Automatic conveying device for helium leak check of air-conditioning heat exchanger cores and using method

An automatic conveying device and heat exchanger technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of affecting product quality, easily knocking down fins, and low production efficiency, so as to reduce labor intensity and Production cost, avoid rewinding, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

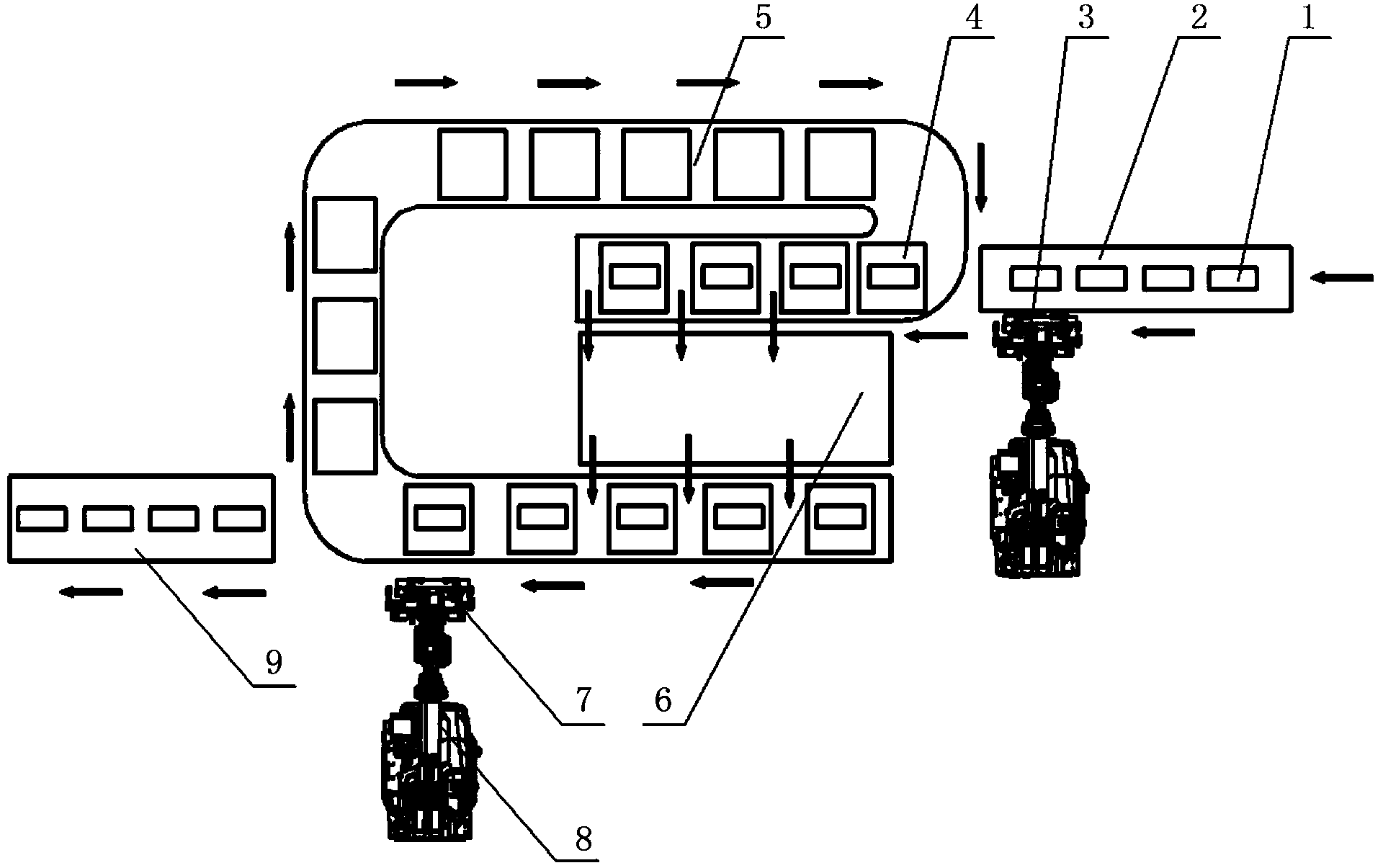

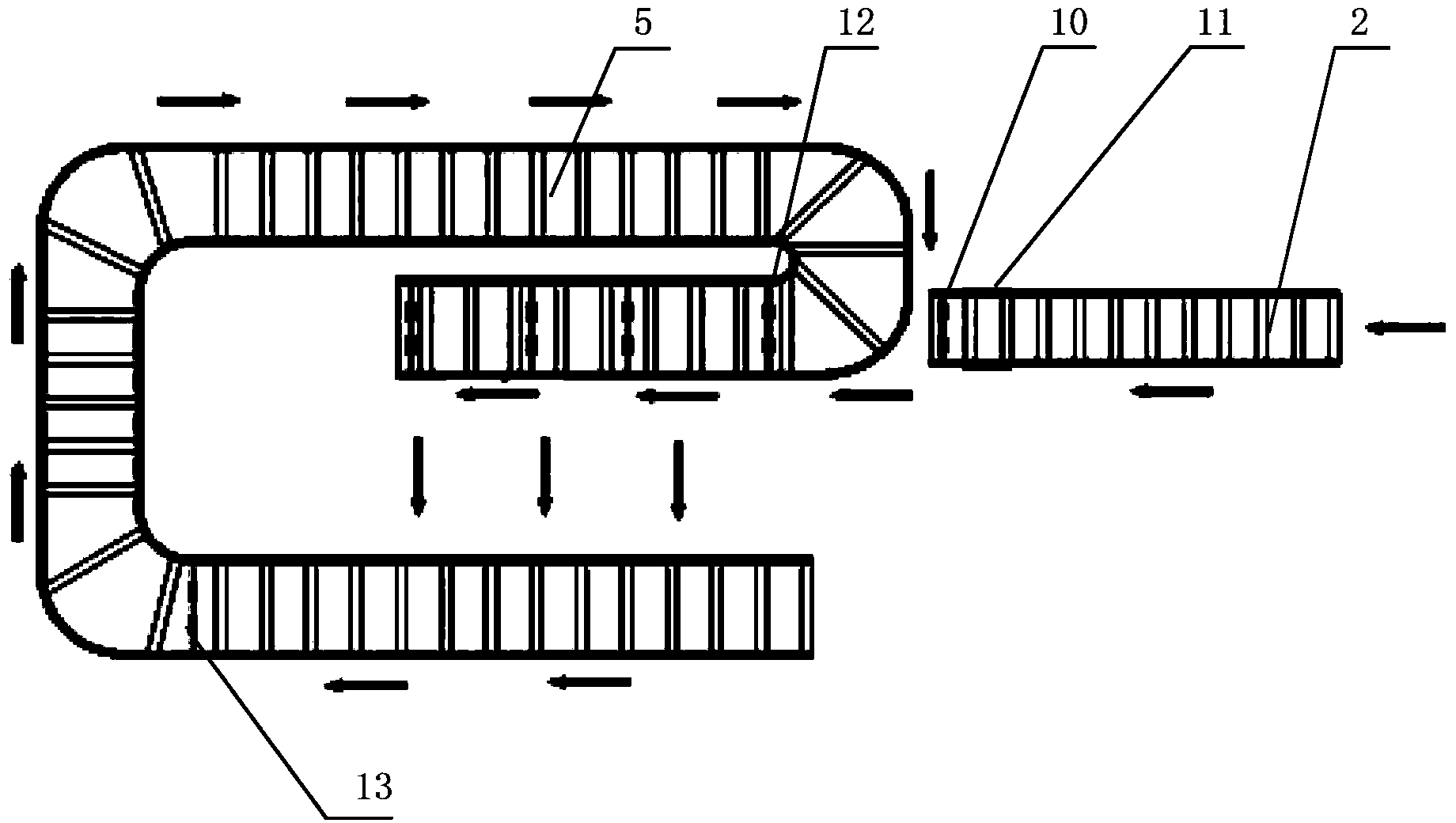

[0022] Attached below figure 1 And attached figure 2 The automatic conveying device for helium gas leak detection of the core body of the air conditioner heat exchanger according to the embodiment of the present invention and its usage method will be further described.

[0023] An automatic conveying device for helium gas leak detection of the core body of an air conditioner heat exchanger, including a transition conveying line body 2, a feeding robot and a gripper 3, a tray 4, a helium gas inspection logistics circulation line body 5, a helium gas inspection box 6, Visual imaging device 7, blanking robot and gripper 8, assembly line body 9, first stop device 10, correcting device 11, second stop device 12 and third stop device 13, wherein: transition conveying line body 2 Located on the far right side of the automatic conveying device, it is used to connect with the previous process. During operation, the heat exchanger core 1 completed in the previous process is continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com