Super-strength polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and ultra-high-strength technology, applied in the field of building waterproof materials, can solve the problems of insufficient physical indicators such as wear resistance and impact resistance, and poor performance of polyurethane waterproof coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] 1. Raw material composition

[0088] Group A is divided into:

[0089] Polyether N220 60.0 parts by weight

[0090] Polyether Dl2000 15.0 parts by weight

[0091] MDI-100 25.0 parts by weight

[0092] Group B is divided into:

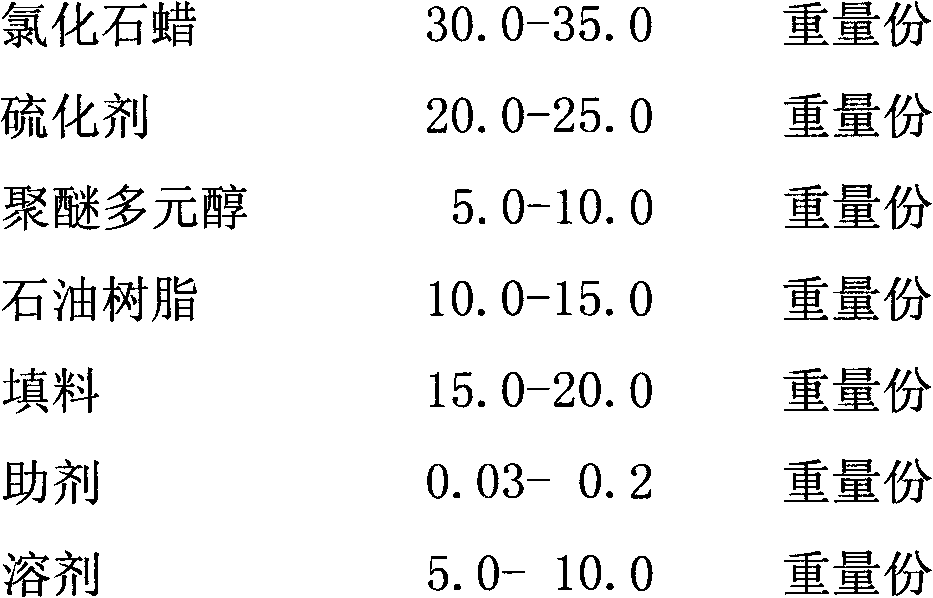

[0093]

[0094]

[0095] 2. Preparation method

[0096] The preparation method of polyurethane waterproof coating of the present invention carries out according to the following steps:

[0097] a. First, spray the reactor with solvent twice and then dry it for later use;

[0098] b. Check the tightness of the joints of the reactor and the suitability of the vacuum pump to ensure that the vacuum in the reactor can meet the production requirements of the product;

[0099] c. Start the vacuum pump, open the vacuum valve and the suction valve, and draw the quantitative ratio of polyether in the formula into the reaction kettle. Then, close the vacuum valve;

[0100] d. Turn on the high-speed mixer, and at the same time open the steam va...

Embodiment 2

[0107] 1. Raw material composition

[0108] Group A is divided into:

[0109] Polyether EP2000 65.0 parts by weight

[0110] Polyether Dl2000D 20.0 parts by weight

[0111] MDI-50 15.0 parts by weight

[0112] Group B is divided into:

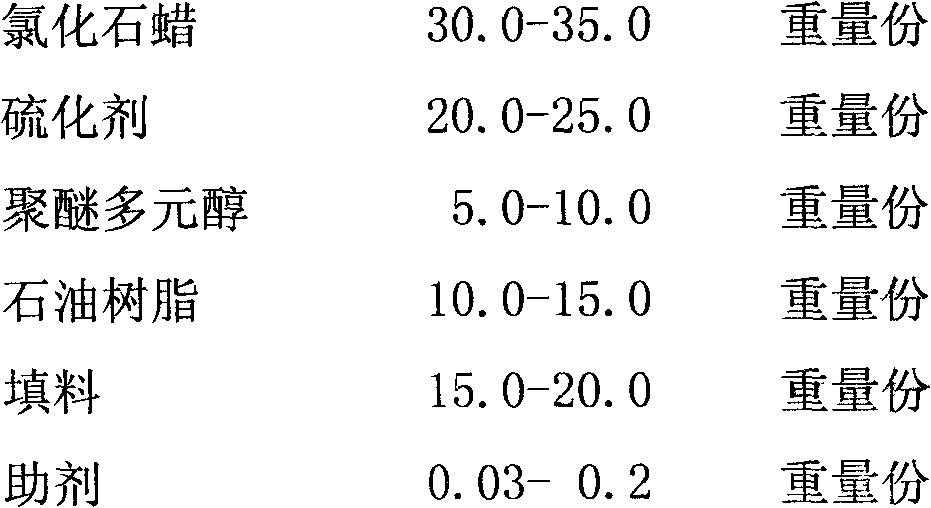

[0113]

[0114]

[0115] 2. Preparation method

[0116] The preparation method of polyurethane waterproof coating of the present invention carries out according to the following steps:

[0117] a. First, spray the reactor with solvent twice and then dry it for later use;

[0118] b. Check the tightness of the joints of the reactor and the suitability of the vacuum pump to ensure that the vacuum in the reactor can meet the production requirements of the product;

[0119] c. Start the vacuum pump, open the vacuum valve and the suction valve, and draw the quantitative ratio of polyether in the formula into the reaction kettle. Then, close the vacuum valve;

[0120] d. Turn on the high-speed mixer, and at the same time open the steam ...

Embodiment 3

[0127] 1. Raw material composition

[0128] Group A is divided into:

[0129]

[0130]

[0131] Group B is divided into:

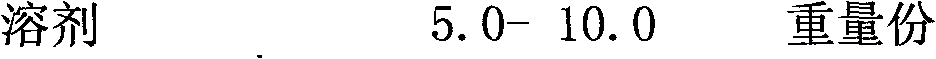

[0132]

[0133] 2. Preparation method

[0134] The preparation method of polyurethane waterproof coating of the present invention carries out according to the following steps:

[0135] a. First, spray the reactor with solvent twice and then dry it for later use;

[0136] b. Check the tightness of the joints of the reactor and the suitability of the vacuum pump to ensure that the vacuum in the reactor can meet the production requirements of the product;

[0137] c. Start the vacuum pump, open the vacuum valve and the suction valve, and draw the quantitative ratio of polyether in the formula into the reaction kettle. Then, close the vacuum valve;

[0138] d. Turn on the high-speed mixer, and at the same time open the steam valve that supplies heat to the reactor, and start to heat up. When the temperature rises to 80°C, turn on the vacuum pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com