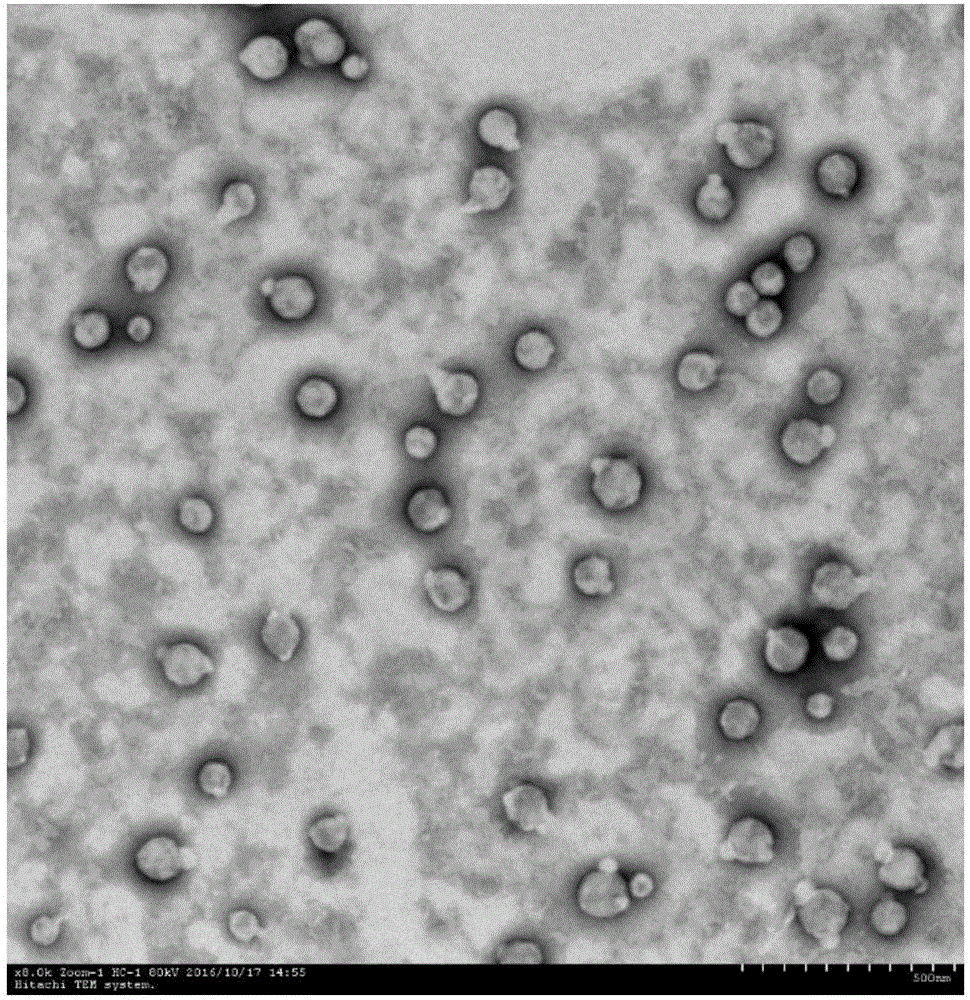

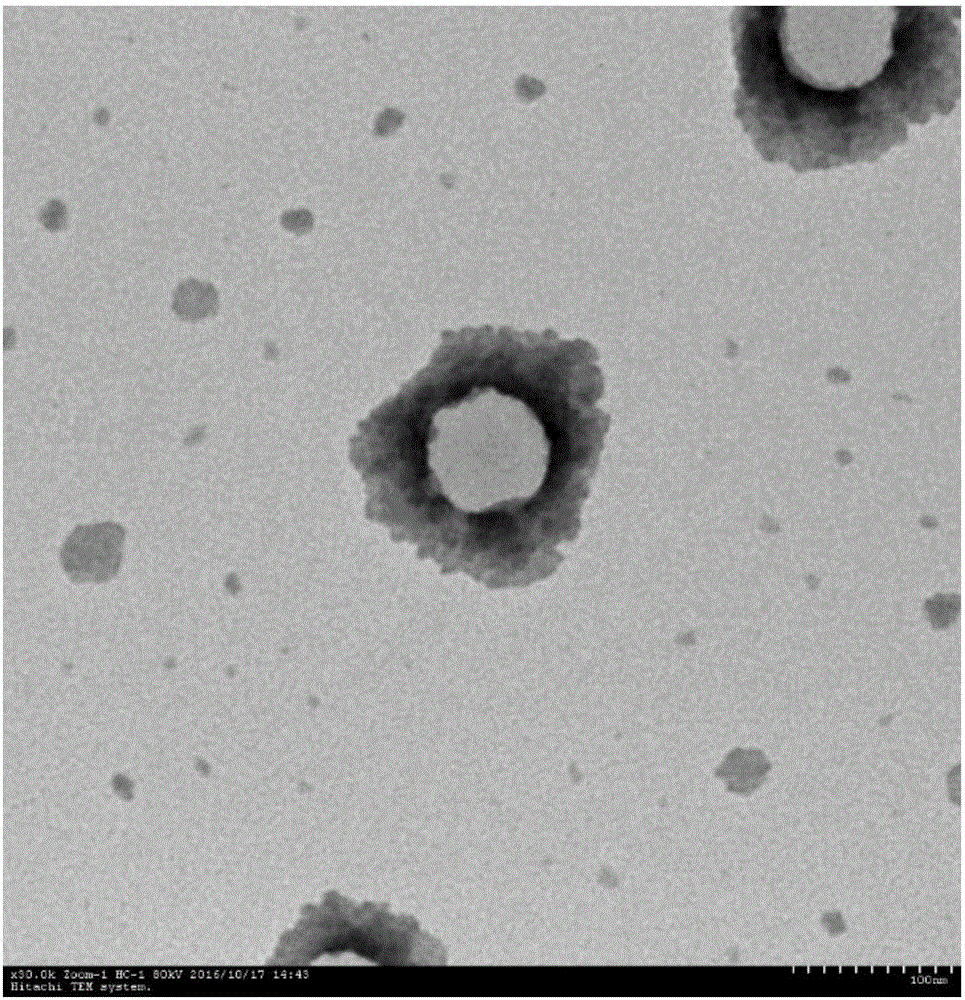

Fluorosilicone-modified polyacrylate emulsion as well as preparing method and application thereof

A technology of polyacrylate emulsion and fluorine-silicon modification, which is applied in the field of fluorine-silicon modified polyacrylate core-shell emulsion and its preparation, to achieve the effects of reducing industrial waste, convenient transportation, and reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

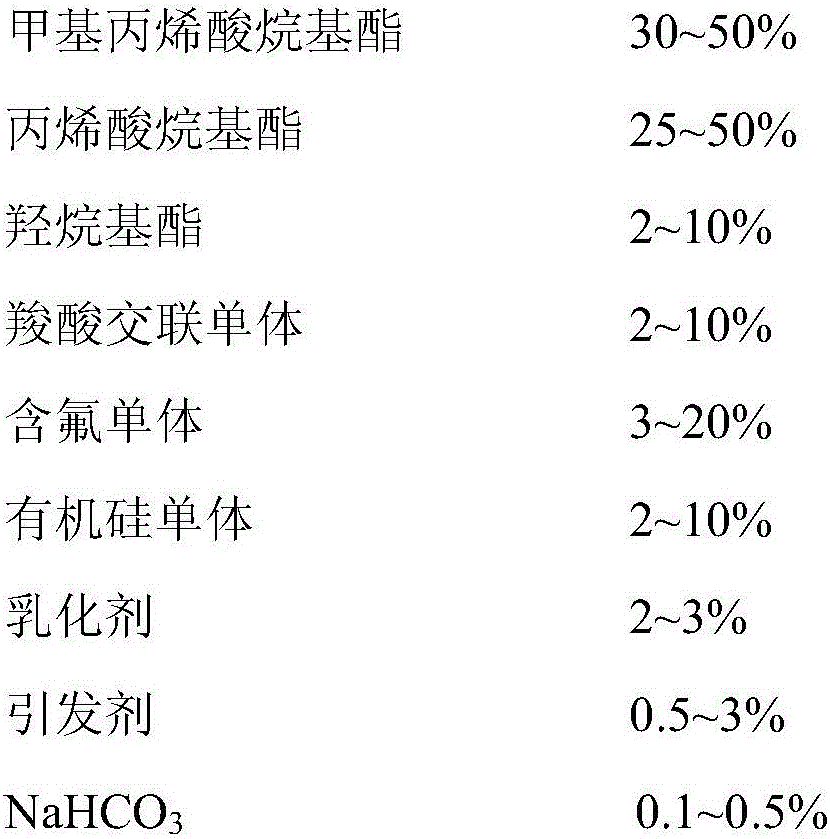

[0047] 1) Synthesis of fluorine-silicon modified core-shell emulsion

[0048] The first step, the preparation of seed emulsion: weigh 15g methyl methacrylate, 51g butyl acrylate, 0.5g methacrylic acid, mix well, as nuclear monomer;

[0049] Take by weighing 0.3g potassium persulfate initiator and dissolve with 30g deionized water to obtain initiator solution;

[0050] 100g deionized water, 0.3gNaHCO 3 , 1.7g sodium dodecylbenzenesulfonate and 30% of the above-mentioned initiator solution quality drop into in the 1000ml four-neck flask that stirrer, thermometer, condensation tube, dropping funnel are housed, stir, treat that water-bath heats up to 80 ℃, then slowly add 10% nucleomonomer dropwise, and at the same time, keep the system temperature at 80°C for reaction, and keep warm for 15 minutes after the dropwise addition. Then start to slowly add the remaining nucleomonomers dropwise, and keep the reaction at 80°C for 30 minutes after the remaining nucleomonomers are droppe...

Embodiment 2

[0059] 1) Synthesis of fluorine-silicon modified core-shell emulsion

[0060] The first step is the preparation of seed emulsion. Weigh the above-mentioned 14g ethyl methacrylate, 49g ethyl acrylate, and 0.5g acrylic acid as core monomers, and mix them uniformly;

[0061] Take by weighing 0.5g potassium persulfate initiator and dissolve with 30g deionized water to obtain initiator solution;

[0062] 80g deionized water, 0.5gNaHCO 3 , 1.5g sodium lauryl sulfate and 10% of the quality of the above-mentioned initiator emulsion are dropped into a 1000ml four-necked flask equipped with a stirrer, a thermometer, a condenser tube, and a dropping funnel, stirred, and when the water bath is heated to 80°C , and then slowly drop 15% of the nucleomonomer, while maintaining the system temperature at 80° C. for a period of time. After the dropwise addition, keep warm for 15 minutes. Then start to slowly add the remaining nucleomonomers dropwise, and after the nucleomonomers are complet...

Embodiment 3

[0069] 1) Synthesis of fluorine-silicon modified core-shell emulsion

[0070] The first step is the preparation of seed emulsion. Weigh the above-mentioned 16g propyl methacrylate, 45g isooctyl acrylate, and 0.5g acrylic acid as core monomers, and mix them uniformly;

[0071] Take by weighing 0.3g potassium persulfate initiator and dissolve with 30g deionized water to obtain initiator solution;

[0072] 20% of 100g deionized water, 0.3gNaHCO3, 1.7g alkyl diphenyl oxide sodium sulfonate and above-mentioned initiator solution quality are dropped into the 1000ml four-neck flask that stirrer, thermometer, condenser tube, dropping funnel are equipped with During the process, stir, and when the water bath is heated to 80°C, slowly add 20% nucleomonomer dropwise, while maintaining the system temperature at 80°C for reaction, and keep warm for 15 minutes after the dropwise addition. Then start to slowly add the remaining nucleomonomers dropwise, and after the nucleomonomers have bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com