Adsorption type high pressure natural gas dehydration process and device

A dehydration device and natural gas technology, applied in the direction of gas fuel, petroleum industry, dispersed particle separation, etc., can solve the problems of poor cooling and separation effect, high cost of explosion-proof motor, large cooling water consumption, etc., to achieve good cooling effect and avoid high and low The effect of alternating temperature and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

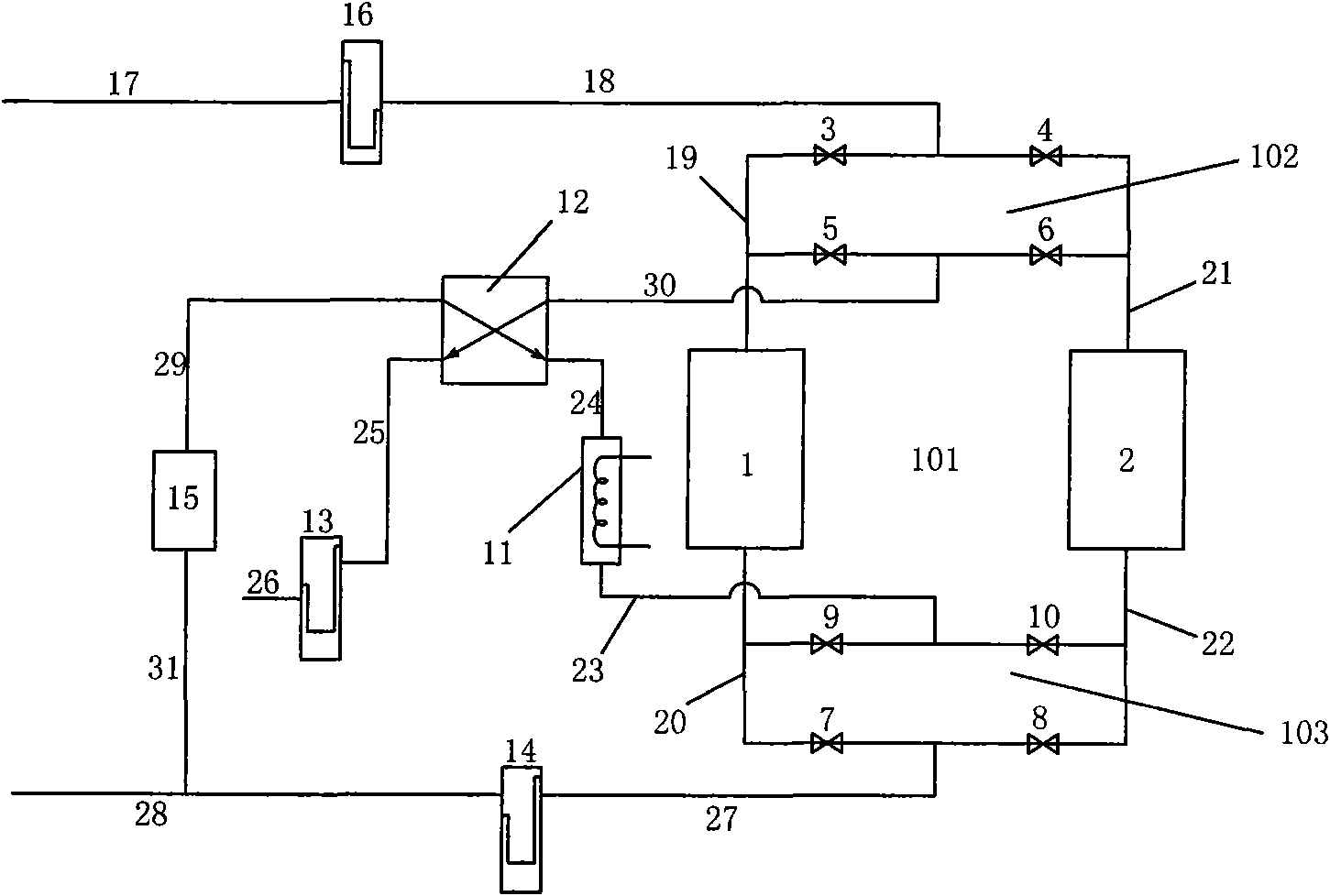

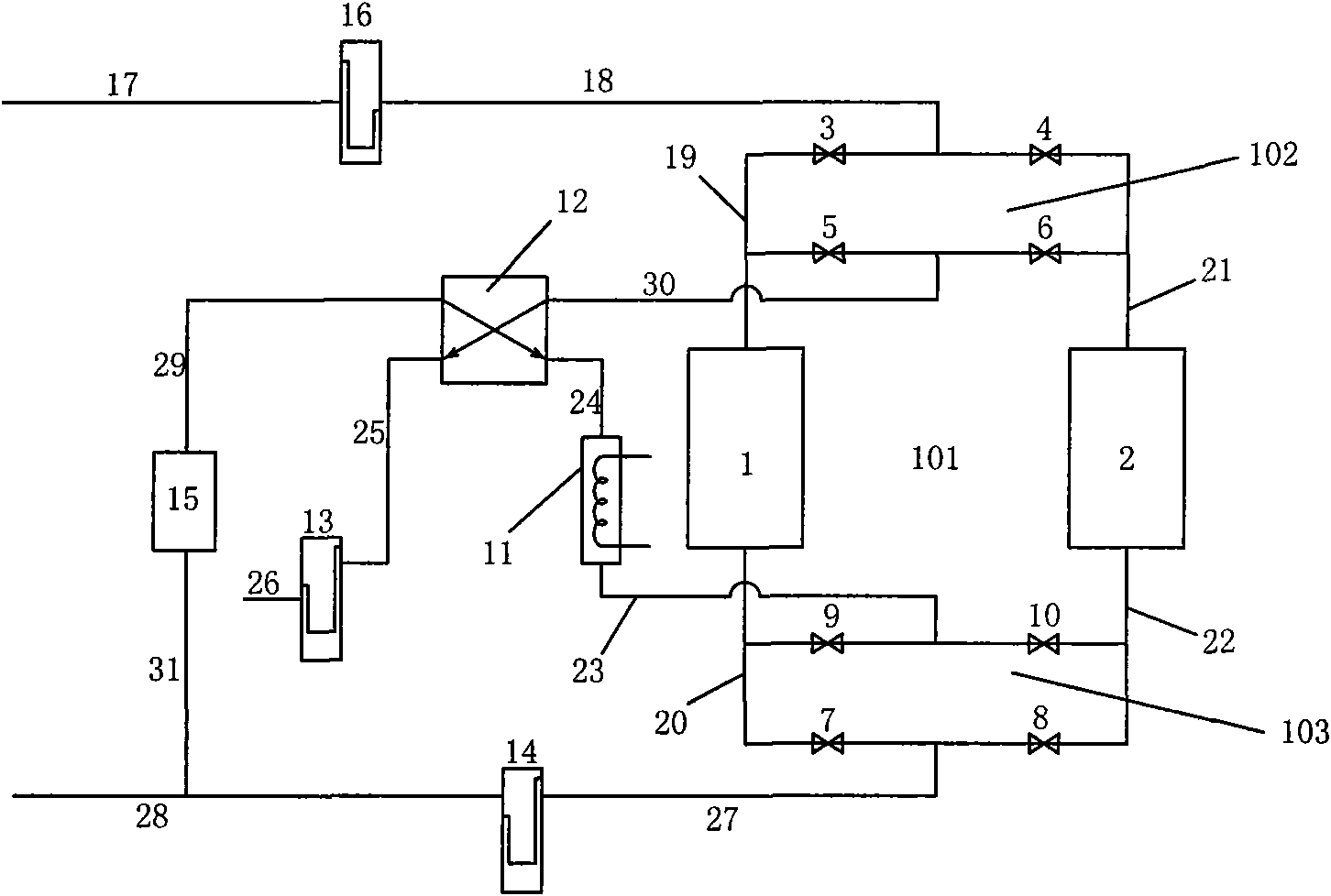

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] The adsorption type high-pressure natural gas dehydration process of the present invention comprises the following steps:

[0039] (1) Adsorption

[0040] (1.1) Filtration and separation of the free liquid contained in the raw gas;

[0041] (1.2) introducing the gas obtained after the treatment of step (1.1) into the tower for adsorption and drying;

[0042] (1.3) filtering the gas obtained after the treatment in step (1.2) to separate the solid dust particles in the gas;

[0043] (1.4) Part of the gas obtained after the treatment in step (1.3) is introduced into the gas utilization system, and the other part is introduced into the step (2) for regeneration;

[0044] (2) regeneration

[0045] (2.1) decompressing the gas introduced through step (1.4) to obtain low-temperature and low-pressure dry gas;

[0046] (2.2) The low-temperature, low-pressure drying gas and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com