Beer wastewater treatment method

A treatment method, technology of beer wastewater, applied in food industry wastewater treatment, natural water body treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor impact load resistance, large amount of residual sludge, large infrastructure investment, etc., to achieve Structural stability, improvement of soil structure, and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

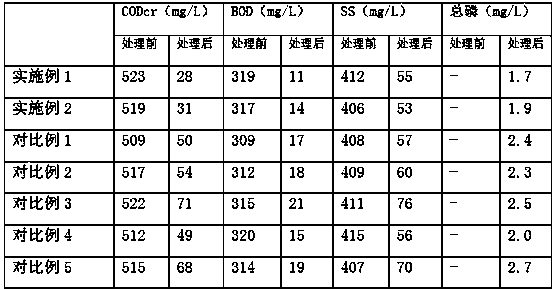

Examples

Embodiment 1

[0027] A kind of processing method of beer wastewater:

[0028] (1) Pretreatment: The wastewater collected from a beer company is filtered through a mechanical grid to filter out large particles of floating matter, and most of the suspended matter such as wheat grains, diatomaceous earth, and other small particles of suspended matter contained in beer wastewater are filtered Lose;

[0029] (2) Precipitation treatment: add hectorite composite treatment agent to the pretreated beer wastewater, the addition amount is 0.05% of the mass of beer wastewater, and stir while adding the treatment agent, the stirring speed is 50r / min; hectorite composite treatment agent The treatment agent is: disperse 1 part of hectorite into 150 parts of deionized water under constant stirring, and after it is fully swollen, obtain hectorite colloid, and mix 0.2 part of ethylenediamine with stirring speed of 1000r / min Adding, while dispersing 2 parts of polyaluminum chloride in 150 parts of water, dis...

Embodiment 2

[0034] A kind of processing method of beer wastewater:

[0035] (1) Pretreatment: The wastewater collected from a beer company is filtered through a mechanical grid to filter out large particles of floating matter, and most of the suspended matter such as wheat grains, diatomaceous earth, and other small particles of suspended matter contained in beer wastewater are filtered Lose;

[0036] (2) Precipitation treatment: add hectorite composite treatment agent to the pretreated beer wastewater, the addition amount is 0.08% of the mass of beer wastewater, stir while adding the treatment agent, the stirring speed is 40r / min; hectorite composite treatment agent The treatment agent is: disperse 1 part of hectorite into 120 parts of deionized water under constant stirring, and after it is fully swollen, obtain hectorite colloid, and mix 0.2 part of ethylenediamine with stirring speed of 1000r / min Add, and at the same time disperse 2 parts of polyaluminum chloride in 120 parts of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com