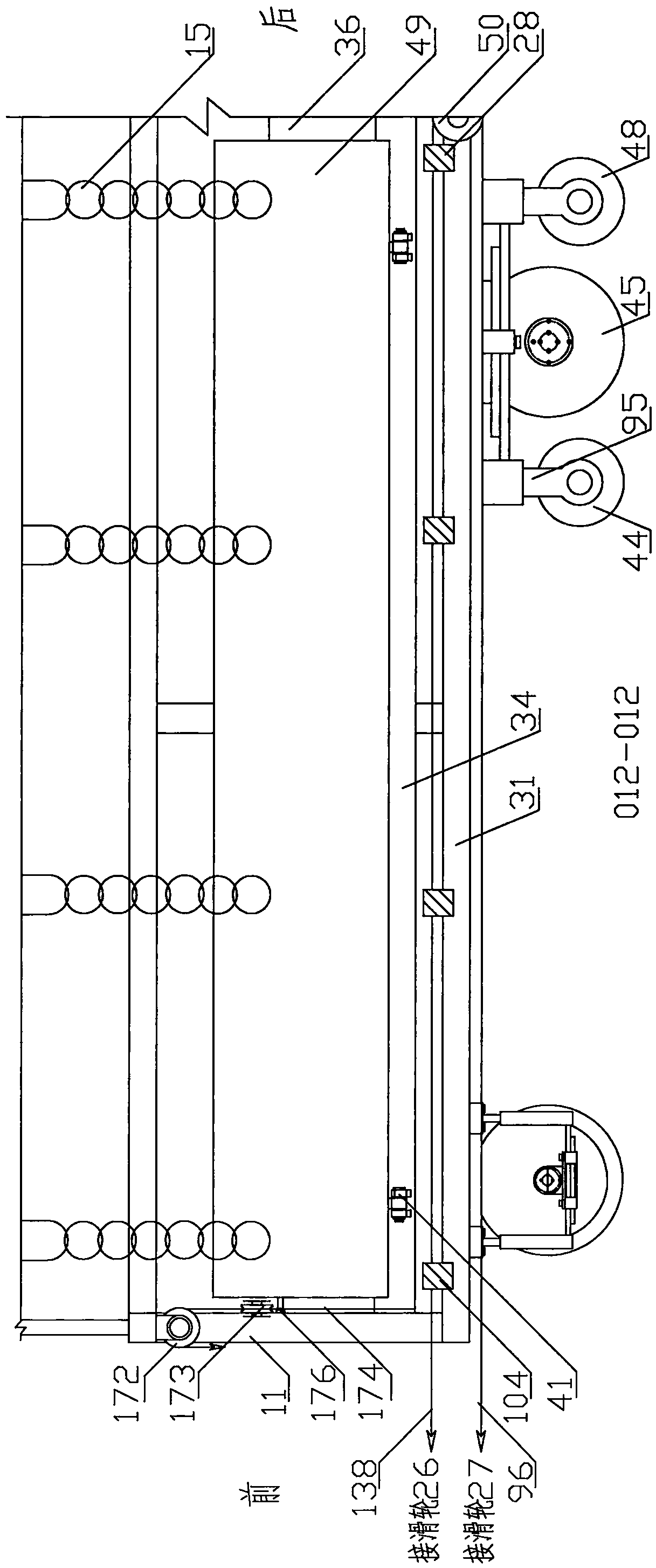

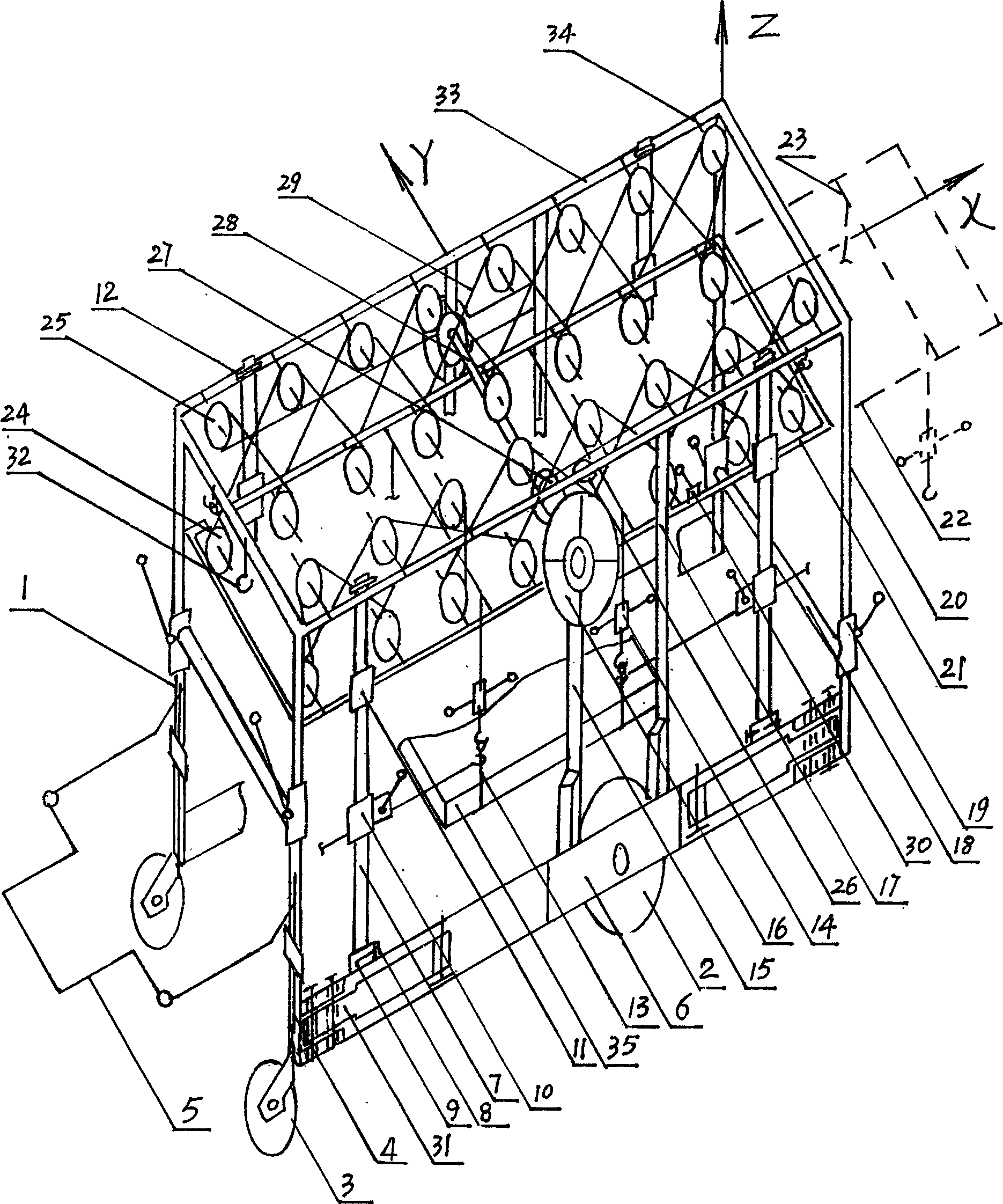

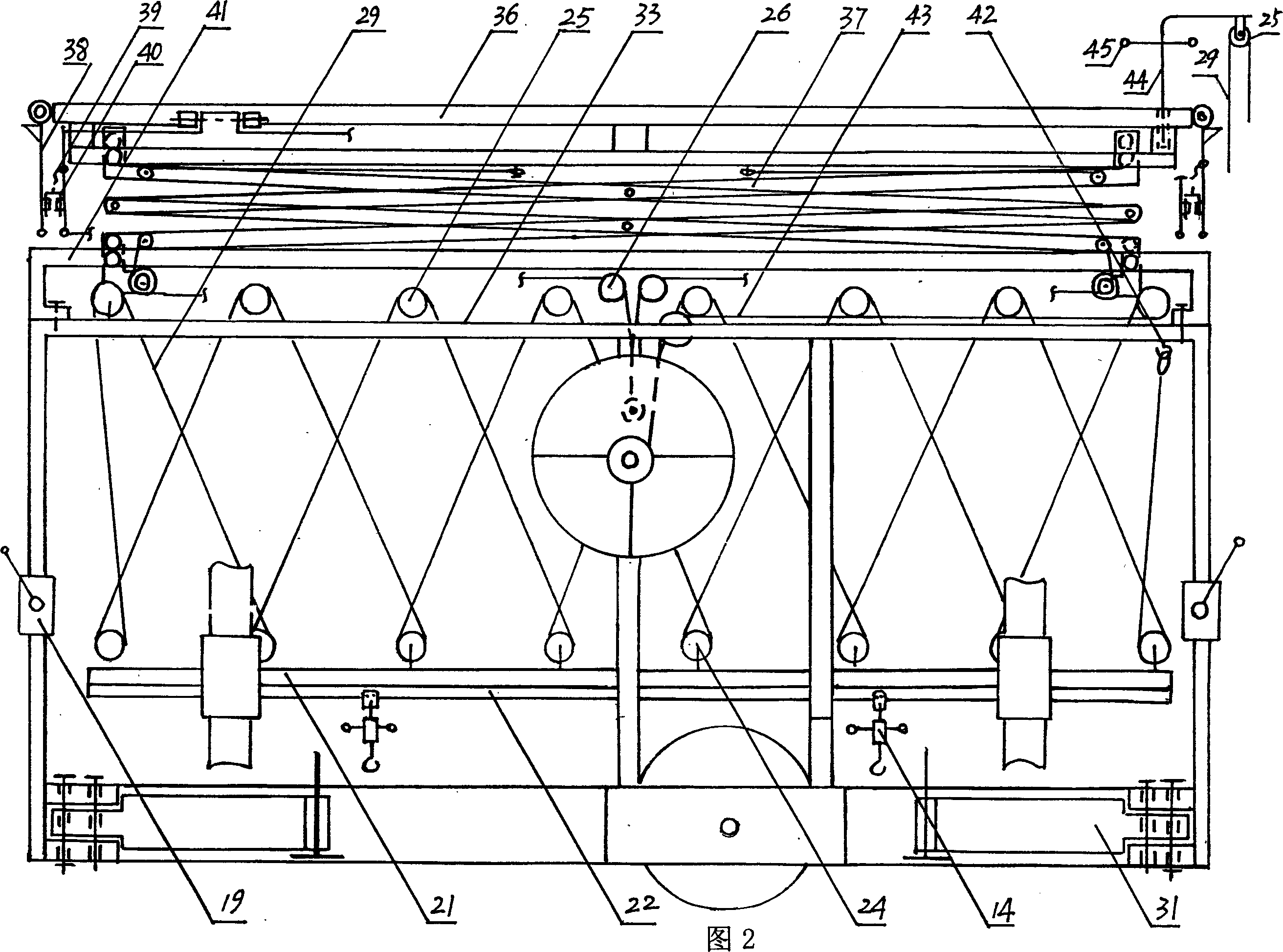

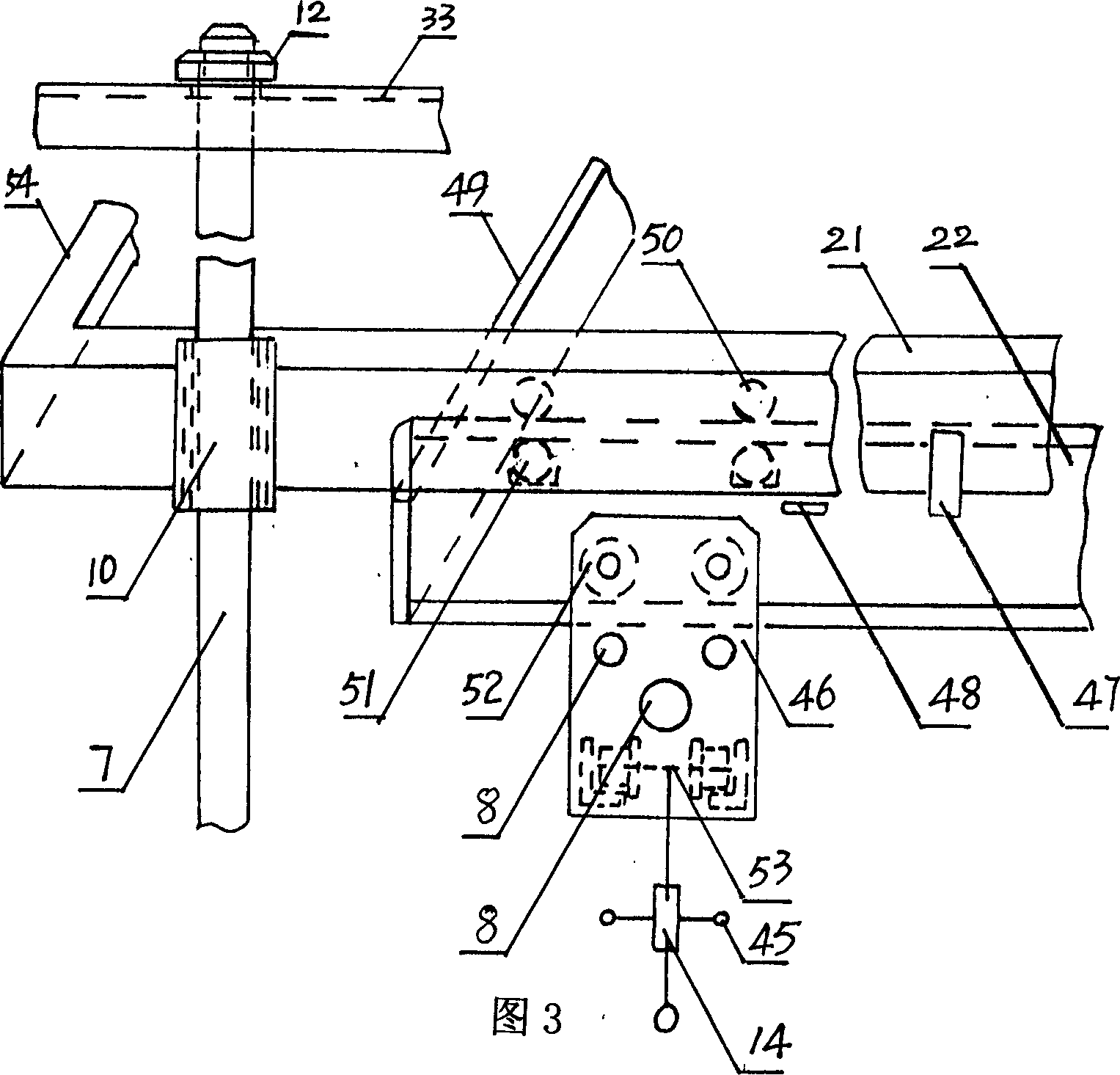

Mounting equipment car

InactiveCN108178074ARealize mechanized constructionReasonable structural stressLifting devicesTravelling gearAutomatic controlMechanical equipment

The invention discloses a mounting equipment car. The mounting equipment car consists of power equipment, a chassis, a car body, electric equipment and the like, and is characterized in that a first extension column 6, a second extension column 12, a third extension column 24 and a fourth extension column 43 are correspondingly mounted at the upper sections of inner cavities of stand columns at four corners of a box; the other end of each stand column is connected to the top of the box; the top of the box can be vertically lifted to lift equipment; an extension lifting crane is mounted at thetop in the box; more than one layers of cross beam support structures and drive connecting devices are mounted on the inner and outer sides of a channel between longitudinal components on the two sides of the box to form a rotary recovered movable plane support structure; the equipment can be carried on cross beams; the cross beams can be automatically recovered on the two sides of the box; and the section of the box is n-shaped. The mounting equipment car reduces the equipment mounting construction flow, removes various cranes, vehicles, forklifts and tools in traditional construction, once finishes lifting, transportation and installation on one car, achieves automatic control and precise installation, realizes mechanical equipment installation, and greatly improves the equipment mounting efficiency.

Owner:白天海

Tunnel bottom concrete side-slipping lining construction method and side-slipping needle beam bottom board trolley

InactiveCN102434171AEasy dischargeImprove construction conditionsUnderground chambersTunnel liningSlip lineTraction system

The invention discloses a tunnel bottom concrete side-slipping lining construction method capable of overcoming the bubble defect and a side-slipping needle beam bottom board trolley. The method sequentially comprises construction steps of in-position of a formwork group, side-slipping pouring of concrete and longitudinal movement of the trolley. Guiding tracks matched with designed linear dimension of a tunnel construction face are respectively and fixedly connected in front of and on the back of the lower portion of a beam frame assembly of the side-slipping needle beam bottom board trolley. The formwork group consists of a pair of slide formworks, the pair of slide formworks is symmetrical with a vertical face where the central line of a beam frame is located and is respectively connected with the guiding tracks through a sliding guide mechanism, and the sliding guide mechanism is connected with the beam frame assembly through a side-slipping traction system. The tunnel bottom concrete side-slipping lining construction method is capable of overcoming the defects of bubbles on the surface of concrete, overlap-joint slab staggering of new and old concrete, temperature cracking and the like, has the advantages of being reliable in structure, quick in lining speed, good in construction quality and safe in construction, reducing interference of construction conditions and the like, and is mainly used for side-slipping lining construction of tunnel bottom concrete.

Owner:广汉金达隧道机械有限公司

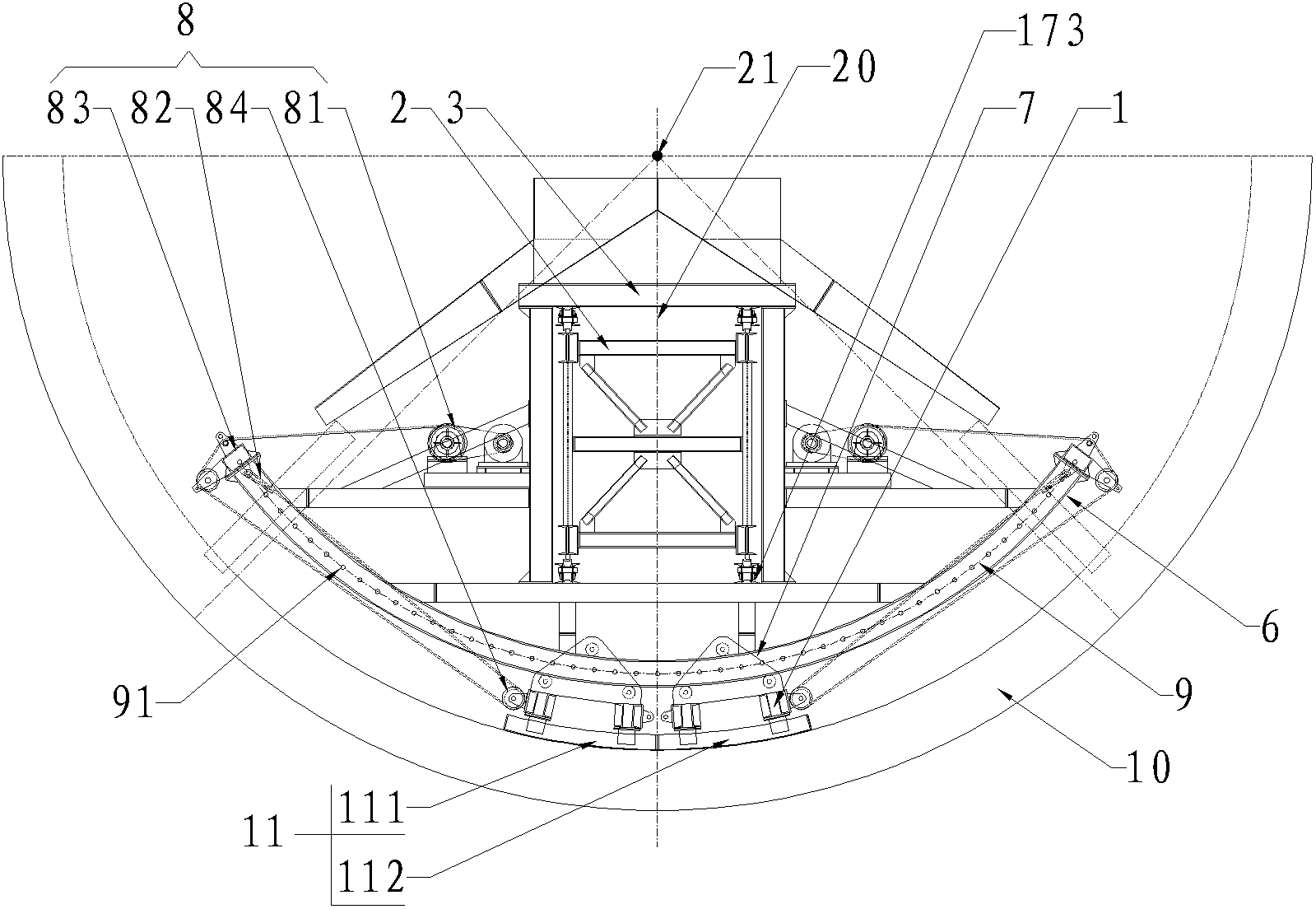

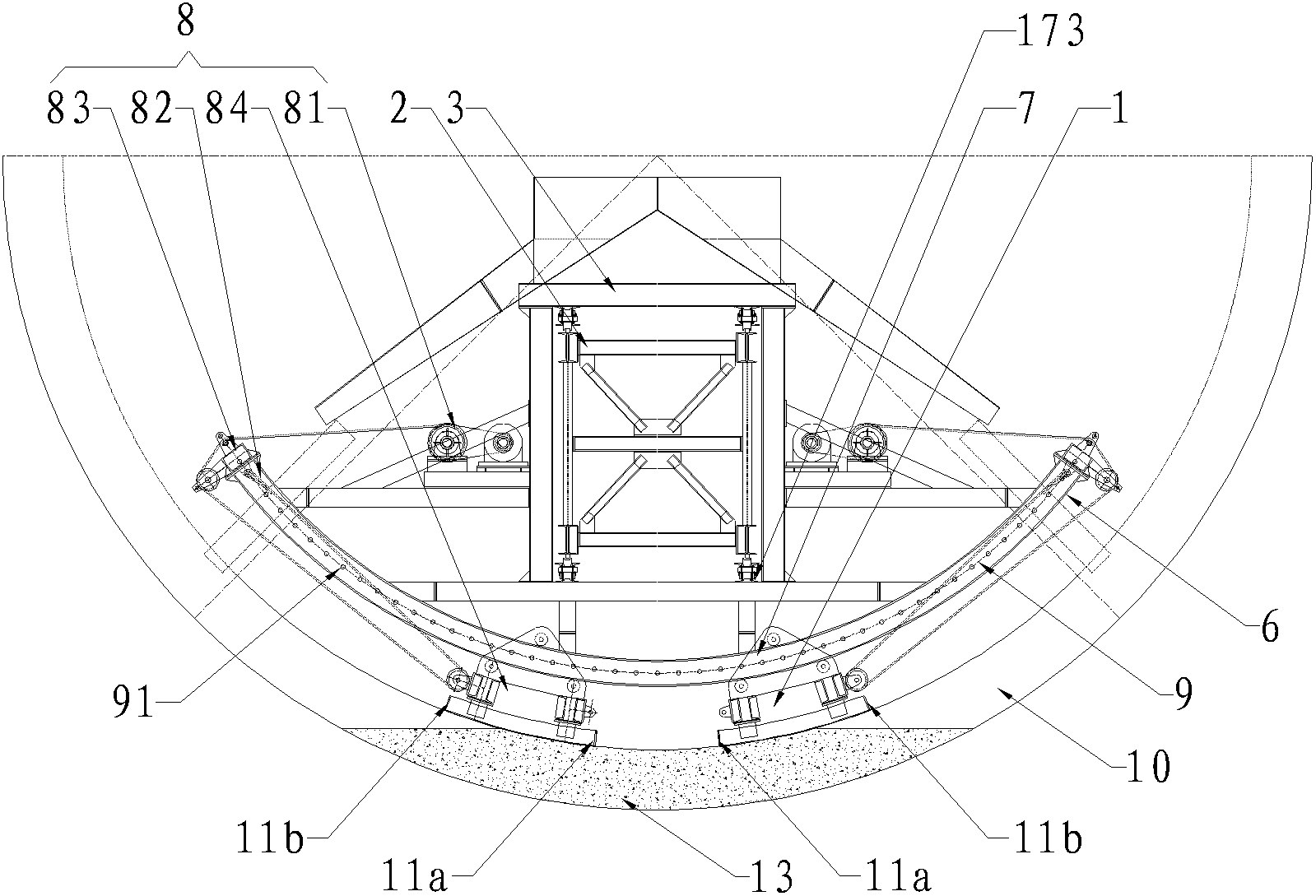

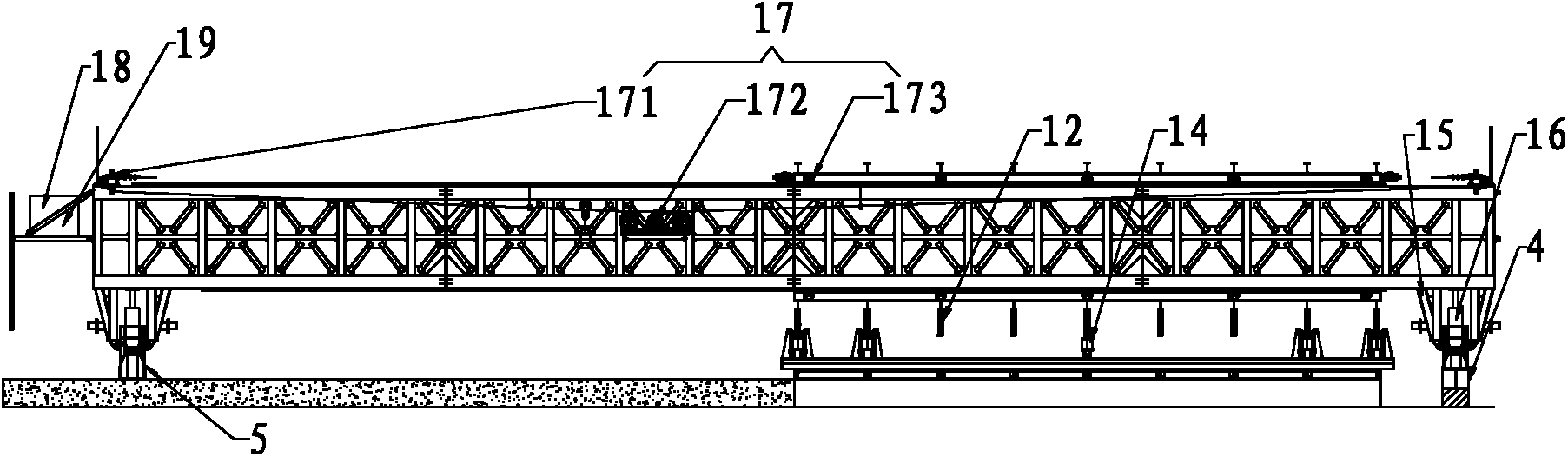

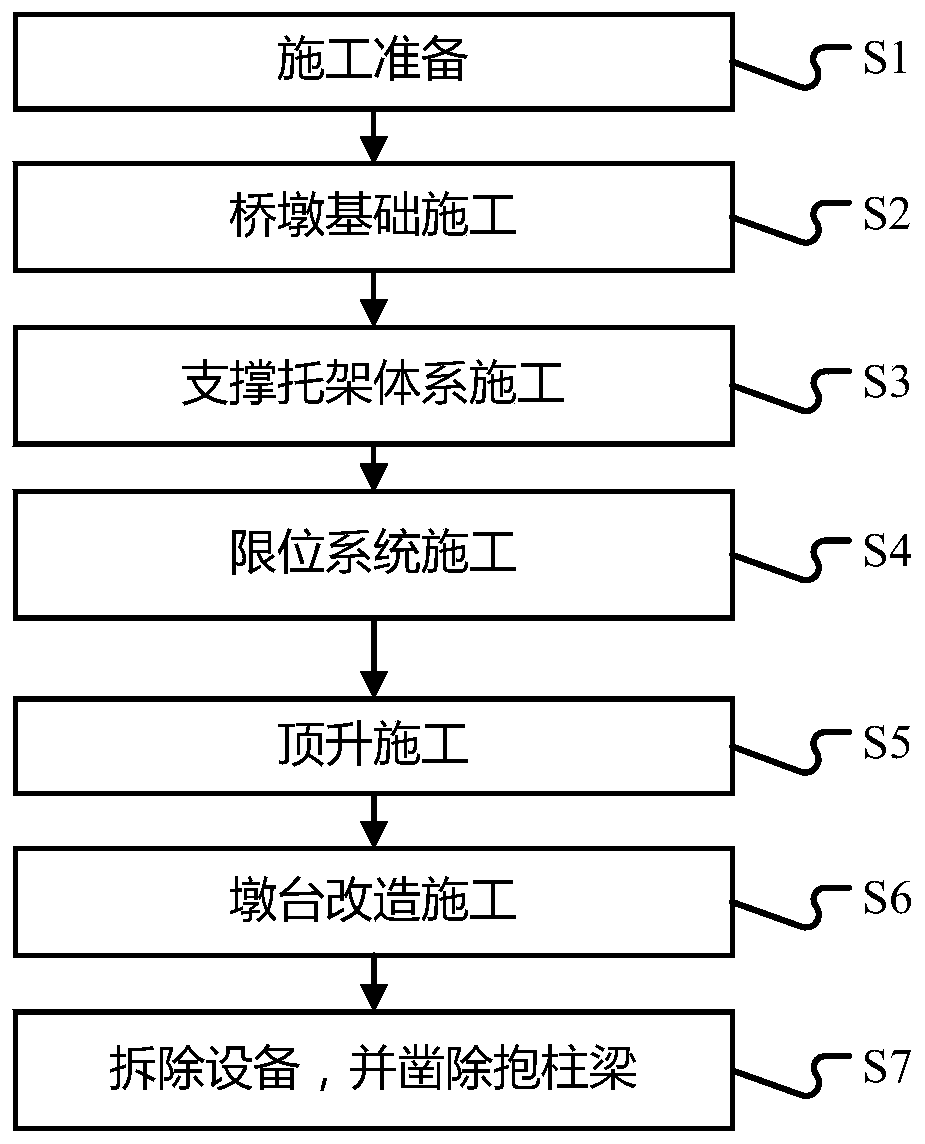

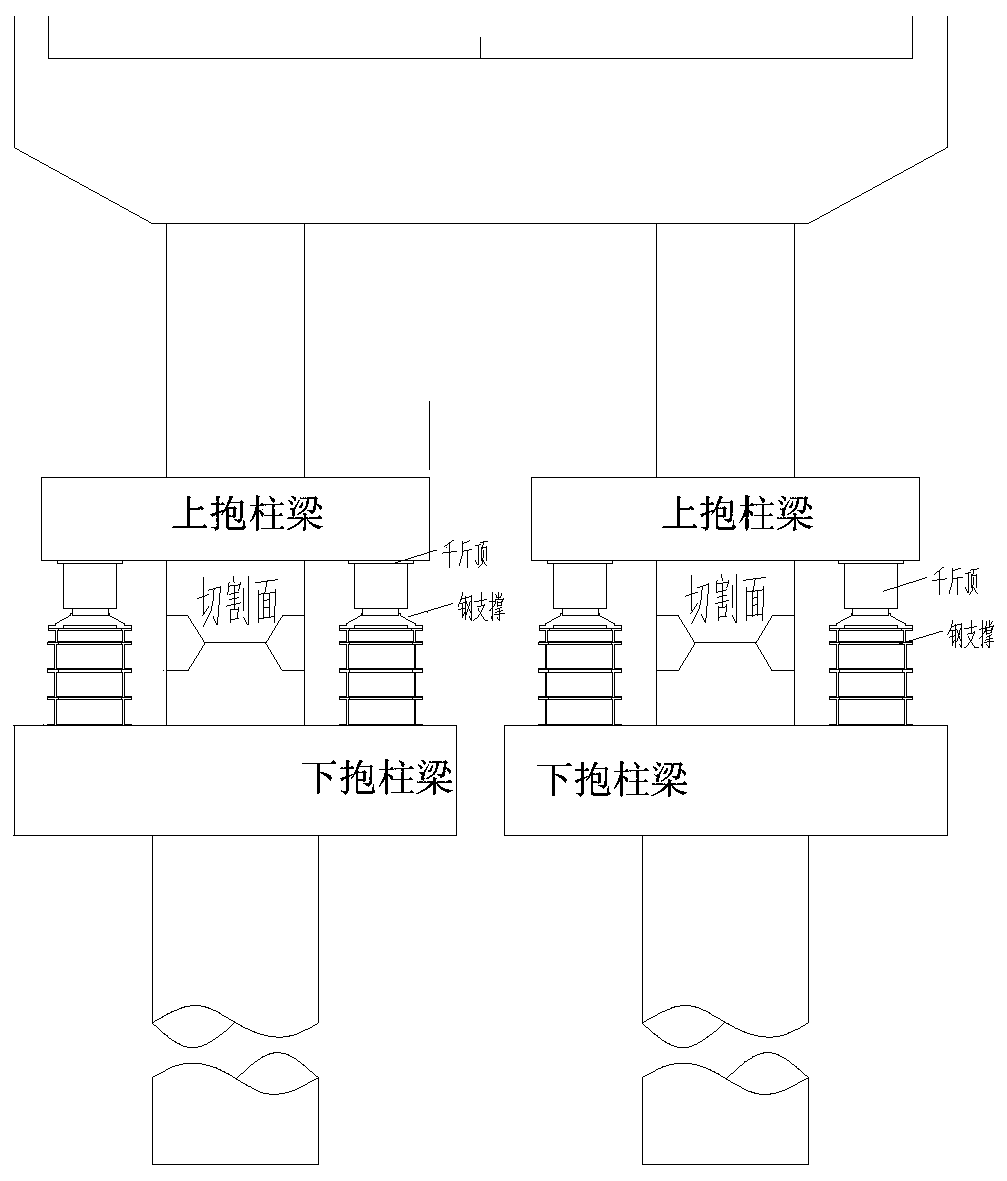

Integral synchronous jacking transformation method of overpass railway flyover

InactiveCN110700117AAlternate jacking for continuous operation safe and controllableSo as not to damageBridge structural detailsBridge erection/assemblySupporting systemArchitectural engineering

The invention provides an integral synchronous jacking transformation method of an overpass railway flyover. Jacks are jacked alternately, continuous operation can be achieved, and safety and controllability are achieved. Due to the fact that alternate jacking is adopted for jacking, in the jacking process of alternate jacking, the beam body is in the state that the two sets of jacks are alternately supported, when the two sets of jacks are alternately supported, the displacement of the beam body is in the controllable state, in each set of supporting state, the compression amount of the supporting system is hardly changed, and therefore the internal force of the beam body is hardly changed. In the operation mode, the displacement of the beam body is continuously in a controlled state fromthe beginning of jacking to the end of jacking. The pressure of each jack is continuously monitored, so that it can be ensured that the beam body can be prevented from being damaged in the jacking process, and the whole bridge jacking system is also in a safe and controllable state. The method is suitable for a series of projects which need to be integrally lifted for construction due to insufficient clearance under the existing flyover, navigation or other conditions.

Owner:CHINA RAILWAY 14TH CONSTR BUREAU GRP 4TH ENG

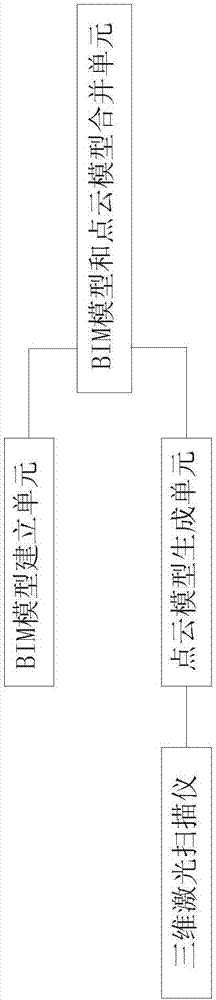

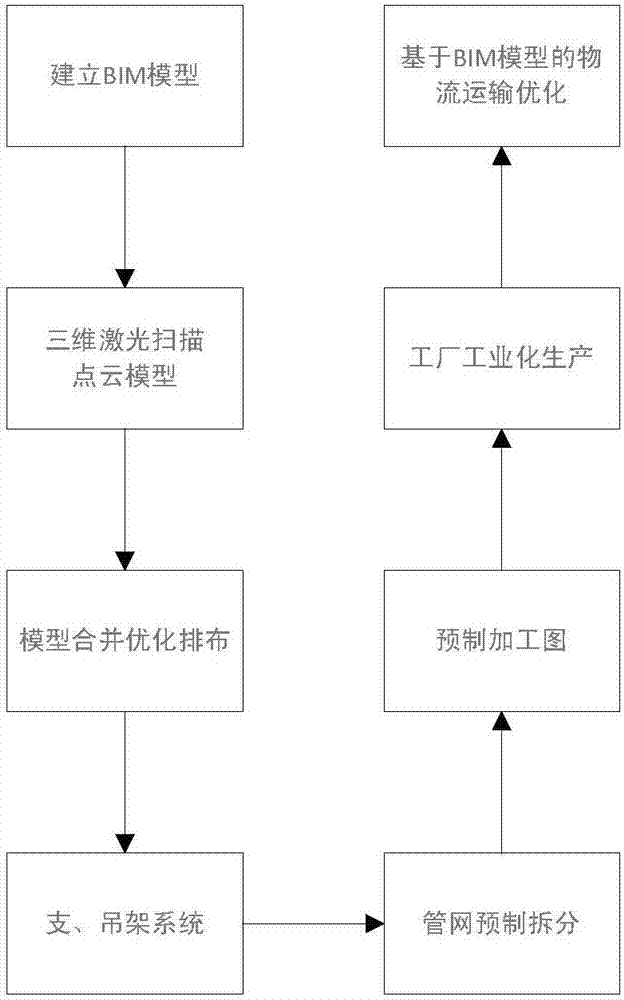

System and method for carrying out prefabrication and field assembly in electromechanical pipe network factory based on building information modeling (BIM)

PendingCN107133431ASatisfy the structural conditionsLow environmental requirementsGeometric CADDetails involving processing stepsPoint cloudLaser scanning

The invention discloses a system and a method for carrying out prefabrication and field assembly in an electromechanical pipe network factory based on building information modeling (BIM). The system comprises a BIM model establishment unit, a three-dimensional laser scanner, a point cloud model generation unit, a BIM model and point cloud model merging unit; the method mainly comprises the steps of establishing a BIM model, carrying out three-dimensional laser scanning to obtain a point cloud model, carrying out merging and optimized configuration on the BIM model and the point cloud model, designing a supporting and hanging bracket system, carrying out prefabricated disassembly on a pipe network and outputting a prefabrication manufacturing drawing, enabling a factory to produce a pipe network according to the prefabrication manufacturing drawing, and transporting the pipe network to the field for assembling. The system and the method help to greatly improve the construction efficiency while meeting the structure conditions of prefabrication manufacturing.

Owner:广州市镒辰智造科技有限公司

Multifunctional engineering installation vehicle

InactiveCN1544307AEasy to operateImprove installation qualityLifting devicesHydraulic cylinderPull force

The present invention discloses a multifunctional engineering installation vehicle used for engineering construction, which comprises a vehicular support frame, a walking and the like. In the vehicle as a gantry supporting frame structure, a extensible guide supporting frame for X axial movement is connected forwards with a Z axial direction tunable movable lift hook; at the C axial movement extensible guide supporting frame, there is an outside force acting at the Z axial direction, which can be a pull force of a armored rope or a cylinder rod clean and jerk force of the hydraulic cylinder and used for pushing the X axial movement extensible guide supporting frame for a vertical motion; a lifting platform is installed at the vehicle roof to execute pipe laying pipe laying, anti-corrosion, heat preservation, laying and maintenance of cable rope and crane span structure, and the like; the Z axial direction tunable movable lift hook inside the vehicle is used for lifting and loading articles of merchandise to realize installation of equipments; a labor saving and quick-releasing pipeline frame is allocated for carriage of pipelines; a ground tray is allocated, which is used for lifting, loading and transporting large and heavy workpieces. The multifunctional engineering vehicle is a powerful machinery for constructions, and the plurality of functions mentioned above greatly improves the installation quality, saves 2 times for the human energy and improves the work efficiency more than 10 times.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

Compound concrete anti-corrosion and rust-resistant agent

The invention discloses a compound concrete anti-corrosion and rust-resistant agent which comprises the following components in parts by weight: 15-30 parts of a polycarboxylic acid water reducing agent, 3-12 parts of sodium dodecyl sulfate, 15.7-20.6 parts of N-dimethylethanolamine, 1-5 parts of sodium molybdate, and 50-60 parts of water. The compound concrete anti-corrosion and rust-resistant agent can block capillary holes in the concrete, improves the chloride ion permeability resistance of concrete, can significantly alleviate the damage of chloride ions on a reinforcing steel bar passivation film, enhances the sulfate corrosion resistant ability of the concrete, has excellent rust-resistant performance and good repair performance, can enhance durability of the concrete and the comprehensive anti-corrosion ability of the concrete, and significantly improves the durability of buildings.

Owner:HUNAN CONSTR ENG GRP COR +1

Coating material for surface coating of waterproof membrane and preparation method thereof

ActiveCN101575475AHigh tensile strengthHigh elongationMulticolor effect coatingsPolymer sciencePolymer

The invention relates to a coating material for the surface coating of a waterproof membrane and a preparation method thereof. The coating material is prepared by the following method of: mixing and synthesizing a raw material consisting of a component A, a component B, a component C and a component D to obtain a polymer emulsion, wherein the component A comprises 90.0-130.0 weight portions of deionized water; the component B comprises 9.0-22.0 weight portions of deionized water, 0.5-1.5 weight portions of sulfate and 0.1-1.0 weight portion of polymerizing agent; the component C comprises 98.0-128.5 weight portions of deionized water, 0.2-5.0 weight portions of sulfate, and 2.5-4.5 weight portions of polymerizing agent; the component D comprises 150.0-260.0 weight portions of acrylic acid ester, 3.0-10.0 weight portions of methacrylic acid, 5.0-20.0 weight portions of organic fluorine and 5.0-20.0 weight portions of organosilicon; filling a filling material, a nano-material and an additive in the polymer emulsion and carrying out uniform dispersion simultaneously; adjusting the pH value to 8-9 by an ammonia; adding a thickener subsequently and filtering the solution, thus obtaining the colorful nano-fluorine silicone-acrylate coating materials. The coating materials are uniformly coated on the surface of the waterproof membrane, and the solidified and bonded colorful nano-fluorine silicone-acrylate coating has high tensile strength, large fracture elongation, good weathering resistance and low-temperature resistance, excellent heat resistance and stability and various color types.

Owner:KESHUN WATERPROOF TECH CO LTD

Organic bentonite composition modified emulsified asphalt and its preparing method

The invention relates to an organobentonite composition modified emulsified bitumen and its preparing method. The bitimen is composed of 60-62 protions base bitumen,34-36.4 protions water,0.5-0.8 protions cationic emulsifier,1-3 protions organobentonite,2-4 protions butadiene styrene latex,0.1-0.2 protions thickening agent.Its prparing method comprises: mixing emulsifier solution uniformly, then mixing and emulsifying with base bitumen by emulsifying machine, then adding organobentonite and thickening agent to emulsified bitumen, mechanically stirring, mixing uniformly and deforming to obtain modified emulsifier bitumen. The invention has advantages of fine capability, high production efficiency, easy control, convenient operation and low cost.

Owner:NORTHWEST NORMAL UNIVERSITY

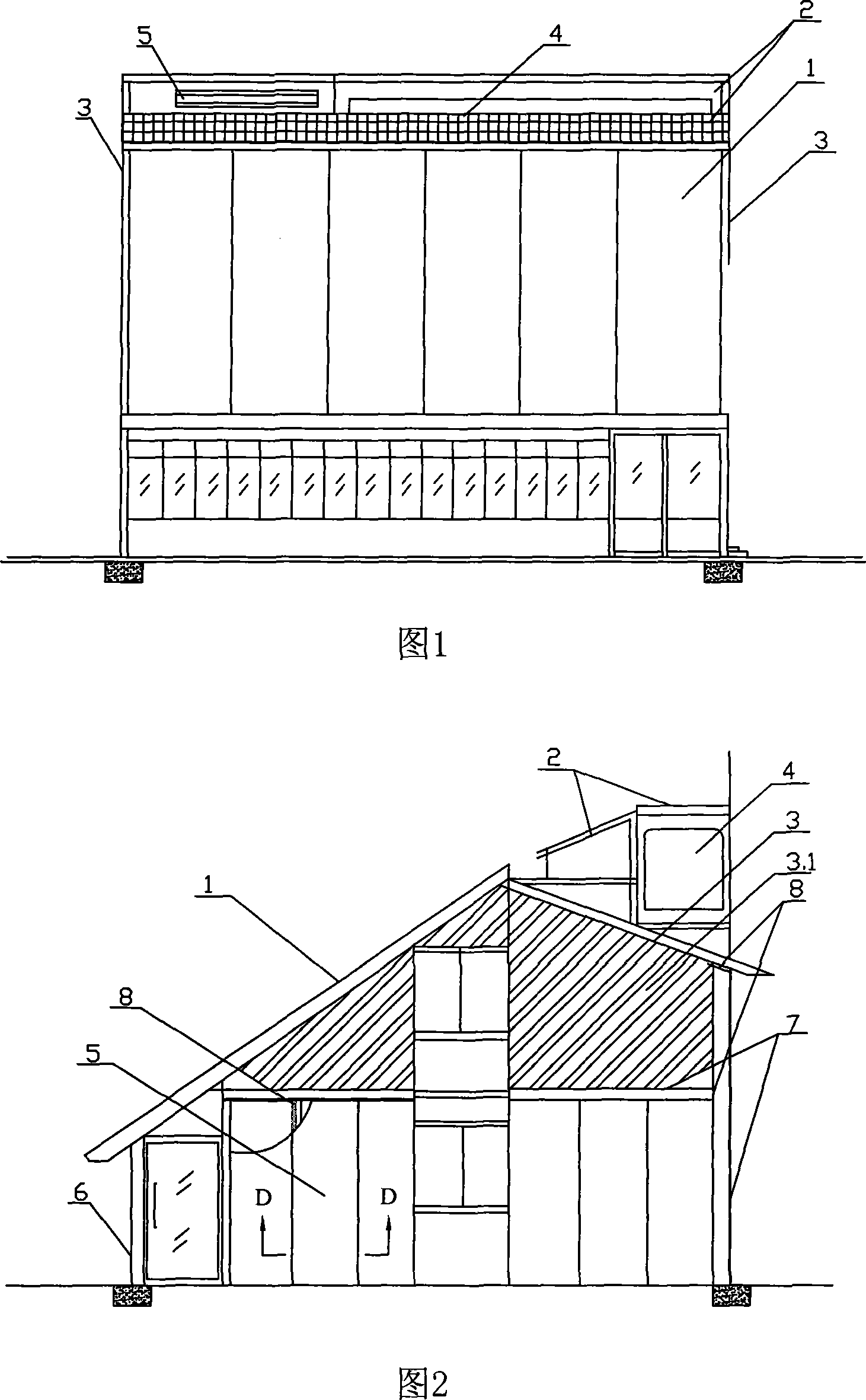

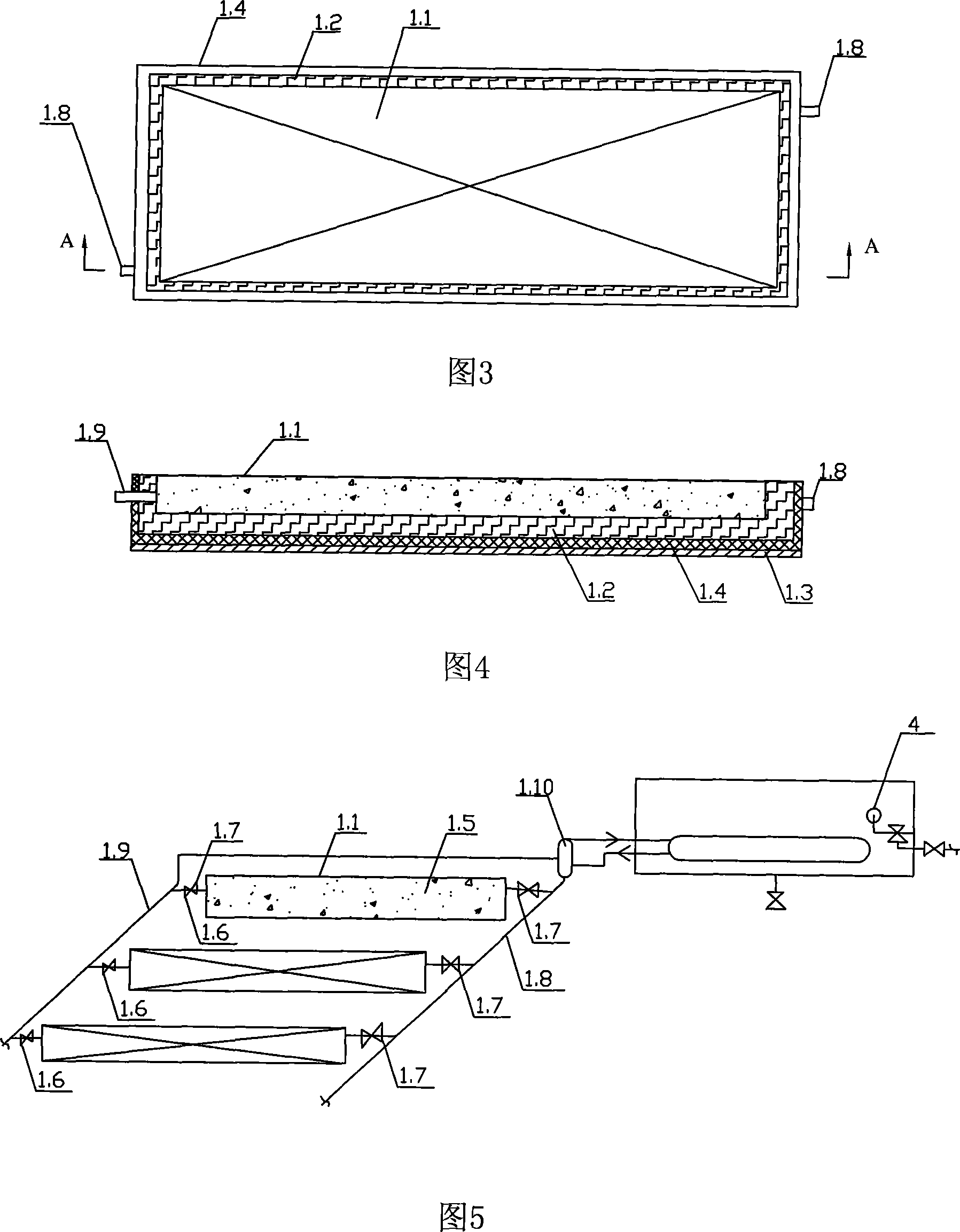

Factory produced solar energy integration ecological energy-saving building

InactiveCN101122149ALow costEfficient use ofRoof covering using slabs/sheetsRoof covering using tiles/slatesThermal energyBuilding design

The invention relates to an energy saving building, in particular to a modularized and combined solar all-in-one ecological energy saving building with functions manufactured in the factory as required by the users. The solar all-in-one ecological energy saving building of the invention includes a solar collector heat preserving roof, a film solar battery heat preserving roof, a solar generating curtain wall and a main wall surface; all the assembly components are fixed on a main steel frame of the building to form the all-in-one structure; the building is provided with a solar heat-collecting converter, which is connected with the solar heat collector heat preserving roof by a pipe. The building stores the heat converted from light in the solar converter, so as to supply heat energy (heat supply, warming and air conditioning) to buildings; stores the electric energy converted from light in the accumulated battery, so as to supply electric energy (lighting and power) to buildings. The building design achieves self-contained energy.

Owner:王剑英 +1

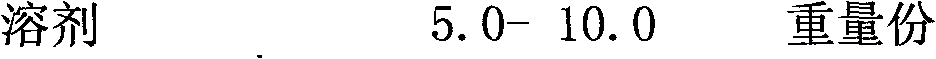

Super-strength polyurethane waterproof coating and preparation method thereof

InactiveCN102433061AElastomerImprove strong adhesionPolyurea/polyurethane coatingsSolventChlorinated paraffins

The invention relates to a super-strength two-component polyurethane waterproof coating which is made of petroleum resin. The polyurethane waterproof coating is prepared by the following method. The raw materials of the polyurethane waterproof coating comprise a component A and a component B, wherein the component A contains 60.0-70.0 parts of polyether diol, 10.0-20.0 parts of polyether polyol and 15.0-25.0 parts of chain extender by weight; and the component B contains 30.0-35.0 parts of chlorinated paraffin, 20.0-25.0 parts of vulcanizing agent, 5.0-10.0 parts of polyether polyol, 10.0-15.0 parts of petroleum resin, 15.0-20.0 parts of filler, 0.03-0.1 parts of assistant and 5.0-10.0 parts of solvent by weight. Since the petroleum resin is added into the raw materials of the super-strength two-component polyurethane waterproof coating and has unsaturated bonds which can be bonded with polyurethane in the generation process of the polyurethane to increase the length of molecular chains, the tensile strength and the elongation at break of the coating film are greatly improved and the mechanical properties are better than that of the product in which the petroleum resin is not added. At the same time, since the price of the petroleum resin is low, the material is convenient to obtain, the cost of the two-component polyurethane waterproof coating product is low and the economic benefit is greater.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

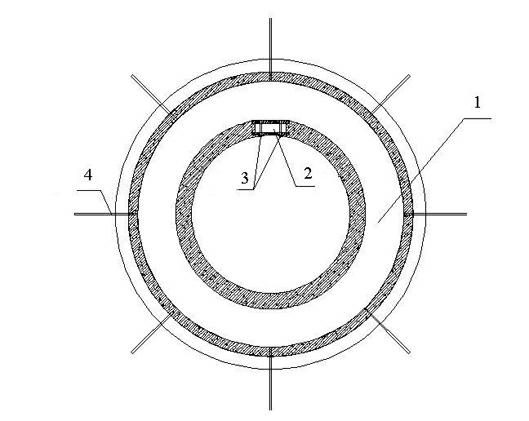

Freezing method of frozen wall of inclined shaft

The invention provides a freezing method of a frozen wall of a frozen wall of an inclined shaft, solving the problems of difficulty in digging in the construction because an aquifer of the inclined shaft is frozen and low construction speed and meeting safe and rapid construction requirements of the aquifer of the inclined shaft. The freezing method comprises the following steps of: drilling multiple rows of freezing holes which are parallel to each other and vertically distributed, on the group, along an axial freezing range of the inclined shaft, wherein the row number of the freezing holes is determined according to the cross section size of the inclined shaft and the required freezing time, the freezing holes at the lateral part and the freezing holes at the end part respectively go deep into a water-resisting layer in the depth, water in the aquifer at the lower part is isolated by the water-resisting layer, and the freezing holes at the top go deep into the top of the inclined shaft in depth; then arranging a freezing pipe and a liquid supply pipe in each drilled freezing hole, wherein the freezing pipe and the liquid supply pipe in each drilled freezing hole are communicated with an external freezing station; and finally, starting the freezing station and enabling low-temperature saline water prepared by the freezing station to flow in the each freezing pipe to absorb heat of the stratum around each freezing pipe to form a frozen cylinder, wherein all frozen cylinders are continuously enlarged and further connected to form the frozen wall which can resist earth pressure and water pressure.

Owner:YANKUANG GRP CO LTD +1

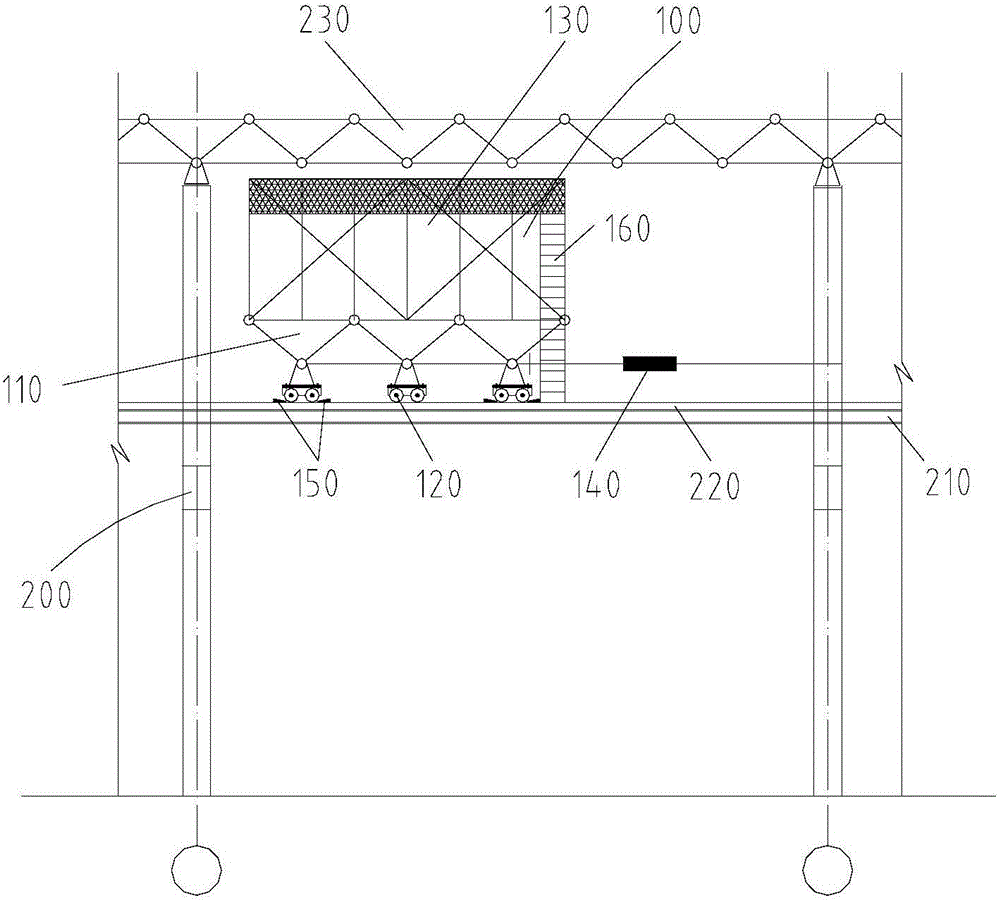

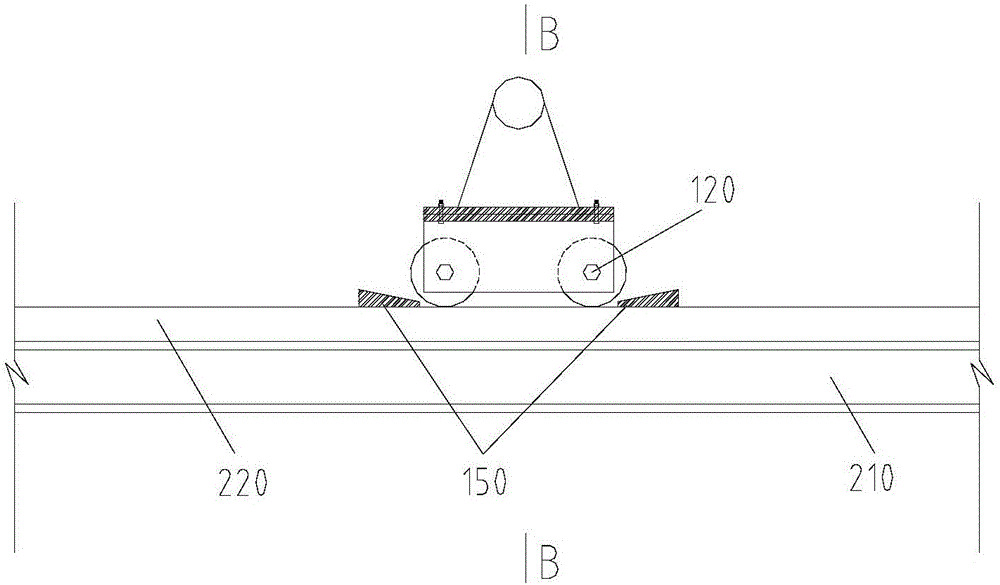

Sliding platform and construction method for separately mounting grid structures on high altitudes

ActiveCN106223595AMeet the requirements of continuous installationGood sliding safetyBuilding support scaffoldsOverhead craneIndustrial Factory

The invention discloses a sliding platform and a construction method for separately mounting grid structures on high altitudes. The sliding platform for separately mounting the grid structures on the high altitudes is arranged in an industrial factory building. The industrial factory building is provided with crane beams, and overhead crane tracks are arranged on the crane beams. The sliding platform for separately mounting the grid structures on the high altitudes comprises a grid structure type sliding platform, a scaffold operating platform and pulling equipment. The grid structure type sliding platform is slidably arranged on the overhead crane tracks via a plurality of sliding rollers; the scaffold operating platform is arranged on the upper surface of the grid structure type sliding platform; the pulling equipment is connected onto the grid structure type sliding platform, so that the grid structure type sliding platform can slide along the overhead crane tracks. The mounting quality of the grid structures, with bolt-sphere joints, of the industrial factory building can be sufficiently guaranteed, the time and labor can be saved, and the safety of staffs for constructing the grid structures on the high altitudes and the safety of construction staffs below the staffs can be guaranteed. The sliding platform and the construction method have the advantages of flexibility, convenience, speediness and low cost. Besides, merits can become obvious along with increase of ratios of the longitudinal lengths to the span of the grid structure.

Owner:CHINA IPPR INT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com