Patents

Literature

86results about How to "Avoid rewinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

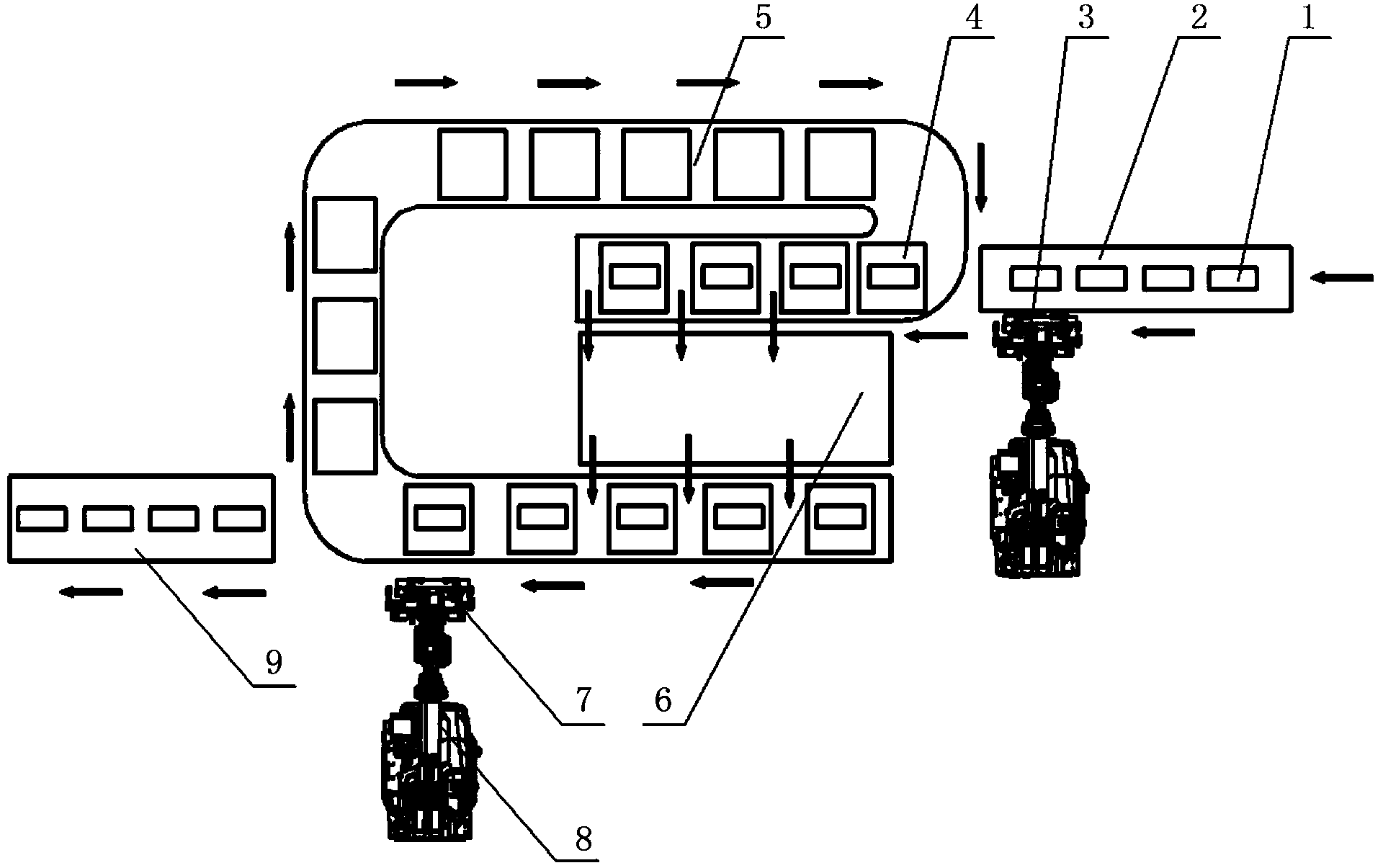

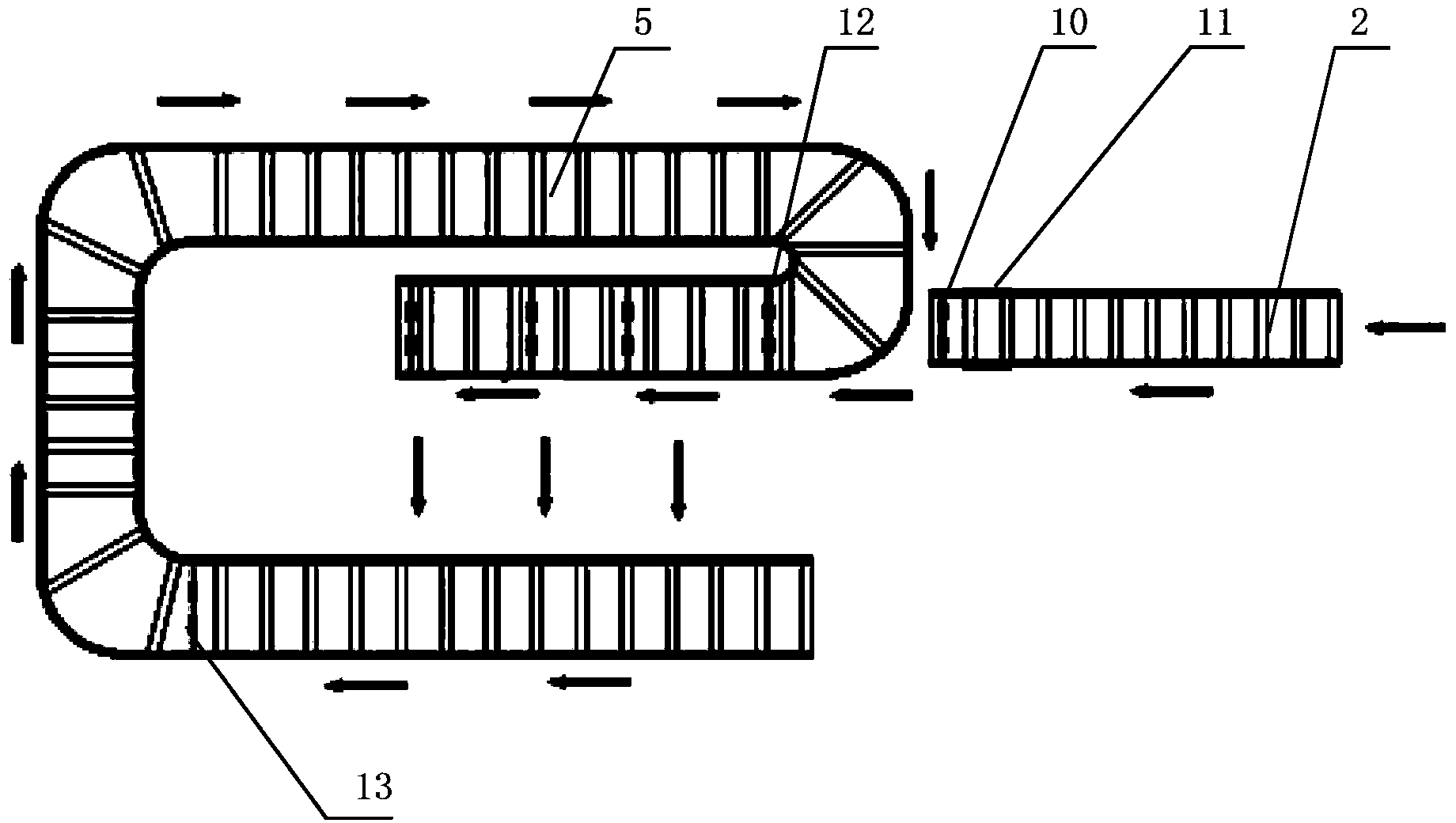

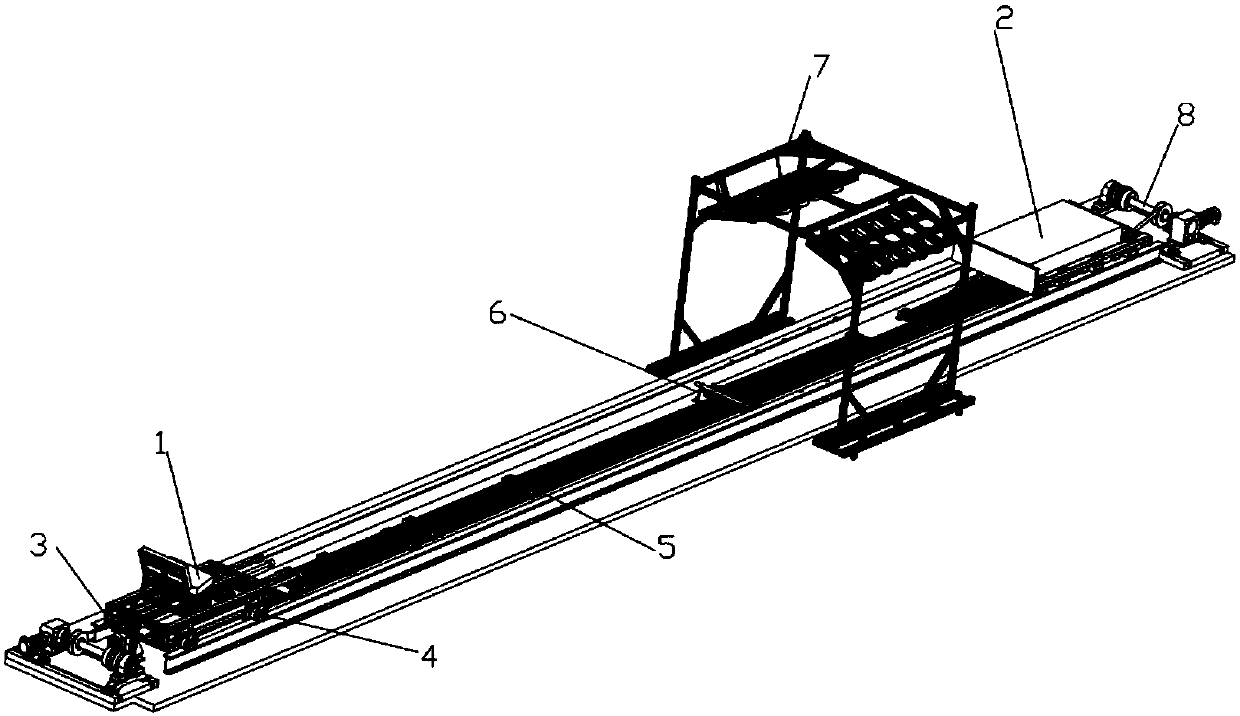

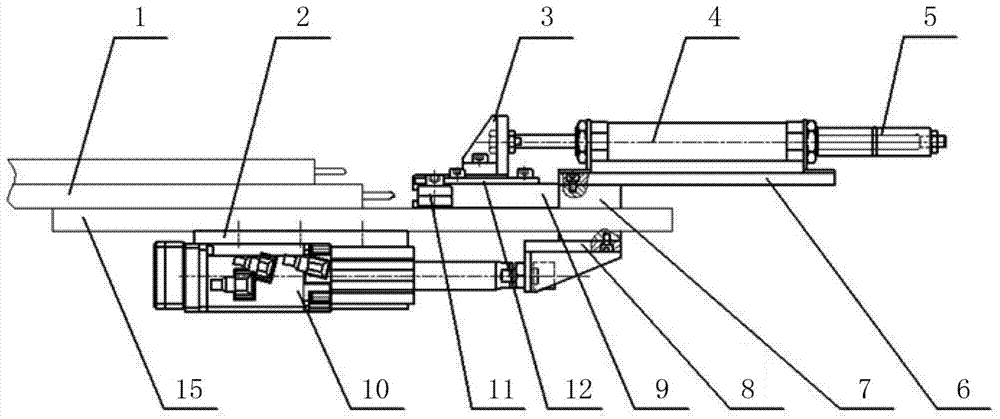

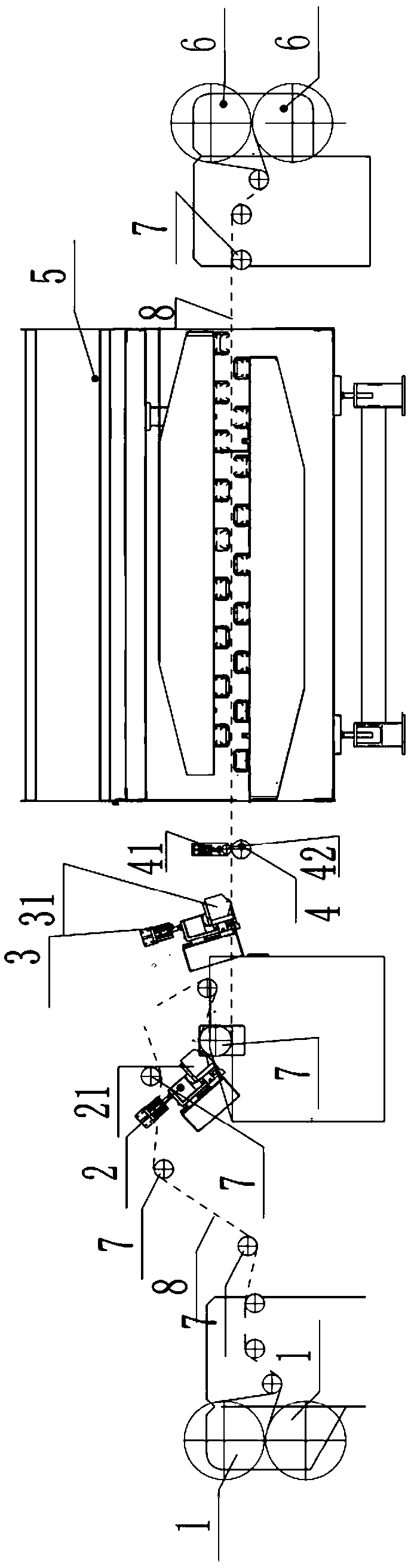

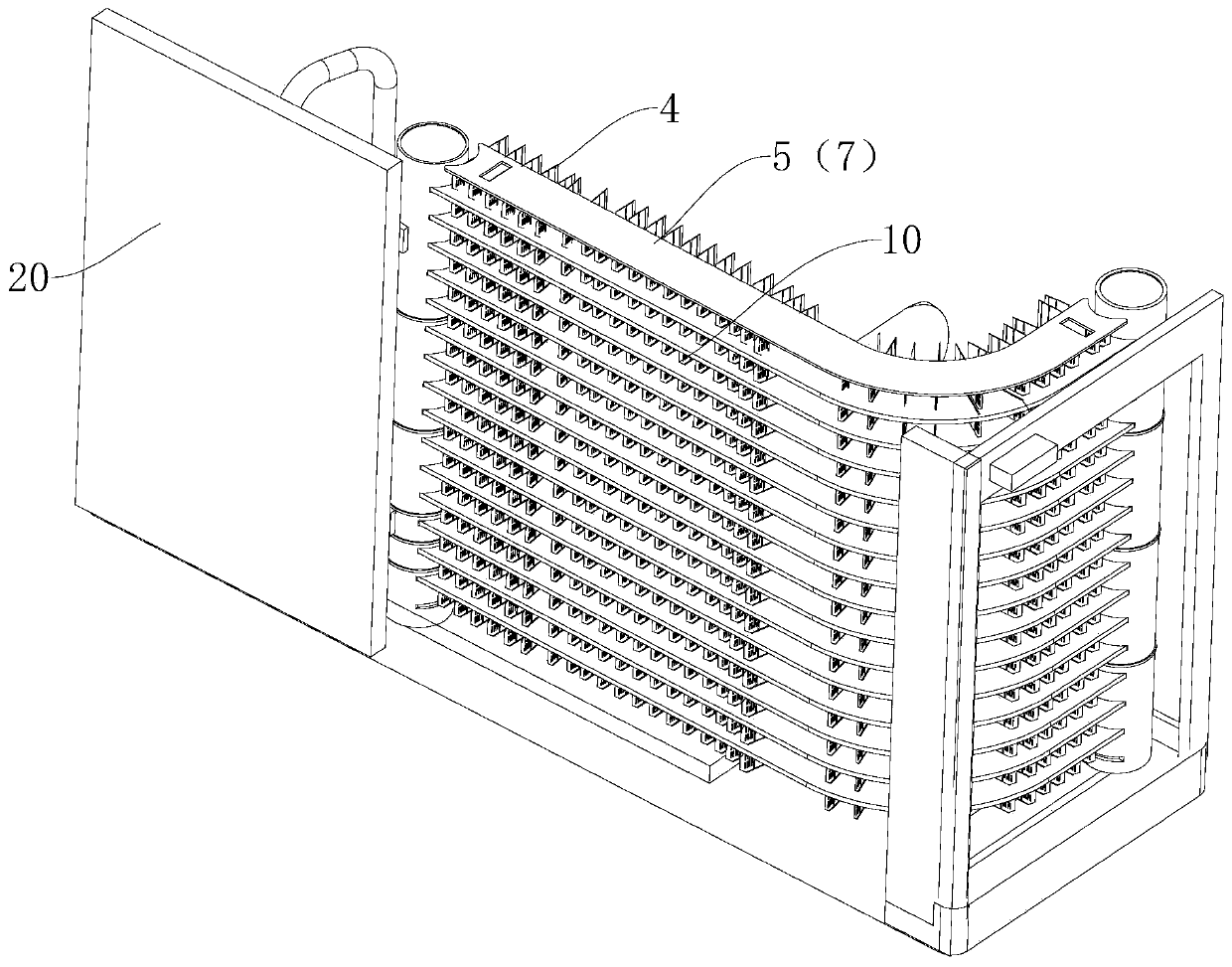

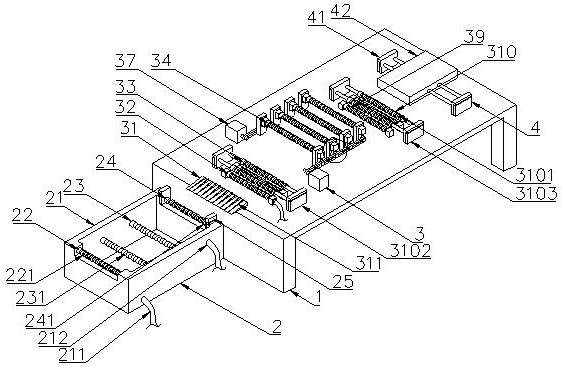

Automatic conveying device for helium leak check of air-conditioning heat exchanger cores and using method

ActiveCN104355111AReduce labor intensityReduce manufacturing costConveyor partsMechanical conveyorsProcess engineeringAir conditioning

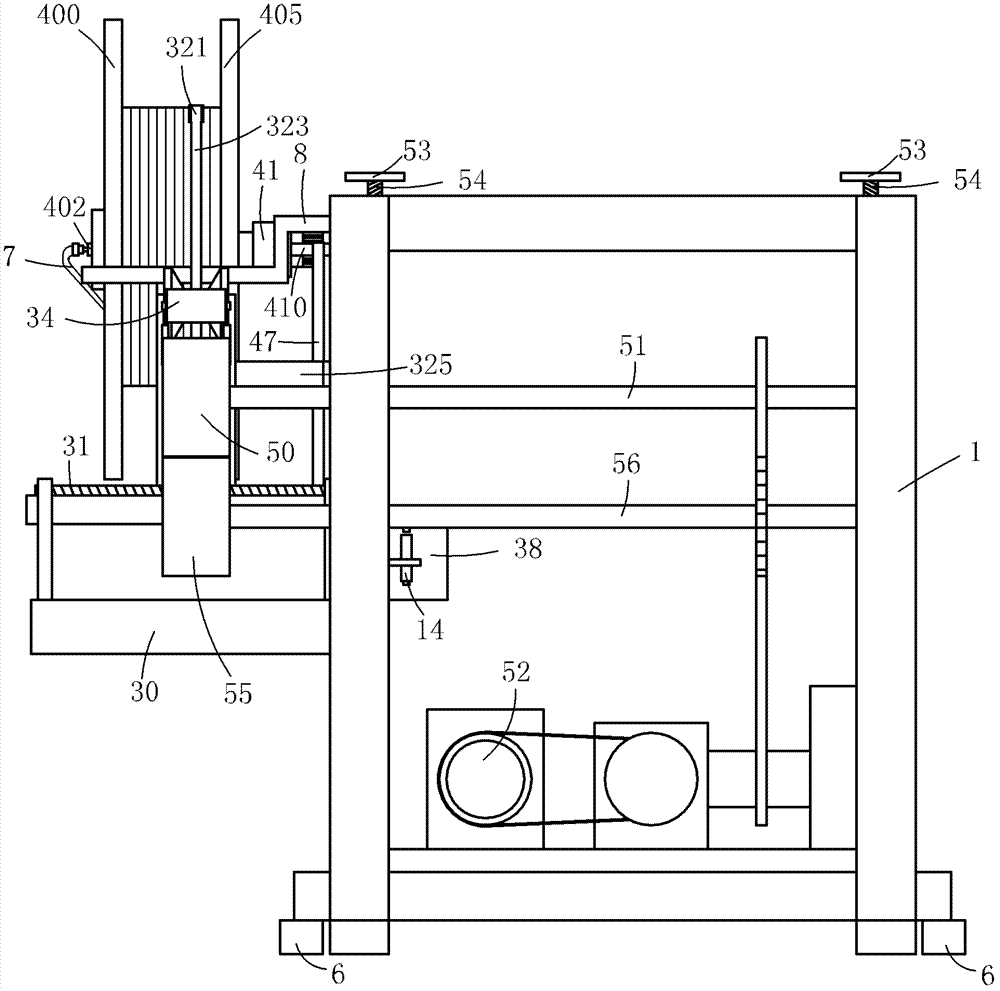

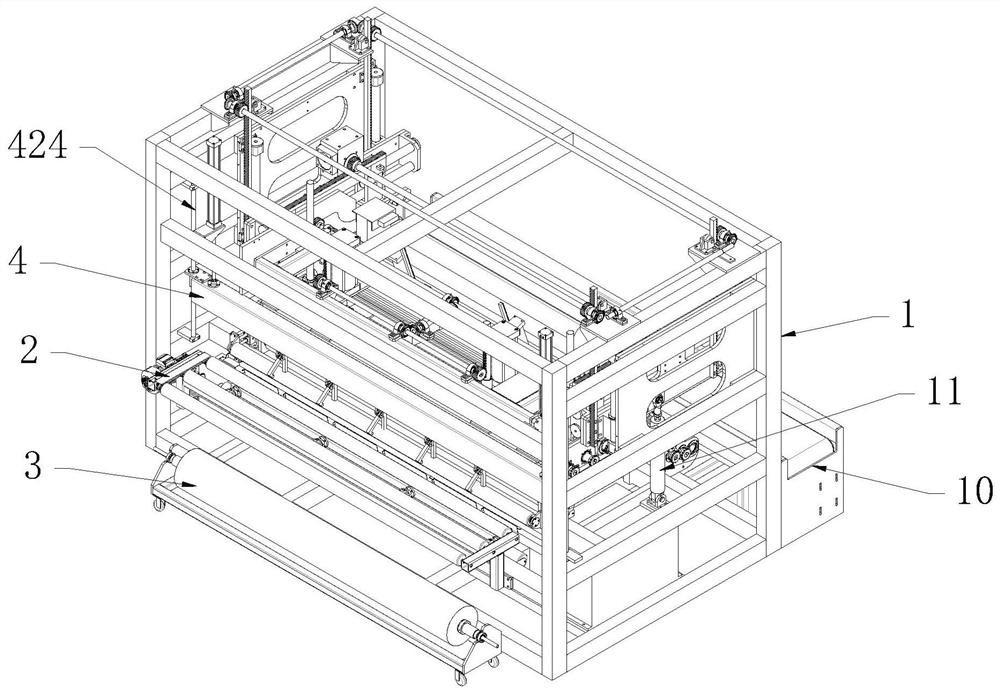

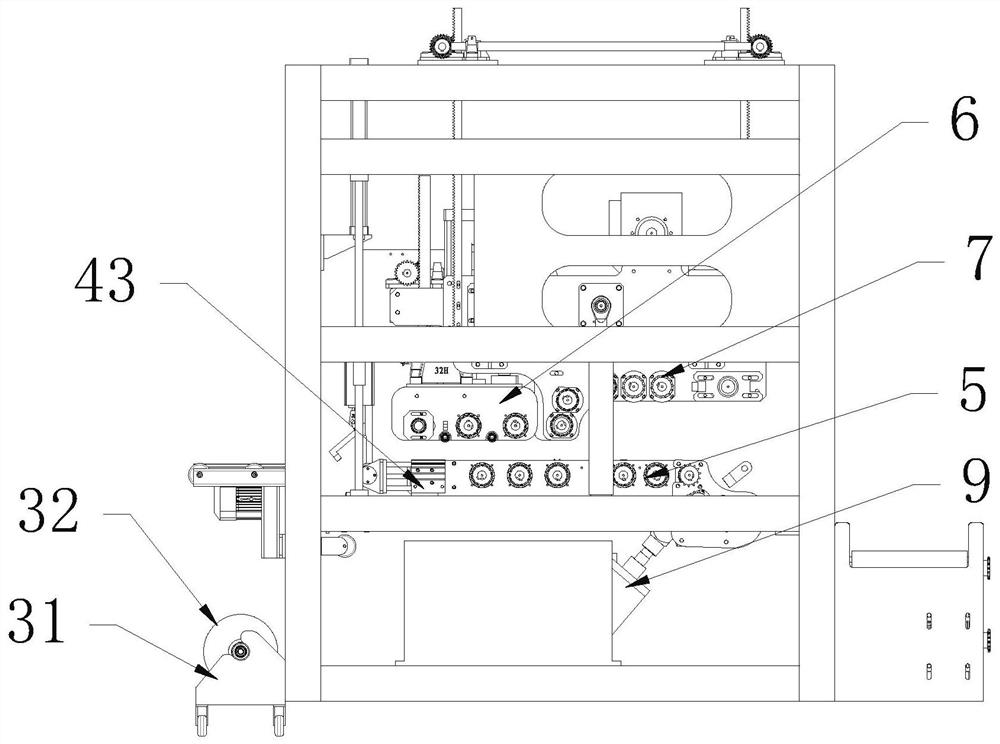

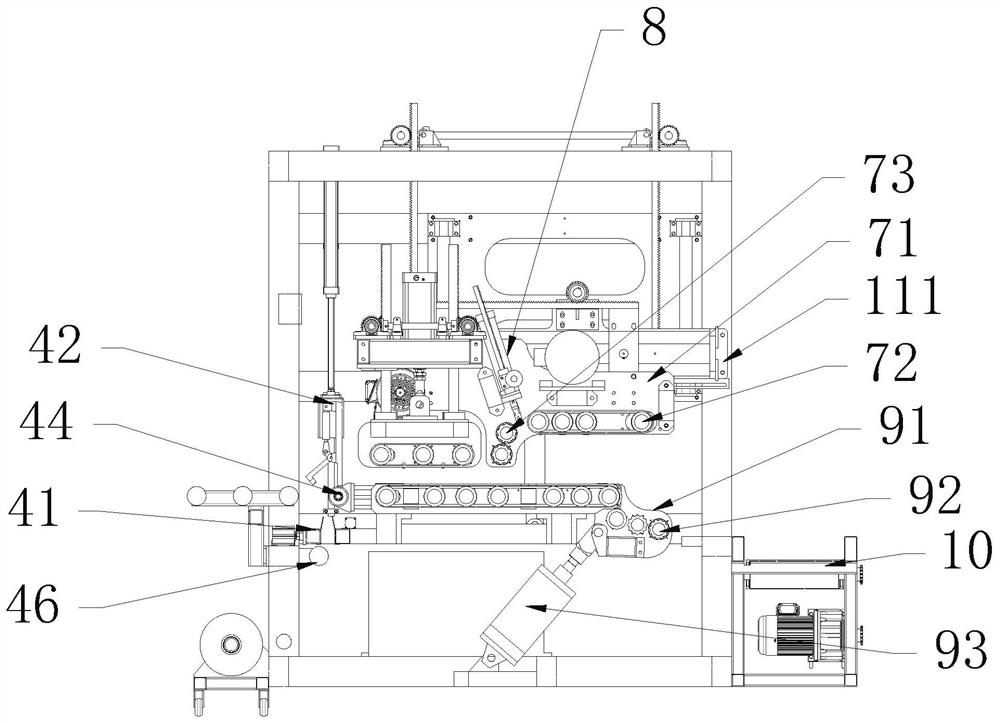

An automatic conveying device for helium leak check of air-conditioning heat exchanger cores and a using method belong to the technical field of manufacturing equipment of air-conditioning heat exchanger cores. The automatic conveying device for helium leak check of the air-conditioning heat exchanger cores comprises a transitional conveying line body, a feeding robot and gripping apparatus, a helium detection logistics circulating line body, a helium detection box, a vision imaging device, a discharging robot and gripping apparatus, and the like, wherein the helium detection logistics circulating line body is located in the central position of the automatic conveying device; the inlet of the helium detection box is connected with one section of the helium detection logistics circulating line body; a plurality of outlets of the helium detection box are connected with the other section of the helium detection logistics circulating line body, which is parallel to the helium detection box. According to the automatic conveying device, the air-conditioning heat exchanger cores are conveyed by the vision imaging device, and the robot and gripping apparatuses instead of manual work under the condition of not changing the original technological process of production, a specific operation method is adopted to achieve the purposes of improving the equipment production efficiency, reducing the labor intensity and ensuring the product quality, and the effect is remarkable.

Owner:SHENYANG ZHONGZE INTELLIGENT EQUIP CO LTD

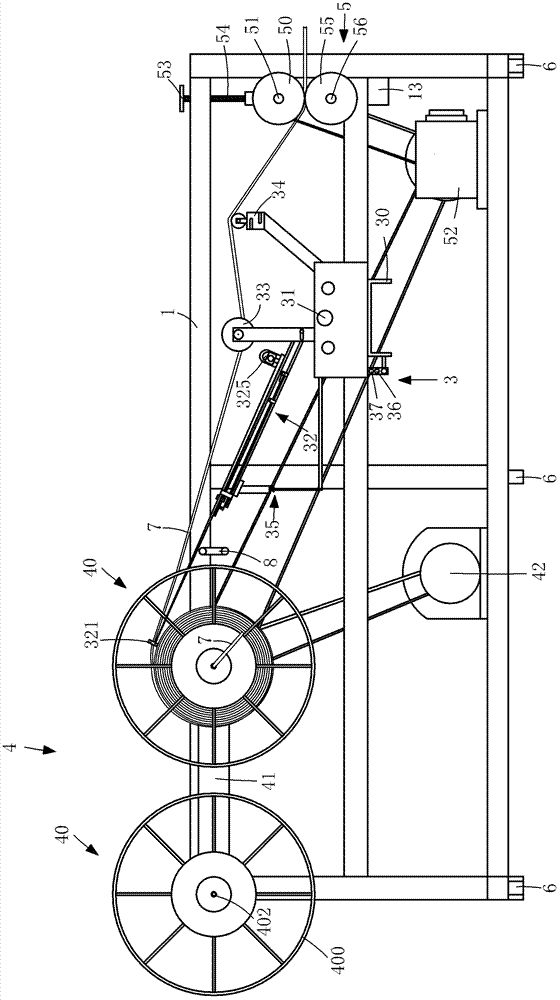

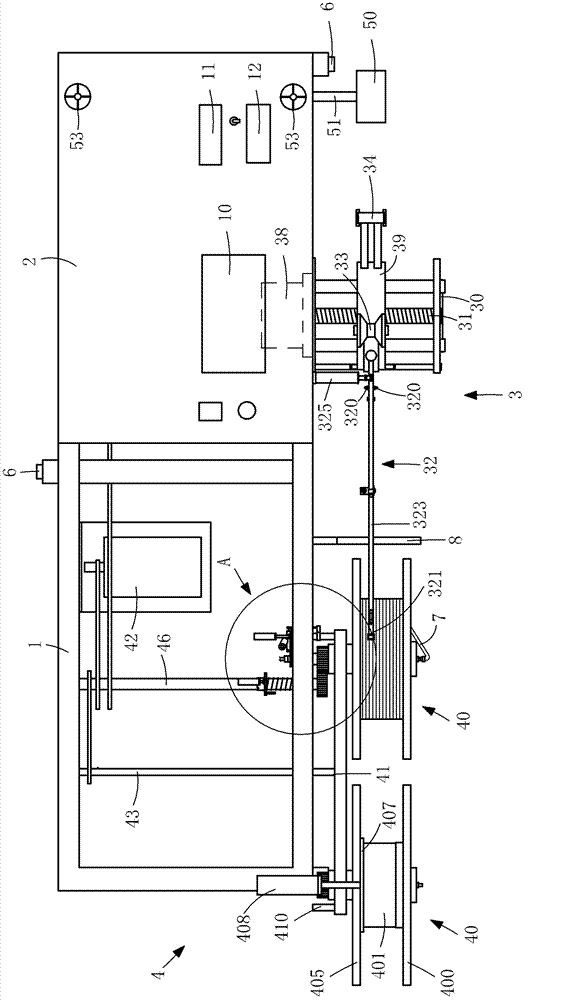

Plastic flexible pipe winder

InactiveCN102701002AAvoid deformationEvenly arrangedFilament handlingProduction lineEconomic benefits

The invention discloses a plastic flexible pipe winder and relates to the technical field of winding equipment. The plastic flexible pipe winder orderly comprises a feeding device, a strand oscillator and a winding device, wherein the feeding device, the strand oscillator and the winding device are connected with an electric control device; the plastic flexible pipe winder also comprises an inflating device for inflating a plastic flexible pipe; the inflating device comprises an air inlet pipe connected with an opening of the plastic flexible pipe; the air inlet pipe corresponds to the position of the winding device, and an air stopping device for preventing the air in the plastic flexible pipe from returning to a production procedure section is arranged at upstream of the air inlet pipe. The plastic flexible pipe winder can be joined with a production line of the plastic flexible pipe and can automatically finish winding work of the plastic flexible pipe under the condition of ensuring that the plastic flexible pipe is not stacked and deformed, so the operation is stable and reliable, the automatic degree is high, the production efficiency is improved, the labor intensity of a worker is reduced, the production cost is reduced, and the economic benefit of an plastic flexible pipe enterprise is increased.

Owner:董长国

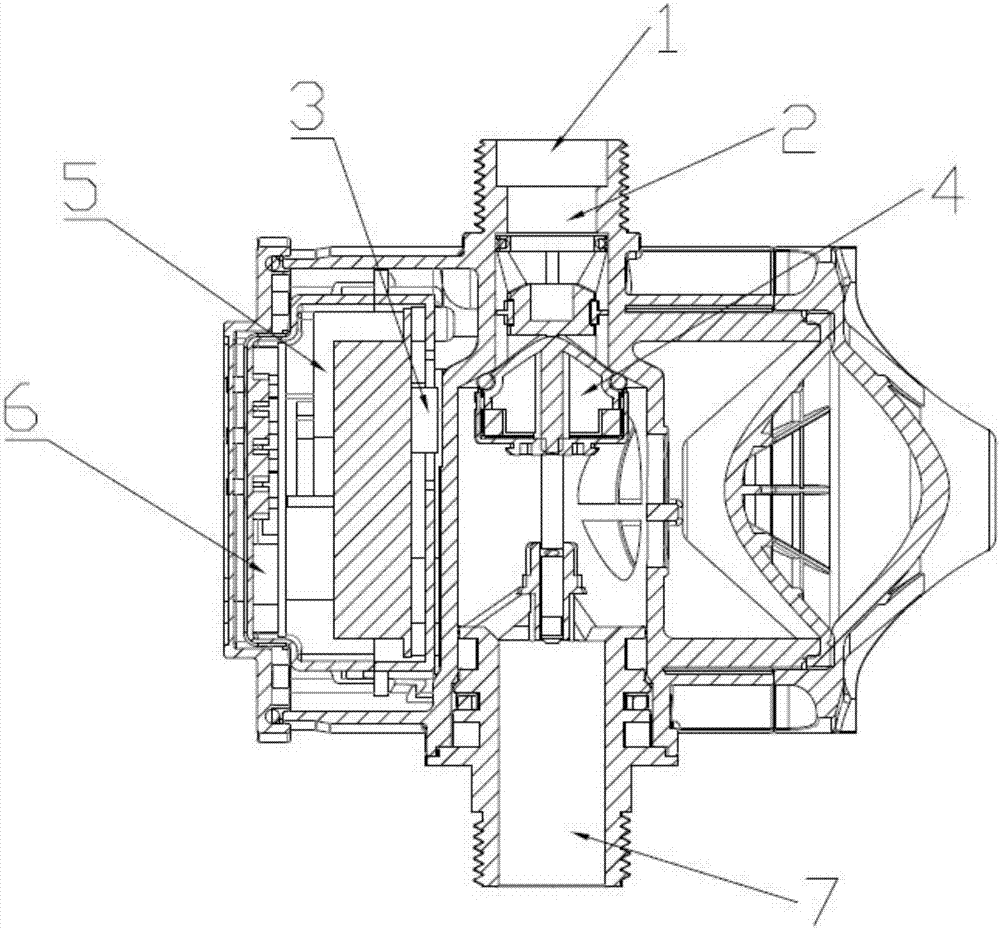

Air conditioner leak detection system and leak detection method thereof

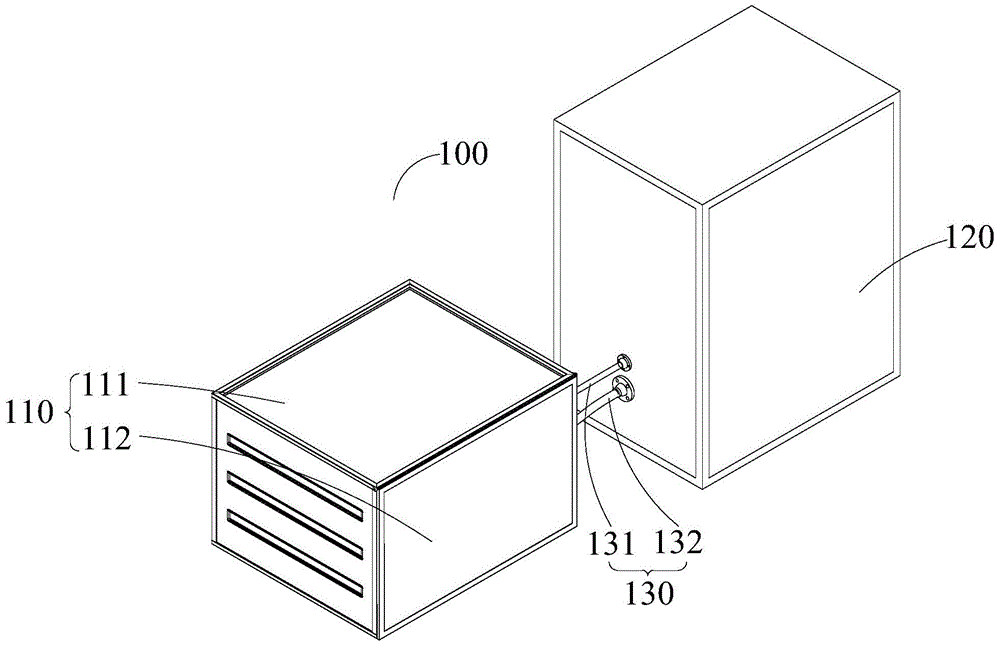

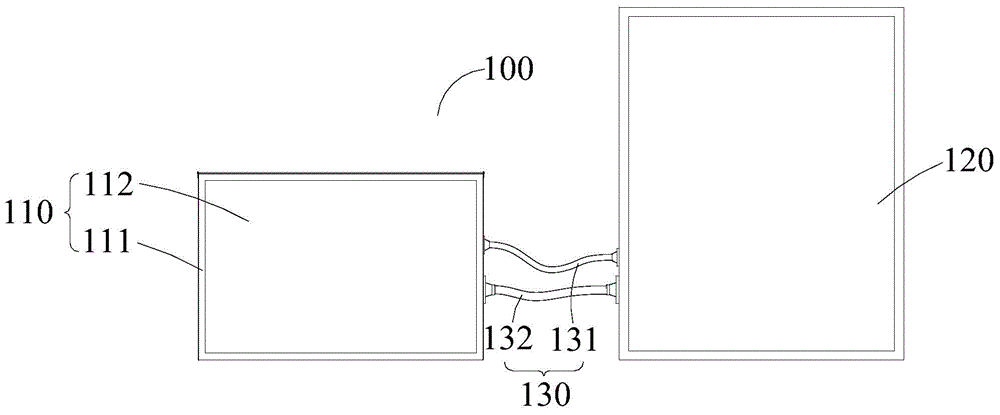

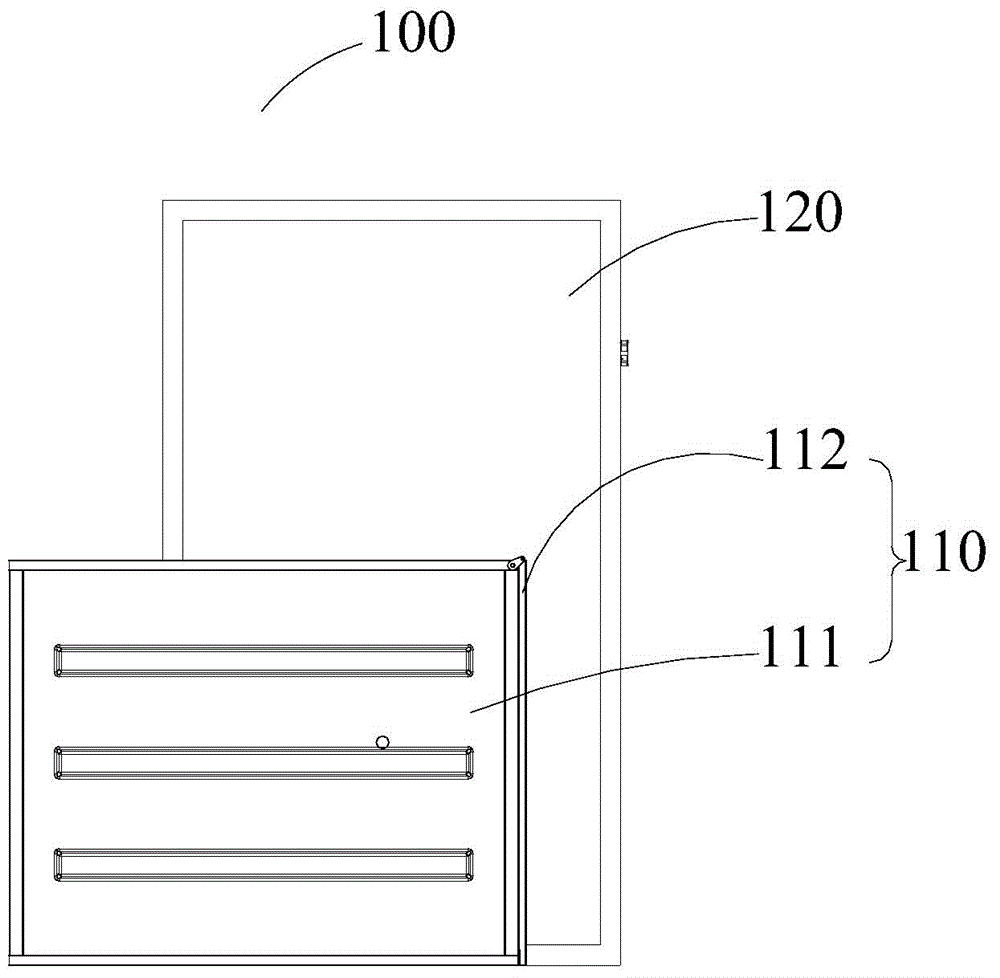

InactiveCN104062083AAvoid Solder Joint LeakageAvoid rewindingDetection of fluid at leakage pointEngineeringLeak detection

The invention provides an air conditioner leak detection system and a leak detection method of the air conditioner leak detection system. The air conditioner leak detection system comprises a helium leak detection device and a vacuumizing negative-pressure device. The helium leak detection device is communicated with the vacuumizing negative-pressure device through a pipeline. An air conditioner is placed in the vacuumizing negative-pressure device. The vacuumizing negative-pressure device comprises a leak detection box and an opening and closing door sheet. The opening and closing door sheet is mounted on the leak detection box. The pipeline comprises a leak detection pipe and a breather pipe. One end of the leak detection pipe is mounted on the helium leak detection device. The other end of the leak detection pipe penetrates through the leak detection box and is mounted on the air conditioner. One end of the breather pipe is mounted on the helium leak detection device. The other end of the breather pipe is mounted on the leak detection box. The air conditioner leak detection system and the leak detection method of the air conditioner leak detection system achieve the purposes of reducing staff for improving efficiency, shortening the production cycle and improving the uniformity of product quality.

Owner:GREE ELECTRIC APPLIANCES INC

Efficient cleaning and ventilating structure for high-rise building

ActiveCN113280428AAvoid flyingAvoid rewindingDucting arrangementsMechanical apparatusVentilation tubeClassical mechanics

The invention relates to the technical field of building ventilation, in particular to an efficient cleaning ventilation structure for a high-rise building. The efficient cleaning ventilation structure comprises a first ventilation pipe and a second channel pipe which are in sliding sleeve connection with each other in the ventilation airflow flowing direction, a stretchable adjusting mechanism for controlling the first ventilation pipe and the second channel pipe to stretch out and draw back is arranged between the first ventilation pipe and the second channel pipe, a filter screen is arranged in the first ventilation pipe, a ventilation fan is arranged in the second channel pipe, a clearing mechanism arranged in a lifting mode is arranged at the top of the first ventilation pipe, the clearing mechanism cleans the filter screen, a blocking mechanism is arranged in the second ventilation pipe and located on the front side of the ventilation fan, and when the filter screen is cleaned, the blocking mechanism blocks the second ventilation pipe. Dust cleared from the filter screen is timely collected into a dust collection assembly through the cooperation of a rolling brush assembly and an air blowing assembly in the clearing mechanism, the cleared dust is prevented from flying away, and the dust is also prevented from being rolled back when the ventilation structure is started again.

Owner:浙江天和建筑设计有限公司

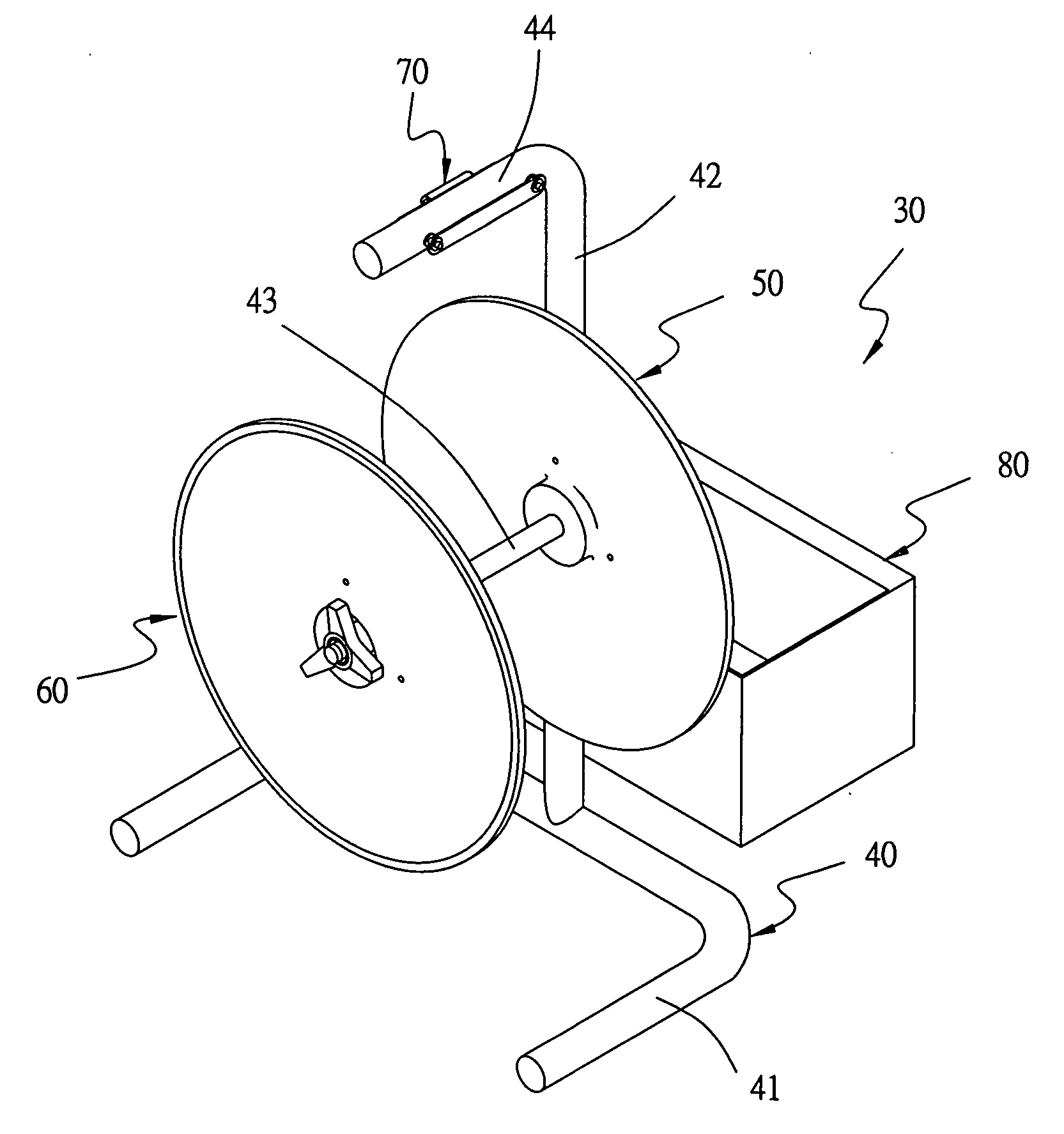

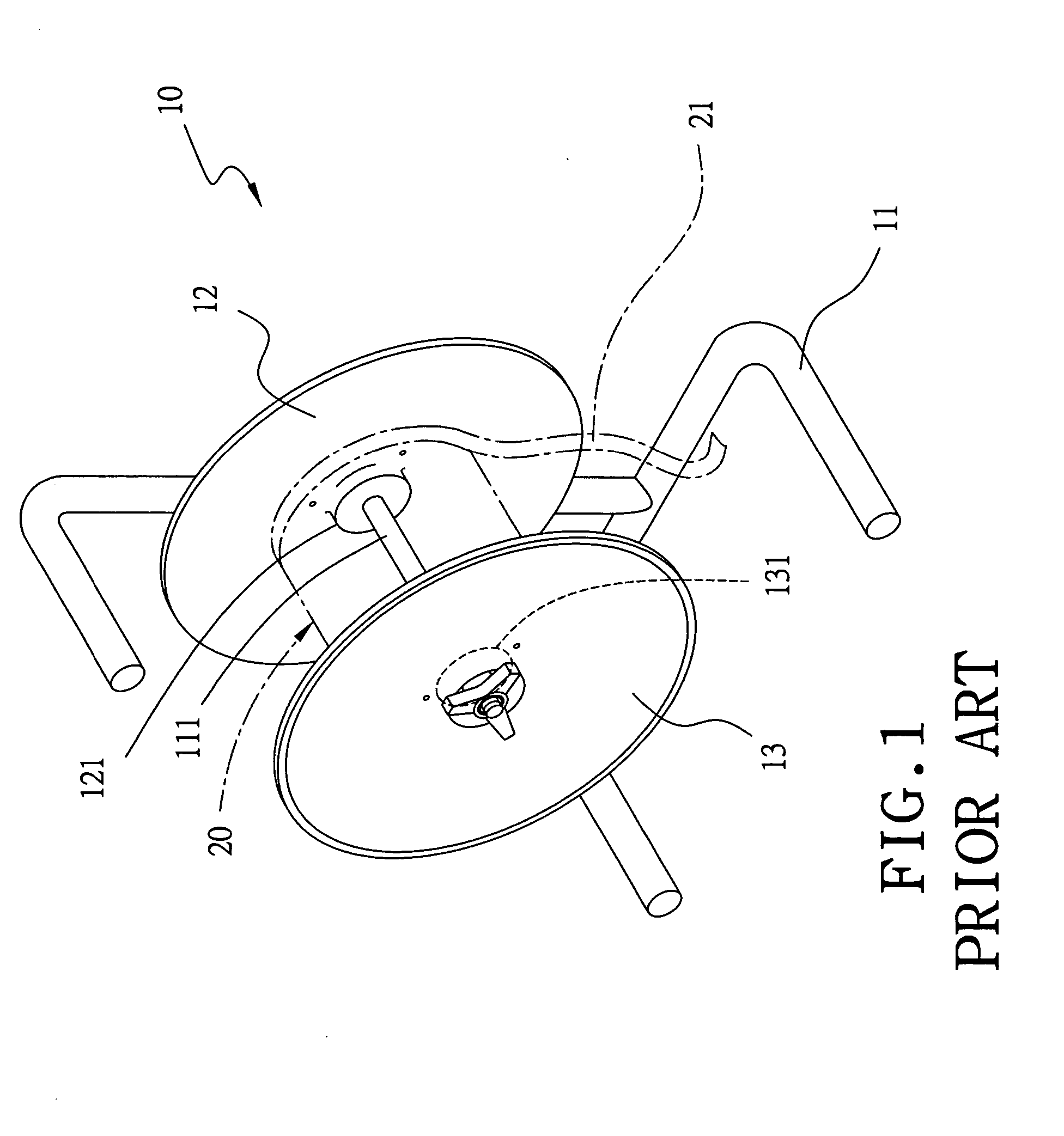

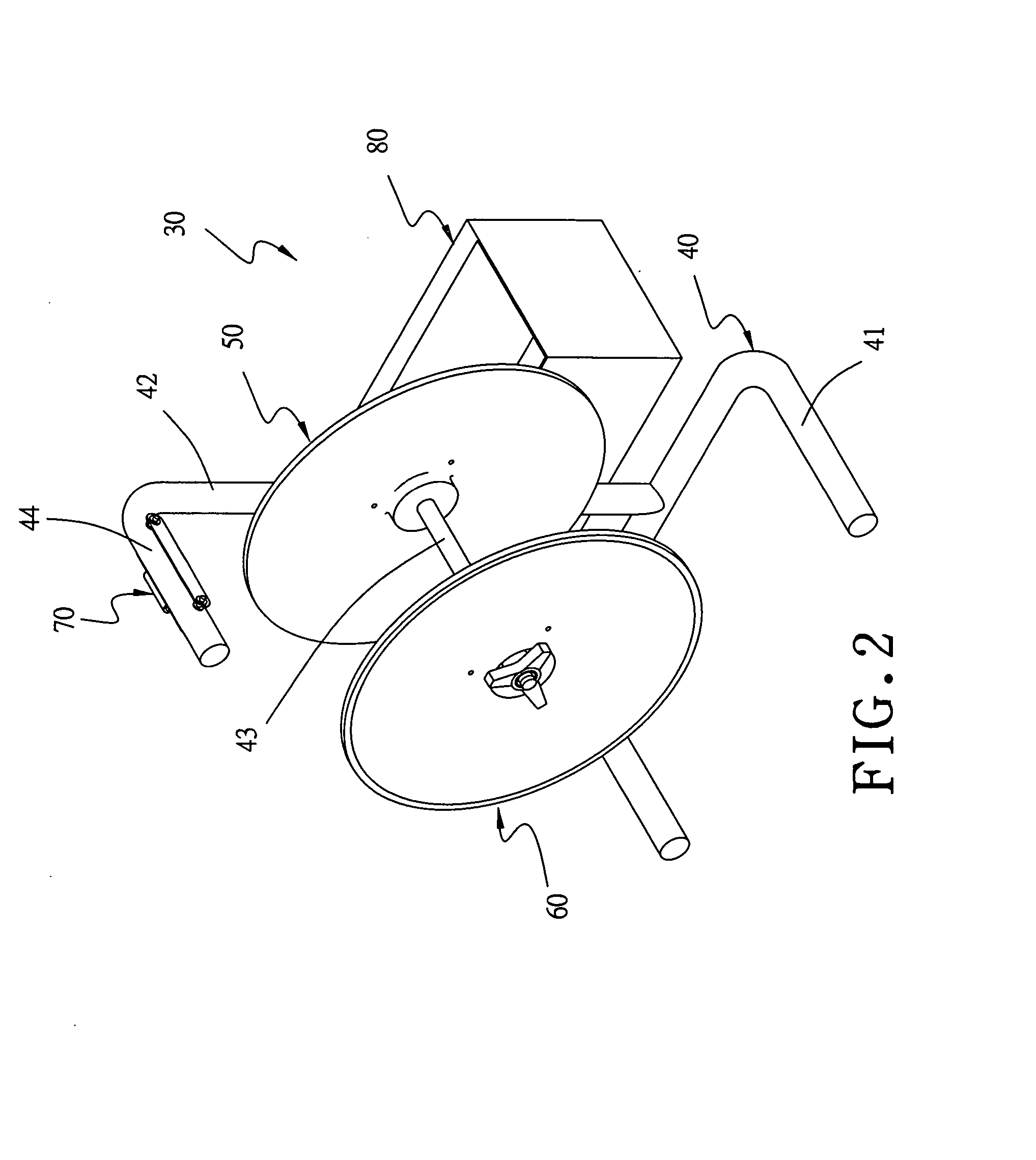

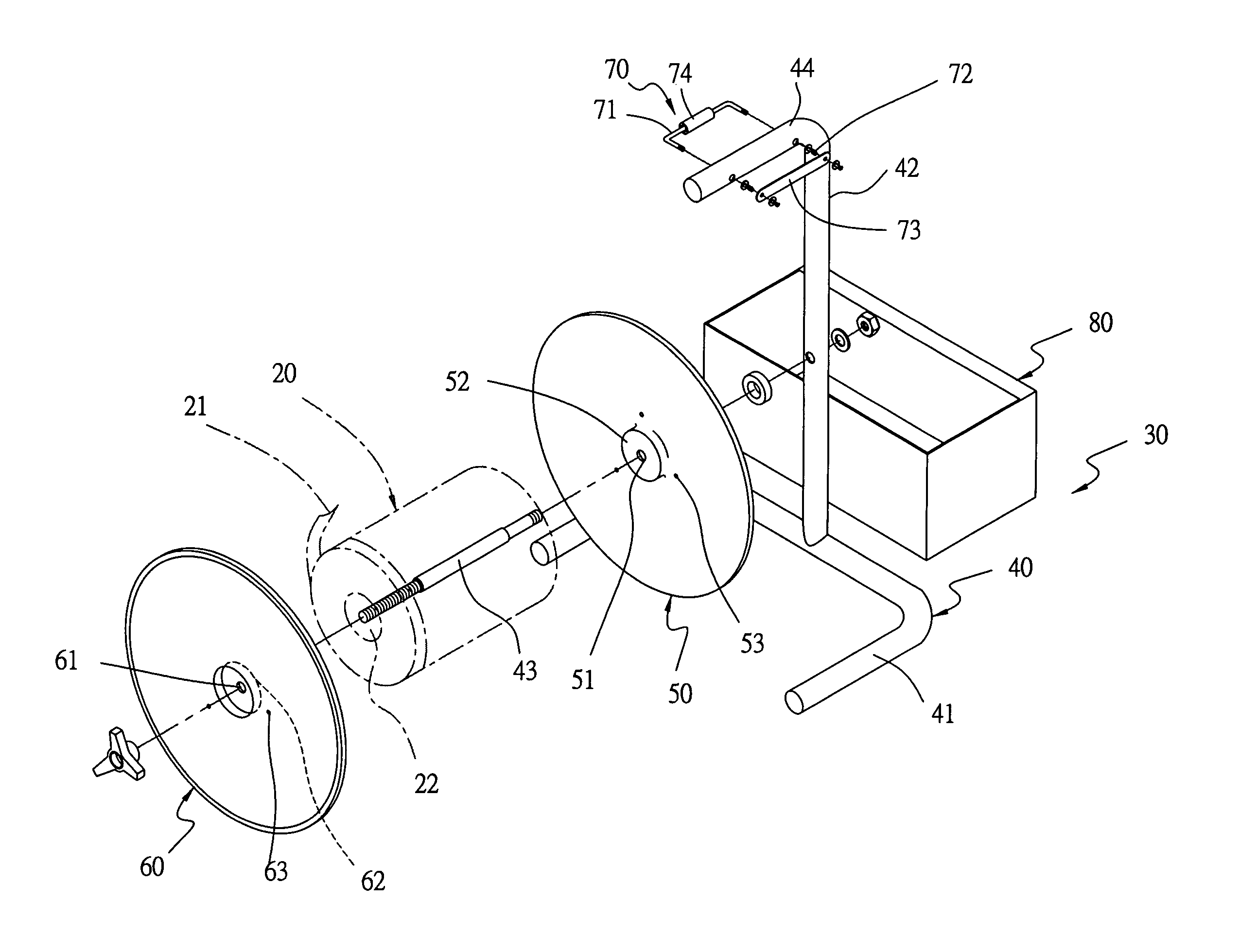

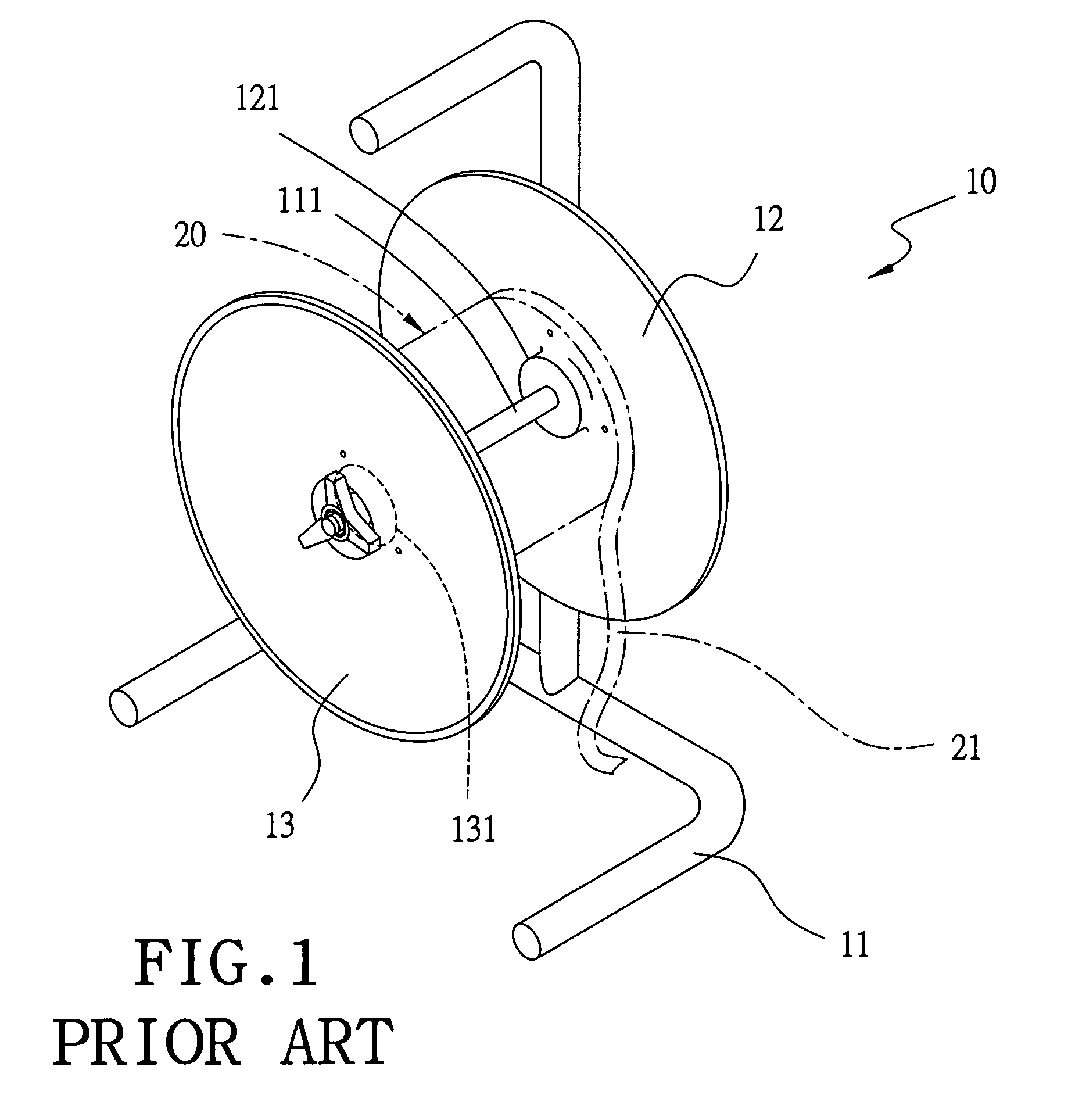

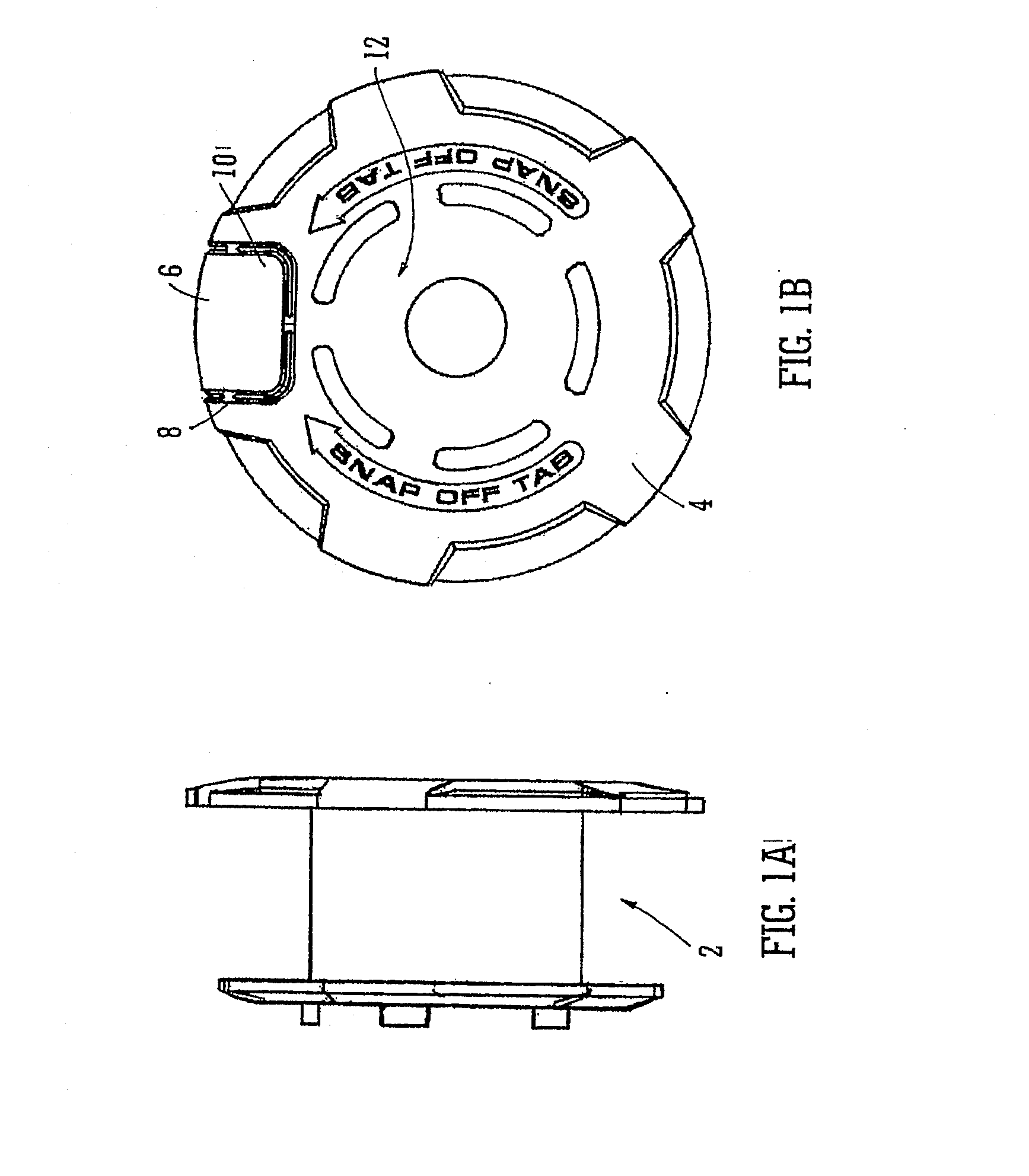

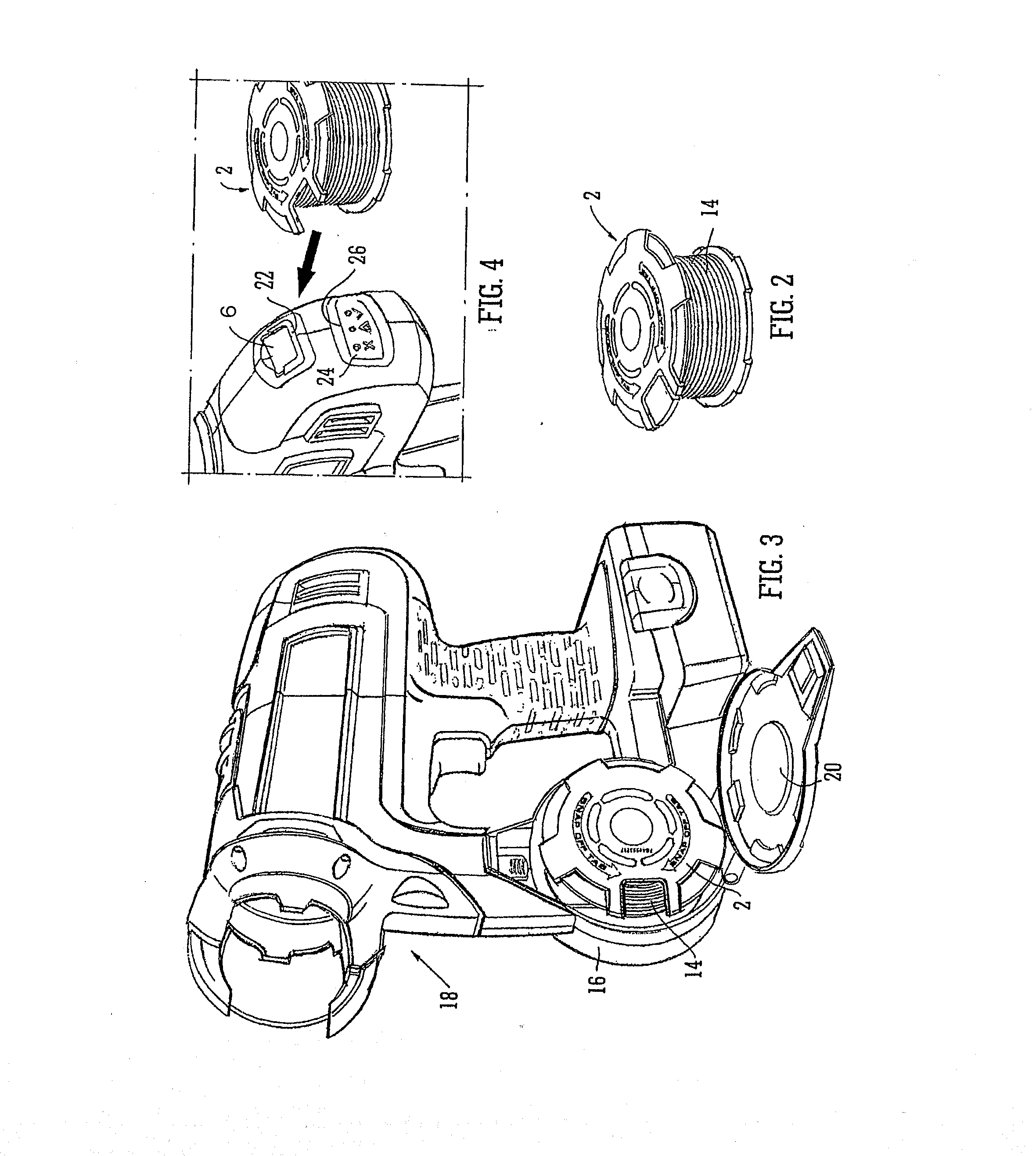

Strap-reel frame

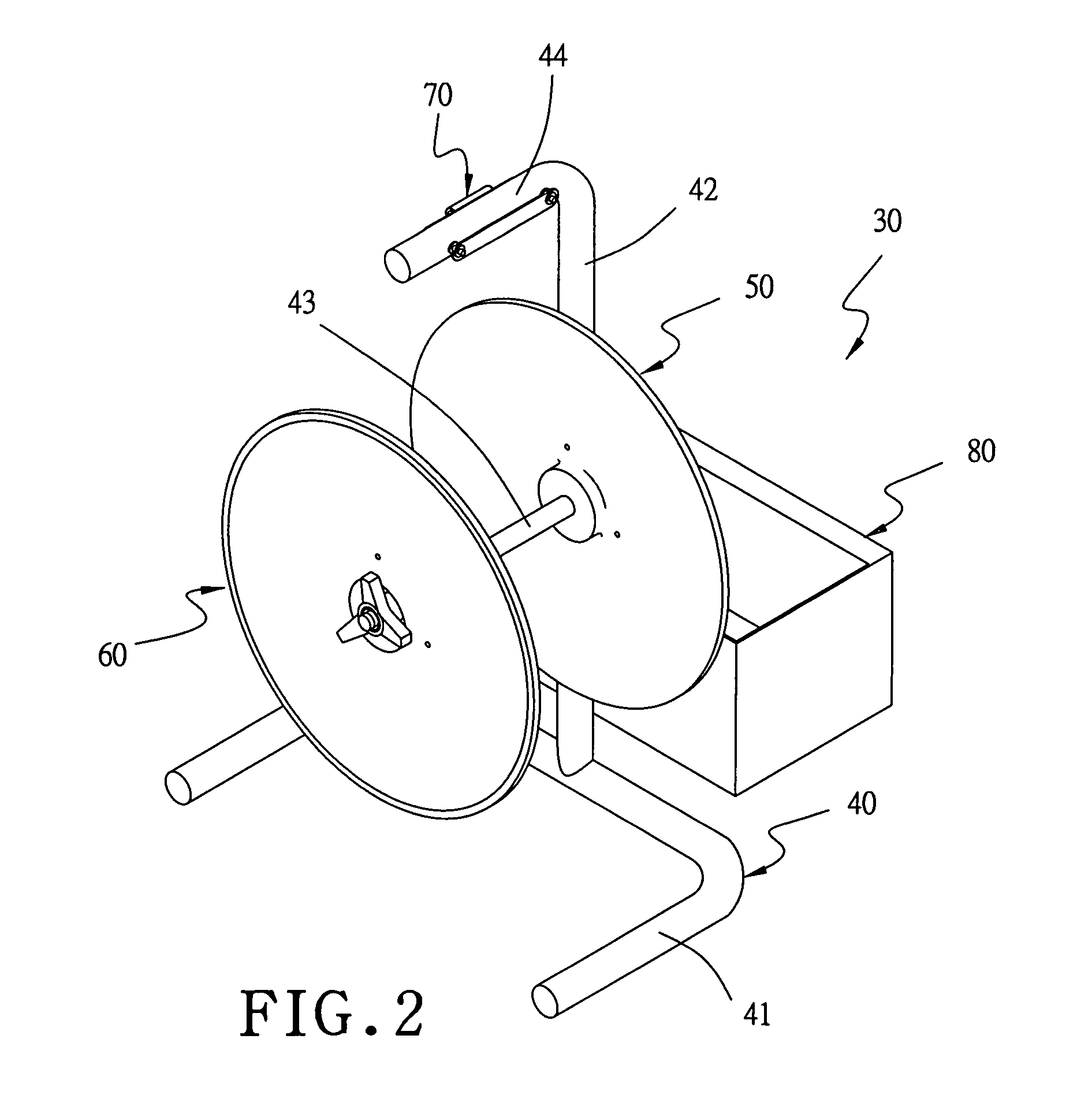

InactiveUS20060032967A1Convenience of pressingConvenience of handlingContainers for annular articlesFilament handlingMechanical engineeringEngineering

A strap-reel frame includes a frame body having a shaft horizontally provided thereon for fitting an inner disc and an outer disc which respectively have the central portion formed with a columnar projection for fitting the opposite ends of a strap reel. A strap-clamping rod is provided above the shaft of the frame body, having a strap-clamping unit assembled thereon. A strap-passing gap can be formed for a strap to pass therethrough after the press member of the strap-clamping unit is pressed inward and the strap in the strap-passing gap can be clamped in position after the press member is released. In addition, two reel end connectors with a comparatively large diameter can be respectively covered over the two columnar projections and then fixed on the inner and the outer disc for fitting a strap reel.

Owner:CHEN HSIU MAN YU

Strap-reel frame

InactiveUS7004422B1Increase the areaConvenience of easeContainers for annular articlesFilament handlingMechanical engineeringEngineering

A strap-reel frame includes a frame body having a shaft horizontally provided thereon for fitting an inner disc and an outer disc which respectively have the central portion formed with a columnar projection for fitting the opposite ends of a strap reel. A strap-clamping rod is provided above the shaft of the frame body, having a strap-clamping unit assembled thereon. A strap-passing gap can be formed for a strap to pass therethrough after the press member of the strap-clamping unit is pressed inward and the strap in the strap-passing gap can be clamped in position after the press member is released. In addition, two reel end connectors with a comparatively large diameter can be respectively covered over the two columnar projections and then fixed on the inner and the outer disc for fitting a strap reel.

Owner:CHEN HSIU MAN YU

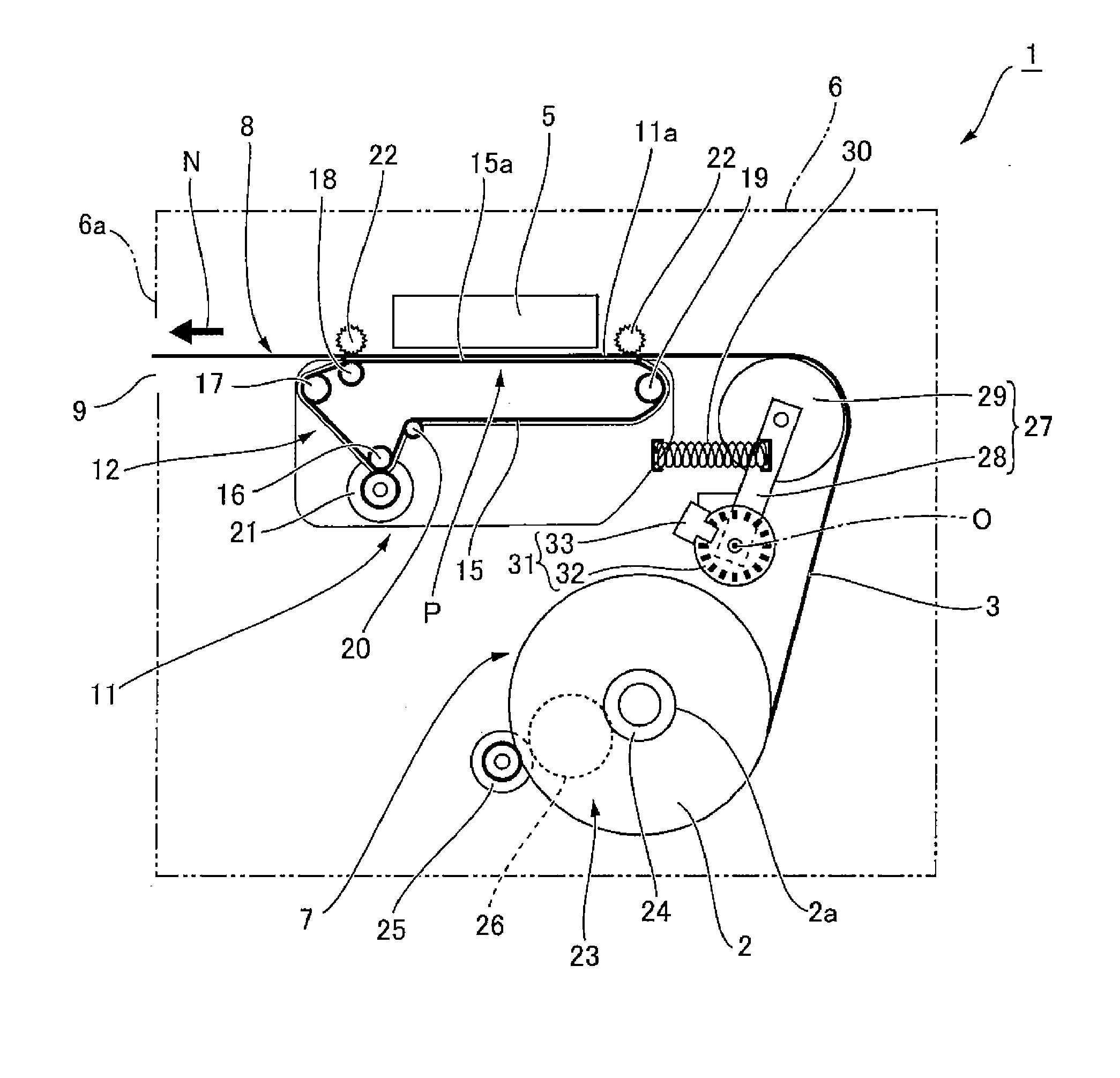

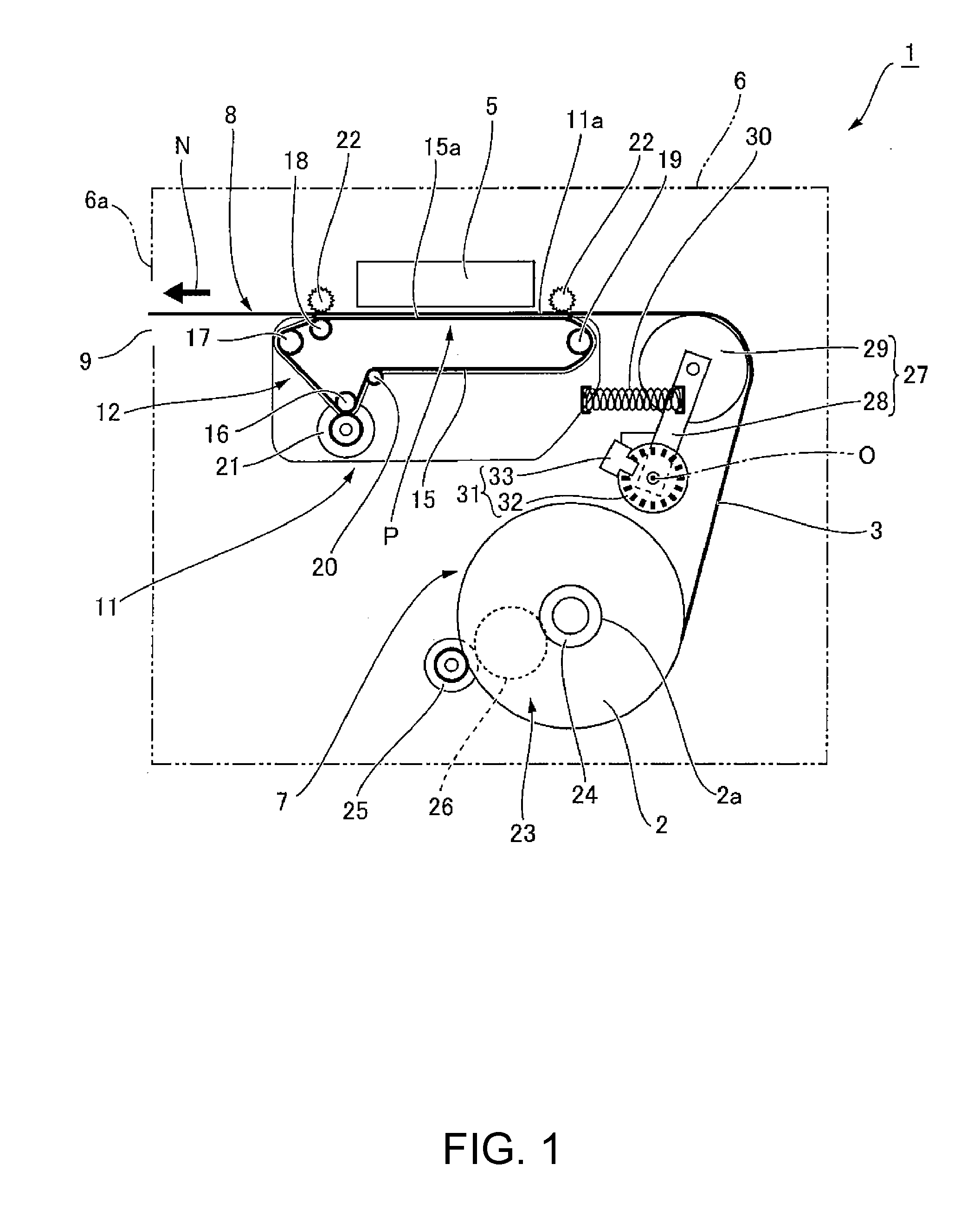

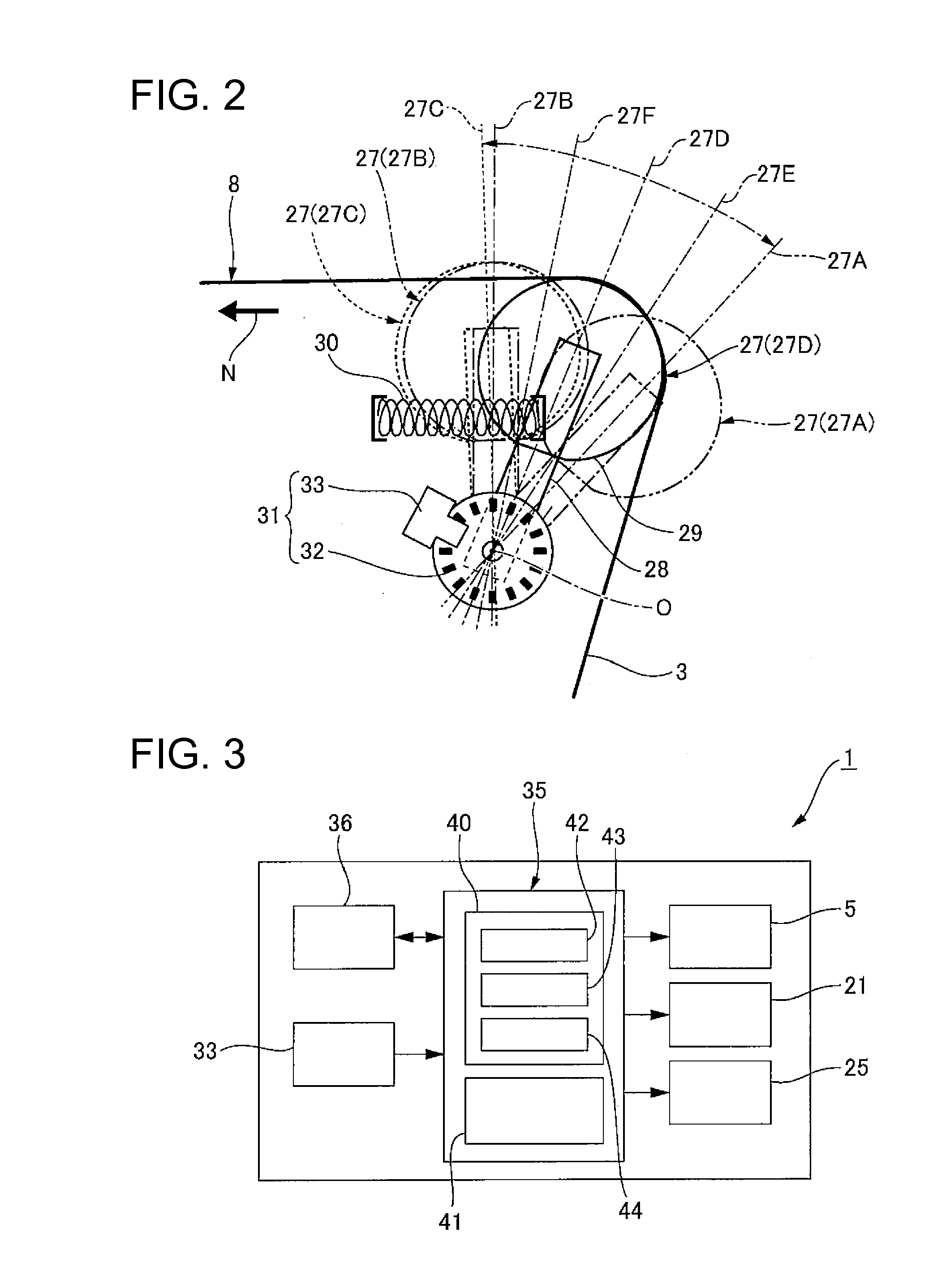

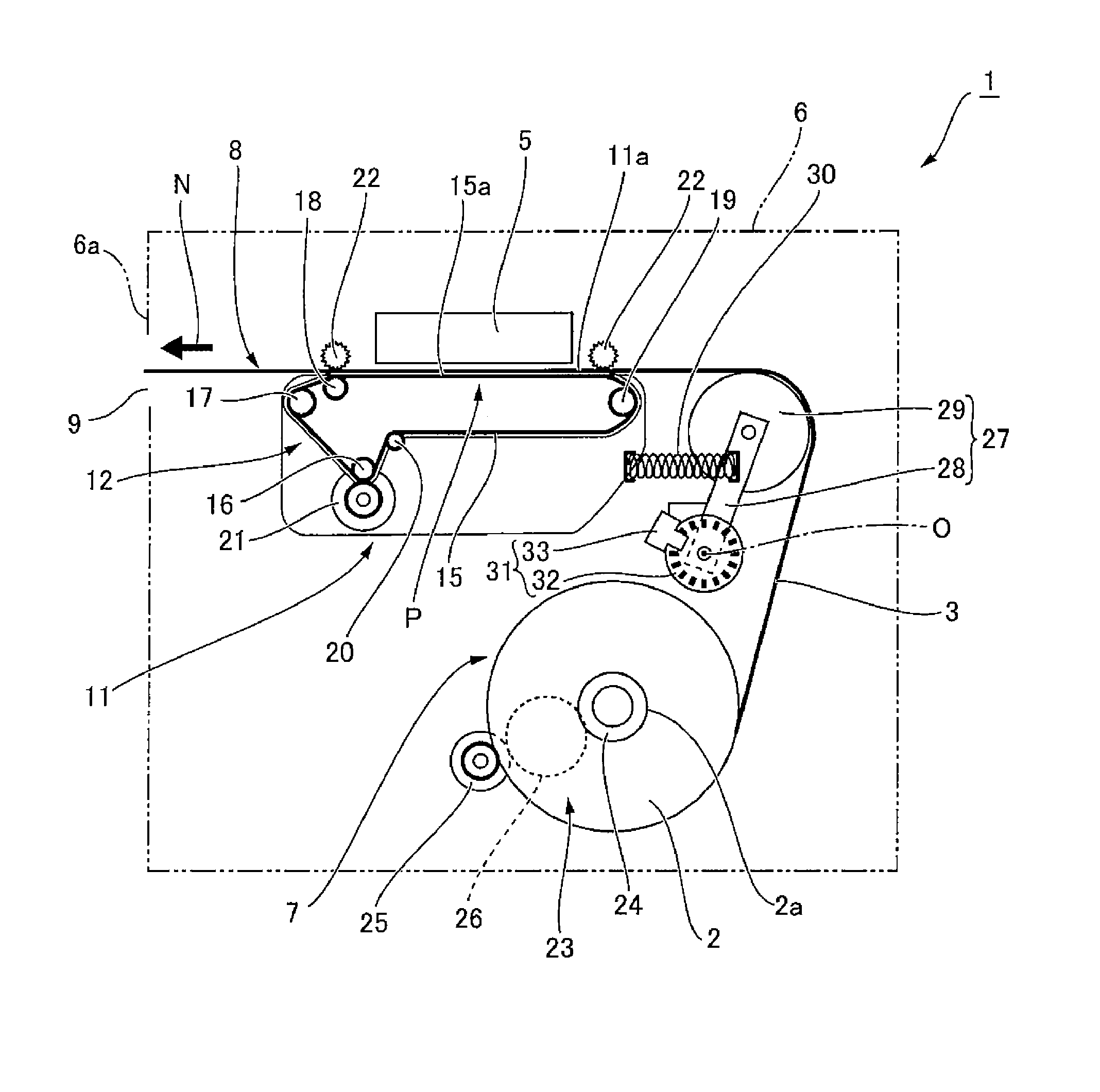

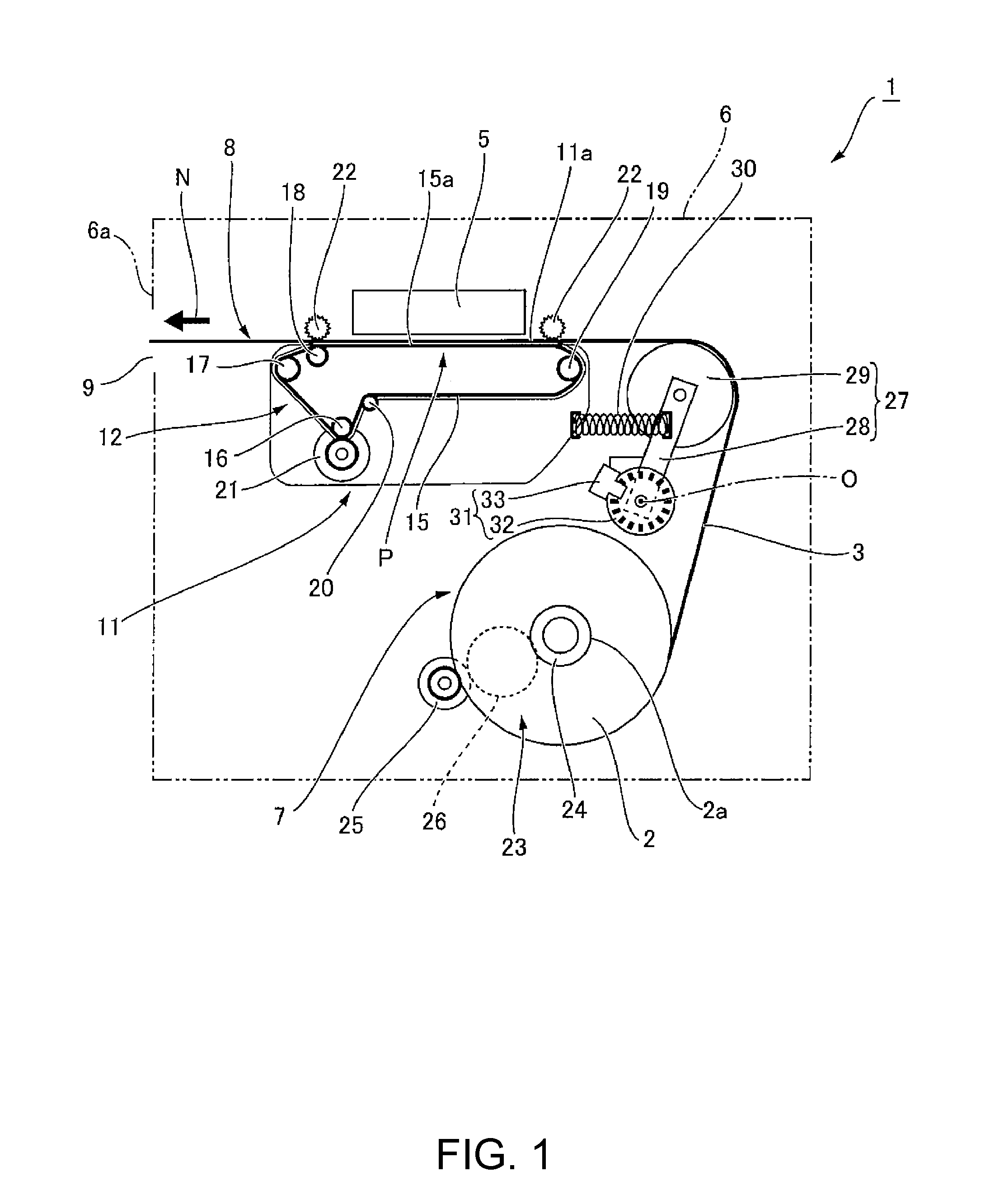

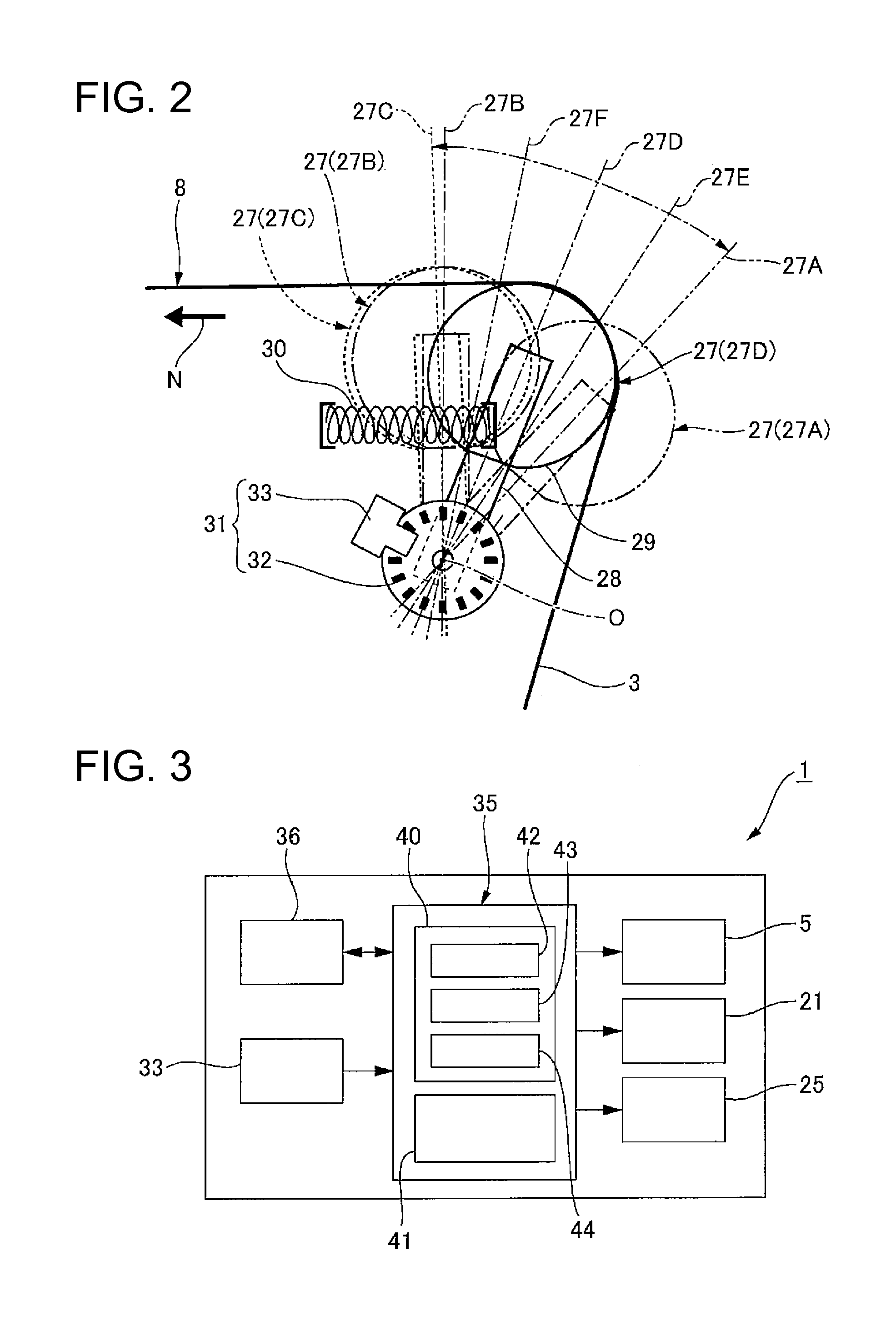

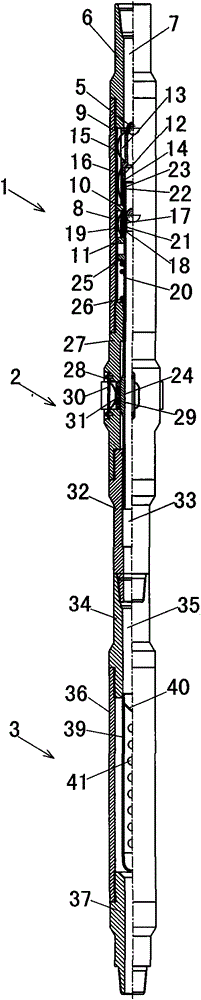

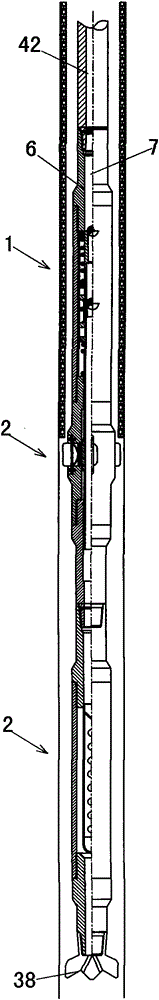

Media conveyance device, printer, and control method of a printer

ActiveUS20150328909A1Avoid rewindingEliminate slackFilament handlingOther printing apparatusComputer printingOperation mode

Owner:SEIKO EPSON CORP

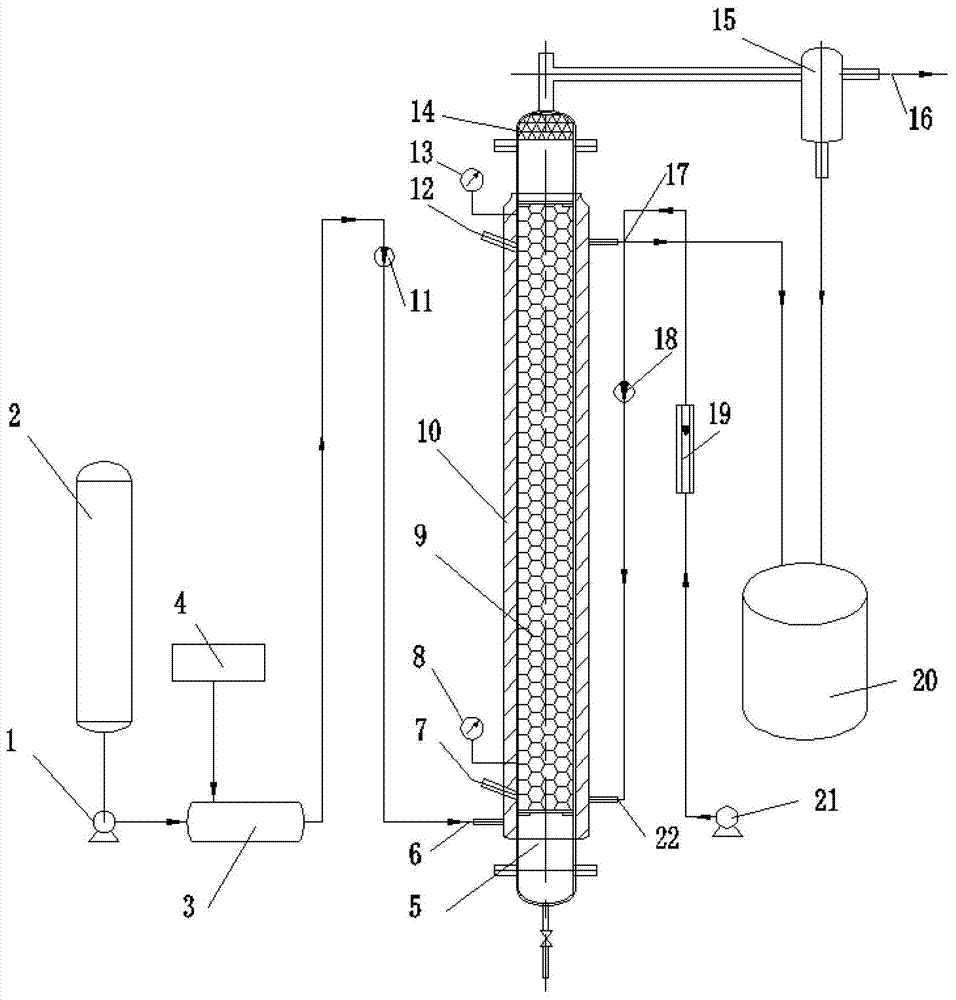

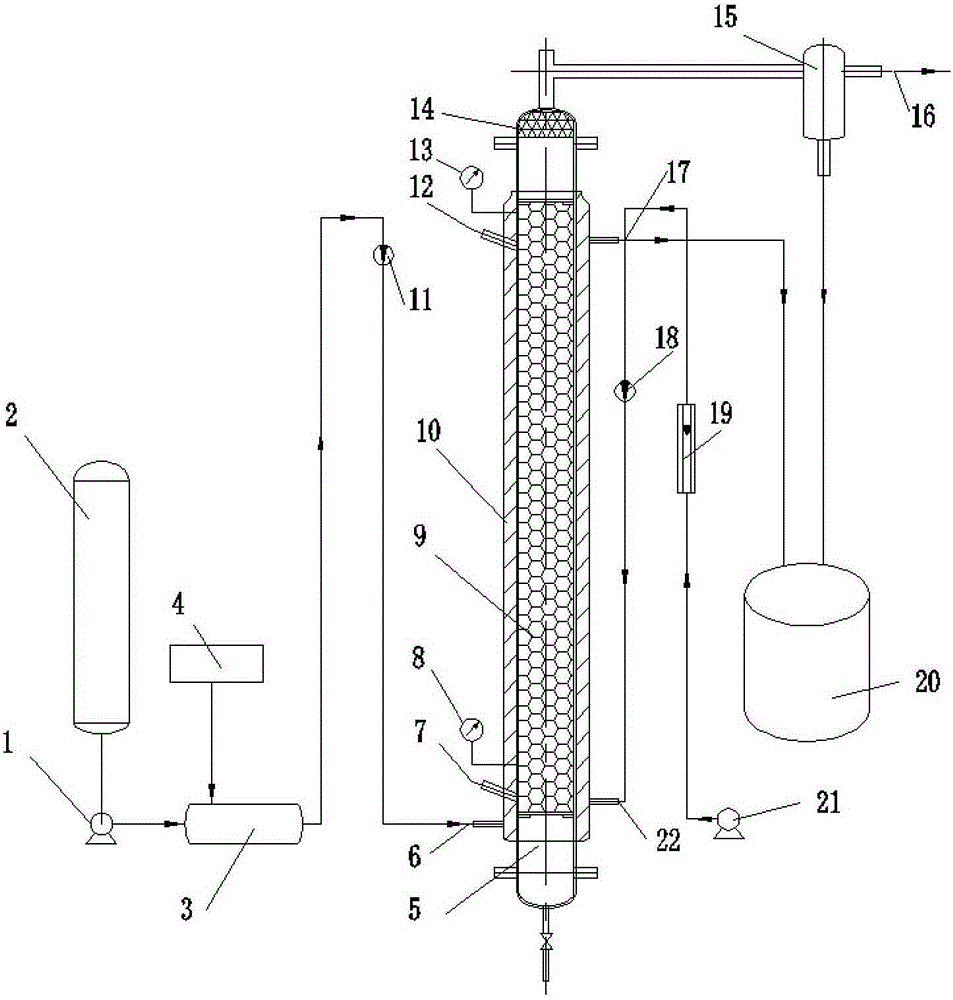

Oxidizing valence-adjusting equipment for oxidizing Pu (III) to Pu (IV)

ActiveCN104328291AIncrease profitReduced disposal burdenRadioactive decontaminationRadiation resistantNitric oxide

The invention belongs to the technical field of nuclear fuel reprocessing and discloses an oxidizing valence-adjusting equipment for oxidizing Pu (III) to Pu (IV). The equipment mainly comprises an oxidizing tower, a feed liquid receiving tank and a NOX storage tank, wherein a feed liquid outlet is formed at the upper end of the oxidizing tower, a Pu (III) feed liquid inlet and a NOX feed inlet are formed at the lower end, and the feed liquid outlets at the upper parts of the feed liquid receiving tank and the oxidizing tower are connected by virtue of a pipeline; the main body of the oxidizing tower and packing in the tower are both radiation-resistant and nitric acid corrosion-resistant materials; a heating device is arranged on the outer tower wall of the oxidizing tower; the Pu (III) feed liquid enters the oxidizing tower from the Pu (III) feed liquid inlet at the lower part of the oxidizing tower; NOX gas provided by the NOX storage tank enters into the oxidizing tower from the NOX feed inlet at the lower part of the oxidizing tower separately or together with carrier gas; the valence-adjusted feed liquid enters the feed liquid receiving tank from the feed liquid outlet at the upper part of the oxidizing tower. The equipment is large in processing scale, high in NOx utilization ratio, safe and stable in valence-adjusting process and low in processing burden of nitric oxide tail gas.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Collision-type trolley power device

The invention discloses a collision-type trolley power device which comprises a trolley reset device and a trolley driving device. The trolley reset device is used for pulling a trolley back to two ends of a collision track and comprises a motor, a reduction gearbox, a coupling, an electromagnetic clutch, a reset roller, a brake, a reset belt, an anti-false-triggering device and a trolley displacement measuring device. The power of the motor is transmitted to the electromagnetic clutch through the reduction gearbox and the coupling, and the reset roller is connected to the electromagnetic clutch. The trolley driving device comprises elastic ropes, elastic rope tension adjusting devices, guiding devices and disengaging devices. The elastic ropes are connected to a trolley through long rods.In a trolley reset process, the elastic ropes are tensioned. In a test, the electromagnetic clutch is disconnected, the trolley accelerates under the tension of the elastic ropes, and the trolley andthe elastic ropes are separated by the disengaging devices when the trolley reaches a predetermined speed. The adjustment of a trolley collision speed can be realized by the numbers of the elastic rope tension adjusting devices and the elastic ropes.

Owner:湖南立中科技股份有限公司

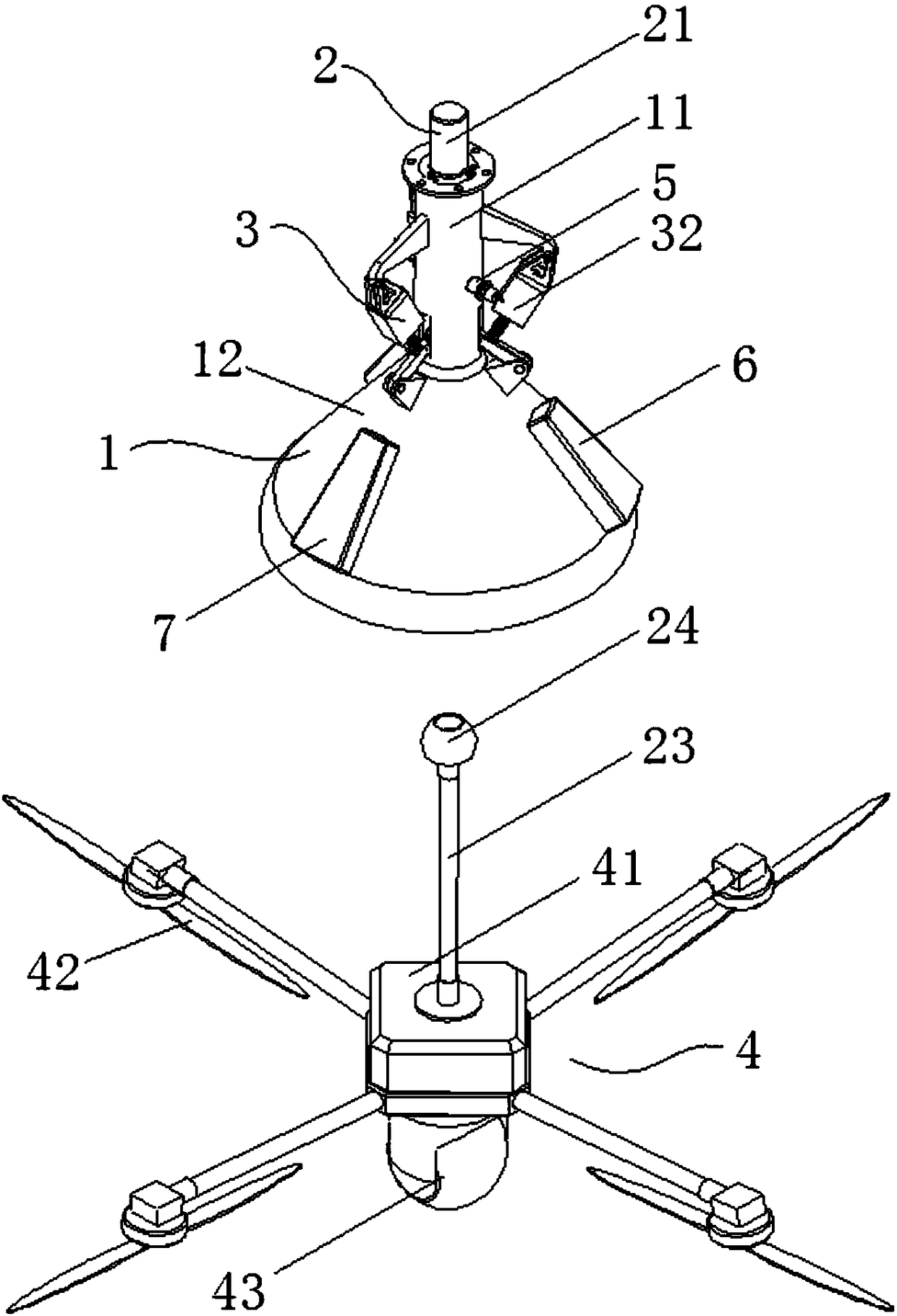

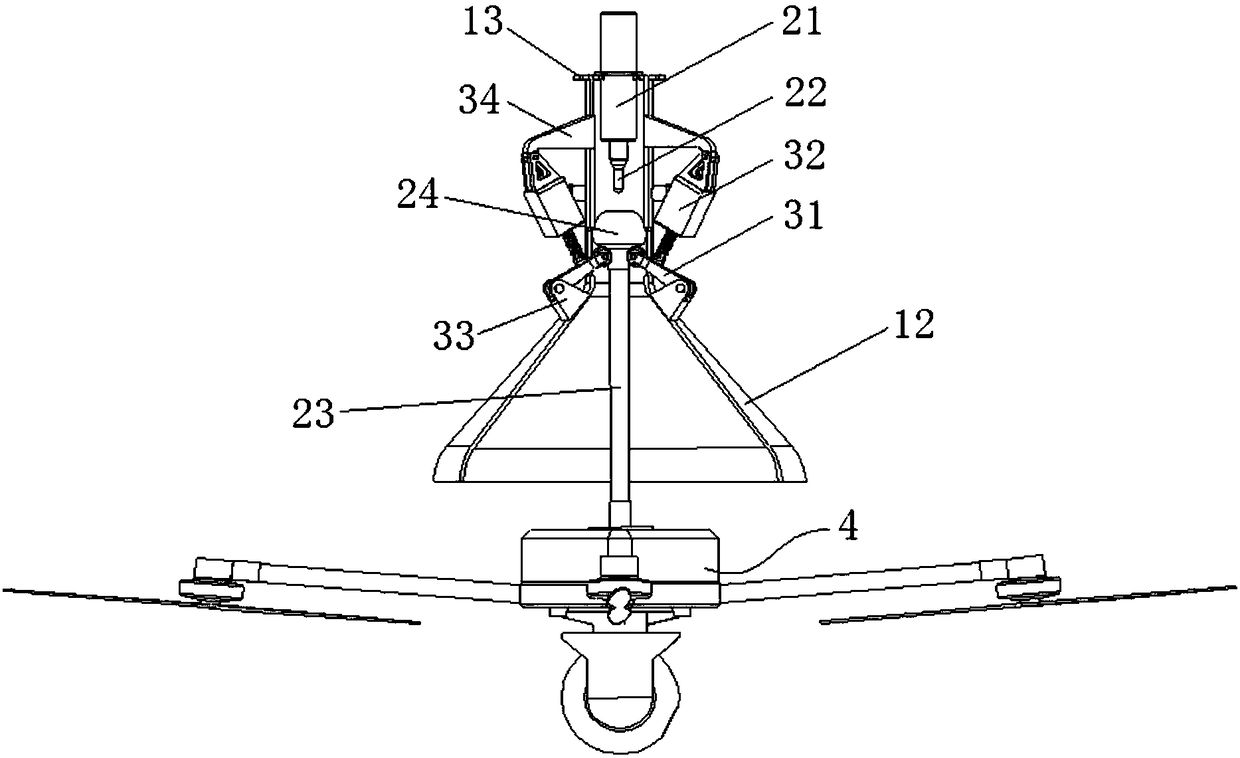

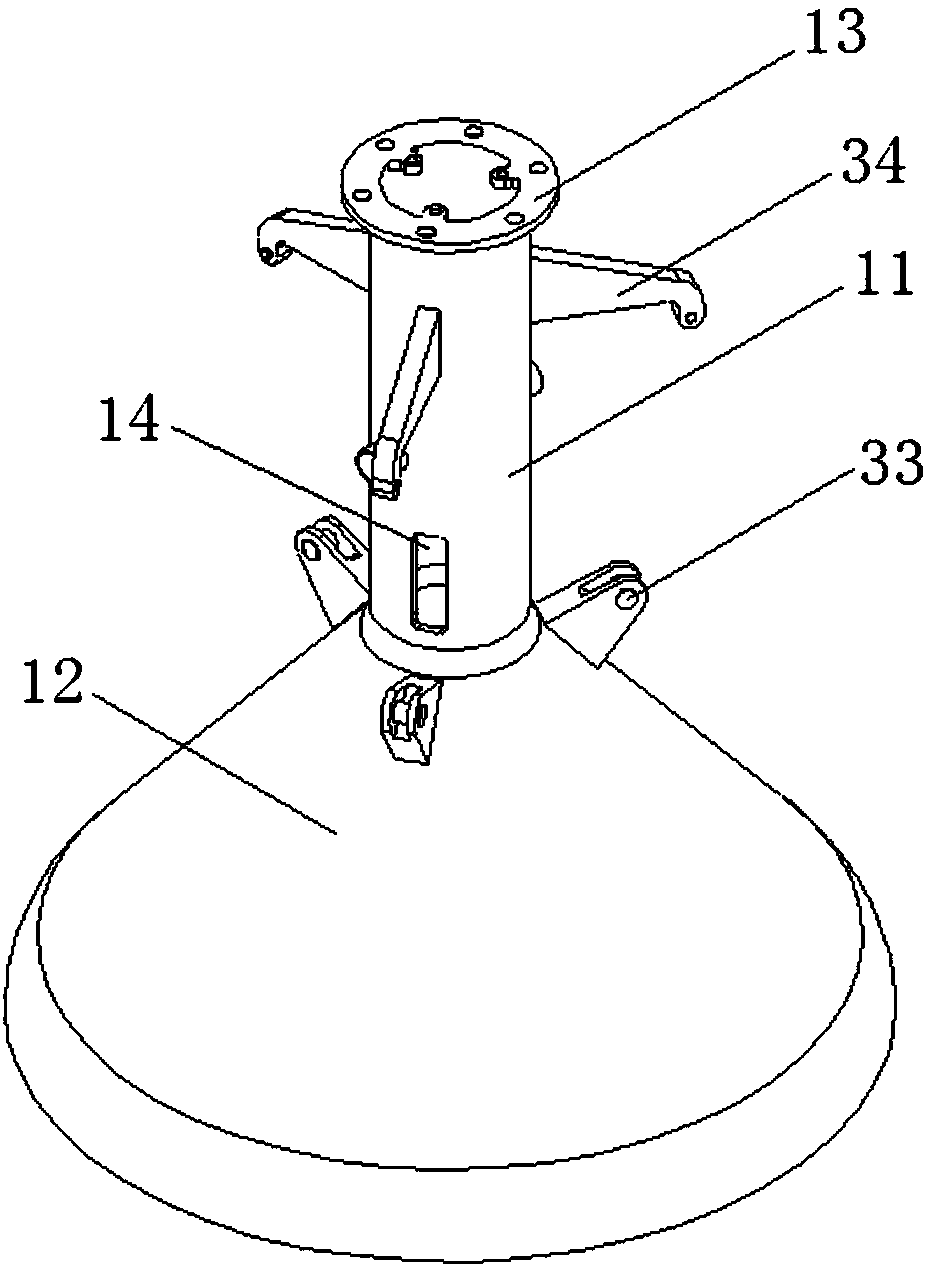

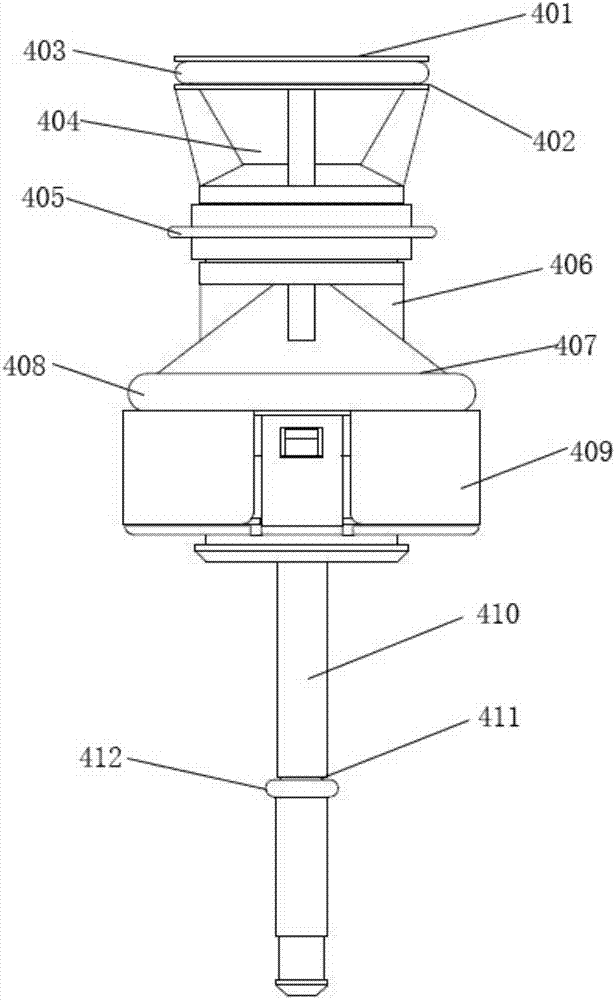

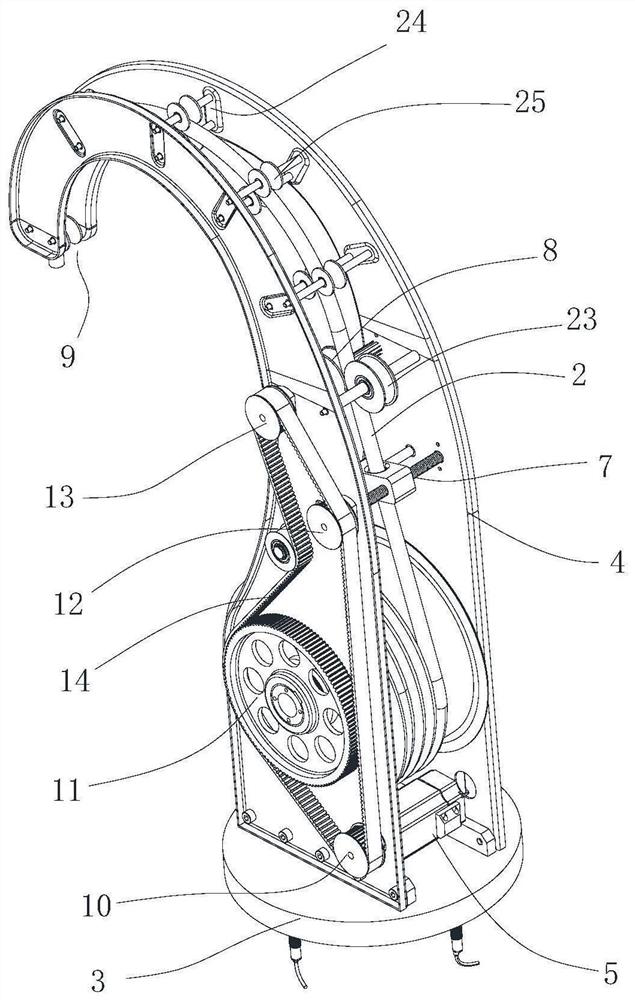

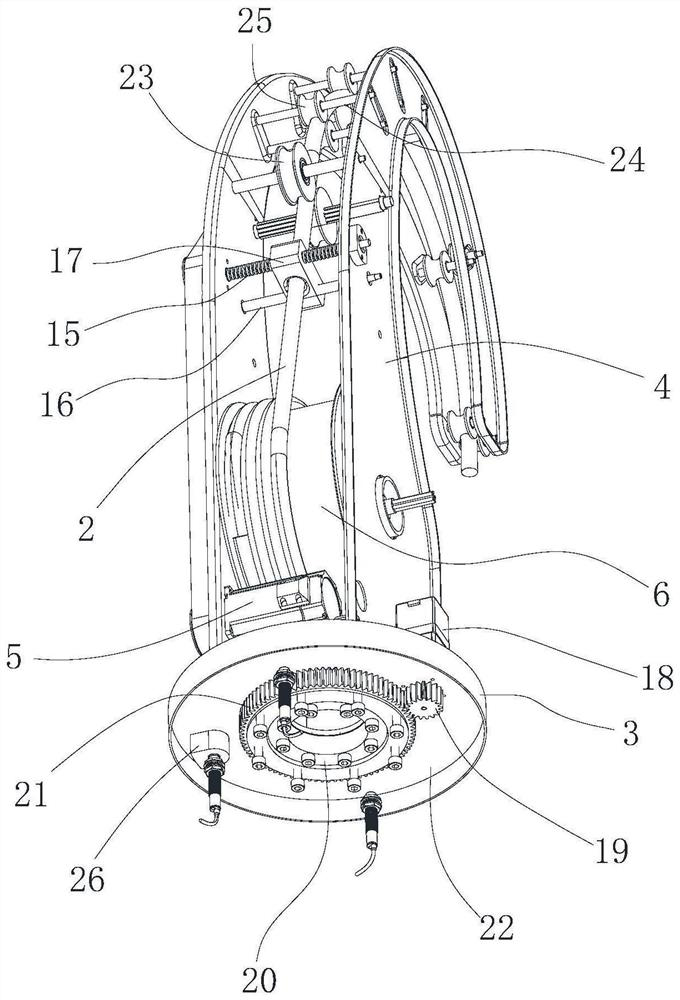

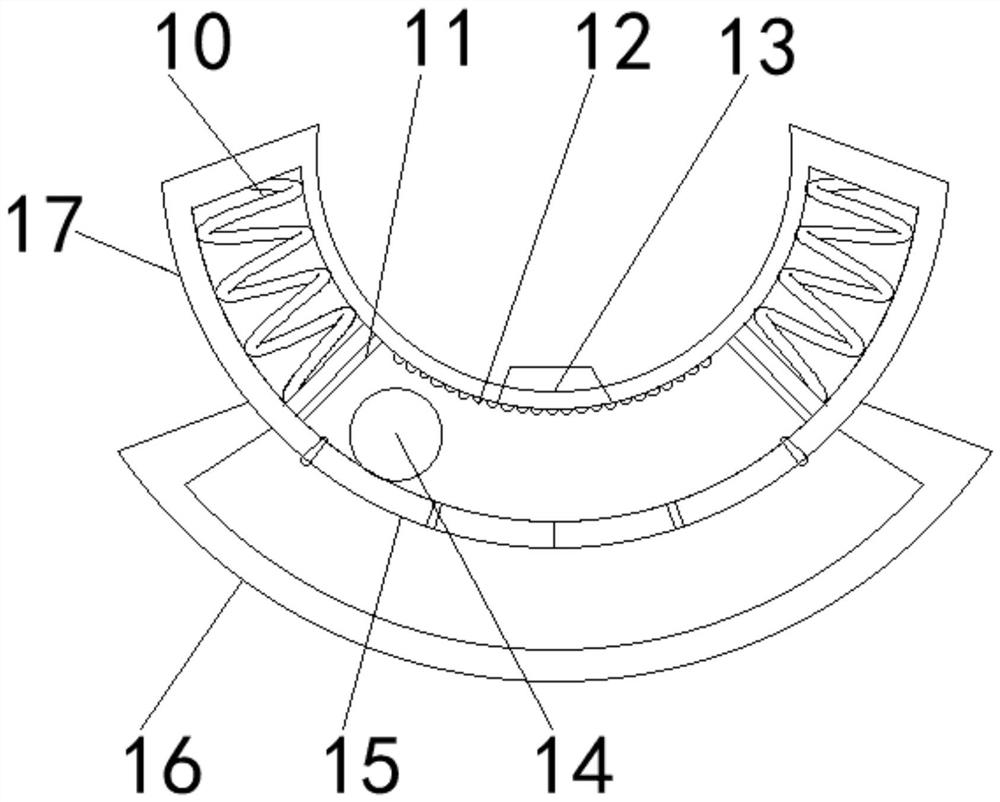

Suspension type unmanned aerial vehicle capture charging device and method

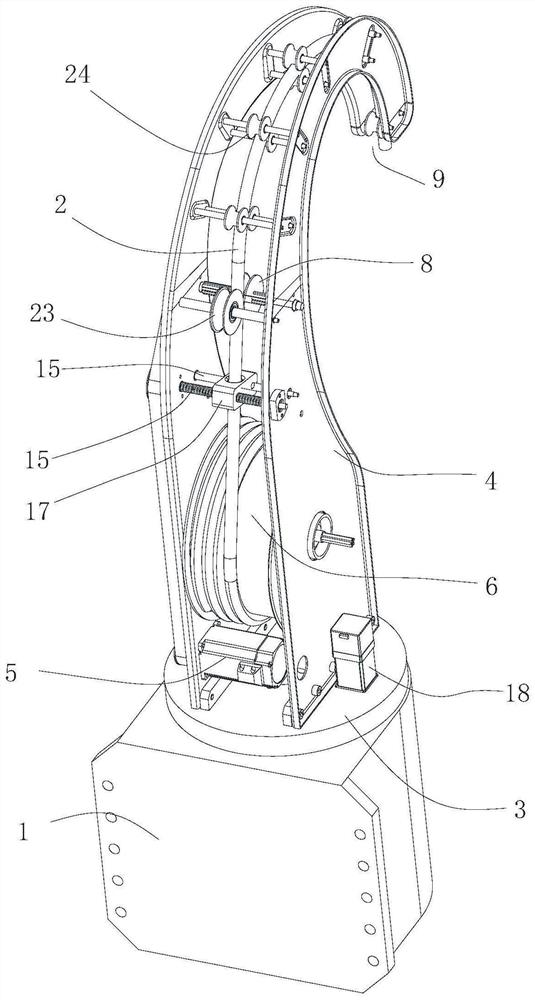

PendingCN108128208AReliable captureAchieve lockingCharging stationsElectric vehicle charging technologyLinear motionEngineering

The invention relates to a suspension type unmanned aerial vehicle capture charging device and method. The suspension type unmanned aerial vehicle capture charging device includes a foundation bracket, a locking and charging unit and a capturing and releasing unit, wherein the locking and charging unit includes a linear motion outputting mechanism, a charging column and a capture adapting pole. The linear motion outputting mechanism is mounted on the top portion of the foundation bracket, and the outputting end of the linear motion outputting mechanism is downward. The charging column is mounted at the outputting end of the linear motion outputting mechanism, and the capture adapting pole is mounted on the top portion of an unmanned aerial vehicle. An adapting ball head is arranged on thetop portion of the capture adapting pole, a charging interface for charging the unmanned aerial vehicle is arranged in the center of the top portion of the adapting ball head, and the charging interface is matched with the charging column. The capturing and releasing unit includes a plurality of supporting assemblies, and the supporting assemblies are at the same height and are circumferentially distributed along the foundation bracket. The supporting assemblies are connected with the outputting ends of the supporting assemblies-a driving mechanism. The driving mechanism of the supporting assemblies is used to drive the supporting assemblies to move closer to each other so as to fixedly clamp the adapting ball head, and drive the supporting assemblies to separate from each other to releasethe fitting ball head.

Owner:张健

Media conveyance device, printer, and control method of a printer

ActiveUS9238379B2Avoid rewindingEliminate slackRecording apparatusOther printing apparatusOperation modeEngineering

Owner:SEIKO EPSON CORP

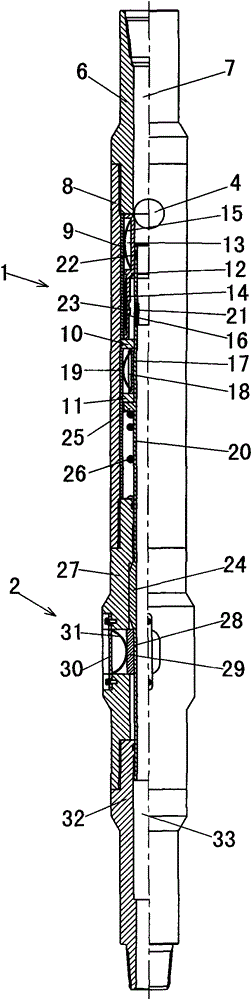

Ball-throwing type controllable wall scraper and method for cleaning inner wall of sleeve

InactiveCN104453787ARealize wall scrapingCleared smoothlyCleaning apparatusControl systemEngineering

The invention provides a ball-throwing type controllable wall scraper and a method for cleaning the inner wall of a sleeve. The ball-throwing type controllable wall scraper comprises a control system, a cutter system, at least one first steel ball and at least one second steel ball, wherein the first steel balls and the second steel balls control the control system to work. The first steel balls are thrown into the control system, so that the first steel balls push a second piston to move downwards, when the second piston moves downwards and enables all cutter feeding blocks to move downwards to push cutters on all rings to pop out of cutter through holes, buckle structures between a first piston and the second piston are connected, and then wall scraping operation can be conducted; the second steel balls are then thrown into the control system, the second steel balls drive the buckle structures to separate from each other, the second piston moves upwards under the action of all reset springs, the cutter feeding blocks also move upwards, so that all the cutters retract to the cutter through holes, and then the wall scraper is restored to an initial state. According to the ball-throwing type controllable wall scraper, at least two steel balls different in size are thrown into a tool, so that the cutters pop out or retract, obstacles on the inner wall of the sleeve are smoothly removed, downhole potential safety hazards are effectively removed, the cutters will not get stuck, and the service life of the cutters is long.

Owner:XINJIANG GRAND OILFIELD TECH

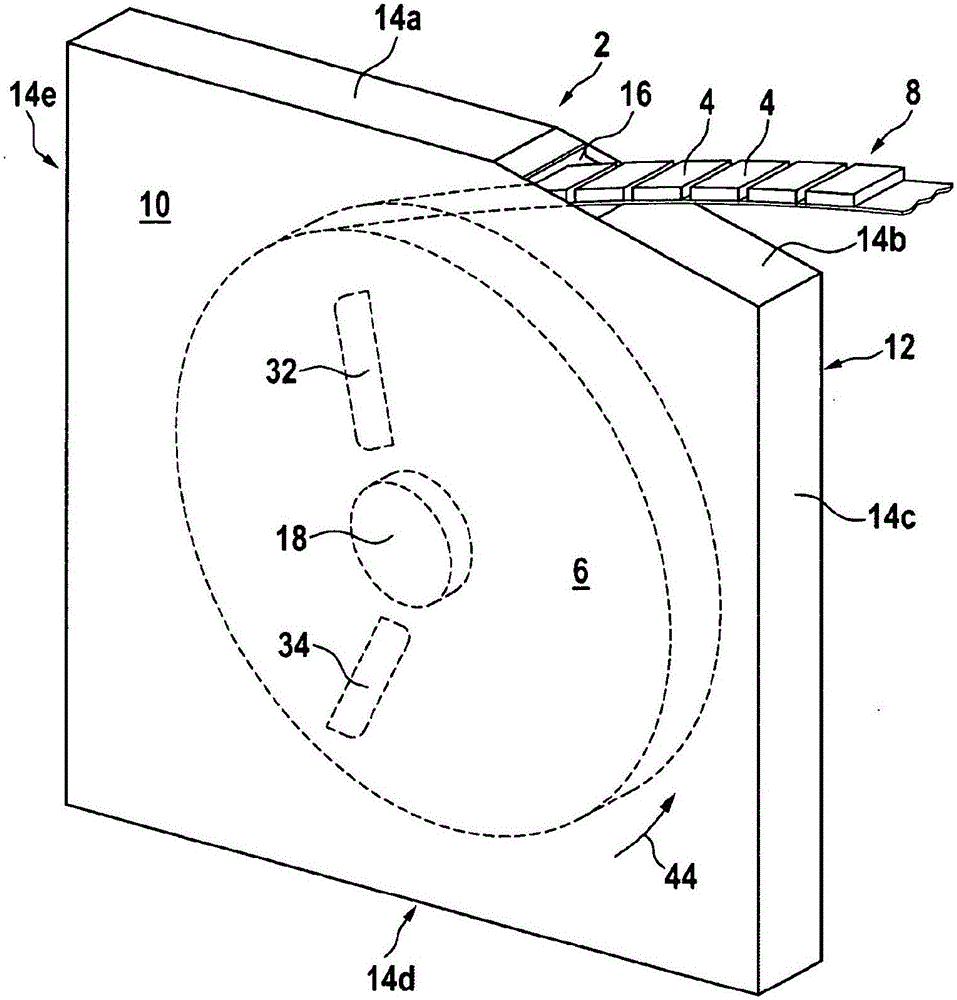

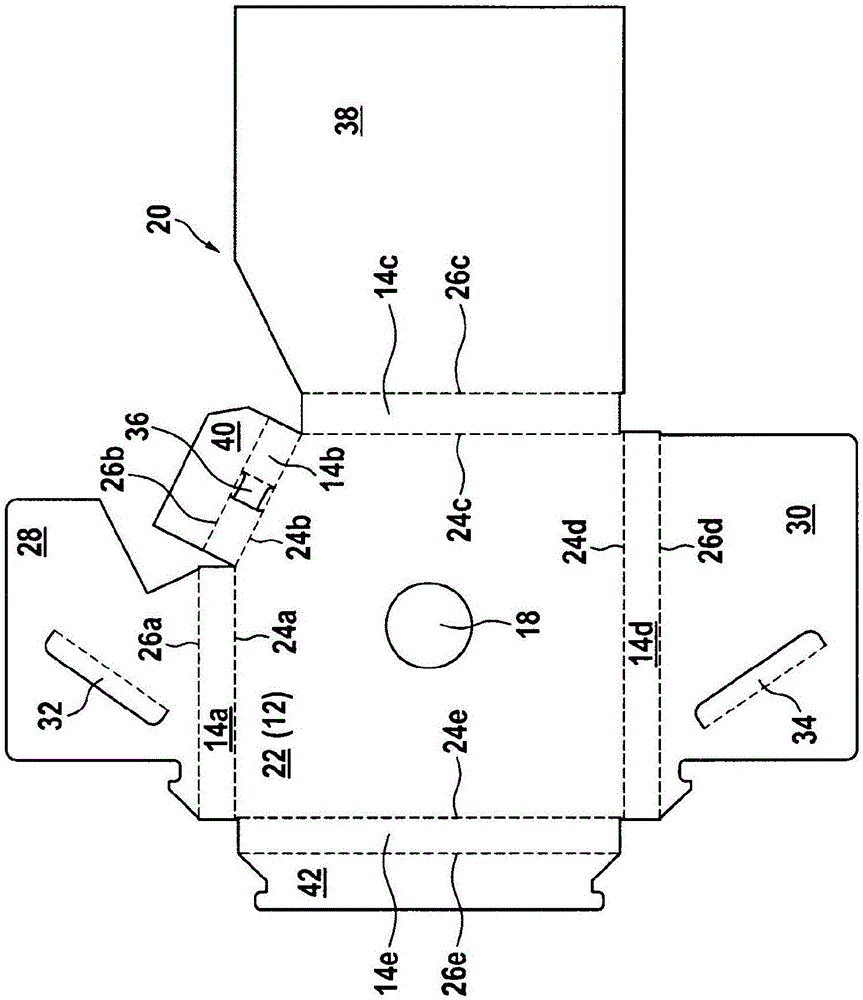

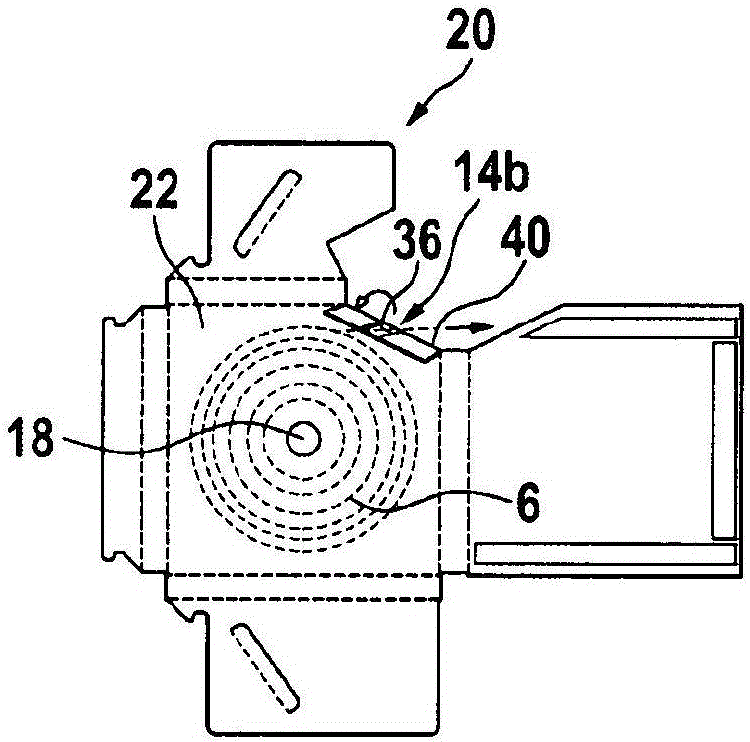

Container for receiving balance-weight roller

InactiveCN106414273AAvoid tiltingAvoid rewindingSmall article dispensingRotating bodies balancingMechanical engineering

The present invention relates to a container intended for receiving a strip that is studded with balance weights (4) and forms a belt (8) and intended for dispensing the same to a transporting and cutting-to-length mechanism. The container is formed as a casing (2) that is closed substantially on all sides and has two spaced-apart side walls, which receive the belt roller (6) between them, and also a peripheral wall (14), which connects the side walls to one another and has a dispensing opening (16) for the belt (8) to pass through. On the inner side of at least one of the side walls (10, 12) there is formed at least one restrainer (32, 34) that lies against the belt or the belt roller and spreads at an angle to prevent a return movement of the belt or the belt roller.

Owner:WEGMANN AUTOMOTIVE GMBH & CO KG

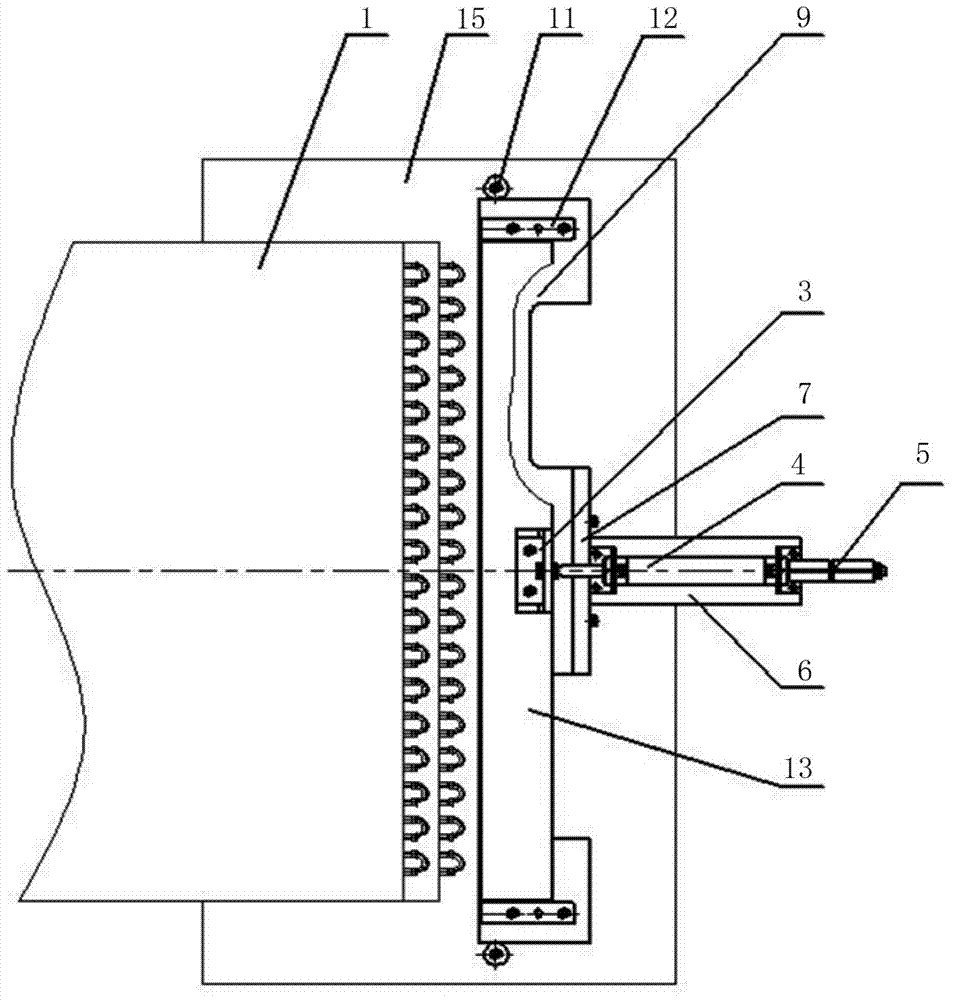

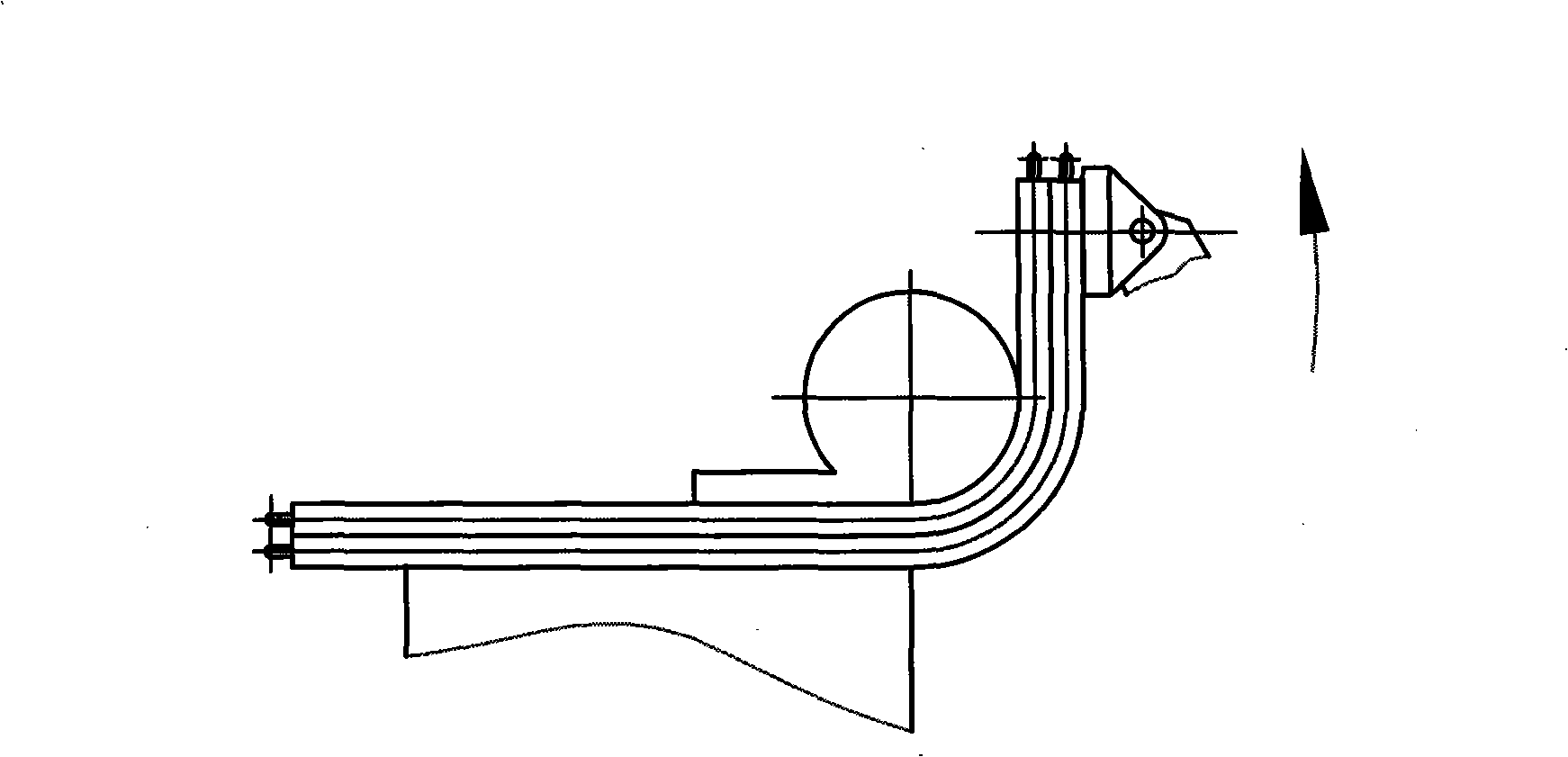

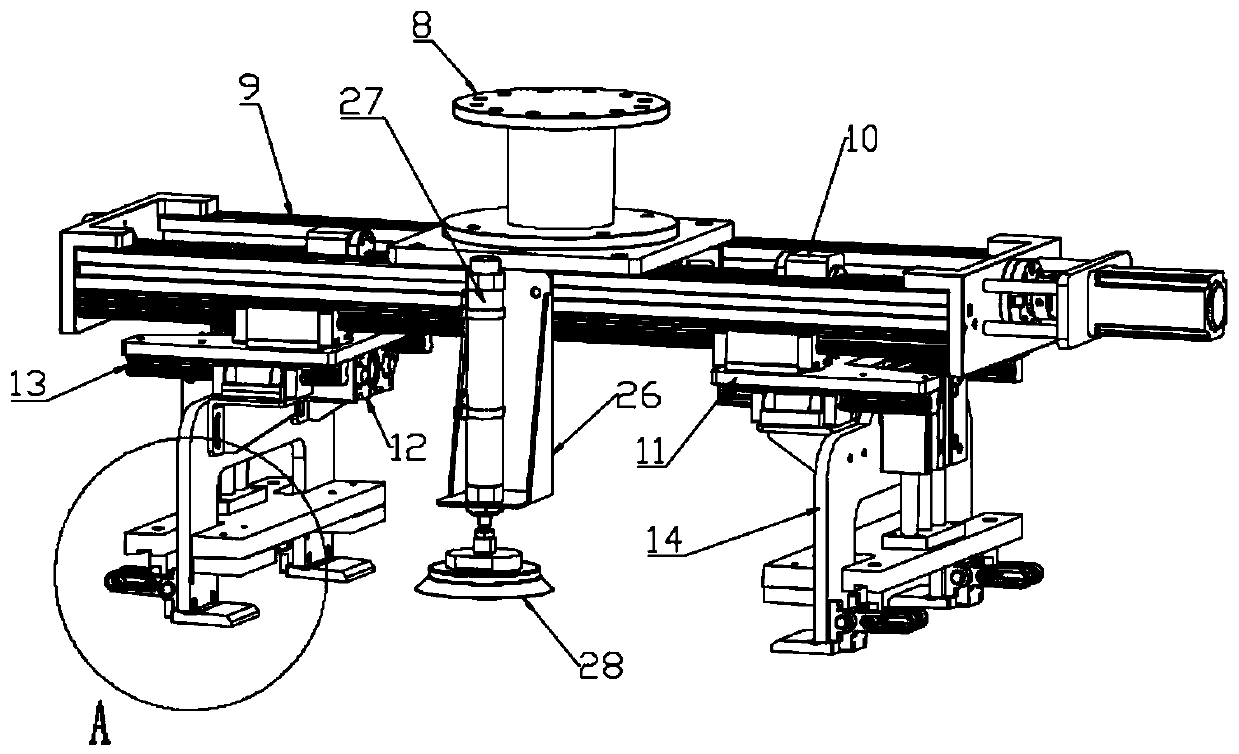

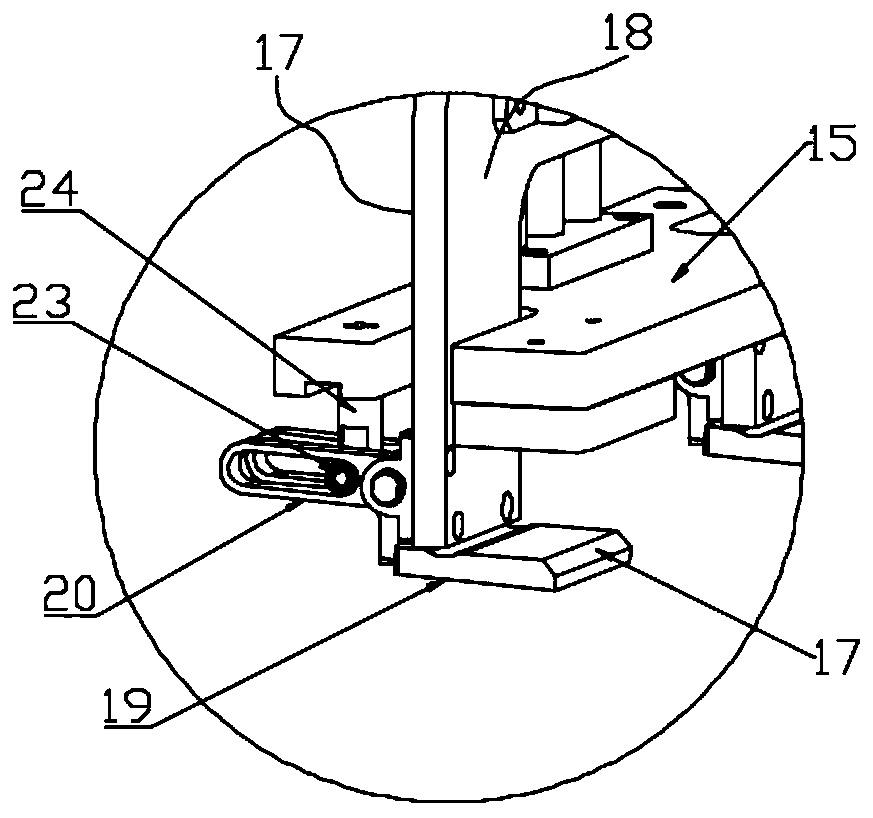

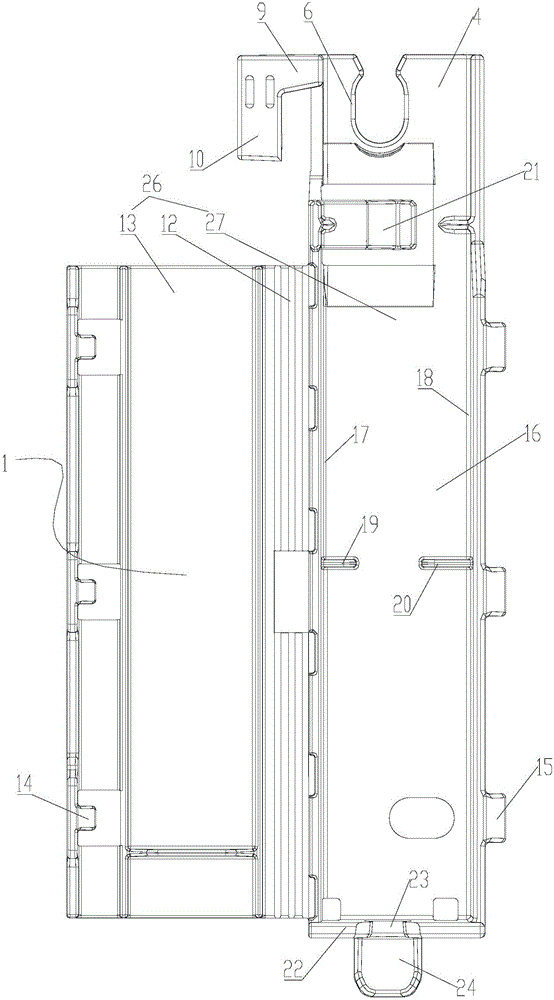

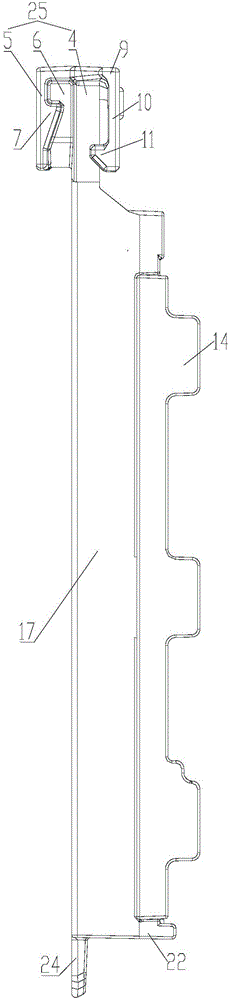

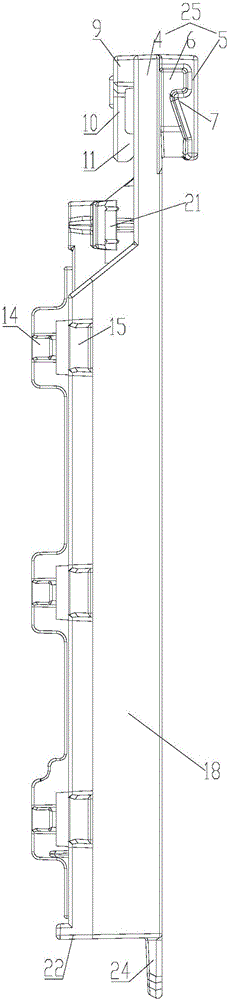

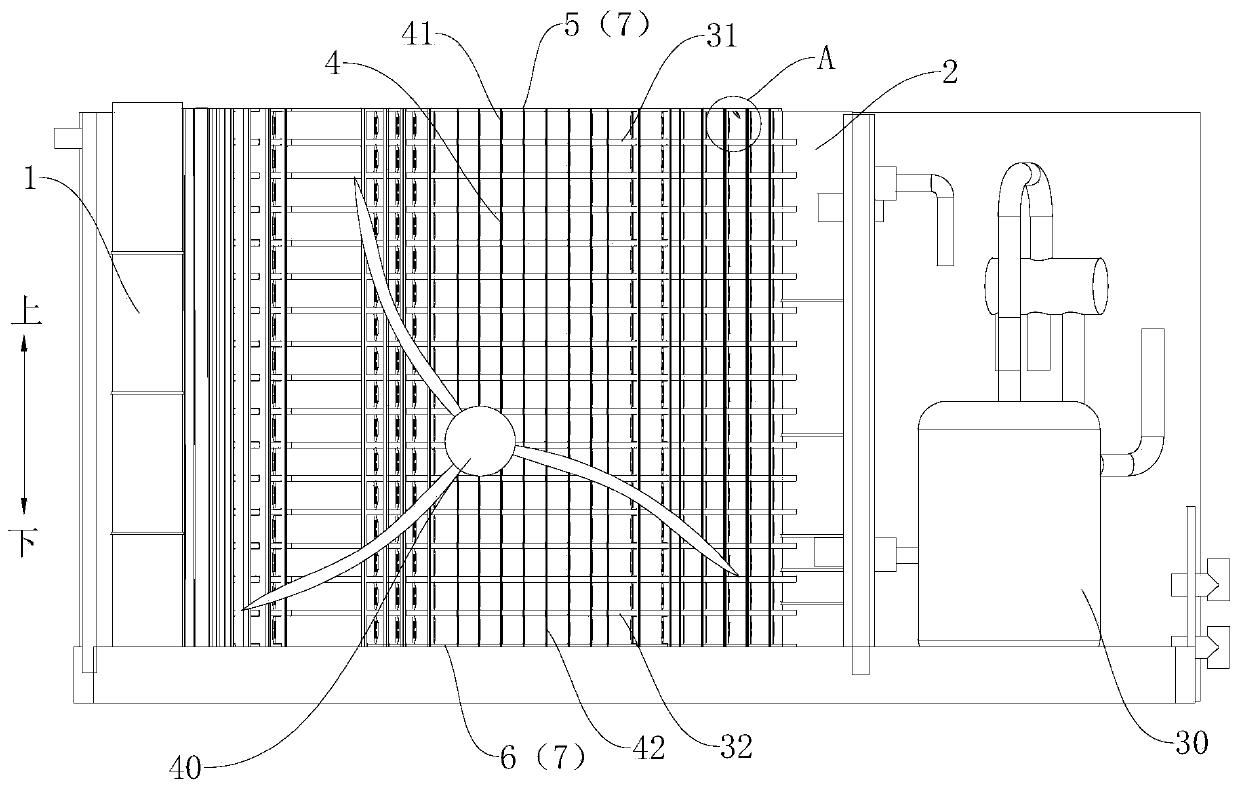

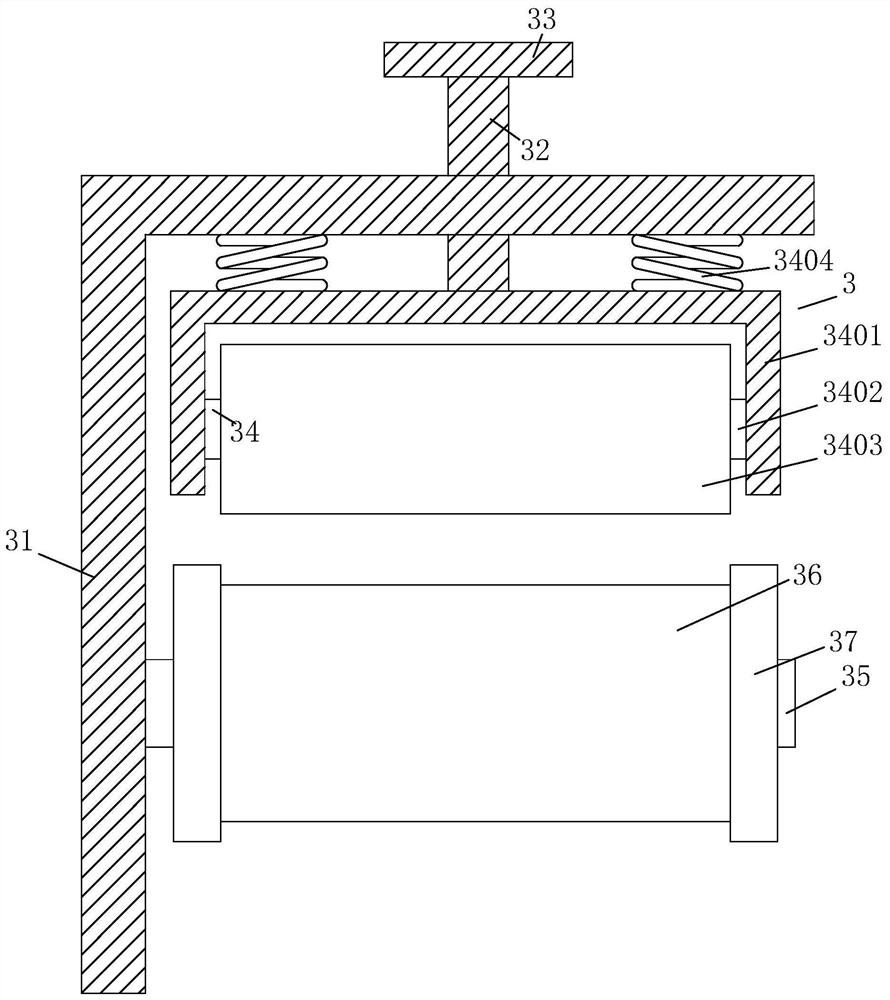

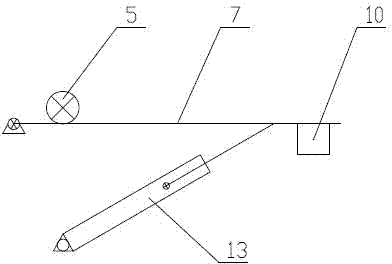

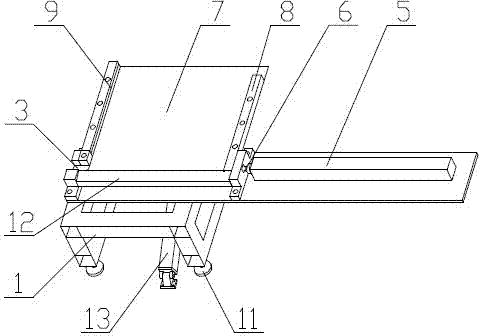

Anti-reversing device for air conditioning heat exchanger core L-shaped bending machine

The invention provides an anti-reversing device for an air conditioning heat exchanger core L-shaped bending machine and belongs to the production field of refrigeration equipment. The specific structure of the device is as follows: an electric cylinder mounting base (2) is fixed on the working bedplate (15) of the bending machine and an electric actuator (10) fixed on the electric cylinder mounting base (2) is fixed with an electric cylinder connecting plate (8); the lower end of a connecting plate (7) is fixed with the electric cylinder connecting plate (8), while the upper end of the connecting plate (7) is fixed with an air cylinder mounting plate (6), and the side surface of the connecting plate (7) is fixed with a lower plate (9); an air cylinder (4) is fixed with an upper plate (13) by use of a mounting base (3); the upper plate (13) is connected with the lower plate (9) in a sliding manner and the lower plate (9) is connected with the working bedplate (15) in a sliding manner; during working, the electric actuator (10) drives the lower plate (9) to slide and the air cylinder (4) drives the upper plate (13) to slide. The device is capable of effectively avoiding fin reversing; the quality and the yield of the heat exchange products are improved.

Owner:SHENYANG ZHONGZE INTELLIGENT EQUIP CO LTD

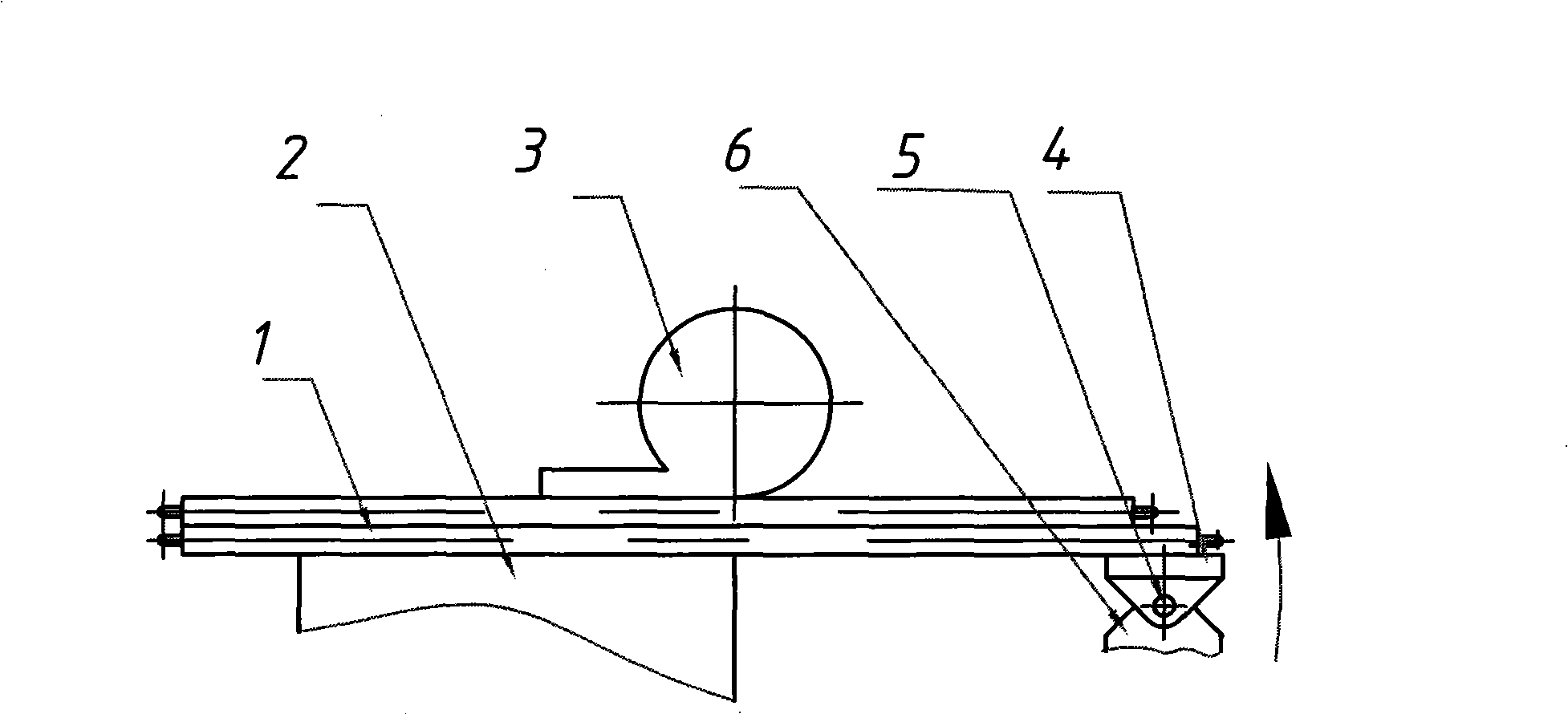

Bending method of air conditioning condenser and press brake

InactiveCN101537448ANot easy to rewindSmall relative pressureEvaporators/condensersRelative pressureEngineering

The invention relates to a bending method of an air conditioning condenser. The uppermost layer of a multi-layer condenser blade is bended firstly, and then the second layer of the condenser blade and the third layer of the condenser blade are bended successively. The bending method has the advantages that the required total bending moment is small, the relative pressure between the condenser blade and a bend mold and among layer and layer of the condenser blade is also small, and the condenser blade can not be rewound easily. When the condenser blade is bended, the horizontal moving power, the horizontal moving speed and the linear velocity during the rotation of the lowest layer of the condenser blades on the bend molds are increased. Therefore, the condenser blade can not be hindered by the resistance in the horizontal direction in bending, and the occurrence of rewinding phenomena can be prevented.

Owner:ZHONGSHAN JINGDA TEKE MACHINERY CO LTD

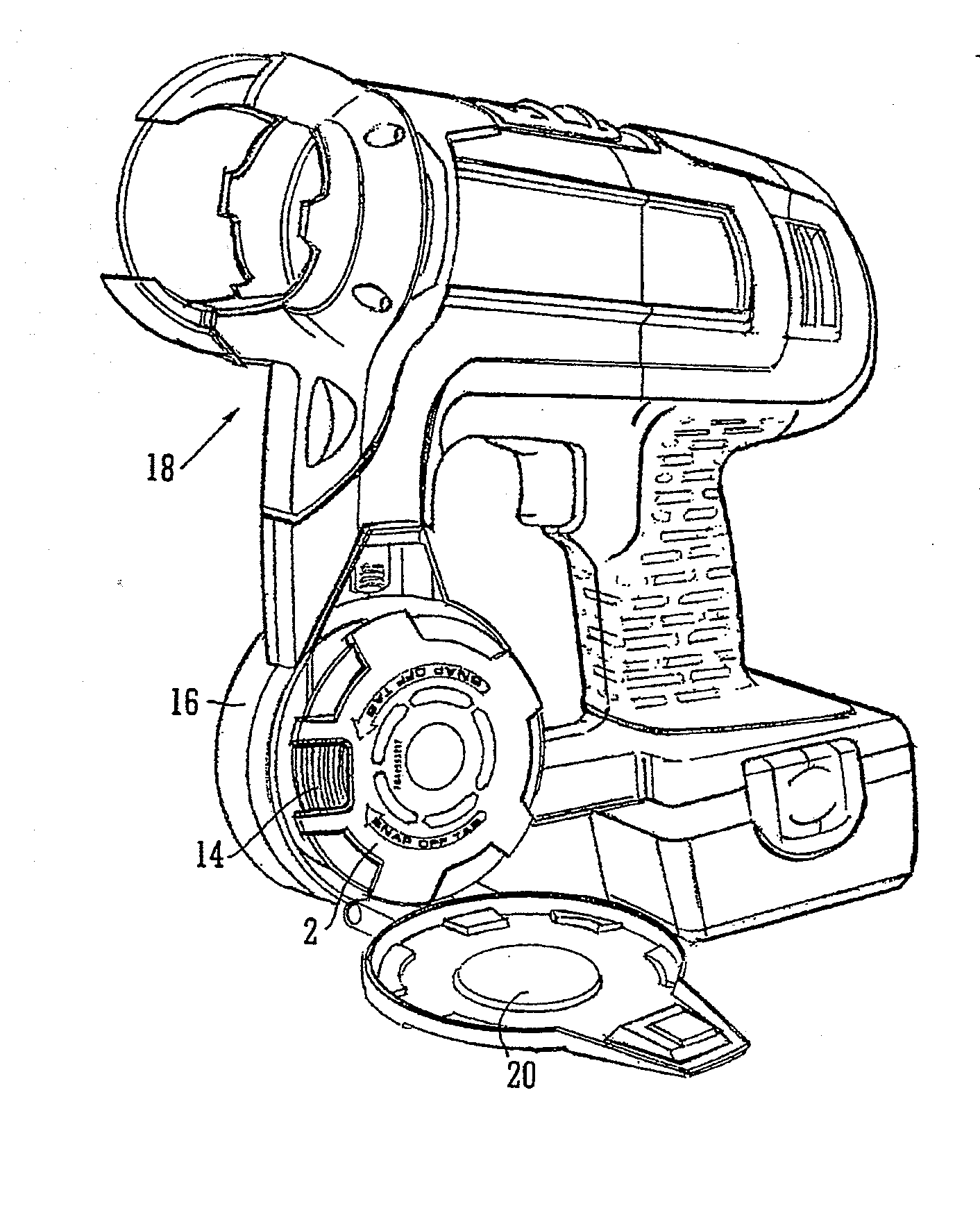

Consumable authentication

ActiveUS20160376042A1Avoid rewindingGuaranteed uptimeContainer decorationsLevel indicationsEngineeringMechanical engineering

Owner:HUSQVARNA AB

Parallel-type two-side coating machine

InactiveCN105499078AAvoid rewindingImprove equipment usageLiquid surface applicatorsCoatingsEquipment useCooking & baking

The embodiment of the invention discloses a parallel-type two-side coating machine, and aims to solve the problems that the conventional coating machine adopts single surface coating, needs repeated unwinding and winding, is low in equipment use rate, and has high possibility of changing base material performance. The parallel-type two-side coating machine comprises disclosed by the embodiment comprises an unwinding assembly, a back surface coating assembly, a front surface coating assembly, a baking assembly and a winding assembly; an unwinding opening of the unwinding assembly, a coating machine head I of the back surface coating assembly, a coating machine head II of the front surface coating assembly, a baking passage of the baking assembly and a winding opening of the winding assembly form a coating passage for conveying base materials through a plurality of guide rollers in sequence.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

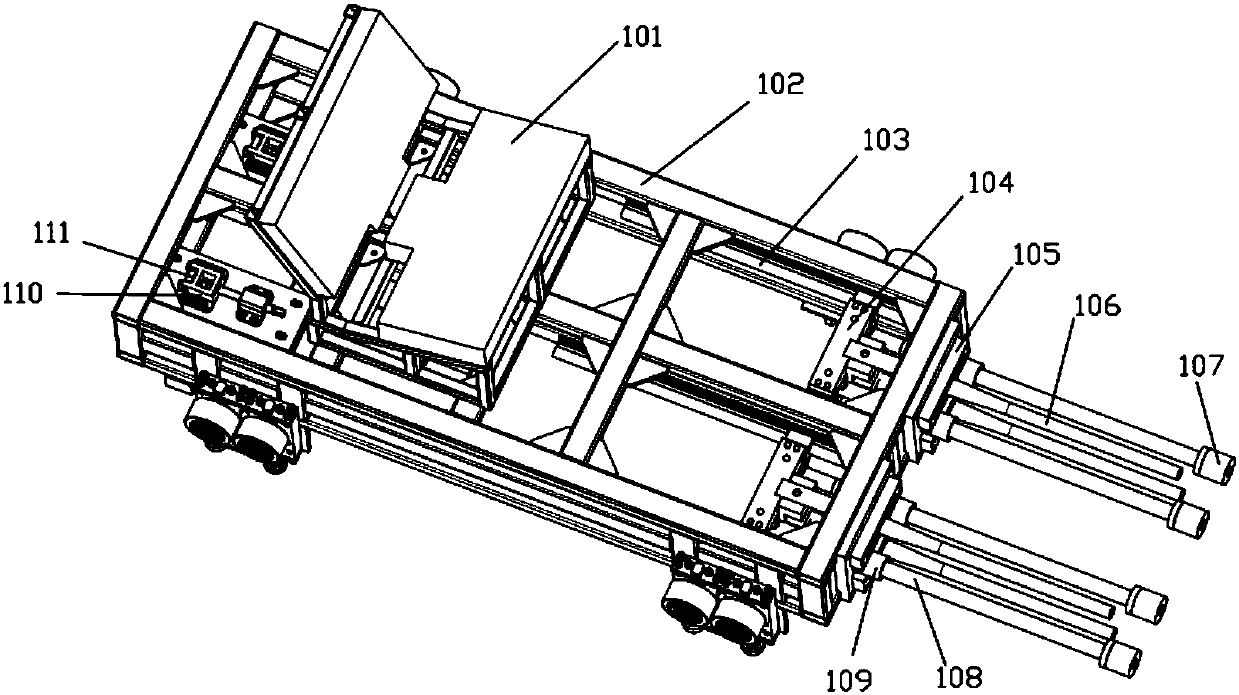

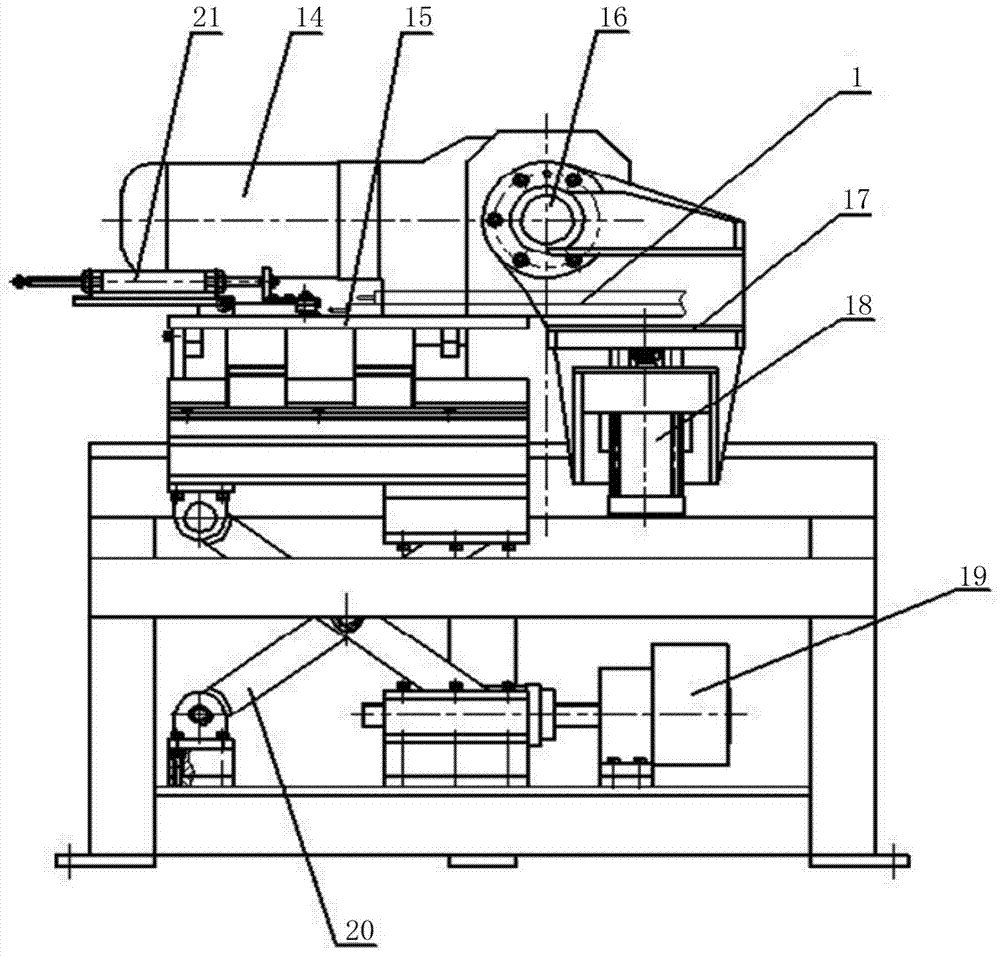

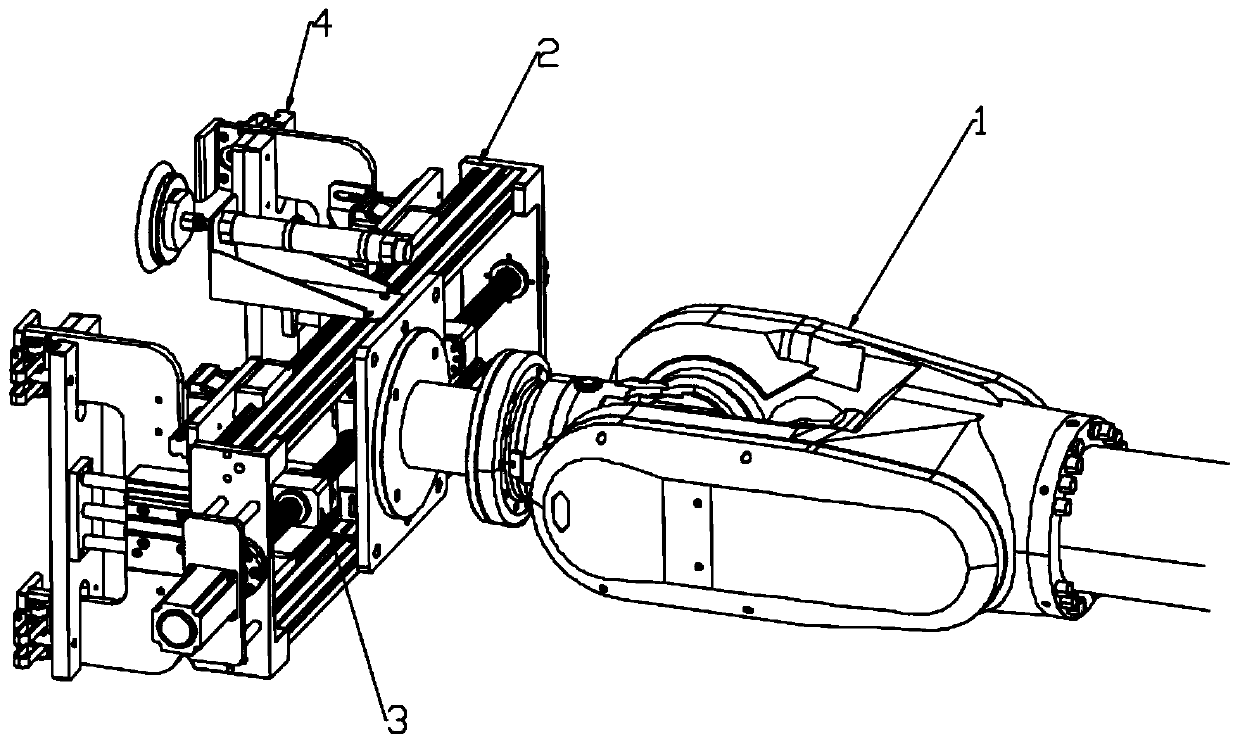

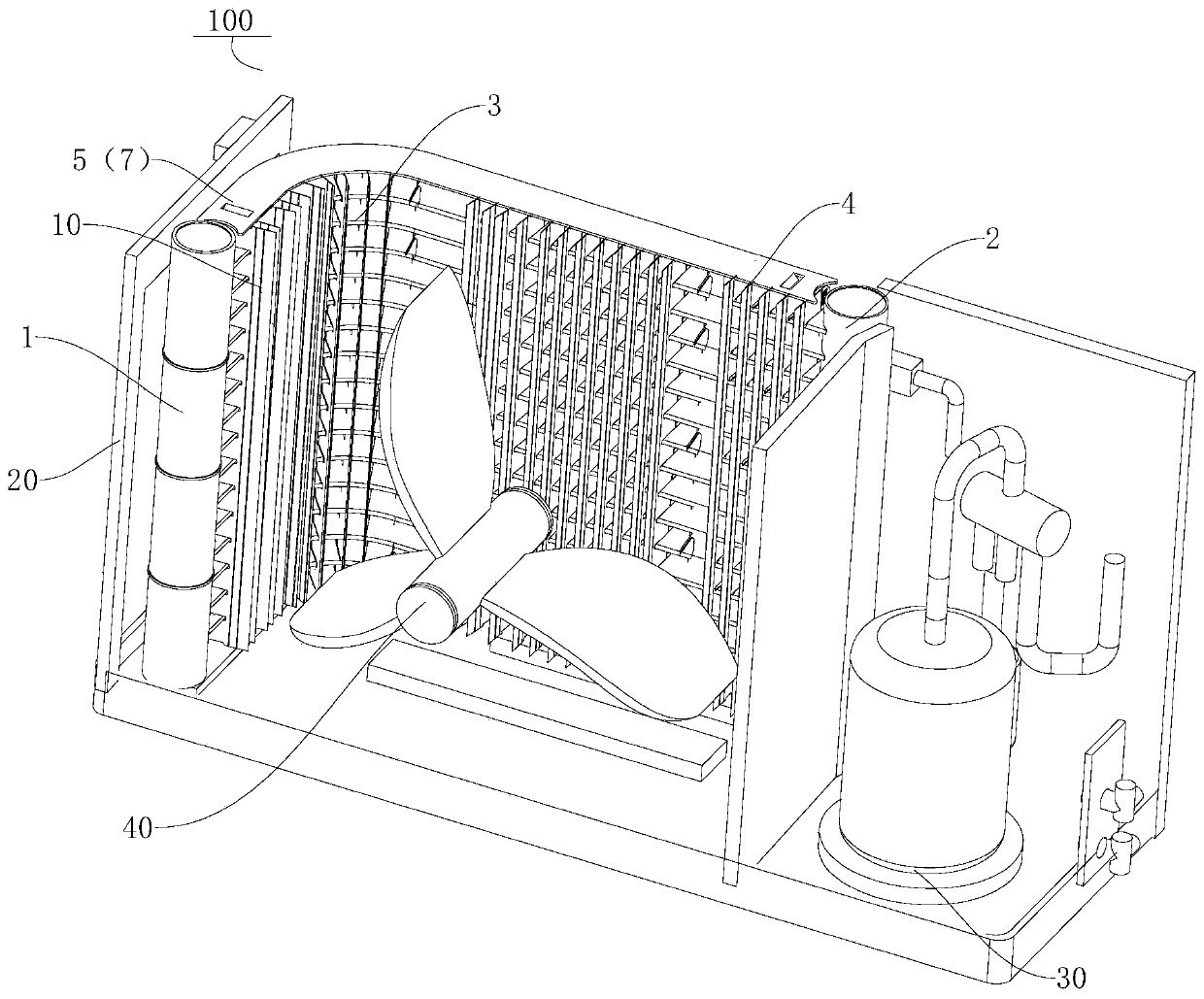

Heat exchanger carrying device and automatic device used for heat exchanger tube-expanding process

PendingCN111112487AIncrease productivityReduce labor intensityMetal-working feeding devicesPositioning devicesProcess engineeringManual handling

The invention provides a heat exchanger carrying device. The heat exchanger carrying device comprises an industrial robot and a carrying clamp, wherein the carrying clamp is mounted on the industrialrobot; the carrying clamp comprises a position regulating assembly and a clamping assembly; the clamping assembly is connected onto the position regulating assembly, and is regulated in position through the position regulating assembly; the clamping assembly is used for clamping a heat exchanger; the clamping assembly can clamp a heat exchanger in a first direction and a second direction, the first direction is a direction along a plate surface of the heat exchanger, and the second direction is a direction perpendicular to the plate surface of the heat exchanger. The automatic carrying deviceis suitable for carrying the heat exchanger by the industrial robot, and can quickly carry to realize automatic loading and unloading for tube-expanding of the heat exchanger, so that production efficiency is improved, conventional manual operation can be replaced, and labor intensity of staff is reduced.

Owner:GREE ELECTRIC APPLIANCES CHONGQING +1

Air conditioning device and temperature sensing bulb support installation structure

ActiveCN106369698AAchieve fixationImprove assembly efficiencyLighting and heating apparatusAir conditioning systemsEngineeringAir conditioning

The invention provides an air conditioning device and a temperature sensing bulb support installation structure. The temperature sensing bulb support installation structure comprises a temperature sensing bulb support and an air-conditioning outdoor unit side plate, the temperature sensing bulb support comprises a first clamping part, the air-conditioning outdoor unit side plate is provided with a second clamping part, and the temperature sensing bulb support is installed on the air-conditioning outdoor unit side plate through a clamping structure formed by the first clamping part and the second clamping part. According to the air conditioning device and the temperature sensing bulb support installation structure, there is no need to cover a temperature sensing bulb with the temperature sensing bulb support and then insert the temperature sensing bulb support into a condenser, the temperature sensing bulb can be effectively protected, the assembly efficiency of the temperature sensing bulb can be improved, and the problem that the temperature sensing bulb support and the temperature sensing bulb fall off because of fin toppling and loose fixing can be avoided.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

A pipeline spraying equipment

Owner:东台市高科技术创业园有限公司

Heat exchanger and air conditioner comprising same

PendingCN109813147AImprove heat transfer efficiencyAvoid rewindingStationary conduit assembliesAir conditioning systemsEngineeringMicro heat exchanger

The invention discloses a heat exchanger and an air conditioner comprising the same. The heat exchanger comprises a first flow collection tube, a second flow collection tube and a plurality of heat exchange tubes, wherein the first flow collection tube and the second flow collection tube are arranged in a spaced mode; the heat exchange tubes are arranged in the length direction of the first flow collection tube at the intervals; the two ends of each heat exchange tube are connected with the first flow collection tube and the second flow collection tube correspondingly; a protective plate is arranged at least one side of the heat exchange tubes in the length direction of the first flow collection tube; the protective plate is located on the outermost side of the heat exchange tubes; and atleast part of fins are connected between the protective plate and the heat exchange tube nearest to the protective plate. According to the heat exchanger provided by the invention, the fins of the heat exchanger can be protected against fin collapse during transportation.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

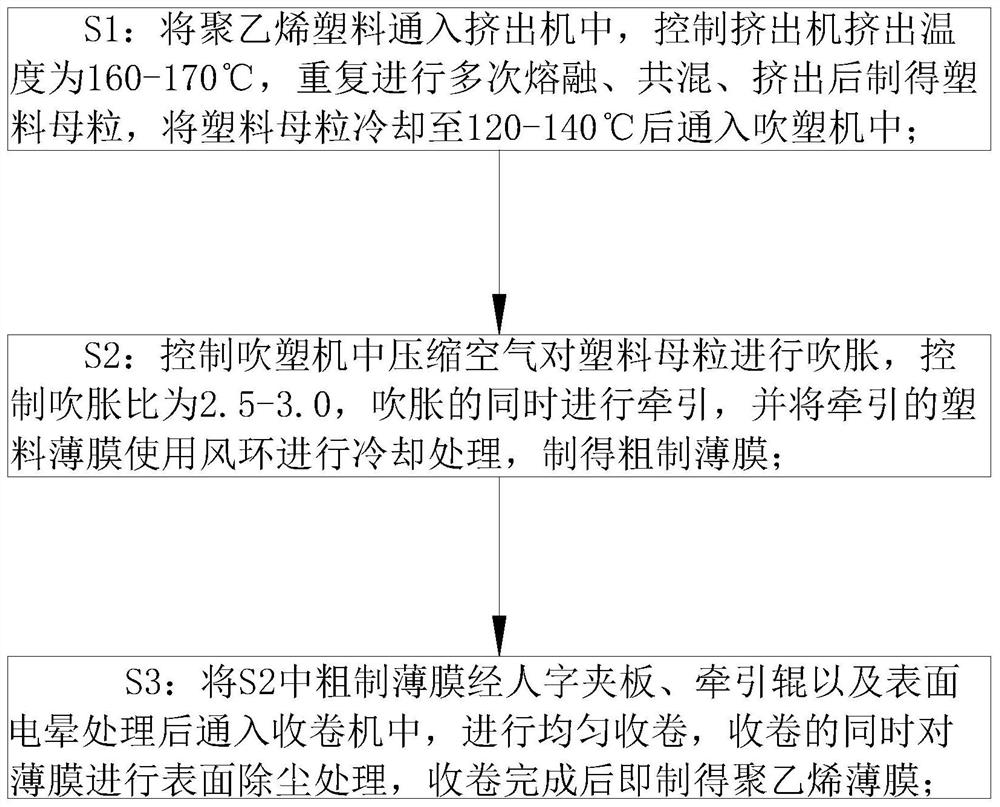

Film manufacturing process

PendingCN111844826AAvoid rewindingAvoid misalignmentFlat articlesCleaning processes and apparatusPhysicsAdhesive glue

The invention relates to the field of film production equipment, in particular to a film manufacturing process. The film manufacturing process comprises an underframe, wherein the upper end of the underframe is fixedly connected with a transverse plate; two sides of the upper end of the transverse plate are provided with guiding mechanisms; the middle of the back surface of the upper end of the transverse plate is fixedly connected with a second supporting plate; and one side of the transverse plate is provided with a film winding drum through a driving mechanism. According to the film manufacturing process, a clamping mechanism is arranged on a winding drum of the film winding drum, when in use, one stretched end of a film can be clamped on the winding drum by using a first clamping plateand a second clamping plate of the clamping mechanism without needing glue and the like, and the situation that the partial film sticks on the winding drum when the film is taken later is avoided; and the two guide mechanisms are arranged on the transverse plate, when in use, the motion track of the film is fixed by guide rollers with two retaining rings of the two guide mechanisms, and meanwhile, the film is pressed by pressing rollers of a flattening frame, so that the phenomenon that the film deviates in the winding process is avoided, and the situation that the workload is increased due to the fact that workers rewind the film is avoided.

Owner:王福

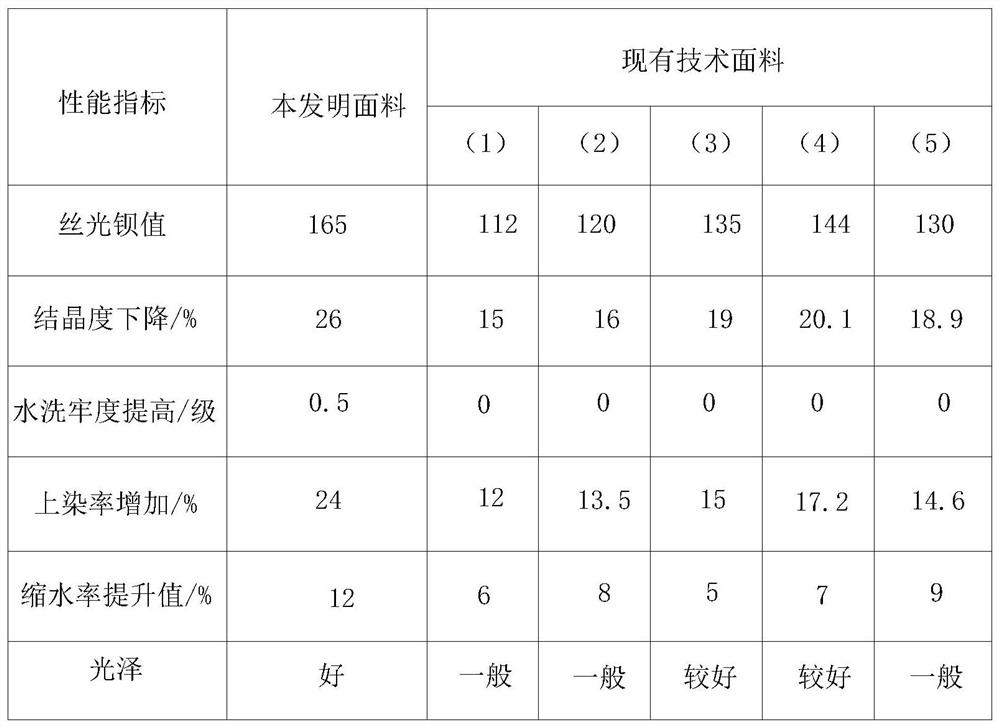

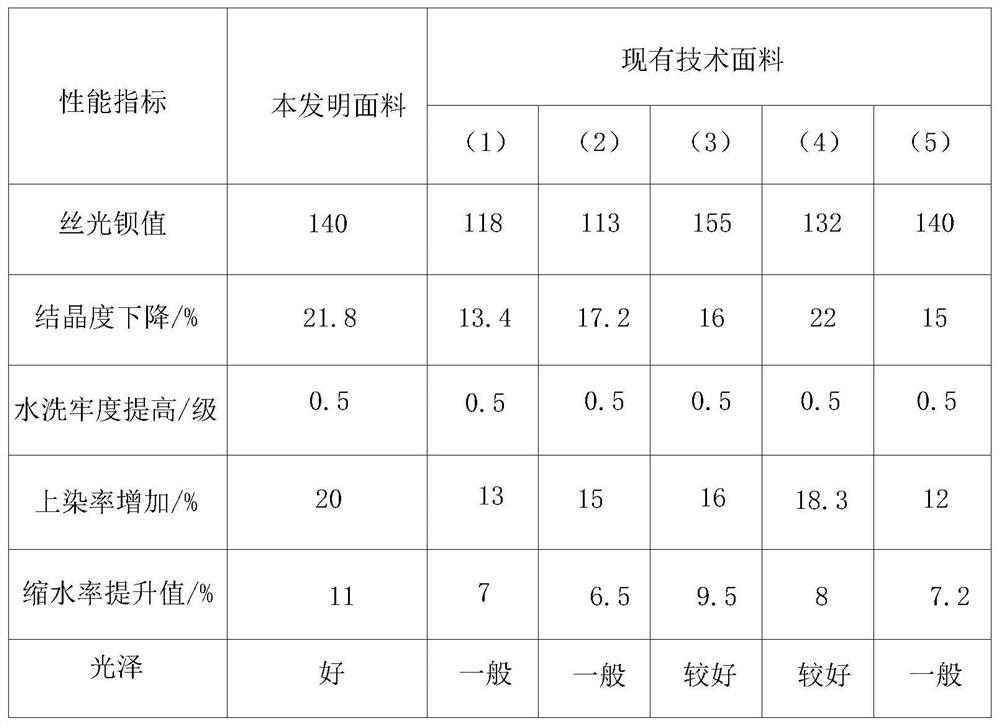

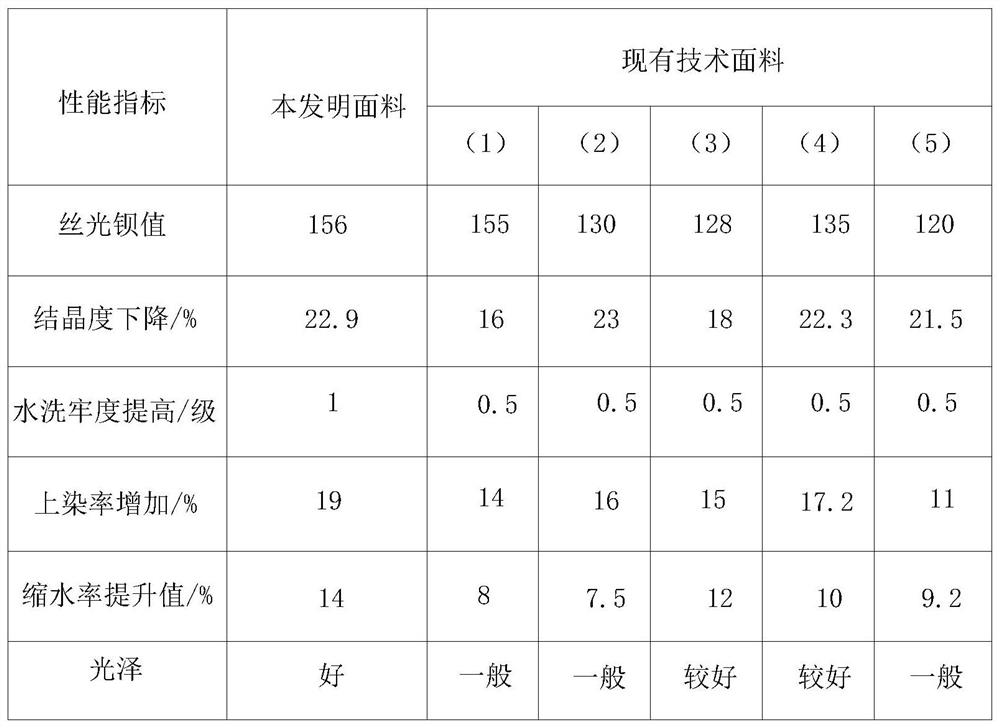

Crystal cotton three-mercerized fabric and processing method thereof

PendingCN113355825AMeet tension requirementsImprove yieldMercerising of yarns/threads/filamentsMercerising of indefinite length fabricsYarnTextile technology

The invention belongs to the technical field of textiles, and particularly relates to a crystal cotton three-mercerized fabric and a processing method thereof. Fibers are subjected to liquid alkali or liquid ammonia tension mercerization and then are processed into yarns under conventional procedures, and finished mercerized yarns are prepared through procedures of singeing, reeling, mercerizing, dyeing, setting and the like. The mercerized yarns produced by the method are uniform in mercerizing, full in color and good in dyeing effect. By a mercerizing device, the fabric automatically passes through a caustic soda solution and clear water, so that the fabric keeps certain tension all the time, the tension requirement of fabric mercerizing is met, the softness is improved, and the finished product rate of the fabric can be effectively improved; and the yarns only need to be mercerized once after fiber mercerizing, so that two times of reeling, drying and rewinding are avoided, the production and processing cost is saved, and the yarn loss is reduced.

Owner:HONGDOU GROUP WUXI YUANDONG CLOTHING

Novel water pump pressure control device

PendingCN107061246AExtended service lifeImprove adsorption capacityPositive displacement pump componentsPump controlMicrocontrollerWater flow

The invention provides a novel water pump pressure control device, which includes a water inlet and a water outlet; a check valve assembly is arranged between the water inlet and the water outlet; a pressure sensor is arranged at the water inlet; the pressure sensor is connected with the water outlet. The control module is electrically connected; the check valve assembly includes a magnet, and a reed switch is arranged next to the magnet; the reed switch is electrically connected to the control module; the control module is electrically connected to the water pump; the water pump pressure control device passes The pressure sensor detects the pressure in the pipeline, and then uses the single-chip microcomputer to control the start and stop of the water pump; and uses the magnet on the check valve and the reed switch on the control board to detect the water flow in the pipeline, and displays the pressure and other information through the digital tube; The check valve structure with a raised silicone sleeve ensures that the controller can keep the water pump running with a small flow rate, which improves the service life of the water pump.

Owner:ZHEJIANG MONRO MACHINERY & ELECTRONICS

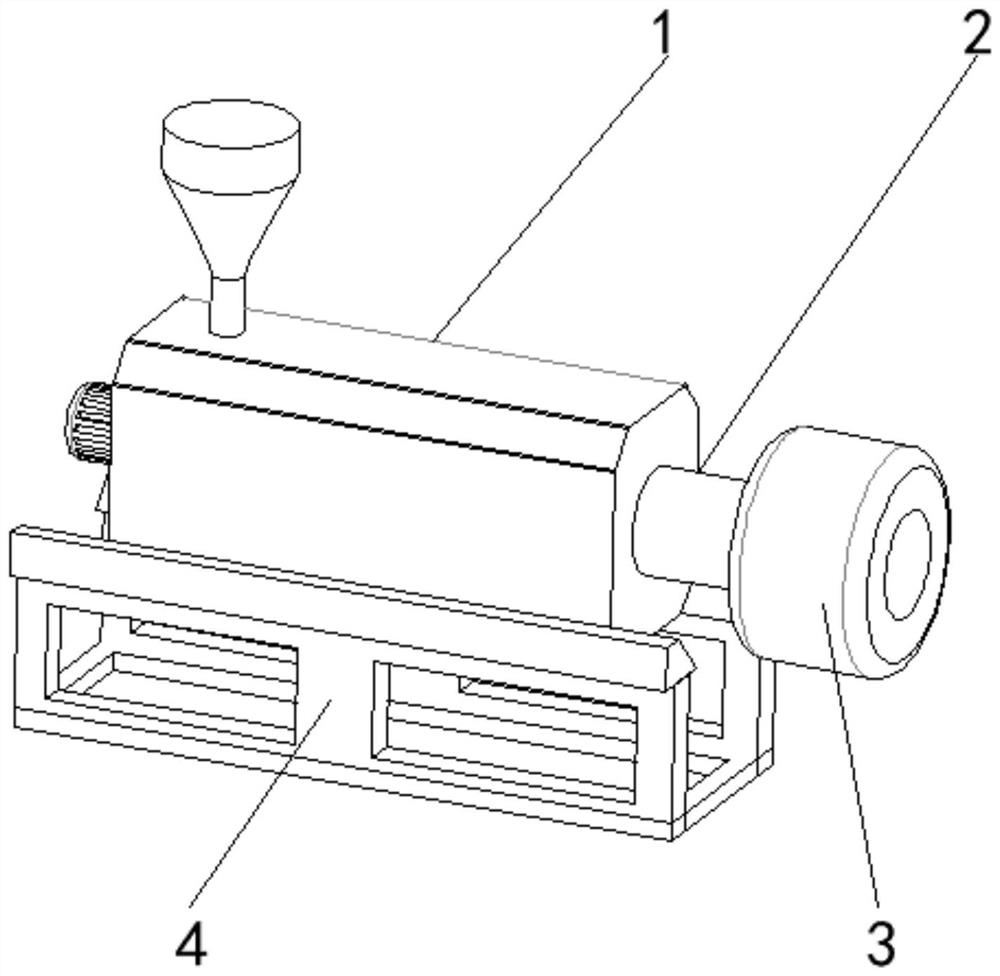

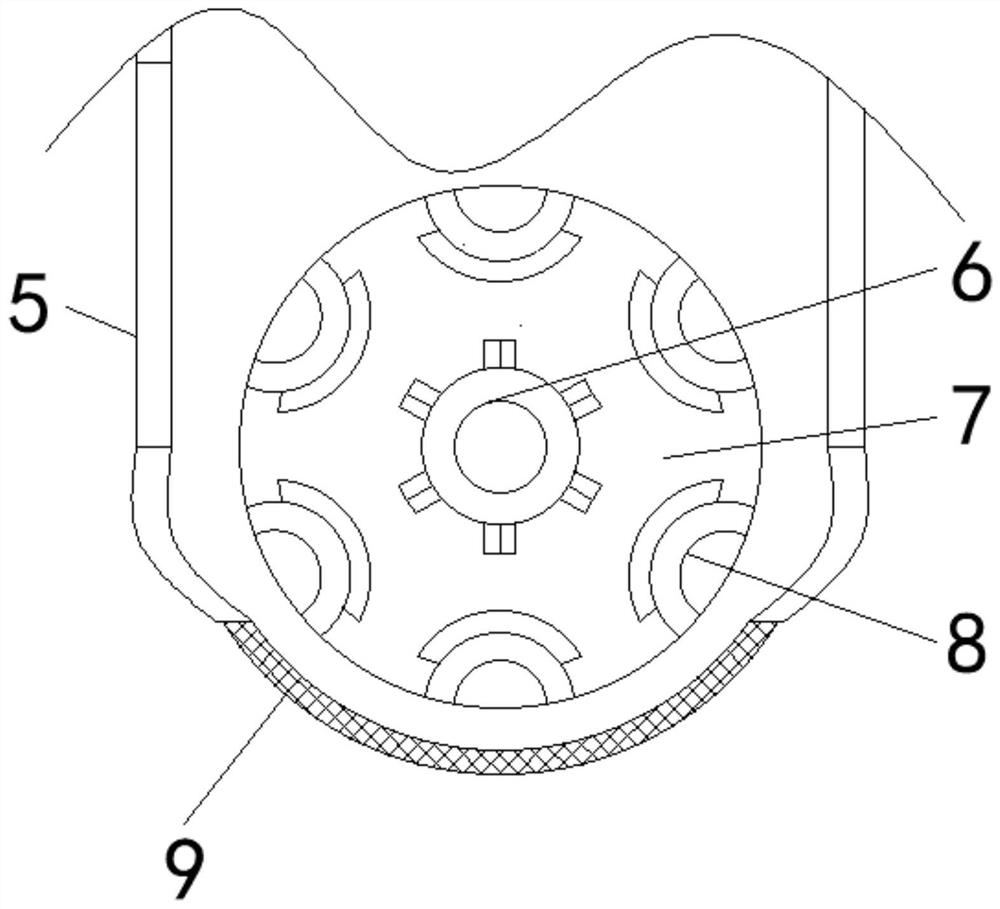

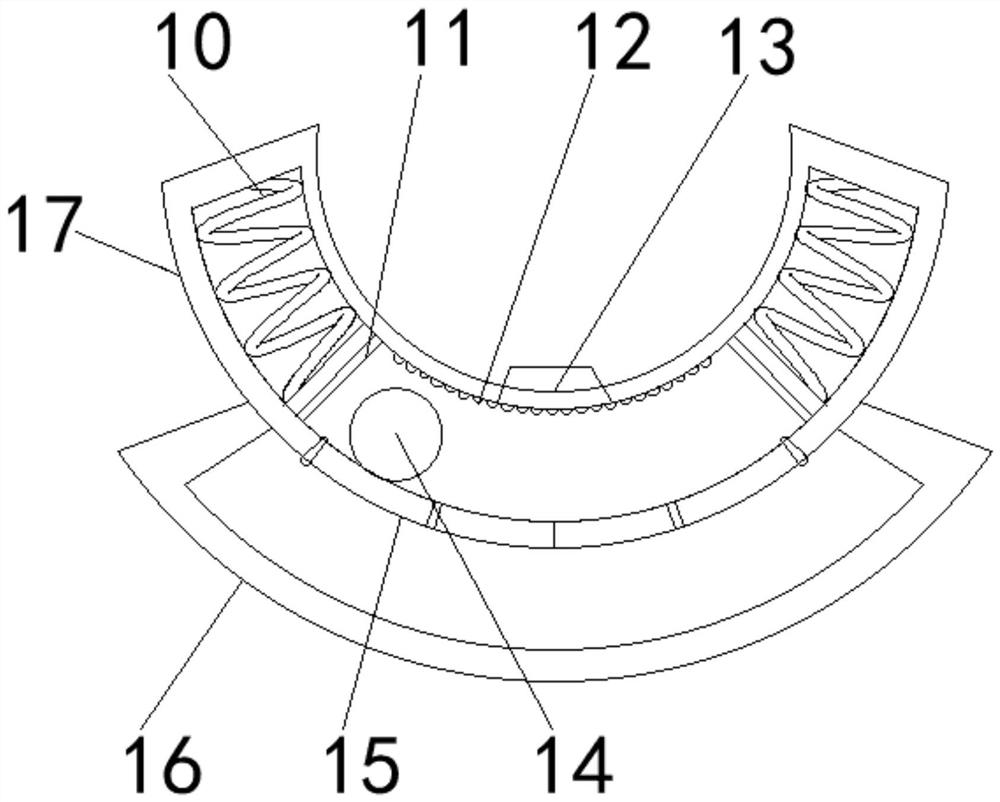

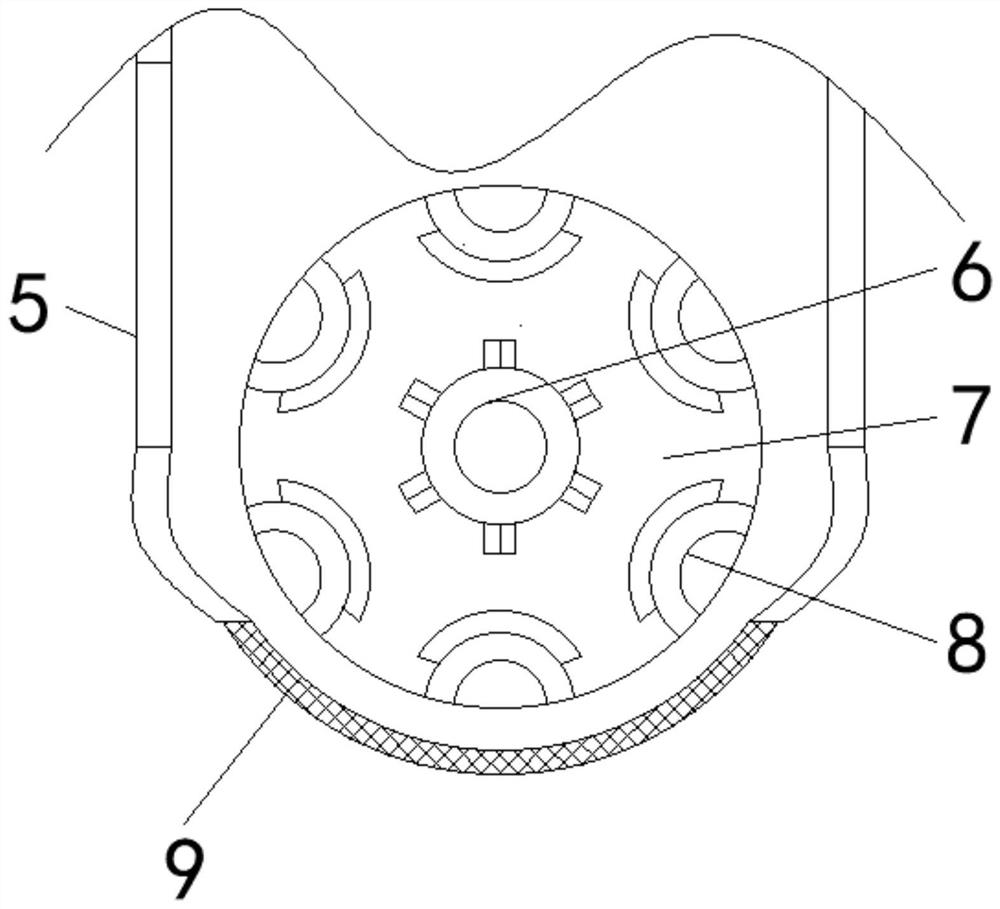

Energy-saving and environment-friendly plastic cold pelletizing system

InactiveCN111645298AGuaranteed stabilityReduce frictionSievingDrying solid materials without heatHydraulic cylinderGear wheel

The invention relates to the technical field of plastic processing, and in particular relates to an energy-saving and environment-friendly plastic cold pelletizing system. The energy-saving and environment-friendly plastic cold pelletizing system comprises a rack, as well as a water cooling mechanism, a screening mechanism and a pelletizing mechanism which are sequentially arranged on the rack inthe first direction, wherein the water cooling mechanism comprises a water cooling tank, a separation roll, a first guide roll and a draining roll, and a water inlet pipe and a water outlet pipe whichcommunicate with an inner cavity of the water cooling tank are respectively arranged on the side wall of the water cooling tank; the screening mechanism comprises a screening plate, first pressing rolls, second pressing rolls, second guide rolls, lifting bearings, cams, servo motors, a gear chain assembly, third pressing rolls and fourth pressing rolls, flow guide holes are formed in the first pressing rolls and the second pressing rolls along the axes, and the water outlet pipe communicates with the first pressing rolls and the second pressing rolls through a universal joint; and the pelletizing mechanism comprises a hydraulic cylinder and a cutting die. According to the energy-saving and environment-friendly plastic cold pelletizing system, the cooling and drying effects of the plasticpelletizing system are improved, and the energy-saving and environment-protecting development concept is met.

Owner:福州市长乐区白英设计有限公司

Mattress roll-packing machine

PendingCN112340088ADeal with it in placeAvoid damageWrapping material feeding apparatusWrappingLogistics managementStructural engineering

The invention relates to the technical field of mattress packing, and particularly discloses a mattress roll-packing machine. The machine comprises a rack, a feeding device, a film unwinding device, afilm pulling device, a first conveying device, a pressing device, a roll-packing device, a sealing device, a rocker arm device and a discharging conveying device. According to the machine, a film unwinding mode of a traditional roll-packing machine is changed, the film pulling device is used for lifting a film, low-position film feeding is achieved, film back-rolling is effectively prevented, meanwhile, the pressing device is arranged for pressing conveying, it can be guaranteed that the film can be tightly attached to a mattress, gaps generated between the mattress and the film are reduced,and it is guaranteed that roll-packing treatment is in place. An adjusting device is further arranged for adjusting a roll-packing interval, a mattress roll-packing size can be adjusted according to the actual production requirement, and the machine can be adjusted to meet different logistics requirements, and avoid film roll-packing damage.

Owner:广东耐锢科技有限公司

Synchronous driving type automatic charging pile

PendingCN113459850AEasy to swing out of the rackEasy to useCharging stationsElectric vehicle charging technologyEngineeringControl theory

The invention relates to the technical field of charging piles, in particular to a synchronous driving type automatic charging pile which comprises a base, a charging wire, a rotating table rotationally arranged on the base and a hanging arm arranged on the base. The synchronous driving type automatic charging pile further comprises a take-up and pay-off driving part, a take-up and pay-off wheel, a synchronous transmission assembly, a wire arrangement assembly and a friction wheel. The take-up and pay-off driving part is in driving connection with the synchronous transmission assembly, the wire arranging assembly and the friction wheel are both arranged between the take-up and pay-off wheel and the wire outlet, and the synchronous transmission assembly is in transmission connection with the take-up and pay-off wheel, the wire arranging assembly and the friction wheel. The synchronous driving type automatic charging pile is novel in structure, and when a charging wire is wound around the winding wheel, the wire arranging assembly drives the charging wire to swing and move left and right, so that the charging wire is evenly wound around the winding wheel, and the charging wire is prevented from being repeatedly wound around the same position of the winding wheel; and the charging wire can be conveniently and smoothly sent out or wound and stored.

Owner:广东新意通讯科技有限公司

Pipeline spraying equipment

ActiveCN112791888AExtended service lifeAvoid damageSpraying apparatusElectric machineryStructural engineering

The invention provides pipeline spraying equipment, and relates to the field of pipeline machining. The pipeline spraying equipment comprises an injection molding machine, a spraying mechanism, a grinding mechanism and a guide plate, a support is arranged on the outer wall of the bottom end of the injection molding machine, a discharging opening is formed in the outer wall of one end of the injection molding machine, the spraying mechanism is arranged on the outer wall of the discharging opening, a spraying pipe which is annularly distributed is arranged on the inner wall of the spraying mechanism, a rotating shaft is arranged on the inner wall of the spraying pipe, an output shaft of the rotating shaft is connected with a rotating motor through a coupler, a rotating roller is arranged on the outer wall of the rotating shaft, the outer wall of the rotating roller is connected with the grinding mechanism, the inner wall, close to the rotating roller, of the spraying pipe is connected with the guide plate, and a spray head is arranged on the outer wall of the bottom end of the spraying pipe. According to the pipeline spraying equipment, when an extrusion layer makes contact with the spray head, grinding blocks on the extrusion layer can smash small caking particles, a small part of chemical powder adhering to the pipeline spraying equipment can be vibrated to fall off, and the self-cleaning effect is achieved.

Owner:东台市高科技术创业园有限公司

A kind of oxidation adjustment equipment for oxidizing pu(iii) to pu(iv)

ActiveCN104328291BIncrease profitReduced disposal burdenRadioactive decontaminationEngineeringNitric oxide

The invention belongs to the technical field of nuclear fuel reprocessing and discloses an oxidizing valence-adjusting equipment for oxidizing Pu (III) to Pu (IV). The equipment mainly comprises an oxidizing tower, a feed liquid receiving tank and a NOX storage tank, wherein a feed liquid outlet is formed at the upper end of the oxidizing tower, a Pu (III) feed liquid inlet and a NOX feed inlet are formed at the lower end, and the feed liquid outlets at the upper parts of the feed liquid receiving tank and the oxidizing tower are connected by virtue of a pipeline; the main body of the oxidizing tower and packing in the tower are both radiation-resistant and nitric acid corrosion-resistant materials; a heating device is arranged on the outer tower wall of the oxidizing tower; the Pu (III) feed liquid enters the oxidizing tower from the Pu (III) feed liquid inlet at the lower part of the oxidizing tower; NOX gas provided by the NOX storage tank enters into the oxidizing tower from the NOX feed inlet at the lower part of the oxidizing tower separately or together with carrier gas; the valence-adjusted feed liquid enters the feed liquid receiving tank from the feed liquid outlet at the upper part of the oxidizing tower. The equipment is large in processing scale, high in NOx utilization ratio, safe and stable in valence-adjusting process and low in processing burden of nitric oxide tail gas.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

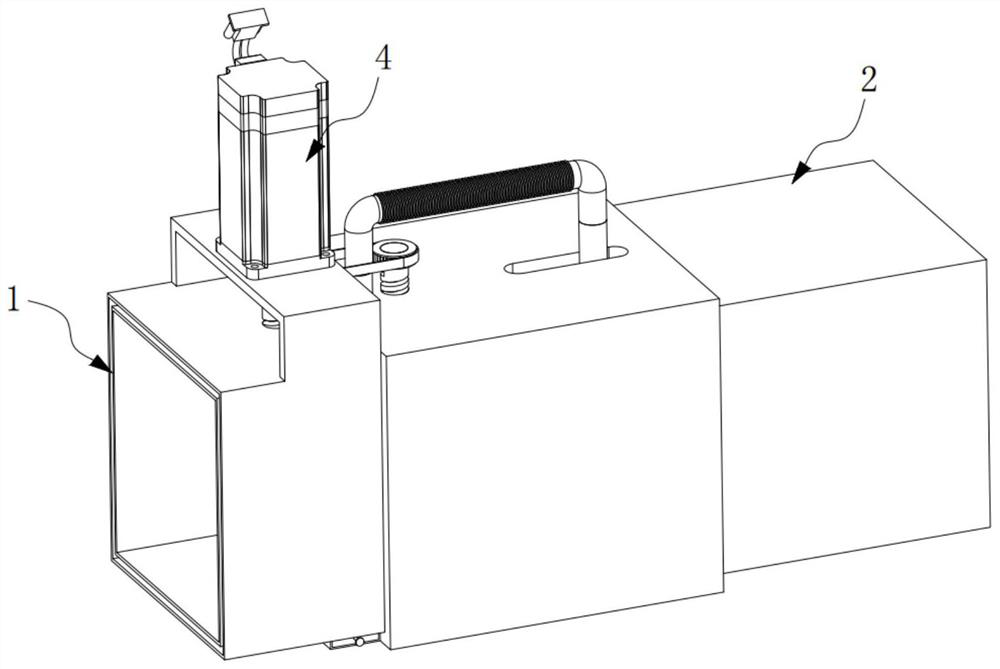

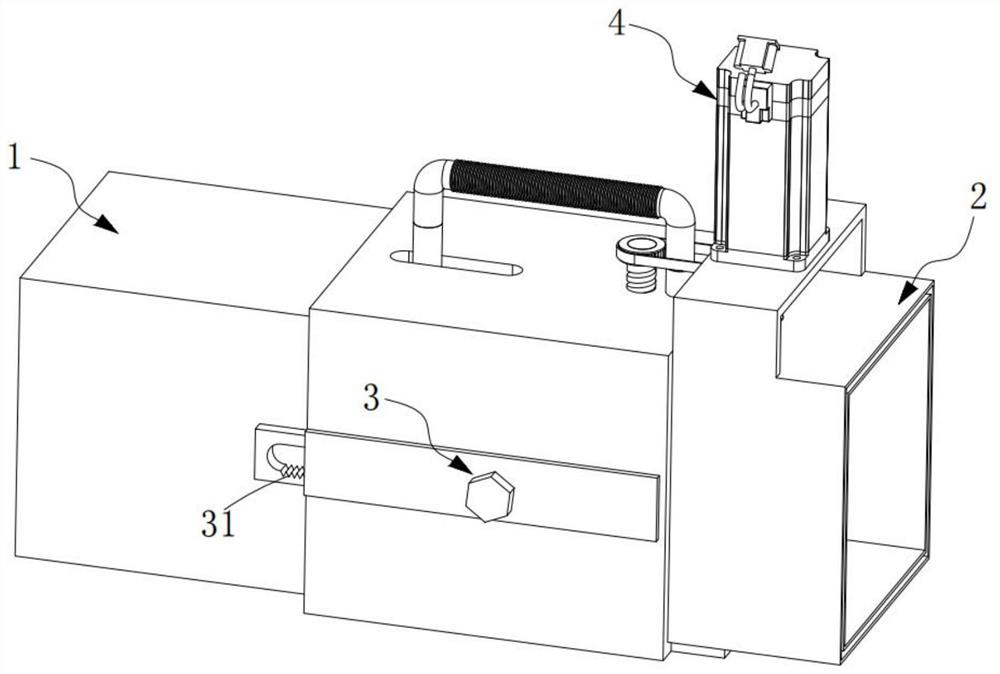

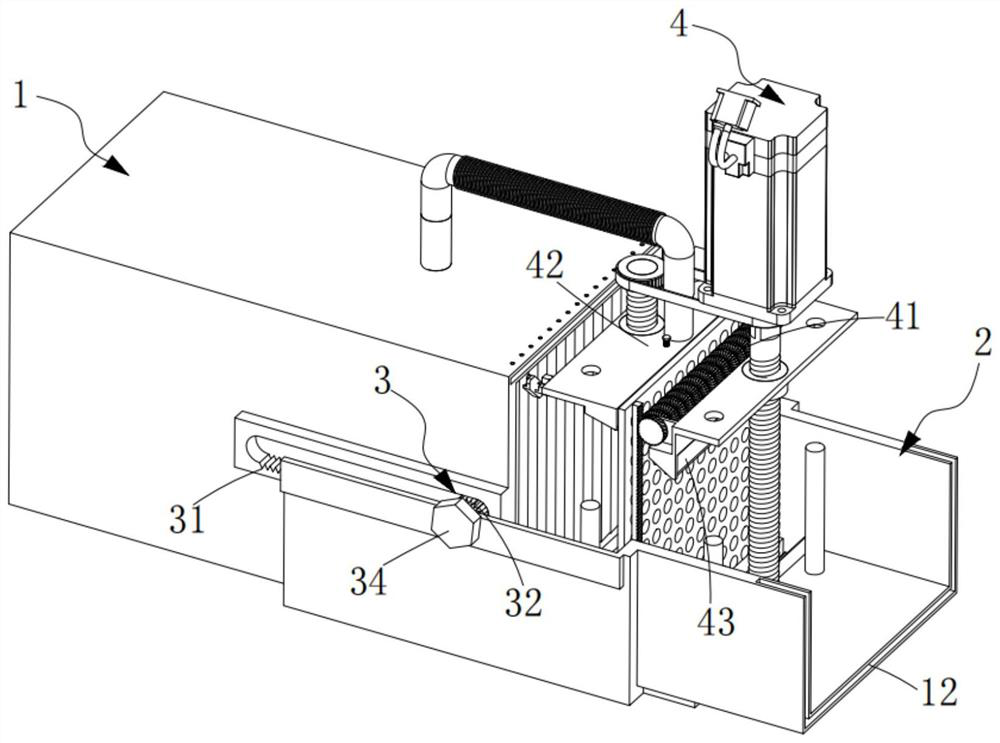

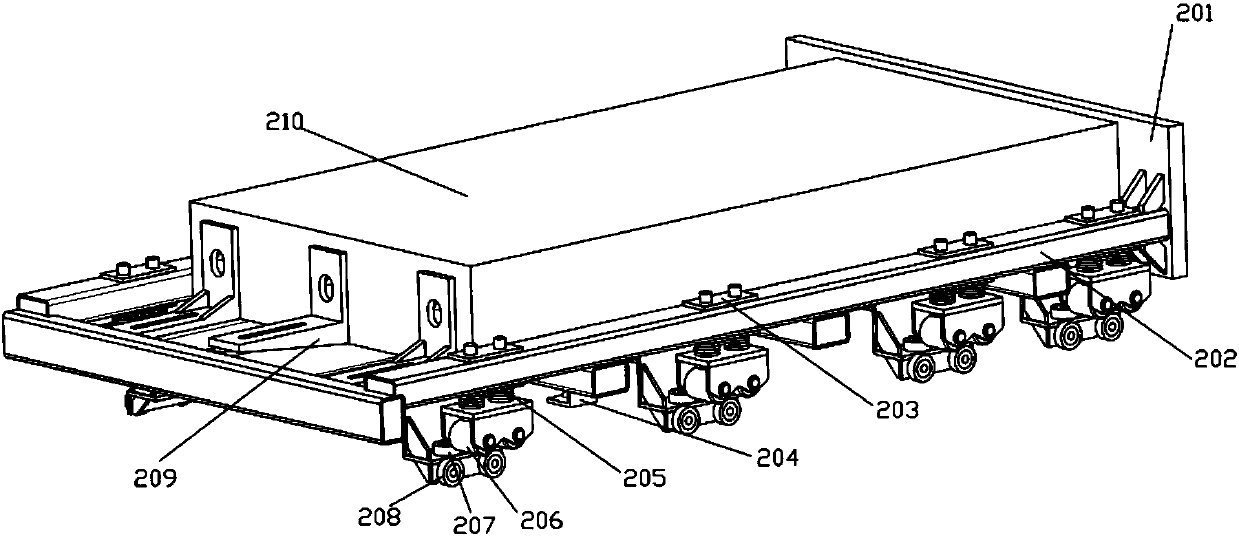

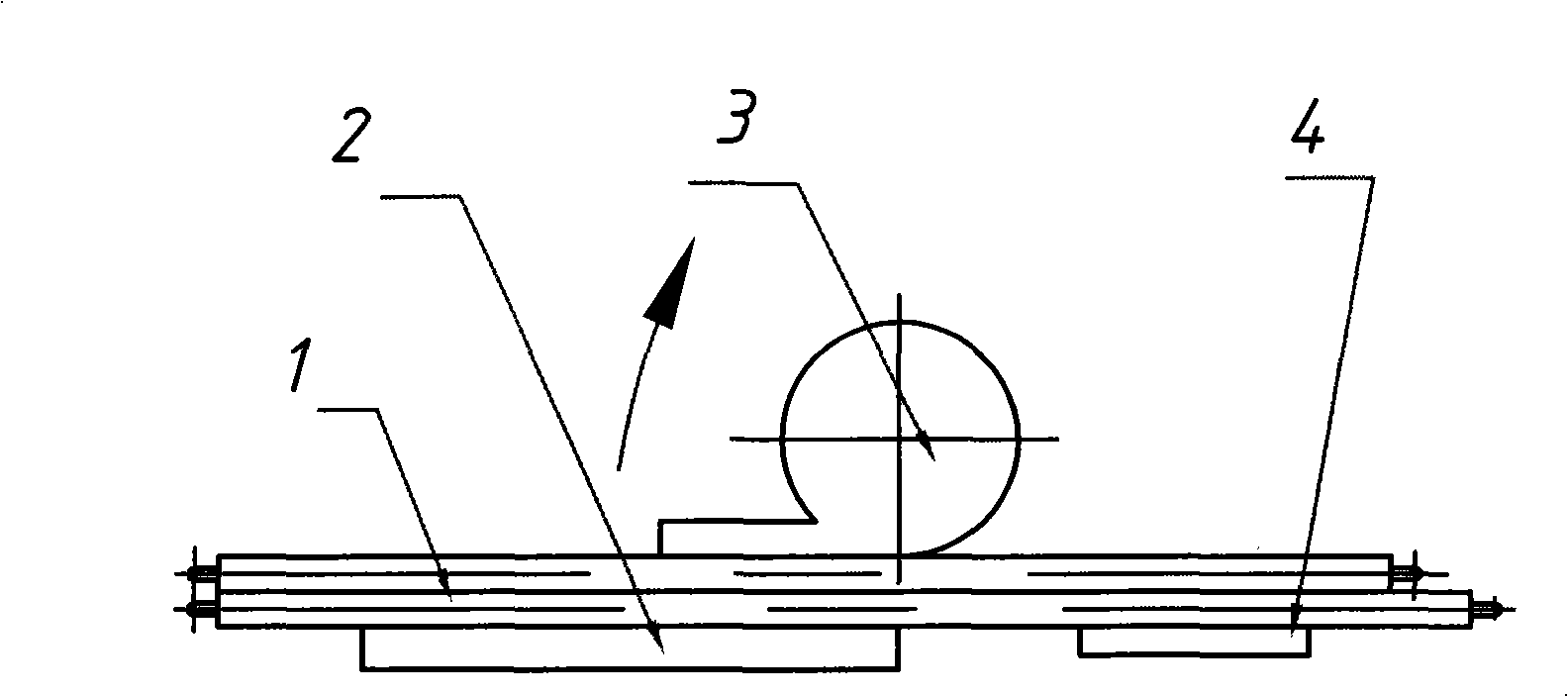

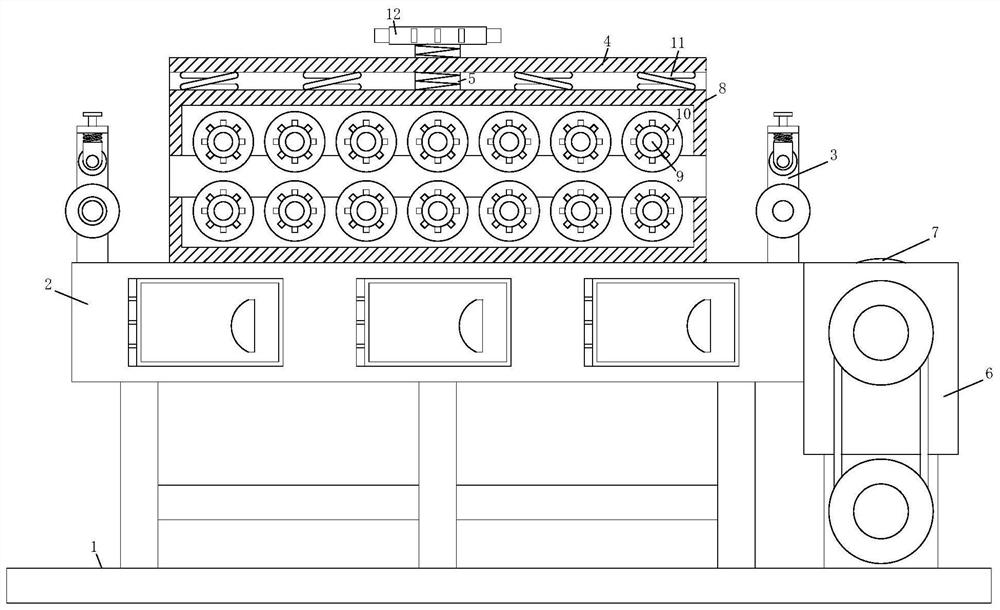

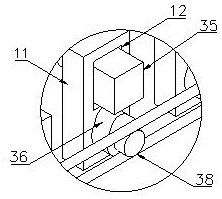

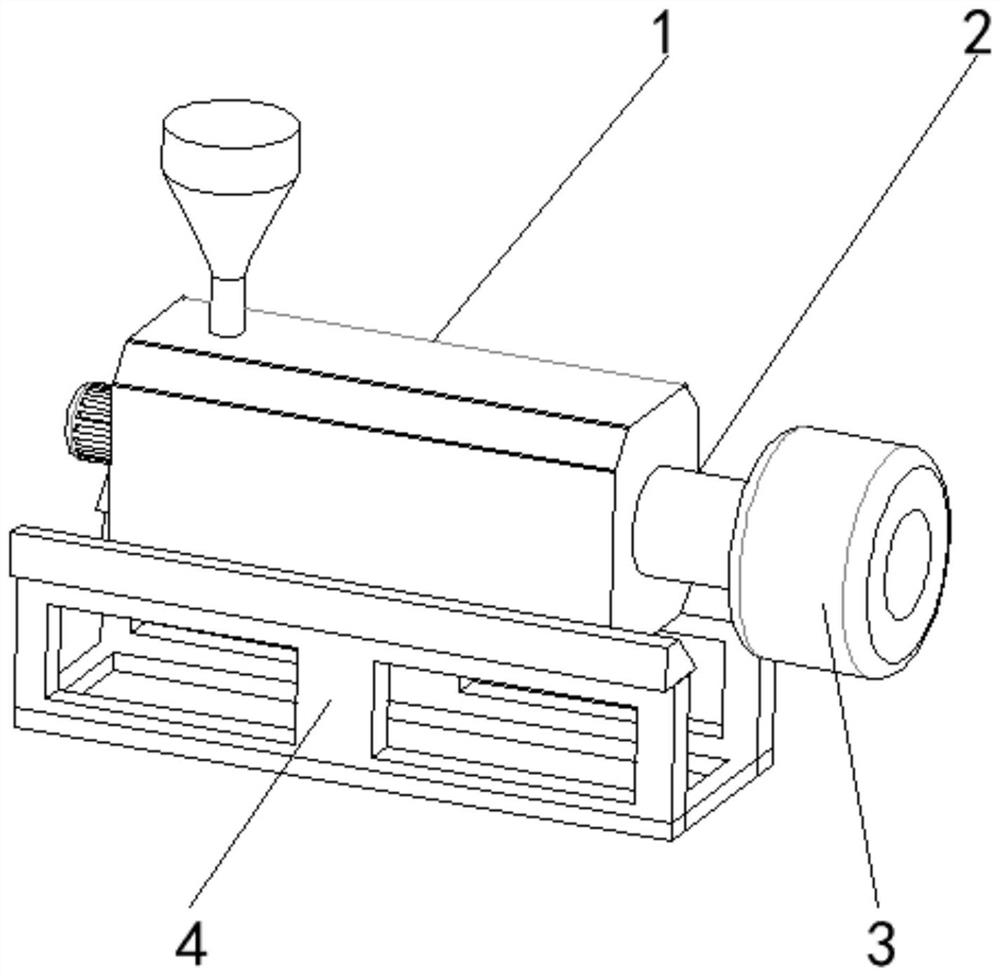

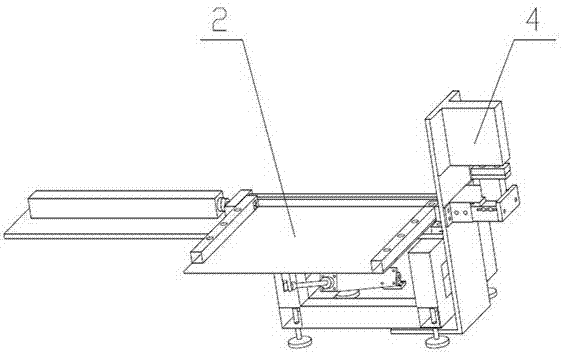

Automatic assembly mechanism for ballast iron core E sheet

InactiveCN103700483AAchieve installationRealize automatic feedingTransformersInductances/transformers/magnets manufactureMechanical engineeringBallast

The invention discloses an automatic assembly mechanism for a ballast iron core E sheet. The automatic assembly mechanism for the ballast iron core E sheet comprises a rack (1), a feeding device (2) and a vertical press fitting device (4), wherein the feeding device (2) comprises a feeding cylinder (5), a support plate (7) and a material replenishing cylinder (13); the support plate (7) is provided with a single-edge guide rail (12); the vertical press fitting device (4) comprises a material pressing cylinder (14), a T-shaped press head (15) and a guide frame (16) provided with a horizontal channel (161); a vertical through slot (162) penetrating through the bottom of the guide frame (16) is arranged right below the T-shaped press head (15); the guide frame (16) is provided with an elastic hanging device; a clamp for receiving the E sheet pressed by the T-shaped press head (15) is arranged right below the vertical through slot (162). The automatic assembly mechanism for the ballast iron core E sheet is high in production efficiency and stable in product quality.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com