Dyeing wastewater treatment agent and preparation method thereof

A printing and dyeing sewage and treatment agent technology, which is applied in the direction of adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, treatment effect needs to be improved, and high treatment cost, so as to achieve no secondary pollution, Good treatment effect and rapid precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

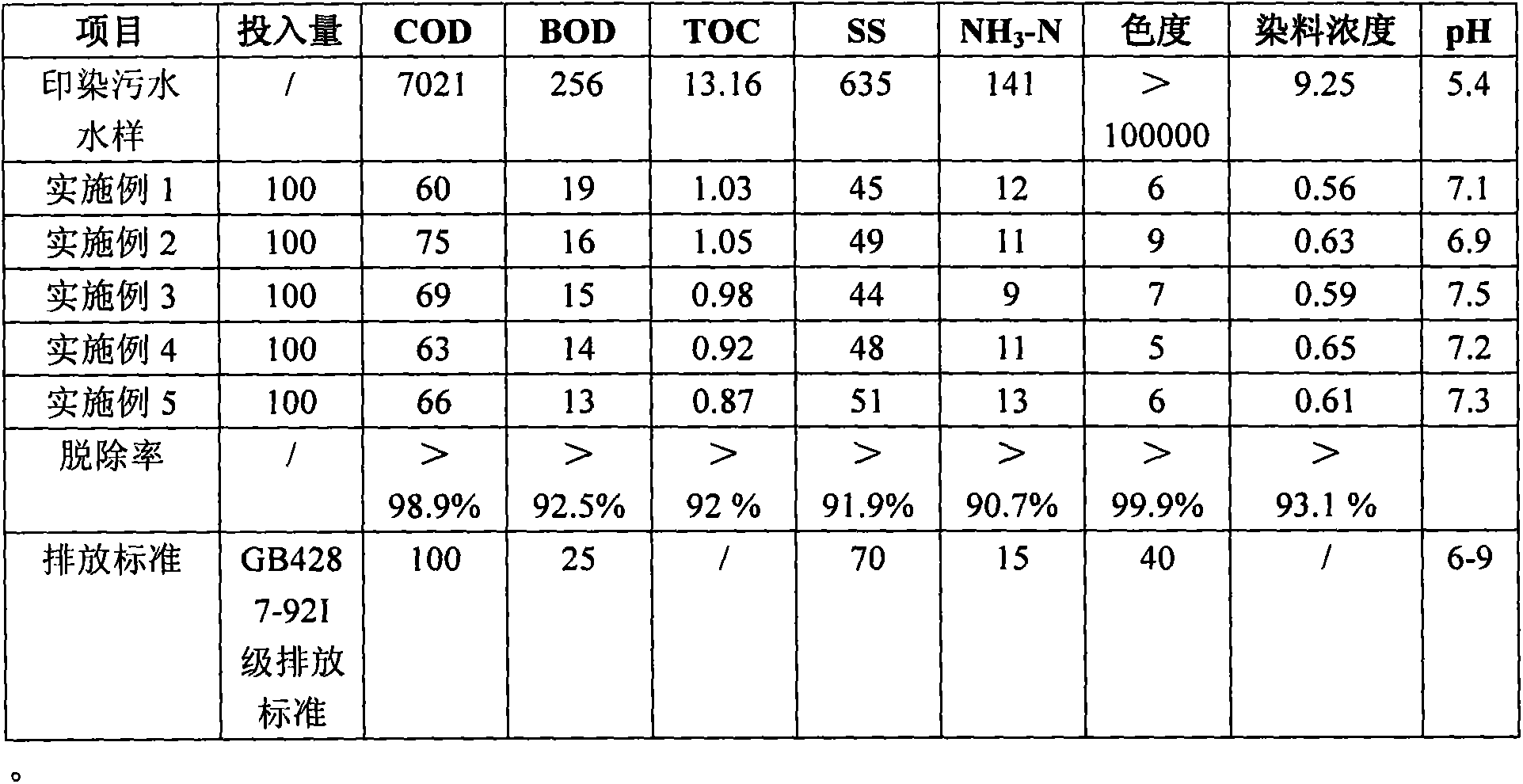

Examples

Embodiment 1

[0039] A printing and dyeing sewage treatment agent, the printing and dyeing sewage treatment agent comprises the following raw materials in parts by weight: 2 parts of ferrous sulfate, 20 parts of magnesium sulfate, 2 parts of polyacrylamide, 20 parts of ferric nitrate, 1 part of nickel nitrate, polymerized chloride 40 parts of aluminum, 20 parts of modified diatomite, 22 parts of sepiolite powder, 10 parts of cross-linked rectorite, 5 parts of chitosan-graphene composite material, graphene nanolayer / MnO 2 Complex 3 parts.

[0040] A preparation method of printing and dyeing sewage treatment agent, the preparation steps are as follows:

[0041] A, take raw material according to weight portion, add ferrous sulfate, magnesium sulfate, modified diatomite, sepiolite powder, cross-linked rectorite into pulverizer, pulverize into 100 mesh powder, add polyacrylamide;

[0042] B. Add ferric nitrate, nickel nitrate, and polyaluminum chloride into the container, each raw material is a...

Embodiment 2

[0045] A printing and dyeing sewage treatment agent, the printing and dyeing sewage treatment agent comprises the following raw materials by weight: the printing and dyeing sewage treatment agent comprises the following raw materials by weight: 6 parts of ferrous sulfate, 20 parts of magnesium sulfate, 2 parts of polyacrylamide, 15 parts of iron nitrate, 3 parts of nickel nitrate, 40 parts of polyaluminum chloride, 15 parts of modified diatomite, 13 parts of sepiolite powder, 15 parts of cross-linked rectorite, 10 parts of chitosan-graphene composite material, Graphene nanolayer / MnO 2 1 part of the complex.

[0046] A preparation method of printing and dyeing sewage treatment agent, the preparation steps are as follows:

[0047] A, take raw material according to weight portion, add ferrous sulfate, magnesium sulfate, modified diatomite, sepiolite powder, cross-linked rectorite into pulverizer, pulverize into 110 mesh powder, add polyacrylamide;

[0048] B. Add ferric nitrate...

Embodiment 3

[0051] A printing and dyeing sewage treatment agent, the printing and dyeing sewage treatment agent comprises the following raw materials in parts by weight: 10 parts of ferrous sulfate, 25 parts of magnesium sulfate, 0.5 parts of polyacrylamide, 15 parts of ferric nitrate, 3 parts of nickel nitrate, polymerized chloride 55 parts of aluminum, 12 parts of modified diatomite, 16 parts of sepiolite powder, 13 parts of cross-linked rectorite, 7 parts of chitosan-graphene composite material, graphene nanolayer / MnO 2 Compound 2 parts.

[0052] A preparation method of printing and dyeing sewage treatment agent, the preparation steps are as follows:

[0053] A, take raw material according to weight portion, add ferrous sulfate, magnesium sulfate, modified diatomite, sepiolite powder, cross-linked rectorite into pulverizer, pulverize into 130 mesh powder, add polyacrylamide;

[0054] B. Add ferric nitrate, nickel nitrate, and polyaluminum chloride into the container, each raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com