Patents

Literature

69results about How to "Easy to settle and separate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric dewatering and desalting appliance for crude oil

InactiveCN1482212AReduce moisture contentEnhanced electrical coalescenceLiquid separation by electricityDewatering/demulsification with electric/magnetic meansElectricityOil water

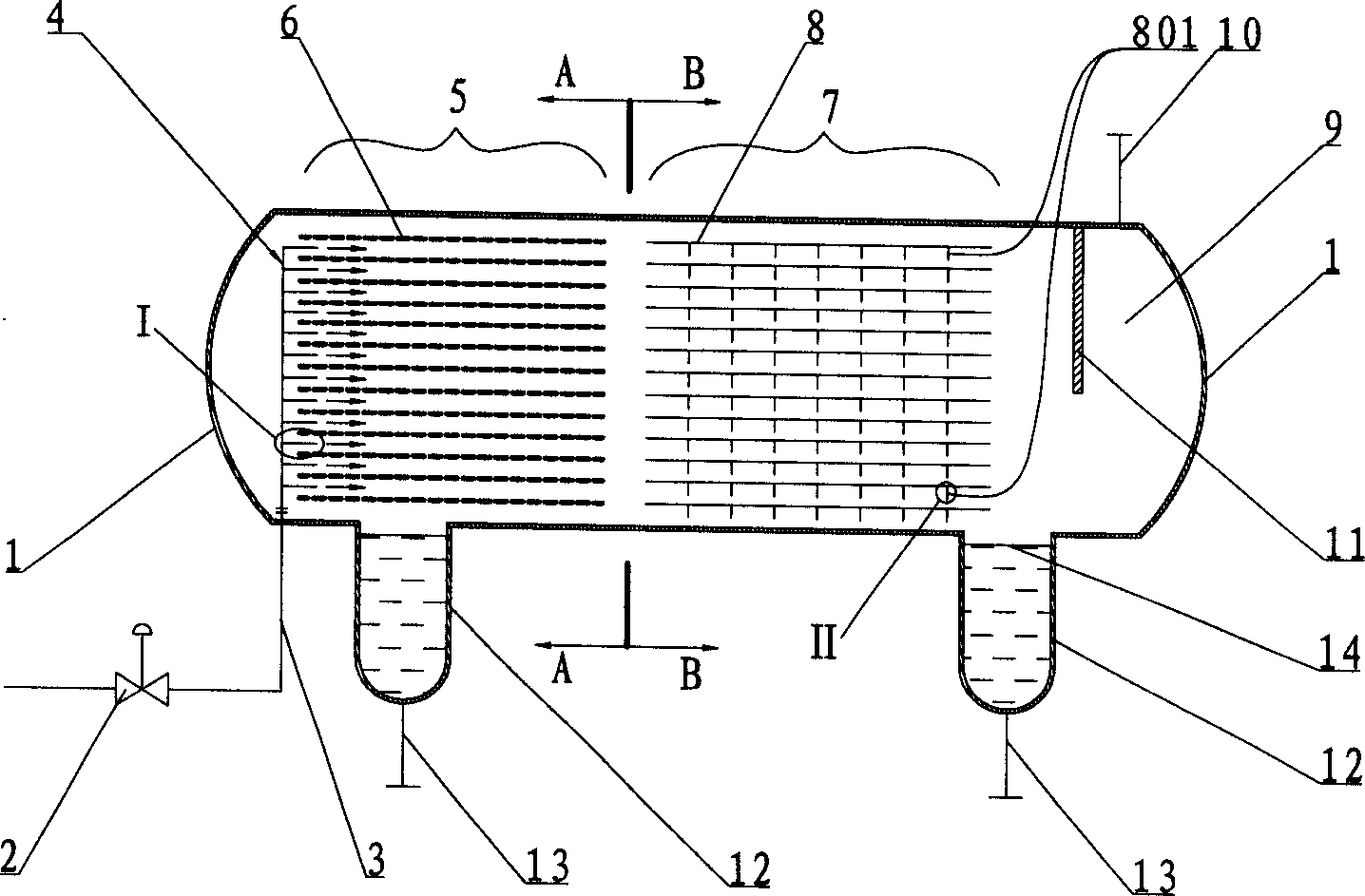

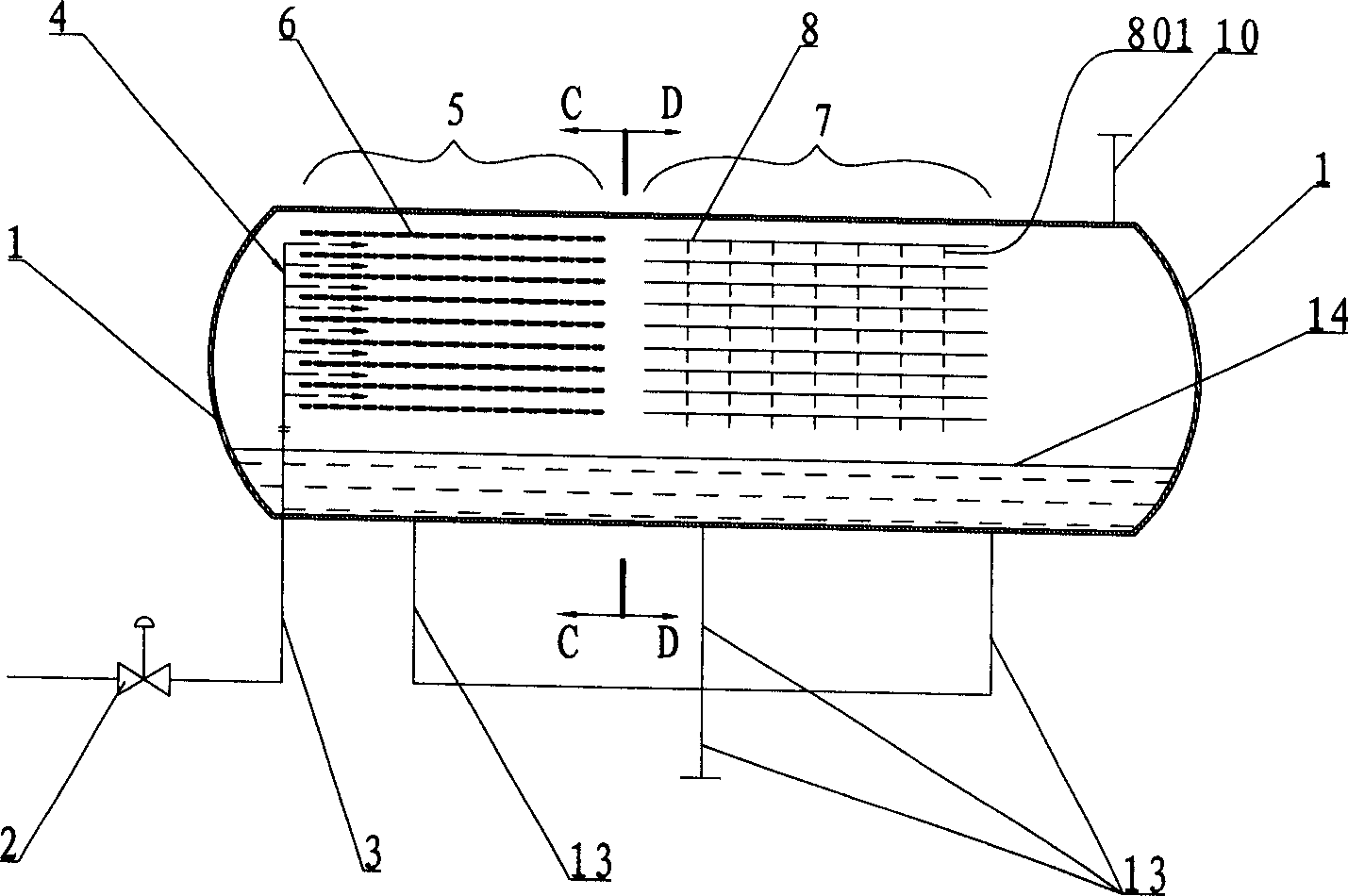

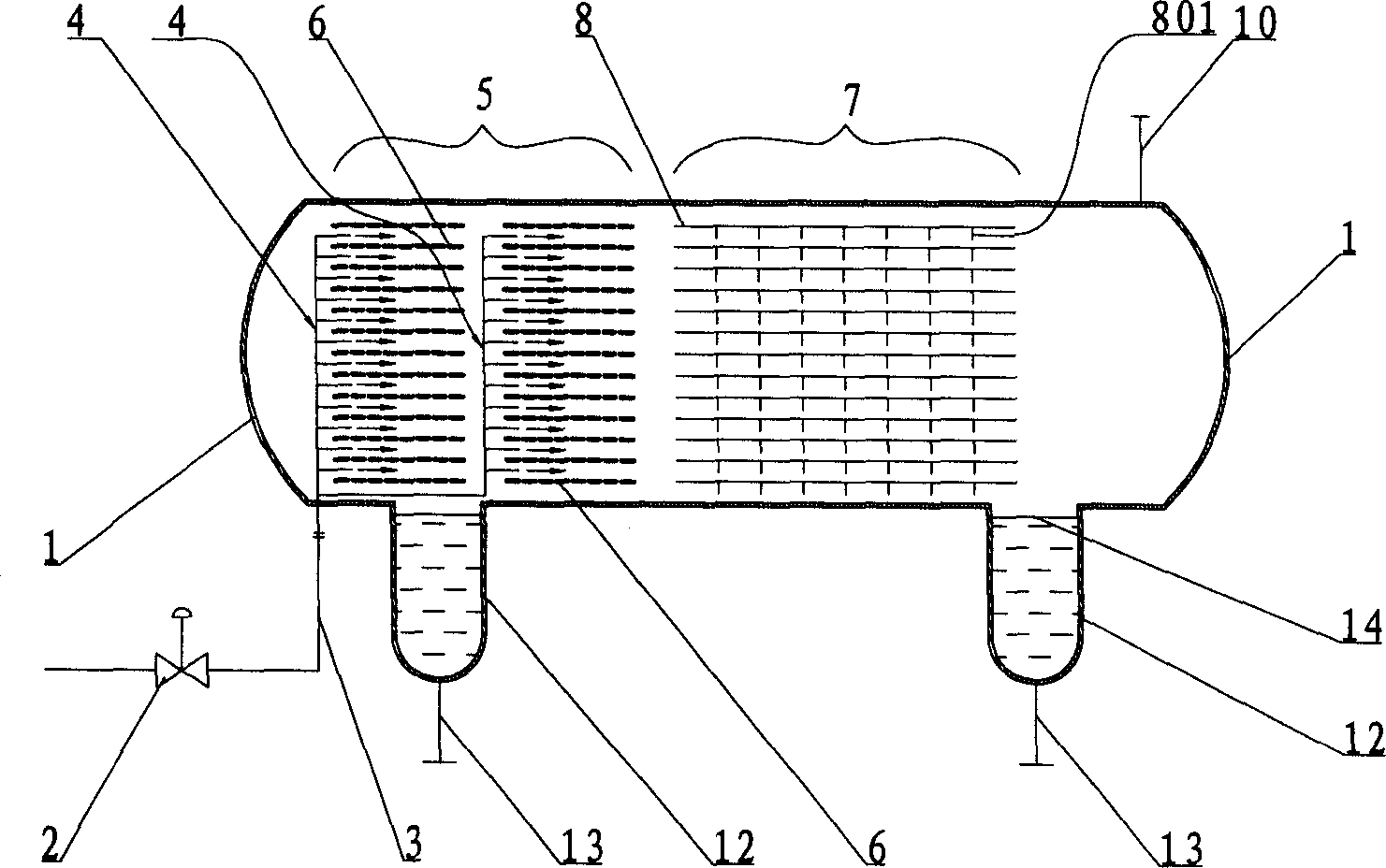

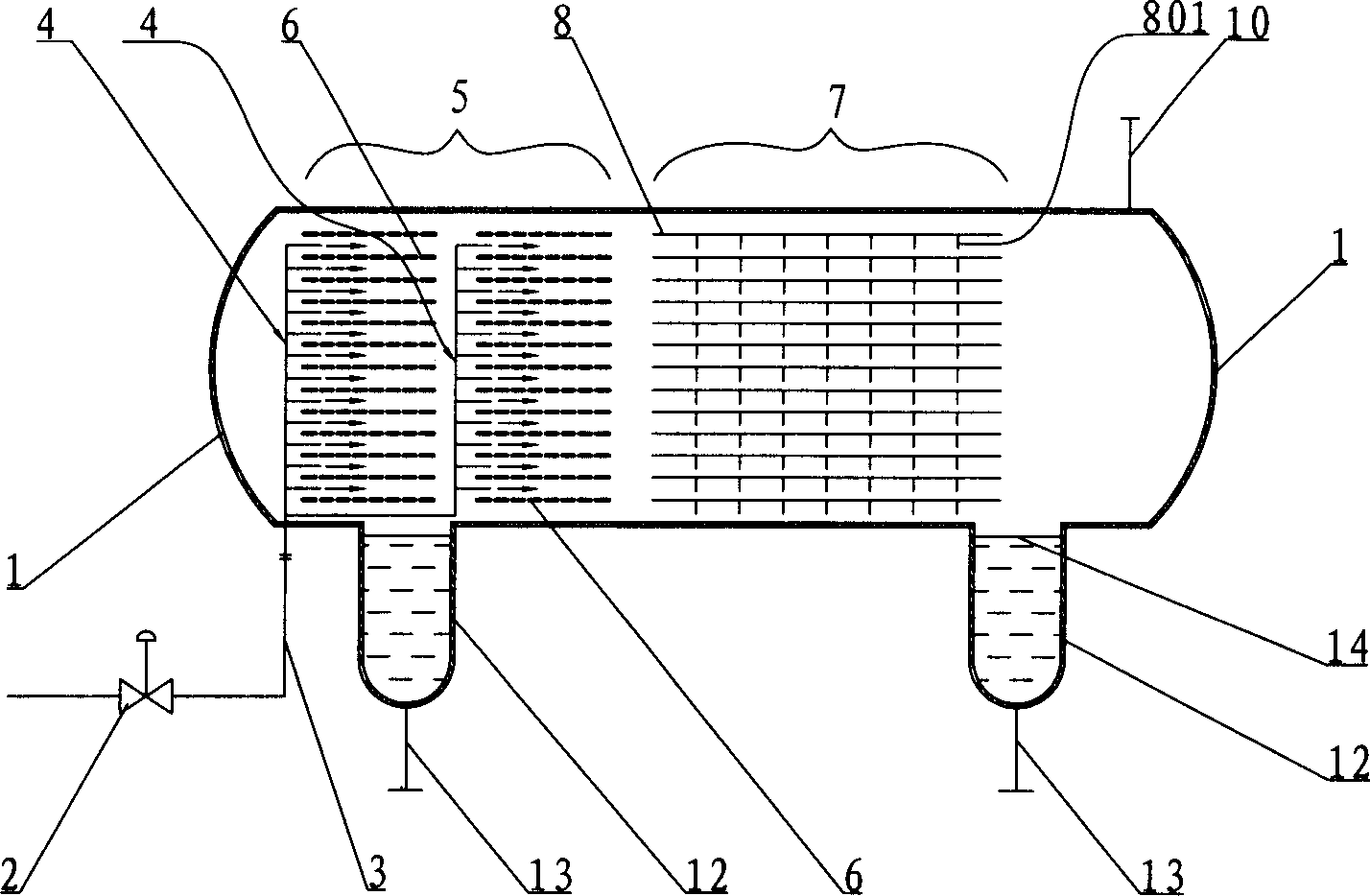

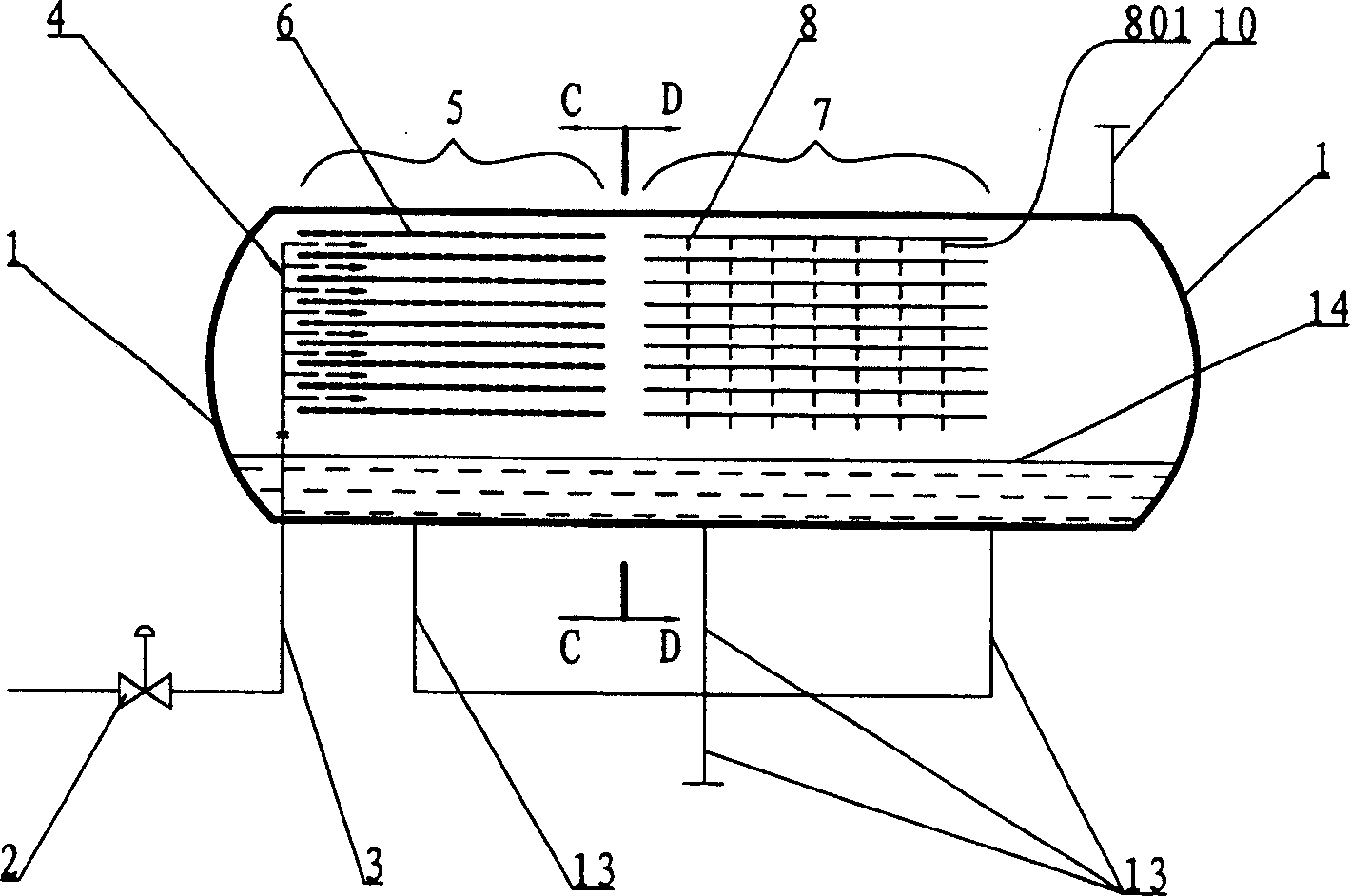

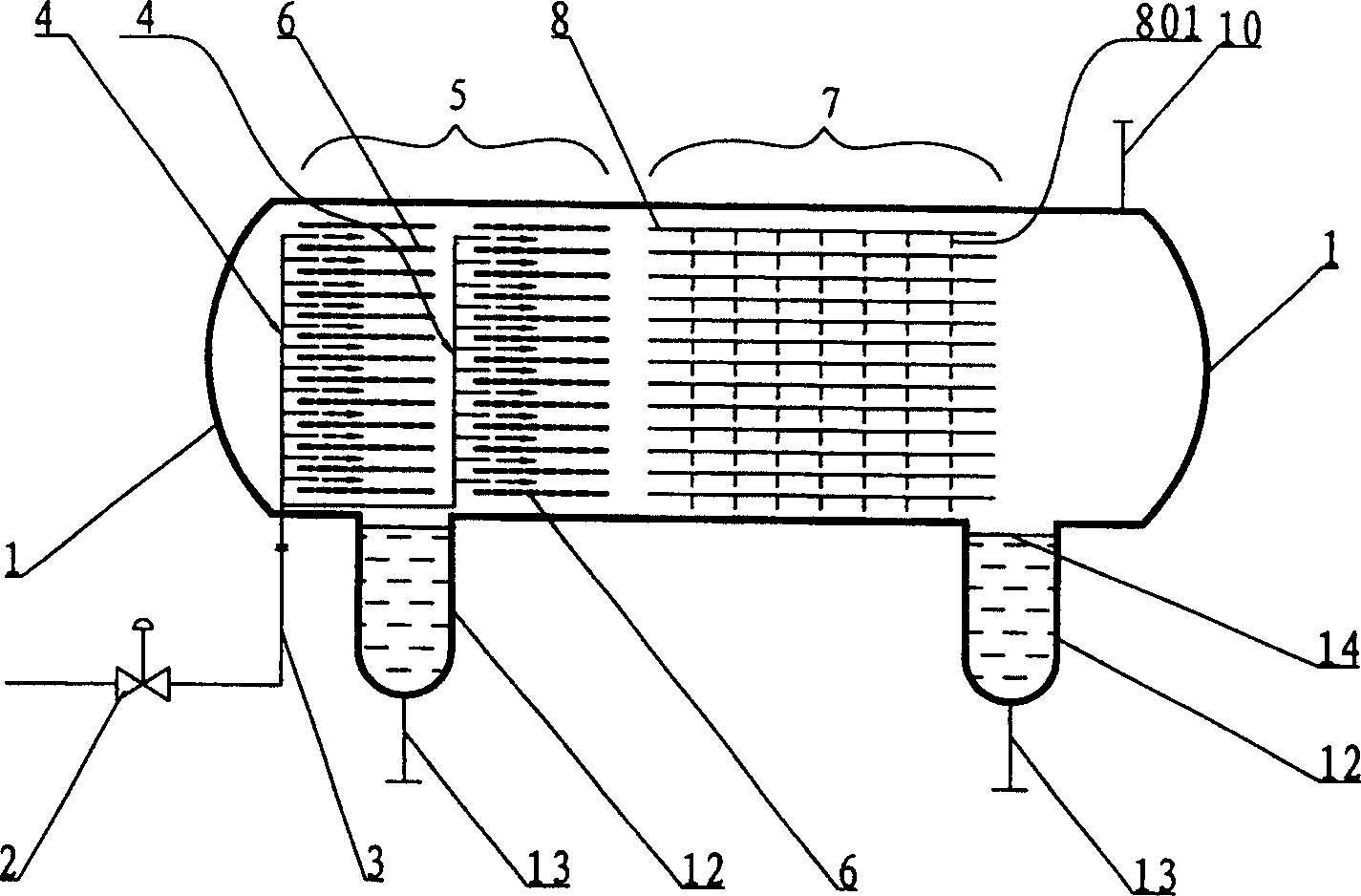

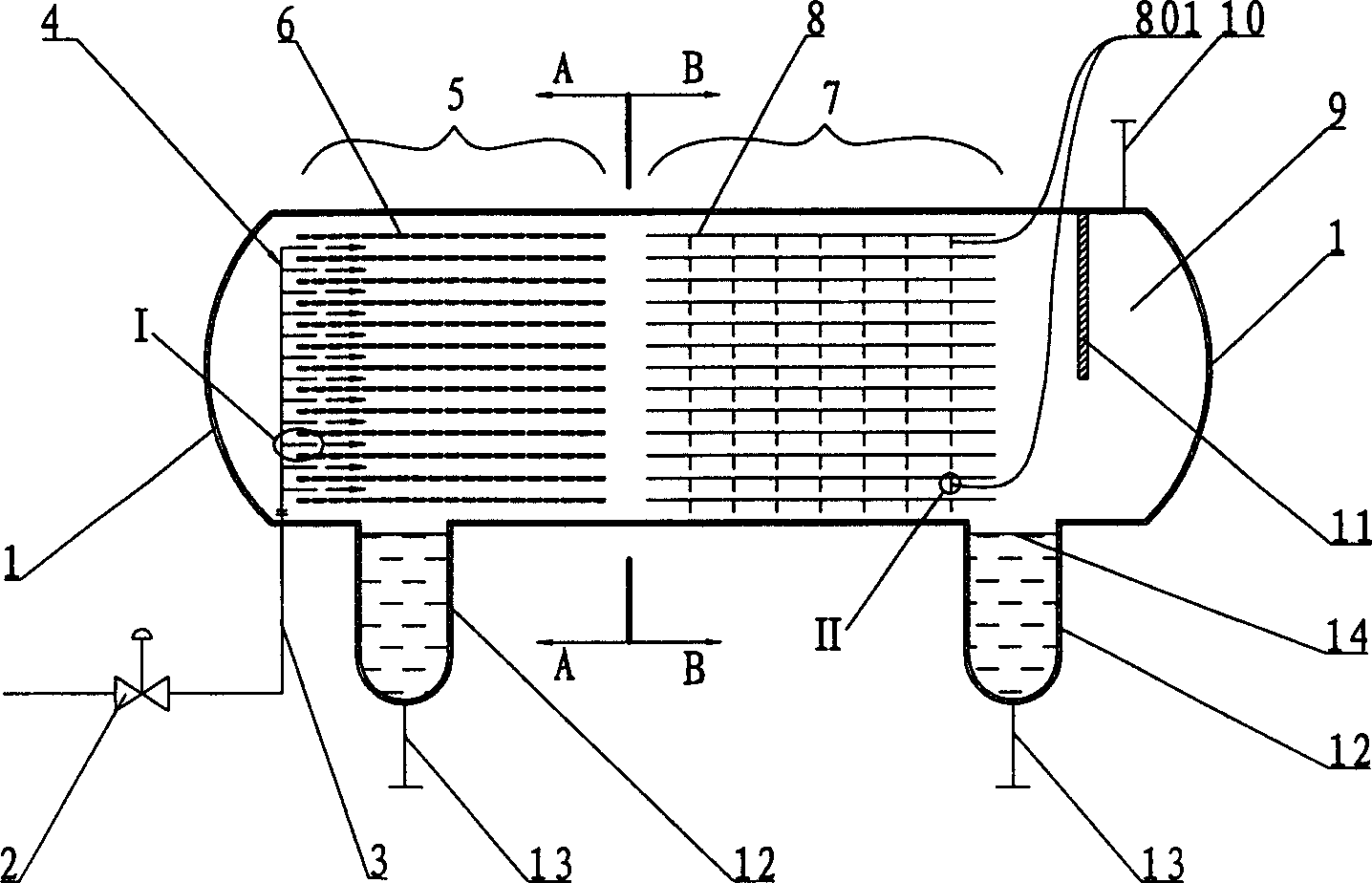

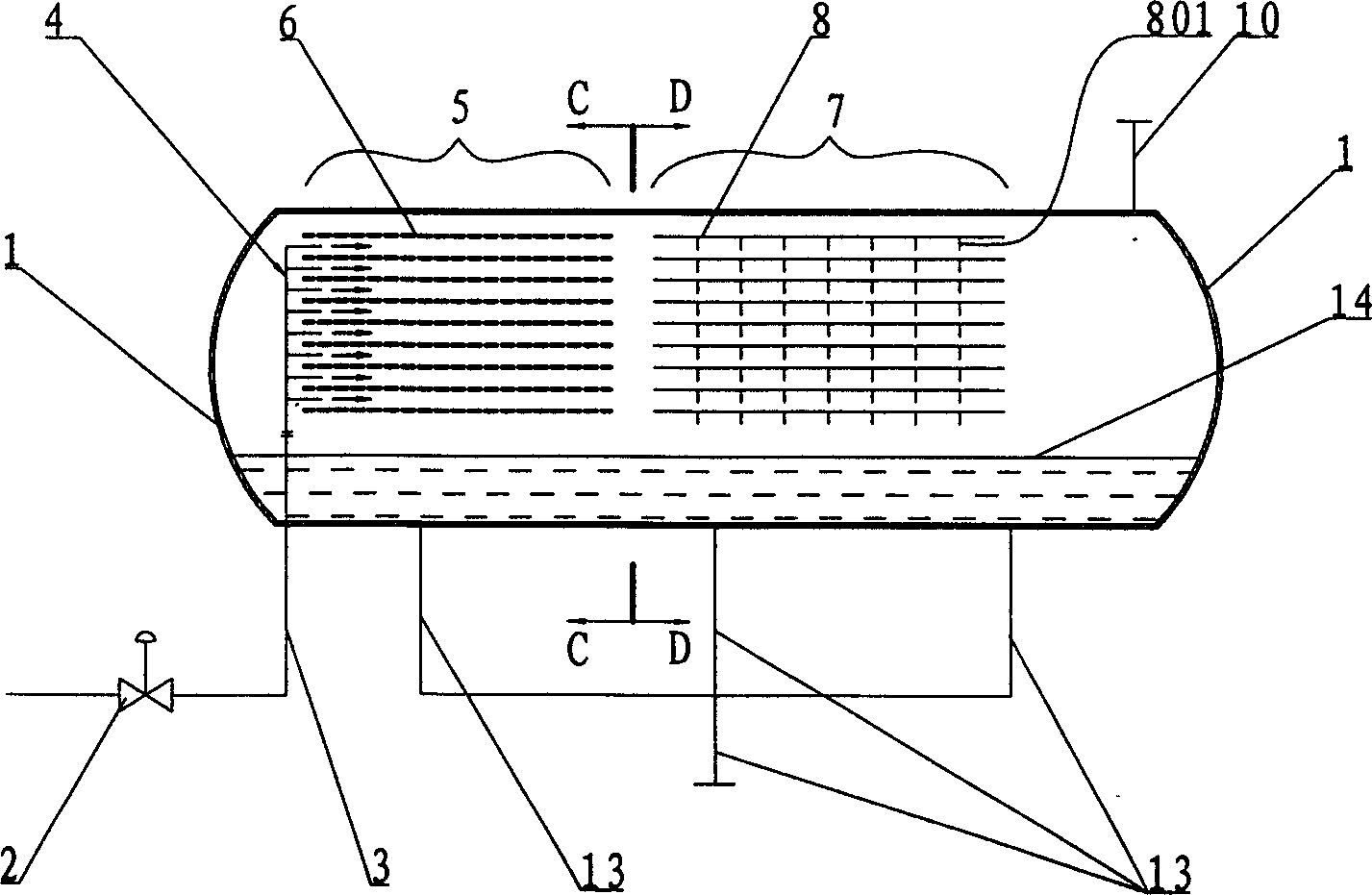

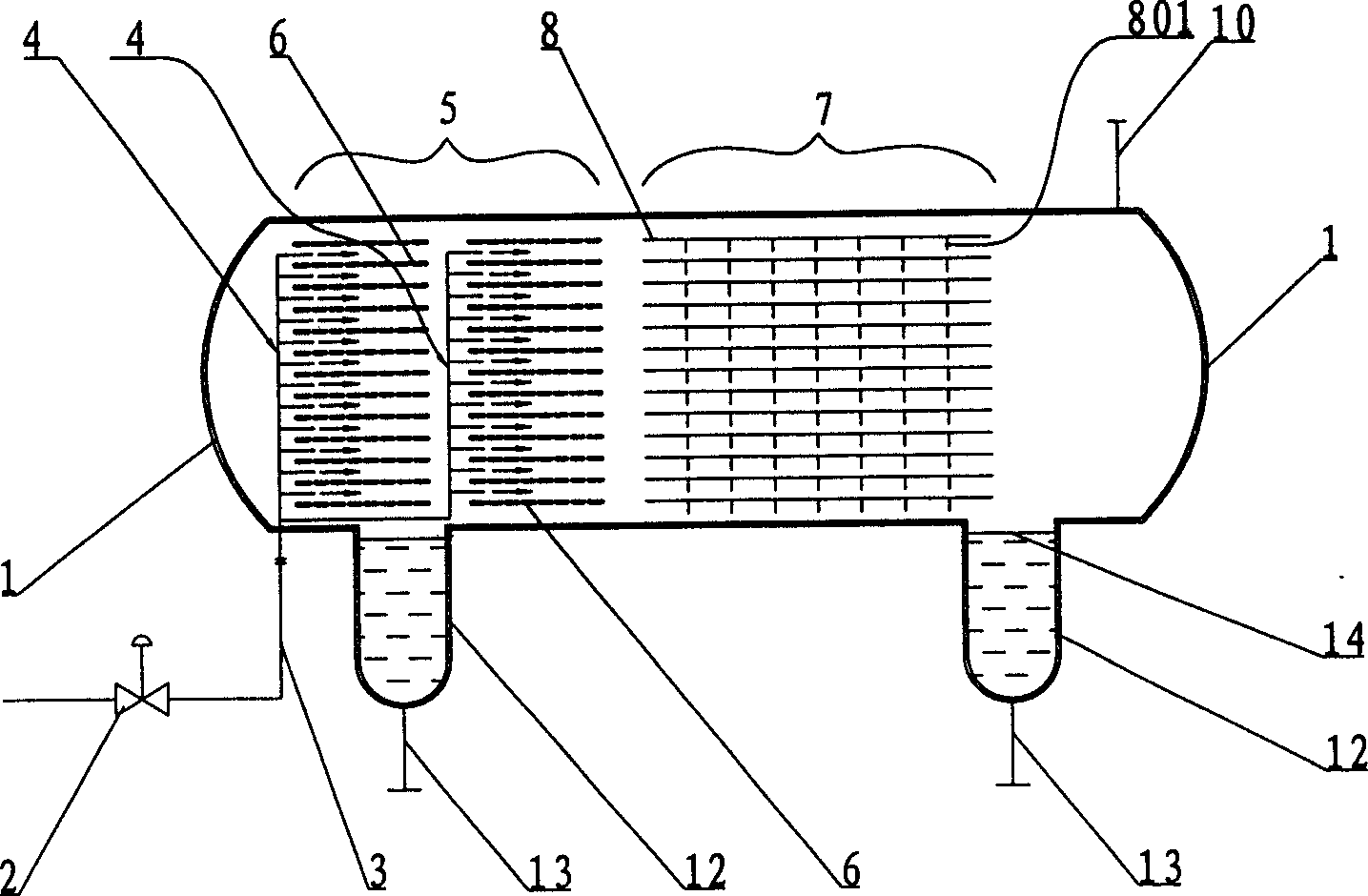

The electrical raw oil desalting and dewatering device for petrochemical industry features its direct material feeding in strong electric field and horizontal flow of raw oil. The electrical raw oildesalting and dewatering device of the present invention has material distributor and strong electric field coalescence area in tank axial direction and oil outlet pipe in the top of the raw oil purifying area, with the strong electric field coalescence area being provided with at least two layers of parallel electrode plates parallel to or perpendicular to the tank axis. The material distributor is provided with nozzles to spray mixed oil-water material into the strong electric field between two adjacent electrode plates. Between the strong electric field coalescence area and the purified raw oil outlet, deposit separating area may be set.

Owner:CHINA PETROCHEMICAL CORP +1

Electric heating dilution furnace

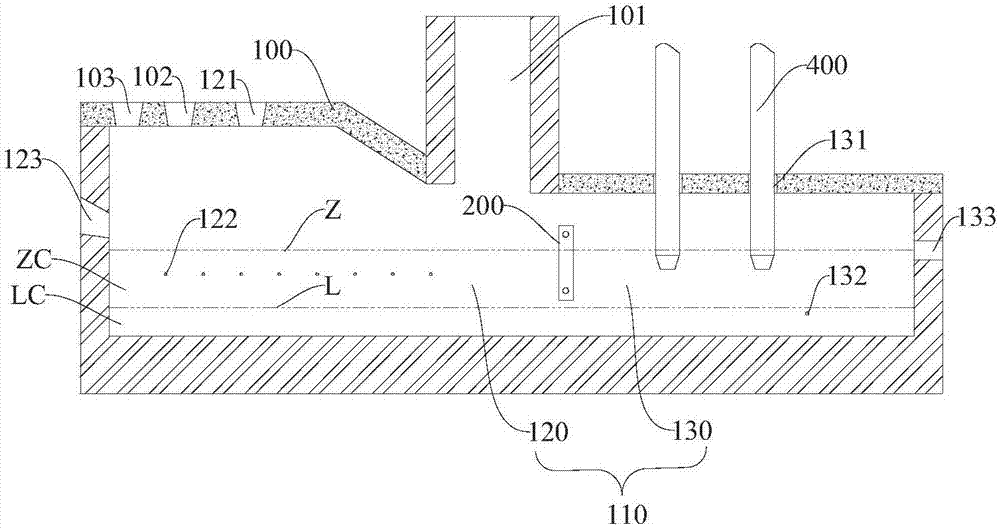

PendingCN107036443ALess investmentSmall footprintCrucible furnacesProcess efficiency improvementSlagElectrode insertion

The invention discloses an electric heating dilution furnace. The electric heating dilution furnace comprises a furnace body, a separation wall, a spraying gun and an electrode, wherein a furnace cavity is defined in the furnace body; the furnace body is provided with a smoke outlet; the separation wall is arranged in the furnace cavity for dividing the furnace cavity into a blowing area and a settling area for communicating up and down; the blowing area is provided with a charging port and a spraying gun insertion hole; the settling area is provided with an electrode insertion hole, a sulfonium outlet and a slag outlet; the spraying gun is inserted in the spraying gun insertion hole for blowing oxygen-enriched gas and a reducing agent into a slag layer in the blowing area; and the electrode is inserted in an electrode insertion hole, and extends into a slag layer in the settling area. The electric heating dilution furnace has the advantages of a side blowing furnace and the electric heating dilution furnace, and is excellent in dilution effect, high in metal recovery rate, low in investment and small in floor area.

Owner:CHINA ENFI ENGINEERING CORPORATION

Electric desalting dewatering device for crude oil

InactiveCN1605615AReduce moisture contentEnhanced electrical coalescenceDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

The present invention is one electric raw oil desalting and dewatering apparatus for petrochemical industry. The present invention features the direct material feeding under strong electric field and the horizontal flow of raw oil. The electric raw oil desalting and dewatering apparatus has a tank with oil-water mixture inlet, axial strong electric field coagulation area with at least two layers of parallel planar electrode plates perpendicular to the axis of the tank, purified raw oil outlet with oil outlet pipe, material distributor inside the tank with nozzles to jet oil-water mixture into the strong electric fields between every two adjacent electrode plates, and depositing separation area set between the strong electric field coagulation area and the purified raw oil outlet.

Owner:CHINA PETROCHEMICAL CORP +1

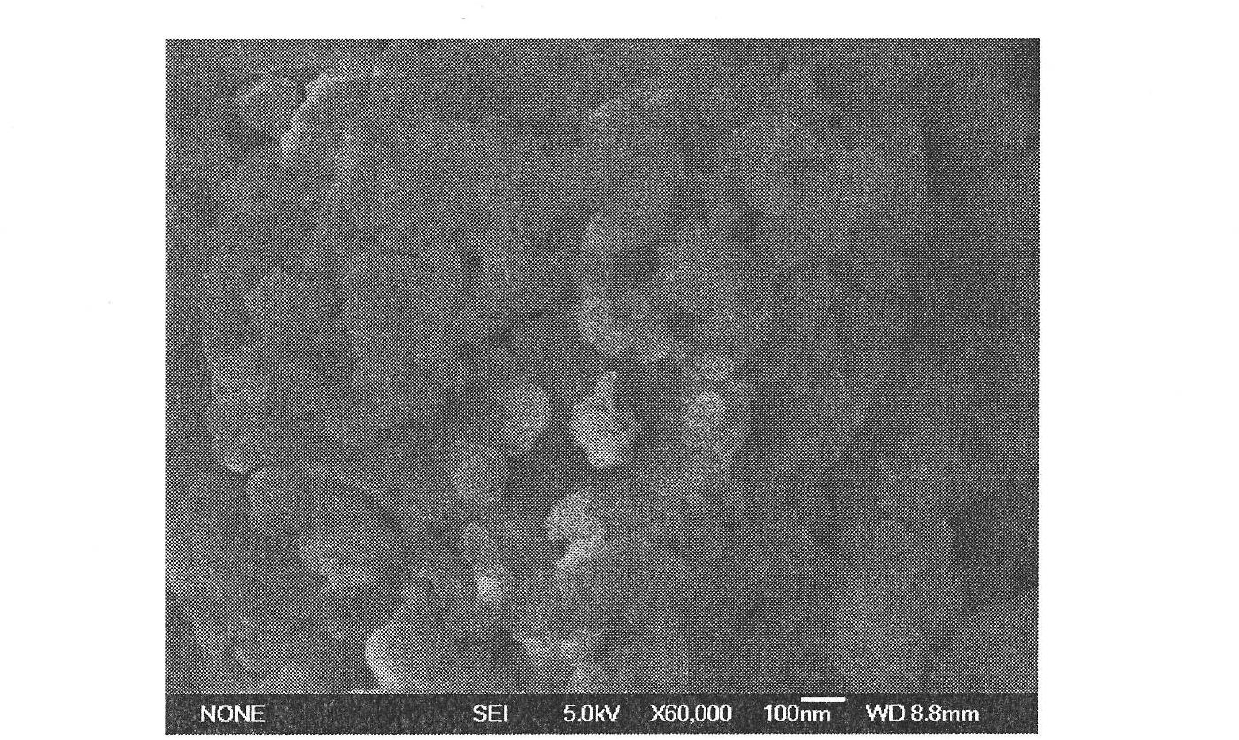

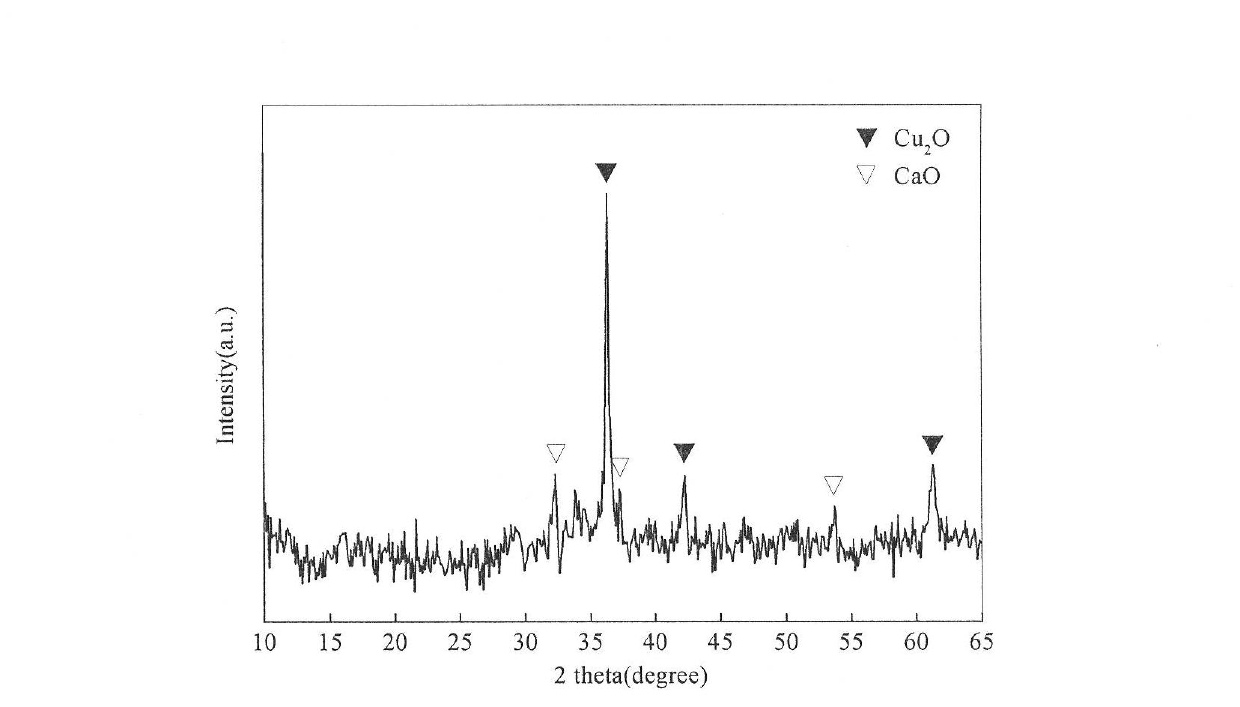

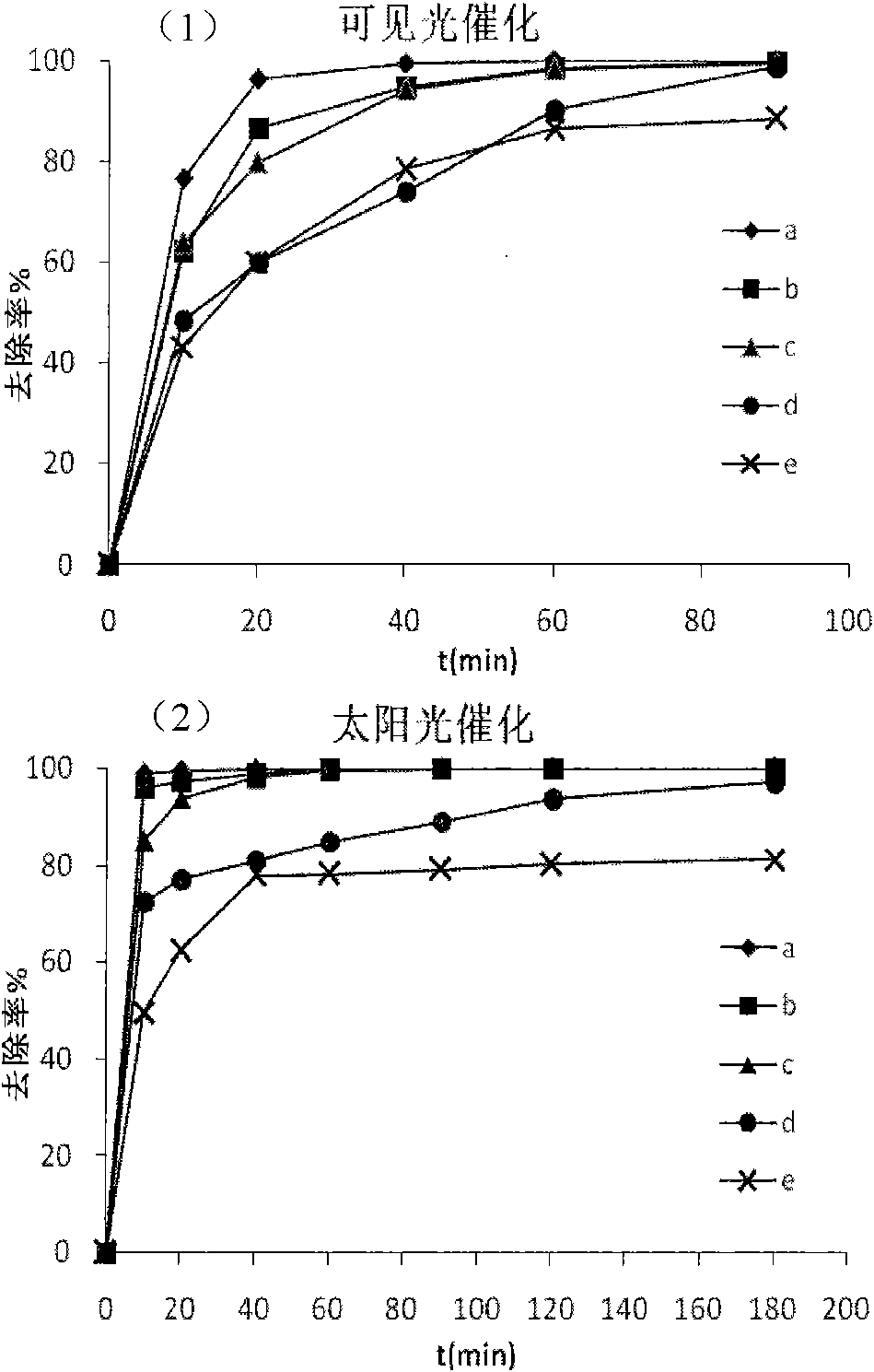

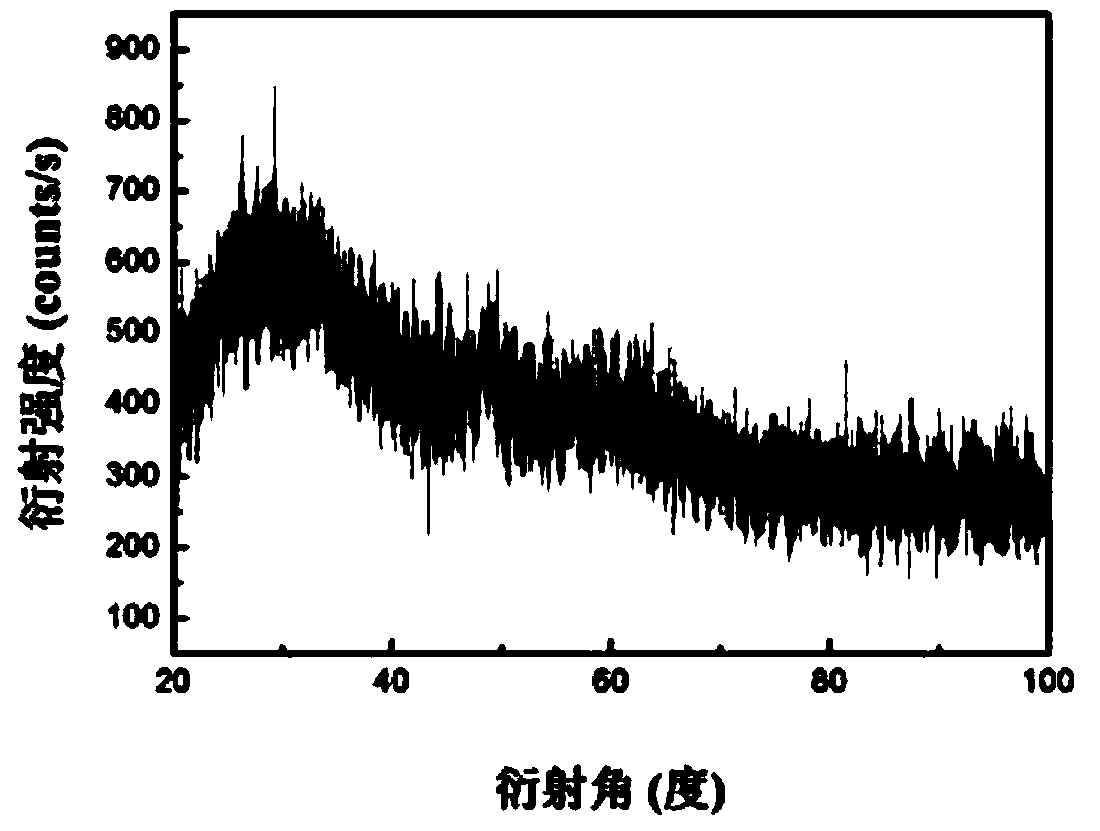

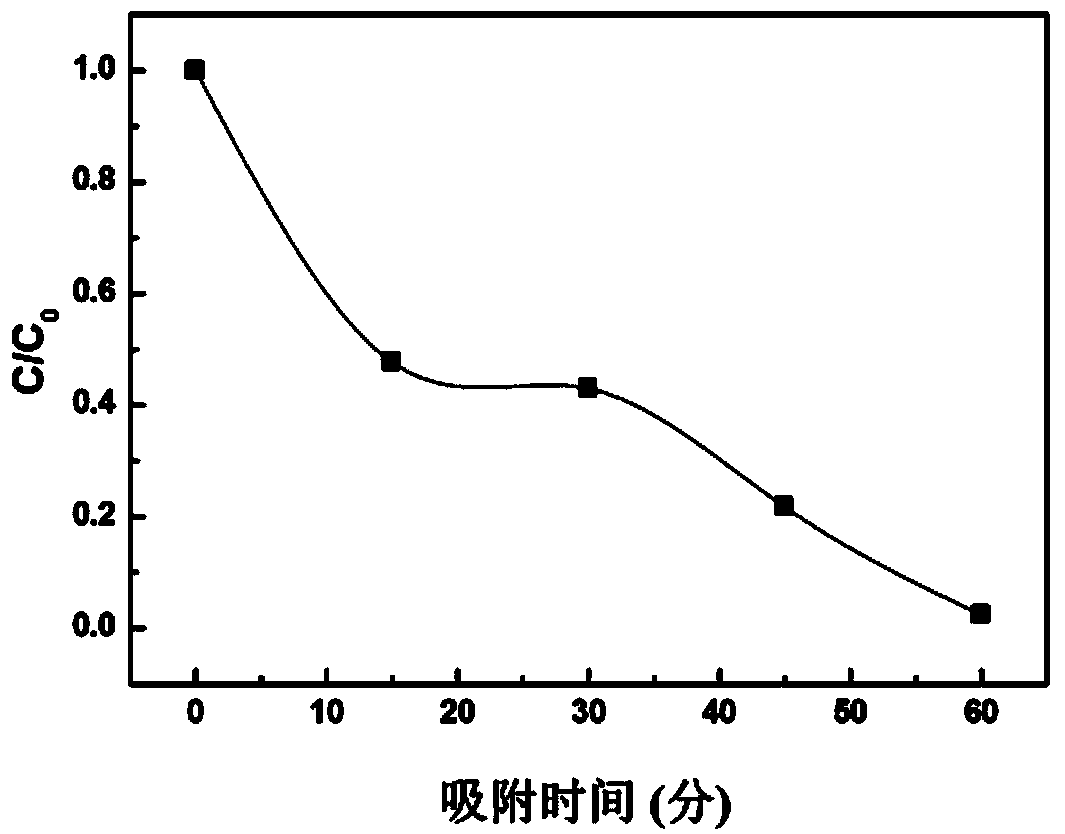

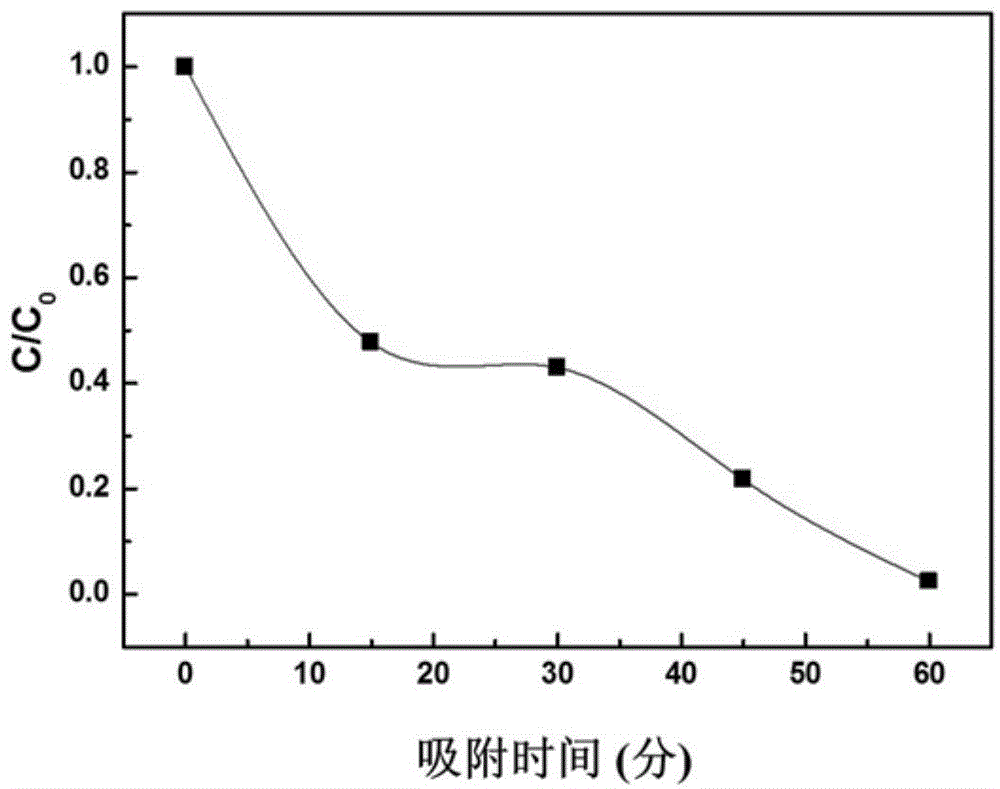

Abandoned shell/nanometer Cu2O composite photocatalyst material as well as preparation and application thereof

InactiveCN102553590AHigh catalytic activityEasy to settle and separateCatalyst carriersWater/sewage treatment by irradiationIonPollutant

The invention provides an abandoned shell / nanometer Cu2O composite photocatalyst material as well as a preparation method and application of the photocatalyst material. The preparation method mainly comprises the steps of activation of shells and in-situ hydrolysis and load of nanometer Cu2O and concretely comprises the steps of: activating the abandoned shells at a high temperature to enhance the alkalinity and porosity, adsorbing and in situ hydrolyzing univalent copper ions in solution by utilizing the developed porosity and alkalinity of the activated shells, drying, dehydrating, tightly loading nanoscale globular Cu2O particles on the surface of the shells and synthetizing the composite photocatalyst material. The invention relates to resource recovery and high-value utilization of wastes on raw materials, utilization of visible light and sunlight on energy and treatment of organic pollutants difficult to degrade by water body on application. The nanometer Cu2O / shell composite photocatalyst material has important significance in environmental protection and the activity of the composite photocatalyst material is greatly superior to that of the nanometer Cu2O.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

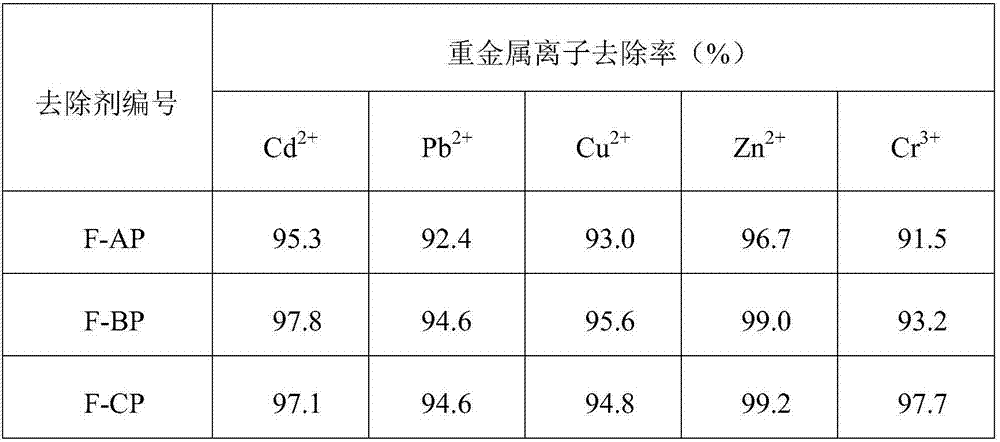

Heavy metal ion removing agent with self-flocculating function and synthesis method thereof

ActiveCN106995221AHigh chelation capacityImprove applicabilityWater contaminantsWater/sewage treatment by flocculation/precipitationSynthesis methodsWastewater

The invention discloses a heavy metal ion removing agent with a self-flocculating function. The heavy metal ion removing agent takes a starch-(C6H10O5)n-structure as a molecular chain subject and active hydroxyl is grafted with epichlorohydrin and linear-chain polyamine and carries a cationic group -N(CH3)<3+>; amino is connected with a functional group -CSS<->. The invention further relates to a synthesis method and application of the heavy metal ion removing agent with the self-flocculating function. By adopting the heavy metal ion removing agent disclosed by the invention, efficient chelating and absorption and self-flocculating precipitation on heavy metal ions are realized; a function of effectively removing complicated wastewater containing the heavy metal ions is greatly improved under the condition that a flocculating agent or a coagulant does not need to be additionally added; the heavy metal ion removing agent can be effectively applied to treatment of various complicated wastewater containing the heavy metal ions.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

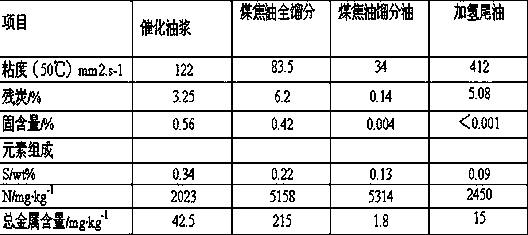

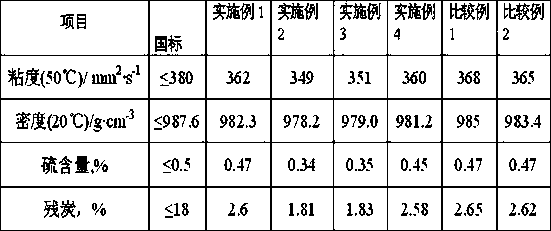

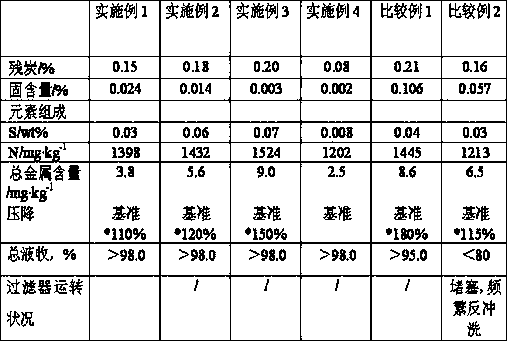

Production method of low-sulfur marine fuel oil

PendingCN111088068ARealize purificationImprove use valueTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses a production method of a low-sulfur marine fuel oil. The production method comprises the following steps: mixing catalytic slurry oil with a first additive, carrying out settling separation after the mixing treatment, obtaining a first material and residues after the separation; introducing the first material into a hydro-processing unit, carrying out a hydrogenation reaction under the action of a hydro-processing catalyst and hydrogen, introducing a liquid-phase effluent obtained after the reaction into a clarification unit, subjecting clarified oil to solid-liquid separation to obtain purified oil slurry, and mixing the purified oil slurry with an inferior raw material (hydrogenation tail oil) to obtain the low-sulfur marine fuel oil. According to the method, thesolid content and the sulfur content of the catalytic slurry oil can be reduced, high-quality purified slurry oil is produced, and the high-quality purified slurry oil is blended with residual oil toproduce the insufficient low-sulfur marine fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

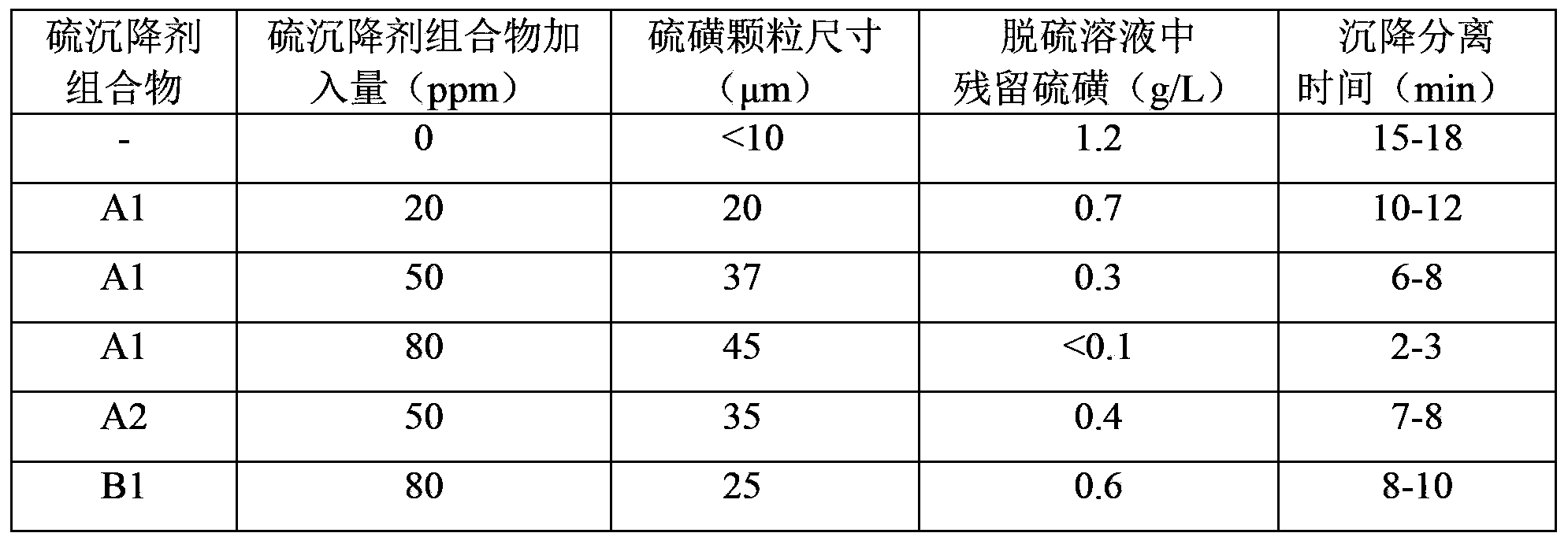

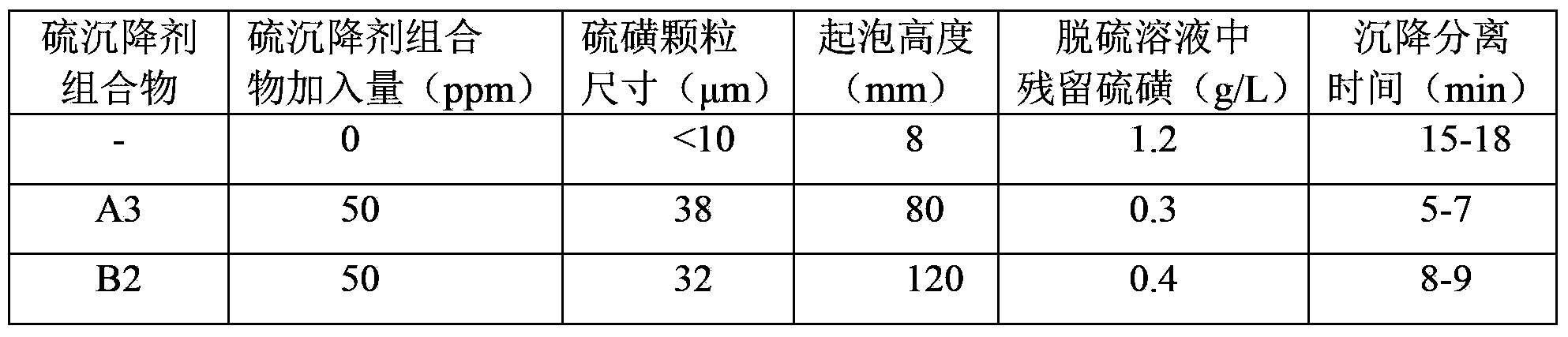

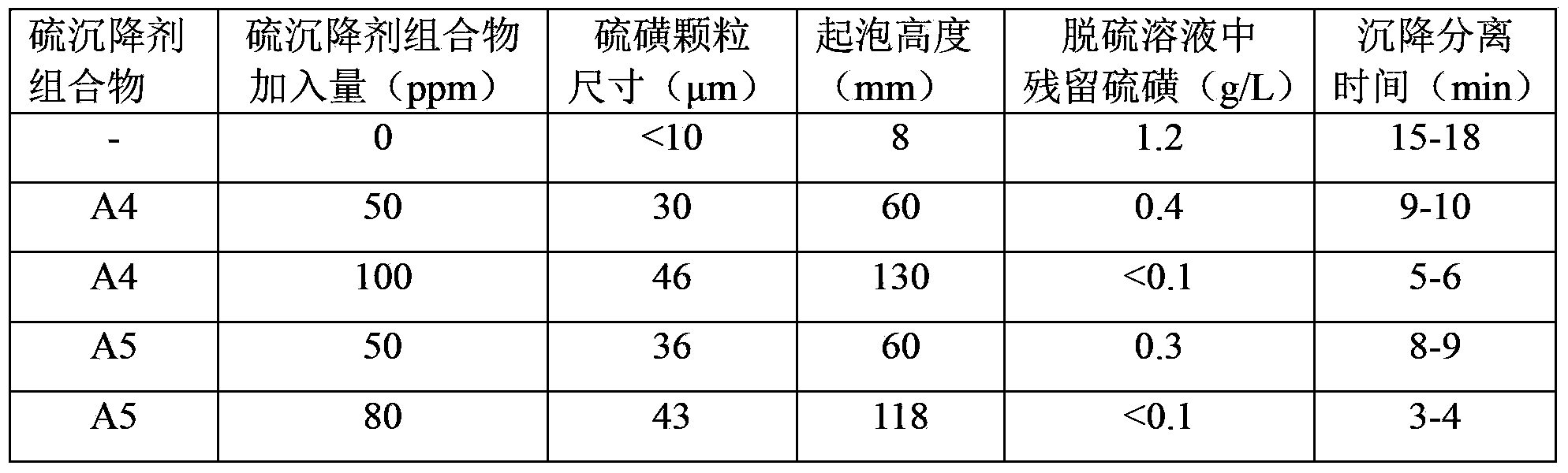

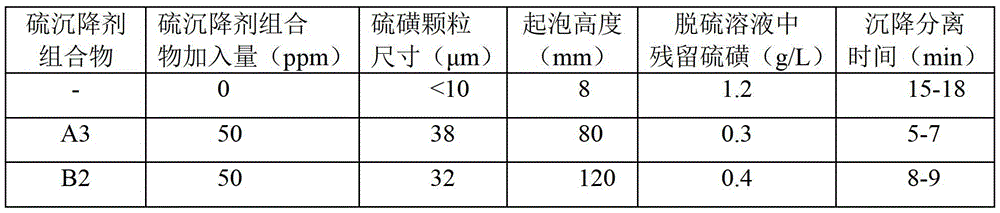

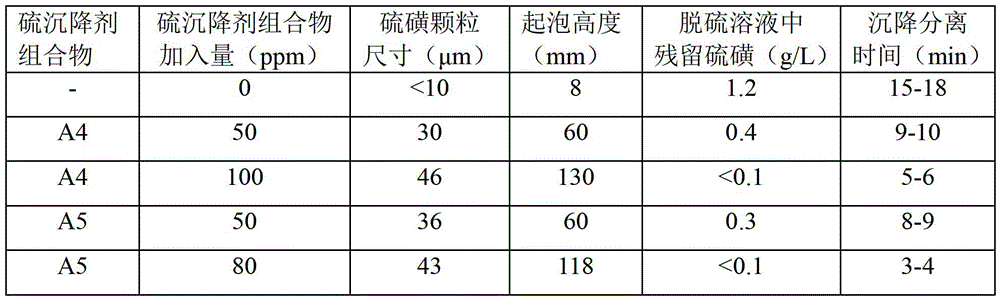

Sulfur deposition agent composition and method for improving liquid phase catalytic oxidation desulphurization effect

ActiveCN104138708AEasy to settle and separateSettling fastDispersed particle separationCatalytic oxidationSulfur deposition

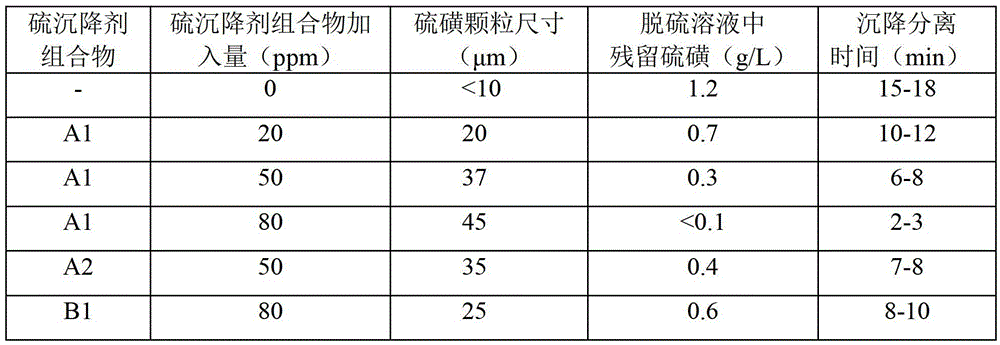

The invention provides a sulfur deposition agent composition including a flocculant, alkyl phenol polyoxyethylene ether with the degree of polymerization of 8-12, alkyl phenol polyoxyethylene ether with the degree of polymerization of 4 - 6 and a cosolvent. The invention also provides a method for improving the liquid phase catalytic oxidation desulfurization effect. When the sulfur deposition agent composition is used for liquid phase catalytic oxidation desulfurization process, large sulfur particles (up to maximum 46 [mu]m can be obtained, the sulfur deposition agent composition can effectively inhibit the sulfur foam production, and improve the sedimentation rate of sulfur particles, and more than 96% of the sulfur particles in a desulfurization solution can be rapidly settled.

Owner:CHINA PETROLEUM & CHEM CORP +1

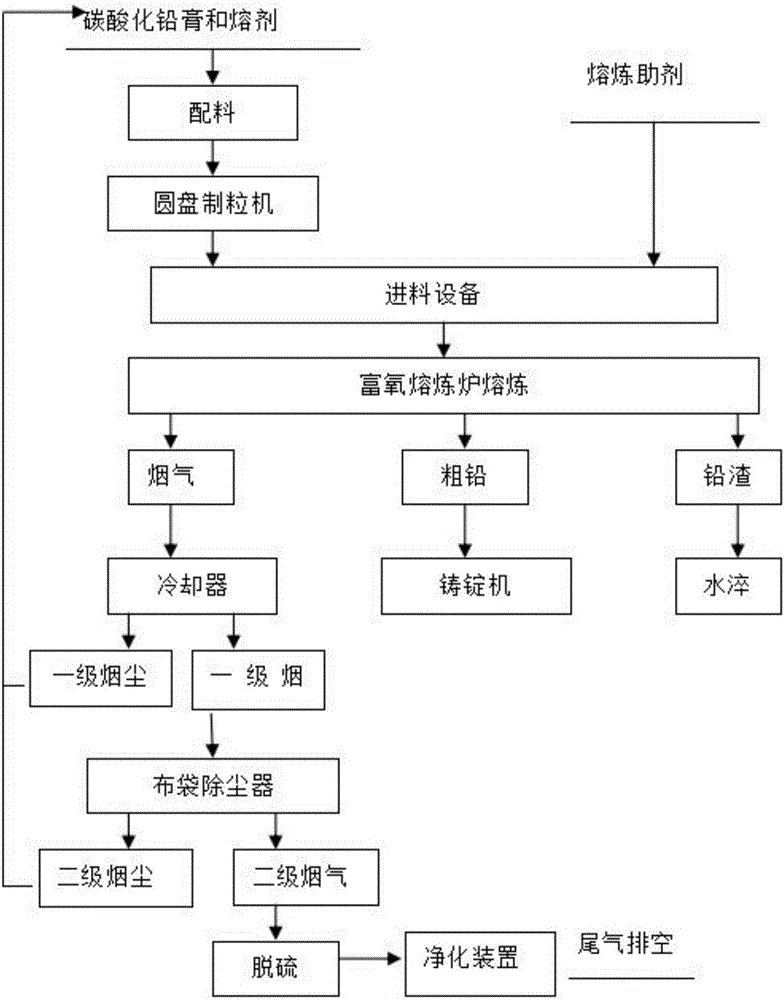

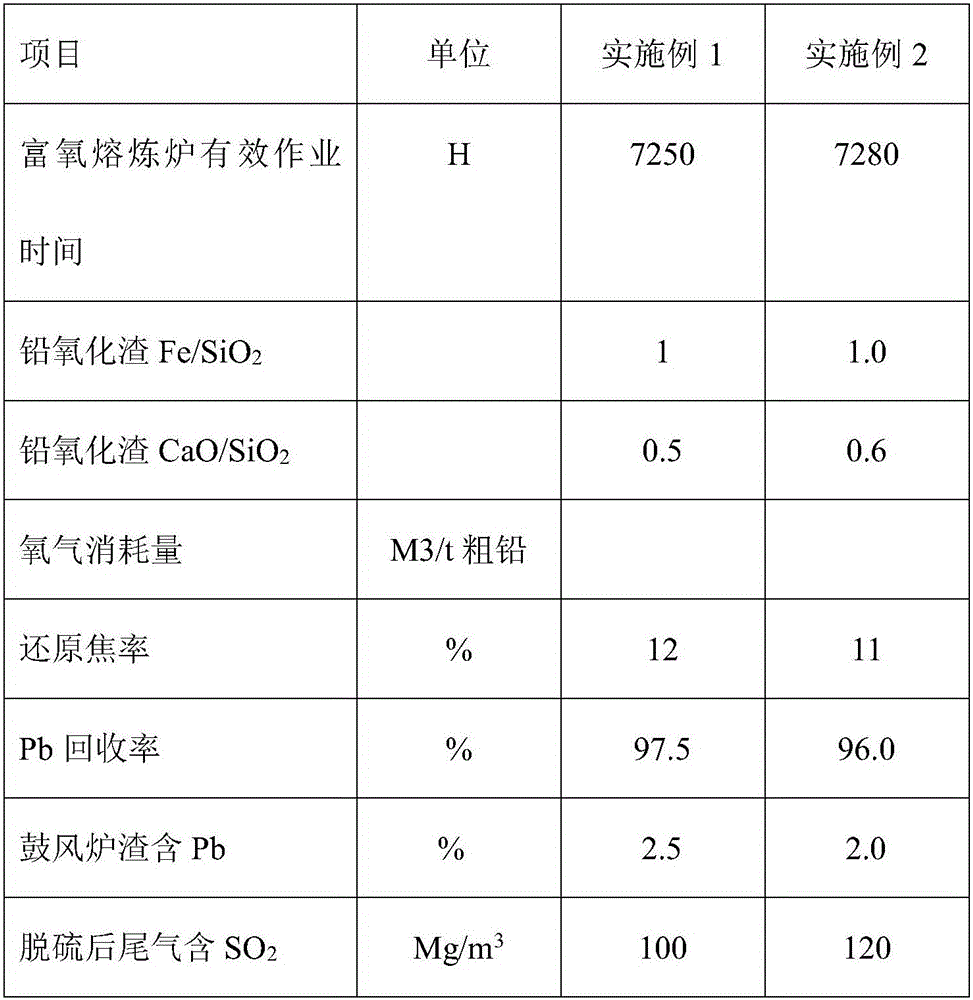

Smelting process for efficient and energy-saving secondary lead

The invention relates to a smelting process for efficient and energy-saving secondary lead. The smelting process comprises the following process steps that after burdening of lead paste which is separated out through automatic disassembly of a waste lead-acid battery and is carbonated and solvent, burdenings are sent into an oxygen-enriched smelting furnace to be subjected to smelting, and crude lead, lead slag and low-concentration SO2 flue gas are produced; and after residual heat recovery and dust collection through a dust collector, the SO2 flue gas is sent to a desulfurization system, is desulfurized and is discharged with standard level, wherein the lead slag, serving as vitrified general wastes, is sold to a cement plant as a raw material; the crude lead is electrolytically refined to obtain refined lead and anode slime, and the refined lead and the anode slime are sold; and a system of realizing the process is composed of an oxygen-enriched side-blown smelting furnace, feeding equipment, slag water quenching equipment, cooling equipment, dust collection equipment and desulfurization equipment. According to the smelting process, with process design and system improvement, elements including Pb, Ag, Cu, Sb and Sn are cleanly and efficiently recovered.

Owner:ANHUI HUAXIN LEAD IND GROUP

Efficient sewage ammonia nitrogen removal agent

InactiveCN108557976AEasy to handleGood flocculation effectWater contaminantsWater/sewage treatment by ion-exchangeSodium BentoniteTreatment effect

The invention discloses an efficient sewage ammonia nitrogen removal agent which consists of the following components in parts by weight: 30-50 parts of magnesium salt, 20-45 parts of phosphate, 10-15parts of ferric sulfate, 10-20 parts of calcium carbonate, 5-10 parts of modified bentonite, 10-20 parts of modified coal ash, 5-15 parts of modified zeolite, 2-10 parts of an attapulgite compound adsorbent, 20-30 parts of sodium hypochlorite and 5-12 parts of a coagulant aid. The efficient sewage ammonia nitrogen removal agent has the beneficial effects that metallic salts, phosphate and ammonium ions form precipitate in water, effective adsorption and ion exchange of ammonia nitrogen in the water can be carried out through the modified bentonite, the modified coal ash, the modified zeoliteand the attapulgite compound adsorbent, ammonia in the water can be converted into nitrogen which is removed later through the sodium hypochlorite, the pH value of sewage can be adjusted by the calcium carbonate, the flocculation effect of the precipitate can be improved by the coagulant aid, precipitate sedimentation and separation can be promoted, and the agent is applicable to wide pH value ranges, has a good treatment effect on low-concentration ammonia nitrogen wwaste3water, and is environmental-friendly.

Owner:东莞市顶盛环保科技有限公司

Two-way solvent extraction method of regenerated base oil

InactiveCN104178332AHigh yieldEnvironmental protection is goodTreatment with plural serial refining stagesLubricant compositionAmyl alcoholDistillation

The invention relates to a two-way solvent extraction method of regenerated base oil. The method comprises the following steps: extracting distillate oil separated from waste lubrication oil in a two-stage reduced pressure distillation manner by virtue of a mixed solvent composed of N-methyl-2-pyrrolidone, butyl alcohol and amyl alcohol; further carrying out reduced pressure distillation on raffinate oil after the extraction so as to separate out a mixed solvent and a regenerated base oil product; carrying out the reduced pressure distillation on an extracting liquid after the extraction so as to separate the mixed solvent and residues; recycling the mixed solvents. The method has the advantages of high extraction efficiency, good settlement separation effect and high base oil yield. In addition, the N-methyl-2-pyrrolidone is nearly harmless to a human body and an environment, so that the quality of refined oil is improved; a carclazyte refining process is omitted, so that the environment is prevented from being polluted by carclazyte slag, and the yield of the regenerated base oil is improved at the same time.

Owner:ANHUI GUOFU LUBRICANT IND

Method of dissolving high grade gibbsite type bauxite by bayer process

InactiveCN1923696AEasy to settle and separateImprove silicon content indexAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxides/hydroxidesSiliconMaterials science

The invention discloses a high-grade aluminum trihydrate bauxite stripping method through Baeyer method, which is characterized by the following: increasing the content of pre-stripped silicon pulp; adding circulated mother liquid after normal silicon pre-stripping reaction; adjusting pulp to normal content; stripping in the flux course.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

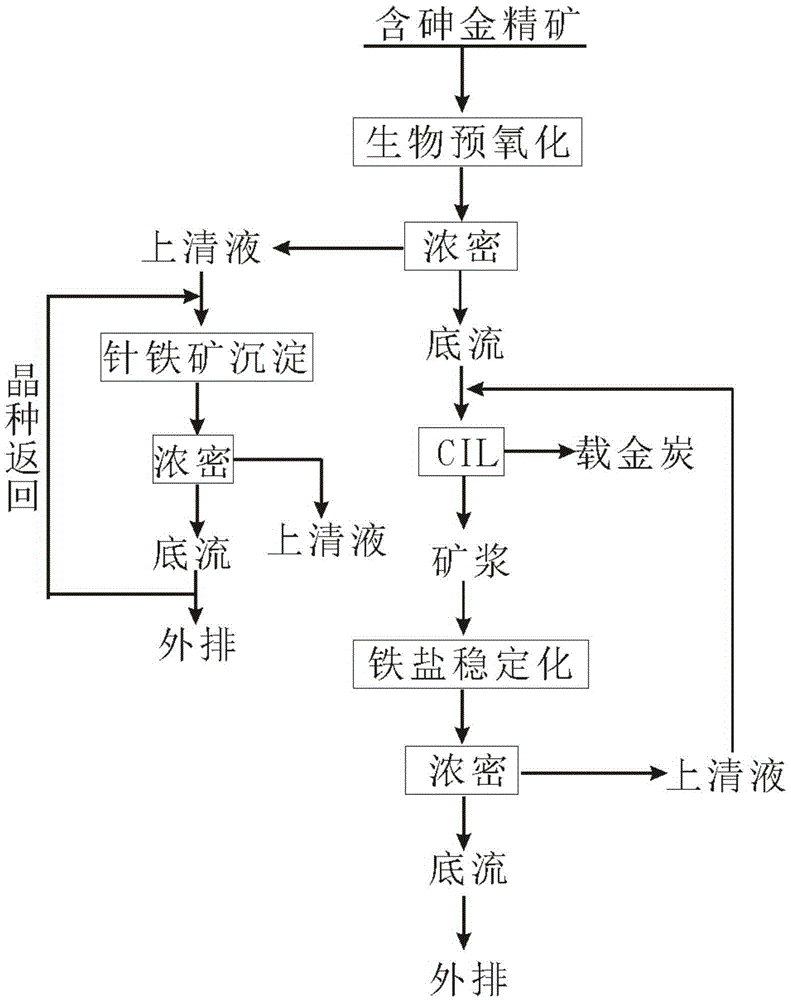

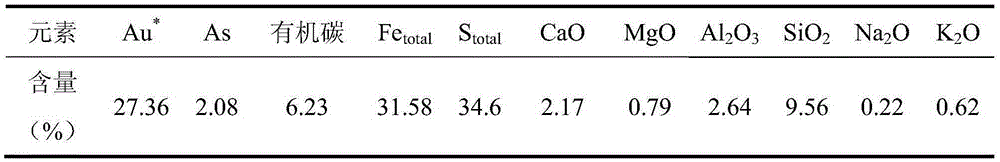

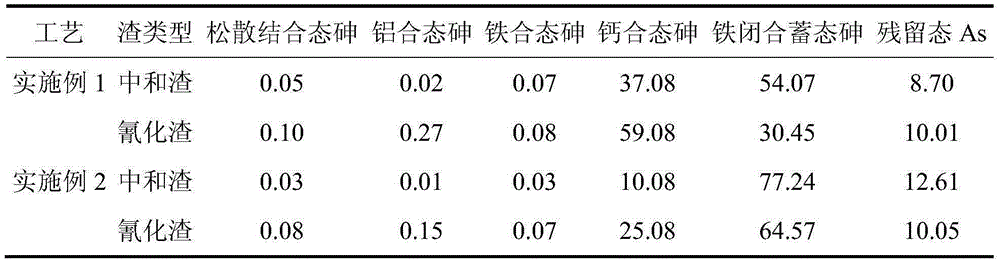

Harmless treatment method of arsenic-bearing slag liquid of biological preoxidation-cyanidation gold extracting process of arsenic-bearing gold concentrate

The invention discloses a harmless treatment method of arsenic-bearing slag liquid of the biological preoxidation-cyanidation gold extracting process of arsenic-bearing gold concentrate. The method includes the steps of firstly, pre-oxidizing the arsenic-bearing gold concentrate with a biological tank leaching process to obtain pre-oxidized ore pulp; secondly, performing solid-liquid separation on the pre-oxidized ore pulp to obtain first supernate and first underflow; thirdly, pre-neutralizing the first supernate, and performing solid-liquid separation on the pre-neutralized first supernate to obtain second supernate and second underflow; fourthly, performing goethite iron precipitation and arsenic fixing on the second supernate for 2-4 hours, and then performing solid-liquid separation to obtain overflow liquid and third underflow, allowing the overflow liquid to enter the biological tank leaching process, allowing part of the third underflow serving as seed crystal to return to the reaction device of the iron precipitation and arsenic fixing, and discharging the rest of third underflow; fifthly, performing cyanidation carbon-in-pulp leaching on the first underflow to obtain ore pulp; sixthly, performing ferric salt aeration arsenic fixing on the ore pulp obtained in the fifth step. The method provides necessary technical support for the environment-friendly, efficient and low-cost development of the arsenic-bearing gold concentrate.

Owner:厦门紫金矿冶技术有限公司

Method for processing cationic dye wastewater by utilizing direct dye wastewater

InactiveCN101811746ARealize resource utilizationReduce processing costsOther chemical processesWater/sewage treatment by sorptionSludgeDyeing wastewater

The invention relates to a method for processing cationic dye wastewater by utilizing direct dye wastewater. The method comprises the following steps: drying hybridization sludge obtained from hybridizing direct dye wastewater by barium sulfate, and crushing the sludge to obtain hybridization sludge adsorbent of 200-300 meshes; adding the hybridization sludge adsorbent which accounts for 3%-5% of the cationic dye wastewater by weight into the cationic dye wastewater to be processed, stirring and separating solid and liquid to obtain adsorption sludge the moisture content of which is 60%-80% and supernatant, carrying out advanced processing on supernatant and then discharging, wherein the chrominance removal rate of the supernatant is above 90%, and the COD removal rate is above 60%. The adsorption sludge is regenerated to obtain regeneration sludge absorbent with the same effect as hybridized sludge absorbent. The invention has the characteristics of simple method, good adsorption property, easy settlement and separation, ability of recycling and the like. The method solves the problem of sludge processing, and simultaneously processes cationic dye wastewater to realize the processing of waste with process of waste and the recycling utilization of waste, thus the method can be promoted and applied to processing of cationic dye and other organic fine chemical enterprise wastewater.

Owner:TONGJI UNIV

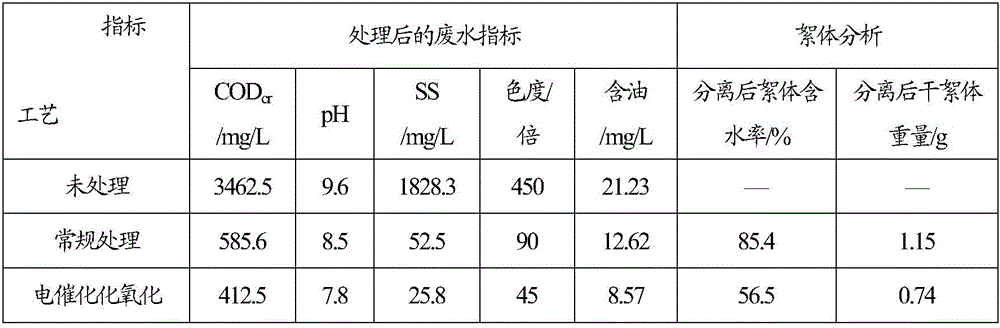

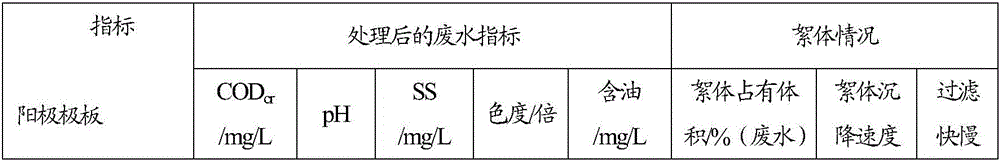

Treatment method for wastewater of oil and gas field

ActiveCN106315960AReduce passivationReduce scaling and corrosionWaste water treatment from quariesWater/sewage treatmentFlocculationTreatment effect

The invention discloses a treatment method for wastewater of oil and gas fields. The treatment method comprises the following steps: carrying out electrocatalytic oxidation treatment on wastewater under the pulsed power supply condition, then adding a magnetic flocculant for carrying out flocculation precipitation reaction, and carrying out magnetic separation and solid-liquid separation, so as to obtain treated oil and gas field wastewater. The treatment method disclosed by the invention has good treatment effect on the wastewater of the oil and gas fields, recycling utilization rate of the treated wastewater is high, the technology is simple and automated control can be easily realized.

Owner:SOUTHWEST PETROLEUM UNIV +1

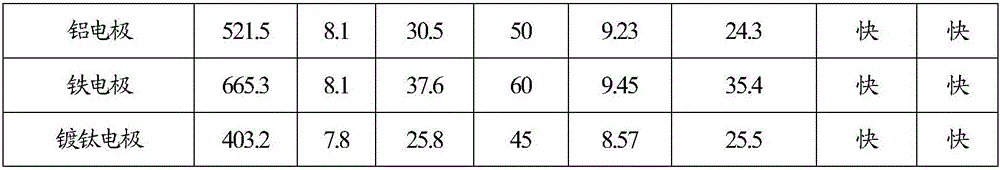

Ethyl polyethylene polyamine polymethacrylate chelating flocculant and preparation method thereof

InactiveCN103112937APromote the growth of flocsThe flocs are dense and coarseWater/sewage treatment by flocculation/precipitationCarbon disulfidePolyethylene polyamine

The invention discloses an ethyl polyethylene polyamine polymethacrylate heavy metal chelating flocculant and a preparation method thereof. The method adopts a technical scheme comprising the following steps of: carrying out addition reaction on polyethylene polyamine and ethylene oxide under an alkaline condition to prepare N-ethyl polyethylene polyamine, carrying out ester exchange reaction on N-ethyl polyethylene polyamine and methyl methacrylate in the presence of a catalyst and a polymerization inhibitor to synthesize ethyl polyethylene polyamine methacrylate, synthesizing ethyl polyethylene polyamine polymethacrylate through free radical polymerization, and then performing reaction on ethyl polyethylene polyamine polymethacrylate and carbon disulfide under the alkaline condition to generate the ethyl polyethylene polyamine polymethacrylate chelating flocculant. The ethyl polyethylene polyamine polymethacrylate chelating flocculant overcomes defects such as low relative molecular mass and no functional groups on sectional chain links of high-polymer heavy-metal chelating flocculants. The ethyl polyethylene polyamine polymethacrylate chelating flocculant not only has a good chelating function, but also has an excellent flocculating property, is applicable to the treatment of various heavy metal wastewater, and has broad popularization application value.

Owner:HUNAN UNIV OF SCI & TECH

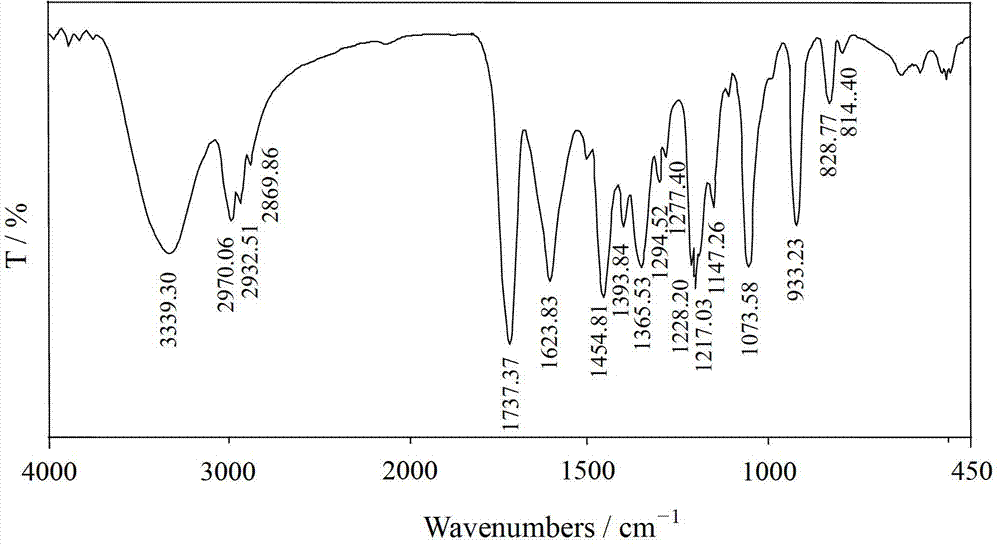

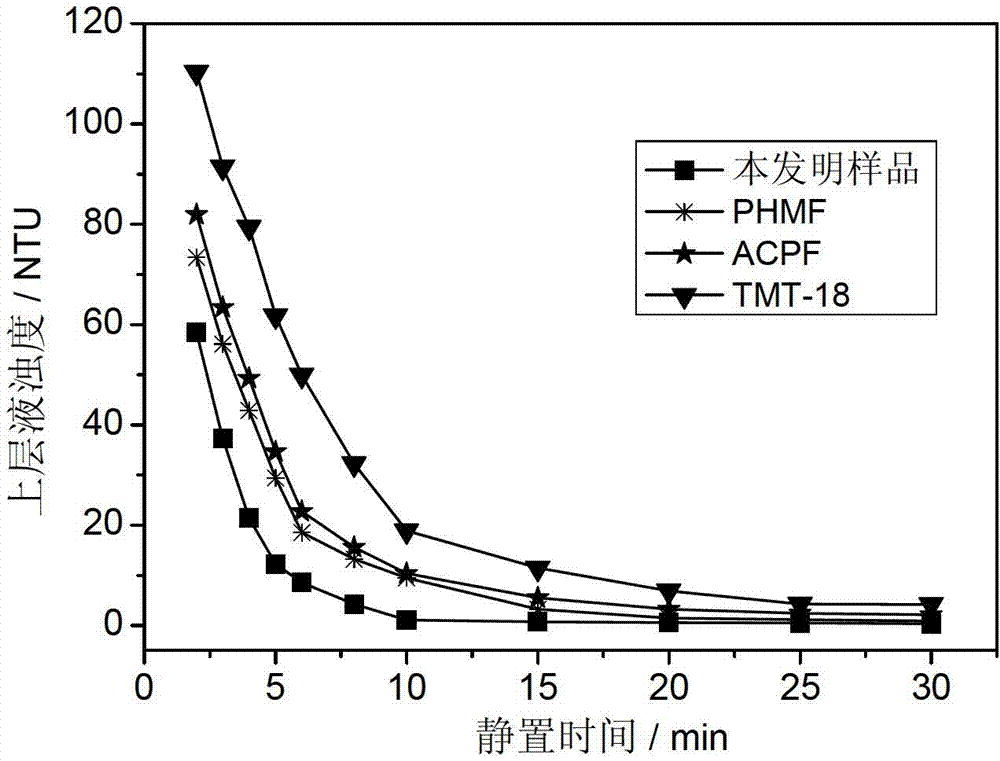

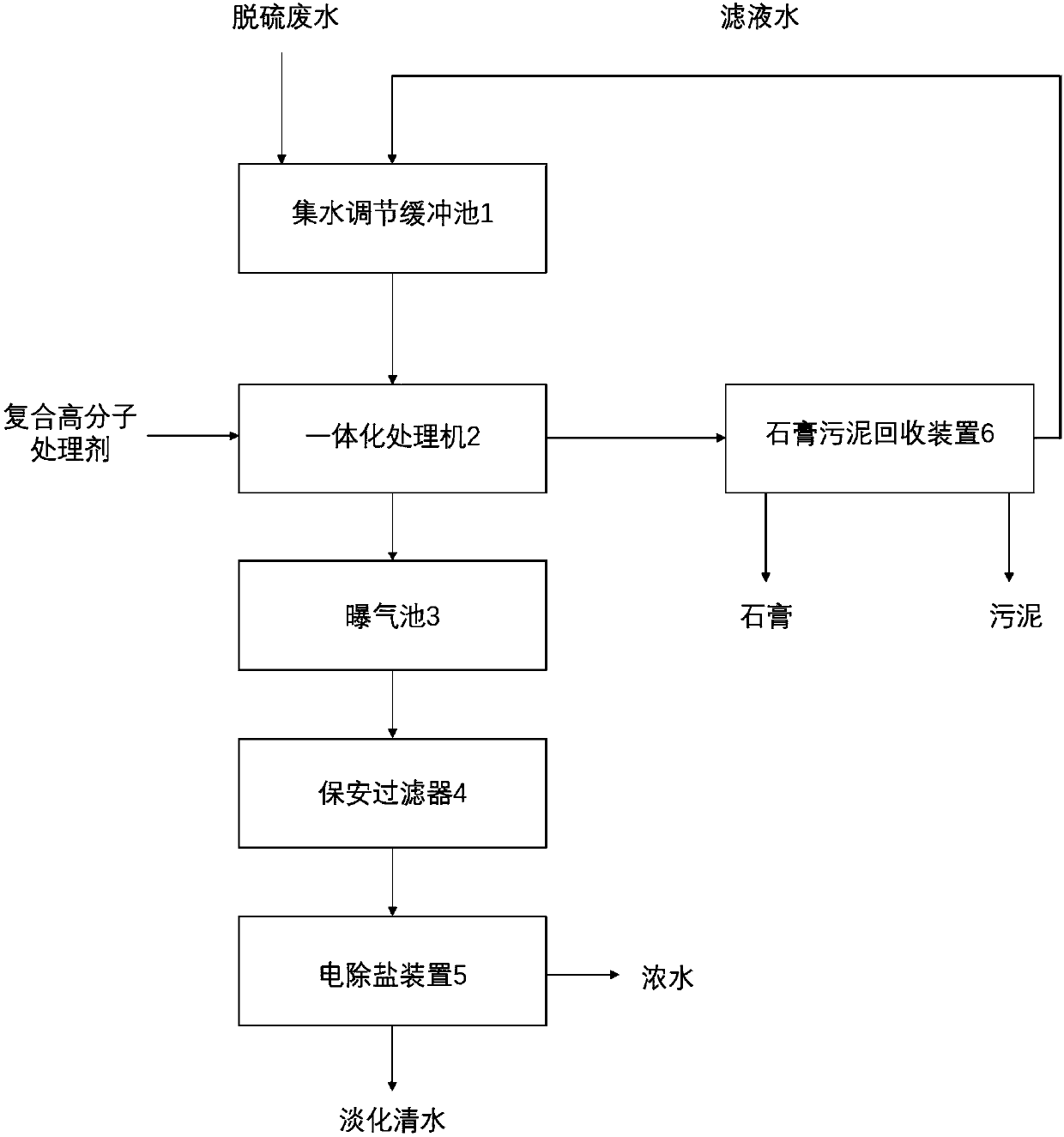

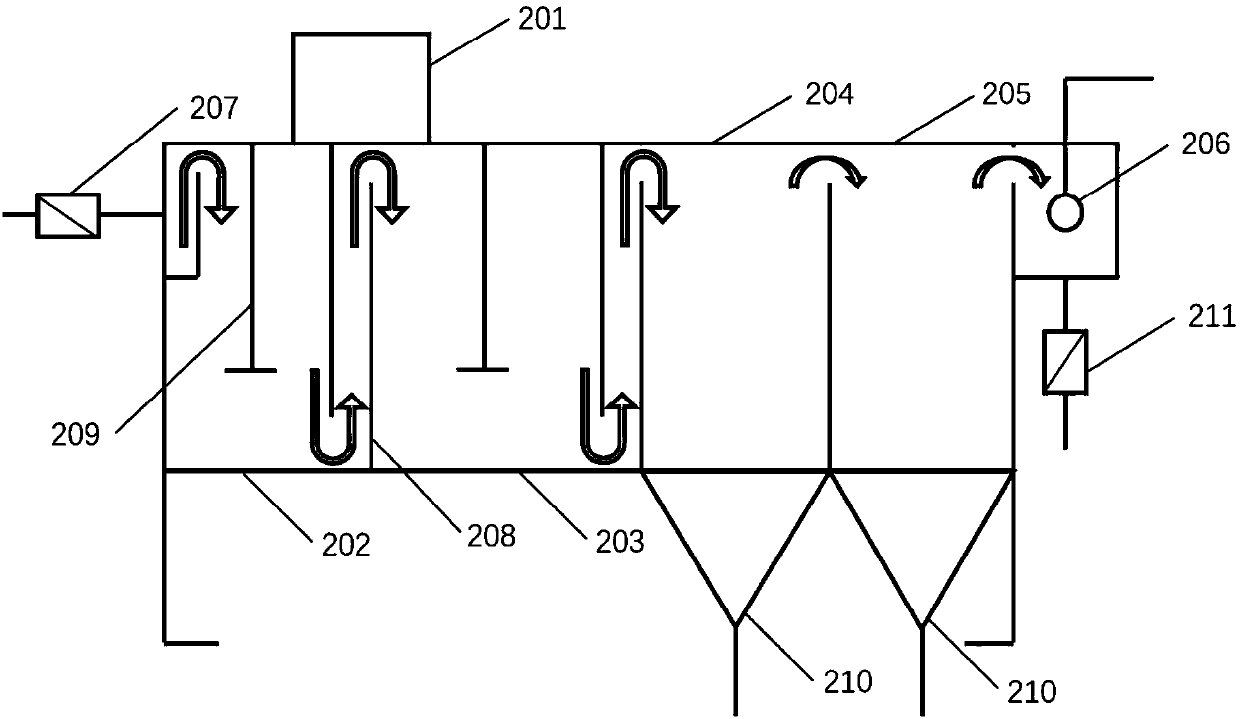

Desulfurization waste water treatment system and treatment method thereof

ActiveCN107867770AImprove efficiencyEasy to settle and separateTreatment involving filtrationWaste water treatment from gaseous effluentsParticulatesElectricity

The invention relates to a desulfurization waste water treatment system and a treatment method thereof. The system comprises a water collecting, adjusting and buffering pond, an integral treatment machine, an aeration pond, a security filter and an electro-deionization device. The integral treatment machine is provided, so that integral treatment of two essential processes of removing heavy metalsand fine suspended matters in desulfurization waste water is realized, the heavy metals contained in the waste water are chelated into a chelate compound, and the fine suspended matters per se in thewaste water are combined and flocculated into flocculating constituents; a chelating process and a flocculating process are performed in stages, so that the reaction processes are prevented from interfering with each other, and are facilitated synergistically; clear water deposited after integral treatment is desalted fully by an electro-deionization technology, and switching between an electro-deionization process and an electrode regeneration process is realized automatically based on transduction. The desulfurization waste water treatment system has the advantages of high automatic fine control degree, and stable and efficient treatment effect.

Owner:湖南钜晟环保科技股份有限公司

Smelting process for efficient and energy-saving regenerated lead

InactiveCN110551899AResolve recovery rateReduce lossesProcess efficiency improvementLead smeltingSmelting process

The invention discloses a smelting process for efficient and energy-saving regenerated lead. The smelting process for the efficient and energy-saving regenerated lead is characterized by comprising the following steps: step S1, preparation for a lead raw material for smelting; step S2, treatment for a lead paste; step S3, forming for the lead smelting raw material; step S4, smelting treatment; andstep S5, by-product aftertreatment. The invention further discloses the efficient and energy-saving regenerated lead prepared according to the smelting process for the efficient and energy-saving regenerated lead. The smelting process for the efficient and energy-saving regenerated lead is capable of efficiently, rapidly and safely smelting lead scraps and wastes into the regenerated lead, so that resource recycling is realized, waste is turned into wealth, and the problems of low metal recovery rate and high lead content of slag in an existing smelting process for regenerated lead, and environment pollution caused by the generation of lots of smoke containing lead, sulfur dioxide and acid mist, are solved; and the smelting process for the efficient and energy-saving regenerated lead hasthe advantages of being high in lead direct-recovery rate, comprehensive recovery rate and labor productivity, low in precious metal loss, and high in economic value, ecological value and social value.

Owner:骆驼集团(安徽)再生资源有限公司

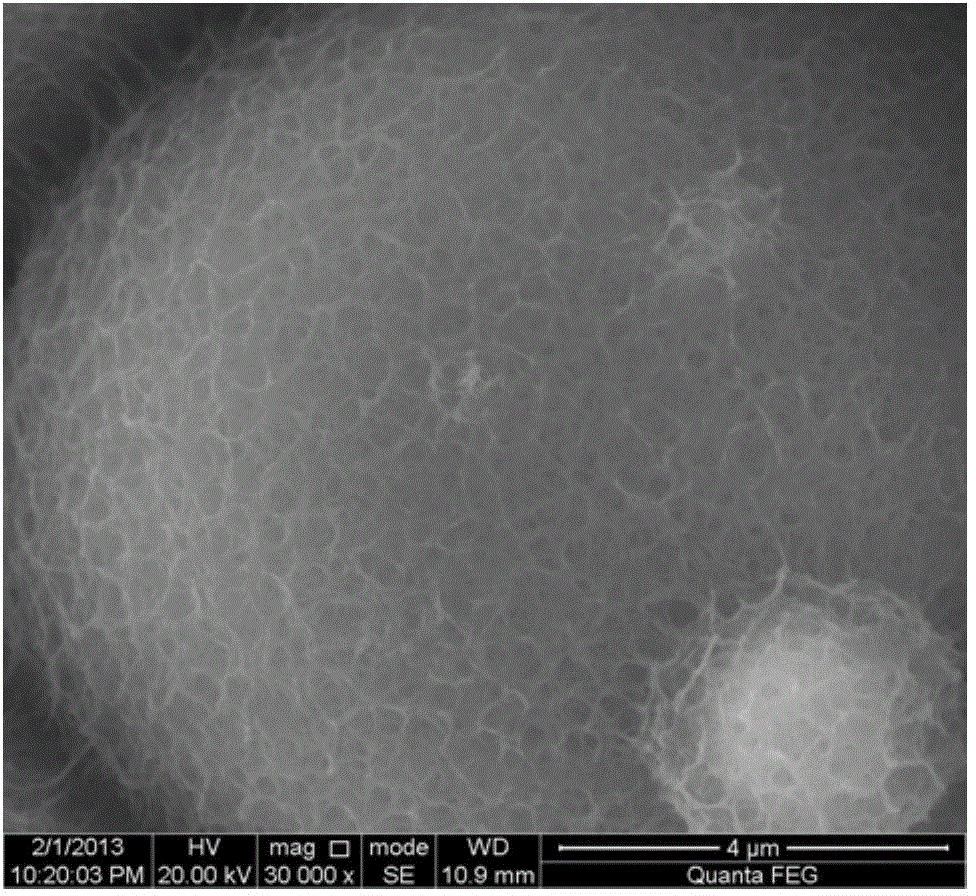

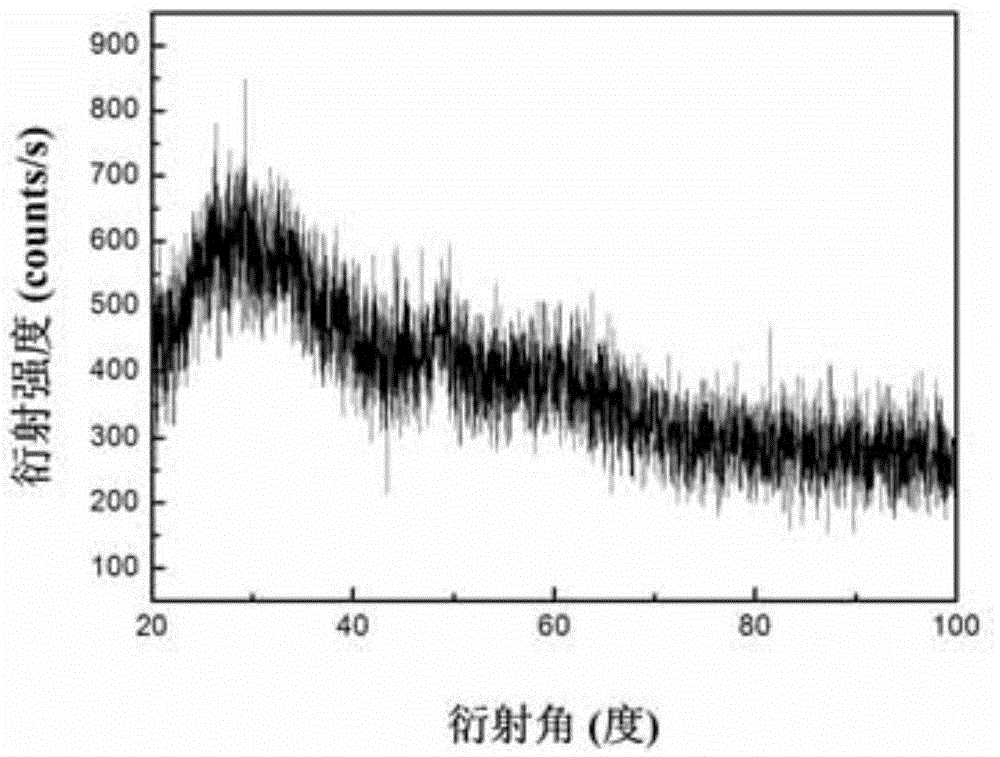

Core-shell type amorphous metal oxide adsorbent, as well as preparation method and application thereof

ActiveCN103623770AEasy to recycleEasy to reuseOther chemical processesWater contaminantsSorbentAmorphous metal

The invention discloses a core-shell type amorphous metal oxide adsorbent, as well as a preparation method and an application thereof and relates to the amorphous metal oxide adsorbent, as well as the preparation method and the application thereof. The invention aims at solving the problems that the nano-metal oxide adsorbent prepared by an existing method is easy to inactivate and agglomerate in a water solution, less prone to sedimentation and difficult to recover and reutilize. The core-shell type amorphous metal oxide adsorbent is prepared from amorphous alloy powder through a hydrothermal method. The method comprises the following steps: 1) placing sodium hydroxide and water into a closed reaction container, then adding the amorphous alloy powder for reaction, and then naturally cooling to room temperature to obtain a reaction product; and 2) regulating the pH value to neutrality, then standing and separating to obtain a solid product, and drying the solid product till constant weight to obtain the core-shell type amorphous metal oxide adsorbent. The core-shell type amorphous metal oxide adsorbent can be used as a toxic Cr<6+> ion adsorbent for adsorbing toxic Cr<6+> ions in water.

Owner:HARBIN INST OF TECH

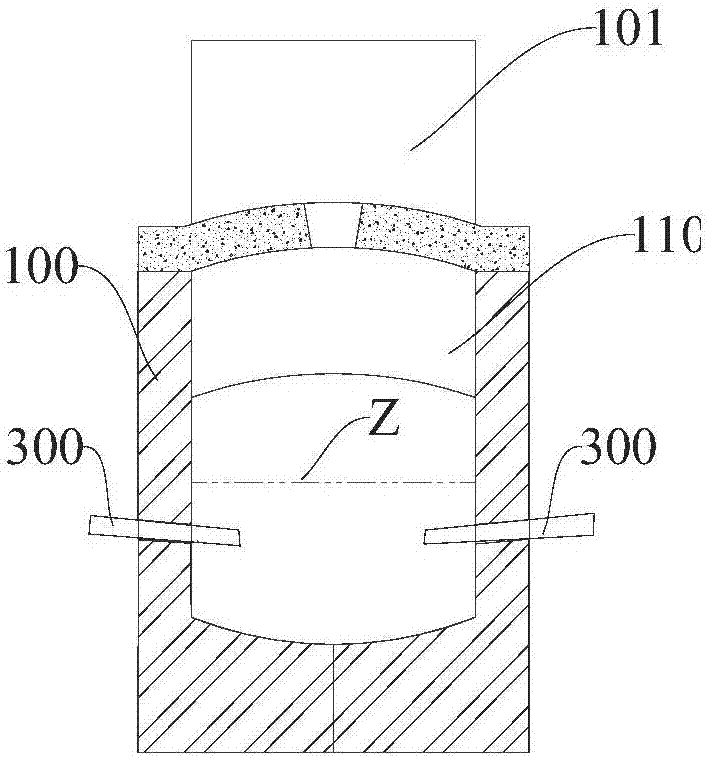

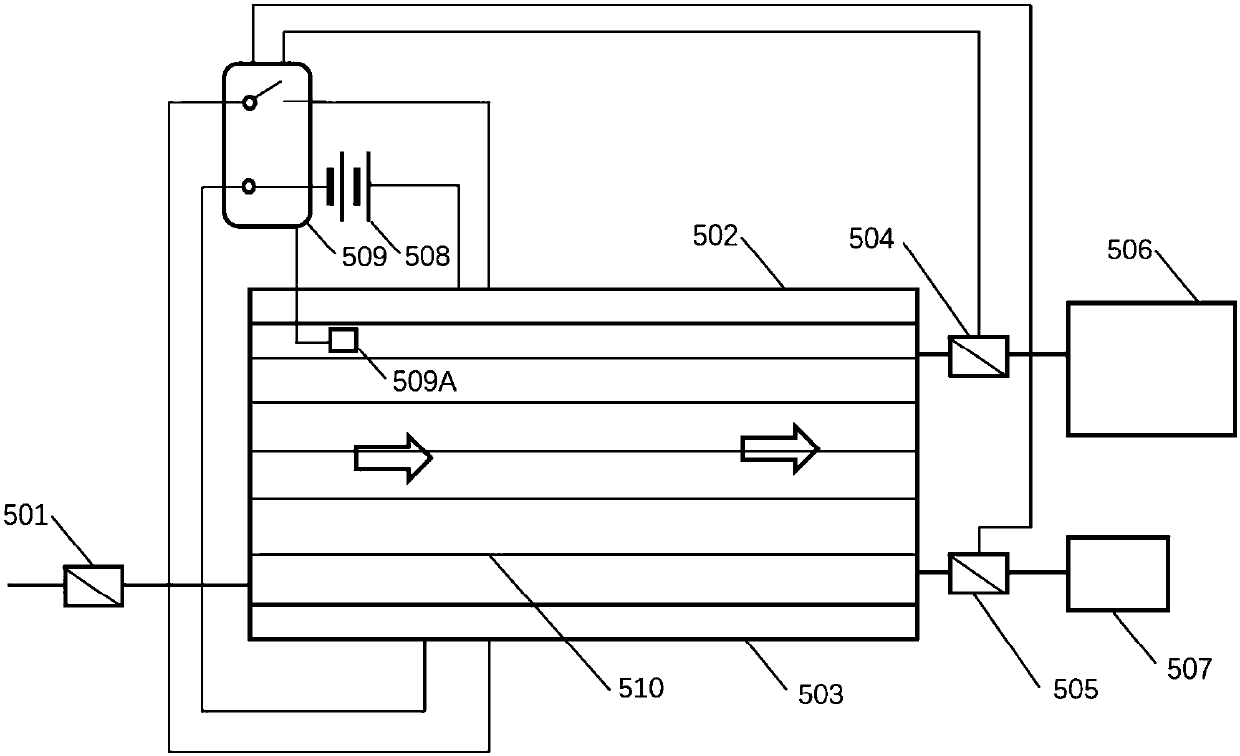

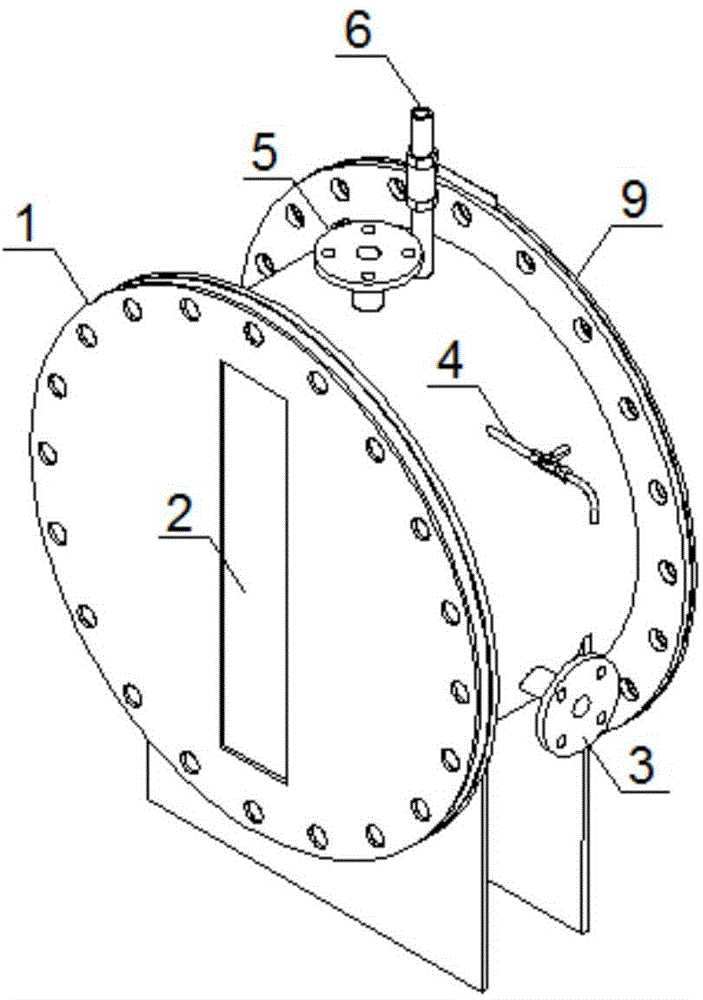

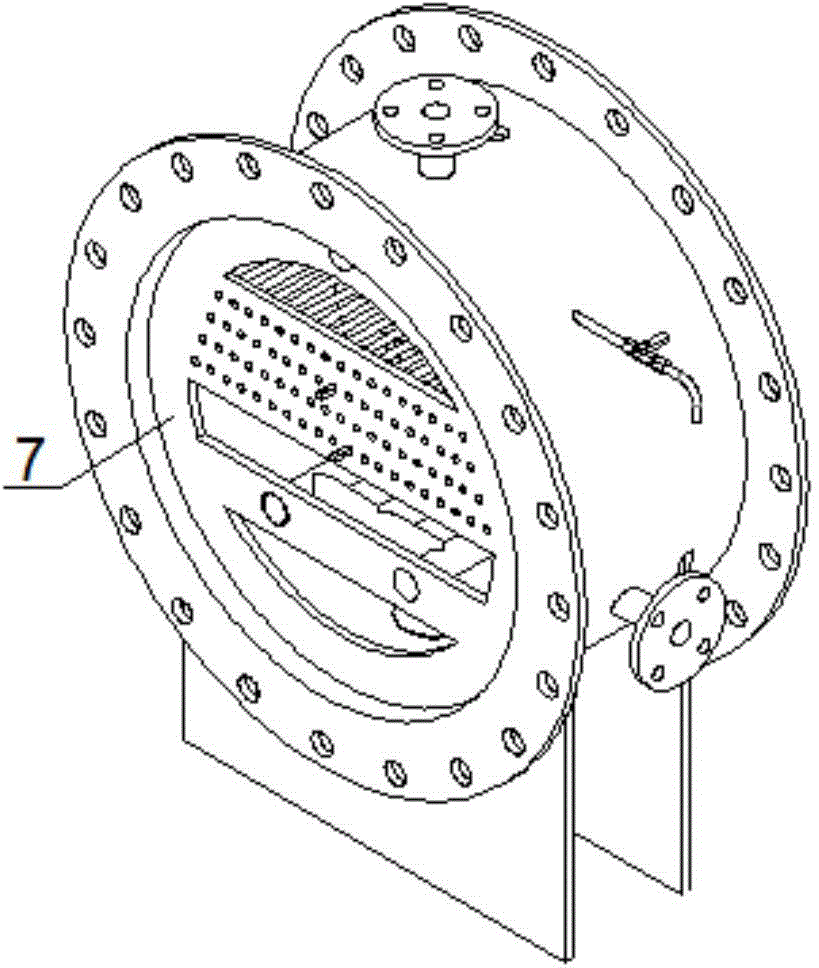

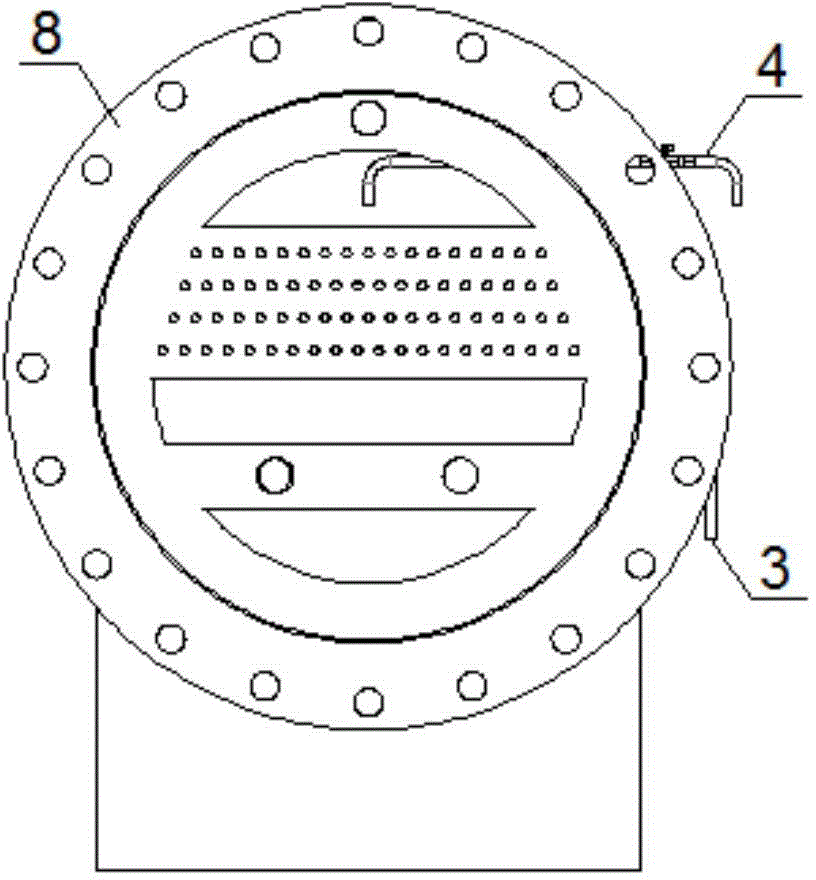

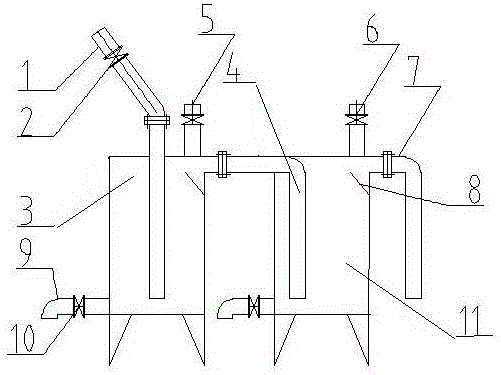

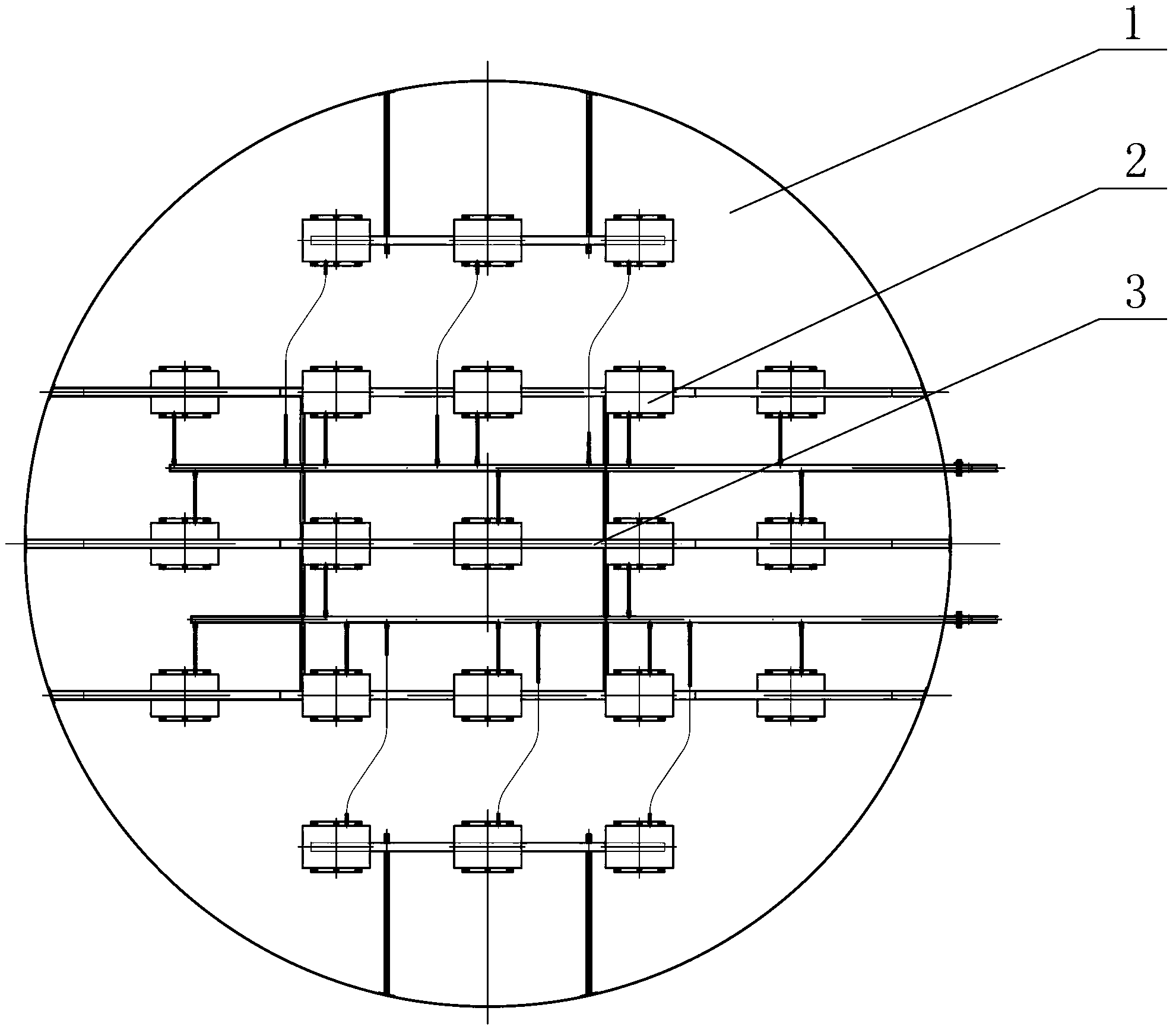

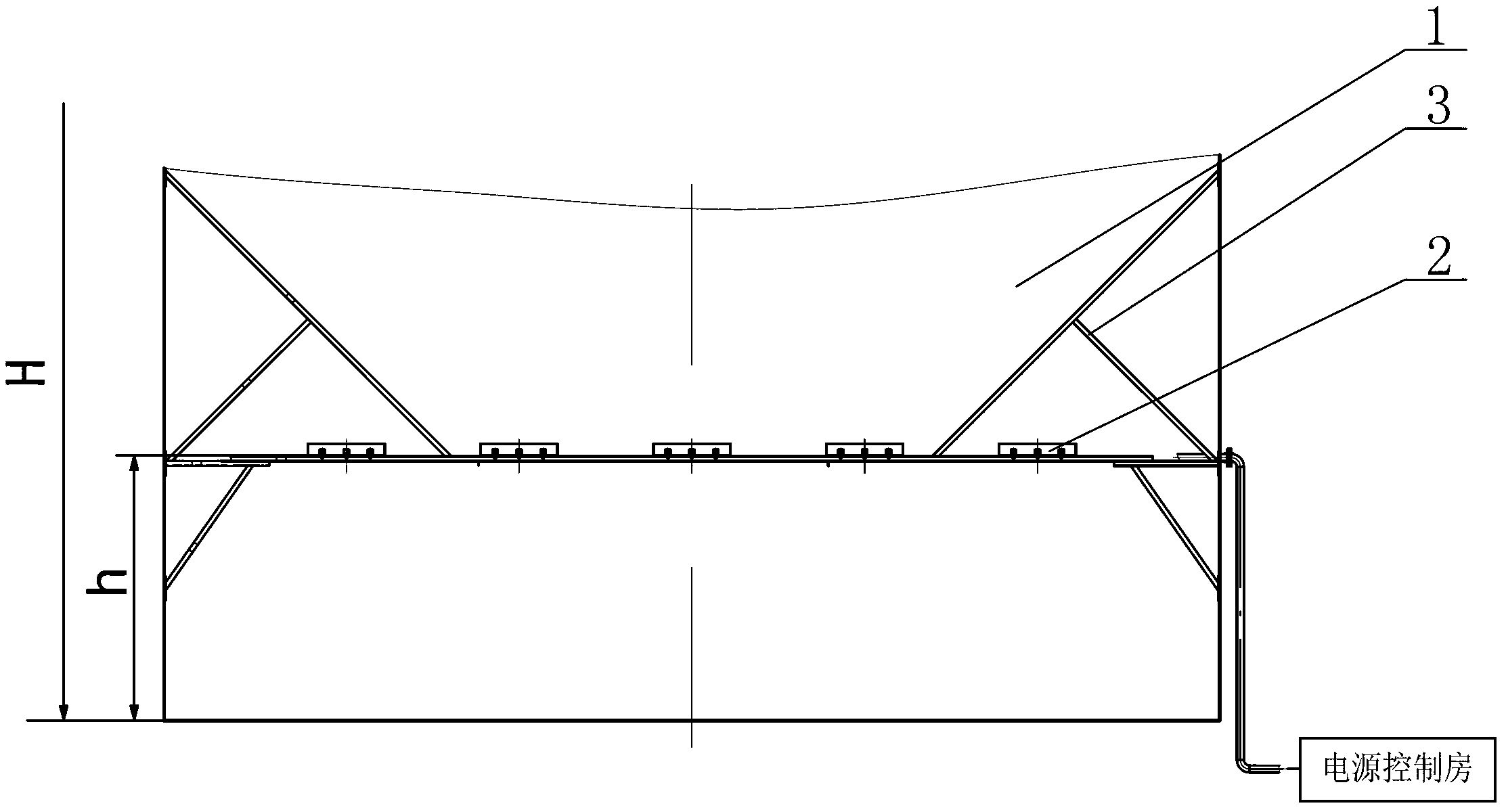

Real-liquid flowing electrical dewaterer evaluation device

A real-liquid flowing electrical dewaterer evaluation device comprises a main housing provided with a coalescence module inside. The upper portion of the main housing is provided with a liquid collecting tube and a discharging port, the bottom of the main housing is provided with a drainage port, the outer side of the main housing is provided with a liquid distributing tube and a sampling device, one end of the main housing is provided with a stainless steel end cover, and the other end is provided with a transparent viewing window; the coalescence module comprises front and rear end plates and four layers of horizontal electrode plates installed between the front and rear end plates; the electrode plates are provided with bare electrodes, are made of 8mm stainless steel bars in a welded manner and are connected to high-voltage wires and grounded wires respectively; the housing is provided with a grounded wire. The oil-water separating effect is achieved through high electric field, and emulsion with few moisture flows out of a test machine after gathering through the liquid collecting tube for post treatment; the force for driving droplets to operate in the electric field is increased through the high electric field, the collision and coalescence of the droplets are enhanced, the oil-water separating speed is increased, the coalescence module is simple in structure, disassembling is facilitated, and efficiency is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Energy-saving environment-friendly efficient water drainage and silt removal device for flue gas desulfurization chimney

ActiveCN106168380AGuaranteed unobstructedAvoid the dangers of cleanupWaste water treatment from gaseous effluentsWater/sewage treatment by flocculation/precipitationEngineeringControl valves

The invention discloses an energy-saving environment-friendly efficient water drainage and silt removal device for a flue gas desulfurization chimney. The device comprises a first drainage tank and a second drainage tank and is characterized in that both the first drainage tank and the second drainage tank are airtight container, the first drainage tank is communicated with the second drainage tank through an upper conduit, an inlet of the upper conduit is located at an upper overflow port of the first drainage tank, and an outlet of the upper conduit is located in the bottom of the second drainage tank and spaced from the bottom surface; the first drainage tank is communicated with the bottom of the high-altitude chimney through a diversion pipe, a water adding pipe provided with a brake valve is arranged on the top of the first drainage tank, a water adding pipe provided with a brake valve is arranged on the top of the second drainage tank, a lower drainage pipe provided with a brake valve is arranged on the bottom of the first drainage tank, and a lower drainage pipe provided with a brake valve is arranged on the bottom of the second drainage tank; the upper portion of the second drainage tank is communicated with the outside through an upper drainage pipe, an inlet of the upper drainage pipe is located at an overflow port of the second drainage tank, and the diversion pipes and the water feeding pipes are provided with control valves respectively. By the adoption of the device, water accumulated in the flue gas desulfurization chimney can be efficiently and automatically dredged, dust can be discharged, the chimney can be kept clear, dangers of manual aerial cleaning work are avoided, operation is easy and convenient, and the device is safe, environment friendly, low in manufacturing cost and easy to popularize.

Owner:蒙自矿冶有限责任公司

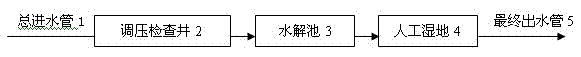

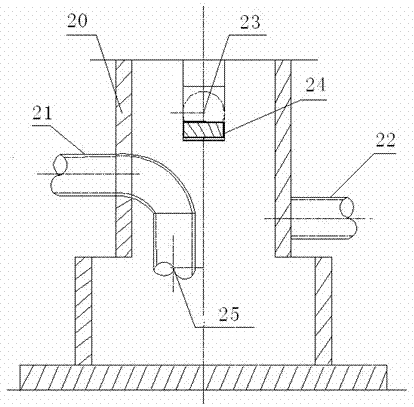

Pressure regulation manhole used for stabilizing constructed wetland inlet water

InactiveCN102730835AEasy to settle and separateReduce adverse effectsBiological water/sewage treatmentConstructed wetlandRural area

The invention discloses a pressure regulation manhole used for stabilizing constructed wetland inlet water. The pressure regulation manhole comprises a pressure regulation manhole body. The pressure regulation manhole also comprises a water inlet pipe, a water outlet pipe and an overflow apparatus connected on the wall of the pressure regulation manhole body. The water outlet pipe is positioned at the middle of the pressure regulation manhole body. The water inlet pipe and the overflow apparatus are positioned on the upper part of the pressure regulation manhole body. The overflow apparatus is arranged above the water inlet pipe. The water inlet pipe is provided with a flow guiding device. The water outlet pipe is connected to a hydrolysis tank and the constructed wetland. The manhole provided by the invention serves as an important component in a constructed wetland treatment process. The manhole can be used for stabilizing inlet water flow rate, and for preventing the impact towards the treatment system. Also, the manhole has a certain suspending solid separation effect. Therefore, the manhole is suitable for domestic sewage pretreatment in different areas, and is especially suitable for distributed and small-scale domestic sewage treatment projects of small towns and rural areas.

Owner:SOUTHEAST UNIV

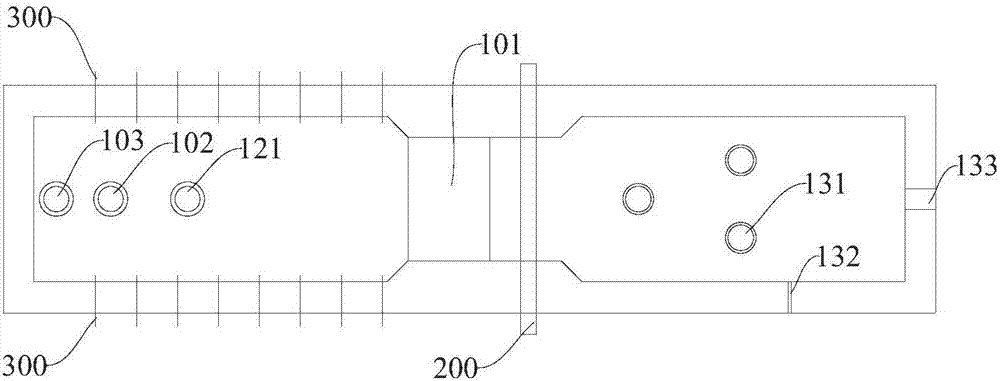

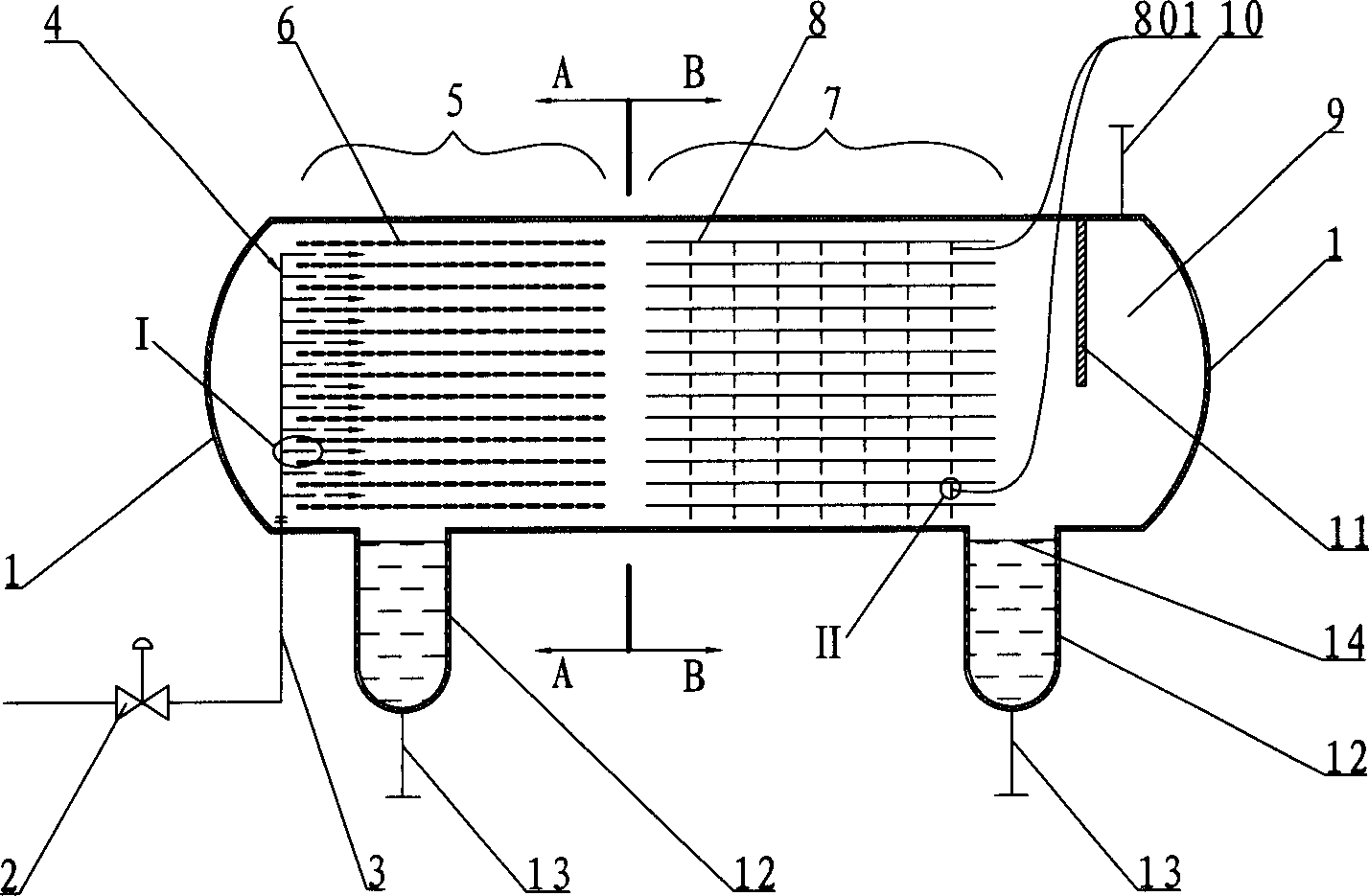

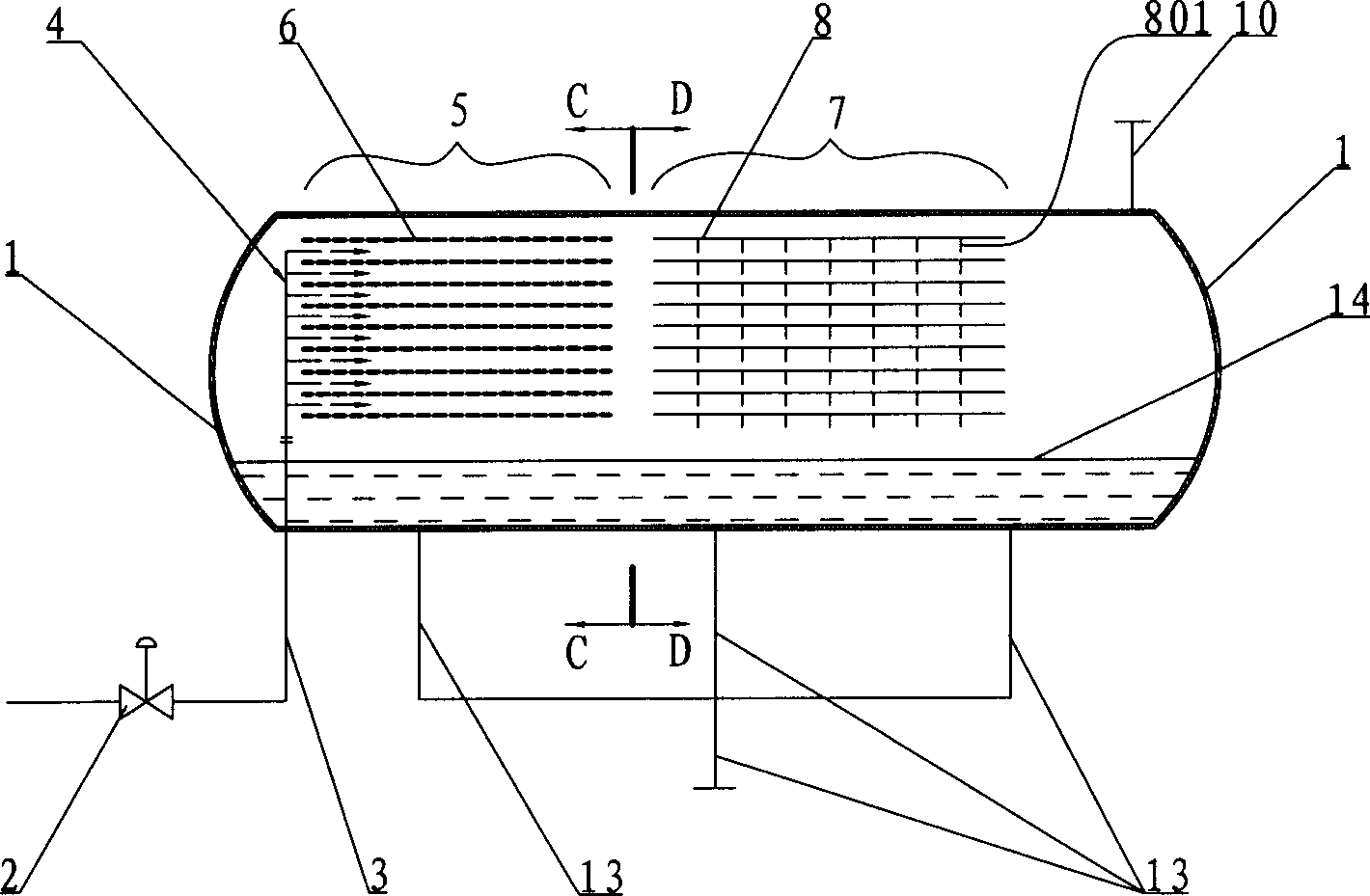

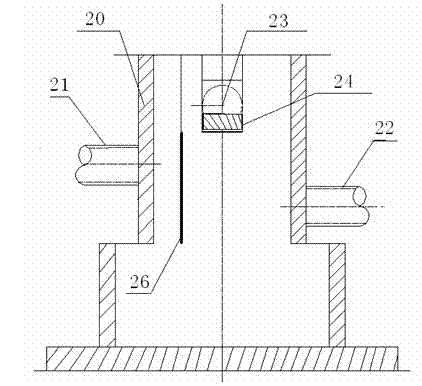

Electric desalting dewatering device for crude oil

InactiveCN1233793CReduce moisture contentEnhanced electrical coalescenceDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

The invention discloses a crude oil electric desalination dehydrator used in the petrochemical industry, in order to solve the problems existing in the existing electric desalination dehydrator that adopt a weak electric field to feed materials, which weakens the electric coalescence in the strong electric field area and the crude oil moves from bottom to top Its main feature is that it can use strong electric field to directly feed and crude oil to flow horizontally during operation. In the electric desalination dehydrator of the present invention, a strong electric field coalescence zone (5) is provided along the axial direction of the tank body from the oil-water mixture inlet end of the tank body (1), and an oil outlet pipe (5) is provided on the top of the tank body purified crude oil outlet end ( 10), the strong electric field coalescence area is provided with at least two layers of planar electrode plates (6) perpendicular to the axis of the tank body, and the electrode plates of each layer are parallel to each other. A feed distributor (4) is arranged in the tank, and a spout is arranged on it, and the oil-water mixture is sprayed into the strong electric field between all adjacent two-layer electrode plates. A settling separation zone (7) can also be set between the strong electric field coalescence zone and the outlet end of the purified crude oil in the tank.

Owner:CHINA PETROCHEMICAL CORP +1

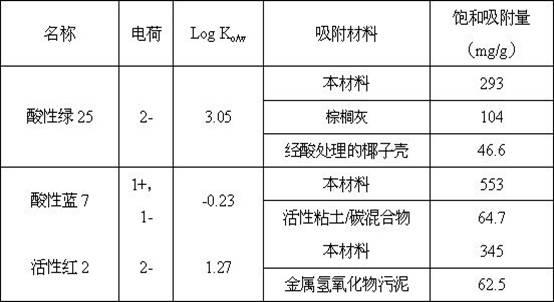

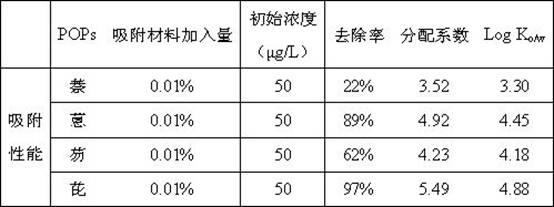

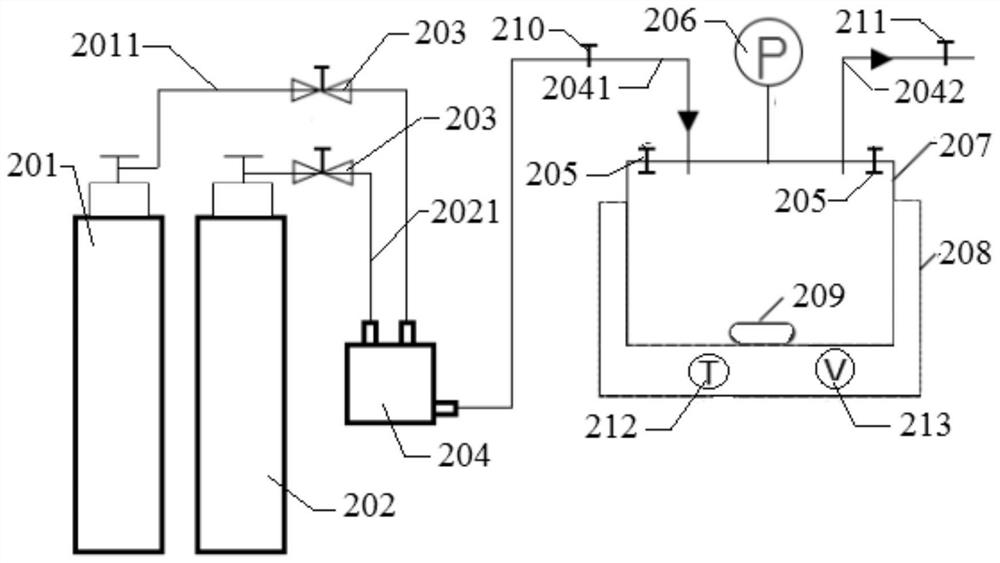

Preparation method of absorbing-enriching material for persistent organic pollutants

InactiveCN102600793AImprove adsorption capacityShort adsorption timeOther chemical processesWater contaminantsMagnesium saltSilicic acid

The invention relates to a preparation method of absorbing-enriching material for persistent organic pollutants. The absorbing-enriching material is white in appearance, takes magnesium silicate material as a framework, and is formed by hybridization through an antistatic agent SN (dimethy octadecyl hydroxyethyl ammonium nitrate). The preparation method comprises the steps of mixing the antistatic agent SN and magnesium salt (magnesium nitrate, magnesium chloride and the like) uniformly, then conducting the synthesis reaction on the mixture and silicic acid or silicate in water solution, then settling, separating, crushing and sieving to obtain SN-magnesium silicate absorbing-enriching material. The material has the advantages of wide raw material resources, simple preparation method, good absorbing and enriching effect and short contact time, and can be applied to the absorption and enrichment of trace amount of persistent organic pollutants in environmental water.

Owner:TONGJI UNIV

Ultrasonic oil-water separation device

InactiveCN102698472AEvenly dispersedLow mechanical strengthEnergy based chemical/physical/physico-chemical processesLiquid separationUltrasound - actionWater storage tank

The invention discloses an ultrasonic oil-water separation device, which comprises a water storage tank. The device is characterized in that a plurality of ultrasonic transmitting vibrating plates are arranged in the water storage tank. The device has the advantages that ultrasonic acts on oil-containing wastewater, so that the oil-water separation effect is good, the recovery rate of oil is high, the consumption of energy required when the device works is low, economic benefits are ensured, and energy conservation and emission reduction are realized at the same time.

Owner:NINGBO SCIENTZ BIOTECH

Method for making blister copper from highly magnetic copper oxide slag in one step and kiln for making blister copper

ActiveCN105087950BEasy to settle and separateReduced settling separationProcess efficiency improvementSmelting processNitrogen

The invention discloses a method for preparing crude copper by one step from high magnetic copper oxide slag and a kiln for preparing the crude copper. The method comprises the following steps: molten high magnetic copper oxide slag is discharged into the kiln capable of horizontally rotating for reduction smelting; a fluxing agent is added to adjust a Fe / SiO2 ratio of the high magnetic copper oxide slag as 1.5-1.8; nitrogen is fed to stir the high magnetic copper oxide slag in the reduction smelting process; after mattes being 15-20 weight% of the high magnetic copper oxide slag or copper concentrates being 30-45 weight% of the high magnetic copper oxide slag are fed for smelting reduction, melts in the kiln are removed slag after clarification and separation; then, a wind port is switched to introduce compressed oxygen-enriched air; the kiln rotates for converting the melts in the kiln to oxidize the mattes in the kiln to obtain the crude copper; then, the melts are removed the slag again after settling separation; and finally, the crude copper is discharged. The method can reduce the copper content and the magnetic iron content in the high magnetic copper oxide slag, improves the fluidity of the oxide slag, is convenient for settling separation of copper in the oxide slag, improves the direct yield of smelted copper, reduces the energy consumption in the smelting process, and enhances the yield.

Owner:YUNNAN TIN

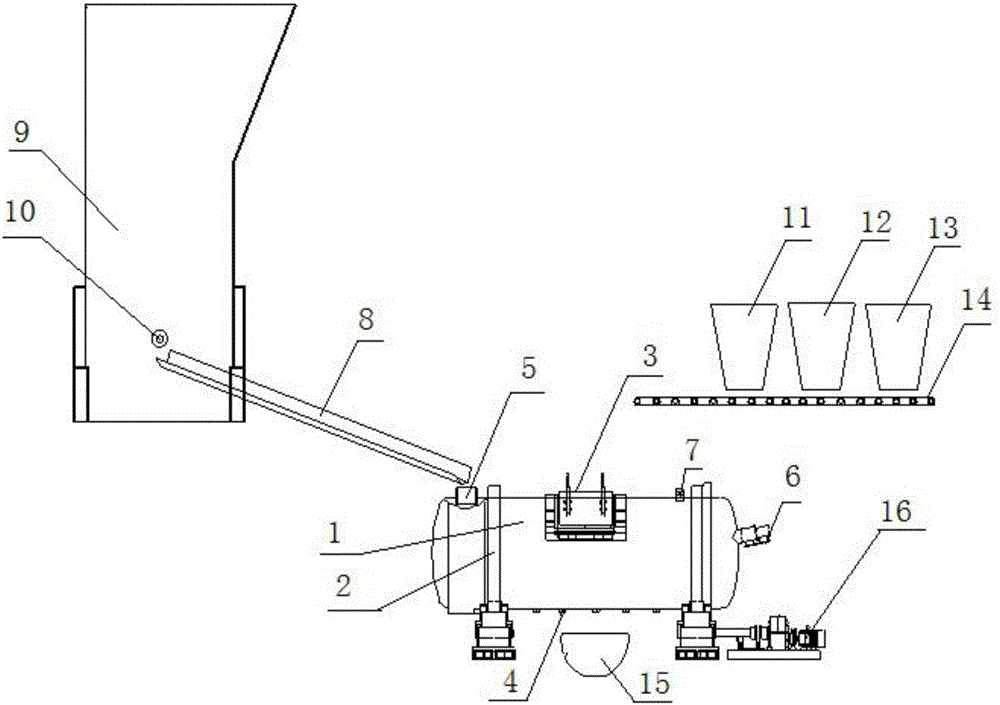

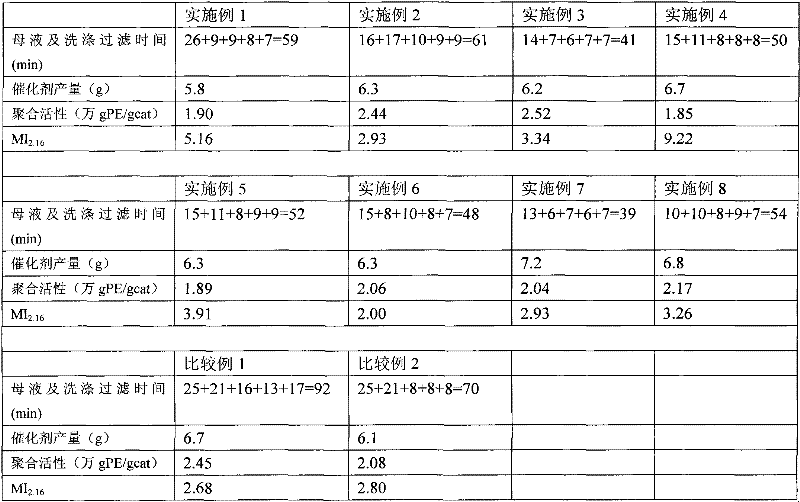

Catalyst used for vinyl polymerization and preparation method thereof

The invention relates to a catalyst used for vinyl polymerization and a preparation method thereof. The nickelic solid catalyst component is prepared through the following steps: firstly reacting magnesium halide with an organic epoxy compound, an organic phosphorous compound and organic alcohol, thus forming a homogeneous solution; mixing the homogeneous solution with metallic nickel powder; andthen reacting with a mixed solution of transition metal titanic halide or derivatives thereof. In the preparation process, an electron donor can be added so as to improve the performance; the catalyst shows high activity and hydrogen regulation sensibility when used for vinyl polymerization; and the added metallic nickel powder is used as a crystal nucleus, thereby being beneficial to the separation of the solid catalyst. The method is favorable for settling out a catalyst mother solution system and is capable of obviously shortening the washing and filtering time of the catalyst, thereby obviously shortening the preparation period of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electric dewatering and desalting appliance for crude oil

InactiveCN1208111CIncrease coalescence speedImprove coalescence performanceLiquid separation by electricityDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

The invention discloses a crude oil electric desalination dehydrator used in the petrochemical industry, in order to solve the problems existing in the existing electric desalination dehydrator that adopt a weak electric field to feed materials, which weakens the electric coalescence in the strong electric field area and the crude oil moves from bottom to top Its main feature is that it can use strong electric field to directly feed and crude oil to flow horizontally during operation. In the electric desalination dehydrator of the present invention, a feed distributor (4) and a strong electric field coalescence area (5) are sequentially arranged along the axial direction of the tank body from the oil-water mixture inlet end of the tank body (1), and the tank body is purified An oil outlet pipe (10) is provided on the top of the crude oil outlet, and at least two layers of planar electrode plates (6) parallel to the axial direction of the tank are provided in the strong electric field coalescence area, and the electrode plates of each layer are parallel to each other. The feed distributor is provided with a spout, which sprays the oil-water mixture into the strong electric field between all adjacent two-layer electrode plates. A settling separation zone (7) can also be set between the strong electric field coalescence zone and the outlet end of the purified crude oil in the tank.

Owner:CHINA PETROCHEMICAL CORP +1

Sulfur precipitator composition and method for improving liquid-phase catalytic oxidation desulfurization effect

ActiveCN104138708BEasy to settle and separateSettling fastDispersed particle separationCatalytic oxidationSulfur deposition

The invention provides a sulfur deposition agent composition including a flocculant, alkyl phenol polyoxyethylene ether with the degree of polymerization of 8-12, alkyl phenol polyoxyethylene ether with the degree of polymerization of 4 - 6 and a cosolvent. The invention also provides a method for improving the liquid phase catalytic oxidation desulfurization effect. When the sulfur deposition agent composition is used for liquid phase catalytic oxidation desulfurization process, large sulfur particles (up to maximum 46 [mu]m can be obtained, the sulfur deposition agent composition can effectively inhibit the sulfur foam production, and improve the sedimentation rate of sulfur particles, and more than 96% of the sulfur particles in a desulfurization solution can be rapidly settled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Core-shell type amorphous metal oxide adsorbent, as well as preparation method and application thereof

ActiveCN103623770BEasy to recycleEasy to reuseOther chemical processesWater contaminantsSorbentAmorphous metal

The invention discloses a core-shell type amorphous metal oxide adsorbent, as well as a preparation method and an application thereof and relates to the amorphous metal oxide adsorbent, as well as the preparation method and the application thereof. The invention aims at solving the problems that the nano-metal oxide adsorbent prepared by an existing method is easy to inactivate and agglomerate in a water solution, less prone to sedimentation and difficult to recover and reutilize. The core-shell type amorphous metal oxide adsorbent is prepared from amorphous alloy powder through a hydrothermal method. The method comprises the following steps: 1) placing sodium hydroxide and water into a closed reaction container, then adding the amorphous alloy powder for reaction, and then naturally cooling to room temperature to obtain a reaction product; and 2) regulating the pH value to neutrality, then standing and separating to obtain a solid product, and drying the solid product till constant weight to obtain the core-shell type amorphous metal oxide adsorbent. The core-shell type amorphous metal oxide adsorbent can be used as a toxic Cr<6+> ion adsorbent for adsorbing toxic Cr<6+> ions in water.

Owner:HARBIN INST OF TECH

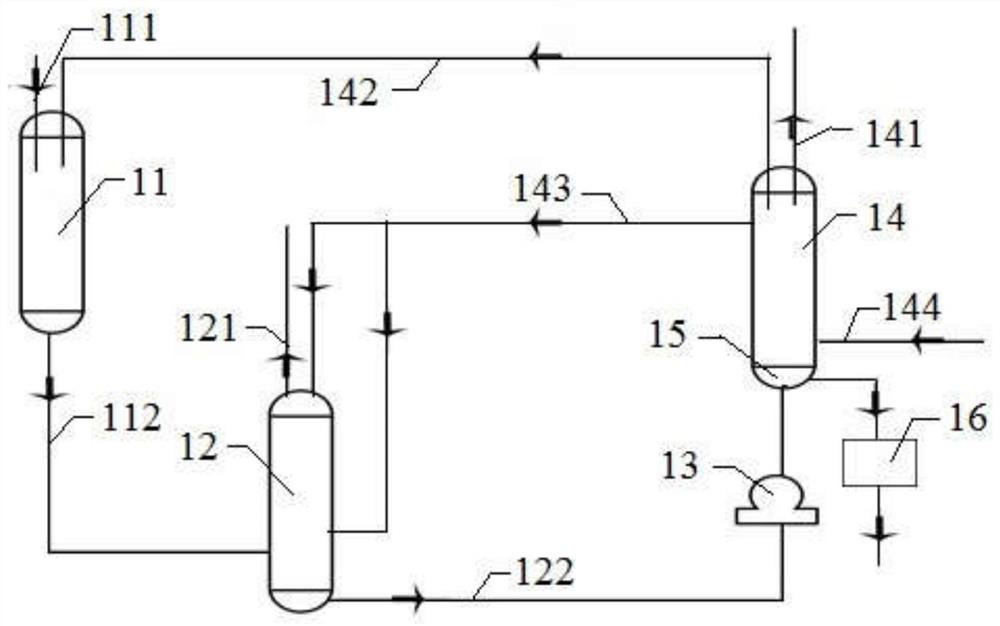

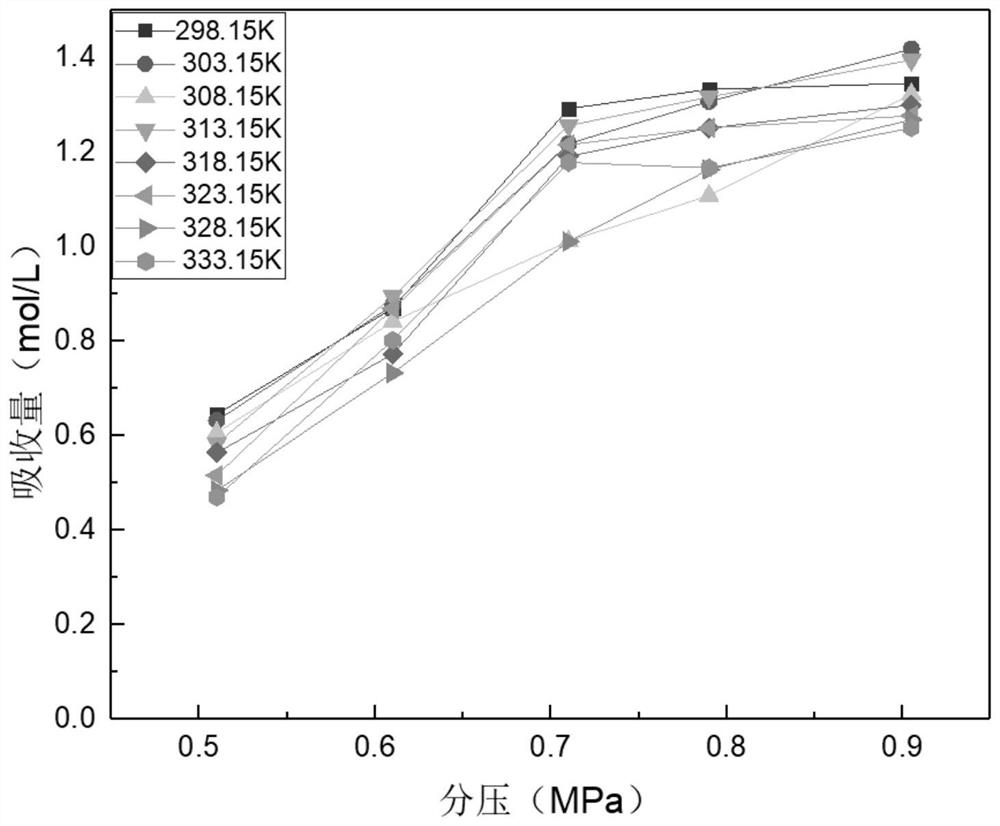

Desulfurization liquid for absorbing H2S, desulfurization system and desulfurization method

ActiveCN111905549ANo need to shorten contact timeEasy to settle and separateDispersed particle separationSulfolanePhysical chemistry

The invention discloses a desulfurization liquid for absorbing H2S, and relates to the field of gas purification and the field of pollution control in the chemical process. The desulfurization liquidis mainly prepared from the following components by weight: 200 parts of an iron-based ionic liquid; 1-100 parts of a cosolvent, wherein the cosolvent comprises sulfolane. The invention also providesa desulfurization system for absorbing H2S by adopting the desulfurization liquid and a desulfurization method for absorbing H2S by adopting the desulfurization system. The invention has the beneficial effects that sulfolane is added into the prepared desulfurization liquid, so the desulfurization liquid has the characteristics of being suitable for high pressure and high concentration, and the desulfurization process is not influenced by CO2 impurity gas; the system and method has important application value in treatment of industrial process gas with high system pressure, high sulfur concentration or high CO2 concentration, such as natural gas, acidic water stripping, biomass gas and alcohol amine liquid refined sulfur-containing tail gas.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com