Water purifying agent for wastewater treatment in rubber accelerator M production and wastewater treatment method

A technology for rubber accelerator and waste water production, which is applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of slow development and achieve fast water purification and use Wide-ranging, high-transparency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

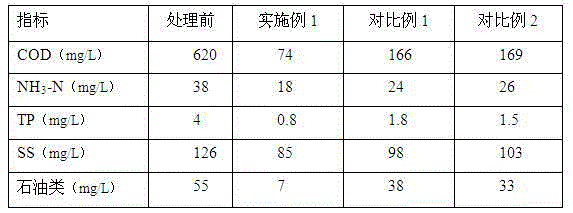

Embodiment 1

[0039] Rubber accelerator M produces the method for waste water treatment with water purifying agent, is characterized in that, method comprises the following steps:

[0040] First add flocculation water purifier to the sewage, stir evenly at a speed of 15 rpm, stir for 0.6 hours, and let it stand for 4 hours; the flocculation water purifier is: polyaluminum chloride 16, polyacrylamide 12, ferrous sulfate 8. Aluminum sulfate 10; then input activated carbon, activated carbon accounts for 3% of the waste water;

[0041] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 15 rpm, stir for 0.5 hours, and let stand for 4 hours; the microbial water purifiers are: nitrifying bacteria Bacteria powder 1.2, denitrification paracoccus bacteria powder 0.9, sulfur bacteria powder 0.6, aniline degrading bacteria powder 0.8, flocculation bacteria powder...

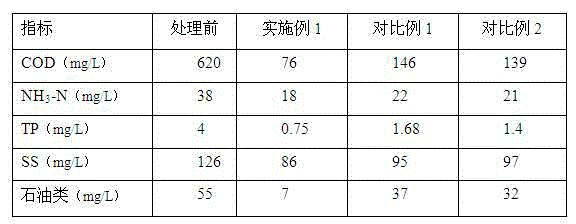

Embodiment 2

[0050] Rubber promotor M produces the method for the treatment of waste water with water purifying agent for waste water treatment, and the method comprises the following steps:

[0051] First add flocculation water purifier to the sewage, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 2 hours; flocculation water purifier is: polyaluminum chloride 4, polyacrylamide 4, ferrous sulfate 2. Aluminum sulfate 5; then put into activated carbon, which accounts for 1% of the waste water;

[0052] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 2 hours; microbial water purifiers are: nitrifying bacteria Bacteria powder 0.5, denitrification paracoccus bacteria powder 0.5, sulfur bacteria powder 0.2, aniline degrading bacteria powder 0.3, flocculation bacteria powder 0.5;

[...

Embodiment 3

[0055] First add flocculation water purifier to the sewage, stir evenly at a speed of 20 rpm, stir for 1 hour, and let it stand for 5 hours; the flocculation water purifier is: polyaluminum chloride 22, polyacrylamide 15, ferrous sulfate 13. Aluminum sulfate 15; add activated carbon again, and activated carbon accounts for 4% of the wastewater;

[0056] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 20 rpm, stir for 1 hour, and let stand for 6 hours; the microbial water purifiers are: nitrifying bacteria Bacteria powder 2.0, denitrification paracoccus powder 1.5, sulfur bacteria powder 0.8, aniline degrading bacteria powder 1.2, flocculation bacteria powder 1.5;

[0057] Then add the enzyme preparation in the above steps, stir evenly at a speed of 20 rpm, stir for 1 hour, and let stand for 8 hours. The enzyme preparation is pectinase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com