Patents

Literature

1496results about How to "Hydrophobic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aromatization catalyst, its preparation method and application

ActiveCN1651141ALipophilicHigh aromatization activityMolecular sieve catalystsHydrocarbonsMolecular sieveAdhesive

An aromatizing catalyst for molifying poor gasoline to prepare high-octane gaseline component or arylhydrocarbon is prepared from the Zn, P and RE metal modified HZSM-5 molecular sieve, Y-type molecular sieve, carrier and adhesive proportionally.

Owner:CHINA PETROCHEMICAL CORP +1

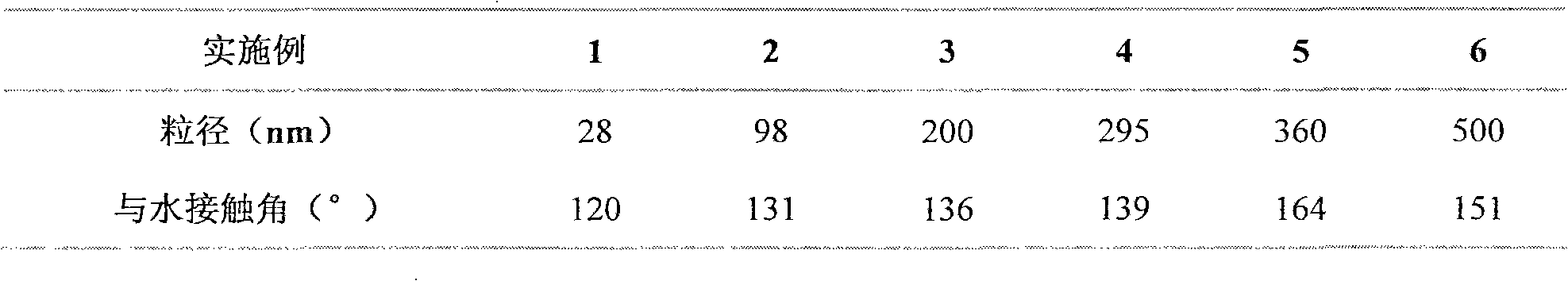

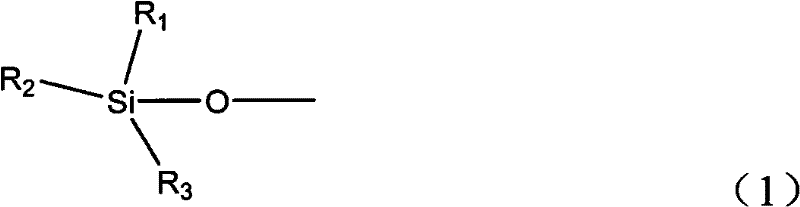

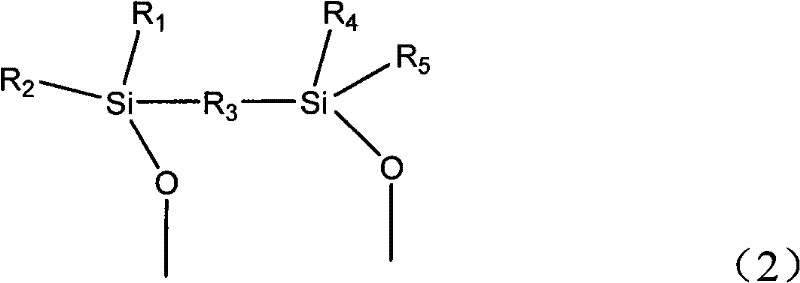

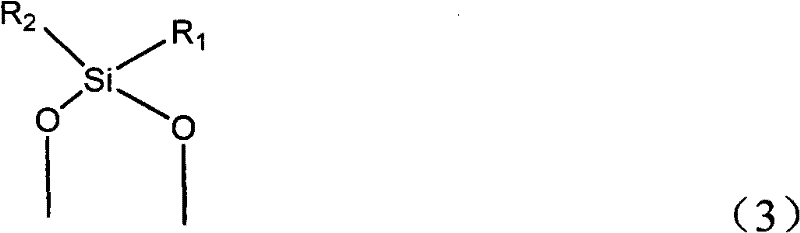

Method for preparing hydrophobic nano-silica with controllable grain diameter

InactiveCN101880478AGood dispersionHydrophobicPigment treatment with organosilicon compoundsSal ammoniacReaction temperature

The invention discloses a method for preparing hydrophobic nano-silica with a controllable grain diameter. The method comprises the following steps of: adding ammonia water and water into absolute ethanol and stirring the mixture for 0.5 to 1 hour at the temperature of between 20 and 70 DEG C; under an alkali condition, performing hydrolytic polycondensation to obtain nano-silica by using the absolute ethanol as solvent and tetraethoxysilane as a raw material; and preparing the hydrophobic nano-silica with the grain diameter in the range of between 20 and 500 nm by using a silane coupling agent as a hydrophobic modifier, wherein the using amount of ammonia water is 40 to 100 percent of the weight of the tetraethoxysilane; the using amount of the absolute ethanol is 12 to 25 times the weight of the tetraethoxysilane; and the using amount of the water is 30 to 150 percent of the weight of the tetraethoxysilane. The preparation method has the advantages of simpleness, easy operation and mild reaction condition. The hydrophobic nano-silica with the controllable grain diameter can be prepared by adjusting proportion and technological parameters of the materials.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing alcohols by selectively hydrogenating aldehydes

ActiveCN102408304AHigh selectivityHydrophobicOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSilanesReaction temperature

The invention relates to a method for preparing alcohols by selectively hydrogenating aldehydes, belonging to hydrogenation technologies. In order to meet the requirements of people on two aspects, i.e. the improving of the selectivity on preparing the alcohols by hydrogenating the aldehydes and the prolonging of the service life of a catalyst currently, the method proposes that: the aldehydes are taken as raw materials; the reaction temperature is 20-300 DEG C; the reaction pressure is 0.1-7.0 MPa; the weight space velocity of the aldehydes is 0.02-20 h<-1>; the aldehydes and hydrogen gas are in contact with a hydrogenation catalyst; and the aldehydes are produced into corresponding alcohols through selectively hydrogenating. In the method, the hydrogenation catalyst comprises a carrier, a metal active component and silane groups; the silane groups are grafted through a silylanizing treatment; and the content of the silane groups in the total weight of the catalyst is 0.05 wt% to 25 wt%. Compared with the existing method, with the adoption of the catalyst in the method provided by the invention, the selectivity is high, the amount of byproducts, such as ethers, esters and acetals is greatly lowered; and meanwhile, the generation amount of carbon deposit is little, so that the catalyst has longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

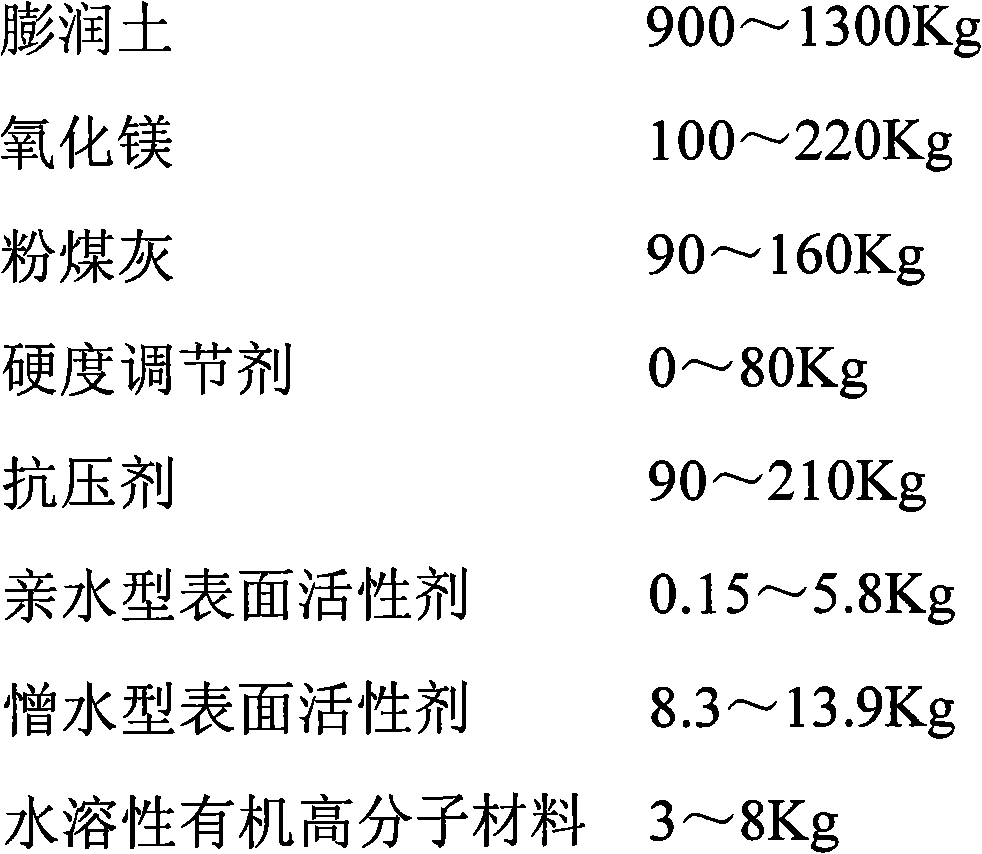

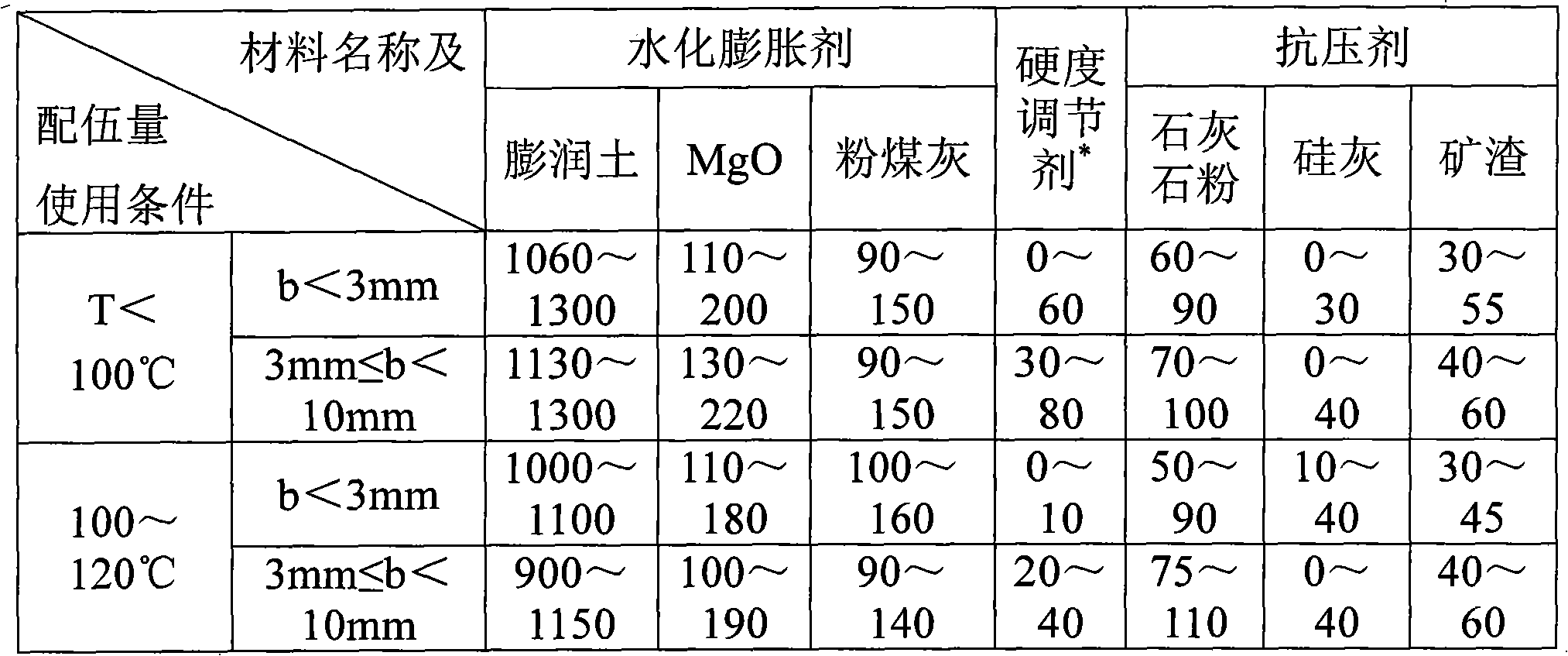

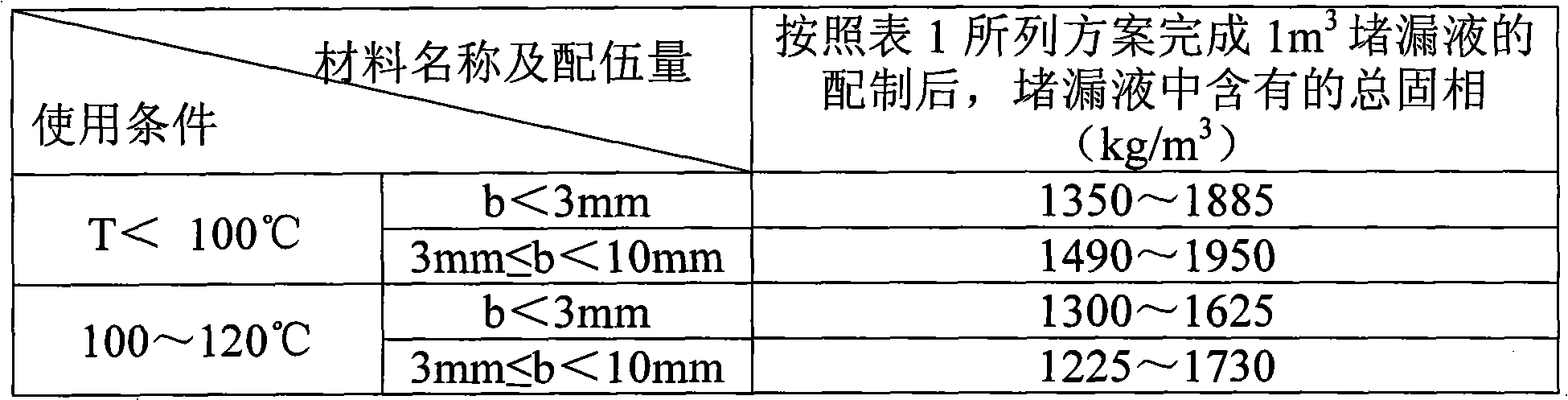

Plugging bearing material for petroleum drilling, and preparation method and application thereof

ActiveCN102061151ASuitable for lipophilic and hydrophilic propertiesGuaranteed preparationDrilling compositionSealing/packingHigh fracturePetroleum

The invention provides a plugging bearing material for petroleum drilling, and a preparation method and application thereof. The plugging bearing material comprises the following components: 900 to 1,200 kilograms of bentonite, 100 to 220 kilograms of magnesium oxide, 90 to 160 kilograms of fly ash, 0 to 80 kilograms of hardness regulator, 90 to 210 kilograms of compression resisting agent, 0.15 to 5.8 kilograms of hydrophilic surfactant, 8.3 to 13.0 kilograms of hydrophobic surfactant and 3 to 8 kilograms of water-soluble organic high polymer material. A plugging material formed by the plugging bearing material has high fracture plugging capability, and a plugging belt formed by the plugging bearing material plays a certain stable role in fracturing rocks. The plugging bearing material, and the preparation method and the application thereof are suitable for processing formation leakage of various forms.

Owner:CHINA PETROLEUM & CHEM CORP +1

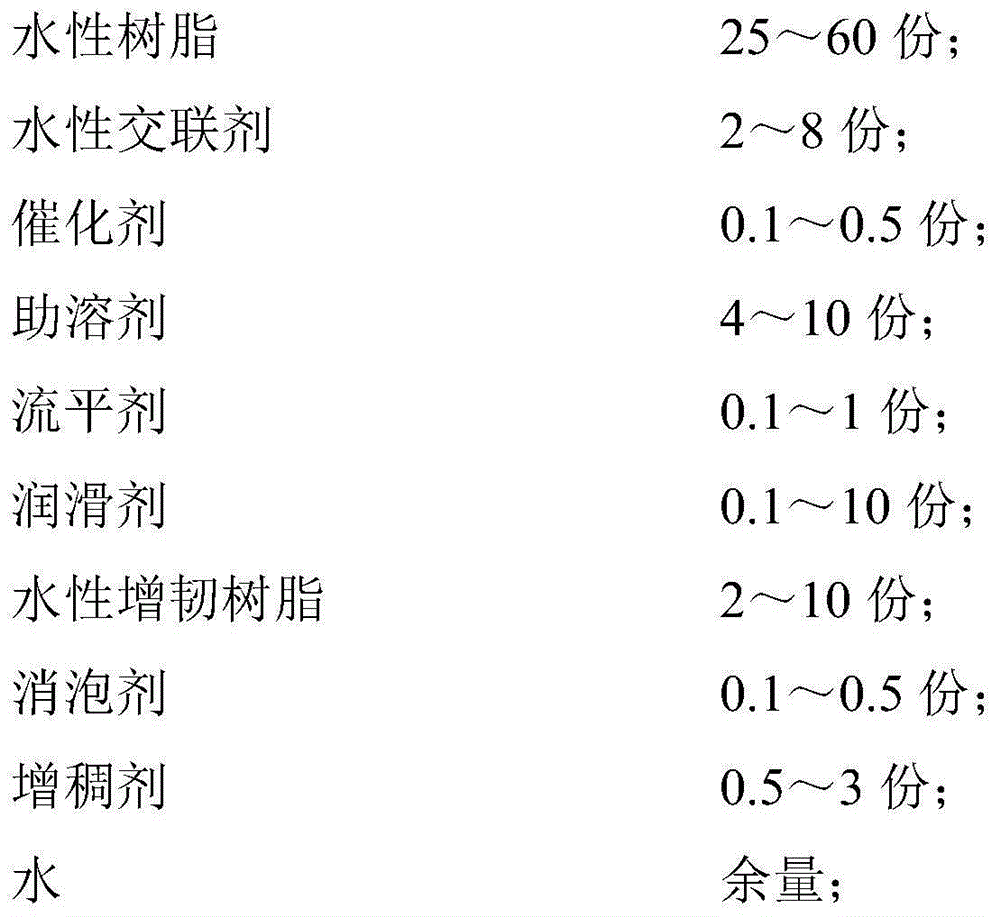

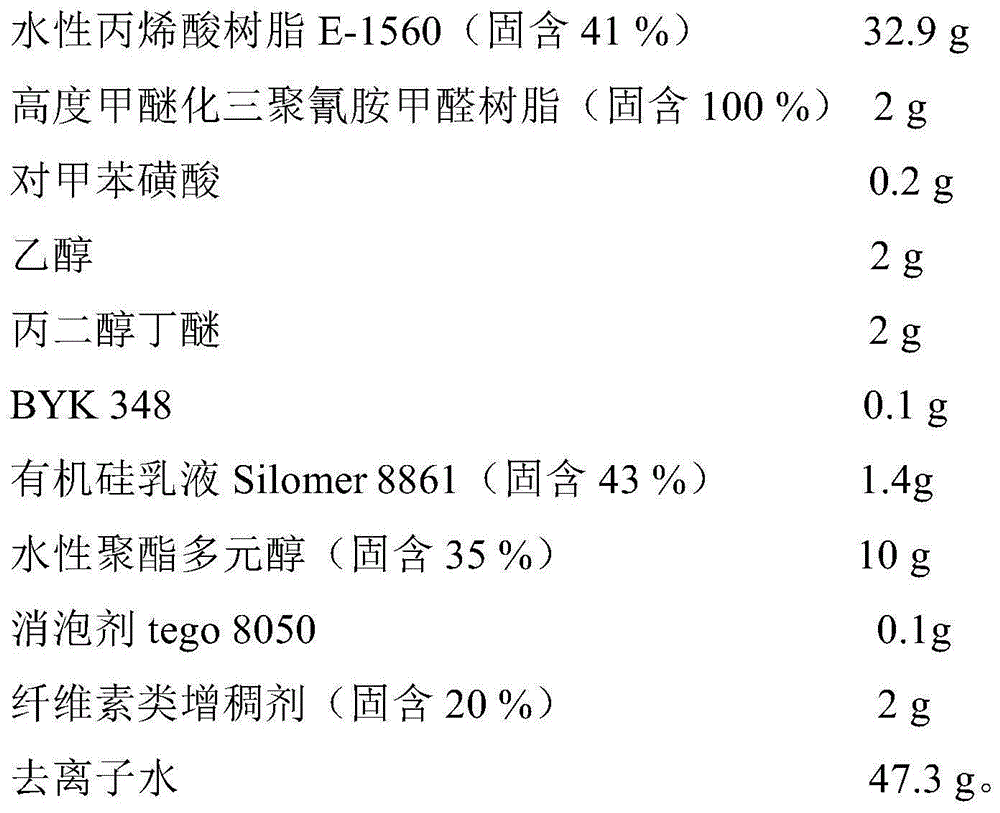

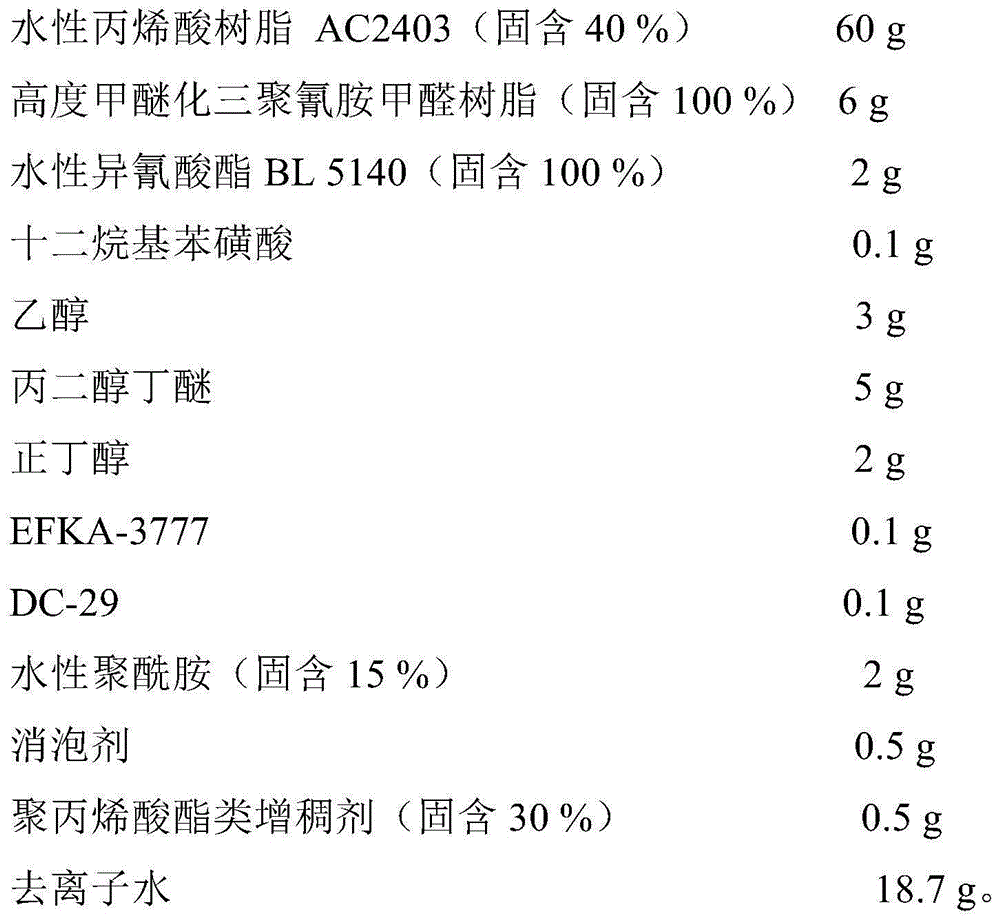

Water-based high-corrosion-resistance coating with excellent stamping performance and preparing method and application of water-based high-corrosion-resistance coating

ActiveCN105038464AEmission reductionReduce pollutionPretreated surfacesAnti-corrosive paintsWater basedMicrometer

The invention belongs to the technical field of surface corrosion prevention and discloses a water-based high-corrosion-resistance coating with excellent stamping performance and a preparing method and application of the water-based high-corrosion-resistance coating. The coating comprises, by mass, 25-60 parts of water-based resin, 2-8 parts of water-based cross-linking agent, 0.1-0.5 part of catalyst, 4-10 parts of cosolvent, 0.1-1 part of flatting agent, 0.1-10 parts of lubricating agent, 2-10 parts of water-based toughening resin, 0.1-0.5 part of defoaming agent, 0.5-3 parts of thickening agent and the balance water, and the total mass parts of the components are 100 parts. According to the water-based high-corrosion-resistance coating, the water-base resin serves as film forming matter, so that good construction performance is achieved, curing is quick, super corrosion resistance can be obtained when the thickness of the coating is 2-5 micrometers, the performance of resisting neutral salt mist is longer than 2,000 hours, resistance to acid salt mist is longer than 500 h, the corrosion grade can reach 9.8 or higher, and the salt mist resisting performance of the coating is maintained unchanged after stamping or bending is carried out.

Owner:GUANGZHOU HUMAN CHEM

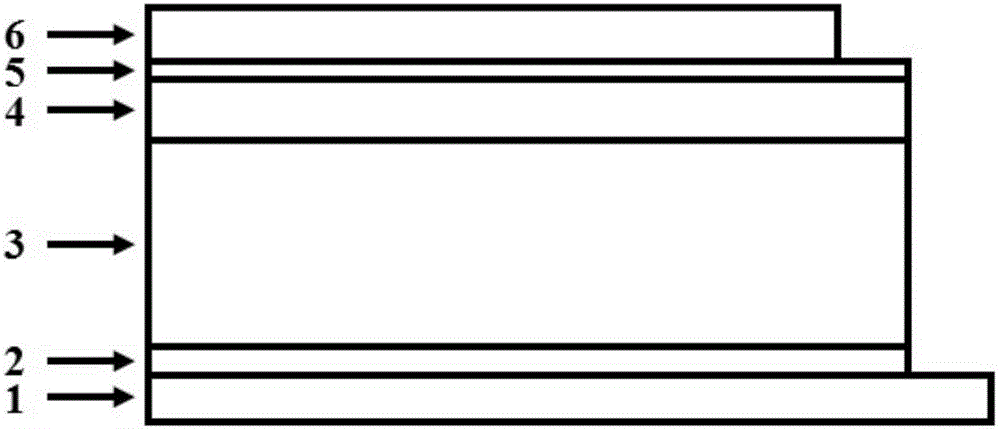

Perovskite solar cell and manufacturing method of perovskite solar cell

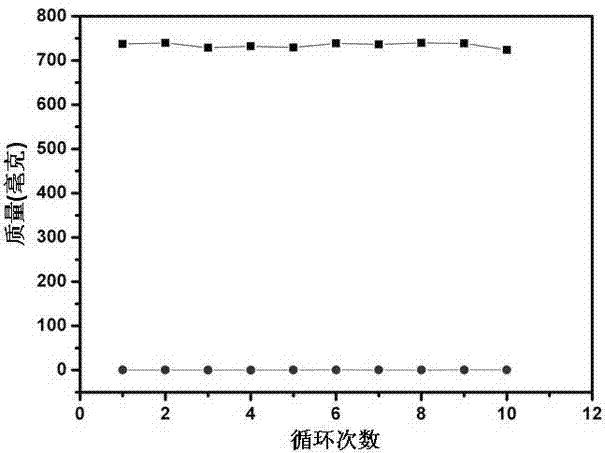

ActiveCN104576930AInsulationImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSilanesEvaporation

The invention discloses a perovskite solar cell. The perovskite solar cell is characterized by sequentially comprising a conductive glass layer, a compact titanium dioxide film, a porous titanium dioxide film, a methylamine lead iodine polycrystalline film, a hole-transport material layer and an evaporation silver electrode layer. Interface modification is carried out on the methylamine lead iodine polycrystalline film through long-chain alkyl silane coupling agents, and the number of carbon atoms of the long-chain alkyl silane coupling agents is larger than six and smaller than sixteen. The invention further discloses a manufacturing method of the perovskite solar cell. Compared with the prior art, the perovskite solar cell and the manufacturing method have the advantages that as interface modification is carried out through the long-chain alkyl silane coupling agents, the recombination of electrons in the cell can be suppressed, and the stability of the cell in the wet environment can be improved.

Owner:NINGBO UNIV

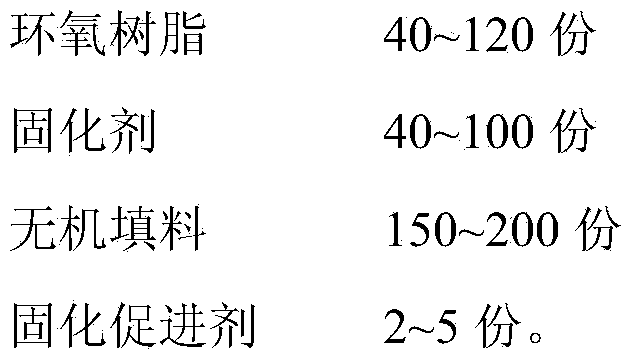

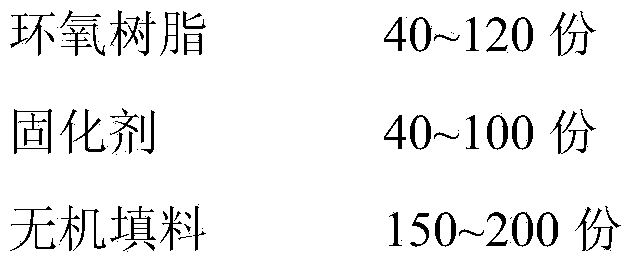

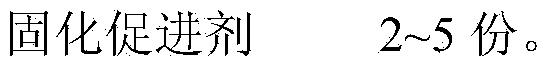

Outdoor electric-insulation modified epoxy resin composition

The invention discloses an outdoor electric-insulation modified epoxy resin composition which comprises an epoxy resin, a curing agent, a curing accelerator and an inorganic filler. The outdoor electric-insulation modified epoxy resin composition has the advantages of high weather resistance, favorable hydrophobicity, high volume resistivity, high tracking resistance, high arc resistance, low thermal expansivity and the like, and can be used for manufacturing suspension insulators for alternating current transmission lines as well as umbrella skirts of cross arms and other outdoor insulation parts. Compared with the silicon rubber umbrella skirt, the umbrella skirt prepared from the composition can prevent birds from damage, resist line walking trampling, avoid shipping damage and the like.

Owner:赛思迈(上海)新材料科技有限公司

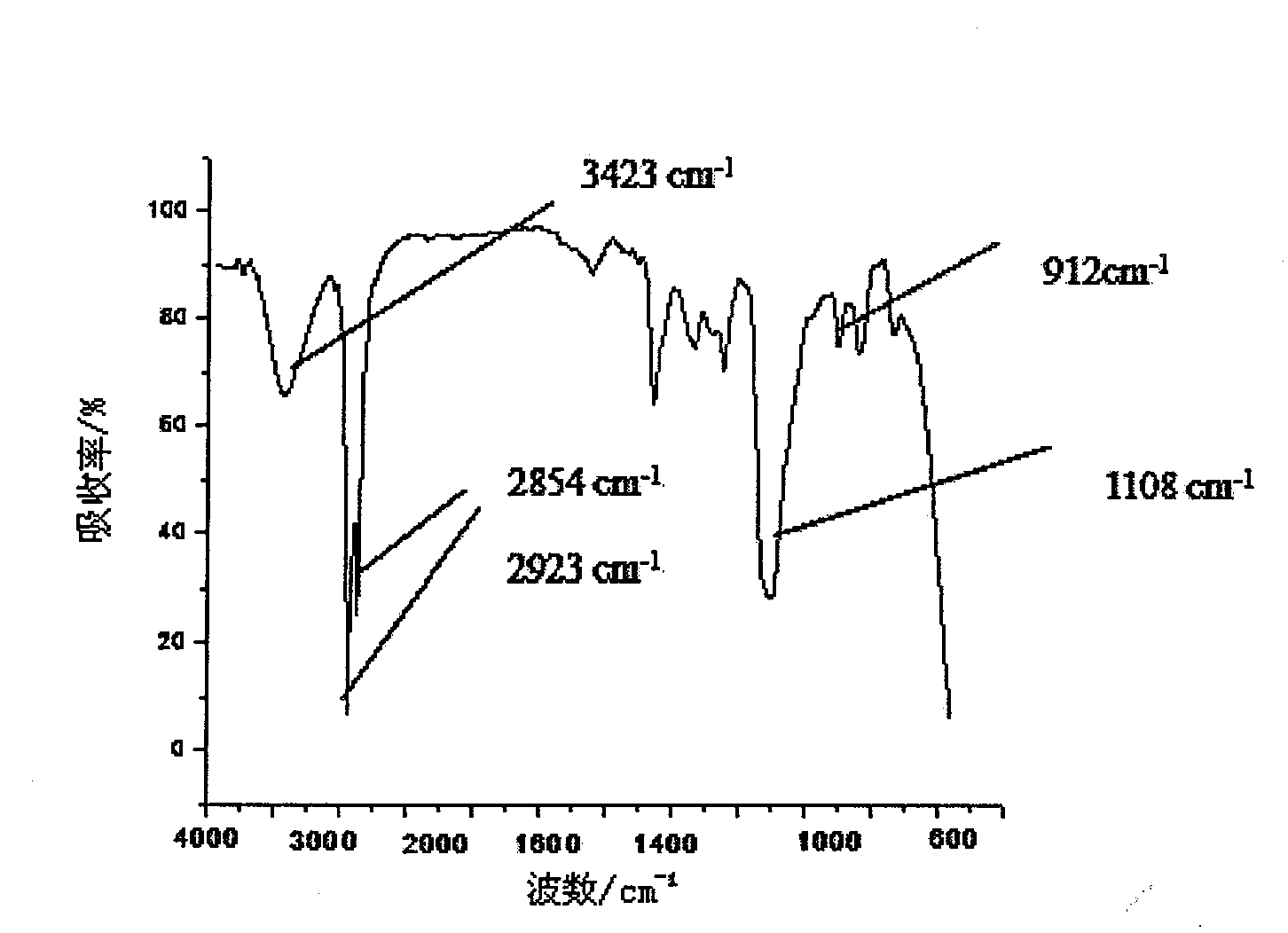

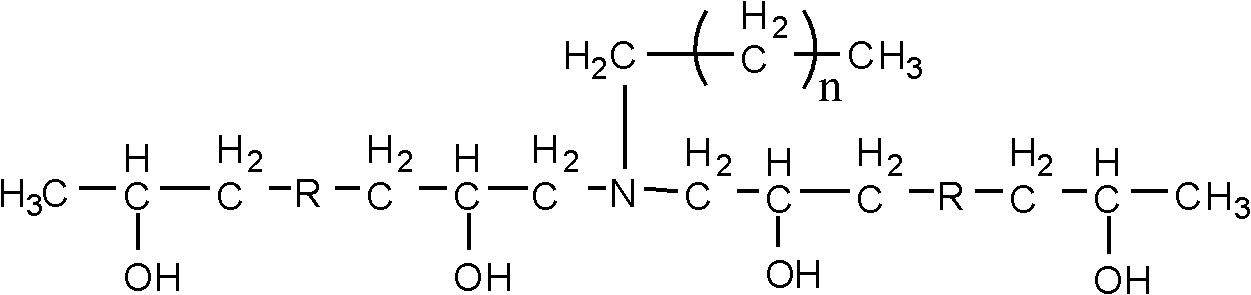

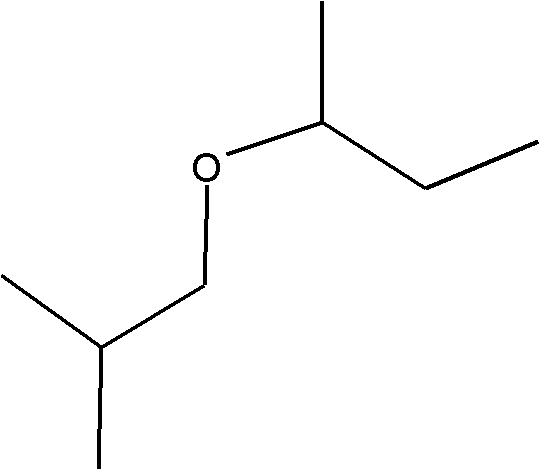

Non-ionic self-emulsifying aqueous epoxy hardener and preparation method and application thereof

InactiveCN101624385AGood self-emulsifying performanceGood flexibilityOrganic compound preparationEpoxy resin adhesivesEpoxyNitrogen

The invention relates to an epoxy hardener, in particular to a non-ionic self-emulsifying aqueous epoxy hardener. The hardener is prepared according to the following steps: adopting hydrophobic alkylamine and hydrophilic diglycidol ether with low molecular weight for reaction so as to obtain a diepoxy compound which has epoxy groups at two ends and a middle nitrogen atom linked with a long hydrophobic alkyl side chain; and adopting alicyclic amine for reaction for purpose of sealing the ends or respectively using the alicyclic amine and hydrophilic amine to seal the two ends, and finally obtaining the amino-terminated non-ionic self-emulsifying aqueous epoxy hardener similar to the structure of surfactant. The hardener can be further mixed with deionized water so that a light-yellow aqueous epoxy resin hardener with 50-60 percent of solids content can be obtained. The hardener has good self-emulsifying effect, is well compatible with epoxy resin and has high stability and good flexibility and surface activating function. The hardener can be widely applied in materials such as aqueous epoxy resin paint, epoxy resin binding agent, aqueous epoxy grouting materials, and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

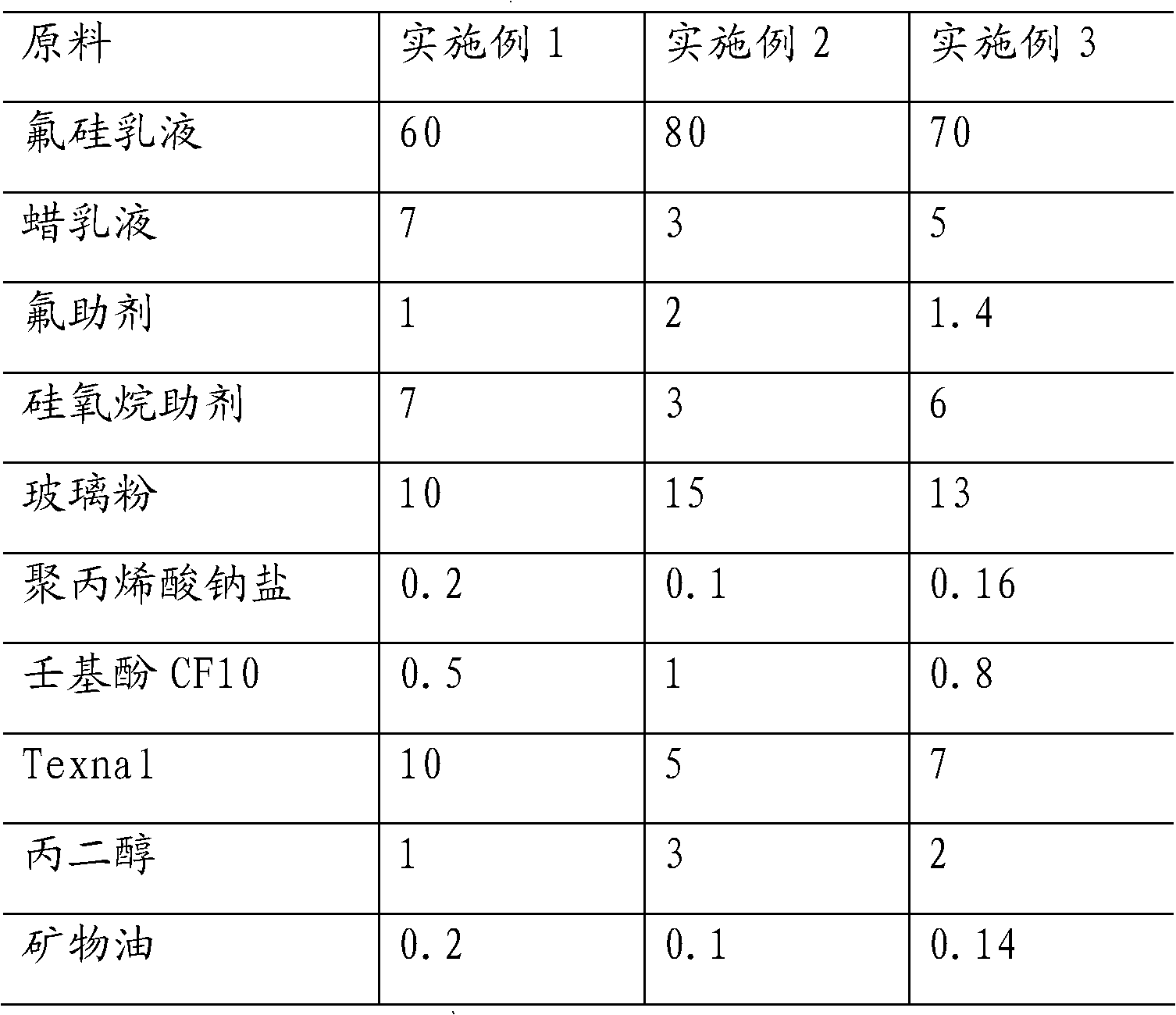

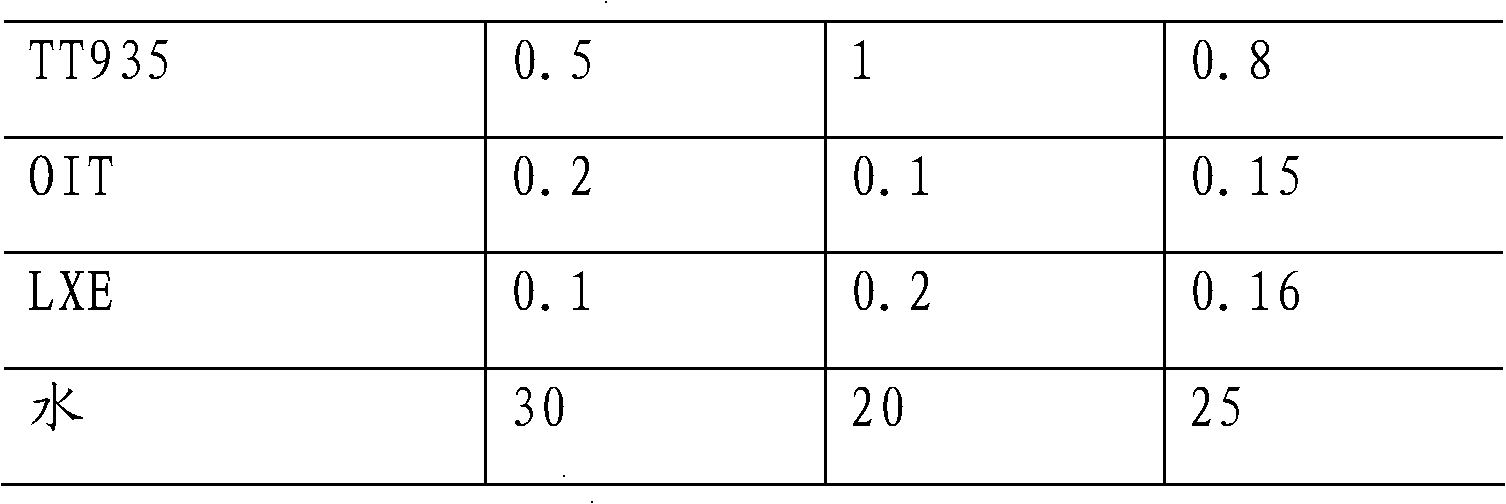

Aqueous antifouling adhesive preventing coating and production method thereof

InactiveCN102002298AHydrophobicWith anti-graffiti performanceAntifouling/underwater paintsPaints with biocidesSolventPolymer

The invention discloses an antifouling adhesive preventing coating which comprises the following components in parts by weight: 60-80 parts of polymer emulsion, 3-7 parts of water repellent agent, 1-2 parts of first adhesive preventing agent and 3-7 parts of second adhesive preventing agent, wherein the polymer emulsion is selected from one of fluorine and silicon modified acrylate emulsion, fluorine emulsion and silicon acrylic emulsion; the water repellent agent is water-soluble wax emulsion; the first adhesive preventing agent is a fluorine modified surface auxiliary agent with a water and oil repellent structure; and the second adhesive preventing agent is polyether modified hydroxyl functional polydimethylsiloxane. The invention also discloses a preparation method of the antifouling adhesive preventing coating. The coating of the invention has the performances of low surface energy, water and oil repellency, oil fouling resistance, adhesive sticker bonding prevention, and the like and has favorable antifouling adhesive preventing function and superhigh scrubbing resistance and is rapid and convenient for construction. Compared with the market sold solvent type product, the invention has the characteristic of environmental protection and can be suitable for indoor coating.

Owner:CARPOLY CHEM GRP

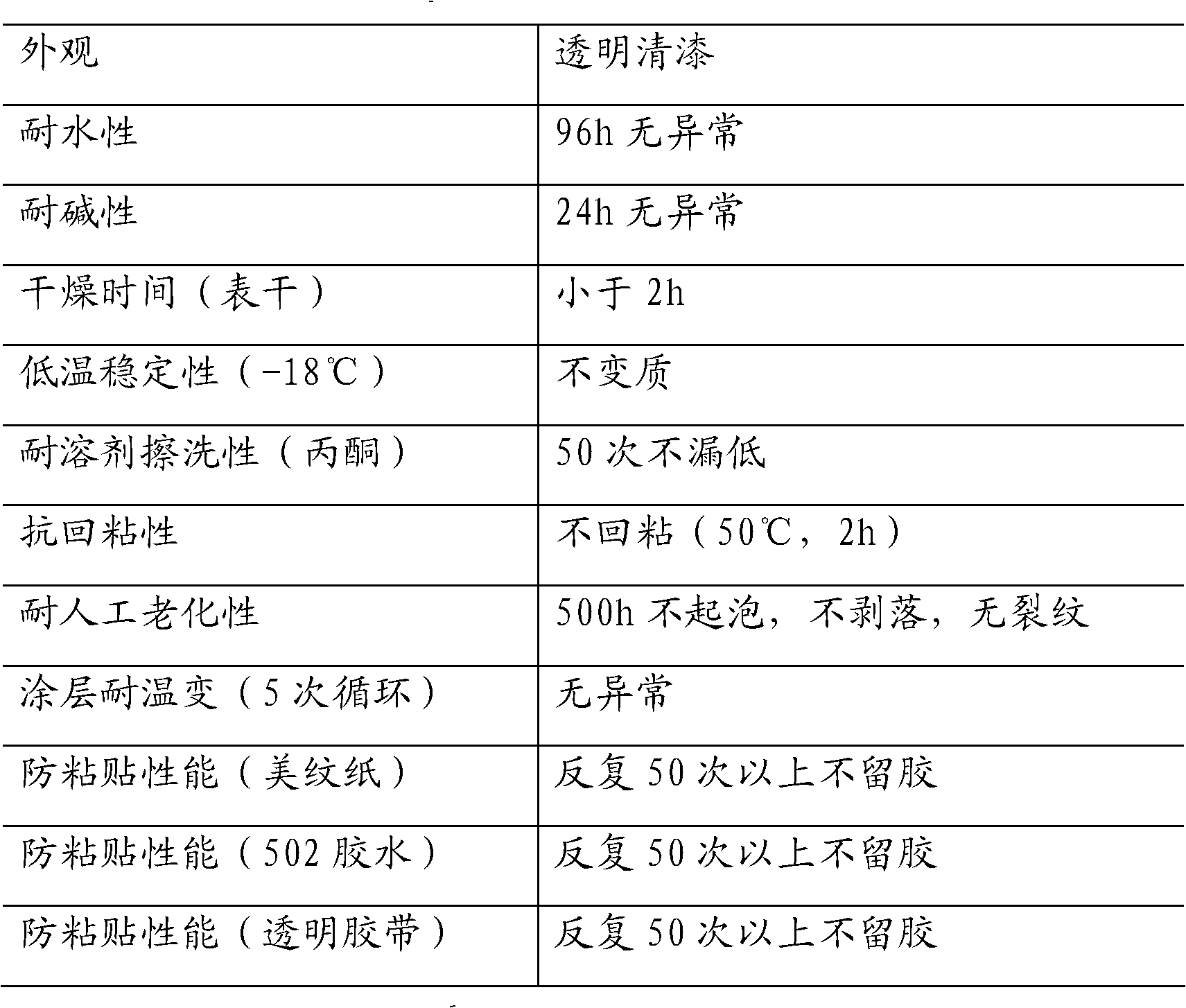

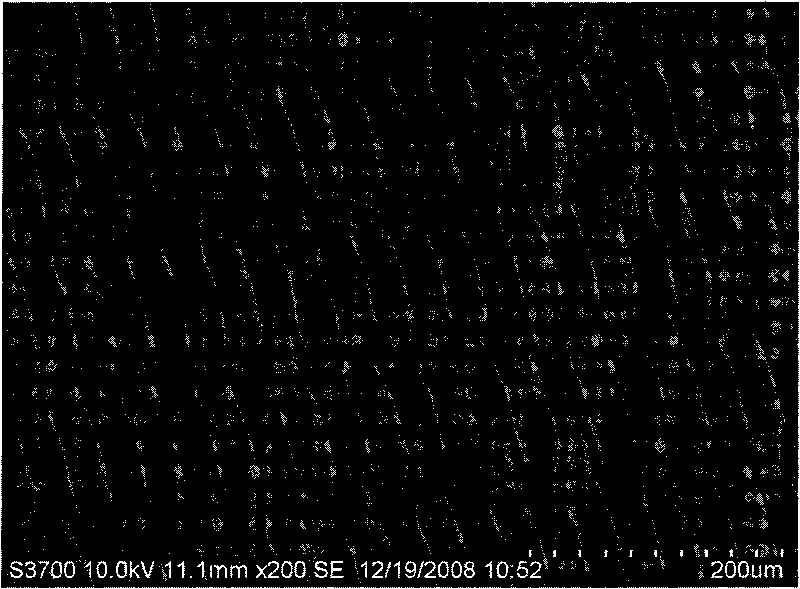

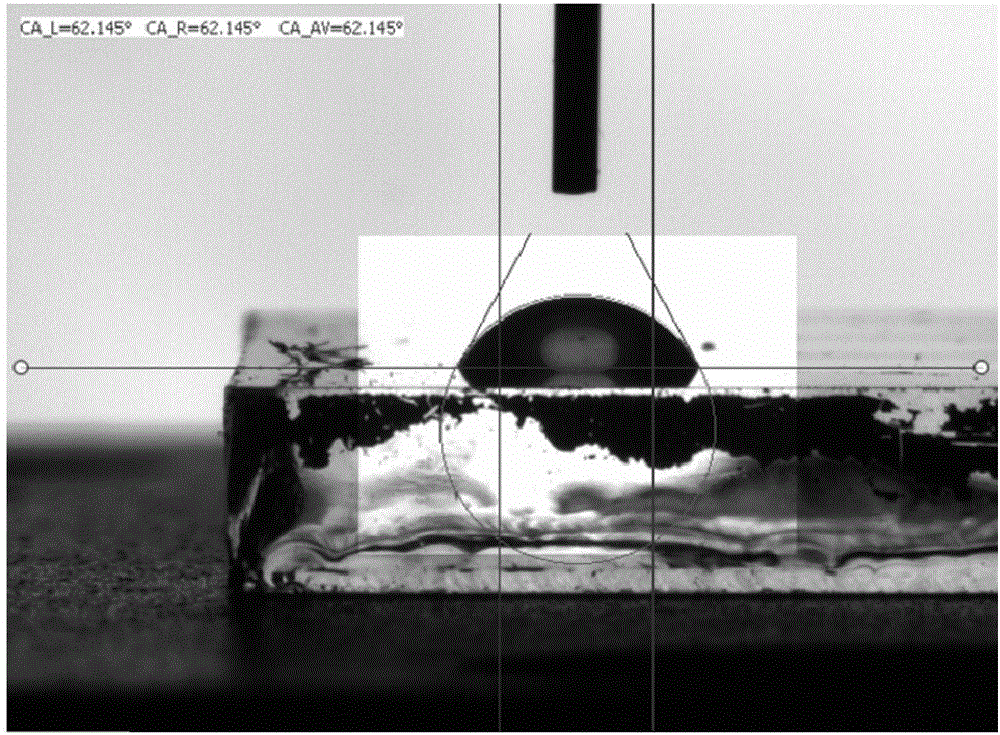

Modified graphene-loaded polyurethane sponge and preparation method thereof

InactiveCN104338519AHydrophobicImprove hydrophobicityOther chemical processesCvd grapheneGraphene coating

The invention relates to modified graphene-loaded polyurethane sponge which is characterized in that a modified graphene coating is loaded on the surface of the polyurethane sponge, and is 0.5mm-1.0mm thick, a silane coupling agent is coated on the surface of the modified graphene, wherein the mass ratio of the silane coupling agent to the graphene is 1 to 100. Experiments prove that by measuring the dewatering effect and the oil absorption capability of the loaded sponge, the sponge is super-hydrophobic from hydrophilic (a contact angle is 161 degrees), the oil absorption capability is remarkably enhanced, and the saturation adsorption amount for diesel reaches 37.89g. According to the modified graphene-loaded polyurethane sponge, the modified graphene is loaded on the sponge by using the silane coupling agent, so that the sponge has super-hydrophobic and super-oleophylic performances, and has a potential application value in a process of remediating a petroleum pollution water body.

Owner:SHANGHAI UNIV

Ice coating resistance paint composition

InactiveCN101514270AEasy to break awayReduce the amount of icingOther chemical processesCoatingsFluoropolymerSolvent

The invention relates to an ice coating resistance paint which has the following main components: 20-70% of fluoropolymer resin, 1-7% of fluorine-containing surfactant, 2-7% of aluminum hydroxide, 1-5% of nano-powder, 0.1-2% of metallic drier, 20-80% of solvent. The ice coating resistance paint composition can perform the best effect in ice coating resistance when applied to high-voltage cables, iron towers, communication lines and the like, thus reducing adhesive force of the ice on the surface of base material and ice concentration on the surface of the base material; then under the effect of wind and natural force, the ice is easy to be separated from the surface of the base material. The ice coating resistance paint has very good binding force on metal matrix, relatively high thermal conductivity, what is more, the outer surface of the paint features low surface tension, high hydrophobicity and ice-phobic property, thus reducing hydration adhesive force at utmost and facilitating the ice to fall off extremely easily and realizing the aim of preventing ice-forming and removing the ice. The method features simple and easy feasibility in engineering, convenient control, relatively low cost and good using effect.

Owner:HARBIN JINTUYUAN SCI & TECH

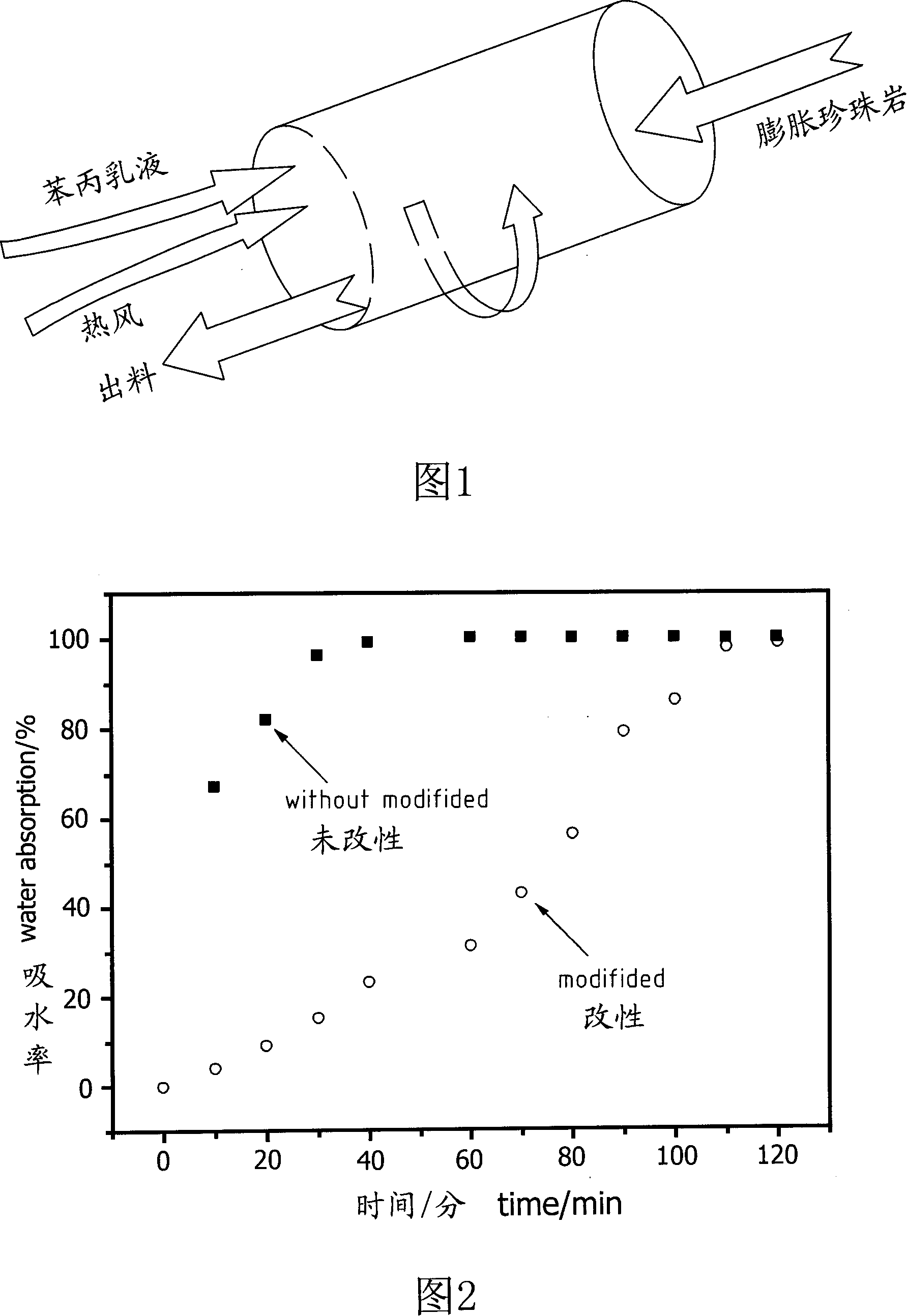

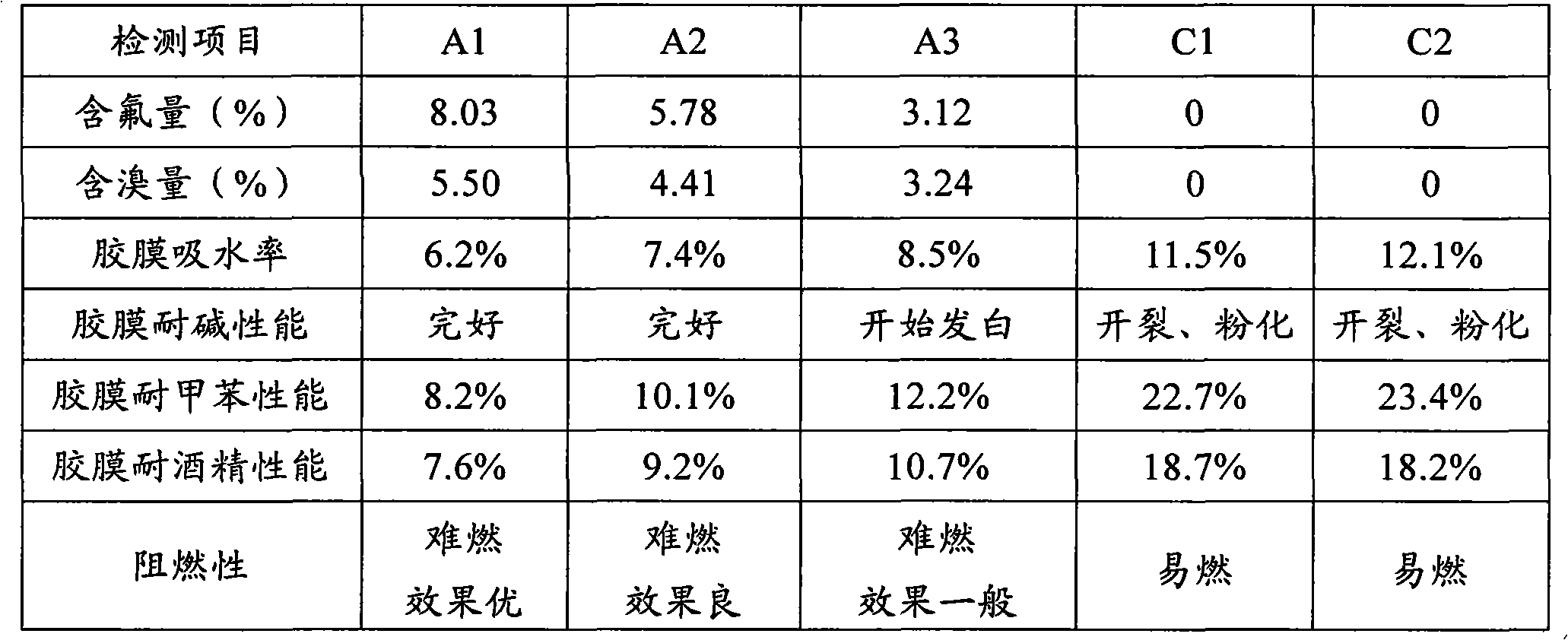

Polymer modified expanded perlite and method for making same

The present invention discloses a polymer modification expansion perlite and the preparation method. The polymer modification expansion perlite is a polymer modification expansion perlite particle used to carry out the surface coating modification by adopting the polymer modifiers. The preparation method is that the expansion perlite is delivered into a rotary drum, and the polymer modifiers are delivered into the rotary drum from the other inlet of the rotary drum in the form of sprayer together with the hot air, the temperature of which ranges from 30 to 150 Celsius system. A polymer film with a certain strength is formed on the surface of the expansion perlite, and the materials are outputted from a discharge hole so as to obtain the polymer modification expansion perlite particle. The present invention has the following advantages: the polymer modifiers completely coat the expansion perlite particle, thus lowering the water absorption and eliminating the defect that the expansion perlite easily absorbs the water with the thermal insulation performance lowered; the polymer film with a certain strength and toughness is formed on the surface of the expansion perlite, thus solving the problem that the expansion perlite is easy to be broken up with lowering the quality of the products in the process of transportation and use; the preparation technique is simple and is easy to be carried out and controlled, thus being beneficial to the industrialized popularization and application.

Owner:宁波荣山新型材料有限公司

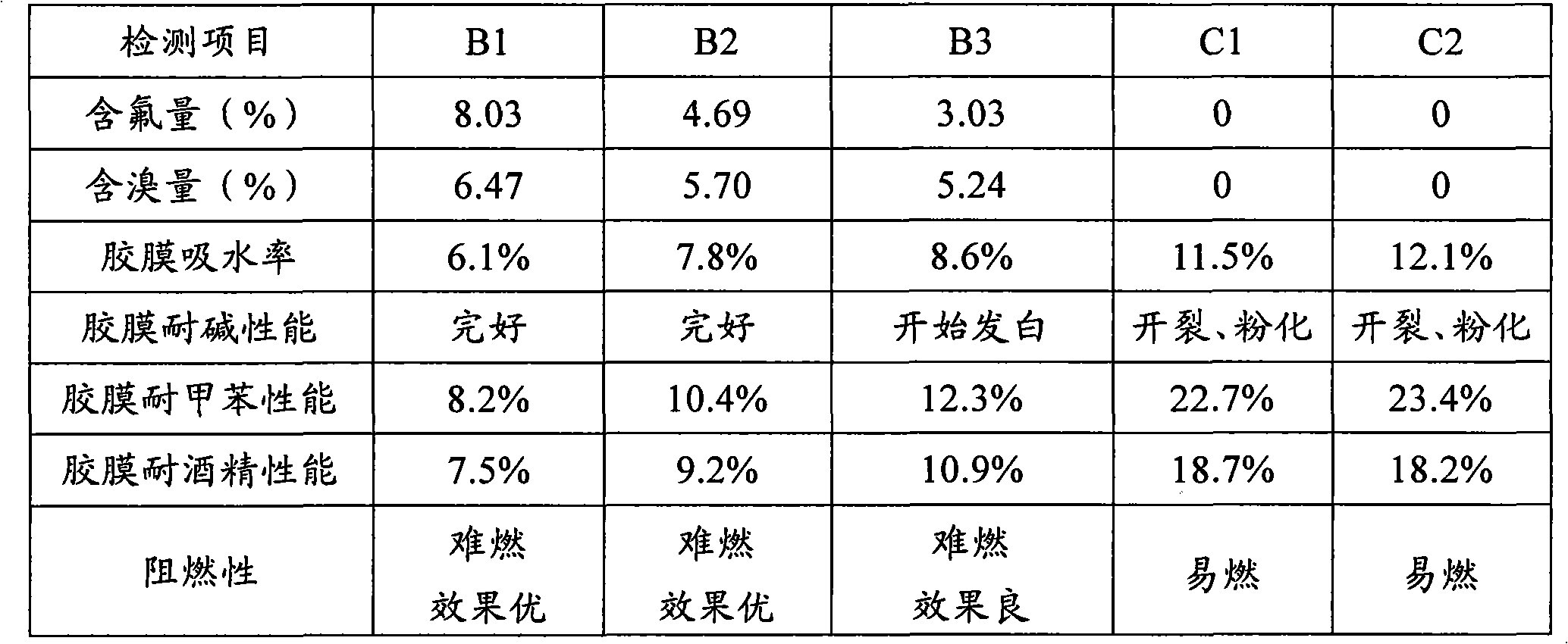

Method for preparing water-based polyurethane resin and water-based polyurethane resin

InactiveCN101935449AImprove stabilityLower surface energyFibre treatmentPolyurethane dispersionWater based

The invention provides a method for preparing a water-based polyurethane resin. The method comprises the following steps of: (1) reacting polyisocyanate, polyether diol and fluorine-containing diol to obtain prepolymer; (2) performing chain extension reaction on the prepolymer, bromine-containing diol and hydrophilic chain extender; and (3) neutralizing the solution by using a salt forming agent, and dispersing and emulsifying the solution by adding water to obtain water-based polyurethane dispersion. The invention also provides the water-based polyurethane resin prepared by the method. The water-based polyurethane resin solves the problems of poor dirt resistance and flame-retardant property of oil-based polyurethane resin and common water-based polyurethane resin.

Owner:丽水市优耐克水性树脂科技有限公司

Preparation and method for drying sludge through deep dehydrating

InactiveCN102229464AImplement processing reduction requirementsNo noiseSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentMechanical pressDewatered sludge

The invention relates to a preparation and a treatment method, and especially relates to a preparation and a method for drying sludge through deep dehydrating. The preparation comprises: 0.000002 to 0.00001 parts of an organic polymeric flocculants, 0.00025 to 0.0025 parts of a coagulating modifier, 0.0005 to 0.00375 parts of a sterilizing deodorant, and 0.00025 to 0.0025 parts of a nucleating converting agent. The method comprises the following steps: a sludge gravity thickening initial dehydrating step, a sludge regulating step, a mechanical press-filtrating step, and a filtrate refluxing step. With the preparation and the method provided by the present invention, sludge deep dehydrating processes can be carried out in series, processing efficiency can be improved, and energy consumption can be reduced. The controllability of the method is high. With the method, recycling is realized.

Owner:ZHEJIANG JIEFENG ENVIRONMENTAL PROTECTION TECH ENG COMPANY

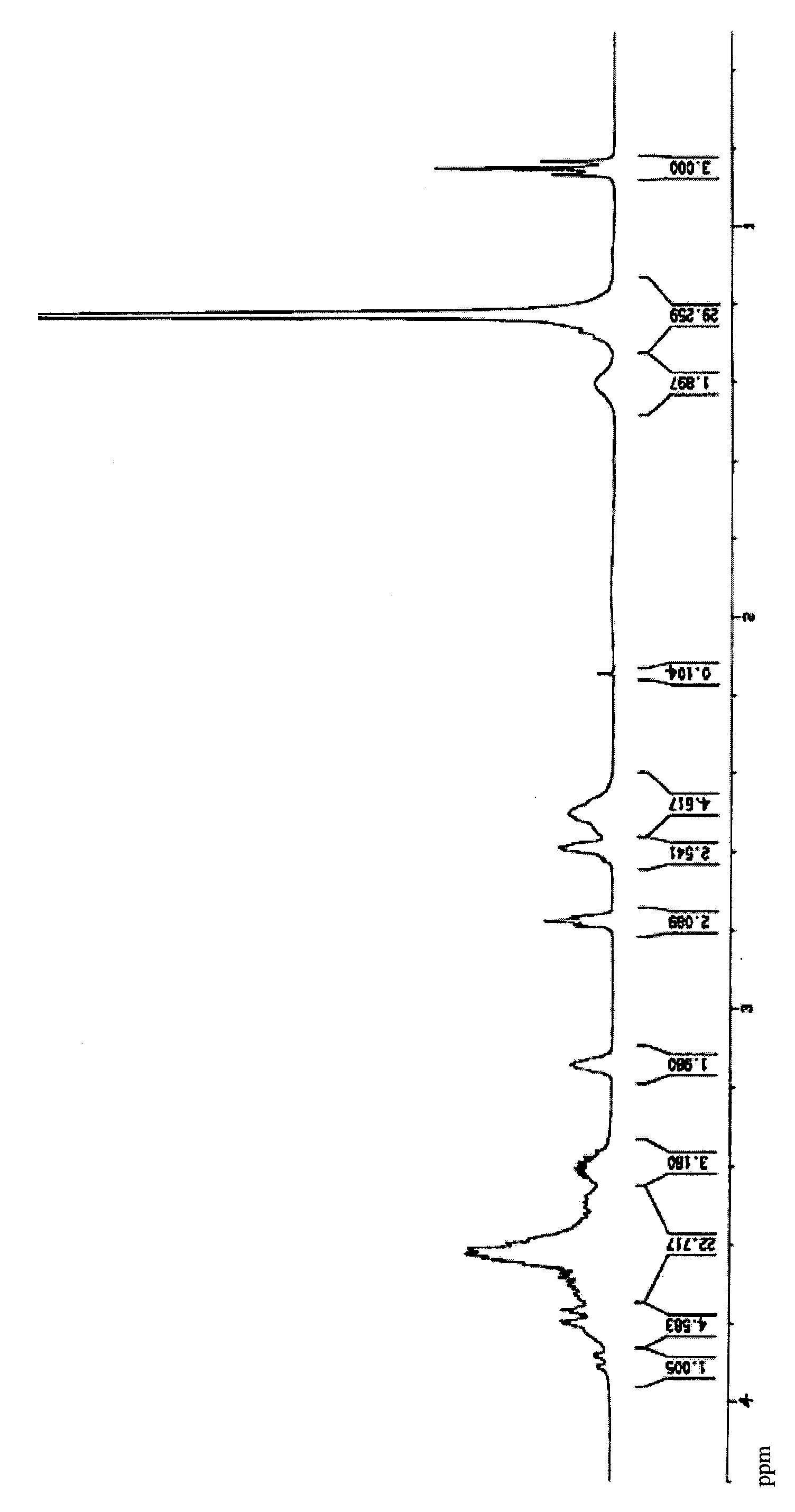

Hydrophobic and oleophyllic bi-component acrylic resin and preparation method and application thereof

The invention discloses a hydrophobic and oleophyllic bi-component acrylic resin and a preparation method and application thereof. The hydrophobic and oleophyllic bi-component acrylic resin comprises an A component and a B component, wherein the A component comprises 10 to 15 weight percent of hard monomer, 15 to 25 weight percent of higher alkyl methacrylates, 5 to 10 weight percent of fluorinated acrylic ester, 8 to 15 weight percent of cross linking monomer, 1 to 3 weigh percent of initiator, 10 to 25 weight percent of butyl acetate and 20 to 32 weight percent of dimethylbenzene; and the B component is an isocyanate curing agent of which the NCO content accounts for 10 to 23 percent of the total weight of the curing agent. The preparation method comprises a step of evenly mixing the A component with the B component which accounts for 14 to 32 weight percent of the A component to prepare the hydrophobic and oleophyllic bi-component acrylic resin. The bi-component acrylic resin has hydrophobic and oleophyllic performance and can serve as a coating for porous materials such as stainless steel metal meshes and filter paper to play a role in separating oil from water.

Owner:SOUTH CHINA UNIV OF TECH

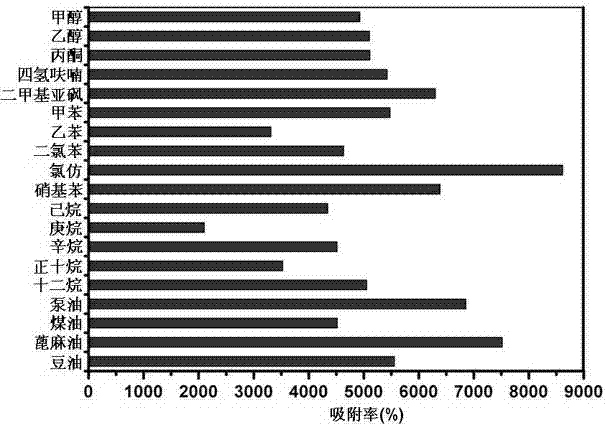

Application method of graphene sponge

InactiveCN102500133AHydrophobicImprove adsorption capacityOther chemical processesSolid sorbent liquid separationOrganic solventDistillation method

The invention discloses an application method of a graphene sponge. The graphene sponge is applied to absorb organic solvents or oils due to the characteristics of strong organic solvent or oil adsorption capacity and high organic solvent or oil adsorption speed. The application method of the graphene sponge can be applied to the filed of sewage treatment or liquid-liquid separation. Furthermore, after the graphene sponge is applied to absorb the organic solvents or oils, the contamination is removed, namely, the organic solvents or oils are eliminated from the graphene sponge or recycled by adopting the low-pressure distillation and extraction or high-temperature distillation methods, thus the graphene sponge can be used repeatedly.

Owner:SOUTHEAST UNIV

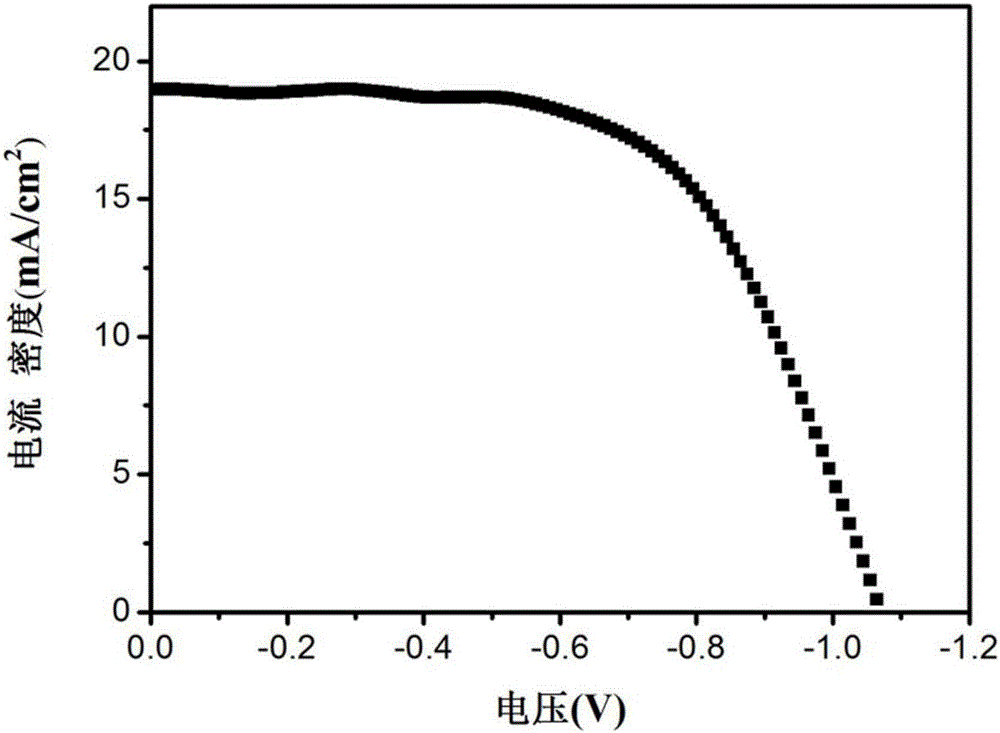

Spiro-OMeTAD/PbS composite hole transport layer based perovskite solar cell and preparation method therefor

ActiveCN106129252AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSolar lightEvaporation

The invention discloses a Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell and a preparation method therefor. The perovskite solar cell comprises a transparent conductive substrate, an oxide electron transport layer, a perovskite solar light absorption layer, the Spiro-OMeTAD / PbS composite hole transport layer and a metal electrode. The perovskite thin film solar cell adopts a simple process; a lead sulfide thin film can be prepared by a large-area evaporation method; and the lead sulfide thin film can be inserted between the Spiro-OMeTAD and the metal electrode layer to be used as a buffer layer. The Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell achieves a high photoelectric conversion efficiency which is as high as 15.11%; the lead sulfide, which is used as the buffer layer between the hole transport layer and the metal electrode, has higher hole mobility, and higher humidity stability and light and heat stability, so that the recombination of electron-hole pairs can be reduced; meanwhile, the stability of the cell can be improved; compared with other buffer layer materials, the lead sulfide can protect a device and improve the performance of the device as well; and therefore, a positive promotion effect is realized on the industrial development of the solar cell.

Owner:WUHAN UNIV

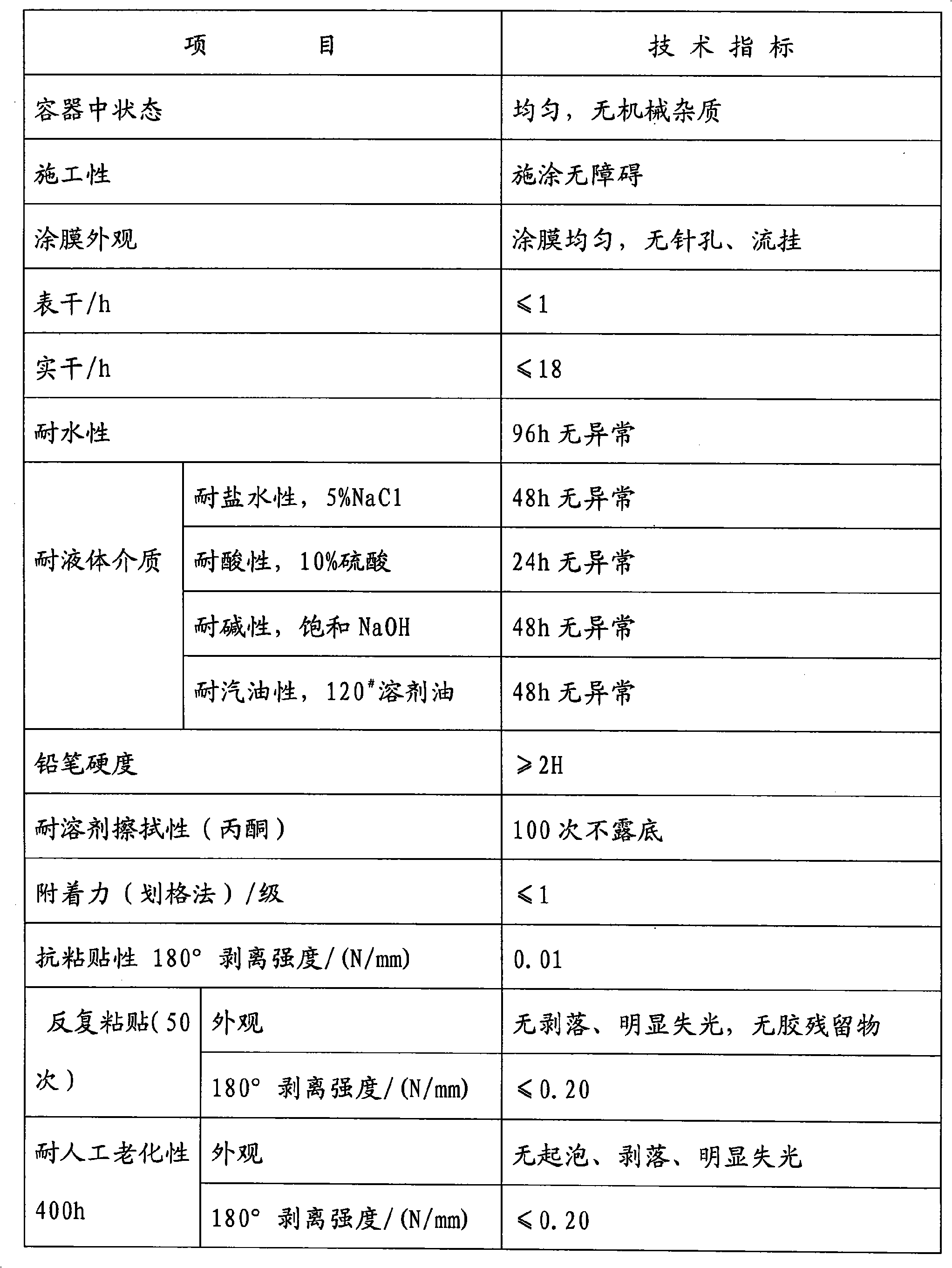

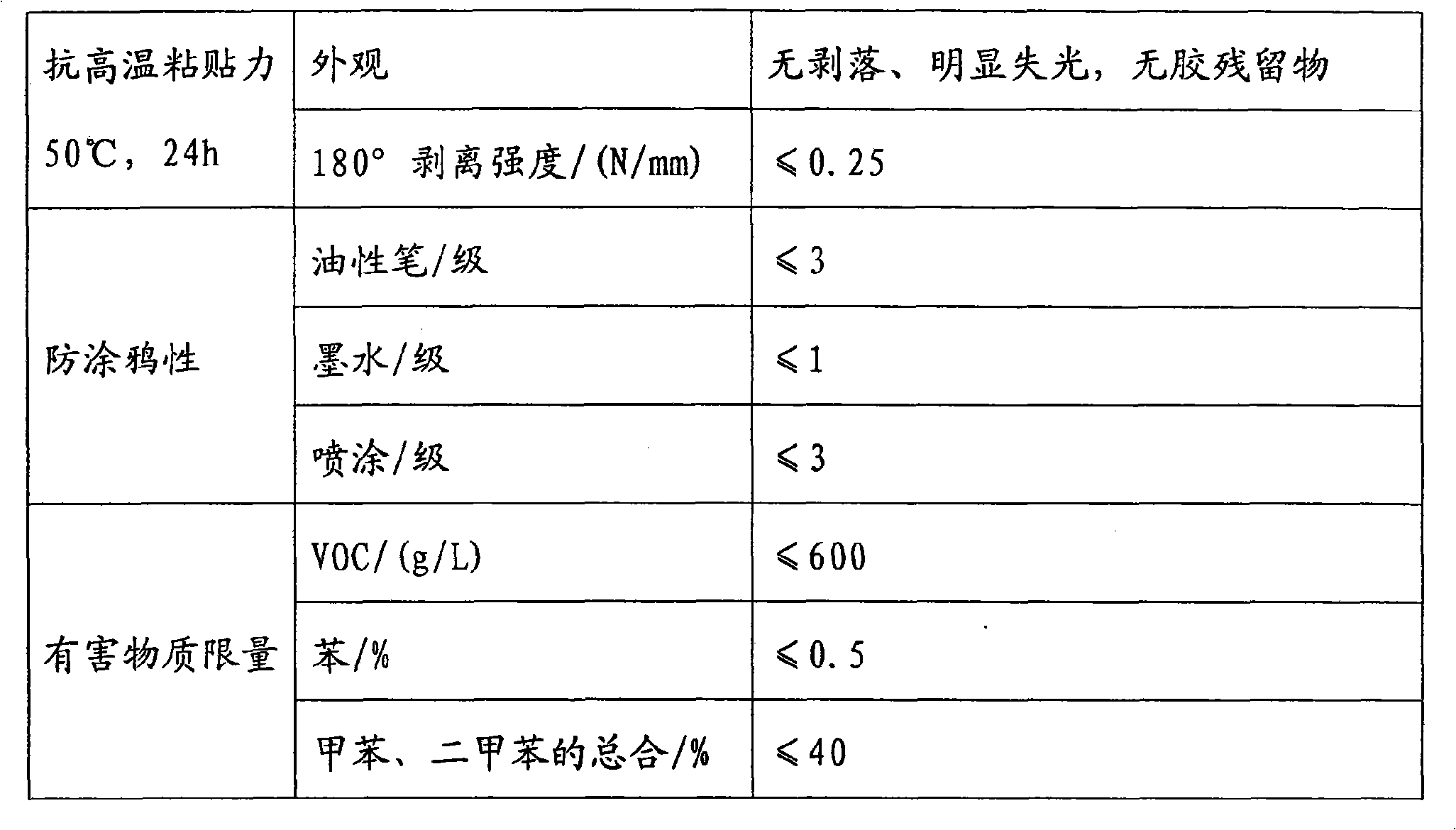

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

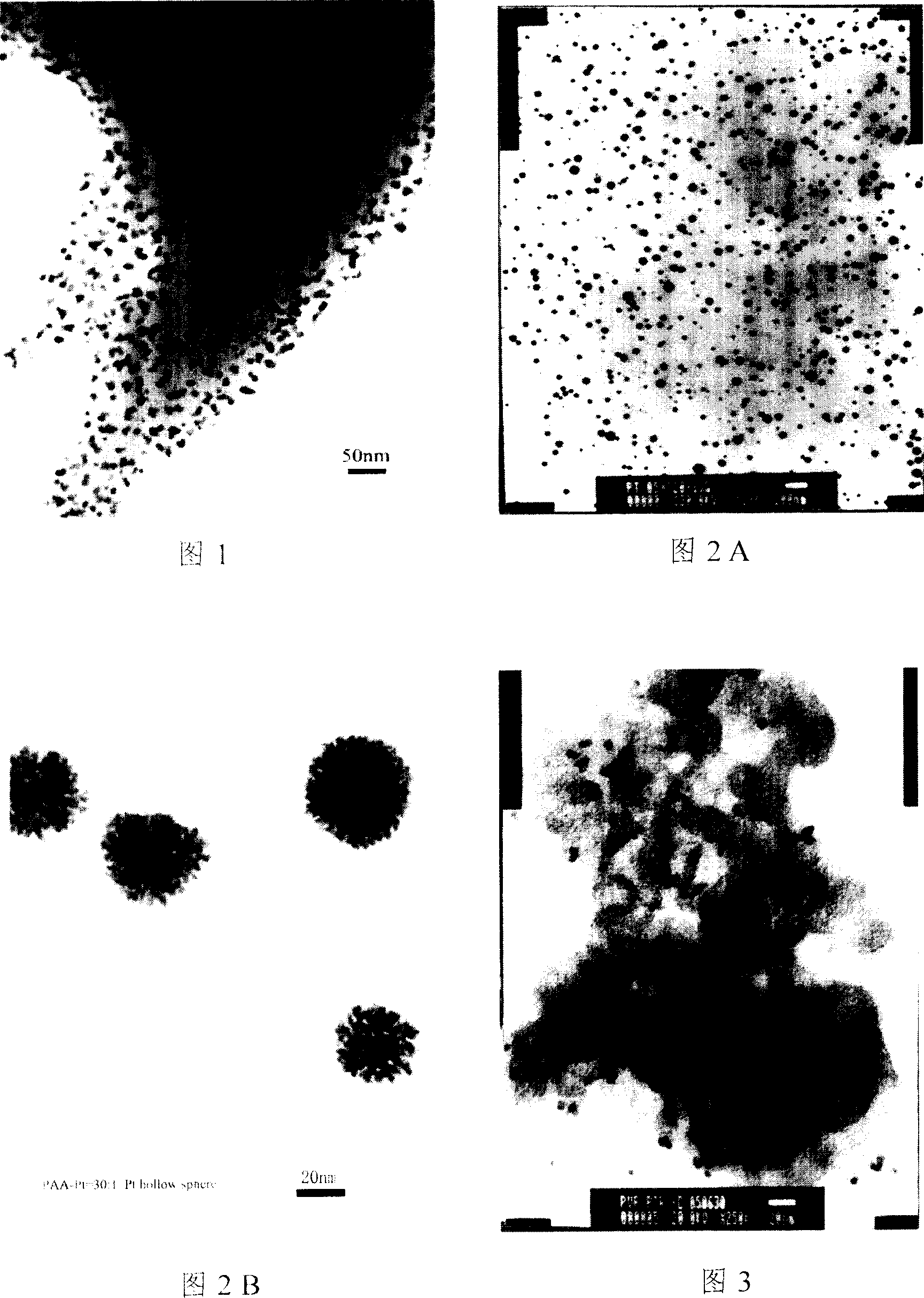

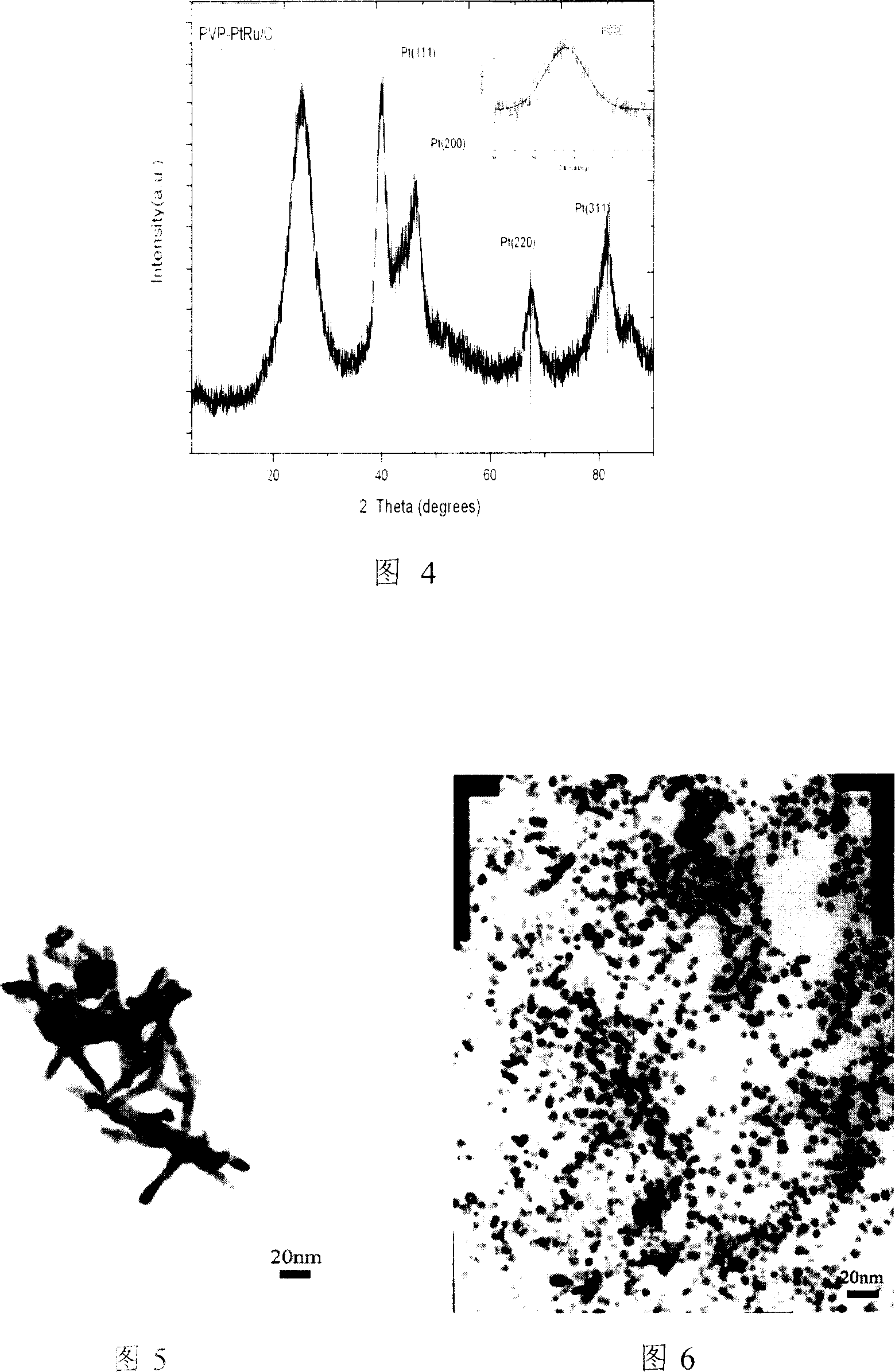

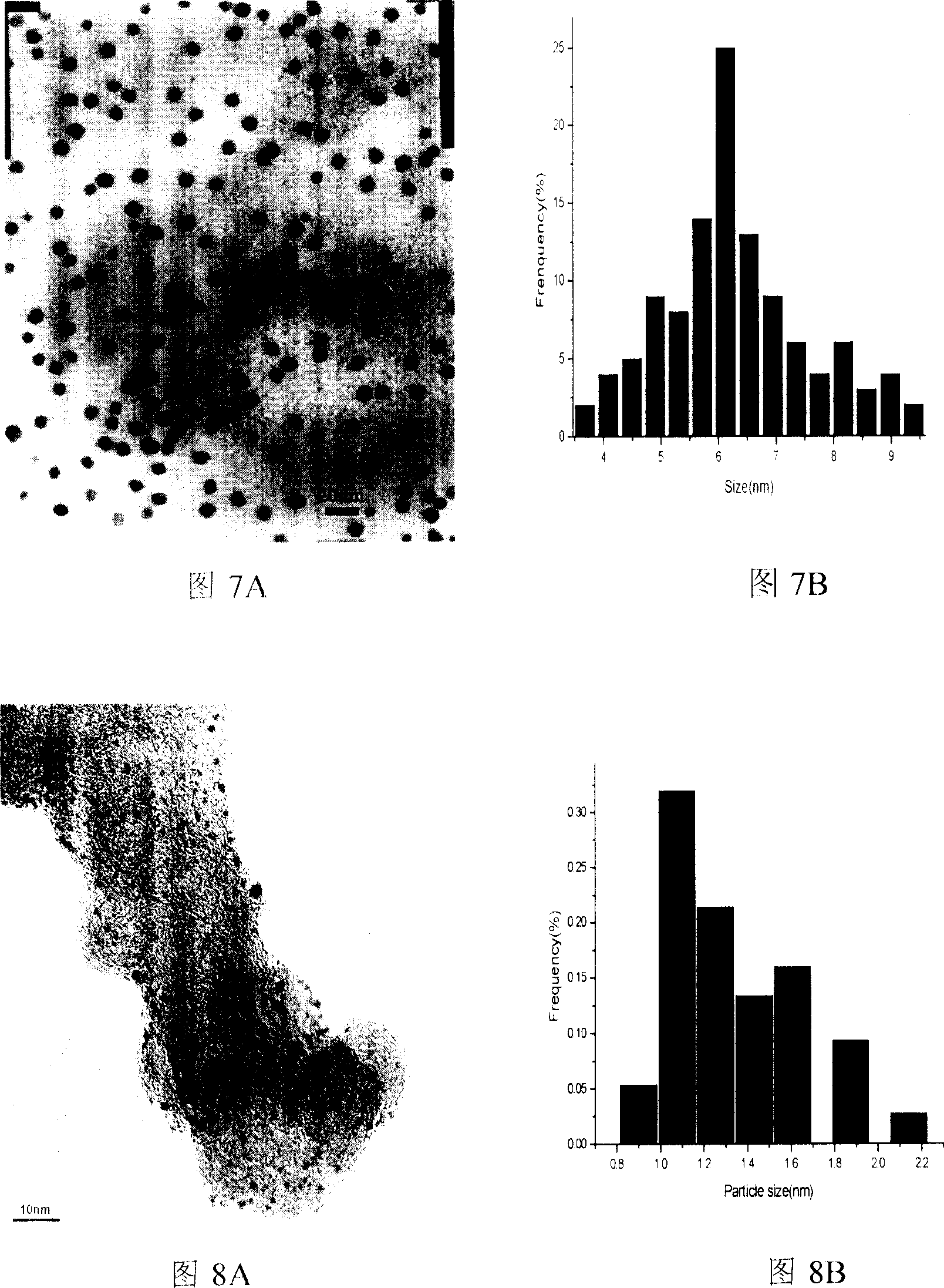

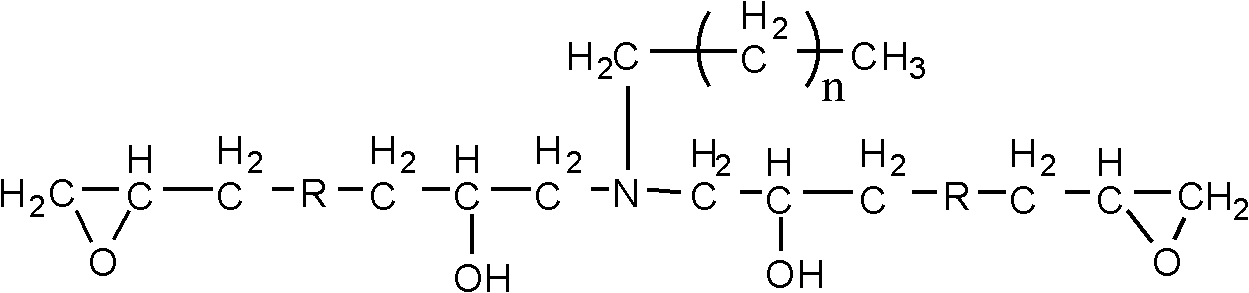

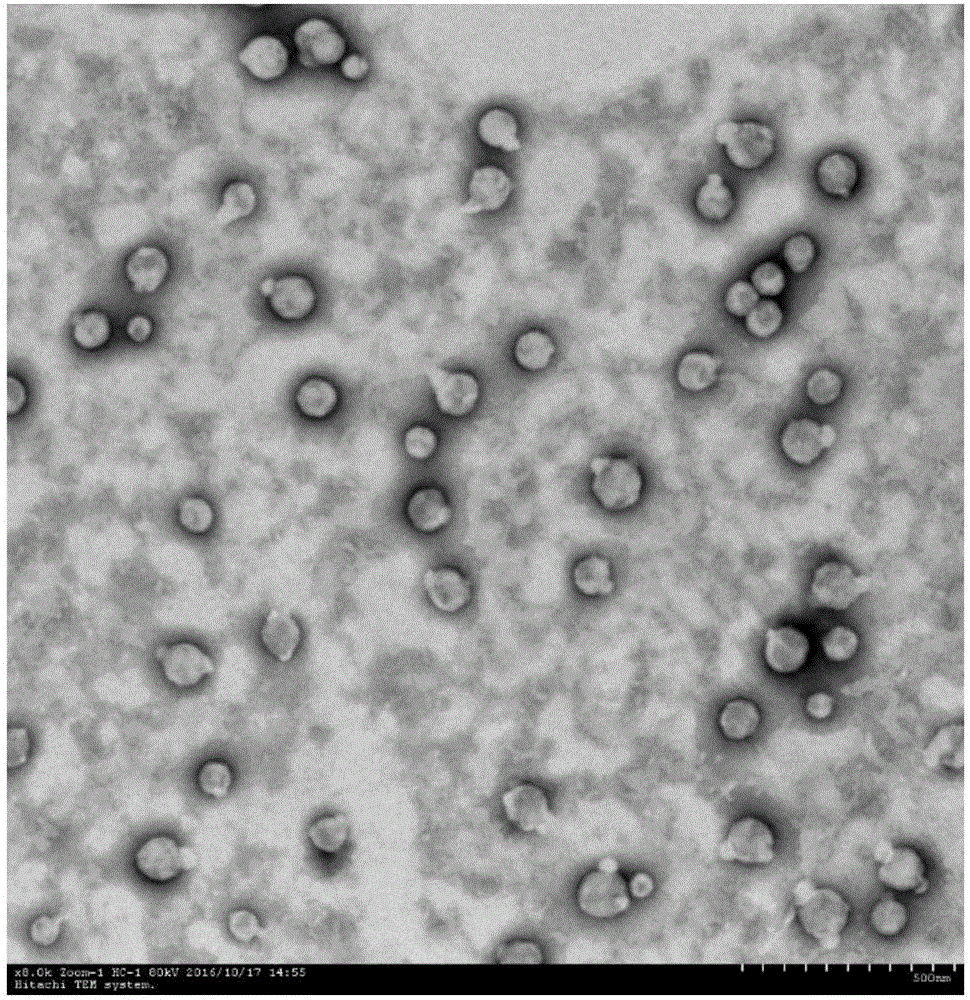

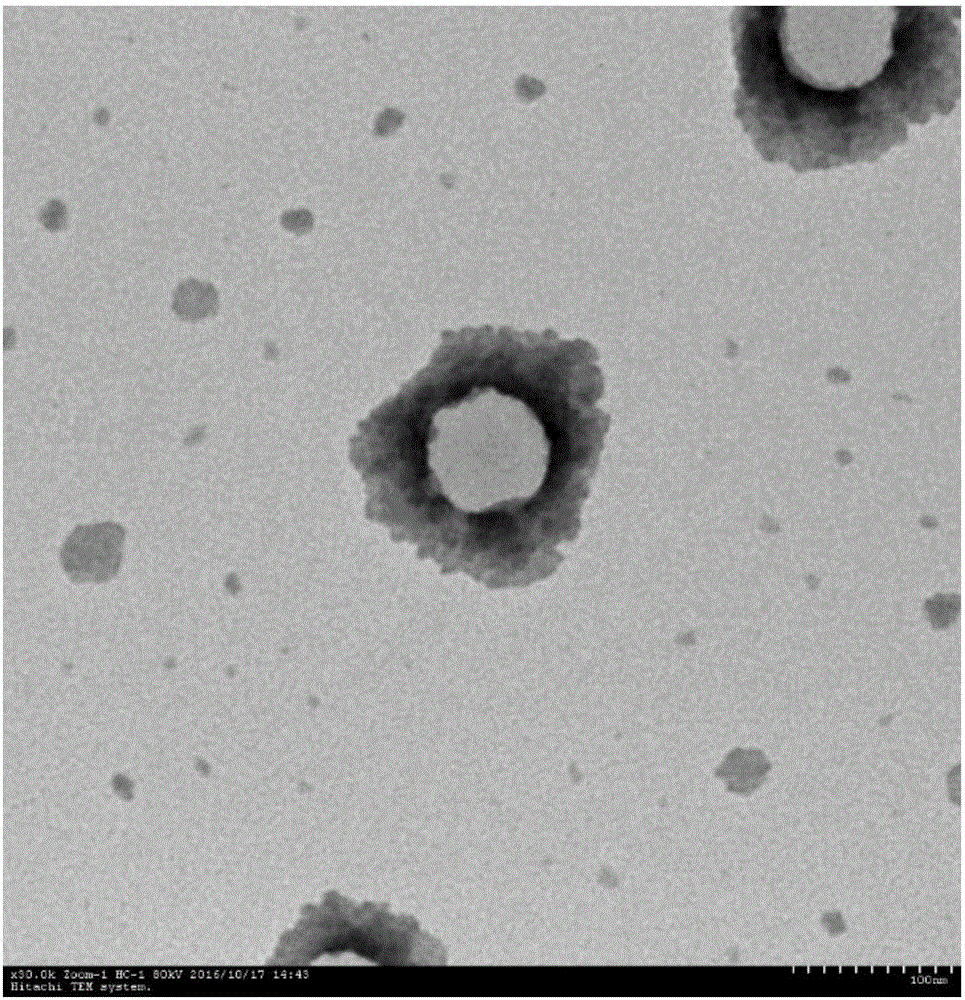

Loaded and non-loaded catalyst and preparing method

InactiveCN101069850ASimple processLow costMetal/metal-oxides/metal-hydroxide catalystsSaline waterActive component

The present invention relates to a preparation method of catalyst whose active component particle form and crystal face orientation can be controlled. Said preparation method includes the following steps: (a), preparing soluble metal salt aqueous solution of active component, the concentration of metal salt in the solution is 1.0 X 10 to the power-6-10mol / L, adding alkali solution to make pH value be 3-9; (b), preparing aqueous solution of protection agent and stabilizing agent, the concentration of protection agent and / or stabilizing agent in said aqueous solution is 1.0 X 10 to the power-5-20mol / L, adding alkali solution to make pH value be 4-9; (c), uniformly mixing two solutions respectively obtained in step a and step b, using reducing agent to make reduction; and (d), adding setting agent into the mixed solution obtained in step c, filtering and drying so as to obtain the non-supported catalyst. Besides, in the step d, after a carrier is added, the settling agent is added further, filtered and dried so as to obtain the supported catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

InactiveCN102618045AGood emulsificationImprove hydrophilicityPaving detailsBuilding insulationsEpoxyRoad surface

The invention discloses waterborne epoxy resin modified emulsified asphalt, which contains emulsified asphalt and self-emulsifying waterborne epoxy resin, wherein the volume ratio of the emulsified asphalt to the self-emulsifying waterborne epoxy resin is 1: (0.2-0.8); the emulsified asphalt is nonionic emulsified asphalt, anionic emulsified asphalt or cationic emulsified asphalt, and the solid content of the emulsified asphalt is 20 to 60 percent; and the self-emulsifying waterborne epoxy resin contains waterborne epoxy resin curing agent, water and liquid epoxy resin in a mass ratio of 1: (0.8-2): (2-5). The invention also discloses a preparation method for the waterborne epoxy resin modified emulsified asphalt and application in preparation of an asphalt type waterproof coating. After the common commercial emulsified asphalt is modified by the waterborne epoxy resin, the break elongation of the emulsified asphalt can be improved, and the modified emulsified asphalt has high adhesive strength with a base plane, certain strength and high waterproof property and ageing resistance; and the modified emulsified asphalt can be used for making the asphalt type waterproof coating, and can also be used for repairing road pavements.

Owner:重庆融极环保工程有限公司

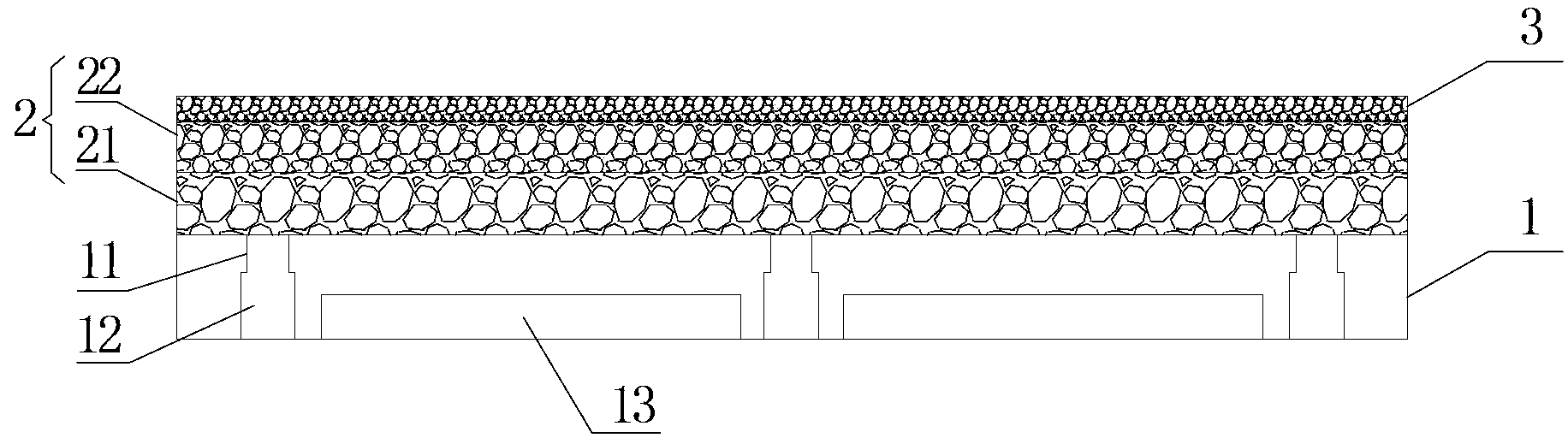

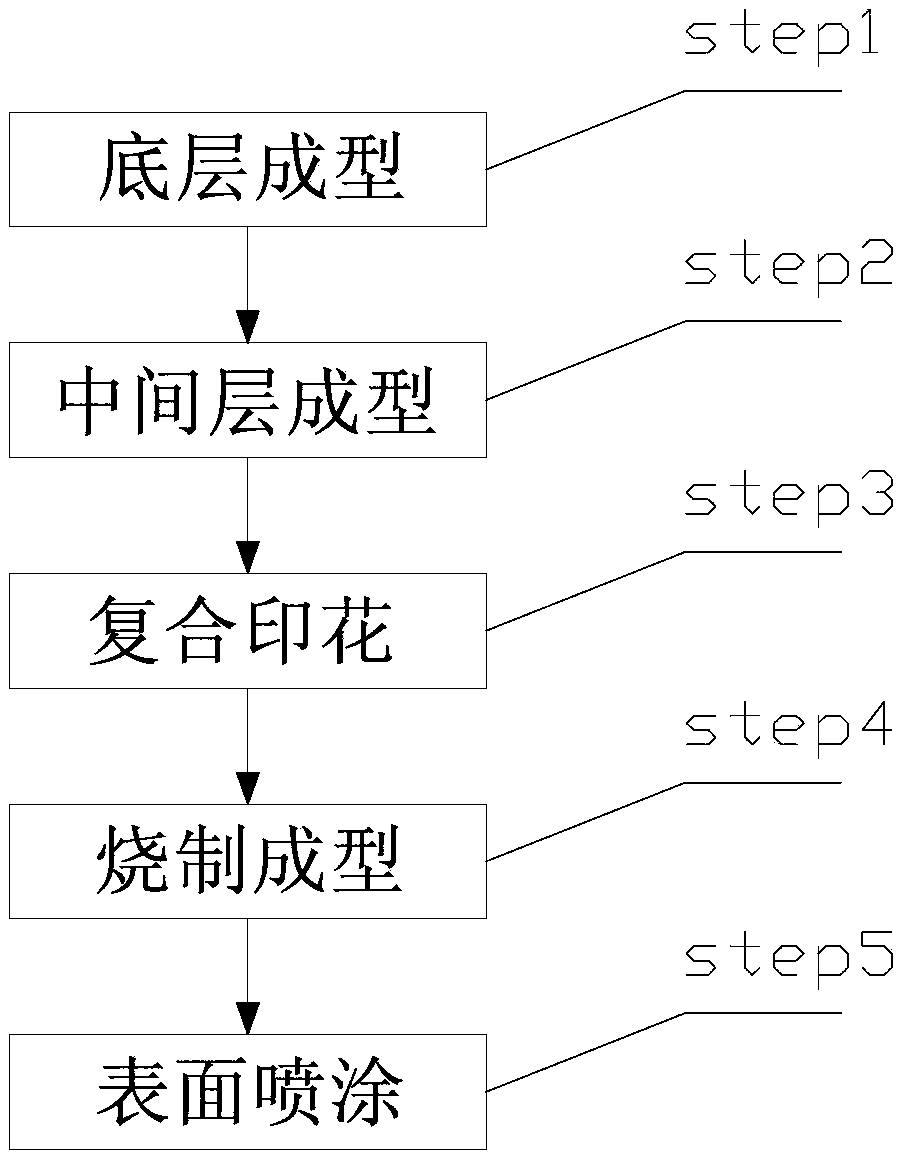

Water permeating and anti-skidding floor tile and manufacturing method thereof

ActiveCN103397767AFill technology gapsImprove the decorative effectLayered productsFlooringSurface layerPorous ceramics

The invention discloses a water permeating and anti-skidding floor tile. The water permeating and anti-skidding floor tile comprises a bottom layer, middle layers and a surface layer all of which are combined together. The bottom layer is a dense ceramic layer, and a water removing hole penetrating through the upper surface and the lower surface of the bottom layer is formed in the bottom layer. The middle layers are porous ceramic layers which are provided with a plurality of through holes, and the effective aperture of each through hole is not larger than that of the water removing hole. The surface layer is a decoration glaze layer, and a plurality of micropores are formed in the decoration glaze layer, and the effective aperture of each micropore is not larger than that of the through holes. Preferably, the middle layers comprise at least two layers, and the effective apertures of the through holes in each layer are reduced gradually from bottom to top. Compared with the prior art, the water permeating and anti-skidding floor tile has the advantages of being good in water permeating performance, anti-skidding effect, mold proofing effect, anti-pollution effect and decorative effect. The invention further provides a manufacturing method of the water permeating and anti-skidding floor tile.

Owner:江显异

Method for producing paper towel

InactiveCN102912676AReduce intensityHigh strengthWater-repelling agents additionReinforcing agents additionFiberPaper towel

The invention relates to a manufacturing method of a crepe paper product. A method for producing a paper towel comprises the following steps of: selecting 70-80 % of bleached softwood pulp and 20-30 % of straw pulp as raw materials; pulping the pulp by using a pulper, after beating the pulp by using a disc mill and adding auxiliary materials of an expanding agent, a softening agent and a wet strength agent to the pulp, molding, dehydrating and squeezing the pulp by using a Harper fourdrinier system; creping a wet paper sheet in a creping cylinder when the dryness of the wet paper sheet is 30-45 %, wherein an angle between a creping knife and the tangential line of a cylinder surface is 20-30 degrees, the cutting edge angle of a scraping knife sticking to the cylinder surface is 60-85 degrees, and the speed ratio of the creping cylinder and a heating cylinder is 1.15-1.18:1; and then drying the wet paper sheet by using the heating cylinder; and winding, rewinding and slicing the paper sheet so as to obtain a finished product. The method for producing the paper towel, provided by the invention, has the advantages as follows: through fiber variety and proportion selection and through the adoption of a wet creping process, the paper towel are produced; and the produced the paper towel has the advantages of tensile strength and proper air permeability; and the strength, wet strength, hydrophobicity, air permeability, flexibility and the like of the paper towel all reach higher standards; therefore, high quality and low cost are achieved.

Owner:QUANZHOU HUAXIANG PAPER IND

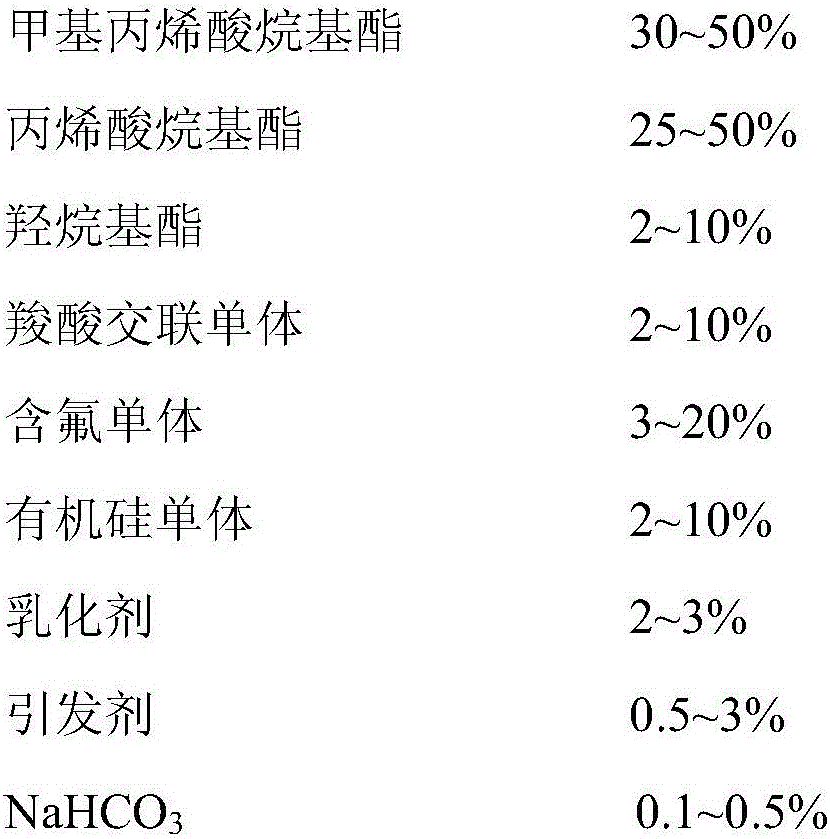

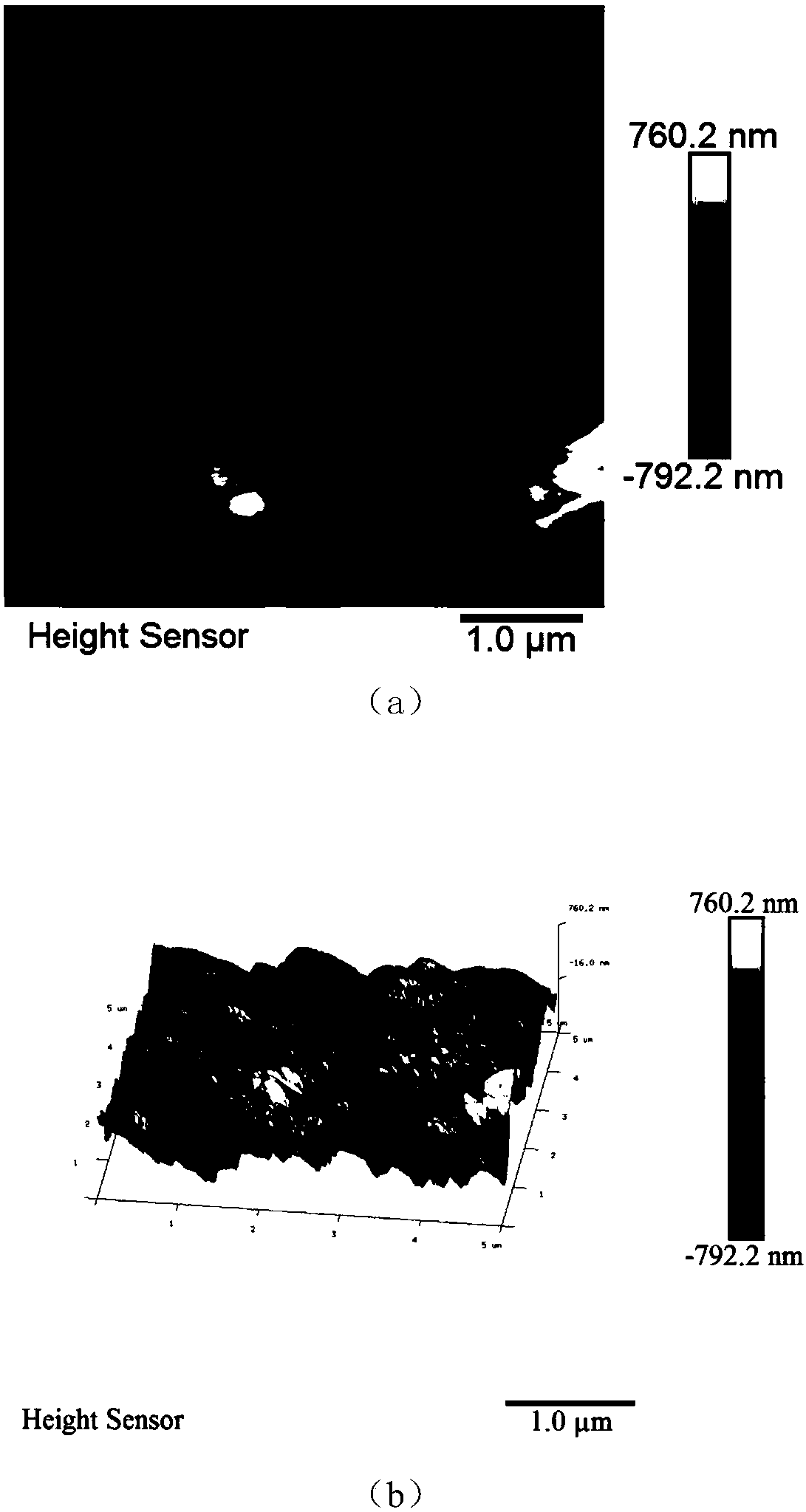

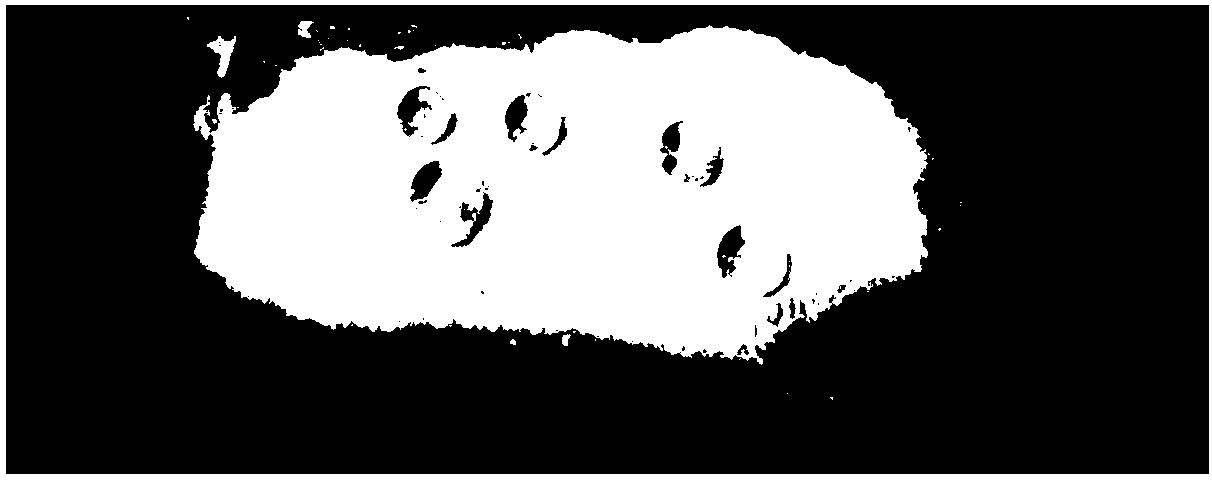

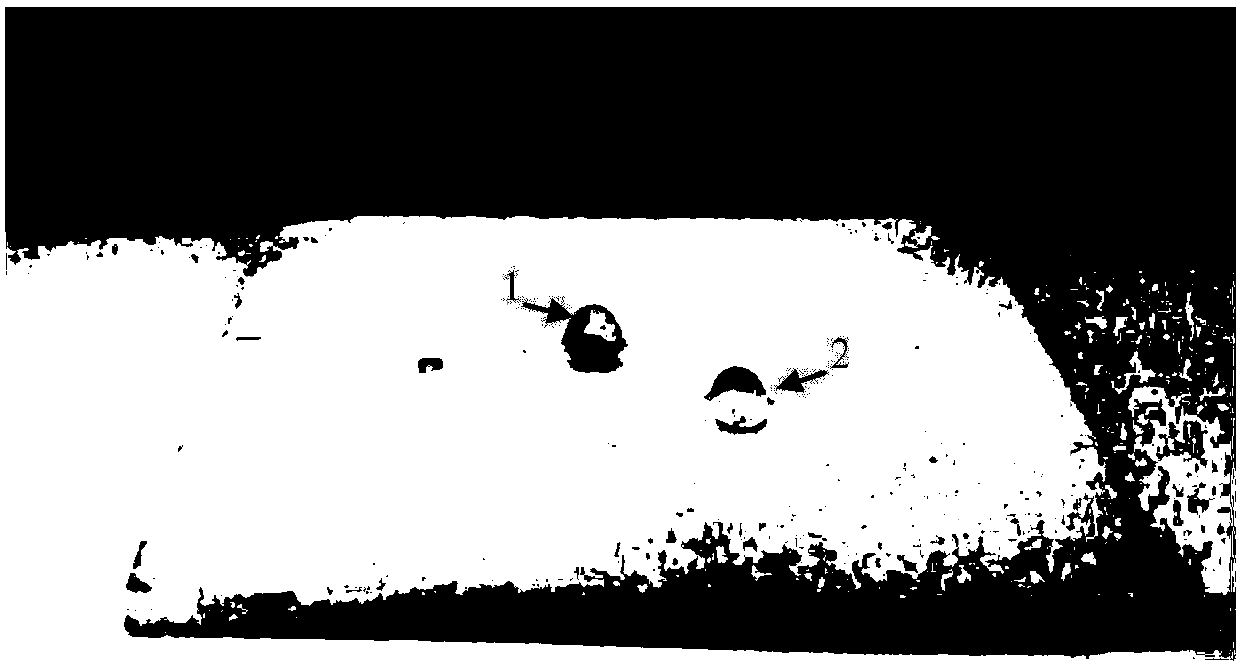

Fluorosilicone-modified polyacrylate emulsion as well as preparing method and application thereof

The invention discloses a fluorosilicone-modified polyacrylate emulsion as well as a preparing method and an application thereof. The preparing method comprises the following steps: first, mixing deionized water, NaHCO3, an emulsifying agent and an initiator solution, stirring, heating, dropwise adding part of core monomers and reacting; then, beginning slowly dropwise adding the rest of core monomers, and after dropwise adding all of the core monomers, reacting to prepare a seed emulsion; then, dropwise adding shell monomers and the rest of initiator solution into the seed emulsion, controlling reaction temperature at 78-82DEG C, filtering after reaction, discharging, and synthesizing a fluorosilicone-modified nanometer acrylic emulsion with a soft-core and hard-shell structure; and adding a protective colloid into the fluorosilicone-modified core-shell emulsion to prepare a spray-dried pre-emulsion and obtain redispersible rubber powder. Compared with common redispersible rubber powder, the redispersible rubber powder has an excellent water resisting property and can be widely applied to the building fields of outer wall paints, dry-mixed mortar and the like. When used for a building paint and mortar, the product can endow the building paint and the mortar with excellent water retention, weather fastness and constructability.

Owner:广东吉美帮新材料有限公司

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Epoxy resin polymer mortar and production process thereof

InactiveCN104261765AImprove stress resistanceImprove impact resistancePolymer sciencePhenylacetic acid

The invention relates to epoxy resin polymer mortar and a production process thereof. The mortar is prepared from the following components in parts by weight: 15-20 parts of epoxy resin slurry, 2-4 parts of an active diluent, 6-8 parts of a curing mixture and 70-80 parts of a base material which are mixed, stirred and mixed, wherein the epoxy resin slurry is prepared from bisphenol A epoxy resin E51, modified epoxy resin, organic bentonite and dioctyl phthalate; the active diluent is prepared from epoxy chloropropane, fatty alcohol and trichloropropane; the curing mixture is prepared from 85 parts of modified phenolic aldehyde amine, hydroxy-terminated liquid nitrile rubber, 2-(3, 4-expoy cyclohexyl) ethyl triethoxyl silane, lauryl phenylacetate and resorcinol; the base material is prepared from ordinary portland cement, quartz sands, hydrophobic expanded perlite, refined graphite powder and sericite powder. The epoxy resin polymer mortar provided by the invention not only has excellent mechanical property and wear resistance, but also has a good adhesive performance, and can be integrally formed with substrate concrete.

Owner:XIAOLANGDI WATER CONSERVANCY & HYDROPOWER ENG CO LTD

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

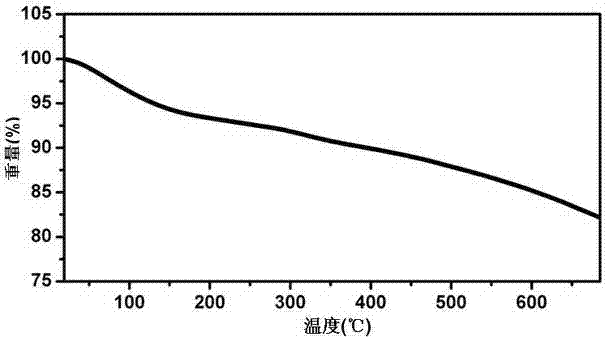

Production formula and method of PVDF (polyvinylidene fluoride)/carbon nano-tube super-hydrophobic film

InactiveCN104826503AImprove and modify pore structureImprove and modify distributionSemi-permeable membranesFiberHollow fibre

The invention discloses a production formula and method of a PVDF (polyvinylidene fluoride) / carbon nano-tube super-hydrophobic membrane. The formula includes, by weight, 5% to 30% of PVDF, 0.005% to 5% of carbon nano-tubes, and 67% to 91% of solvent. The production method includes: evenly dispersing the carbon nano-tubes in the solvent, adding the PVDF, and performing high-speed stirring at 50 DEG C to 100 DEG C to obtain casting solution; producing a flat membrane by scraping, or producing hollow fibers to obtain a primary membrane via a hollow spinneret; solidifying the primary membrane in the non-polar steam environment, and removing solvent residue by deionizing soaking so as to obtain the PVDF / carbon nano-tube super-hydrophobic membrane. The membrane produced by the formula and the method is rich in CNTs on surface and has super-hydrophobic surface and excellent permeability; the method is simple, and operability is high.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of BPPO and PVA-based organic-inorganic hybrid anion exchange membrane

InactiveCN102698616AGood flexibilityFully quaternizedSemi-permeable membranesChlorobenzenePolyvinyl alcohol

The invention discloses a preparation method of a BPPO (Brominated Polystyrene) and PVA (Polyvinyl Alcohol)-based organic-inorganic hybrid anion exchange membrane. The preparation method comprises the following steps: (1), dissolving the BPPO in chlorobenzene, and adding DMF (Dimethyl Formamide), tertiary amine solution, two micromolecule alkoxy silanes and water so as to obtain BPPO (+) / SiO2 materials; (2) dissolving the obtained BPPO (+) / SiO2 materials into DMF mixed solution so as to BPPO (+) / SiO2 solution; (3) dropping the BPPO (+) / SiO2 solution into PVA solution so as to prepare coating liquid; and (4) coating the coating liquid on a basal body so as to form a diaphragm, and drying the diaphragm to obtain the organic-inorganic hybrid anion exchange membrane. According to the invention, quaternary ammonium BPPO, PVA and micromolecule alkoxy silanes are utilized to prepare the hybrid anion exchange membrane containing the quaternary ammonium group and-OH base, the content of the PVA in the membrane can be controlled, and a cross-linked structure can be formed, so that the stability and mechanical performance of the membrane can be reinforced; and moreover, the -OH base in the PVA can promote the H+ ion to transfer, so that the prepared hybrid anion exchange membrane is particularly suitable for diffusion dialysis process, and can separate and recycle acid waste liquid.

Owner:YANCHENG TEACHERS UNIV

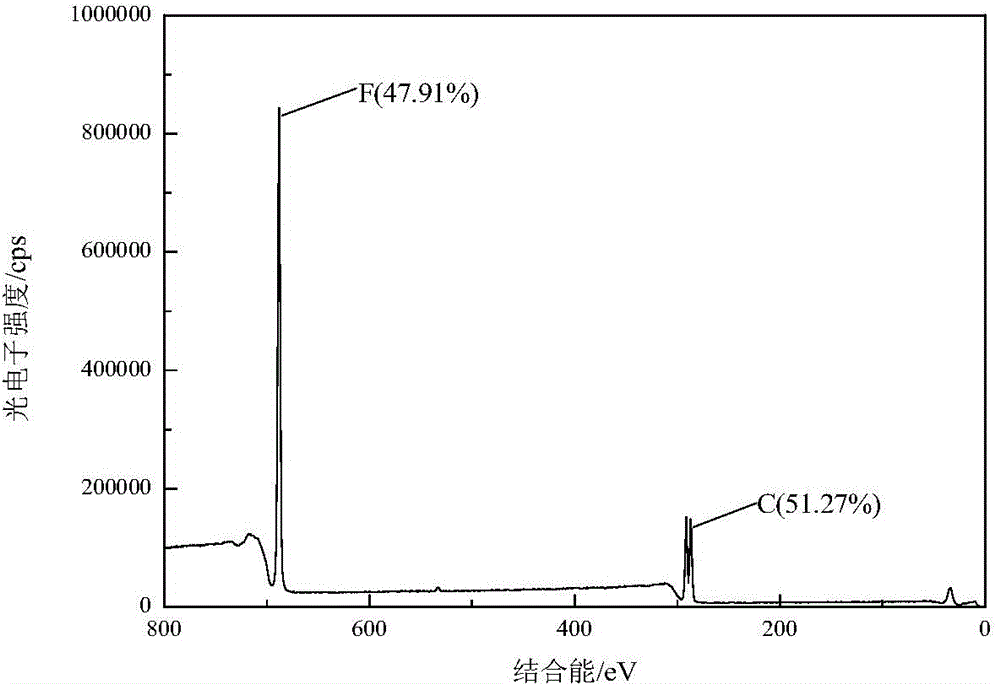

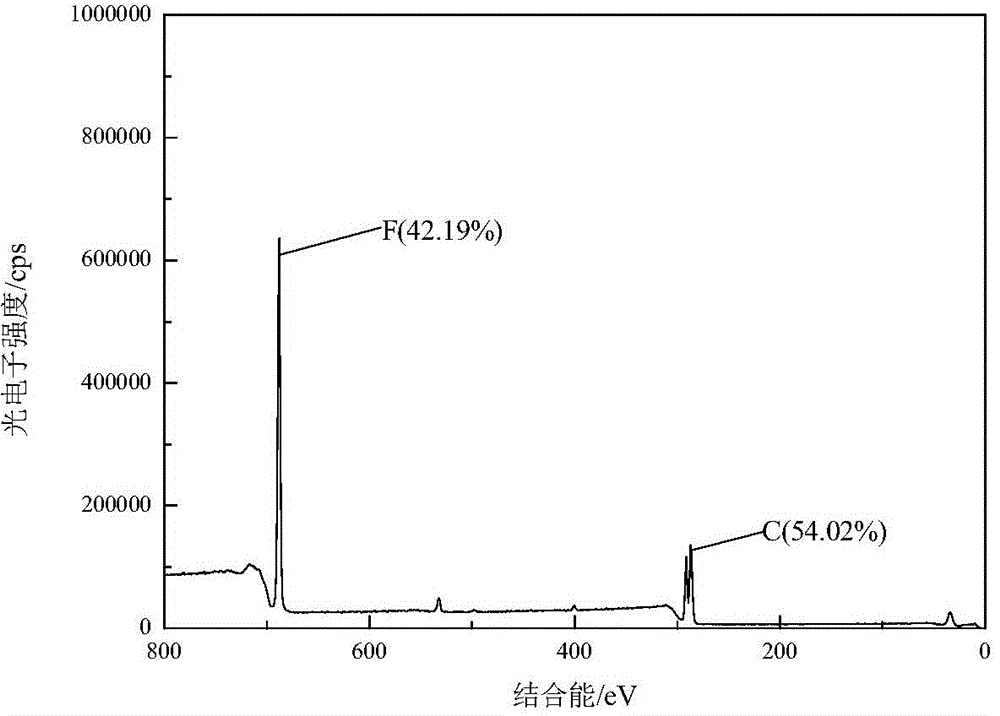

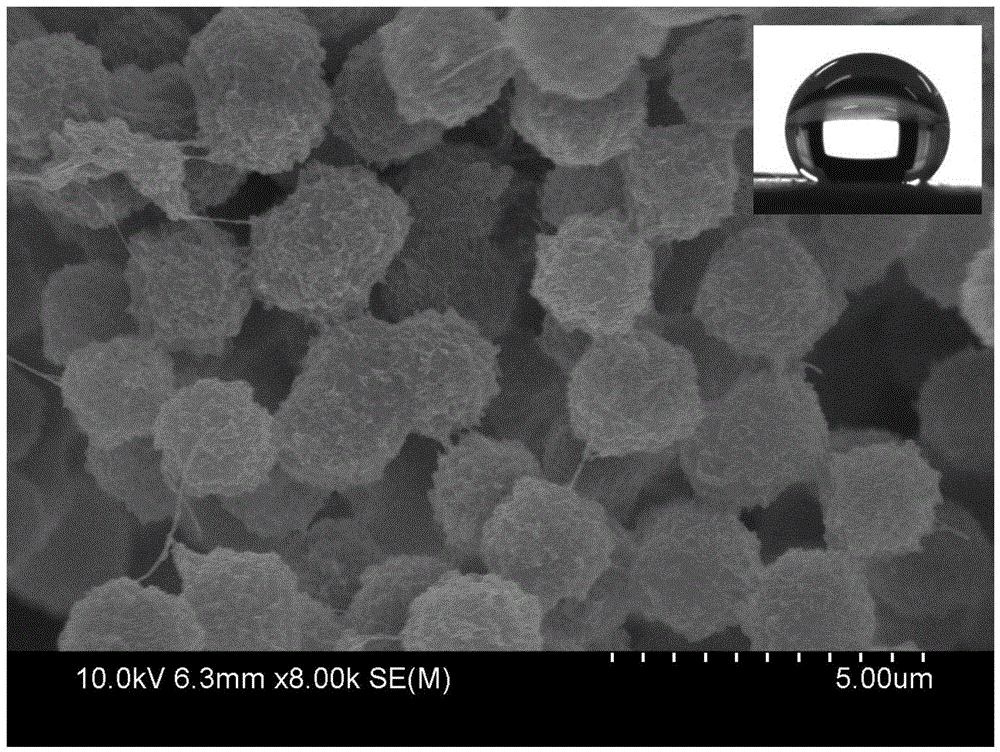

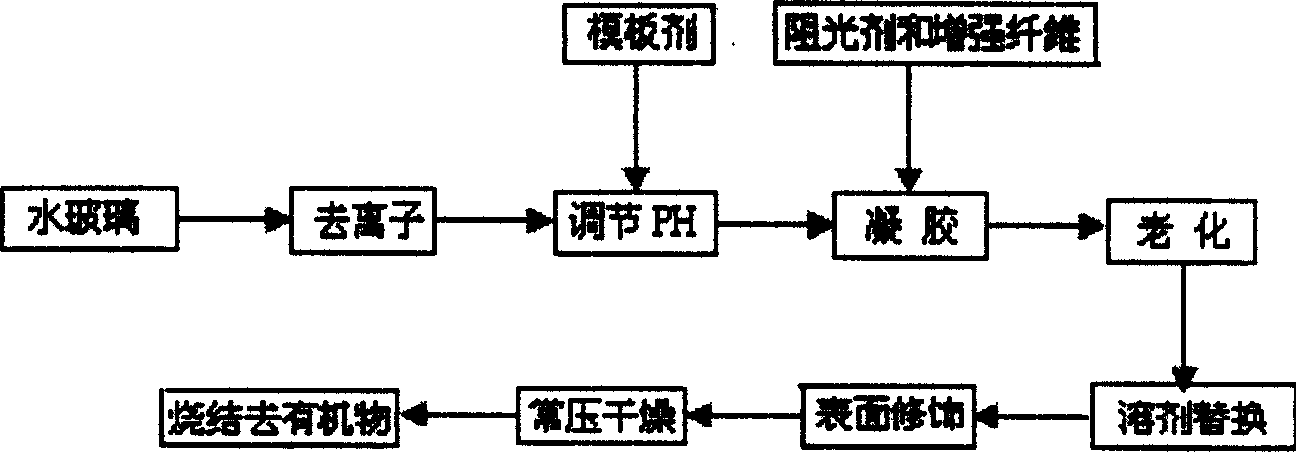

Method for preparing SiO2 aerogel with nanometer apertures under normal pressure

The normal pressure process of preparing SiO2 aerogel with nanometer pores belongs to the field of inorganic non-metal material preparation. The present invention features the cheap water glass as silicon source, the surfactant to alter the surface property of SiO2 aerogel hydrophobicity, the ion exchange resin to eliminate great amount of sodium ions and to lower the effect of the sodium ions on the heat conductivity of SiO2 aerogel, and template agent to control narrow pore size distribution and pore size for realize nanometer level super heat insulating material structure. The normal pressure process has greatly reduced preparation time, and the produced SiO2 aerogel has both hydrophobicity and heat stability and performance similar to SiO2 aerogel produced through supercritical process.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of floating embedding bacterium agents for in-situ remediation of oil polluted water

InactiveCN102888392AAvoid competition effectsImprove purification effectMicroorganism based processesOn/in organic carrierPetroleum PollutionEnvironmental engineering

The invention relates to a preparation method of floating embedding bacterium agents for in-situ remediation of oil polluted water, specifically relating to a technology for fixing oil degradation bacteria by using expanded graphite, sodium alginate and calcium chloride, absorbing and degrading to purify the petroleum polluted water. The preparation method of the floating embedding bacterium agents comprises the following steps: adding petroleum degrading bacteria liquid into sodium alginate sol containing the expanded graphite, mixing uniformly, dropping into calcium chloride solution and cross-linking overnight at 4 degrees centigrade to obtain the floating embedding bacterium agents fixing hydrocarbon degradation bacteria. The floating embedding bacterium agents prepared by the preparation method has the advantages of high mechanical strength, good floatability and mass transfer performance and high degradation efficiency; the floating embedding bacterium agents can be directly put onto the surface of the petroleum polluted water; the embedding bacterium agents can float on an oil-water interface for long term so as to ensure effective contact between the bacterium agent and the petroleum; the embedding technology increases the concentration of microorganisms, prevents the bacteria influencing by the water using environment, effectively improves the degradation efficiency, recovers and recycles conveniently and has no secondary pollution risk.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com