Passive vibration isolation system for dampers of ceilings and sheds

A vibration isolation system and ceiling technology, applied in the field of vibration reduction and vibration isolation, can solve problems such as poor real-time performance and reliability, need for external energy input, and must be connected to the inertial reference system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

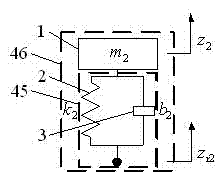

[0056] Such as image 3 ,quality m 2 The vibration state converter 45 consists of a spring k 2 2 with inerter b 2 3 connected in parallel to form a mass m 2 Vibration state converters 45 are connected in series and support mass m 2 1 makes up the mass m 2 Vibration state transition system 46, which is a simple system whose motion can be described by second order differential equation

[0057]

[0058] in, z 2 is quality m 2 displacement of 1, is the displacement input of the system, k 2 and b 2 spring respectively k 2 2 Stiffness and Inerter b 2 3 inertia coefficient.

[0059] Carry out Laplace transformation on the above formula and arrange it to get

[0060]

[0061] make , can be obtained from the above formula z 2 and z r2 The amplitude ratio of the system displacement transmissibility

[0062]

[0063] when When , the system will have anti-resonance phenomenon, and the anti-resonance frequency , at this time, the mass m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com