Application method of graphene sponge

A technology of graphene sponge and application method, which is applied in the application field of graphene sponge, can solve the problems of insufficient adsorption capacity, high cost, and difficulty in preparing large quantities of large pieces, and achieve fast adsorption speed, low cost, and wide application potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of graphene sponge among the present invention is as follows:

[0018] In the first step, measure 35ml of graphene oxide dispersion with a concentration of 2mg / ml, and add 1ml of ammonia water to form a mixed solution; the concentration of ammonia water is 30%, which means that every 100 grams of ammonia water contains 30 grams of hydrogen peroxide.

[0019] In the second step, pour the mixed solution into the reaction kettle, heat it at 180°C for 24 hours, then cool it naturally, and unscrew the reaction kettle to obtain the graphene gel.

[0020] In the third step, the obtained graphene gel is freeze-dried at low pressure to obtain a porous graphene sponge.

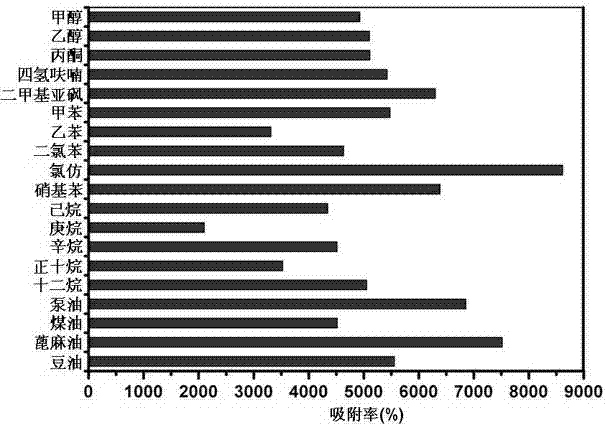

[0021] The organic solvent or grease includes vegetable oil, crude oil, pump oil, dodecane, n-decane, octane, hexane, phenol, nitrobenzene, chloroform, dichlorobenzene, ethylbenzene, toluene, benzene, Dimethyl sulfoxide, tetrahydrofuran, dimethylformamide, acetone, ethanol, methanol, keros...

Embodiment 1

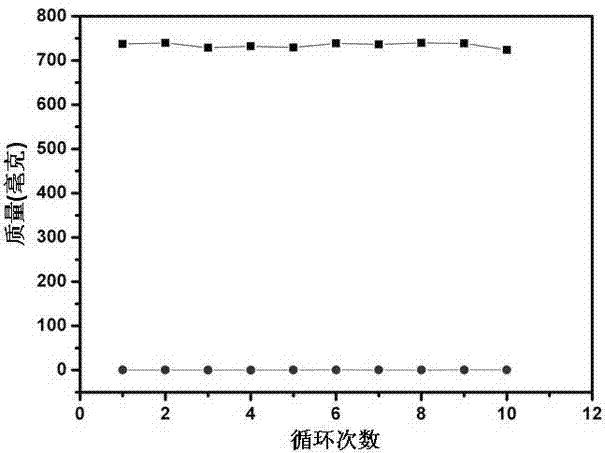

[0037] Using the low-pressure distillation method, the adsorption and desorption cycle experiments were carried out on the graphene sponge adsorbed with toluene. That is, experiment with the same graphene sponge. The specific process is: put the graphene sponge that has absorbed toluene in a closed container, and then use a mechanical pump to pump out the gas in the container to reduce the air pressure in the container. At this time, the toluene will evaporate from the graphene sponge. After the distillation is completed, the graphene sponge is placed in toluene and absorbed again, and the cycle continues. Such as image 3 As shown, the experiment was carried out ten times. image 3 The adsorption and desorption amounts of graphene sponges in each experiment are shown. image 3 Among them, the abscissa indicates the number of cycles of the experiment, a total of ten times; the ordinate indicates the weight of the toluene adsorbed by the graphene sponge, in mg; the upper cur...

Embodiment 2

[0040] Using ethanol as the extractant, the adsorption and desorption cycle experiments were carried out on the graphene sponge adsorbed with dodecane. That is, experiment with the same graphene sponge. The specific process is: soak the graphene sponge adsorbed with dodecane in enough ethanol, and after the dodecane is basically dissolved in ethanol, take out the graphene sponge and place it in a 60°C incubator for 2 hours, and then take out and re-adsorb dodecane, and so cycle ten times. Figure 4 The adsorbed and residual amounts of graphene sponges in each experiment are shown. Figure 4 In , the abscissa represents the number of cycles of the experiment, a total of ten; the ordinate represents the weight of dodecane adsorbed by the graphene sponge, in mg. The upper curve represents the weight of adsorbed dodecane, and the lower curve represents the weight of the graphene sponge after the dodecane in the graphene sponge is distilled under low pressure.

[0041] From Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com