Crystal cotton three-mercerized fabric and processing method thereof

A technology of mercerizing fabrics and processing methods, which is applied in the direction of mercerizing of cotton sliver, mercerizing of indefinite length fabrics, and mercerizing of yarn/thread/filament, etc. It can solve the problems of soft and smooth hand feeling, uneven dyeing, and insufficient shape retention, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

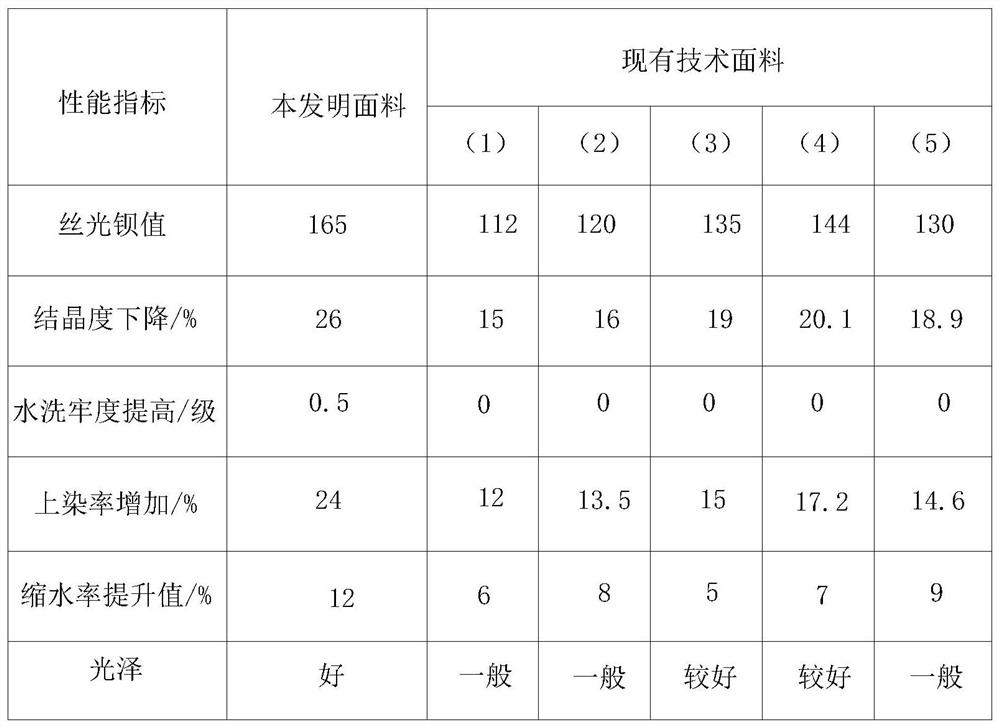

Embodiment 1

[0036] A processing method of 50S / 1 mercerized cotton fiber, comprising the following processing steps:

[0037] 1. Fiber sliver making: The long-staple cotton is blended, cleaned, carded, slivered and rolled, and combed into 50S / 1 fiber sliver.

[0038] 2. Weaving into rope braids: Weave 3 untwisted fiber strips into three-strand braids or ponytail braids according to certain rules, which are used for mercerizing in the subsequent process.

[0039] 3. Mercerizing: multiple fiber ropes are braided on a continuous mercerizing machine for mercerizing. The process includes alkali immersion, tension application, alkali extrusion and water washing. 122s, stretching length 1%, hot water washing temperature 52°C, hot water washing time 62s, room temperature washing time 35s.

[0040] 4. Drying: Put the mercerized fiber rope braids into the dryer for drying.

[0041] 5. Rope braid decompression: decompose the dried fiber braid rope into a single fiber strip and wind it into a tube. ...

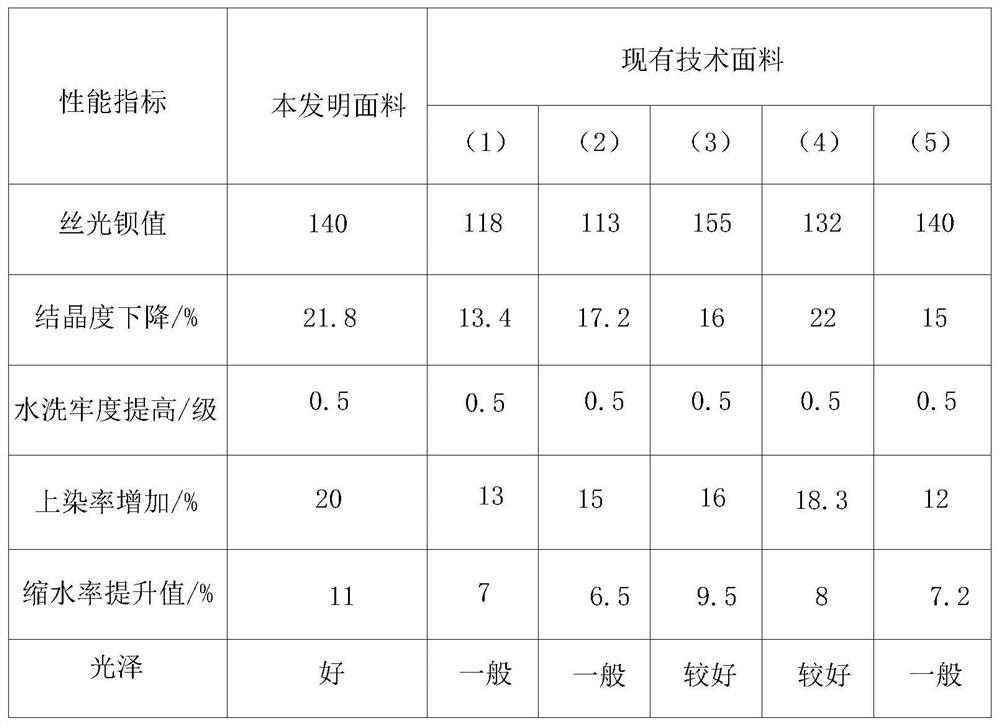

Embodiment 2

[0045] A processing method of 60S / 1 mercerized cotton fiber, comprising the following processing steps:

[0046] 1. Fiber sliver making: The long-staple cotton is blended, cleaned, carded, slivered and rolled, and combed into 60S / 1 fiber sliver.

[0047] 2. Weaving into rope braids: weave 4 untwisted fiber strips into a cable shape according to certain rules.

[0048] 3. Shaking and twisting: the cable-like fiber rope braid is shaken and twisted into 500g by the yarn shaking machine.

[0049] 4. Mercerizing: braid skeined fiber ropes on a skein mercerizing machine for mercerizing. The process includes alkali immersion, tension application, alkali extrusion and water washing. 148s, stretching length 3%, hot water washing temperature 68°C, hot water washing time 41s, room temperature washing time 28s. .

[0050] 5. Drying: Put the mercerized fiber rope braids into the dryer for drying.

[0051] 6. Rope braid decompression: the dried fiber rope braid decomposes into a single ...

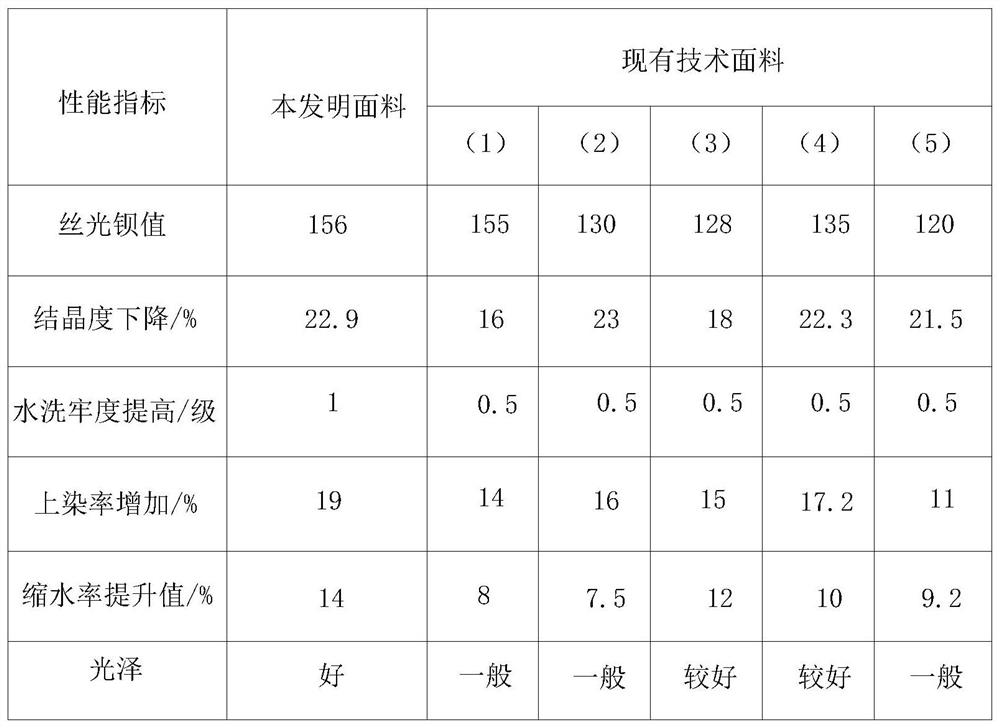

Embodiment 3

[0055] A kind of processing method of 70S / 1 cotton / tencel (90 / 10) roving fiber, comprises following processing steps:

[0056] 1. Fiber sliver making: The long-staple cotton and tencel are mixed at a ratio of 90:10, and then processed into 80S / 1 roving sliver after cotton blending, cleaning, carding, sliver doubling, combing, drawing and roving.

[0057] 2. Weaving into rope braids: Weave three untwisted roving strips into three-strand braids according to certain rules, which are used for mercerizing in the subsequent process.

[0058]3. Mercerizing: The rope-like roving braids are mercerized on a continuous mercerizing machine. The process includes alkali immersion, tension application, alkali extrusion and water washing. It is 118s, the tensile length is 6%, the hot water washing temperature is 79°C, the hot water washing time is 52s, and the room temperature washing time is 29s.

[0059] 4. Drying: Put the mercerized roving braids into the dryer for drying.

[0060] 5. Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com