Patents

Literature

41results about How to "Reduce chemical oxygen demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

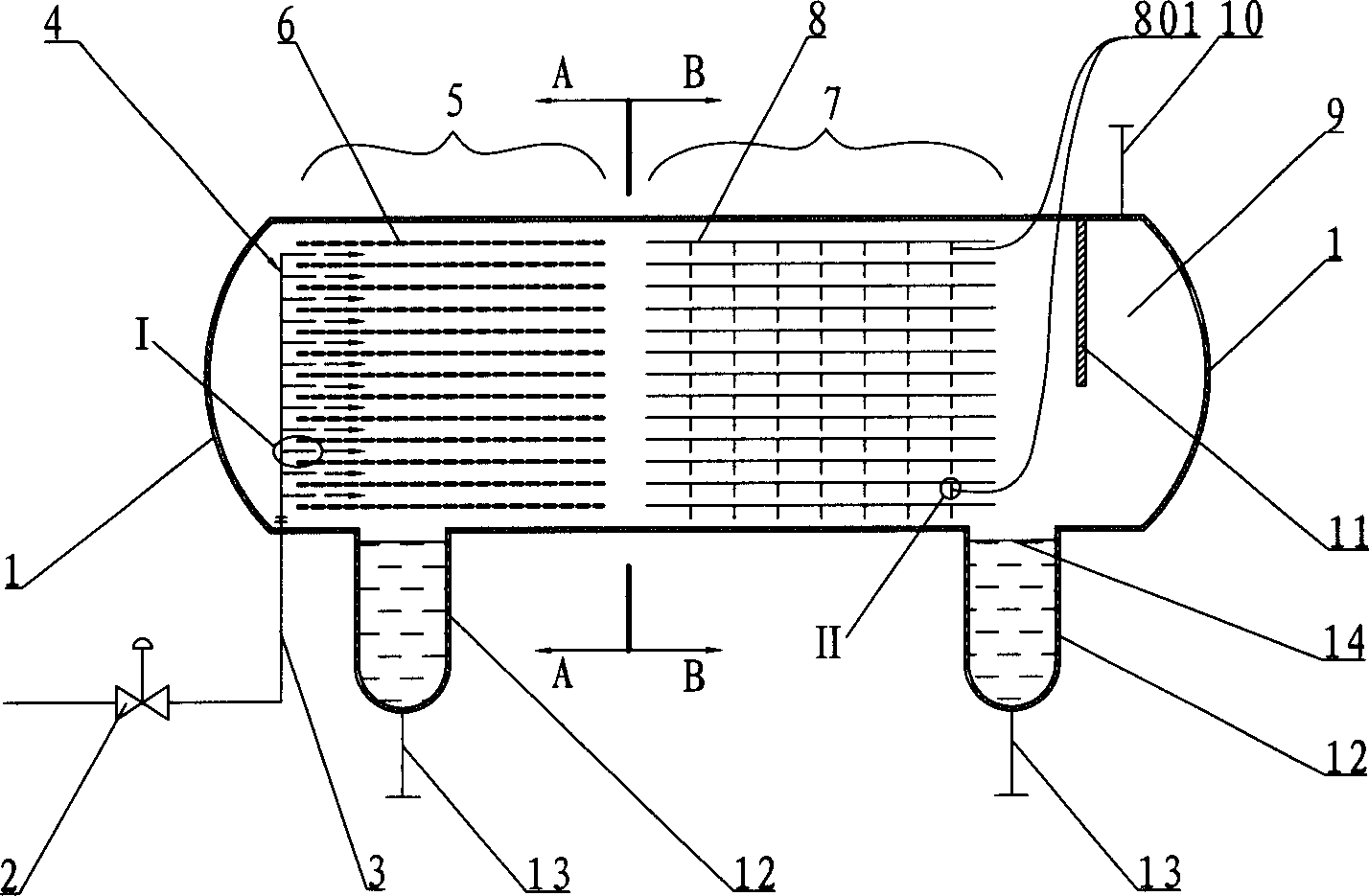

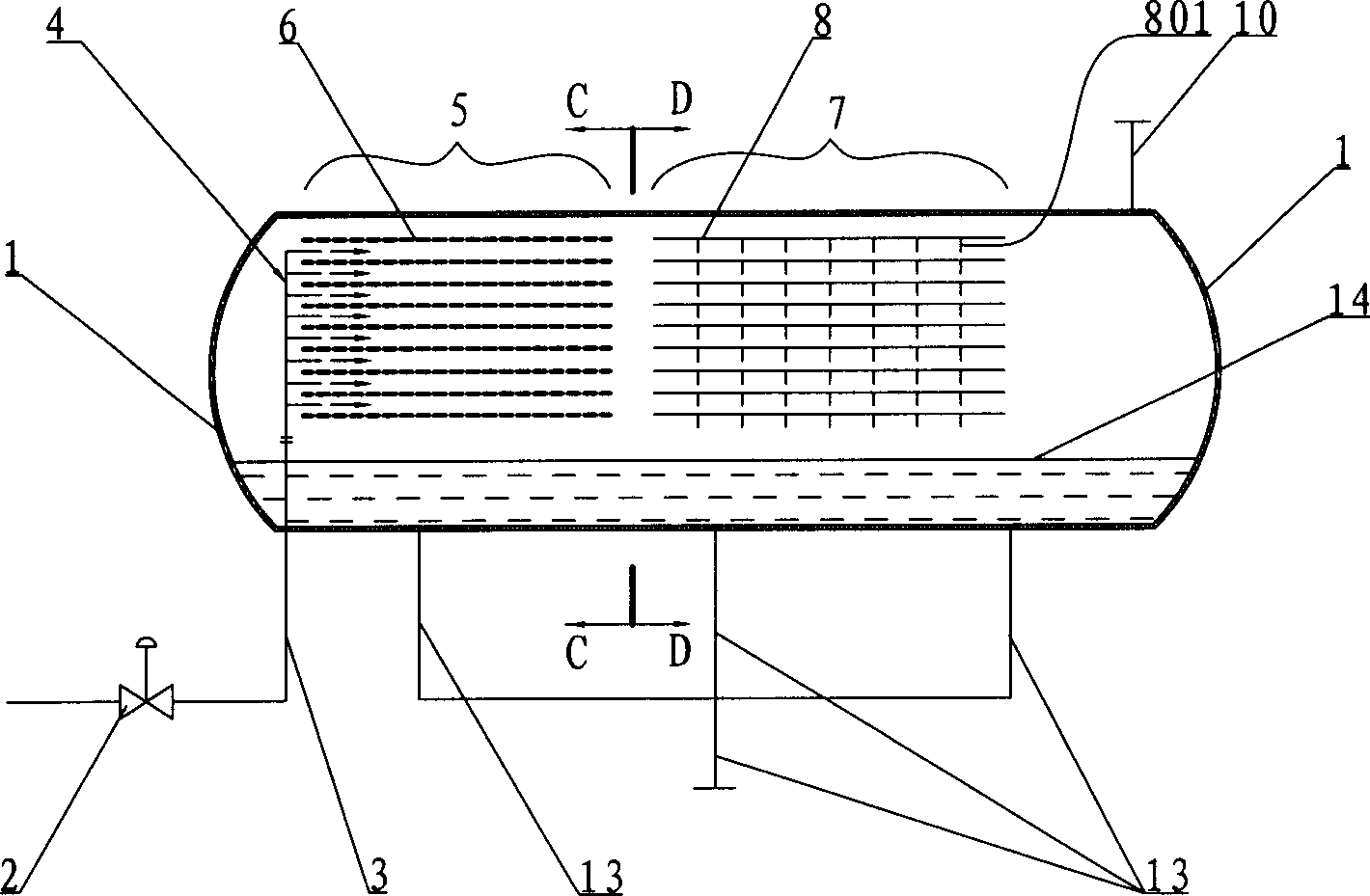

Electric dewatering and desalting appliance for crude oil

InactiveCN1482212AReduce moisture contentEnhanced electrical coalescenceLiquid separation by electricityDewatering/demulsification with electric/magnetic meansElectricityOil water

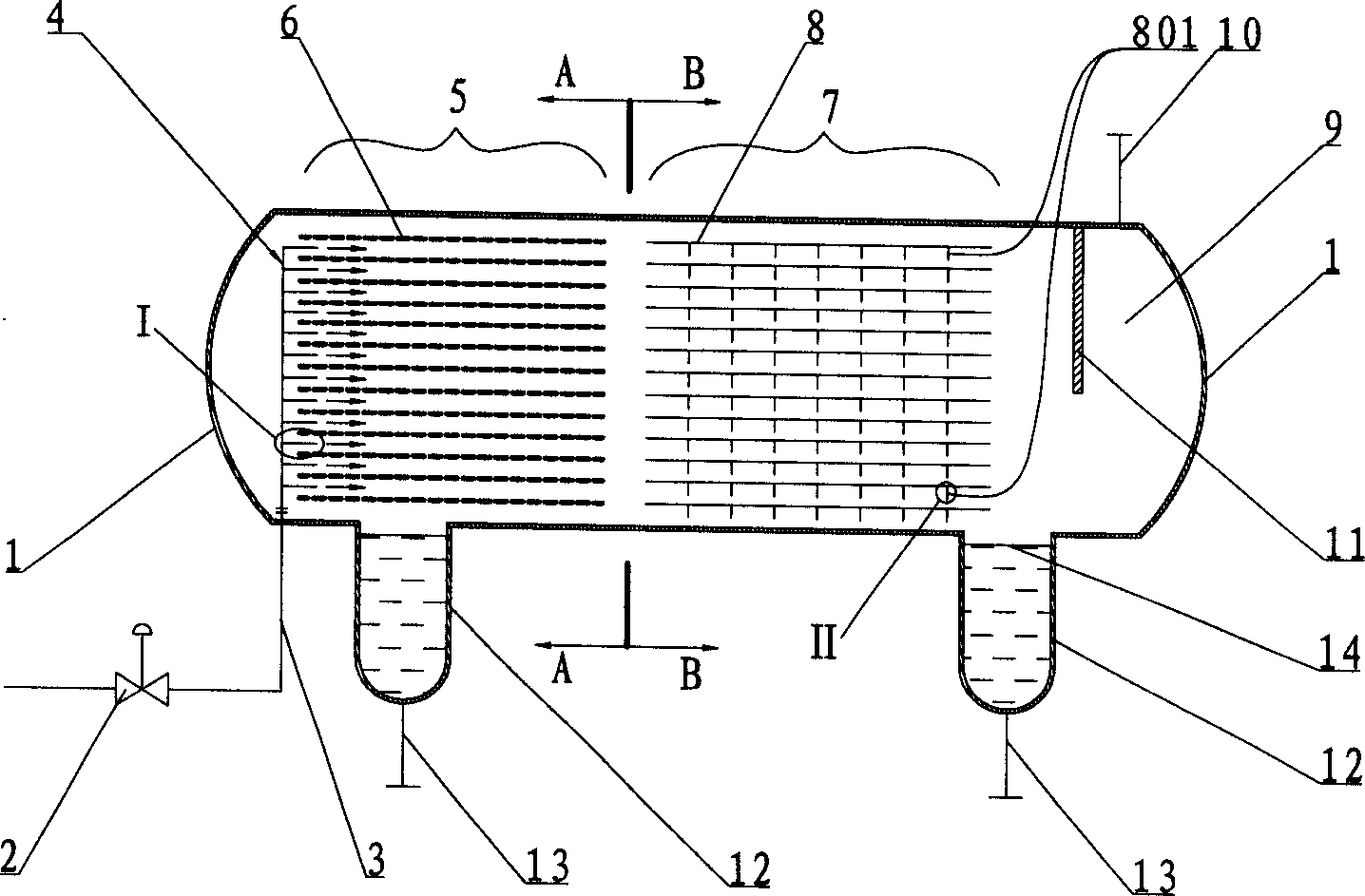

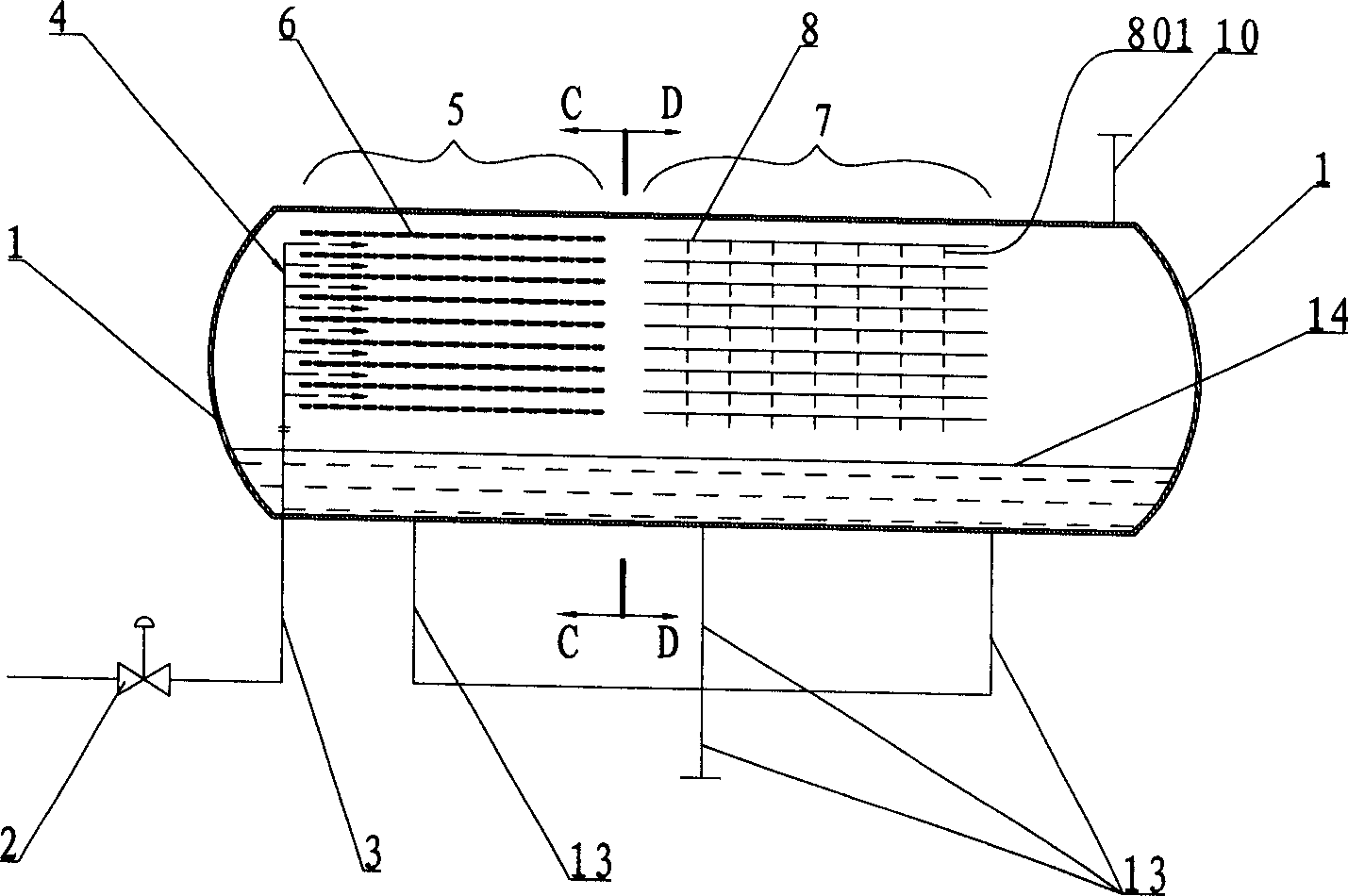

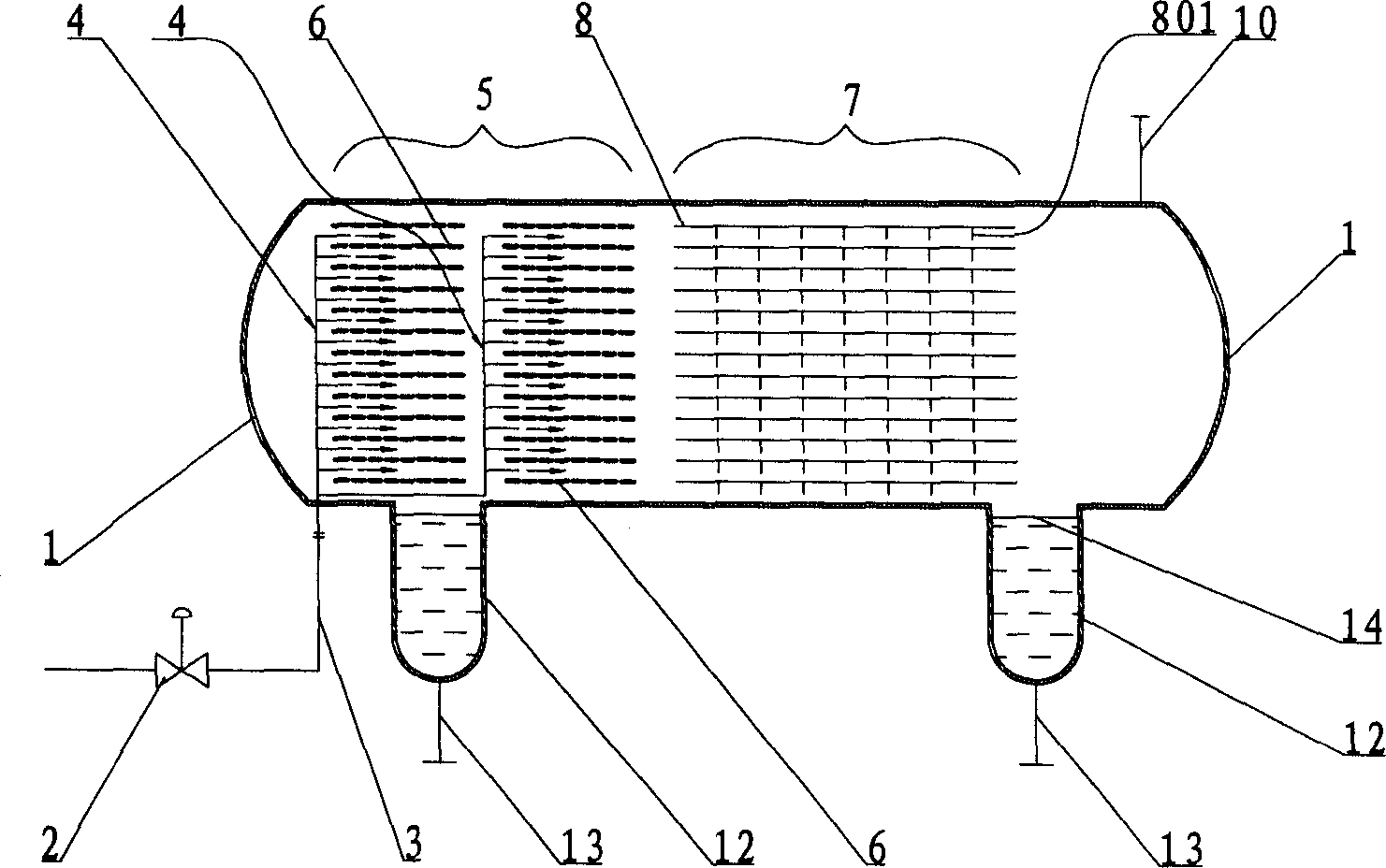

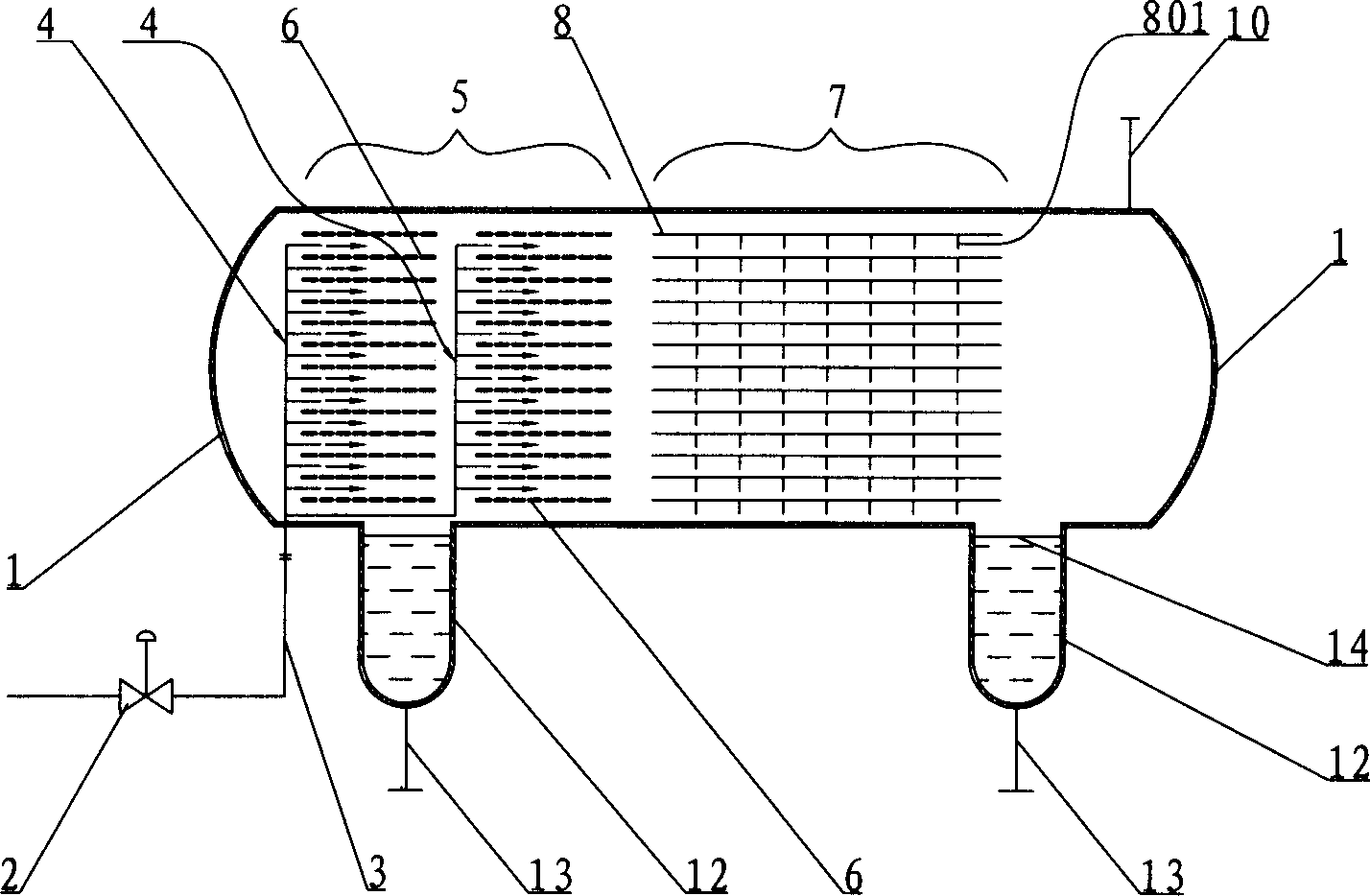

The electrical raw oil desalting and dewatering device for petrochemical industry features its direct material feeding in strong electric field and horizontal flow of raw oil. The electrical raw oildesalting and dewatering device of the present invention has material distributor and strong electric field coalescence area in tank axial direction and oil outlet pipe in the top of the raw oil purifying area, with the strong electric field coalescence area being provided with at least two layers of parallel electrode plates parallel to or perpendicular to the tank axis. The material distributor is provided with nozzles to spray mixed oil-water material into the strong electric field between two adjacent electrode plates. Between the strong electric field coalescence area and the purified raw oil outlet, deposit separating area may be set.

Owner:CHINA PETROCHEMICAL CORP +1

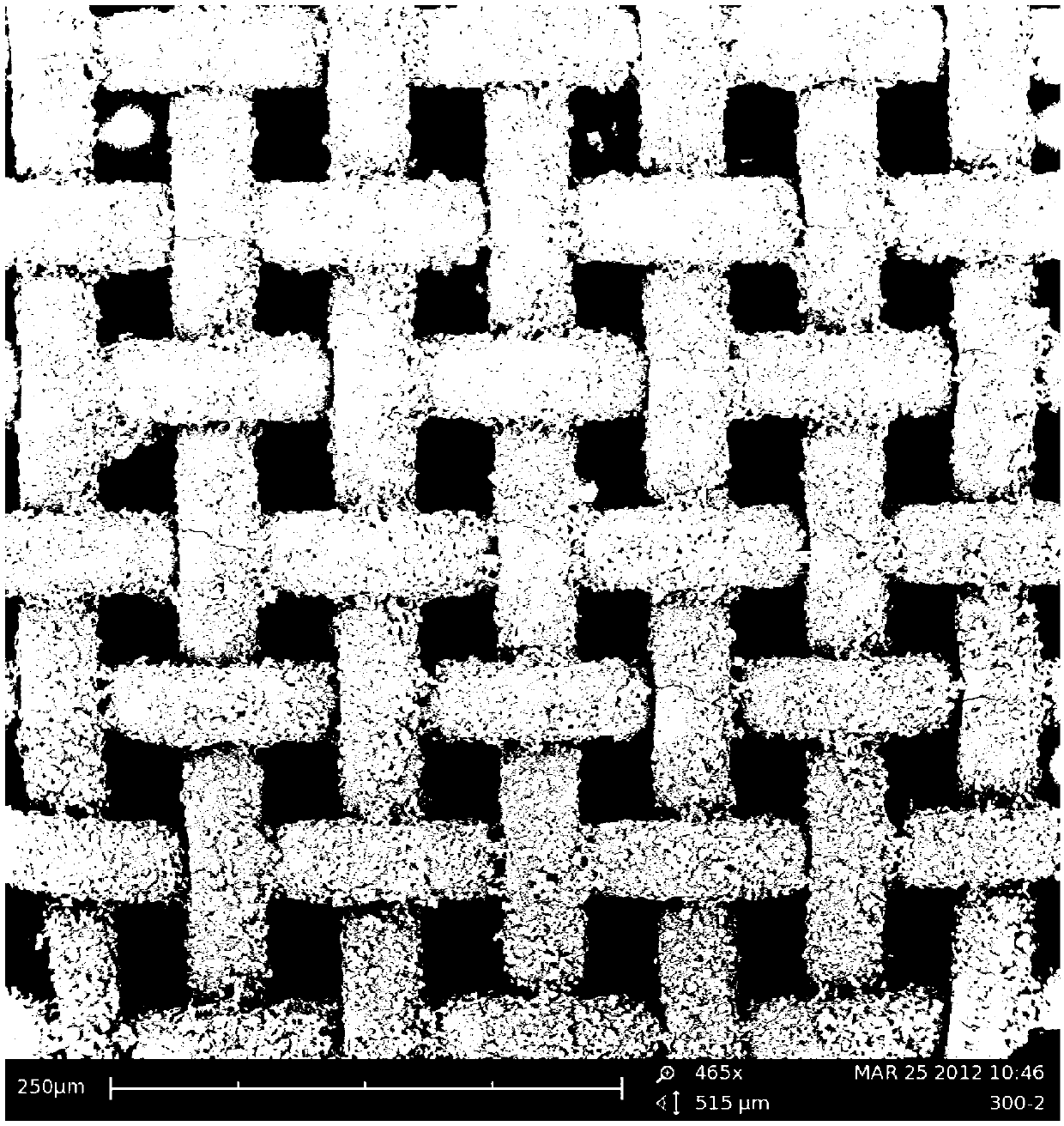

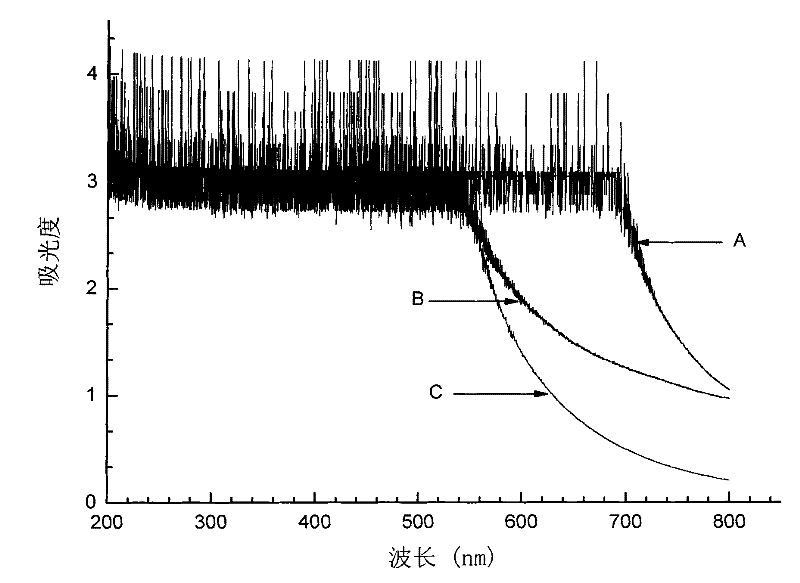

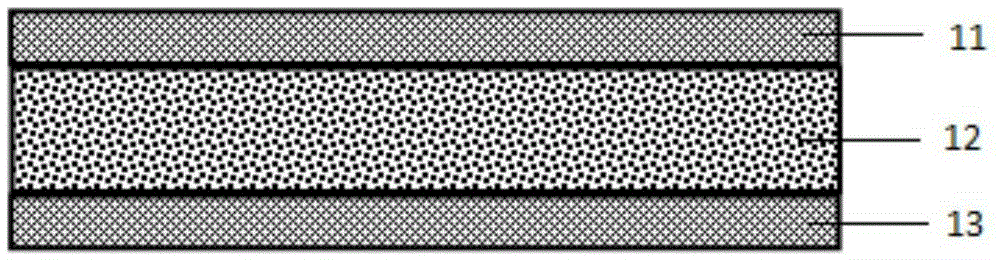

Oily sewage purification net membrane and preparation method and application thereof

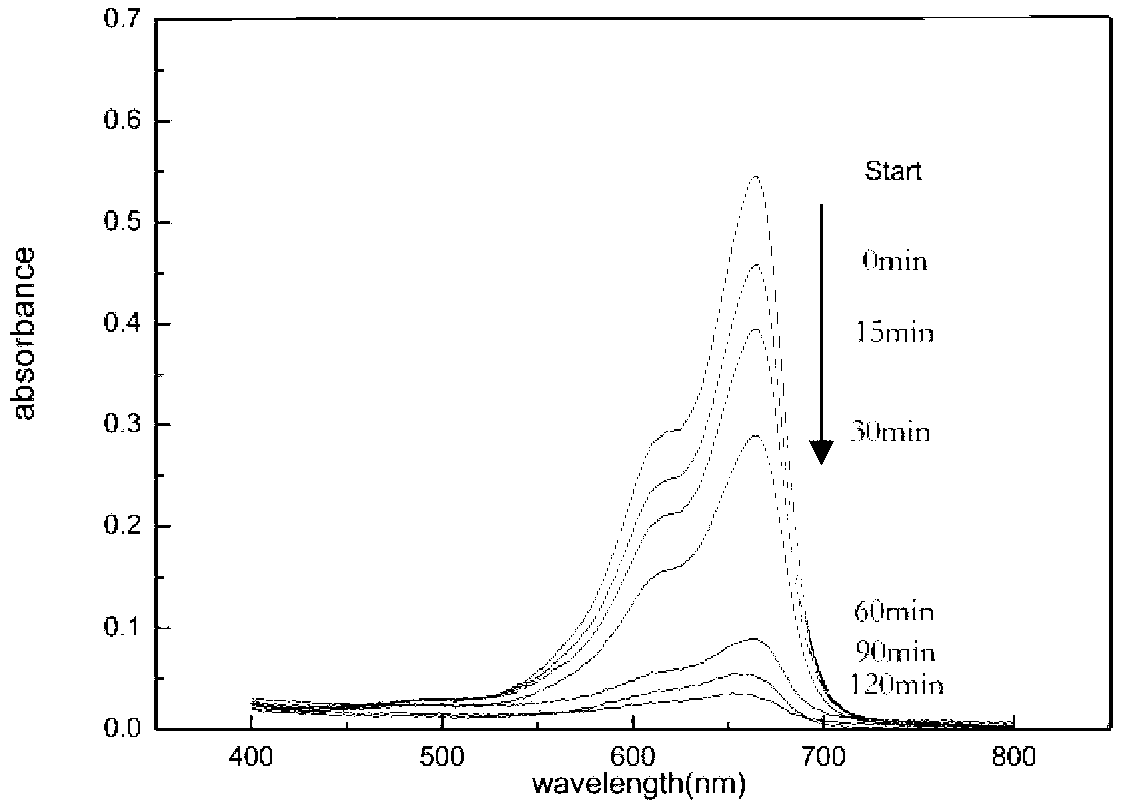

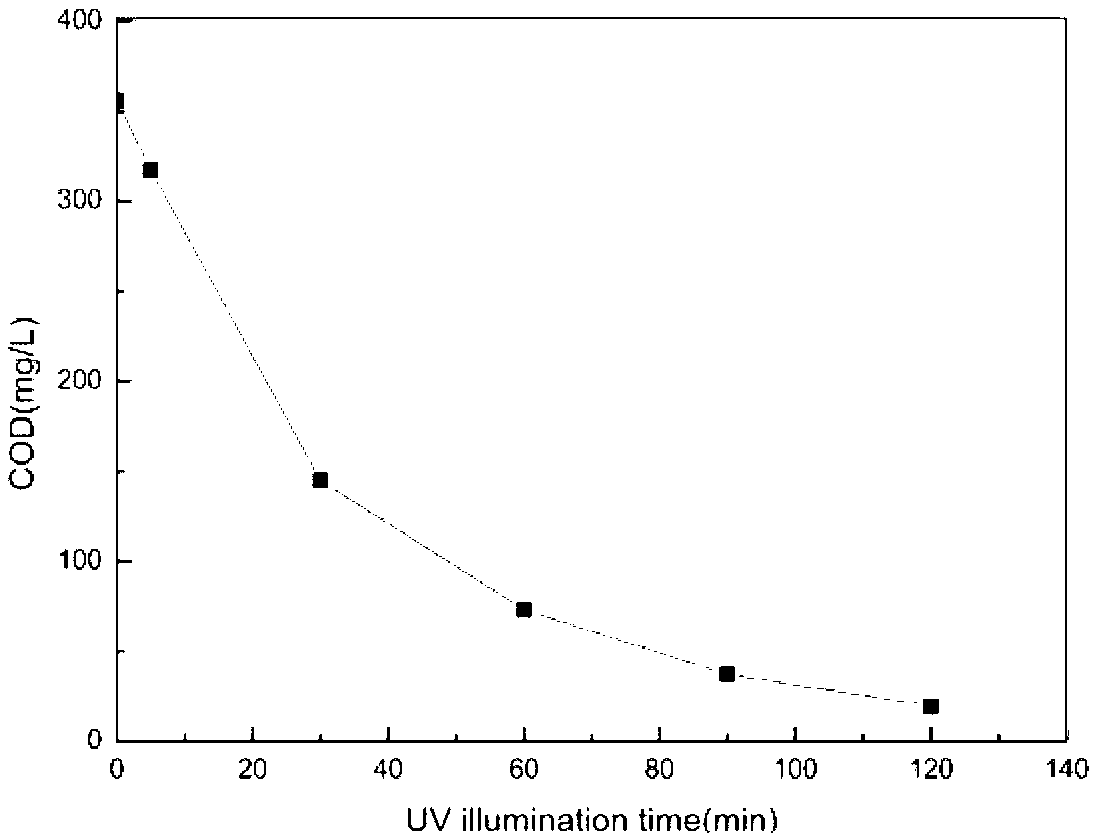

ActiveCN102764536AReduce chemical oxygen demandImprove separation efficiencyFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationPollutantChemistry

The invention discloses a net membrane with oily sewage purification capability and a preparation method and application thereof. The oily sewage purification net membrane is an A / B double-layer composite net membrane, wherein the A layer of net membrane is formed by depositing a TiO2 coating on the net wire surface of a fabric net; and the B layer of net membrane is arranged on the surface of the A layer of net membrane and provided with a photodegradable hydrophobic modifier layer. The oily sewage purification net membrane can be used for simultaneously implementing oil-water separation of oily sewage and degradation of soluble pollutants. The net membrane has super-hydrophobic and super-oleophyllic properties in air, the contact angle between the net membrane and water in the air is more than 150 degrees, and the net membrane has good photo-catalytic property under ultraviolet. The net membrane can be applied to purification, chemical separation, environmental protection and the like of the oily sewage. The net membrane for sewage purification has the advantages of good separation effect, high purification efficiency, low cost, low energy consumption, convenience and the like.

Owner:TSINGHUA UNIV

Electric desalting dewatering device for crude oil

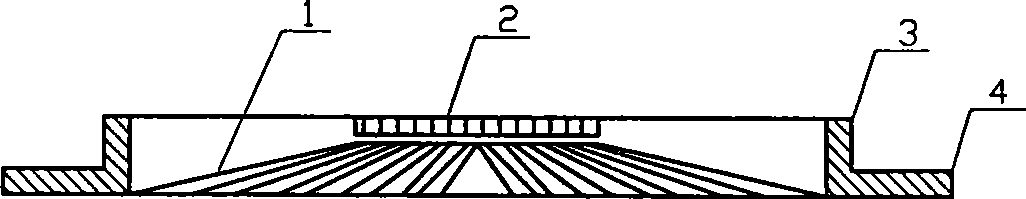

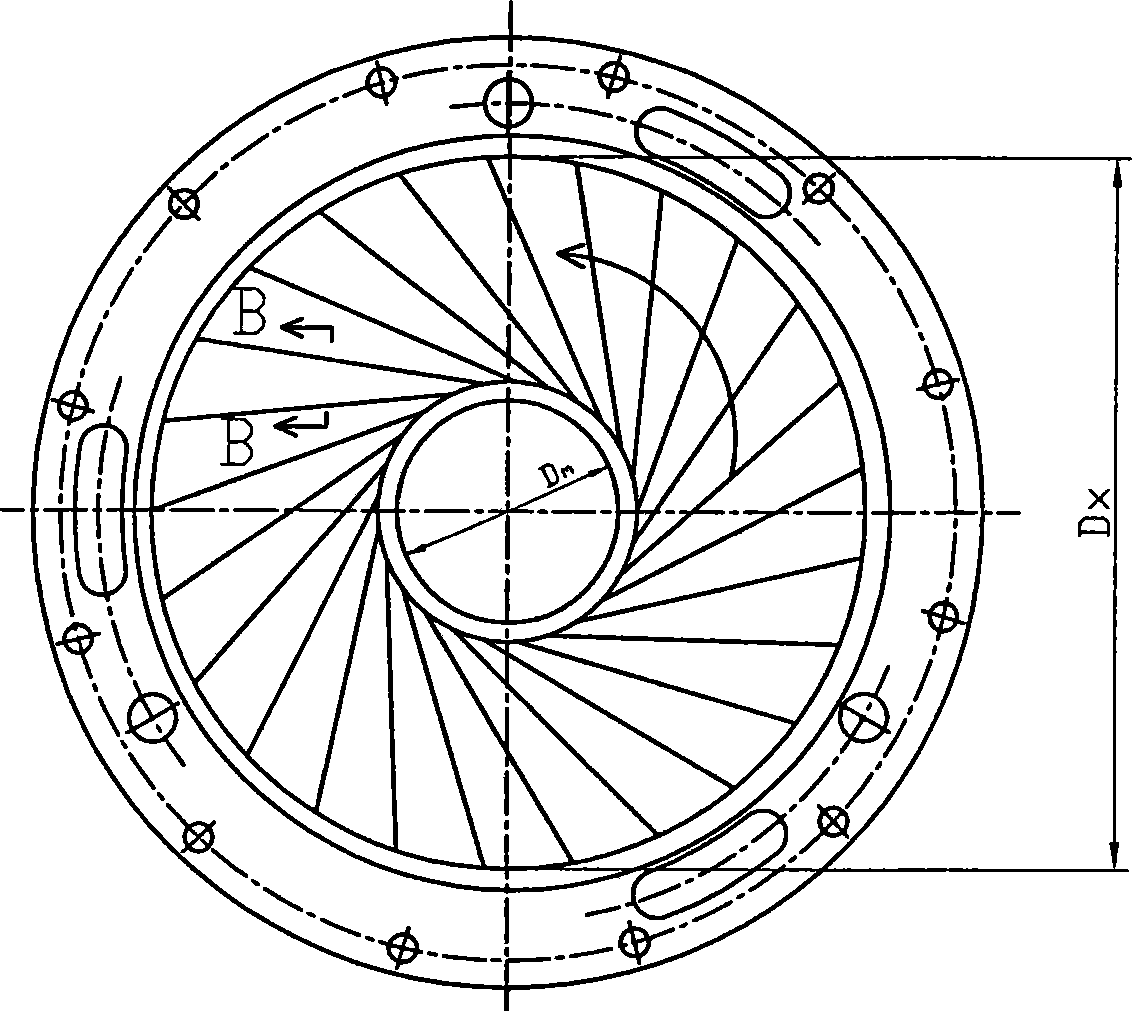

InactiveCN1605615AReduce moisture contentEnhanced electrical coalescenceDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

The present invention is one electric raw oil desalting and dewatering apparatus for petrochemical industry. The present invention features the direct material feeding under strong electric field and the horizontal flow of raw oil. The electric raw oil desalting and dewatering apparatus has a tank with oil-water mixture inlet, axial strong electric field coagulation area with at least two layers of parallel planar electrode plates perpendicular to the axis of the tank, purified raw oil outlet with oil outlet pipe, material distributor inside the tank with nozzles to jet oil-water mixture into the strong electric fields between every two adjacent electrode plates, and depositing separation area set between the strong electric field coagulation area and the purified raw oil outlet.

Owner:CHINA PETROCHEMICAL CORP +1

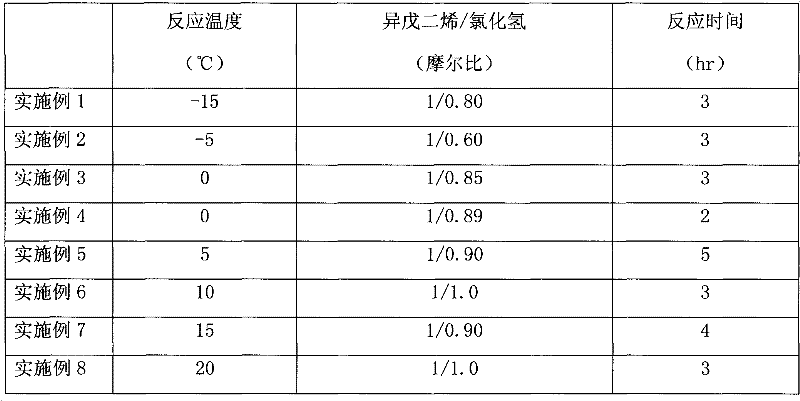

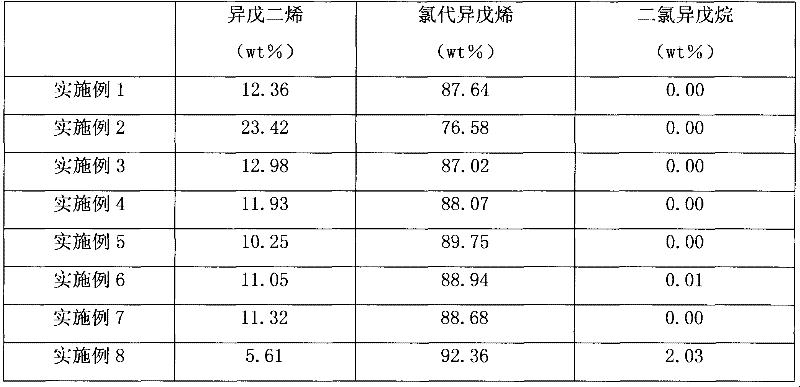

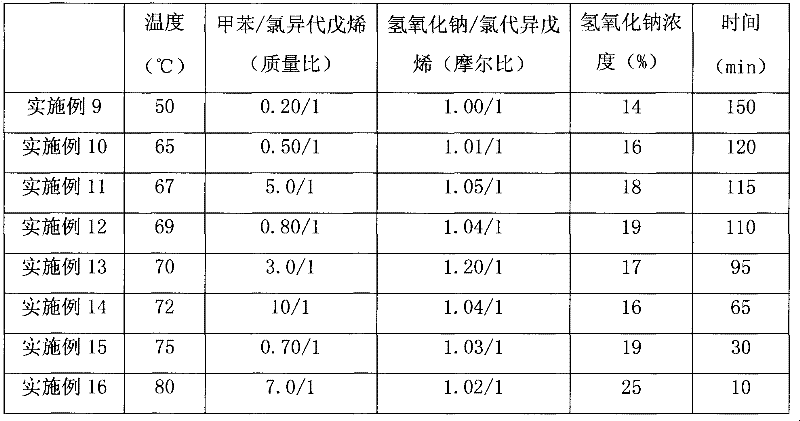

Production method of C5 enol

InactiveCN102381940AInhibit side effectsSimple processPreparation by hydrolysis2-methylbutaneOil phase

The invention relates to a production method of a C5 enol. The production method uses isoprene and hydrogen chloride as raw materials and comprises the following steps: 1) performing addition reaction on isoprene and hydrogen chloride to generate a mixture of 1-chloro-isopentene and 3-chloro-isopentene; and 2) performing a hydrolysis reaction on the product of the addition reaction, adding one or more of toluene, ethylbenzene, n-hexane, cyclohexane, 2-methylpentane, 3-methylpentane, 2,2-dimethylbutane, 2,3-dimethylbutane and heptane as the solvent in the hydrolysis process, separating out the oil phase product after the hydrolysis, and rectifying to obtain products, namely methylbutenol and 3-methyl-2-buten-1-ol. Compared with the C5 enol production process of the prior art, the side reaction, in which dichloro-isopentane is generated, in the addition reaction process is effectively inhibited; after the solvent is added in the hydrolysis reaction, the yield of the hydrolysis reaction can be increased and the purification of the product can be facilitated; the yields of the addition reaction and the hydrolysis reaction are both more than 98% and are obviously increased as compared with the prior art; and the production cost is greatly reduced.

Owner:赵明江

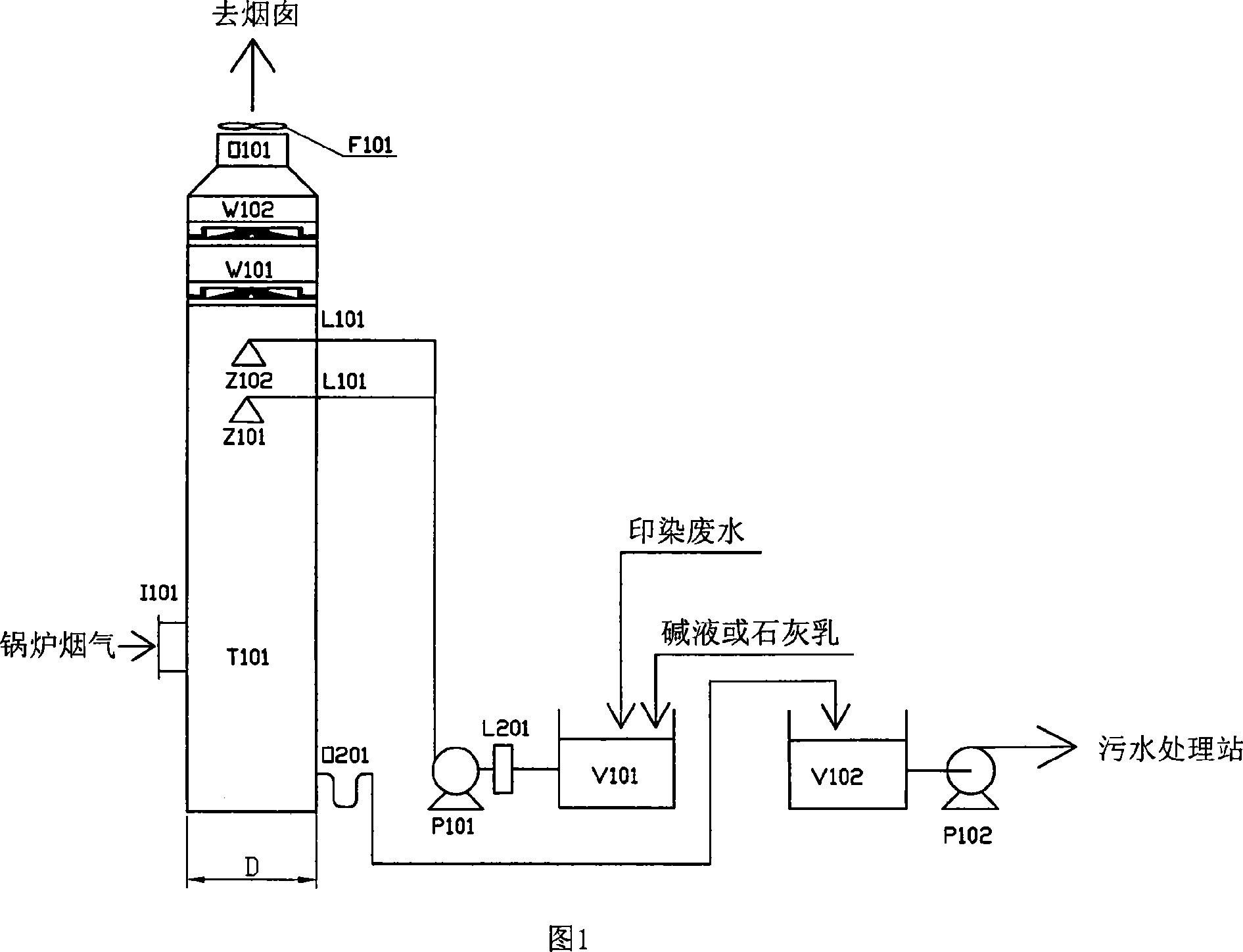

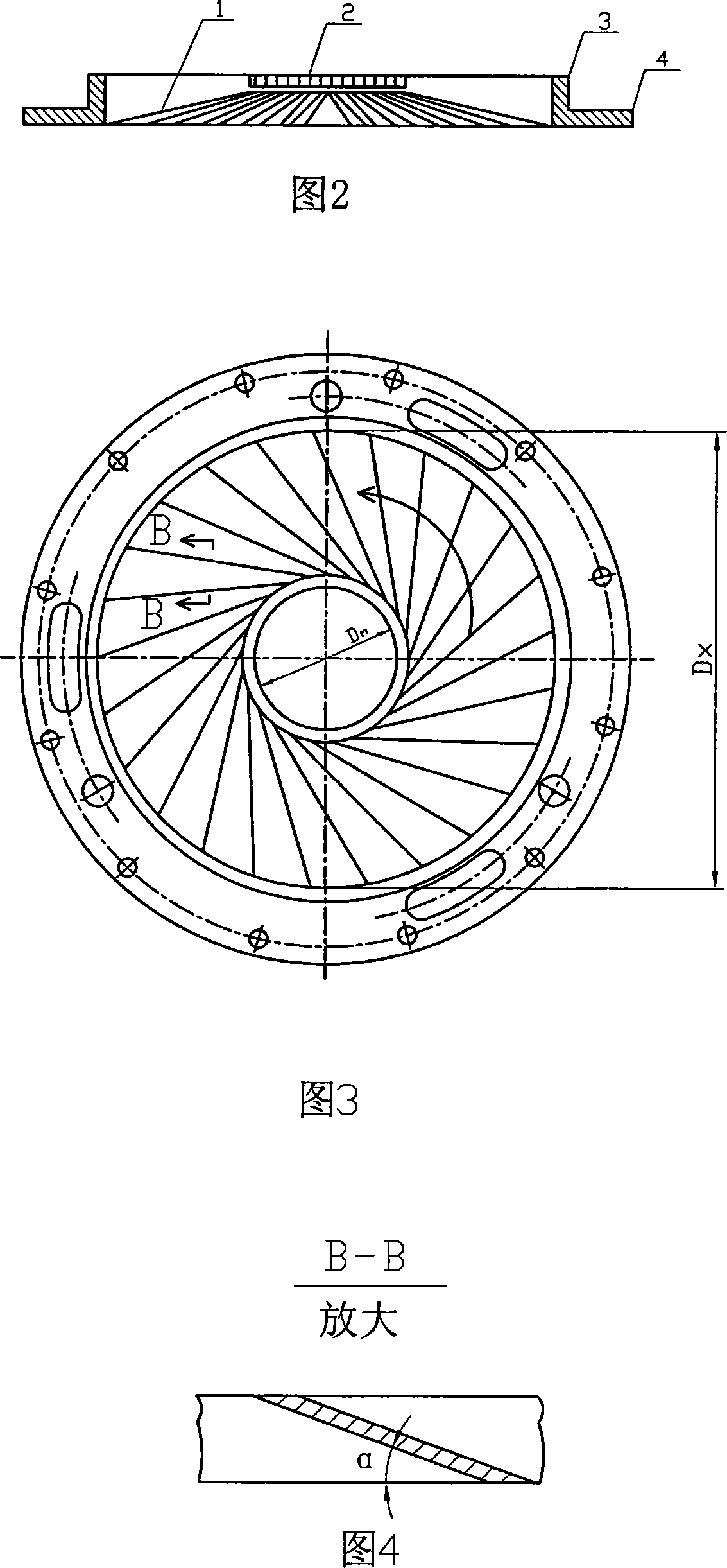

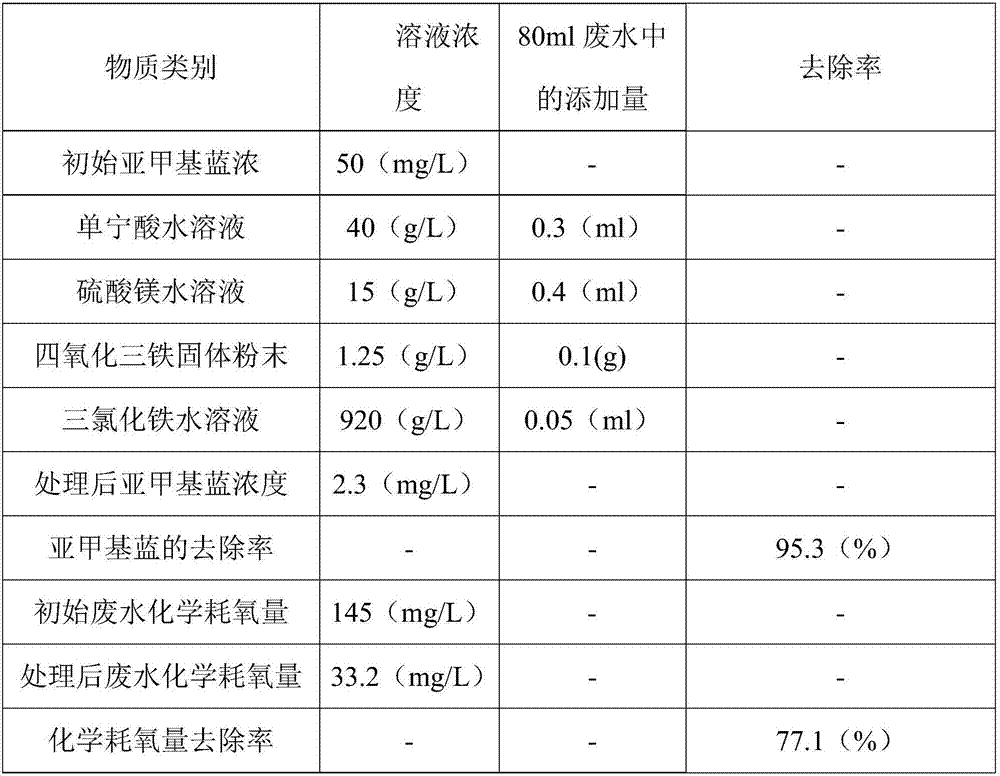

Method for flue gas desulfurization by using dyeing wastewater, and absorption tower

InactiveCN101091874AReduce pollution control costsImprove economic efficiencyDispersed particle separationWater/sewage treatmentFlue-gas desulfurizationSmoke

The invention relates to a method of desulphurization of the waste water and the absorption tower. Its desulphurization method includes: 1) printing waste water pretreatment; 2) the desulphurization about the printing waste water sprays; 3) doctor solution output and so on main steps. The absorption tower contains a tower body, an air outlet on the top of the tower body. The drawing fan is on the outside of the air outlet. The tower in vivo upper side equipped with two defogging levels with two spray levels below. The tower body breast is equipped with the smoke mouth; the tower body base is equipped with the overflow gate. The merit of the invention is that with the printing waste water removing haze in SO2, not only can meet the emission standards, but also can save the sulfuric acid in the printing waste water. Also it can largely reduce chemistry oxygen consumption, which is advantageous in further processing in water disposal plant, and makes the waste water and the waste gas under the comprehensive program of public order. The invention greatly reduces the anti-pollution cost, promotes the business economic benefit, promotes enterprise to implement the waste water and gas governing.

Owner:JIANGSU ZHENGTONG HONGTAI INC

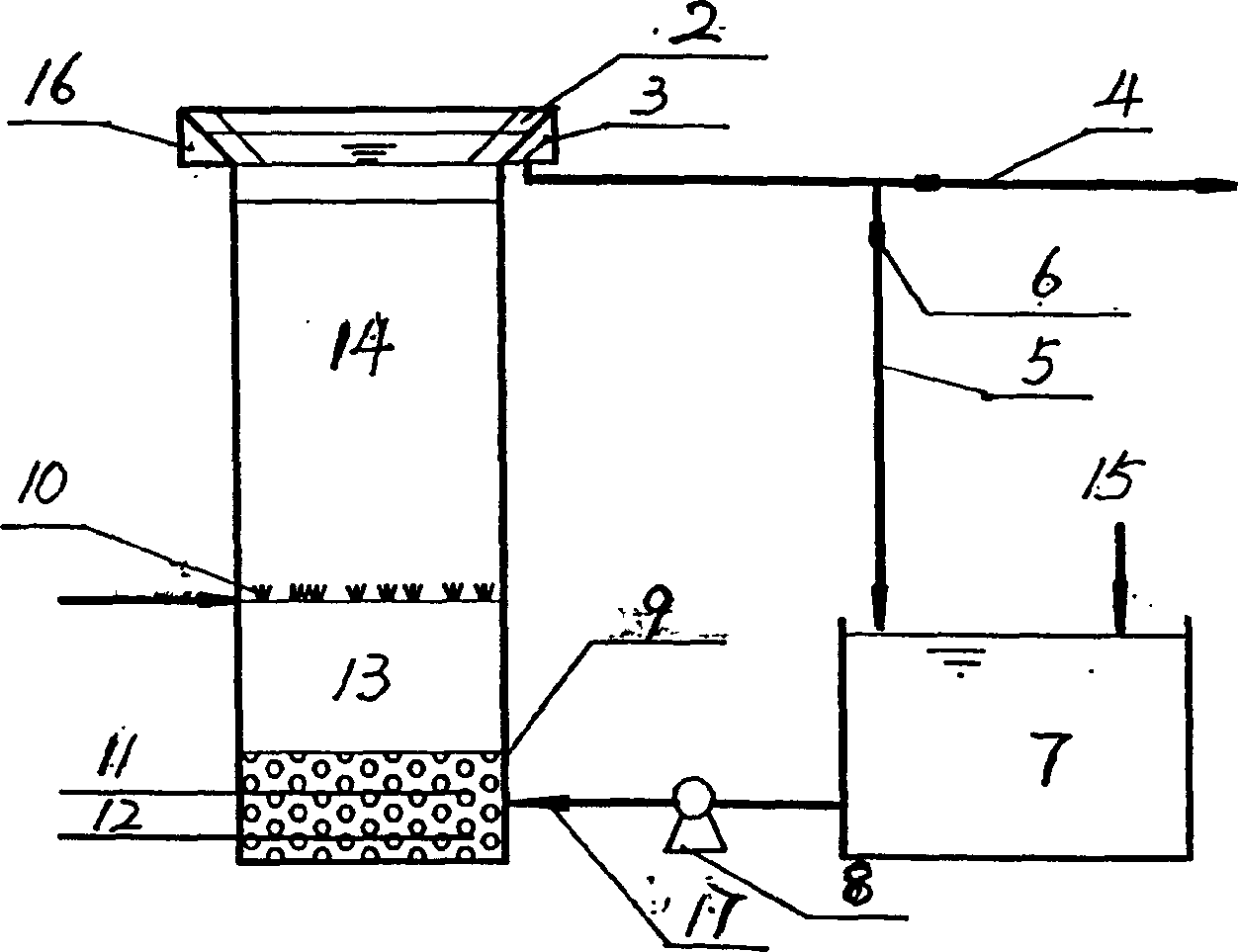

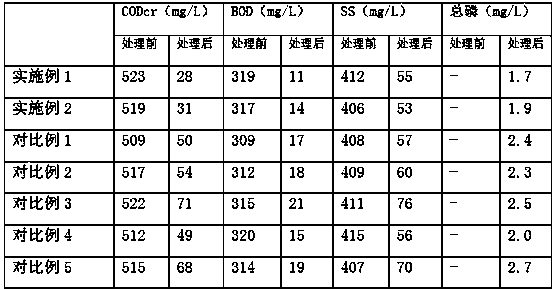

Sewage treatment method and filtering pool

InactiveCN1807282AEasy to handleSimple structureTreatment with aerobic and anaerobic processesNitrationTotal nitrogen

The invention relates to a treatment method for sewage. Wherein, keeping the sewage flowing from lower to upper during the whole process; first, taking denitrifying treatment in hypoxia segment to remove total nitrogen and phosphorus; then, treating in aerobic segment to reduce the COD, BOD5 and SS as well as the ammonia nitrogen by nitration. Besides, the opposite equipment is a vertical-arranged bioaeration filter tank with an aeration pipe on proper position.

Owner:甘肃金桥给水排水设计与工程有限公司

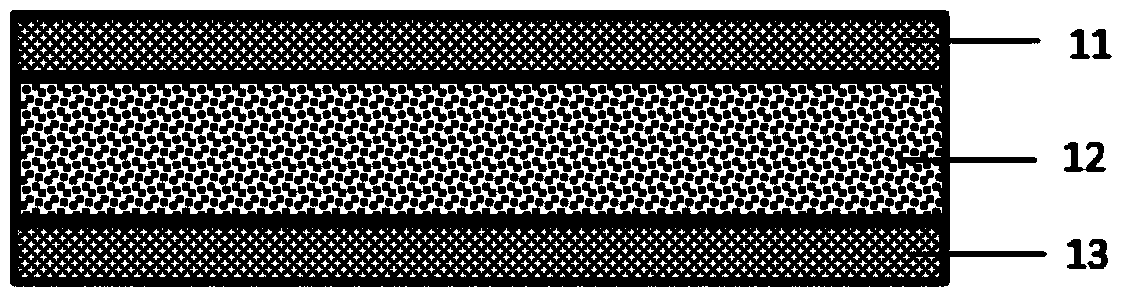

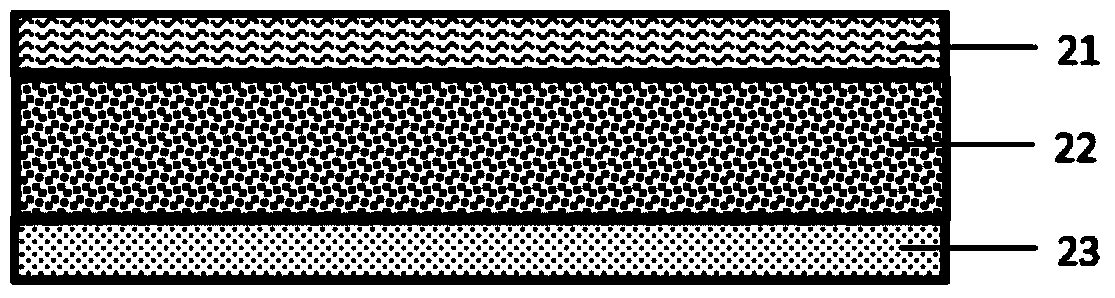

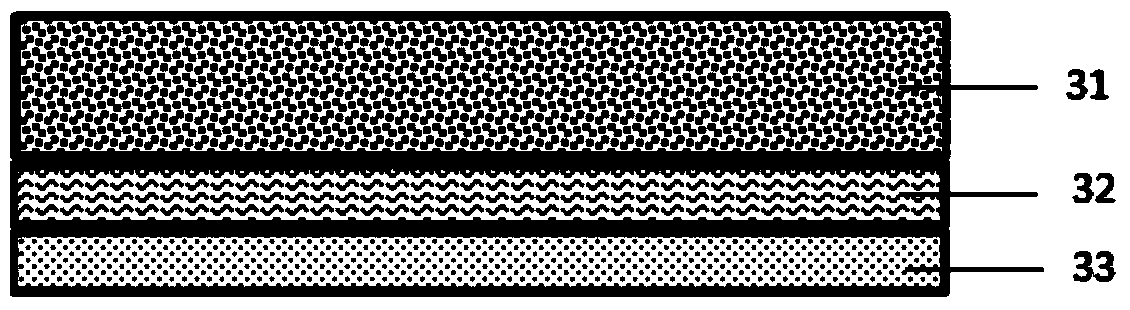

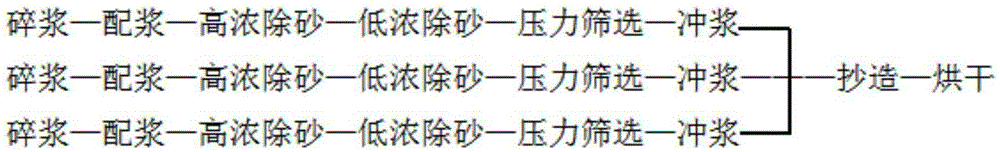

Composite paper making pulp substrate and manufacturing method thereof

ActiveCN103835179ANo emissionsImprove uniformityWaste product additionSpecial paperHigh concentrationFiber

The invention provides a composite paper making pulp substrate and a manufacturing method of the composite paper making pulp substrate. The composite paper making pulp substrate comprises, by weight, 30% to 60% of a surface layer, 20% to 60% of a core layer and 10% to 20% of a bottom layer. The surface layer is made of bamboo fibers and / or cane syrup fibers, the core layer is made of the bamboo fibers or the cane syrup fibers or coal residues or a mixture of the bamboo fibers, the cane syrup fibers and the coal residues, and the bottom layer is made of the bamboo fibers and / or the cane syrup fibers. The manufacturing method includes the steps of repulping, pulp mixing, high concentration desanding, low concentration desanding, pressure screening, slushing, composite paper making, drying and the like. The composite paper making pulp substrate and the manufacturing method have the advantages that the pulp substrate is formed by waste generated through bamboo product processing and food processing and the coal residues discharged by fire coal; when being used as a filtering material, the composite paper making pulp substrate has the good filtering effect on water suspended matter and particulate mater, and can remove organic matter particles and insoluble inorganic matter impurities and reduce the effect of chemical oxygen consumption; no waste water is drained in the process steps, and required water can be recycled.

Owner:苏州吉臣日用品有限公司

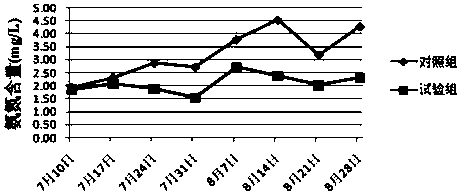

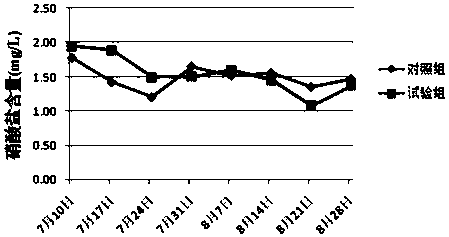

Method of eliminating nitrite and ammonia nitrogen in aquatic culture

InactiveCN1513778AImprove water qualityReduce chemical oxygen demandWater/sewage treatmentMultistage water/sewage treatmentChemistryAlgae

A process for removing nitrite and ammoniacal nitrogen in aquatic products cultivation includes loading H2O2 into an open container, enclosing the container by an osmotic film, attaching the container to an oxygen-enriching machine in water of pond, turning on the machine for slowly diffusing the H2O2 to decompose it into H2O and O2, oxidizing the nitrite and ammoniacal nitrogen to become nitrate by said O2, and adding photosynthesizing bacteria to absorb the nitrate.

Owner:陈永康

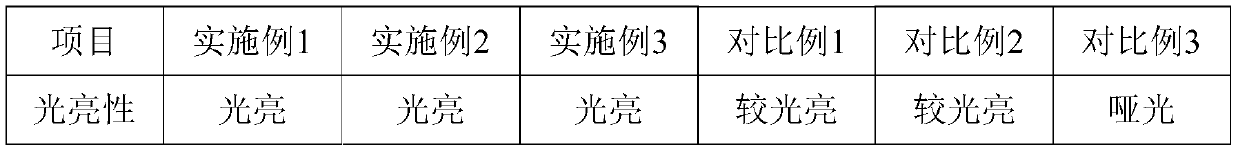

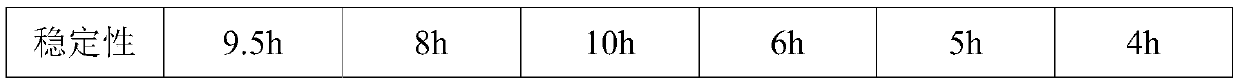

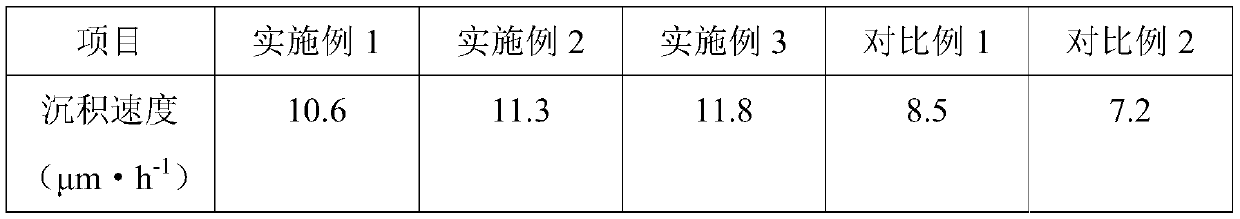

Chemical tin plating liquid and preparation method thereof

ActiveCN110331392AImprove stabilityIncrease brightnessLiquid/solution decomposition chemical coatingTin platingReducing agent

The invention belongs to the technical field of chemical tin plating, and in particular, relates to chemical tin plating liquid and a preparation method thereof. The chemical tin plating liquid contains sulfuric acid, tin salt, complexing agents, multifunctional additives, reducing agents and function auxiliaries; and in the chemical tin plating liquid, the content of the sulfuric acid is 33-40 mL.L-1, the content of the tin salt is 10-15 g.L-1, the content of the complexing agents is 85-95 g.L-1, the content of the multifunctional additives is 0.5-1.2 g.L-1, the content of the reducing agentsis 25-40 g.L-1, and the content of the function auxiliaries is 1-2 g.L-1. The chemical tin plating liquid is excellent in stability, and accelerates the plating layer deposition speed when the stability of the plating liquid is improved.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

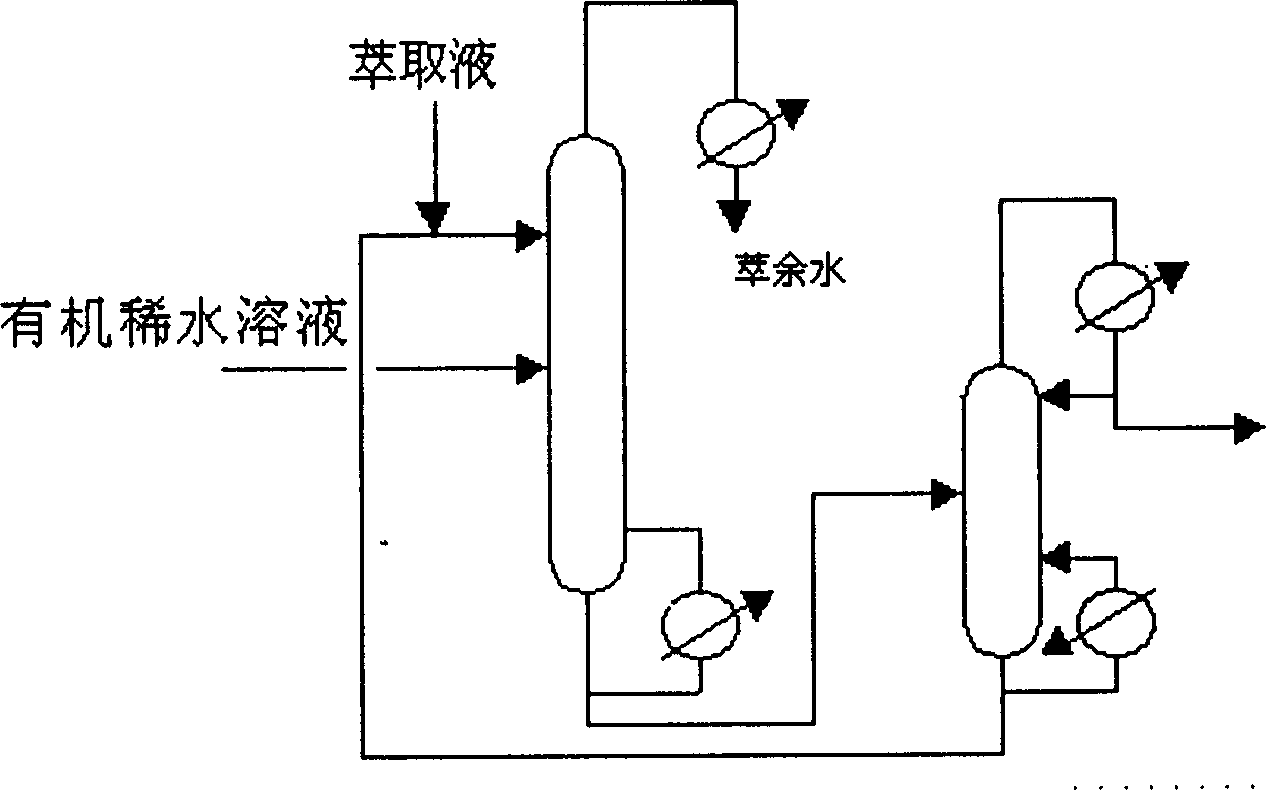

Complexation method for extracting pyrrolidone or its dissolved substance in organic dilute aqueous solution

InactiveCN1687030AReduce chemical oxygen demandHigh recovery rateOrganic chemistryWater/sewage treatment by extractionOrganic acidButyl acetate

The present invention discloses a method for recovering pyrrolidone and its solutrope from organic dilute solution by utilizing complexation extraction process. The organic dilute solution not only contains N-methyl pyrrolidone, but also contains C2, C3 alcohol, ethyl acetate and butyl acetate, also contains small quantity of oligopolymer, their total content is 5.0 wt%. Said invention uses Lewis organic acid or Lewis organic alkali as extracting agent, under the condition of that temperature is 15-50 deg.c, solvent-liquid ratio is 5:1-3 and pH value is 5.0-7.5 makes respective extraction, and under the condition of that the temperature is 70-210 deg.C, pH is 2.0-3.5 and pressure is 0.05-0.1 MPa makes back-extraction, the recovery rate of pyrrolidone and its solutrope in the organic dilute solution can be up to 60-90%.

Owner:上海洁申实业有限公司

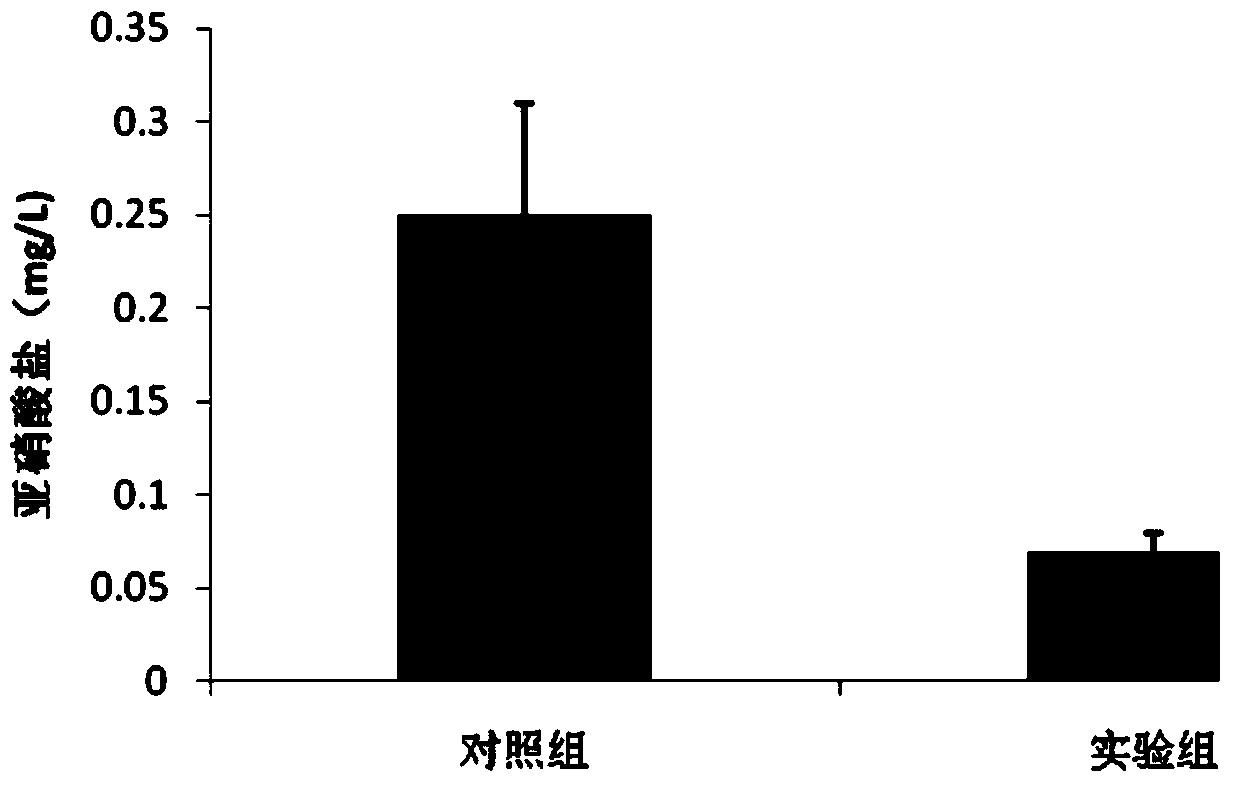

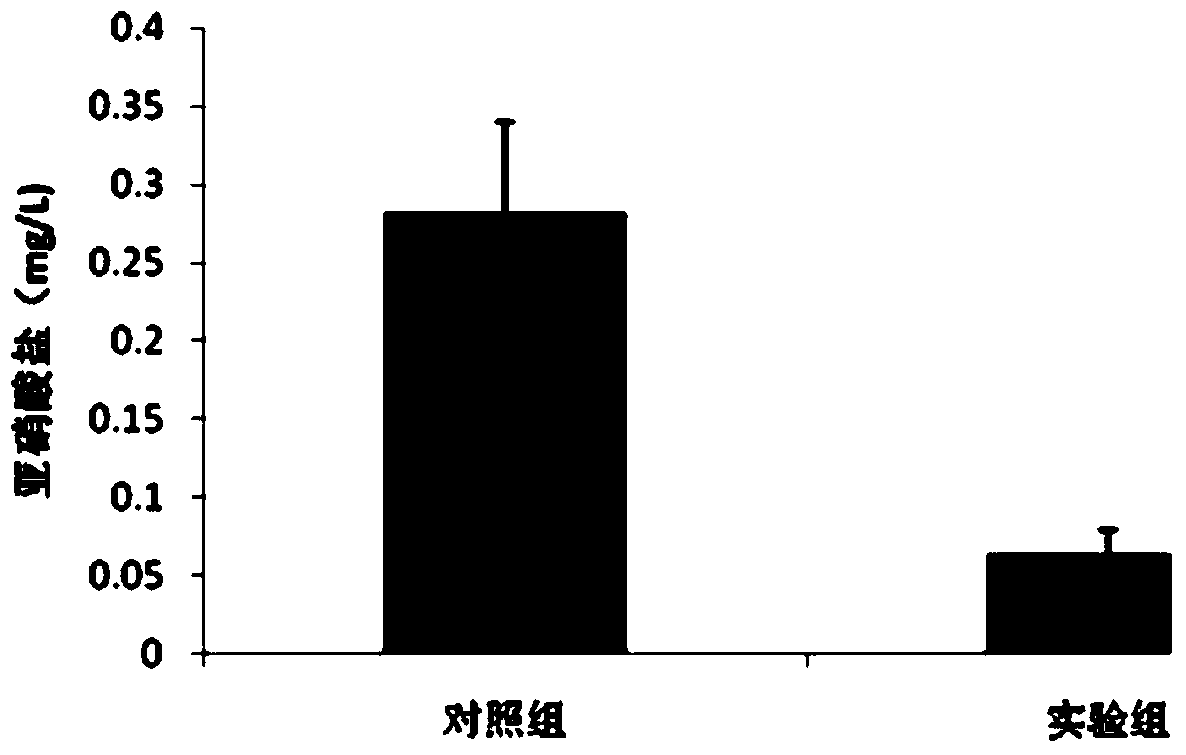

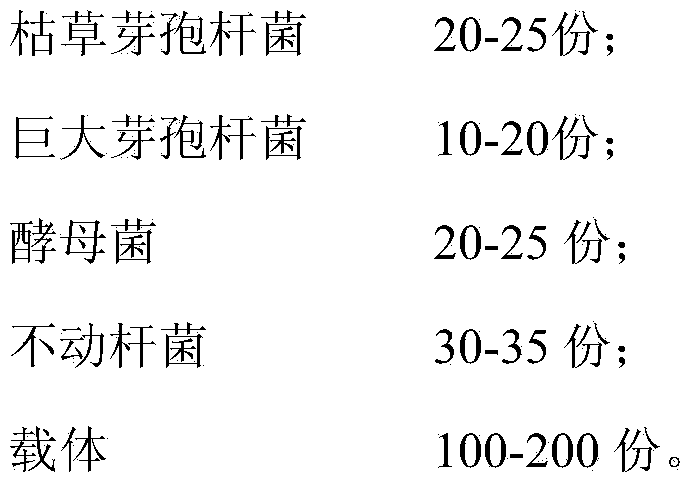

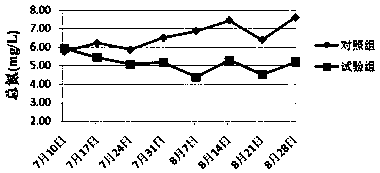

Microbial preparation for brackish water aquaculture, and preparation method and application thereof

InactiveCN104030459APromote reproductionPromote growthBiological water/sewage treatmentBacillus megateriumWater quality

The invention relates to a microbial preparation for brackish water aquaculture, which comprises the following components in parts by weight: 20-25 parts of Bacillus subtilis, 10-20 parts of Bacillus megaterium, 20-25 parts of microzyme, 30-35 parts of Acinetobacter and 100-200 parts of carrier. The preparation method comprises the following steps: sequentially inoculating Bacillus subtilis, Bacillus megaterium, microzyme and Acinetobacter seed culture solutions into a culture medium, fermenting, and mixing the obtained bacterium solution with the carrier substance to obtain the microbial preparation. The microbial preparation is applicable to a culture water body with the salinity range of 0.2-1%. The microbial preparation can obviously improve the water quality of the brackish water aquaculture water body, especially obviously lowers the nitrite content in the water body, and can enhance the flesh texture of the cultured animals.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

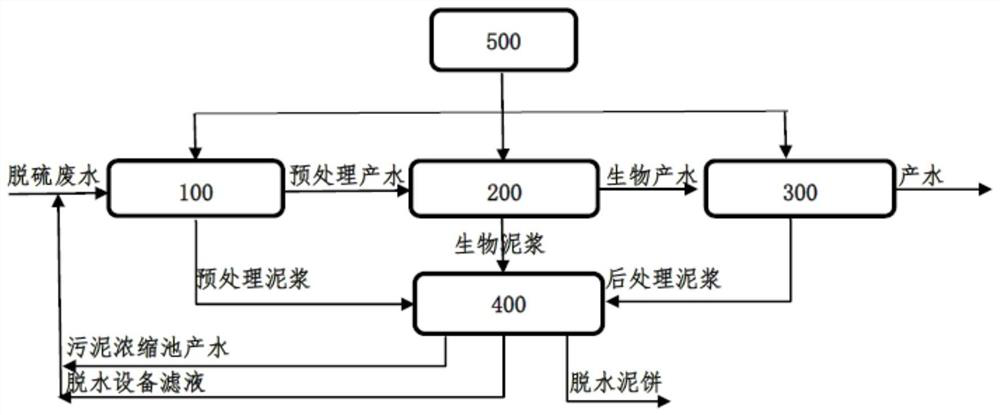

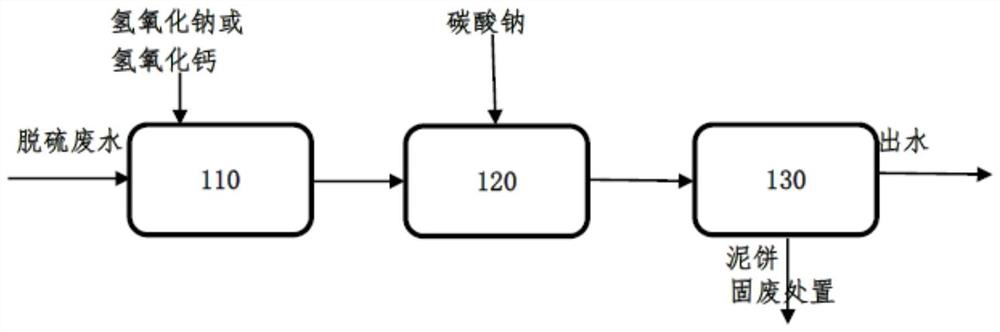

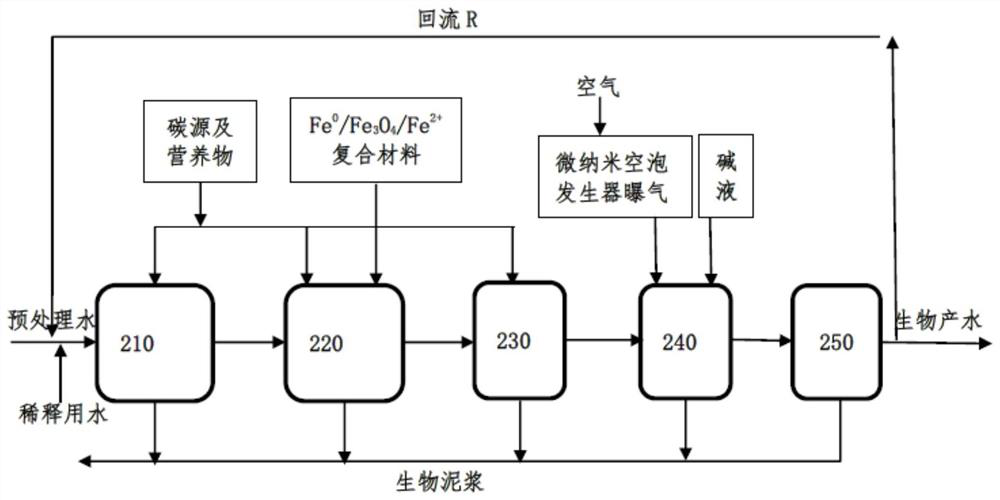

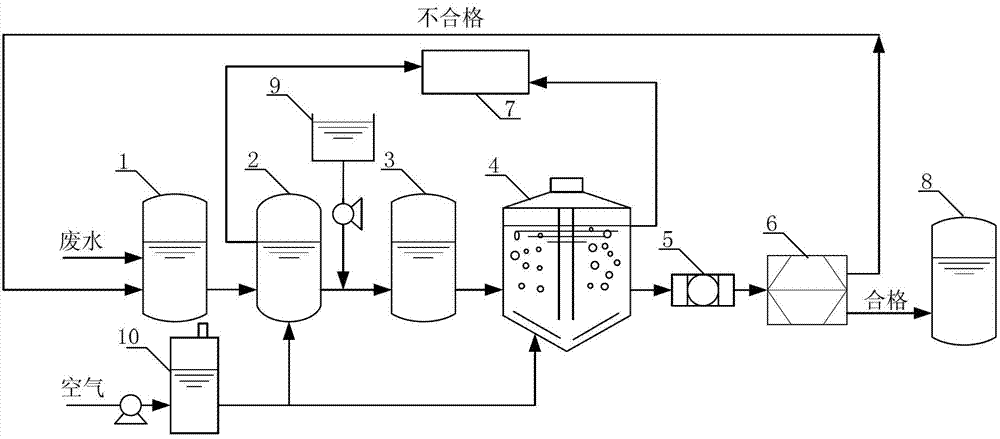

Biological treatment system for removing pollutants in flue gas desulfurization wastewater

ActiveCN111892248AEfficient removalReduce chemical oxygen demandSludge treatment by de-watering/drying/thickeningWater softeningSludgeTreatment system

The invention relates to the field of wastewater treatment, and in particular, relates to a biological treatment system for removing pollutants in flue gas desulfurization wastewater, wherein the system comprises a pretreatment unit, a biological treatment unit, a post-treatment unit and a sludge treatment unit; firstly, the desulfurization wastewater is umped to the pretreatment unit for pretreatment through a high-efficiency flocculation coupling softening process; the pretreated water is pumped to a first-stage facultative / second-stage facultative / anaerobic / aerobic biofilm reactor of the biological treatment unit, selenium, ammonia nitrogen and sulfate in the desulfurization wastewater are removed, COD is degraded, biological produced water is discharged into the post-treatment unit foradsorption and interception, biological treatment residues are removed, and up-to-standard discharge is achieved; slurry generated by the process system is completely collected to the sludge treatment unit for treatment. According to the biological treatment system, on the basis of efficient flocculation pretreatment, selenium, ammonia nitrogen and sulfate in the flue gas desulfurization wastewater can be effectively removed through biological treatment and the COD can be effectively degraded through biological treatment, so that the wastewater is discharged after reaching the standard, and no pollution is caused to the environment.

Owner:张建东

Biological dilution technique for organic sewage

InactiveCN104891672AReduce chemical oxygen demandReduce concentrationWater contaminantsBiological water/sewage treatmentSewageShewanella putrefaciens

The invention discloses a biological dilution technique for organic sewage. The organic sewage with a higher chemical oxygen consumption concentration content and a higher biochemical oxygen demand concentration content and city organic sewage with a higher chemical oxygen consumption concentration content and a lower biochemical oxygen demand concentration content are mixed and uniformly stirred so that the chemical oxygen consumption of mixed organic sewage is 7000ml / L and the biochemical oxygen demand is 8000ml / L, and shewanella putrefaciens is added for culture. Through the adoption of the biological dilution technique disclosed by the invention, the chemical oxygen consumption concentration content and the biochemical oxygen demand concentration content in the organic sewage can be effectively reduced, and the shewanella putrefaciens is used for deep reduction, so that the operation is simple and convenient, and the effect is good.

Owner:汪周启

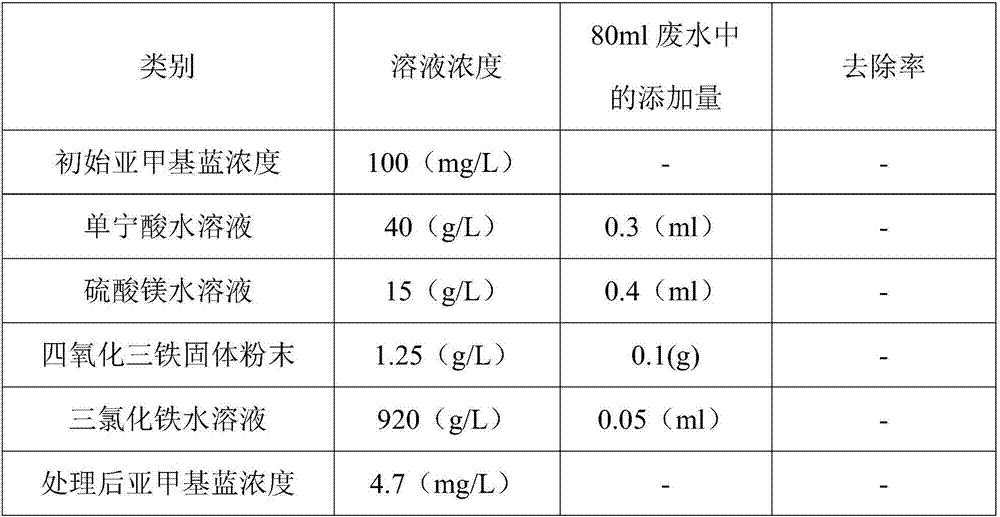

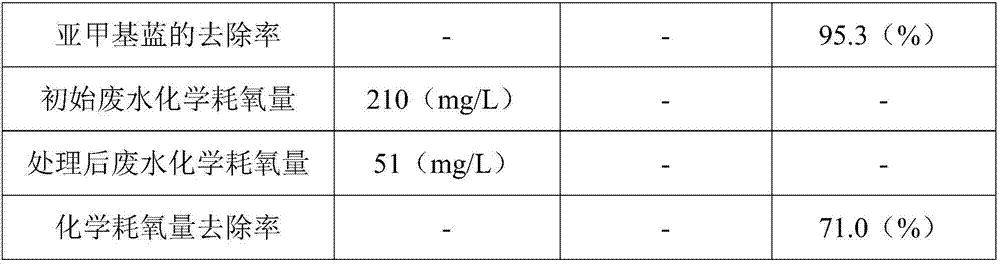

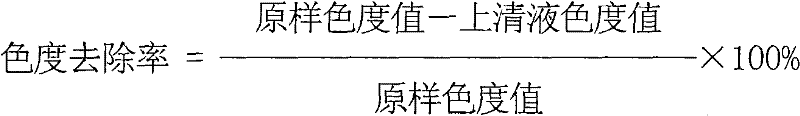

Method for treating methylene blue wastewater

ActiveCN107381869ASimple processEasy to operateWater contaminantsMultistage water/sewage treatmentFlocculationOrganic dye

The invention relates to a method for treating methylene blue wastewater. The method comprises the steps of adding tannin and metal magnesium ions into the methylene blue wastewater, mixing, adding magnetic powder and a flocculating agent so as to form a magnetic flocculate under an alkali condition, and carrying out magnetic separation on the magnetic flocculate by virtue of a magnet, so as to realize the purification of the methylene blue wastewater. The method has the beneficial effects that the operation is simple, the decoloration effect is remarkable, soluble organic dyes in dye wastewater can be effectively removed, and chemical oxygen consumption in water is reduced; and the operation cost is low, the treatment cycle is short, the efficiency is high, the process is simple, no secondary pollution after flocculation, and the method is easy to popularize.

Owner:北京市畜牧业环境监测站

Method for flue gas desulfurization by using dyeing wastewater, and absorption tower

InactiveCN101091874BReduce chemical oxygen demandReduced chemical oxygen demand (COD)Dispersed particle separationWater/sewage treatmentEmission standardDyeing wastewater

Owner:JIANGSU ZHENGTONG HONGTAI INC

Beer wastewater treatment method

ActiveCN110104895AHigh purityImprove exchange capacityTreatment involving filtrationTreatment with aerobic and anaerobic processesFiltrationAnaerobic bacteria

The invention provides a beer wastewater treatment method. The beer wastewater treatment method comprises the following steps that 1, pretreatment is conducted, wherein screening is conducted by usinggrids; 2, sedimentation treatment is conducted, wherein after screening, a hectorite compound treatment agent with the mass being 0.05-0.1% of the mass of beer wastewater is added into the beer wastewater, and stirring is conducted; 3, according to the difference between an aerobic treatment way and an anaerobic treatment way, aerobic bacteria and anaerobic bacteria are added for treatment; 4, furfural is added, polyvinylpyrrolidone is added too, filtration is conducted to obtain filter residues and filter liquor, and the filter liquor is treated wastewater. The reasonable treatment method isadopted, the large-size organic matter, which is difficult to degrade, in the beer wastewater is effectively reduced, the organic matter is hydrolyzed into simple organic matter which is easy to degrade, the SS content in the wastewater is greatly reduced, the removal rate of BODs and CODs in the treated wastewater is high, and the treated wastewater reaches specified emission standards.

Owner:戚馨雨

Freshwater culture pond water quality improver and preparation method thereof

InactiveCN108529740ASave raw materialsFast degradation rateWater treatment compoundsWaste water treatment from animal husbandrySodium carboxymethylcelluloseZeolite

The invention discloses a water quality improvement agent for freshwater aquaculture ponds and a preparation method thereof, and belongs to the field of water quality regulation of aquaculture ponds.The modifier is prepared from potato dry residue, sodium humate, zeolite powder, sodium carboxymethyl cellulose, and inorganic nutrient salts. The effect of the improver is remarkable and lasting, andthe water quality of the freshwater aquaculture pond can be effectively controlled during the high temperature breeding season, and the healthy and sustainable development of the freshwater aquaculture industry is promoted. The improvement agent is easy to manufacture and simple to operate, and can be used for large-scale industrial production.

Owner:江西省农业科学院畜牧兽医研究所

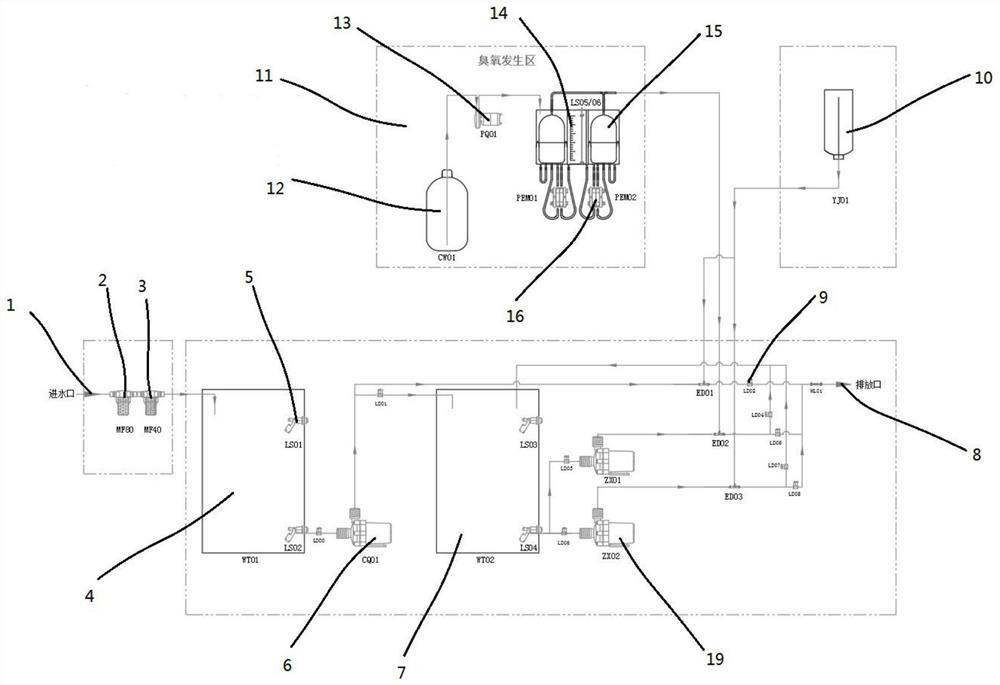

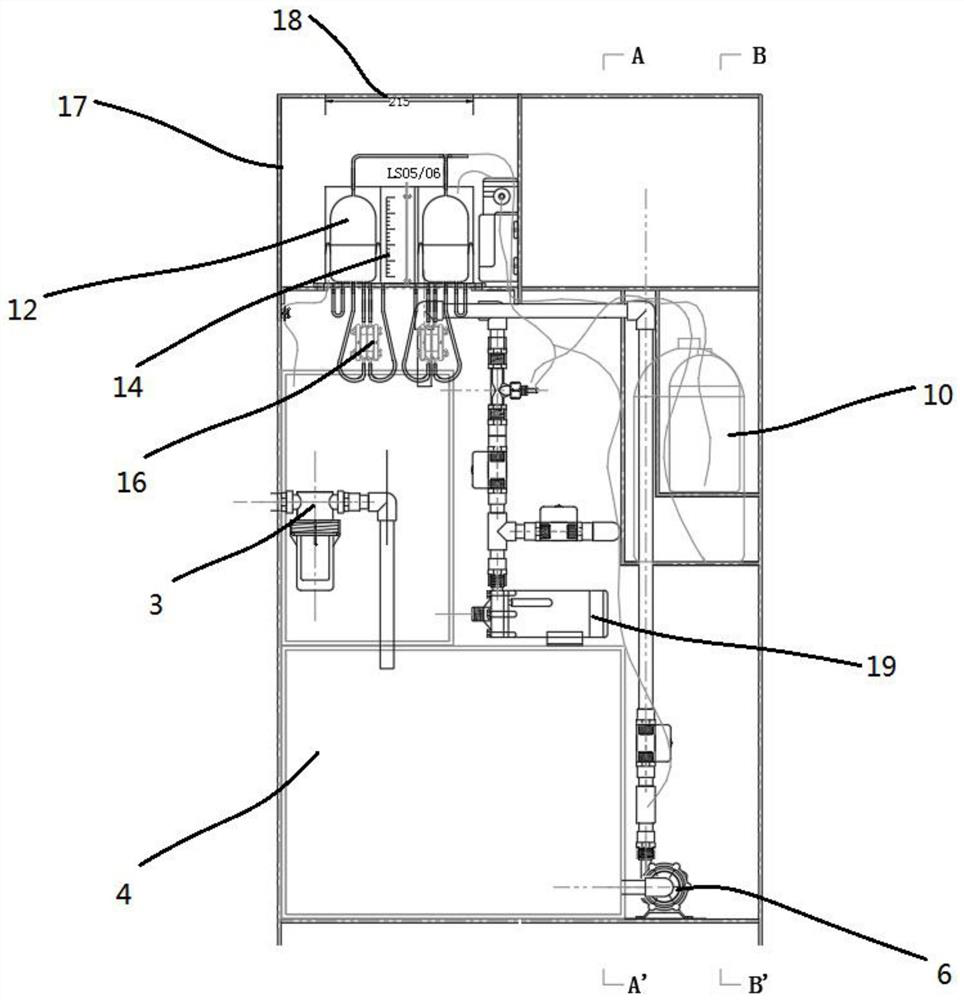

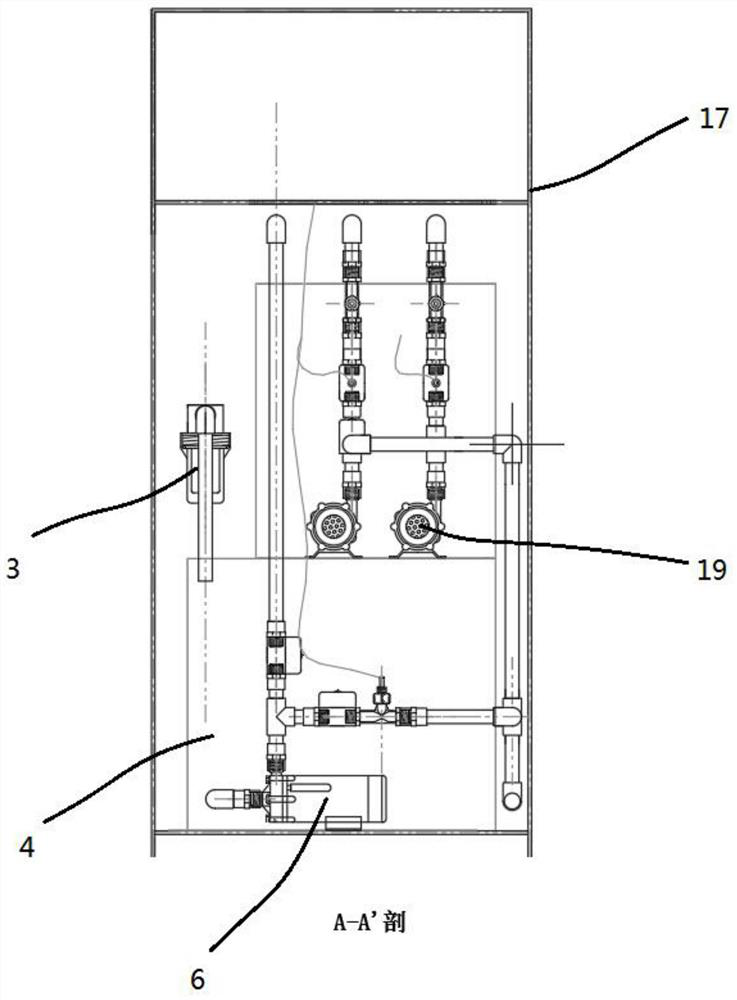

Disinfection equipment suitable for small medical institution

PendingCN112645495ASimple structureSimple processWater treatment parameter controlSpecific water treatment objectivesPeristaltic pumpSewage

The invention discloses disinfection equipment suitable for a small medical institution. The disinfection equipment comprises a device body and an ozone generation area arranged in the device body, wherein a water inlet is formed in one side of the device body, one end of the water inlet is connected with a first peristaltic pump, one end of the first peristaltic pump is connected with a first sewage bucket, one side of the first sewage bucket is connected with a magnetic pump, one side of the magnetic pump is connected with a second sewage bucket through a pipeline, and the second sewage bucket is connected with a discharge port through a pipeline; one side of the magnetic pump is connected with a chemical barrel through a pipeline, and the outlet end of the second sewage barrel is connected with an ozone generation area through a self-priming pump; a reaction chamber and a pure water storage barrel are arranged in the ozone generation area, the pure water storage barrel is connected to the reaction chamber through a pipeline, and an ozone generator is arranged at the bottom of the reaction chamber.

Owner:苏州宏安环境科技有限公司

Method for extracting diosgenin for joint production of starch suger by prehy drolysis of yellow ginger by multienzyme process

InactiveCN1255549CReduce the amount requiredAcid hydrolysis is sufficientSteroidsFermentationBiotechnologyCarbohydrase

The invention provides a saponin extraction method for prehydrolyzing turmeric and co-producing starch sugar by a multi-enzyme method. The method is to first wash the turmeric, grind it into a slurry, then add α-amylase to liquefy, then add glucoamylase to saccharify, then heat up and inactivate, and then the saccharified material is centrifuged to obtain filter cake and starch sugar solution. The ultrafiltration membrane with a molecular weight cut-off of 1000-10000daltons or the microfiltration membrane of 100-200nm is separated to obtain starch sugar solution, and the filter residue is mixed into the centrifugal filter cake to obtain sugar residue, which is hydrolyzed by adding hydrochloric acid or sulfuric acid, and the hydrolyzate is filtered, washed, Drying, solvent extraction to get saponin products. Before acid hydrolysis, the present invention adopts multi-enzyme starch hydrolysis sugar production and membrane separation technology, reduces the total amount of acid hydrolyzate, saponin hydrolysis is more complete, saponin yield is high, waste water volume is small, and chemical oxygen consumption is low. This method can also be used for the extraction of diosgenin from the co-production of starch sugar by the hydrolysis of pendirol.

Owner:TAIGU INVESTMENT WUHAN

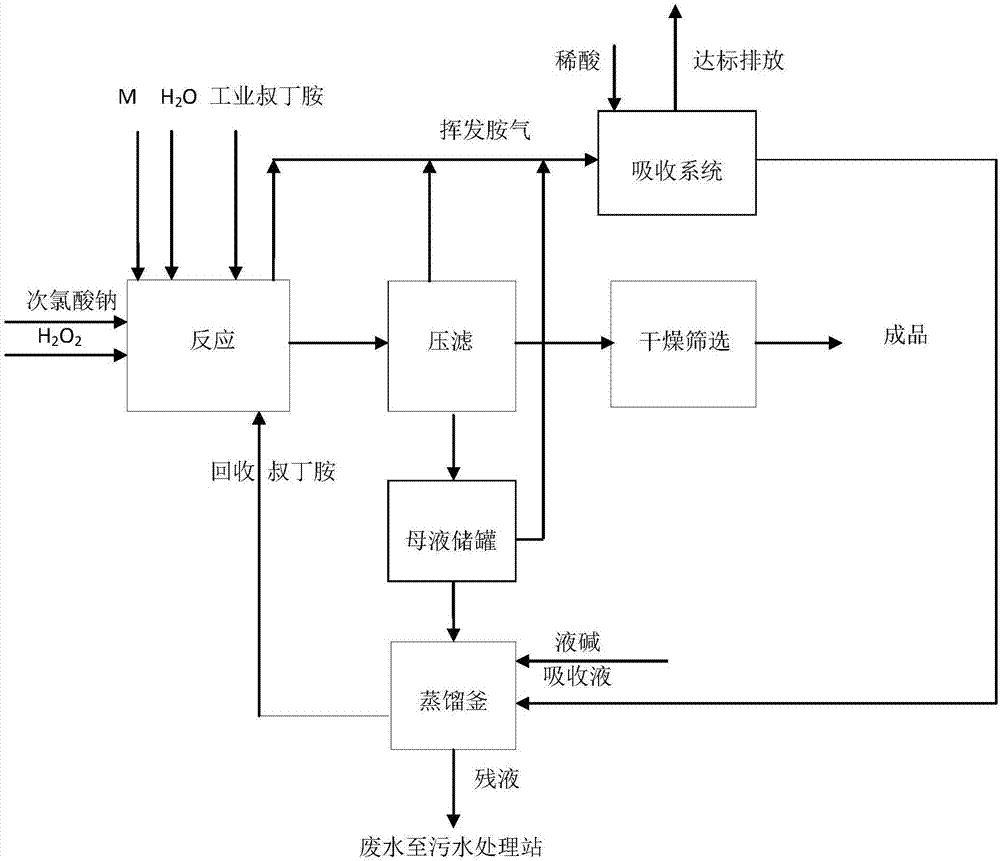

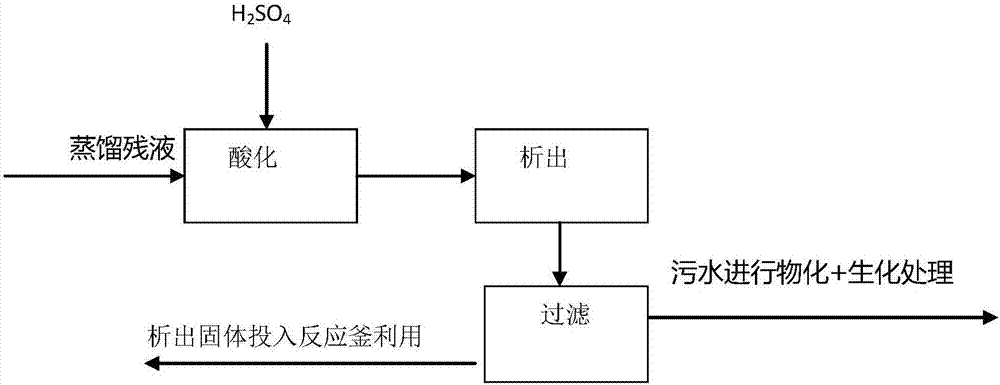

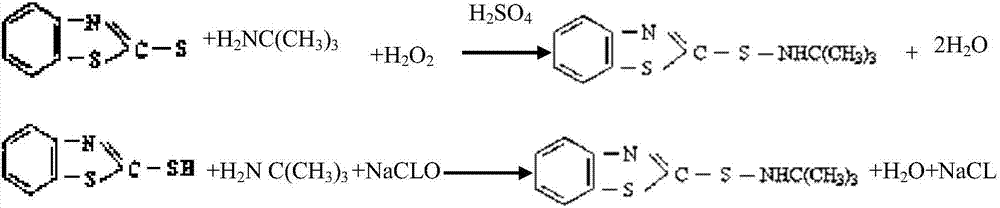

Method for synthesizing sulfenamide-like accelerator TBBS by using solvent purification method rubber accelerator M

InactiveCN107501206AReduce chemical oxygen demandReduce generationOrganic chemistryPurification methodsReaction temperature

The invention discloses a method for synthesizing sulfenamide-like accelerator TBBS (N-cyclohexyl-2-benzothiazolylsulfenamide) by using a solvent purification method rubber accelerator M. The accelerator TBBS is synthesized by using the rubber accelerator M and tert-butylamine as raw materials, by using hydrogen peroxide and sodium hypochlorite as oxidants and by using sulfuric acid as a catalyst; and the method comprises the following optimal production process conditions: (1) a molar ratio of the rubber accelerator M to the tert-butylamine is 1:2.4; and a molar ratio of the rubber accelerator M to the hydrogen peroxide to the sodium hypochlorite is 1:0.6:(0.55-0.65); (2) a reaction temperature is 55-60 DEG C; and (3) reaction time is 2.0-3.0h. The method disclosed by the invention comprehensively solves a technical problem of synthesizing the sulfenamide-like accelerator TBBS by using the solvent purification method rubber accelerator M, product quality indexes are higher than Chinese standard levels, consumption indexes achieve industry relatively-low standards, and the method solves treatment problems of pollutants including wastewater, solid waste and cacosmia.

Owner:QINGDAO AUX CHEM

Method for recovering 2-propylmalonic acid and preparing valproic acid from 2-propylmalonic acid

ActiveCN112142588AHigh purityLow impurity contentOrganic compound preparationCarboxylic acid esters preparationAcid waterMalonic acid

The invention discloses a method for recovering 2-propylmalonic acid and preparing valproic acid from 2-propylmalonic acid, and the method for recovering 2-propylmalonic acid and preparing valproic acid from 2-propylmalonic acid includes the following steps: (1) collecting acid water after centrifuging dipropylmalonic acid, adding ether, ester, chlorinated hydrocarbon and an alcohol (immiscible with water) solvent, stirring, extracting, layering, and drying to obtain dipropylmalonic acid with the recovery rate of more than 90%; and (2) performing esterification, propylation, hydrolysis and acidification on the 2-propylmalonic acid to obtain dipropylmalonic acid, and performing decarboxylation to obtain high-purity valproic acid (the content is greater than or equal to 99.5%). Through recovery and comprehensive utilization of the 2-propylmalonic acid, the production cost of the 2-propylvaleric acid is reduced, and the pressure of subsequent environmental protection treatment is greatlyreduced.

Owner:湖南省湘中制药有限公司

Nuisance free special microelement additive for bastard halibut and pleuronectid and its production process

InactiveCN100399934CLow costPromote growthAnimal feeding stuffAccessory food factorsManganeseGrowth promoting

The trace element feed additive for sea water left-eyed flounder and right-eyed flounder has the effective components comprising Fe 23000-50000 mg / kg, Mn 4000-8000 mg / kg, Zn 25000-48000 mg / kg, Cu 2000-5000 mg / kg, Co 200-400 mg / kg, Se 100-200 mg / kg and I 50-130 mg / kg; and carrier of natural Chinese medicinal stone in the weight range of 60-80 %. Its compounding process includes calculating the added amount of organic chelates and inorganic compounds based on the required ratio of trace elements and their contents in organic chelate or inorganic compound; mixing through stirring in stainless steel stirrer and packing in gold foil bag. The trace element feed additive has obvious growth promoting effect on sea water left-eyed flounder and right-eyed flounder and less water environment pollution.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

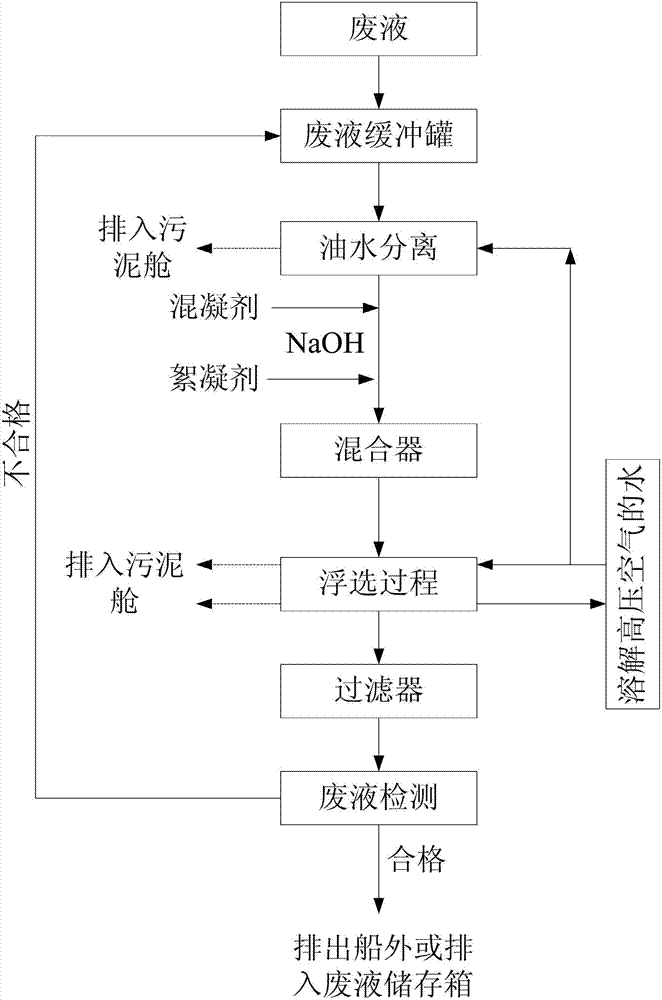

Device and method for treating waste liquor of gas desulphurization system during ship washing

ActiveCN103319026BEasy to handleEnsure water qualityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationLiquid wasteSludge

The invention aims at providing a device and method for treating waste liquor of a gas desulphurization system during ship washing. The device for treating waste liquor of the gas desulphurization system during ship washing comprises a waste liquor buffer tank, an oil water separation tank, a mixer, a floatation chamber, a waste liquor detection system, a sludge cabin and a high pressure air water tank, wherein the waste liquor buffer tank is used for storing waste liquor and then is communicated with the oil water separation tank by virtue of a water pump, the oil water separation tank is connected with a chemical agent tank in parallel and then is communicated with the mixer, the mixer is communicated with the floatation chamber, the floatation chamber is communicated with the waste liquor detection system by virtue of a filter, waste liquor detected by the waste liquor detection system is discharged into a waste liquor storage tank if the waste liquor meets the specified standard and is discharged into the waste liquor storage tank if the waste liquor does not meet the specified standard, the sludge cabin is respectively communicated with the oil water separation tank and the floatation chamber, and the high pressure air water tank is respectively communicated with the oil water separation tank and the floatation chamber. The device for treating waste liquor of the gas desulphurization system during ship washing can be used for treating floating oil, emulsified oil, particles and heavy metal hydroxide precipitate at the same time, so that structure of equipment is compact, floor space is small, energy is saved, and the treated oil-bearing waste liquor can meet the standard stably.

Owner:上海蓝魂环保科技有限公司

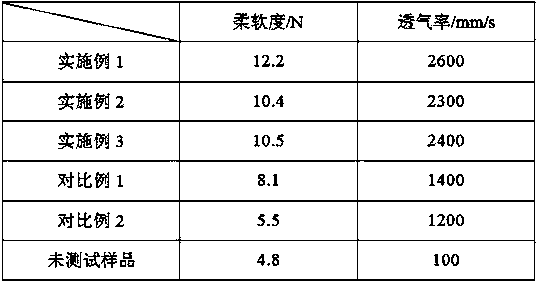

Silicon-free softening agent and preparation method thereof

InactiveCN110644233AImprove natureImprove hydrophilicityGrip property fibresPolymer sciencePolyvinyl alcohol

The invention relates to a silicon-free softening agent and a preparation method thereof. The softening agent is prepared from, by weight, 40-60 parts of beef tallow, 10-20 parts of stearic acid, 6-14parts of diethylenetriamine, 6-10 parts of diethyl sulfate, 4-10 parts of isopropyl alcohol, 3-7 parts of modified polyvinyl alcohol and 1-5 parts of sodium lauryl sulfate. By polyvinyl alcohol modification, polyvinyl alcohol can be better applied to the field of textile auxiliary agents to remarkably improve performances of the silicon-free softening agent, and fabrics using the softening agenthave advantages of high hydrophilicity, freeness of stuffiness in wearing of clothes, fluffiness, softness, freeness of oiliness, closeness to human skin and nature, and the like. In addition, the chemical oxygen demand and the biochemical oxygen demand of sewage can be reduced, and biodegradation of organic silicon macromolecules is reduced.

Owner:广州科丰达新材料科技有限公司

Preprocessing method of hexadecyl trimethyl ammonium bromide for molasses alcohol waste water

InactiveCN101746911BReduce chemical oxygen demandReduce chromaWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentAlcoholWastewater

Owner:SHAANXI NORMAL UNIV

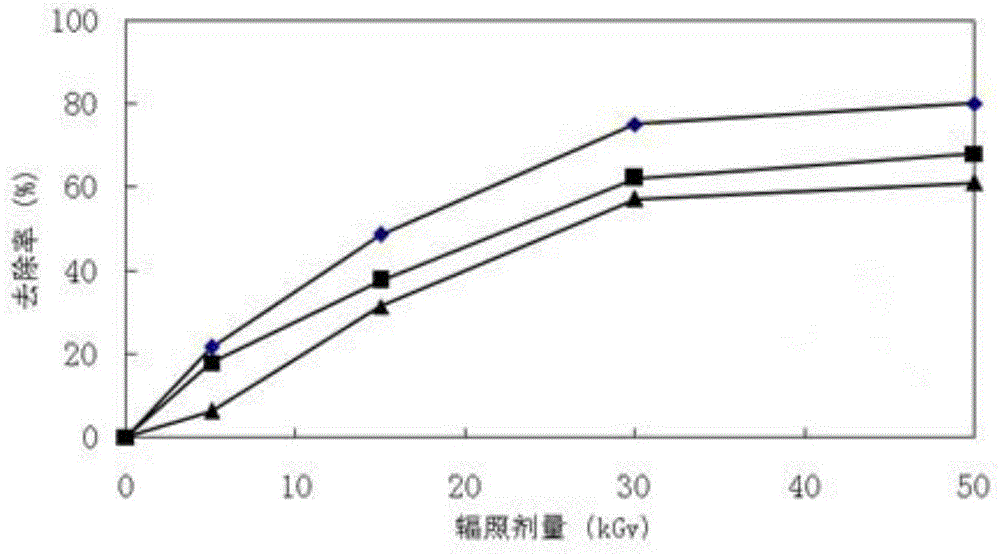

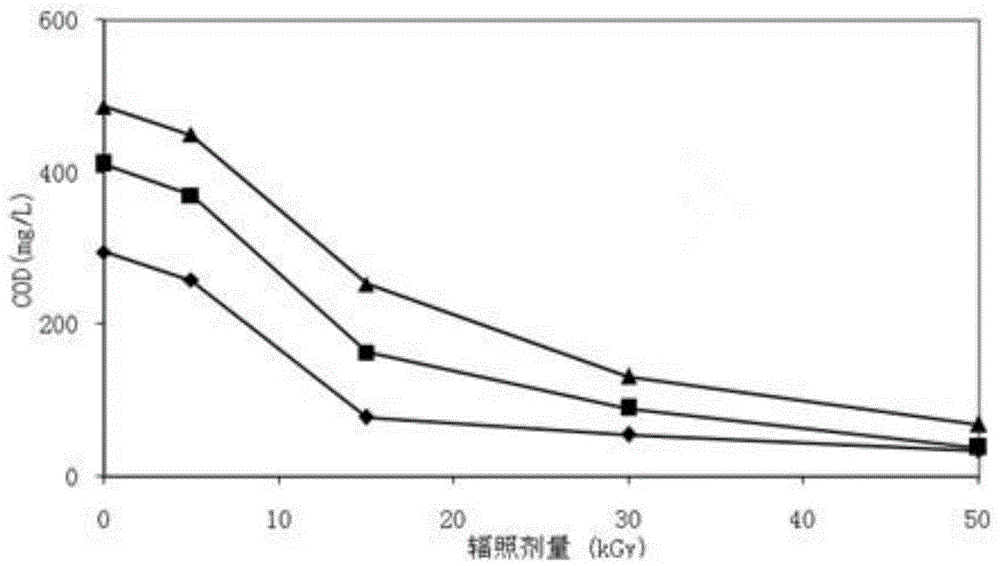

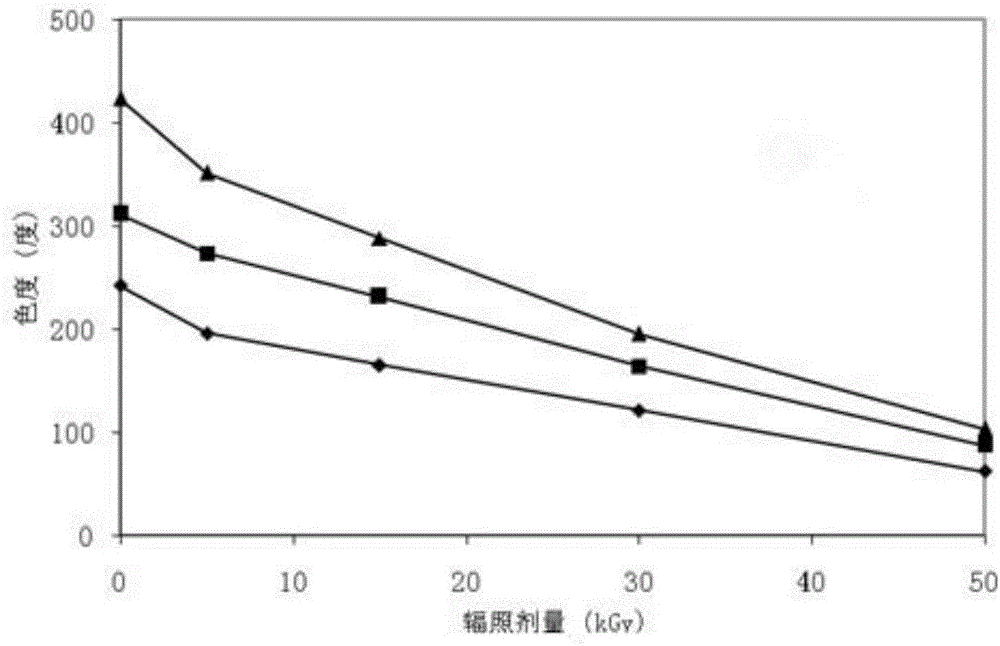

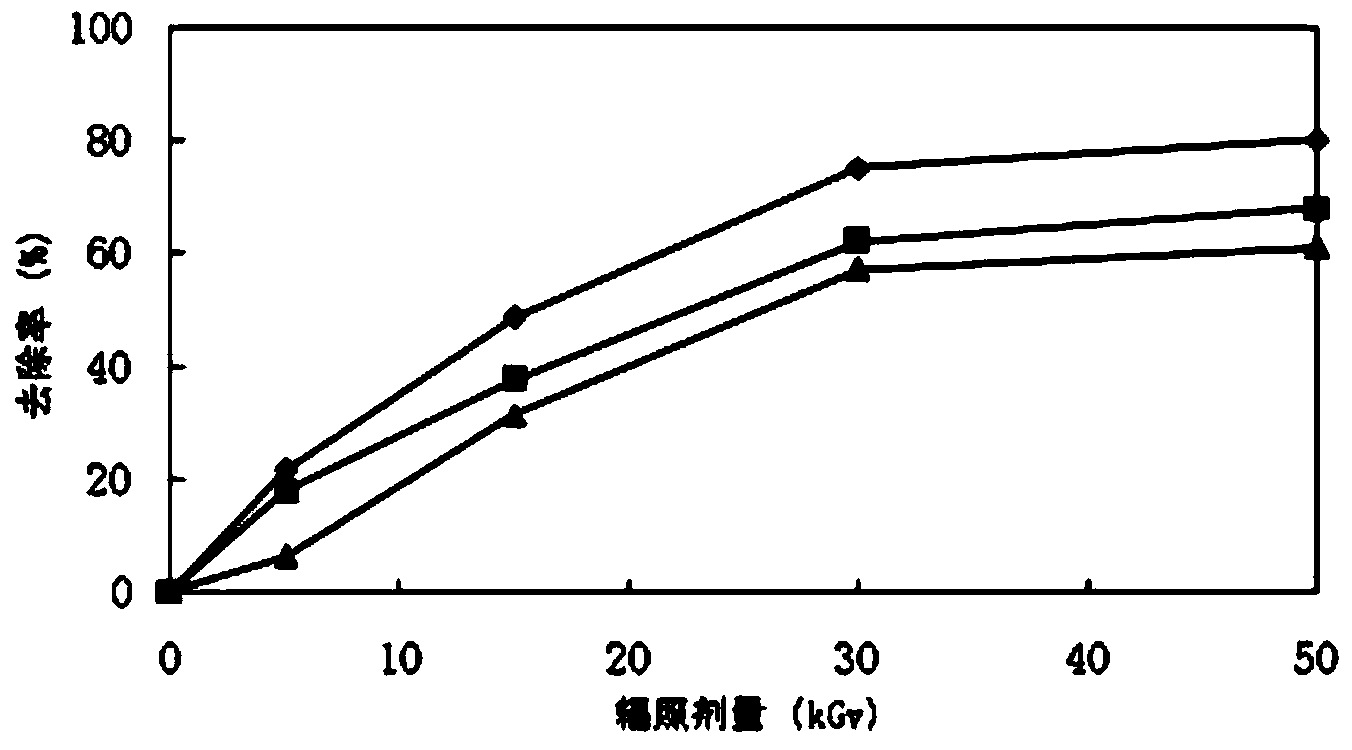

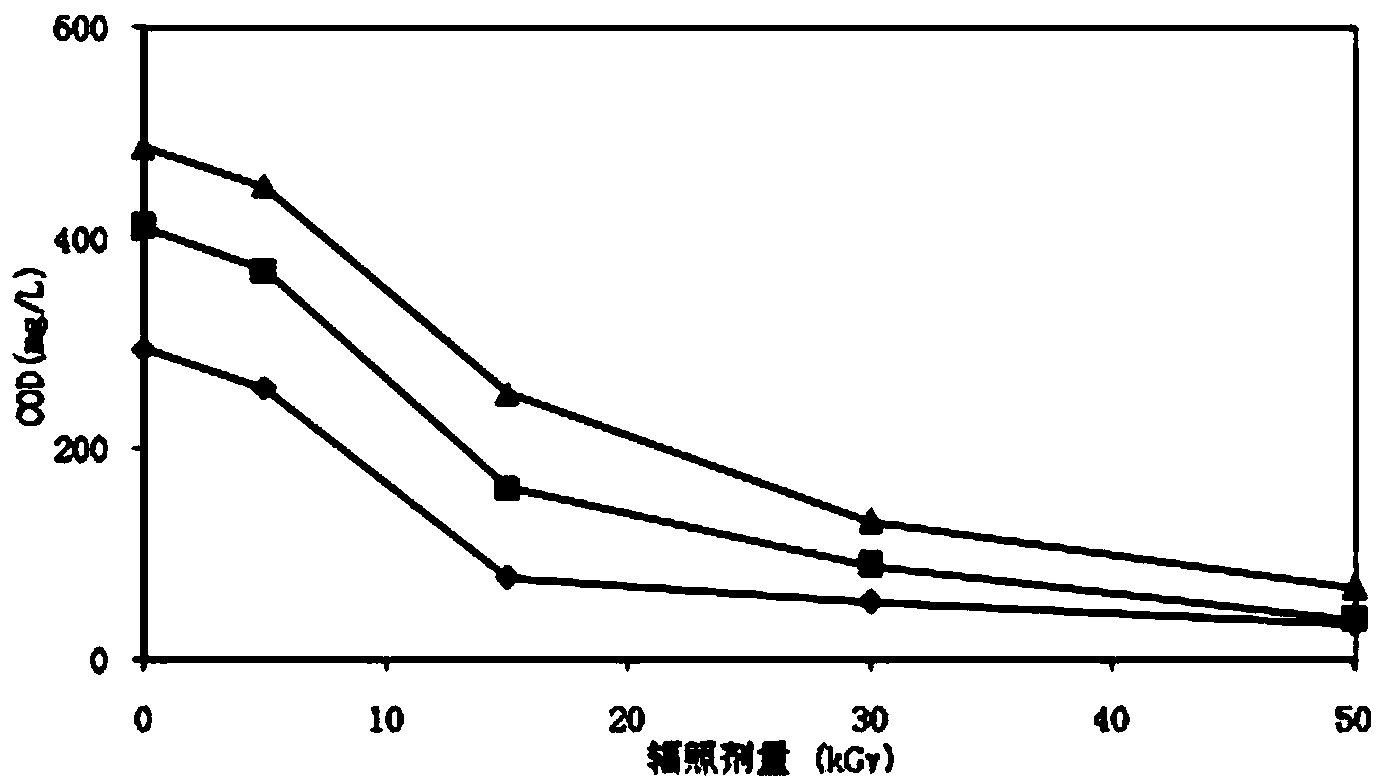

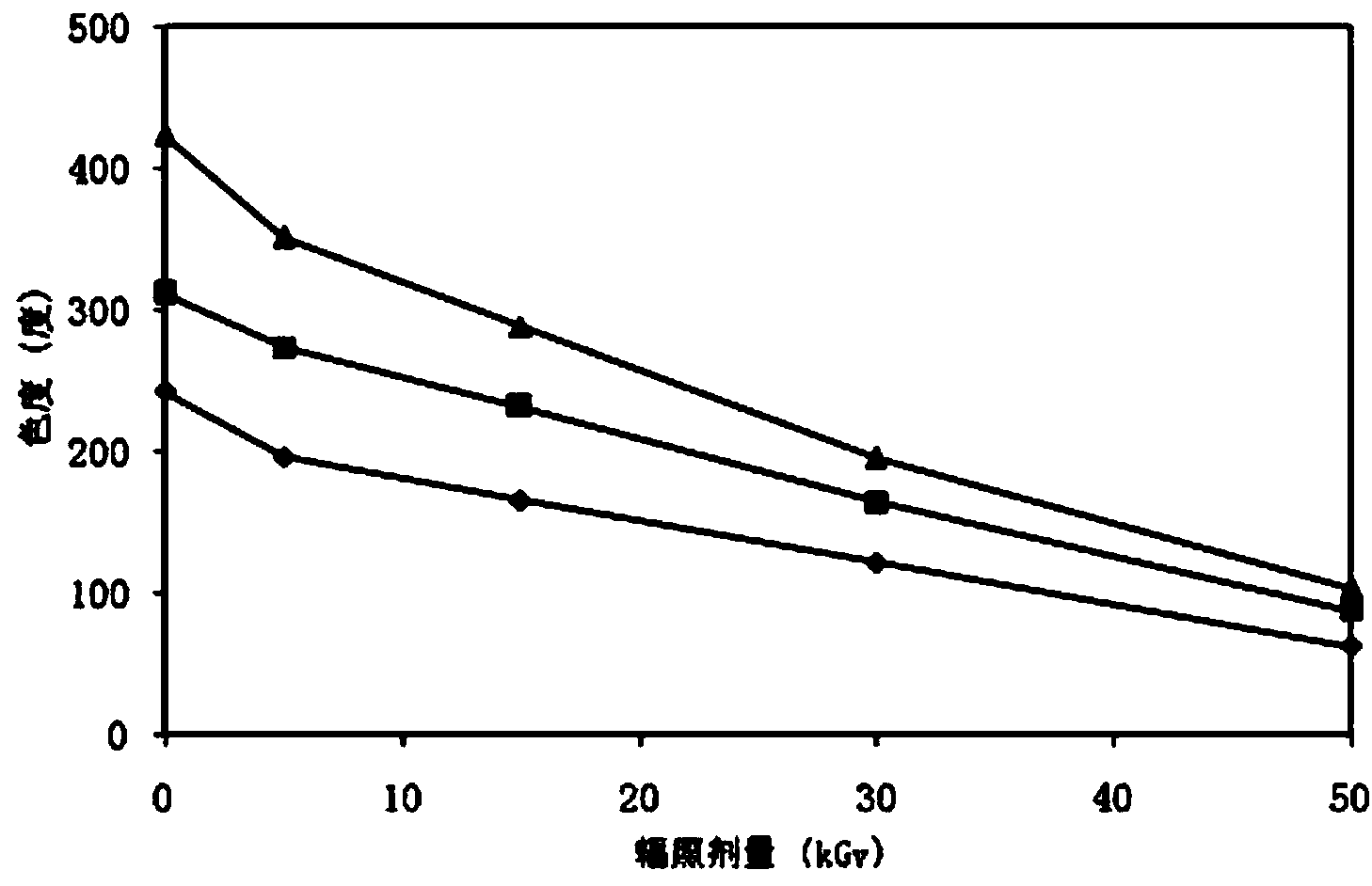

Method for removing humic acids in water by using electron rays

InactiveCN103553177ANo secondary pollutionEasy to handleWater/sewage treatment by irradiationWater contaminantsRedoxPollution

The invention discloses a method for removing humic acids in water by using electron rays, relating to a water treatment method and aiming to solve the problem of secondary pollution caused in the process of removing humic acids in water by using the traditional method for removing humic acids in water. The method comprises the steps of introducing air to a natural water with humic acids by using a water pump, and then, continuously irradiating the electron rays into the natural water by using an electron accelerator. According to the invention, the electron rays react with water molecules to generate various active free radical particles, then, the active free radical particles are subjected to oxidation reduction reaction with humic acids in water to degrade the molecules of humic acids into micromolecular substances, and any other substances are not needed to be treated, so that secondary pollution is avoided. The method is used for removing humic acids in water.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

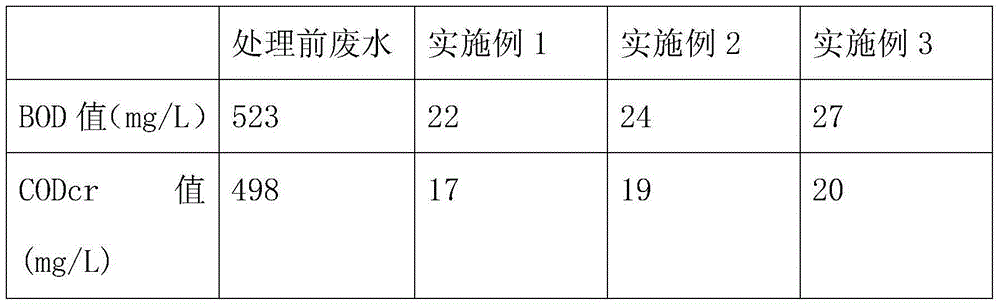

Treatment method of beer brewing wastewater

InactiveCN103979714AReduce biological oxygen consumptionReduce chemical oxygen demandWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSilica gelCeramic membrane

The invention relates to a treatment method of beer brewing wastewater. The treatment method comprises the following steps: (1) adjusting the pH of the beer brewing wastewater to be neutral; (2) adding silica gel into the beer brewing wastewater, wherein the weight of silica gel is 4.0-4.5wt% of the beer brewing wastewater, and slightly stirring for 1-2 hours after addition; (3) after stirring, filtering the beer brewing wastewater and filtering to obtain a beer brewing wastewater filtrate; (4) after filtering, enabling the beer brewing wastewater filtrate to pass through a ceramic membrane, wherein the molecular weight of the ceramic membrane is 3000, collecting permeate; and (5) enabling the permeate to pass through the ceramic membrane with the molecular weight of 300, and collecting the permeate to obtain the treated beer brewing wastewater. The BOD (Biochemical Oxygen Demand) value of the treated beer brewing wastewater is reduced from 523mg / L to 22mg / L-27mg / L and the CODcr (Chemical Oxygen Demand) value is reduced from 498mg / L to 17mg / L-20mg / L.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

Method for removing humic acids in water by using electron rays

InactiveCN103553177BNo secondary pollutionEasy to handleWater/sewage treatment by irradiationWater contaminantsRedoxNatural water

The invention discloses a method for removing humic acids in water by using electron rays, relating to a water treatment method and aiming to solve the problem of secondary pollution caused in the process of removing humic acids in water by using the traditional method for removing humic acids in water. The method comprises the steps of introducing air to a natural water with humic acids by using a water pump, and then, continuously irradiating the electron rays into the natural water by using an electron accelerator. According to the invention, the electron rays react with water molecules to generate various active free radical particles, then, the active free radical particles are subjected to oxidation reduction reaction with humic acids in water to degrade the molecules of humic acids into micromolecular substances, and any other substances are not needed to be treated, so that secondary pollution is avoided. The method is used for removing humic acids in water.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

Composite papermaking pulp substrate and its preparation method

ActiveCN103938482BImprove uniformityImprove flatnessWaste product additionSpecial paperFiberHigh concentration

The invention provides a composite papermaking pulp substrate and a manufacturing method of the composite papermaking pulp substrate. The substrate comprises a surface layer, a core layer and a bottom layer. The surface layer is made from bamboo fiber, cane syrup fiber and powdered activated carbon. The core layer is made from bamboo fiber, cane fiber, modal fiber, jute pulp fiber and coal slag particles. The bottom layer is made from bamboo fiber, ramie pulp fiber and cane syrup fiber. The manufacturing method of the composite papermaking pump substrate includes the steps of repulping, pulp matching, high-concentration sand removing, low-concentration sand removing, pressure screening, slushing, composite papermaking with pulp, drying and the like. The composite papermaking pulp substrate and the manufacturing method of the composite papermaking pulp substrate have the advantages that waste from bamboo and hemp product machining, food processing and spinning production and coal slag discharged by coal burning are used for manufacturing the pulp substrate; when the pulp substrate is used as filter material, suspended solids and particles in water can be well filtered out, organic particles and insoluble inorganic impurities can further be removed, and the effect of chemical oxygen consumption is reduced; waste water is not discharged out in the technological steps, and required water can be used cyclically.

Owner:苏州吉臣日用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com