Treatment method of beer brewing wastewater

A technology for producing wastewater and treatment methods, which is applied in the fields of food industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of reducing chemical oxygen consumption and biological oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A method for treating beer production wastewater, the treatment method comprising the following steps: (1) adjusting the pH of the beer production wastewater to neutrality; (2) adding silica gel to the beer production wastewater, and the weight of silica gel added is 4.5wt of the weight of the beer production wastewater %, after adding, stir slightly for 2 hours; (3) After the stirring is completed, filter the beer production wastewater to obtain the beer wastewater filtrate; (4) After filtering, pass the beer wastewater filtrate through the ceramic membrane, the molecular weight of the ceramic membrane is 3000, and collect the permeate (5) Pass the permeate through a ceramic membrane with a molecular weight of 300, and collect the permeate, which is the treated beer production wastewater.

Embodiment 2

[0013] A method for treating beer production wastewater, the treatment method comprising the following steps: (1) adjusting the pH of the beer production wastewater to neutrality; (2) adding silica gel to the beer production wastewater, and the weight of silica gel added is 4wt% of the weight of the beer production wastewater , stirred slightly for 1 hour after adding; (3) After the stirring, the beer production wastewater was filtered to obtain the beer wastewater filtrate; (4) After filtration, the beer wastewater filtrate was passed through a ceramic membrane with a molecular weight of 3000, and the permeate was collected; (5) Pass the permeate through a ceramic membrane with a molecular weight of 400, and collect the permeate, which is the treated wastewater from beer production.

Embodiment 3

[0015] A method for treating beer production wastewater, the treatment method comprising the following steps: (1) adjusting the pH of the beer production wastewater to neutrality; (2) adding silica gel to the beer production wastewater, and the weight of silica gel added is 4.5wt of the weight of the beer production wastewater %, stir gently for 1 hour after adding; (3) After the stirring is completed, filter the beer production wastewater to obtain the beer wastewater filtrate; (4) After filtering, pass the beer wastewater filtrate through the ceramic membrane, the molecular weight of the ceramic membrane is 3000, and collect the permeate (5) Pass the permeate through a ceramic membrane with a molecular weight of 500, and collect the permeate, which is the treated beer production wastewater.

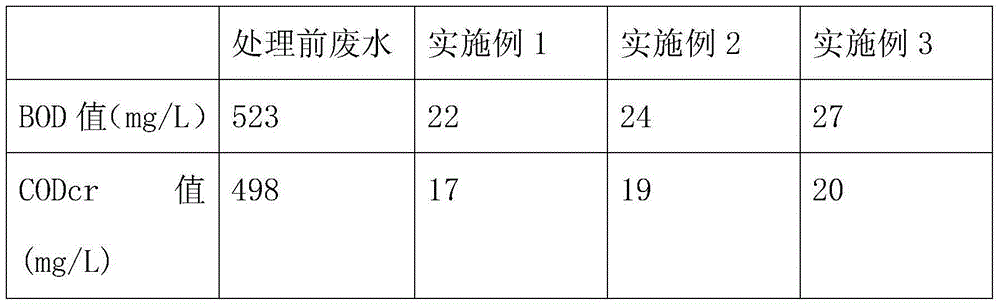

[0016] The BOD value and CODcr value in beer production wastewater before and after treatment are as follows.

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com