A kind of environment-friendly water tank and its production process

A production process and water tank technology, applied in the field of environmental protection water tanks and their production processes, can solve the problems of reduced service life, use safety problems, easy corrosion of the cover, etc., to achieve good corrosion, resist erosion, improve service life and The effect of safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

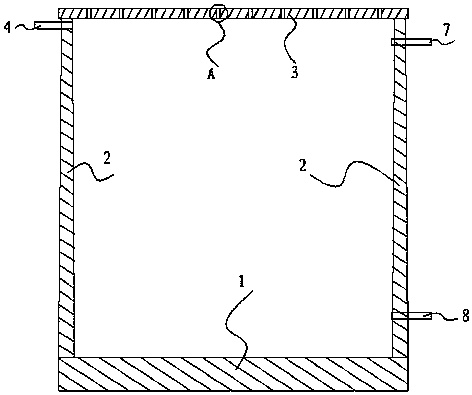

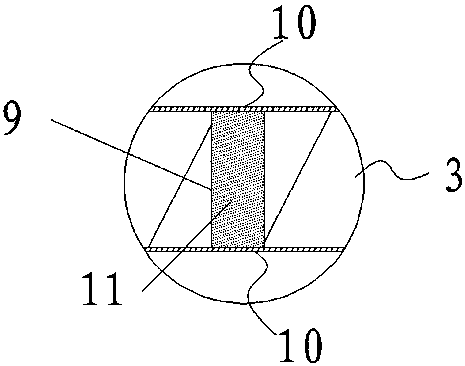

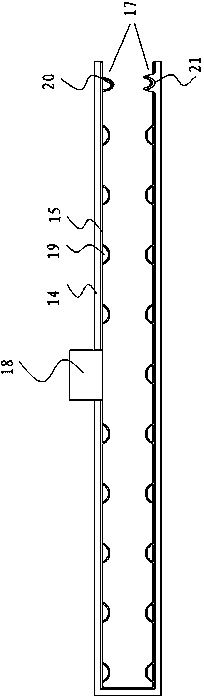

[0030] Such as Figure 1-Figure 5 As shown, an environmentally friendly water tank includes a base 1 and a side wall 2 arranged on the base 1, the upper end of the side wall 2 is provided with a water tank cover 3; the base 1 is circular, and the base 1 and the side wall 2 is integrally cast and formed, and the side wall 2 is provided with a water inlet 7, a water outlet 8 and a water overflow 4; the surfaces of the base 1, the side wall 2, and the water tank cover 3 are all sprayed with an epoxy resin layer 10.

[0031] The base 1, the side wall 2 and the water tank cover 3 are all made of carbon steel.

[0032] The water tank cover 3 is circular, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com