Tension Control Device

A tension control and resistance device technology, applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of uneven dyeing, discount of dyeing effect, etc., to achieve the effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

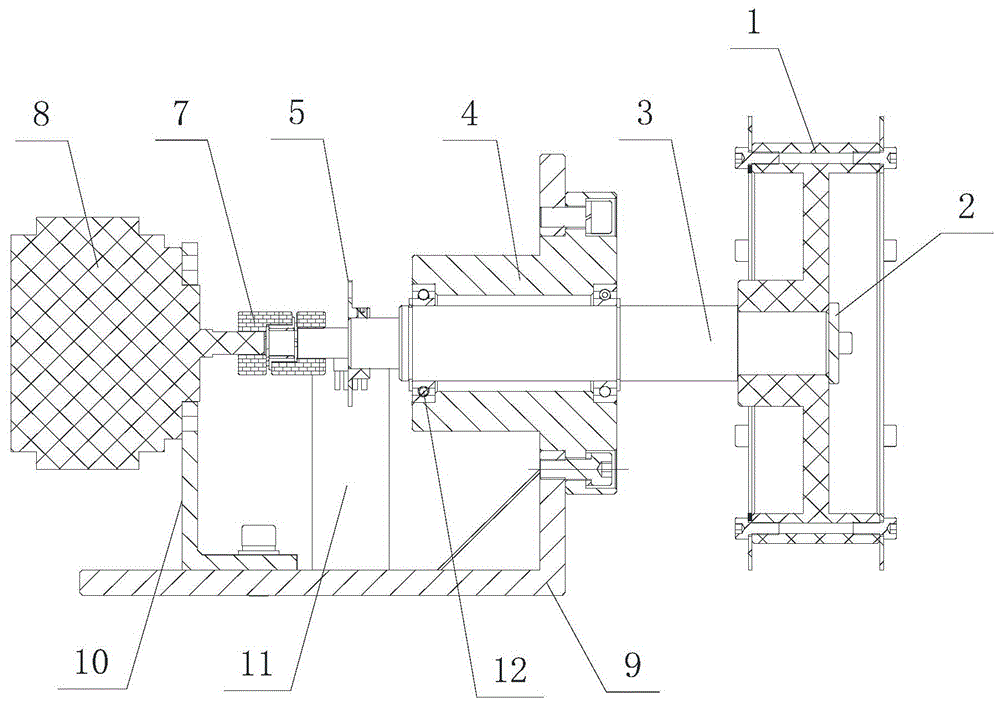

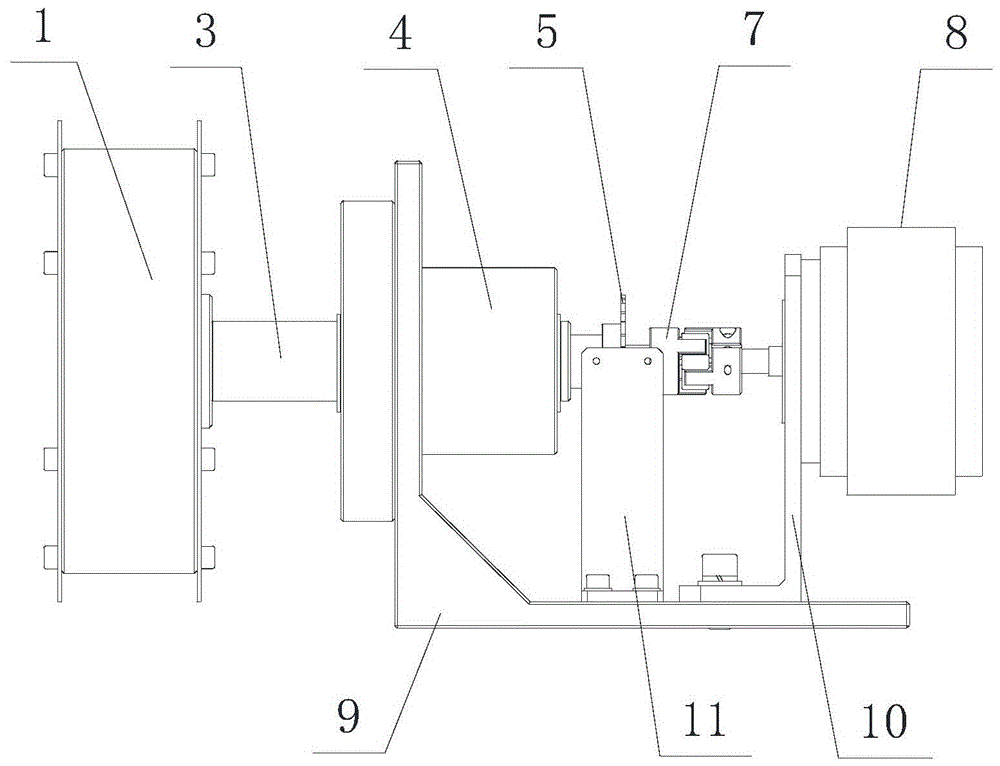

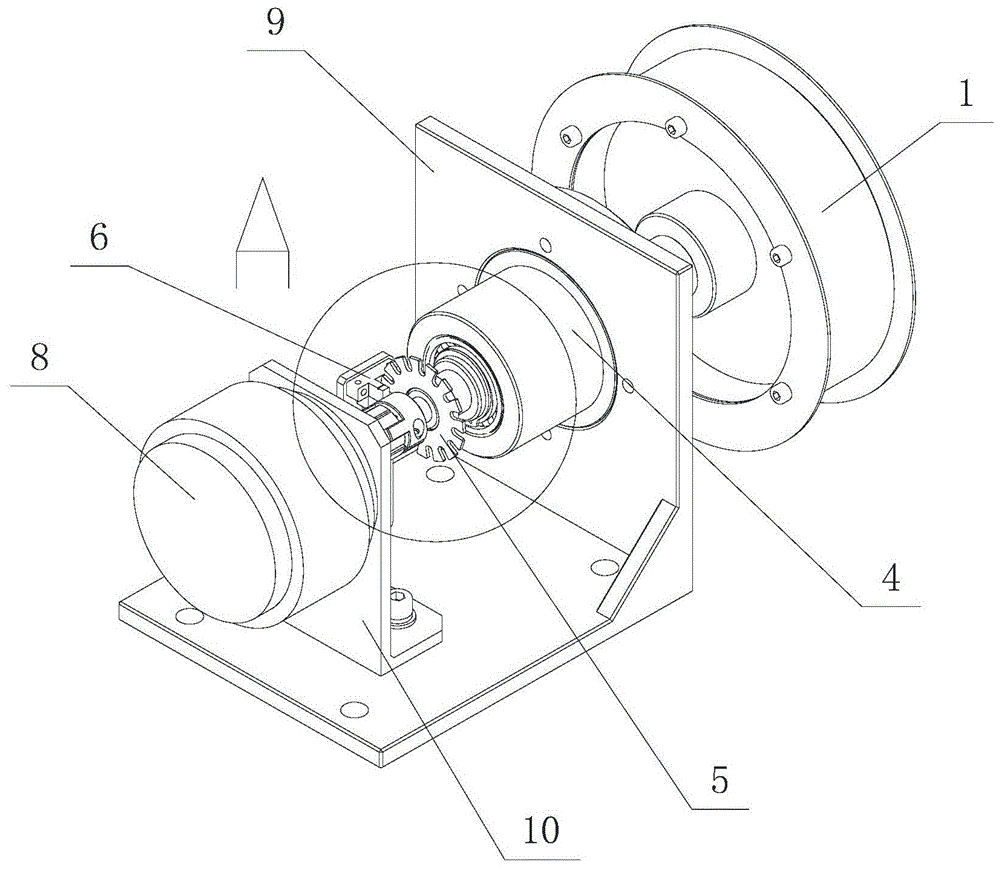

[0020] Example: see figure 1 , figure 2 , image 3 and Figure 4 , a tension control device, including a pulley 1 that passes through the belt, and a rotating shaft 3 that fixes the pulley 1, and is also provided with a length measurement device and a resistance device, and the length measurement device and the resistance device are both connected to the electrical equipment of the equipment The control box is connected, and the outer edge surface of the belt pulley 1 in contact with the belt is a knurled surface.

[0021] Preferably, the length measuring device is a photoelectric proximity switch 6 and a photoelectric aperture wheel 5 matched with the photoelectric proximity switch 6 , and the photoelectric aperture wheel 5 is coaxially arranged with the belt pulley 1 .

[0022] Preferably, the resistance device is a magnetic powder brake 8 coaxially arranged with the pulley 1 .

[0023] Preferably, the photoelectric aperture wheel 5 is fastened on the rotating shaft 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com