Patents

Literature

1211 results about "Polyaluminum chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

Toner coagulant processes

InactiveUS6495302B1Simple and economical processGood dispersionDevelopersSURFACTANT BLENDPolymer chemistry

A toner process including, for example, mixing a latex with a colorant wherein the latex contains resin and an ionic surfactant, and the colorant contains a surfactant and a colorant; adding a polyaluminum chloride; affecting aggregation by heating; adding a chelating component and a base wherein the base increases the pH of the formed aggregates; heating the resulting mixture to accomplish coalescence; and isolating the toner.

Owner:XEROX CORP

Toner coagulant processes

InactiveUS20020187415A1Simple and economical processGood dispersionDevelopersSURFACTANT BLENDPolymer chemistry

A toner process including, for example, mixing a latex with a colorant wherein the latex contains resin and an ionic surfactant, and the colorant contains a surfactant and a colorant; adding a polyaluminum chloride; affecting aggregation by heating; adding a chelating component and a base wherein the base increases the pH of the formed aggregates; heating the resulting mixture to accomplish coalescence; and isolating the toner.

Owner:XEROX CORP

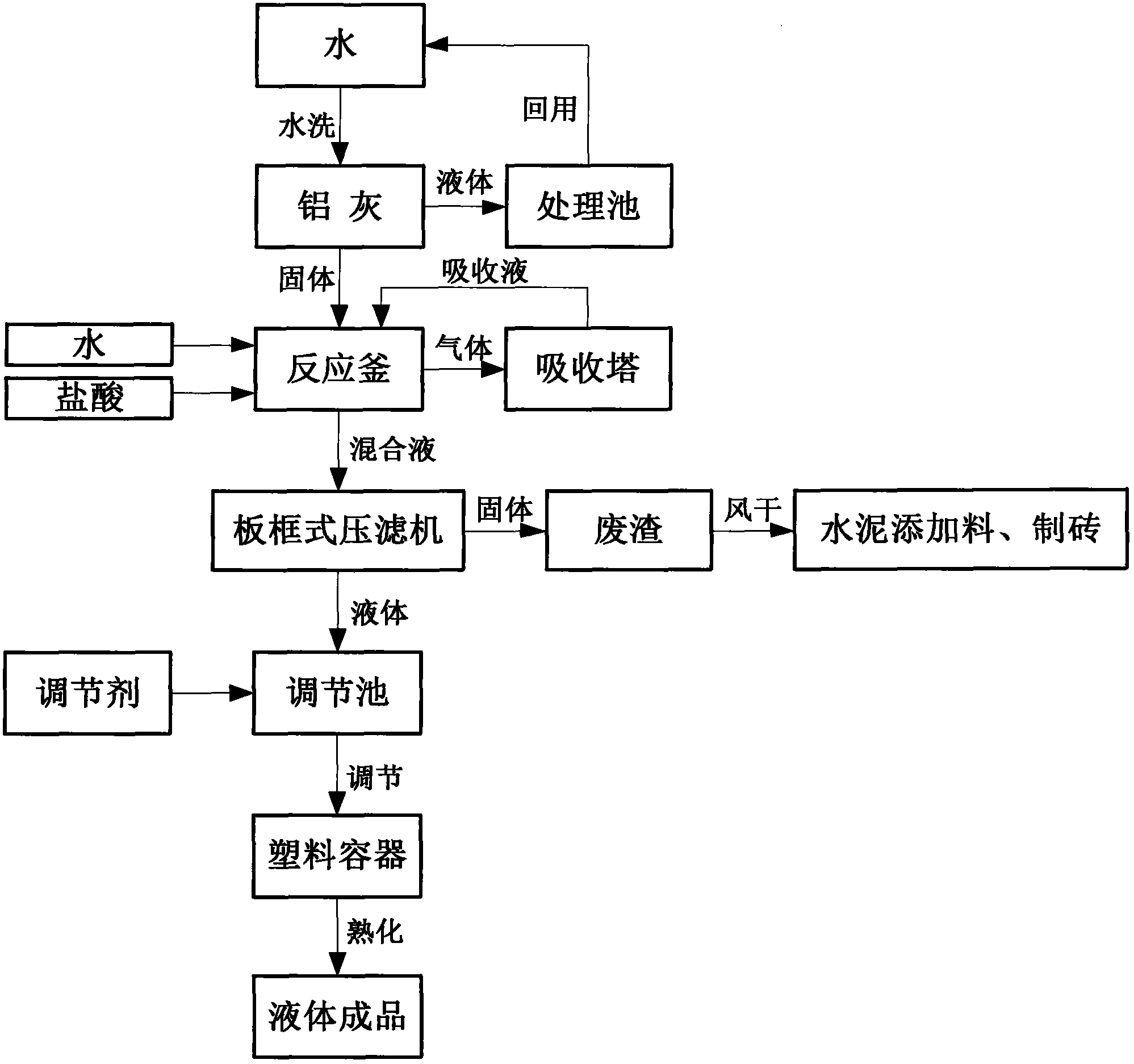

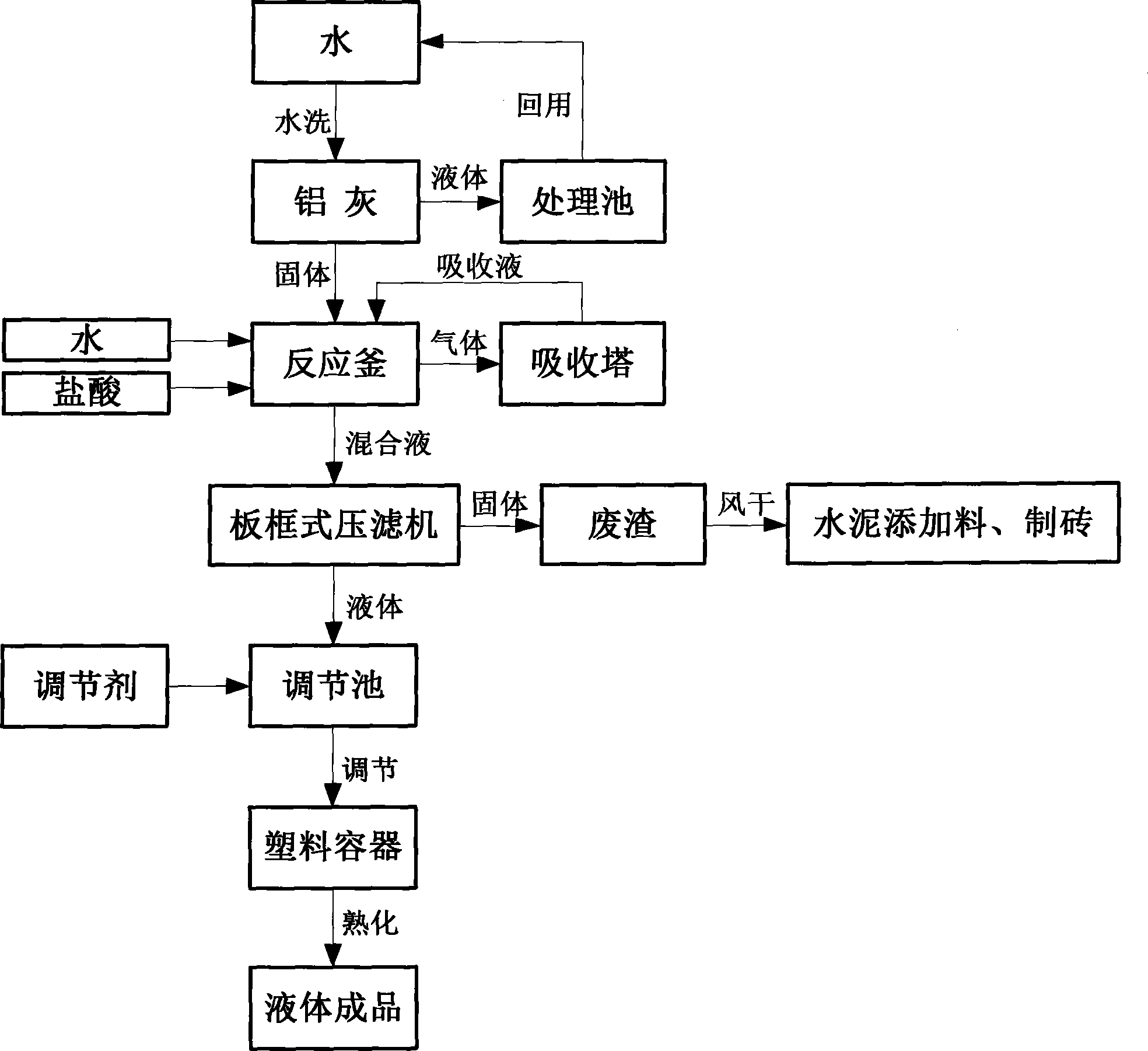

Method for preparing flocculant liquid polyaluminum chloride from aluminum ash

InactiveCN102674422ANo secondary pollutionAvoid secondary pollutionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminate

The invention discloses a method for preparing flocculant liquid polyaluminum chloride from aluminum ash, belonging to the technical field of solid waste treatment environment protection. The method comprises the following steps: uniformly mixing and stirring aluminum ash and water in a volume ratio of 1:(3-5), and soaking for 5-8 hours; pumping the solution into a reaction kettle, adding hydrochloric acid and water in an aluminum ash / hydrochloric acid / water volume ratio of 1:(2.5-3.0):(3.0-4.0), and reacting at 85-100 DEG C for 2-3 hours; carrying out solid-liquid separation with a plate and frame type filter-press, and adding a regulator to regulate the aluminum oxide content and basicity of the liquid, wherein if quicklime is used as the regulator, the volume ratio of the liquid to the quicklime is 1:(0.054-0.086), if aluminum dust is used as the regulator, the volume ratio of the liquid to the aluminum dust is 1:(0.023-0.04), and if solid calcium aluminate is used as the regulator, the volume ratio of the liquid to the solid calcium aluminate is 1:(0.042-0.063); and standing and aging for 48-72 while controlling the temperature at 50-60 DEG C, thereby obtaining the liquid polyaluminum chloride finished product. The invention has the advantages of simple technique, low cost and no secondary pollution, and is a good method for recycling aluminum ash.

Owner:李松 +2

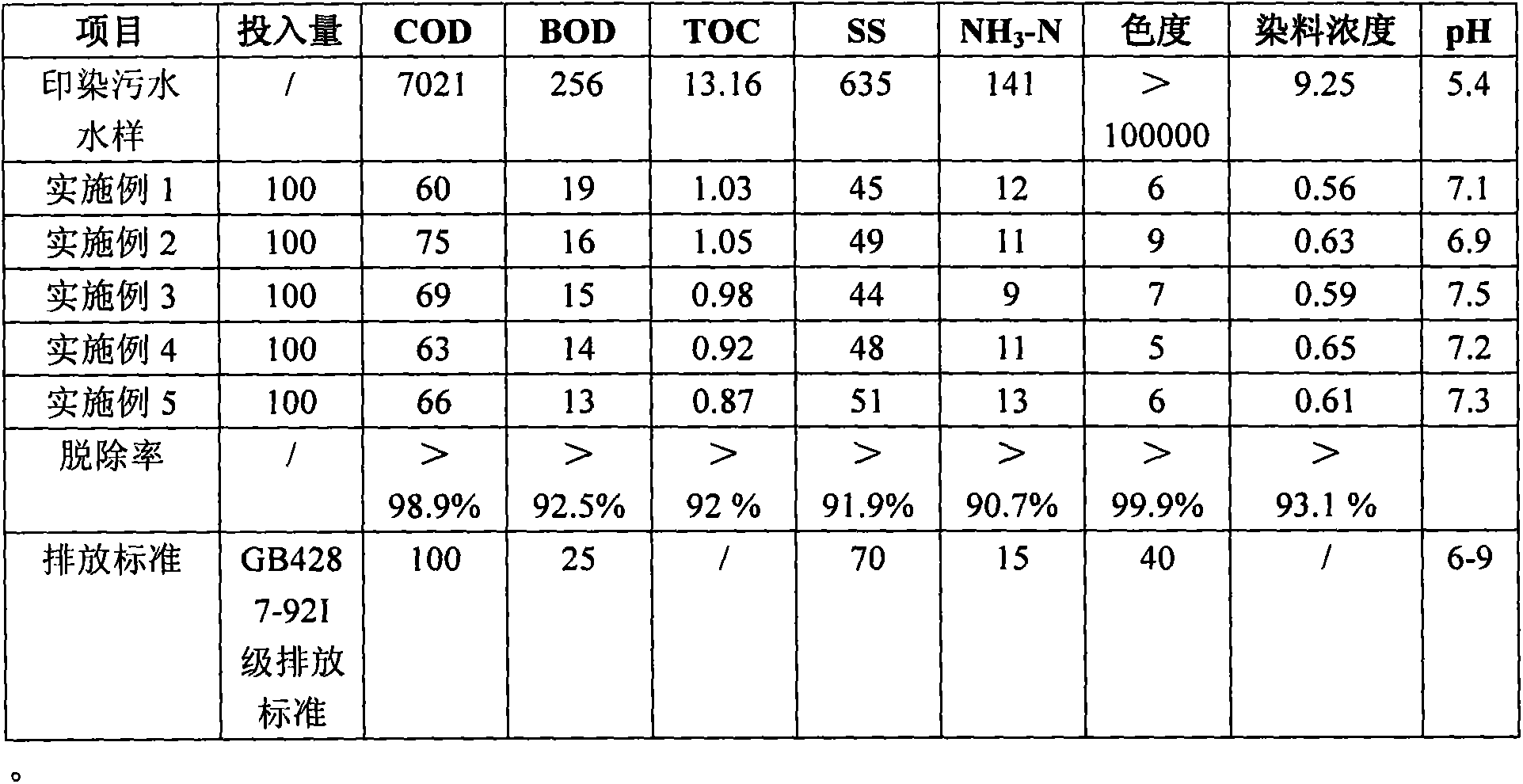

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

Papermaking wastewater treating agent and preparation method thereof

ActiveCN103641245ASustainable processingIncrease concentrationWater/sewage treatment by ion-exchangeWaste water treatment from plant processingStarch xanthatePolyacrylamide

The invention relates to the technical field of wastewater treatment, and in particular relates to a papermaking wastewater treating agent and a preparation method thereof. The papermaking wastewater treating agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 10-20 parts of magnesium sulfate, 0.5-1.5 parts of polyacrylamide, 15-25 parts of ferric nitrate, 1-5 parts of nickel nitrate, 35-50 parts of polyaluminum chloride, 15-30 parts of starch xanthate, 2-5 parts of tetrasodium 2-phosphonobutane-1, 2, 4-tricarboxylate, 0.5-1 part of zinc sulfate, 1-3 parts of benzotriazole, 16-30 parts of modified kieselguhr, 5-20 parts of cross-linked rectorite and 5-8 parts of a chitosan-graphene composite material. The papermaking wastewater treating agent disclosed by the invention is wide in using range, simple in treatment process, small in drug consumption, good in treatment effect, stable in performance and good in effluent quality and is capable of effectively reducing the cost of water treatment, so that the papermaking wastewater treating agent has a very good economic benefit and a wide social benefit.

Owner:SHANTOU LONGHU DISTRICT YUEAN PAPER

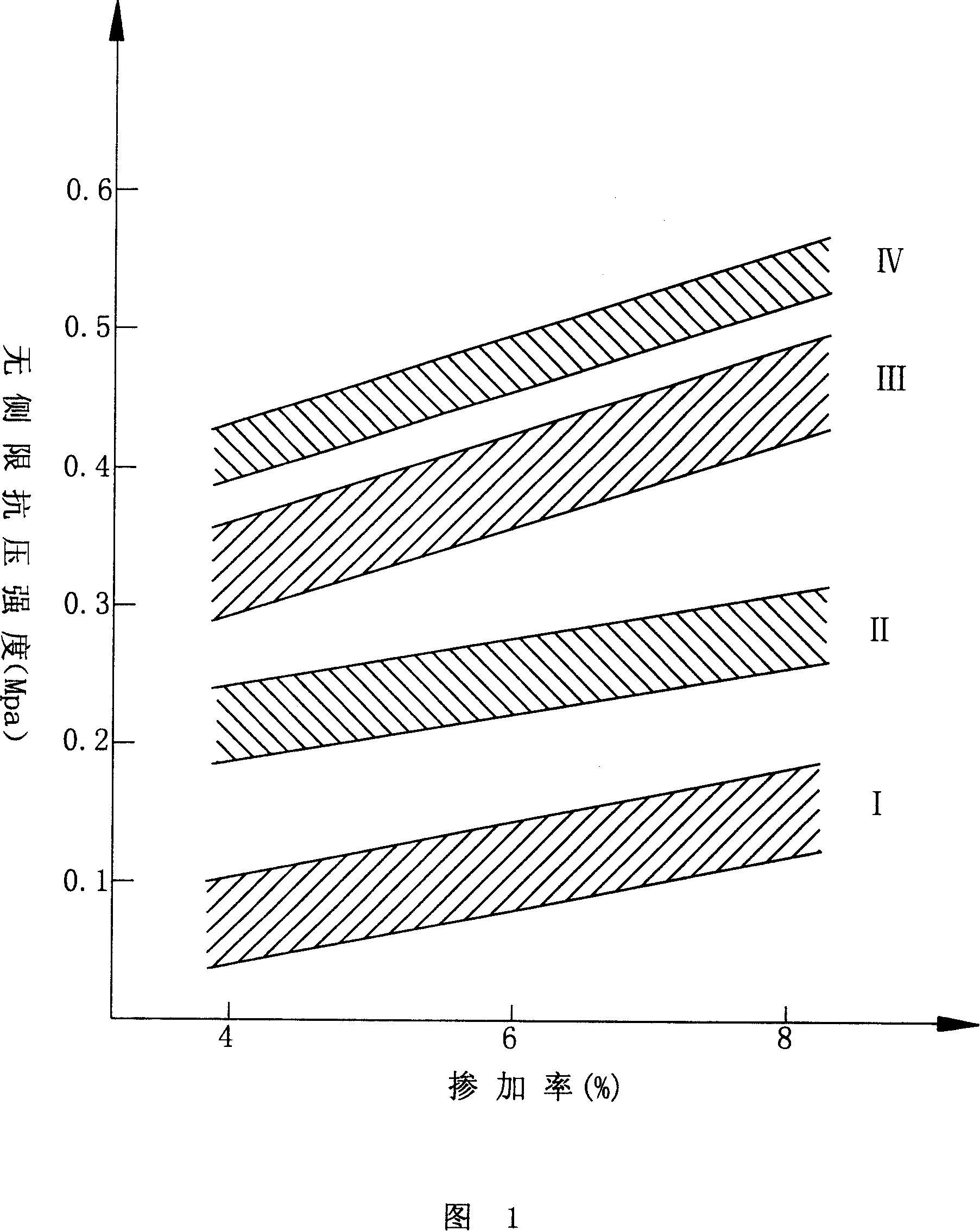

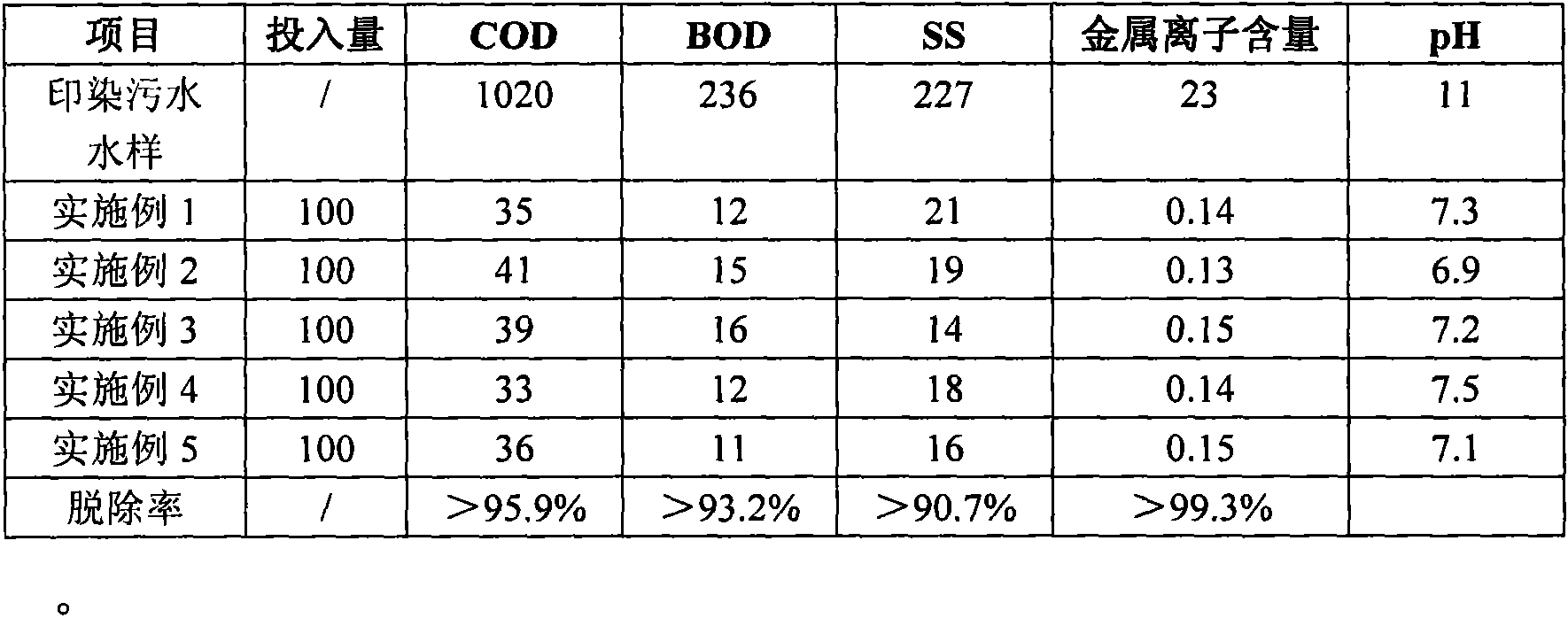

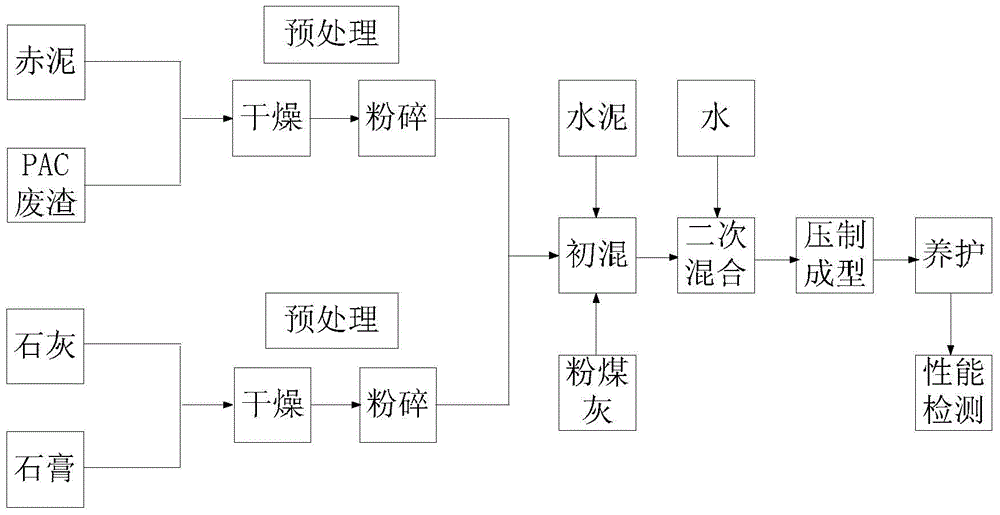

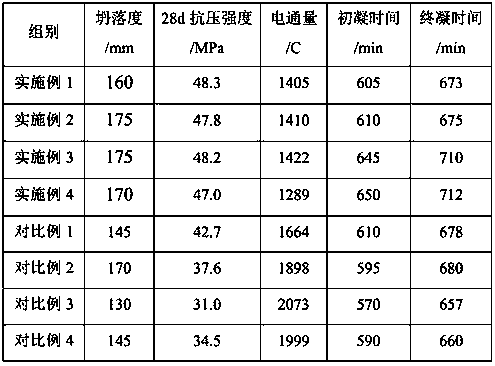

Braking-free brick mainly prepared from polyaluminum chloride waste residues and red mud and preparation method thereof

The invention relates to a braking-free brick mainly prepared from polyaluminum chloride waste residues and red mud and a preparation method thereof. Raw materials for preparing the braking-free brick comprise the red mud, the polyaluminum chloride waste residues, an active mineral material, lime and gypsum. The preparation method comprises the following steps: uniformly mixing the raw materials in proportion, adding 8-12 parts of water, stirring, mixing, carrying out compression molding, sprinkling water and curing. The preparation method has the advantages that the red mud and the PAC (polyaluminum chloride) waste residue are used as the main raw materials, pulverized fuel ash, cement, the lime and the gypsum are added, so that the using amount of an excitant is reduced, the strength of the brick is improved, the usability of the braking-free brick can be improved, meanwhile the national standard requirements are completely satisfied, a gel material does not need to be added in a production process, the heat energy does not need to be consumed, the accumulation of the red mud and the PAC is reduced in a larger sense, and the pollution to environments due to the emission of the red mud and the PAC waste residues is solved.

Owner:SHANDONG UNIV

Extraction of Sulfate from Water

InactiveUS20120031850A1Reduce metal contentLess soluble in waterSedimentation separationRadioactive contaminantsAluminium chlorideAluminite

Sulfate anions and divalent metal ions, such as magnesium, strontium and barium, in water are removed by treating the water with polyaluminum chloride, usually together with lime, to form ettringite and similar crystalline species which are readily removable by settling, filtration and the like. Iron is also removed by oxidation in a variation of the process. The process is particularly useful for treating aqueous solutions used in well treatment, where flowback fluids can provide some of the divalent metal ions necessary to form the ettringite-like materials, thus reducing the amount of lime otherwise necessary and further facilitating recycling of the fluid.

Owner:SMART CHEM SERVICES LP

Toner coagulant processes

InactiveUS20020187416A1Simple and economical processGood dispersionDevelopersSURFACTANT BLENDPolymer chemistry

A toner process including, for example, mixing a latex with a colorant wherein the latex contains resin and an ionic surfactant, and the colorant contains a surfactant and a colorant; adding a polyaluminum chloride; affecting aggregation by heating; adding a chelating component and a base wherein the base increases the pH of the formed aggregates; heating the resulting mixture to accomplish coalescence; and isolating the toner.

Owner:XEROX CORP

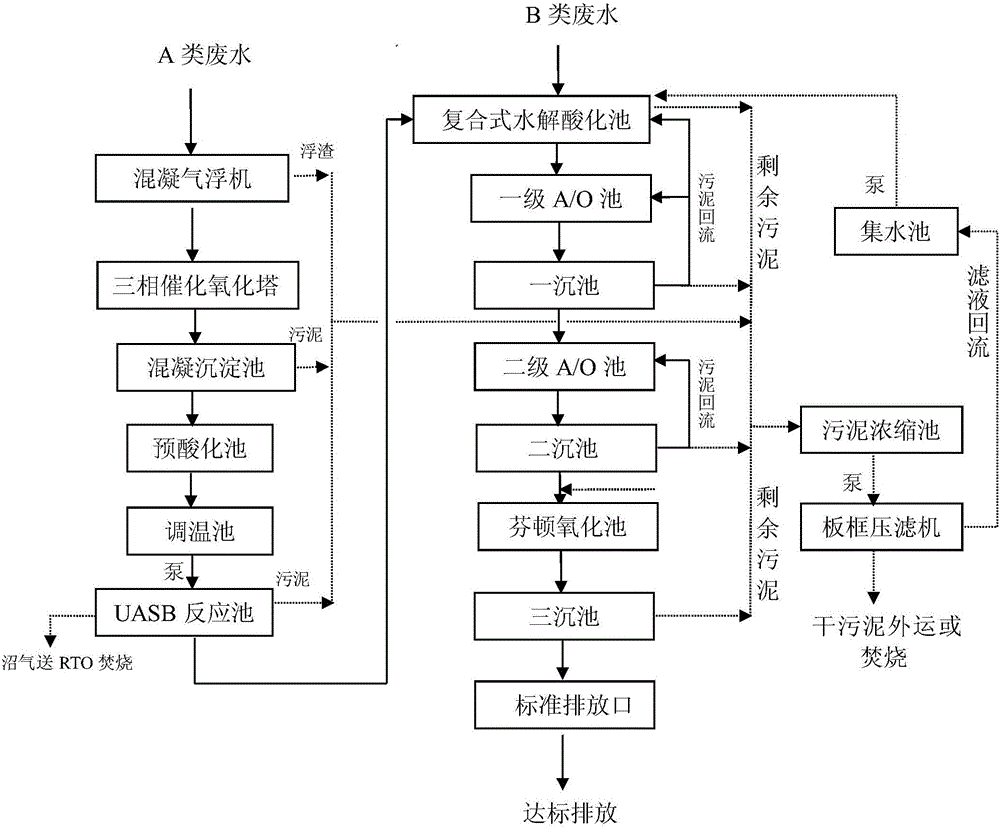

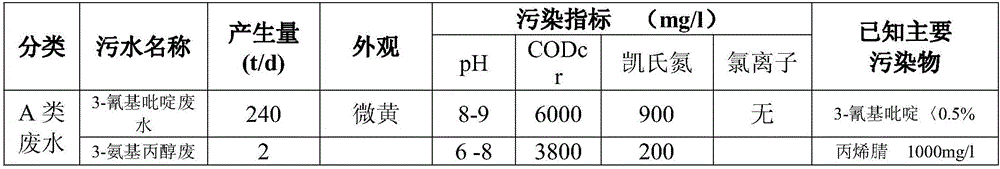

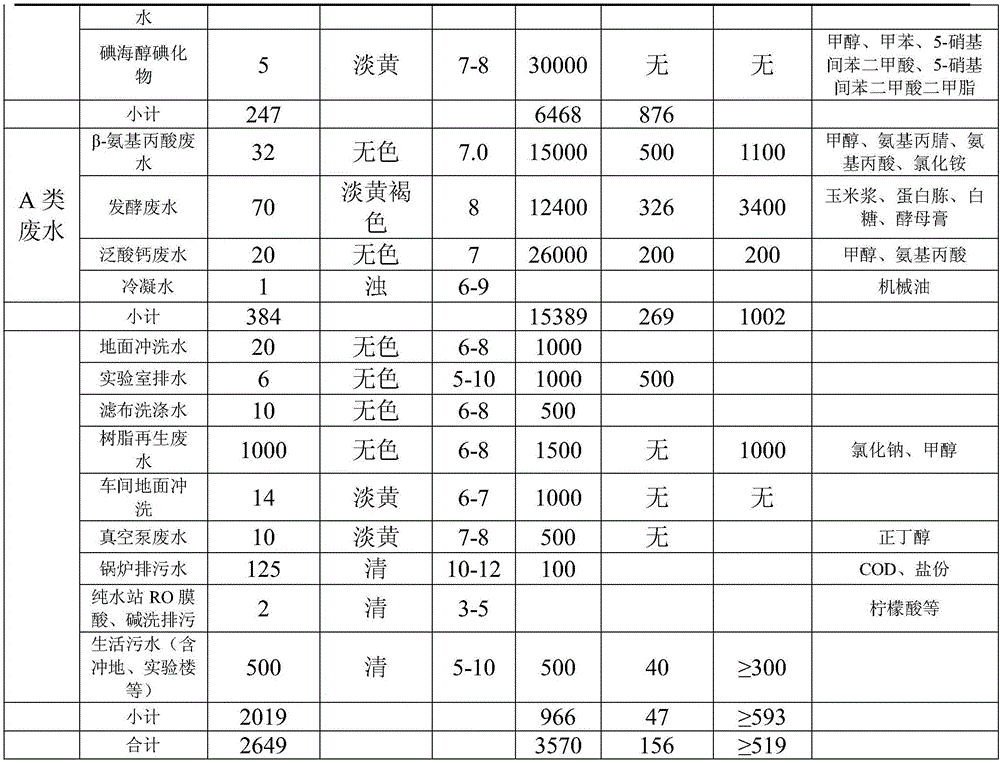

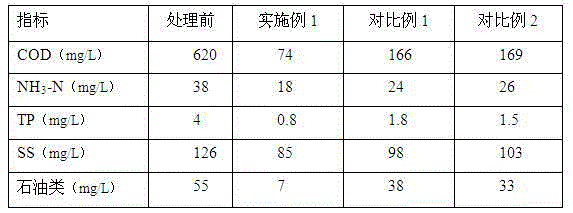

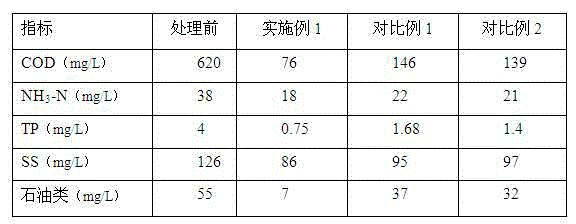

Pharmaceutical wastewater treatment process

ActiveCN106007221AHigh activityHigh removal rateSludge treatment by de-watering/drying/thickeningWater treatment parameter controlCatalytic oxidationHydrolysis

The invention relates to the technical field of wastewater treatment, and discloses a pharmaceutical wastewater treatment process which comprises steps: preforming wastewater pre-treatment and comprehensive treatment, pumping wastewater into a coagulation gas floatation clarifier, adding polyaluminum chloride and polyacrylamide in a water input pipeline through a coagulation medicine adding system, then enabling mixed wastewater to enter a three-phase catalytic oxidation tower, a coagulative precipitation tank, a pre-acidification pool, a thermoregulation pool, a UASB reaction pool and a combined type hydrolysis acidification pool sequentially, subjecting the mixed wastewater to hydrolysis acidification, enabling the wastewater to enter a primary A / O pool, a primary precipitation pool, a secondary A / O pool, a secondary precipitation pool, a Fenton oxidation pool and a tertiary precipitation pool sequentially, and discharging standard outlet water from a standard discharging opening. The process has the advantages of stable running effect, high ammonium-nitrogen removal rate, and low running cost, thereby being suitable for treatment of wastewater, which is refractory to degrade, in the pharmaceutical industry.

Owner:ZHEJIANG HUANYAO ENVIRONMENTAL CONSTR

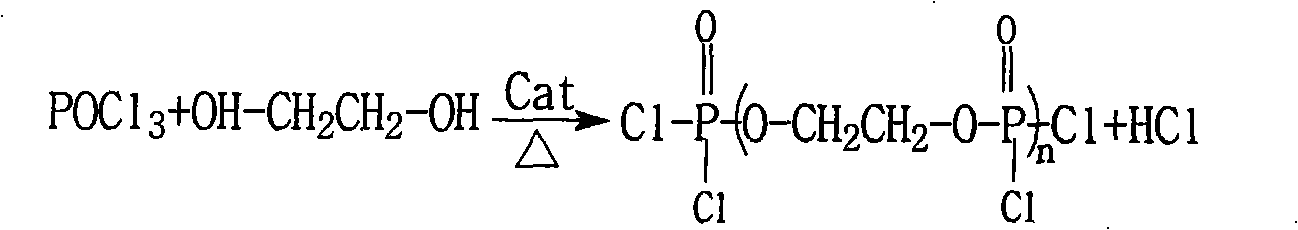

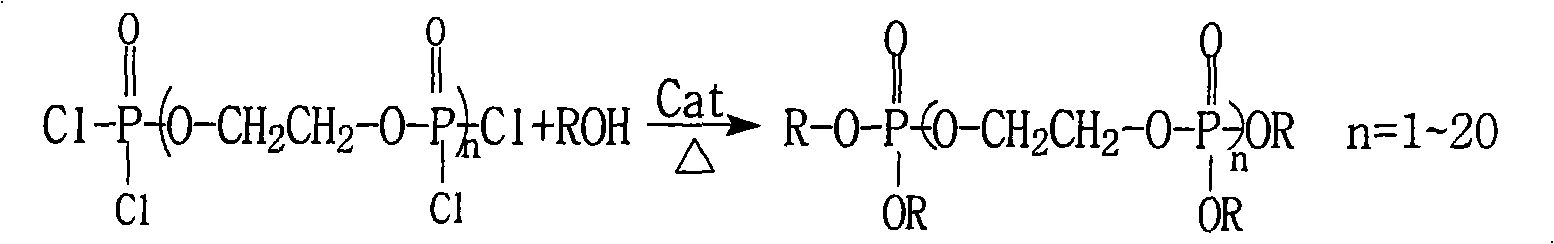

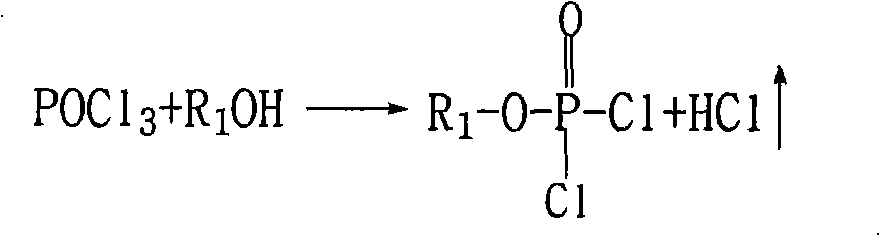

Preparation of low polyphosphate

InactiveCN101293896ALow priceRaw materials are easy to getGroup 5/15 element organic compoundsAlcoholAluminium chlorohydrate

The invention relates to an improved preparation method of an oligomeric phosphate ester, and is characterized in that the method comprises the steps of: obtaining dichloro-monoalkyl phosphate ester monomer through the reaction of phosphorus oxychloride and a monohydric alcohol performing the polymerization of the dichloro-monoalkyl phosphate ester monomer with a dihydric alcohol, and blocking end with a monohydric alcohol. Compared with the prior art, the inventive preparation method has the advantages of easily accessible raw materials, low corrosiveness, low cost (reducing cost by about 50%), no dangerous chemicals as raw materials, good safety, synthesis under relatively low temperature and low pressure, simple process, high production safety factor, simple equipment and operation, and no pollution in production process. The produced hydrogen chloride during reaction can be directly used in production of polyaluminum chloride.

Owner:JIANGSU YOKE TECH

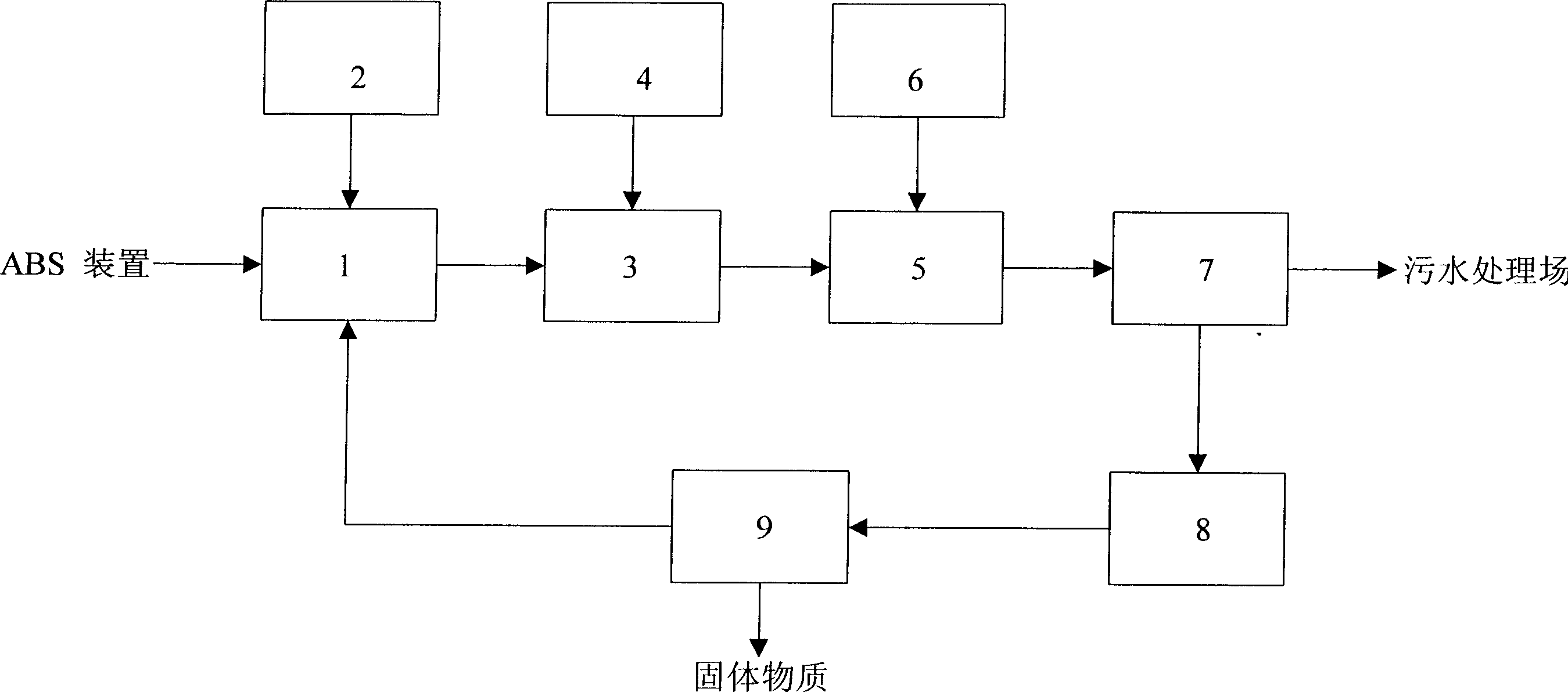

ABS sewage treating method

InactiveCN1417143AImprove biodegradabilityGuarantee normal productionMultistage water/sewage treatmentAluminium chlorohydrateSewage

The ABS sewage treating process includes the steps of: adding inorganic acid to regulate pH of sewage from ABS production to 6-8 while stirring; adding polyaluminum chloride in the amount of 50-200 ppm of ABS sewage while stirring; adding polyacrylamide in the amount of 1.7-6.7 ppm of ABS sewage while stirring; still standing to form water phase and settlings phase, and exhausting the water phaseto subsequent sewage treating field; and solid-liquid separation of the settlings with the liquid being returned to pH regulating step and the solid matter being recovered. The twice flocculation andsettlement separating process can eliminate SS content in ABS sewage and makes ABS sewage capable of being treated biochemically.

Owner:PETROCHINA CO LTD

River channel sewage treating agent and preparation method thereof

InactiveCN106976995AImprove adsorption capacityEffective settlementWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionMicrobial agentPolyacrylamide

The invention discloses a river channel sewage treating agent and a preparation method thereof; the river channel sewage treating agent comprises chitosan, polyacrylamide, a microbial agent, modified attapulgite clay, activated carbon, diatomite, sodium chloride, zeolite, polyaluminum chloride, limestone, and saw dust. The preparation method comprises: adding the chitosan, modified attapulgite clay, activated carbon, sodium chloride and polyaluminum chloride into a reaction container, adding water, mixing, and ultrasonically treating for 20-30 min; adding the microbial agent and polyacrylamide, mixing, soaking for 20-40 min, drying the mixture, and crushing; mixing well saw dust, diatomite, zeolite and limestone with the crushed mixture. The treating agent of the invention is applicable to river channel sewage treatment, and can adsorb and settle contaminants in a river channel and degrade the contaminants to clear the river channel sewage thoroughly.

Owner:合肥永泰新型建材有限公司

High-strength coral aggregate concrete and preparation method thereof

ActiveCN108218350AReduce hydration temperature riseReduce or avoid temperature cracksMetakaolinSeawater

The invention discloses high-strength coral aggregate concrete which is prepared from the following ingredients in parts by weight: 260-350 parts of low-heat marine Portland cement, 35-50 parts of flyash floating beads, 35-50 parts of mineral powder, 8-16 parts of silica fume, 8-16 parts of metakaolin, 2-6 parts of nano silicon dioxide, 2-6 parts of polyaluminum chloride, 550-679 parts of coral reef sand, 890-1000 parts of coral reef and 180-256 parts of seawater. The high-strength coral aggregate concrete has the advantages that the pelagic engineering construction cost is lowered, and environment-friendly and energy-saving requirements of civil engineering are also met.

Owner:CCCC SECOND HARBOR ENG +2

Water purifying agent for wastewater treatment in rubber accelerator M production and wastewater treatment method

ActiveCN104478095AHigh transparencyImprove water purification effectMultistage water/sewage treatmentBiological water/sewage treatmentPectinaseNitrifying bacteria

The invention belongs to the technical field of environment-friendly water treatment, particularly relates to a water purifying agent for wastewater treatment in rubber accelerator M production and further relates to a method for treating rubber accelerator M production wastewater by adopting the water purifying agent. The water purifying agent contains a flocculation water purifying agent, a microbial water purifying agent and an enzyme preparation, wherein the flocculation water purifying agent is prepared from polyaluminum chloride, polyacrylamide, ferrous sulfate and aluminum sulfate; the microbial water purifying agent is prepared from nitrobacterium powder, paracoccus denitrificans powder, thiobacterium powder, aniline degrading bacteria powder and flocculating bacteria powder; the enzyme preparation is prepared from pectinase, cellulase, oxidoreductase, lysozyme and alkaline proteinase. The water purifying agent and the method have the beneficial effects that by adopting the water purifying agent for wastewater treatment, disclosed by the invention, the water purifying effect is good, the water purifying speed is high, the safety is high, and no secondary pollution is caused; materials with adsorption capacity are used as raw materials and are assisted with microbes, so as to treat the wastewater, so that the range of use is wide, the transparency of treated water is extremely high, and recycling can be achieved.

Owner:安徽优盾信息科技有限公司

Wastewater treating agent, preparation method and wastewater treatment method

ActiveCN105174500AEasy to handleImprove efficiencyBiocideSpecific water treatment objectivesIron sulfateSodium phosphates

The invention relates to a wastewater treating agent, a preparation method and a wastewater treatment method. According to the oil paint wastewater treating agent, the formula comprising a corrosion inhibitor, a scale inhibitor, a sterilizing agent and a flocculating agent is adjusted, and an auxiliary chemical is added, so that the wastewater treatment process is easy to control, the treatment period is short, and the treatment effect is remarkably improved; the wastewater treating agent comprises the corrosion inhibitor, the scale inhibitor, the sterilizing agent, the flocculating agent and the auxiliary chemical; the corrosion inhibitor comprises sodium polyphosphate, calcium gluconate, alkyl epoxy sodium carboxylate, potassium iodide and gelatin; the scale inhibitor comprises trisodium phosphate, tannin, sodium humate, sulfoacid copolymers and TH-0100 type reverse osmosis scale inhibitors; the sterilizing agent comprises potassium permanganate, didodecyl dimethyl dibenzyltinoammonium chloride and nano-zinc oxide; the flocculating agent comprises lignin, chitosan, quaternary amine type cationic starch, polyaluminum chloride , polymeric ferric sulfate and diatomite earth; the auxiliary chemical comprises polyaspartic acid and alky epoxy carboxylate. An experiment result proves that the wastewater treating agent has an excellent effect.

Owner:上海云火环境科技有限公司

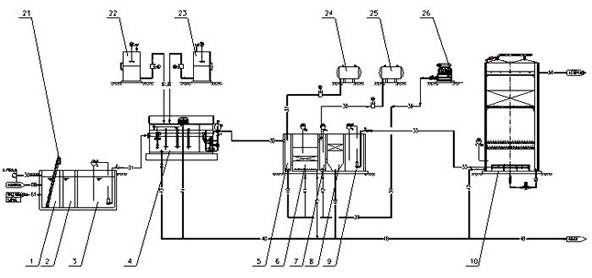

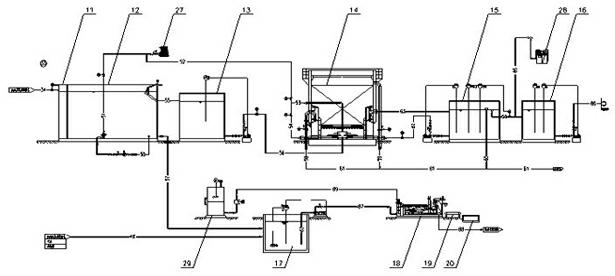

Device for treating wastewater during production of pentaerythritol

ActiveCN102557359AImprove biodegradabilityEfficient removalMultistage water/sewage treatmentElectrolysisPentaerythritol

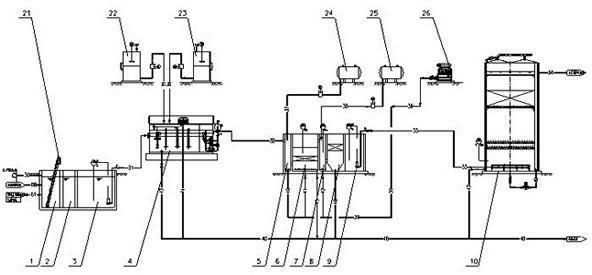

The invention relates to a device for treating wastewater during production of pentaerythritol. The device comprises a grille groove, a mechanical grille, an oil isolating pool, an adjusting pool, a combined air floater, an aerated micro-electrolysis system, a high-efficiency anaerobic reactor, an improved SBR reaction tank, a water-collecting pool, an anaerobic biological filter, a monitoring pool, a recycling water pool, an acid adding system, an alkali adding system, a polyaluminum chloride (PAC) dosing system, a polyacrylamide (PAM) dosing system, a sludge pool, a sludge pressing filter system, a blast blower and on-lien monitoring instruments such as PH, COD, a liquidometer, a thermometer and the like, wherein the aerated micro-electrolysis system comprises an acid adjusting pool, a micro-electrolysis reaction tank, a neutral coagulation reaction tank, a settling pool and an intermediate water pool; and all the systems are connected with one another sequentially through pipelines. The device treats the wastewater during production of the pentaerythritol by a combined air floatation, aerated micro-electrolysis, biological treatment and aerated biological filter combined method, so that the effluent quality meets the requirement.

Owner:贵州绿色环保设备有限公司 +1

Water purifying agent for wastewater treatment in rubber accelerator production and wastewater treatment method

ActiveCN104478096AHigh transparencyImprove water purification effectMultistage water/sewage treatmentBiological water/sewage treatmentPectinaseRedox enzymes

The invention belongs to the technical field of environment-friendly water treatment, particularly relates to a water purifying agent for wastewater treatment in rubber accelerator production and further relates to a method for treating rubber accelerator production wastewater by adopting the water purifying agent. The water purifying agent contains a flocculation water purifying agent, a microbial water purifying agent and an enzyme preparation, wherein the flocculation water purifying agent is prepared from polyaluminum chloride, polyacrylamide, ferrous sulfate and aluminum sulfate; the microbial water purifying agent is prepared from nitrobacterium powder, paracoccus denitrificans powder, thiobacterium powder, aniline degrading bacteria powder and bacillus larvae powder; the enzyme preparation is prepared from pectinase, cellulase, oxidoreductase, xylanase and alkaline proteinase. The water purifying agent and the method have the beneficial effects that by adopting the water purifying agent for wastewater treatment, disclosed by the invention, the water purifying effect is good, the water purifying speed is high, the safety is high, and no secondary pollution is caused; materials with adsorption capacity are used as raw materials and are assisted with microbes, so as to treat the wastewater, so that the range of use is wide, the transparency of treated water is extremely high, and recycling can be achieved.

Owner:江苏建霖环保科技有限公司

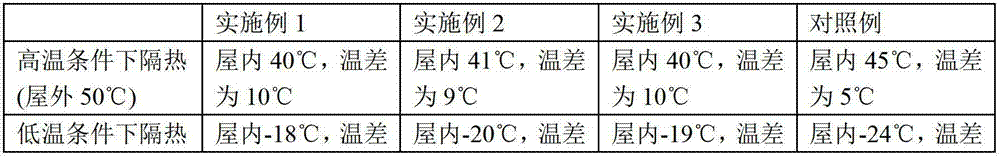

Long fiber glass reinforced hydrophobic perlite thermal baffle for buildings and method for manufacturing same

InactiveCN101718122ASimple structureImprove flexural performanceConstruction materialHeat proofingAluminium chlorideFireproofing

The invention relates to a novel fireproofing and heat preservation material for buildings, in particular to a long fiber glass reinforced hydrophobic perlite thermal baffle for the buildings. The long fiber glass reinforced hydrophobic perlite thermal baffle for the buildings is characterized by comprising the following raw materials in percentage by weight: 25 to 50 percent of expanded perlite, 30 to 55 percent of paste or white cement, 5 to 15 percent of filler, 0 to 10 percent of silicate cotton, 0 to 3 percent of retarding agent, 1 to 5 percent of inflating medium, 0.5 to 5 percent of polyaluminum chloride and 1 to 3 percent of water repellent. Due to good fire resistance, good heat insulation and preservation property, mechanical property and construction property, the product of the invention meets the fire resisting and energy saving requirements of the modern buildings, belongs to an environmentally-friendly material and has no pollution to the environment.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Paint wastewater treatment system

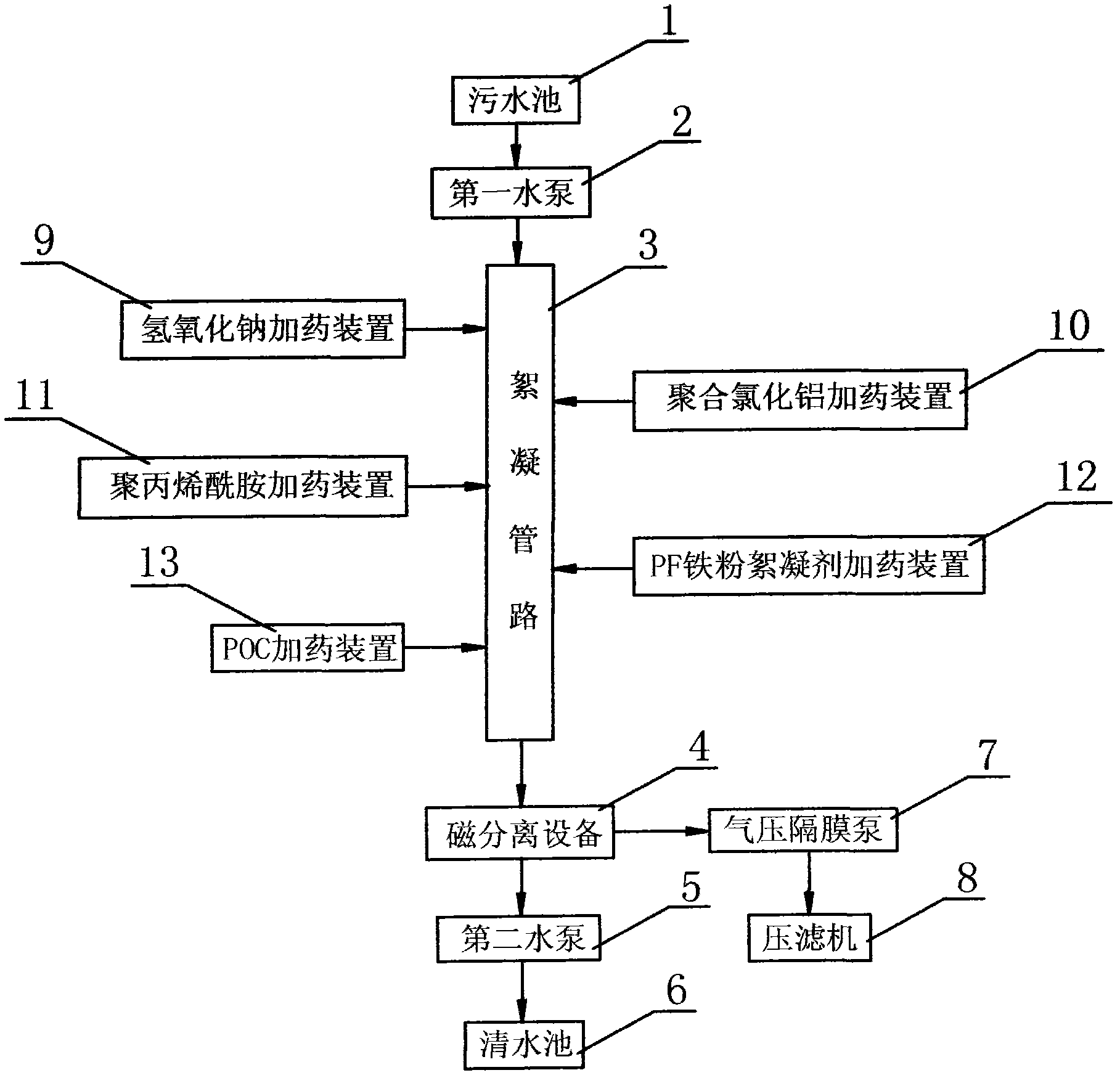

InactiveCN102992533AExtended stayGood flocculation effectMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationMagnetic rotationIron powder

The present invention provides a paint wastewater treatment system with characteristics of low investment and low running cost. The paint wastewater treatment system comprises a sewage tank, a flocculation pipeline, a first water pump, a second water pump, an agent addition device, a magnetic separation device and a clear water tank, wherein a water inlet pipe of the magnetic separation device is communicated with the sewage tank through the flocculation pipeline and the first water pump, a water outlet pipe of the magnetic separation device is communicated with the clear water tank through the second water pump, the agent addition device is communicated with the flocculation pipeline, and is sequentially provided with a sodium hydroxide addition device, a polyaluminum chloride addition device, a polyacrylamide addition device and a PF iron powder flocculant addition device along a wastewater flow direction, the magnetic separation device comprises a mud water separation tank provided with a water inlet pipe and a water outlet pipe, a magnetic rotation disc arranged inside the mud water separation tank through a rotation shaft, a mud scraping plate and a residue cleaning region, the rotation shaft is connected with a power device through a speed reducer, and the mud scraping plate is fixed between the residue cleaning region and the magnetic rotation disc, and contacts the magnetic rotation disc.

Owner:CHANGSHU KOHLER

Water purifying agent for aquaculture, and preparation method thereof

InactiveCN107162093AGood coagulation effectPurify thoroughlyWater/sewage treatment by centrifugal separationWater contaminantsFiberWater quality

The invention discloses a water purifying agent for aquaculture, and a preparation method thereof. The water purifying agent comprises, by weight, 50-60 parts of tourmaline particles, 30-50 parts of modified zeolite, 20-30 parts of polyaluminum chloride, 15-25 parts of potassium ferrate, 10-20 parts of copper sulfate, 3-8 parts of carbon black, 10-30 parts of activated carbon fibers, 2-8 parts of diatomaceous earth, 3-8 parts of calcium oxide and 1-5 parts of magnesium oxide. The preparation method comprises the following steps: crushing and uniformly mixing the tourmaline particles, modified zeolite, polyaluminum chloride, potassium ferrate, copper sulfate, carbon black, activated carbon fibers, diatomaceous earth, calcium oxide and magnesium oxide to obtain a powder, and drying the powder to produce the water purifying agent for aquaculture. The water purifying agent for aquaculture has the advantages of physical purification and chemical preparation synergism, obvious coagulation effect, and fastness and thoroughness in purification, and is suitable for large-scale promotion.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

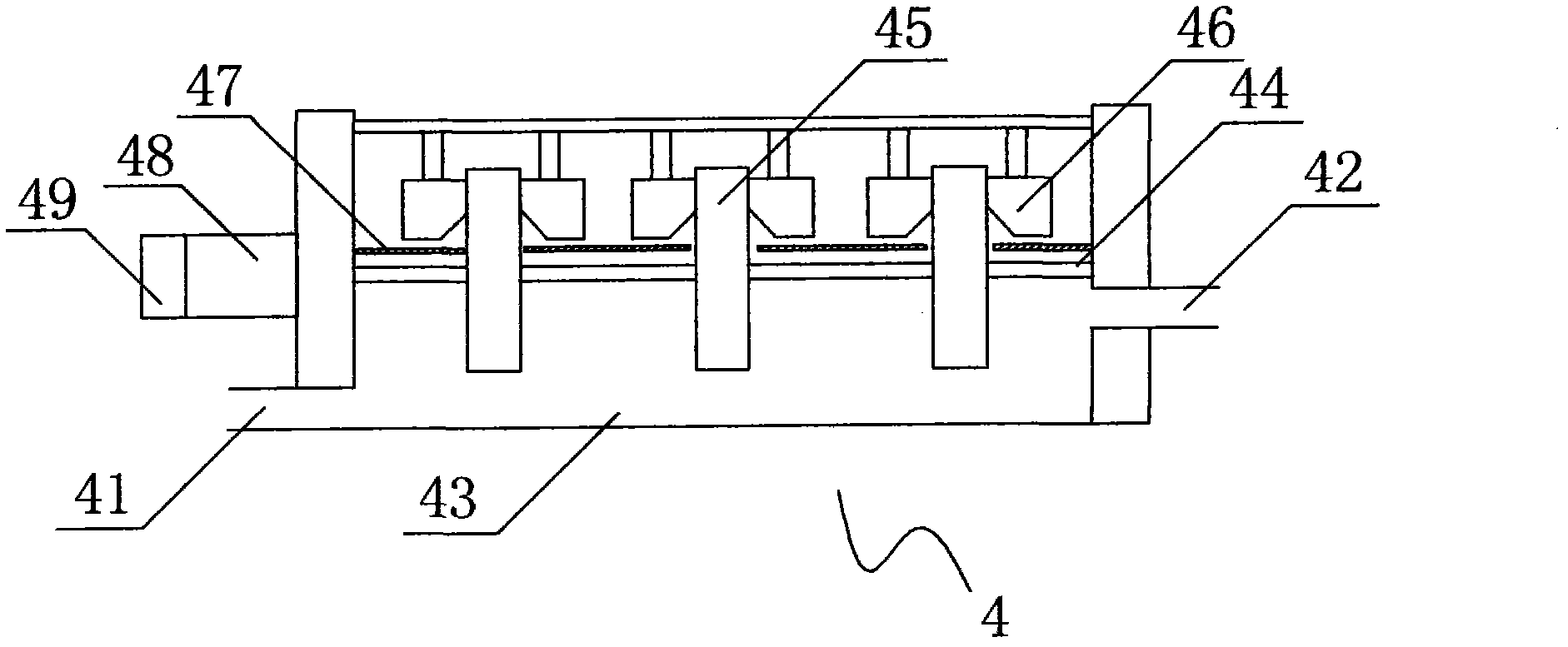

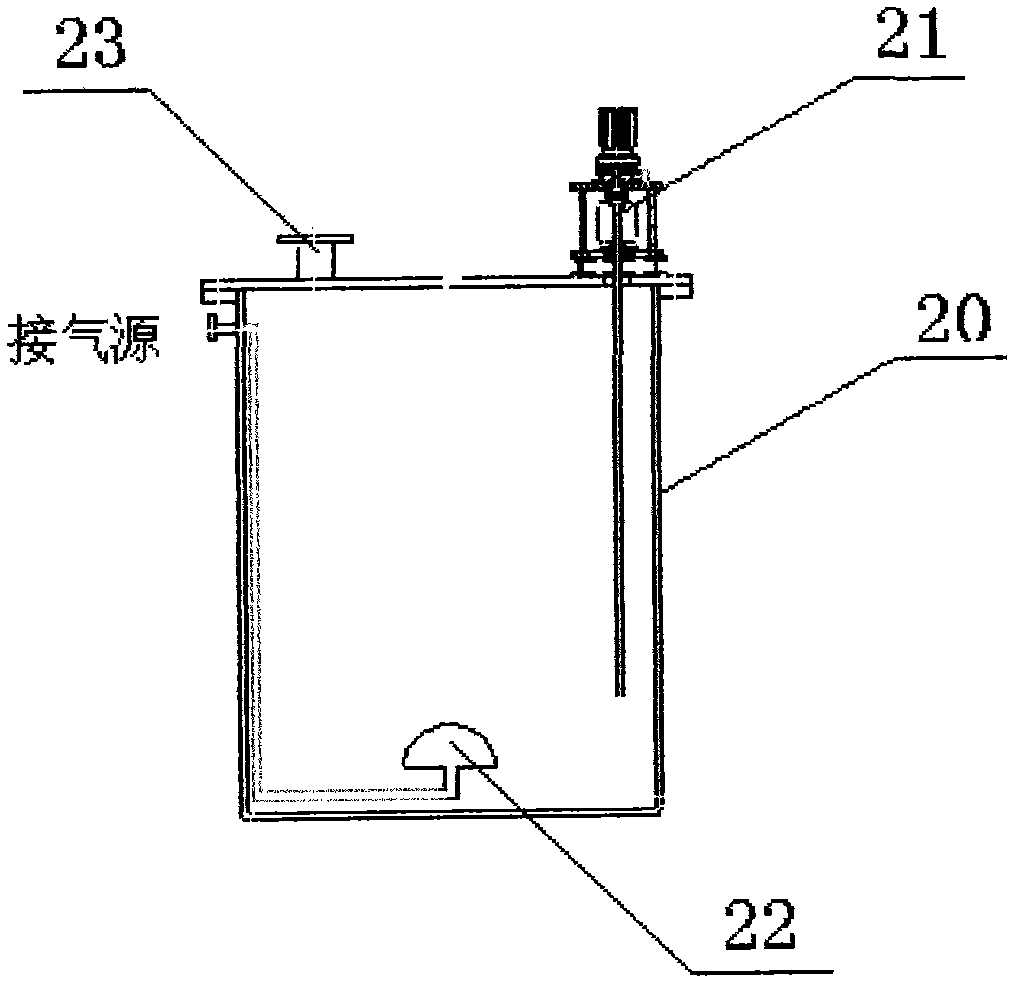

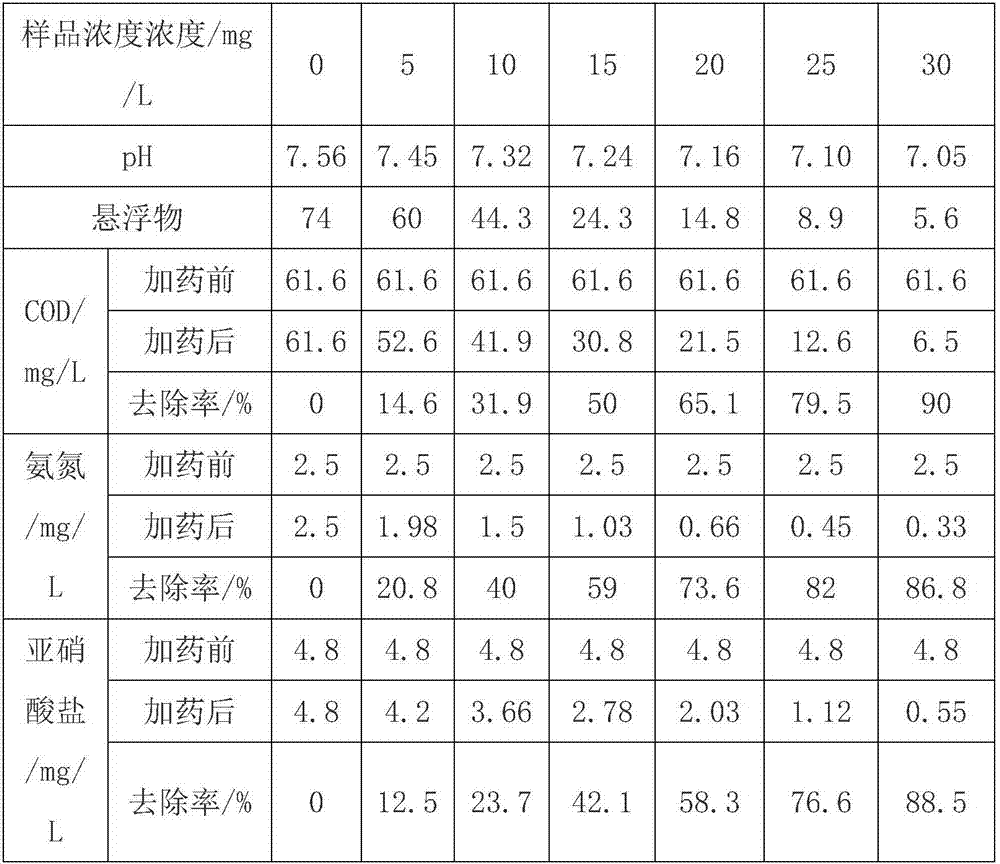

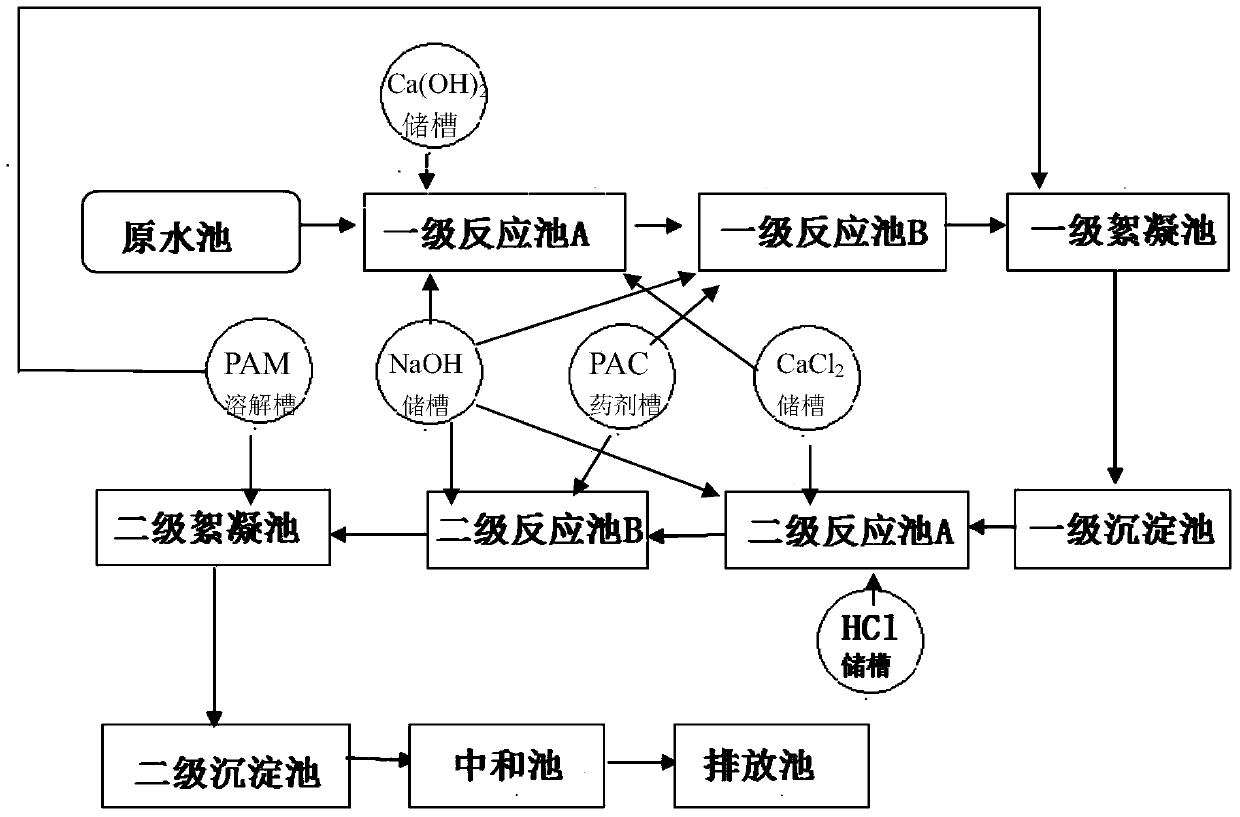

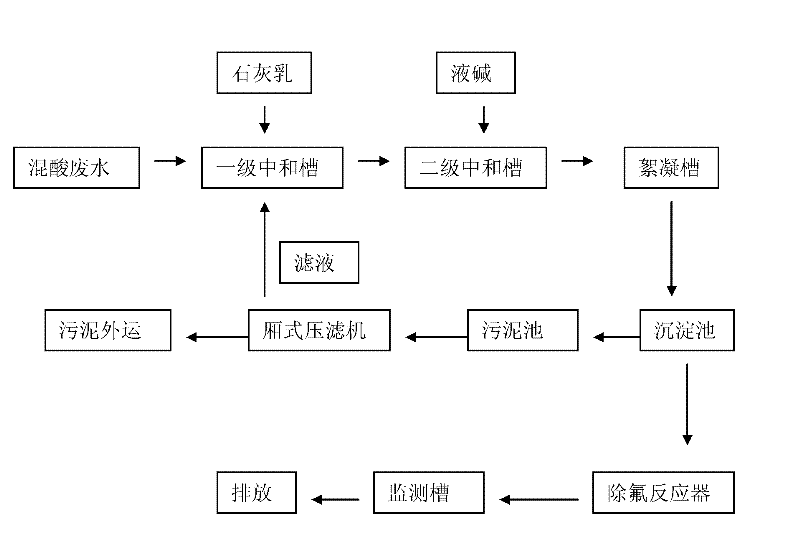

Fluoride-contained wastewater treatment method and device

InactiveCN103991984AReduce dosageReduce processing costsWater contaminantsMultistage water/sewage treatmentIon contentWater quality

The invention discloses a fluoride-contained wastewater treatment method. Calcium hydroxide, sodium hydroxide and calcium chloride as well as sodium hydroxide and sodium chloride two-stage chemical precipitation reaction is adopted, meanwhile, PAM (Polyacrylamide) and PAC (Polyaluminum Chloride) flocculating settling is assisted, so that the fluorine concentration of effluent is greatly reduced; after fluoride-contained wastewater is treated by using the method, main pollution factors in the water are within the national normative standard range, and the fluorine ion content is reduced by about 3 times as comparison with the former fluorine ion content; the dosages of sodium hydroxide and calcium chloride and the wastewater treatment cost is greatly reduced. The invention also provides a fluoride-contained wastewater treatment device based on the treatment method. The fluoride-contained wastewater treatment method disclosed by the invention is simple and practical in process and capable of adapting to the changes of water quality and quantity and has a certain flexibility and adjustability; meanwhile, the treatment device is convenient to manage, operate and maintain.

Owner:HEFEI HAREON SOLAR TECH

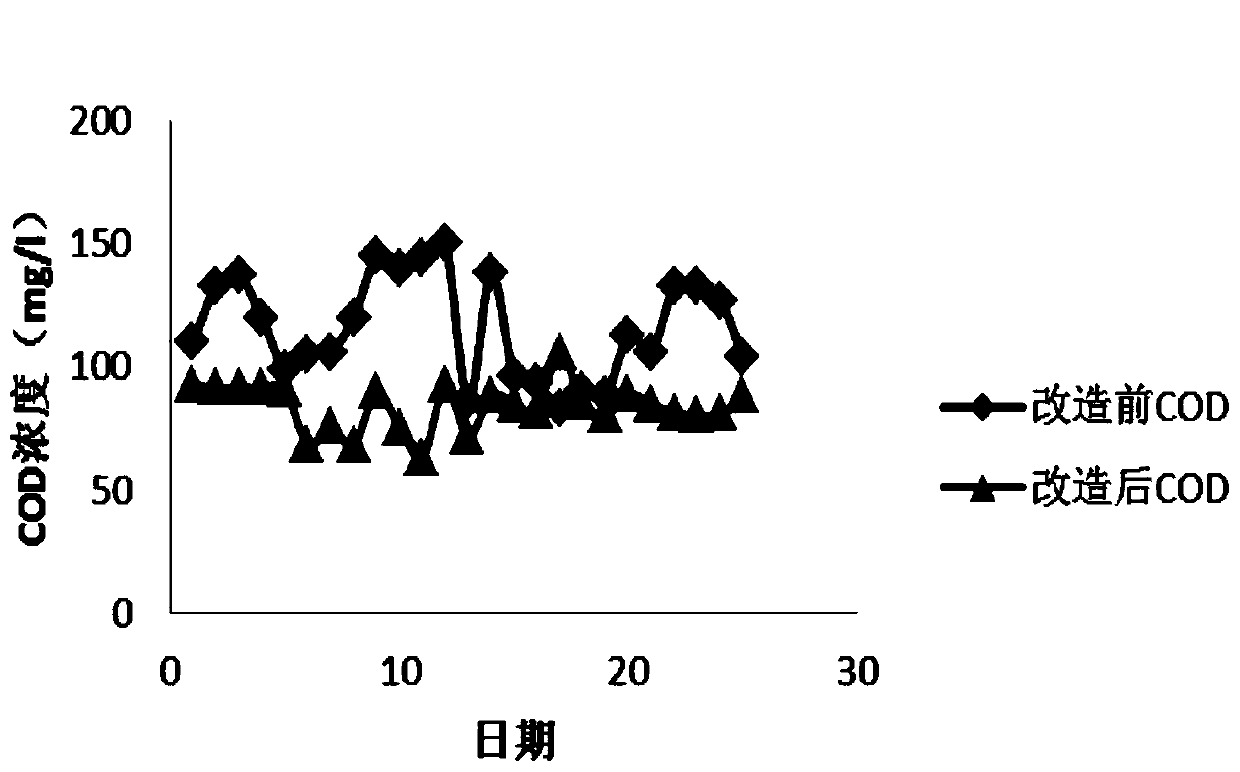

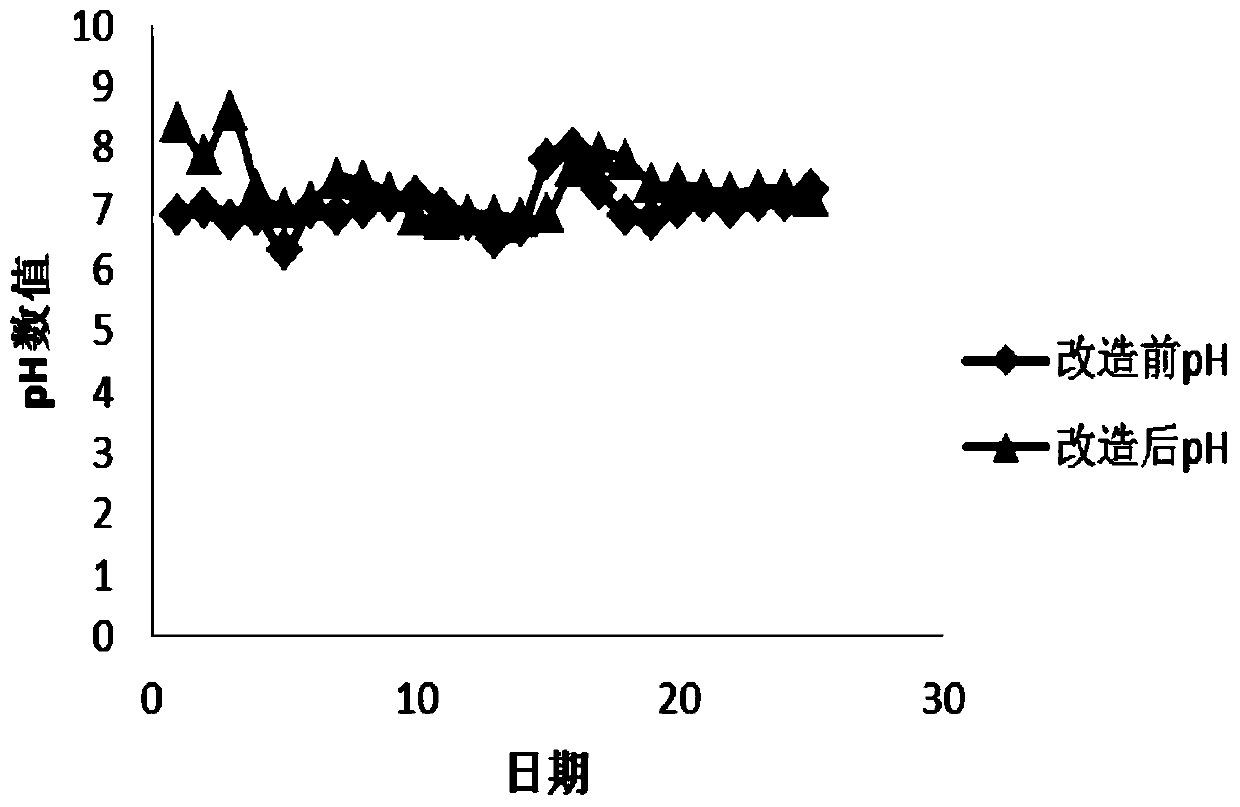

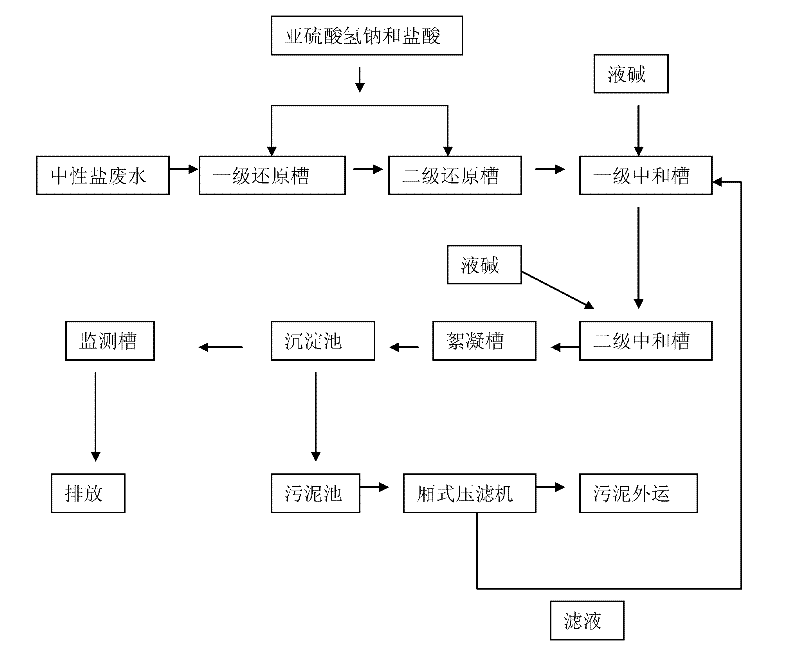

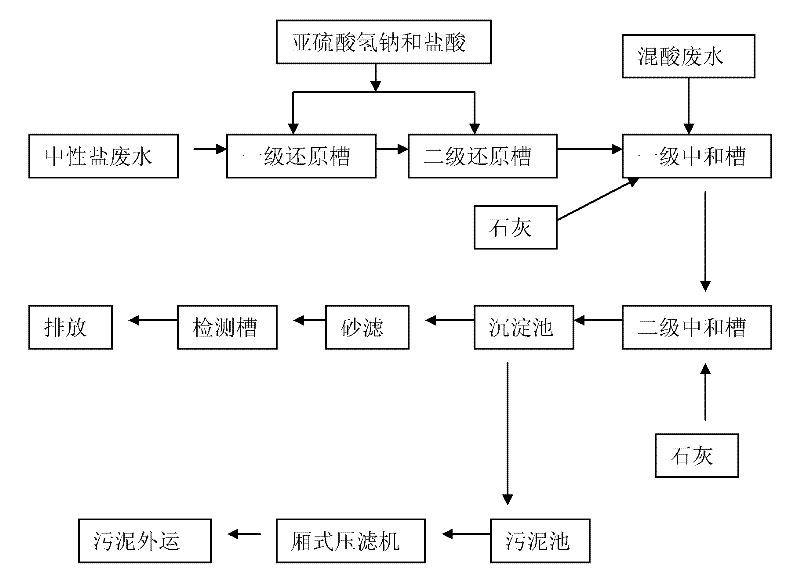

Method for sludge reduction for cold rolling pickling wastewater in steel industry

ActiveCN102211828AReduce productionReduce processingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgePolyacrylamide

The invention belongs to the technical field of sludge reduction for cold rolling pickling wastewater in the steel industry, and discloses a method for sludge reduction for the cold rolling pickling wastewater in the steel industry. In the method disclosed by the invention, neutral salt wastewater and wastewater mixed with acid are completely and separately treated to obtain sludge containing hazardous wastes and general sludge respectively, and the sludge output of each unit is reduced by accurately adding chemical agents at each unit; in the technology for treating the neutral salt wastewater, caustic soda liquid is respectively added in a first stage neutralizing tank and a second stage neutralizing tank; in the technology for treating the wastewater mixed with acid, the treatment is performed by using a lime and austic soda liquid combination method; and in the treatment of a neutralizing tank, the pH value is controlled between 1.5 and 3.0, and the pH value during neutralization reaction is controlled between 8.2 and 8.7; and a flocculation process is adopted after the neutralization reaction, polyaluminum chloride, polyacrylamide and other flocculants are added for reacting and are mixed so as to enlarge pollutant particles. By use of the method, the output water can stably reach the standard, and the water treatment cost per ton is reduced.

Owner:SHANGHAI MEIJIA WATER TREATMENT TECH

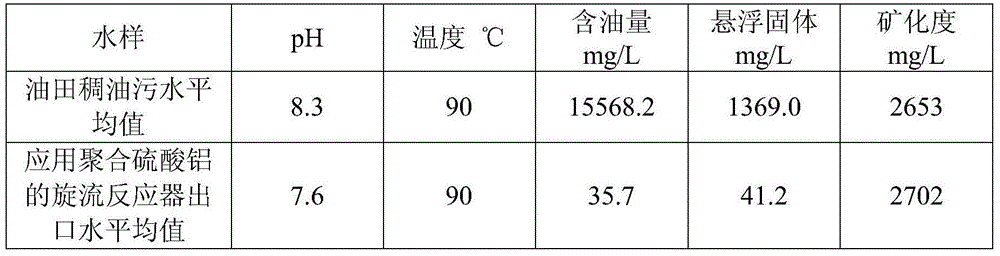

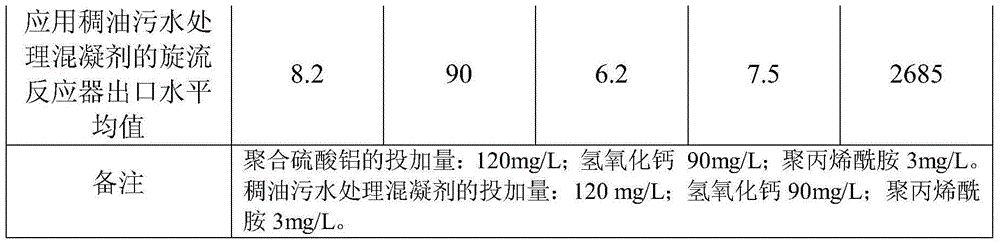

Thick oil sewage treatment coagulating agent, and preparation method and application thereof

InactiveCN104085970ASimple preparation processInverted demulsificationFatty/oily/floating substances removal devicesLiquid separationAluminium chlorohydrateSulfate

The invention relates to an oilfield sewage treatment coagulating agent, particularly a thick oil sewage treatment coagulating agent. The thick oil sewage treatment coagulating agent comprises the following components in percentage by weight: 15.0-25.0% of polyaluminum chloride, 5.0-10.0% of polyzinc sulfate silicate, 0.5-1.0% of ammonium polydimethyldiallylchloride and 5.0-10.0% of 3.0G polyamide-amine. The preparation method comprises the following steps: adding the polyaluminum chloride and polyzinc sulfate silicate into water in percentage by weight, completely dissolving, adding the ammonium polydimethyldiallylchloride and 3.0G polyamide-amine, stirring uniformly, and regulating the pH value to 3.0-5.0 to obtain the thick oil sewage treatment coagulating agent. The thick oil sewage treatment coagulating agent has the advantages of low consumption and low price, and is suitable for a multifunctional swirl reactor treatment technique. The thick oil sewage treatment coagulating agent has the functions of reverse demulsification and water purification, and has favorable purifying effect on the thick oil high-temperature sewage. The preparation method is simple and easy to implement.

Owner:KARAMAY SANDA NEW TECH

High thermal conductivity silicon carbide ceramic material and preparation method thereof

The invention discloses a high thermal conductivity silicon carbide ceramic material and a preparation method thereof. The high thermal conductivity silicon carbide ceramic material is characterized by being prepared from the following raw materials in parts by weight: 70-80 parts of silicon carbide, 9-12 parts of silicon nitride, 4-6 parts of stainless steel powder, 6-8 parts of titanium powder, 2-3 parts of polyaluminum chloride, 1-2 parts of a silane coupling agent KH-570, 4-5 parts of cryolite powder, 3-4 parts of quartz, 2-4 parts of sintering additives and 80-100 parts of deionized water. The stainless steel powder added increases the sintering compactness of the ceramic and reduces the sintering temperature, so that the resources are saved; silicon nitride is added to improve the hardness, thermal conductivity and insulating property of the ceramic are improved; the added sintering additives improve the sintering performance of the ceramic and increase the sintering density, so that the service life of the ceramic is prolonged.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

Method for preparing solid polymeric aluminum ferric sulfate

InactiveCN101423259ASolve pollutionExtended service lifeIron sulfatesWater/sewage treatment by flocculation/precipitationLiquid productCatalytic oxidation

The invention discloses a preparation method of solid polymeric ferroaluminum sulfate, comprising the following steps: (1) basic ferric sulfate is prepared from ferrous sulfate; (2) water, sulfuric acid and hydrogen peroxide are added into the basic ferric sulfate in sequence, stirring and standing; (3) an aluminized compound is added and further stirred; (4) being self-cured and precipitated under dry condition; and (5) being aged at room temperature and crushed so to obtain a product. The invention uses a blast oxidation process and solves the pollution problem which is generated by the catalytic oxidation process in the traditional iron-based coagulant industry. The polymeric ferroaluminum sulfate is a solid product; compared with the liquid product, the polymeric ferroaluminum sulfate has advantages of storage and transportation, has long service life, and does not need evaporation or decompression evaporation process, and the coagulation active component of the product is retained to the largest extent. Quality indicators such as basicity, active component, and the like are all higher than the quality indicators in the prior art. When in actual implementation and embodiment of water body, the effect of the polymeric ferroaluminum sulfate is better than the effect of the inorganic coagulant such as polyaluminum chloride polymeric ferroaluminum sulfate and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Photomagnetic composite flocculant and preparation method thereof

InactiveCN103241812AEasy to handleNo pollution in the processWater/sewage treatment by magnetic/electric fieldsEnergy based wastewater treatmentAluminium chloridePulp and paper industry

The invention discloses a photomagnetic composite flocculant and a preparation method thereof. The preparation method comprises the following steps: compounding a magnetic fluid (SiO2 / Fe3O4) and cationic polyacrylamide (PAM) in a polyaluminum chloride (PAC) solution to prepare a magnetic fluid composite flocculant; and combining with modified TiO2 powder to obtain the cationic PAM-TiO2 / SiO2 / Fe3O4 photomagnetic composite flocculant, wherein the cationic PAM:TiO2:SiO2:Fe3O4 mol ratio is (3-5):(4-6):(2-3):1. The preparation method disclosed by the invention has the advantages of simple production conditions and low cost; and the prepared photomagnetic composite flocculant has the advantages of low consumption, favorable decolorization and decontamination effects, no environmental pollution, and no toxic or harmless effect on the human body, is easy to recover and reutilize, and is suitable for sewage treatment of dyeing wastewater, oily wastewater, cultivation wastewater and the like.

Owner:JIANGSU UNIV

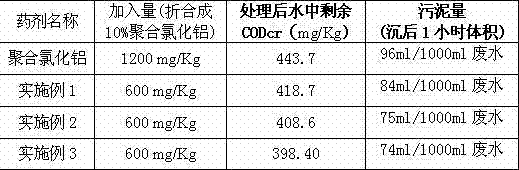

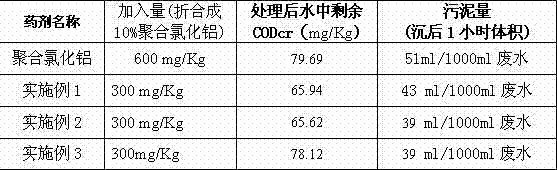

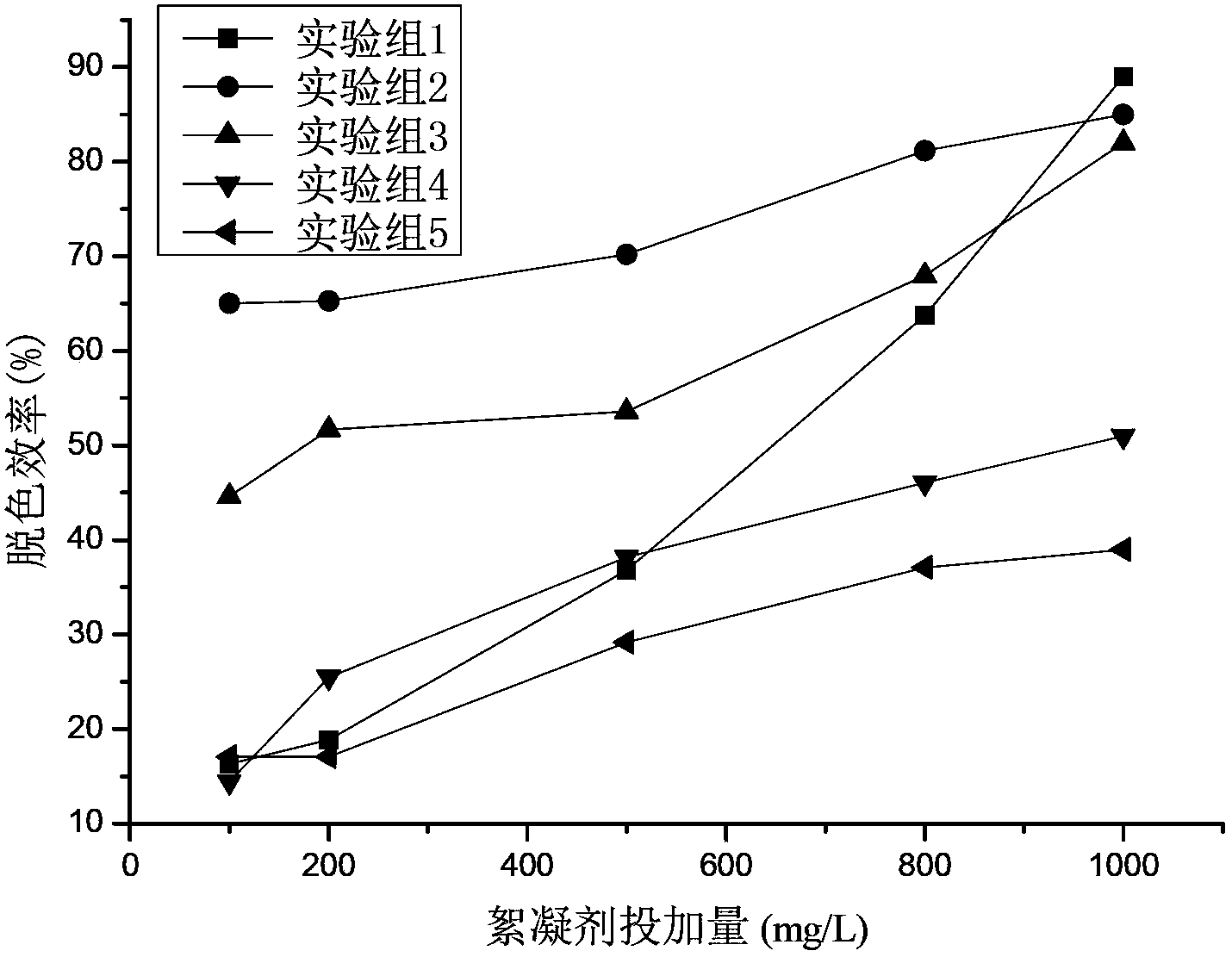

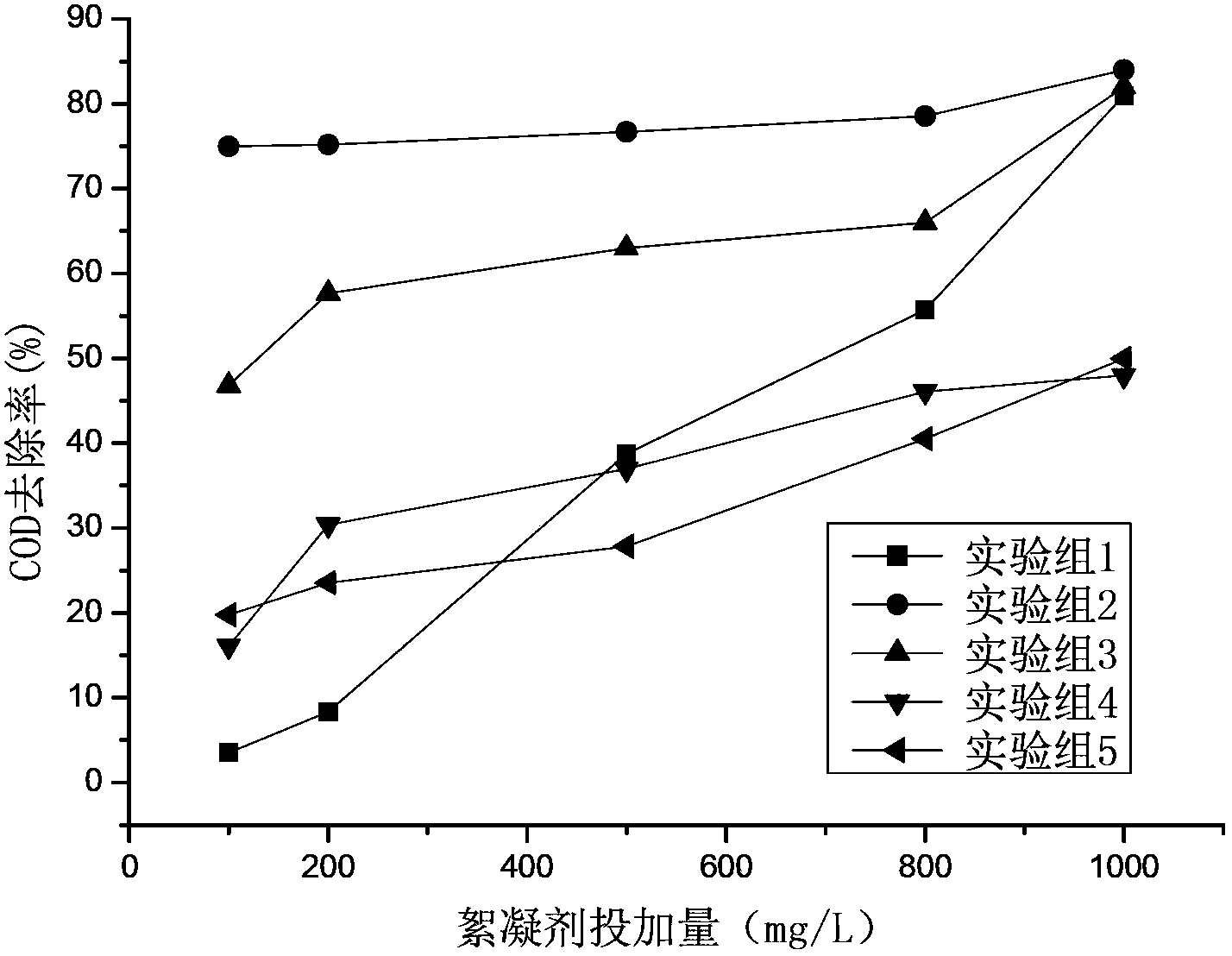

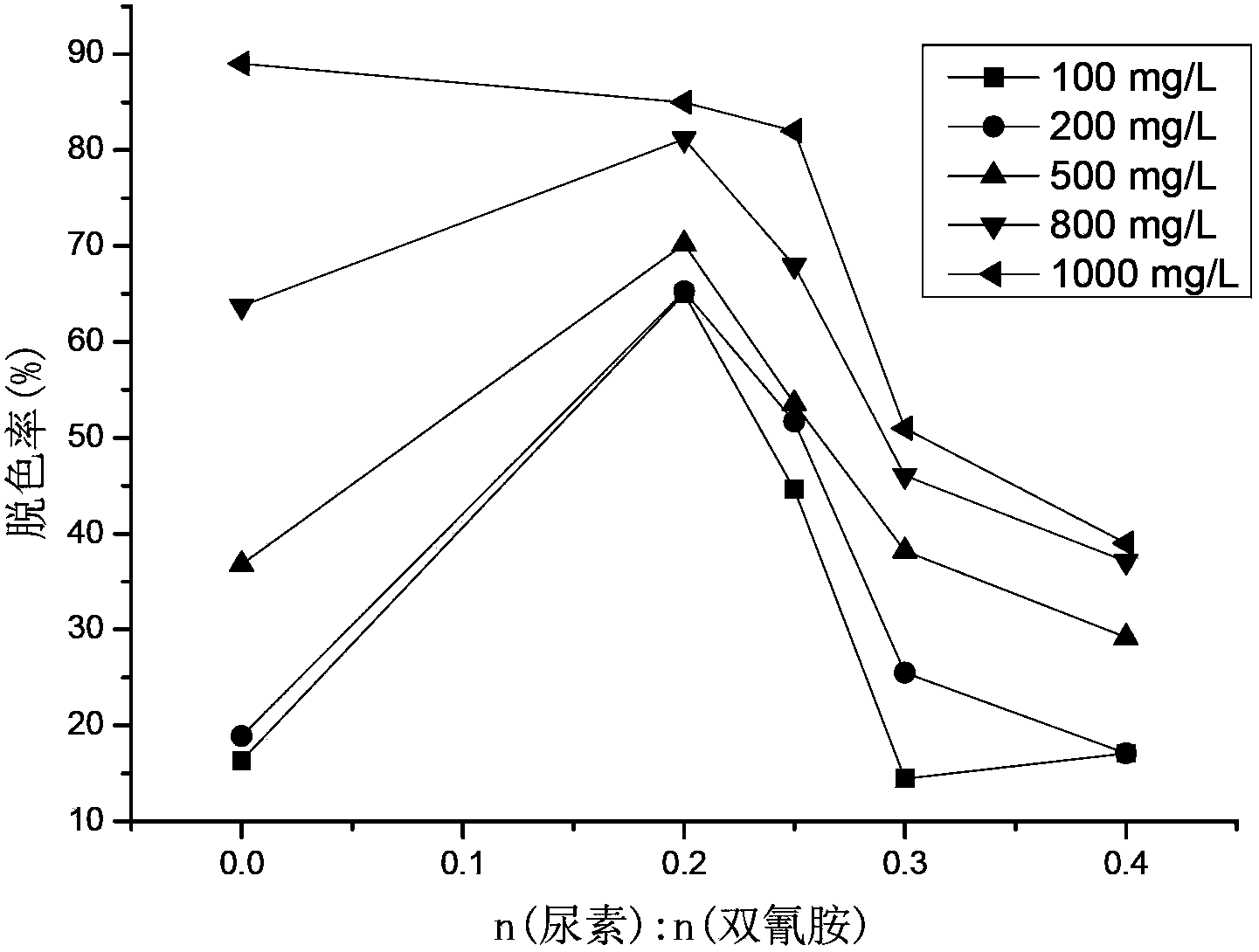

Special efficient polyaluminum chloride for printing and dyeing wastewater, and preparation method thereof

ActiveCN104761030AReduce dosageExcellent COD removal rateWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateLarge dose

The invention relates to a wastewater treatment agent, and especially relates to a special efficient polyaluminum chloride for printing and dyeing wastewater, and a preparation method thereof. The technical problems of large dose, low COD removal rate and use restriction of and high use cost of polyaluminum chloride in the prior art and low COD removal rate and high use cost of some composite polyaluminum chloride which are certainly applied are solved in the invention. The preparation method comprises the following steps: adding an aluminum-containing raw material into hydrochloric acid, and stirring for fully reacting to obtain a salt with the basicity of 60-90% and a polyaluminum chloride liquid of aluminum trioxide and with the concentration of 4-16%; and adding enough inorganic acid into the polyaluminum chloride liquid into a stirring tank, and fully reacting to prepare the special efficient polyaluminum chloride for printing and dyeing wastewater.

Owner:杭州萧山三江净水剂有限公司

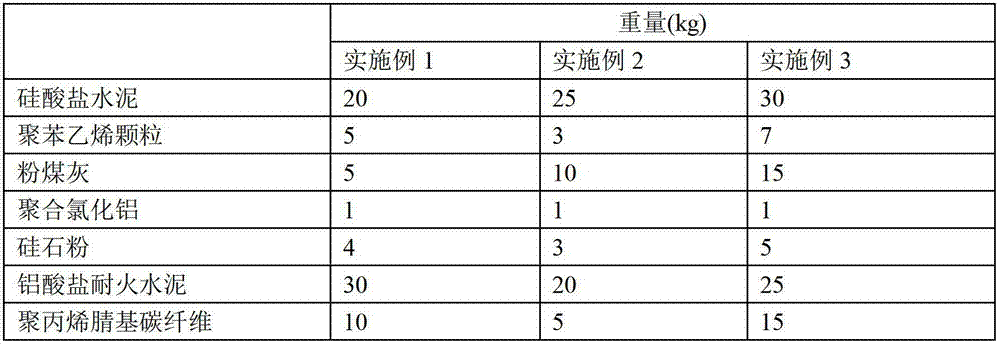

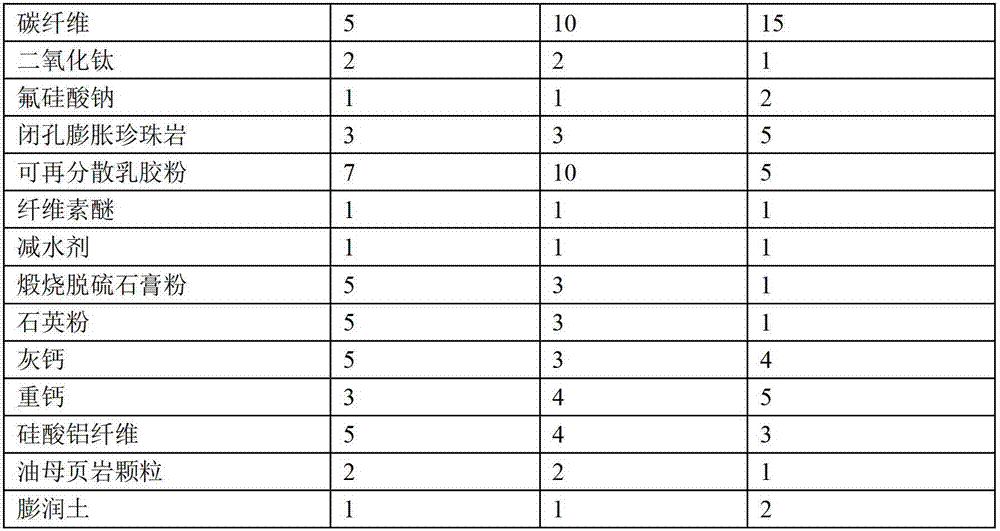

Cement-based thermal insulation material

The invention provides a cement-based thermal insulation material, which belongs to the technical fields of building materials. The cement-based thermal insulation material comprises, by weight, 20 to 30 parts of Portland cement, 3 to 7 parts of polystyrene particles, 5 to 15 parts of fly ash, 1 part of polyaluminum chloride, 3 to 5 parts of silica powder, 20 to 30 parts of aluminate refractory cement, 5 to 15 parts of the polyacrylonitrile-based carbon fibers, 5 to 15 parts of carbon fibers, 1 to 2 parts of titanium dioxide, 1 to 2 parts of sodium fluosilicate, 3 to 5 parts of closed-cell expanded perlite, 5 to 10 parts of redispersible latex powder, 1 part of cellulose ether, 1 part of a water reducer, 1 to 5 parts of calcined desulfurization gypsum powder, 1 to 5 parts of quartz powder, 3 to 5 parts of gray calcium, 3 to 5 parts of heavy calcium, 3 to 5 parts of alumina silicate fibers, 1 to 2 parts of oil shale particles and 1 to 2 parts of bentonite. The cement-based thermal insulation material provided by the invention has the advantages of easily available raw materials and a good thermal insulation effect.

Owner:苏州市德莱尔建材科技有限公司

Preparation method for modified dicyandiamide-formaldehyde flocculating agent and application of flocculating agent product

InactiveCN103351454ASimple processHigh removal rateWater contaminantsWaste water treatment from textile industryAluminium chlorideAluminium chlorohydrate

The invention relates to a preparation method for a modified dicyandiamide-formaldehyde flocculating agent and application of a flocculating agent product, which belongs to the technical field of wastewater treatment. The invention provides the preparation method for the modified dicyandiamide-formaldehyde flocculating agent to overcome the problems of uneasy operation, poor decolouring and a low COD removal rate in the prior art. The preparation method comprises the following steps: adding a most part of the raw material formaldehyde, dicyandiamide and urea into a reactor, then adding aluminum chloride and carrying out a react at a temperature of 30 to 40 DEG C; and then adding residual formaldehyde, heating to a temperature of 45 DEG C, adding an ammonium salt modifier, controlling temperature, carrying out a reaction, heating to a temperature of 65 to 75 DEG C and carrying out a reaction for 2 to 3 h so as to obtain the modified dicyandiamide-formaldehyde flocculating agent. The preparation method provided by the invention has the advantages of simple process, no need for preparation of a fresh polyaluminum chloride solution, mild reaction conditions and easy operation, and the prepared flocculating agent has a good decolouring effect and a high COD removal rate.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com