Low-quality heavy oil and residual oil hydrotreatment combined process capable of prolonging service life of catalyst

A technology for hydrogenation of residual oil and low-quality heavy oil, applied in the field of hydrogenation, can solve the problems of difficulty in obtaining products and benefits, high density of residual oil, and many impurities, and achieve the effects of improving operating performance, reducing pressure drop, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

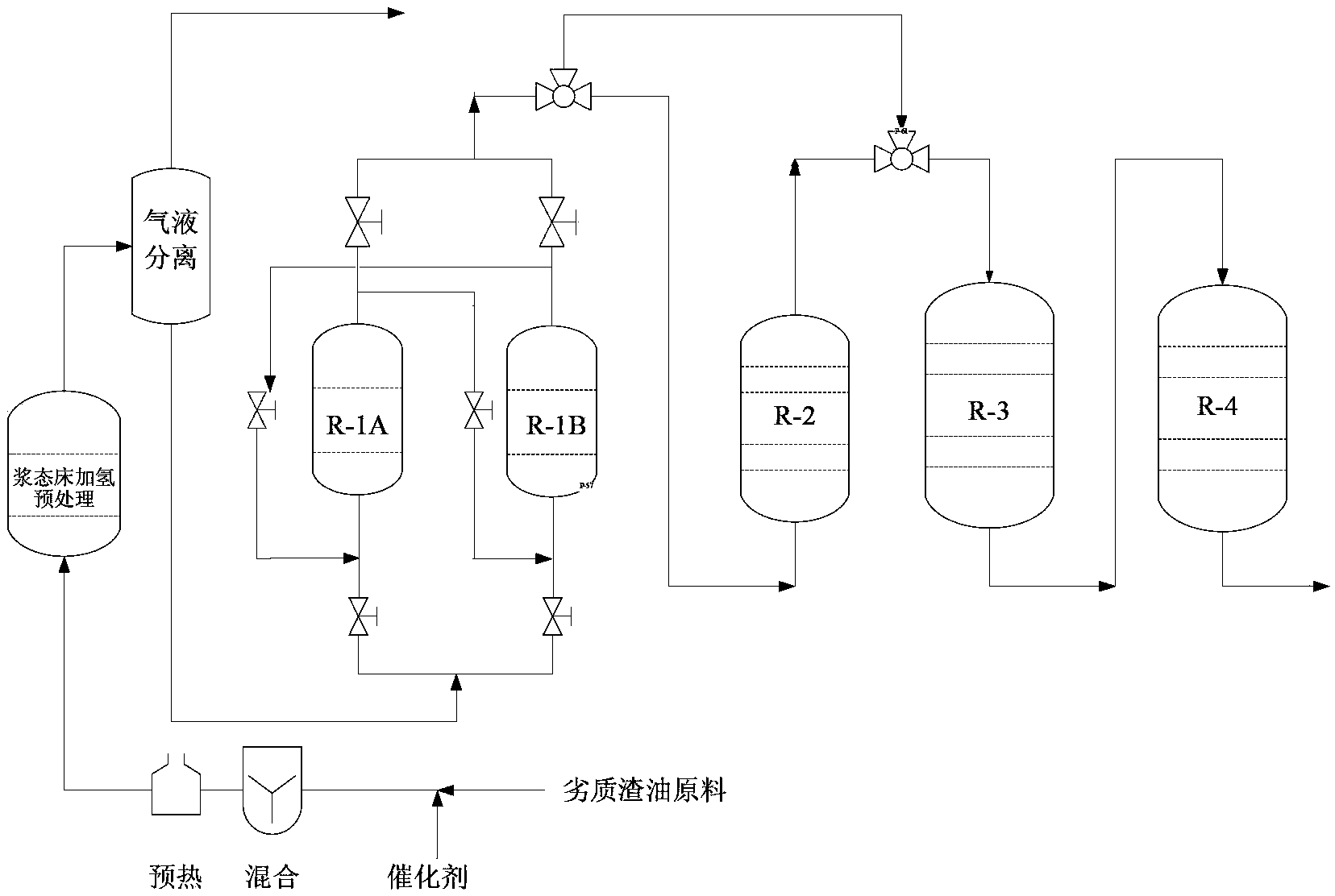

Embodiment 1

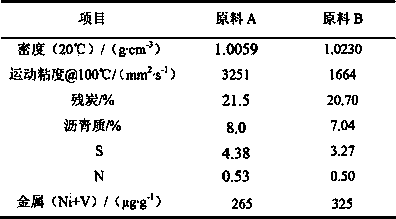

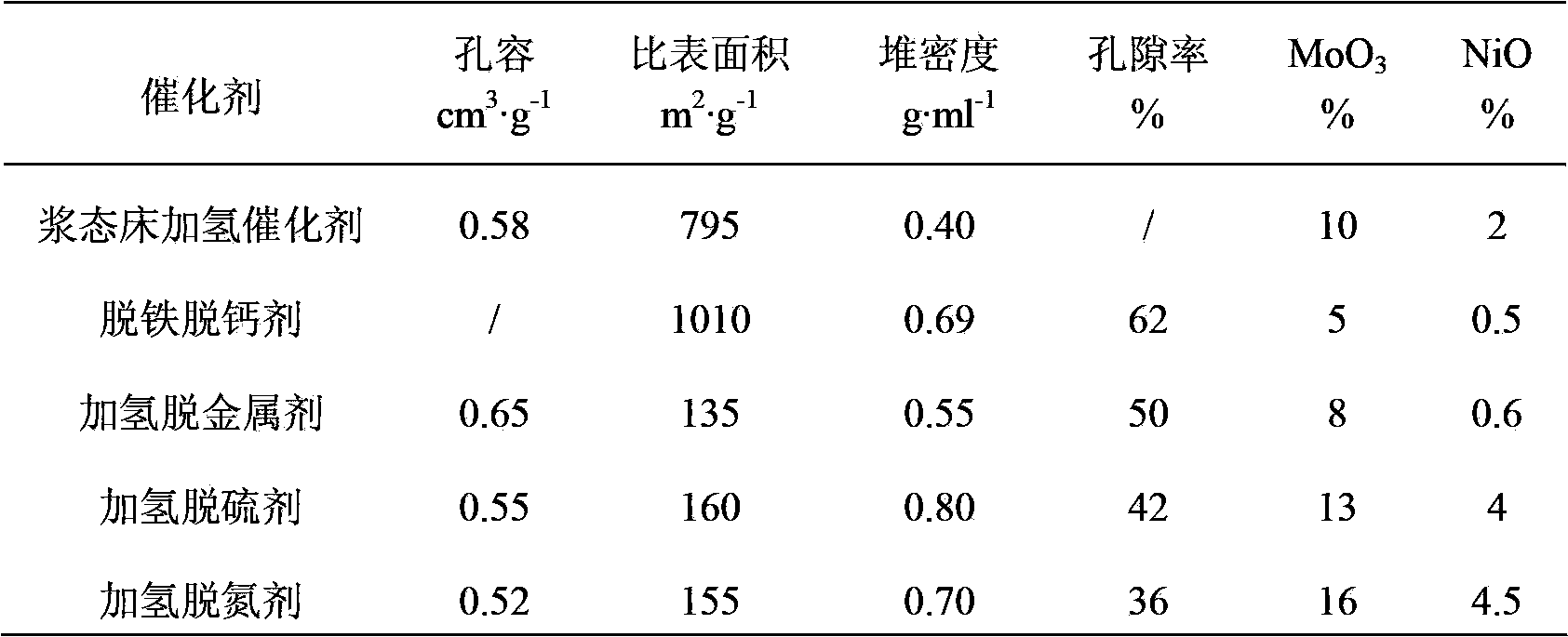

[0062] Use raw material A as raw material (see Table 1 for properties), and process it for 2000 hours under the combined process flow. Slurry bed hydrogenation pretreatment process conditions are as follows: hydrogen pressure 18.0MPa; temperature 430°C; liquid hourly volume space velocity 0.6h -1 The volume ratio of hydrogen to oil is 1000; the slurry bed catalyst is a composite catalyst of carbonaceous particles and molybdenum oxide, the addition amount is 5%, and the slurry bed hydrogenation catalyst is prepared according to the method in Example 2 of CN102049252A. The process conditions of fixed bed hydrotreating are as follows: hydrogen pressure 18.0MPa; temperature 390℃; liquid hourly volume space velocity 0.3h -1 ; The volume ratio of hydrogen to oil is 1000. The catalysts loaded in each reactor are hydrodeferrification and decalcification catalysts, hydrodemetallization catalysts, hydrodesulfurization catalysts and hydrodenitrogenation catalysts in sequence. The hydro...

Embodiment 2

[0064] Using raw material B as raw material (see Table 1 for properties), it was treated by combined process for 2000h. Slurry bed hydrogenation pretreatment process conditions are as follows: hydrogen pressure 12.0MPa; temperature 390°C; liquid hourly volume space velocity 0.2h -1 The volume ratio of hydrogen to oil is 800; the slurry bed hydrogenation catalyst is the same as in Example 1, which is a composite catalyst of carbonaceous particles and nickel oxide, and the addition is 0.5%. The process conditions of fixed bed hydrotreating are as follows: hydrogen pressure 12.0MPa; temperature 385°C; liquid hourly volume space velocity 0.25h -1 ; The volume ratio of hydrogen to oil is 800. The catalysts loaded in each reactor are hydrodeferrification and decalcification catalysts, hydrodemetallization catalysts, hydrodesulfurization catalysts and hydrodenitrogenation catalysts in sequence. Catalyst and addition ratio are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com