Patents

Literature

133 results about "Natural gas dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

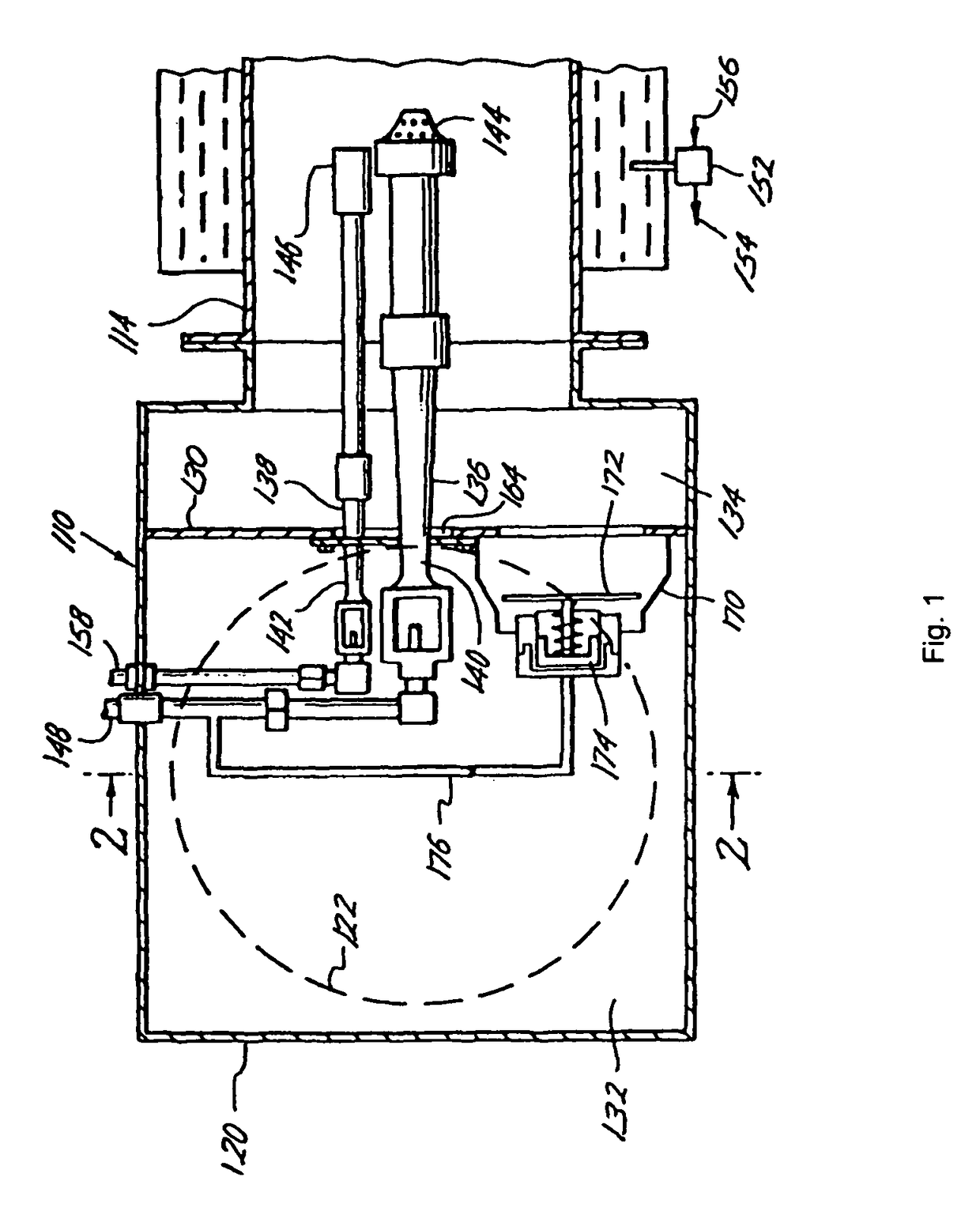

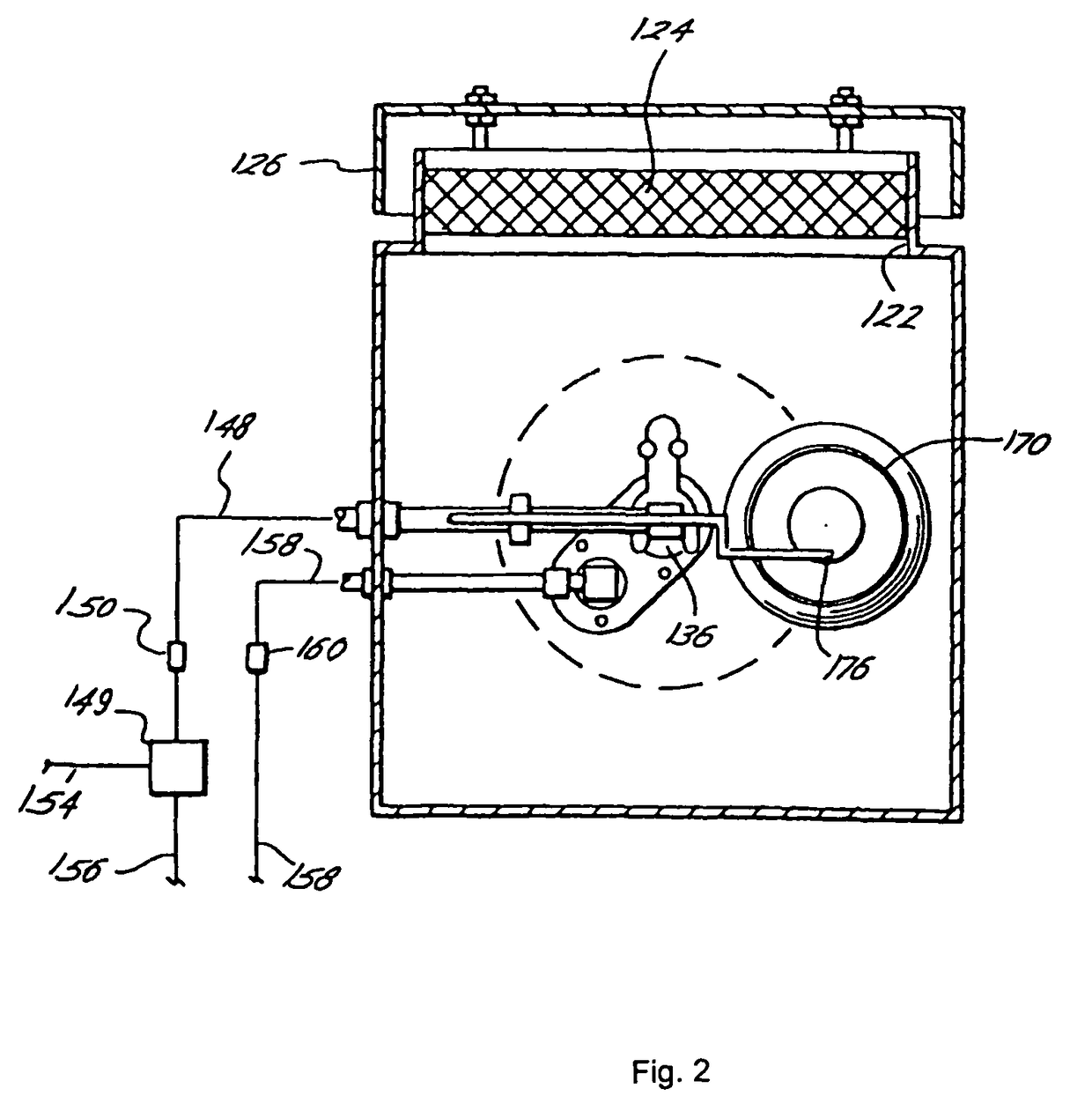

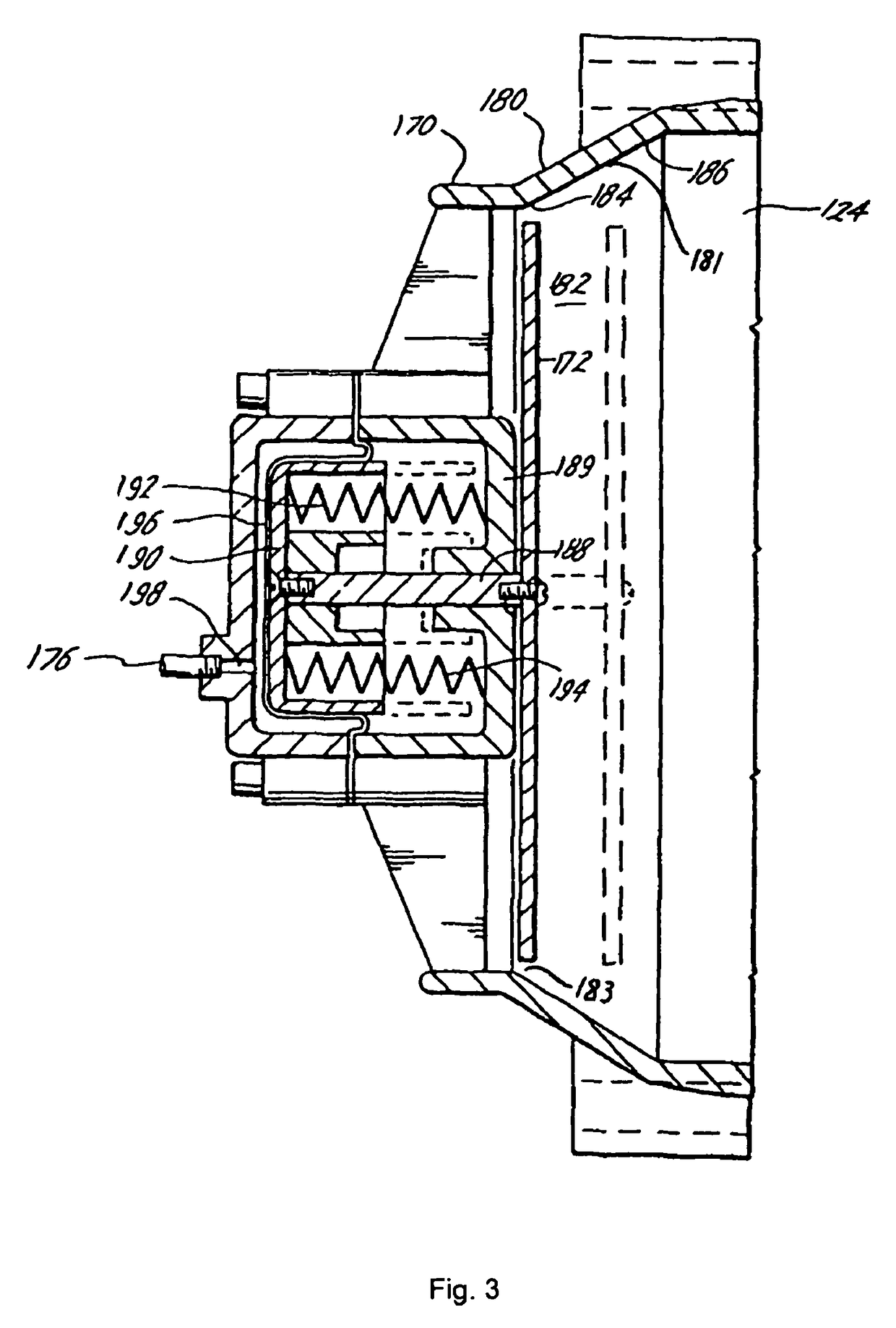

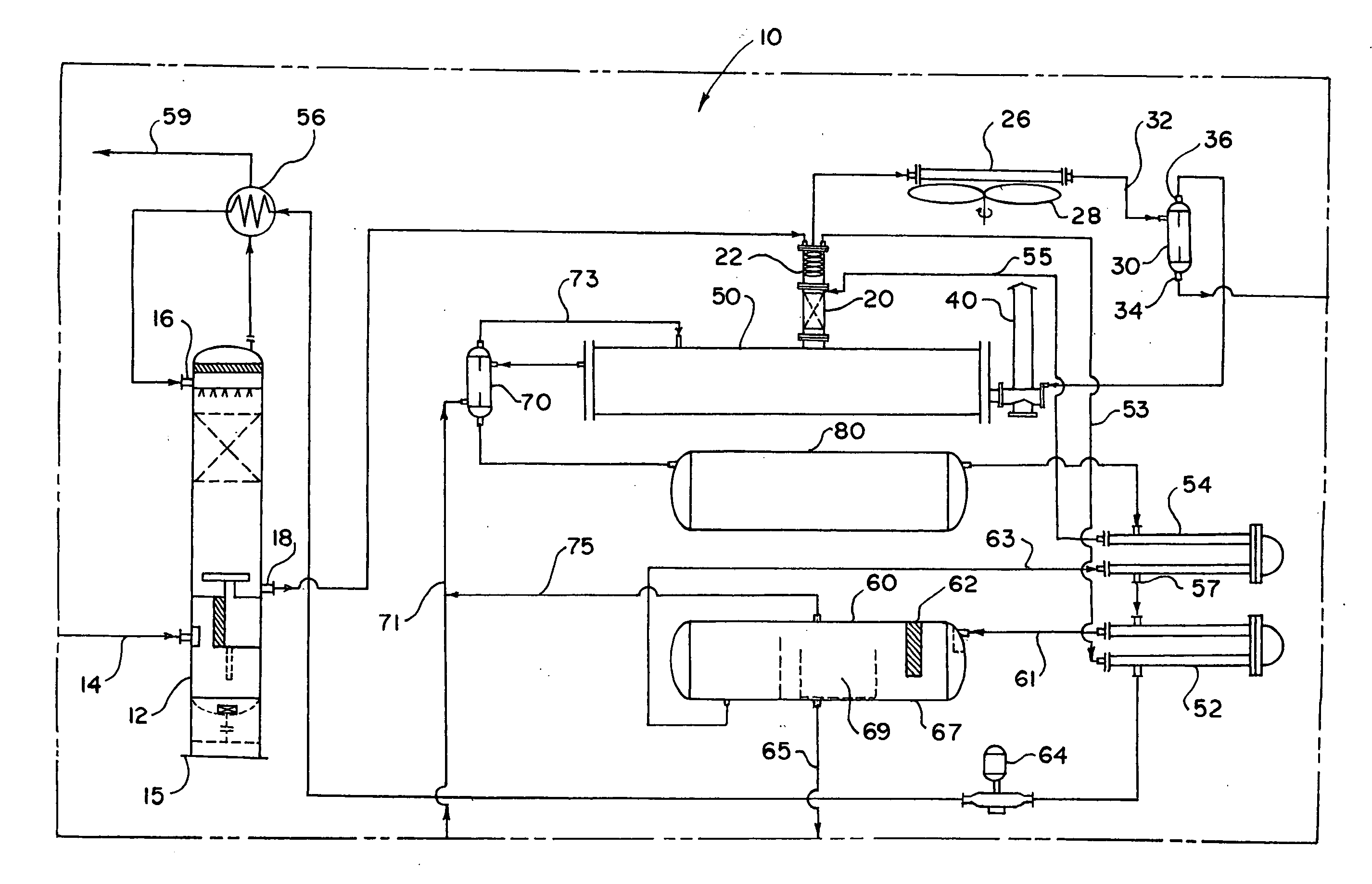

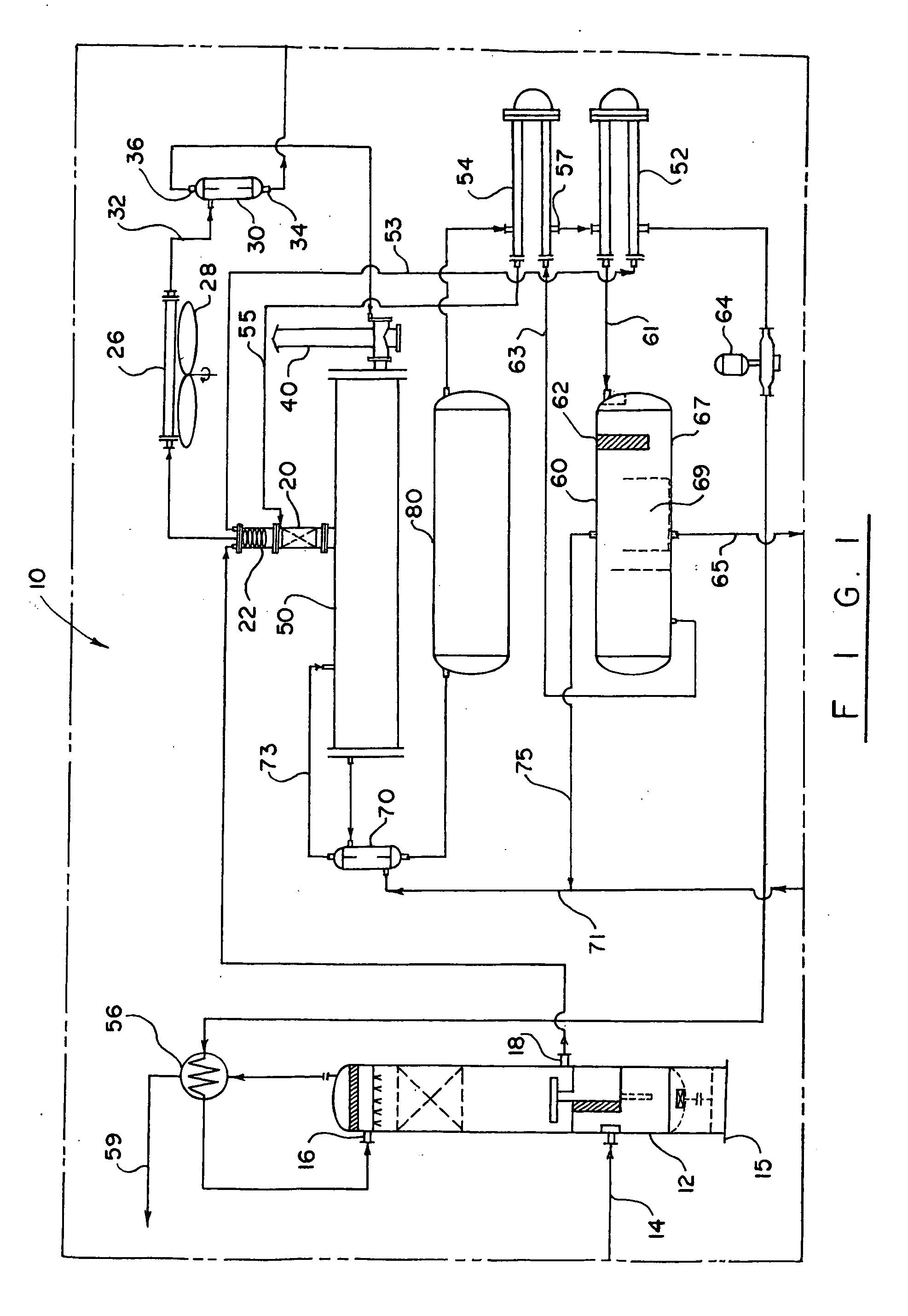

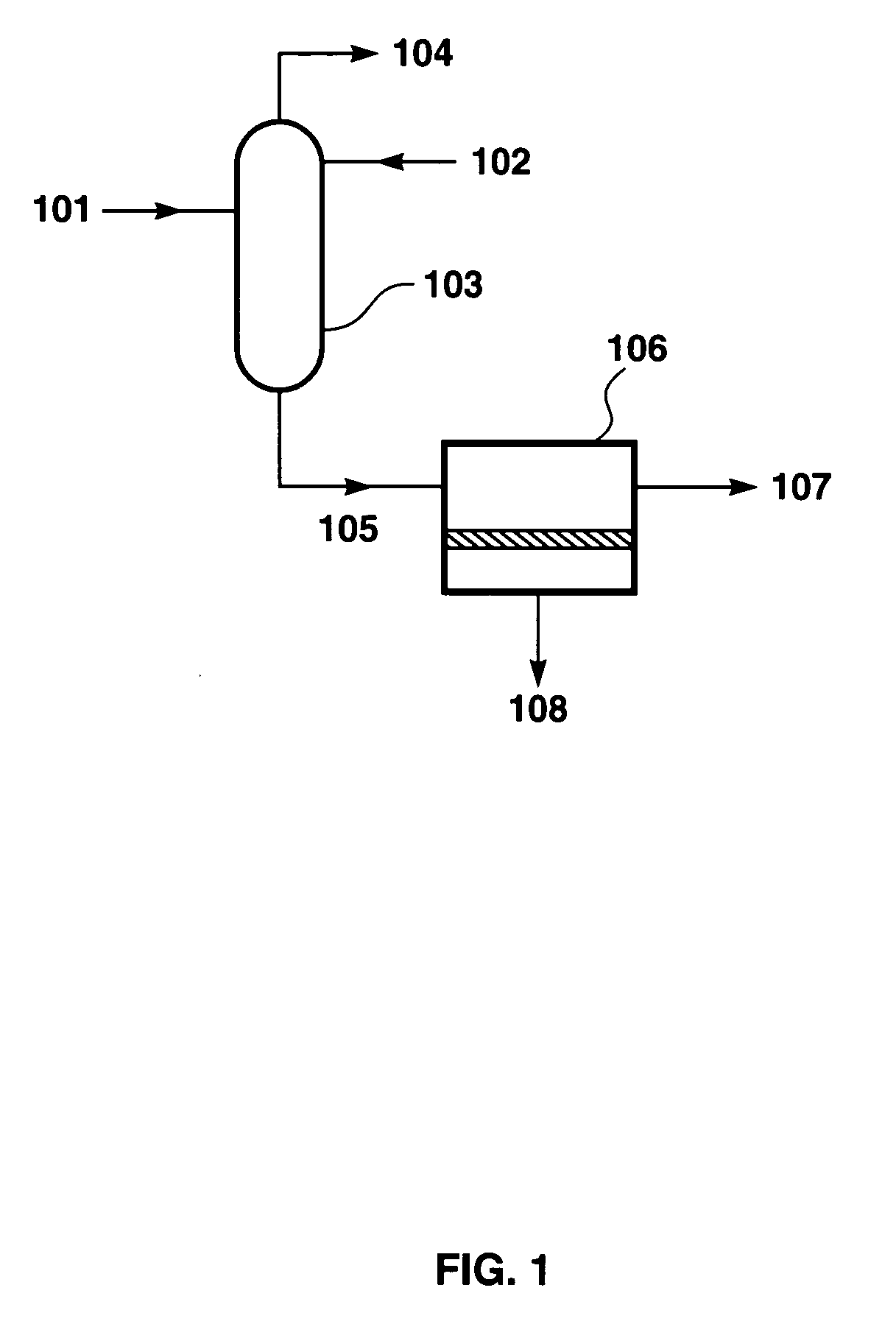

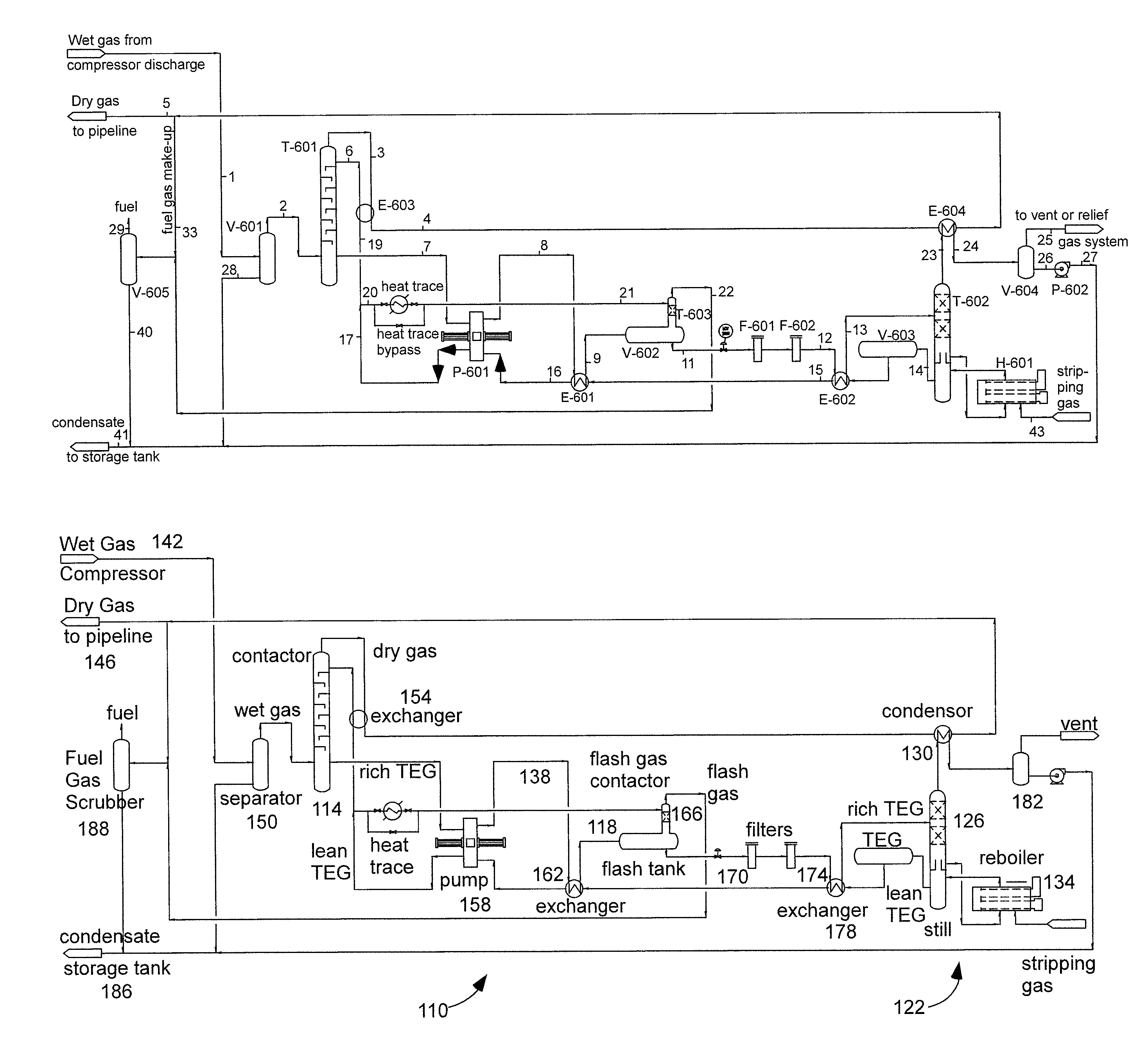

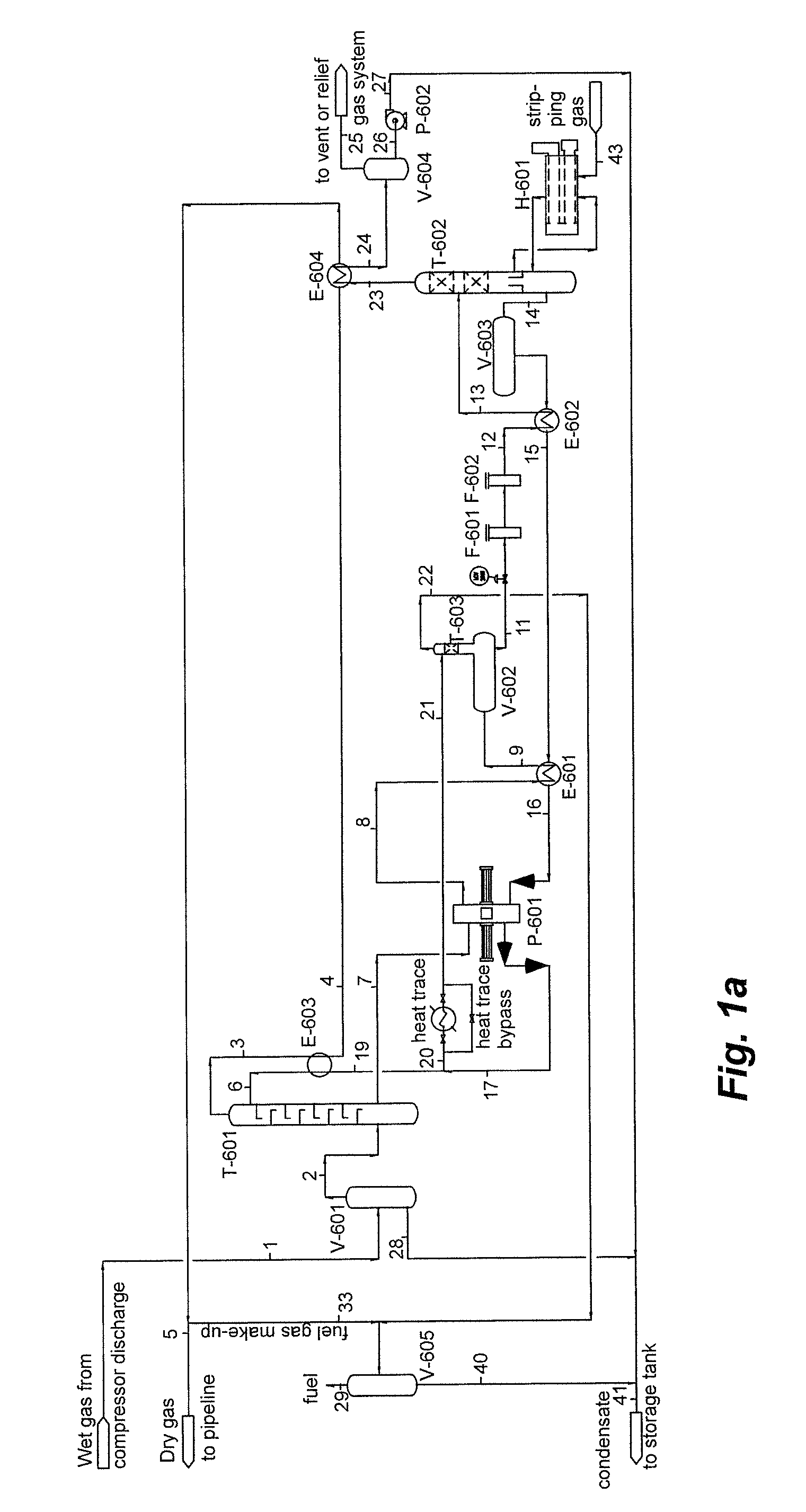

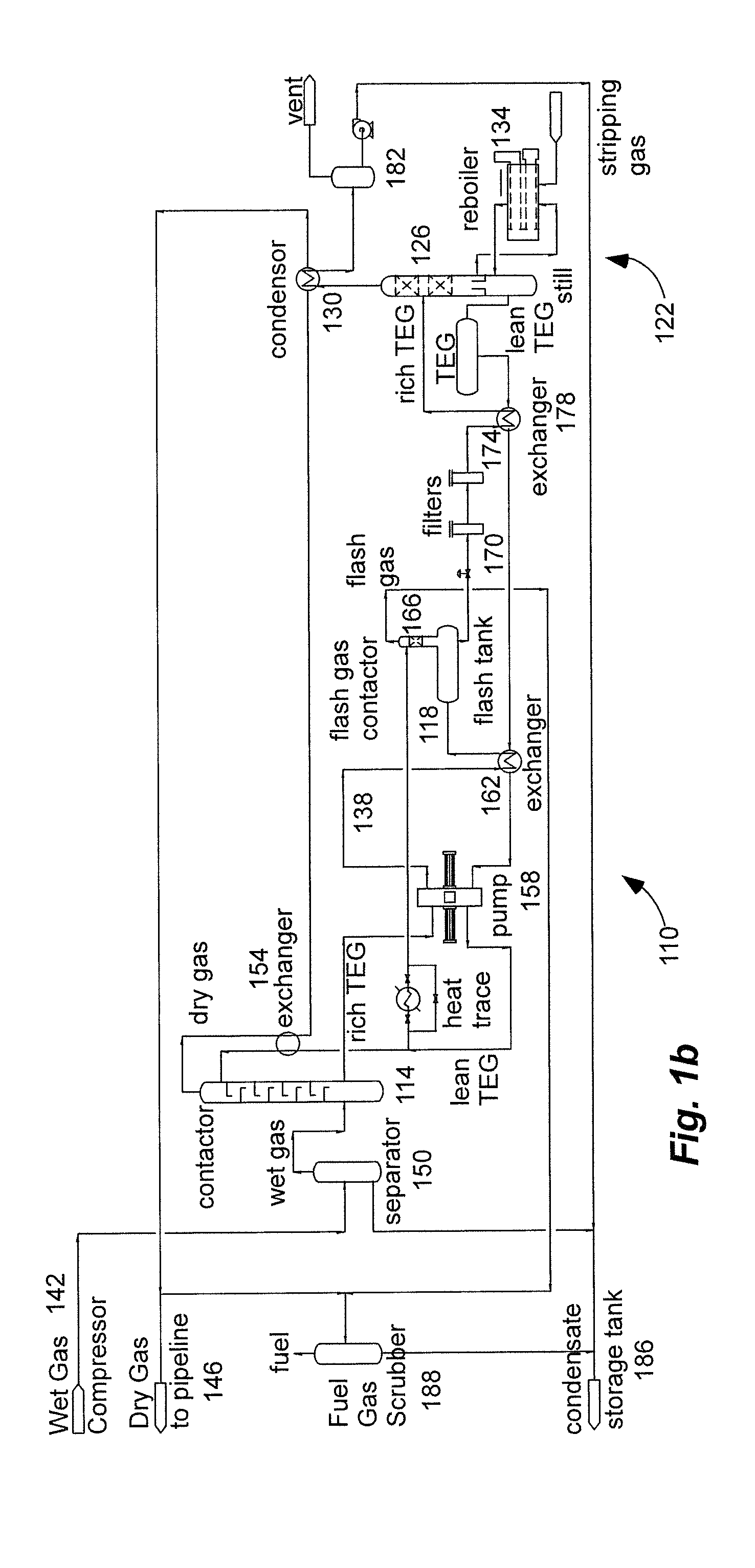

Natural gas dehydrator and system

InactiveUS20070084341A1Easy to operateLiquid degasificationUsing liquid separation agentLiquid hydrocarbonsNatural gas dehydration

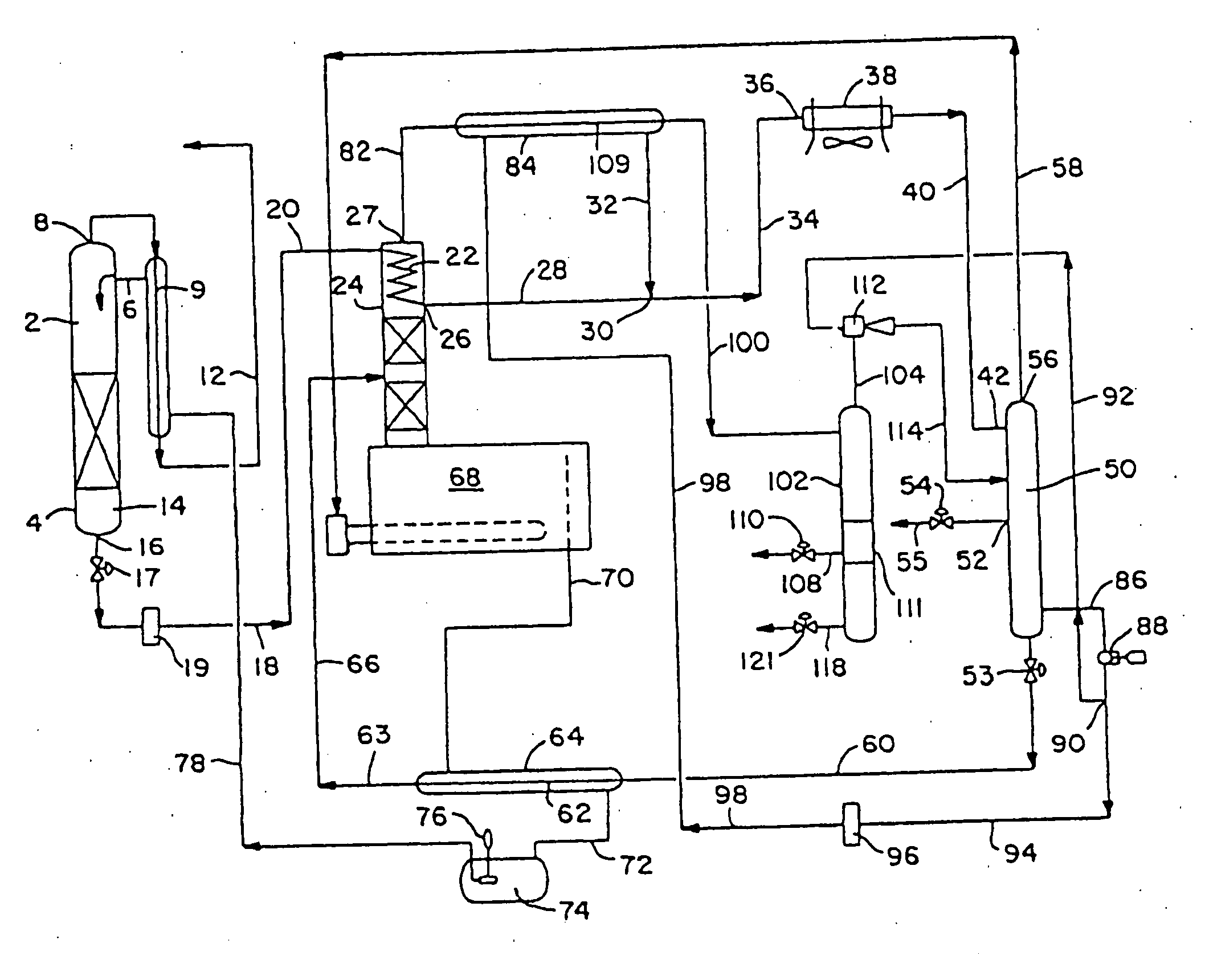

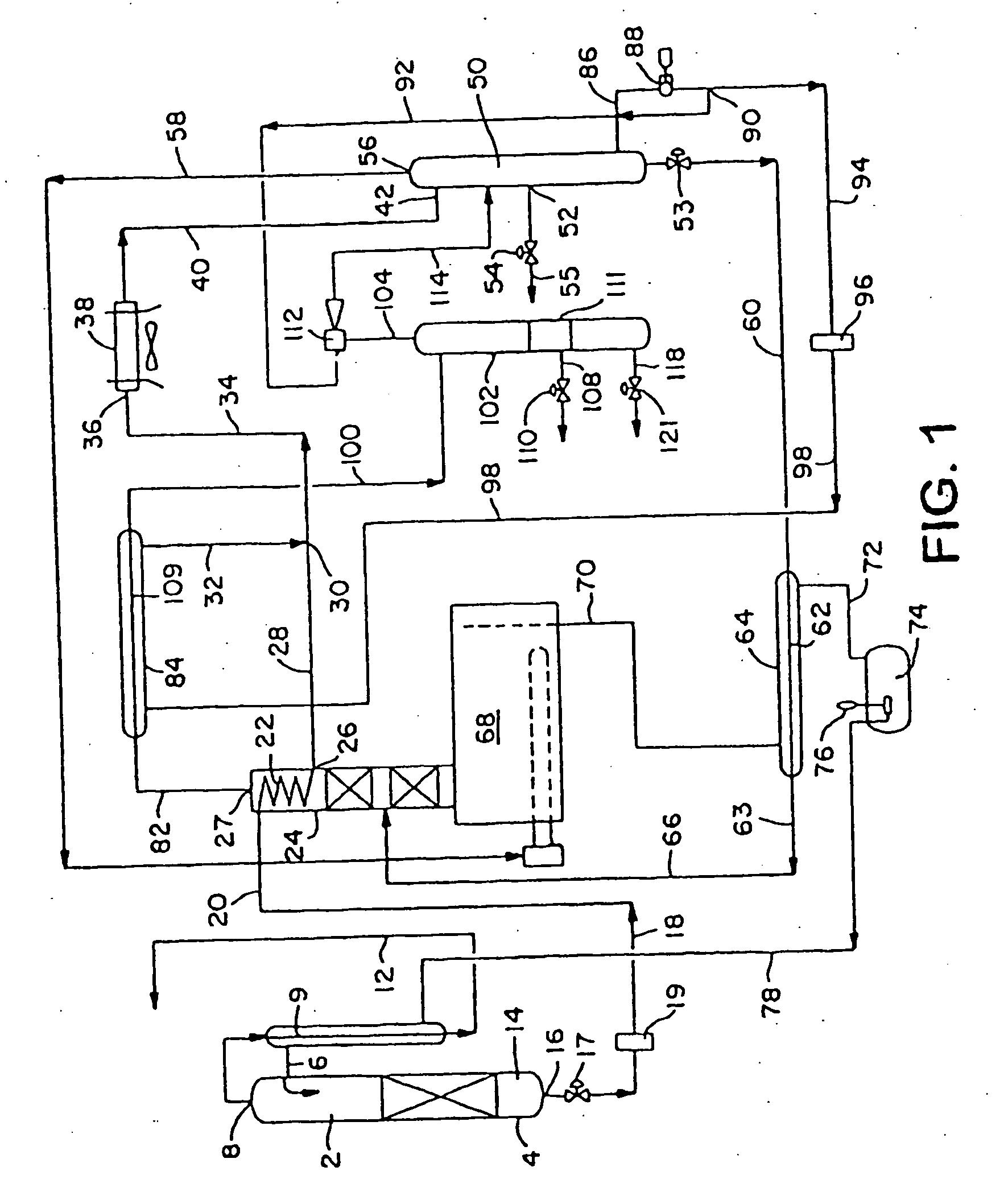

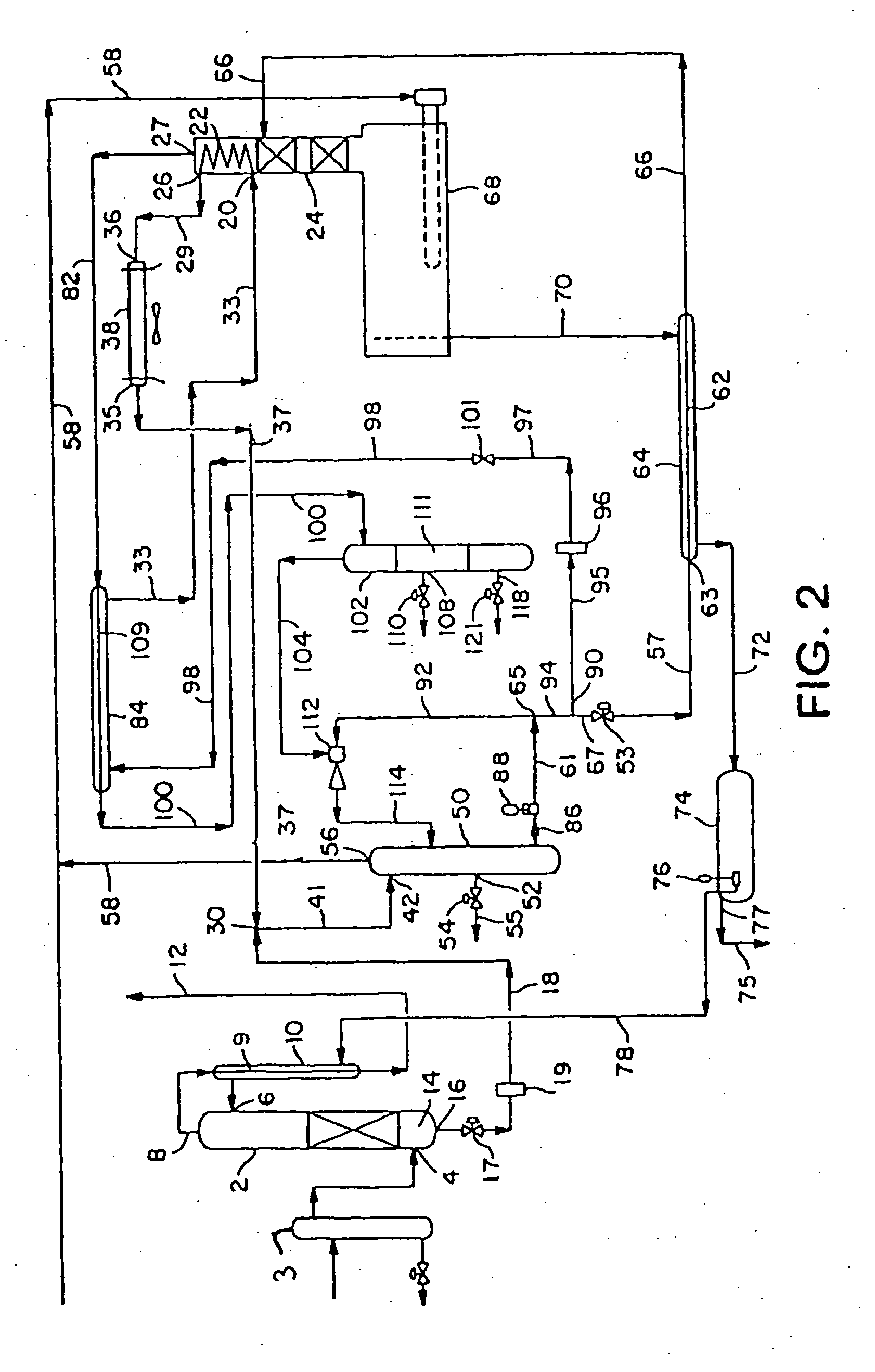

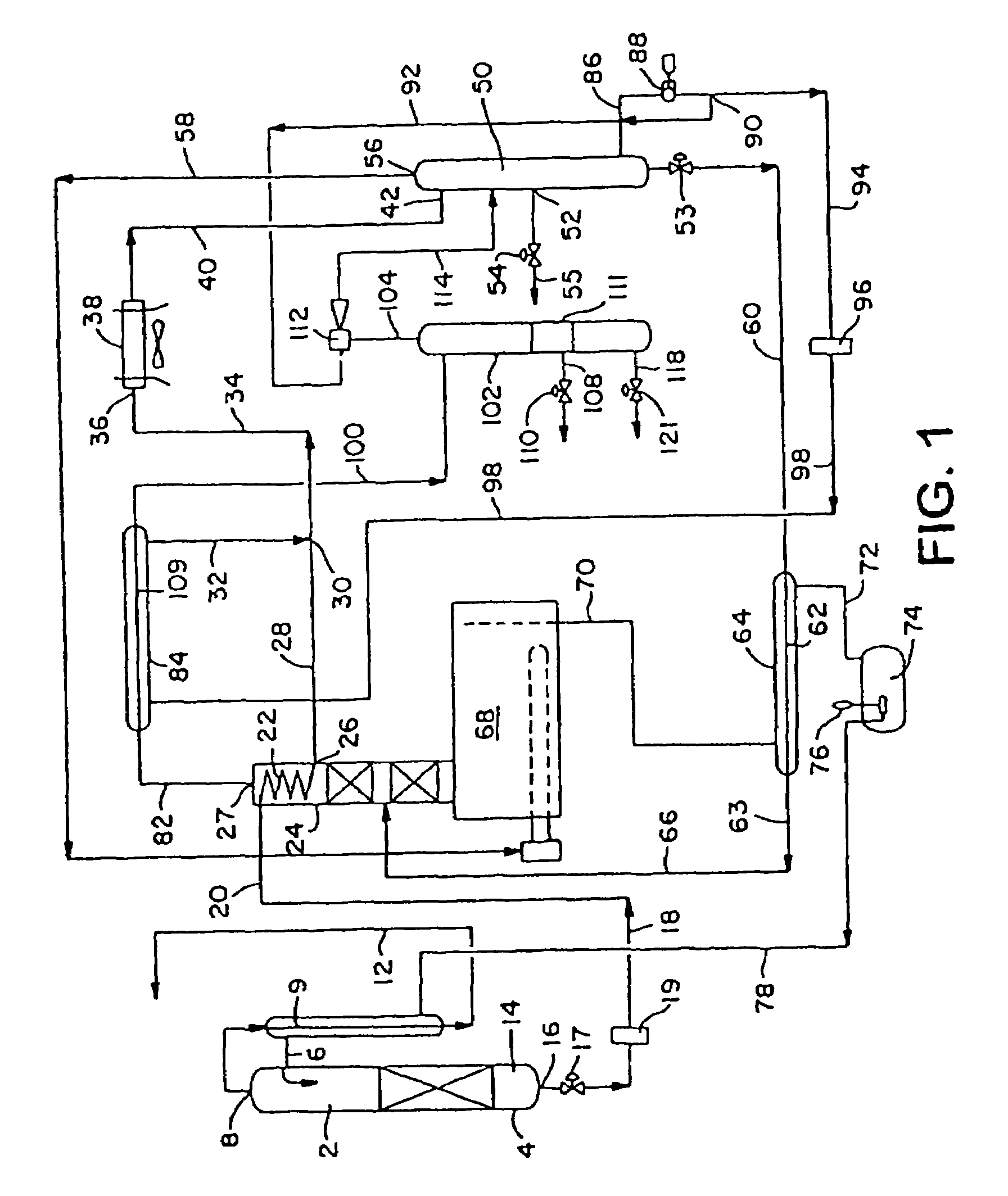

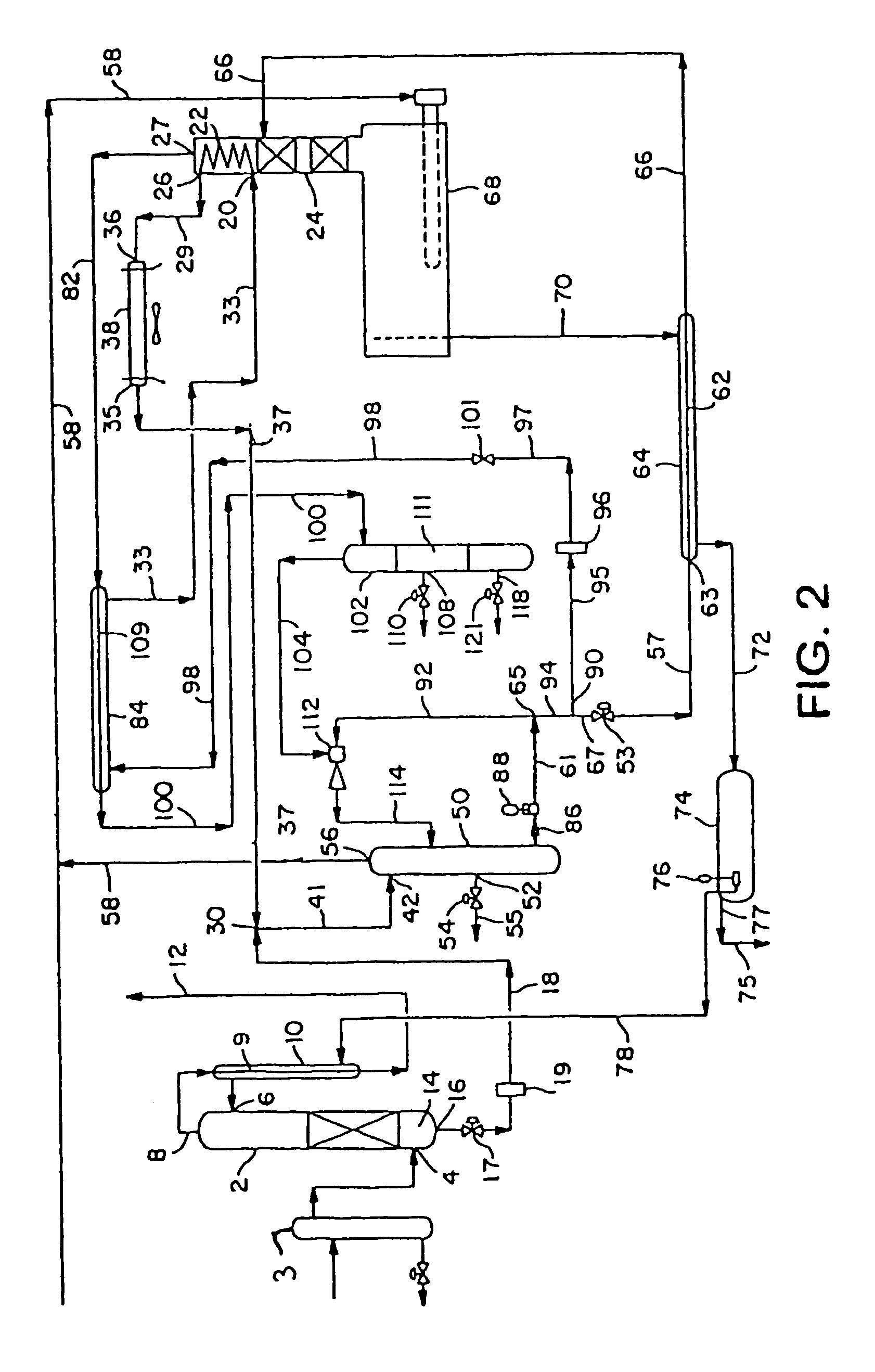

The present invention provides a natural gas dehydrator and method for recirculation of gaseous or combustible materials so that they are not released into the atmosphere and to provide fuel for the process. Likewise, liquid hydrocarbons are collected.

Owner:HEATH RODNEY T +1

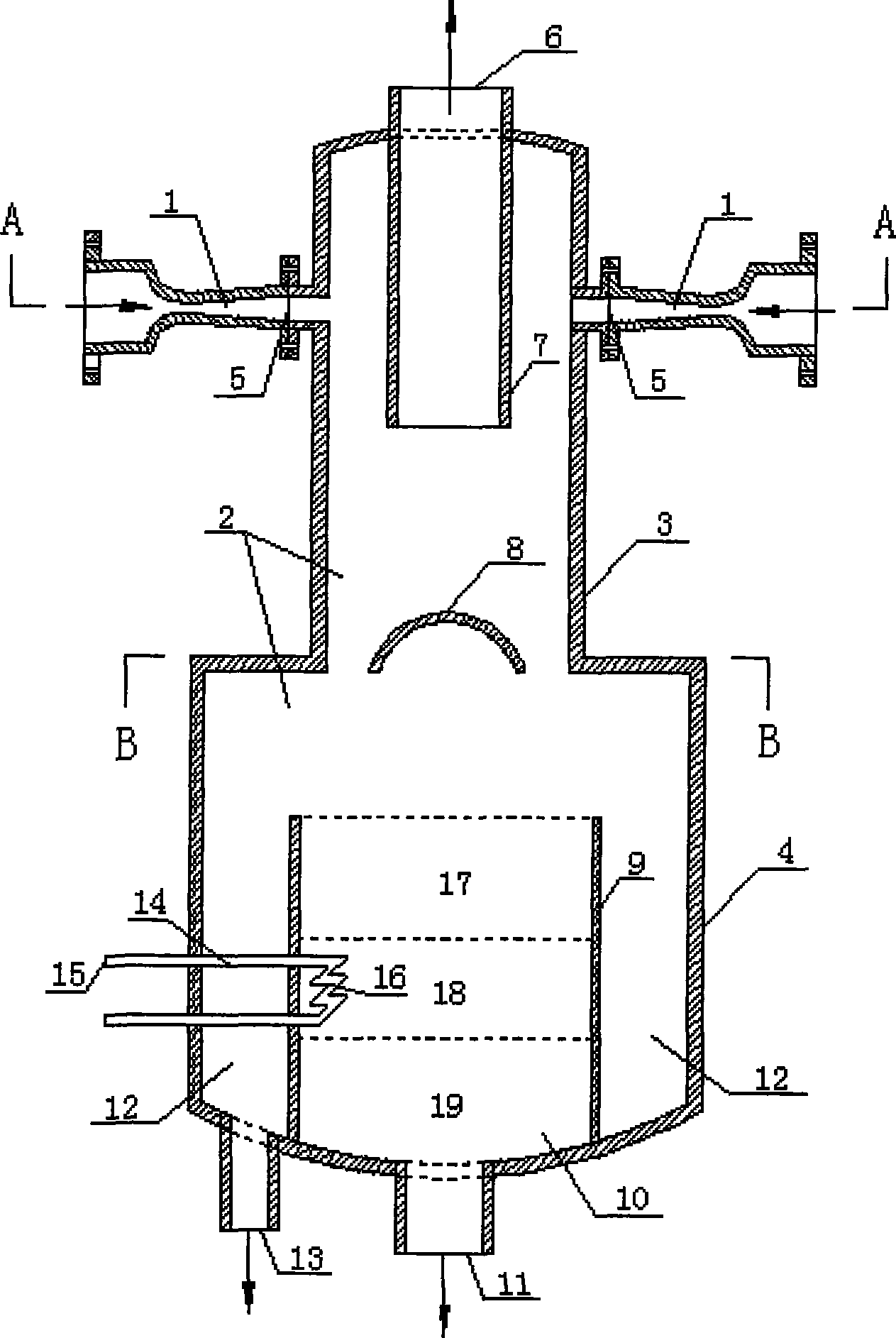

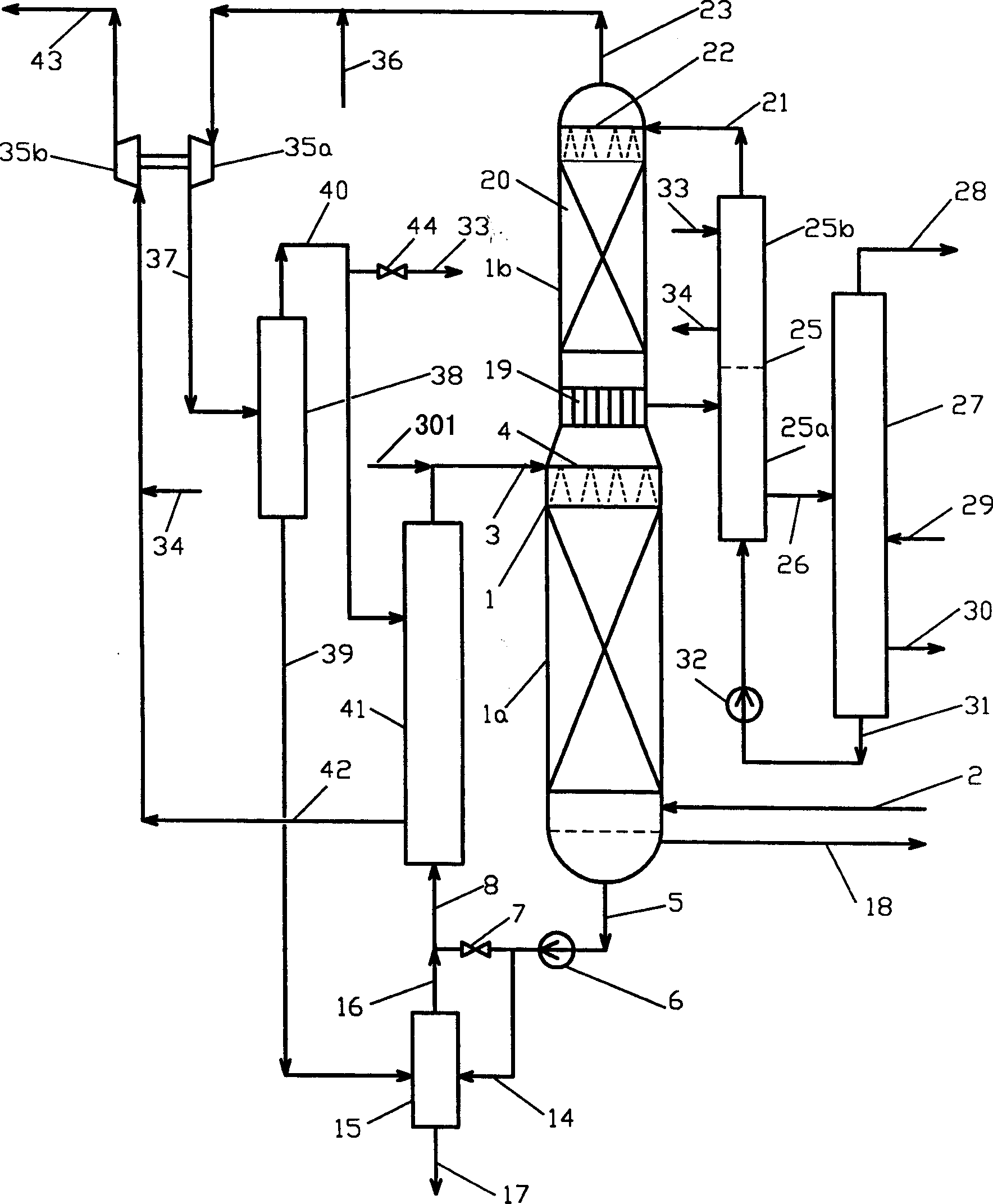

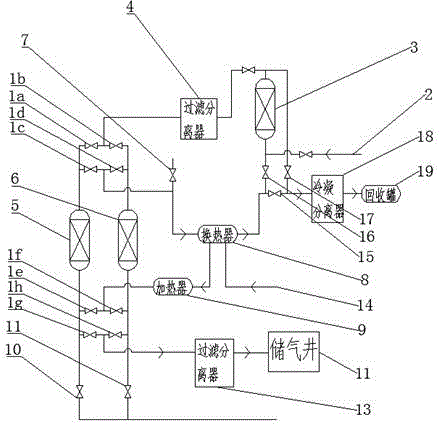

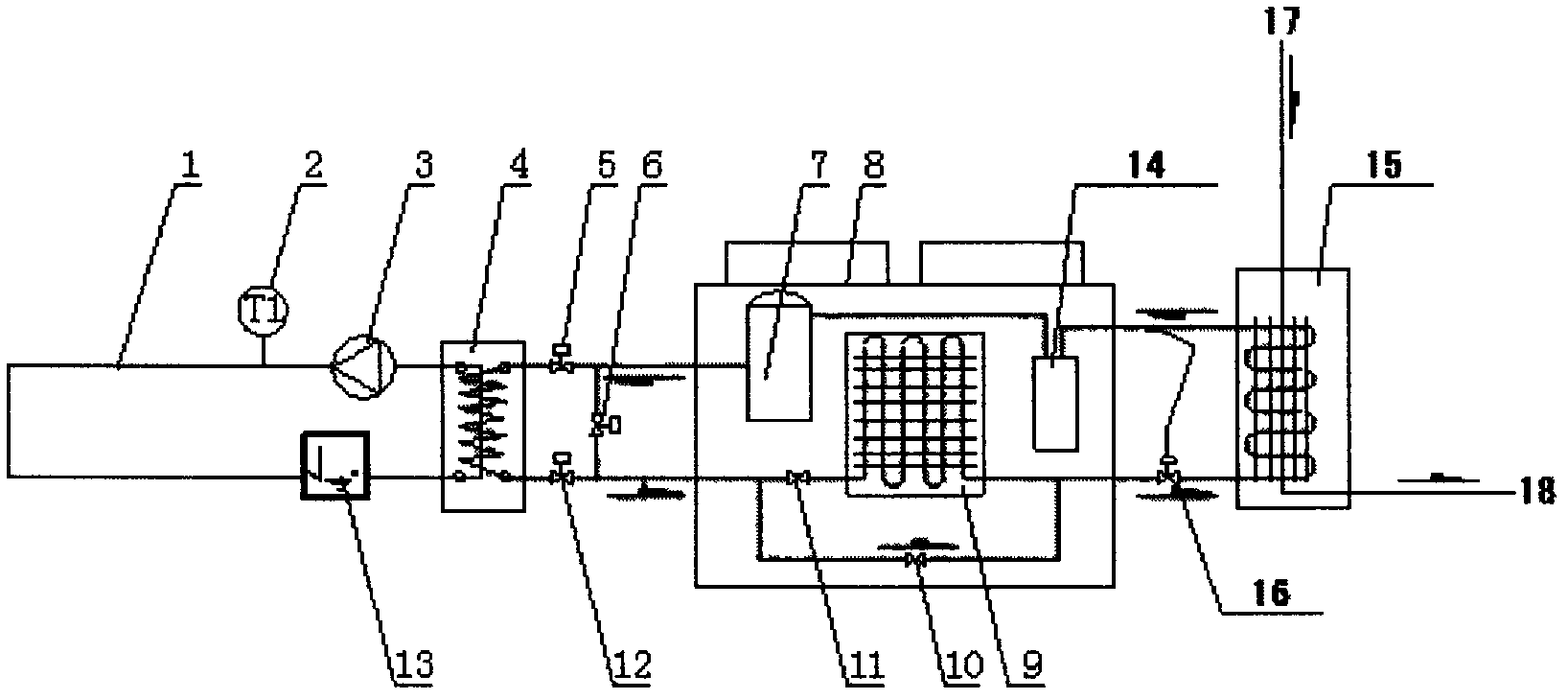

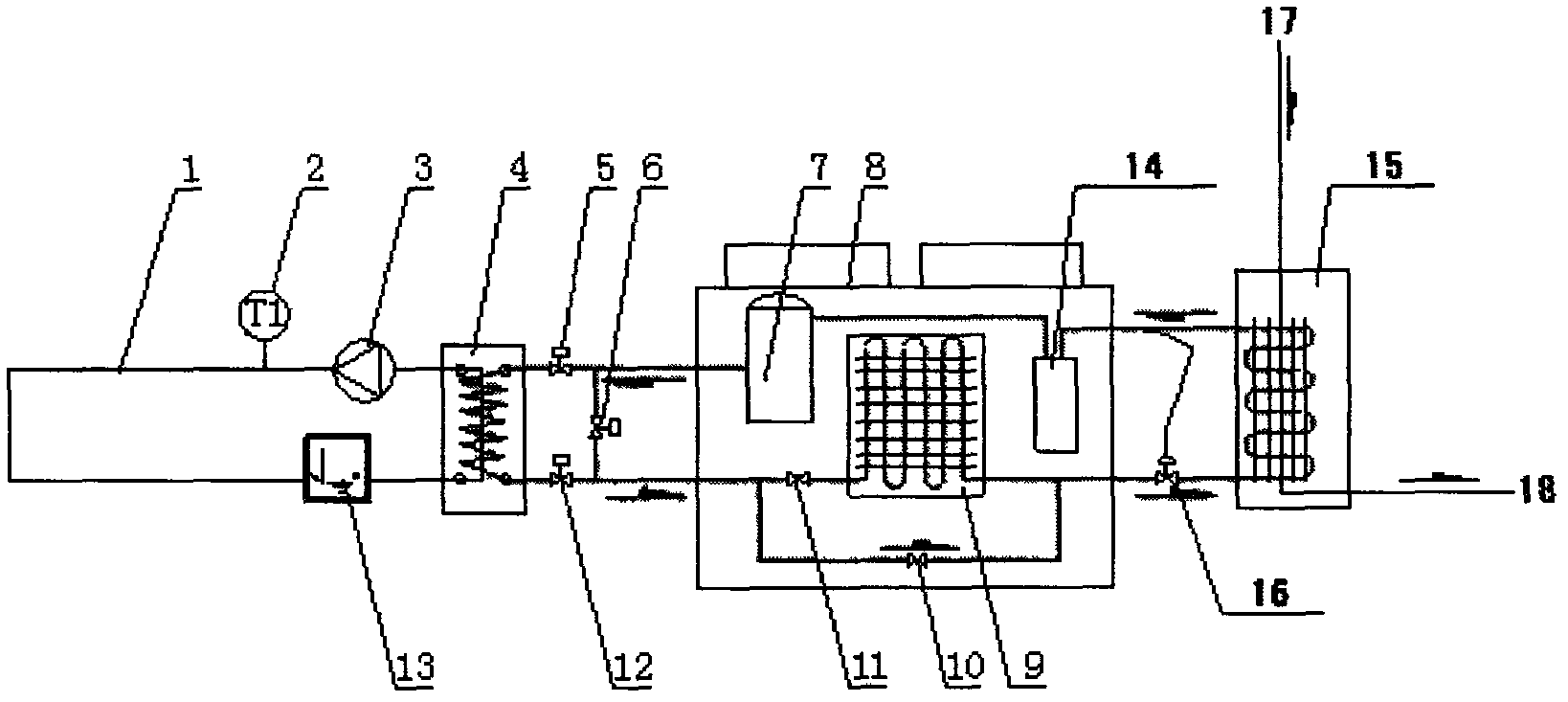

Natural gas absorbent regeneration and energy conservation technology and device

InactiveCN103071475AAvoid wastingReduce dosageGaseous fuelsCombustible gas purificationCompressed natural gasNatural gas dehydration

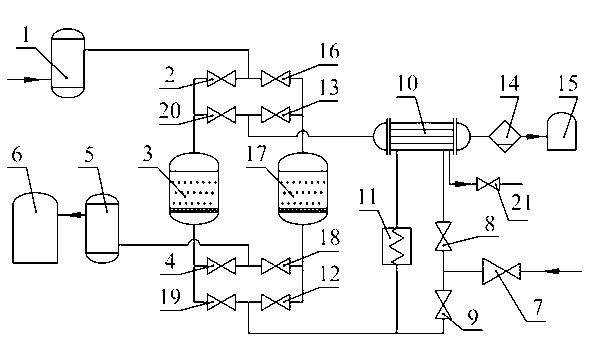

The invention relates to a natural gas absorbent regeneration and energy conservation technology and a natural gas absorbent regeneration and energy conservation device. The technology and the device can overcome the defects that the energy consumption is great and the heating time is long when the absorbent is regenerated. The technical scheme is as follows: a process of two towers is adopted, one tower is used for dehydration of natural gas and the other one is used for regeneration of natural gas. The two towers are switched for dehydration and regeneration of natural gas. During dehydration of natural gas, compressed natural gas first enters into the dehydration tower A to be dehydrated and obtain dried natural gas after being separated by a front filter separator, then the natural gas enters into a gas storage tank after being separated by a back filter separator; during heating and regeneration of absorbent, after flow reduction and depressurization, the regenerated natural gas is first heated in a heat exchanger and a heater and enters into the dehydration tower B to regenerate the absorbent, then, the natural gas enters into the heat exchanger to be cooled, and finally the natural gas enters into a recovery tank after being separated by a condensation separator; and during cold blowing and regeneration of the absorbent, after flow reduction and depressurization, the regenerated natural gas enters into the dehydration tower B to cold blow and reduce the temperature of the absorbent. According to the technology, complementary utilization of energy is achieved, energy consumption in absorbent regeneration is reduced, and energy-saving operation of the device is realized.

Owner:SOUTHWEST PETROLEUM UNIV

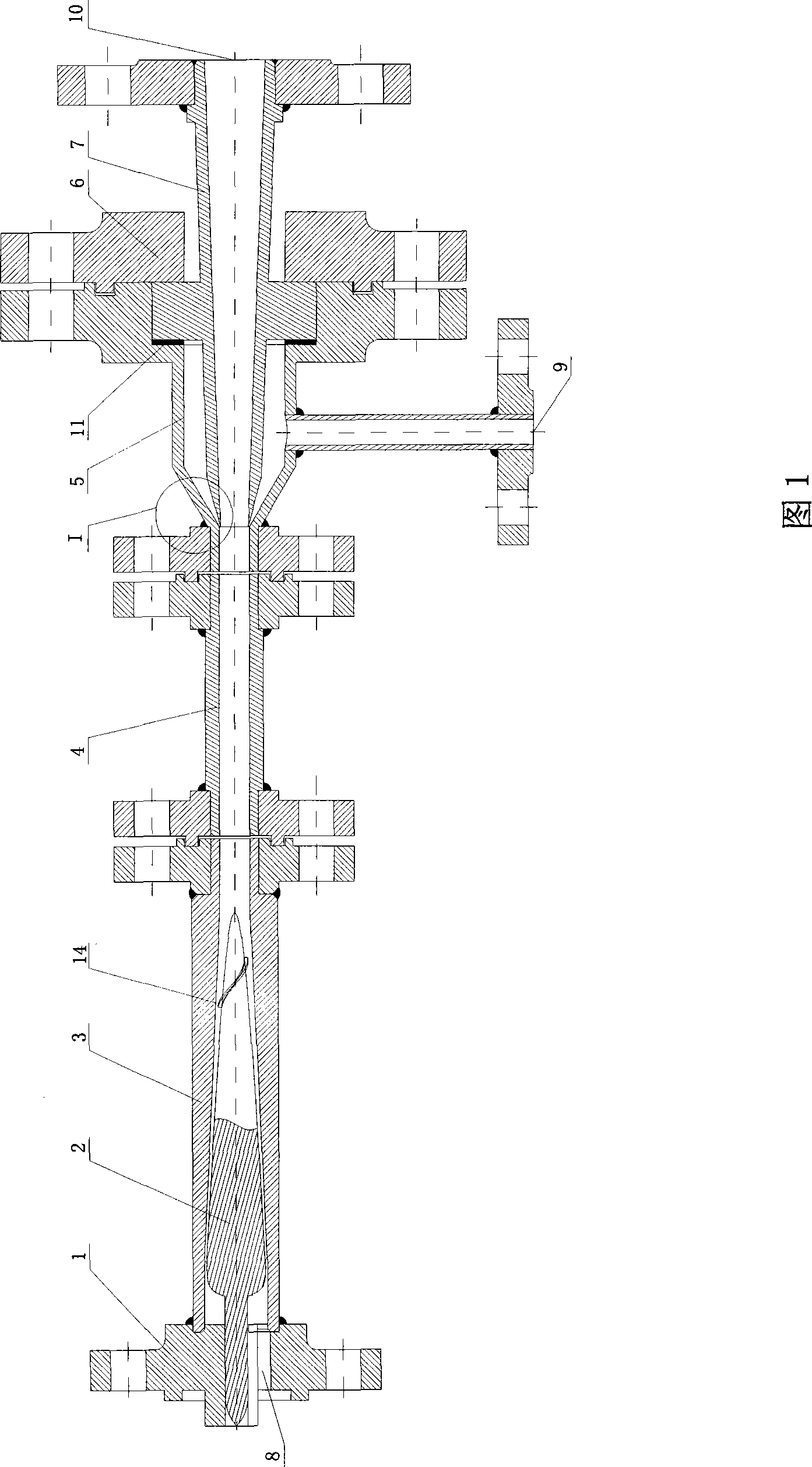

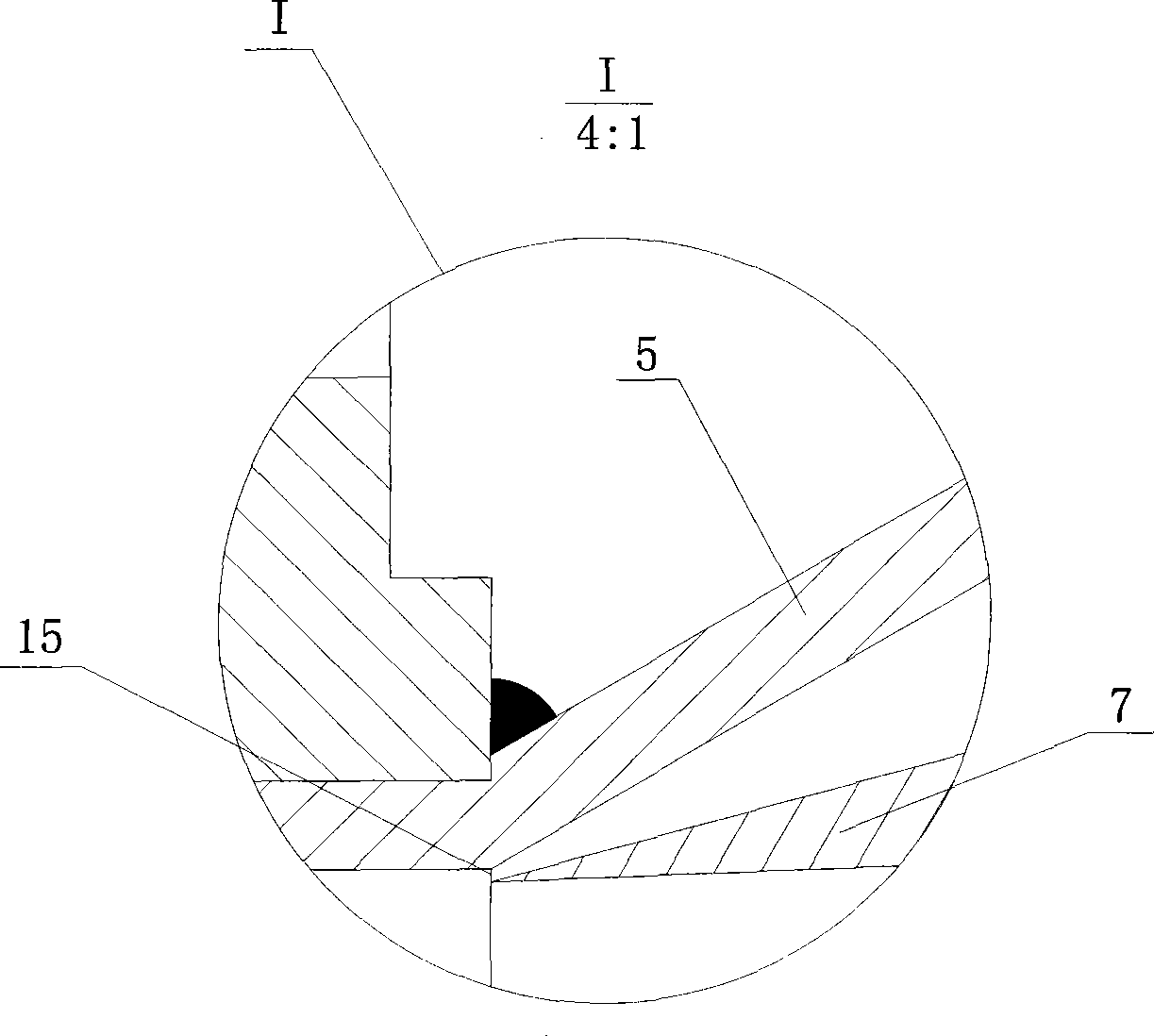

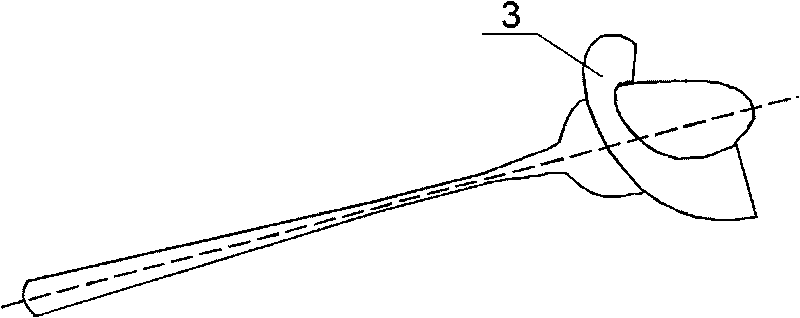

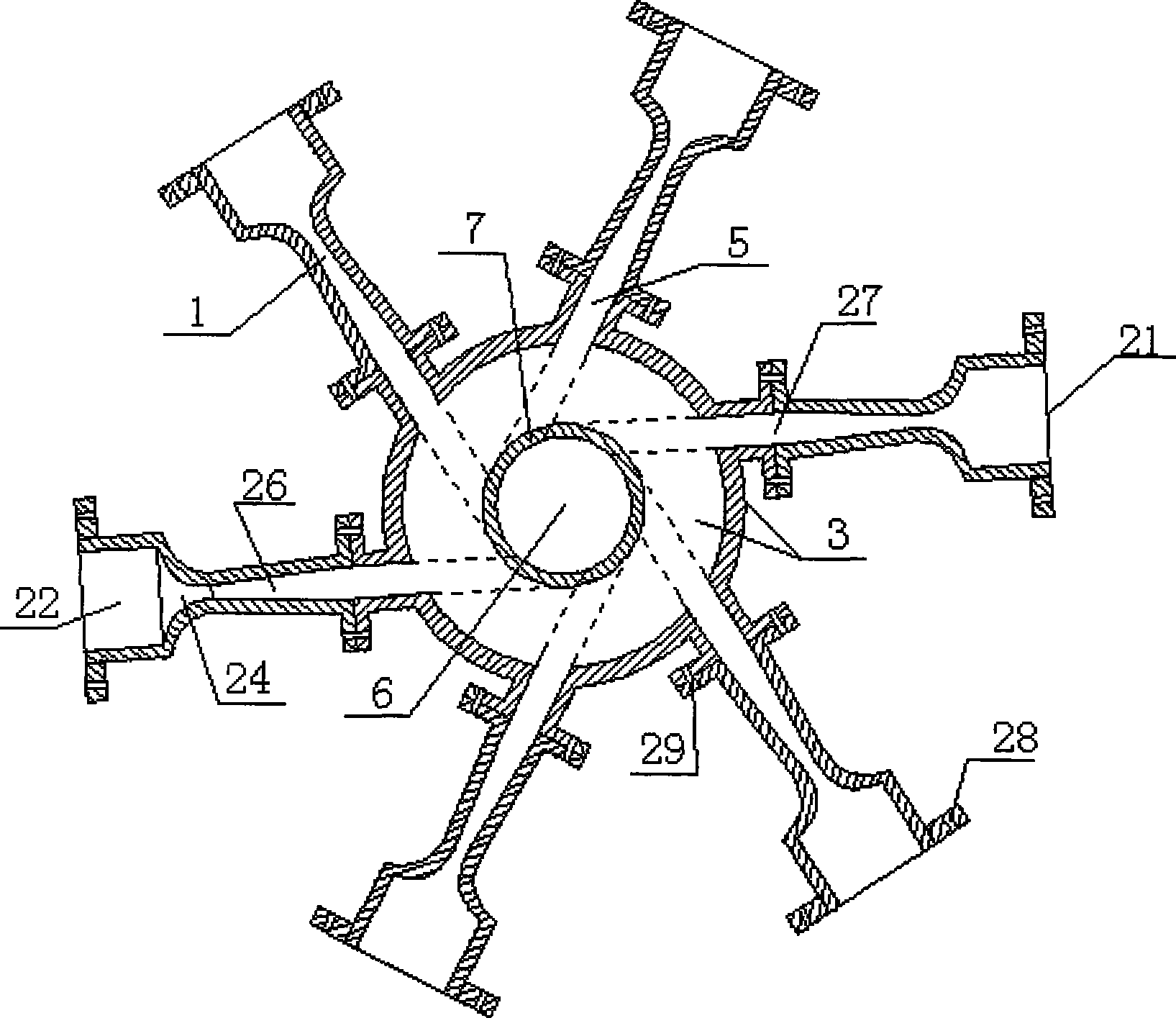

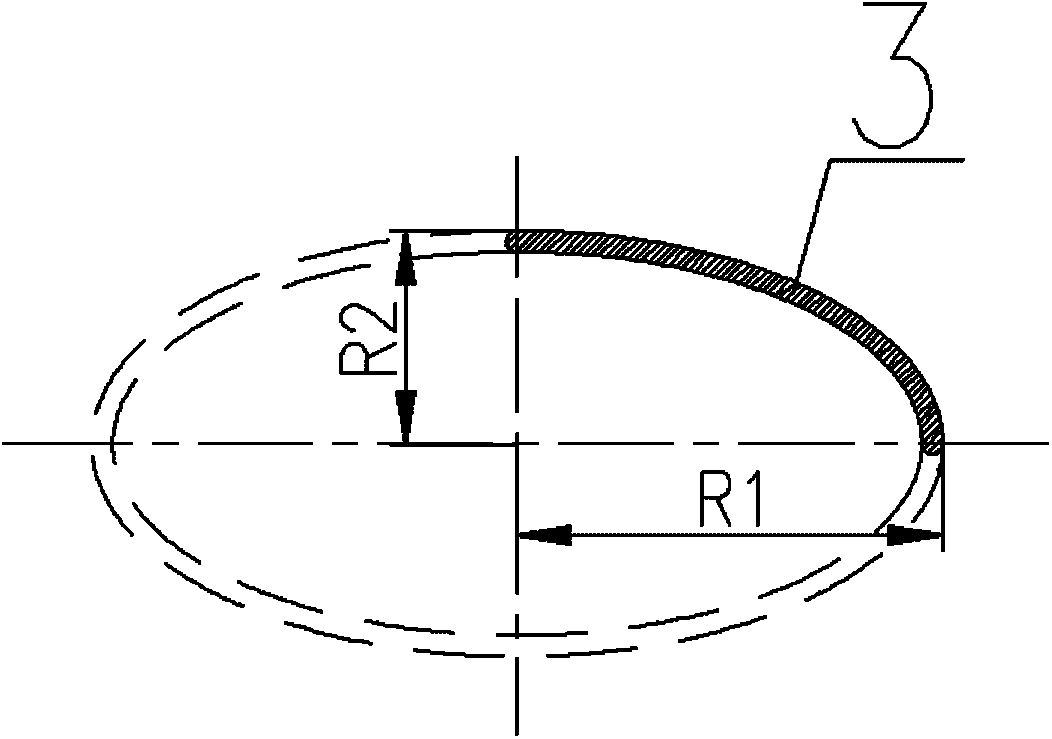

Low flow resistance supersonic speed gas purification and separation device

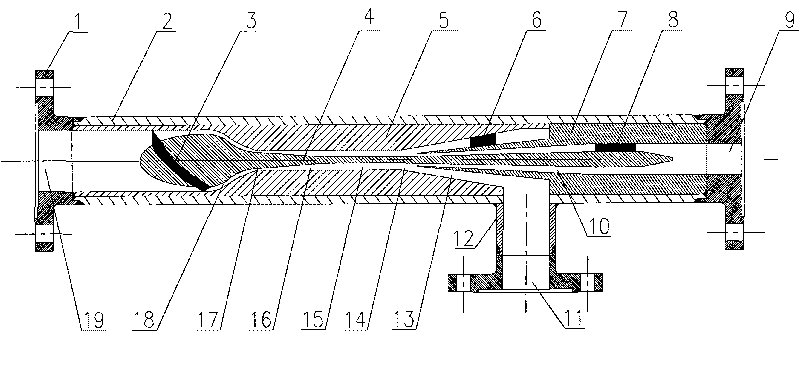

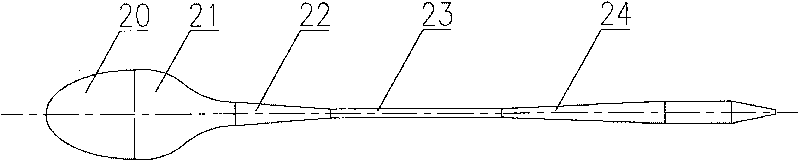

InactiveCN101380537ASimple structureUnmanned operationGaseous fuelsDispersed particle separationEngineeringSupersonic speed

The invention relates to a low flow resistance supersonic device for purifying and separating gas and is applied to the field of gas separation and purification such as natural gas dehydration, etc. Natural gas enters a laval nozzle by a gas inlet, the temperature and pressure thereof lowers, the speed is increased, then the gas mixture floating at high speed flows through a whirl vane, the swirl with high speed is produced, the swirl with high speed enters a separation pipe, for the temperature becomes low, when the gas is below ground pressure and saturation temperature, the water or partial dew points in the gas are condensed into liquid, for the centrifugal forces born are different, the liquid from the gas by condensation is 'flung' to the wall of the pipe and forms a very thin layer of liquor film, the liquid flows out of the separation pipe through the ring-shaped groove between the separation pipe and a diffuser pipe and flows out from the liquor outlet. Then the dry gas in which water is removed enters the diffuser pipe, and the gas flows out of the separation device by the gas outlet. The device does not comprise motion components and structure is simple; and the circulation transversal area of the laval nozzle in the device is ring-shaped and can be processed easily.

Owner:BEIJING UNIV OF TECH

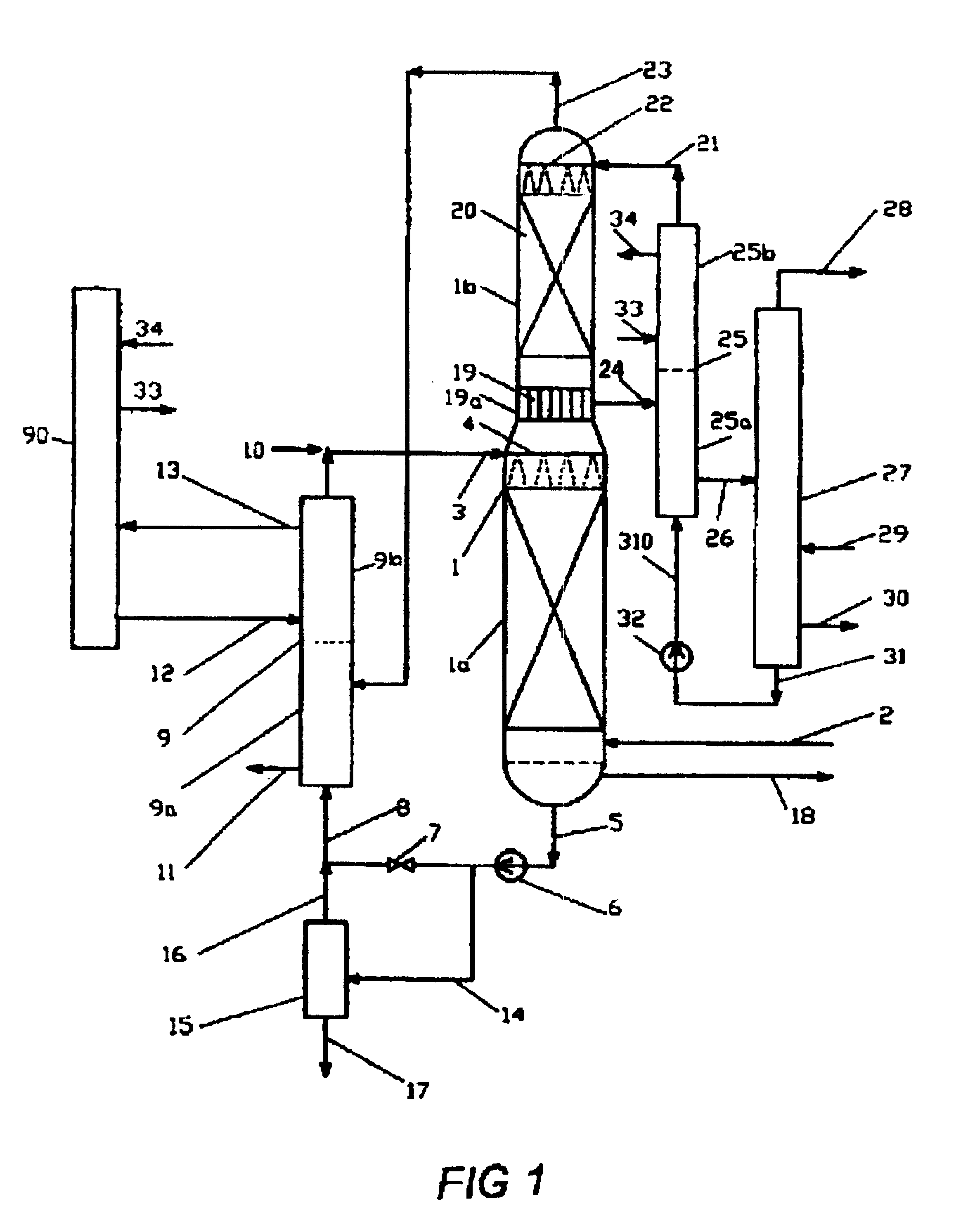

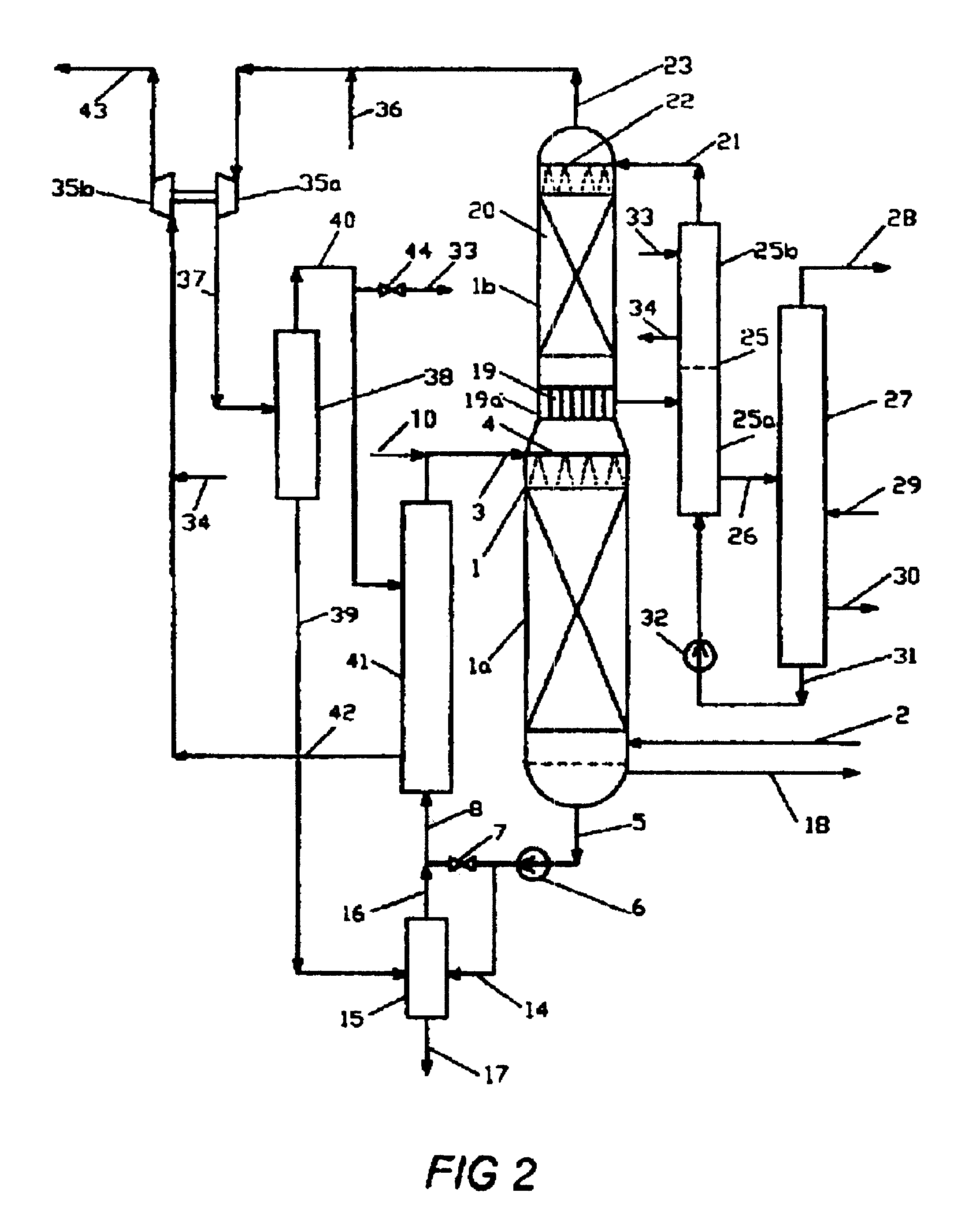

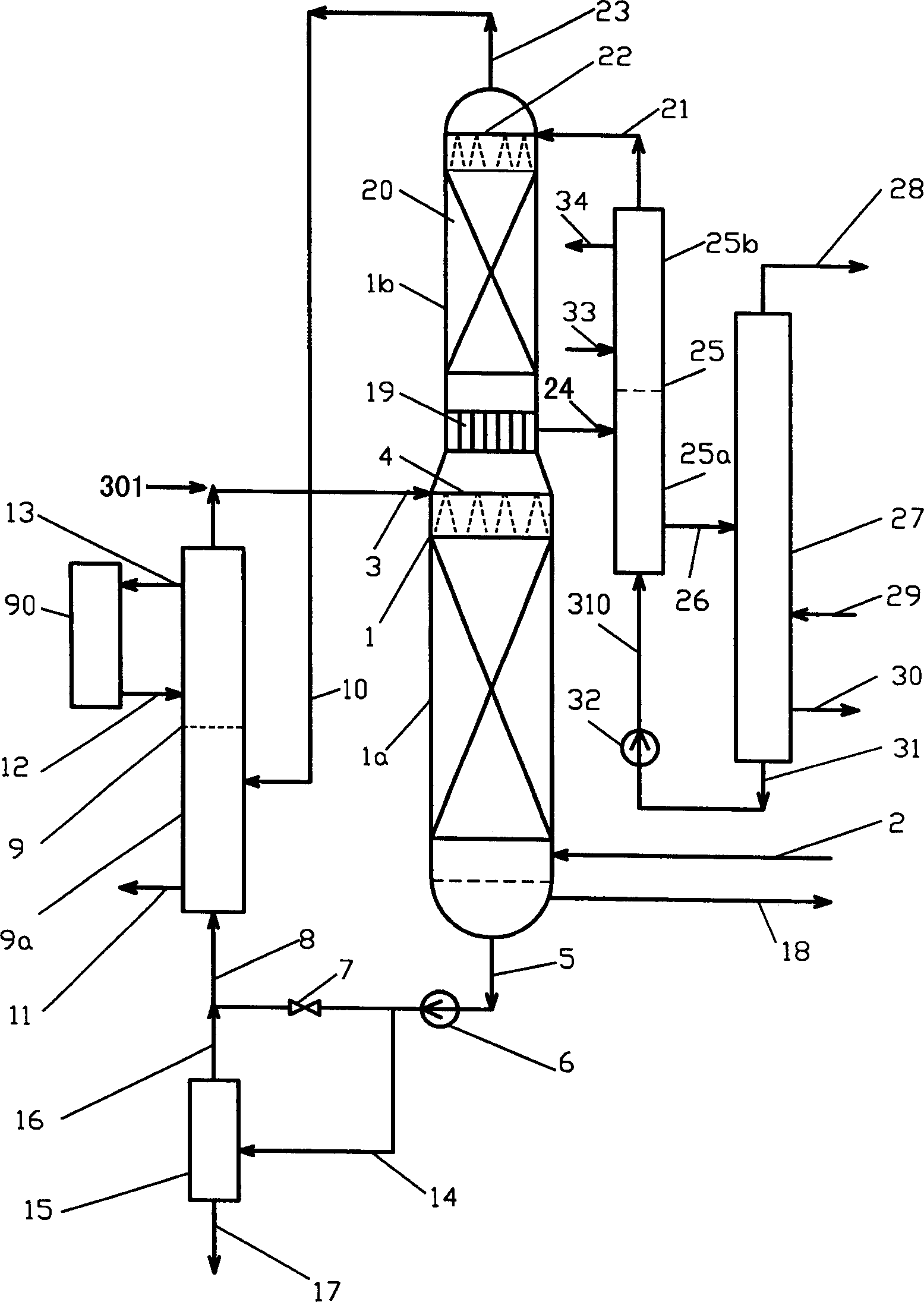

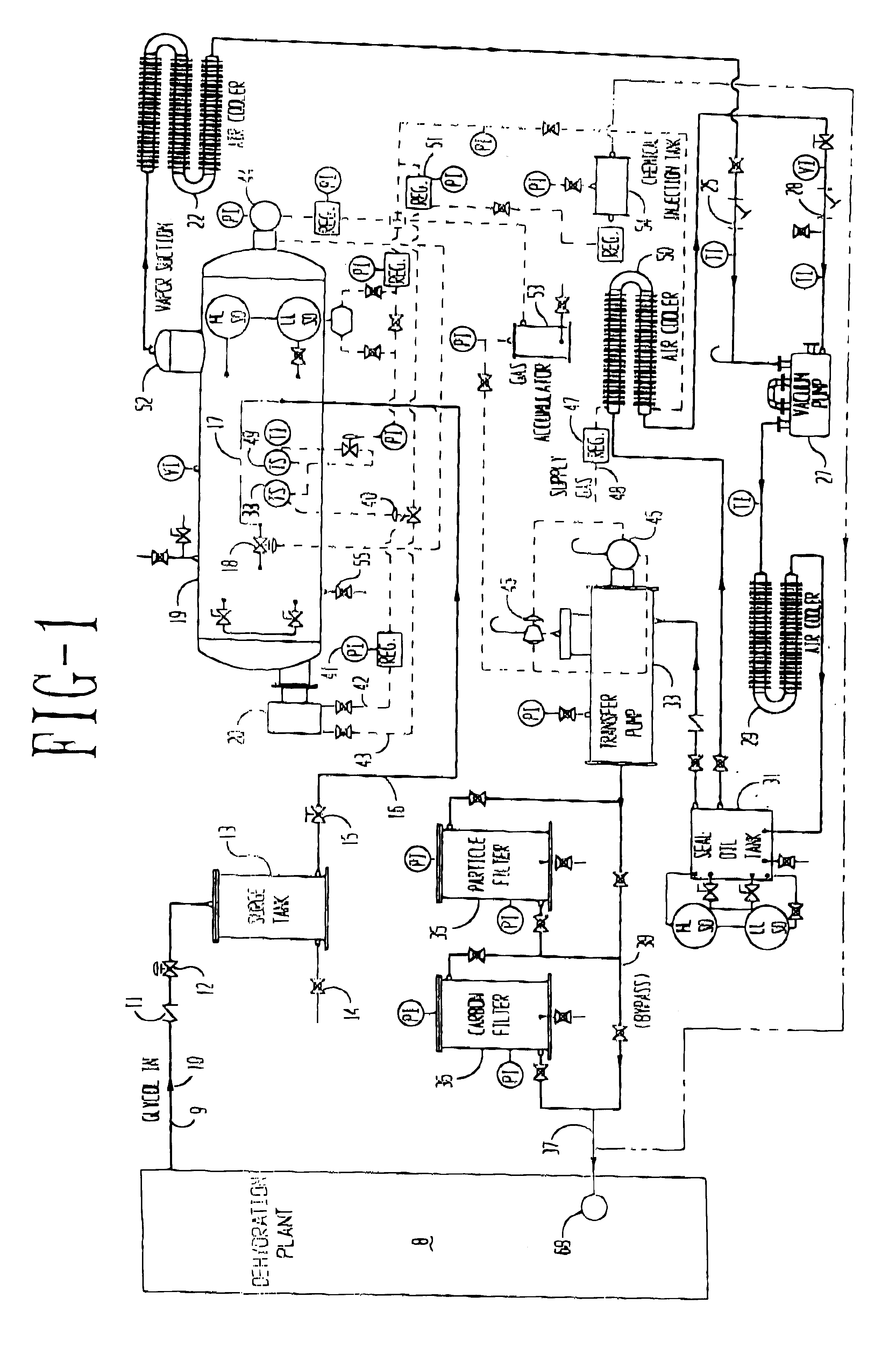

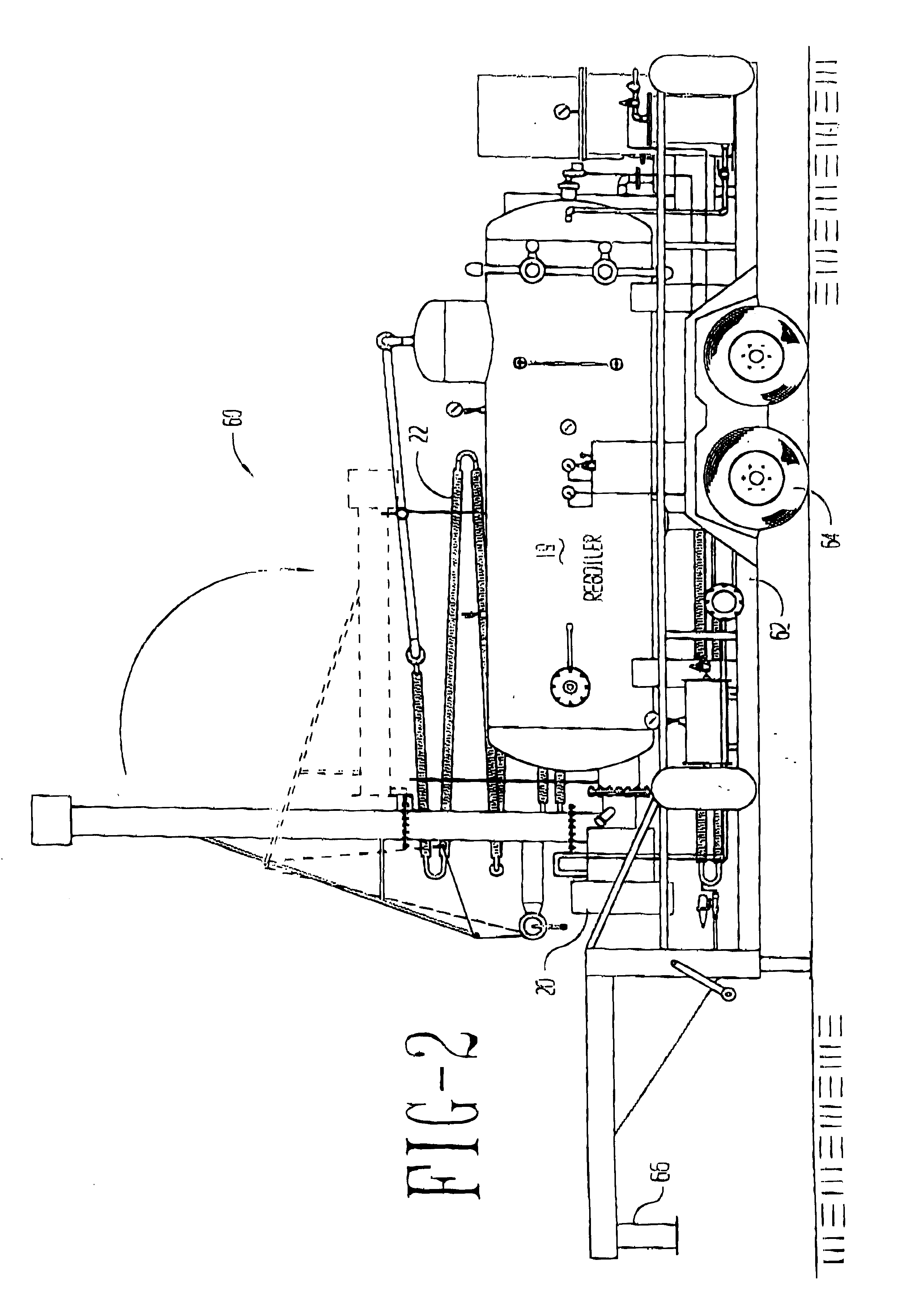

Natural gas dehydrator and system

InactiveUS7531030B2Easy to operateLiquid degasificationUsing liquid separation agentAtmospheric airLiquid hydrocarbons

The present invention provides a natural gas dehydrator and method for recirculation of gaseous or combustible materials so that they are not released into the atmosphere and to provide fuel for the process. Likewise, liquid hydrocarbons are collected.

Owner:HEATH RODNEY T +1

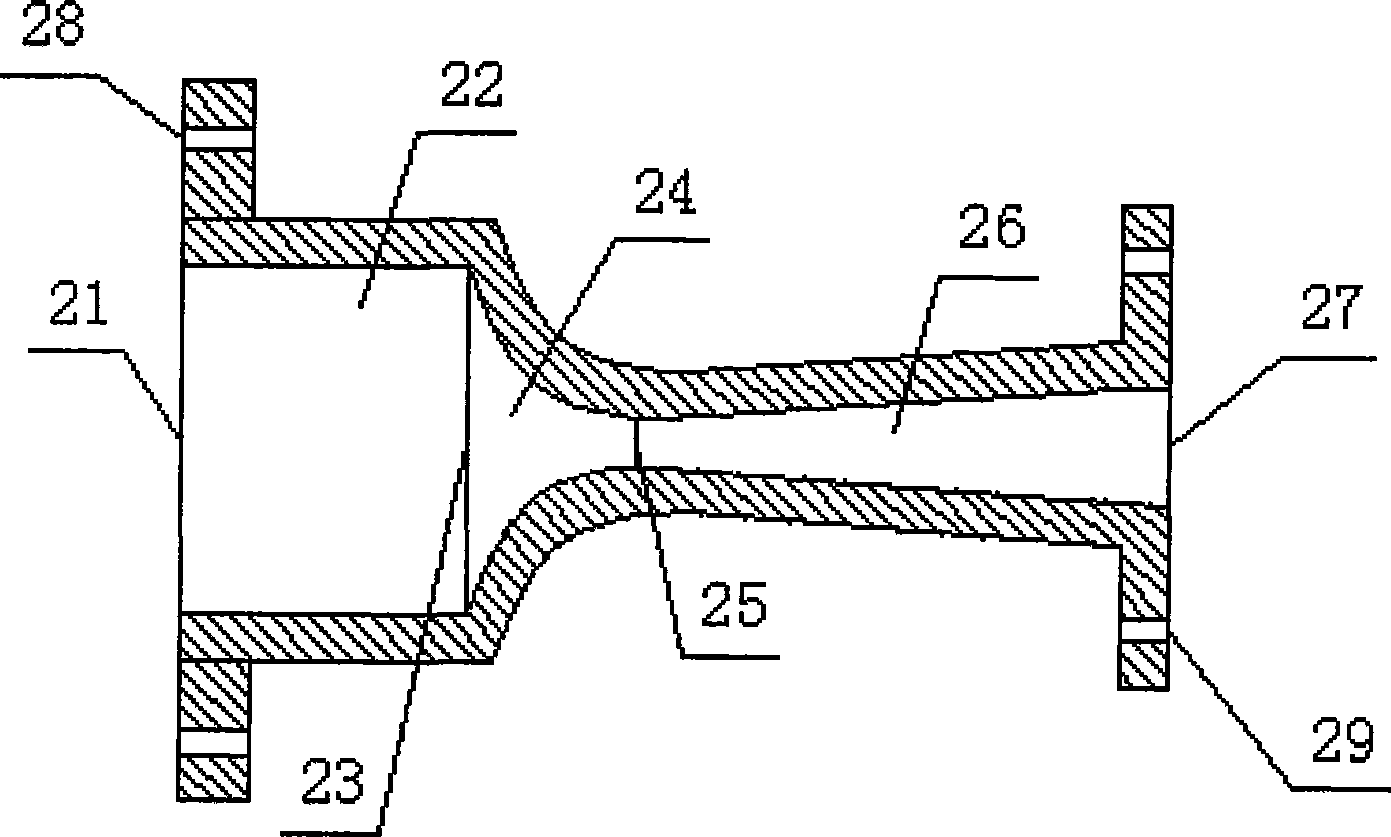

Ultrasonic gas cyclone condensing and separating device

InactiveCN101745246ASolving the Eddy Dissipation ProblemReduce radial velocity gradientDispersed particle separationVapor condensationCycloneNatural gas dehydration

The invention relates to an ultrasonic gas cyclone condensing and separating device applied to the field of gas purification, in particular to the field of natural gas dewatering and heavy hydrocarbon separation. Natural gas generates a cyclone by spiral cyclone blades, enters an Laval nozzle to adiabatically expand to an ultrasonic velocity and form low temperature and low pressure so that water and heavy hydrocarbon in the natural gas are condensed into liquid drops; meanwhile, a higher tangential velocity is generated to fling the water and the heavy hydrocarbon which are condensed to the wall surface under the action of a strong cyclone field; liquid flows into a liquid-collecting cavity from a liquid shunt hole and is discharged from a liquid outlet by a liquid-discharging pipe; and dry gas enters a circular diffuser pipe, is recovered by pressure and is discharged from a dry gas outlet. The shrinking section of the Laval nozzle of the device is designed by using a bicubic curve method to reduce flowing loss; the spiral cyclone blades can enhance the cyclone, generate greater tangential velocity and have good enhance effect. The device has simple structure, easy process and stable and reliable operation without movable parts.

Owner:文闯

Control of an adjustable secondary air controller for a burner

InactiveUS7905722B1Easy to adjustAllow useFluid heatersFuel supply regulationCombustorPetroleum product

The present invention relates to a system and method for controlling a burner's adjustable secondary air controller. Specifically, the system relates to a control logic for the control of an air supply to a burner such as a natural gas burner used in the production and / or processing of liquid and gaseous petroleum products and in natural gas dehydration systems.

Owner:HEATH RODNEY T +2

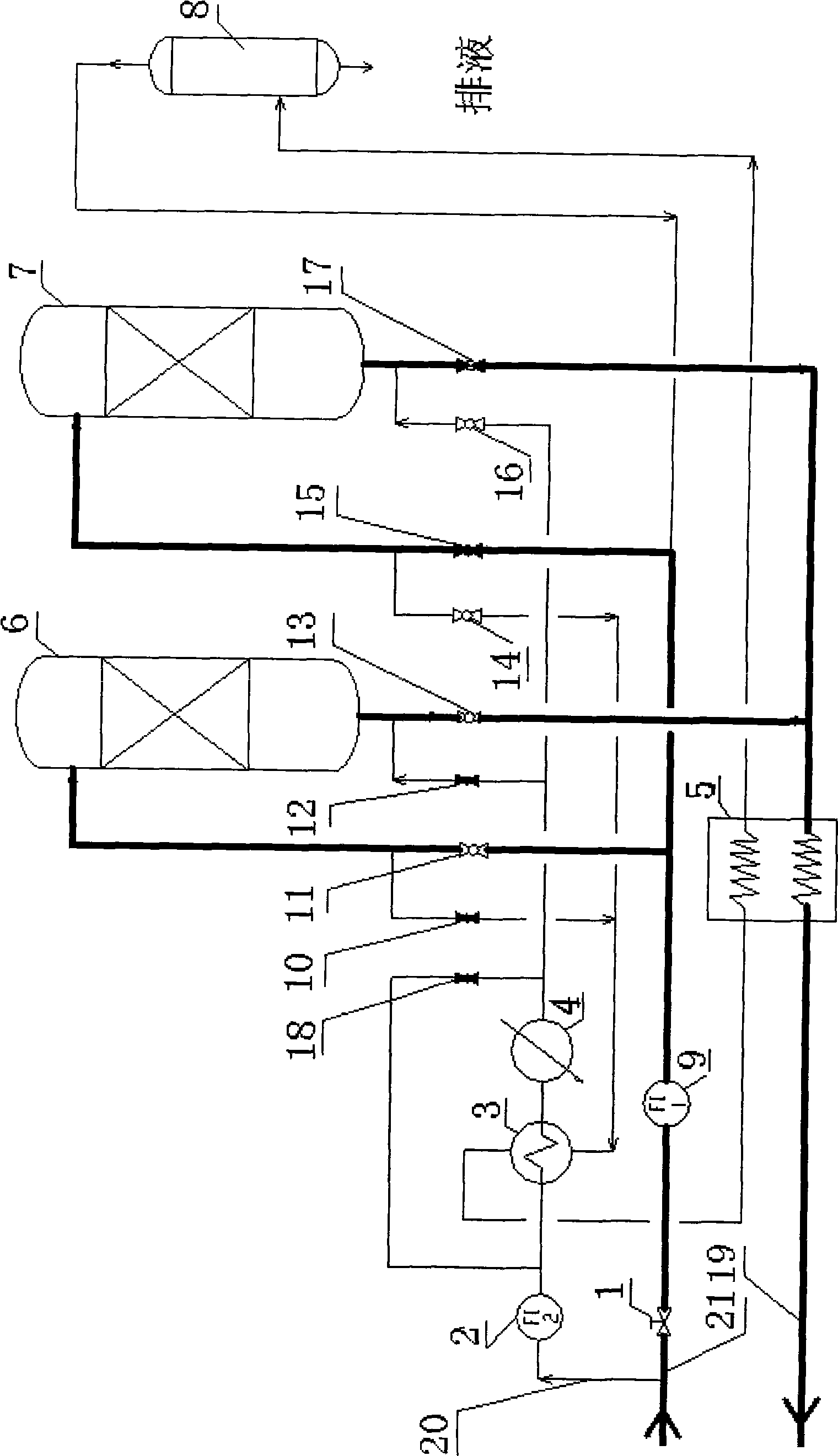

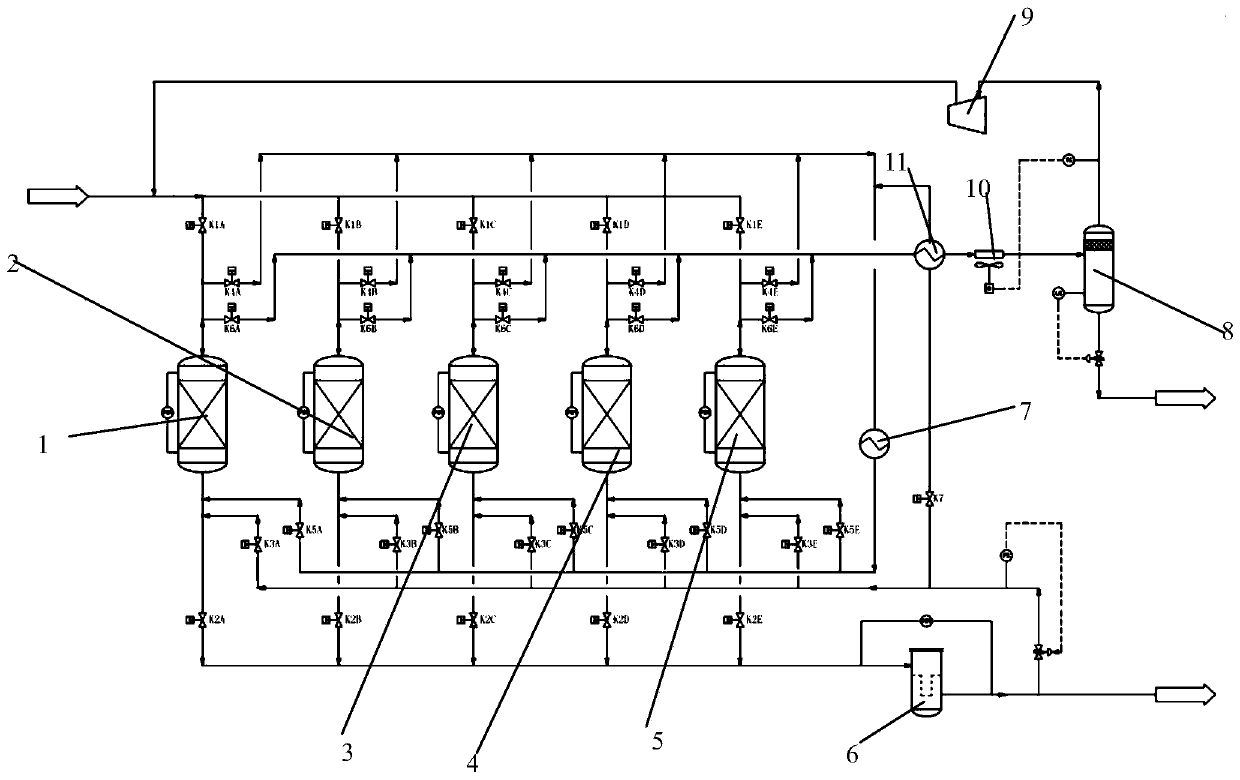

De-heavy hydrocarbon apparatus and process for gas dehydration

The invention relates to a technique for removing water vapor and heavy hydrocarbon by using natural gas, in particular to a device for removing water vapor and heavy hydrocarbon by using the natural gas in the places such as a natural gas collecting and transmitting station, an individual well mouth, associated gas treatment station extending to oil field or the like without a large scale centralized purifying treatment station, and the technique thereof. The invention is characterized in that the natural gas can be used for completing the technique for removing water vapor and heavy hydrocarbon through alternate circulation process of adsorption and resolution by the device for removing water vapor and heavy hydrocarbon. The technique simplifies the process, saves the investment, land occupation and cost, leads the water and the heavy hydrocarbon being above C6 to be removed while the natural gas or associated gas is concentrated and transmitted, and ensures the dew points of the water and hydrocarbon to reach the level being the same as low temperature process.

Owner:XIAN CHANGQING TECH ENG

Adsorption type high pressure natural gas dehydration process and device

InactiveCN101899341AReduce the temperatureImprove cooling effectDispersed particle separationGaseous fuelsNatural gas dehydrationProduct gas

The invention provides an adsorption type high pressure natural gas dehydration process and a device, and the Joule-Thomson effect is utilized for converting the pressure loss during the process of reducing the pressure of high pressure natural gas into cold energy of low-temperature gas flow, thereby carrying out heat exchange on the cold gas flow and hot gas flow, cooling the hot gas flow, increasing the temperature of the cold gas flow, effectively reducing the energy loss, simplifying equipment and saving energy. The method comprises three steps of adsorption, regeneration and switching, and the device increases a pressure reducing valve and a heat exchanger for treatment of finished product gas, thereby not using a cooling fan during the cooling process, saving electrical energy, avoiding troubles caused by explosion prevention of a motor and being safe and energy-saving.

Owner:XIAN UNIONFILTER PURIFICATION EQUIP

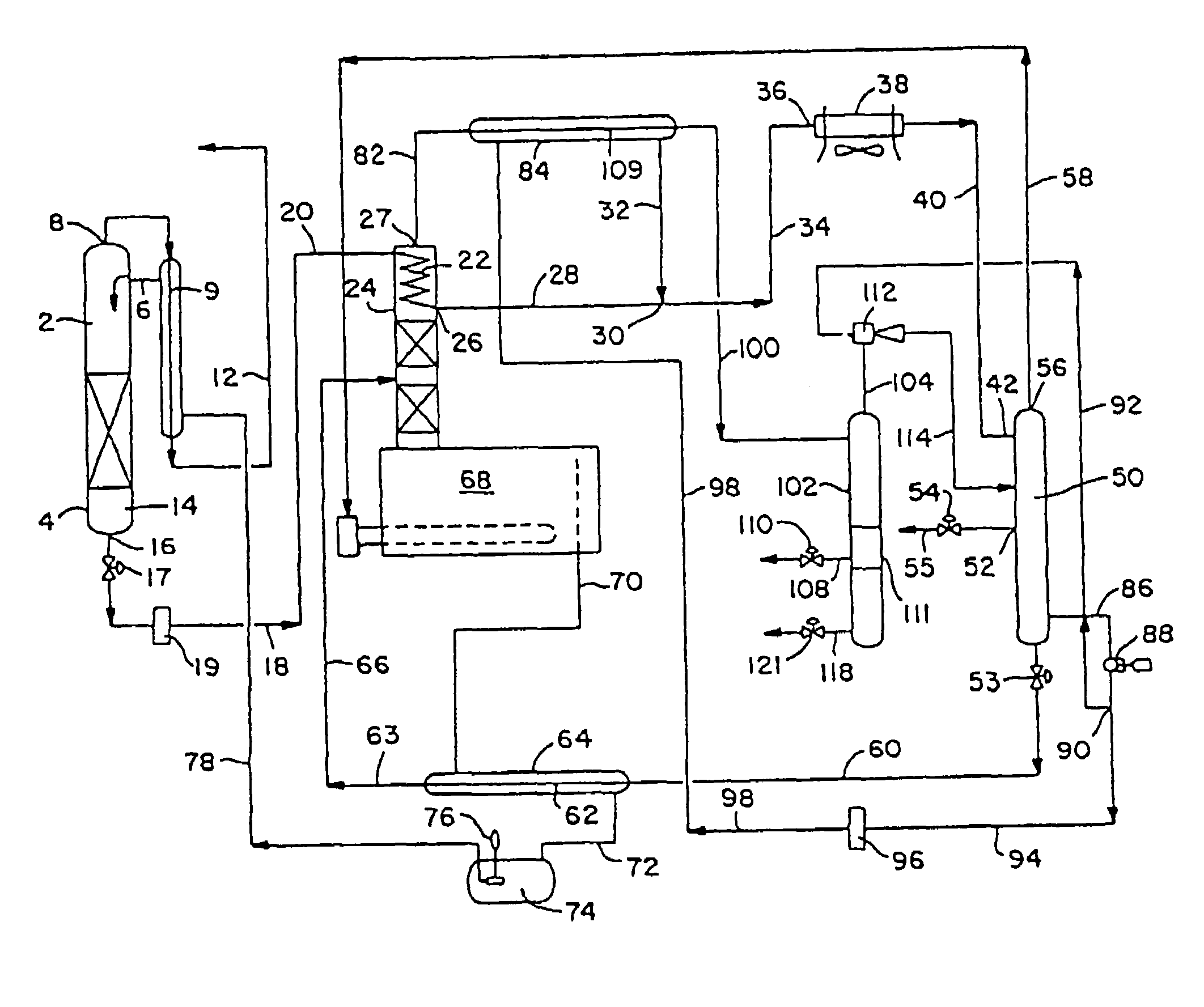

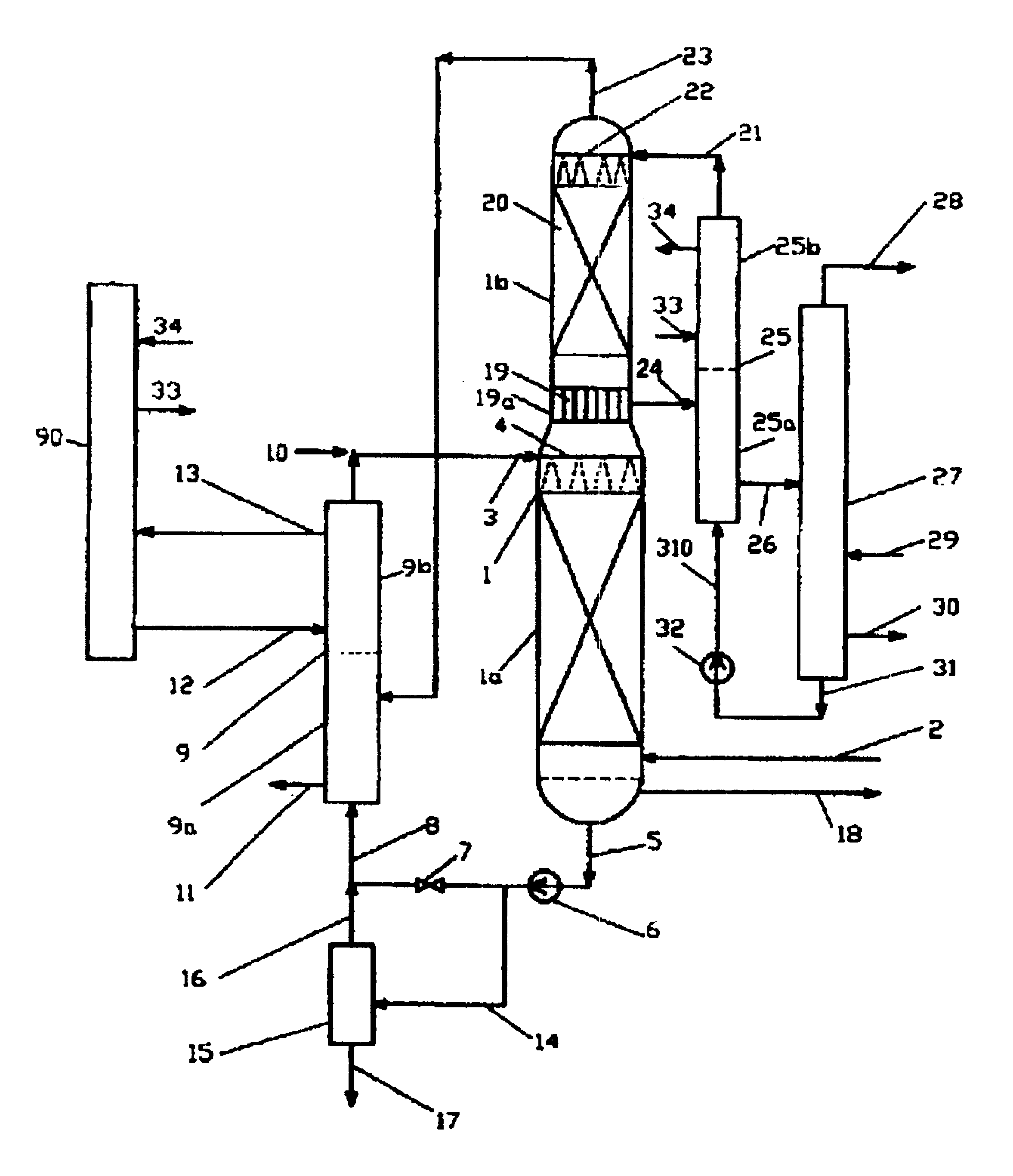

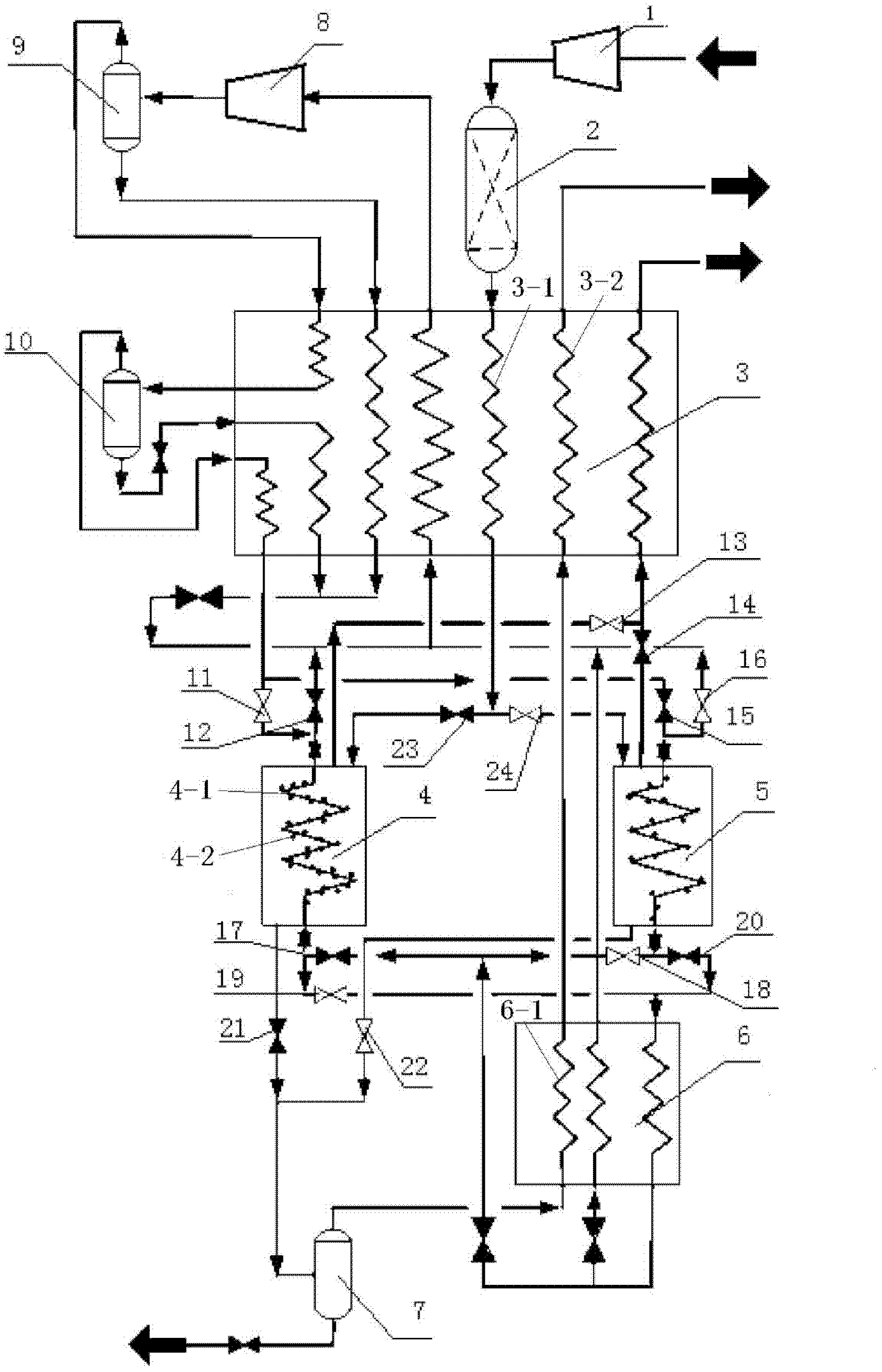

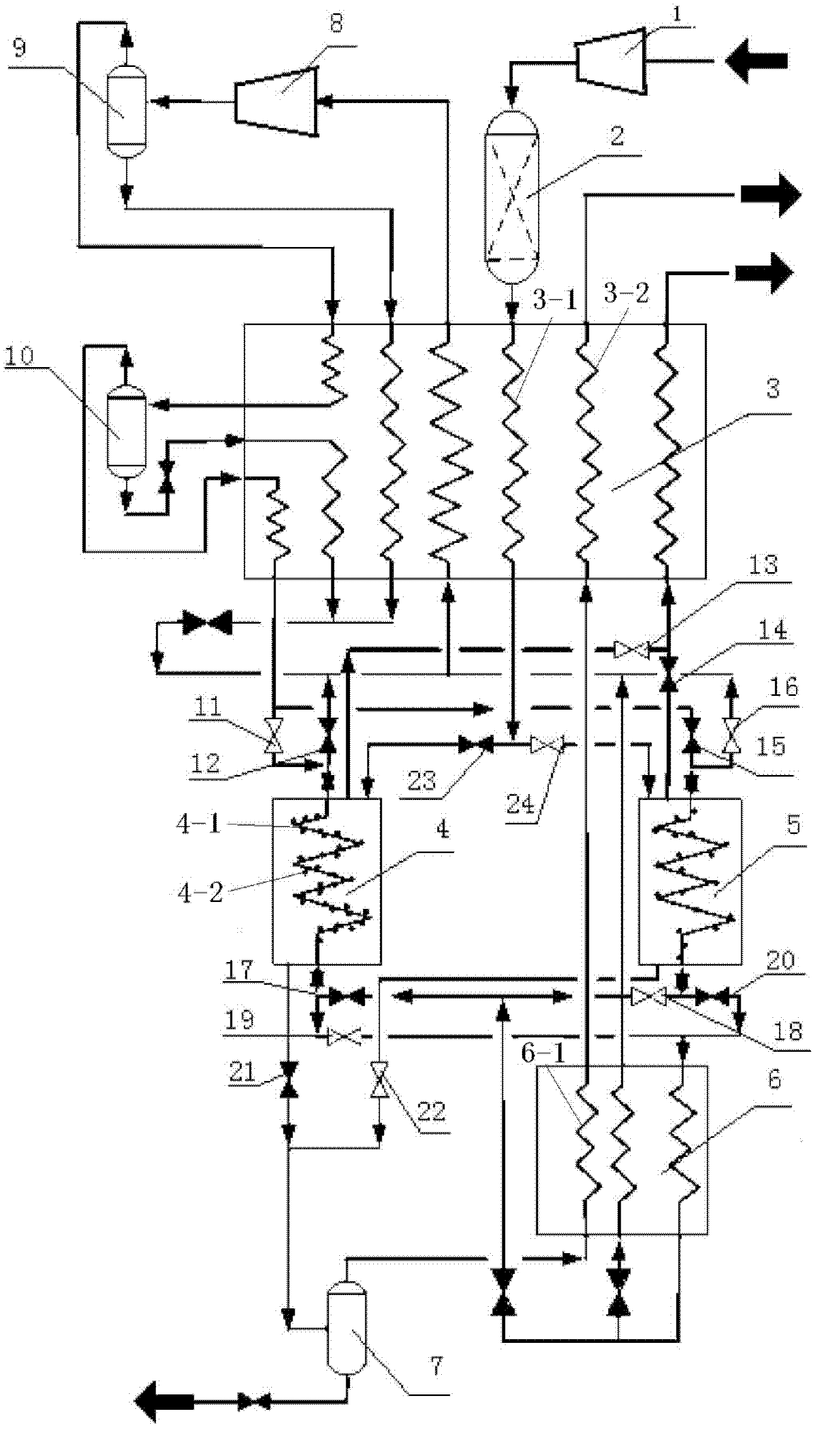

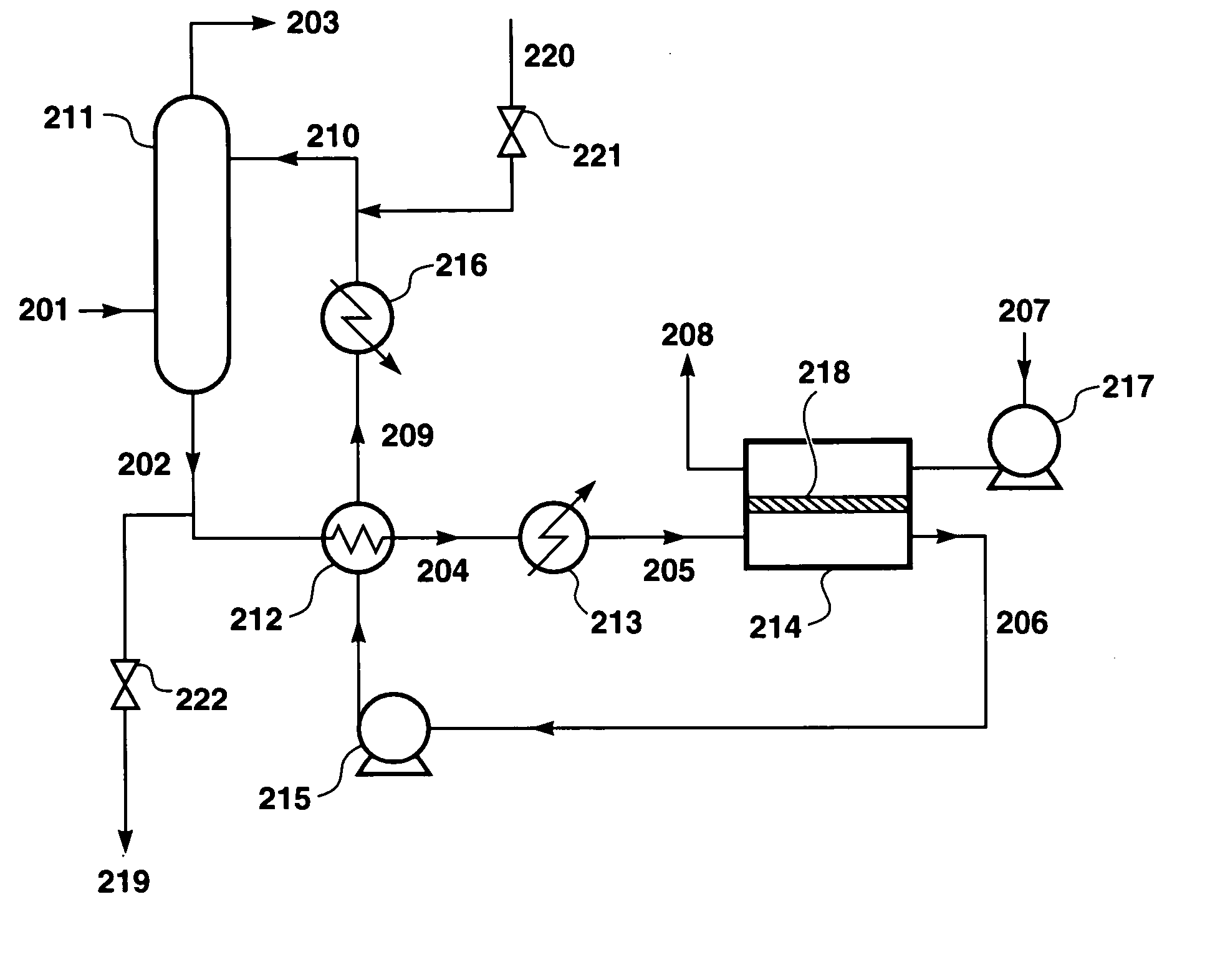

Comprehensive natural gas processing

InactiveUSRE39826E1Efficient and cost-effective comprehensive processingLow costSolidificationLiquefactionNatural-gas processingTransport medium

The present invention related to a process and an apparatus for efficient and cost-effective comprehensive processing of natural gas, including the removal of moisture and the recovery of the higher hydrocarbons components (C2+). The said apparatus comprises the following major components: an integrated natural gas processor with a dehydration section and a higher hydrocarbons absorption section; a heat transport medium cooler; an absorbent cooler; a fractional distiller for separating the light oil from the heavy oil absorbent; an inhibitor regenerator; and a refrigeration unit. The present invention provides a low-cost natural gas comprehensive processorprocessing that is universally applicable to both terrestrial and off-shore natural gas exploitation. The said apparatus also provides an efficient and cost-effective natural gas dehydrator when the dehydration section is used independently without incorporating the absorption section.

Owner:LU YINGZHONG

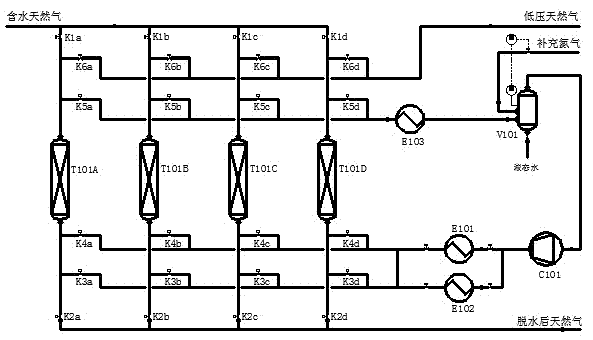

Natural gas multi-tower external cycle anaerobic regeneration dewatering method

ActiveCN103173256AAvoid reactionImprove dehydration efficiencyDispersed particle separationGaseous fuelsSorbentNatural gas dehydration

The invention relates to a natural gas multi-tower external cycle anaerobic regeneration dewatering method, and particularly relates to a natural gas dewatering device and a technique of an LNG (liquefied natural gas) preparation station for large-scale concentrated treatment of natural gas pipeline transportation. The dewatering method is characterized by comprising the steps of absorbing moisture in gas in saturated gas by an adsorbent under a normal-temperature condition through an adsorption tower; carrying out anaerobic regeneration on the adsorbent in the adsorption tower by external regenerated gas, utilizing in a recycling manner, and desorbing impurity components such as water and heavy hydrocarbon adsorbed on the adsorbent, so as to carry out the next adsorption process by the adsorption tower, wherein each adsorption tower passes through the processes of adsorption, decompression, purging, heating, cooling and boosting. The technique has the characteristics of simple flow, high dewatering efficiency, low energy consumption and the like; the service life of the adsorbent is prolonged; and the operating cost is reduced.

Owner:四川科比科油气工程有限公司

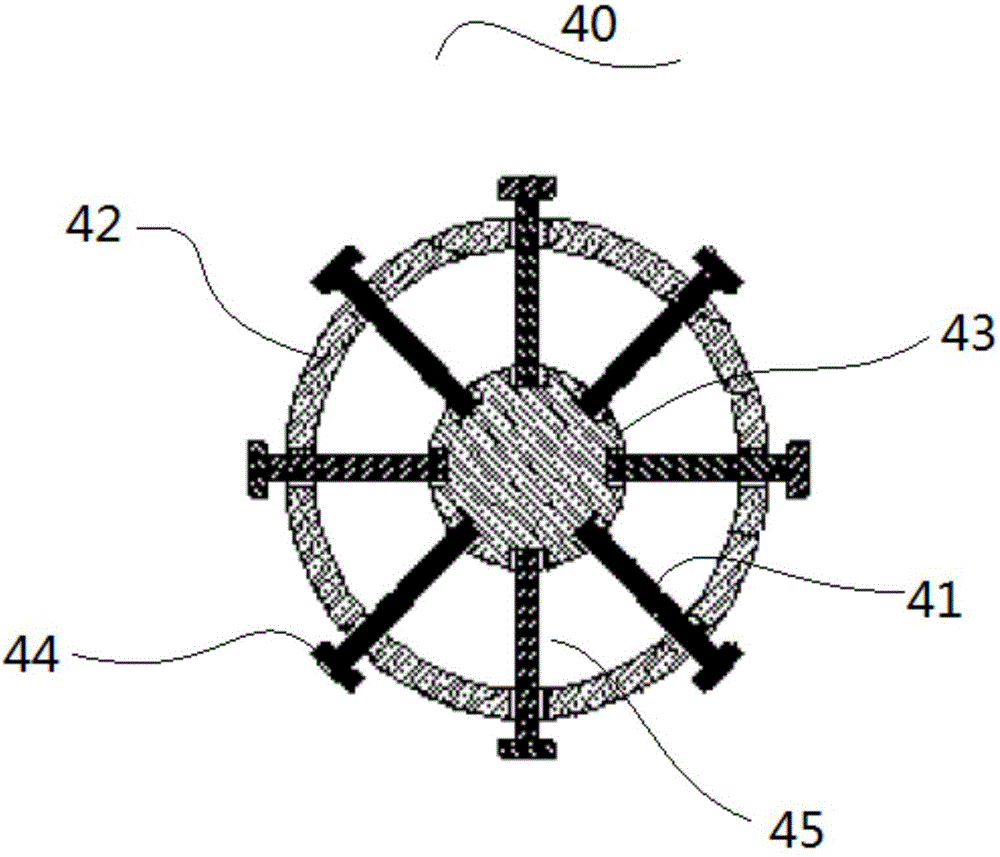

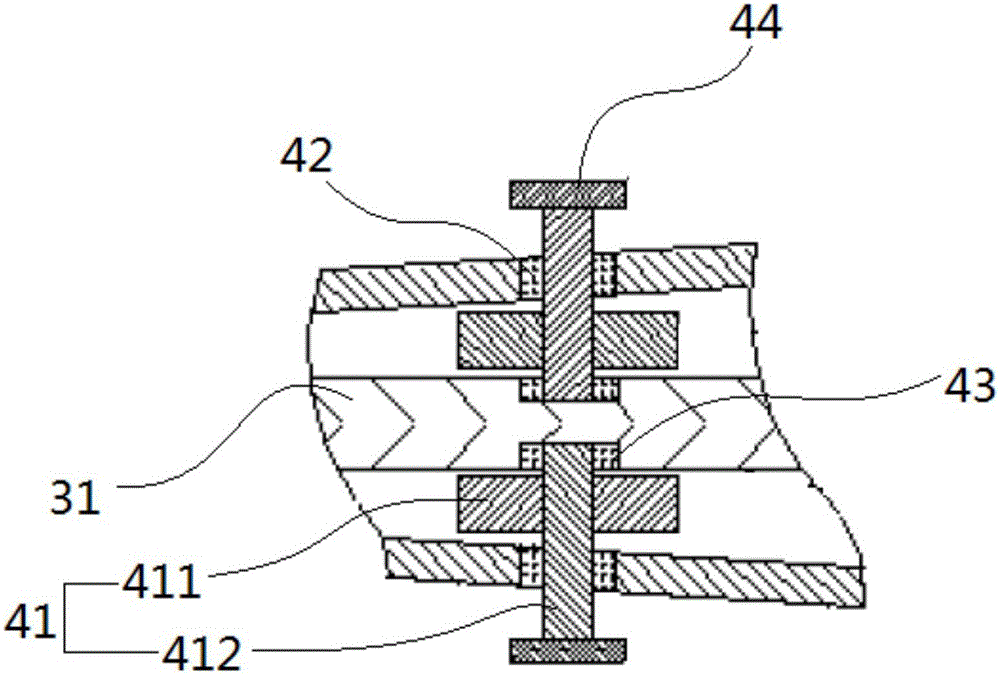

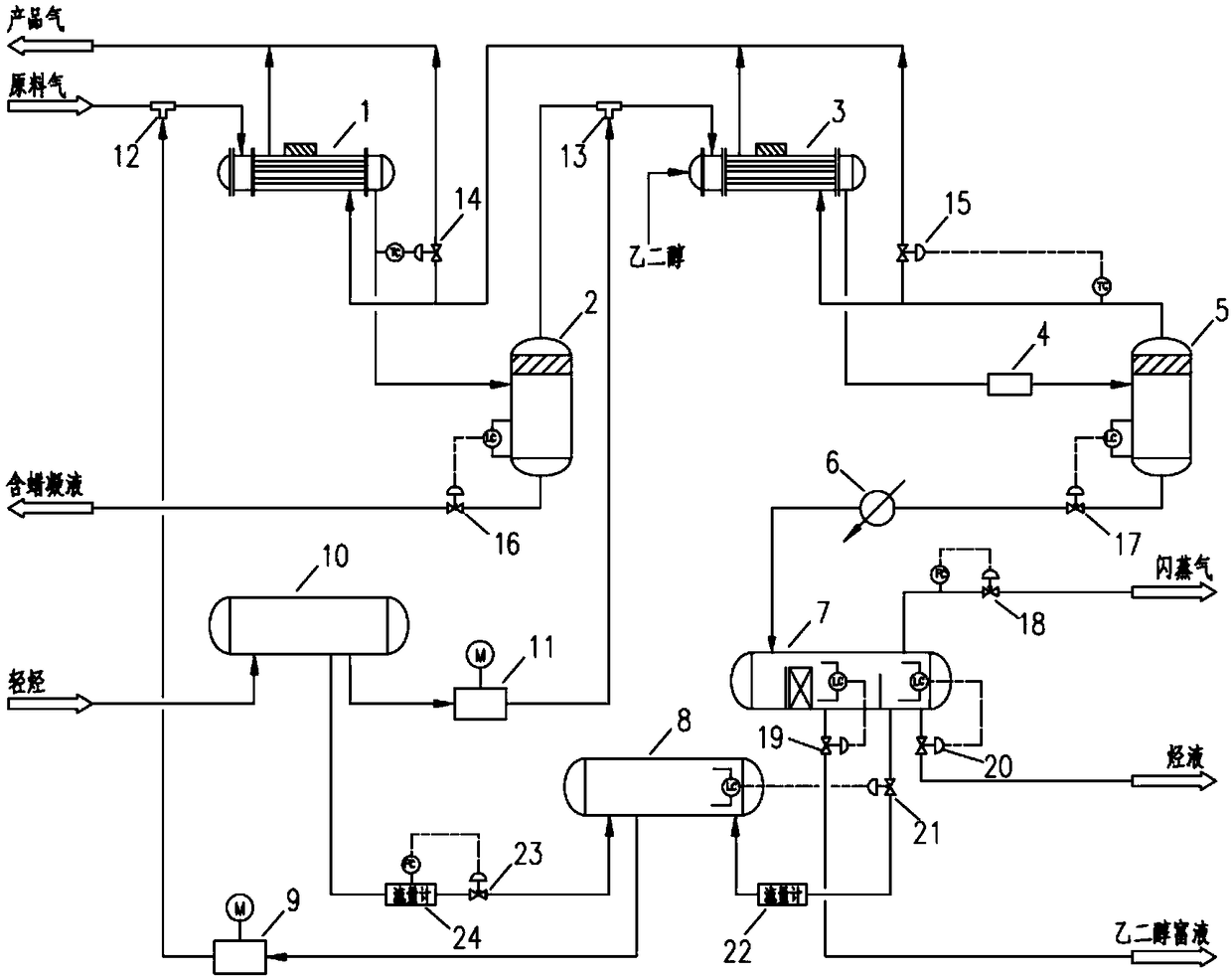

Hypergravity-process triglycol natural gas dehydration system and process using system

ActiveCN104194854APromote absorptionImprove dehydration efficiencyGaseous fuelsHypergravityVapor–liquid separator

The invention discloses a hypergravity-process triglycol natural gas dehydration system which is characterized in that the outlet of a filtering separator is connected with the side inlet of a first hypergravity machine; the upper outlet of the first hypergravity machine is connected with the inlet of a gas-liquid separator; the lower outlet of the hypergravity machine is connected with the inlet of a heat exchanger; the outlet of the heat exchanger is connected with the inlet of a buffer tank; the outlet of the buffer tank is connected with the upper inlet of a second hypergravity machine; the upper outlet of the second hypergravity machine is connected with the inlet of a flash evaporation tank; the outlet of the flash evaporation tank is connected with the inlet of a pump; the outlet of the pump is connected with the upper inlet of the first hypergravity machine. According to the system, the characteristics of the enhanced absorption reactions of the hypergravity machines are utilized and high efficiency of triglycol is combined; the system has the advantages of simple equipment structure, small occupied area, easiness for dehydration, good operating flexibility, high efficiency and the like, and is a novel technology for removing the moisture in natural gas of an offshore platform.

Owner:BEIJING UNIV OF CHEM TECH +2

Skid-mounted device for ultrasonically dehydrating, removing liquid, purifying and separating for natural gas

InactiveCN101544921AEfficient separationAvoid it happening againGaseous fuelsNatural gas dehydrationThree-phase

The invention relates to a skid-mounted device for ultrasonically dehydrating, removing liquid, purifying and separating for natural gas, belongs to an energy-saving purification device of heat engineering, and is mainly applied in the field of dehydrating, removing liquid, purifying and separating for natural gas. The device consists of a gas purification device and a gas separation device. Wet natural gas enters an ultrasonic separation spray pipe respectively; because the temperature is reduced, water and heavy paraffin hydrocarbon components in the natural gas become liquid and then are condensed to form high-speed rotational flow to tangentially flow into a hydrate separator cylinder; and then three-phase separation of the natural gas, condensate and water is carried out, and simultaneously the hydrate is prevented from being generated. The device efficiently separates out the water and the heavy hydrocarbon liquid from the natural gas without adding any chemical drugs, has the advantages of energy conservation, environmental protection, compact structure, and little occupied area, reduces the running cost, can achieve unmanned operation and free maintenance, and can be applied to remote or severe environmental land and offshore platforms.

Owner:SICHUAN ZHONGKEDA OIL&GAS NEW TECH

Rectification-type supersonic cyclone separator

The invention discloses a rectification-type supersonic cyclone separator belonging to the field of moisture-containing natural gas dehydration. The rectification-type supersonic cyclone separator comprises a cyclone, a separator and a diffuser which are sequentially connected, wherein a rectifier is arranged in the diffuser; and when the rectification-type supersonic cyclone separator is used, moisture-containing natural gases enter the separator and are subjected to gas-liquid separation after being swirled by the cyclone so as to form swirled dry natural gases, and the swirled dry natural gases flow out of the rectification-type supersonic cyclone separator after being rectified by the rectifier. The rectification-type supersonic cyclone separator disclosed by the invention is small in size and high in efficiency, and the moisture-containing natural gases can be subjected to gas-liquid separation without other chemical agents; in addition, water vapor in the natural gases can be condensed and separated in a low-temperature and low-pressure environment by only using the own structure of the separator, and then, the left dry natural gases are stored in a diffusion runner provided with the rectifier to ensure that the pressure and the temperature are restored, so that swirling effects in the dry natural gases are eliminated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

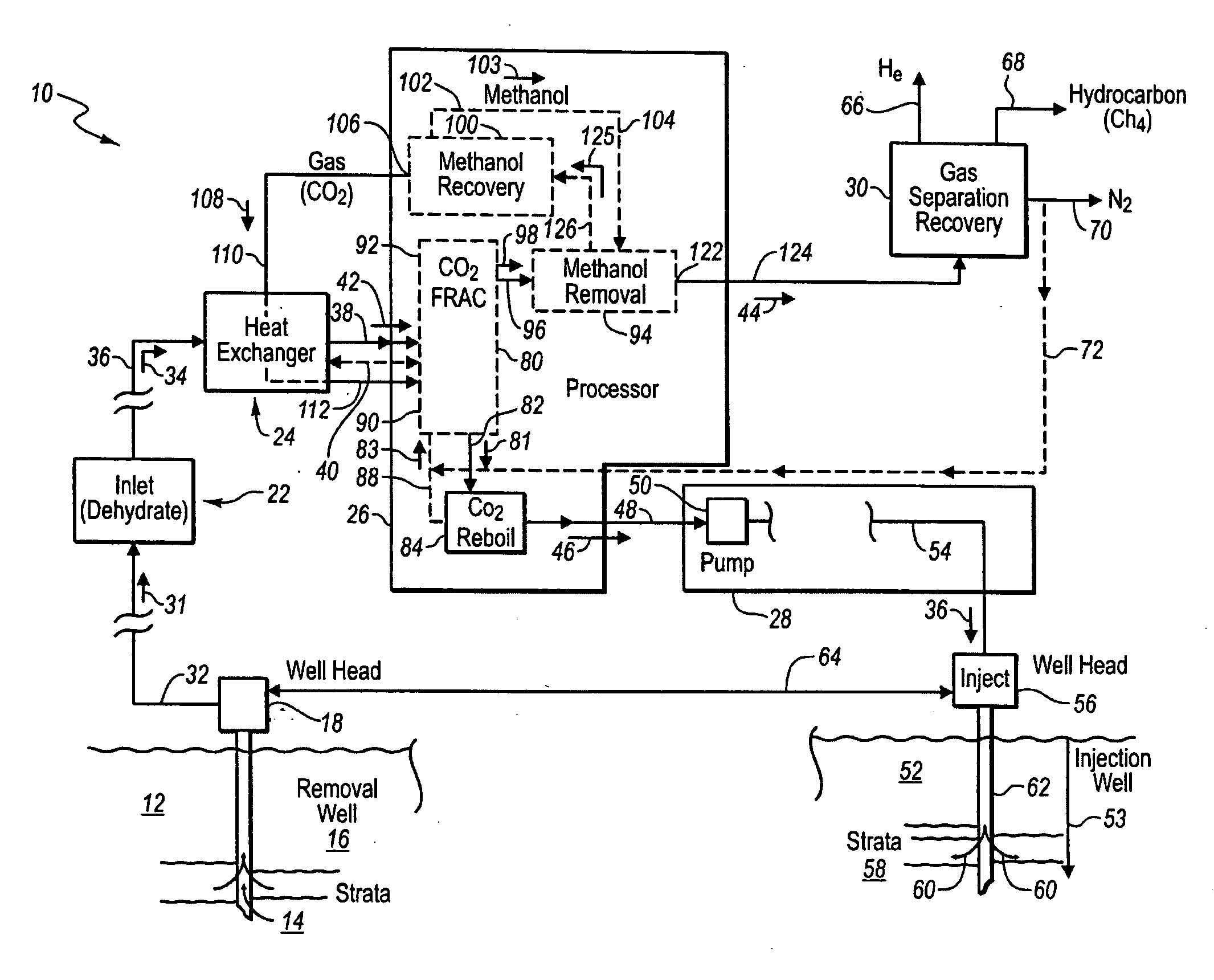

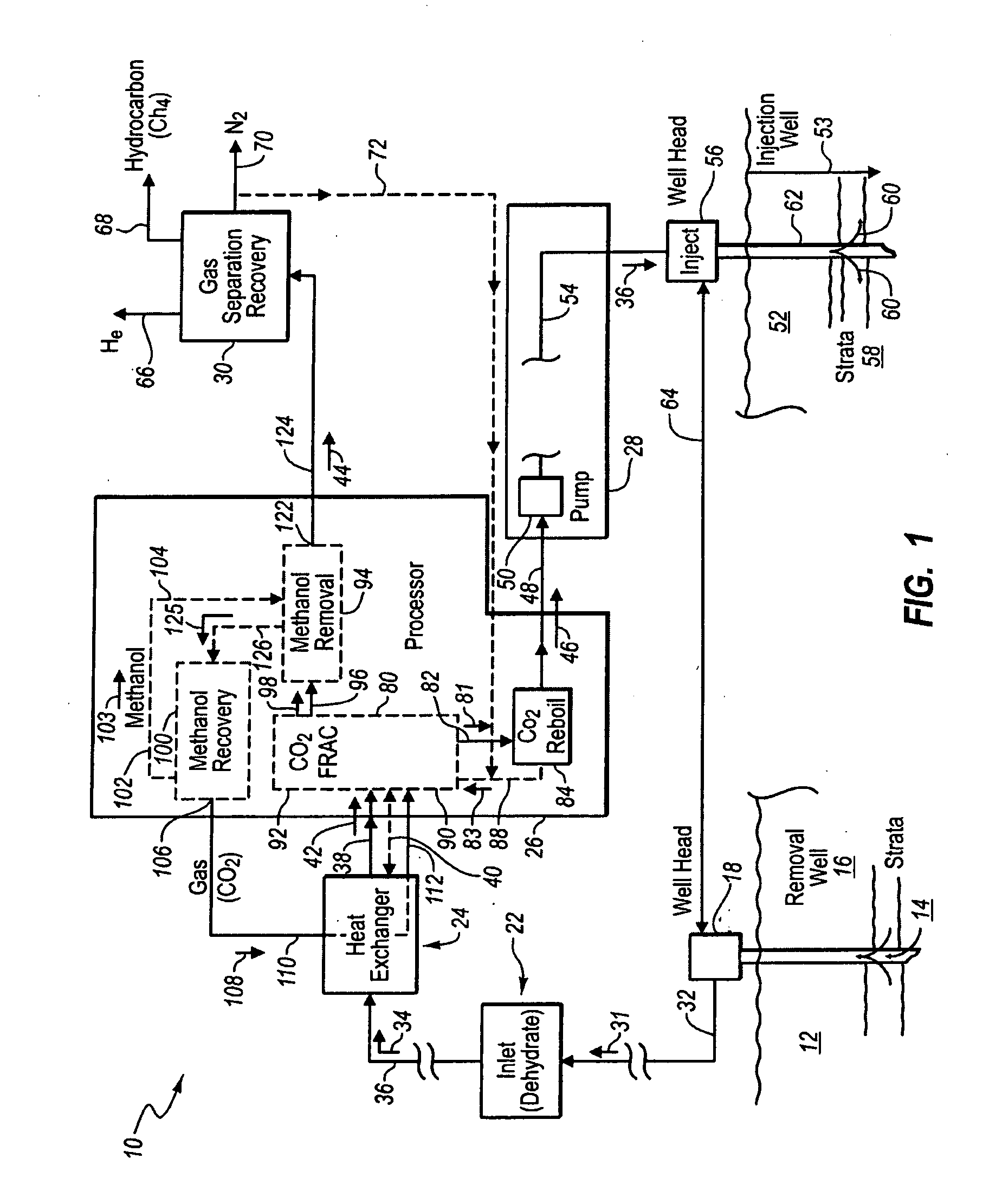

System for Dehydrating and Cooling a Produced Gas to Remove Natural Gas Liquids and Waste Liquids

Produced natural gas containing carbon dioxide is dehydrated and chilled to liquefy the carbon dioxide and then fractionated to produce a waste stream of liquid carbon dioxide and hydrogen sulfide. Natural gas liquids may be first separated and removed before fractionation. After fractionation, the waste stream is pressurized and transmitted to a remote injection well for injection either for disposal of the waste stream and preferably to urge hydrocarbons toward the producing well. A hydrocarbon stream proceeds from fractionation to a methanol absorber system which removes carbon dioxide gas. The hydrocarbon stream is thereafter separated into at least hydrocarbon gas, nitrogen and helium. Some of the nitrogen is reintroduced into a fractionation tower to enhance the recovery of hydrocarbons. A methanol recovery system is provided to recover and reuse the methanol. The hydrocarbons are sold as natural gas and the helium is recovered and sold. Excess nitrogen is vented.

Owner:KATHY ANN STINSON NICHOLES IN HER REPRESENTATIVE CAPACITY AS TRUSTEE OF THE DONALD L STINSON 1994 TRUST U A DTD OCTOBER 24 1994 AS AMENDED

Hydrocarbon processing

ActiveUS20130306520A1Low costSave energyHydrogenLiquid hydrocarbon mixture recoveryNatural gas dehydrationProcess engineering

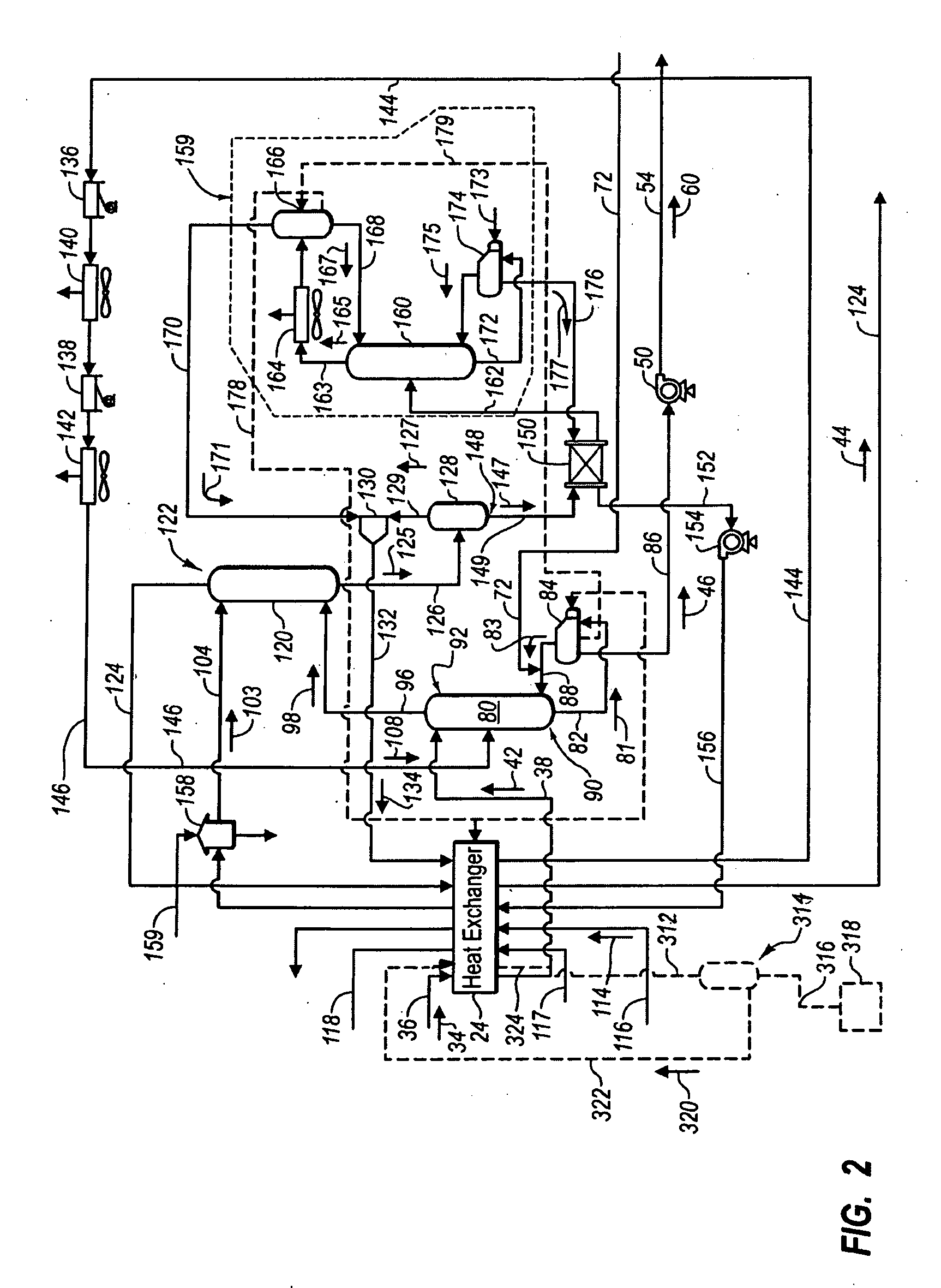

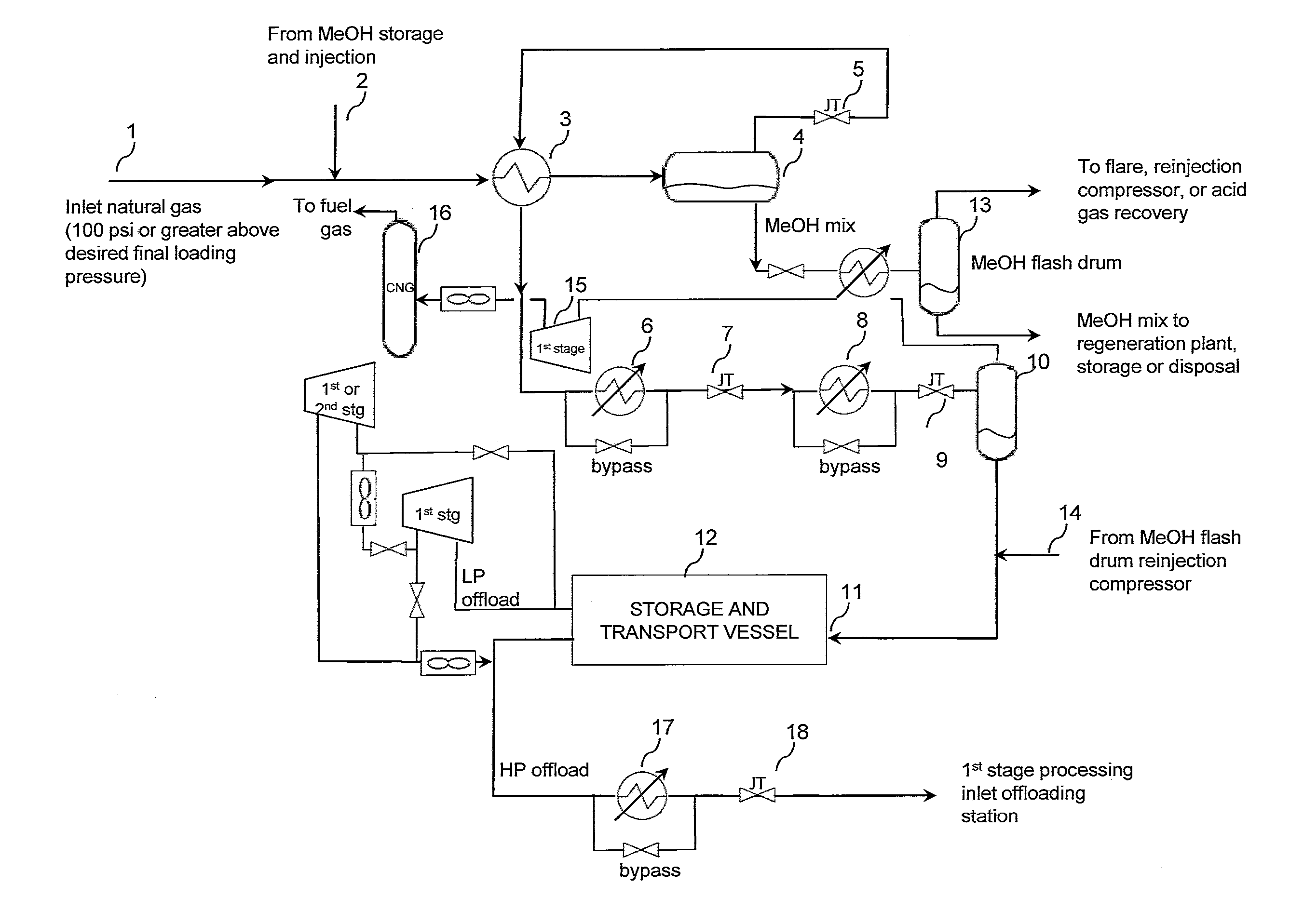

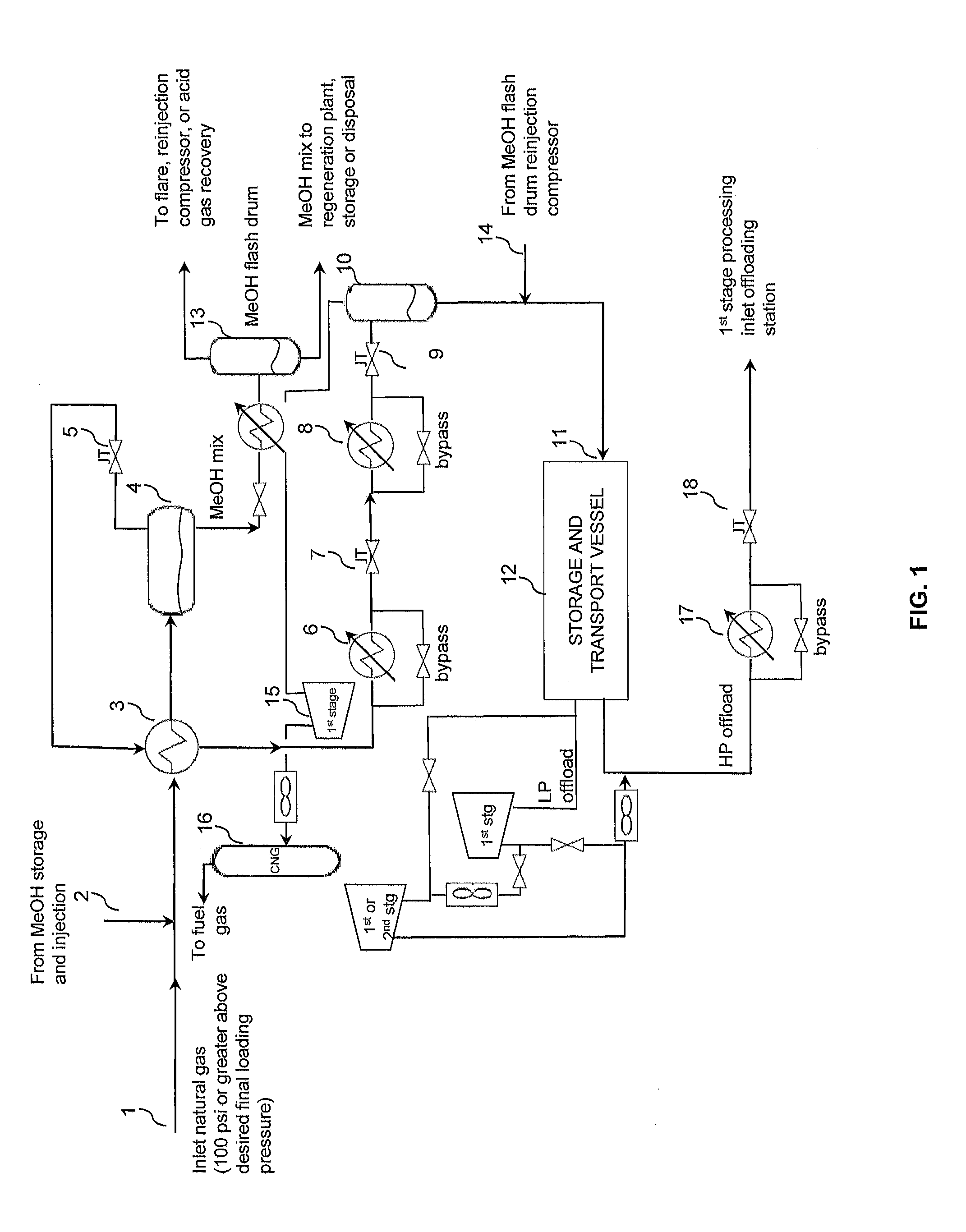

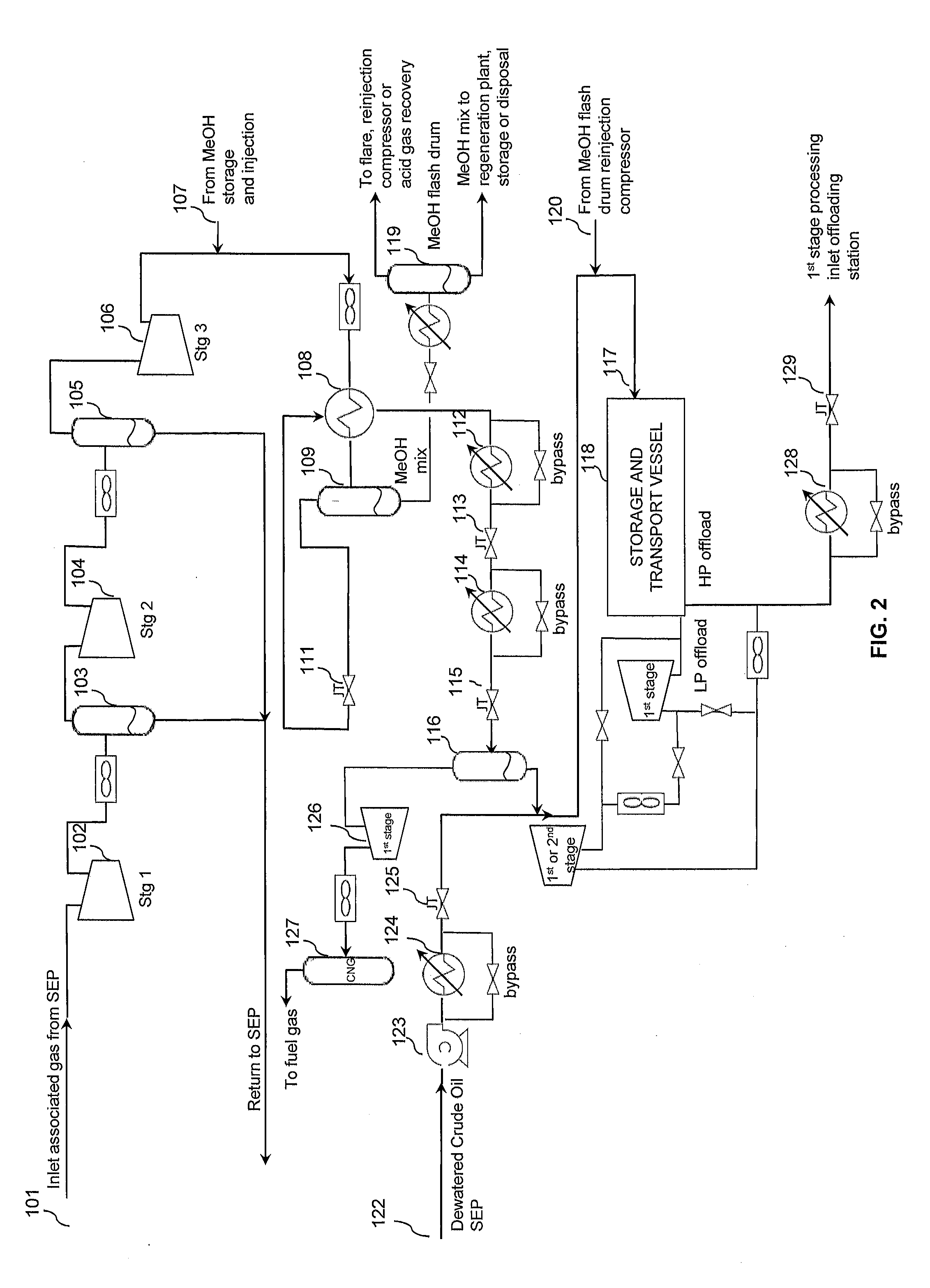

A method for processing raw natural gas for storage and transport in a storage vessel at a storage pressure greater than the raw natural gas dense phase pressure, which includes the steps of receiving the raw natural gas in a flow path at an inlet pressure greater than the storage pressure; if necessary, dehydrating the raw natural gas; and continuously releasing the dehydrated raw natural gas from the flow path at a release pressure and a release temperature into a storage vessel until the pressure of the dehydrated raw natural gas in the storage vessel reaches the storage pressure, avoiding the solidification of any impurities in the raw natural gas. Also, a method of processing crude oil having dissolved raw natural gas for storage and transport in a storage vessel at a storage pressure greater than the bubble point pressure, includes the steps of receiving the crude oil at an inlet pressure greater than the storage pressure, and loading the crude oil into the storage vessel until the crude oil reaches the storage pressure, without separating any dissolved raw natural gas from the crude oil. Alternatively, raw natural gas is separated from the crude oil, and compressed to at least the storage pressure, dehydrating the raw natural gas, and recombining the dehydrated raw natural gas with the crude oil prior to loading into the storage vessel, avoiding the solidification of any impurities in the raw natural gas.

Owner:NIKIFORUK COLIN

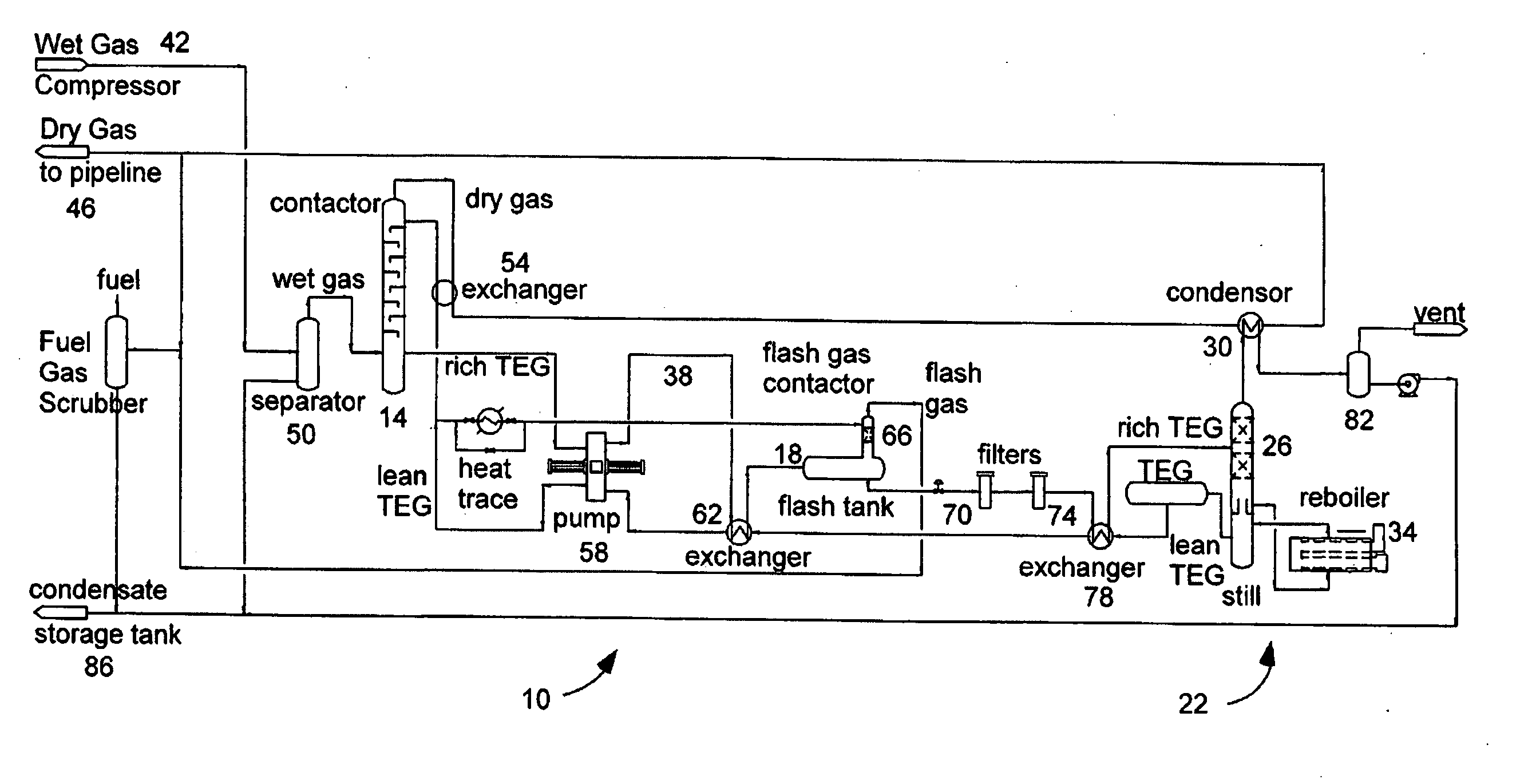

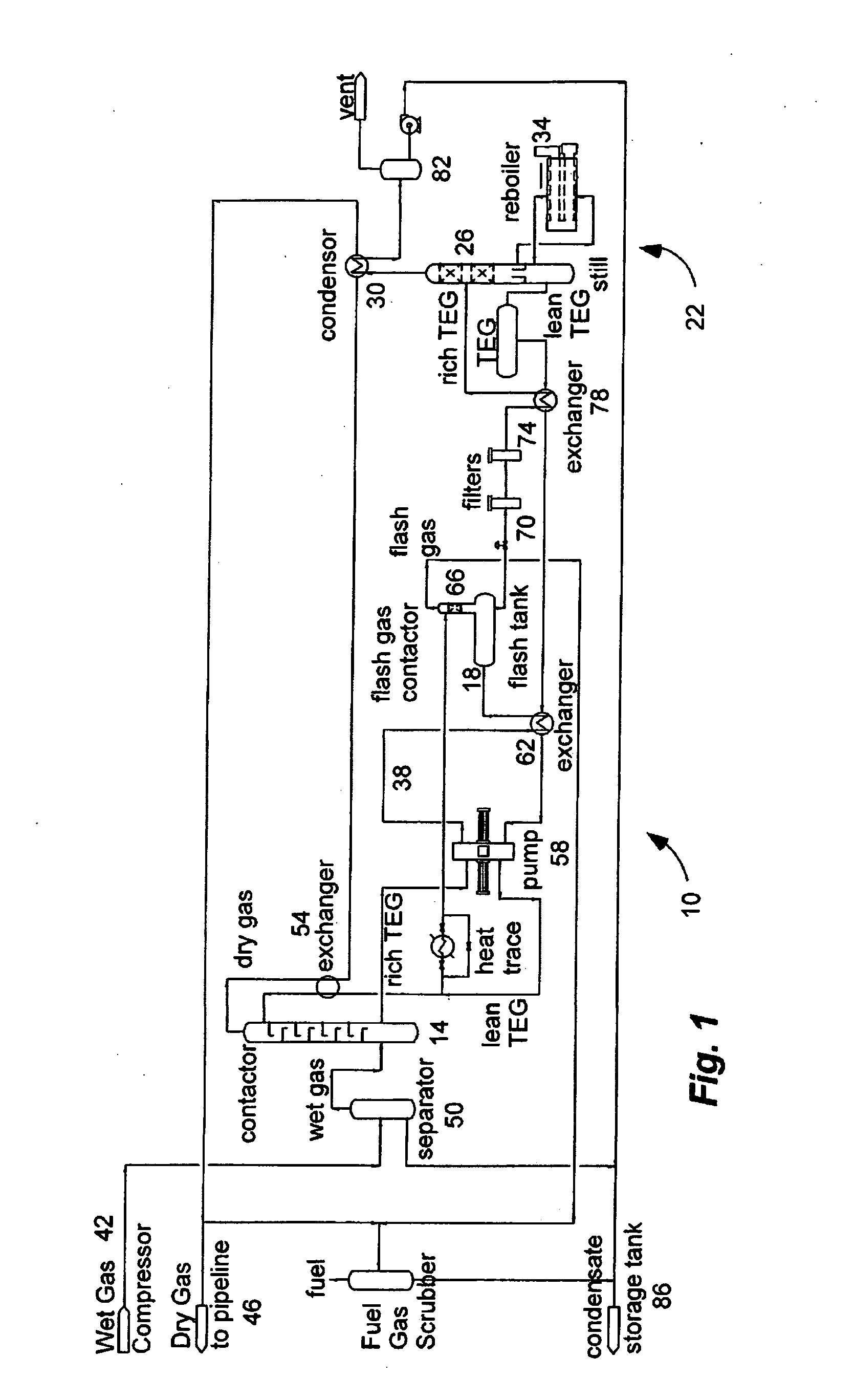

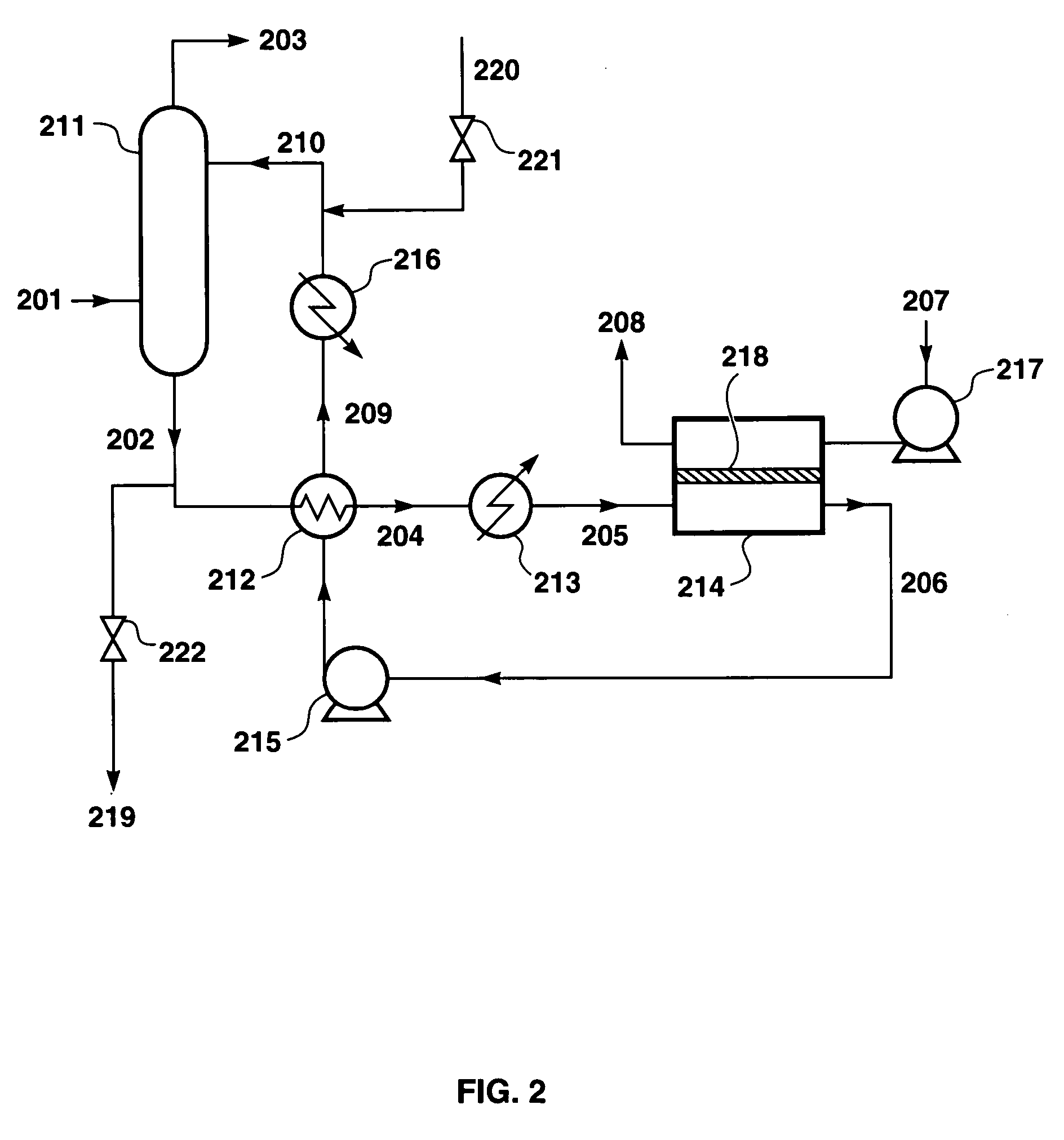

System for dehydrating natural gas

InactiveUS20100281775A1Low costReduce the amount requiredGas treatmentHydrogen separationReboilerNatural gas dehydration

An apparatus and process for dehydrating a wet natural gas while removing volatile organic compounds (VOC). The well-produced natural gas is contacted with a dehydrating agent, such as glycol, which absorbs water from the natural gas. The mixture of dehydrating agent / water and heavy hydrocarbons is conveyed through a heat exchanger, separator and reboiler for removing VOC and recovering the dehydrating agent for recirculation. A stripping column is coupled to an outlet of the reboiler for stripping the dehydrating agent of any traces of water that is flashed out in the reboiler. Light hydrocarbons removed from the mixture are re-circulated as flash gas in the reboiler, thereby reducing the amount of make-up fuel necessary in the heating process.

Owner:GLY TECH SERVICES

Ultra-low emission natural gas dehydration unit with continuously fired reboiler

InactiveUS20110247489A1Prevent freezingEffective destructionDispersed particle filtrationGaseous fuelsReboilerDesiccant

A natural gas dehydration system and method includes a contactor, a flash tank, and a still interconnected by a desiccant circulation system. A continuously fired reboiler is coupled to the still and the flash tank to bum the flash gas from the flash tank and heat the desiccant.

Owner:WITHERSPOON JOSEPH A

Integrated natural gas treating apparatus

InactiveCN1401735ALess investmentReduce consumptionSolidificationLiquefactionPlate heat exchangerNatural-gas processing

A natural gas processing apparatus for dewatering the natural gas and separating light oil at same time is composed of comprehensive processor consisting of dewatering and separating zones, heat exchanger for heat-carrying medium, heat exchanger for oil, fractionator, suppressant regenerator, and refrigerating system.

Owner:吕应中

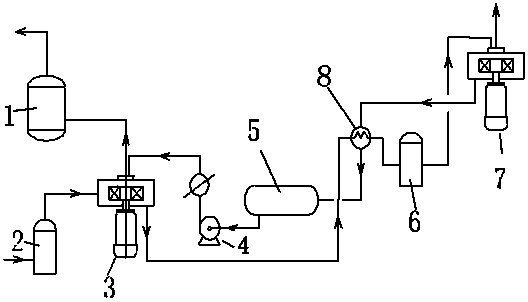

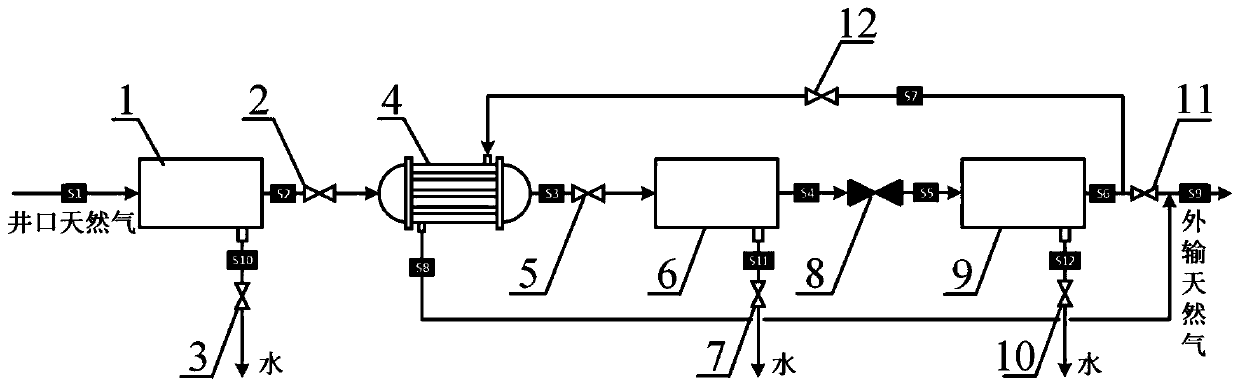

Device and method for dehydrating and dehumidifying wellhead natural gas

InactiveCN110408445ALittle impact on qualityProduction environment safetyGaseous fuelsFluid removalWellheadProcess engineering

The invention provides a device and a method for dehydrating and dehumidifying wellhead natural gas, and belongs to the technical field of natural gas. The device comprises a gas-liquid preseparator,a heat exchanger, a first-stage gas-liquid separator, a throttling tube, a final-stage gas-liquid separator, and control valves on all pipeline. Free water in water-containing high-pressure wellhead natural gas is removed in the gas-liquid preseparator to obtain a preliminarily dehumidified wet natural gas, then the preliminarily dehumidified wet natural gas successively enters the heat exchangerand the first-stage gas-liquid separator to achieve cooling, separation and dehumidification, the dehumidified gas is depressurized and cooled by the throttling tube, and then enters the final-stage gas-liquid separator, and a gas obtained after the separation is natural gas that meets the moisture requirement, wherein all or a part of the natural gas is recovered by the heat exchanger, and then is imported to an outside natural gas transporting pipeline network. The device has the advantages of no moving parts, simple structure and high reliability, and realizes organic combination of coolingcondensation and water removal separation only by using the self energy conversion of the natural gas without outside energy input in the running process in order to achieve the purpose of dehydrating and dehumidifying the wellhead natural gas.

Owner:UNIV OF SCI & TECH BEIJING

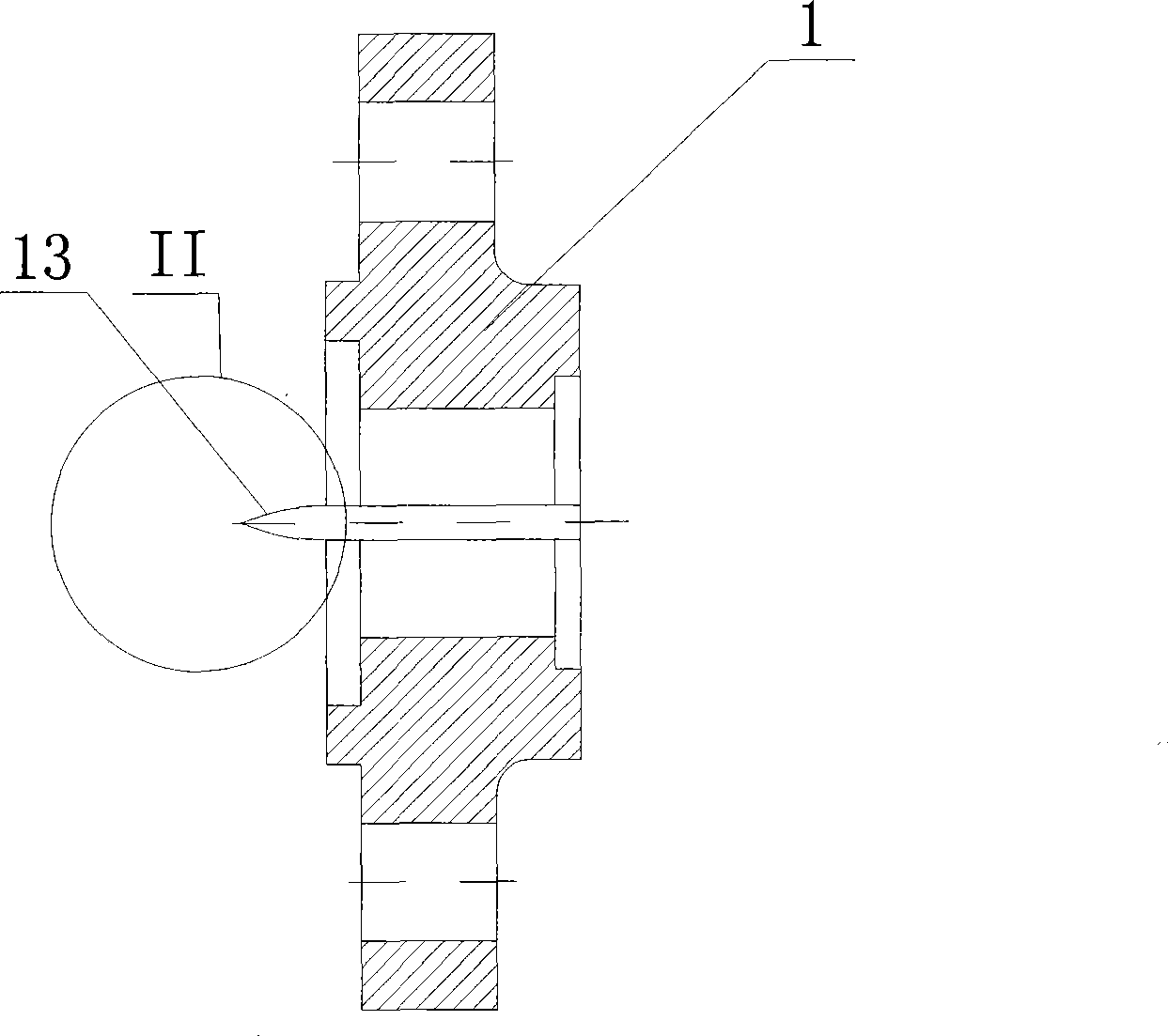

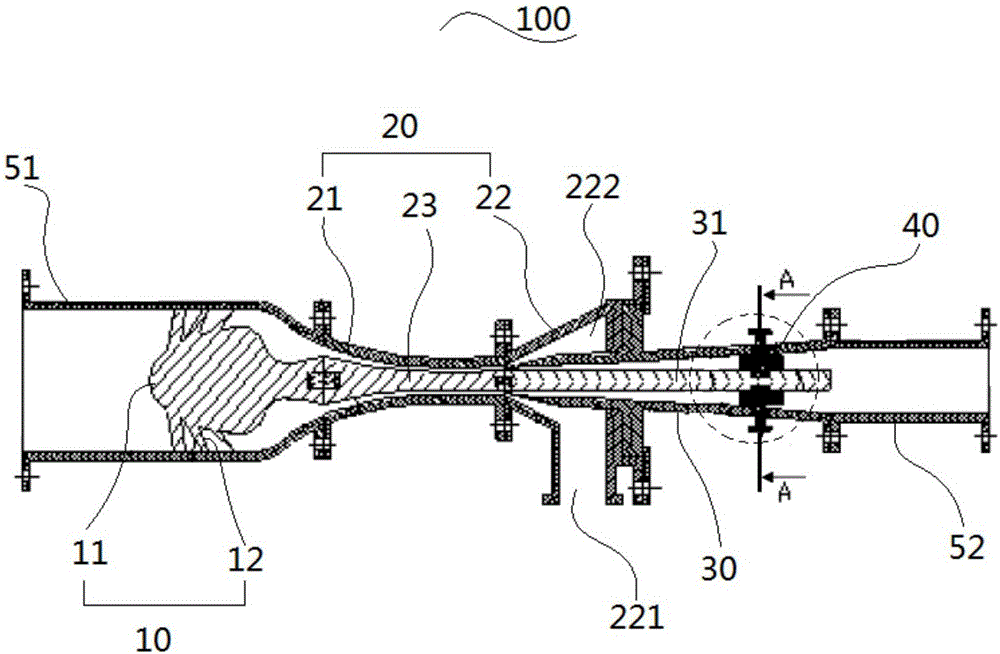

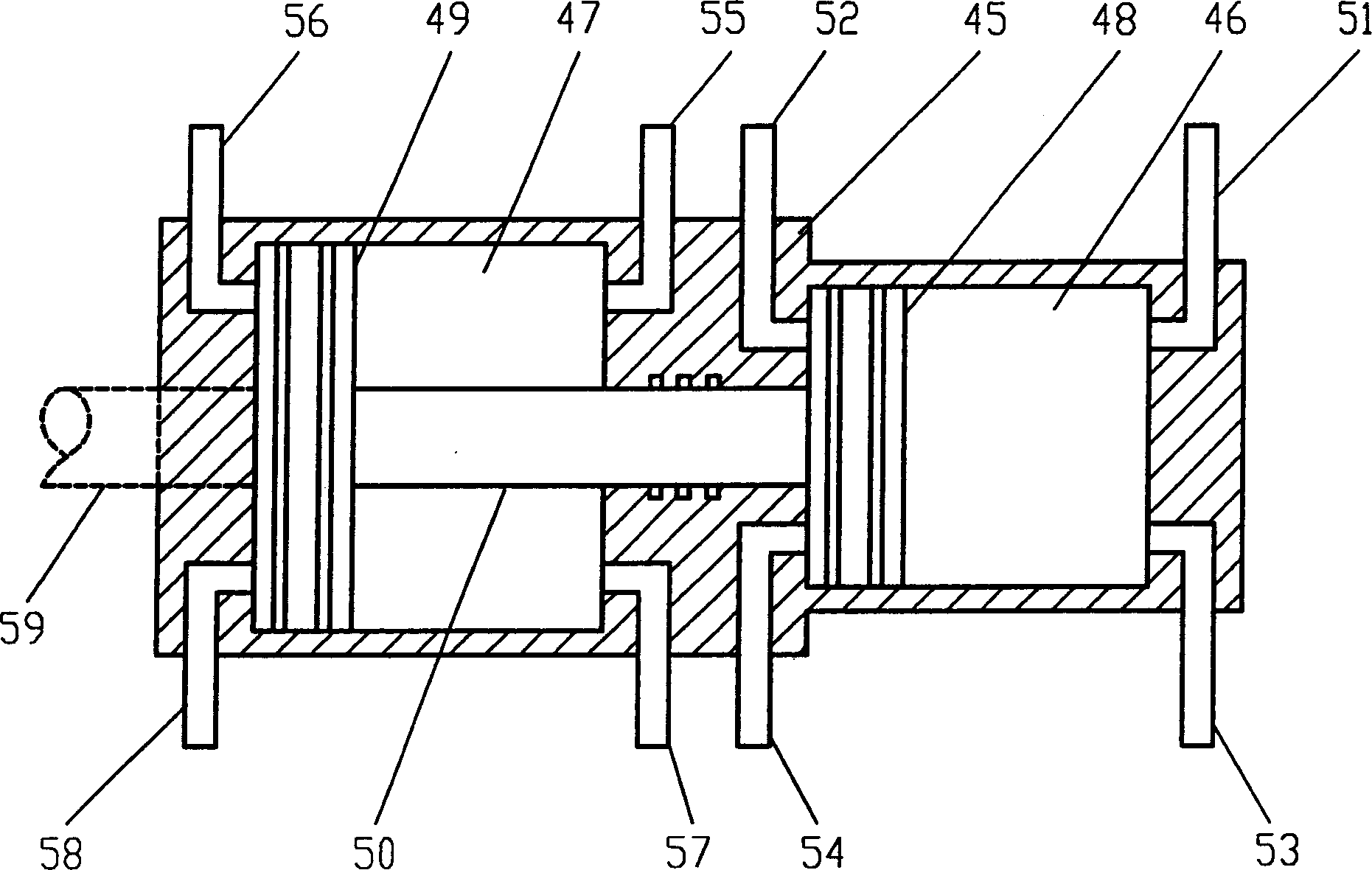

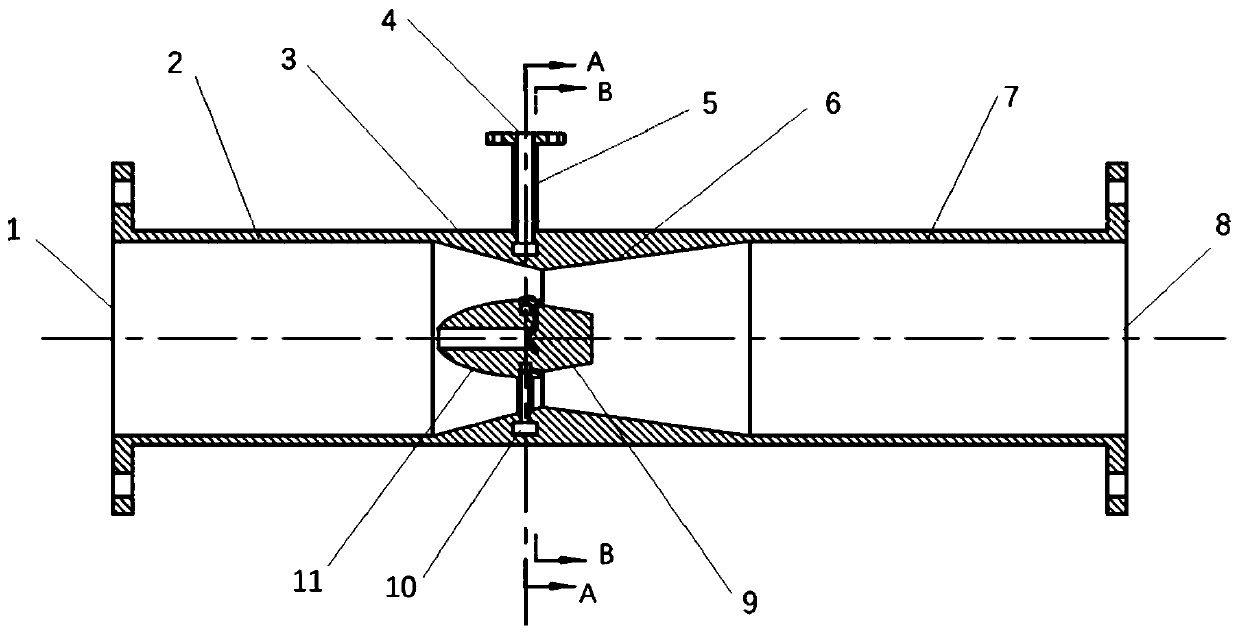

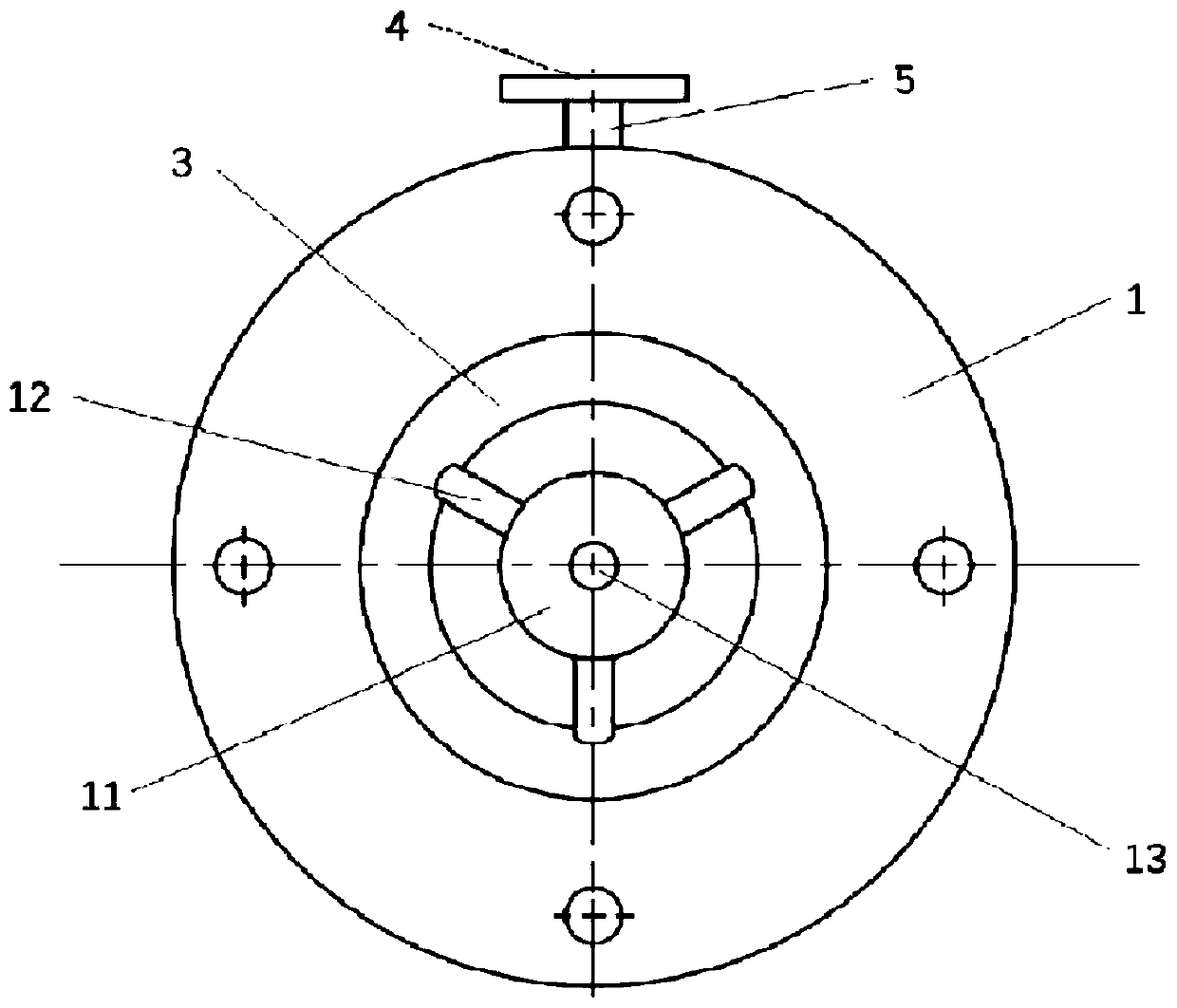

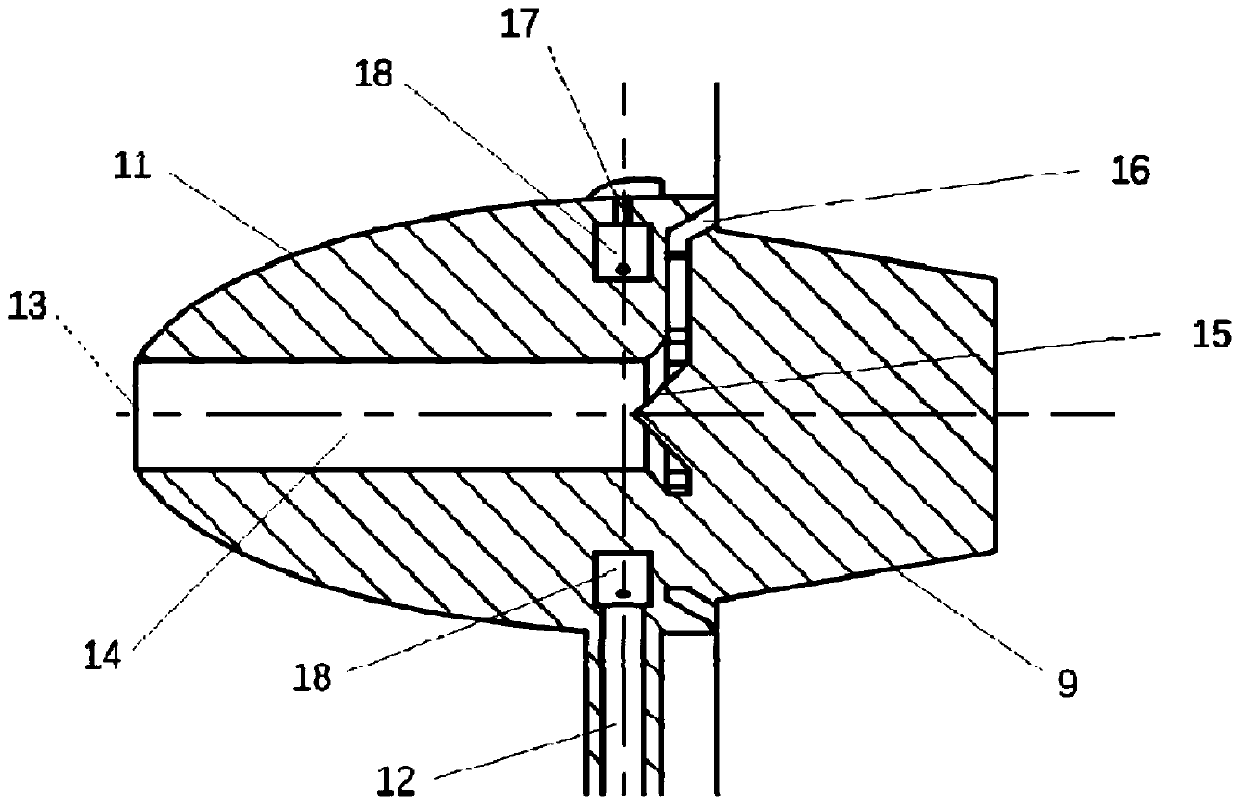

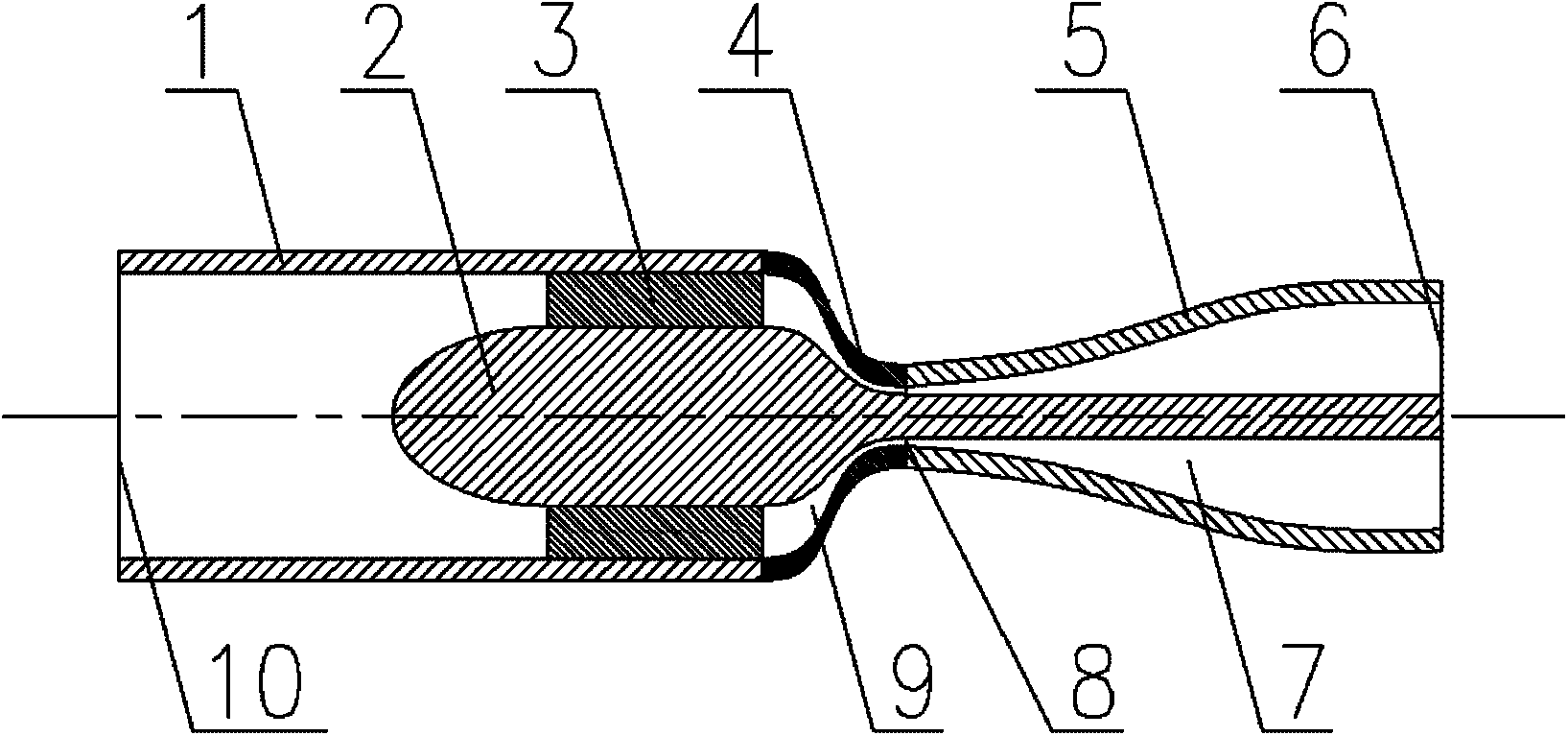

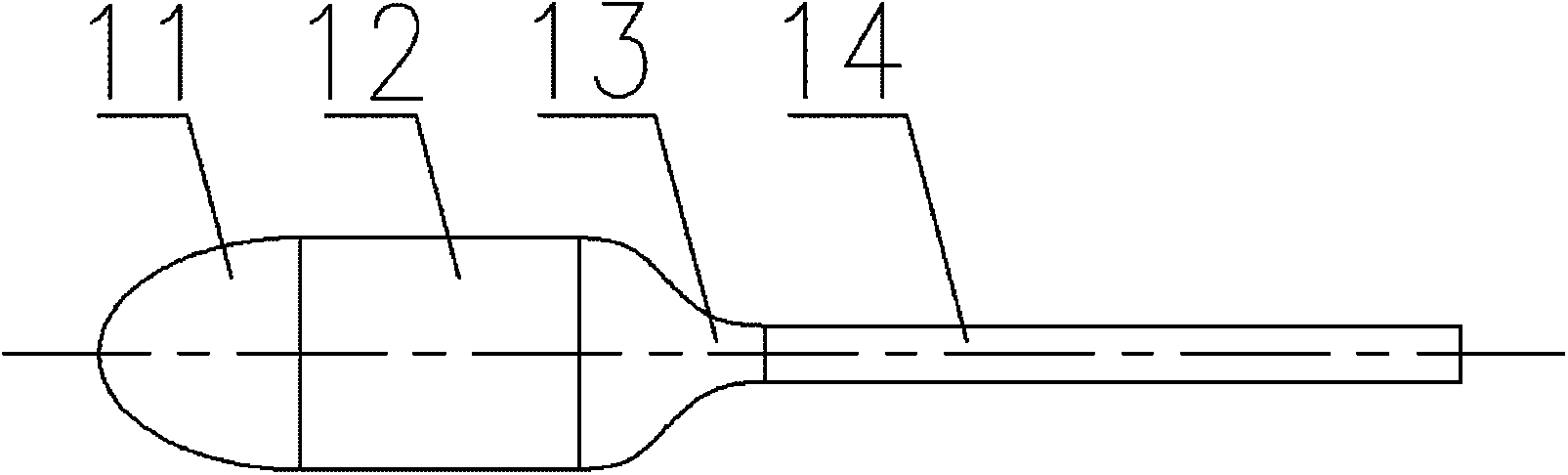

Tubular parallel flow type gas-liquid contact absorber

ActiveCN111471499AImprove gas-liquid mass transfer efficiencyCompact structureDispersed particle separationGaseous fuelsStraight tubeNatural gas dehydration

The invention discloses a tubular parallel flow type gas-liquid contact absorber which comprises a gas steady flow straight pipe section, a gas contraction acceleration section, a gas dispersion expansion section and a gas-liquid uniform mixing mass transfer absorption section which are connected in sequence; liquid absorbent injection atomization parts are arranged in the gas contraction acceleration section and the gas dispersion expansion section; each of the liquid absorbent injection atomization parts comprises a built-in ellipsoidal flow guide cone and a trapezoidal cone, a flow guide cone liquid annular flow channel is arranged in the ellipsoidal flow guide cone, an outer pipe liquid annular flow channel is communicated with the flow guide cone liquid annular flow channel through aplurality of liquid annular flow channel connecting pipes, and a plurality of liquid incident small holes are evenly distributed in the outer wall face of the flow guide cone liquid annular flow channel in the circumferential direction, an auxiliary atomized gas flow channel is axially arranged in the ellipsoidal flow guide cone, and an auxiliary atomized gas circular seam is formed in the end face of the tail portion of the ellipsoidal flow guide cone. Purification treatment of natural gas dehydration and deacidification under different working conditions can be achieved, the gas-liquid masstransfer efficiency is high, the structure is compact, the treatment amount is large, operation is easy, and the gas-liquid flow application range is wide. The device is especially suitable for an offshore platform to replace a traditional absorption tower in a natural gas dehydration or deacidification process.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Hydrocarbon injection dewaxing device and technology suitable for dehydration and hydrocarbon removal of wax-containing natural gas

The invention discloses a hydrocarbon injection dewaxing device and technology suitable for dehydration and hydrocarbon removal of wax-containing natural gas. The device comprises a feed gas precooler, a feed gas separator, a feed gas aftercooler, a refrigeration facility, a low temperature separator, a heater and a three-phase separator that are connected in order. The invention has the positiveeffects that: by fully combining the natural gas dehydration and hydrocarbon removal process, a hydrocarbon liquid obtained by heating and separation of a low-temperature alcohol hydrocarbon liquid isinjected into a feed gas precooler inlet feed gas pipeline, external non-waxy light hydrocarbon is injected into a feed gas aftercooler inlet pipeline, hydrocarbon liquid and light hydrocarbon are utilized to change the natural gas composition, most of the paraffin in the feed gas is removed by pre-cooling separation of feed gas, and part of the paraffin is removed by cryogenic refrigeration separation of the feed gas. As hydrocarbon liquid and light hydrocarbon dissolve the paraffin precipitated in a natural gas cooling process, blockage of equipment and valves by colloidal or solid paraffincan be effectively avoided. The device provided by the invention is flexible in operation, and can meet the dewaxing needs of natural gas dehydration and hydrocarbon removal process in different wax-containing gas fields.

Owner:CHINA PETROLEUM ENG & CONSTR +1

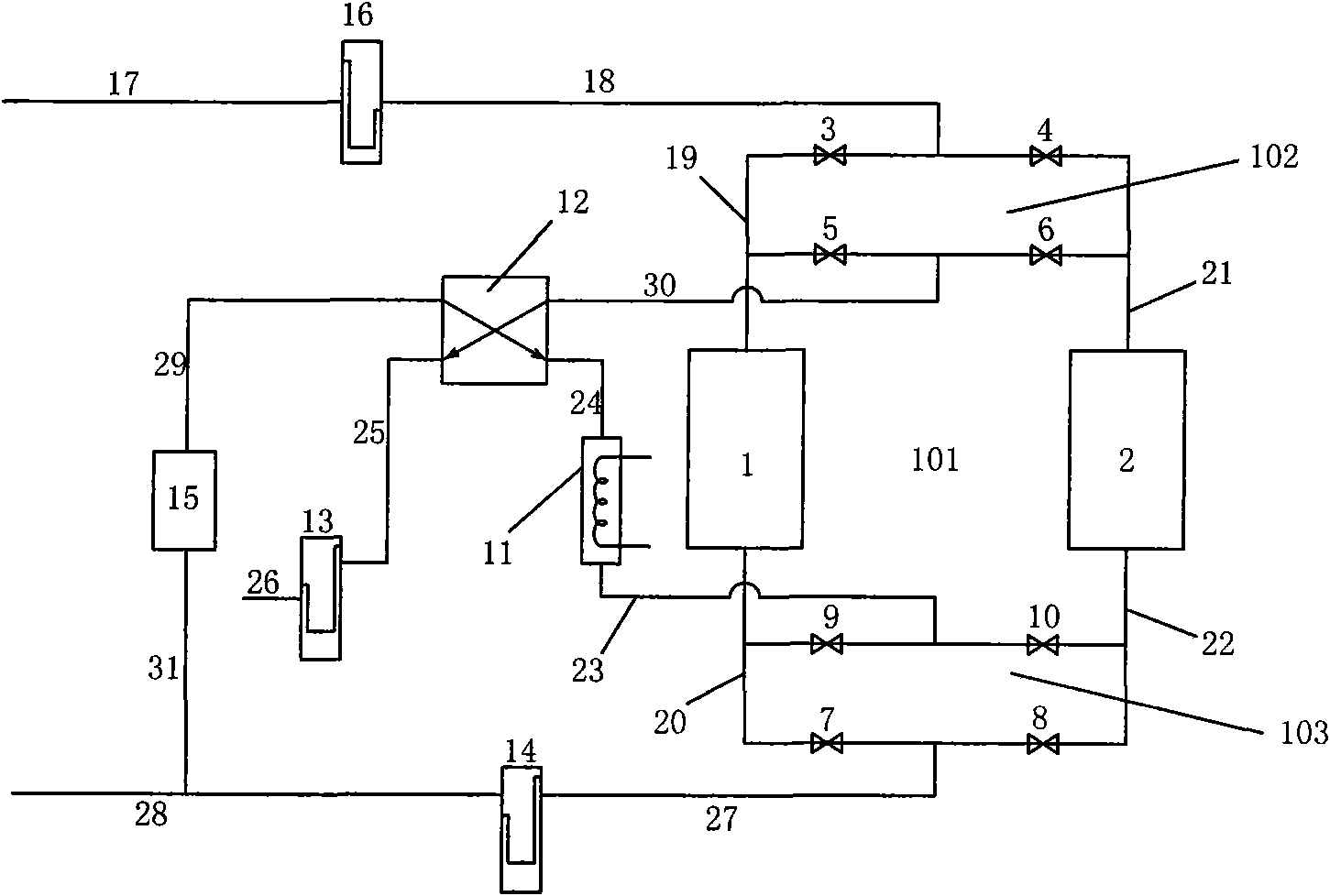

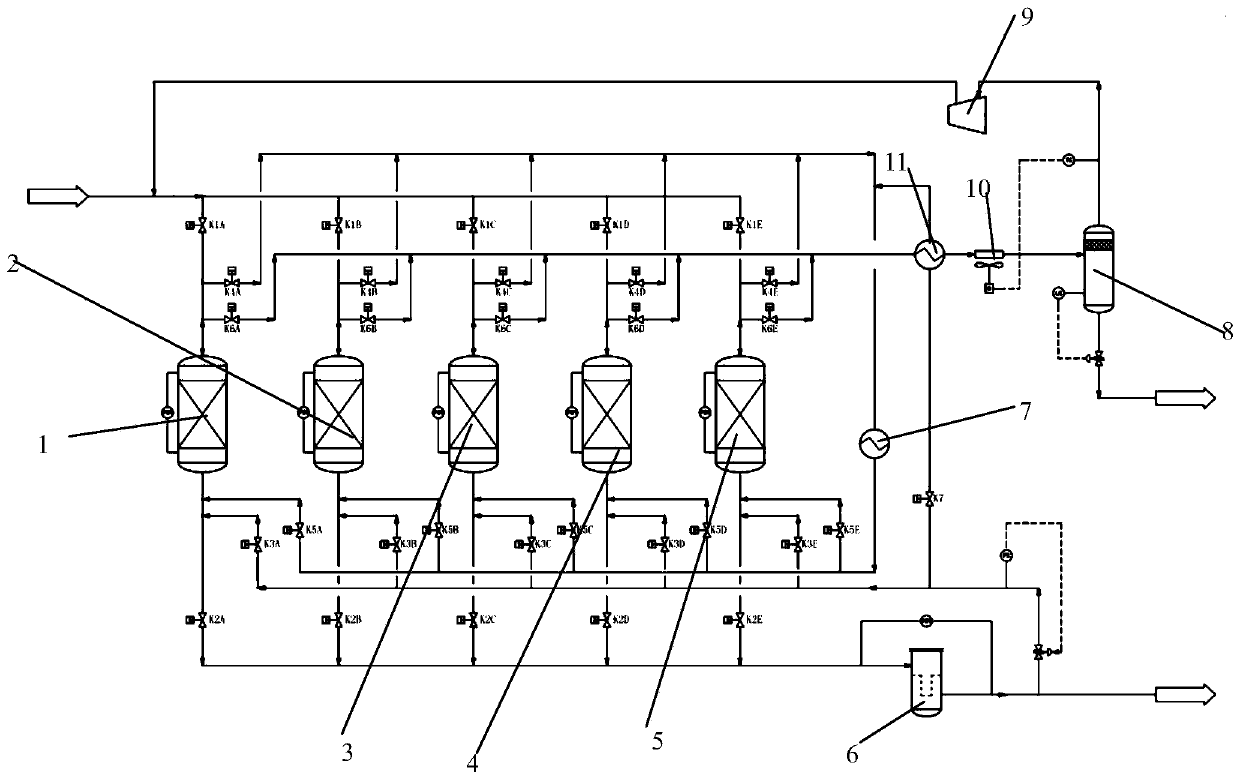

Natural gas molecular sieve adsorption dehydration system provided with heat recycling structure, and method

InactiveCN109957429AReduce heating loadReduce cooling loadGaseous fuelsMolecular sieveVapor–liquid separator

The invention discloses a natural gas molecular sieve adsorption dehydration system provided with a heat recycling structure, and a method. The natural gas molecular sieve adsorption dehydration system comprises an adsorption tower assembly composed of a plurality of adsorption towers, a filter, a heater, a heat recycling heat exchanger, an air cooler, a gas-liquid separator, and a compressor; inthe adsorption tower assembly, at least on adsorption tower is taken as a dehydration tower, at least one adsorption tower is taken as a cooling regeneration tower, at least one adsorption tower is taken as a thermal regeneration tower, and at least one adsorption tower is taken as a standby tower; dehydration, cooling regeneration, and thermal regeneration process is realized through cooperationof a switch valve and the adsorption towers, no exhaust gas is discharged, natural gas waste or adoption of other processing equipment is avoided, device operation flexibility and operation reliability are increased, large scale continuous dehydration operation is realized, and the natural gas molecular sieve adsorption dehydration system can be widely used in natural gas dehydration.

Owner:珠海巨涛海洋石油服务有限公司

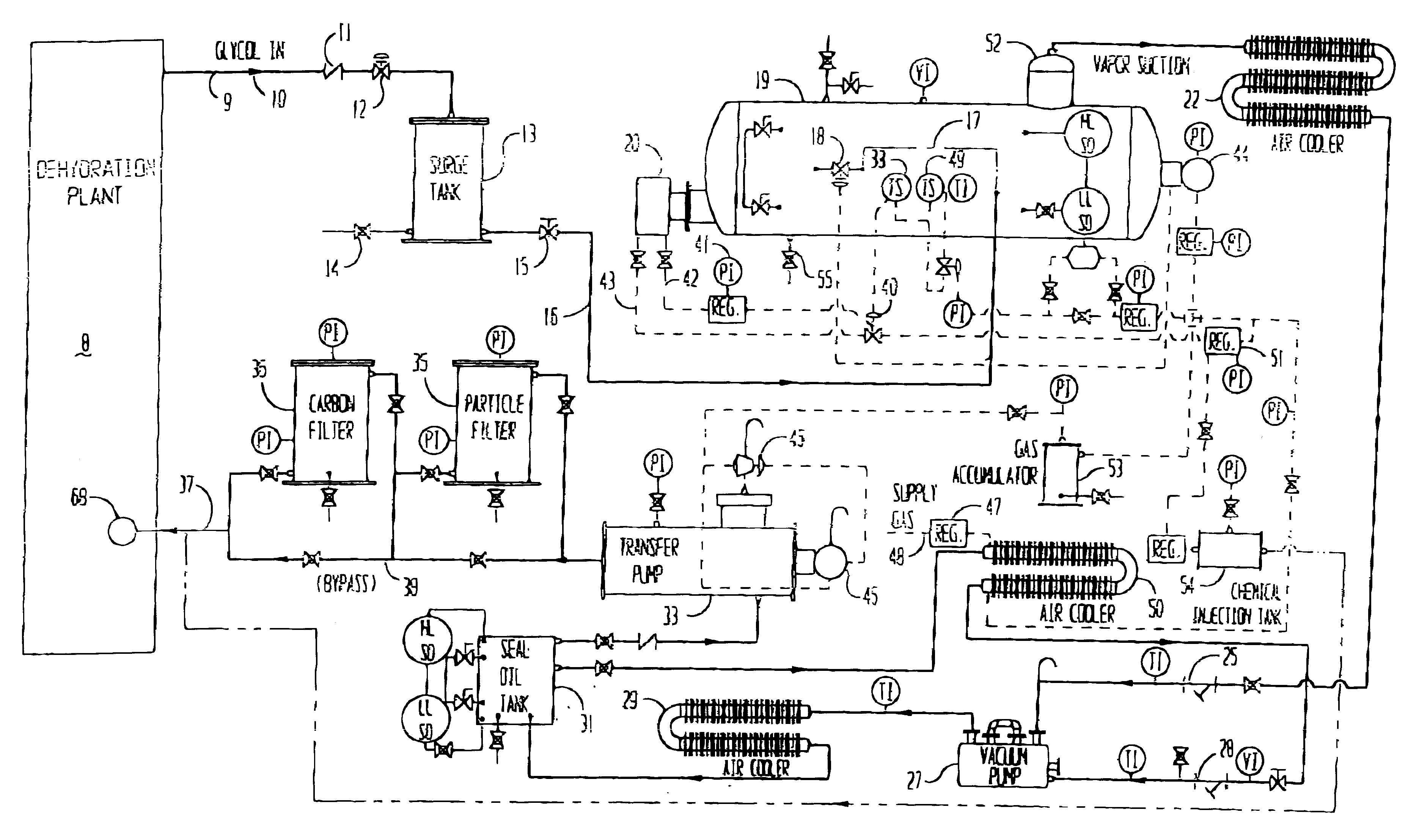

Hazardous waste disposal

InactiveUS6773554B1Reduce amountEliminate riskVapor condensationVacuum distillation separationGlycol degradationNatural gas dehydration

Contaminated glycol is refined by vacuum distillation. Specifically the evaporator is heated to a temperature below the degradation temperature of the glycol. The vacuum is used to bring the flashpoint down sufficiently so that glycol evaporates or flashes at that temperature. The glycol is condensed and filtered through activated granular carbon. The principal use of refining the glycol is to refine the triethylene glycol used in natural gas dehydration plants. For such purposes the equipment is mounted upon a trailer to be taken to the plant for cleaning glycol. In such instance, in addition to refining the glycol, a cleaning agent (which contains a degreaser) is added to the refined glycol. The glycol is refined while the natural gas dehydration plant is in normal operation and therefore it is not necessary to stop the natural gas dehydration plant for refining the glycol used therein. In addition, by the addition of the cleaning agent, the dehydrating plant equipment may be cleansed of hazardous waste. The hazardous waste will be separated and concentrated in the distillation. Therefore, the transportation of the hazardous waste to a disposal location is simplified.

Owner:MOORE JR JOHN W

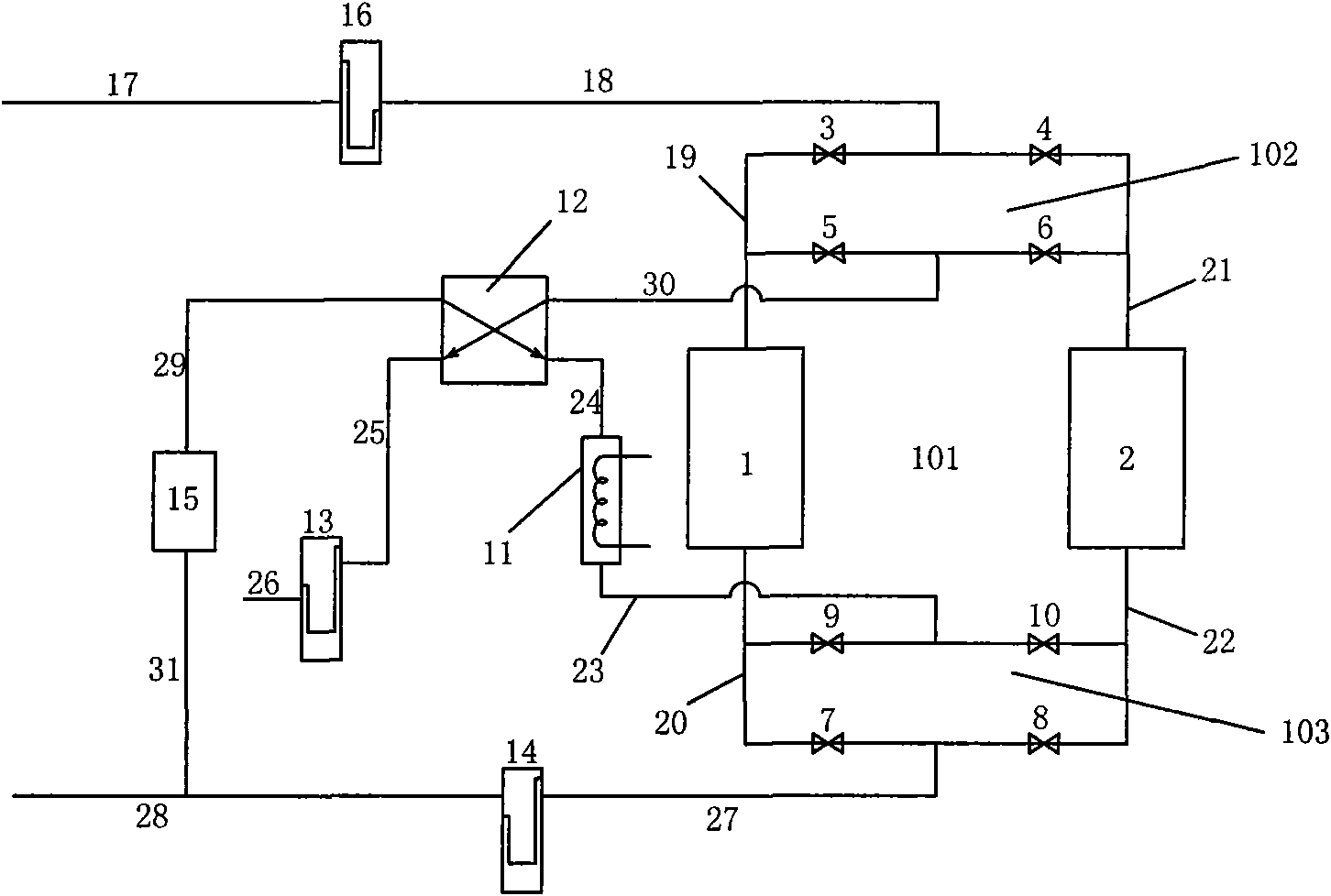

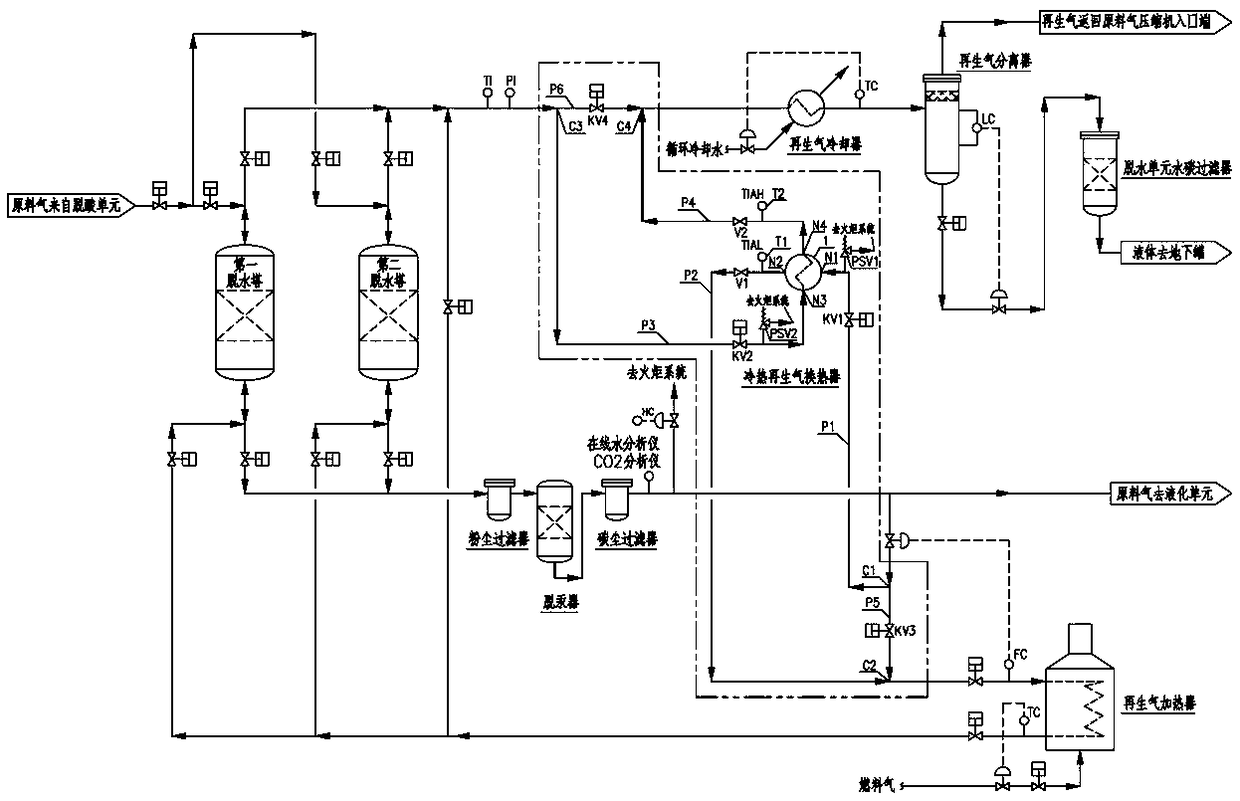

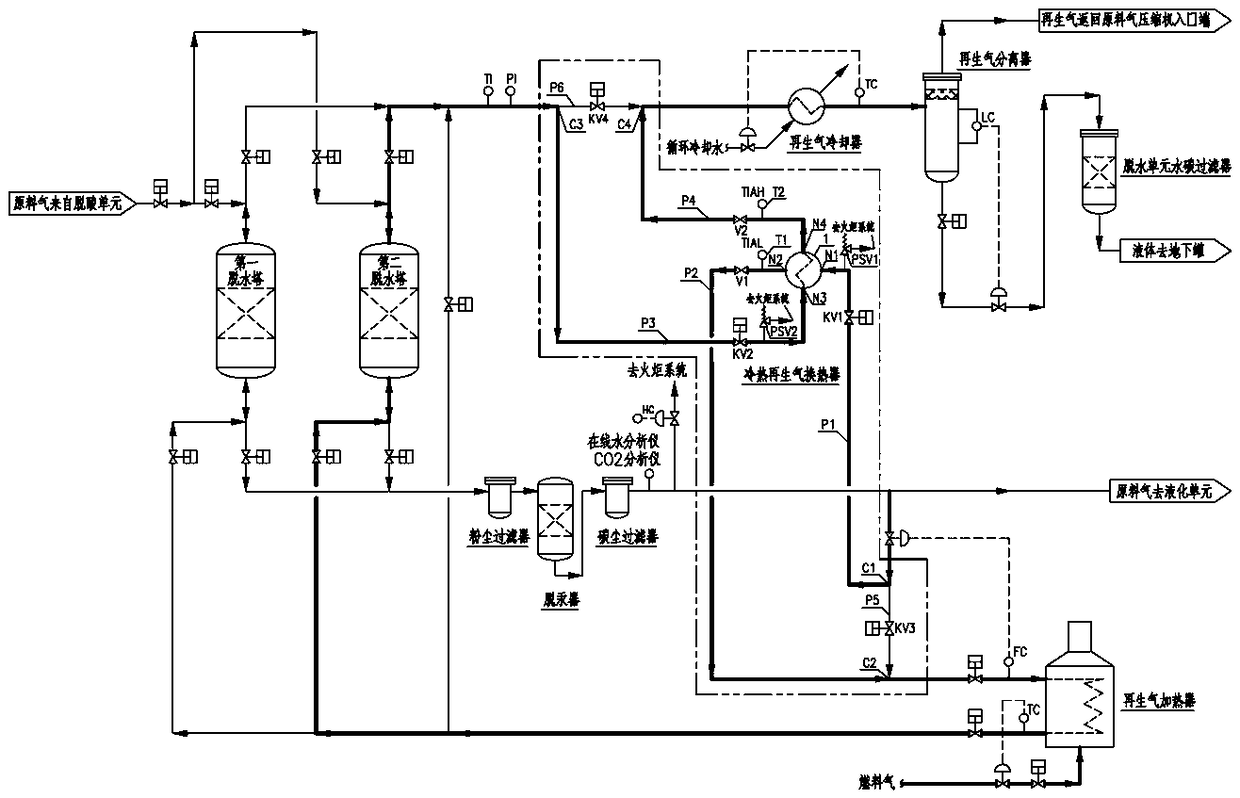

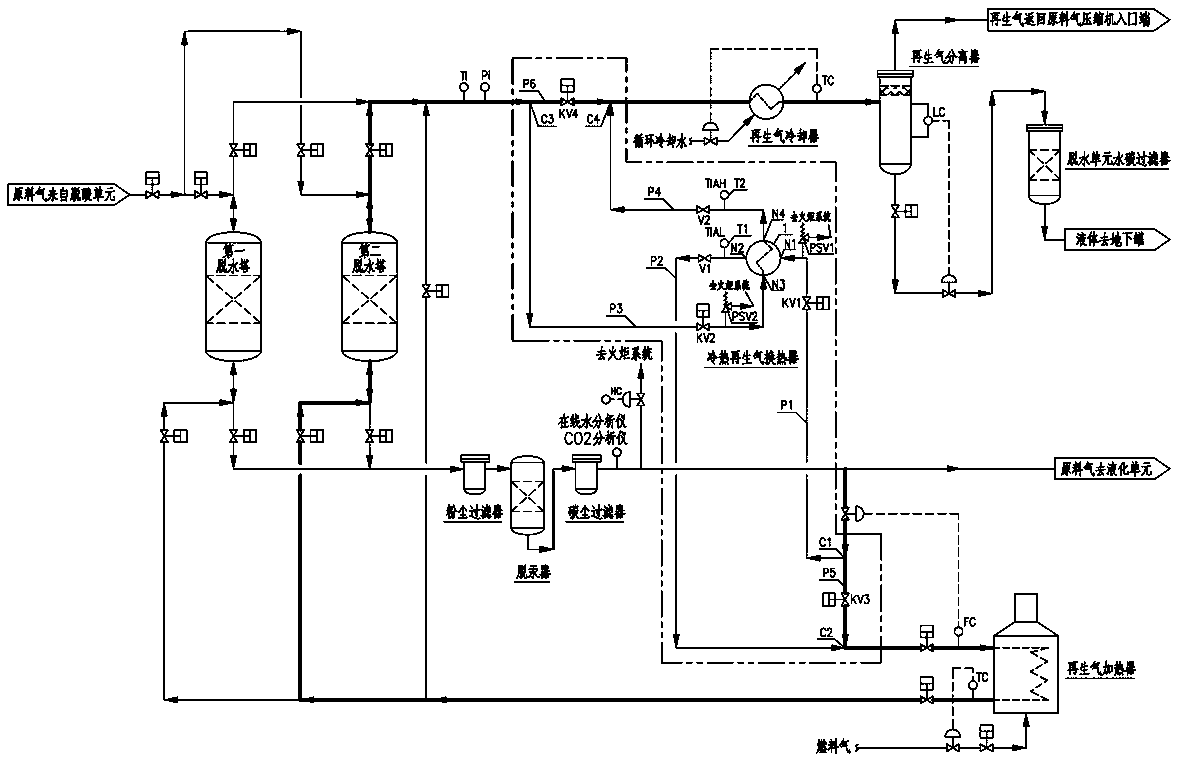

Natural gas dewatering system for using waste heat of molecular sieve regenerated gas

InactiveCN108822909ARealize waste heat recoveryReduce consumptionGas treatmentGaseous fuelsGas heaterGas cooler

The invention discloses a natural gas dewatering system for using waste heat of molecular sieve regenerated gas. The natural gas dewatering system comprises a first dewatering tower, a second dewatering tower, a dust filter, a mercury removal machine, a carbon dust filter, a regenerated gas heater, a regenerated gas cooler, a regenerated gas separator and a dewatering unit water carbon filter; a cold-hot regenerated gas heat exchange mechanism is additionally arranged and comprises a tube shell type cold-hot regenerated gas heat exchanger (1); hot regenerated gas and cold regenerated gas exchange heat in the cold-hot regenerated gas heat exchanger (1); the hot regenerated gas of a tube pass is cooled, and the cold regenerated gas of a shell pass is heated, so that the waste heat of the hotregenerated gas is recycled. A liquefaction plant with daily natural gas treatment capacity of one million standard m<3> / day is used as an example, the total heat regeneration annual operating time of two dewatering towers is 4,000 hours, and 1,800 MW waste heat can be recycled in one year and is equivalent to 268.28 tce (equivalent value) of standard coal. Through the natural gas dewatering system, the waste heat of the molecular sieve regenerated gas is recycled; the pollution to the environment is reduced; the natural gas dewatering system is energy-saving and environmentally friendly.

Owner:EAST CHINA ENG SCI & TECH

Dual-tower molecular sieve dehydration system for natural gas

InactiveCN106281520ALow recovery temperatureReduce consumptionGaseous fuelsDispersed particle separationMolecular sieveGas heater

The invention discloses a dual-tower molecular sieve dehydration system for natural gas. The dual-tower molecular sieve dehydration system comprises a natural gas dehydration pipeline and a regenerated gas recovering pipeline; a molecular sieve drier is arranged as a joint of the natural gas dehydration pipeline and the regenerated gas recovering pipeline; the regenerated gas recovering pipeline comprises a heat exchanger; the heat exchanger is arranged between a condensation separator and the molecular sieve drier; a regenerated gas inlet end passes through the heat exchanger and then enters a regenerated gas heater; a regenerated gas recovery tank is provided with a H2S content detector; the regenerated gas recovering pipeline is provided with a first valve; two desulphurization pipelines are led out from two ends of the first valve and connected with a desulfurization tower, and the desulphurization pipelines enters from the bottom of the desulfurization tower and extends from the top of the desulfurization tower to the regenerated gas recovering pipeline; and the desulphurization pipelines are provided with a second valve and a third valve. The dual-tower molecular sieve dehydration system provided by the invention aims to overcome the problem that proneness to sulfur enrichment in regenerated gas of a conventional natural gas dehydration system influences the quality of regenerated gas and equipment safety, and improves the efficiency of energy utilization.

Owner:ZHAOQING XINAO GAS

Low-temperature removing method of CO2 in natural gas and natural gas liquefying device adopting method

InactiveCN102636002AImprove economyLess one-time investmentSolidificationLiquefactionNatural gas dehydrationRecuperator

The invention provides a low-temperature removing method of CO2 in natural gas and a natural gas liquefying device adopting the method. The invention relates to a purifying method and a liquefying device of the natural gas, which are used for removing the CO2 in the natural gas and solve the problems that a chemical absorption method for removing the CO2 needs to use a chemical agent so that a common corrosion problem exists. The method comprises the following steps of: compressing the natural gas; dehydrating, drying and pre-cooling the natural gas; freezing the natural gas and freezing the CO2 into a solid state and attaching, so as to remove the natural gas of the CO2. The device comprises a refrigerating circulation system, a natural gas compressor, a natural gas dehydrating and drying tower, a pre-cooling heat exchanger and a freezing heat exchanger; an inlet of the natural gas compressor is used as the inlet of the natural gas and an outlet of the natural gas compressor is communicated with the other end of a heat exchange coil pipe in the pre-cooling heat exchanger through the dehydrating and drying tower; and the other end of the heat exchange coil pipe is communicated with one end of a shell side of the freezing heat exchanger and the other end of the shell side of the freezing heat exchanger is used as a discharging end of the liquefied natural gas.

Owner:贾林祥

Air supersonic-velocity condensation and cyclone separation spray pipe

InactiveCN102489081AStrong swirl abilitySwirl enhancement and stabilizationGaseous fuelsDispersed particle separationCycloneOffshore oil and gas

The invention relates to an air supersonic-velocity condensation and cyclone separation spray pipe. The air supersonic-velocity condensation and cyclone separation spray pipe mainly comprises a central body, a cyclone blade, a contraction section and an expansion section, and is mainly applied to air purification, particularly the field of natural gas dehydration and heavy hydrocarbon separation.The cyclone blade is designed by an elliptical blade method, and can effectively strength cyclone; the central body can effectively reduce eddy dissipation, and the curve of the contraction section can guarantee that the velocity of air flow can be stably increased to sound velocity; the contraction section has a gradually expanded structure, and simple linear design in the conventional device isabandoned; and the curve design can avoid the influence of expansion waves, and the spray pipe is good in aerodynamic performance. In the spray pipe, the velocity of the air flow is supersonic velocity, the residence time is very short, hydrate is avoided, and chemical agents and relative recovery systems are not needed to be added. Moreover, the spray pipe has the advantages of supporting unmanned operation, along with no movement component, compact structure, small occupied space and the like, is particularly suitable for development of oil and gas fields of boundary and desert, and offshore oil and gas fields, and has a wide application range.

Owner:文闯

Natural gas dehydration apparatus

InactiveUS7132008B2Reduce moistureReduce pointsUsing liquid separation agentIsotope separationSorbentNatural gas dehydration

A process and corresponding apparatus for dehydrating gas, especially natural gas. The process includes an absorption step and a membrane pervaporation step to regenerate the liquid sorbent.

Owner:MEMBRANE TECH & RES

Method for heat tracing by recovering waste heat of oil-gas dehydrating and purifying device

InactiveCN102606885AThe heat tracing method wraps the heat tracing pipe where it is necessary to prevent freezingPrevent freezingPipeline systemsNatural gas dehydrationEngineering

The invention relates to a method for preventing freezing of oil-gas pipelines in sewage discharge or carrying with much water in winter, which includes: recovering heat discharged from a vent of an air compressor in a refrigerating unit on an oil-gas dehydrating and heavy-hydrocarbon removing device by a stainless steel plate type heat exchanger, and heating circulating water in a heat tracing copper pipe to prevent freezing of the pipelines in winter by heat tracing. In the method for heat tracing by recovering the waste heat of the air compressor of the refrigerating unit, procedures and equipment are simple, additional refrigerating equipment is omitted, investment is low, energy is saved, consumption is reduced, and freezing prevention is effective. Besides, by the method, the problems of fires, explosion and the like caused by short circuit due to the fact that a heat tracing belt is aged and damaged in the conventional electric heat tracing manner can be effectively solved, and excellent freezing prevention effect is achieved.

Owner:ANJI JIANGNAN REFRIGERATION ELECTRICAL APPLIANCE

System and method for natural gas dehydration

InactiveUS20150128802A1Resists and prevents releaseMaintain temperatureLiquid degasificationUsing liquid separation agentCombustorReboiler

A natural gas dehydration system and method includes a contactor, a flash tank, and a still interconnected by a desiccant circulation system. A reboiler is coupled to the still and the flash tank to burn the flash gas from the flash tank and heat the desiccant. A secondary burner is associated with a vent stack of the reboiler to burn the flash gas from the flash tank when not firing the reboiler.

Owner:MONEYHUN EQUIP SALES & SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com