Low flow resistance supersonic speed gas purification and separation device

A gas purification and separation device technology, applied in separation methods, gas fuel, and dispersed particle separation, etc., can solve problems such as salt crystallization blockage of triethylene glycol circulation pipeline, large loss of triethylene glycol, influence of triethylene glycol flow, etc. , to achieve the effect of saving raw material cost, good separation effect and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

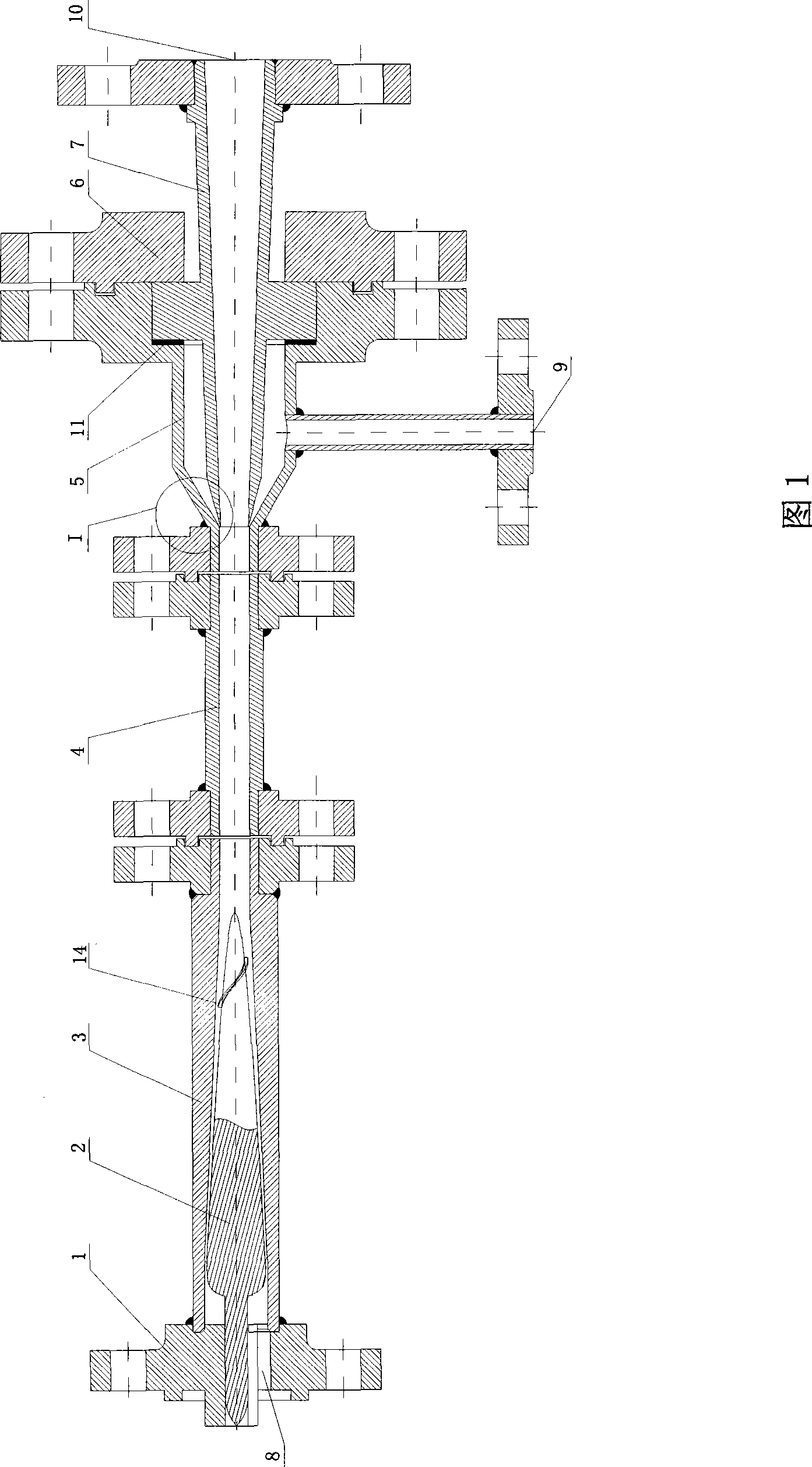

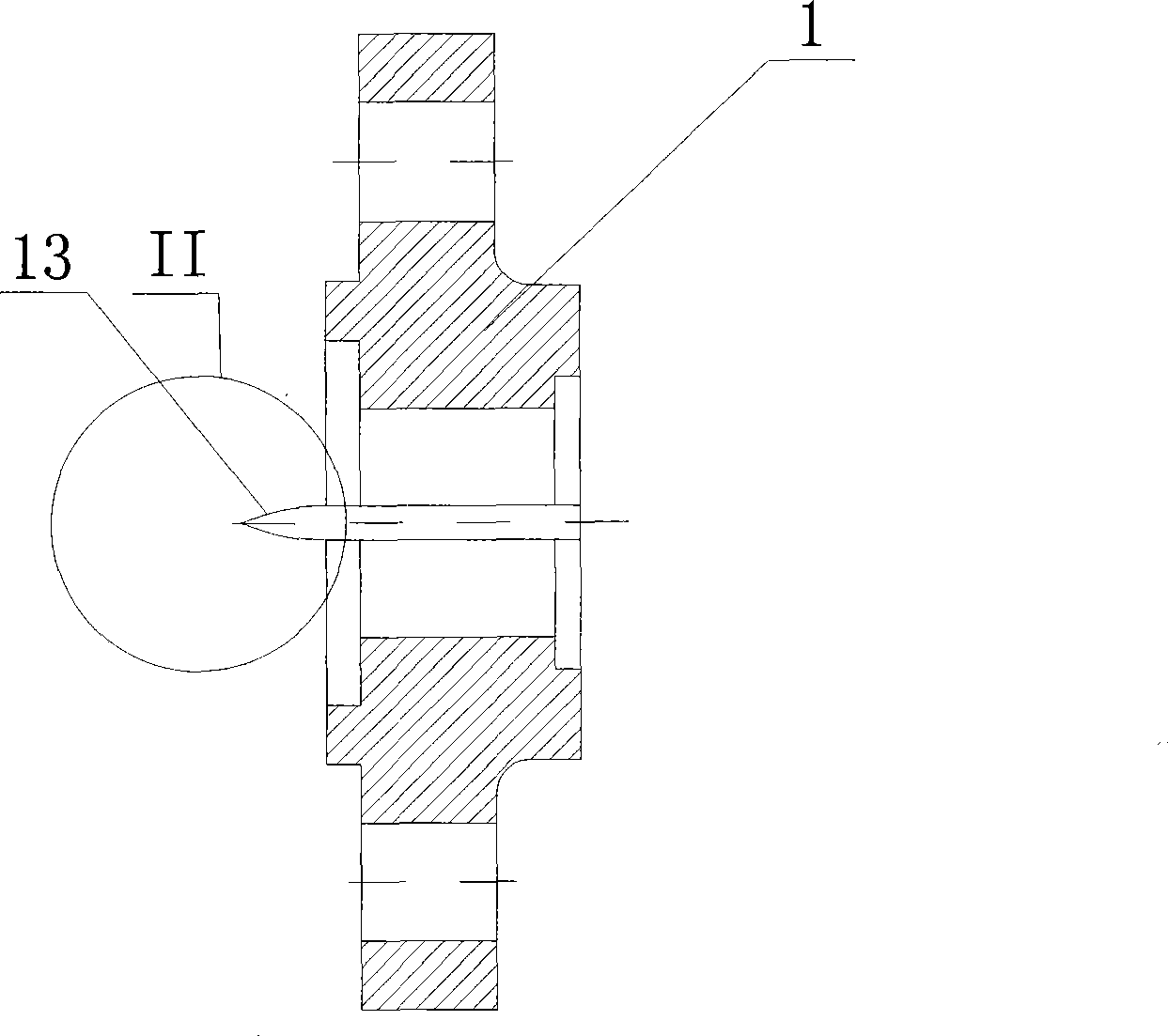

[0044] Example 1 is as Figure 5 The application of the low-resistance supersonic gas purification separation device shown. When the gas to be input is natural gas, the gas first passes through the condenser 16 to reduce the temperature of the gas entering the low-resistance supersonic gas purification and separation device, and then passes through the gas-liquid separator 17 to initially separate the liquid produced by condensation in the gas, Afterwards, through the device of the present invention, the liquid outlet 9 of the device is connected to the liquid-liquid separator 18, in order to carry out secondary separation to the separated liquid and heavy alkanes, and the gas after the purification and separation passes through the dry gas of the diffuser tube 7 Exit 10 discharges. When the present invention is implemented, when there are specific requirements on the outlet gas pressure of the device, conventional methods can be used to adjust the back pressure of the dry ga...

example 2

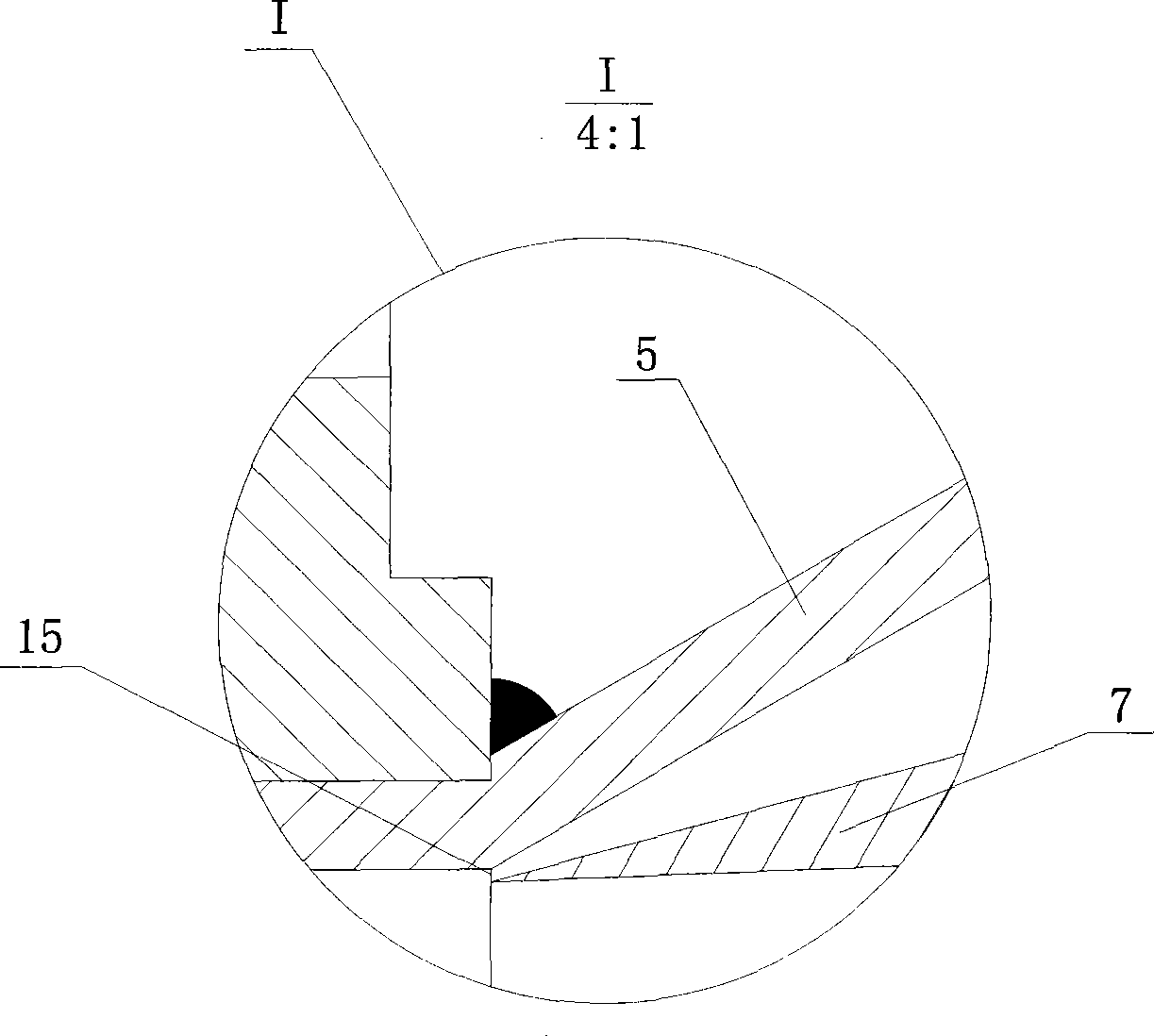

[0045] Example 2: Under the condition that other conditions remain unchanged, the structural form of the swirler 14 can be changed. Different swirl vane arrangement positions, heights, lengths, degrees of rotation, and numbers will produce different centrifugal accelerations, and at the same time will have different pressure loss. Generally speaking, the longer the length of the blade arrangement, the greater the degree of rotation, and the greater the number, the greater the centrifugal acceleration will be, and the pressure loss will increase; on the contrary, the smaller the centrifugal acceleration will be, and the pressure loss will be reduced. In the implementation of the above system, multiple low flow resistance gas purification and separation devices can be arranged in parallel according to the needs, and a single or multiple cyclones can be selected to work according to the actual working conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com