Production formula and method of PVDF (polyvinylidene fluoride)/carbon nano-tube super-hydrophobic film

A carbon nanotube and super-hydrophobic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of small pore size and inability to meet high permeation flux, and achieve large aspect ratio and enhanced Effect of mechanical properties and thermal stability, good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

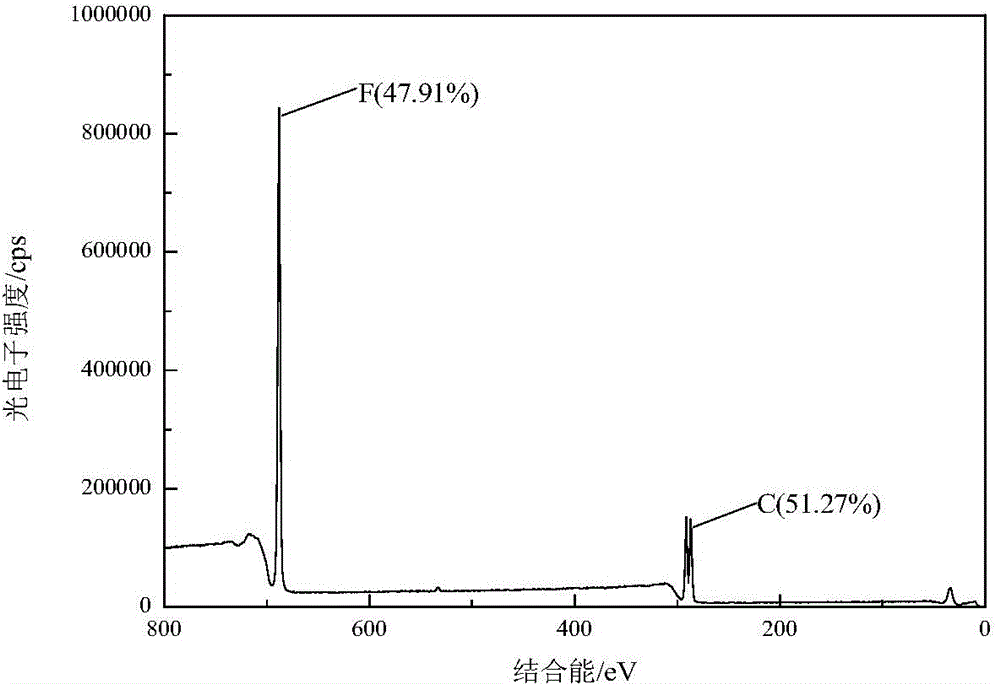

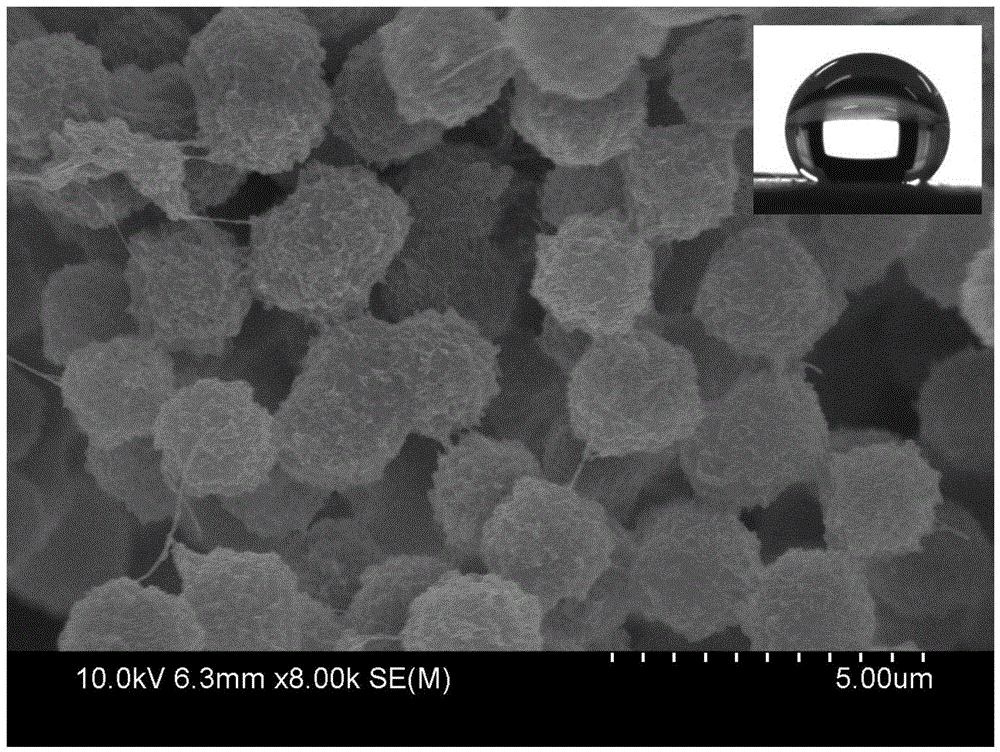

Embodiment 1

[0030] Weigh 1 g of carboxylated carbon nanotubes (0.4-8 nm in diameter) and add them into 159 ml of N,N-dimethylformamide, and disperse them evenly by ultrasonication for 1 h. Afterwards, 40g of PVDF was added to the above solution while stirring, stirred for 4 hours under the condition of heating in a water bath at 80°C to dissolve completely, and a uniformly mixed casting solution was obtained after defoaming in a vacuum oven at 80°C. Use a scraper to scrape the casting liquid on a polyethylene plate to prepare a nascent flat film, and then place the nascent flat film in a closed environment at 40°C and a relative humidity of water vapor of 80% until it solidifies into a PVDF film; place the PVDF film on the Soak in deionized water for 24 hours to completely remove the residual solvent in the PVDF membrane to obtain the PVDF / carbon nanotube super-hydrophobic membrane.

[0031] The PVDF / carbon nanotube superhydrophobic membrane that this embodiment makes is carried out perfo...

Embodiment 2

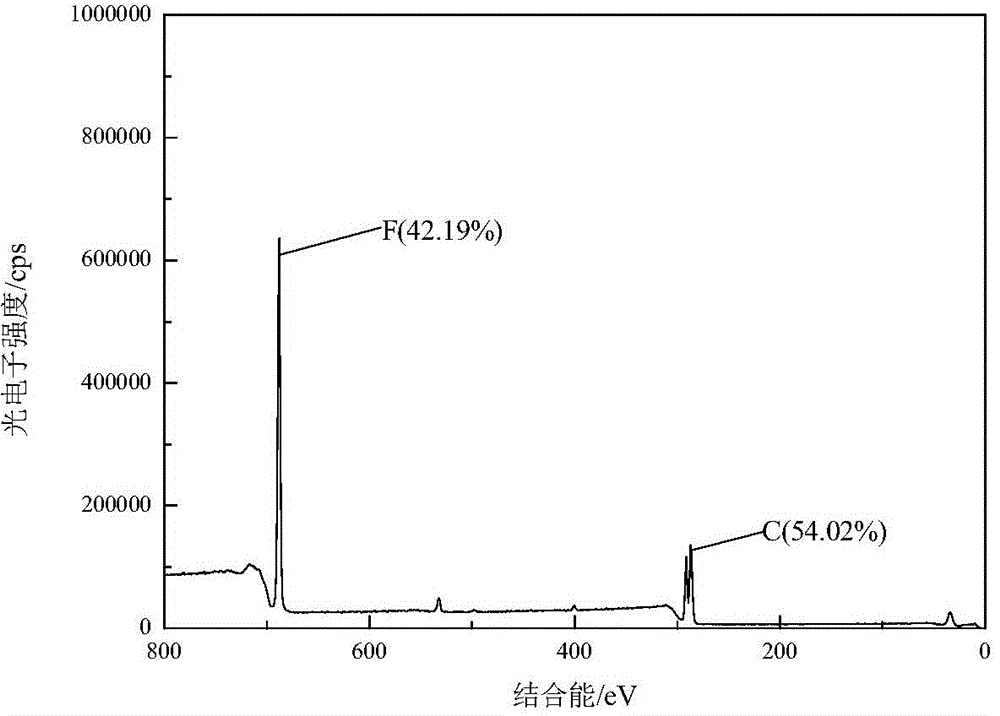

[0038] Weigh 1 g of carboxylated carbon nanotubes (0.4-8 nm in diameter) and add them into 159 ml of N,N-dimethylformamide, and disperse them evenly by ultrasonication for 1 h. Afterwards, 40g of PVDF was added to the above solution while stirring, stirred for 4 hours under the condition of heating in a water bath at 80°C to dissolve completely, and a uniformly mixed casting solution was obtained after defoaming in a vacuum oven at 80°C. Use a scraper to scrape the casting solution on a polyethylene plate to prepare a nascent flat film, and then place the nascent flat film in a closed environment at 40 ° C and a relative humidity of water vapor of 99% until it solidifies into a PVDF film; place the PVDF film on the Soak in deionized water for 24 hours to completely remove the residual solvent in the PVDF membrane to obtain the PVDF / carbon nanotube super-hydrophobic membrane.

[0039] The PVDF / carbon nanotube superhydrophobic membrane that this embodiment makes is carried out p...

Embodiment 3

[0041] Weigh 1 g of carboxylated carbon nanotubes (0.4-8 nm in diameter) and add them into 159 ml of N,N-dimethylformamide, and disperse them evenly by ultrasonication for 1 h. Afterwards, 40g of PVDF was added to the above solution while stirring, stirred for 4 hours under the condition of heating in a water bath at 80°C to dissolve completely, and a uniformly mixed casting solution was obtained after defoaming in a vacuum oven at 80°C. Use a scraper to scrape the casting solution on a polyethylene plate to prepare a nascent flat film, and then place the nascent flat film in a closed environment at 60°C and a relative humidity of water vapor of 80% until it solidifies into a PVDF film; place the PVDF film on the Soak in deionized water for 24 hours to completely remove the residual solvent in the PVDF membrane to obtain the PVDF / carbon nanotube super-hydrophobic membrane.

[0042]The PVDF / carbon nanotube superhydrophobic membrane that this embodiment makes is carried out perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com