Patents

Literature

144results about How to "Unmanned operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

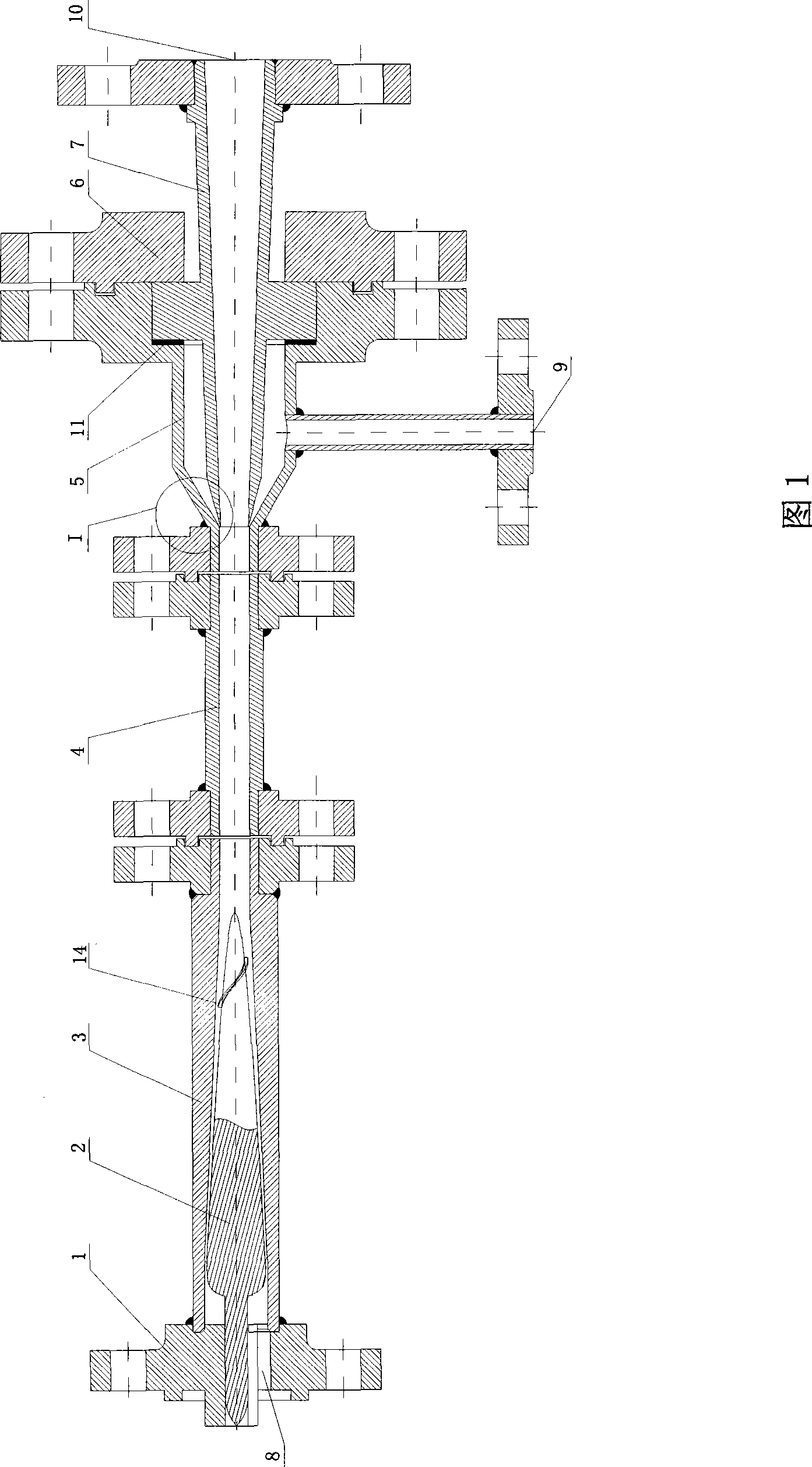

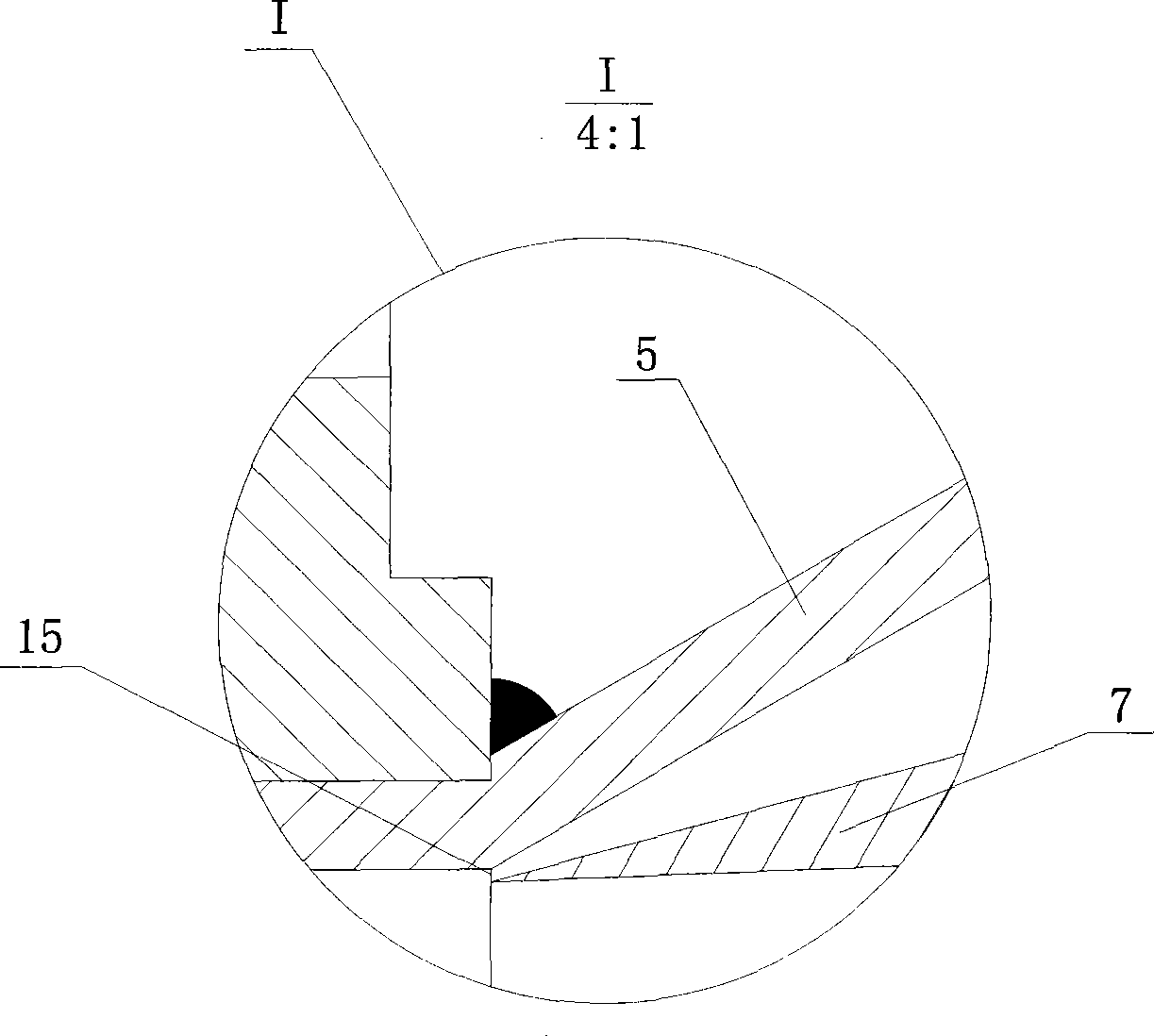

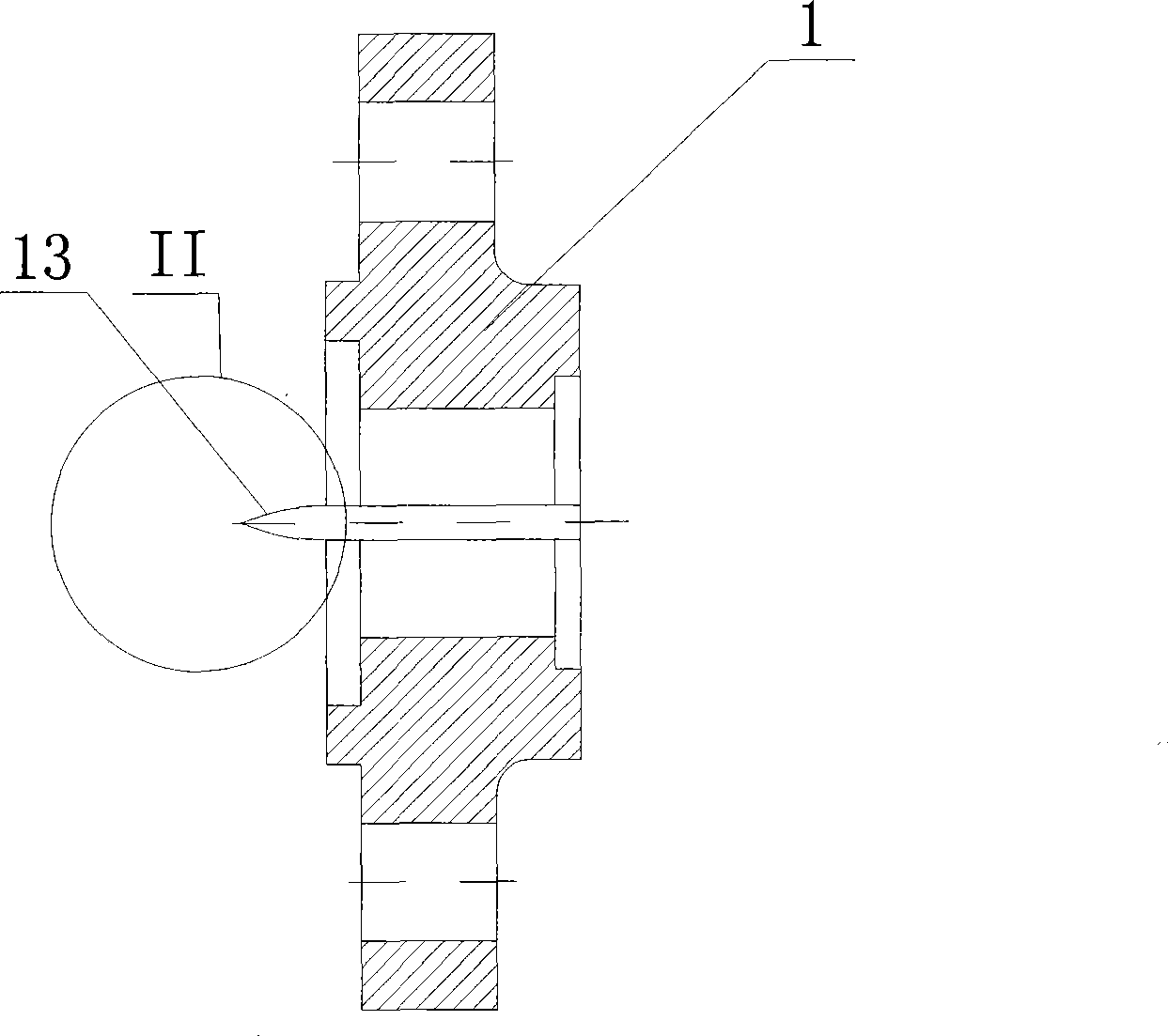

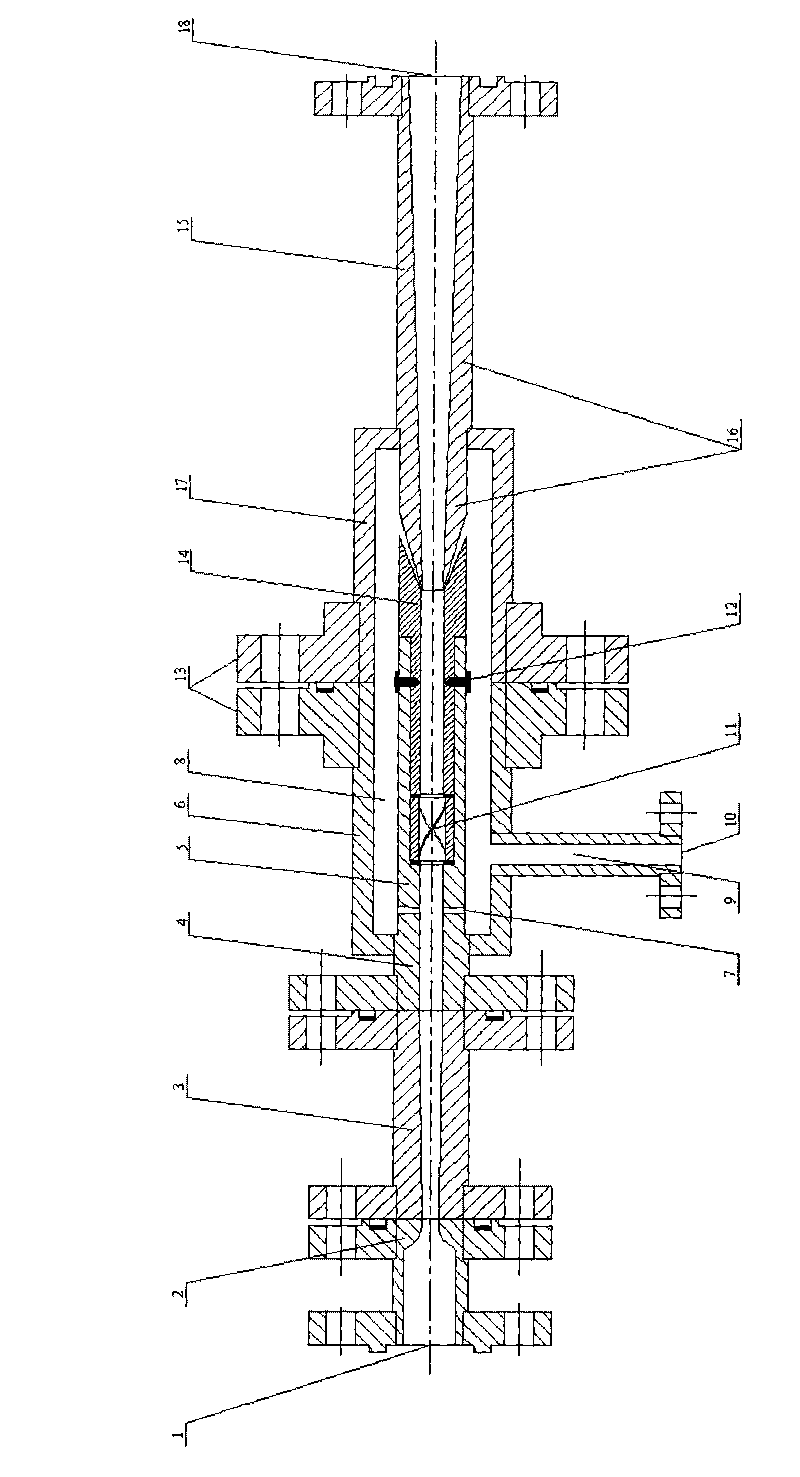

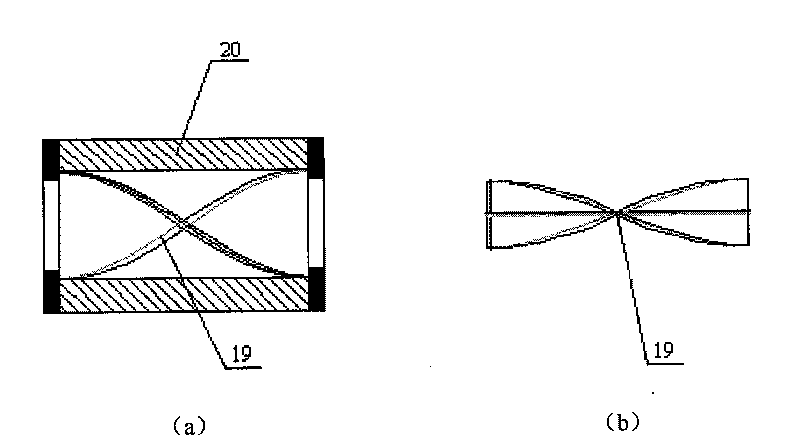

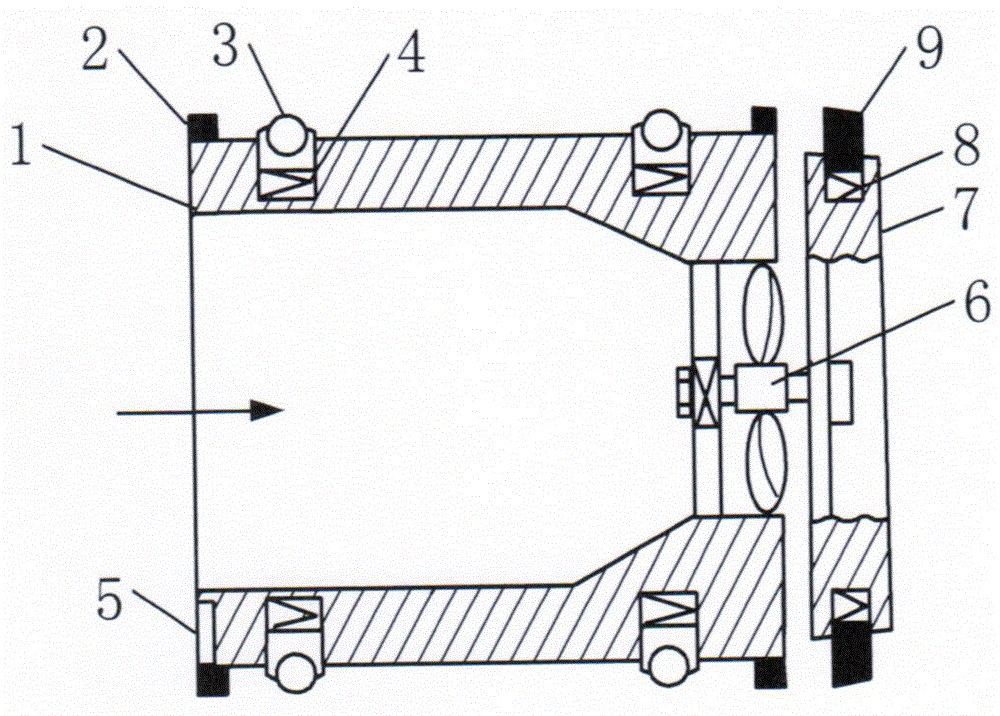

Low flow resistance supersonic speed gas purification and separation device

InactiveCN101380537ASimple structureUnmanned operationGaseous fuelsDispersed particle separationEngineeringSupersonic speed

The invention relates to a low flow resistance supersonic device for purifying and separating gas and is applied to the field of gas separation and purification such as natural gas dehydration, etc. Natural gas enters a laval nozzle by a gas inlet, the temperature and pressure thereof lowers, the speed is increased, then the gas mixture floating at high speed flows through a whirl vane, the swirl with high speed is produced, the swirl with high speed enters a separation pipe, for the temperature becomes low, when the gas is below ground pressure and saturation temperature, the water or partial dew points in the gas are condensed into liquid, for the centrifugal forces born are different, the liquid from the gas by condensation is 'flung' to the wall of the pipe and forms a very thin layer of liquor film, the liquid flows out of the separation pipe through the ring-shaped groove between the separation pipe and a diffuser pipe and flows out from the liquor outlet. Then the dry gas in which water is removed enters the diffuser pipe, and the gas flows out of the separation device by the gas outlet. The device does not comprise motion components and structure is simple; and the circulation transversal area of the laval nozzle in the device is ring-shaped and can be processed easily.

Owner:BEIJING UNIV OF TECH

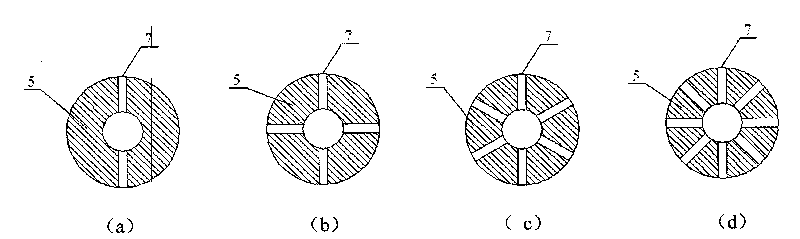

Production process of superfine composite fiber

InactiveCN1399012AHigh degree of automationUnmanned operationMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber bundle

The Haidao superfine composite fiber producing process includes pre-crystallization of Dacron polyester slice and low smelting point polyester slice in a pre-crystallizer, drying in a drying tower, heating extrusion and smelting in a screw extruder to form spinnable melt, measuring in spinning measuring pump, distributing the two kinds of melt for homogeneous mixing, jetting out from the spinning jet, cooling to form, bundling and oiling, passing through spinning channel and winding by winder to form Haidao composite fiber bundle.

Owner:辽阳天利海岛纤维有限公司

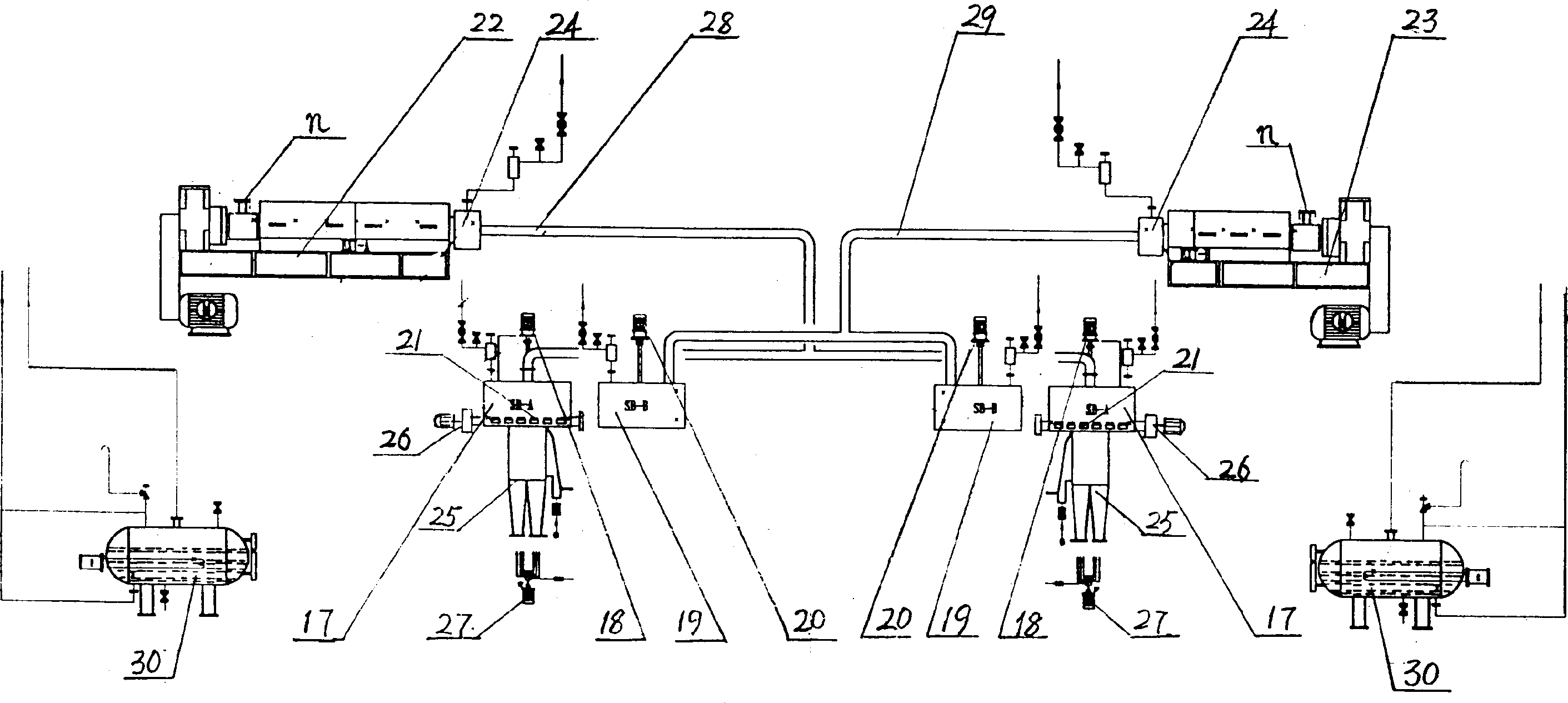

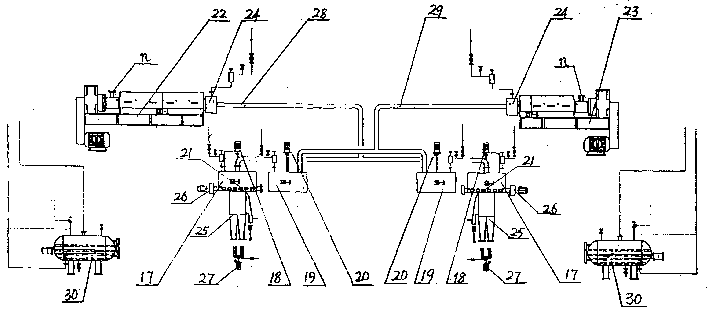

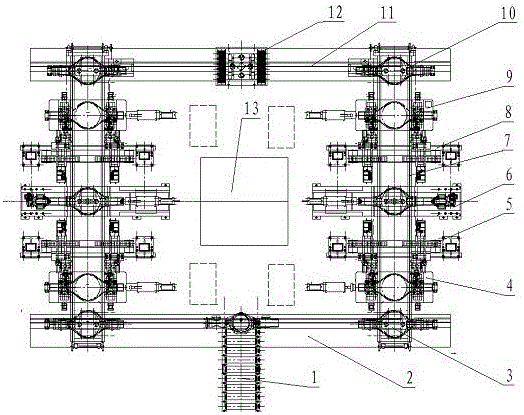

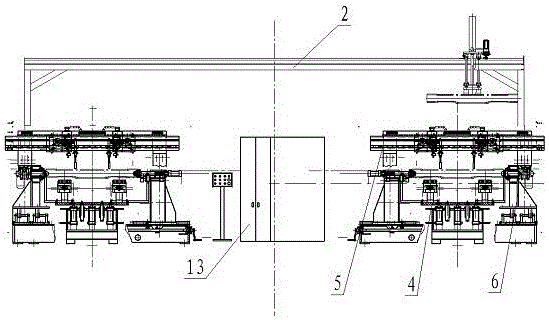

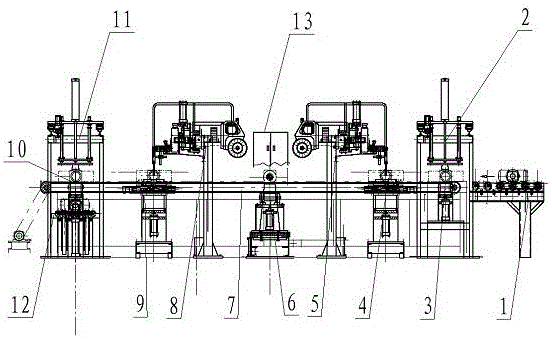

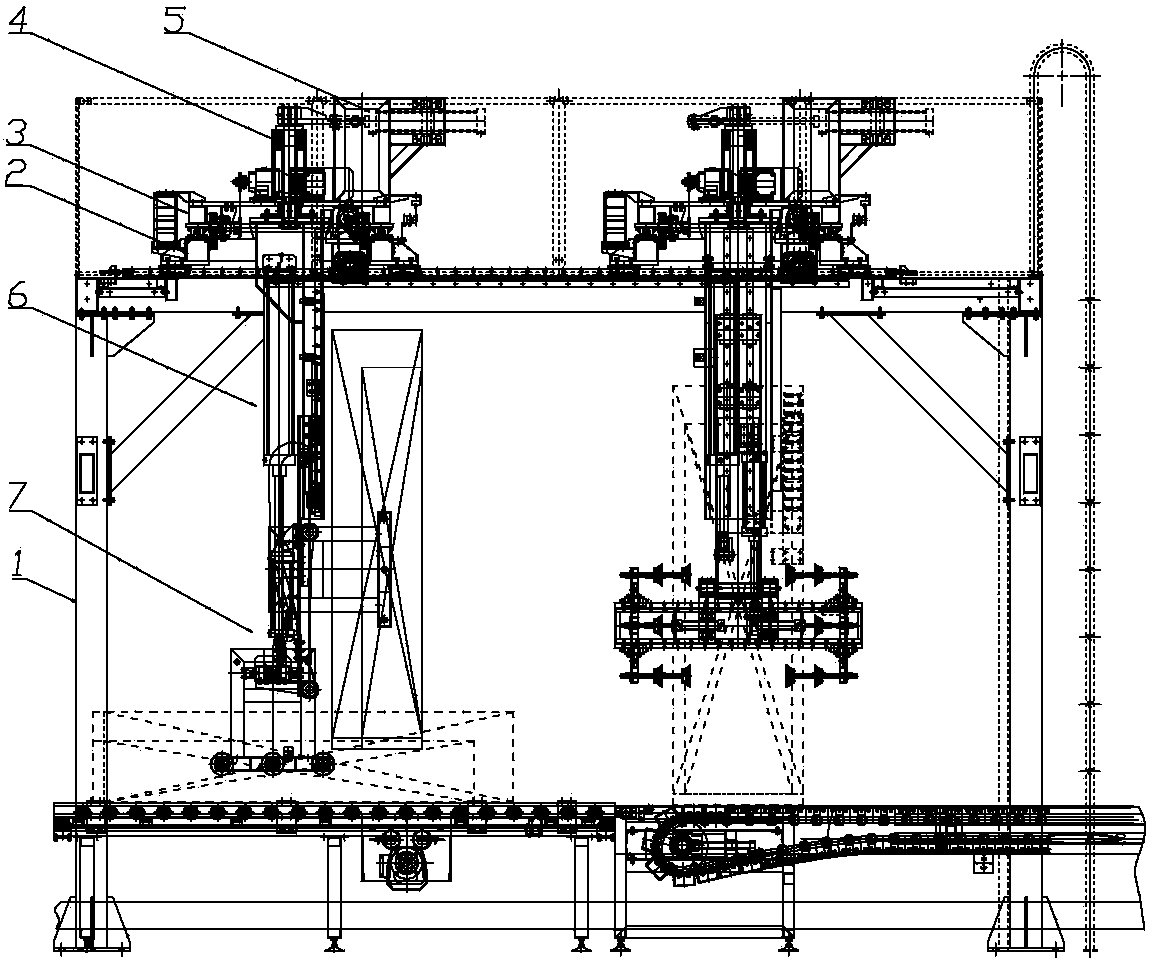

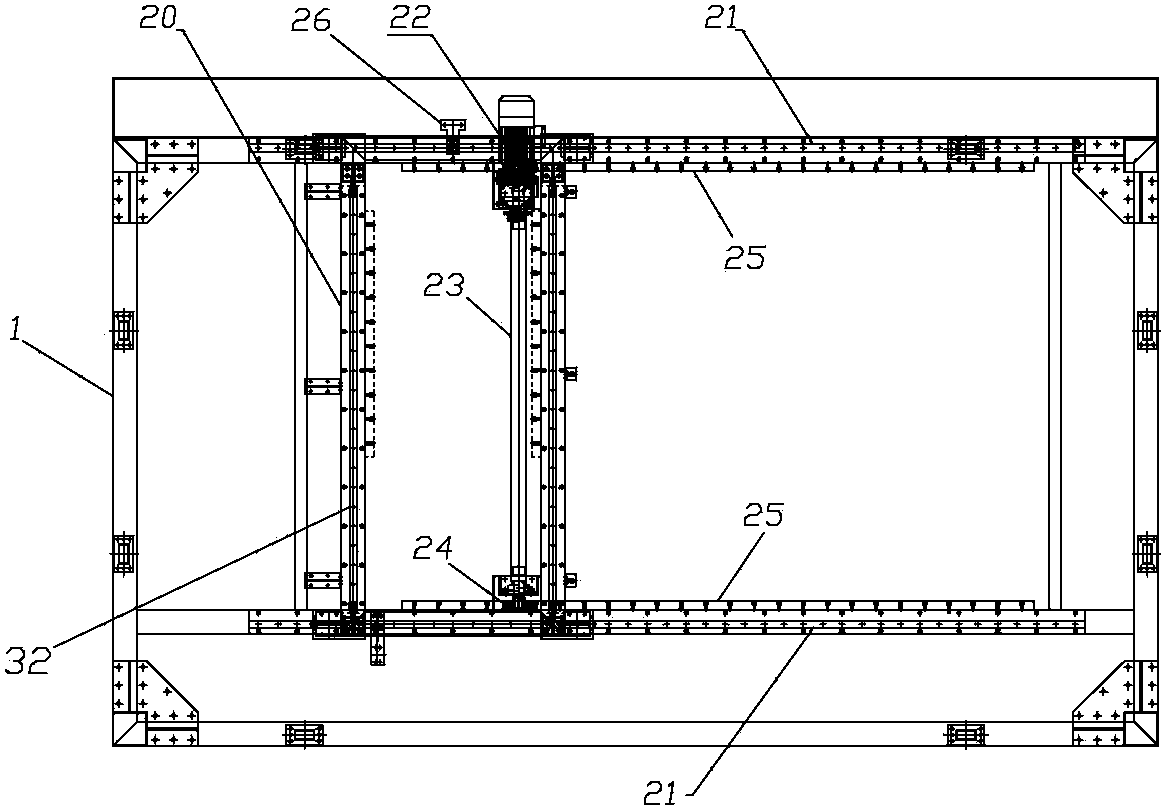

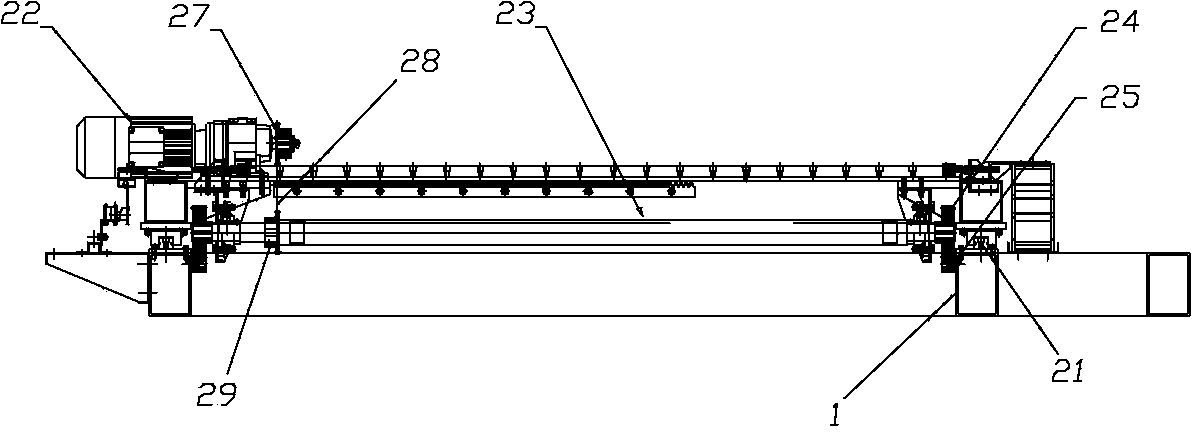

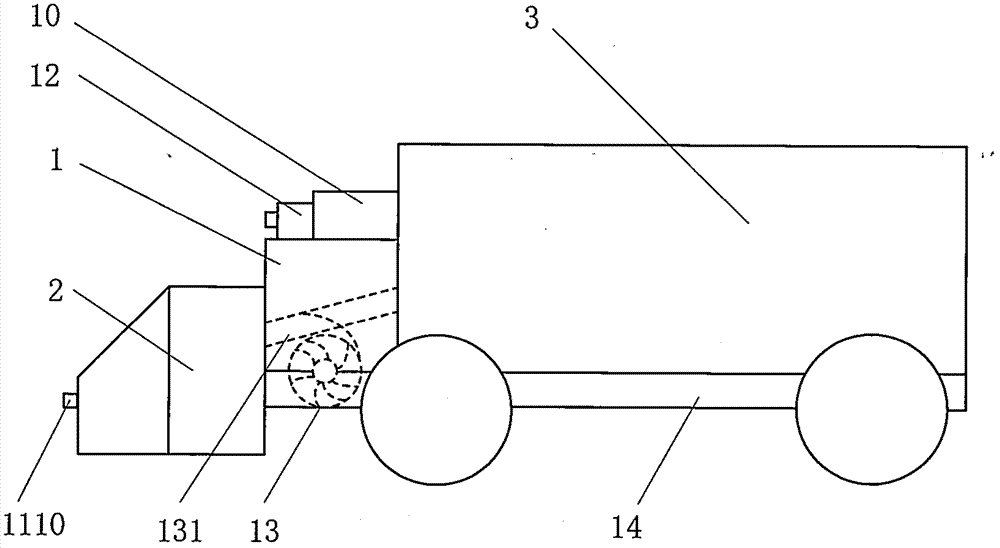

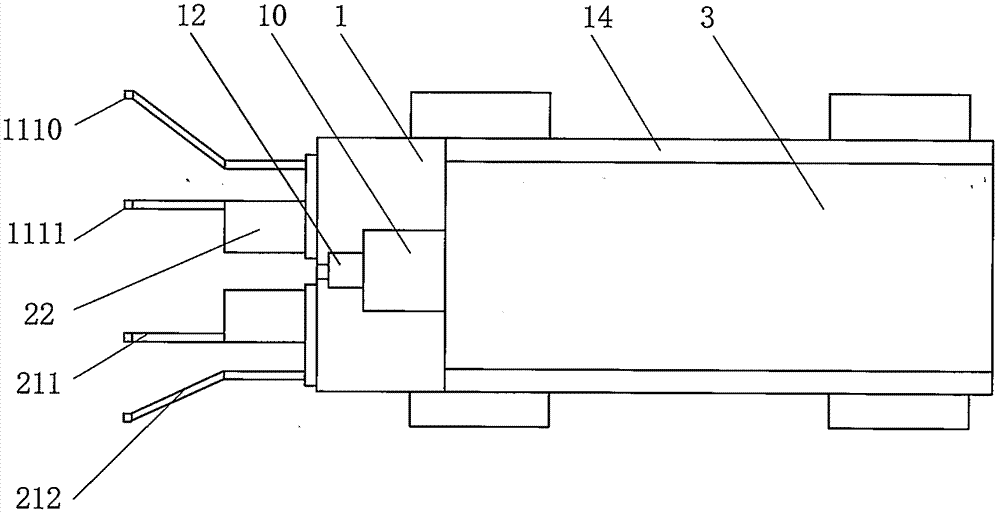

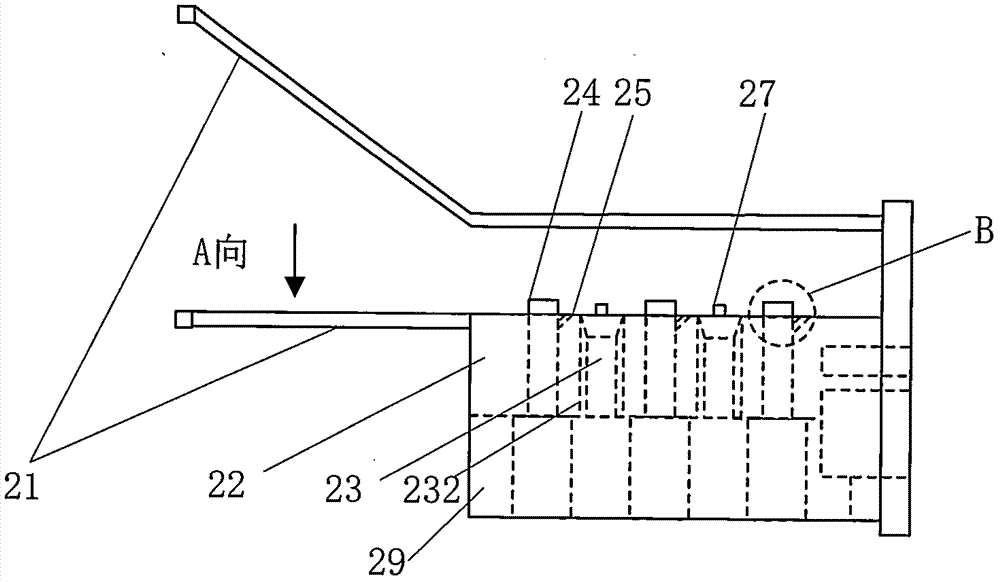

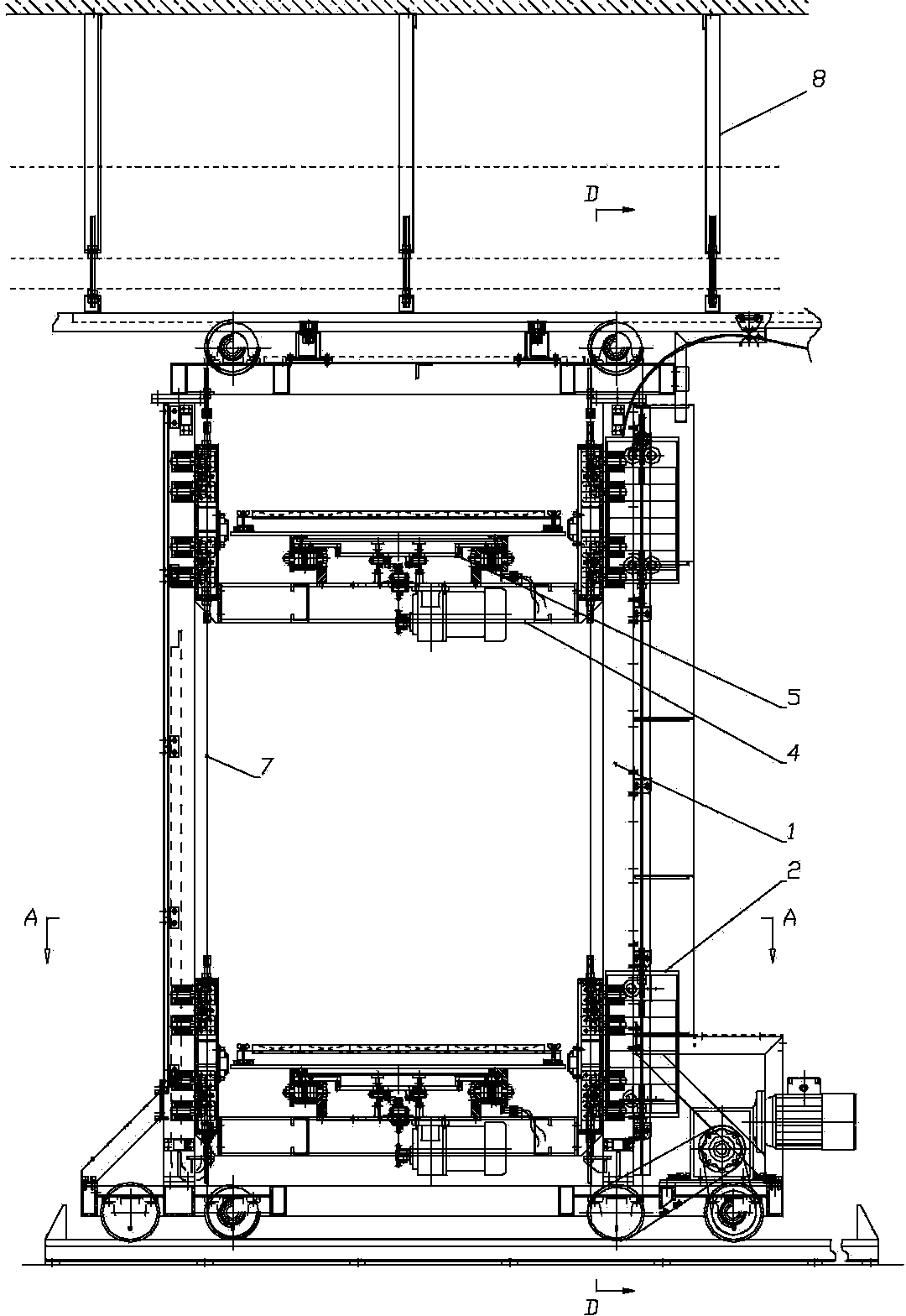

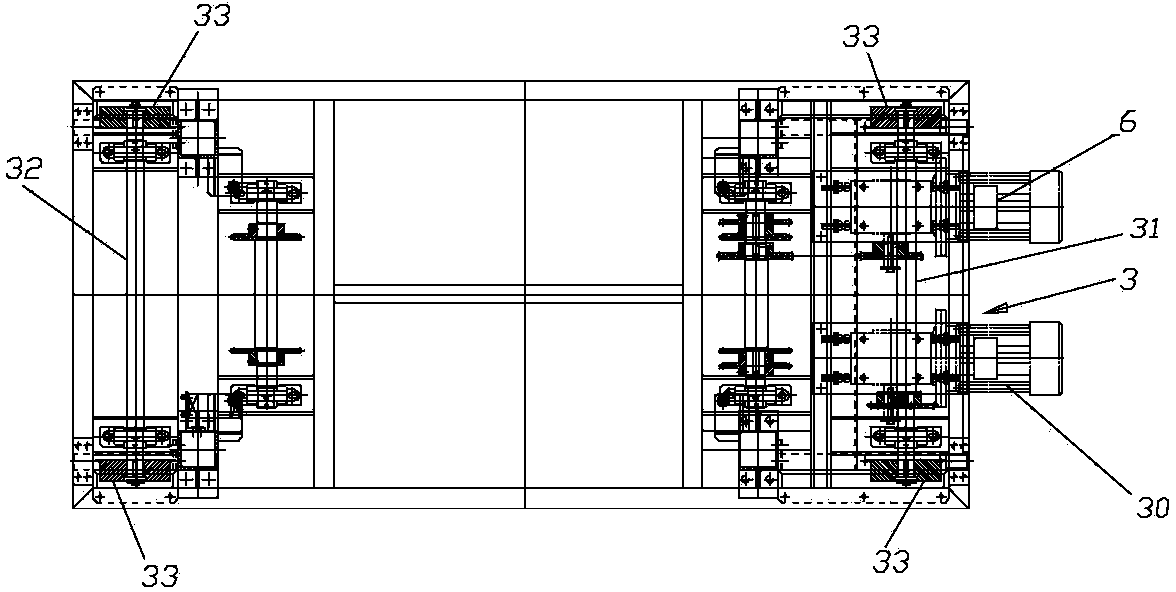

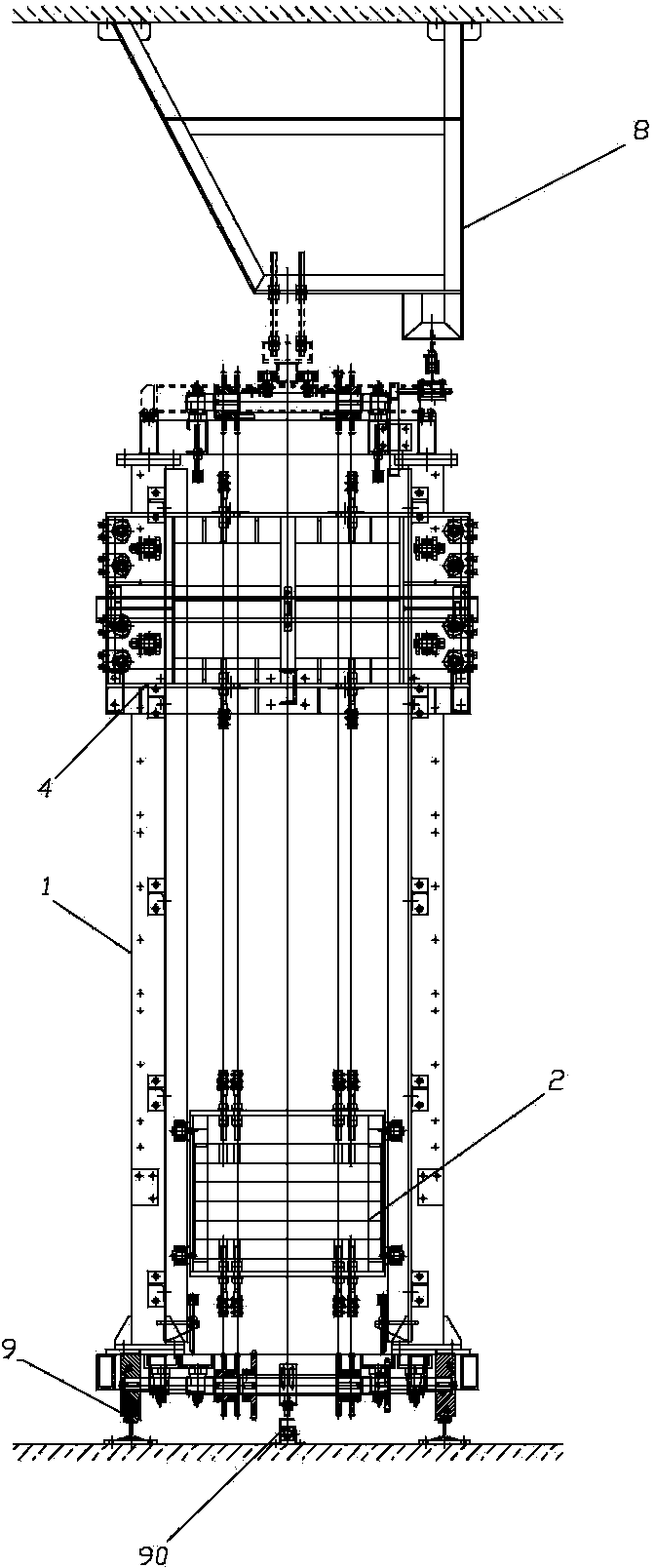

Axle housing body straight slit automatic welding production line and control method thereof

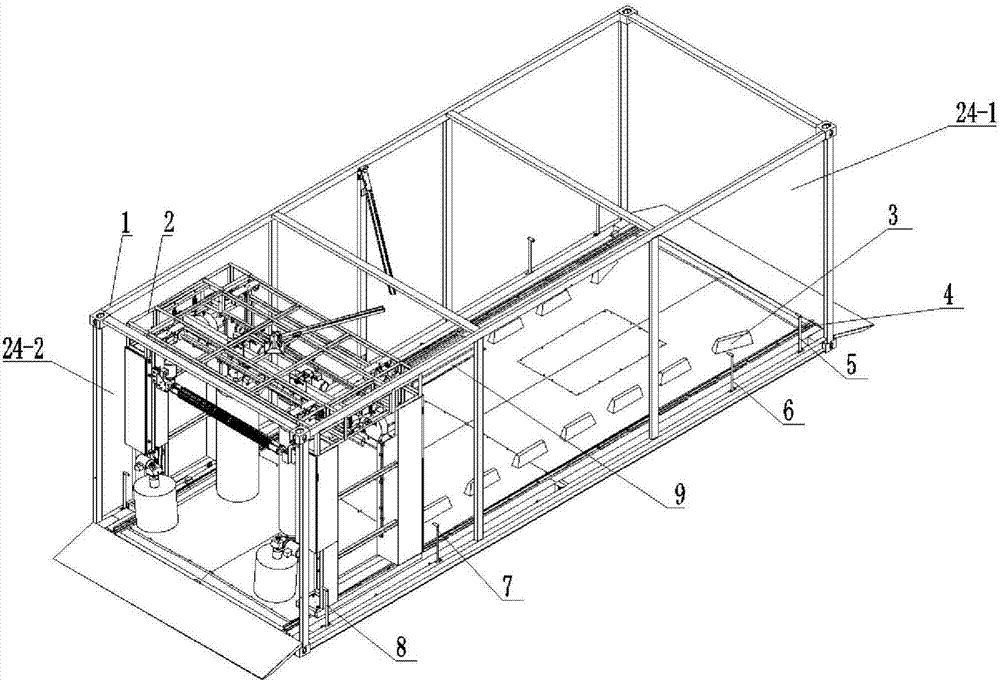

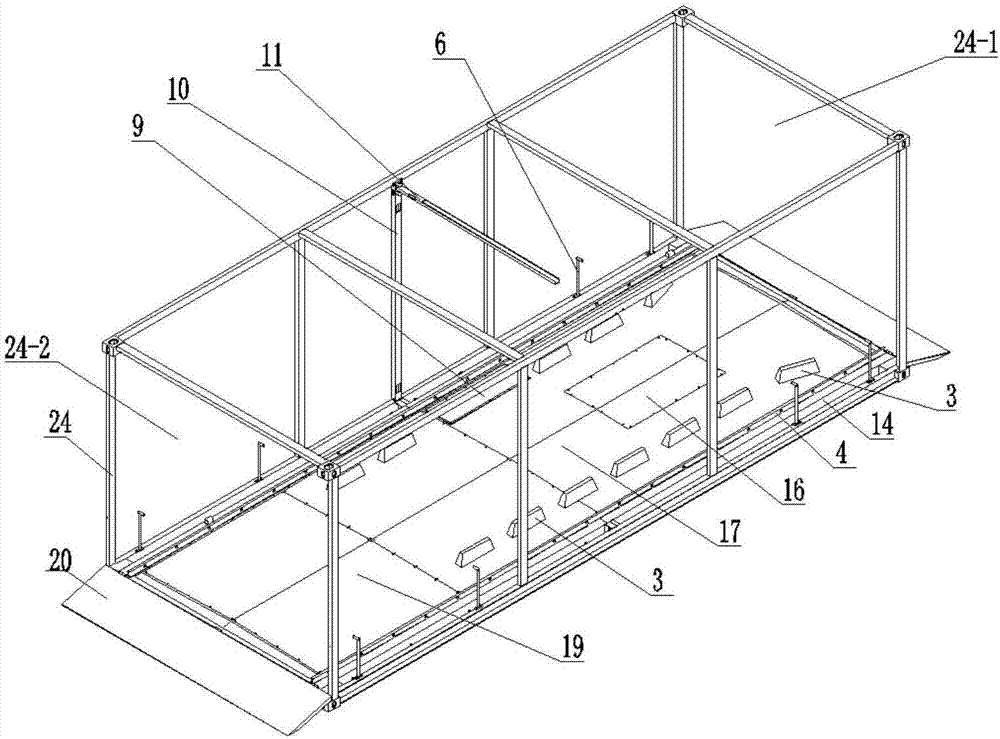

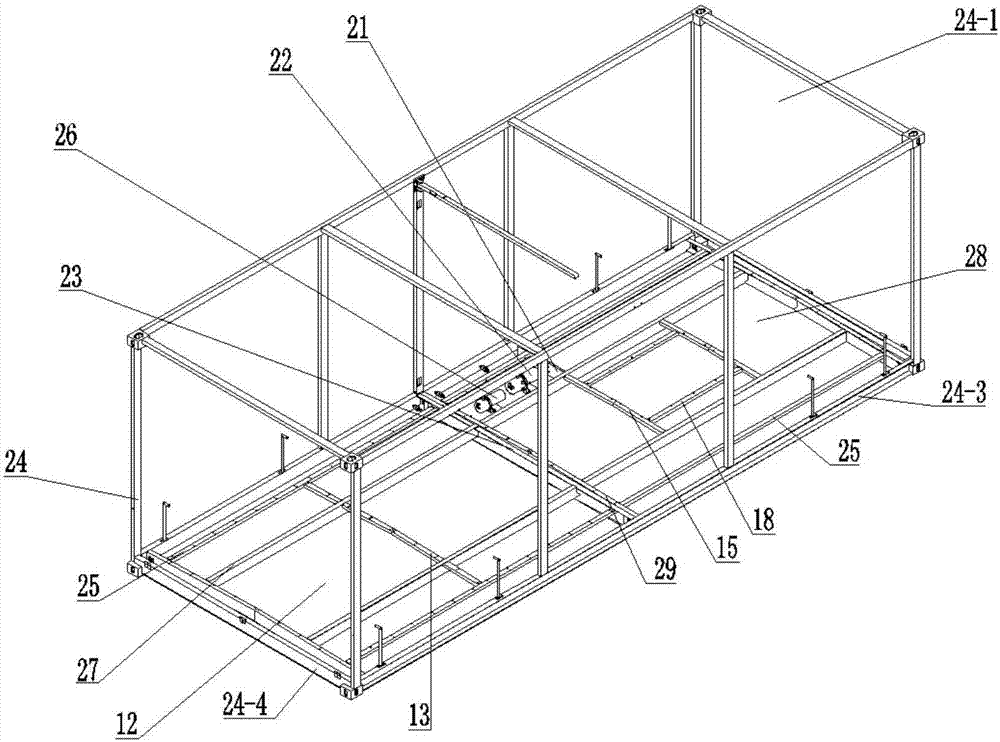

ActiveCN106334889AWith swing functionReliable structural lockingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineElectrical control

The invention discloses an axle housing body straight slit automatic welding production line and a control method thereof. The production line is characterized by being composed of two welding lines, a feeding line and a discharging line. The production control method of the production line comprises the feeding line action, the welding action and the discharging line action. An aerial move loading magnetic attraction type automatic carrying feeding and discharging system is adopted in the whole production line, through automatic turnover, double-face welding of an axle housing straight slit can be completed, functions of welding slit automatic tracking, automatic gun clearing, wire shearing and silicon oil spraying are achieved, an electrical control system is arranged for achieving automatic running, program control and monitoring of actions of a whole production line device, line mixing production of varieties can be achieved, unmanned operation is achieved, the automation degree is high, and the production efficiency is high.

Owner:SHANDONG PENGXIANG AUTOMOBILE

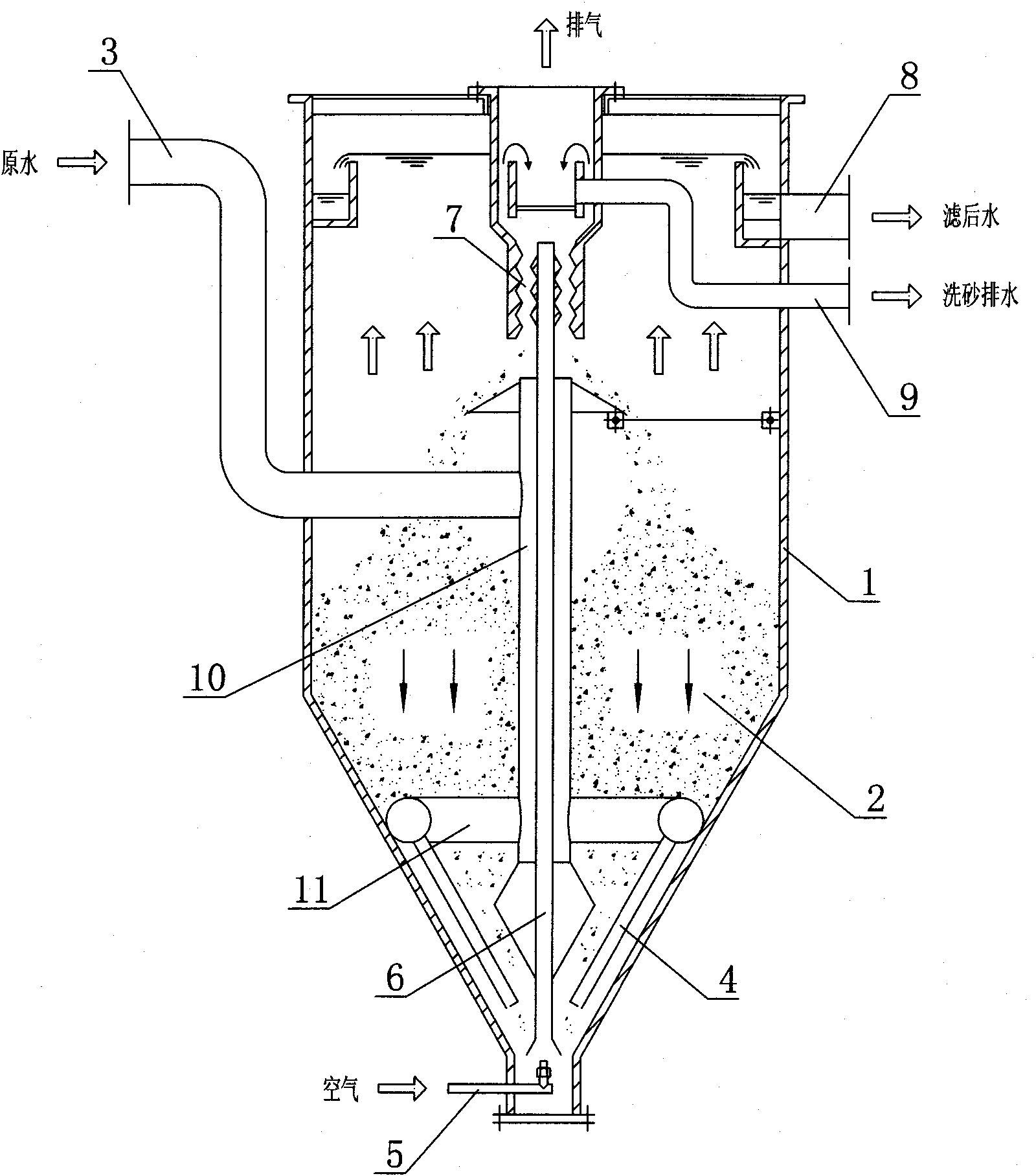

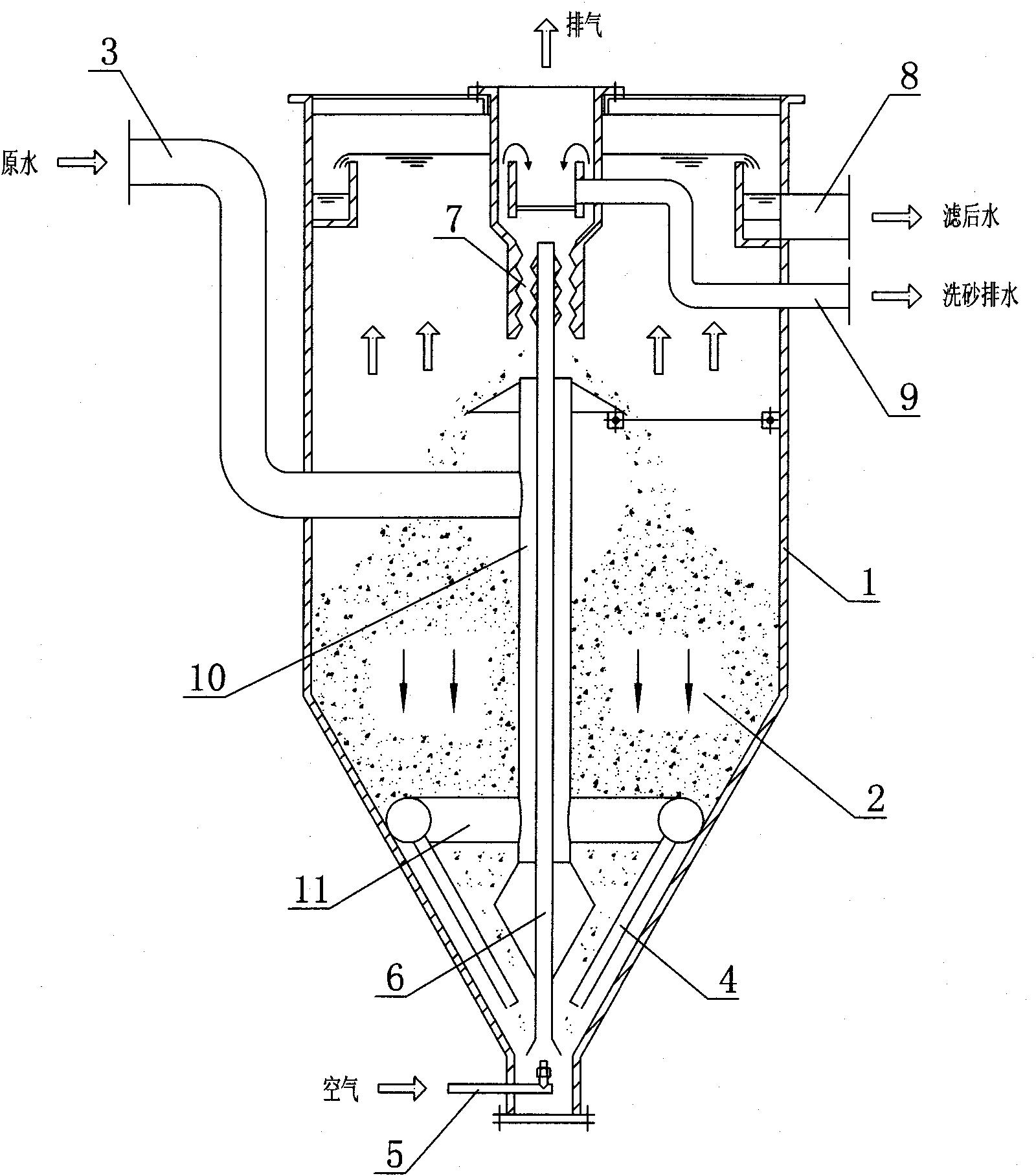

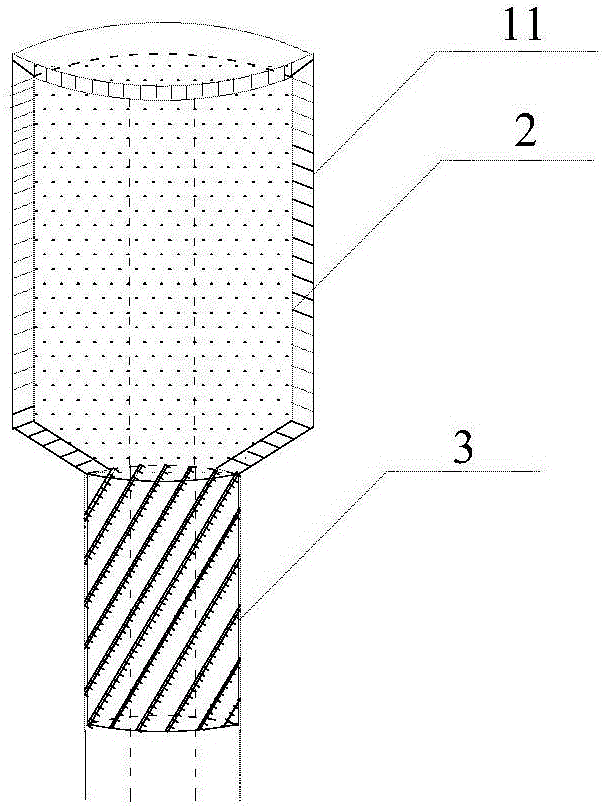

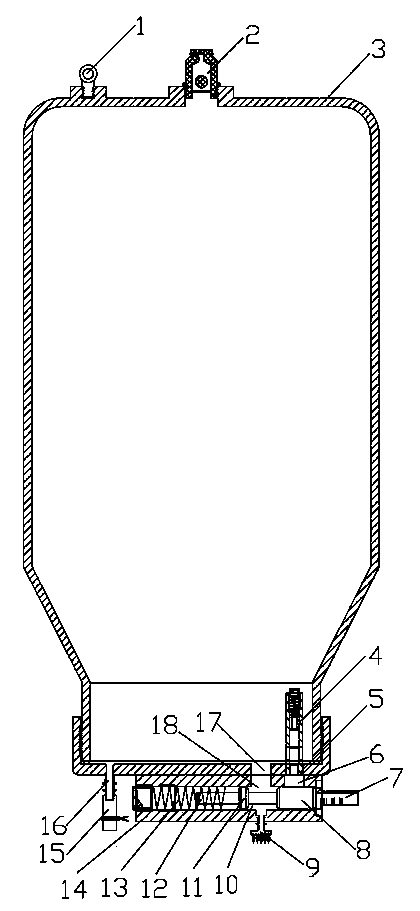

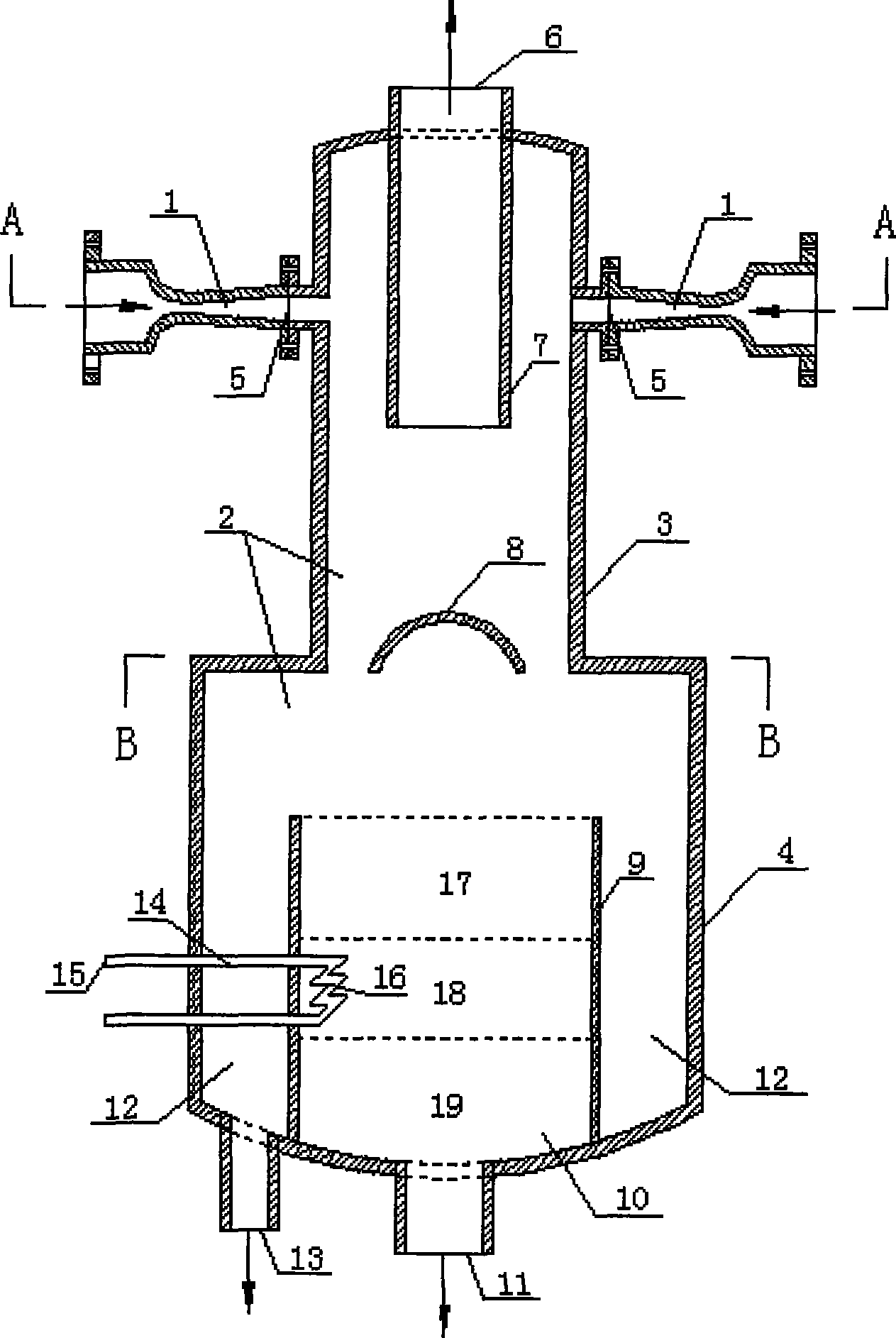

Ripple runner sand washing moving bed sand filter and water treatment process thereof

InactiveCN102210947AReasonable designImprove effluent qualityLoose filtering material filtersGravity filtersSlow sand filterSand filter

The invention relates to a ripple runner sand washing moving bed sand filter and a water treatment process thereof. The ripple runner sand washing moving bed sand filter is characterized in that the upper part of the outer shell of the sand filter is cylindrical, the lower part is obconical, the lower part of the outer shell of the sand filter is provided with filter sand, the outer shell of the sand filter is internally provided with a water distribution assembly which comprises a water inlet pipe, a water distribution branch as well as a water inlet central vertical pipe and a water distribution ring pipe used for connecting the water inlet pipe and the water distribution branch pipe, the outer shell of the sand filter is internally provided with a sand lifting pipe and a ripple runner sand washer, the bottom of the outer shell of the sand filter is provided with an air tube, and the upper part of the outer shell of the sand filter is provided with a water outlet pipe and a sand washing drain pipe. The invention also comprises a water treatment process of the ripple runner sand washing moving bed sand filter. The ripple runner sand washing moving bed sand filter provided by the invention has reasonable design, a sand filter layer at the lower part is obconical, the filtering cross section is gradually increased when water passes through the filtering layer from down to up, and the filtering speed is gradually reduced, thus effluent quality can be improved while the total content of filter sand can be reduced, sand filter material can be cleaned in a circulating way, no-man management can be realized, and water resource can be saved to the utmost extent.

Owner:蔡玉良

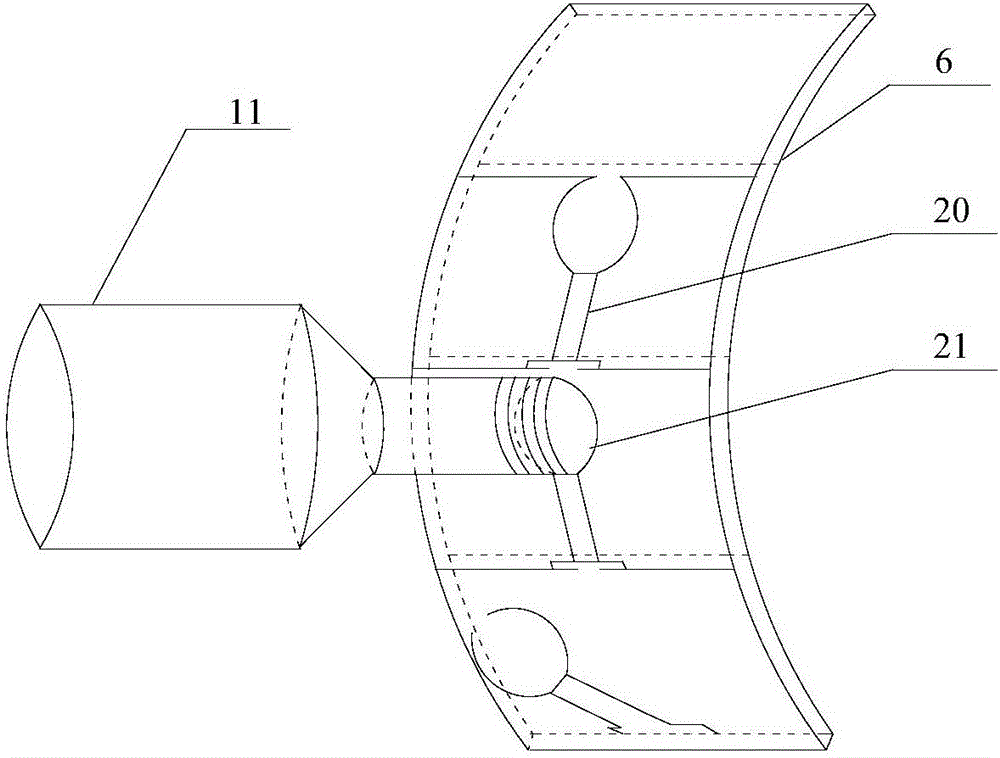

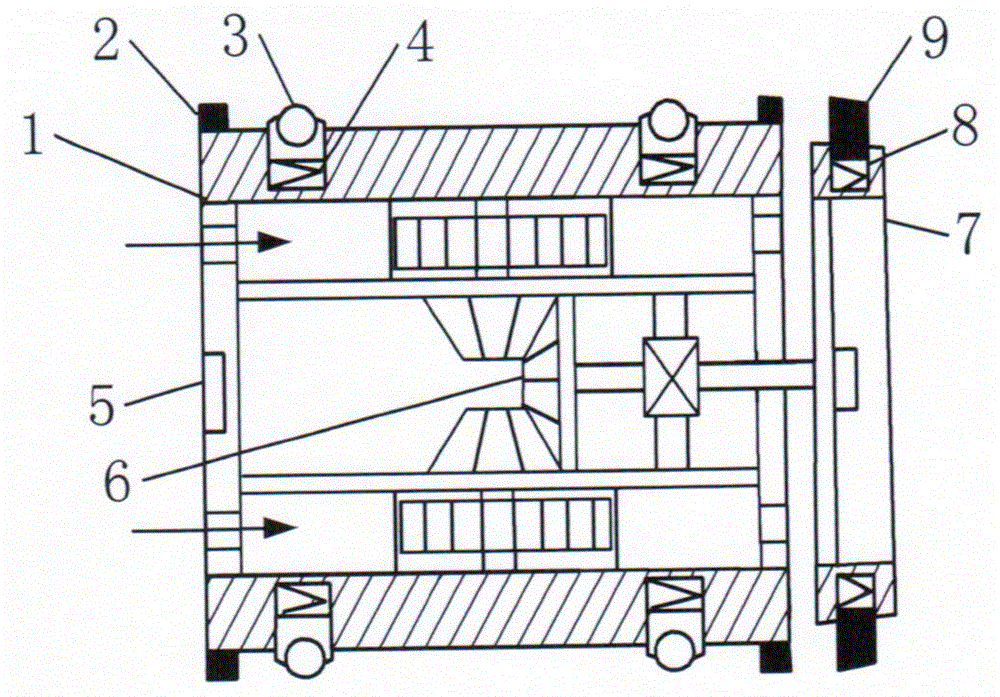

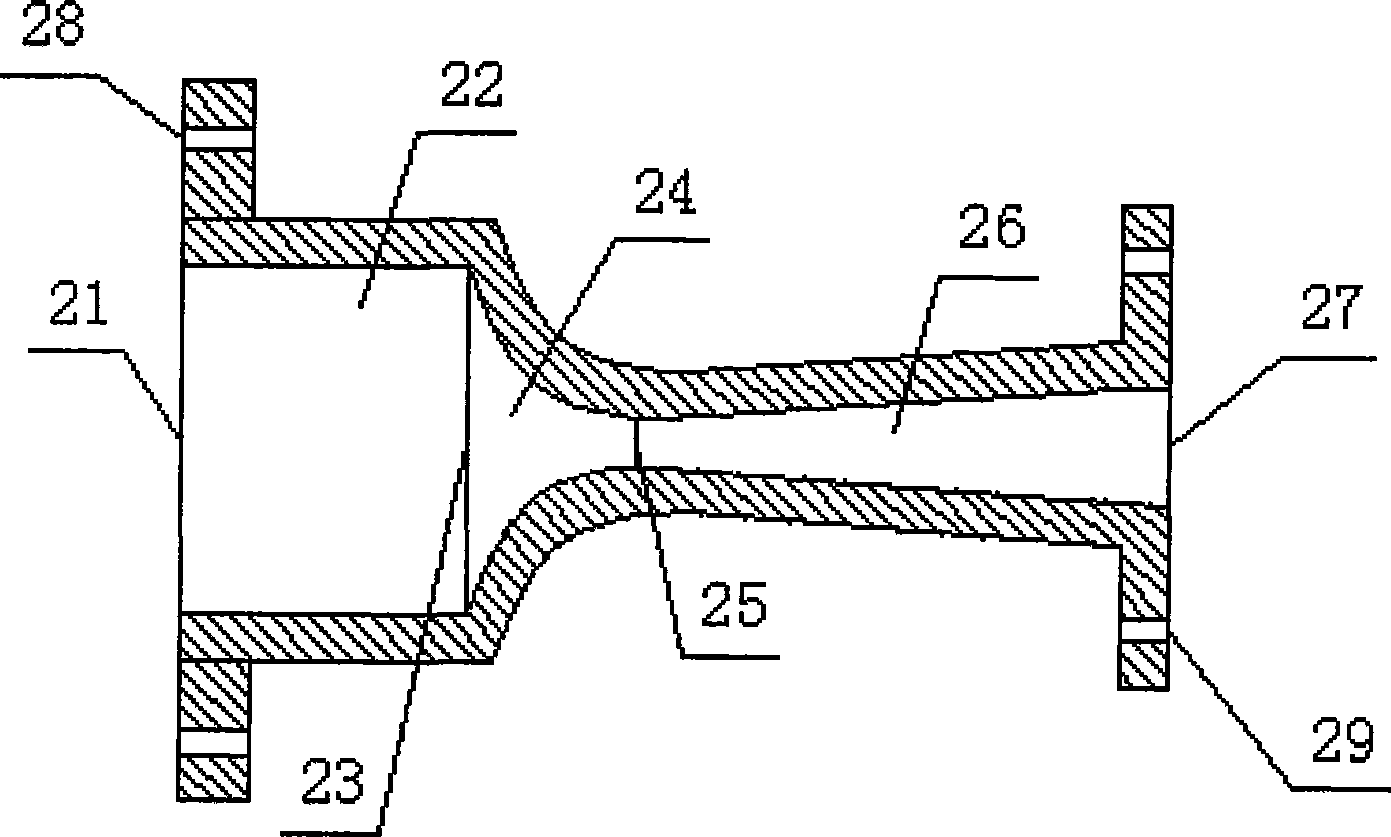

Moisture recycling supersonic speed gas-purification separation device

InactiveCN101690865AEfficient purificationEfficient separationDispersed particle separationFluid removalEngineeringMoisture recycling

The invention relates to a moisture recycling supersonic speed gas-purification separation device for moisture recycling, dehydration, liquid removal, purification and separation; the device comprises a convergent divergent nozzle, a recycling port, a recycling separation cavity, a straight length and a diffuser pipe; the left end of a tapering section of the convergent divergent nozzle is provided with a moisture inlet, the right end thereof is connected with an inner shell body in the straight length by the diverging section of the convergent divergent nozzle, a swirler is arranged in the inner shell body of the straight length, and the right end of the swirler is provided with a swirler fixed sleeve which is hollow, and the right end of the swirler fixed sleeve and the left end of the inner shell of the diffuser pipe form a ring-shaped channel. The recycling separation cavity is formed between the straight length and the diffuser pipe, the recycling port is arranged on the wall surface of the inner shell body of the straight length, so as to effectively lead liquid drops in the remaining recycling gas to be separated out in a swirling way. The device realizes moisture recycling, purification and separation, so as to improve the separation efficiency and environmental-protection benefit; furthermore, the device has the advantages of no chemical pollution, environmental protection and energy saving, compact structure and high circulating and utilizing value.

Owner:SICHUAN ZHONGKEDA OIL&GAS NEW TECH

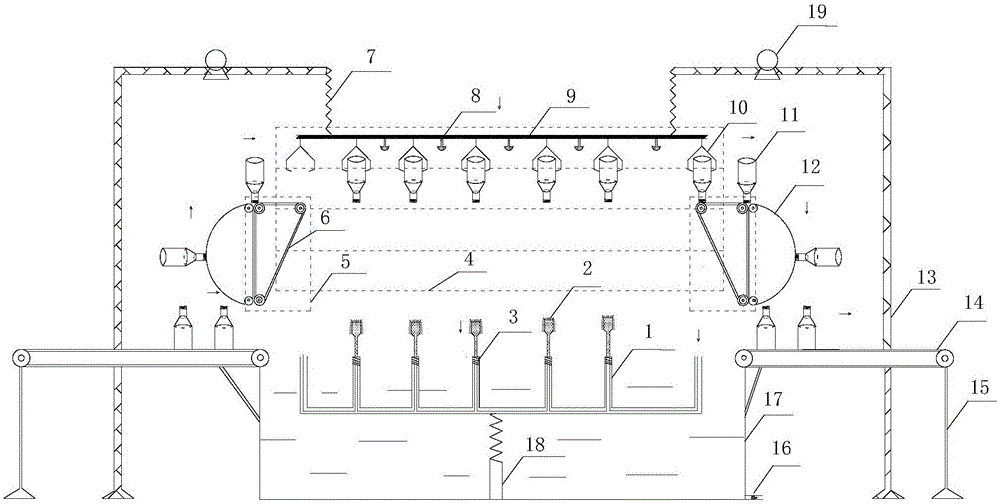

Threaded-mount bottle washing apparatus and threaded-mount bottle washing method

InactiveCN106238426AFunction as a bottle capEasy to cleanHollow article cleaningDrying gas arrangementsBrush deviceBottle

The invention relates to a threaded-mount bottle washing apparatus and a threaded-mount bottle washing method. The threaded-mount bottle washing apparatus comprises a bottle washing mechanism, a bottle conveying mechanism for conveying a to-be-washed threaded-mouth bottle to the bottle washing mechanism, and a bottle receiving mechanism for receiving a washed threaded-mouth bottle. The bottle washing mechanism comprises a first support which is fixed. A horizontal extensible track capable of moving up and down is connected to the first support. A plurality of mechanical grippers for clamping the bottoms of threaded-mouth bottles are arranged at the lower side of the extensible track and are capable of rotating around an own axis thereof and sliding along the extensible track. A water tank is arranged below the extensible track. A hollow pipe capable of moving up and down is arranged in the water tank. A plurality of vertical supporting water inlet pipes communicating with the hollow pipe are arranged on the hollow pipe. A brush device directly facing a mechanical gripper is mounted at the upper end of each supporting water inlet pipe, and comprises a screw-type brush for matching with the mouths of the threaded-mouth bottles and a cylindrical brush. The threaded-mount bottle washing apparatus is simple in structure, and is capable of effectively washing threaded-mouth bottles, and especially capable of sufficiently washing the threaded mouths of the bottles.

Owner:CHANGAN UNIV

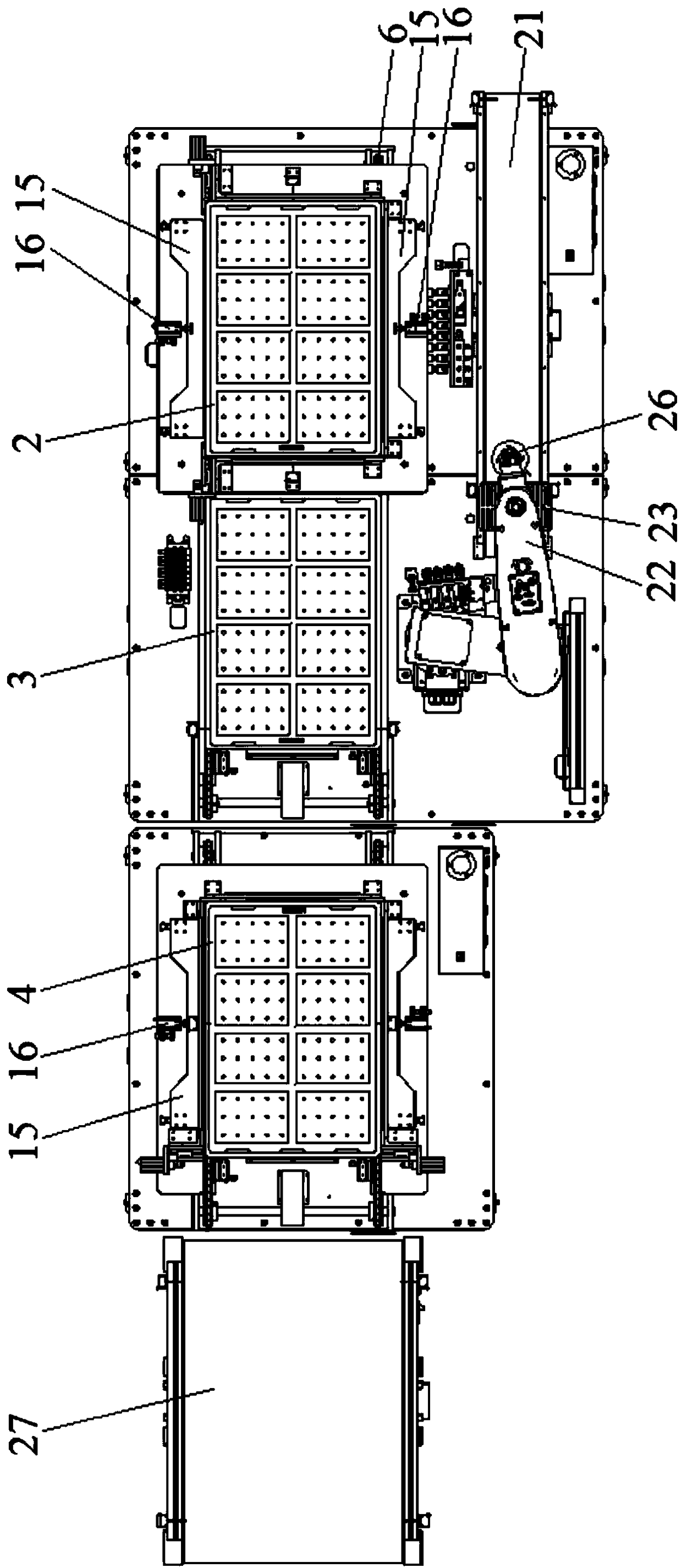

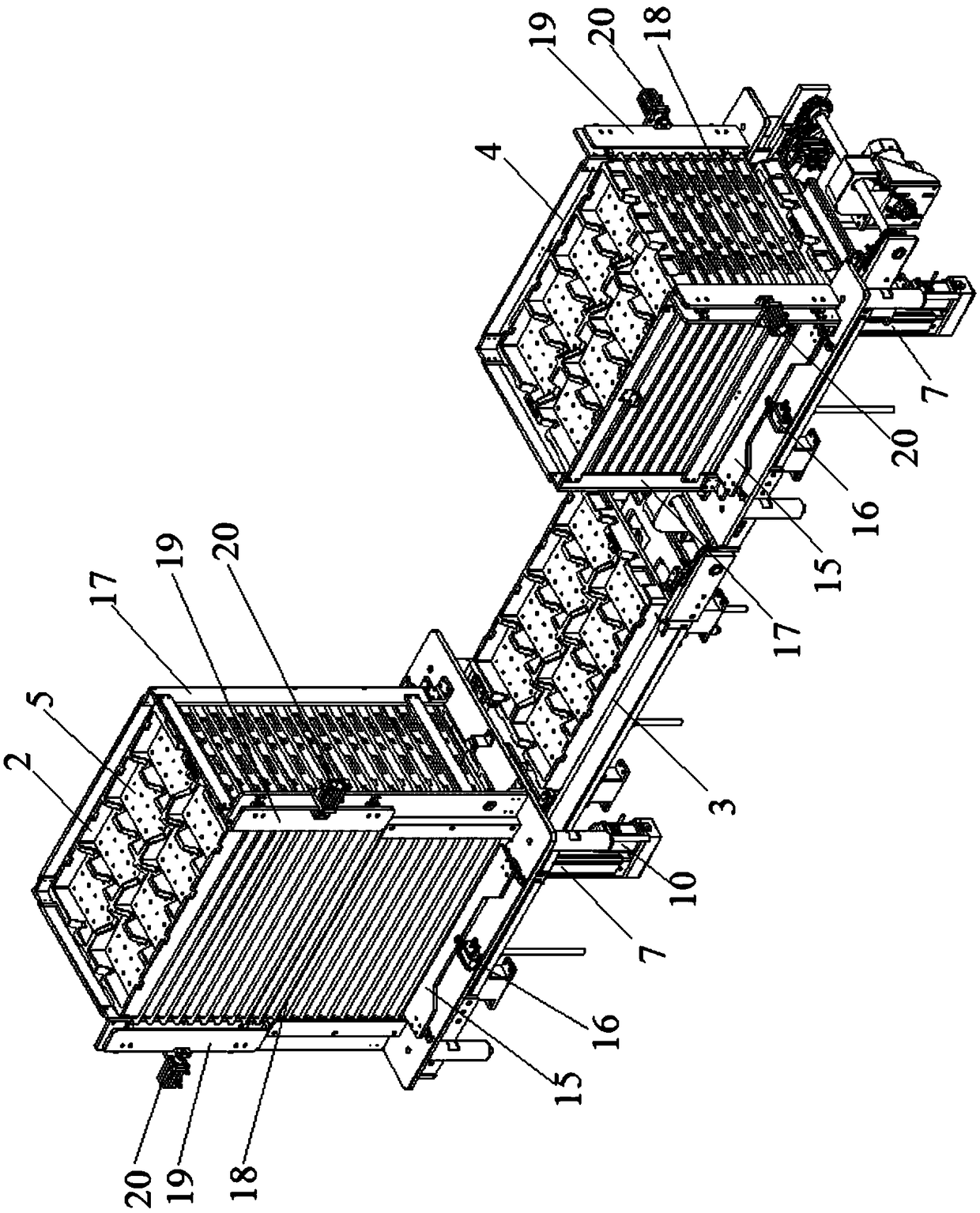

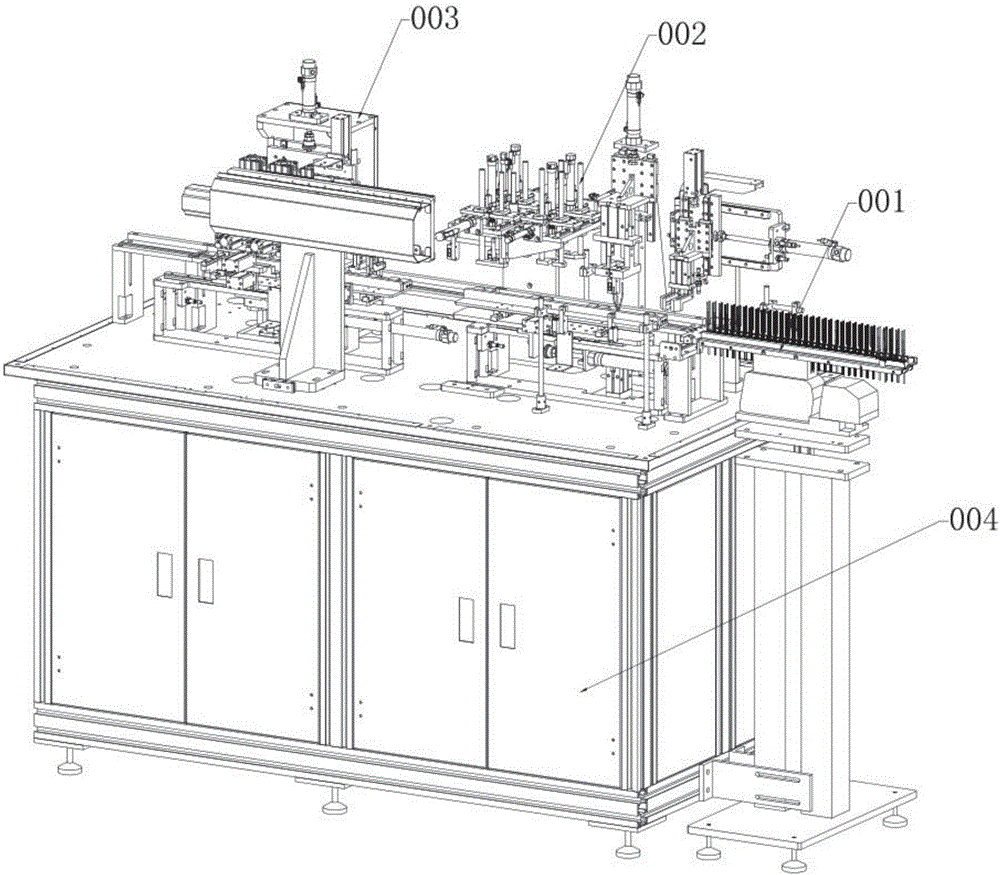

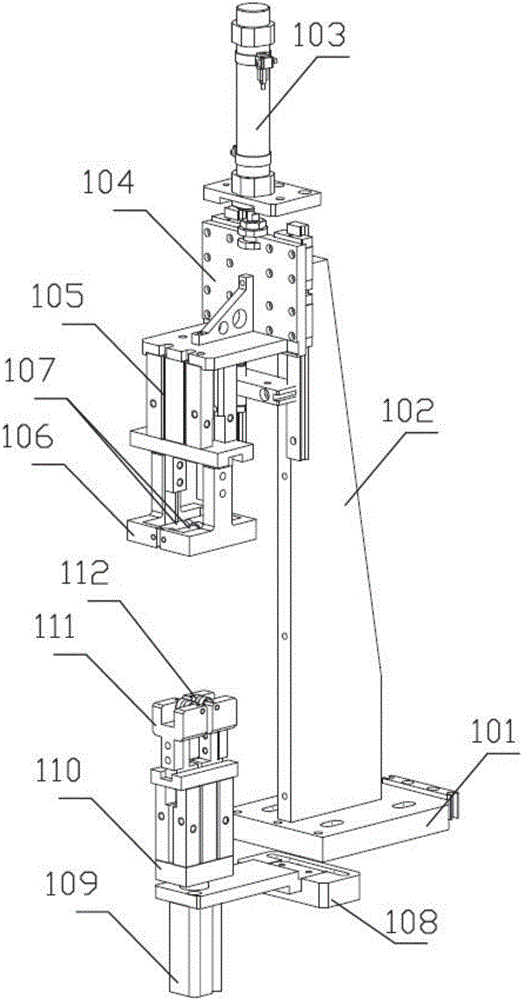

Tray-type automatic board collector and use method thereof

ActiveCN108861621ARealize automatic deliveryUnmanned operationConveyorsStacking articlesEngineeringManipulator

The invention relates to a tray-type automatic board collector and a use method thereof. The tray-type automatic board collector comprises a frame, a feeding area, a board collecting area and a temporary storage area are sequentially arranged on the frame from front to back, a lifting mechanism is arranged at the bottom of the feeding area or / and the temporary storage area and drives a tray to rise and fall, a stopper is arranged on the lifting mechanism, a first cylinder controls the stopper to be opened towards two sides, so that the lifting mechanism falls by the distance of the thickness of one tray, or the first cylinder controls the stopper to be converged towards the center, so that all trays except for the bottommost tray are lifted by the stopper, the bottommost tray falls to a first conveying device and is driven to the board collecting area, a printed-circuit board component is moved into the tray of the board collecting area by a manipulator, the tray fully filled with theprinted-circuit board is conveyed to the temporary storage area and stored in the temporary storage area, and the trays are integrally moved onto a third conveying device when a certain number of trays are stored in the temporary storage area. According to the tray-type automatic board collector, the trays can be automatically conveyed, the printed-circuit board component is automatically collected, manual board collection is completely replaced, unmanned operation is implemented in the whole process, the board is automatically collected, workers are decreased, and efficiency is improved.

Owner:ZHUHAI GOTECH INTELLIGENT TECH

Air conditioner inverting and erecting manipulator

ActiveCN103465247AHarm reductionMeet the process requirementsGripping headsRotational axisEngineering

The invention relates to the technical field of manipulators, in particular to an air conditioner inverting and erecting manipulator which comprises a bracket, a transverse trolley mechanism, a longitudinal trolley mechanism, a horizontal rotating shaft mechanism, a horizontal rotating cylinder mechanism, a liftable overturning mechanism and a clamping mechanism, wherein the transverse trolley mechanism is arranged on the bracket in a manner of moving transversely; the longitudinal trolley mechanism is arranged on the transverse trolley mechanism in a manner of moving longitudinally; the horizontal rotating shaft mechanism and the horizontal rotating cylinder mechanism are arranged at the transverse trolley mechanism; the horizontal rotating cylinder mechanism drives the horizontal rotating shaft mechanism to rotate, the horizontal rotating shaft mechanism drives the liftable overturning mechanism to rotate, the liftable overturning mechanism drives the clamping mechanism to ascend, descend and overturn; the clamping mechanism is provided with a horizontal vacuum pipe sucker. The air conditioner inverting and erecting manipulator not only can meet the technological requirements of production, but also realizes efficient and unmanned operation, and can be used for reducing damages to people, ensuring the product quality, improving the production efficiency and reducing the product cost.

Owner:GUANGDONG WEICHUANG WUYANG INTELLIGENT EQUIP CO LTD +1

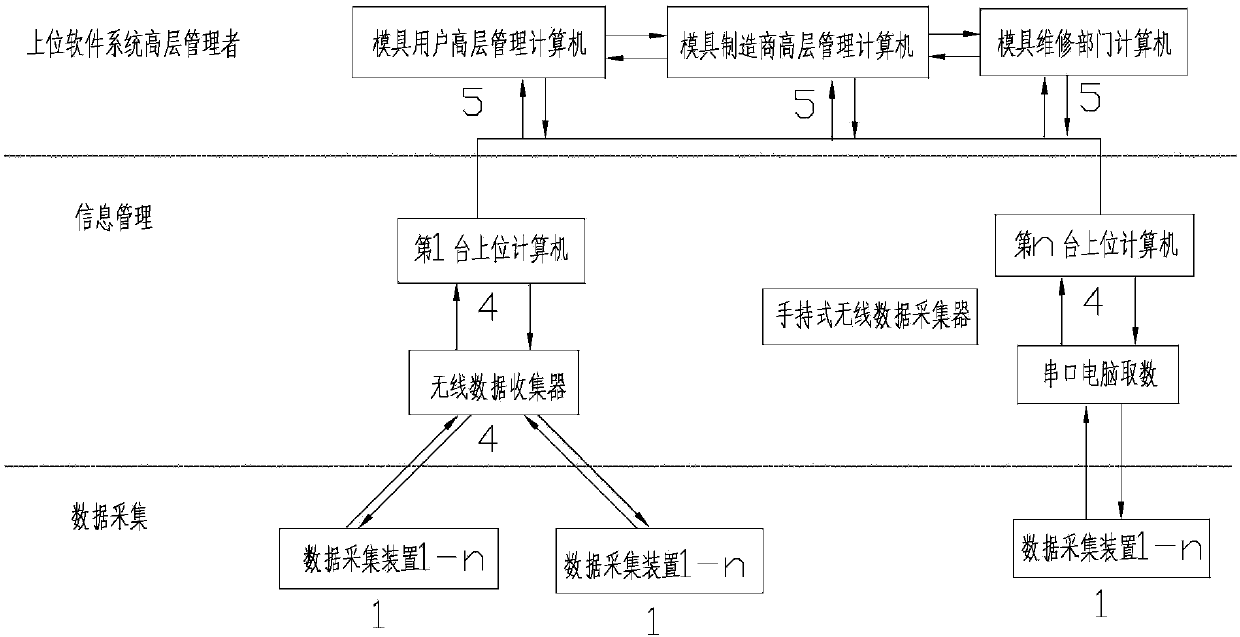

Die management method and die management system

ActiveCN103996092AImprove mold lifeLow investment costResourcesManufacturing computing systemsRemote computerData collector

The invention relates to a die management method and a die management system. According to the die management method, data collection devices arranged at dies are used for collecting die station information; information data of all dies in a specific area are sent to a data collector of the specific area by transmission paths; the data collector sends the data to a host computer, a database is established at the host computer, and a die management information file that can be checked is formed; a die using situation of the area is estimated; host computers in all specific areas send data to remote computers of a higher management layer, a die manufacturer and a die maintenance department by the internet; the remote computers carry out comprehensive estimation on states of all dies; and heavy maintenance time of all dies is predicted, early warning information is sent out in advance and a maintenance instruction is issued, and the die manufacturer and the die maintenance department send workers to carry out heavy maintenance on the dies. According to the invention, the die manufacturer and the die maintenance department can obtain die information comprehensively in real time and thus maintenance can be carried out on the die timely, thereby prolonging the service lives of dies.

Owner:QINGDAO HAIER ROBOT CO LTD +2

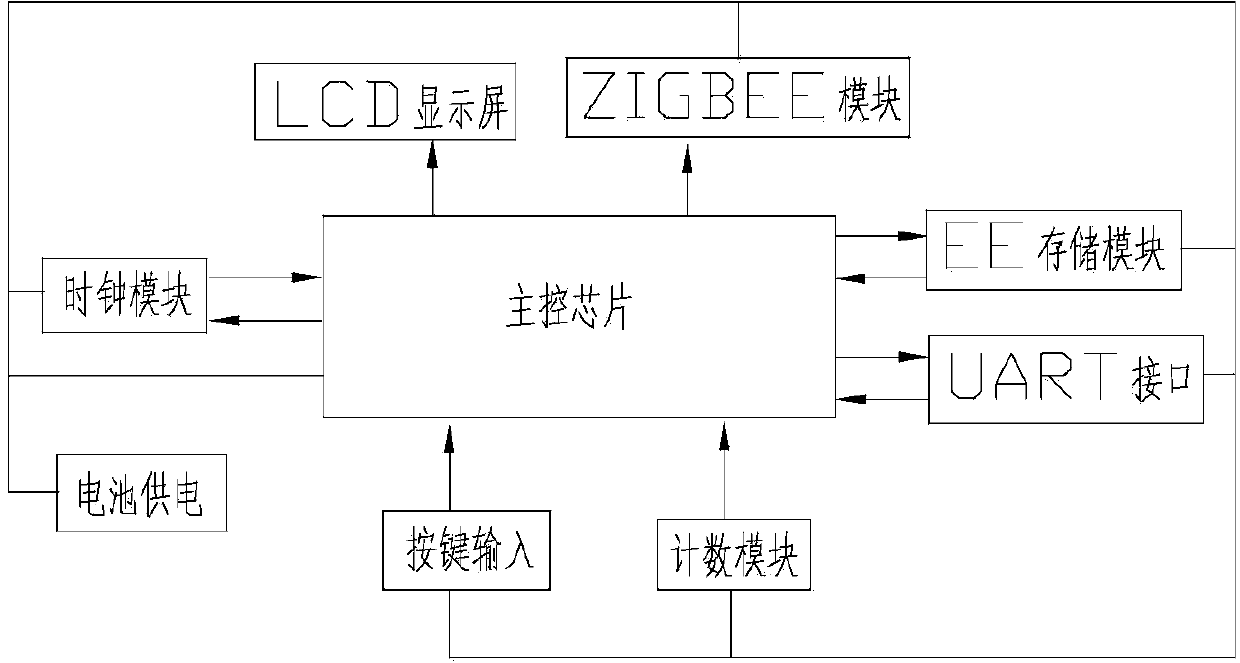

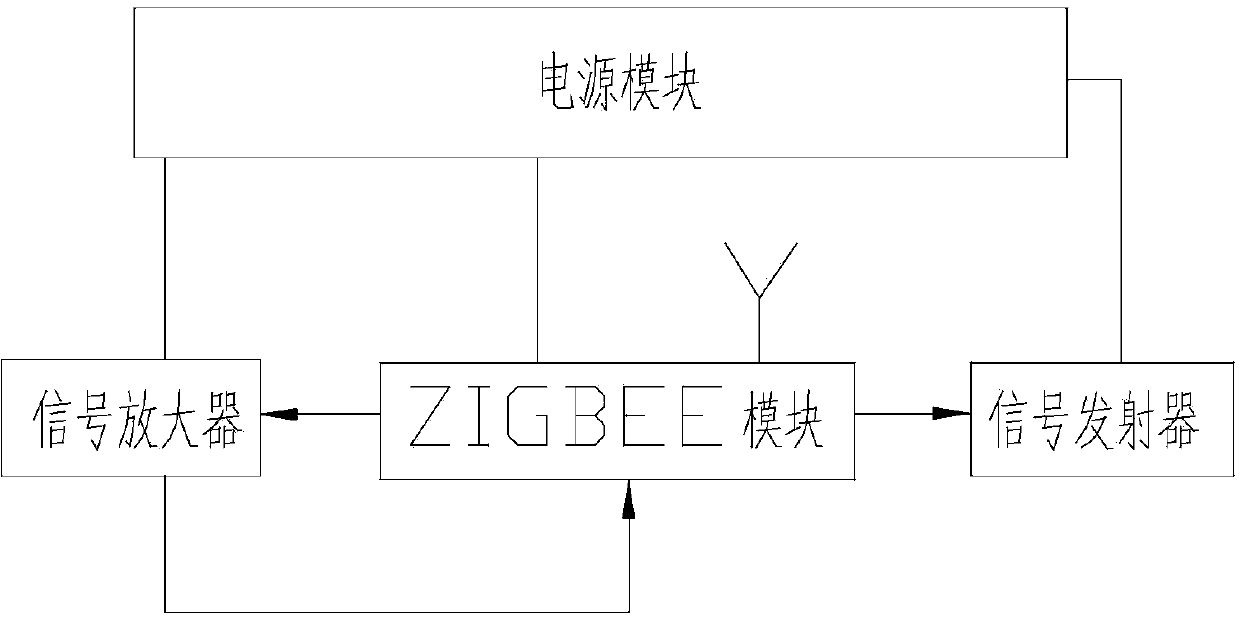

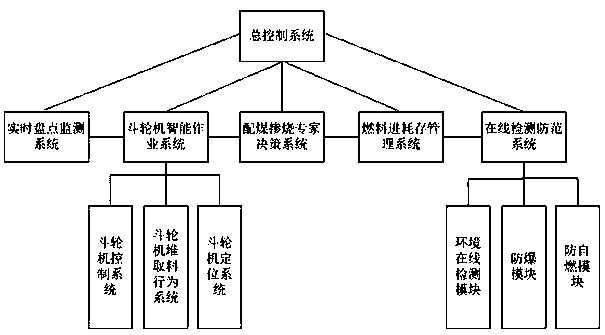

Digital coal yard intelligent control scheme based on GPU computing

ActiveCN108919761APrecise positioningUnmanned operationCo-operative working arrangementsLogisticsSpontaneous combustionLaser scanning

The invention discloses a digital coal yard intelligent control scheme based on GPU computing. The digital coal yard intelligent control scheme comprises a master control system, a real-time inventorymonitoring system, a bucket intelligent operation system, an coal blending mix-burning expert decision-making system, a fuel input and consumption management system and an online detection and prevention system. The digital coal yard intelligent control scheme is characterized in that the master control system is located in a master control room, is composed of a parallel computer group and performs big data calculation by using a GPU; the real-time inventory monitoring system acquires 4D data of a coal pile through laser scanning and transmits the 4D data to the master control system for coal pile parameter identification and judgment, and then simulates to generate a dynamic and visible 4D model; the bucket intelligent operation system performs the collection and transmission of data such as mass, temperature, humidity, heat, impurity of the coal pile and the position of a bucket through an intelligent chip reading device; the coal blending mix-burning expert decision-making systemis used for calculating a blending scheme according to the current situation of coal storage in a coal yard to form a cost optimization ranking table; the fuel input and consumption management systemperforms storage and coding by a SQL Server database, and the calculation amount is output to the master control system for deployment; and the online detection and prevention system comprises an environmental online detection module, an explosion-proof module and an anti-spontaneous combustion module. The digital coal yard intelligent control scheme based on GPU computing uses the system integration and heterogeneous data fusion technology to realize the fusion and sharing of relational data, real-time data and spatial data.

Owner:HUNAN CHANGZHONG MACHINERY

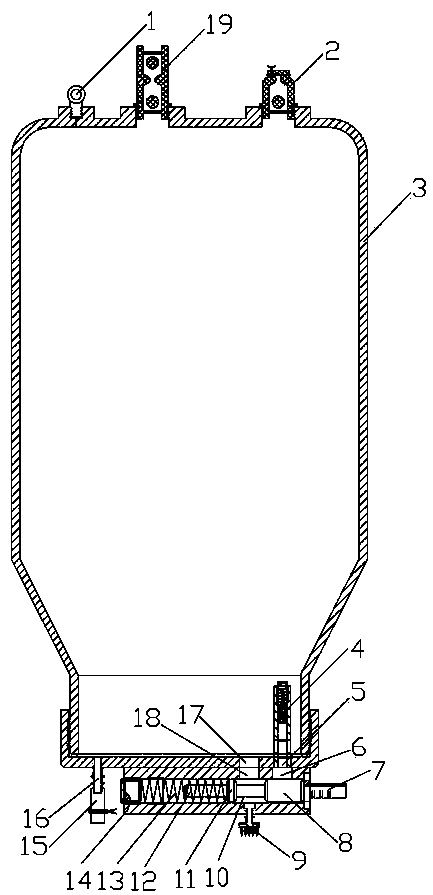

Water-saving-valve-controlled drip irrigation tank

InactiveCN104160922AReduce power consumptionLow investment costClimate change adaptationWatering devicesAgricultural irrigationDrip irrigation

The invention relates to agricultural irrigation devices, in particular to a water-saving-valve-controlled drip irrigation tank. The water-saving-valve-controlled drip irrigation tank is provided with a closed tank body, a ventilation overflow stop valve is arranged at the top of the tank body, and a water inlet and a water outlet are formed in the bottom of the tank body. The water-saving-valve-controlled drip irrigation tank is characterized in that a water inlet one-way valve is arranged on the inner side of the water inlet in a butt joint mode, an in-out linkage water valve is arranged at the bottom of the tank body and provided with a valve body, a piston cavity provided with a piston and a compression spring is arranged in the valve body, and a water inlet pipe is installed at the end, close to the piston, of the valve body to be communicated with the piston cavity. A water supply opening is formed in the valve body to be communicated with the water inlet in the bottom of the tank body, and a transition water opening is formed to be communicated with the water outlet in the bottom of the tank body. A water drip distribution device is further arranged on the valve body and communicated with the piston cavity. The water-saving-valve-controlled drip irrigation tank overcomes the defects that blocking occurs easily when drip irrigation is conducted through a water dropper, water yield cannot be adjusted, the water dropper is complex in structure, high in manufacturing cost and short in service life, and a system is large in power consumption. Meanwhile, the water-saving-valve-controlled drip irrigation tank is more stable and more reliable in work, low in failure rate and wide in agricultural crop irrigation application range.

Owner:HUBEI FOR LONG PIPE TECH CO LTD

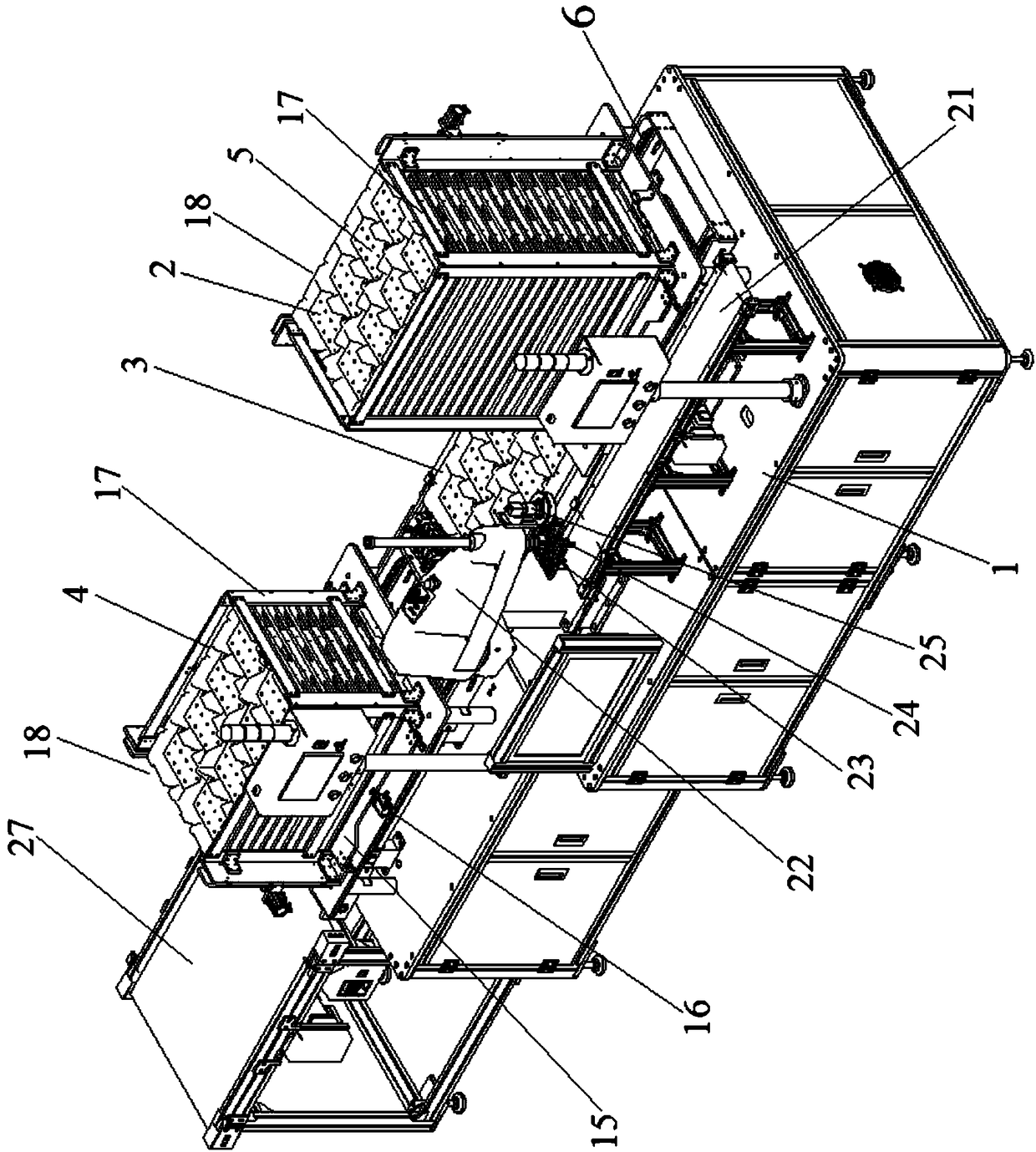

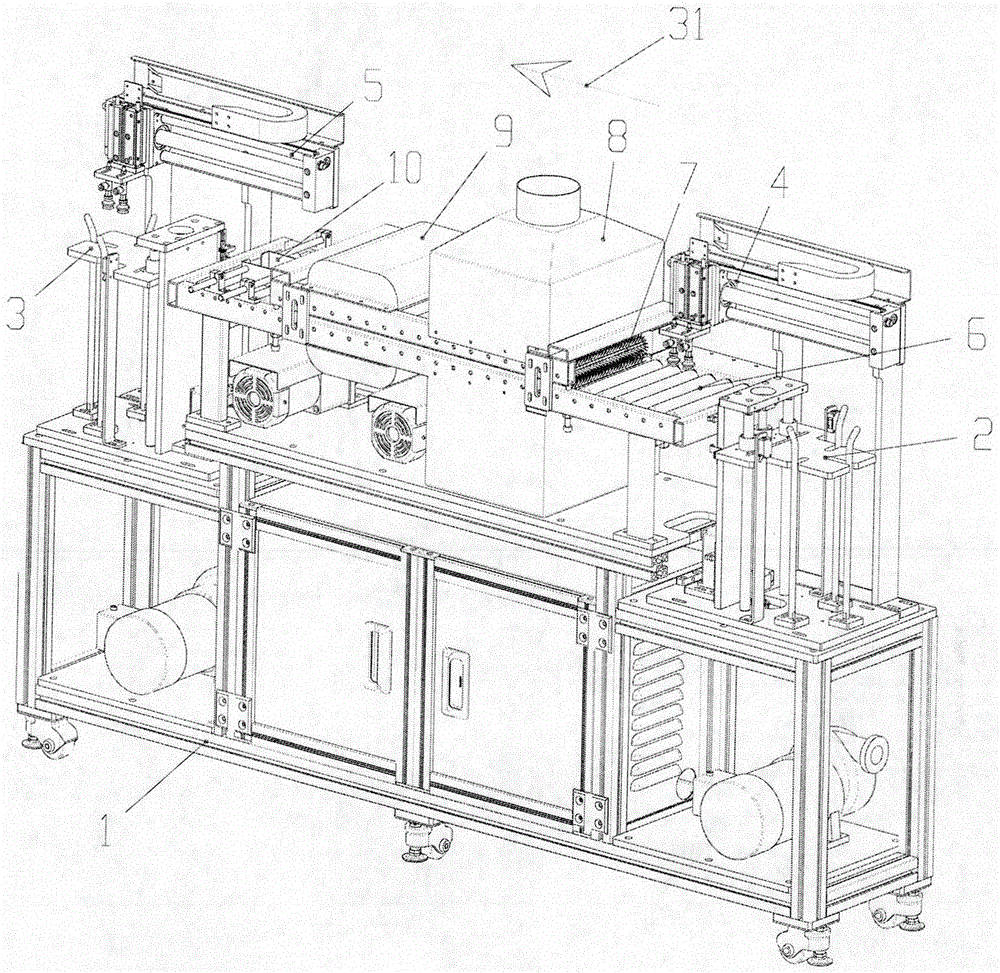

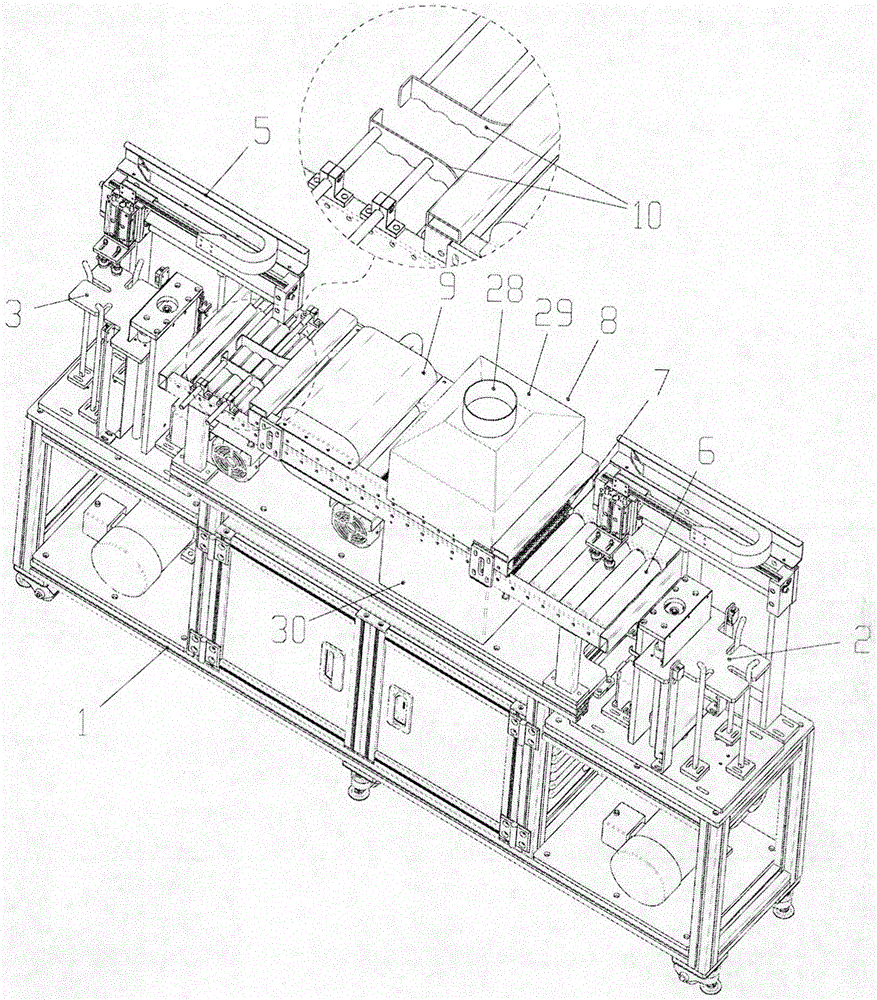

Full-automatic cleaning treatment assembly line for high-clean battery cover plate

InactiveCN105665317AEasy to grabGuaranteed cleanlinessDrying machines with progressive movementsCleaning using toolsEngineeringAssembly line

The invention relates to industrial automation equipment and in particular to automatic machinery cleaning equipment. A full-automatic cleaning treatment assembly line for a high-clean battery cover plate comprises a rack, dynamic stock bins, manipulators, a conveyor belt, a hairbrush stick, a cleaning chamber, a drying chamber and a guide mechanism, wherein the dynamic stock bins and the manipulators are fixedly connected to the two ends of the rack assembled by aluminum profiles; the conveyor belt is arranged between the dynamic stock bins; the manipulators are arranged at the upper parts of the corresponding dynamic stock bins; and the hairbrush stick, the cleaning chamber, the drying chamber and the guide mechanism are sequentially arranged on the conveyor belt in the conveying direction. The full-automatic cleaning treatment assembly line for the high-clean battery cover plate is suitable for realizing automatic cleaning treatment of the battery cover plate in the machine manufacturing process, realizes unmanned cleaning treatment on the battery cover plate and also ensures the cleaning quality due to supplementation of multiple cleaning processes.

Owner:珠海兴立新能源有限公司

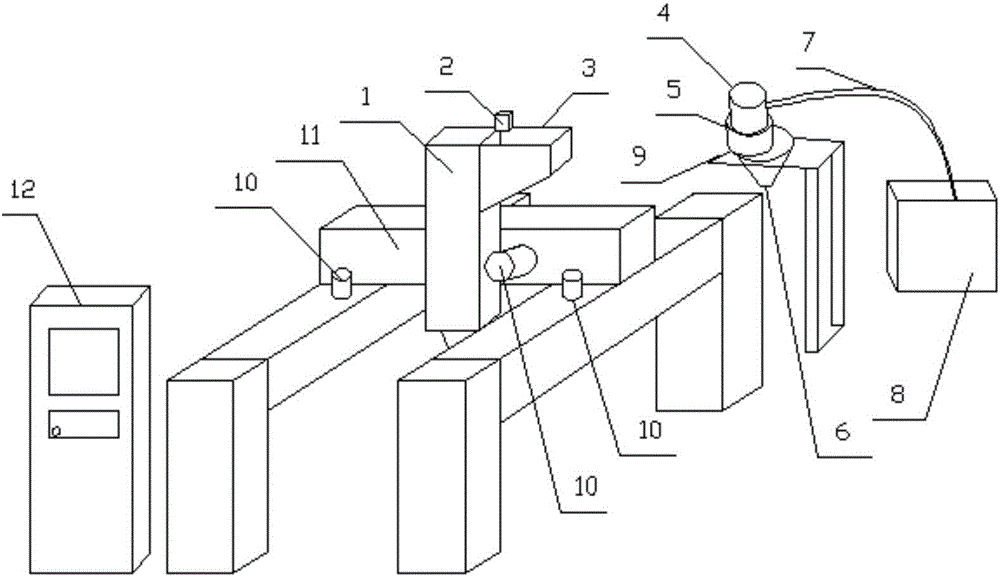

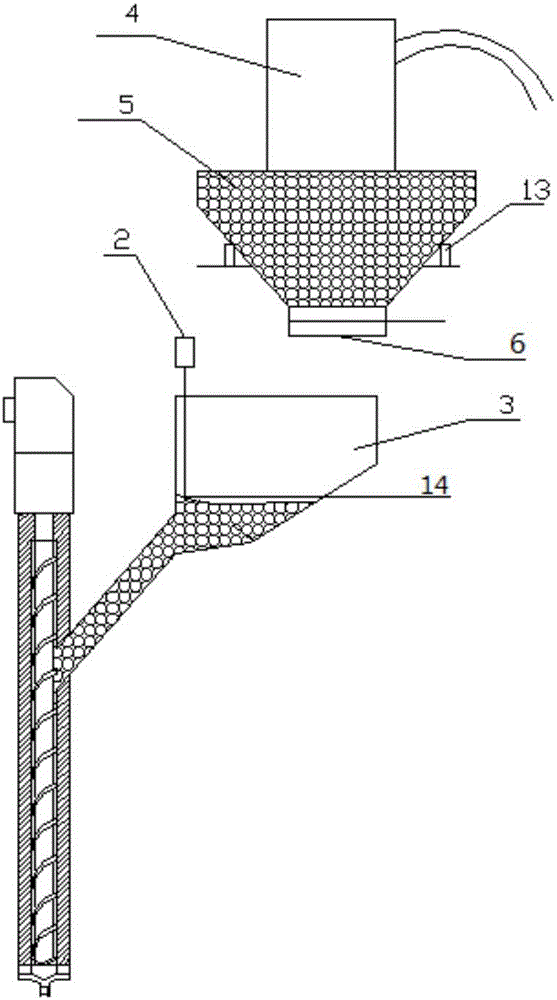

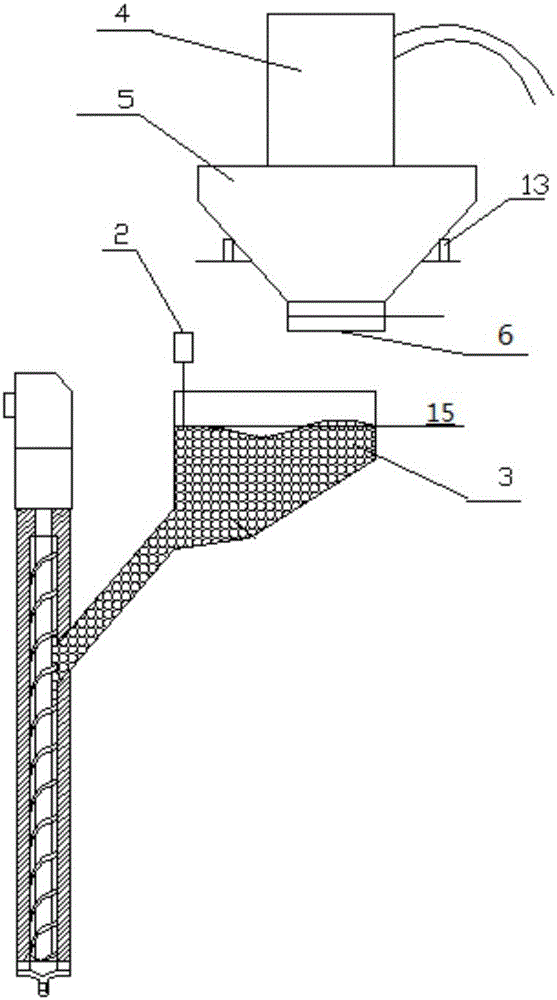

Automatic feeding system of FDM (frequency-division multiplexing) printing equipment

InactiveCN106312073AAvoid quality problemsUnmanned operationAdditive manufacturing apparatusElectricityControl system

The invention provides an automatic feeding system of FDM (frequency-division multiplexing) printing equipment. The automatic feeding system comprises a printing extrusion mechanism, a printing cartridge hopper mounted at the upper part of the printing extrusion mechanism, a photoelectric detection device electrically connected with the printing cartridge hopper to detect a material level of the printing cartridge hopper, a charging cartridge selectively communicated with the printing cartridge hopper and a material bucket, a weighing sensor electrically connected with the charging cartridge to detect material weight in the charging cartridge, and a control system, wherein the control system charges the printing cartridge hopper via the charging cartridge and the charging cartridge via the material bucket based on a material level detection signal emitted by the photoelectric detection device and a material weight signal emitted by the weighing sensor. The automatic feeding system of the FDM printing equipment can continuously and automatically fill a printing material in the charging cartridge into the printing hopper in a printing process, ensures continuity of the printing process, and avoids quality defects of a printing model and time waste arising from printing miss of a printer due to the lack of the printing material and untimely filling of the printing material by an operator.

Owner:NINGXIA KOCEL MOLD

Medium-drive dirt cleaning machine for transmission pipelines

InactiveCN104607426AWith automatic walkingWith automatic conversionHollow article cleaningImpellerEngineering

The invention provides a medium-drive dirt cleaning machine for transmission pipelines. The medium-drive dirt cleaning machine is characterized in that sealing rings sleeve the front side and the rear side of a barrel, the barrel is provided with traveling support wheels via compensating springs, a cutting head is mounted at the front of the barrel via a rotary shaft, and cutters are mounted on the annular periphery of the cutting head via cutter springs; a positioning sensor is arranged on the barrel, a driving rotary mechanism is arranged in the barrel, and impeller or impeller and bevel gear transmission effects can be realized by the driving rotary mechanism. The medium-drive dirt cleaning machine has the advantages that an impeller can rotate under the effects of media in the transmission pipelines, so that the cutters can be driven to rotate to cut dirt; the medium-drive dirt cleaning machine has automatic traveling, automatic switching and automatic dirt cleaning functions, has automatic tracking positioning and unmanned operation ability and is suitable for the transmission pipelines for petroleum or other medium.

Owner:冯洪仁

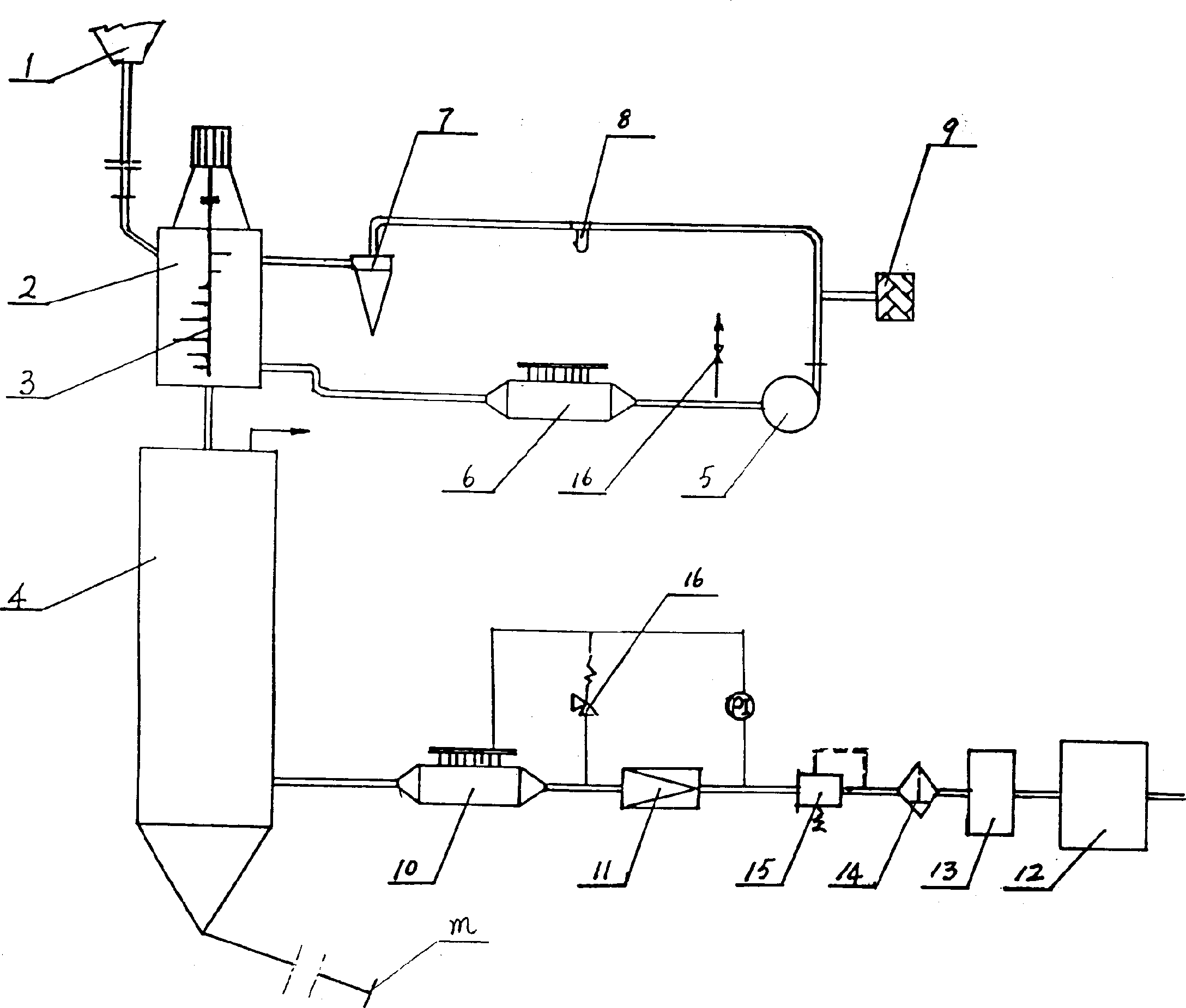

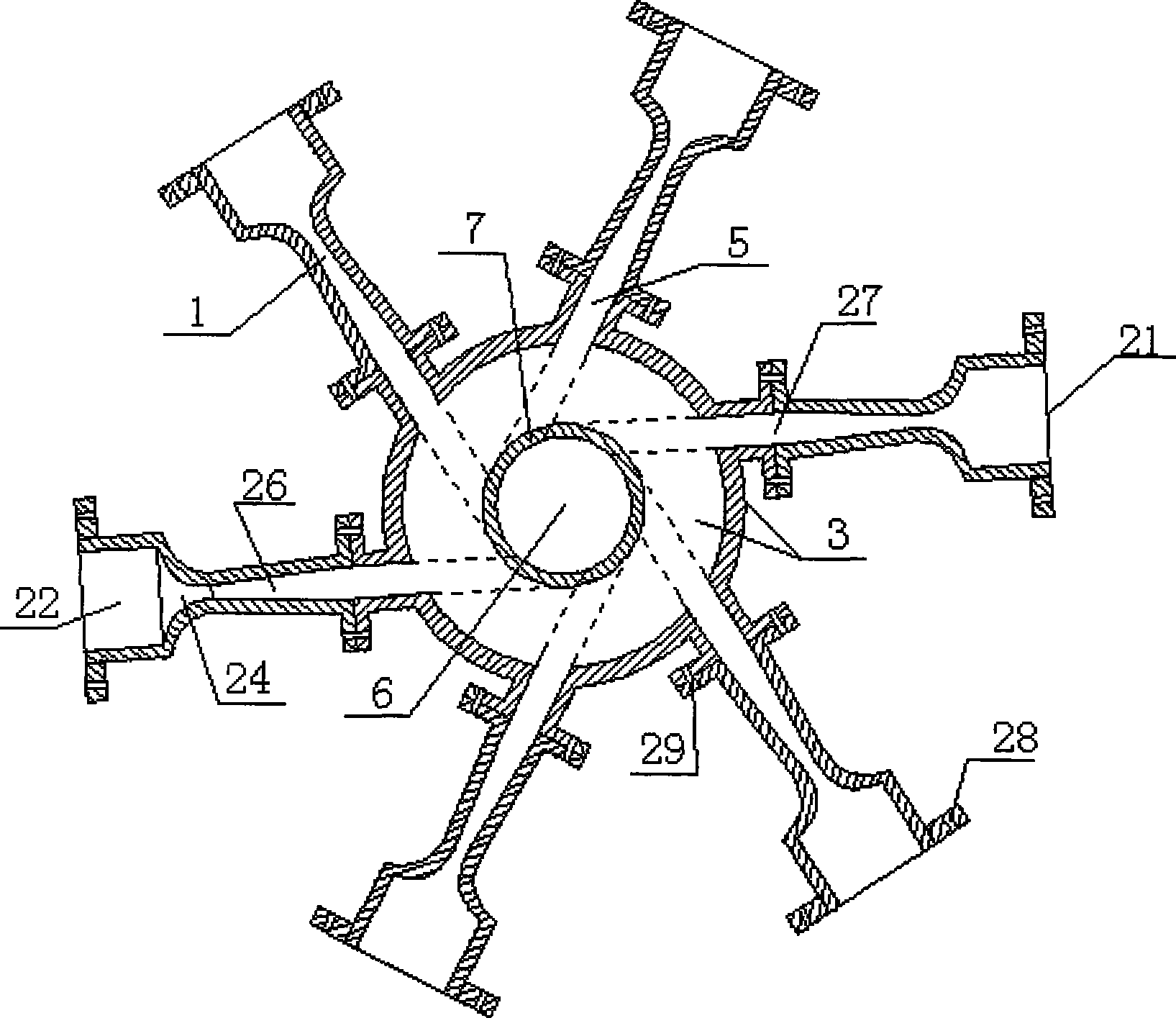

Skid-mounted device for ultrasonically dehydrating, removing liquid, purifying and separating for natural gas

InactiveCN101544921AEfficient separationAvoid it happening againGaseous fuelsNatural gas dehydrationThree-phase

The invention relates to a skid-mounted device for ultrasonically dehydrating, removing liquid, purifying and separating for natural gas, belongs to an energy-saving purification device of heat engineering, and is mainly applied in the field of dehydrating, removing liquid, purifying and separating for natural gas. The device consists of a gas purification device and a gas separation device. Wet natural gas enters an ultrasonic separation spray pipe respectively; because the temperature is reduced, water and heavy paraffin hydrocarbon components in the natural gas become liquid and then are condensed to form high-speed rotational flow to tangentially flow into a hydrate separator cylinder; and then three-phase separation of the natural gas, condensate and water is carried out, and simultaneously the hydrate is prevented from being generated. The device efficiently separates out the water and the heavy hydrocarbon liquid from the natural gas without adding any chemical drugs, has the advantages of energy conservation, environmental protection, compact structure, and little occupied area, reduces the running cost, can achieve unmanned operation and free maintenance, and can be applied to remote or severe environmental land and offshore platforms.

Owner:SICHUAN ZHONGKEDA OIL&GAS NEW TECH

Cotton picking robot

InactiveCN107182448AGuarantee the effect of picking cottonAchieve scaleManipulatorPicking devicesMachine visionEngineering

The invention relates to a cotton picking robot, and belongs to the technical field of agricultural machinery. According to the robot, the whole unmanned picking process of cotton is achieved, and the functions comprise automatic moving and machine vision guiding cotton picking. The robot comprises an automatic mobile platform, a vision cotton picking head and a cotton collection bin. The automatic mobile platform conducts path planning and real-time guiding according to GPS information, real-time path and posture adjustment is conducted according to vision and an automatic row-controlled sensor, mobile platform posture and speed tracking is conducted according to an angular acceleration sensor and acceleration sensor information, when picking tasks are completed or a failure occurs or the electric quantity and cotton picking weight reach a limiting value, returning is conducted. The vision cotton picking head conducts visual identification on the cotton mature degree and the spacial position through a machine, and a cotton picking spindle unscrews the cotton off in a rotating stretching mode and then retracts into a picking box, and the cotton is scraped off through a cotton brushing pad. The picked cotton is conveyed to the cotton collection bin installed on the automatic mobile platform through wind power.

Owner:庞川

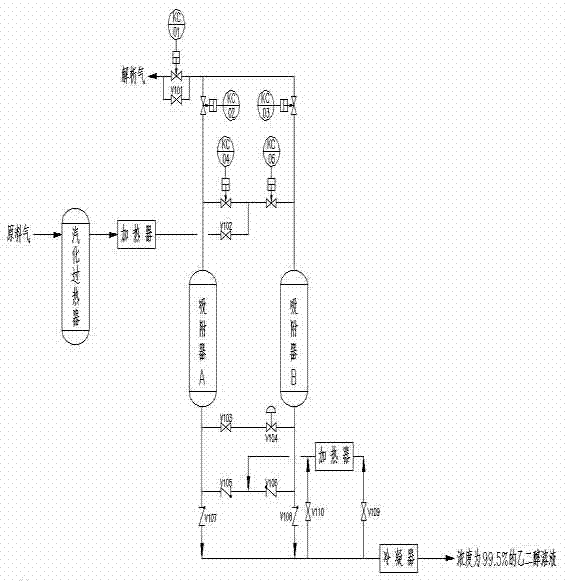

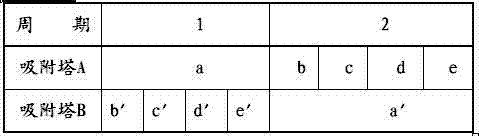

Dewatering method for glycol production process

ActiveCN102951999AHigh yieldShort processHydroxy compound separation/purificationThermodynamicsSorbent

The invention relates to a dewatering method for a glycol production process. The dewatering method comprises the technological steps of an absorption adsorption tower A and an absorption adsorption tower B, wherein the absorption adsorption tower A has the following operation steps of a. , absorptionadsorption: delivering glycol steam into the absorption adsorption tower A to absorbadsorb, condensing, collecting the glycol, and stopping to delivering the raw material gas after absorbingadsorbing; b. , reverse pressure drop: opening a valve to carry out reverse pressure drop, desorbing the impurity components, and emptying; c. , temperature raising: heating the absorbed adsorbed regeneration gas, and delivering the absorbed adsorbed regeneration gas into the absorption adsorption tower A, so as to regenerate an absorbing adsorbing agent; d. , cooling; and e. , pressure raising pressure. The operation steps of the absorption adsorption tower B are the same as the operation steps of the absorption adsorption tower A, but the times are mutually staggered. The dewatering method has the advantages that the fault-free operation is realized, the annual operation time can reach more than 300 days, the flow process is short, the investment is saved, the recovery rate of the glycol is high, the service life of the absorbing adsorbing agent is long, and the replacement time of the absorbing adsorbing agent is generally 15 to 20 years under normal operation conditions.

Owner:ALLY HI TECH CO LTD

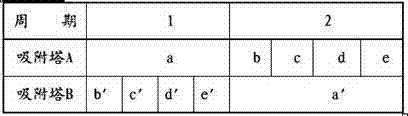

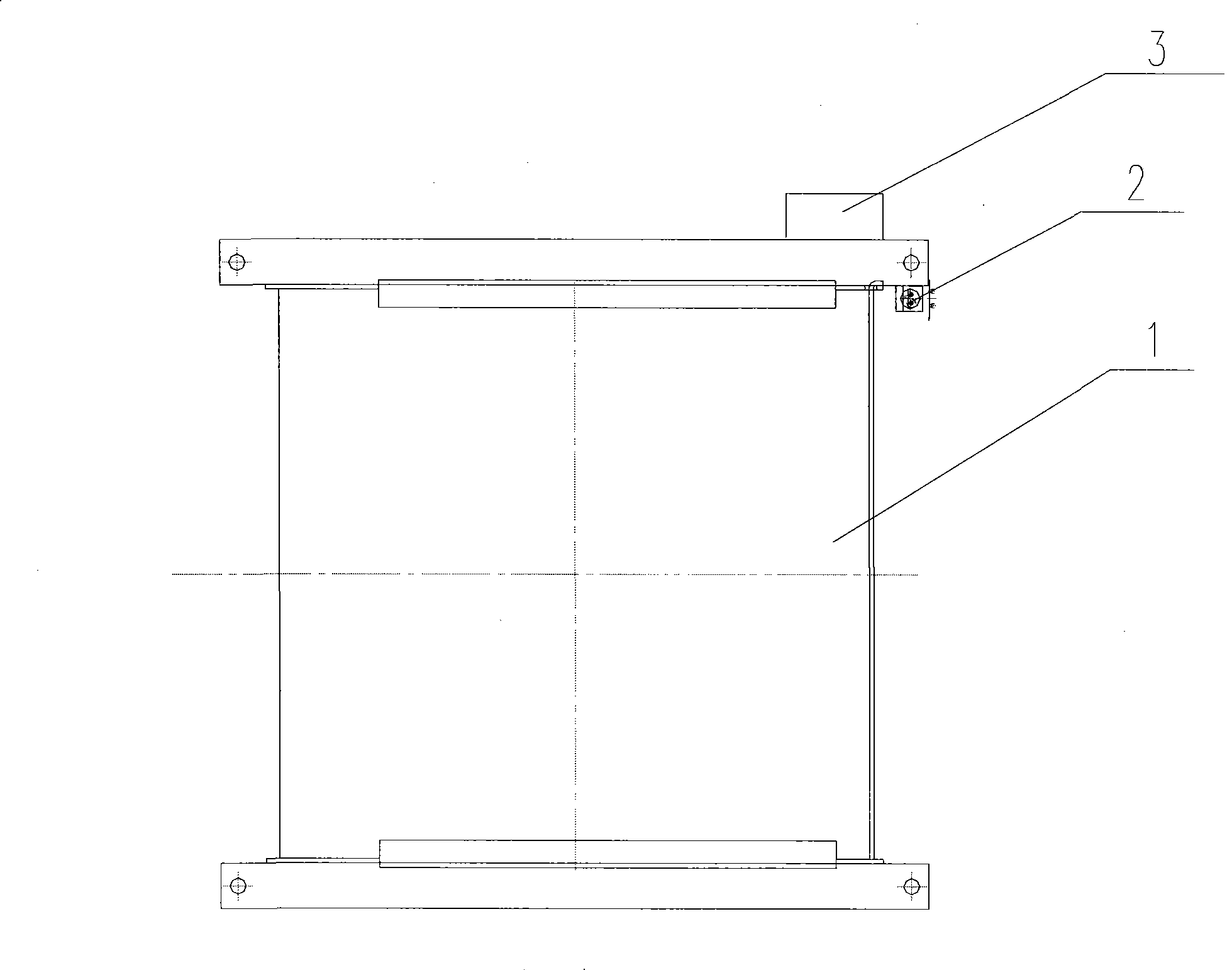

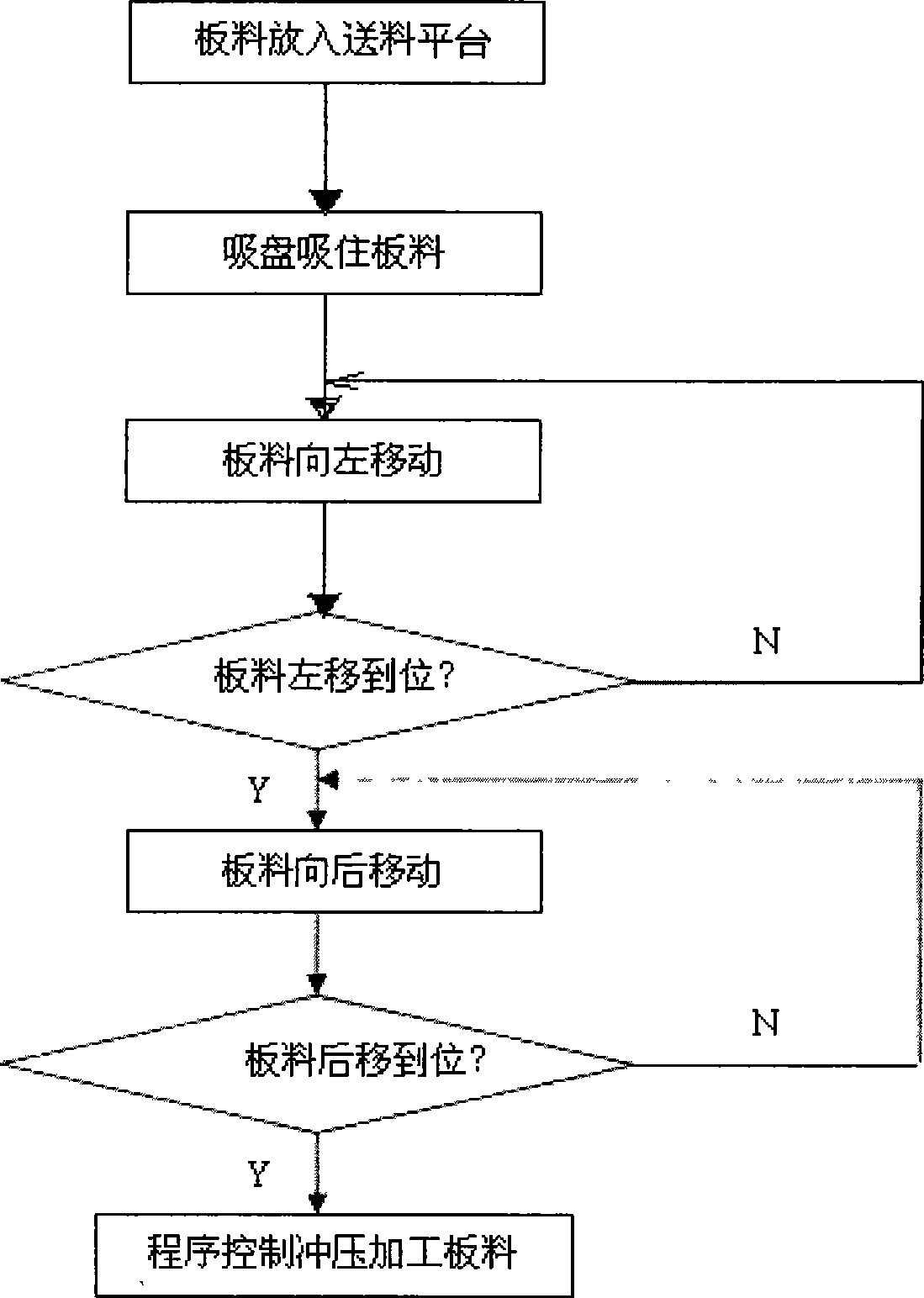

Sheet-material automatic positioning system

InactiveCN101396708AImprove efficiencyHigh repeat positioning accuracyMetal-working feeding devicesPositioning devicesEngineeringElectromagnetic valve

The invention relates to a plate positioning device of a numerical control punch and discloses an automatic plate positioning system; the system comprises a positioning base, a feed platform which is arranged at the top part of the positioning base, computer control systems, a detector, an electromagnetic valve, a positioning block, a pneumatic mechanism and a pneumatic clamp; the positioning block is arranged at the edge of the positioning base and the detector is arranged below the positioning block; the upper part of the pneumatic mechanism is arranged on the feed platform and the lower part of the pneumatic mechanism is fixed in the base; the computer control systems are connected by the pneumatic clamp and the pneumatic mechanism of the electromagnetic valve. The invention can realize automatic positioning of the plate before being punched and the precision of repeated positioning is high; moreover, the positioning precision can be automatically detected.

Owner:武汉楚天数控设备制造有限公司

Automatic access lifter

ActiveCN103466508AHarm reductionMeet the process requirements of productionLifting devicesEngineering

The invention relates to the technical field of lifting access equipment, in particular to an automatic access lifter, comprising a frame, a weight assembly, a weight guide track, a basket assembly, a telescopic tray mechanism, a trolley power mechanism, a lifting power mechanism, a trolley guide track and a chain. The automatic access lifter can meet the technical demands of production and realizes efficient and unmanned operation, so harm to people can be reduced, product quality is ensured, the production efficiency is improved and the production cost is reduced.

Owner:GUANGDONG WEICHUANG WUYANG INTELLIGENT EQUIP CO LTD +1

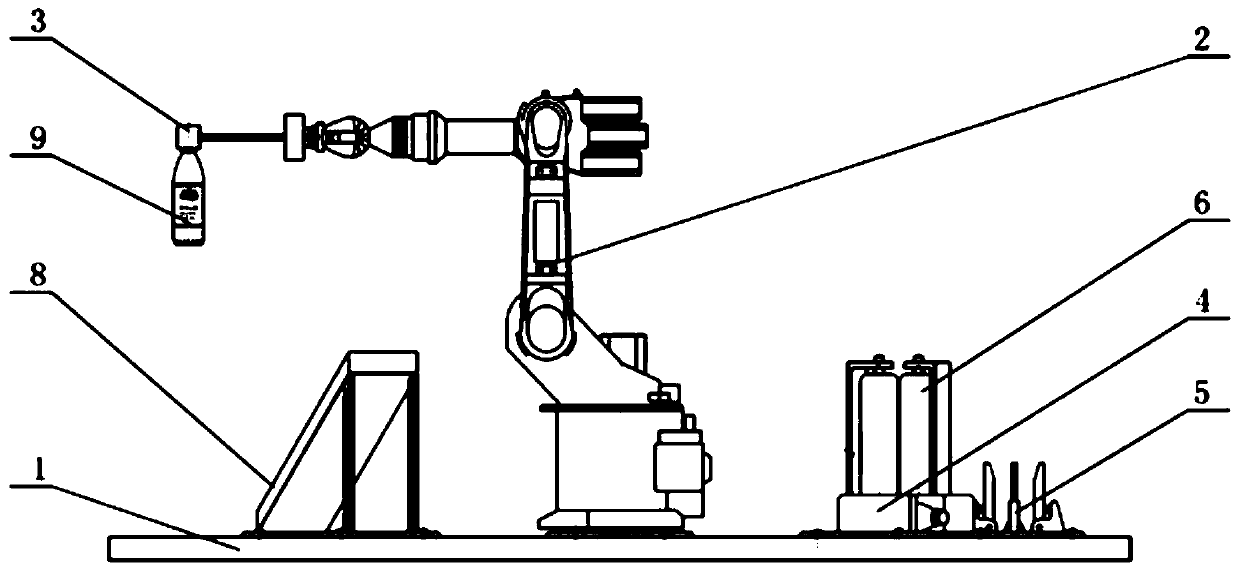

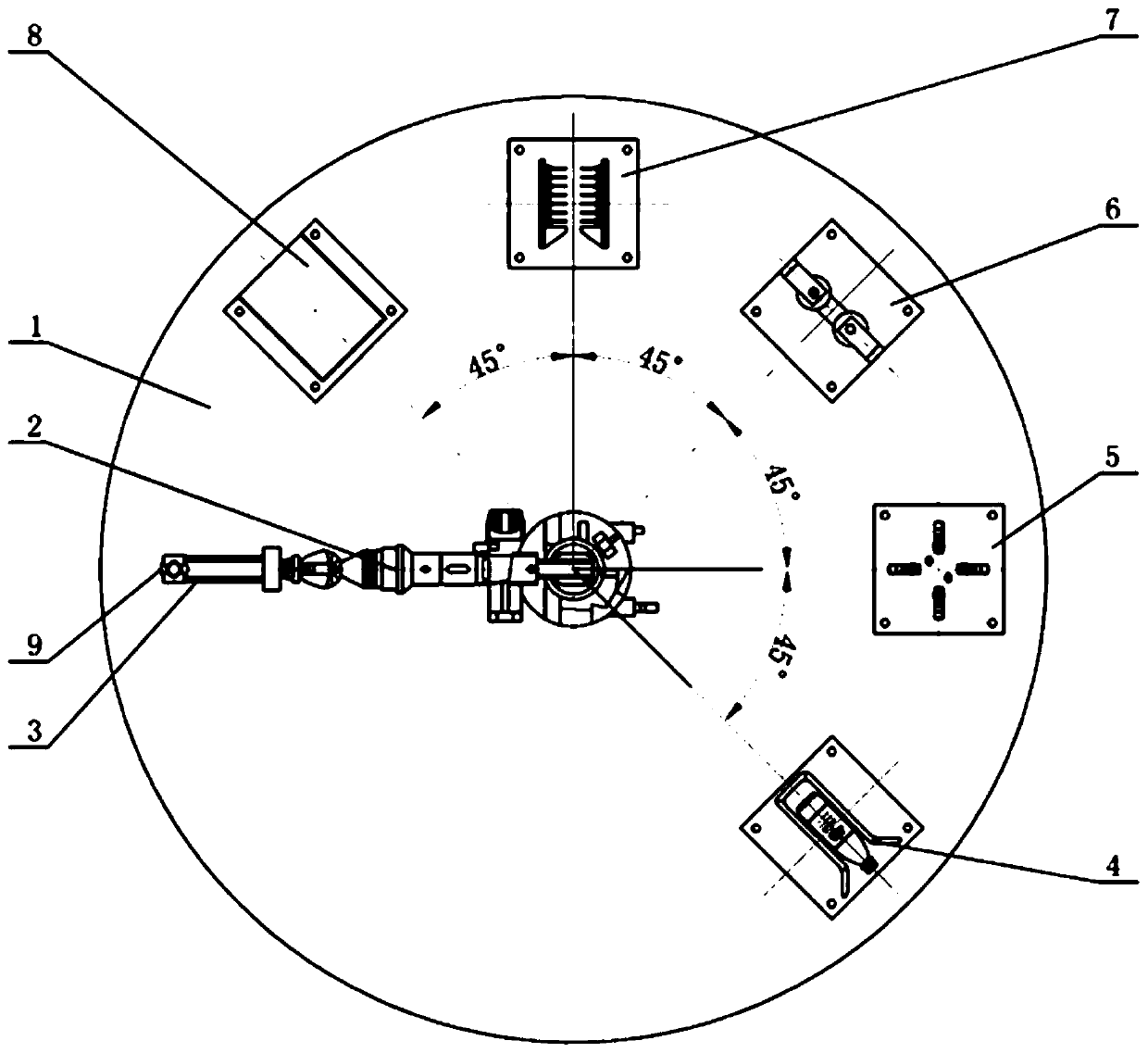

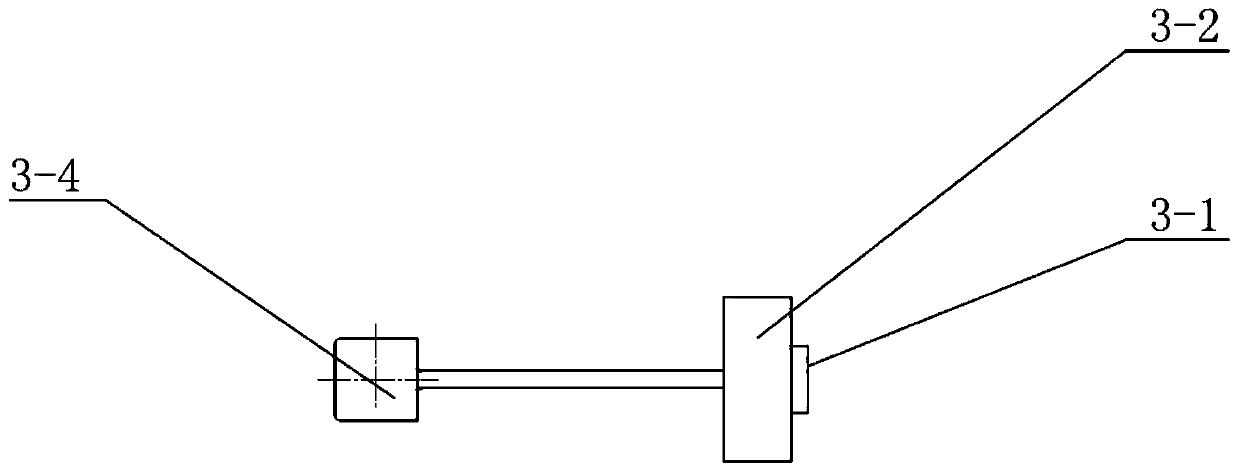

Intelligent industrial robot device for recycling waste plastic bottle

InactiveCN110355901AAccurate removalUnmanned operationPlastic recyclingHollow article cleaningBottle capSix degrees of freedom

The invention discloses an intelligent industrial robot device for recycling a waste plastic bottle. A machine arm is arranged on a base and fixed on the base; a plastic bottle clamping jaw is arranged at the front end of the upper part of the machine arm; a plastic bottle is arranged between two clamping jaw bodies of the plastic bottle clamping jaw; a waiting station clamp is arranged on the upper right part of the base; a bottle cap removing station clamp is arranged on the right part of the base; a flattening station clamp is arranged on the upper right part of the base; a trademark removing station clamp is arranged on the upper part of the base; and a blanking station clamp is arranged on the upper left part of the base. According to the intelligent industrial robot device for recycling the waste plastic bottle, by adopting the mechanical arm and the special clamps, the full-automatic grabbing, overturning, unscrewing of a bottle cap, discharging of residual liquid in the bottle,scraping of a trademark and other actions of the waste plastic bottle can be realized, the recycling efficiency is obviously improved, the labor intensity is reduced, and the flexibility and adaptability of the plastic bottle recycling device are improved by using the six-degree-of-freedom mechanical arm.

Owner:刘亦晴

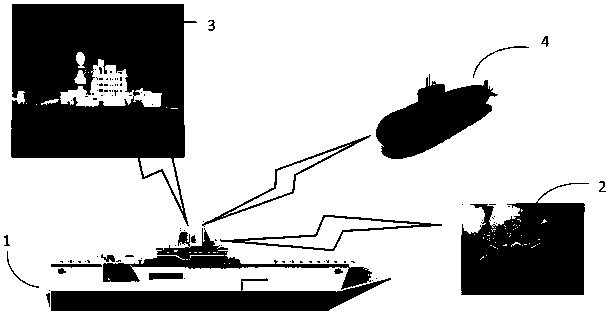

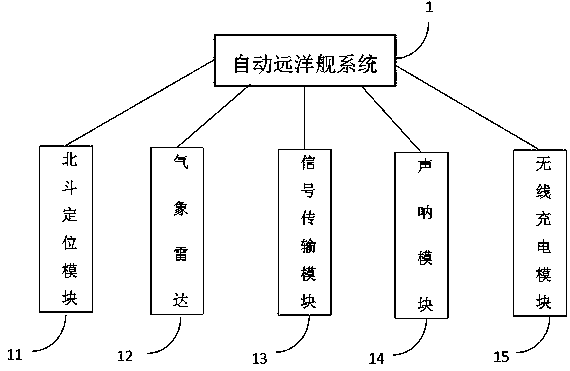

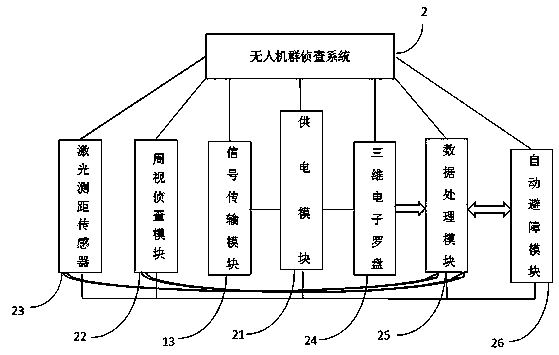

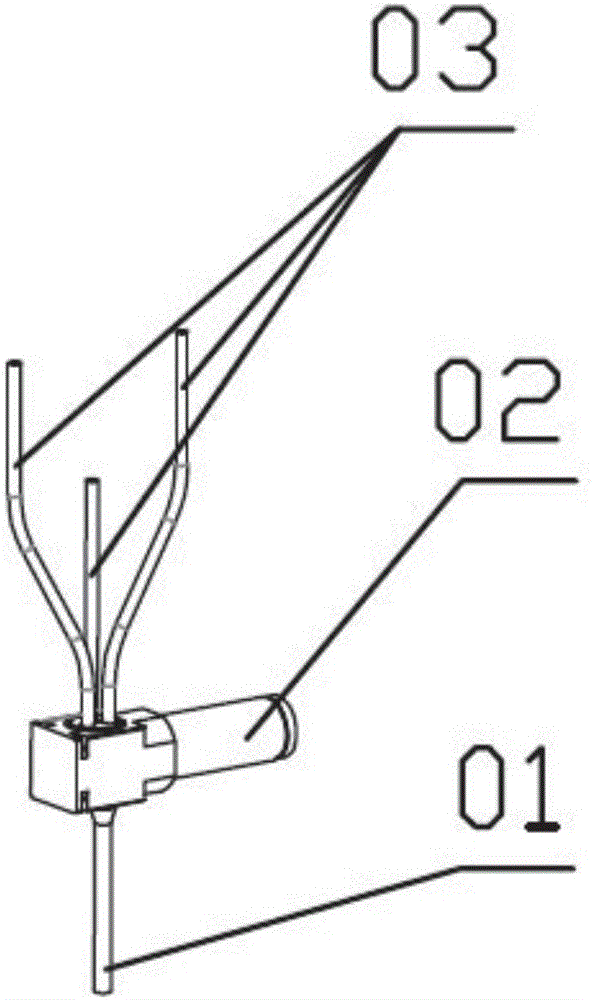

Automatic remote sea detection system

InactiveCN108693849ASolve the problem of high cost of remote sea detection and high risk of detection personnelUnmanned operationMeasurement devicesTotal factory controlMarine engineeringCommand system

The invention relates to an automatic remote sea detection system. An automatic ocean-going ship carries an unmanned aerial vehicle group and an underwater unmanned ship to a designated sea area, andthen automatically releases the unmanned aerial vehicle group and the underwater unmanned ship for remote sea detection, and feeds back the information of an unmanned aerial vehicle group reconnaissance system and an underwater unmanned vehicle reconnaissance system to a land command system. The unmanned aerial vehicle group reconnaissance system and the underwater unmanned ship reconnaissance system acquire image information in the target sea area in real time, obtain sea area image information, and transmit the sea area image information to the automatic ocean-going ship system. The land command system receives the sea area image information sent by the automatic ocean-going ship system, and generates decision information according to the position of a suspicious target marked via the obtained sea area image information and the weather condition of the location. The automatic ocean-going ship system receives decision information, and then executes the decision, and transmits an execution result of the decision information to the land command system. The system can achieve the remote sea detection in a large range, is low in cost and is high in security.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

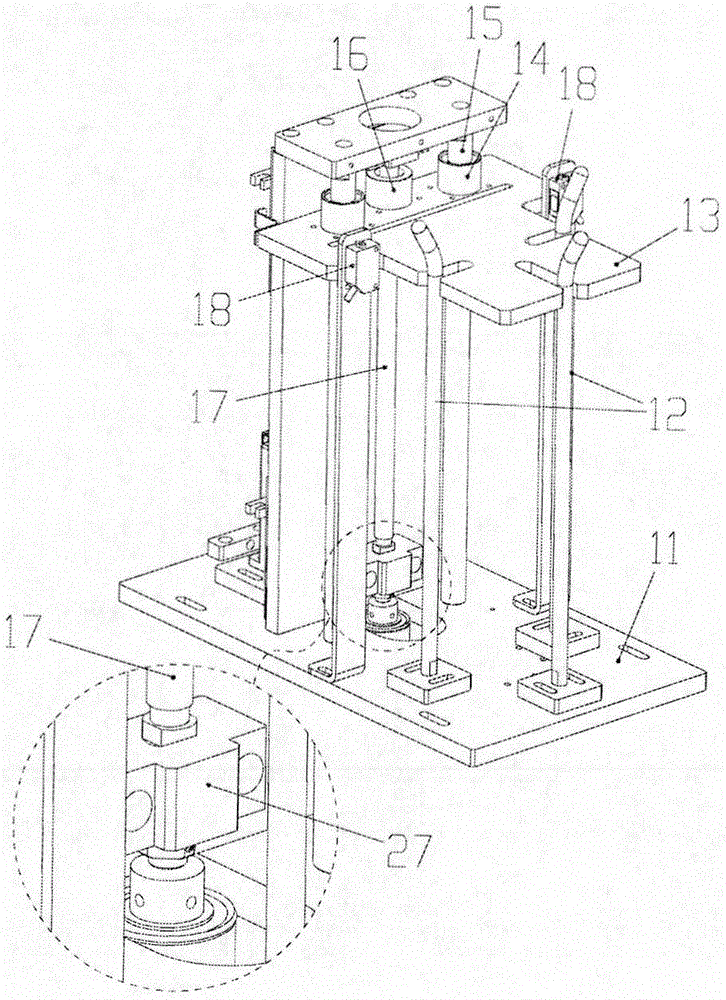

Full-automatic guide valve comprehensive performance testing platform

ActiveCN105865775AUnmanned operationUnattendedMachine part testingMeasurement of fluid loss/gain rateElectrical controlEngineering

The invention provides a full-automatic guide valve comprehensive performance testing platform, which is completely fully automatic, unmanned and unattended, has the advantages of stability in equipment working, accurate detection and high reliability and is suitable for a modern automatic production mode. The full-automatic guide valve comprehensive performance testing platform comprises a feeding device, a reshaping device, a sealing device, a testing frame, a detection valve terminal and an electric control system, wherein the feeding device, the reshaping device, the sealing device and the detection valve terminal are all mounted on the testing frame; the feeding device is used for conveying test pieces to pass through the reshaping device, the sealing device and the detection valve terminal in sequence and putting into an appointed region according to a detection result; the reshaping device is used for carding a test piece pipeline into a straight regular product, wherein all pipes are parallel to the same plane and ESC pipes are arranged at an interval of 36mm; the sealing device is used for automatically sealing all the pipes of the test pieces before detection; the detection valve terminal is used for detecting properties of all the test pieces.

Owner:SHANGHAI BIESE MECHANICAL & ELECTRICAL EQUIP TECH CO LTD

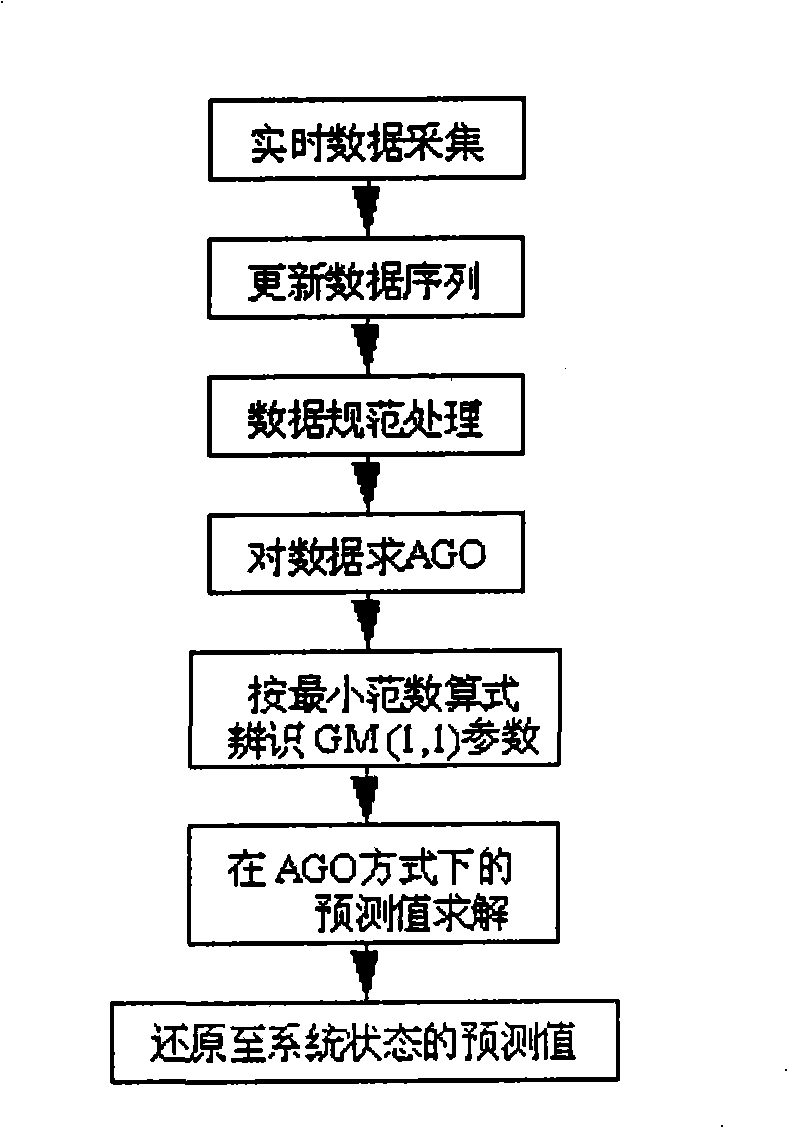

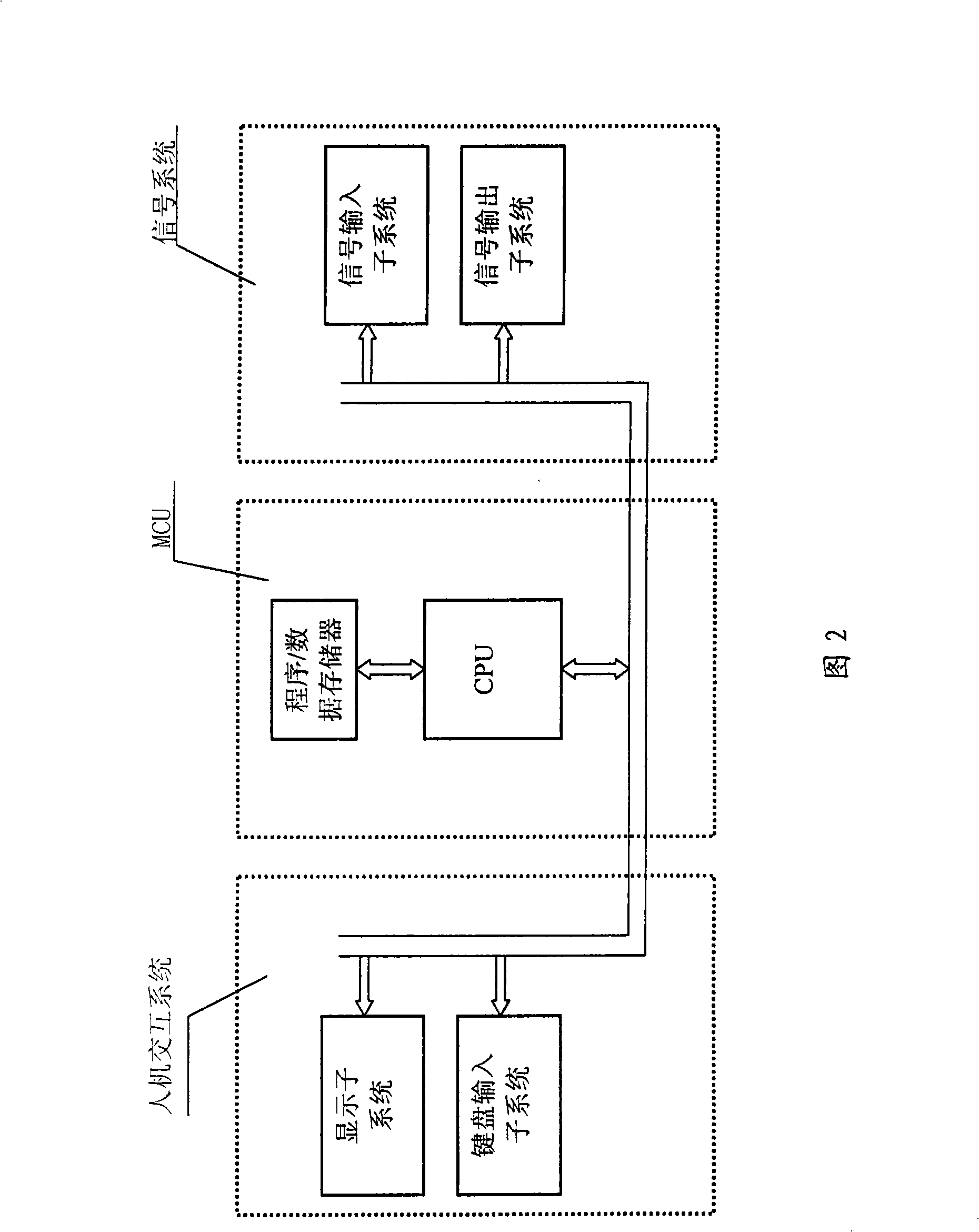

Fuzzy intelligent control system for casting water processing medicament

InactiveCN101301538AImprove dynamic characteristicsImprove adjustment qualityControlling ratio of multiple fluid flowsMixer accessoriesFuzzy control systemBusiness forecasting

The invention relates to a fuzzy intelligent system for additi0n of a water treatment medicament, the applied method comprises the steps of: in the first place, establishing a forecasting model of the controlled object online in light of the state and operating quantity of the controlled object, forecasting the control result maintaining the current operating quantity with the model, then in a control target evaluation, evaluating the control effect of the system and generating the result which adjusts weights of the fuzzy control, in terms of the current state and forecasting result of the controlled object, as a result of that, the fuzzy control can confirm the optimal operating increment. With an eye to vast territory of our country and plenty of tap water and sewage disposal plants, the invention has extremely extensive application and market prospects.

Owner:WUHAN HUAKAI SCI & TECH

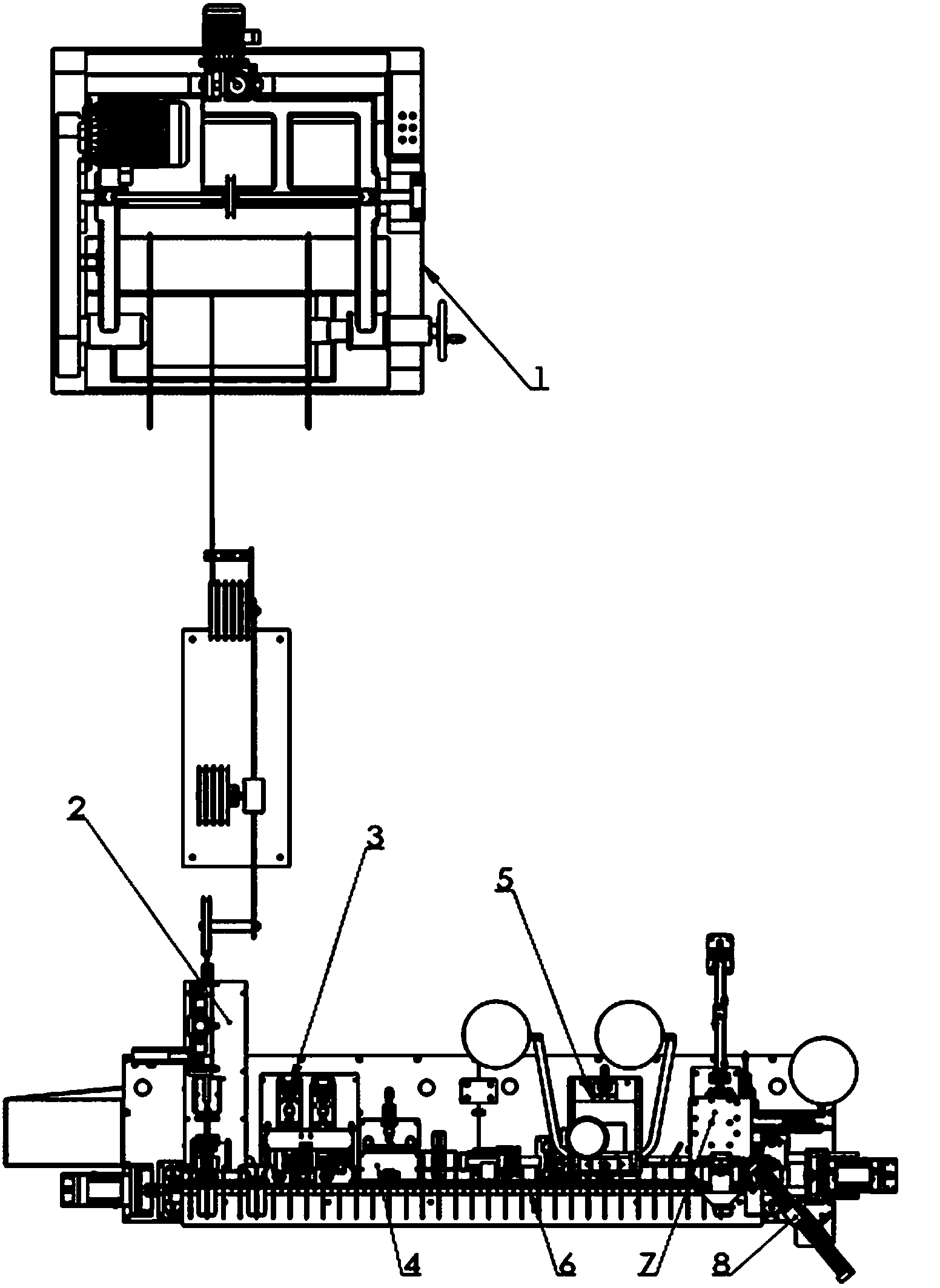

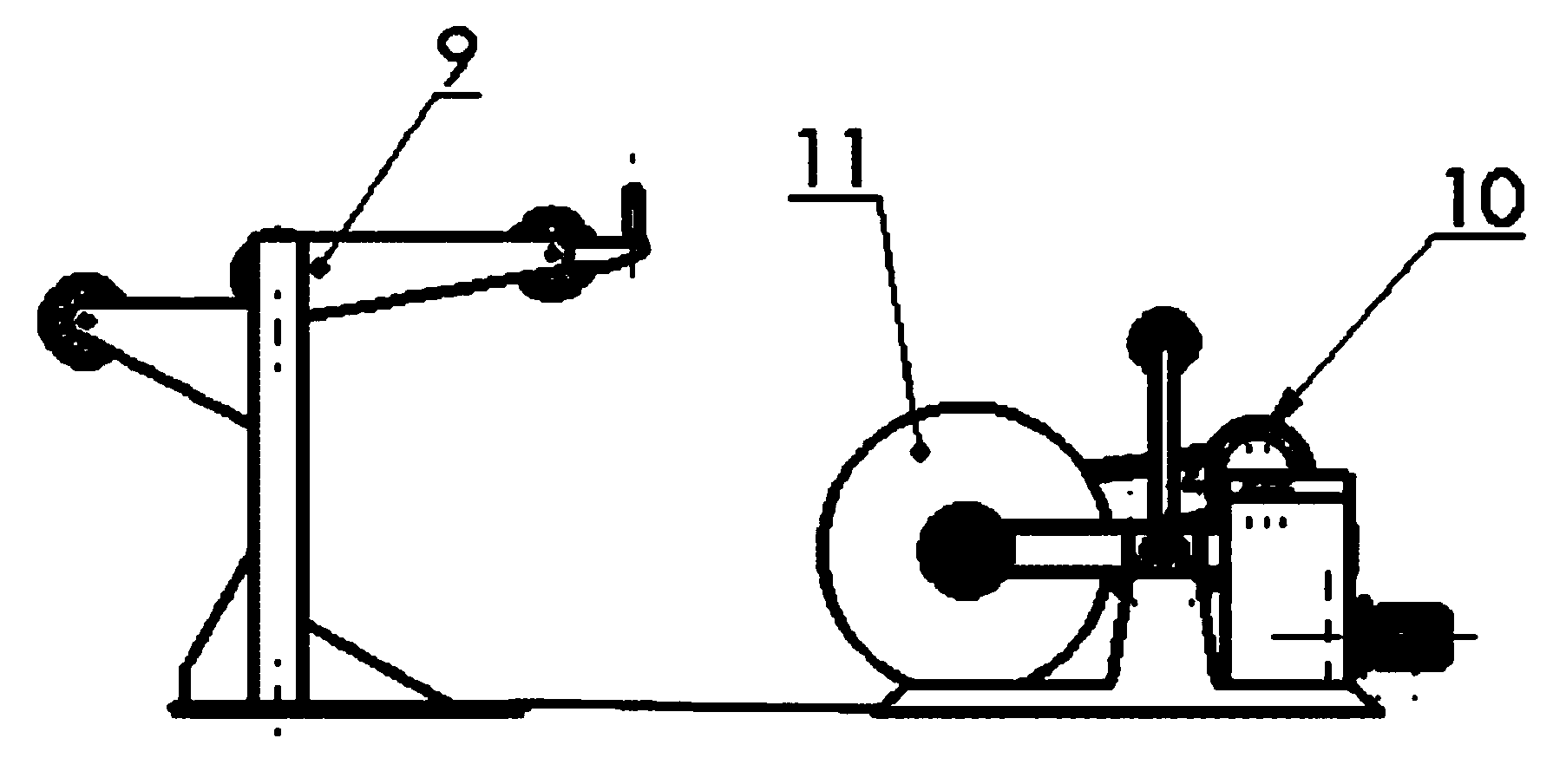

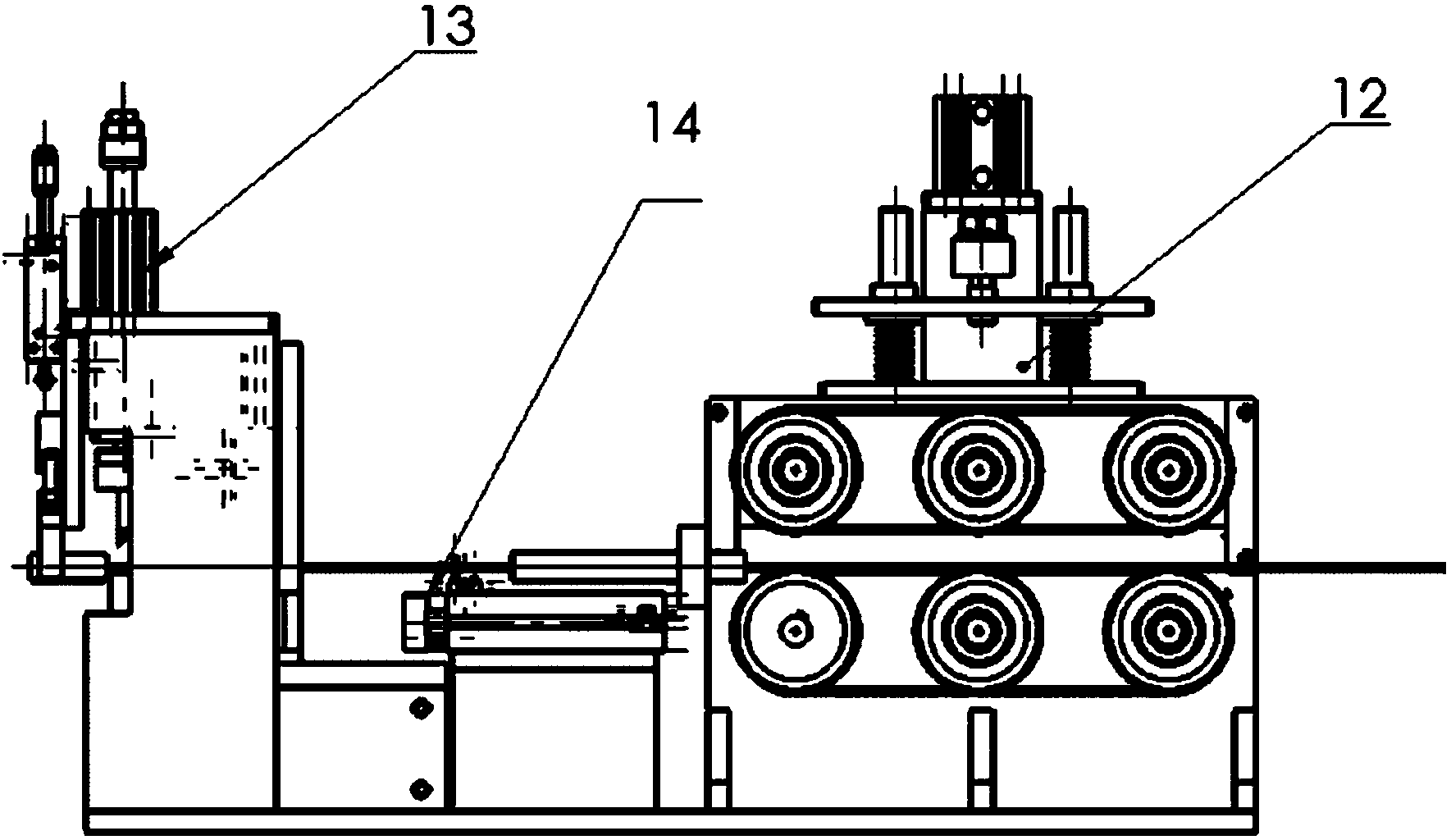

Intelligent integrated two-core plug device

InactiveCN104124596AIncrease productivityImprove qualityContact member assembly/disassemblyConnection formation by deformationEngineeringFixed length

The invention relates to an intelligent integrated two-core plug device comprising power line pay-off machine (1), an automatic power line fixed-length cutting and tail peeling portion (2), a power line head peeling and inner core wire separation portion (3), a power line head inner core wire separation portion (4), a power line head and terminal riveting and fixing portion (5), a power line moving portion between stations (6), a power line head terminal loading skeleton portion (7), and an automatic power line material-taking portion (8). The provided intelligent integrated two-core plug device has the following beneficial effects: full-automatic two-core power plug line production and assembling can be realized; the production efficiency is high; the product quality is excellent and stable; and the production cost is low and the like.

Owner:HEFEI PASE MECHANICAL AUTOMATION

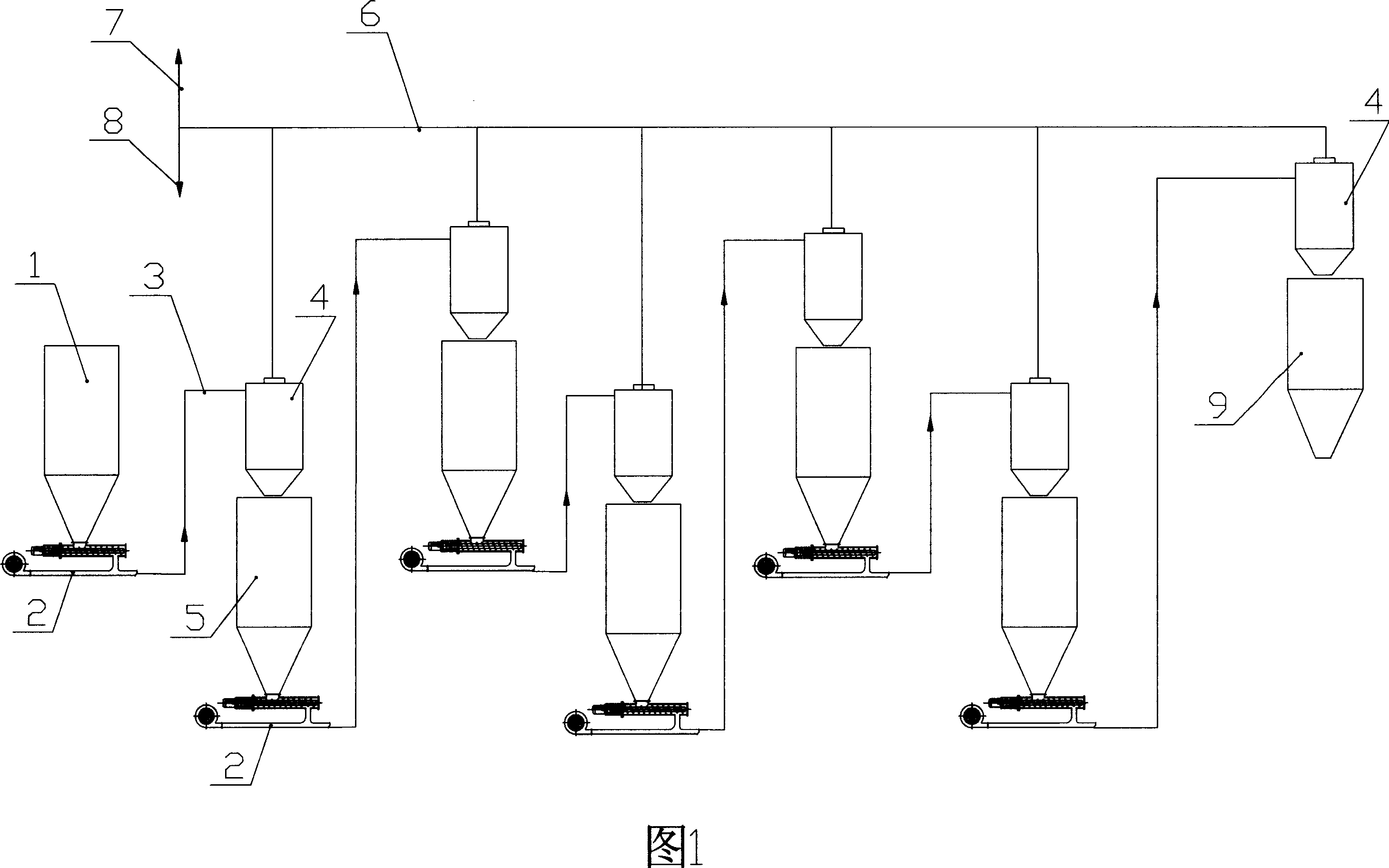

Method for continuous drying regenerative piece of polyester bottle, and dedicated drying equipment

InactiveCN101004322AReduce labor intensityLabor savingDrying solid materials with heatHearth type furnacesAutomatic controlPolyester

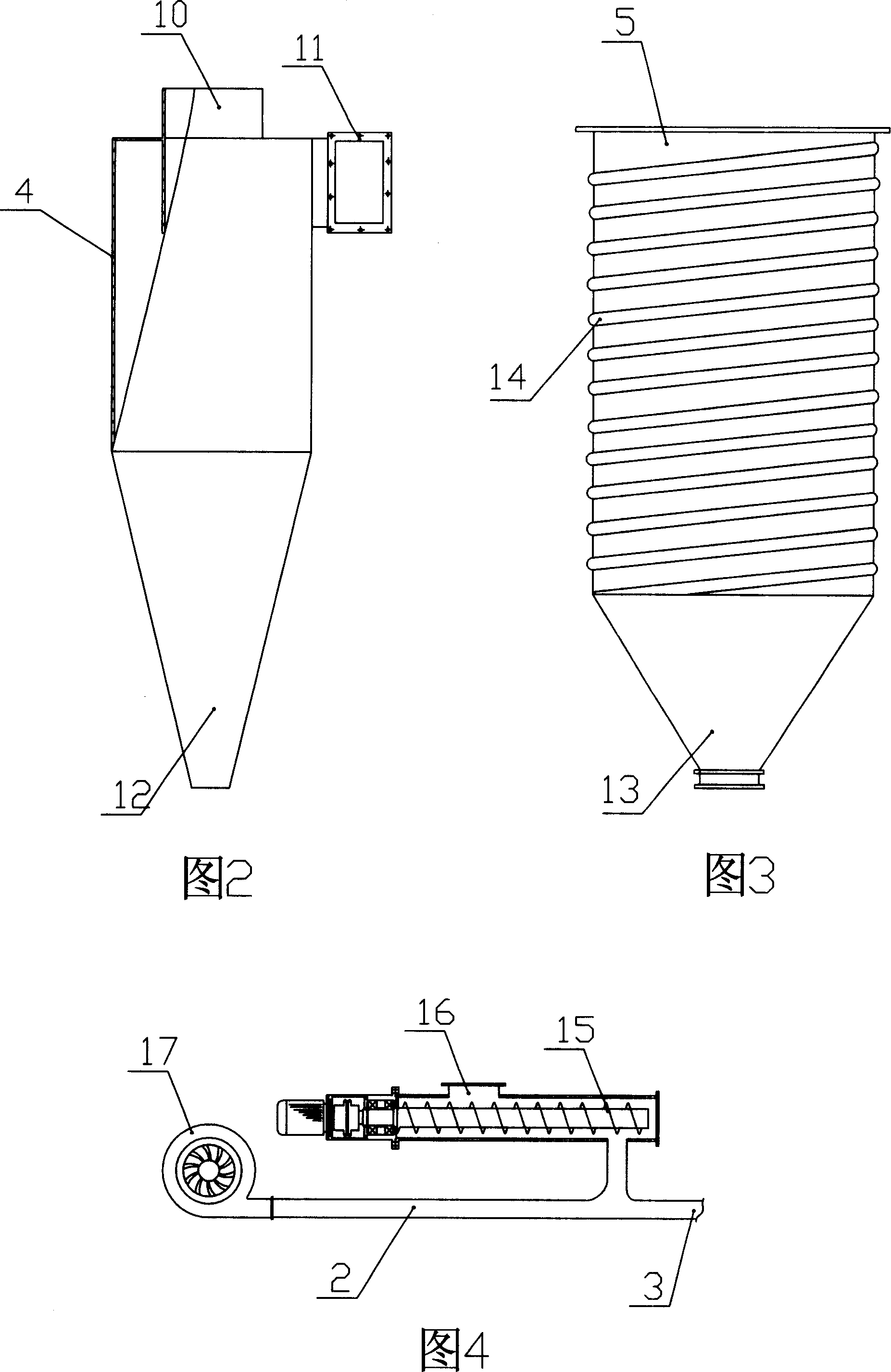

A method for continuously drying regenerated polyester bottle sheet includes sending said bottle sheets to cyclone separator under common action of hot air fan and conveyer belt, dropping bottle sheets into insulated bunker after bottle sheet is separated from hot air, dropping bottle sheet in bunker onto another fan and conveyer belt combined unit to enter another circulation after bottle sheets are stored in said bunker for certain period and realizing purpose of drying by carrying out numbers of circulations. The device for realizing said method is also disclosed.

Owner:ZHEJIANG HUAXIN CHEM FIBER

Car washing method

ActiveCN106985794AUnmanned operationAvoid accidental injuryCleaning apparatus for vehicle exteriorsApparatus for meter-controlled dispensingControl systemWater circulation

The invention discloses a car washing method. An existing car washing method needs worker involvement and usually does not have the sewage recycling function. A movable integrated car washer adopted by the car washing method comprises a control system, a framework and water circulation system and a car washing system. A to-be-washed car is limited through four positioning assemblies. A clean water pump and a sewage pump are started, sewage in a sewage tank is purified and then pumped into a clean water tank, and the clean water tank provides water for each water outlet point of the car washing system. A gantry framework moves along guide rails under driving of a traveling motor. Transverse brushes wash the upper portion of the car, and vertical brushes wash the car head part, the car tail part and two sides of the car, small vertical brushes wash the lower portions of the two sides of the car, and air knives blow the washed car dry. The car washing method can recycle sewage and is suitable for movable car washing devices.

Owner:浙江澜象智能科技有限公司

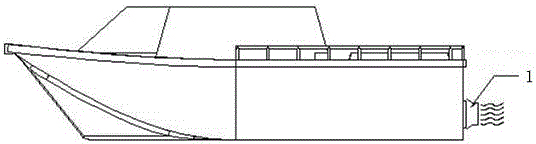

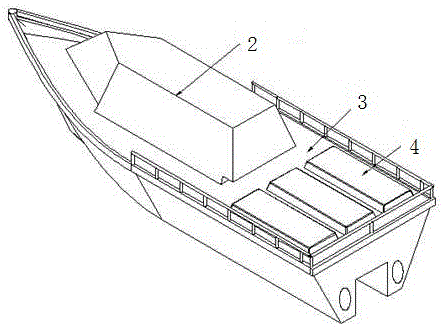

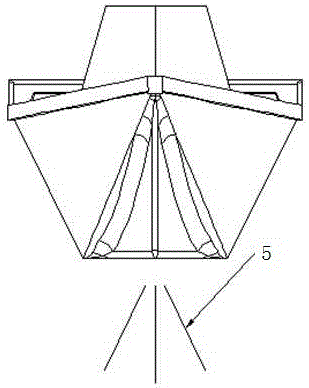

Intelligent sailing/remote control unmanned working boat used for fishing of fishery

InactiveCN106516022AEliminate risks to personal life safetySimplify power configurationFishing vesselsFishingIntelligent lightingRemote control

The invention provides an intelligent sailing / remote control unmanned working boat used for fishing of the fishery to overcome deficiencies in the prior art. The intelligent sailing / remote control unmanned working boat used for fishing of the fishery comprises a power unit, lamp cabins and an unmanned boat body. By adoption of the intelligent sailing / remote control unmanned working boat with the functions of automatic sailing, intelligent navigation and full-automatic operation of boat equipment, manual fish luring on the sea is replaced, the intelligent sailing / remote control unmanned working boat is specially used for light seining fishing operation, personal life safety risks existing in traditional operation are fundamentally eliminated, and benefits of fishing of the fishery are remarkably improved; and the light seining fishing operation mode is fundamentally changed, light luring fishing boats boom, benefits of fishermen are finally improved, and the marine resources and the marine environment are better protected.

Owner:GUANGZHOU HG MARINE CO LTD

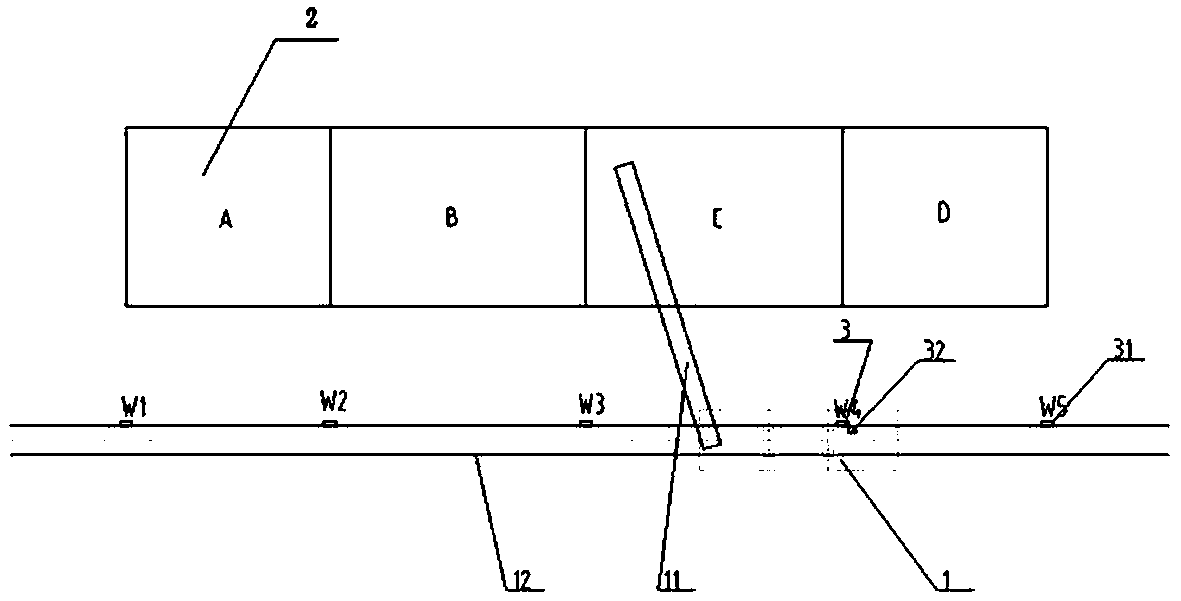

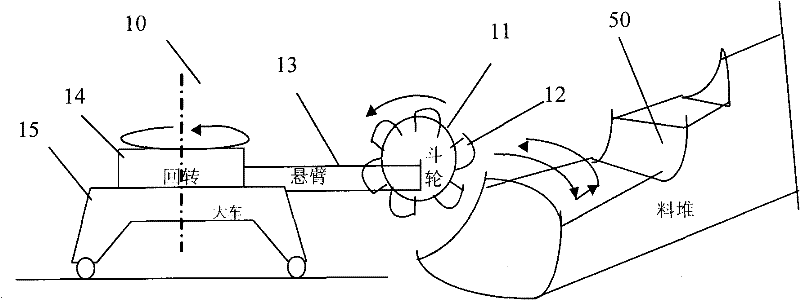

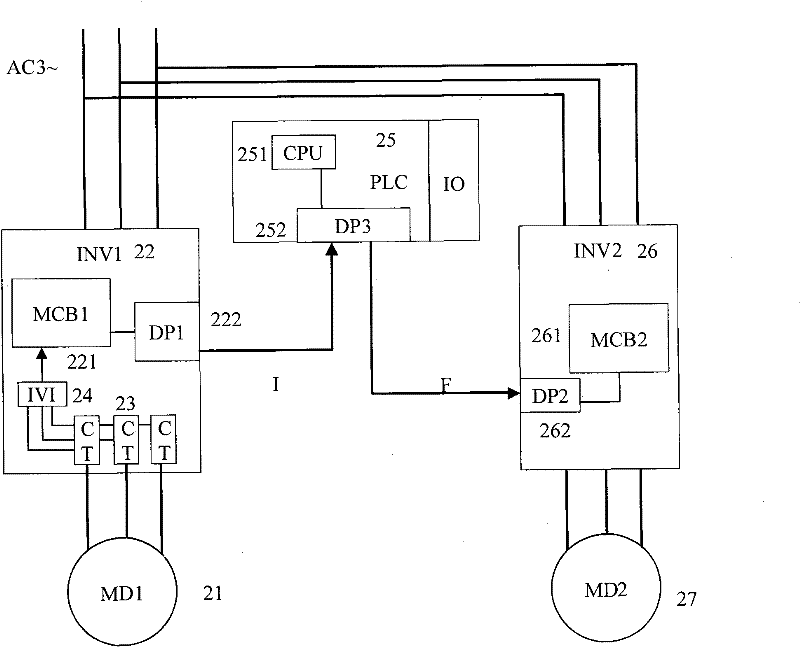

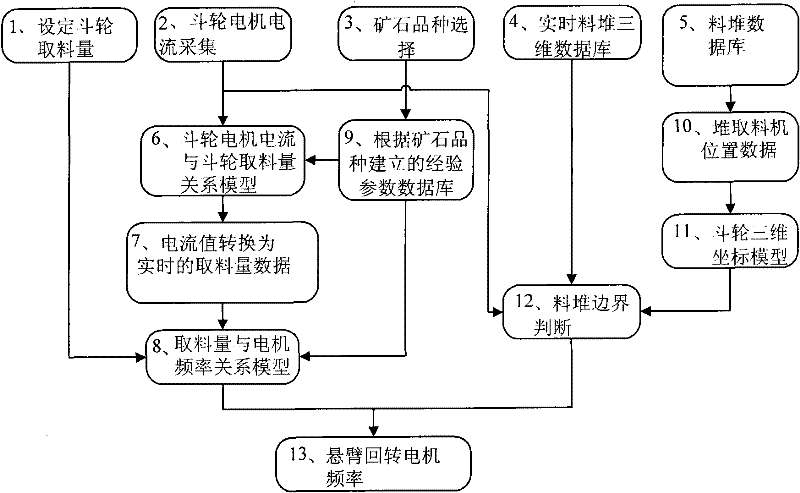

Automatic material taking control device and method of material piling and taking machine

ActiveCN101776867BAccurately reflectRespond quicklyLoading/unloadingProgramme control in sequence/logic controllersElectric machineControl engineering

The invention discloses an automatic material taking control device and a method of a material piling and taking machine. Because the invention has a function of collecting the current of a motor of a bucket wheel, establishes a relational model between the current of the motor of the bucket wheel and the material taking amount of the bucket wheel, and establishes a relational model between the material taking amount of the bucket wheel and the frequency of a rotary motor of a cantilever, under the action of the relational models, the rotary speed of the cantilever can be determined by the frequency of the rotary motor of the cantilever and can be controlled by the current of the motor of the bucket wheel in the automatic material taking process, and the current of the motor of the bucketwheel can accurately and quickly reflect the material taking amount of the bucket wheel, thereby effectively forming a closed loop control process to well control the material taking amount of the bucket wheel. In addition, because the invention has a function of judging the material pile boundary, when each material taking process reaches the material pile boundary, the invention can carry out judgment automatically and adjust the position of the material piling and taking machine to carry out the rotary material taking process for the next time, and the processes are carried out repeatedly and circularly to automatically complete the material taking process of the whole material pile, thereby realizing unmanned operation.

Owner:BAOSHAN IRON & STEEL CO LTD

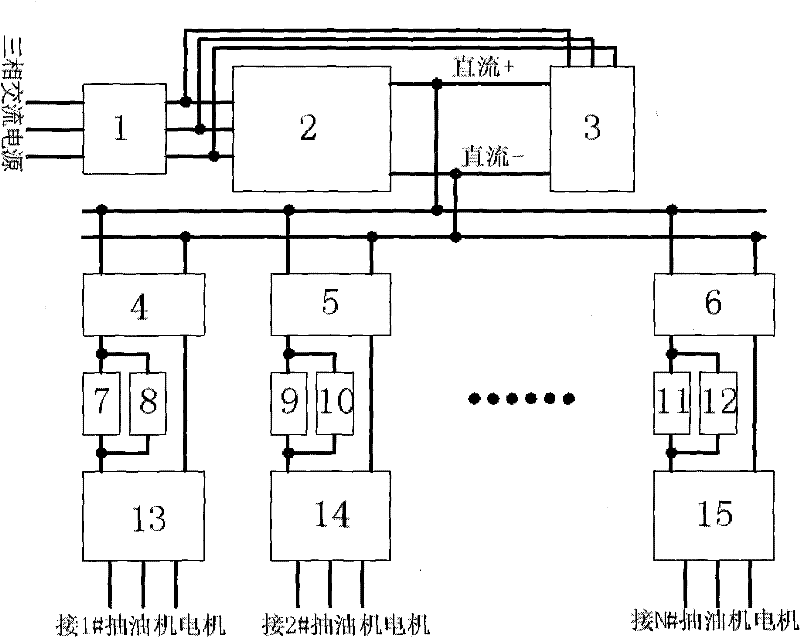

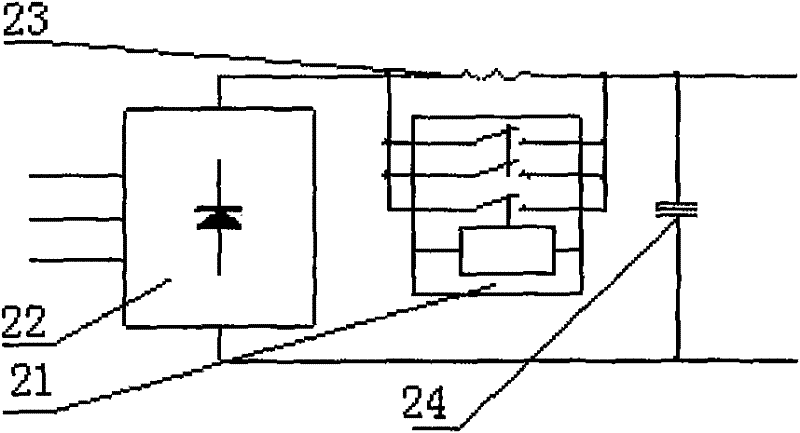

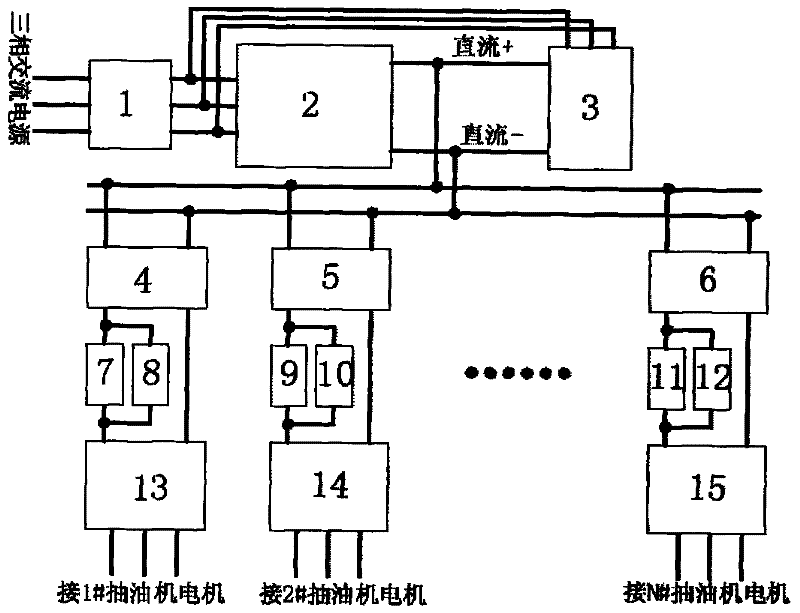

A centralized control cabinet for pumping unit well site

InactiveCN102299670AHigh power saving rateImprove reliabilityMultiple ac dynamo-electric motors controlFailure rateHigh rate

The invention relates to a centralized control cabinet for pumping unit well sites. The device includes an air switch A, a soft-start rectifier power supply, a sub-well inverter device, an energy feedback unit, and a housing. The air switch A, soft-start rectifier power supply, sub-well The well inverter device and the energy feedback unit are packaged in the shell, the split well inverter device includes N inverter devices, the air switch A is connected to the soft-start rectifier power supply, and the output of the soft-start rectifier power supply terminal is connected to the input terminal of the energy feedback unit, the output terminal of the energy feedback unit is connected between the air switch A and the soft-start rectifier power supply, and the input terminals of the N inverters are connected to the same bus, the The bus bar is connected to the DC output end of the soft-start rectifier power supply, and the output ends of the N inverters are respectively connected to the N pumping unit motors one by one. Compared with the prior art, the present invention has the advantages of high power saving rate, low failure rate of power grid failure, convenient and cost-saving maintenance, maintenance, and the like.

Owner:谭雪开

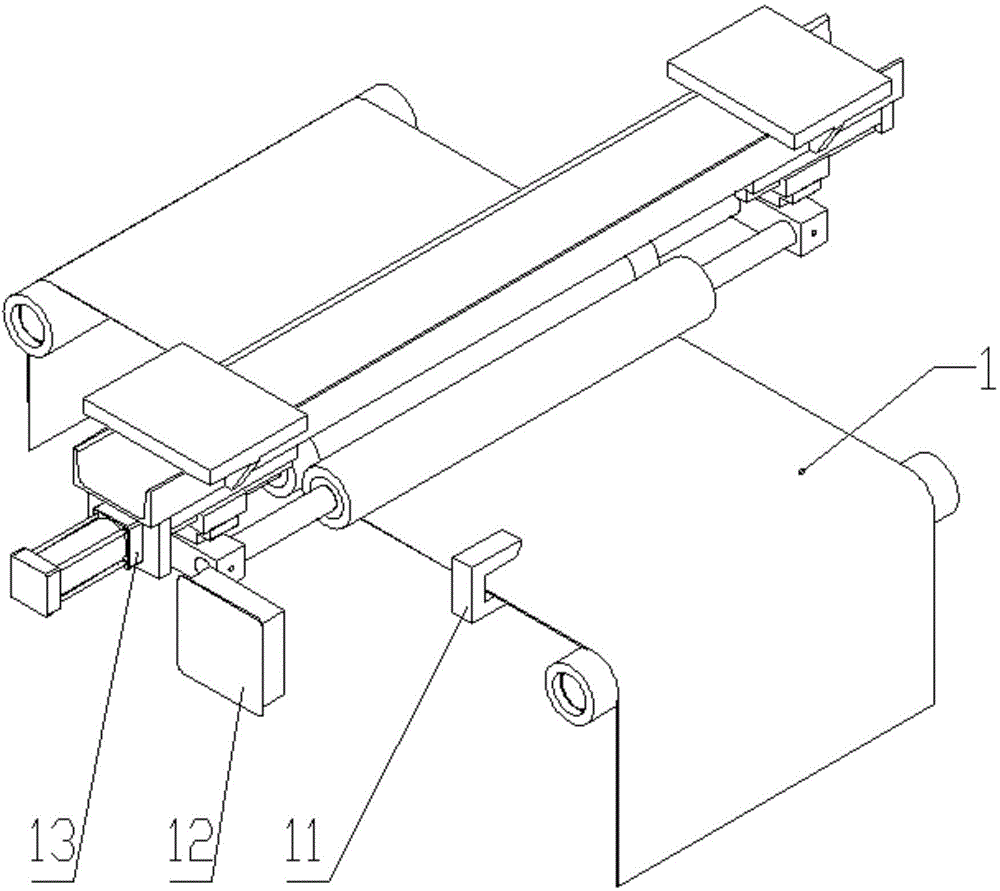

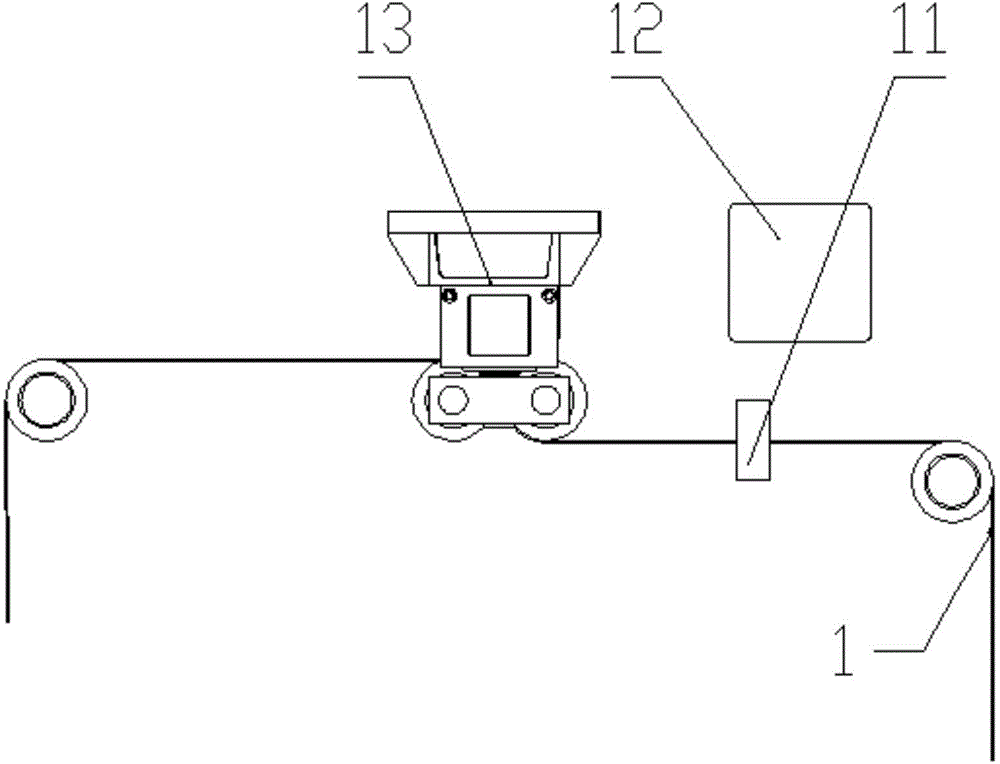

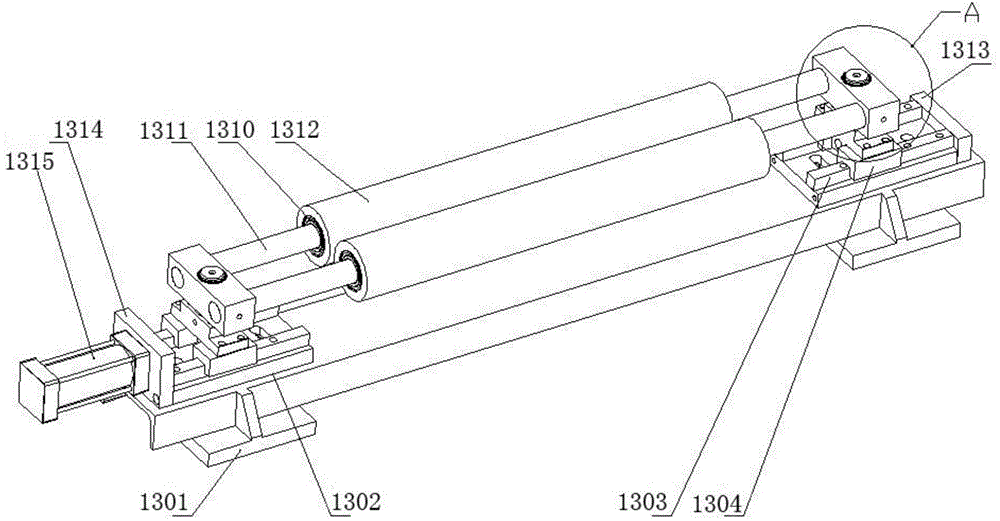

Maintenance-free system of belt of conveyor

ActiveCN104891132AReduced commissioning timeSimple structureConveyorsControl devices for conveyorsEngineeringPosition sensor

The invention provides a maintenance-free system of a belt of a conveyor. The maintenance-free system comprises an automatic deviation rectifying system and an automatic tensioning system. The automatic deviation rectifying system comprises a belt edge position sensor, a deviation rectifying controller and a belt deviation rectifying execution mechanism. The deviation rectifying controller controls the belt deviation rectifying execution mechanism to move by combining real-time position information of belt edges. The automatic tensioning system comprises a belt tensile force detection system, a belt tensile force controller and a belt tensile force adjusting execution mechanism. The belt tensile force controller is used for controlling the belt tensile force adjusting execution mechanism to carrying out front and back movement. The maintenance-free system is simple in structure, debugging time of a belt conveyor is greatly reduced, stability of devices is improved, and potential safety hazards are reduced.

Owner:NANTONG YIGAO MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com