Patents

Literature

50results about How to "Realize long cycle operation" patented technology

Efficacy Topic

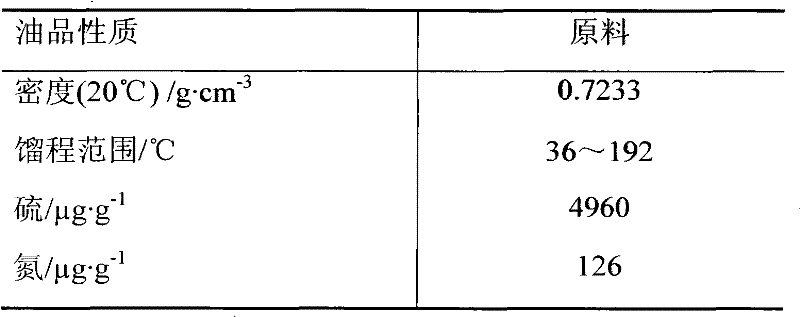

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aromatization catalyst, its preparation method and application

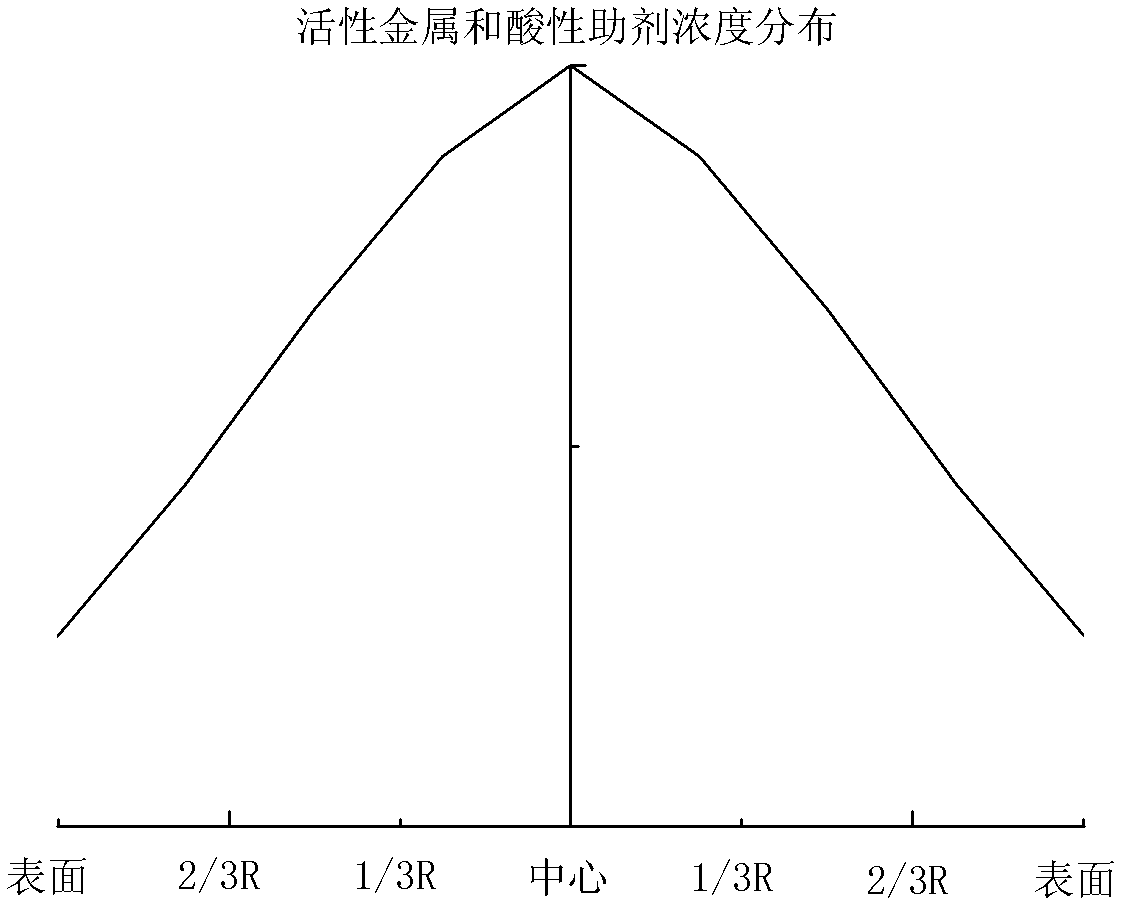

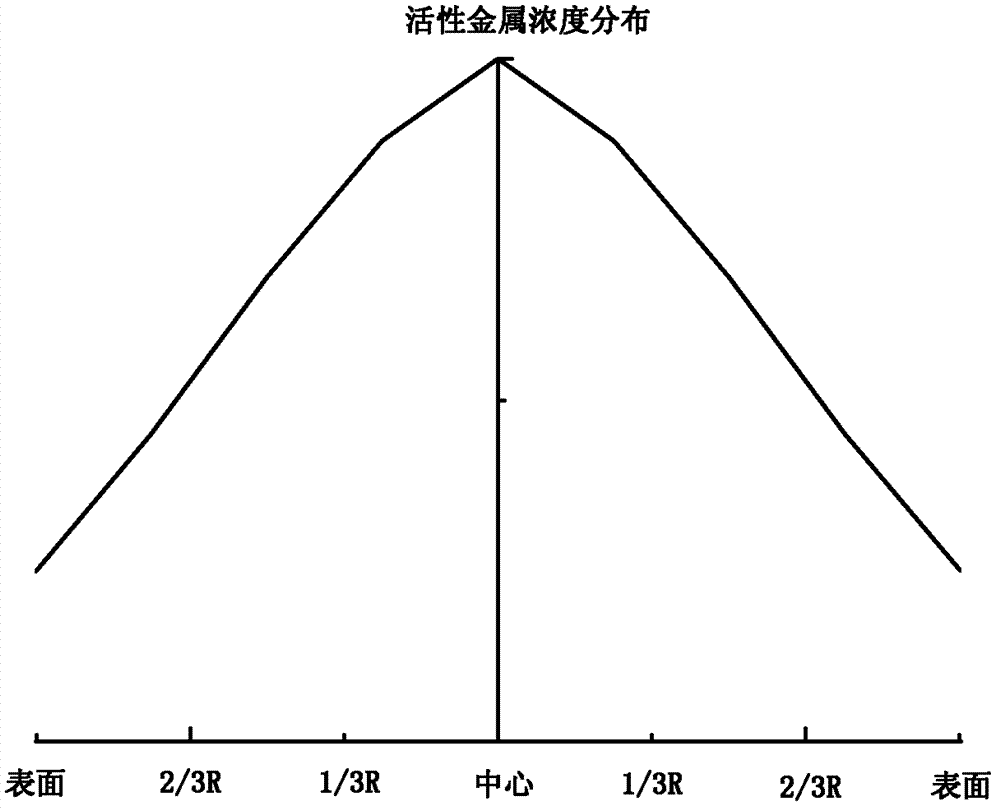

ActiveCN1651141ALipophilicHigh aromatization activityMolecular sieve catalystsHydrocarbonsMolecular sieveAdhesive

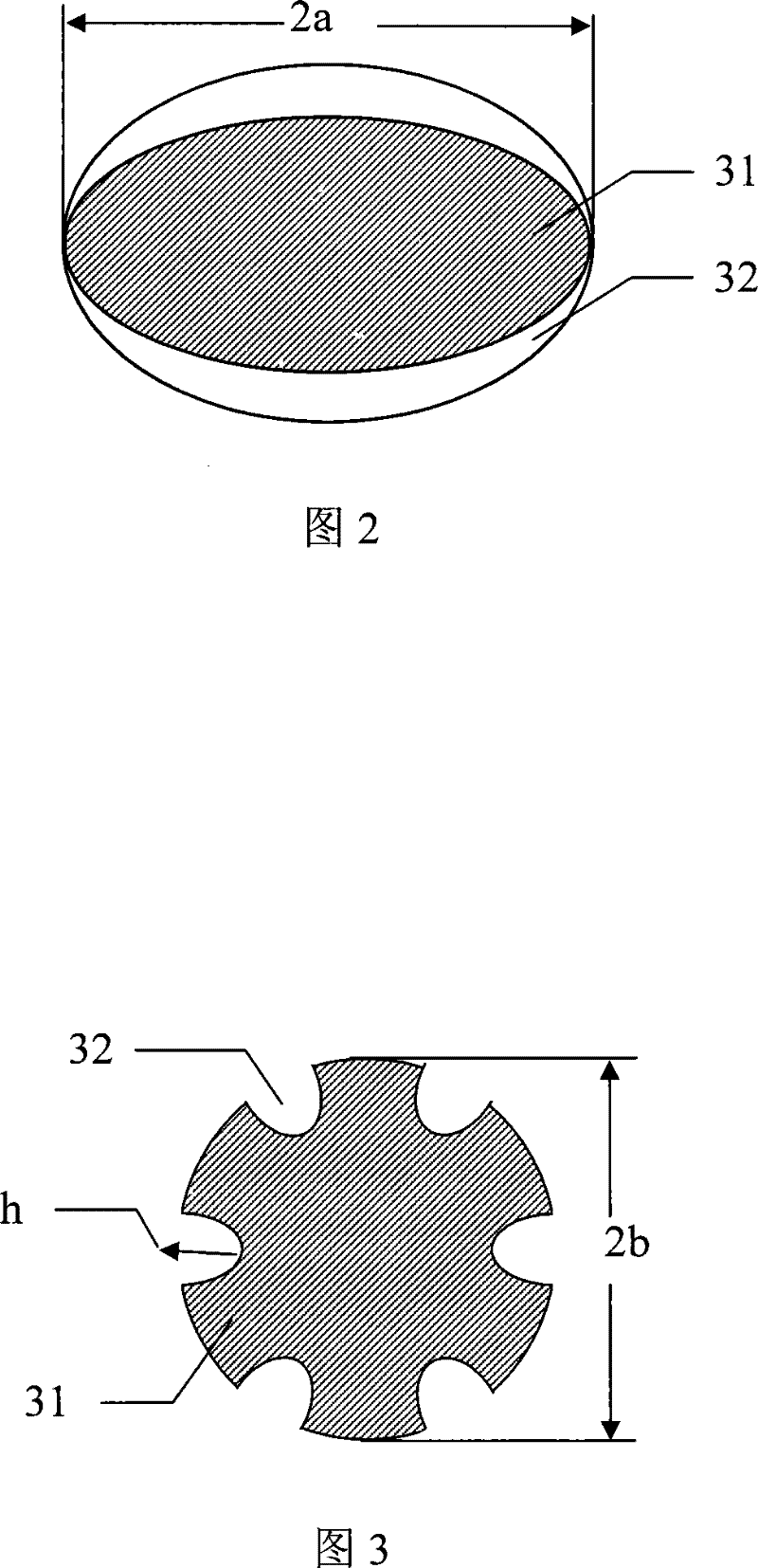

An aromatizing catalyst for molifying poor gasoline to prepare high-octane gaseline component or arylhydrocarbon is prepared from the Zn, P and RE metal modified HZSM-5 molecular sieve, Y-type molecular sieve, carrier and adhesive proportionally.

Owner:CHINA PETROCHEMICAL CORP +1

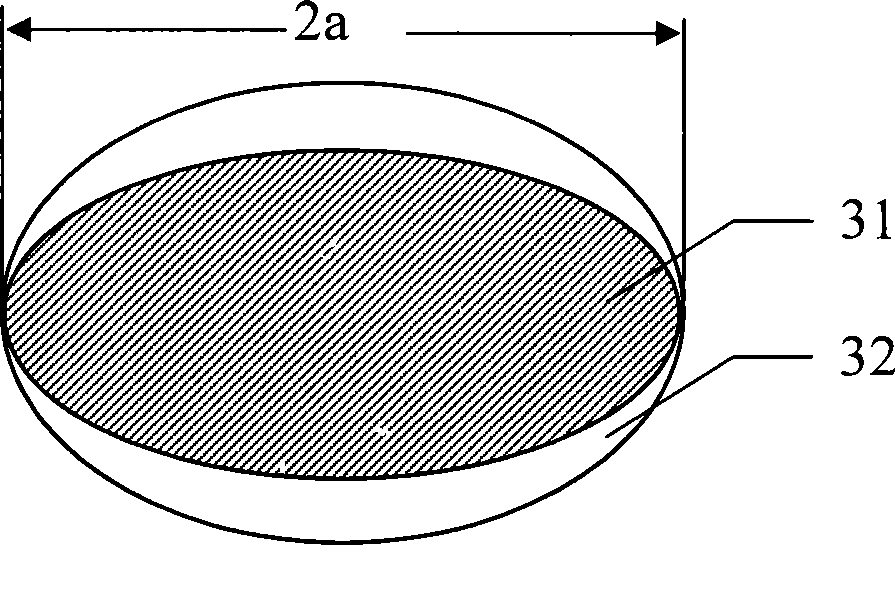

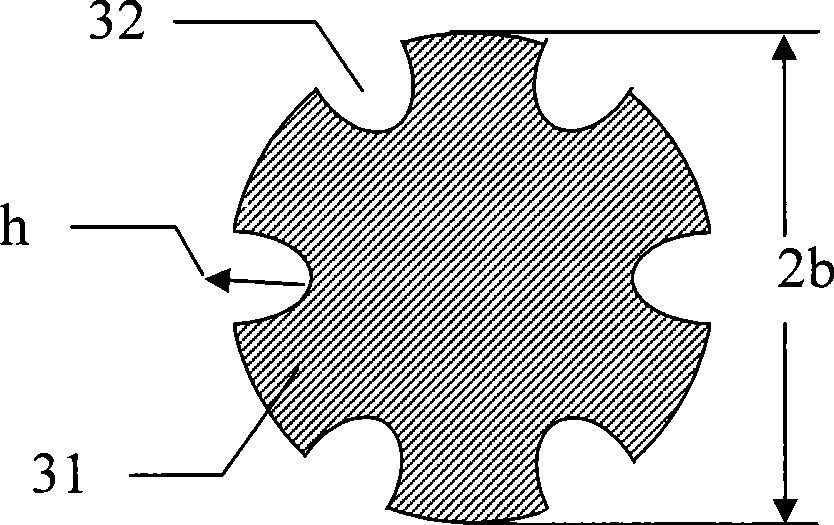

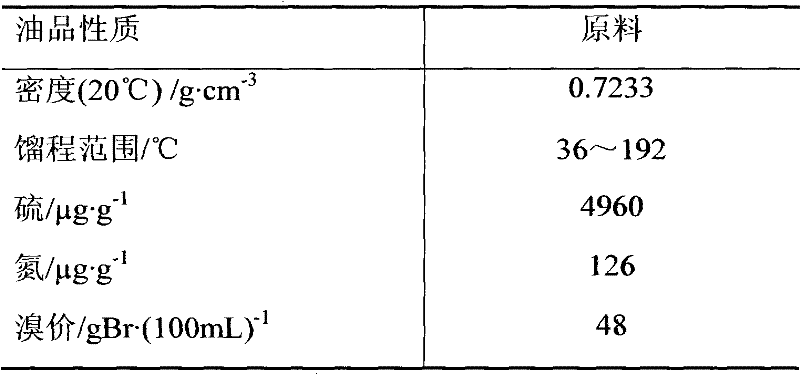

Method for hydrotreating high-sulfur and high-metal residual oil

ActiveCN101519603AHigh porosityReduced inactivation rateRefining to eliminate hetero atomsNaphthaHydrogen

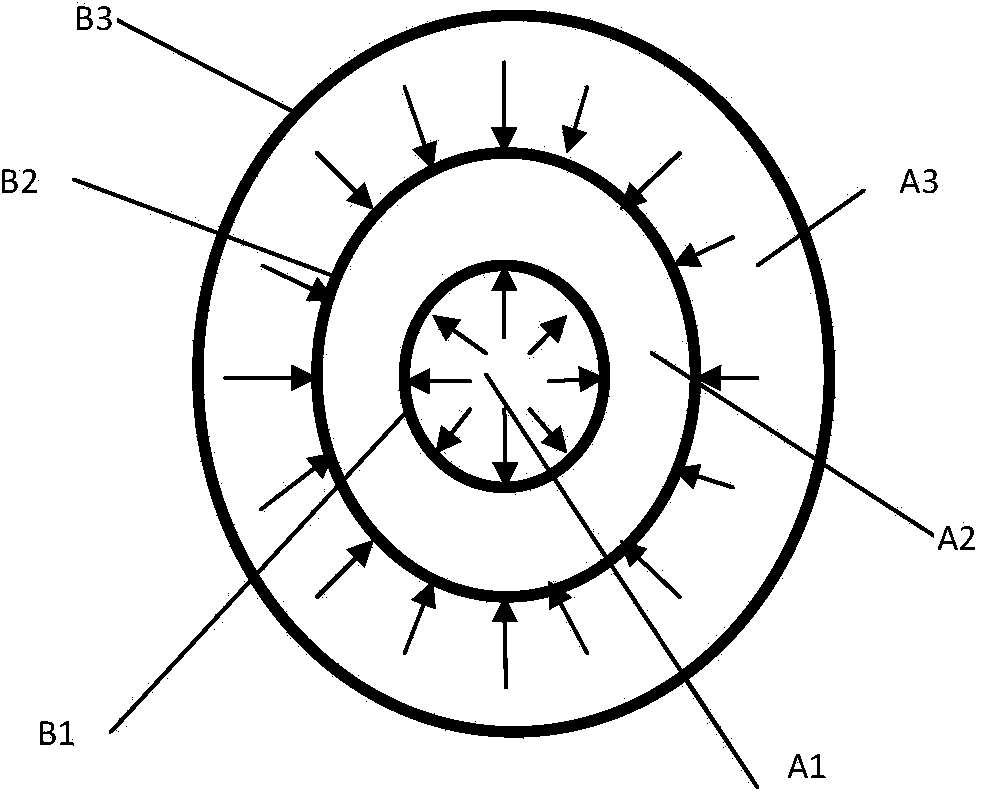

The invention provides a method for hydrotreating high-sulfur and high-metal residual oil, which comprises the following steps: the residual oil and catalytic cracking recycle oil are in contact with a residual oil hydrogenation catalyst in the presence of hydrogen gas and under the hydrotreating reaction condition so as to carry out a hydrotreating reaction; the reaction product is separated to obtain gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. The residual oil hydrogenation catalyst is a combination of at least two catalysts, namely, an up-flow reactor catalyst and a fixed-bed hydrogenation catalyst and the two catalysts are respectively put in an up-flow reactor and a fixed-bed reactor; the ratio of the up-flow reactor catalyst and the fixed-bed hydrogenation catalyst is 30:70 to 70:30. The method can treat the high-sulfur and high-metal residual oil and effectively slow down the ascending speed of the pressure drop of the fixed-bed catalyst bed, thus realizing the long-term running of the device. Besides, the method can combine the residual oil hydrotreating and catalytic cracking more effectively and has better implementation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

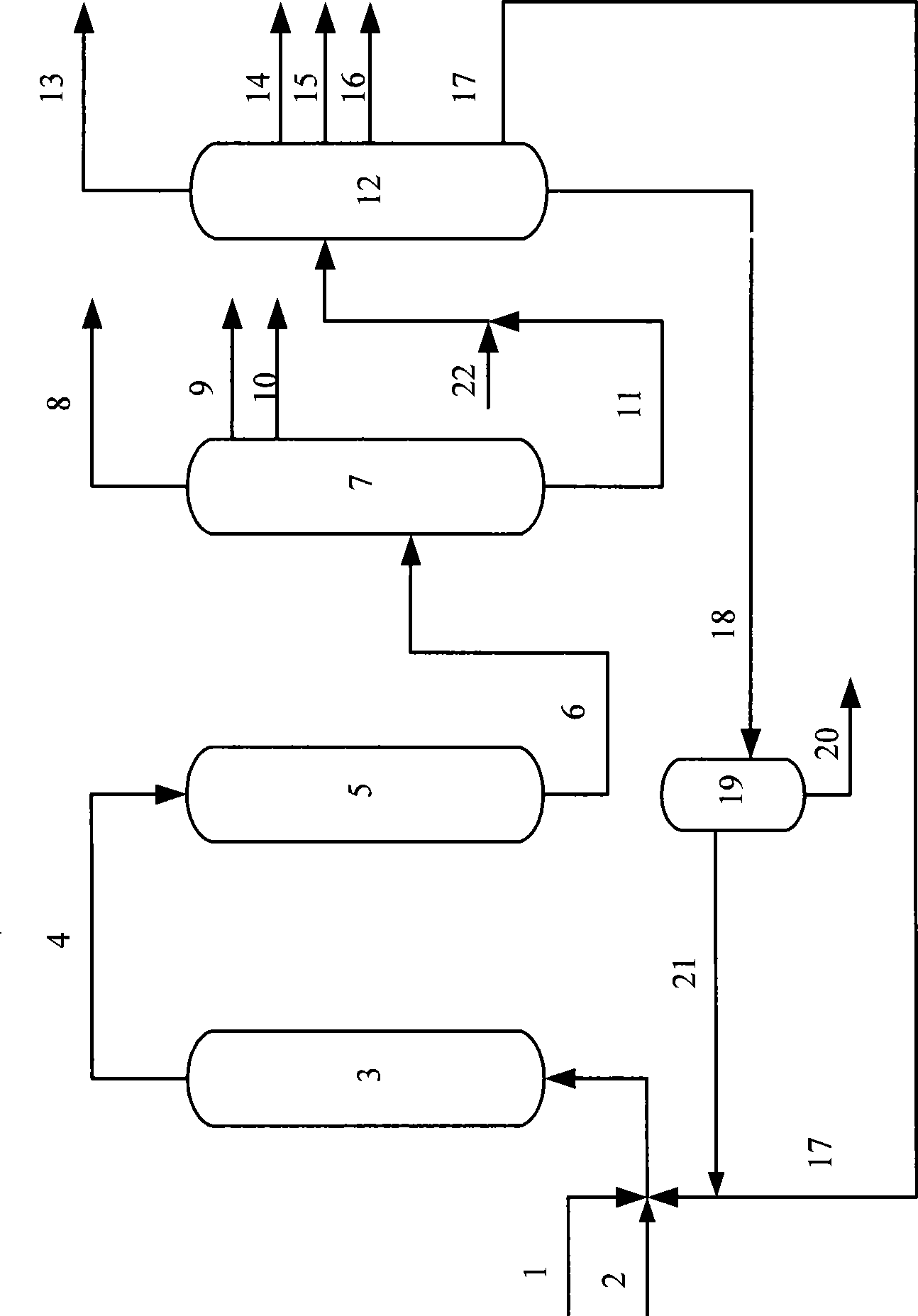

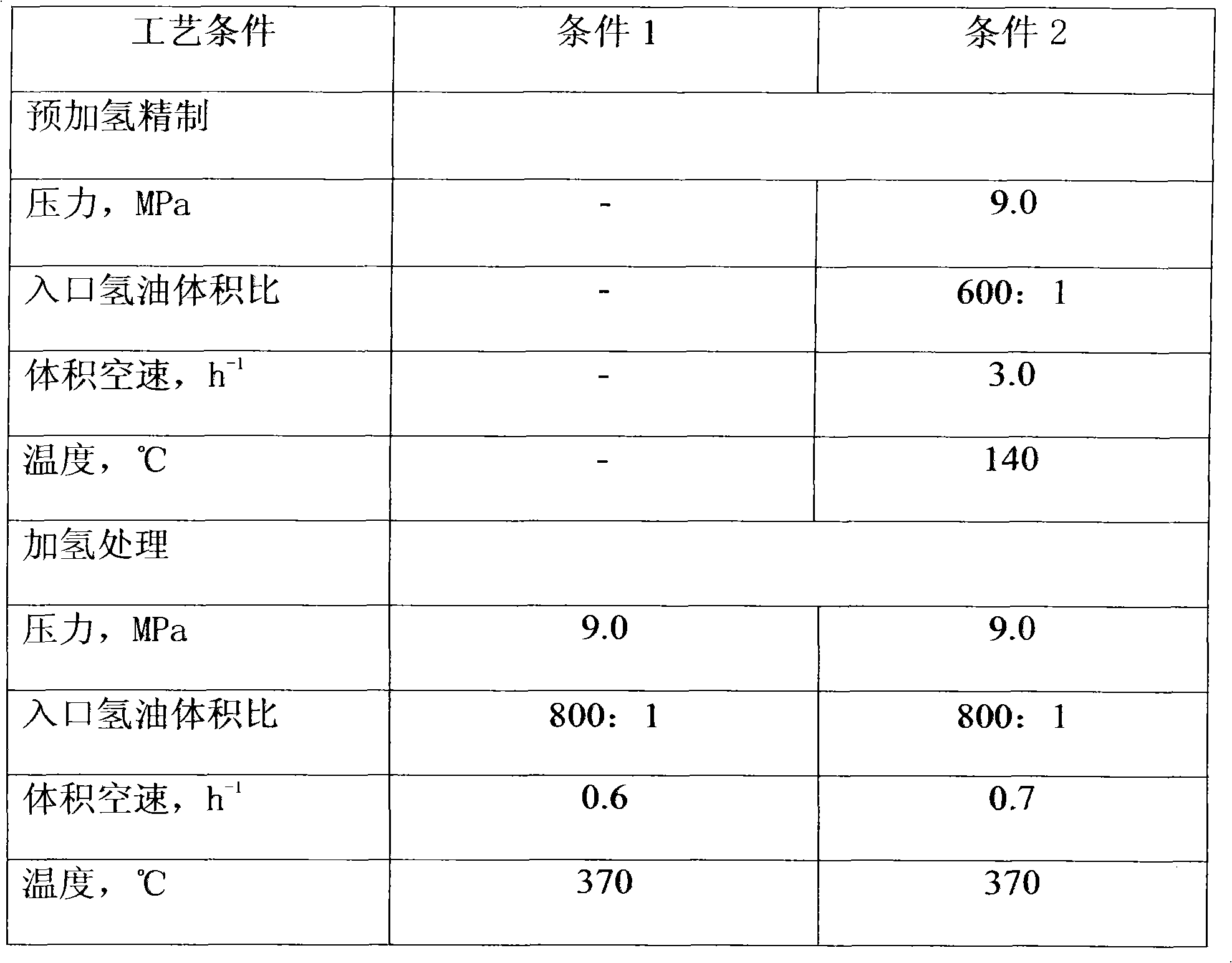

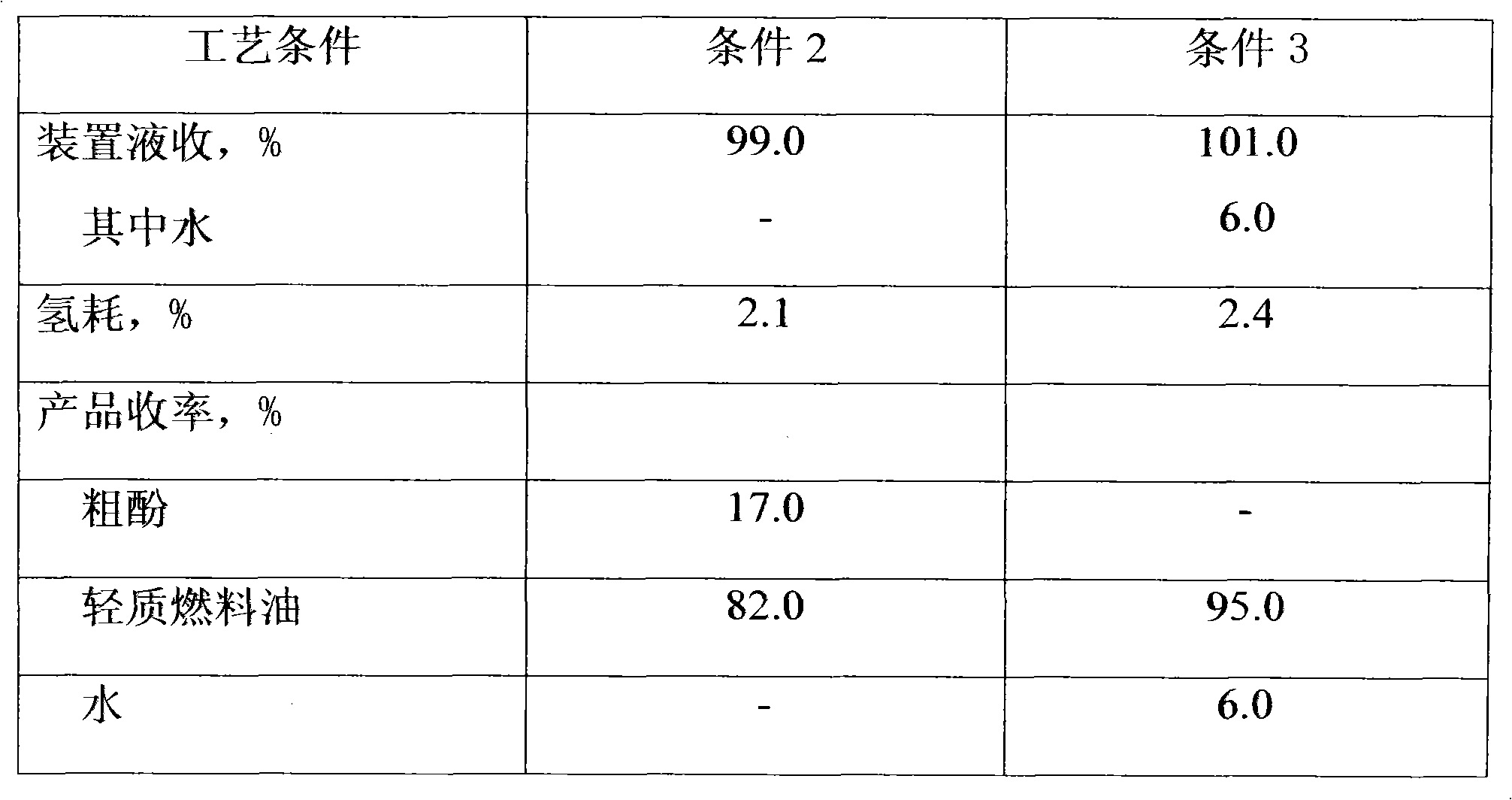

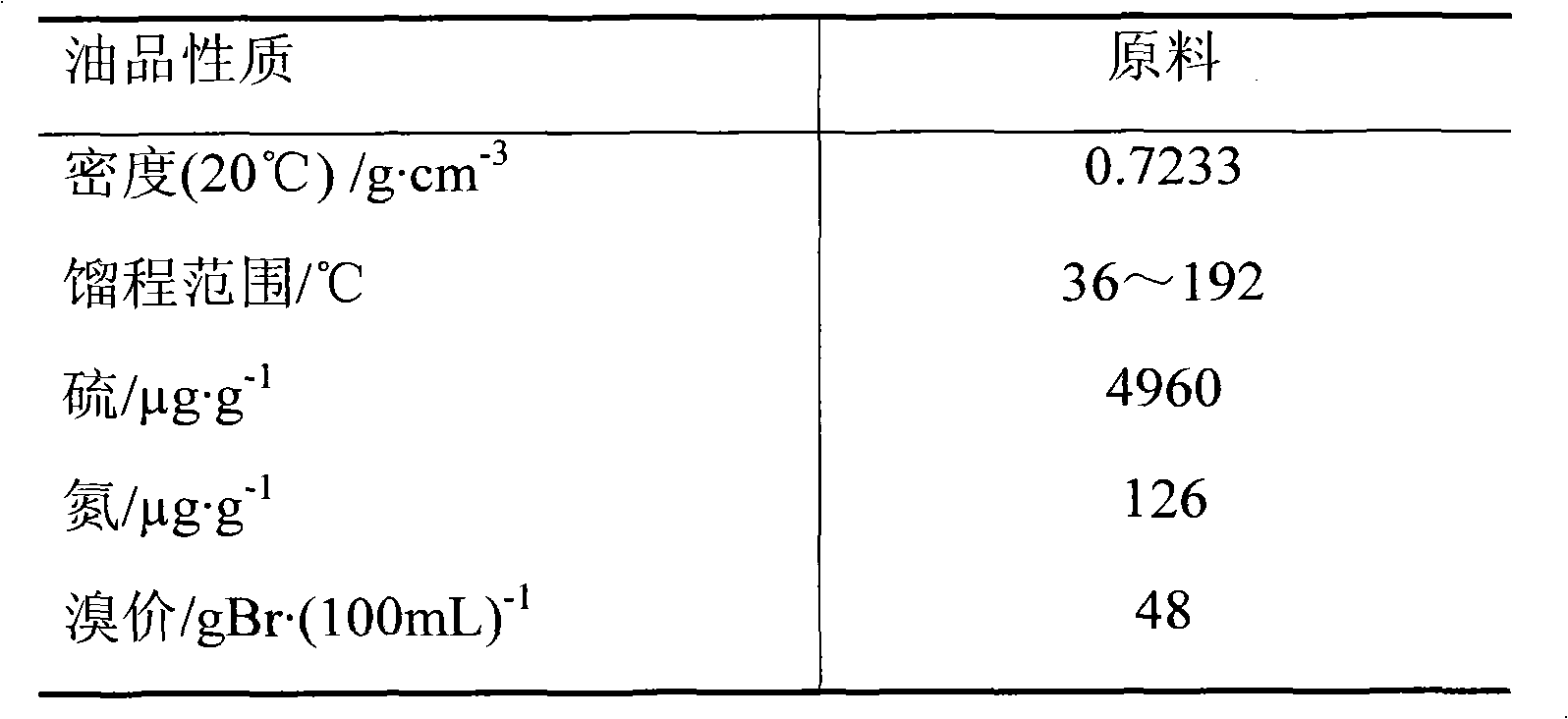

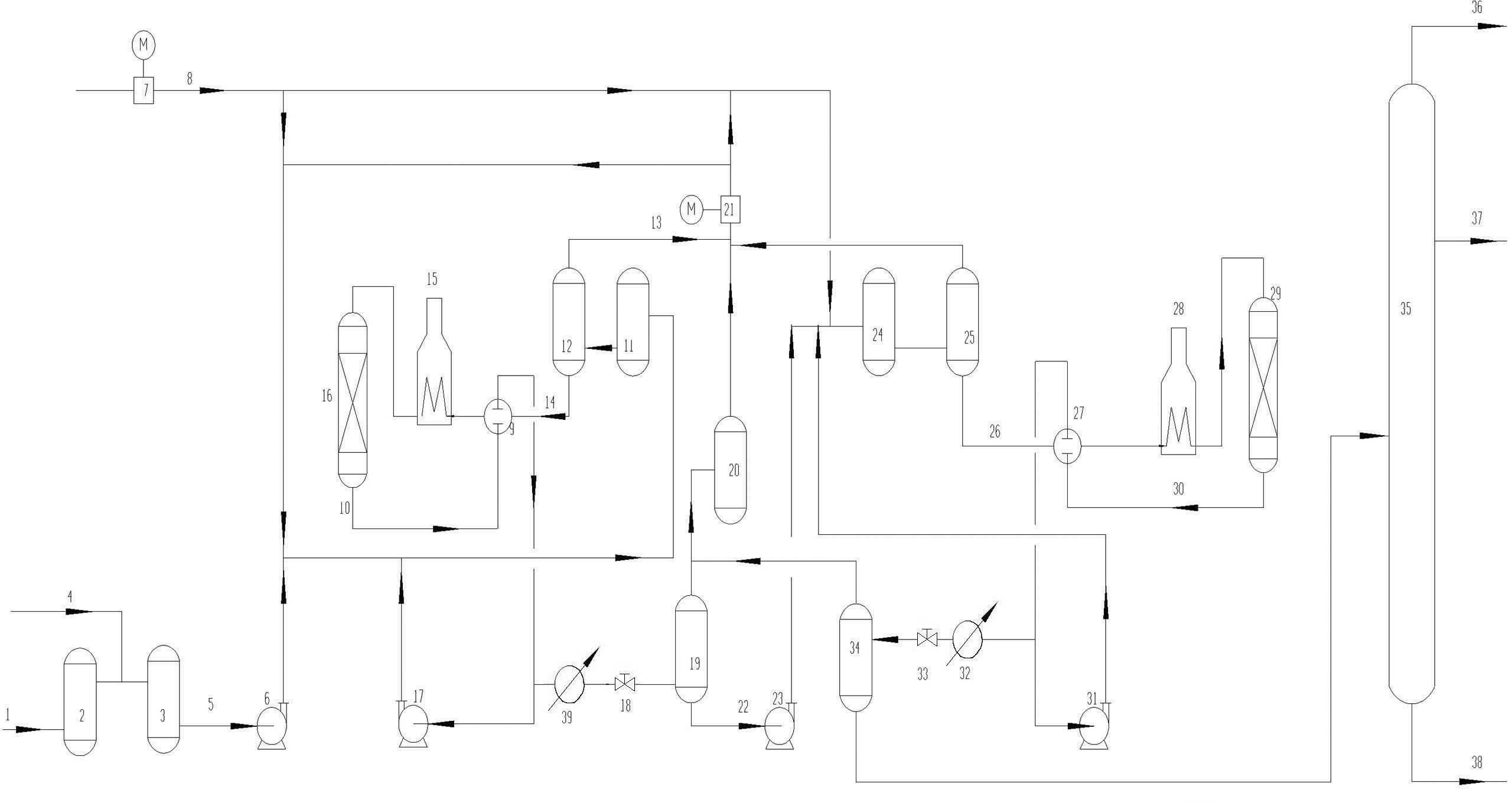

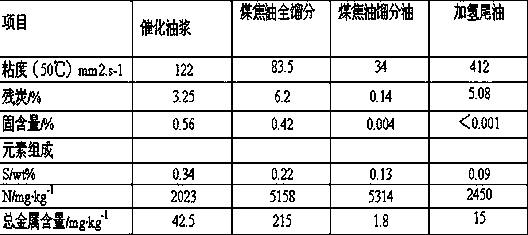

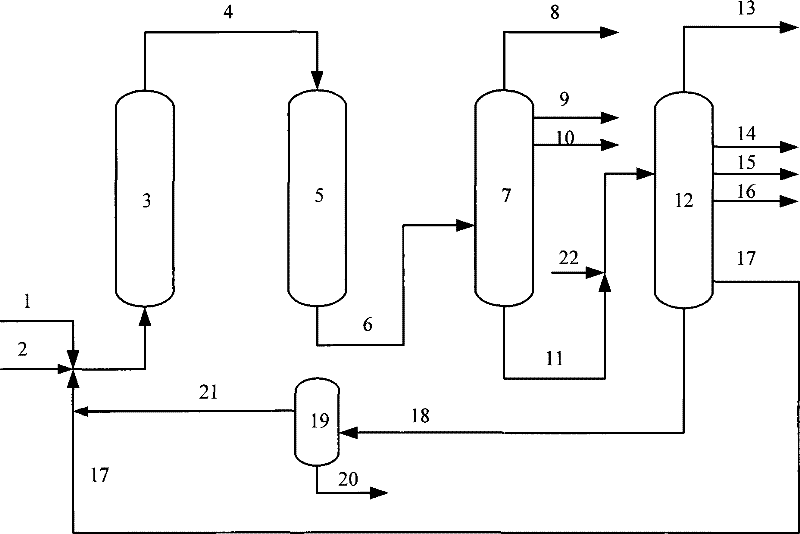

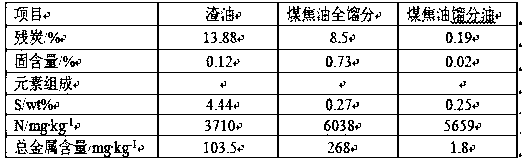

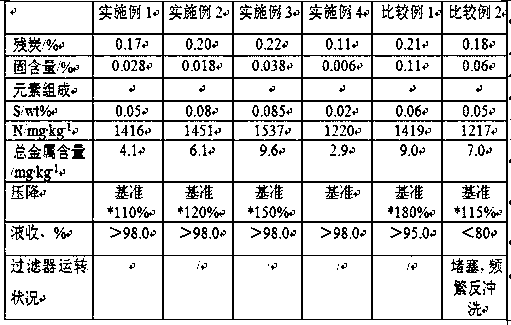

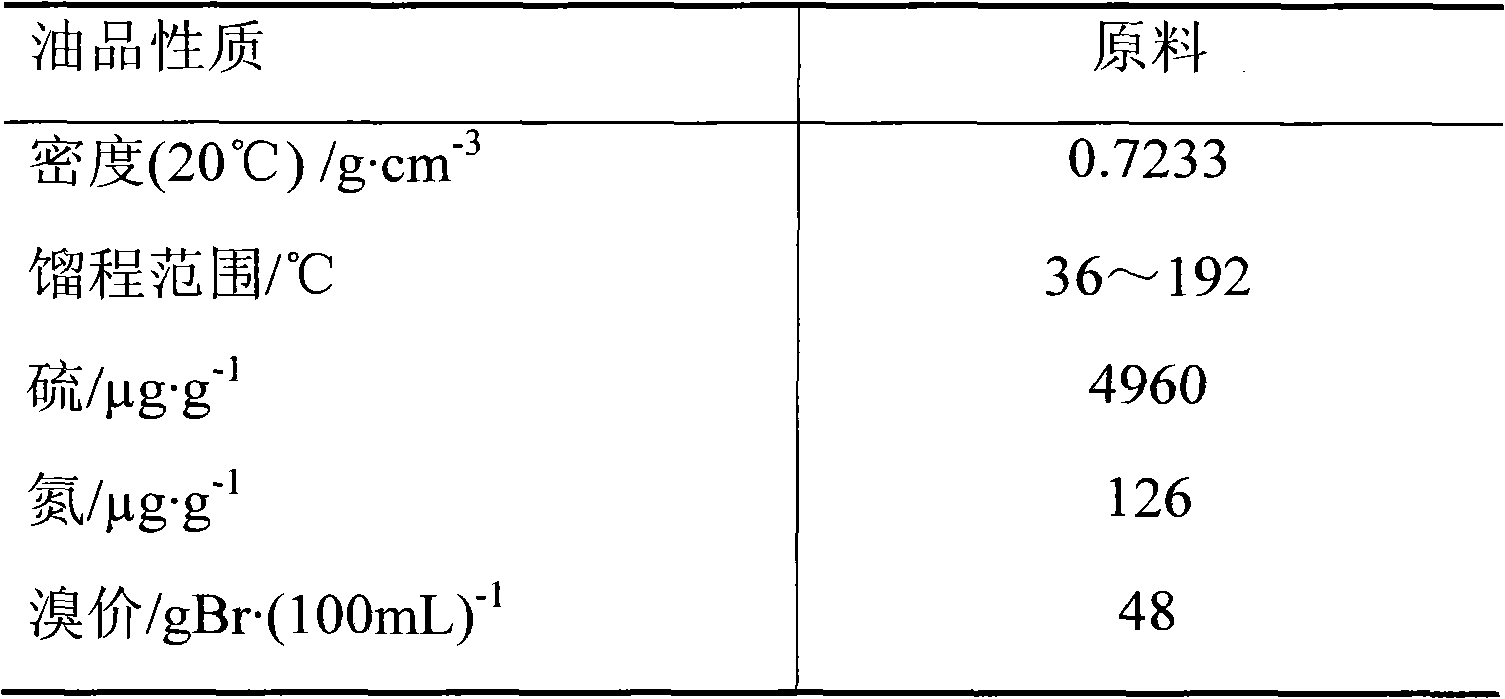

Processing method of medium-low temperature coal tar

ActiveCN102465033AImprove economyOperation cycle solutionOrganic chemistryOrganic compound preparationSlagFuel oil

The invention discloses a processing method of medium-low temperature coal tar. According to the method, whole fraction of the medium-low temperature coal tar which has been undergone dehydration and slag removal is firstly distilled to obtain a light fraction and a heavy fraction. The heavy fraction is used as modified asphalt or heavy fuel oil and the like. A phenolic compound is separated from the light fraction by an acid-base extraction method so as to obtain a crude phenol product. Hydrogenation saturation of alkene from dephenolized raw oil is carried out by a hydro-pretreating method. The prehydrogenation raw oil contacts with a main hydrofining catalyst for desulphurization, nitrogen removal, aromatic saturation and other reactions. In comparison with the prior art, by the adoption of the method provided by the invention, components which influence long-term operation of a hydrogenation device can be fundamentally removed; the operation period of the device can be obviously prolonged; the crude phenol product can be obtained; and the utilization rate of raw materials and the whole economy of a processing device can be raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

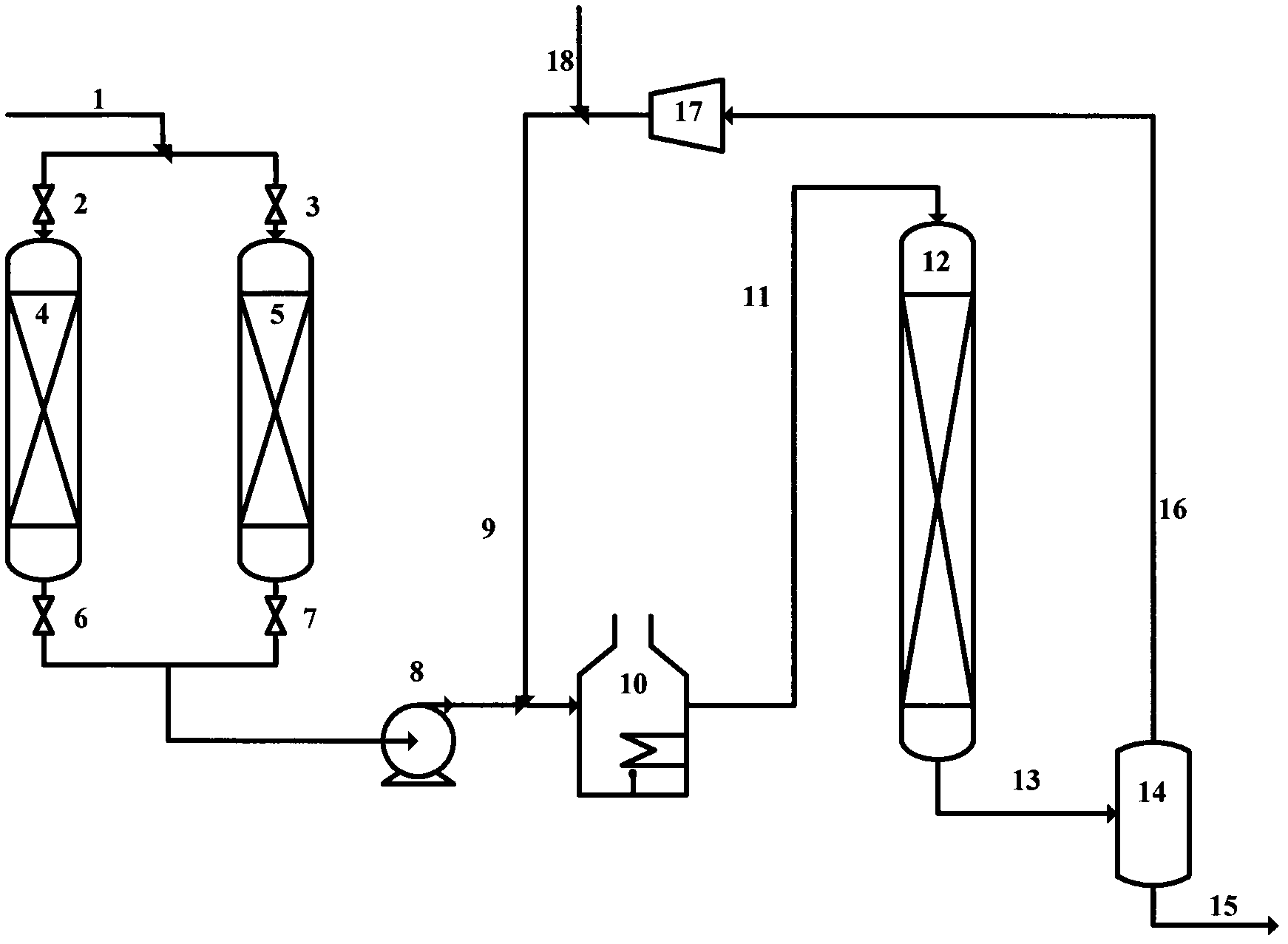

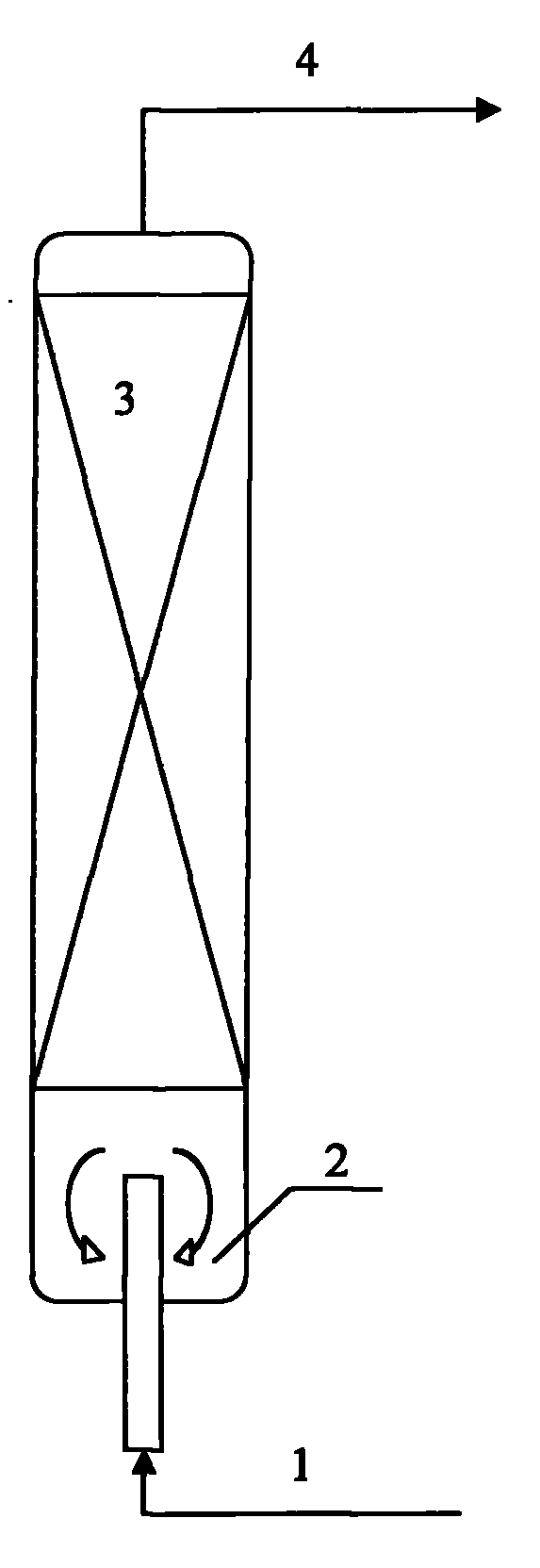

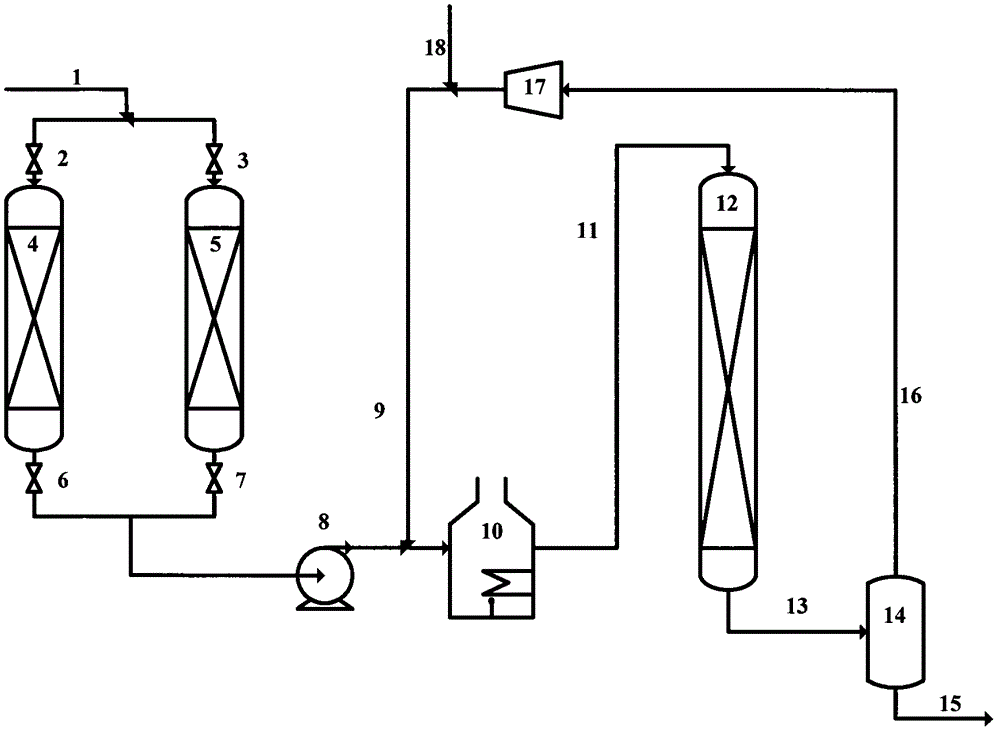

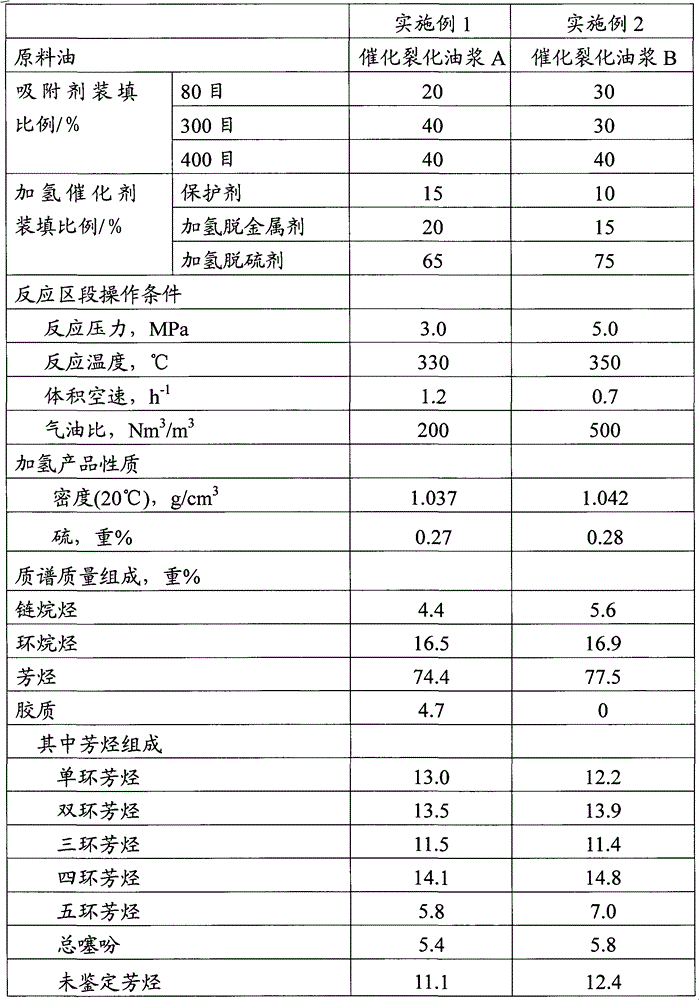

Method for preparing needle coke material by catalytic cracking slurry

ActiveCN103013567AProtection reachedRealize long cycle operationTreatment with hydrotreatment processesHydrogenation reactionSulfur

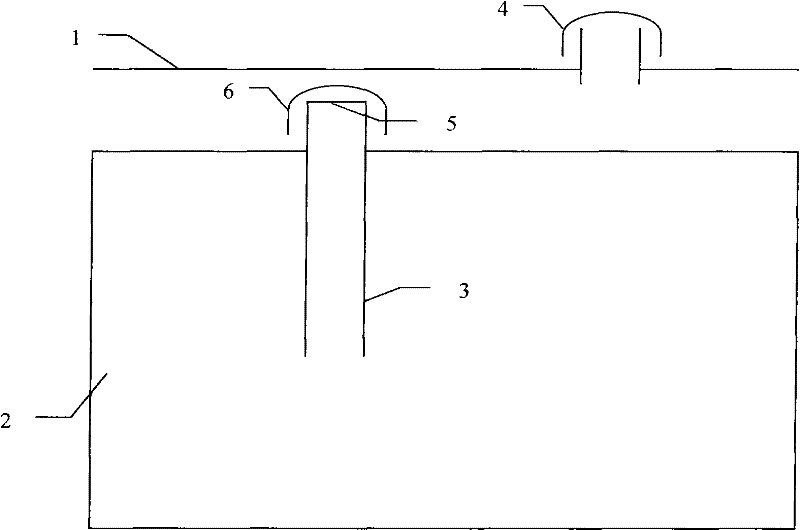

The invention discloses a method for preparing a needle coke material by catalytic cracking slurry. A protective zone and a hydrogenation reaction zone are arranged; catalytic cracking oil firstly enters the protective zone to adsorb most of catalytic cracking catalyst powder, then is mixed with hydrogen to be fed into a heating furnace, and enters the hydrogenation reaction zone to carry out hydrogenation treatment after being heated. Most of catalytic cracking catalyst powder entrained in the catalytic cracking slurry can be filtered to achieve the purpose of protecting a primary hydrogenation catalyst and achieving long-term operation by providing the protective zone in front of the hydrogenation reaction zone. In addition, most of sulphur in the catalytic cracking slurry is removed by hydrorefining of the catalytic cracking slurry, and the produced qualified needle coke material is produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

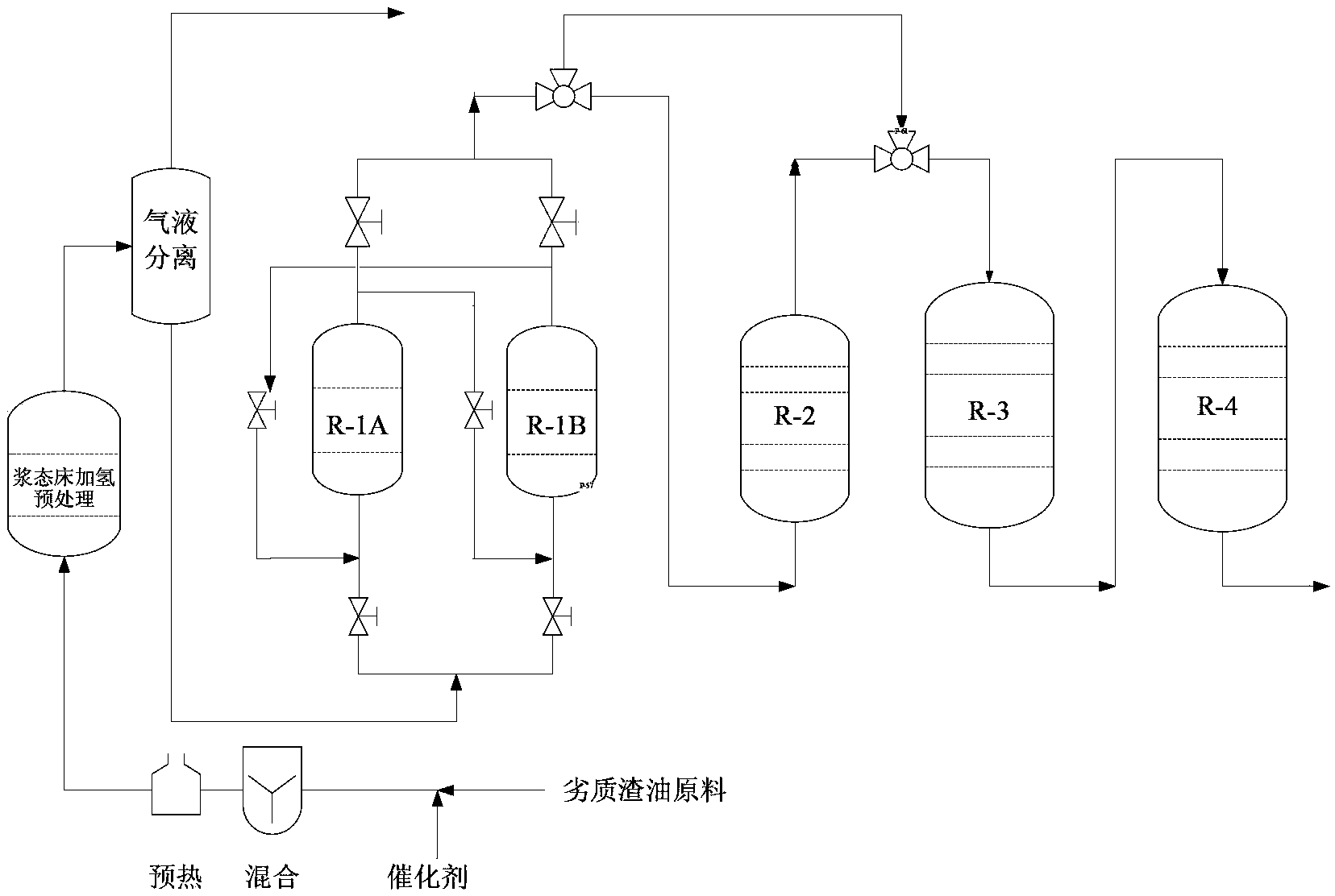

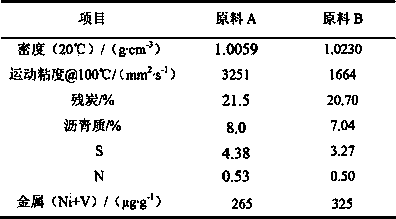

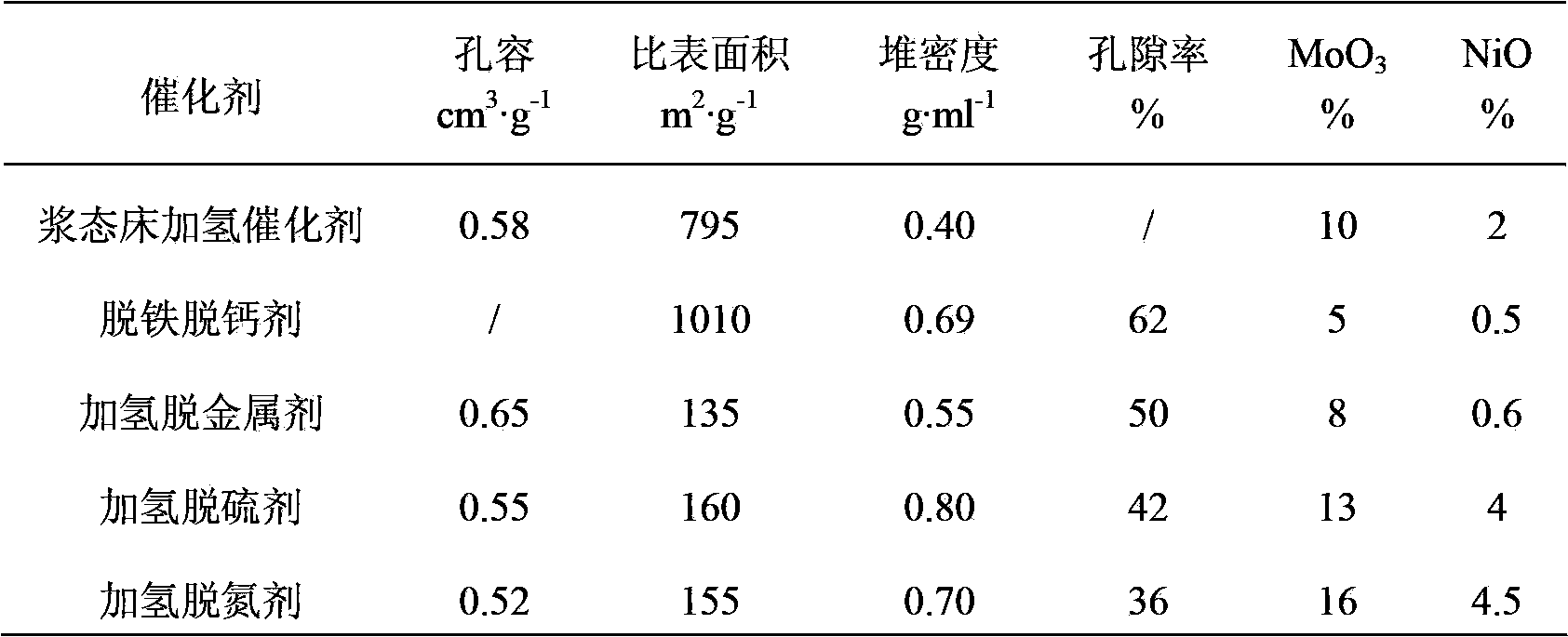

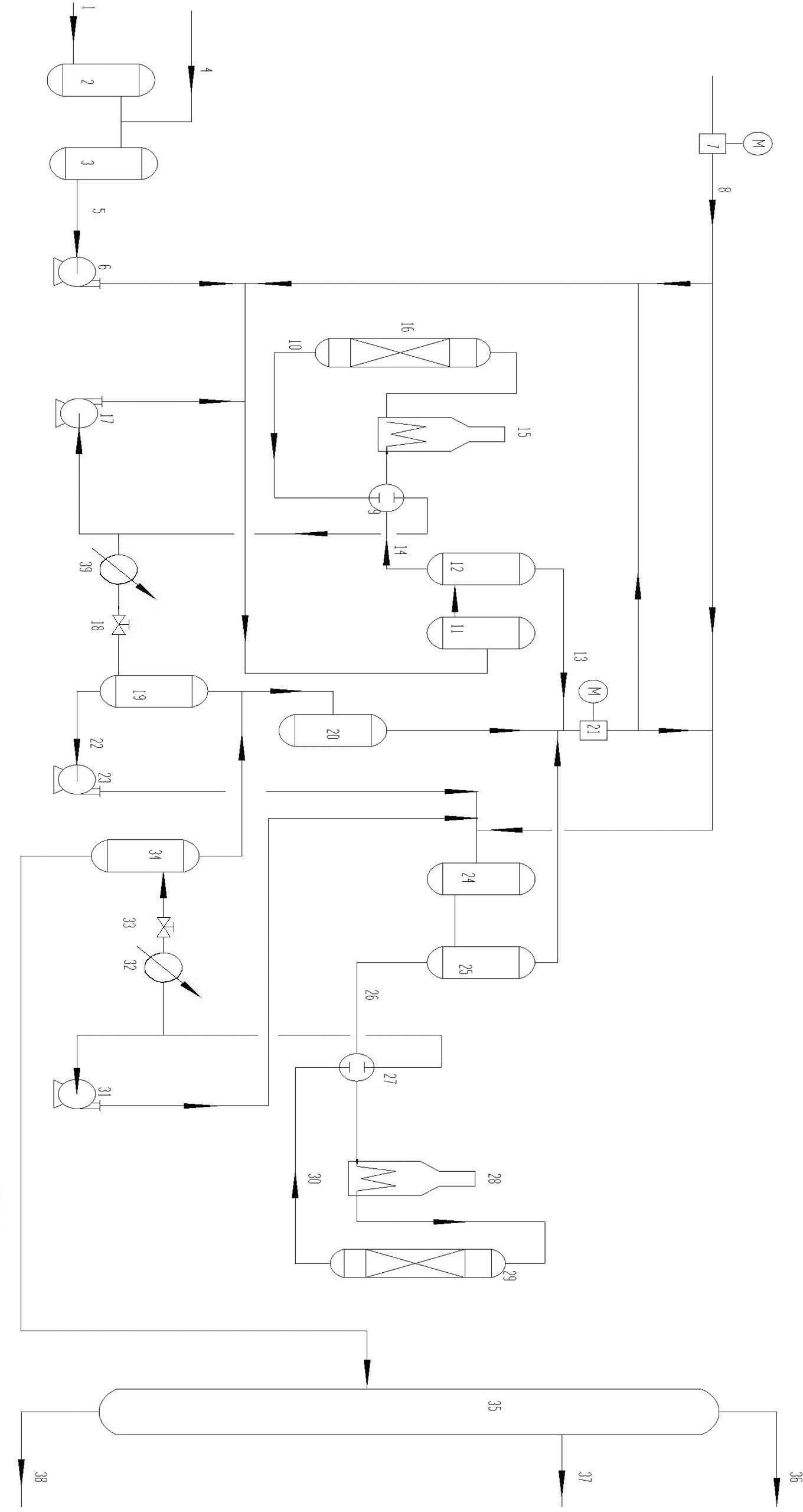

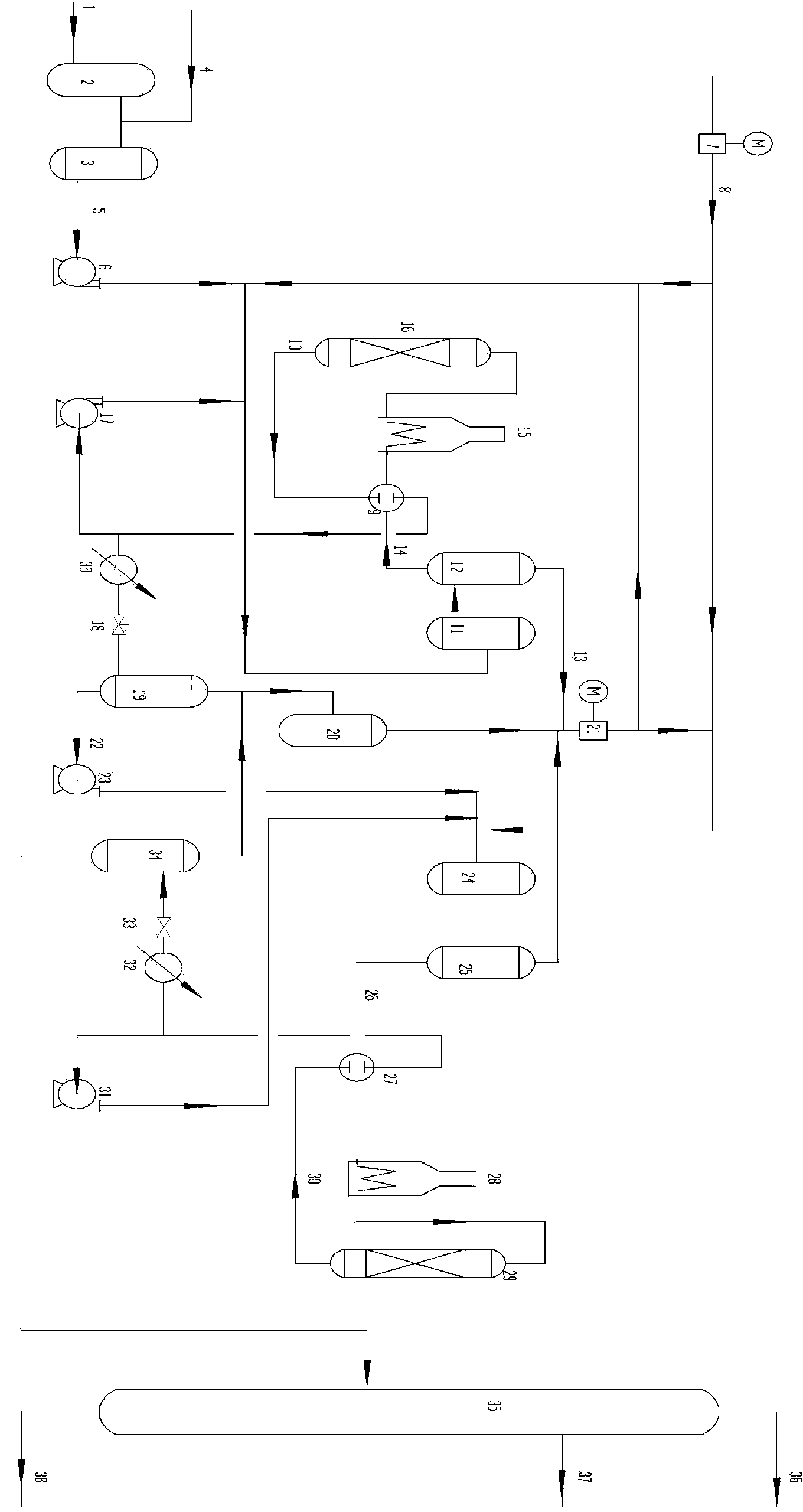

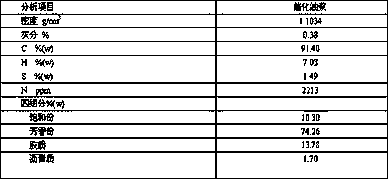

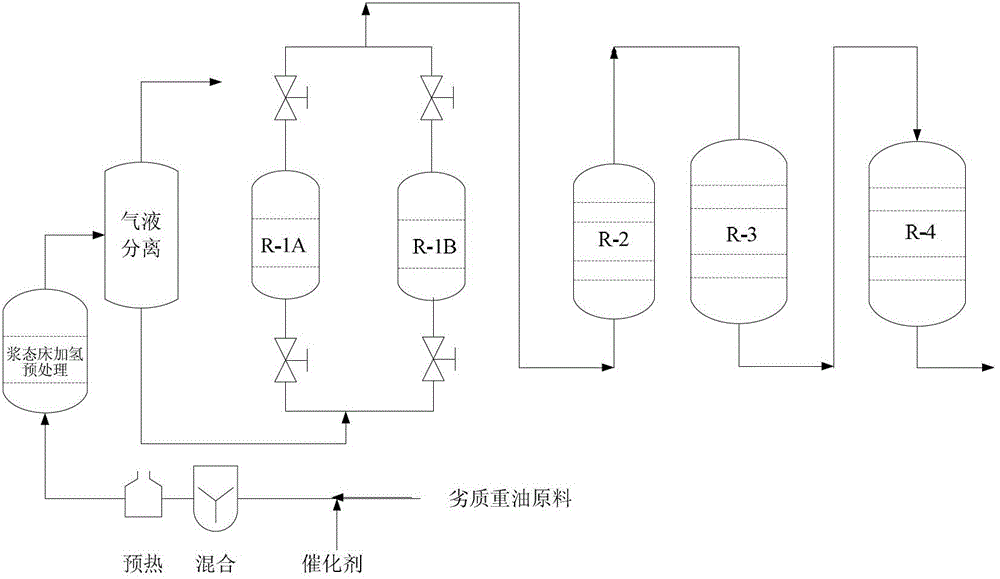

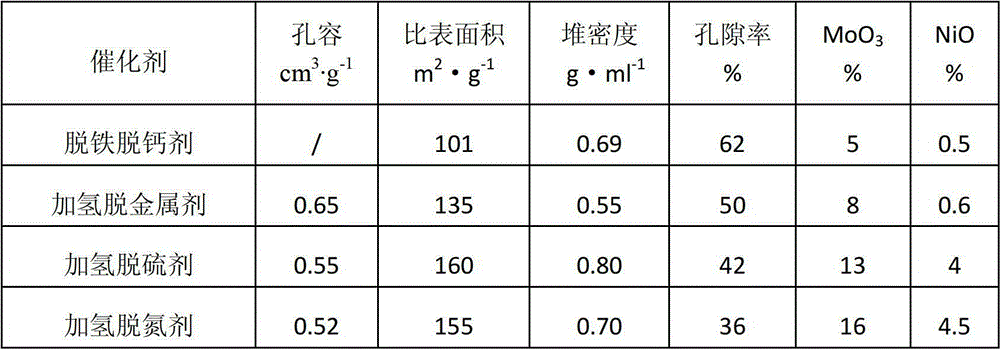

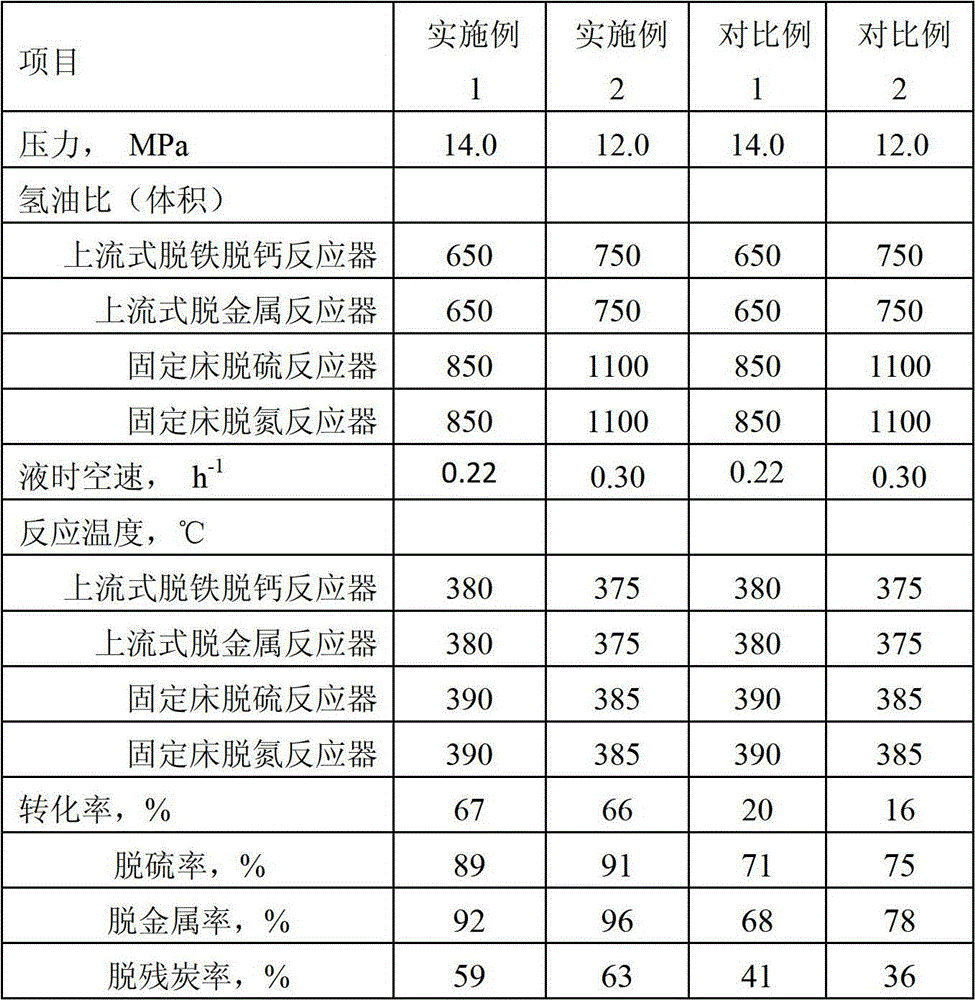

Low-quality heavy oil and residual oil hydrotreatment combined process capable of prolonging service life of catalyst

ActiveCN103540349AExtended service lifeImprove long-cycle performanceTreatment with hydrotreatment processesLiquid productSlurry

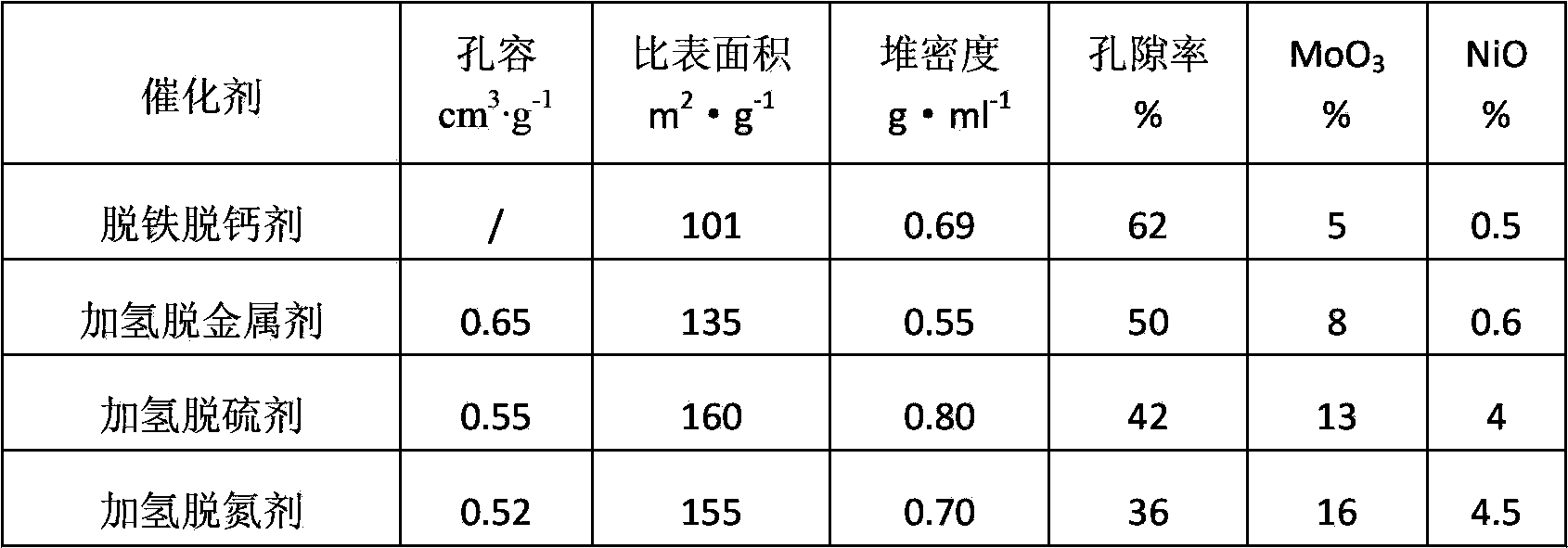

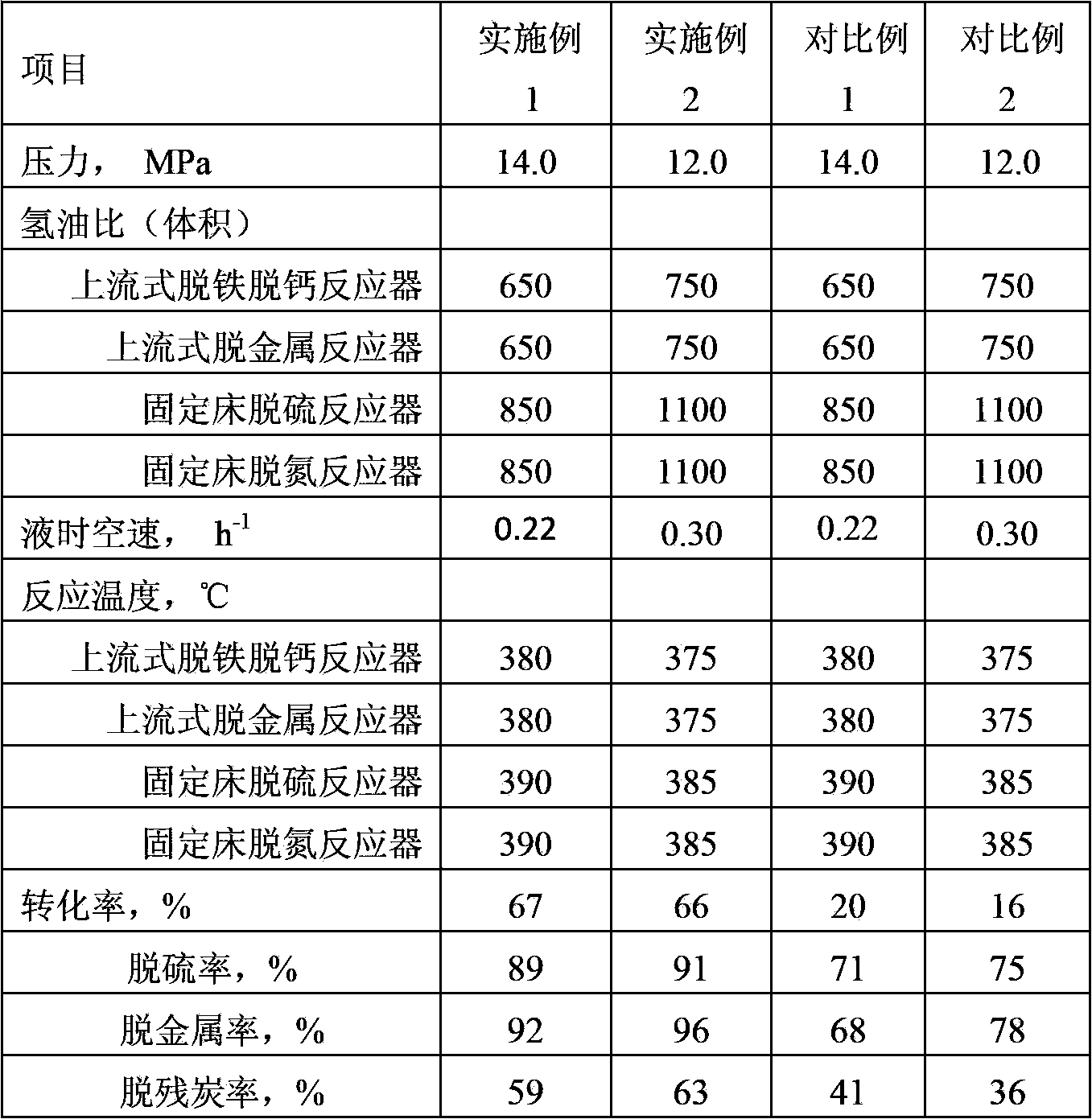

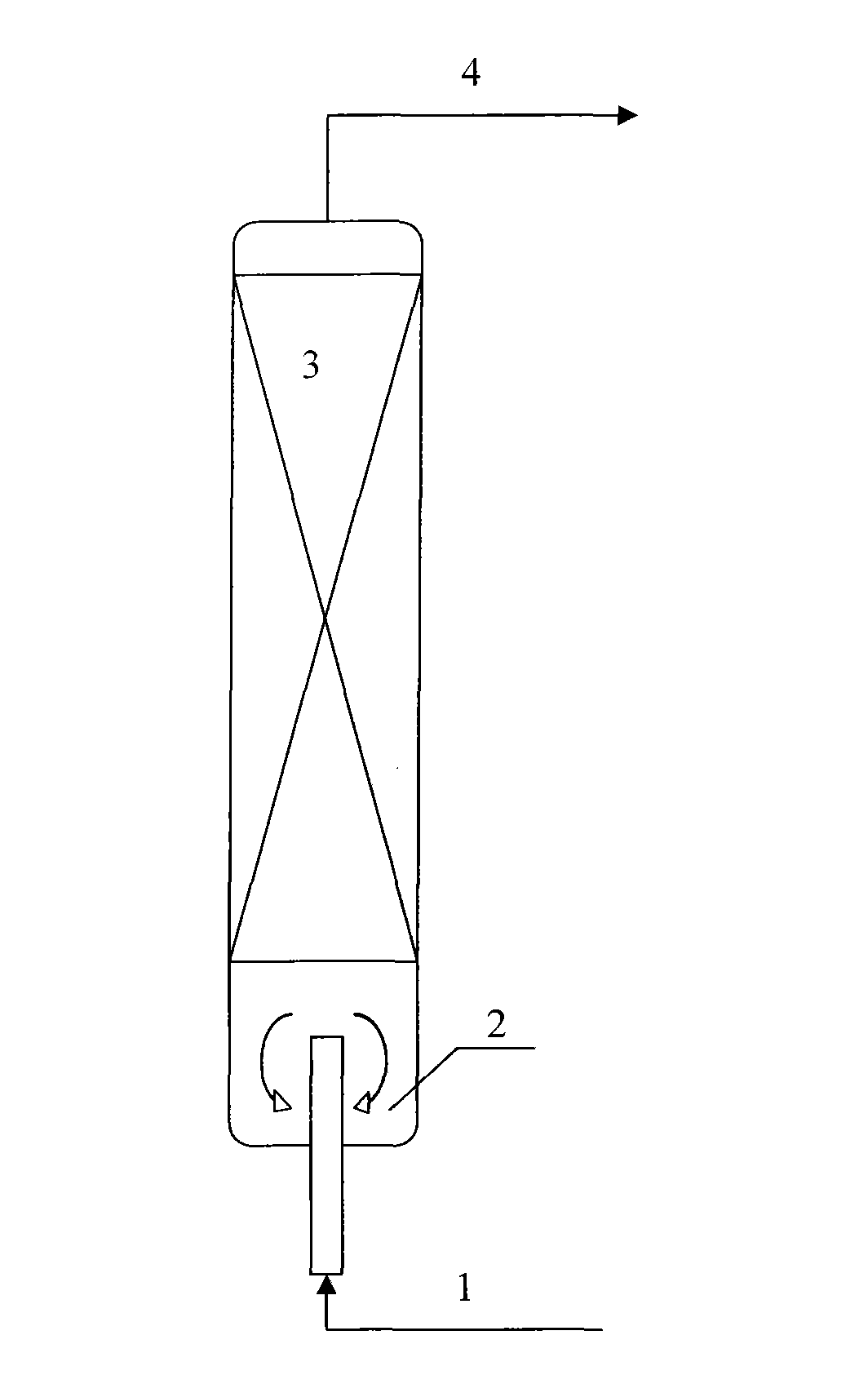

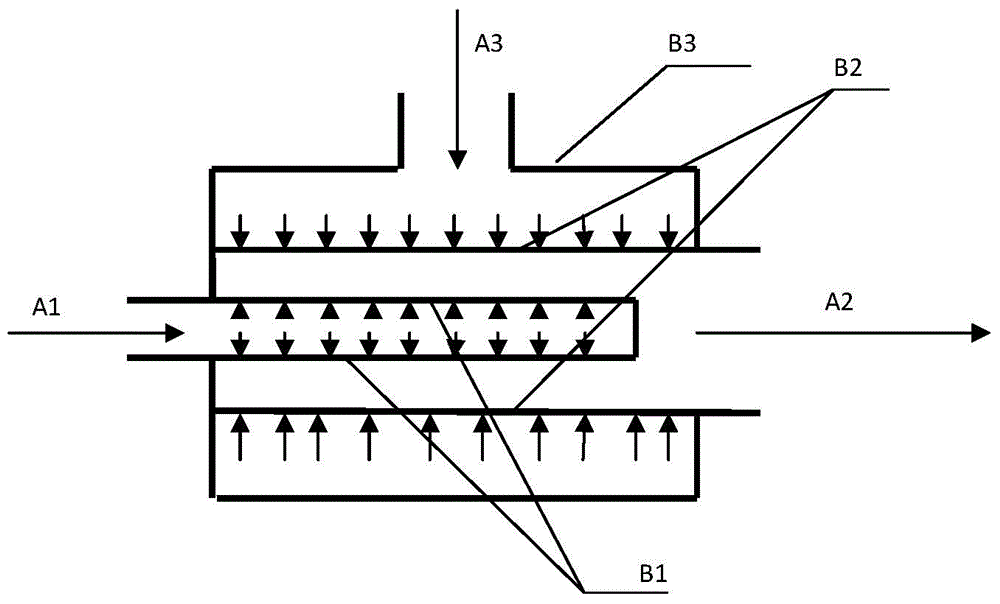

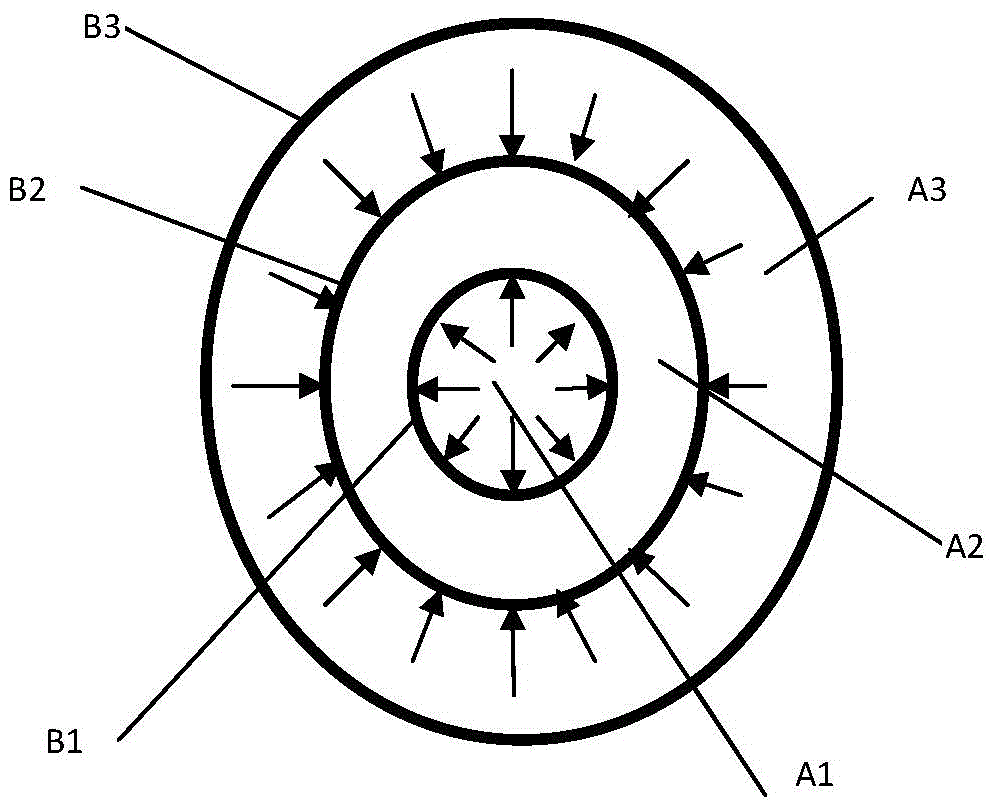

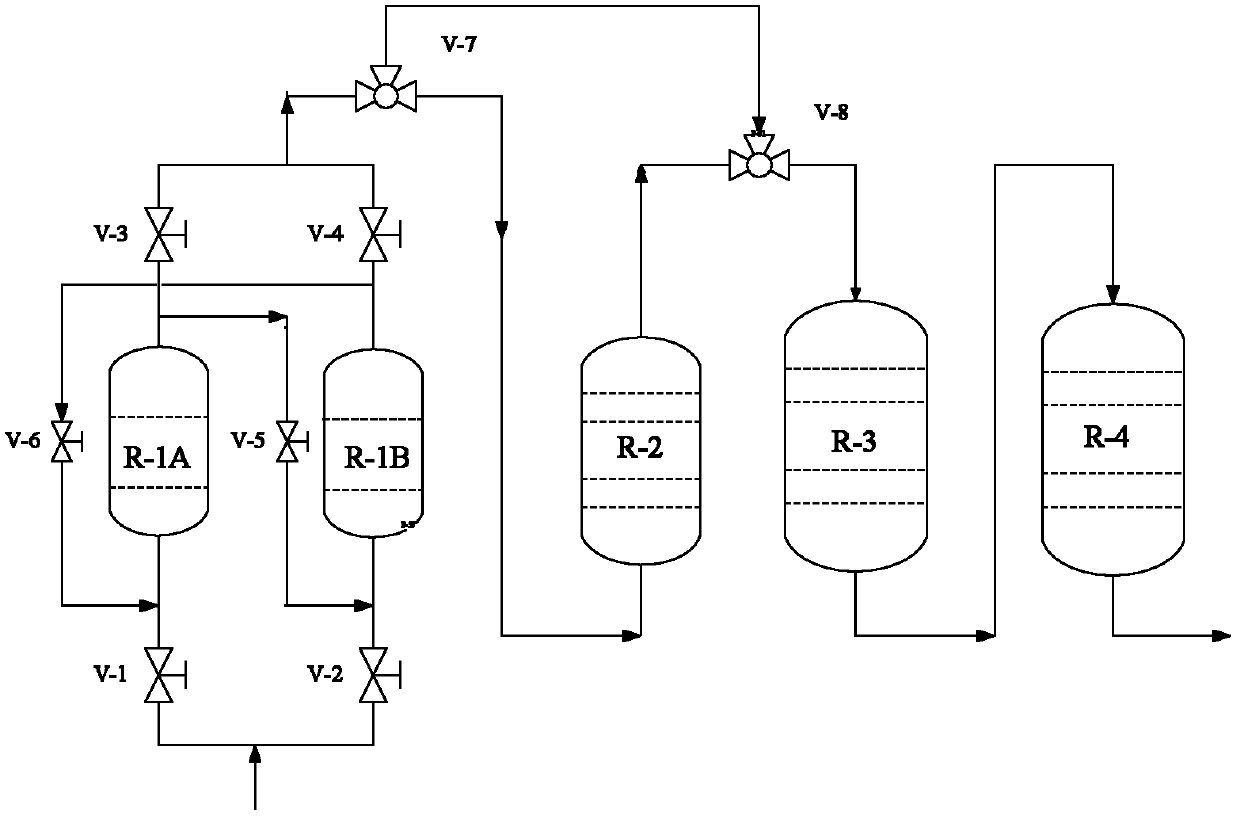

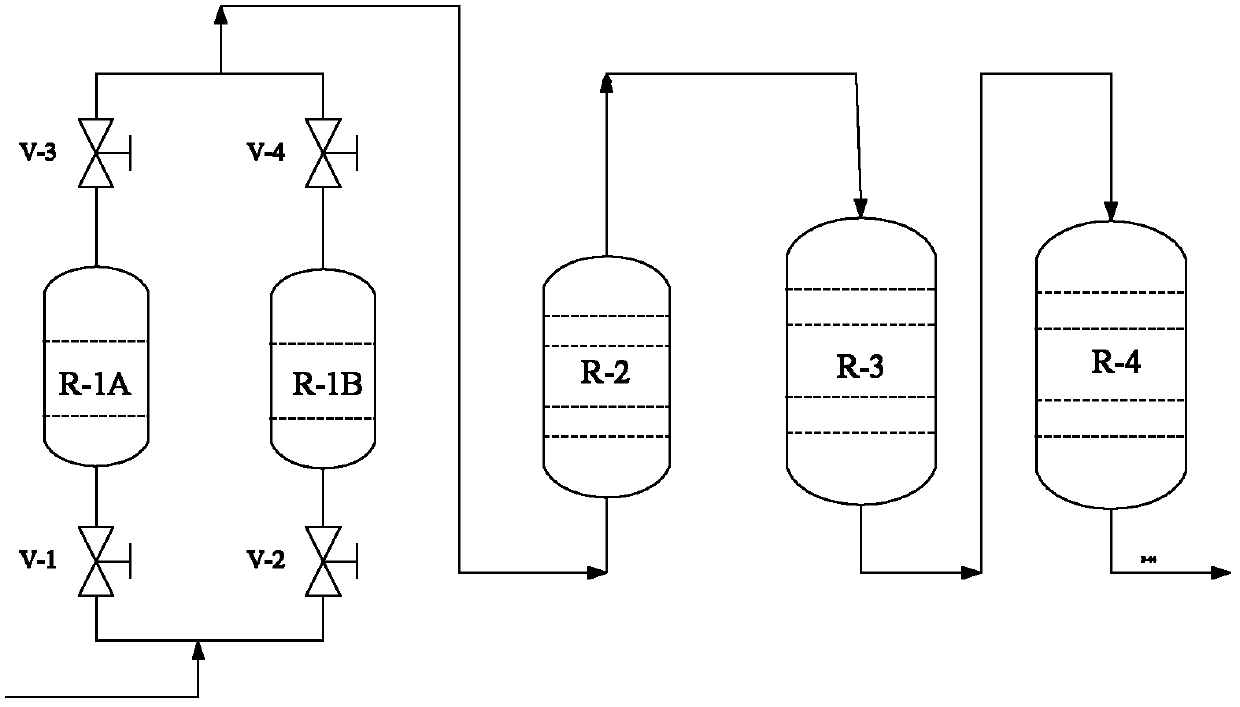

The invention relates to a low-quality heavy oil and residual oil hydrotreatment combined process. The low-quality heavy oil and residual oil hydrotreatment combined process is characterized in that firstly a heavy oil raw material is subjected to hydrogenation pretreatment by a slurry bed, after the gas-liquid separation is carried out, a liquid product is subjected to hydro-upgrading through a stationary bed, wherein a hydrogenation pretreatment part of the slurry bed comprises a slurry bed hydrogenation reactor and a slurry bed hydrogenation catalyst, reactors used for a hydro-upgrading part of the slurry bed mainly comprise two up-flow deferrization and decalcification reactors connected in parallel, one up-flow demetalization reactor, one fixed bed desulfurization reactor and one stationary bed denitrification reactor sequentially. The low-quality heavy oil and residual oil hydrotreatment combined process has the advantages of being capable of improving the hydrogenation impurity removal capacity of the catalyst, prolonging the life cycle of the catalyst, treating residual oil with high metal content, high sulfur, high nitrogen and high asphaltene and effectively slowing down the ascending velocity of pressure drop of the reactors, so that the long-period operation of the device is realized.

Owner:PETROCHINA CO LTD

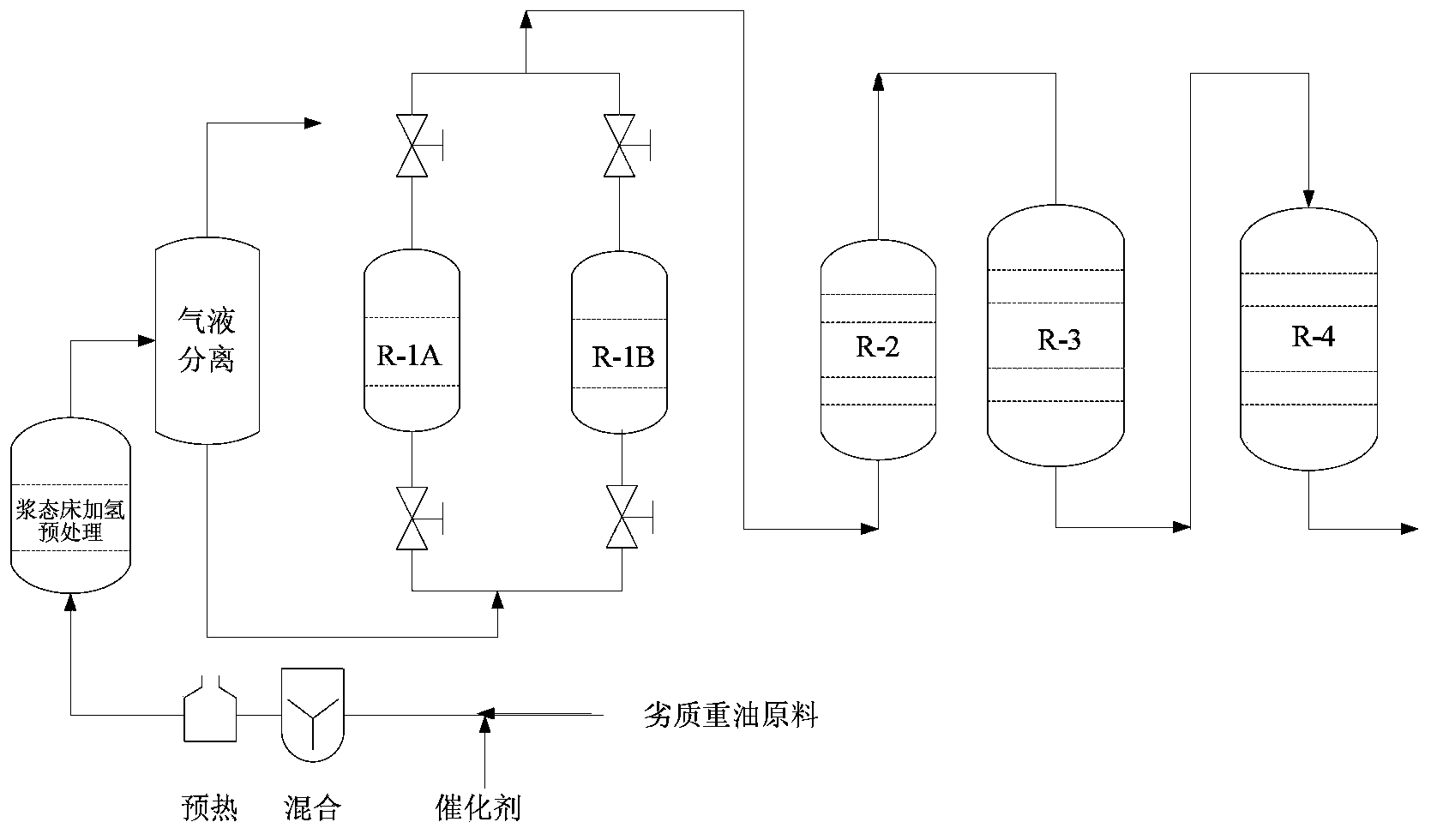

Hydrotreating combined process for inferior heavy oil and residual oil

ActiveCN103540350AHigh demetallizationImprove desulfurizationTreatment with hydrotreatment processesSlurry reactorFuel oil

The invention relates to a hydrotreating combined process for inferior heavy oil and residual oil. The hydrotreating combined process comprises the following steps of: firstly pretreating the heavy oil and / or residual oil raw material in a slurry reactor; carrying out gas-liquid separation, and hydro-upgrading the liquid-phase product in a fixed bed, wherein the hydro-pretreating part of the slurry reactor comprises a straight cylinder type slurry reactor pretreatment reactor and a slurry reactor hydro-catalyst, and the reactors used in the fixed bed hydro-upgrading part sequentially and mainly include two parallel up-flow type deferrization-decalcification reactors, one up-flow type demetalization reactor, one fixed bed desulfurization reactor and one fixed bed denitrification reactor. By adopting the hydrotreating combined process provided by the invention, not only are the hydrotreating and impurity removal capacities of the catalyst improved, but also the running cycle of the device is prolonged. The hydrotreating combined process provided by the invention can be applied to treating the inferior heavy oil and residual oil, which are high in sulfur content, metal content, and asphalt content; the conversion ratio is 30-80%; the raising rate of the pressure drop of the reactors can be effectively reduced so as to achieve the long-period running of the device.

Owner:PETROCHINA CO LTD

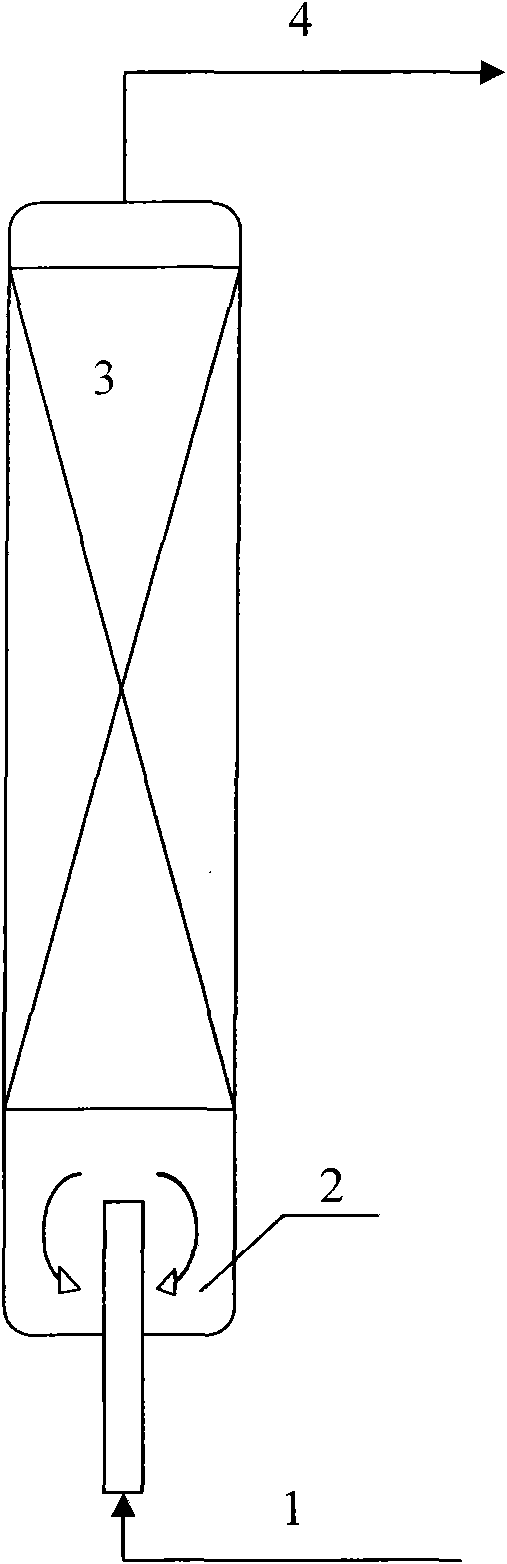

Method for hydrotreating coking distillate

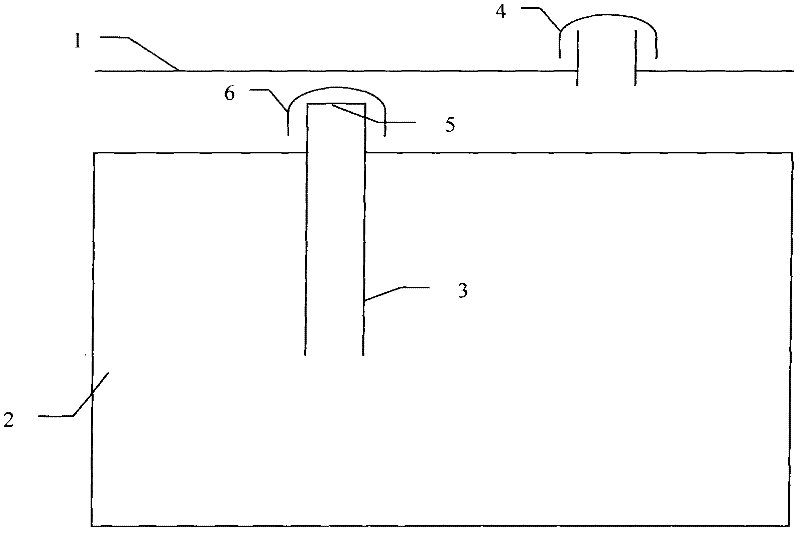

ActiveCN102041065ARealize long cycle operationAvoid stickingTreatment with hydrotreatment processesChemistryIron sulfide

The invention discloses a method for hydrotreating coking distillate. In the method, after being mixed, raw material oil and hydrogen enter into a reactor from the bottom, a part of mechanical impurities, such as fine coke power, coke particles, iron sulfide, and the like, are separated after the raw oil and the hydrogen pass through a mechanical impurity sedimentation and deposition region, the material flow goes up to contact a hydrogenation catalyst bed layer for carrying out the hydrogenation reaction, and then the material flow is discharged from the top of the reactor. The method can be used as the pre-hydrogenation process of the coking distillate, also can be used as the main hydrogenation process of the coking distillate, or can be used in the pre-hydrogenation process and the main hydrogenation process at the same time. The method for hydrotreating coking distillate does not need to make great change to the traditional devices, and can realize long-period operation of the devices and enhance economic benefits with small investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing needle coke material by catalytic cracking slurry

ActiveCN103013567BProtection reachedRealize long cycle operationTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for preparing a needle coke material by catalytic cracking slurry. A protective zone and a hydrogenation reaction zone are arranged; catalytic cracking oil firstly enters the protective zone to adsorb most of catalytic cracking catalyst powder, then is mixed with hydrogen to be fed into a heating furnace, and enters the hydrogenation reaction zone to carry out hydrogenation treatment after being heated. Most of catalytic cracking catalyst powder entrained in the catalytic cracking slurry can be filtered to achieve the purpose of protecting a primary hydrogenation catalyst and achieving long-term operation by providing the protective zone in front of the hydrogenation reaction zone. In addition, most of sulphur in the catalytic cracking slurry is removed by hydrorefining of the catalytic cracking slurry, and the produced qualified needle coke material is produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

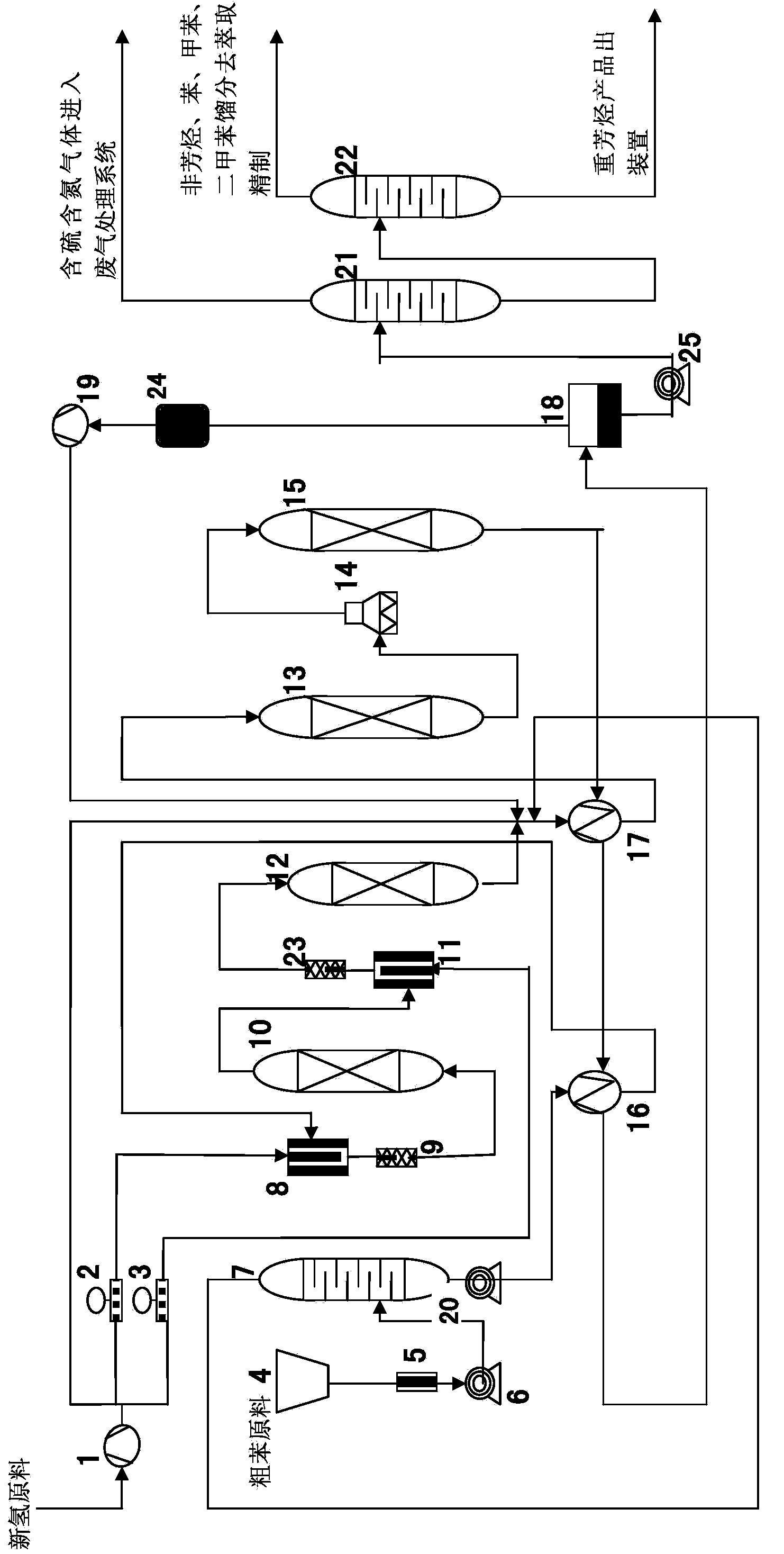

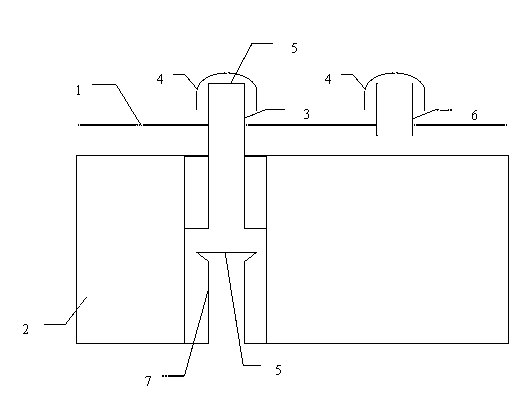

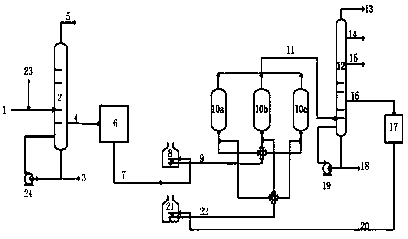

Full liquid phase hydrogenation method of coal tar

ActiveCN102585899ALess investmentRealize long cycle operationTreatment with hydrotreatment processesNaphthaFluid phase

The invention discloses a full liquid phase hydrogenation method of coal tar, which is characterized by comprising the following steps that coal tar raw materials respectively perform full liquid phase pre-hydrogenation reaction and full liquid phase main hydrogenation reaction, and main hydrogenation generated oil respectively generates naphtha products, diesel products and tail oil products through oil gas-liquid separation and distillation. The full liquid phase hydrogenation method enables the coal tar to perform the pre-hydrogenation reaction and the main hydrogenation reaction under the full liquid phase. The method can be suitable for hydrogenation modification of full fraction coal tar of any one or more of high-temperature coal tar, middle-temperature coal tar and low-temperature coal tar. During hydrogenation, coking can be effectively inhibited, reaction heat is controlled, energy loss is reduced, long-period running of a coal tar hydrogenation device is achieved, hydrogen consumption of the whole hydrogenation device can be reduced, investment of a compressor is reduced, and clean naphtha, diesel and tail oil products with sulfur nitrogen contents smaller than 400 parts per million (ppm) can be obtained.

Owner:CHANGLING PETRO CHEM ENG DESIGN

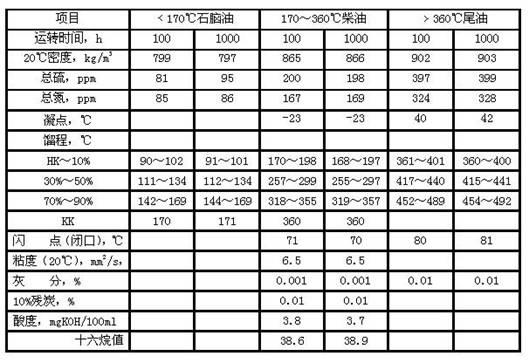

Full fraction crude benzene hydrogenation method and catalyst

ActiveCN103910596ARealize long cycle operationImprove use valueHydrocarbon purification/separationHydrocarbonsHydrogenStatic mixer

The invention discloses a full fraction crude benzene hydrogenation method and a catalyst, belonging to the technical field of all fraction crude benzene processing. The method comprises steps of firstly allowing crude benzene fraction over 70DEG C and hydrogen to pass through a corpuscule generator and a static mixer sequentially, so as to mix the two raw materials into uniform corpuscule raw material with diameter of 0.1-20mu m; fully saturating the corpuscule raw material through hydrogenation through the catalytic action of the low temperature hydrogenation catalyst under the conditions of certain pressure, air speed and temperature, so as to convert the corpuscule raw material into stable saturated compound; mixing the oil generated through low temperature hydrogenation with fresh hydrogen, circulating hydrogen and less than 70DEG C crude benzene fraction from a pre-fraction tower, then hydrogenating again, gas stripping and fraction distilling the oil generated by hydrogenating full fraction crude benzene so as to obtain light arene fraction and heavy arene product, then predistilling, extracting and rectifying so as to obtain pure benzene, methylbenzene, xylene and non-arene products. According to the method, the problem of coking of full fraction crude benzene raw material in high temperature hydrogenation is solved, and the crude benzene hydrogenation device can run for long period.

Owner:XUZHOU LONGHUI CHEM TECH

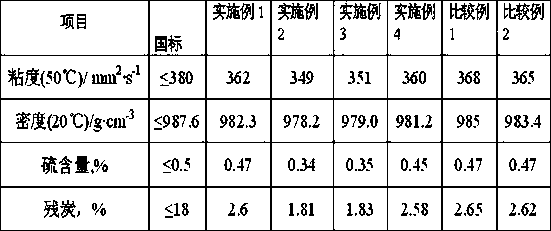

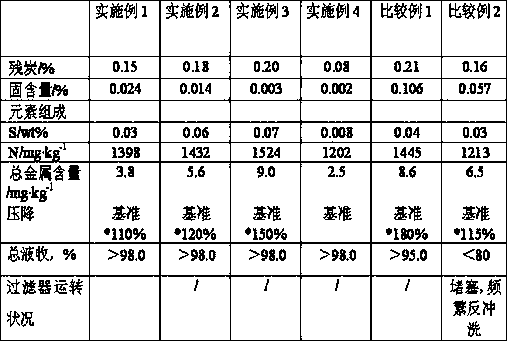

Production method of low-sulfur marine fuel oil

PendingCN111088068ARealize purificationImprove use valueTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses a production method of a low-sulfur marine fuel oil. The production method comprises the following steps: mixing catalytic slurry oil with a first additive, carrying out settling separation after the mixing treatment, obtaining a first material and residues after the separation; introducing the first material into a hydro-processing unit, carrying out a hydrogenation reaction under the action of a hydro-processing catalyst and hydrogen, introducing a liquid-phase effluent obtained after the reaction into a clarification unit, subjecting clarified oil to solid-liquid separation to obtain purified oil slurry, and mixing the purified oil slurry with an inferior raw material (hydrogenation tail oil) to obtain the low-sulfur marine fuel oil. According to the method, thesolid content and the sulfur content of the catalytic slurry oil can be reduced, high-quality purified slurry oil is produced, and the high-quality purified slurry oil is blended with residual oil toproduce the insufficient low-sulfur marine fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

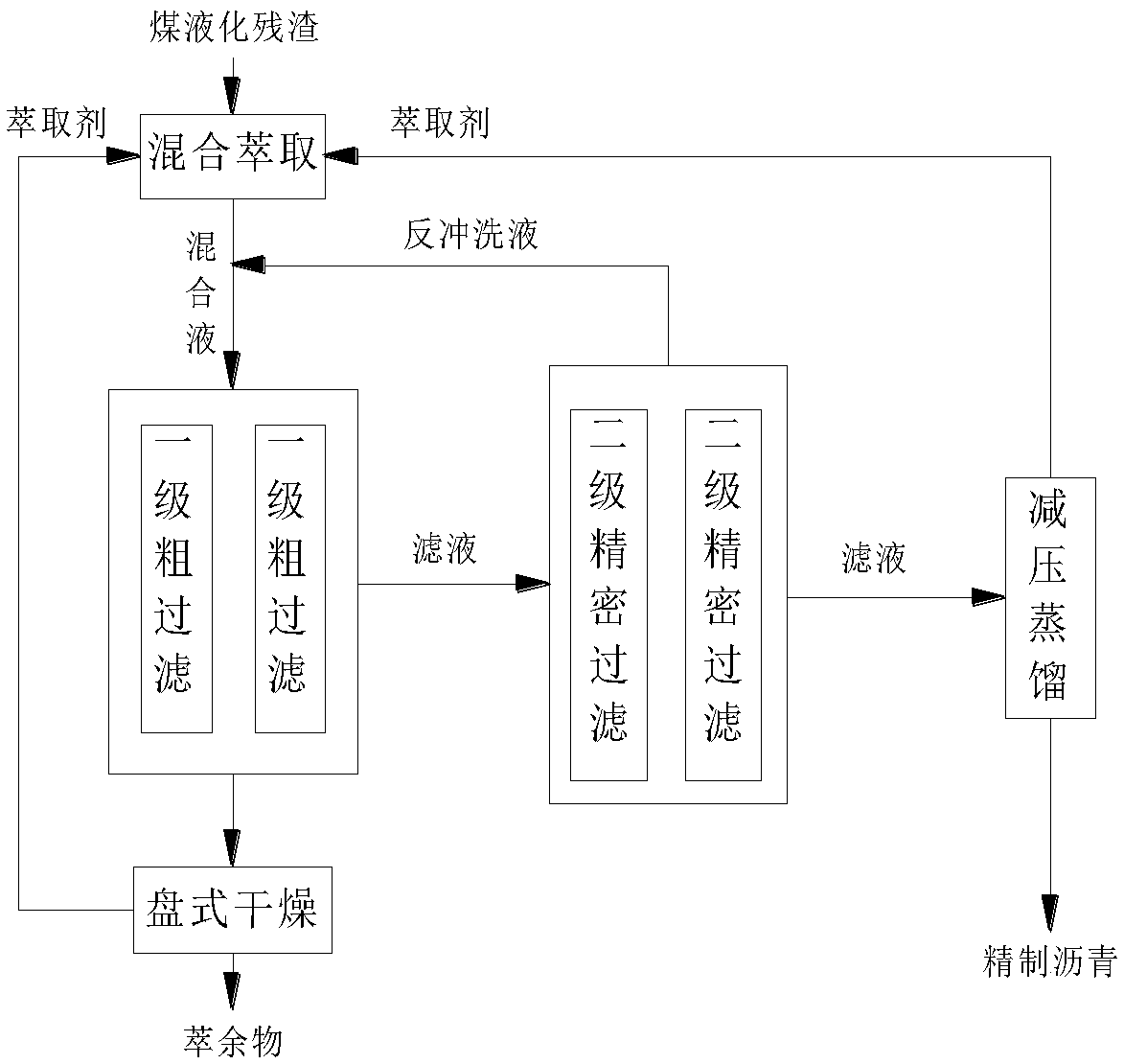

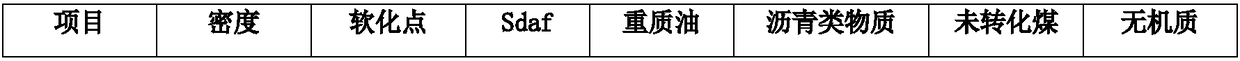

Method and system to prepare asphalt with coal liquefaction residue

InactiveCN108410491AThe type is not limitedAdaptableWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionProcess engineeringAsphalt

The invention relates to a method and system to prepare asphalt with coal liquefaction residue. The system comprises a mixing extracting device, a first filter unit, a second filter unit, a drying device and a distilling device; the mixing extracting device is communicated with the first filter unit; the first filter unit is communicated with the drying device; the first filter unit is communicated with the second filter unit, and the second filter unit is communicated with the distilling device, wherein the first filter unit at least includes a first filter and a second filter; the second filter unit at least includes a third filter and a fourth filter. Each of the two filter units in the system includes two filters arranged in alternate manner, so that continuous production of asphalt isachieved.

Owner:CCTEG CHINA COAL RES INST +1

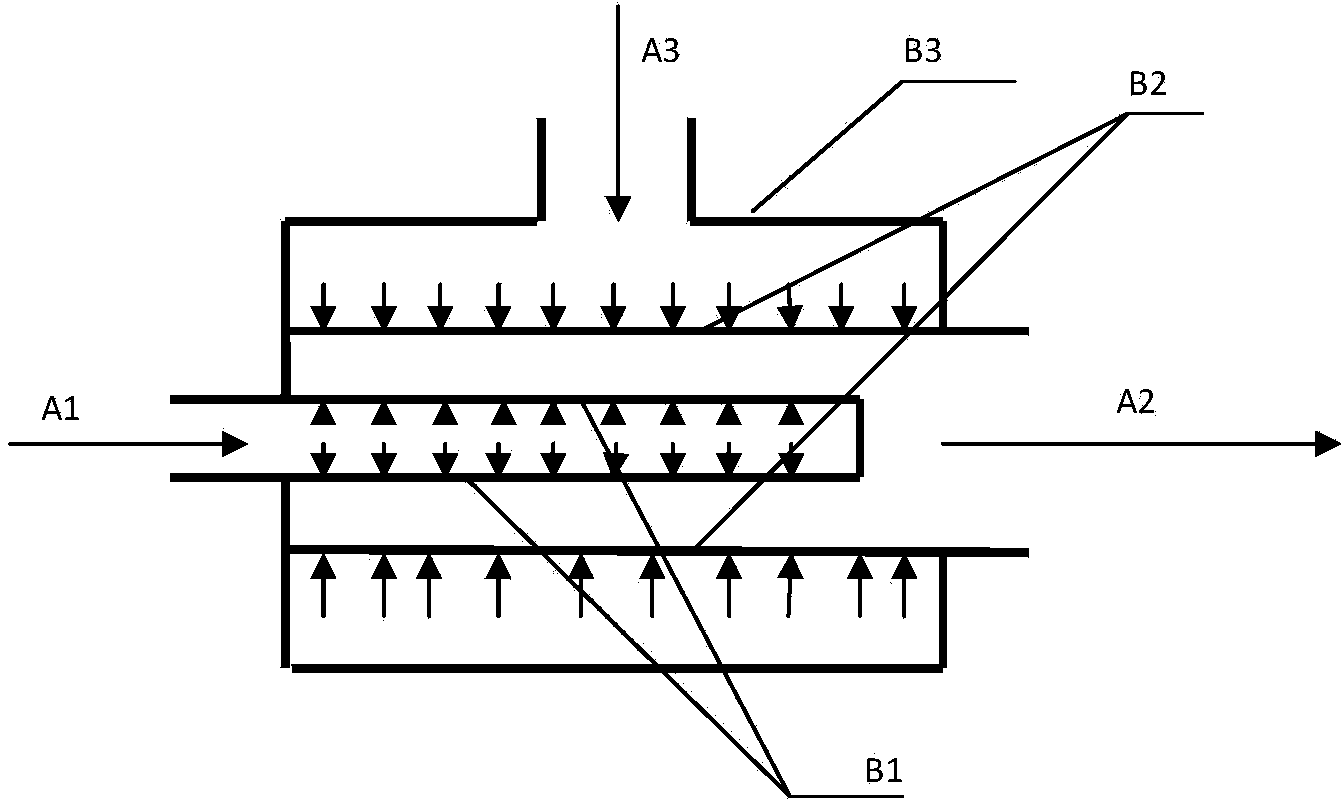

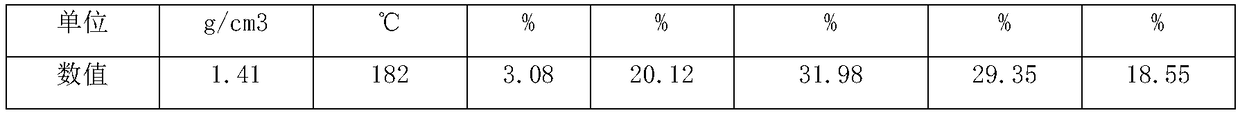

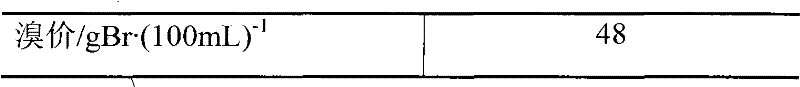

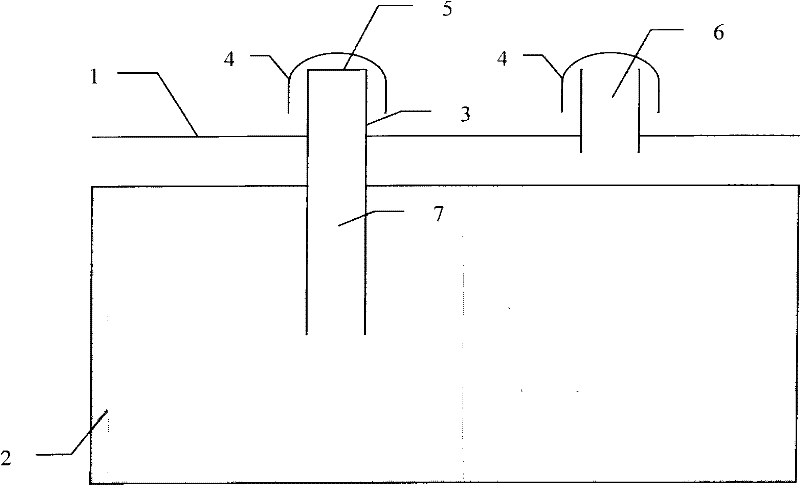

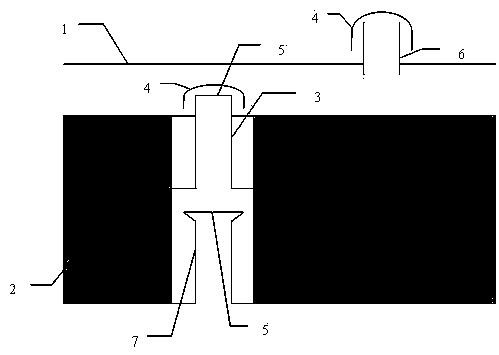

Fouling basket and hydrogenation technological method for reducing skimming of catalyst

ActiveCN102441348AProlong the effective timeReduce operational complexityChemical/physical processesHydrocarbon oils treatmentDifferential pressureEngineering

The invention discloses a fouling basket and a hydrogenation technological method for reducing the skimming of a catalyst. The fouling basket which runs through a whole catalyst bed layer is adopted; a partition plate is arranged at the middle and the bottom of the fouling basket; an overflow pipe is welded on each partition plate; a pressure rupture film is arranged at the top of each overflow pipe; and the bottoms of the overflow pipes are communicated with the lower part of the fouling basket or a gas-liquid distribution disk of a next catalyst bed layer through the partition plates. The rupture differential pressure of the pressure rupture films is lower than 0.45 MPa and higher than 0.1 MPa. With the adoption of the fouling basket and the hydrogenation technological method, when the upper part of the catalyst bed layer is subjected to coking or blockage, the shutdown of a device for the skimming is not needed, and the catalyst at the lower part of the bed layer can also be maximally utilized, so that the waste is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas-liquid distributor capable of reducing catalyst skimming and hydrogenation process

ActiveCN103100354AWithout human interventionReduce operational complexityChemical/physical processesHydrocarbon oils treatmentHydrogenation reactionHydrogenation process

The invention provides a gas-liquid distributor capable of reducing catalyst skimming and a hydrogenation process. According to the invention, a scale depositing basket penetrating a whole catalyst bed is employed; the middle part and the bottom of the scale depositing basket are respectively provided with a separator plate; an overflow pipe is welded on the separator plate on the bottom, a pressure rupture disk is mounted on the top of the overflow pipe, and the bottom of the overflow pipe penetrates the separator plate to be communicated with the subjacent catalyst bed; the top of an overflow pipe on the middle part penetrates a gas-liquid distribution disc. When the upper part / lower part of the catalyst bed has a great pressure drop, the pressure rupture disk on the top of the overflow pipe at the upper part / lower part ruptures under the action of pressure difference, and a gas-liquid material flow can continue flowing downwardly to participate in a hydrogenation reaction. According to the method provided by the invention, great improvement of a conventional apparatus is not needed, long-period running of the apparatus can be realized with small investment, a catalyst in the whole bed can be fully utilized, the pressure drop in a reactor can be reduced at the same time, production safety is guaranteed, and economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Whole-fraction crude benzene hydrogenation method and catalyst

InactiveCN104016824ARealize long cycle operationImprove use valueHydrocarbon purification/separationHydrocarbonsBenzeneHydrogen

The invention discloses a whole-fraction crude benzene hydrogenation method and a catalyst, and belongs to the technical field of whole-fraction crude benzene processing. According to the whole-fraction crude benzene hydrogenation method, firstly crude benzene fraction at the temperature being higher than or equal to 70 DEG C and hydrogen sequentially pass through a micro-particle generator and a static mixer, the two raw materials are mixed to form uniform micro particles with the diameter of 0.1-20 microns, and the micro-particle-state raw material is hydrogenated to be sufficiently saturated in the presence of a low-temperature hydrogenation catalyst and under the conditions of the certain pressure, air speed and temperature so that the raw material is converted into a stable saturated compound; low-temperature hydrogenated oil is mixed with new hydrogen, recycle hydrogen and crude benzene fraction coming from a pre-fractionating tower and having a temperature being lower than 70 DEG C, and then the mixture is hydrogenated; the hydrogenated whole-fraction crude benzene generated oil is subjected to gas stripping and fractional distillation to obtain light arene fraction and heavy arene products; and finally a separation flow comprising pre-distillation, extraction and rectification is carried out to obtain purified petroleum benzene, methylbenzene and non-arene products. By virtue of the whole-fraction crude benzene hydrogenation method and the catalyst, the problem of coking in a process of high-temperature hydrogenation of whole-fraction crude benzene raw materials is solved, and the long-term circulation of the crude benzene hydrogenation device is realized.

Owner:XUZHOU LONGHUI CHEM TECH

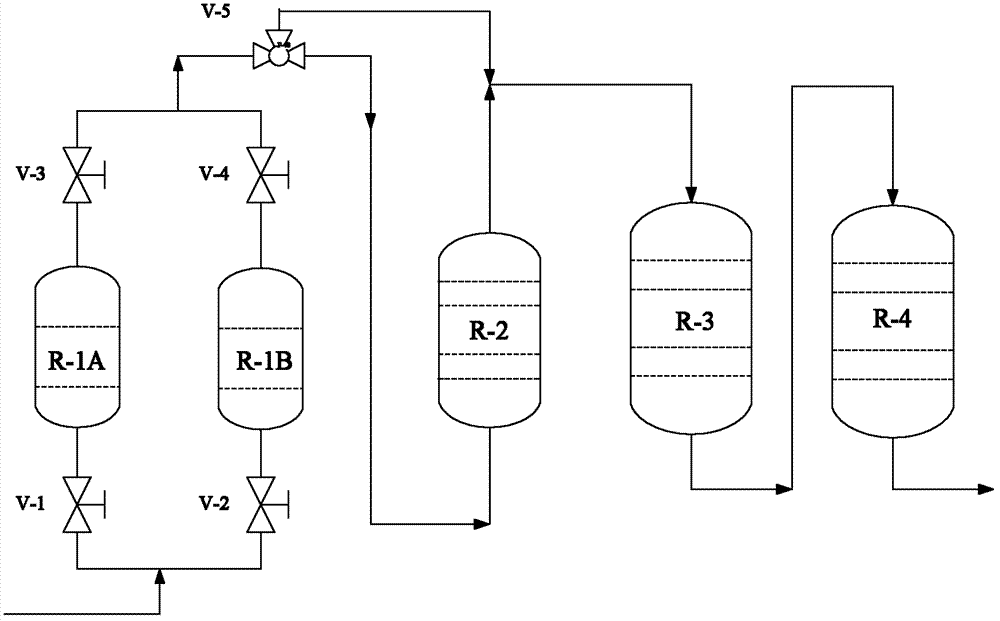

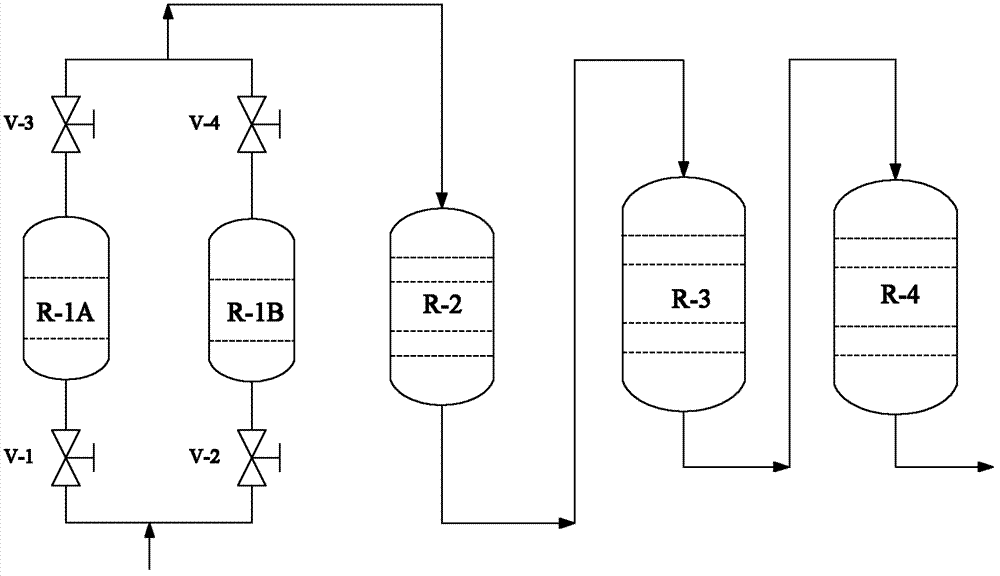

Low-grade heavy-oil hydrotreatment process for maximally improving catalyst utilization rate

ActiveCN102952579AHigh demetallizationHigh denitrificationTreatment with hydrotreatment processesSulfurLower grade

The invention provides a low-grade heavy-oil hydrotreatment process for maximally improving catalyst utilization rate. The process comprises more than two upflow desferri and decalcification reactors, an upflow demetallization reactor, a fixed-bed desulphurization reactor and a fixed-bed denitrification reactor. By using the simple and flexible hydrotreatment process, goals of both improving hydrogenation and impurity-removing capability of the catalyst and maximally increasing operating period of devices can be achieved. If hydrogenation catalysts are appropriately selected, effects can be relatively good. The process is especially suitable for processing residual oil with high sulfur, high metal content, and high asphaltene, and can realize long-period operation for the devices.

Owner:PETROCHINA CO LTD

Inferior heavy oil hydrotreatment process

ActiveCN102952581AHigh demetallizationHigh denitrificationTreatment with hydrotreatment processesSulfurFuel oil

The invention provides an inferior heavy oil hydrotreatment process capable of improving catalyst utilization rate. In the inferior heavy oil hydrotreatment process, two parallelly connected upflow type deferrization and decalcification reactors, an upflow type demetalization reactor, a fixed bed desulfurization reactor and a fixed bed denitrification reactor are used. By adopting simple and flexible hydrotreatment steps and properly selecting effective catalysts, catalyst hydrogenation and impurity removal capability can be improved finally, and the purpose of prolonging running periods of devices to the greatest extent can be achieved. The inferior heavy oil hydrotreatment process is particularly applicable to treating residual oil high in sulfur, metal content and asphaltene and capable of realizing long-term running of the devices.

Owner:PETROCHINA CO LTD

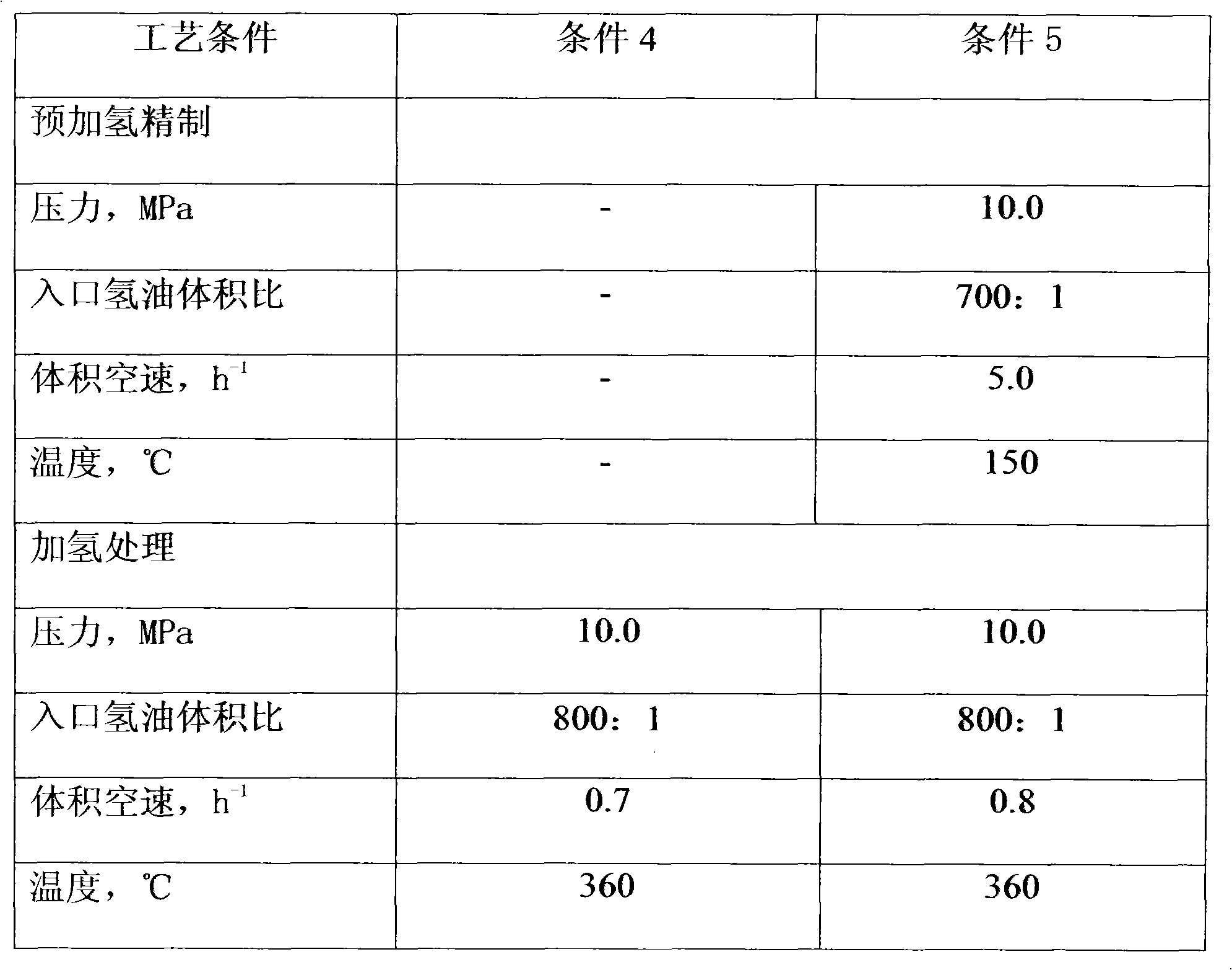

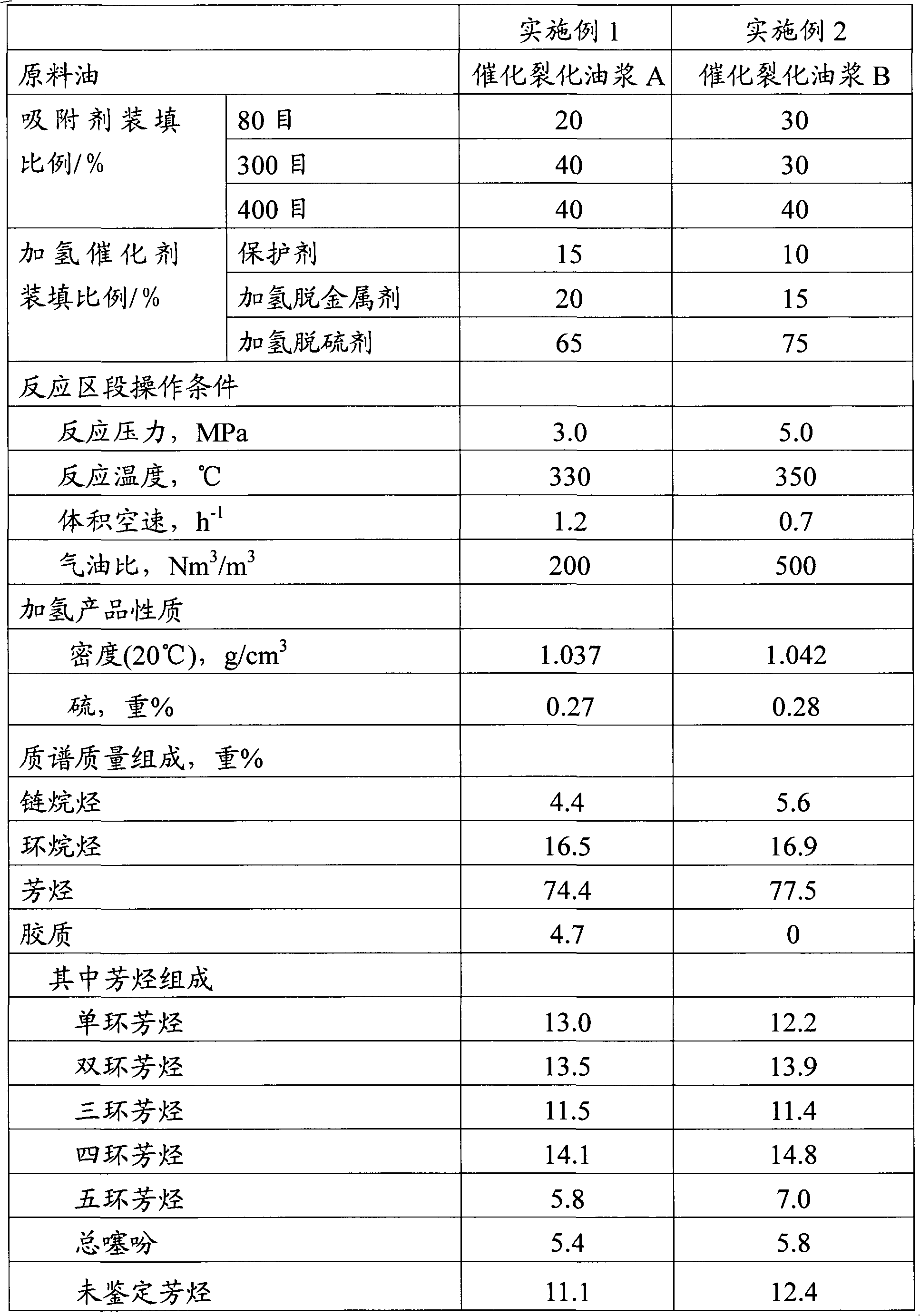

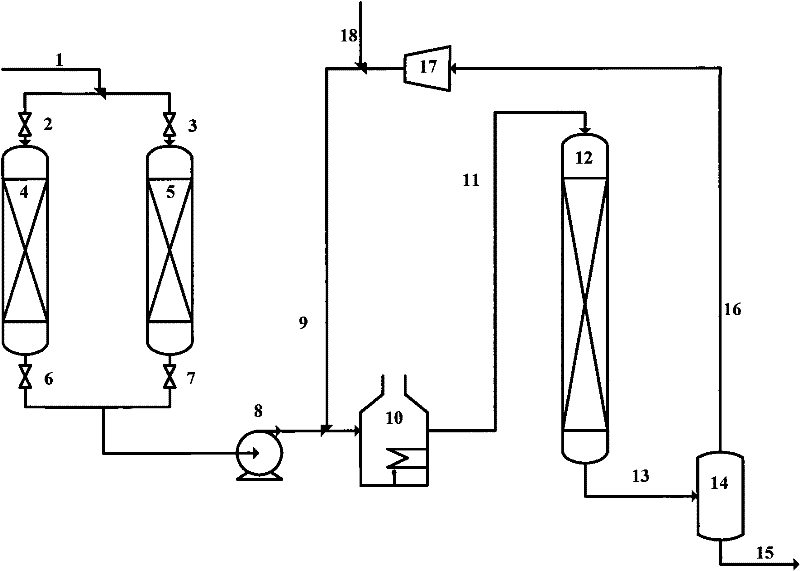

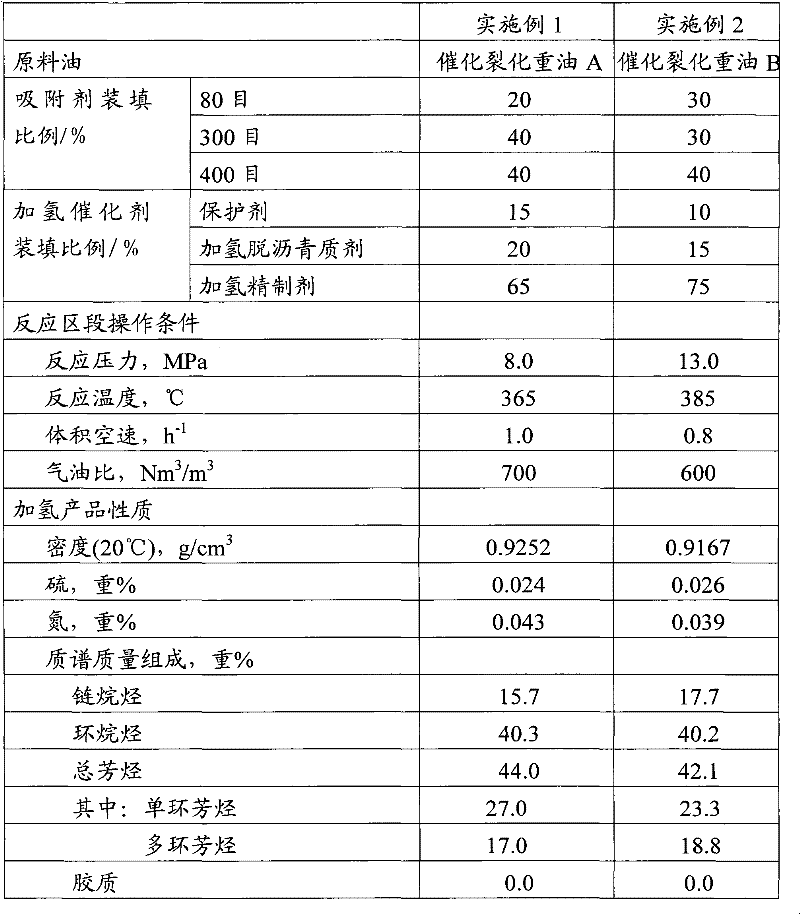

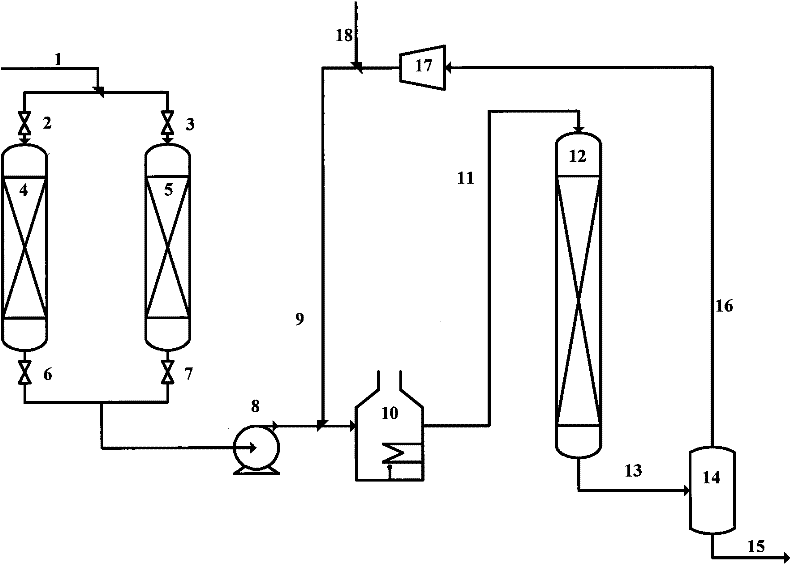

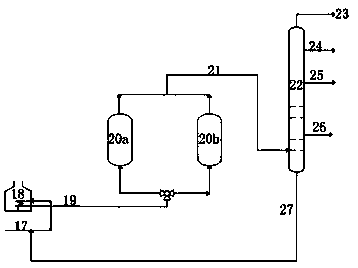

Hydrogenation method for catalytic cracking heavy cycle oil

ActiveCN102344827AProtection reachedRealize long cycle operationTreatment with hydrotreatment processesHydrogenation reactionFuel oil

A hydrogenation method for catalytic cracking heavy cycle oil. The invention includes a protective zone and a hydrogenation reaction zone, wherein the protective zone is filled with an adsorbent which is capable of absorbing catalyst fines of the catalytic cracking, and the hydrogenation reaction zone is filled with hydrogenation protective agent, hydrogenation asphaltene removing catalyst and hydrogenation refining agent; catalytic cracking heavy cycle oil enters into the protective zone first, absorbs most of the catalytic cracking catalyst fines, then is mixed with hydrogen to enter a heater, and is hydrogenated in the hydrogenation reaction zone after heating. According to the invention a protective zone is arranged before the hydrogenation reaction zone to filter most of the catalytic cracking catalyst fines laden in the catalytic cracking heavy cycle oil, so as to protect the main catalyst and realize long-time cycle running. In addition, a protective reactor connected in parallel in the protective zone conducts switch operation under low pressure, low temperature and non-hydro conditions, and is safe, reliable and convenient for application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Full liquid phase hydrogenation method of coal tar

ActiveCN102585899BLess investmentRealize long cycle operationTreatment with hydrotreatment processesNaphthaFluid phase

The invention discloses a method for full liquid phase hydrogenation of coal tar, which is characterized in that it comprises the following steps: coal tar raw materials are respectively subjected to a full liquid phase prehydrogenation reaction and a full liquid phase main hydrogenation reaction; the main hydrogenation produces oil After oil-gas-liquid separation and distillation, naphtha products, diesel products and tail oil products are produced respectively. The present invention makes coal tar carry out pre-hydrogenation reaction and main hydrogenation reaction in full liquid phase, and the method can be applied to the hydrogenation modification of any one or several full-fraction coal tars in high, medium and low temperature coal tars , in the hydrogenation process, it can effectively inhibit coking, control the heat of reaction, reduce energy loss, realize the long-term operation of the coal tar hydrogenation unit, and at the same time reduce the hydrogen consumption of the entire hydrogenation unit, reduce the investment in compressors, and obtain uniform sulfur and nitrogen content. Clean naphtha, diesel and tail oil products less than 400ppm.

Owner:CHANGLING PETRO CHEM ENG DESIGN

Process method for prolonging operation period of hydrogenation device

ActiveCN102443411AAutomatically openWithout human interventionHydrocarbon oils treatmentRefining to eliminate hetero atomsEconomic benefitsEngineering

The invention provides a process method for prolonging the operation period of a hydrogenation device. A gas and liquid distribution disc is arranged on the top of a catalyst bed layer of a hydrogenation reactor, conventional gas and liquid distributors and standby bubble cap type gas and liquid distributors are arranged on the gas and liquid distribution disc, the standby bubble cap type gas and liquid distributors and the conventional gas and liquid distributors are distributed at intervals, the standby bubble cap type gas and liquid distributors are provided with long center pipes, the long center pipes downward extend into the top catalyst bed layer of the hydrogenation reactor, bubble caps are arranged at the upper parts of the long center pipes, in addition, gaps for flowing materials are formed between the bubble caps and the long center pipes, and the tops of the long center pipes are sealed by pressure blasting films. The method has the advantages that great change on the existing device is not needed, the long-period operation of the device can be realized under the condition of low investment, in addition, catalysts of the whole bed layer are sufficiently utilized, simultaneously, the pressure reduction of the reactor is reduced, the production safety is ensured, and the economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatization catalyst, its preparation method and application

ActiveCN1298425CLipophilicHigh aromatization activityMolecular sieve catalystsHydrocarbonsMolecular sieveAdhesive

An aromatizing catalyst for molifying poor gasoline to prepare high-octane gaseline component or arylhydrocarbon is prepared from the Zn, P and RE metal modified HZSM-5 molecular sieve, Y-type molecular sieve, carrier and adhesive proportionally.

Owner:CHINA PETROCHEMICAL CORP +1

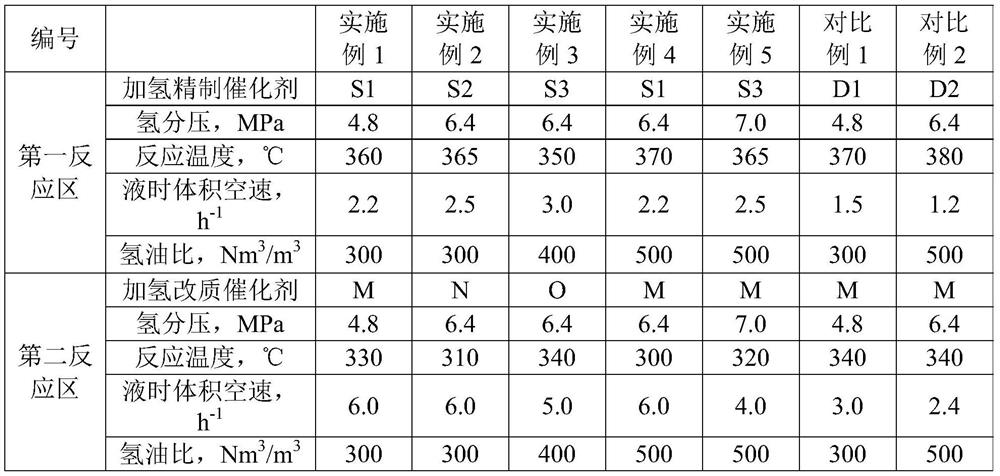

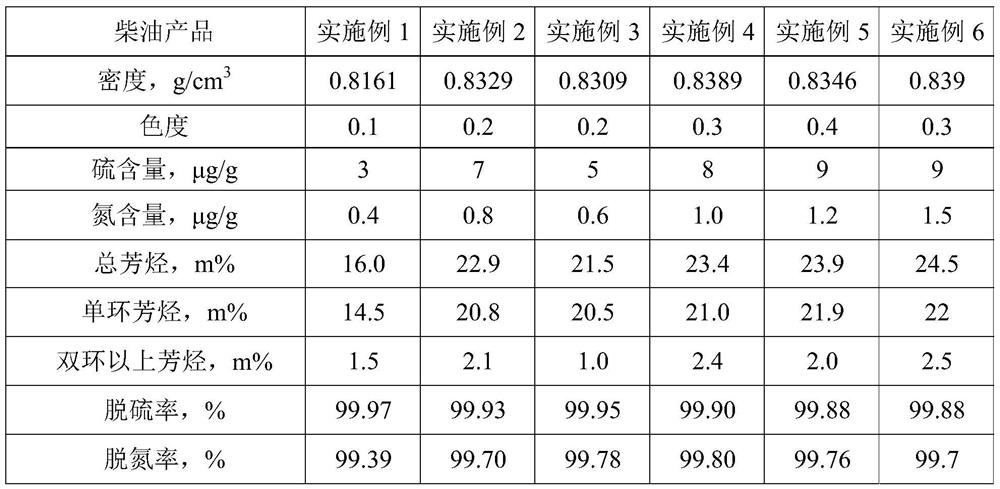

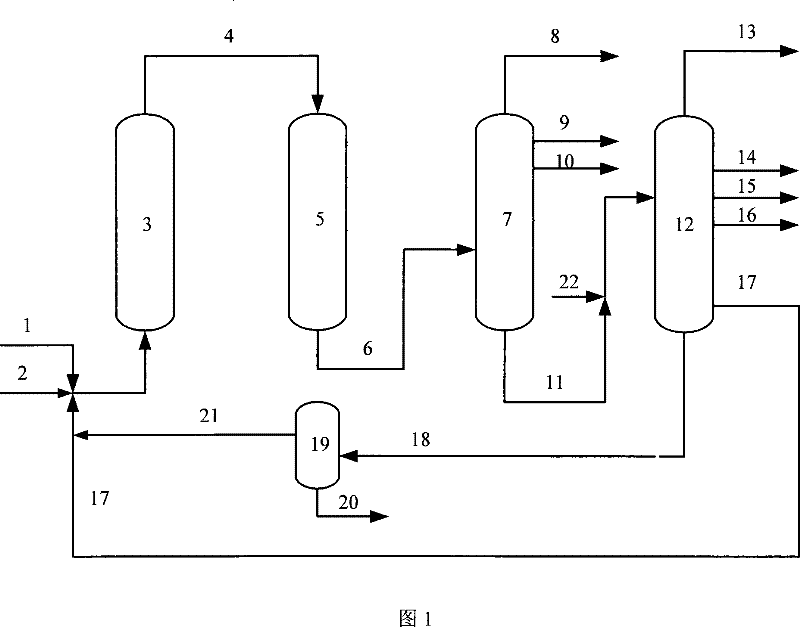

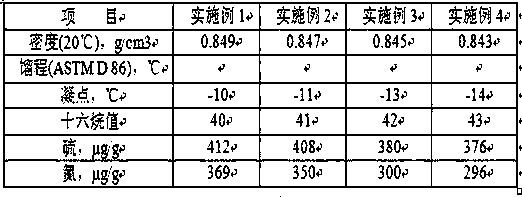

Method for producing clean diesel oil

ActiveCN111849548AExtended operating cycleRealize long cycle operationPhysical/chemical process catalystsTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonPtru catalyst

The invention relates to the technical field of oil refining, and discloses a method for producing clean diesel oil. The method comprises the following steps: a diesel raw material and hydrogen are subjected to a contact reaction with a hydrofining catalyst in a first reaction zone to obtain a first reaction zone effluent; the first reaction zone effluent enters a second reaction zone without separation, the first reaction zone effluent and a hydro-upgrading catalyst are subjected to a contact reaction in the second reaction zone to obtain a second reaction zone effluent, and the second reaction zone effluent is subjected to fractionation, wherein the distillation range of the diesel oil raw material is 140-390 DEG C, the sulfur content is 1000-15000 [mu] g / g, the nitrogen content is 50-3000 [mu] g / g, and the aromatic hydrocarbon content is 10-80 wt%. According to the method provided by the invention, the ultra-low sulfur diesel oil with polycyclic aromatic hydrocarbon content of lessthan 7% and sulfur content of less than 10 [mu] g / g can be produced by using the specific hydrofining catalyst, the whole operation period of the device can be effectively prolonged, and long-period operation is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrotreating high-sulfur and high-metal residual oil

ActiveCN101519603BAvoid problems such as cloggingSlow ascentRefining to eliminate hetero atomsHydrogenNaphtha

The invention provides a method for hydrotreating high-sulfur and high-metal residual oil, which comprises the following steps: the residual oil and catalytic cracking recycle oil are in contact with The invention provides a method for hydrotreating high-sulfur and high-metal residual oil, which comprises the following steps: the residual oil and catalytic cracking recycle oil are in contact witha residual oil hydrogenation catalyst in the presence of hydrogen gas and under the hydrotreating reaction condition so as to carry out a hydrotreating reaction; the reaction product is separated to oa residual oil hydrogenation catalyst in the presence of hydrogen gas and under the hydrotreating reaction condition so as to carry out a hydrotreating reaction; the reaction product is separated to obtain gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. The residual oil hydrogenation catalyst is a combination of at least two catalysts, namely, an up-flow reactor cbtain gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. The residual oil hydrogenation catalyst is a combination of at least two catalysts, namely, an up-flow reactor catalyst and a fixed-bed hydrogenation catalyst and the two catalysts are respectively put in an up-flow reactor and a fixed-bed reactor; the ratio of the up-flow reactor catalyst and the fixed-bed hydatalyst and a fixed-bed hydrogenation catalyst and the two catalysts are respectively put in an up-flow reactor and a fixed-bed reactor; the ratio of the up-flow reactor catalyst and the fixed-bed hydrogenation catalyst is 30:70 to 70:30. The method can treat the high-sulfur and high-metal residual oil and effectively slow down the ascending speed of the pressure drop of the fixed-bed catalyst bedrogenation catalyst is 30:70 to 70:30. The method can treat the high-sulfur and high-metal residual oil and effectively slow down the ascending speed of the pressure drop of the fixed-bed catalyst bed, thus realizing the long-term running of the device. Besides, the method can combine the residual oil hydrotreating and catalytic cracking more effectively and has better implementation effect., thus realizing the long-term running of the device. Besides, the method can combine the residual oil hydrotreating and catalytic cracking more effectively and has better implementation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation technological method for reducing skimming of catalyst

ActiveCN102441349AReduce pressure dropRealize long cycle operationChemical/physical processesHydrocarbon oils treatmentDifferential pressureEconomic benefits

The invention provides a hydrogenation technological method for reducing the skimming of a catalyst, which is characterized in that: a standby gas-liquid distributor is arranged on a catalyst bed layer at the top of a hydrogenation reactor; the standby gas-liquid distributor consists of a long center pipe and a bubble cap; the upper end of the long center pipe is above the catalyst bed layer; the bubble cap is arranged at an upper part of the long center pipe, and a gap for materials to flow exists between the bubble cap and the long center pipe; the opening at the upper end of the long center pipe is closed by a pressure rupture film; the lower part of the long center pipe extends into the catalyst bed layer; and the rupture differential pressure of the pressure rupture films is lower than 0.45 MPa and higher than 0.1 MPa. According to the method provided by the invention, no big change is required to be carried out on the existing device, the long-term operation for the device can be realized with smaller investment, the catalyst of the whole bed layer is sufficiently utilized, and meanwhile, the pressure drop of the reactor is reduced, so that the production safety is ensured, and the economic benefit is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior heavy oil treatment method

PendingCN111088070AIncrease profitHigh economic valueTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses an inferior heavy oil treatment method. The treatment method comprises the following steps: introducing inferior heavy oil into a first hydro-processing unit; carrying out a hydrogenation reaction in the presence of hydrogen and a first hydro-processing catalyst, directly introducing a liquid phase effluent obtained after the reaction into a catalytic cracking unit withoutfractionation, separating a reaction product to obtain catalytic slurry oil, mixing the catalytic slurry oil with a first auxiliary agent, carrying out settlement separation after the mixing treatment, obtaining a first material and residues after separation; introducing the first material into a second hydro-processing unit, carrying out a hydrogenation reaction under the action of a second hydro-processing catalyst and hydrogen, introducing a liquid-phase effluent obtained after the reaction into a clarification unit, obtaining clarified oil after separation, and subjecting the clarified oilto further solid-liquid separation to obtain purified oil slurry. According to the treatment method, heavy oil is cleaned, catalytic slurry oil generated by catalytic cracking can be purified, solidsand sulfur in catalytic slurry oil are removed, and the economic value of the catalytic slurry oil is greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrotreating coking distillate

ActiveCN102041065BRealize long cycle operationAvoid stickingTreatment with hydrotreatment processesHydrogenation reactionEconomic benefits

Owner:CHINA PETROLEUM & CHEM CORP +1

Technique for producing high-end graphite carbon material

ActiveCN111320169AReduce bitumen contentLess componentsCarbon compoundsTreatment with hydrotreatment processesGraphite carbonPtru catalyst

The invention discloses a combined method for producing a high-end graphite carbon material. The method comprises the following steps: fractionating raw oil and vacuum residuum to obtain heavy distillate oil and light distillate oil; discharging the heavy distillate out of the device, optionally and partially circulating the heavy distillate oil back to the bottom of a fractionating tower, feedingthe light distillate oil into a hydrotreating device, performing a hydrotreating reaction in the presence of hydrogen and a hydrotreating catalyst, taking the hydrotreated material as a coking raw material (also called as a green coke raw material); and feeding the coking raw material into a coking device, and carrying out reactions to obtain the high-end graphite carbon material. The method canbe used for continuously producing the high-quality high-end graphite carbon material with a stable performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude benzene hydrofining process

InactiveCN112279745ARealize long cycle operationImprove use valueHydrocarbon purification/separationHydrocarbonsBenzenePtru catalyst

The invention relates to the technical field of chemical production, in particular to a crude benzene hydrofining process, which comprises the following steps: pretreating crude benzene, performing pressurizing by a pump, exchanging heat by a heat exchanger, and pumping the product into a hydrogen mixing tank; fully mixing a crude benzene full-fraction raw material, hydrogen and part of a recycledhydrogenation product in the hydrogen mixing tank, and fully dissolving the hydrogen in the raw material; sending a gas-liquid mixture discharged from the hydrogen mixing tank into a heating furnaceto be heated to 330-340DEG C, and then sending the product into an excessive hydrogen separation tank, and enabling the excessive hydrogen separated from the top of the excessive hydrogen separation tank to enter a tail gas treatment system; feeding the full-liquid-phase crude benzene raw material rich in dissolved hydrogen from the bottom of the excess hydrogen separation tank into a first-stagehydrogenation reactor, and carrying out a full-liquid-phase hydrogenation reaction under the catalytic action of a hydrogenation catalyst under the conditions of a pressure of 6-6.5MPa and a temperature of 340-345DEG C; flowing back one part of a hydrogenation product from the hydrogenation reactor to the hydrogen mixing tank, keeping the reflux quantity at 80% of the hydrogenation product, and subjecting the rest part to heat exchange with the raw material crude benzene, and then letting the rest part enter the gas-liquid separation tank. Therefore, the energy consumption is low, and the benefit is greatly improved.

Owner:江苏合一金属新材料科技有限公司

A combined process of inferior heavy oil and hydrotreating

ActiveCN103540350BSlow ascentRealize long cycle operationTreatment with hydrotreatment processesSlurry reactorPtru catalyst

The invention relates to a hydrotreating combined process for inferior heavy oil and residual oil. The hydrotreating combined process comprises the following steps of: firstly pretreating the heavy oil and / or residual oil raw material in a slurry reactor; carrying out gas-liquid separation, and hydro-upgrading the liquid-phase product in a fixed bed, wherein the hydro-pretreating part of the slurry reactor comprises a straight cylinder type slurry reactor pretreatment reactor and a slurry reactor hydro-catalyst, and the reactors used in the fixed bed hydro-upgrading part sequentially and mainly include two parallel up-flow type deferrization-decalcification reactors, one up-flow type demetalization reactor, one fixed bed desulfurization reactor and one fixed bed denitrification reactor. By adopting the hydrotreating combined process provided by the invention, not only are the hydrotreating and impurity removal capacities of the catalyst improved, but also the running cycle of the device is prolonged. The hydrotreating combined process provided by the invention can be applied to treating the inferior heavy oil and residual oil, which are high in sulfur content, metal content, and asphalt content; the conversion ratio is 30-80%; the raising rate of the pressure drop of the reactors can be effectively reduced so as to achieve the long-period running of the device.

Owner:PETROCHINA CO LTD

Hydrogenation process for reducing catalyst skimming

ActiveCN103102939BWithout human interventionReduce operational complexityTreatment with hydrotreatment processesHydrogenation reactionEconomic benefits

The invention provides a hydrogenation process for reducing catalyst skimming. According to the invention, a fixed bed reactor is used; 2 to 5 beds are arranged in the fixed bed reactor; a top bed is provided with a scale depositing basket penetrating the top bed; the middle part and the bottom of the scale depositing basket are respectively provided with a separator plate; each separator plate is welded with an overflow pipe; and a pressure rupture disk is hermetically mounted on the top of each overflow pipe. When the upper part / lower part of the catalyst beds has a great pressure drop, the pressure rupture disk on the top of the overflow pipe at the upper part / lower part ruptures under the action of pressure difference, and a gas-liquid material flow can continue flowing downwardly to participate in a hydrogenation reaction. According to the process provided by the invention, great improvement of a conventional apparatus is not needed, long-period running of the apparatus can be realized with small investment, a catalyst in the whole beds can be fully utilized, the pressure drop in the reactor can be reduced at the same time, production safety is guaranteed, and economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com