Inferior heavy oil treatment method

A low-quality heavy oil and treatment method technology, applied in the field of oil refining and chemical industry, can solve the problems of high liquid recovery loss, frequent backwashing, pollution, etc., and achieve the effect of increasing the utilization rate of heavy oil, improving the overall value, and improving the economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

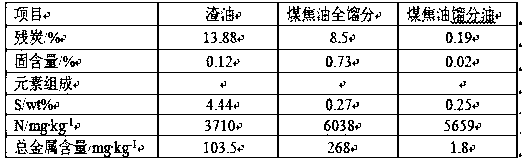

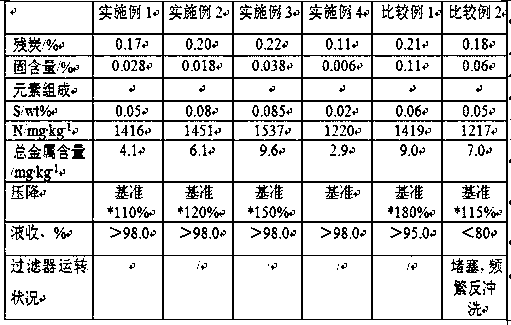

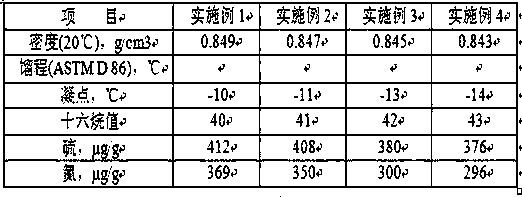

[0048]Example 1. Residual oil is used as raw material, and the inferior heavy oil treatment method described in the present invention is adopted. The inferior heavy oil enters the first hydroprocessing unit (the first hydroprocessing unit adopts a fixed-bed reactor), and the hydrogen and the first hydrogenation The hydrogenation reaction is carried out in the presence of a treatment catalyst. The reaction conditions of the first hydrogenation reactor are: reaction temperature 385°C, reaction pressure 15.5Mpa, volume space velocity 0.28h -1 , the volume ratio of hydrogen to oil is 450; the liquid phase effluent obtained after the reaction directly enters the catalytic cracking unit without fractionation, and the reaction product is separated to obtain dry gas, liquefied gas, catalytic gasoline, catalytic diesel, catalytic heavy cycle oil and catalytic oil slurry; The catalytic oil slurry is firstly mixed with the whole fraction of the first auxiliary agent coal tar, the ratio of...

Embodiment 2

[0050] Example 2 Using residual oil as raw material, using the inferior heavy oil treatment method described in the present invention, the inferior heavy oil enters the first hydroprocessing unit (the first hydroprocessing unit adopts a fixed-bed reactor), and the hydrogen and the first hydrogenation The hydrogenation reaction is carried out in the presence of a treatment catalyst. The reaction conditions of the first hydrogenation reactor are: reaction temperature 385°C, reaction pressure 15.8Mpa, volume space velocity 0.30h -1 , the volume ratio of hydrogen to oil is 500; the liquid phase effluent obtained after the reaction directly enters the catalytic cracking unit without fractionation, and the reaction product is separated to obtain dry gas, liquefied gas, catalytic gasoline, catalytic diesel oil, catalytic heavy cycle oil and catalytic oil slurry; The catalytic oil slurry is first mixed with the first auxiliary agent coal tar whole distillate and the second auxiliary ag...

Embodiment 3

[0052] Example 3 Using residual oil as raw material, using the inferior heavy oil treatment method described in the present invention, the inferior heavy oil enters the first hydroprocessing unit (the first hydroprocessing unit adopts a fixed-bed reactor), and the hydrogen and the first hydrogenation The hydrogenation reaction is carried out in the presence of a treatment catalyst. The reaction conditions of the first hydrogenation reactor are: reaction temperature 390°C, reaction pressure 16.5Mpa, volume space velocity 0.32h -1 , the volume ratio of hydrogen to oil is 550; the liquid phase effluent obtained after the reaction directly enters the catalytic cracking unit without fractionation, and the reaction product is separated to obtain dry gas, liquefied petroleum gas, catalytic gasoline, catalytic diesel oil, catalytic heavy cycle oil and catalytic oil slurry; The catalytic oil slurry is mixed with the first auxiliary agent coal tar distillate oil (fraction -1 , the volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com