Wire-drawing mechanism for woven wire

A wire take-up mechanism and braided wire technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as increased production costs, unqualified products, and failures, and achieve the effect of avoiding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the expensive examiners of the patent office, especially the public, understand the technical essence and beneficial effects of the present invention more clearly, the specific implementation of the present invention is described in detail below in conjunction with the accompanying drawings and embodiments, but all descriptions of the embodiments are It does not constitute a limitation on the technical solution of the present invention, and any equivalent replacement or conceptual change in form but not in substance shall be regarded as the scope of the technical solution disclosed and claimed in the present invention.

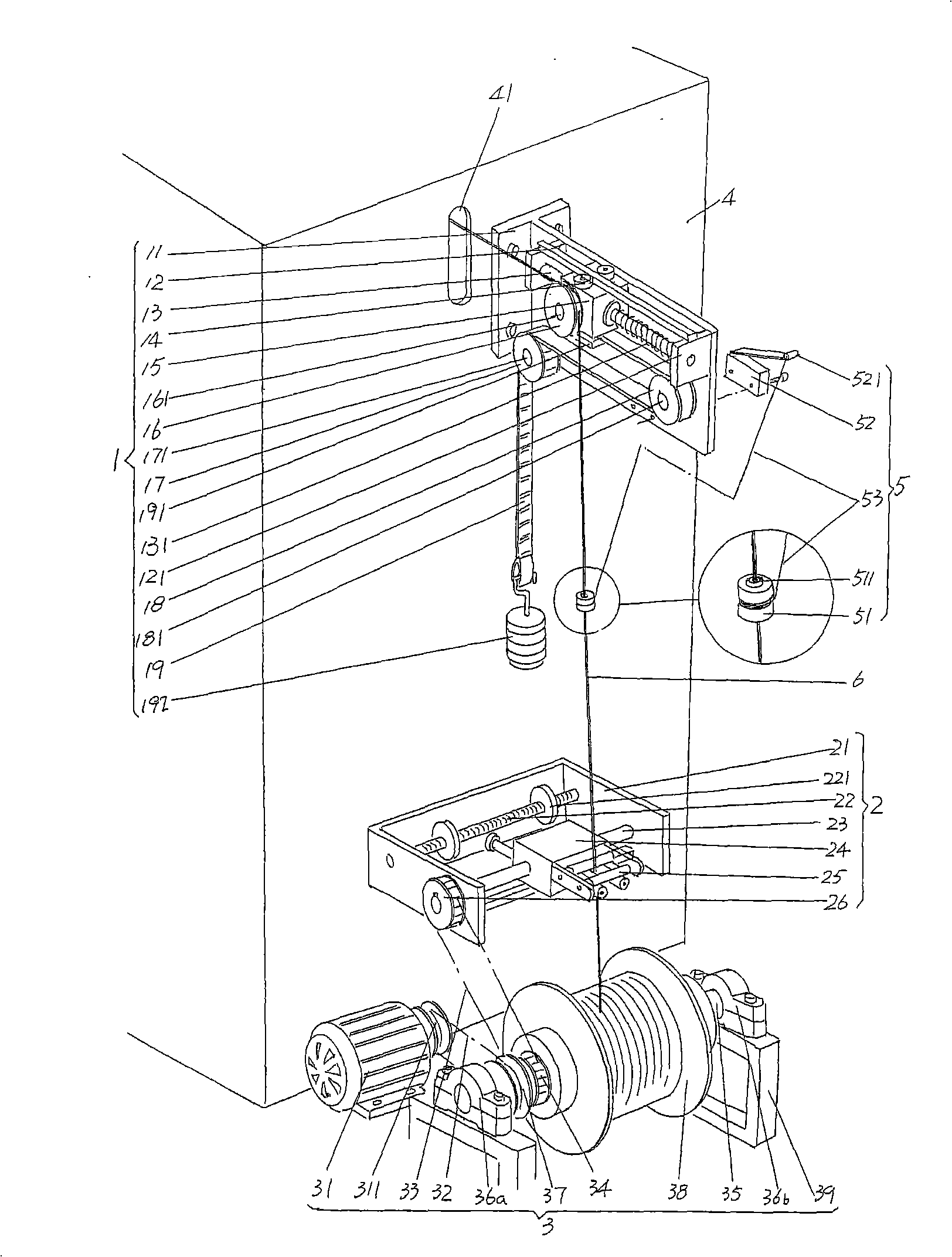

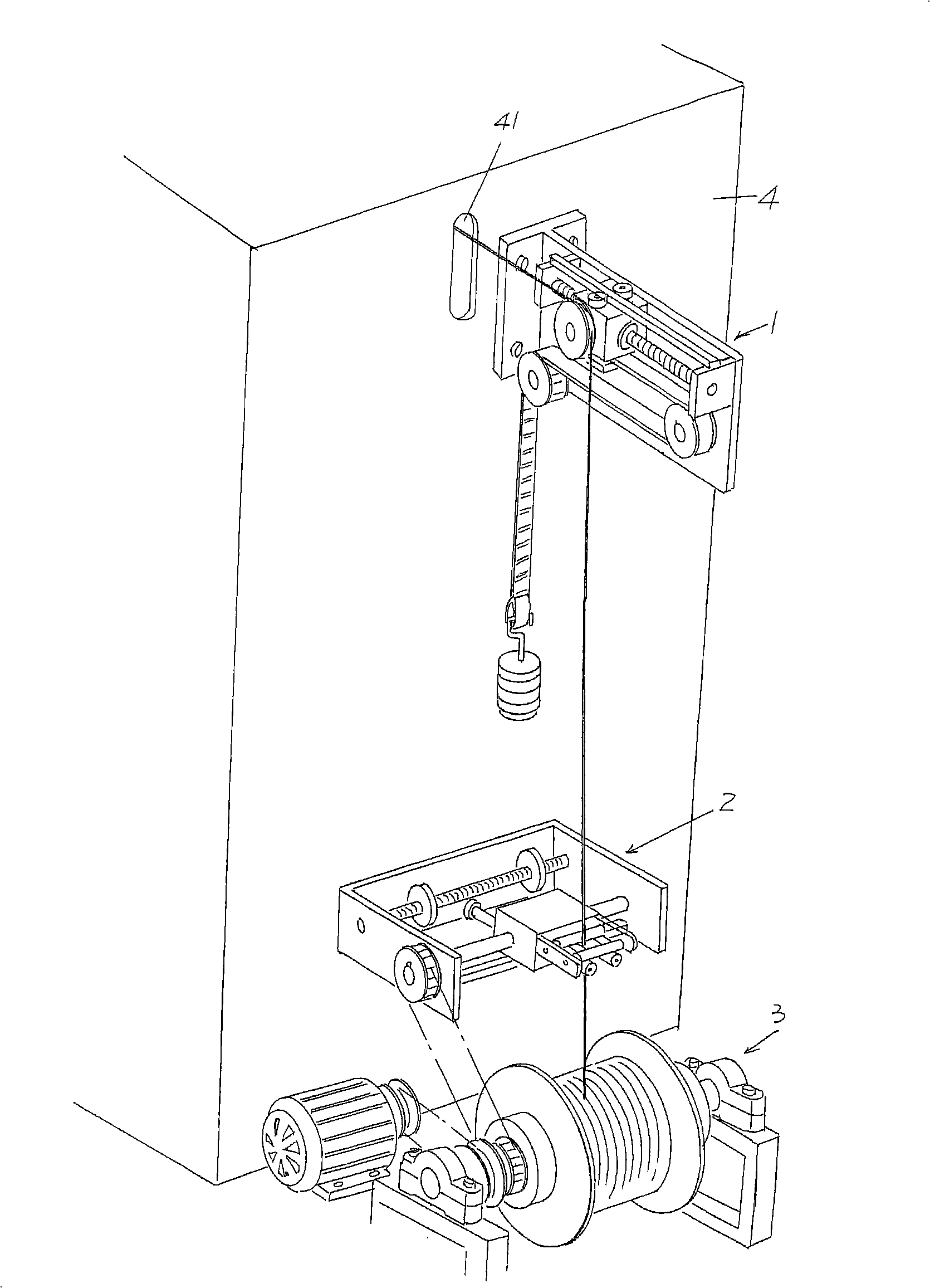

[0016] please see figure 1 In this figure, the applicant shows a braiding machine 4 widely used by wire and cable production enterprises at present, and a tension adjustment device 1 and a reciprocating guide device are respectively arranged on one side of the braiding machine 4 with a braided wire outlet 41. 2 and winding device 3, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com