A solar automatic sewage treatment system and its working method

An automatic treatment and sewage treatment technology, applied in the direction of water/sewage treatment, water/sewage multi-stage treatment, heating water/sewage treatment, etc., can solve the problems of lack of power supply, huge power consumption, low degree of automation, etc. Energy consumption, broad market prospects, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

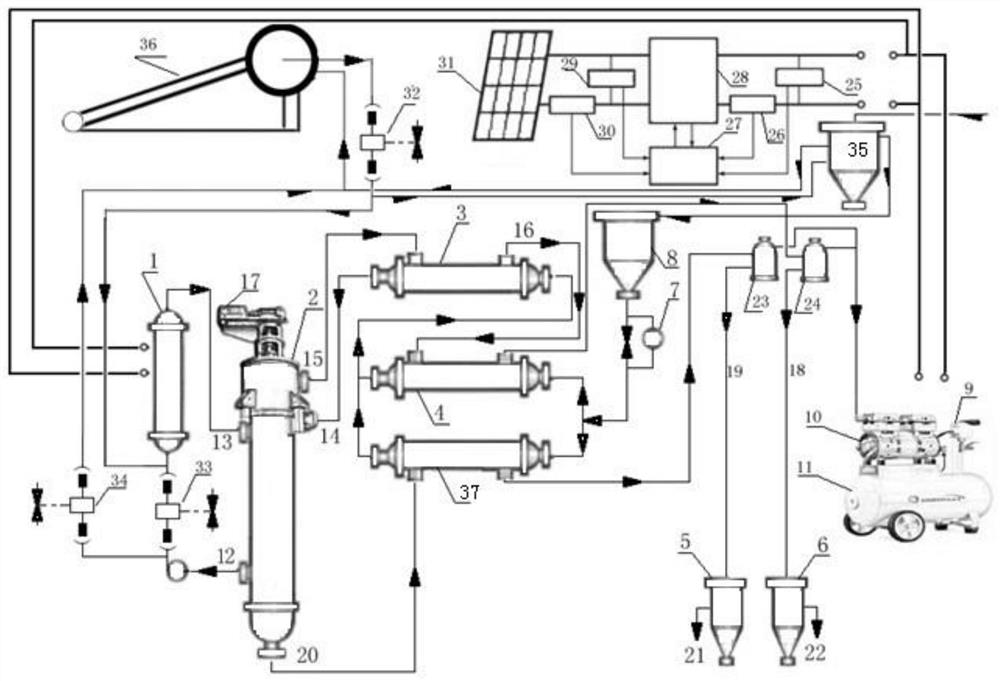

[0043] A solar sewage automatic treatment system, including a solar sewage treatment heat recovery system, a solar sewage heating and electromagnetic auxiliary heating system, a solar power supply and auxiliary system, a solar low pressure evaporation system and a solar sewage treatment automatic control system;

[0044] The heat recovery system for solar sewage treatment includes a raw water solar preheater 35 and a solar water heater 36 connected to each other. The raw water solar preheater 35 is connected to a raw liquid high tank 8, and the raw liquid high tank 8 is respectively connected to the first concentrated liquid exchange through the electromagnetic flowmeter 7. The heat exchanger 4 and the second concentrated liquid heat exchanger 37, the outlet of the first concentrated liquid heat exchanger 4 and the outlet of the second concentrated liquid heat exchanger 37 are all connected with the evaporation liquid condensation heat exchanger 3, and the evaporation liquid con...

Embodiment 2

[0053] A solar sewage automatic treatment system, the structure is as shown in embodiment 1, the difference is that the installation height of the condensed water gas-water separator 24 and the concentrated liquid gas-water separator 23 is 10m, the first water leg pipe and the second The height of the water leg pipe is preferably 9m, thereby forming a vacuum environment of -0.05MPa to -0.095MPa.

[0054] The thin-film evaporator 2 is a scraper thin-film evaporator, and the scraper thin-film evaporator is provided with a motor 17. The function of the motor is to drive the scraper to rotate to form a liquid film and improve evaporation efficiency.

[0055] The control computer 27 is also connected with a dosing pump. With the addition of relevant medicines, the specific dosing type and dosing amount can be controlled according to the raw water composition with reference to the prior art.

Embodiment 3

[0057] A working method of a solar sewage automatic treatment system, including a solar sewage treatment heat recovery process, a solar sewage heating and electromagnetic auxiliary heating process, a solar power supply and an auxiliary process, a solar low-pressure evaporation process, and a solar sewage treatment automatic control process;

[0058] The heat recovery process of solar sewage treatment includes:

[0059] The raw water is pumped to the regulating pool, the dosing pump is added, and then pumped to the raw water solar preheater 35. The raw water is preheated by the hot water from the solar water heater 36 to 30-40°C. The raw water flows to the raw liquid high level tank 8, passes through the electromagnetic flowmeter 7, flows through the first concentrated liquid heat exchanger 4 and the second concentrated liquid heat exchanger 37 respectively, and is further heated by the evaporating liquid condensation heat exchanger 3, and is heated to 35 ~45°C, and then enter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com