Automatic feeding system of FDM (frequency-division multiplexing) printing equipment

A technology of automatic feeding and printing equipment, applied in the direction of additive processing, etc., can solve the problems of PLA material not being applicable, not giving continuous feeding, and unable to realize continuous production, so as to ensure continuity and high degree of intelligent control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Detailed embodiments of the present invention will now be described with reference to the accompanying drawings.

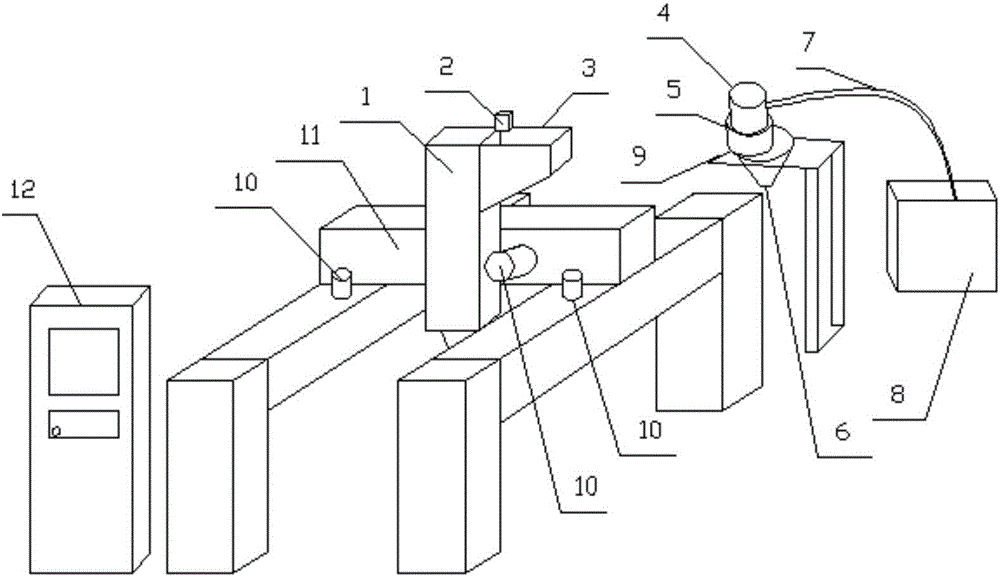

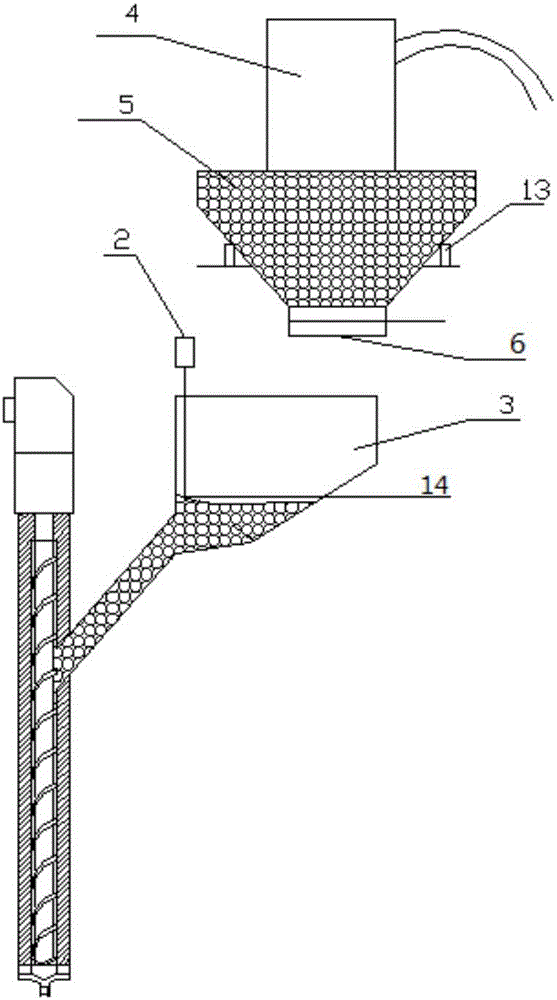

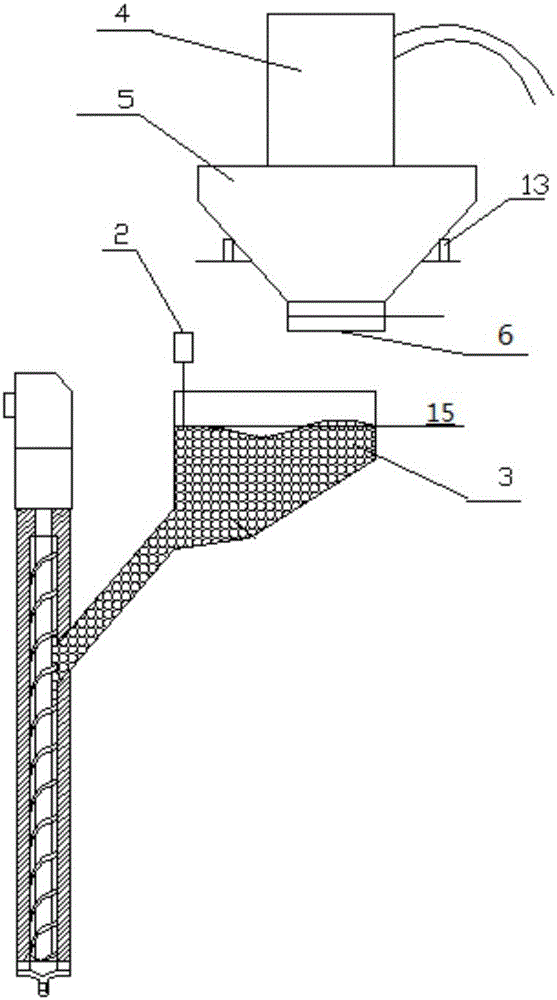

[0030] See attached figure 1 , which shows a schematic structural view of an embodiment of an automatic feeding system for an FDM printing device according to the present invention. Depend on figure 1 It can be seen that in this embodiment, the automatic feeding system of the FDM printing equipment includes: a printing extrusion mechanism 1 for printing and extruding materials; a printing bin hopper 3 installed on the upper part of the printing extrusion To supply printing materials to the printing extrusion mechanism 1, and the printing bin hopper 3 is electrically connected to the photoelectric detection device 2 to detect the position of the material in the printing bin hopper 3; 3 is selectively communicated to supply materials to the printing bin hopper 3, and is selectively communicated with the material hopper 8 to selectively obtain materials from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com