Method for preparing needle coke material by catalytic cracking slurry

A technology for catalytic cracking oil slurry and needle coke raw materials, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc. It can solve the problems of increased pressure drop of fixed bed, difficulty in long-term stable operation, etc., and achieves convenient implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

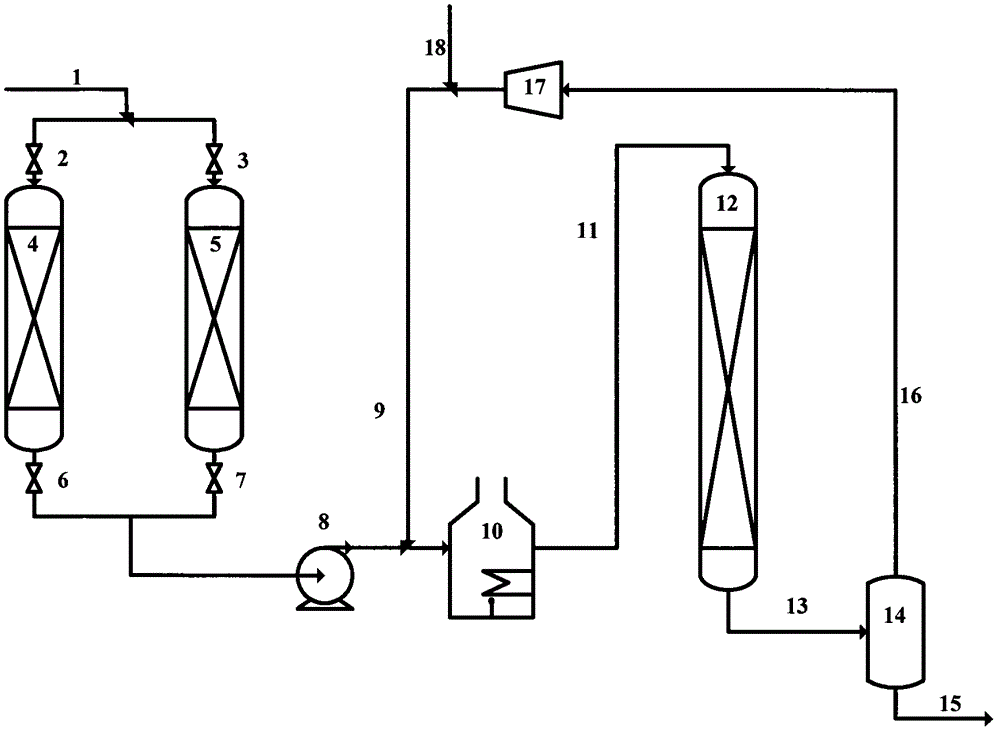

[0034] The catalytic cracking oil slurry A first passes through the protective reactor A, contacts with the adsorbent to filter out most of the catalytic cracking catalyst powder, is pressurized by the raw material oil pump and mixed with hydrogen, then enters the heating furnace, after heating, enters the hydrogenation reactor, and is sequentially combined with hydrogenation Protective agent, hydrodemetallization agent and hydrodesulfurization agent contact. The oil produced by hydrogenation is separated into gas and liquid by a high-pressure separator, and the liquid product is discharged from the device. After being compressed by a compressor, the gas is mixed with new hydrogen and then mixed with raw oil. When the protective reactor A reaches the saturated adsorption capacity and becomes clogged, causing the pressure difference to rise, the protective reactor A is cut off, the adsorbent in it is replaced, and the protective reactor B is cut into the reactor. When the prote...

Embodiment 2

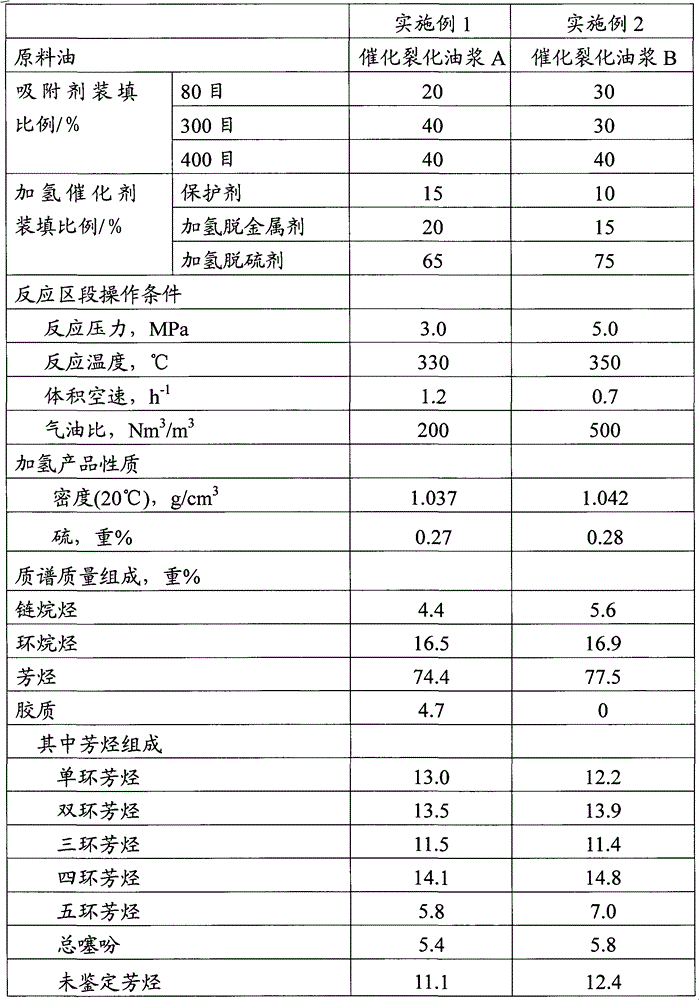

[0037] The process flow of this example is the same as that of Example 1, using catalytic cracking oil slurry B, the loading ratio of the adsorbent in the protection reactor, the loading ratio of the catalyst in the hydrogenation reactor, the hydrogenation reaction conditions and the properties of the hydrogenated oil are shown in the table 2.

[0038] It can be seen from Table 3 that after hydrogenation treatment of catalytic cracking oil slurries A and B, the sulfur content in the hydrogenated oil was less than 0.3% by weight, and only a small amount of hydrogenated and saturated aromatic hydrocarbons with three or more rings were hydrogenated. Hydrogenation and saturation are part of the quality, and the total amount of three-ring and more than three-ring fused aromatic hydrocarbons has increased. The oil produced by hydrogenation can be used as a high-quality needle coke raw material.

[0039] Table 1

[0040] Raw oil properties

FCC Slurry A

Catalytic cra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com