Patents

Literature

70results about How to "Achieving tension adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

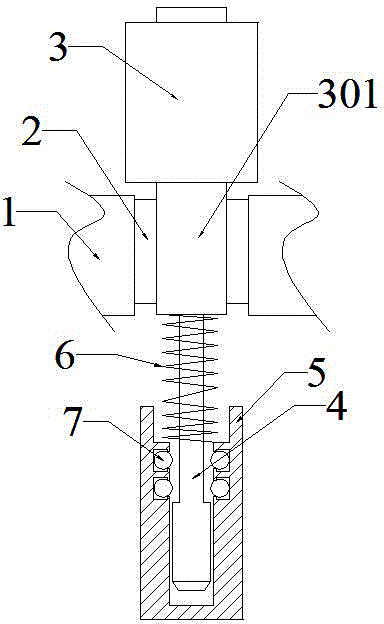

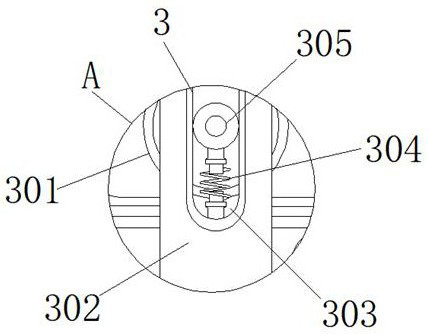

Counterweight tension roller mechanism

InactiveCN102976155AAchieving tension adjustmentSimple structureFilament handlingCoil springEngineering

The invention discloses a counterweight tension roller mechanism, which comprises a stand, a bearing, a tension roller, a friction regulating rod and a regulating box. A roller shaft is vertically in sliding connection with an inner circle of the bearing. A first cambered step is formed at the top end of the regulating box. The radius of the top end of the friction regulating rod is smaller than that of the roller shaft, and a second cambered step is formed between the top end of the friction regulating rod and the roller shaft. A helical spring is arranged outside the friction regulating rod between the first and second steps. The friction regulating rod is divided into an upper loosened section and a lower friction section. The radius of the loosened section is smaller than that of the friction section. A plurality of layers of friction belts are arranged below the first step of the regulating box. Each layer of friction belt comprises a plurality of freely rolling steel balls which are uniformly distributed in a circumferential direction. The counterweight tension roller mechanism has the beneficial effects that the number of the friction belts contacting with the friction regulating rod is changed by changing gravity, and the torque of the roller shaft is regulated through friction force, so that tension is regulated; and the counterweight tension roller mechanism is simple and practical in structure, and the conventional equipment can be favorably improved.

Owner:WUJIANG DONGFEI CHEM FIBER

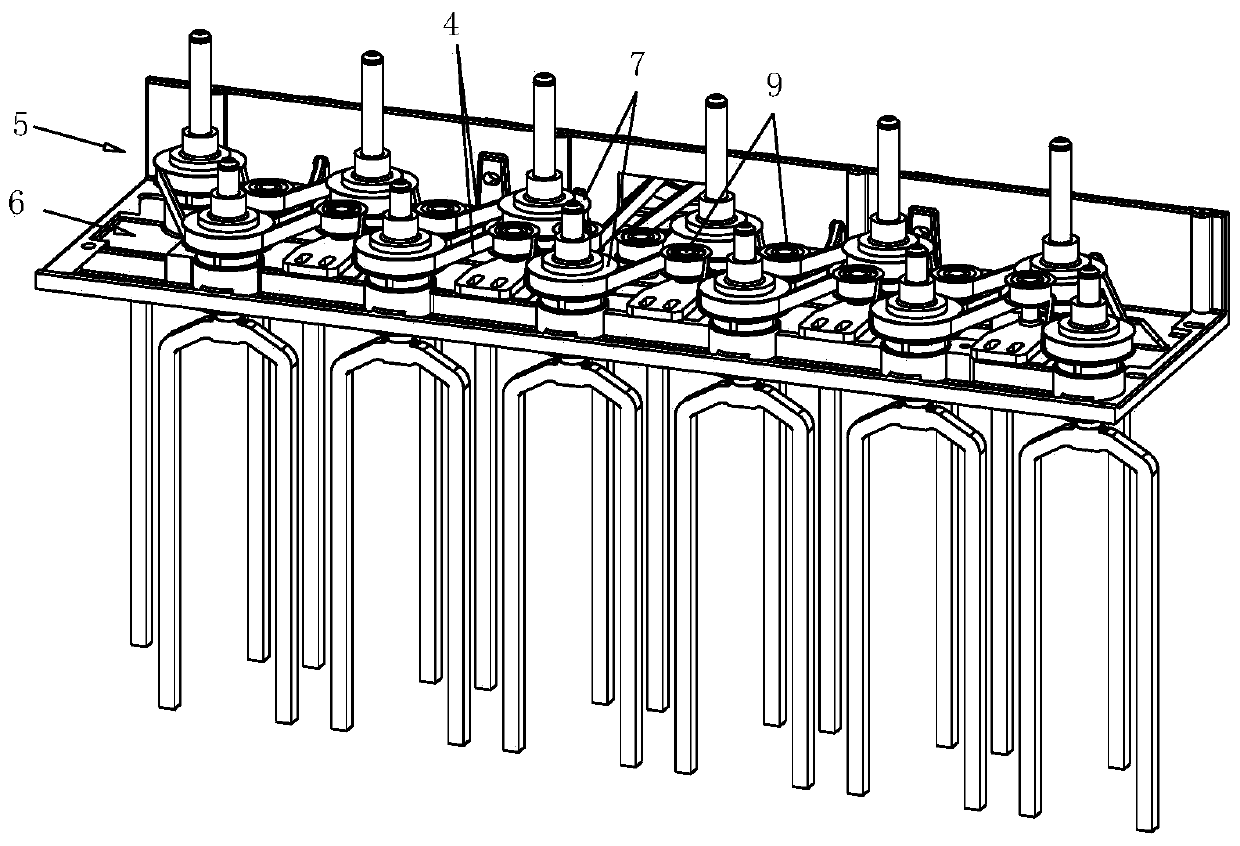

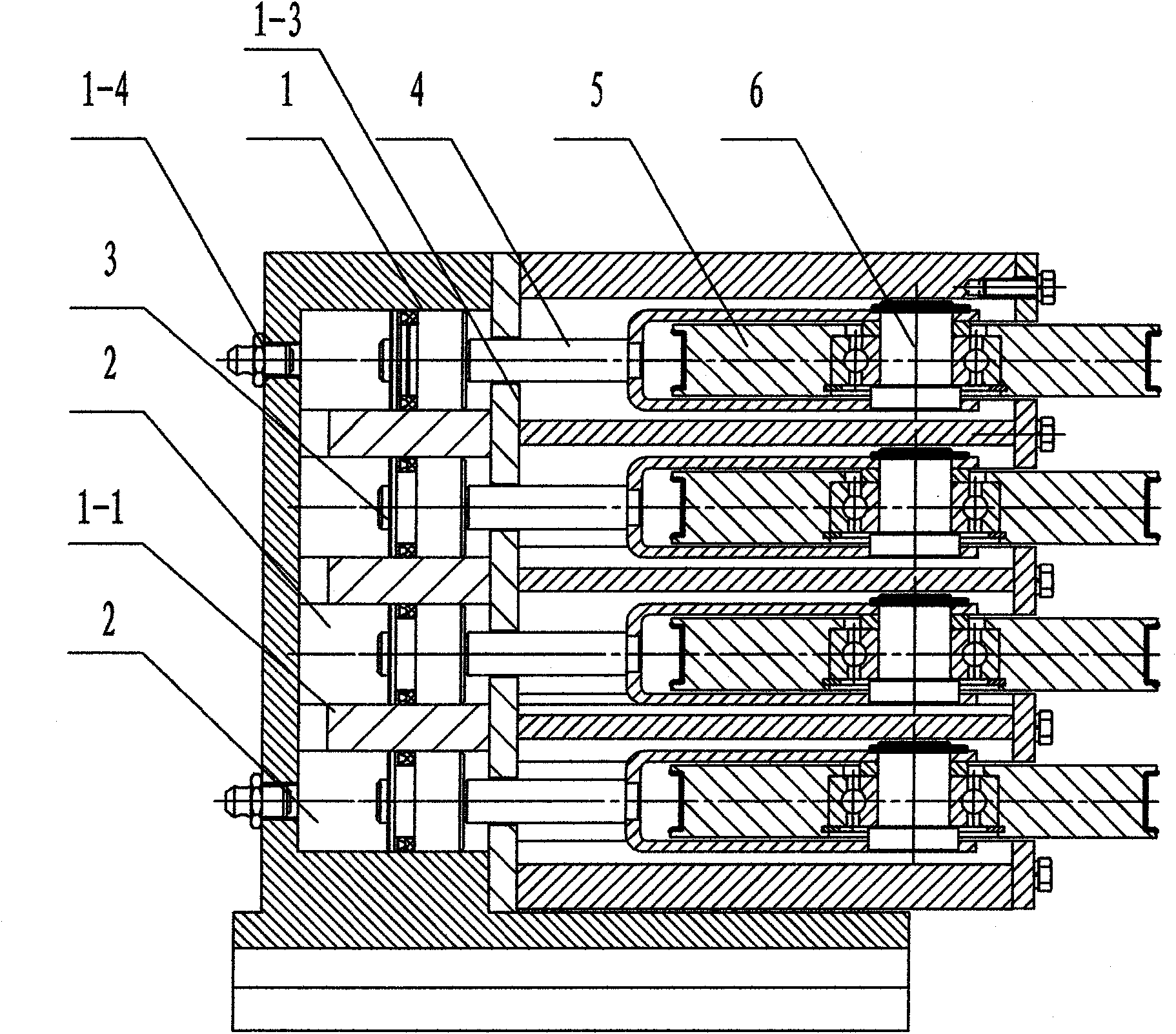

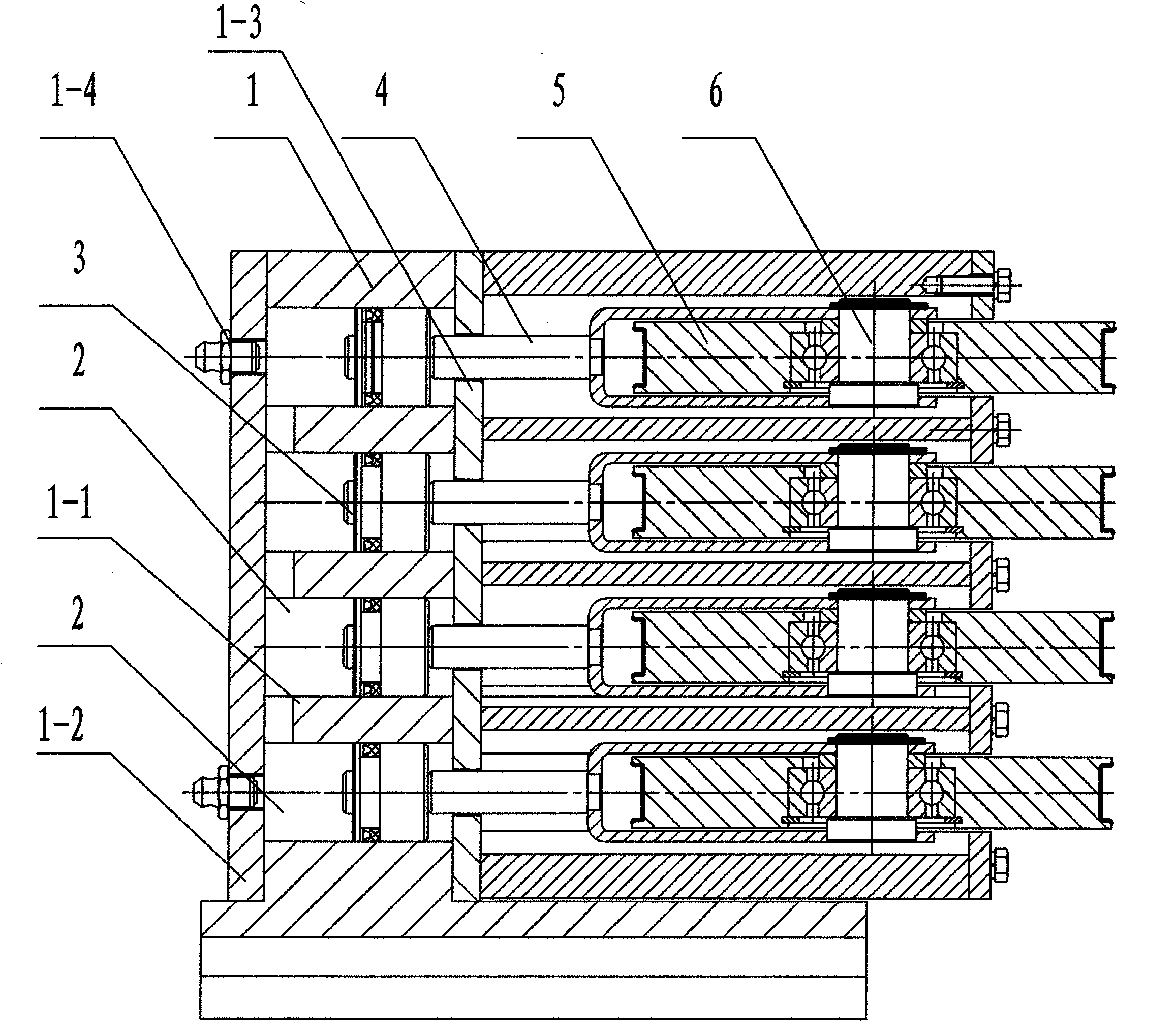

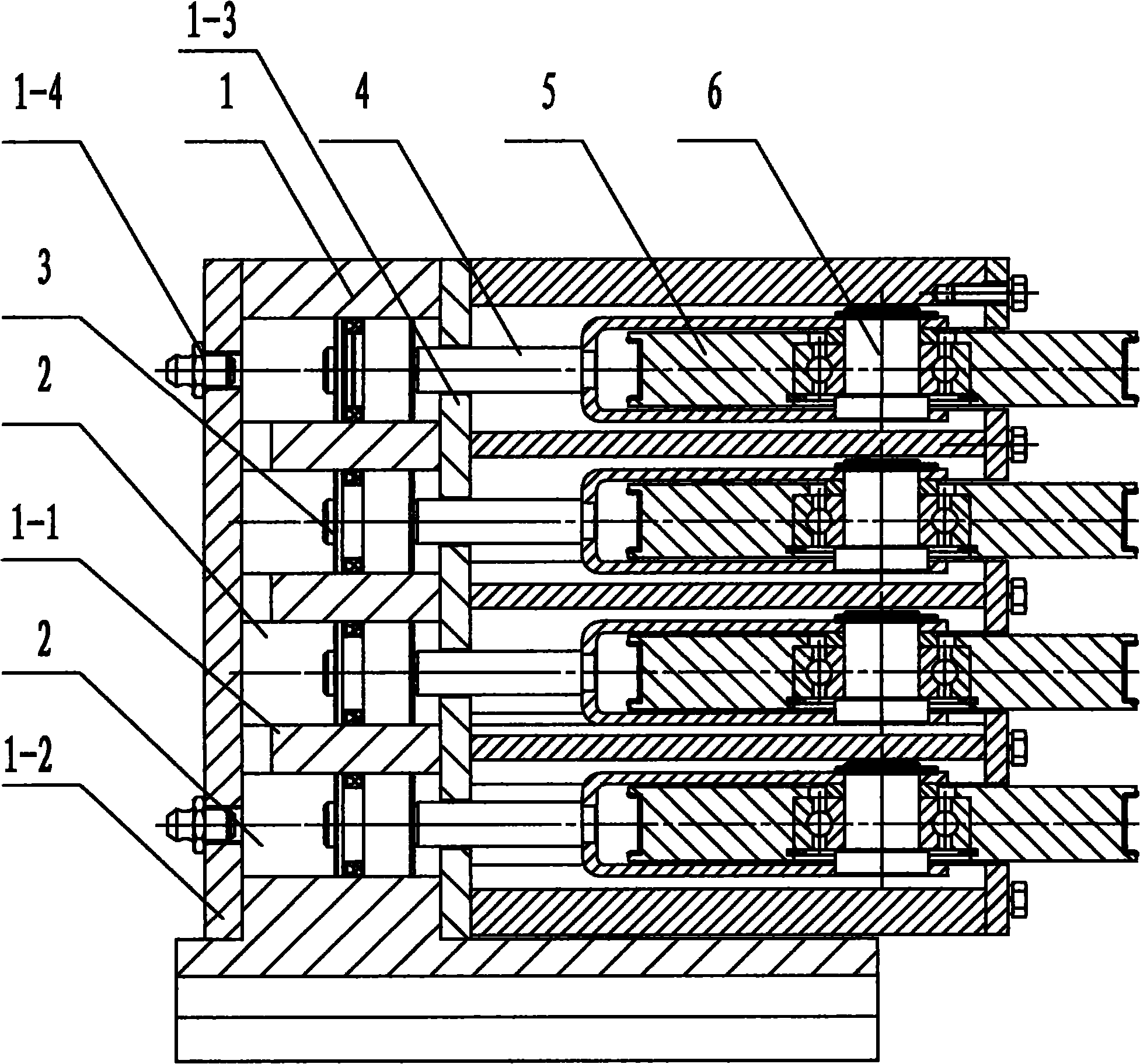

Bead string rope uniform tensioning device with combined hydraulic cylinder

InactiveCN102198703AStable and adjustable tensionReasonable structureWorking accessoriesHydraulic cylinderPiston rod

The invention provides a bead string rope uniform tensioning device with a combined hydraulic cylinder, which comprises the combined hydraulic cylinder, supporting racks, tension pulleys and guide rods, wherein the combined hydraulic cylinder is internally provided with more than two hydraulic cavities sharing an oil feeding port and an oil returning port, one of the hydraulic cavities is provided with a piston rod, the stretching end of each piston rod is connected with one supporting rack, each supporting rack is equipped with one tension pulley and also provided with one guide rod, and the guide rods are sleeved in the combined hydraulic cylinder. The device with reasonable structure can dynamically adjust the position of the tension pulleys through the movement of the piston rods of the combined hydraulic cylinder in order to complete tension adjustment, thereby ensuring that each bead string rope in multi-rope transmission has stable and adjustable tensioning force and the ropes are uniform in tensioning force.

Owner:SHANDONG UNIV

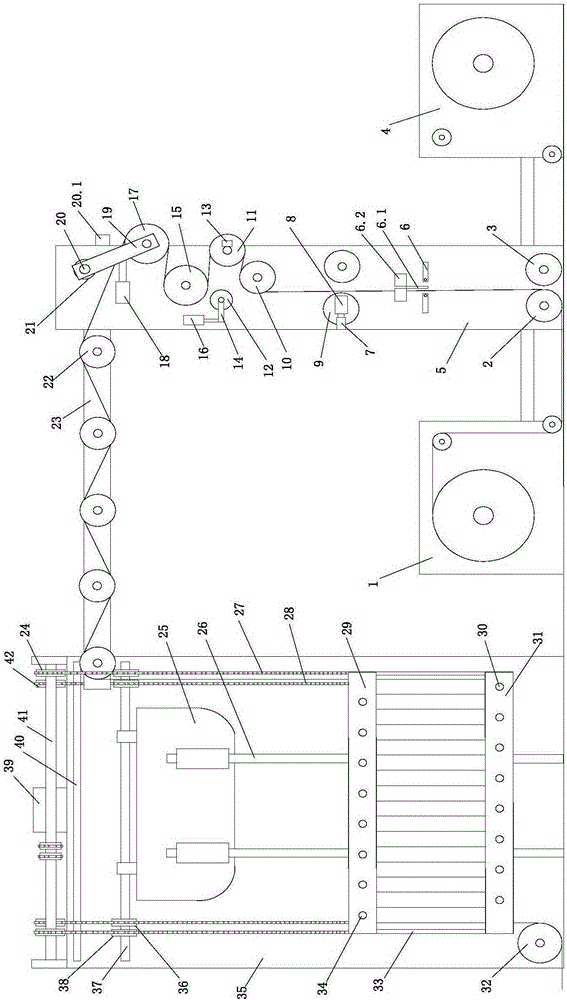

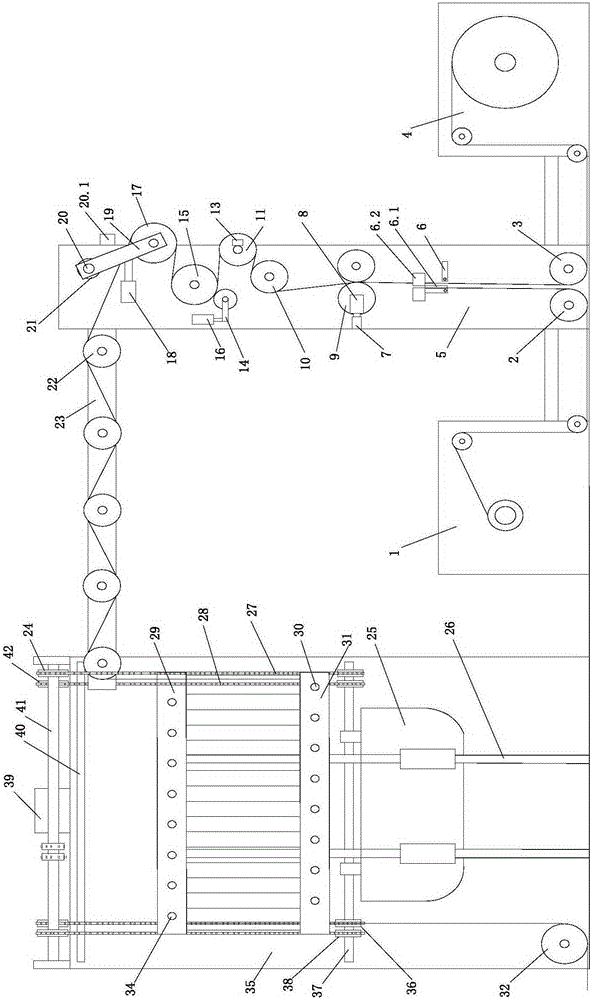

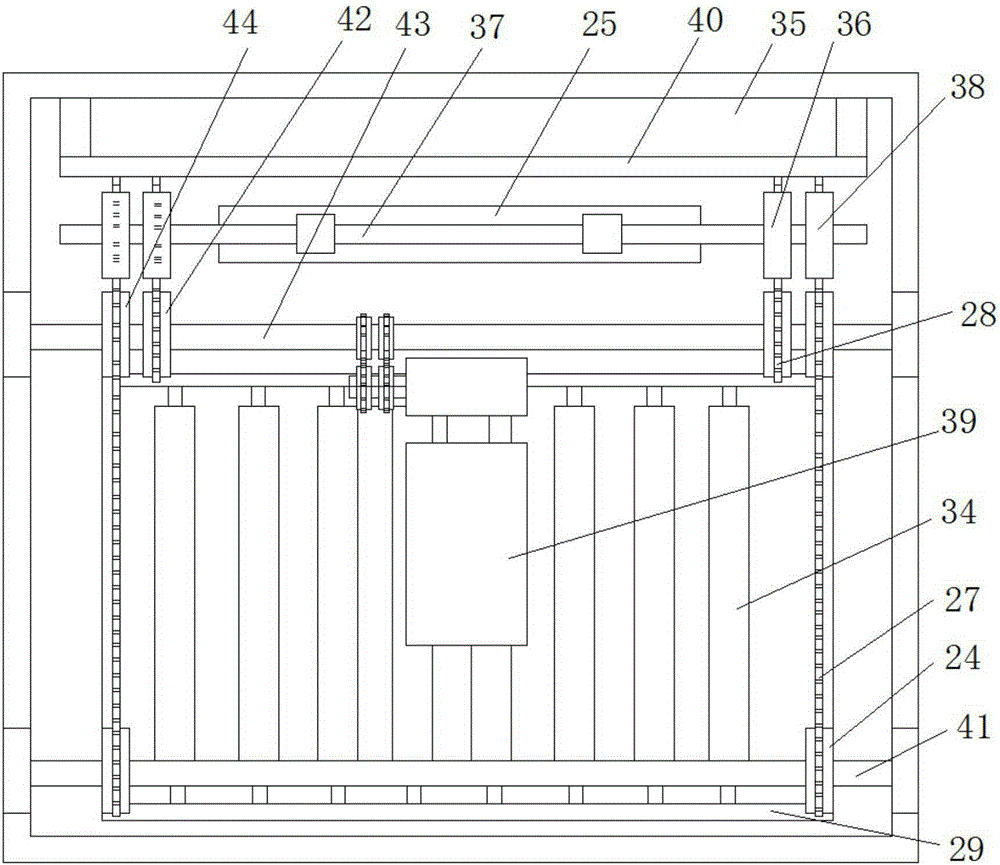

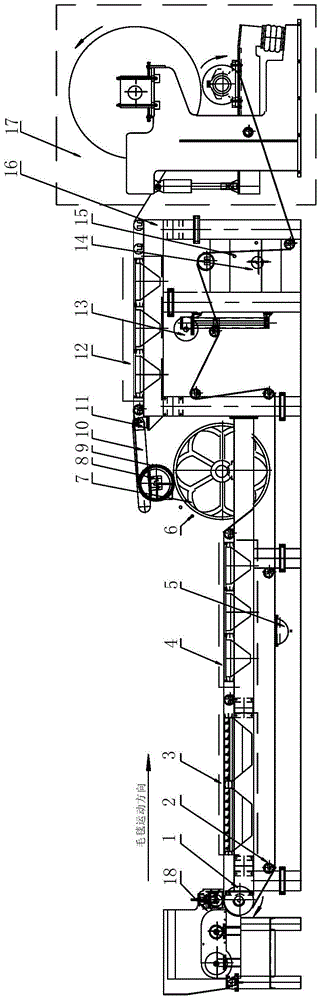

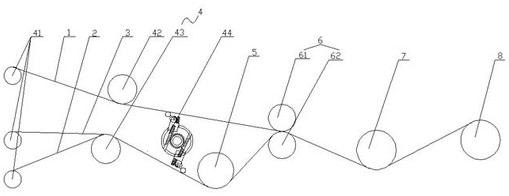

Continuous web feeding system

The invention relates to a continuous production machining system, in particular to a continuous web feeding system. The continuous web feeding system comprises a first web feeding machine, a second web feeding machine, a web cutting device, a web receiving device, a web storage roller pair and a web storage box; the web storage roller pair vertically shifts in the web storage box to store and release webs to be printed; in the process of storing the webs to be printed by the web storage roller pair, the web cutting device and the web receiving device finish web changing work of the web to be printed on the first web feeding machine and the web to be printed on the second web feeding machine, so that the function of continuously feeding webs without halt is achieved, the production efficiency is improved, energy loss is reduced, and then the production cost is reduced.

Owner:CHONGQING HONGJIN PRINTING

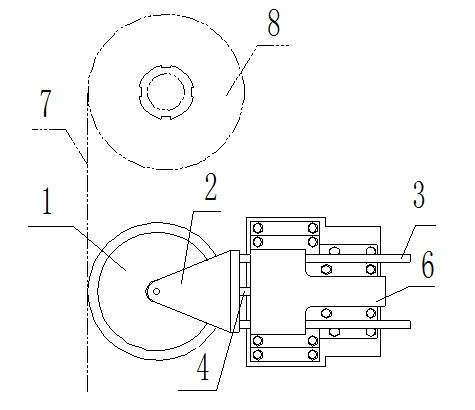

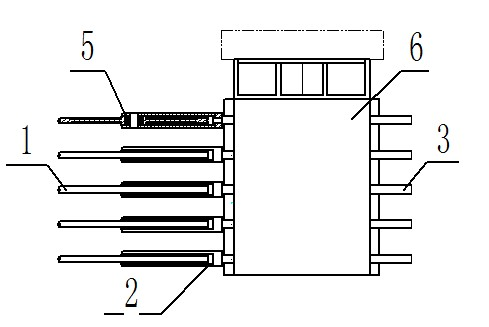

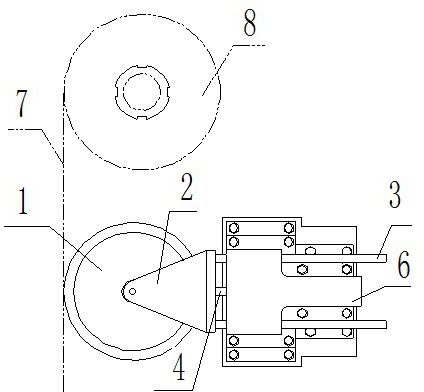

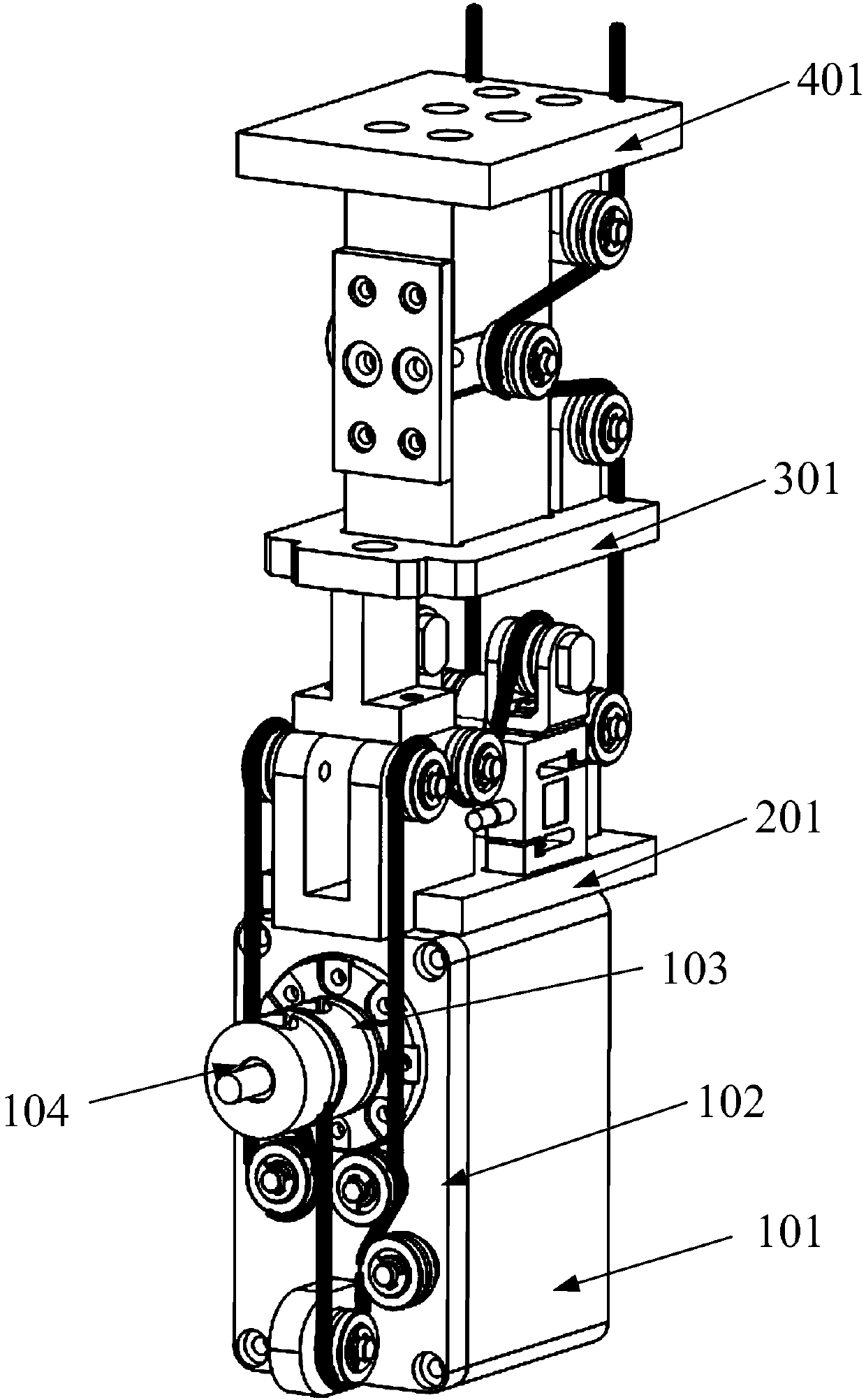

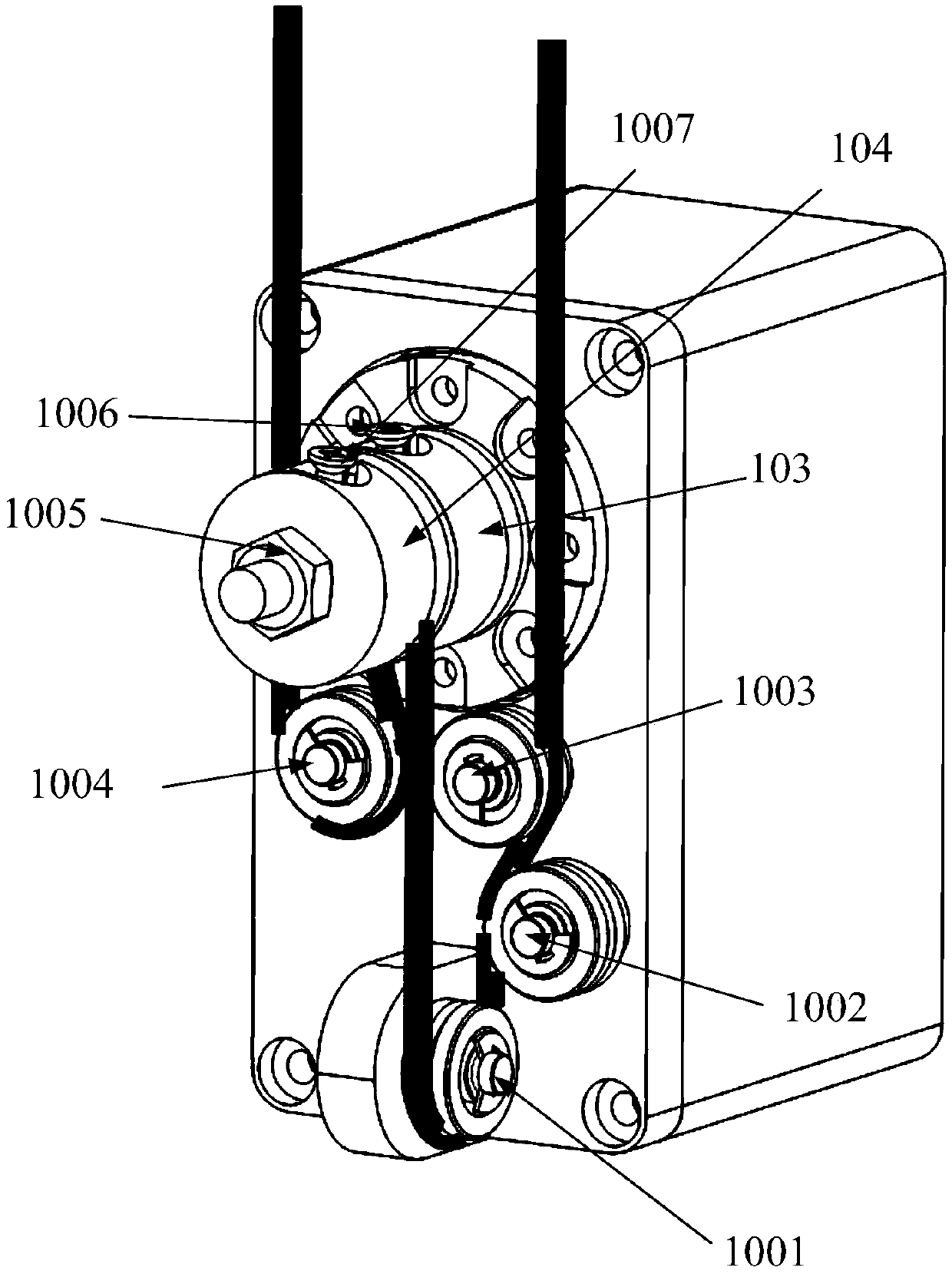

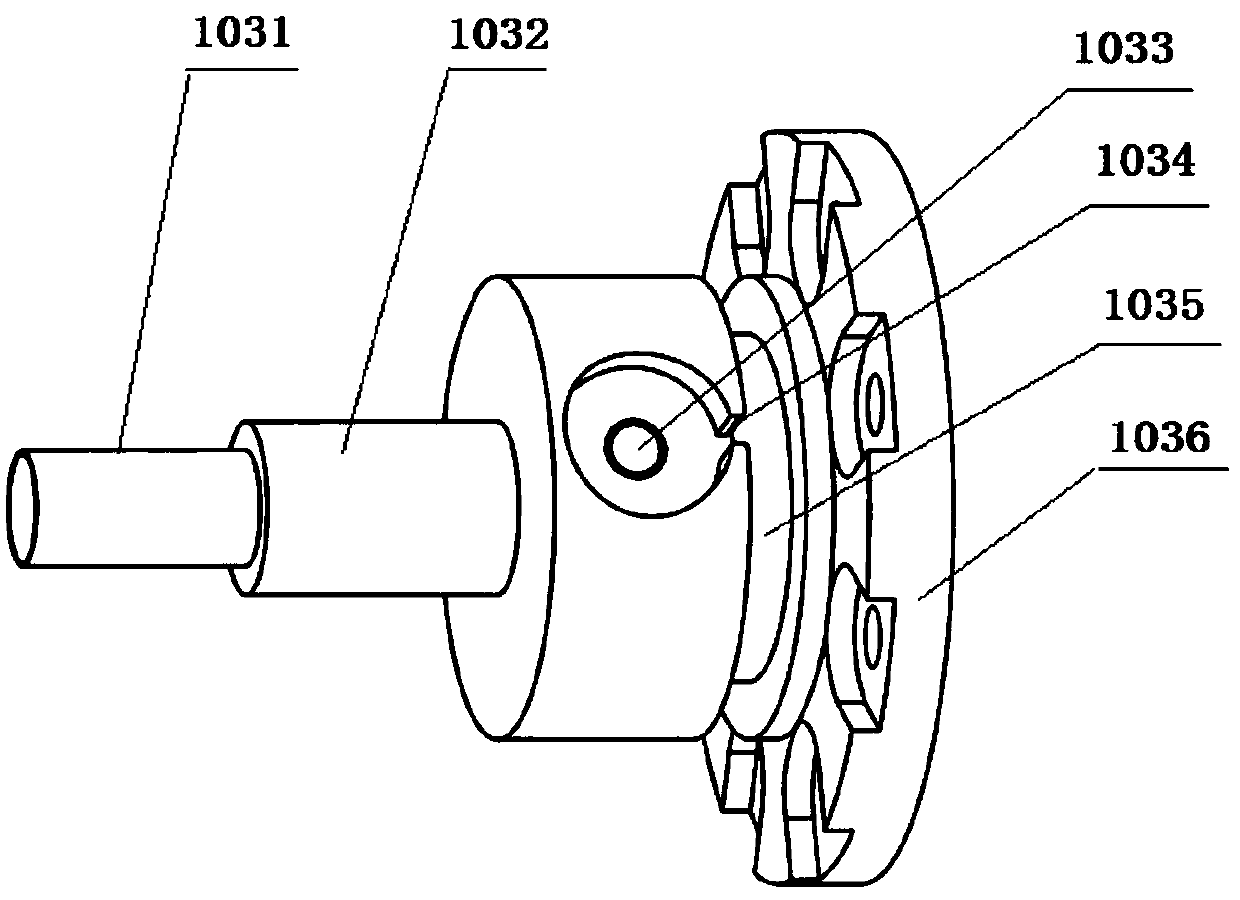

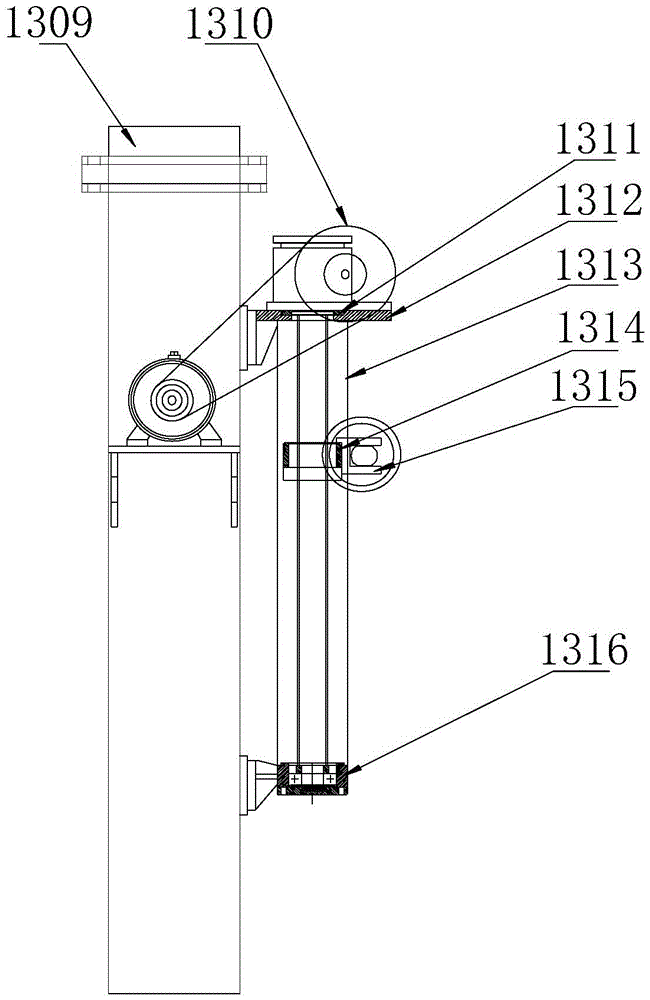

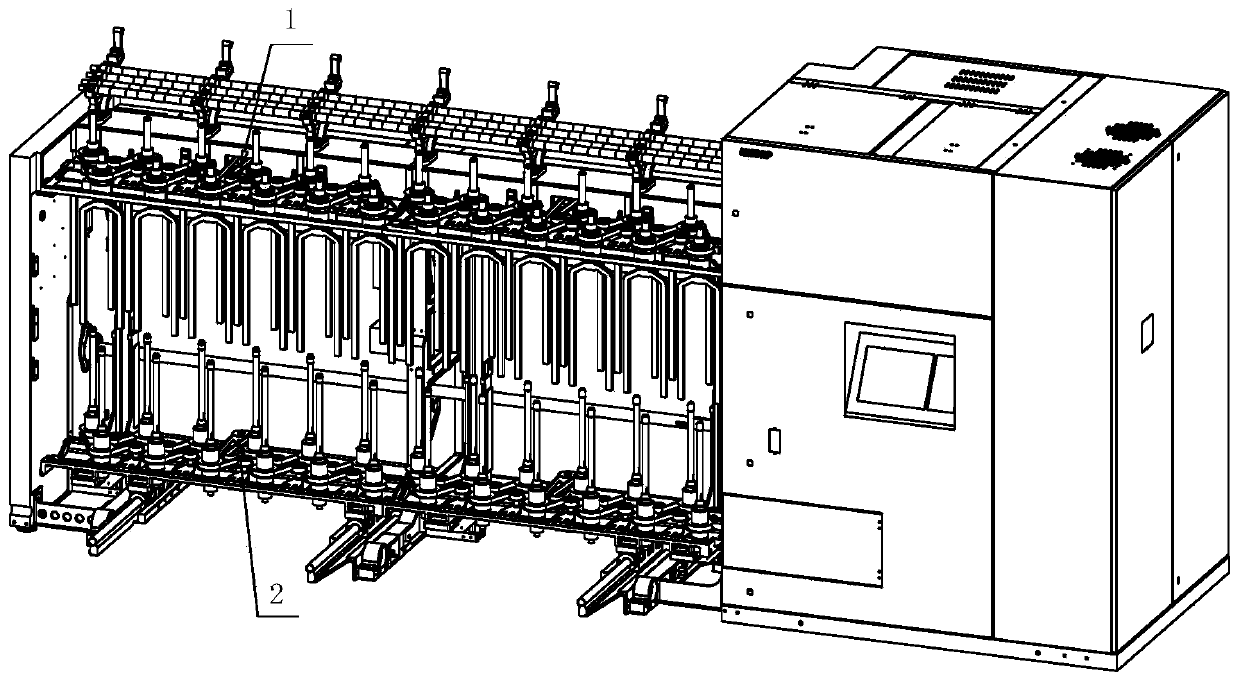

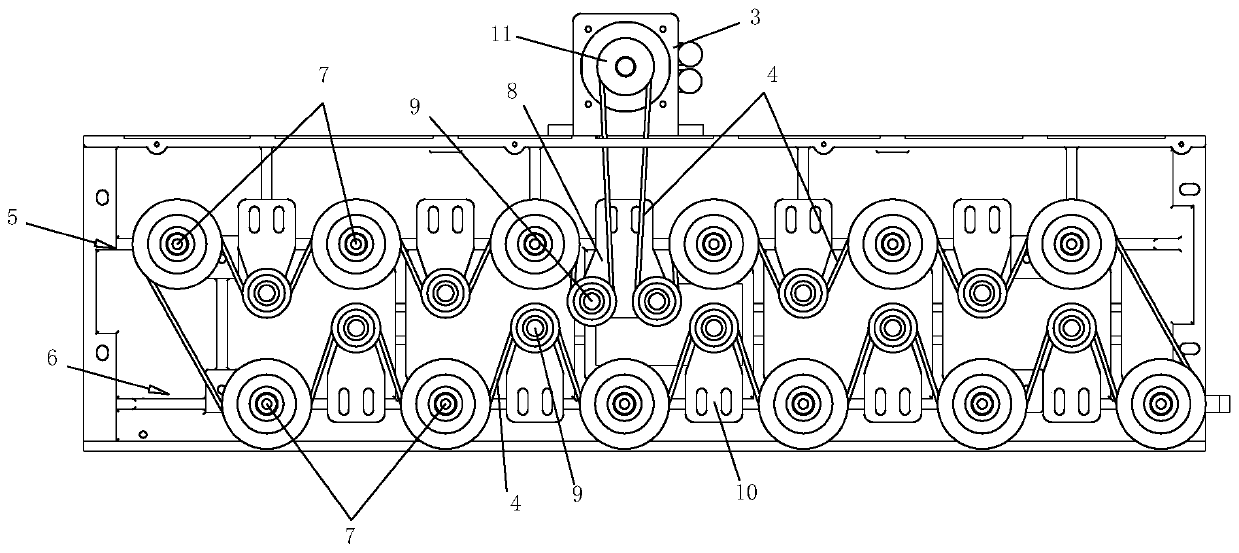

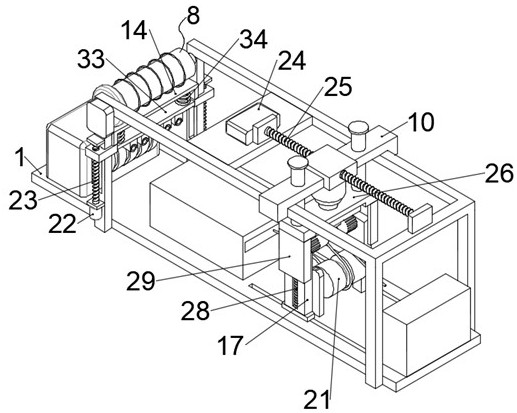

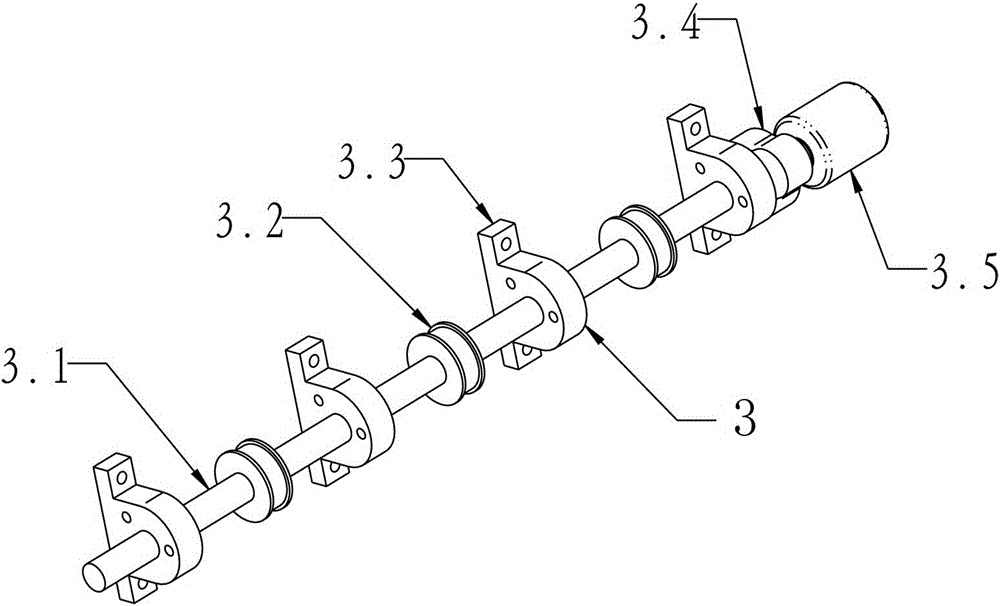

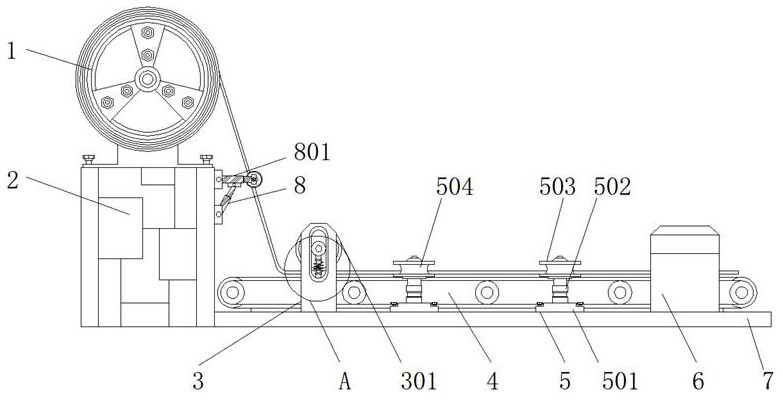

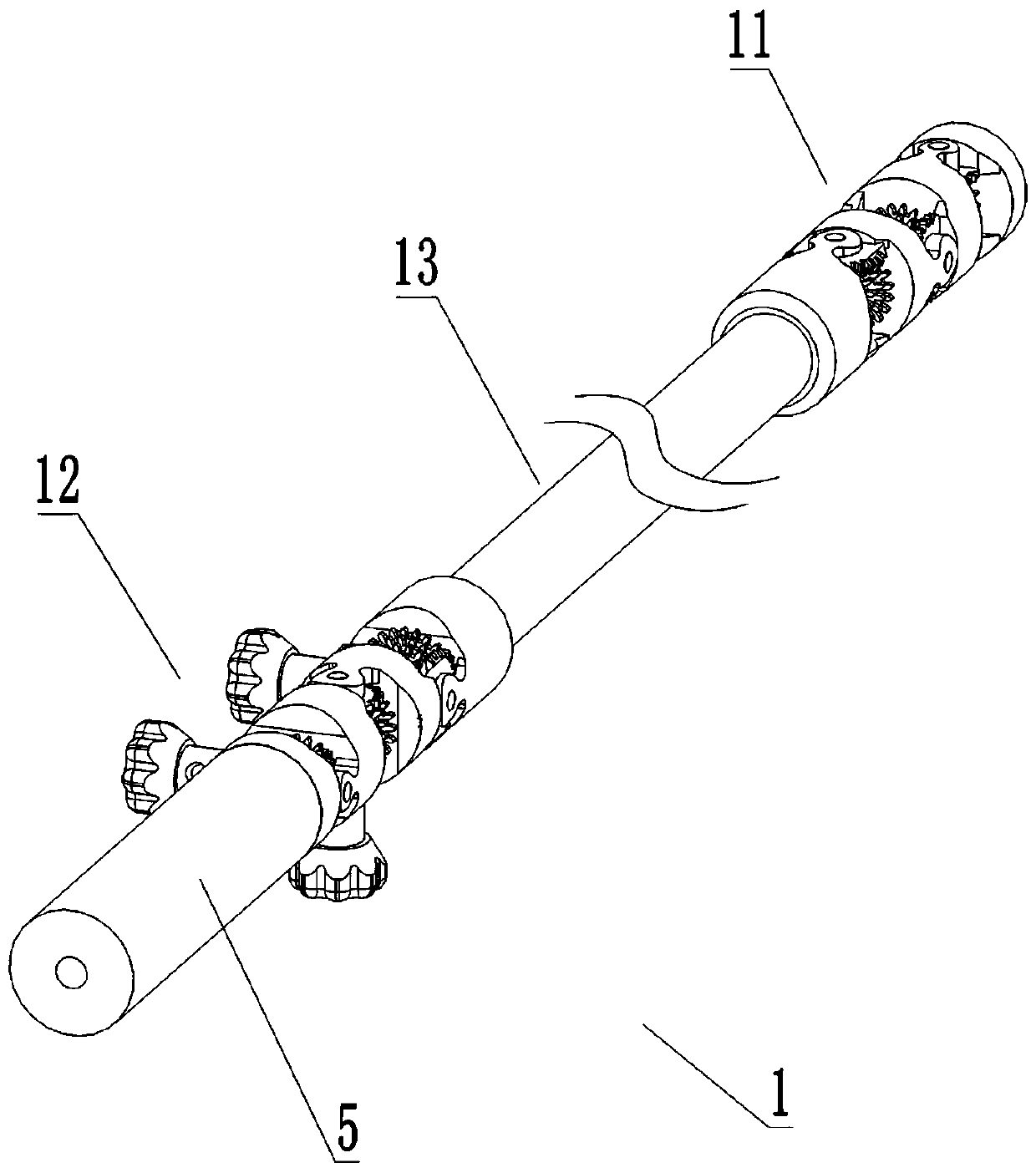

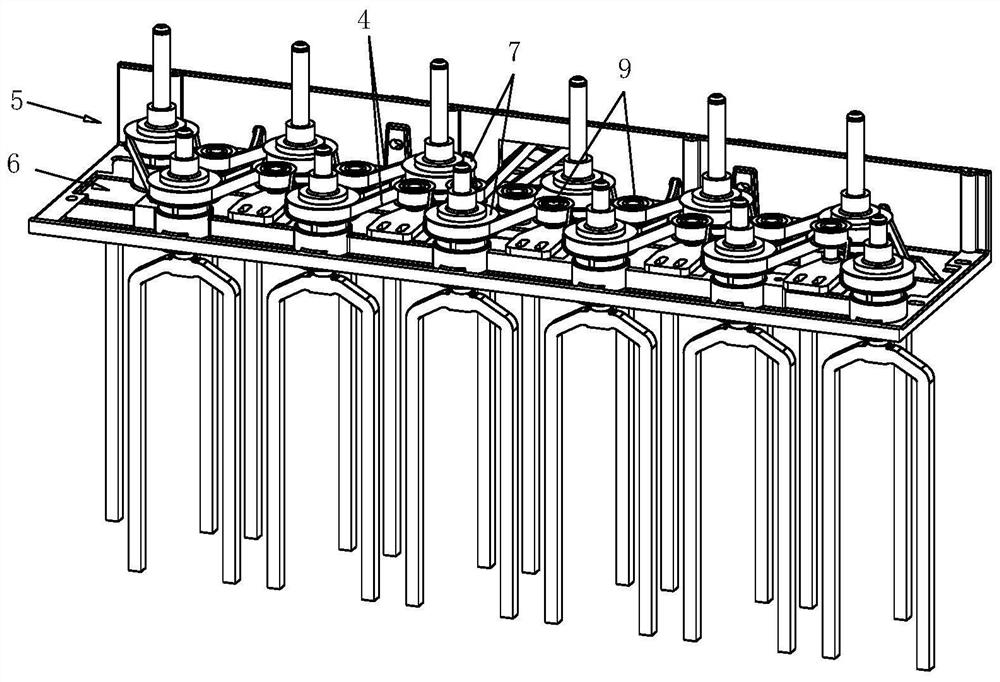

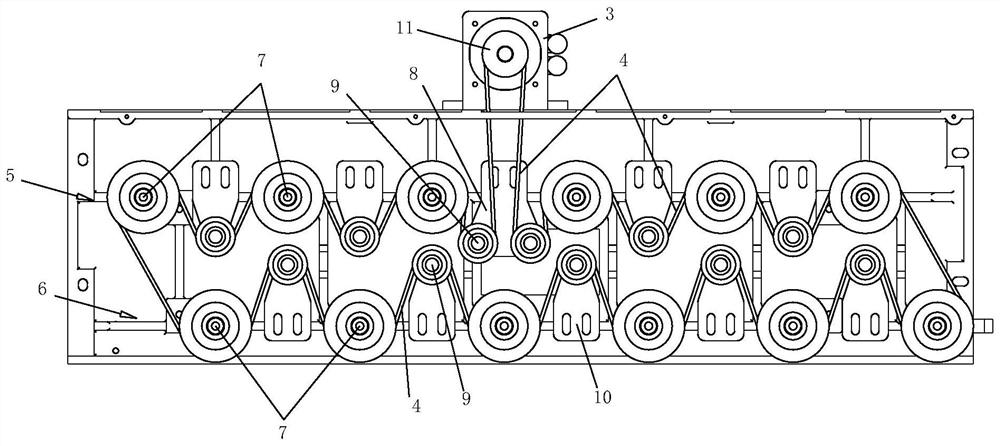

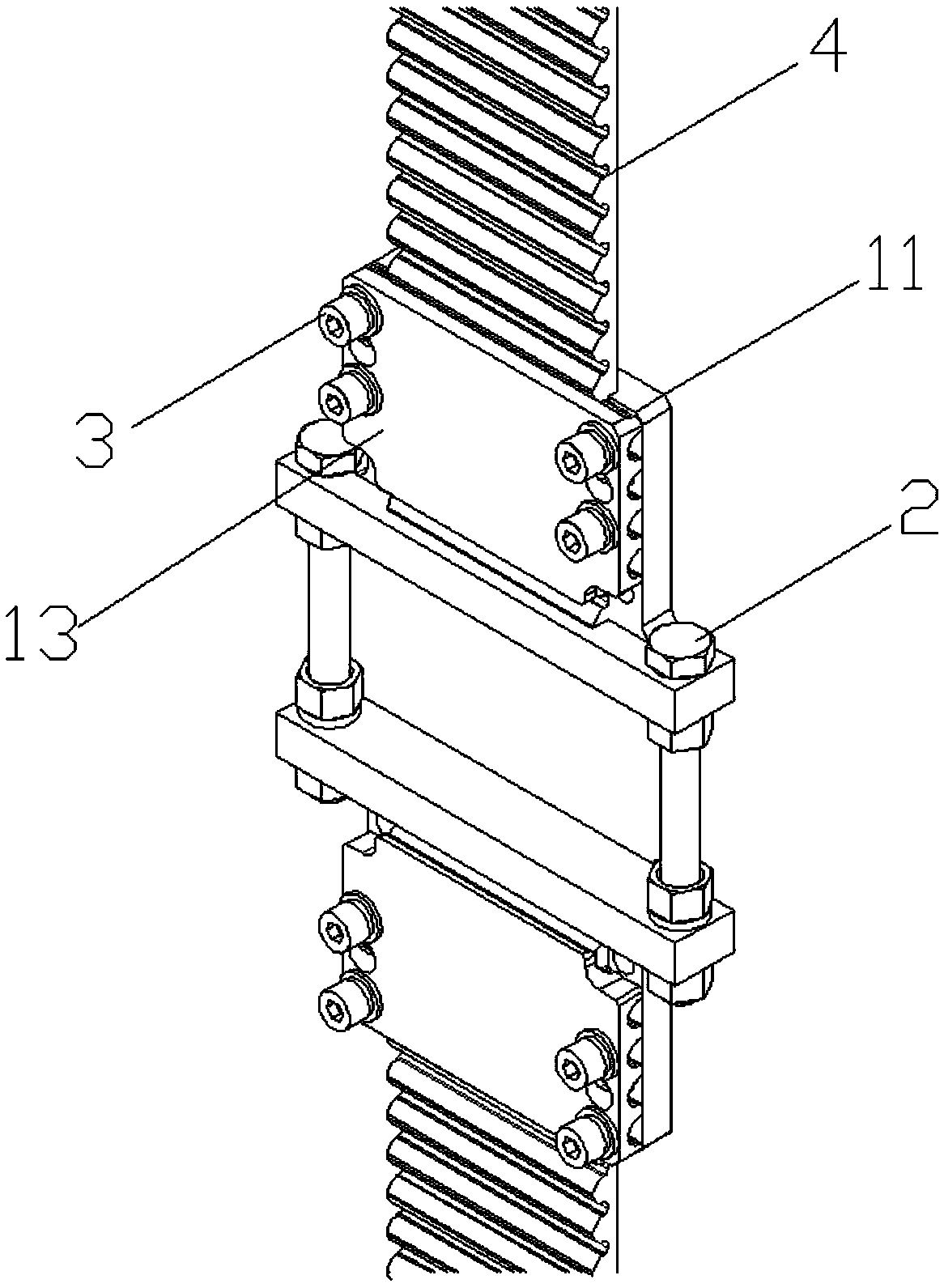

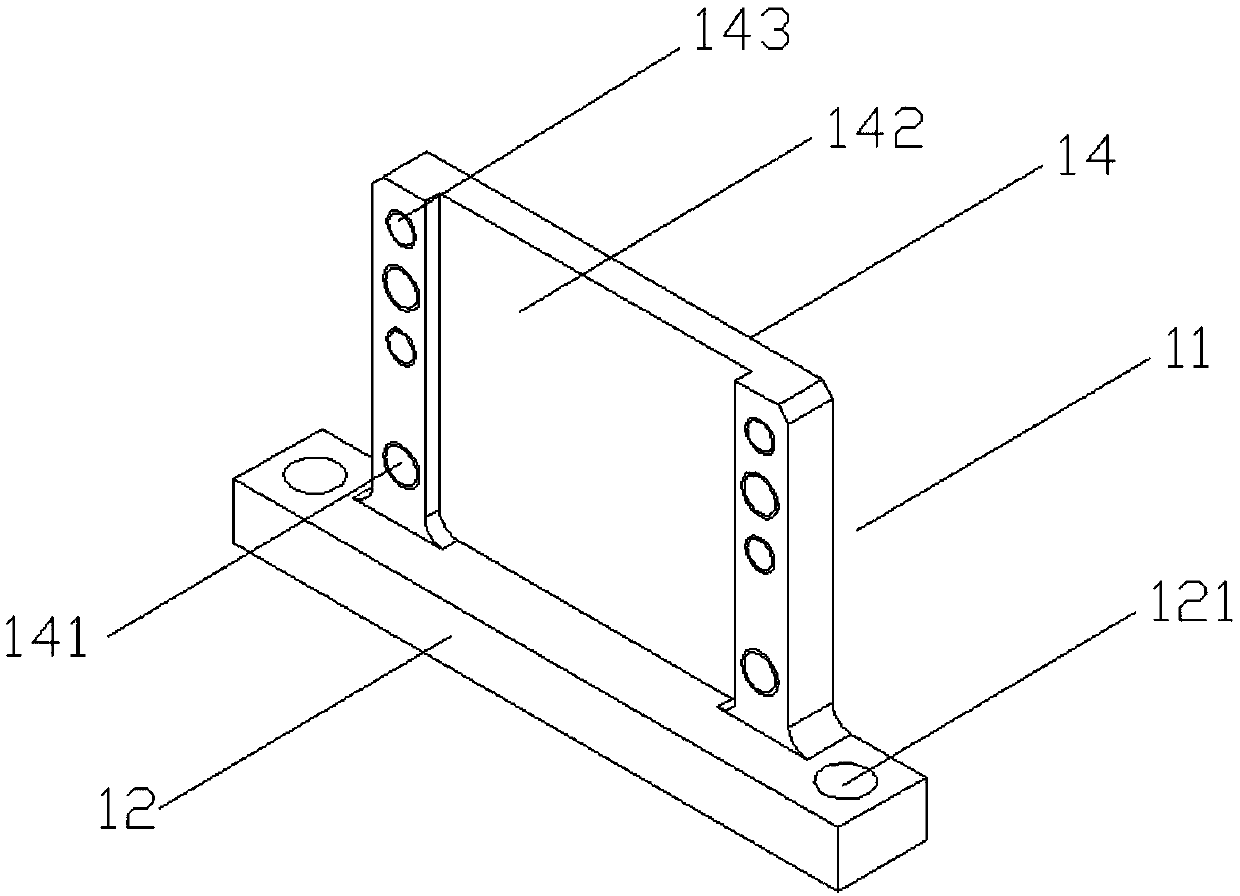

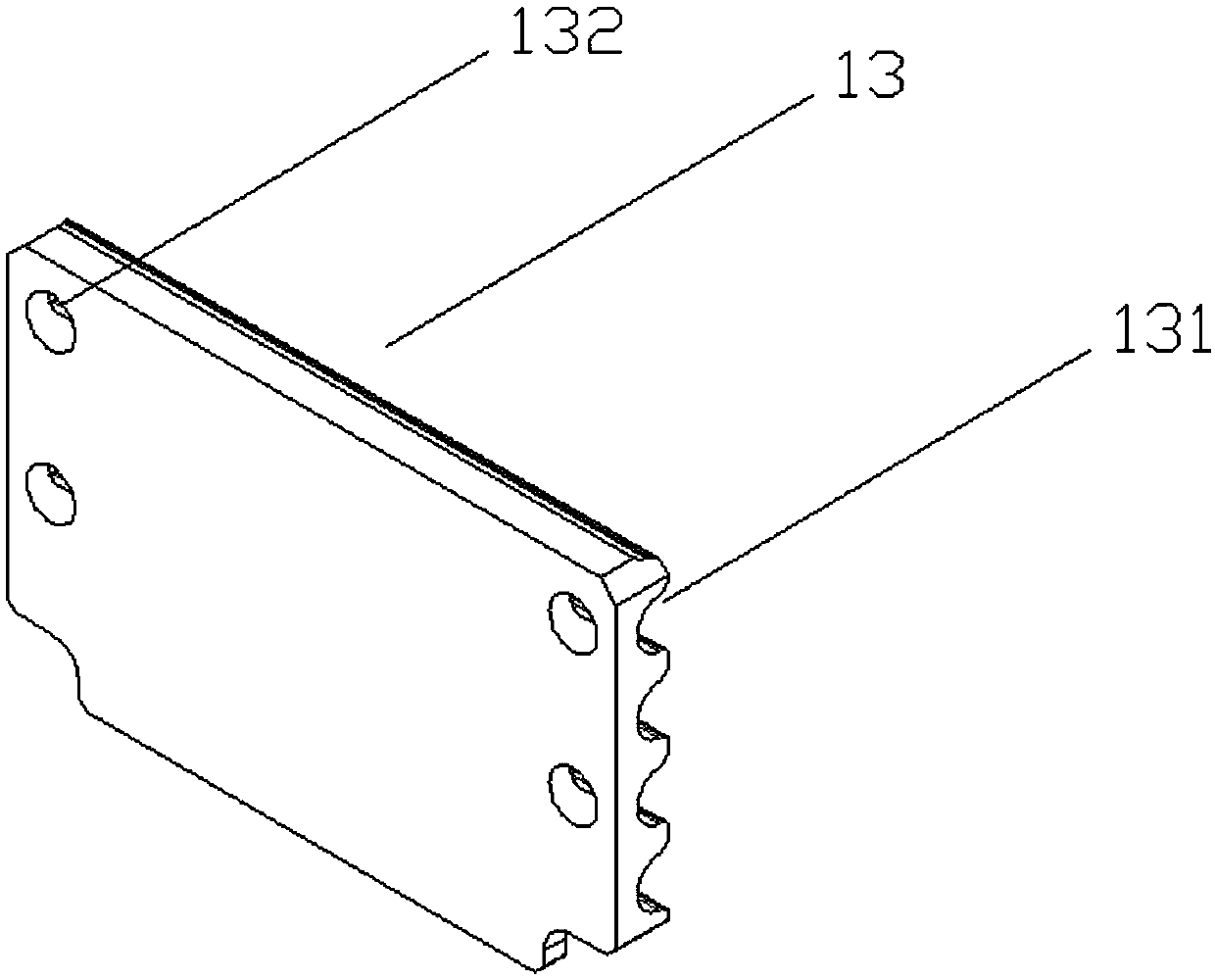

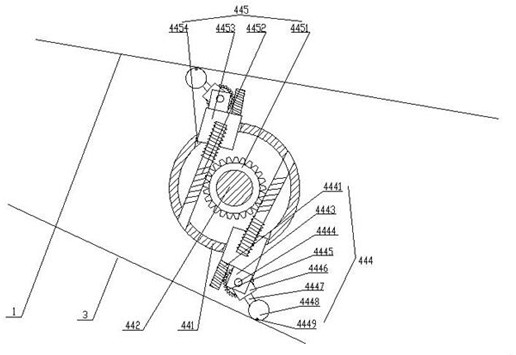

Modularized wire wrapping system of wire drive mechanism

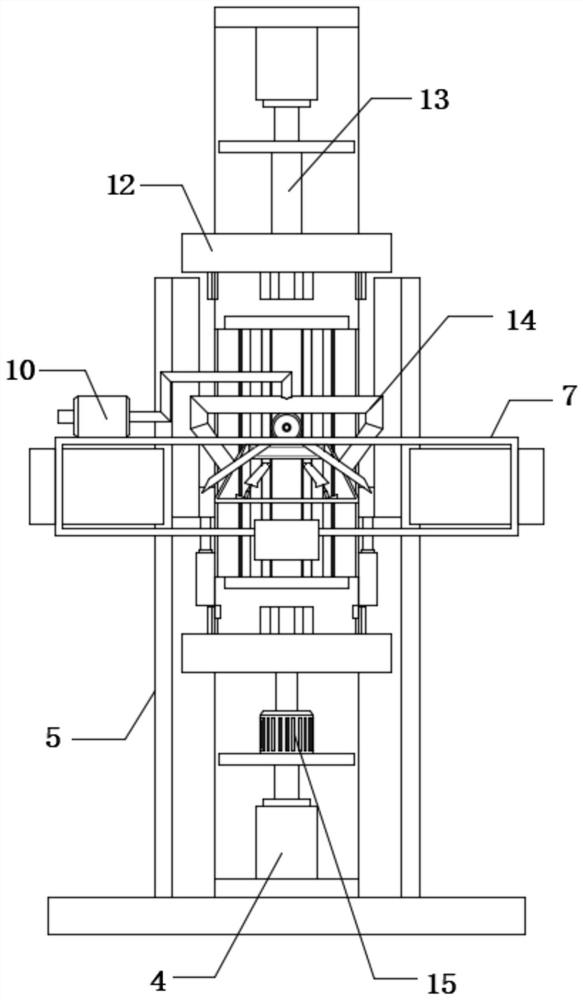

PendingCN109630629ARealize transmissionImplement tension detectionGearingTension measurementComputer moduleEngineering

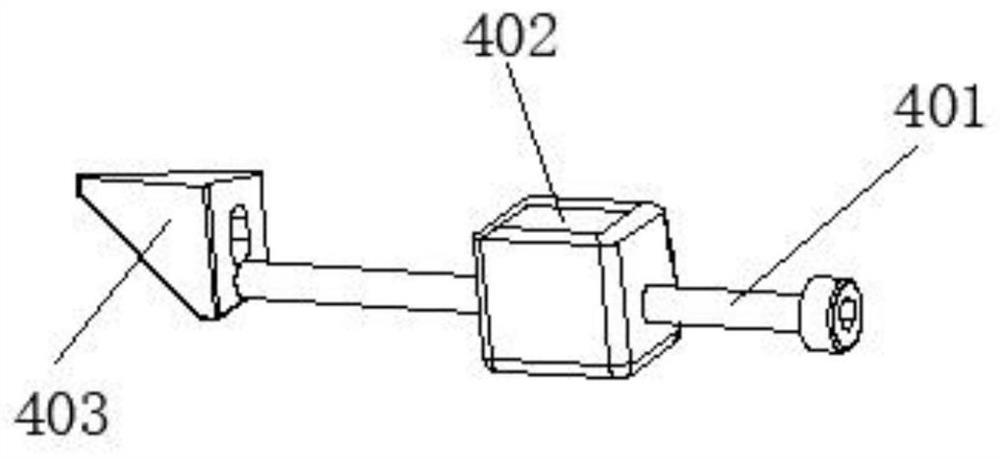

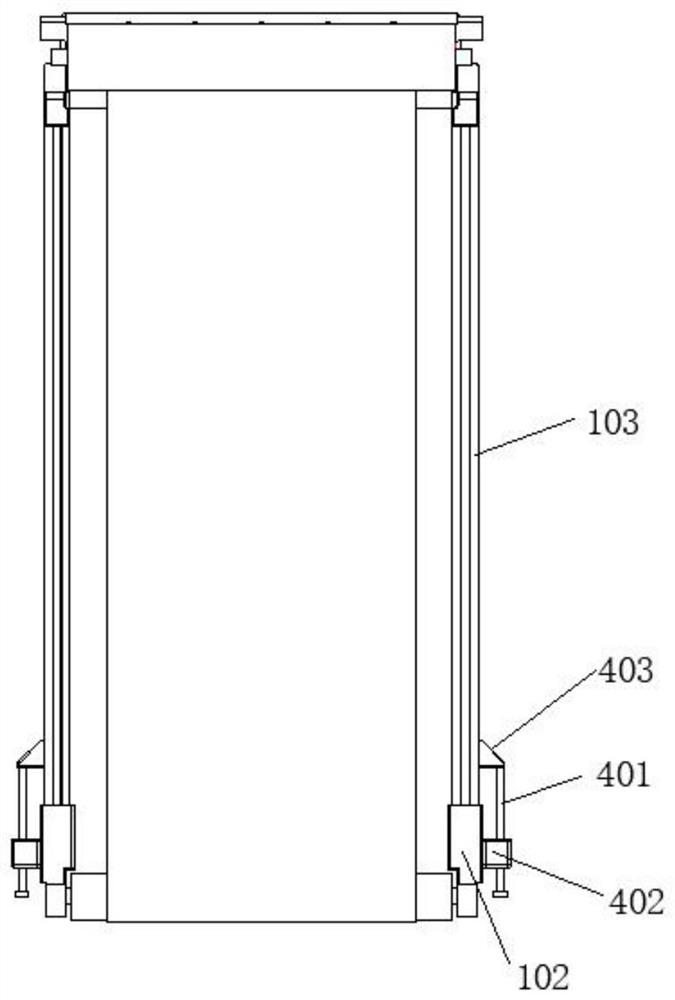

The invention discloses a modularized wire wrapping system of a wire drive mechanism. The modularized wire wrapping system comprises a drive device and a steel wire rope used for transmission, and further comprises a wire wrapping, fixing and pre-tightening module which is used for fixing the tail end of the steel wire rope and preliminarily pre-tightening the steel wire rope, a wire wrapping tension detecting module for detecting tension of the steel wire rope, and a wire wrapping tension regulating module for regulating tension of the steel wire rope, wherein the wire wrapping, fixing and pre-tightening module, the wire wrapping tension detecting module and the wire wrapping tension regulating module are sequentially connected; the steel wire rope is guided out from the wire wrapping, fixing and pre-tightening module, and sequentially wraps across the wire wrapping tension detecting module and the wire wrapping tension regulating module; and the wire wrapping, fixing and pre-tightening module is connected to the drive device, and wraps the steel wire rope under driving of the drive device. The modularized wire wrapping system is small in structure, can realize wire transmission within a narrow space, and improves compactness, aesthetic degree, measurability and reliability of the equipment through a modularized design.

Owner:TIANJIN UNIV

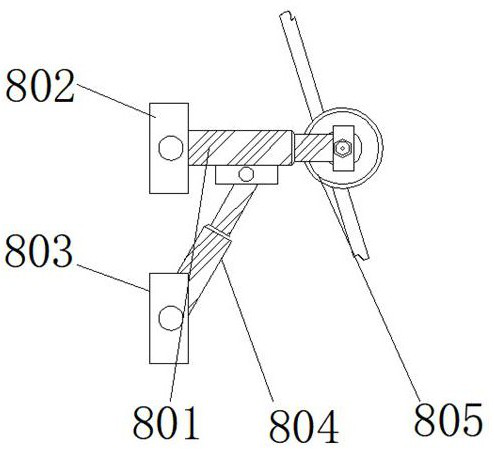

Manual adjustable tension wire tightening mechanism

InactiveCN102744476ADoes not affect cutting stabilityAchieving tension adjustmentElectrical-based machining electrodesSurface roughnessEngineering

The invention discloses a manual adjustable tension wire tightening mechanism. The manual adjustable tension wire tightening mechanism comprises a wire cylinder, an electrode wire, an upper guide wheel, a lower guide wheel, a working table, a beam and a wire tightening device; one end of the electrode wire is wound on the wire cylinder and is fixed at the left end of the wire cylinder; the other end of the electrode wire is wound on the wire cylinder and is fixed at the right end of the wire cylinder after sequentially passing through the upper guide wheel, the wire tightening device and the lower guide wheel; the wire tightening device is arranged on the beam; the beam is arranged on the working table; the wire tightening device comprises a wire tightening guide wheel, an oscillating bar, an oscillating bar connecting pin, a bracket and a counter weight; the rotatable wire tightening guide wheel is arranged at one end of the oscillating bar; the position of the oscillating bar, which is close to the wire tightening guide wheel, is movably connected to a bracket by the oscillating bar connecting pin; the bracket is arranged on the beam by a screw; and the movable counter weight is inserted at the other end of the oscillating bar. By the mode, the manual adjustable tension wire tightening mechanism has simple and practical design structure, is convenient to manufacture, is reliable to install and is flexible to use; by regulating the tension of the linear cutting electrode wire, the loss caused by the loosening and shaking of the electrode wire is avoided, the surface roughness of a cut workpiece is improved and the production efficiency is improved.

Owner:SUZHOU VOCATIONAL UNIV

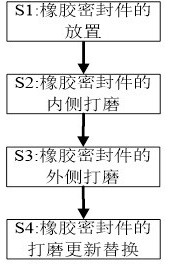

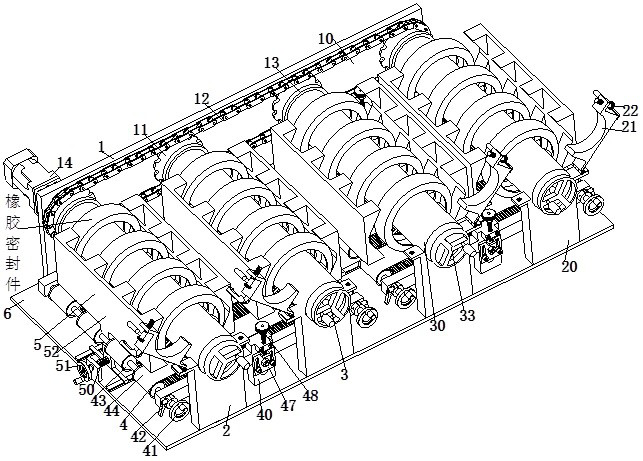

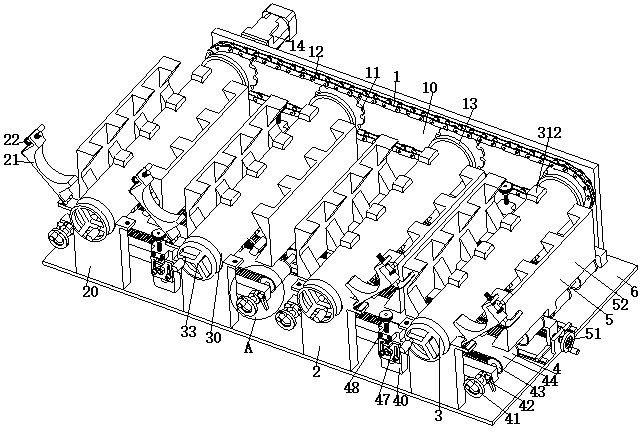

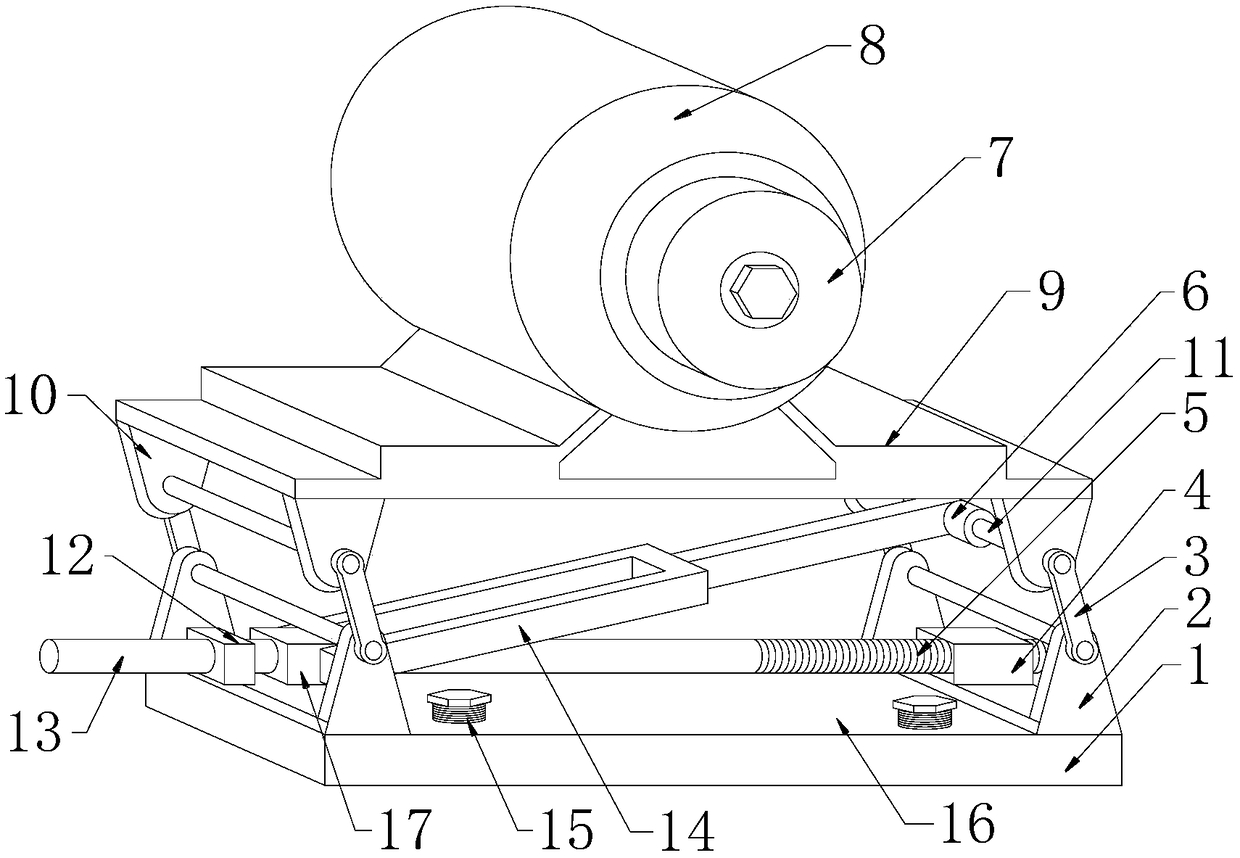

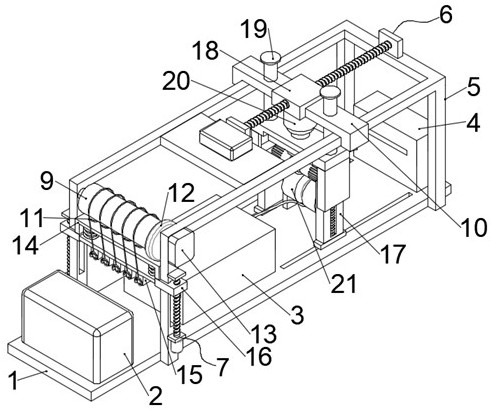

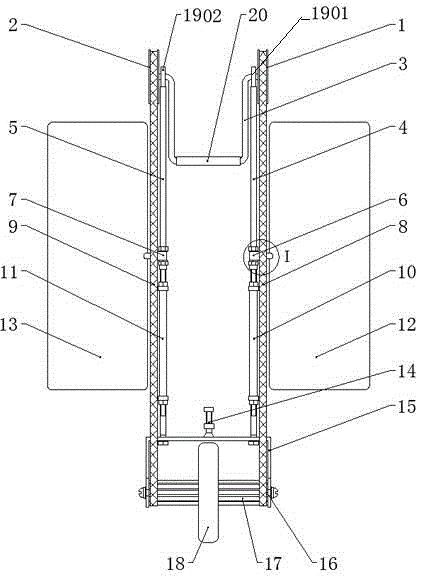

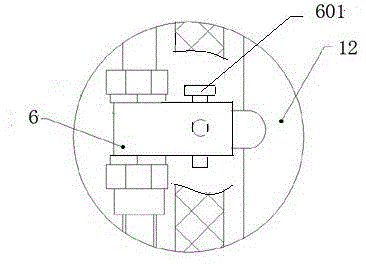

Rubber seal preparation method

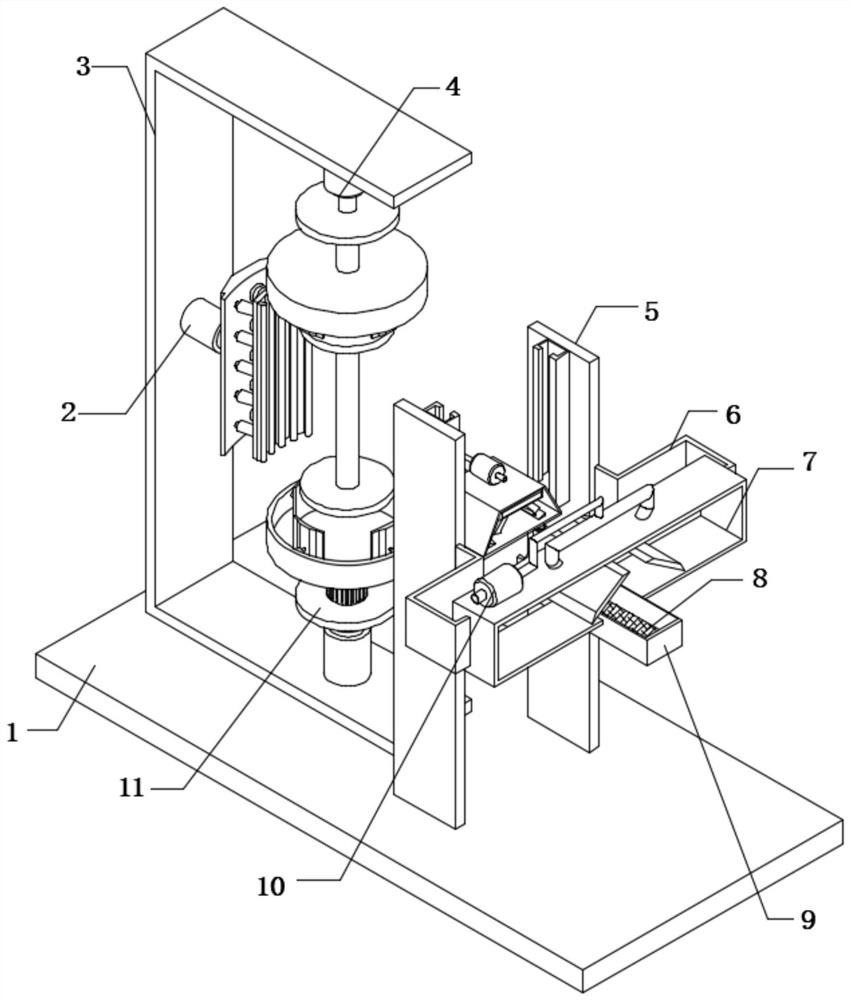

InactiveCN112207673AAvoid shakingPrevents loss of grinding efficiencyEdge grinding machinesGrinding carriagesEngineeringPhysics

The invention provides a rubber seal preparation method. Rubber seal polishing equipment comprises a power output mechanism, a plurality of groups of clamping support placing mechanisms, an executingmechanism, polishing mechanisms, an outer side clamping mechanism and a bottom plate. The multiple groups of clamping support placing mechanisms which are linearly distributed in the length directionof the bottom plate are arranged on the bottom plate. The executing mechanism is connected right above the clamping support placing mechanisms through bearings, a shaft head at one end of the executing mechanism is connected with the power output mechanism through a hexagonal gap plug pin, the power output mechanism is installed on the bottom plate, and the outer side clamping mechanism is arranged between the power output mechanism and the clamping support placing mechanisms. The outer side clamping mechanism is installed on the bottom plate in a sliding fit mode, and the polishing mechanismsare arranged under the outer side clamping mechanism and symmetrically installed on the bottom plate. The problems that a large amount of manpower and time need to be consumed for manually removing burrs and flashes and a joint line, and the quality of burr and flash removal is unstable are solved.

Owner:许计文

Large motor belt tensioning device

InactiveCN108712011APrevent rotationImprove regulation efficiencyMechanical energy handlingEngineering

The invention discloses a large motor belt tensioning device comprising a device body, a motor base and a baseplate base. A nut base is arranged in the middle of the right lower hinge base. The nut base is fixedly connected with the lower hinge base. A rotating shaft is arranged in the middle of the nut base. The rotating shaft is flexibly connected with the nut base. The right end of the rotatingshaft is provided with a lead screw segment which is fixedly connected with the rotating shaft. When the belt of the motor is adjusted by using the device body, the servo motor is turned on to drivethe rotating shaft to rotate and the lead screw segment of the tail end of the rotating shaft is enabled to screw in or screw out of the nut base to drive the connecting rod to move leftward or rightward. In the movement process of the connecting rod, the upper hinge base is also driven to move to be staggered from the position of the lower hinge base through the fixed sleeve ring of the tail endso as to complete adjustment of the belt tensioning degree of the motor. Adjustment of the belt tensioning degree can be completed without performing direct manual action on the motor in the adjustment process so that use of the device body is enabled to be more convenient and rapid and the device has great development prospect in the future.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Arrangement line conveying belt tensioning mechanism

PendingCN106742273AMobile and flexibleLarge adjustment rangeConveyorsPackagingEngineeringMechanical engineering

Owner:SHANDONG SONGYUAN AUTOMATION EQUIP

Wire and cable tensility testing device and tensility testing method

PendingCN109580068AAchieving tension adjustmentTo achieve the purpose of pull testTension measurementEngineeringRaw material

The present invention discloses a wire and cable tensility testing device, including a cable manager. A cable wheel is disposed on the cable manager, and both sides of the cable manager are provided with a cable retractor. The cable retractor includes a retractable rack, and the retractable rack cooperates with a fixed end and a movable end to clamp a cable reel. The fixed end is connected to a retracting power part through a torsiometer. The present invention discloses a tensility testing method, and a retracting cable torque is controlled in real time by the torsiometer to reach a tensilitytesting effect. In the present invention, tensility of the wire and cable can be tested at the same time of retracting and releasing, and tensility of the whole reel of wire and cable can be tested, so that costs of raw materials, labor, testing precision and the like are saved.

Owner:KUNSHAN FUCHUAN ELECTRICAL MACHINERY TECH

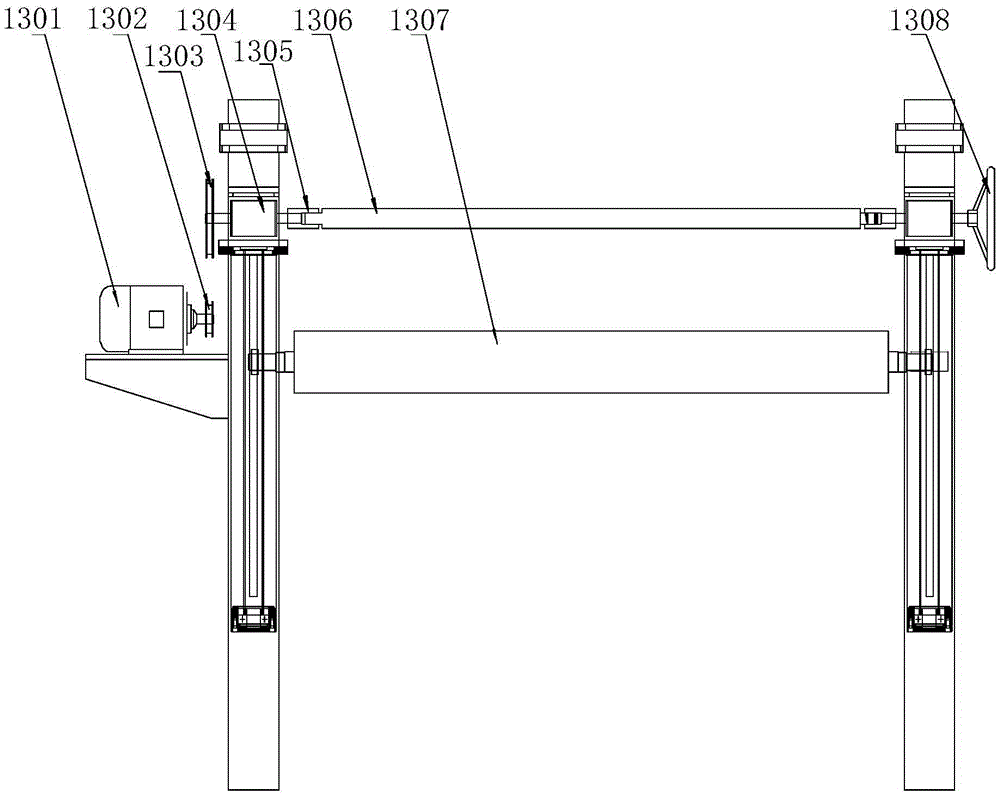

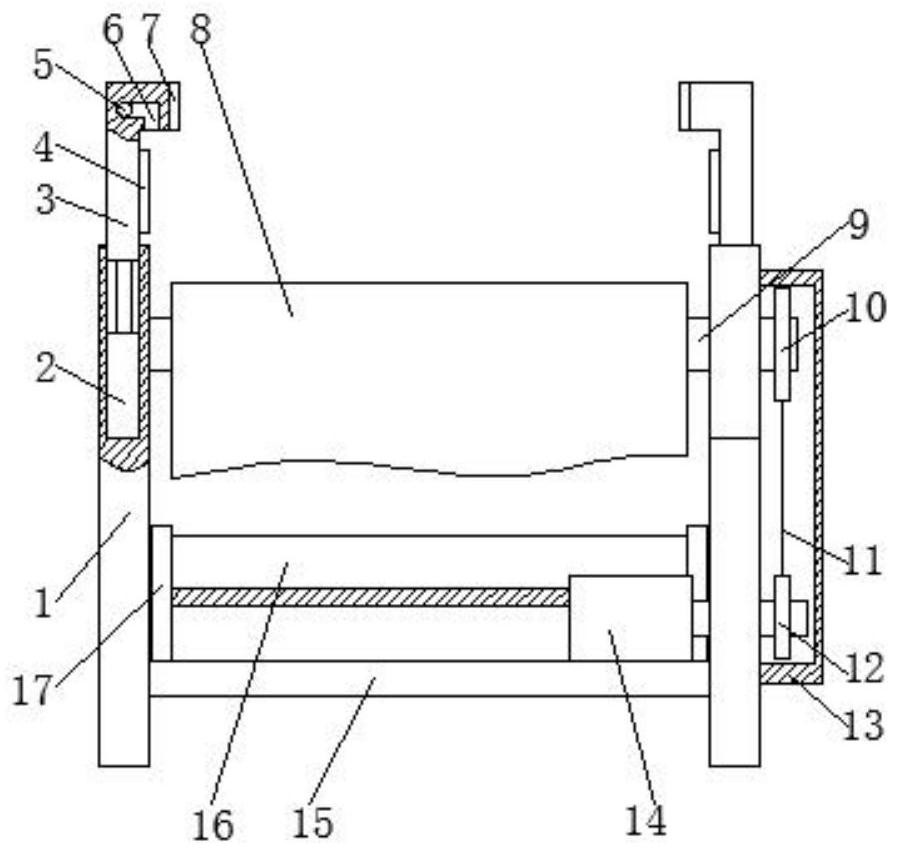

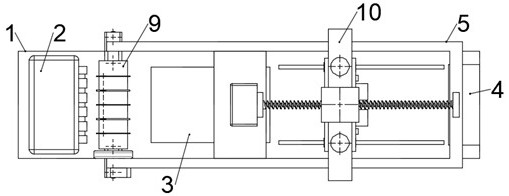

Conveyor belt tension adjusting device and adjusting method

ActiveCN105617747AExtended service lifeImprove stabilityMembrane filtersMoving filtering element filtersMotor driveEngineering

The invention relates to the technical field of slurry dewatering, in particular to a conveyor belt tension adjusting device and adjusting method. The adjusting device comprises a rack, an adjusting motor, two sets of screw lifters, a linkage rod, two nuts and a guide roller; the adjusting motor drives the two sets of screw lifters to rotate synchronously through the linkage rod, so that the guide roller is driven to realize lifting motion; a vacuum manometer is mounted on a vacuum dewatering box below a conveyor belt, and a controller which is connected with the vacuum manometer and the adjusting motor is arranged. The controller receives conveyor belt pressure change information sent by the vacuum manometer, controls working of the adjusting motor and drives the guide roller to lift, so that the tension of the conveyor belt is adjusted. According to the conveyor belt tension adjusting device and adjusting method, the conveyor belt pressure change information sent by the vacuum manometer is taken as a reference value, constant reference is provided for conveyor belt tension adjusting, a fine tuning manner is adopted, the adjustment is rapid and accurate, the service life of a blanket can be prolonged favorably, and the dewatering stability can be improved favorably.

Owner:LIUZHOU JIE TE BUILDING MATERIALS

Industrial electric automatic material conveying device

The invention provides an industrial electrical automation material conveying device, and relates to the technical field of electrical automation equipment. The device discloses comprises a machine frame. The inner side of the machine frame is connected with a conveying roller in a rotating mode. A first air cylinder is arranged inside the machine frame. The output end of the first air cylinder isfixedly connected with a limiting plate. Dust collection cotton is arranged at the side, close to the first air cylinder, of the right side face of the limiting plate, and a rubber strip is arrangedat the side, away from the first air cylinder, of the right side face of the limiting plate. Cleaning liquid is sprayed out through a spray head in a cleaning roller; lubricating oil, protective oil,and dust on the surface of a conveying belt are removed by the match between the spray head and the cleaning roller; the height of the limiting plate can be adjusted, so that the requirement for limiting mechanical parts of different sizes can be met; the flying dust entering the conveying belt or mechanical parts is removed under the action of the dust collection cotton and a dust removal box; and the conveying belt is tensioned and adjusted through auxiliary rollers, and different carrying conditions of the conveying belt are met.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

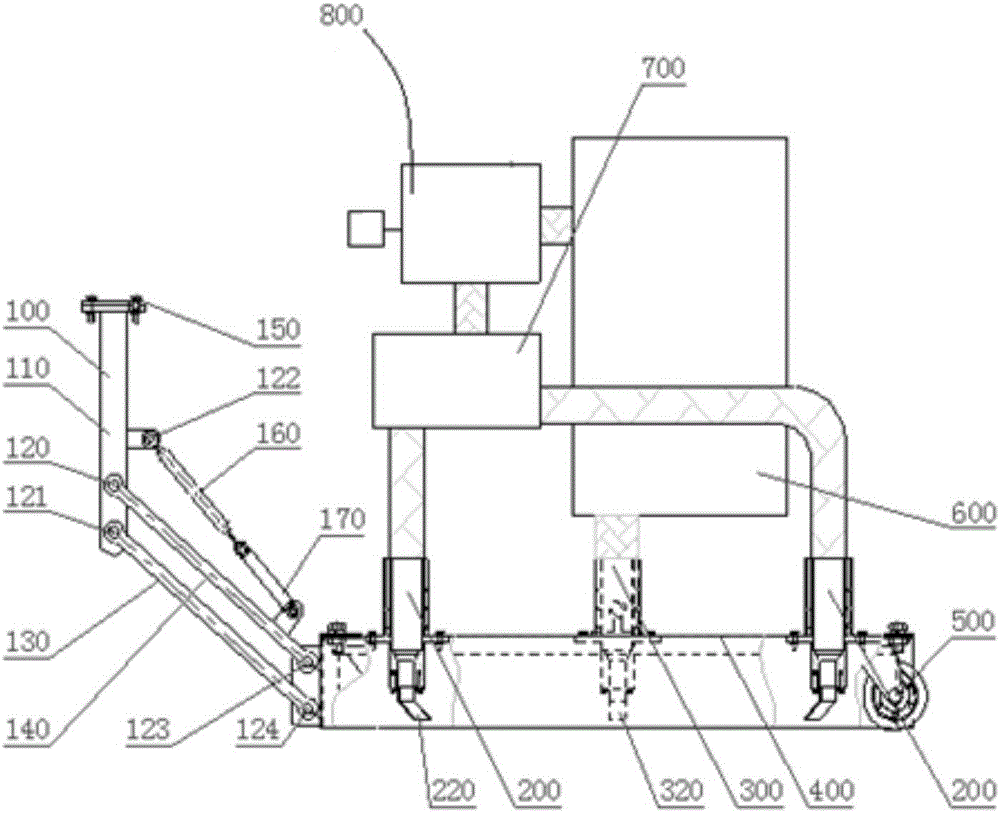

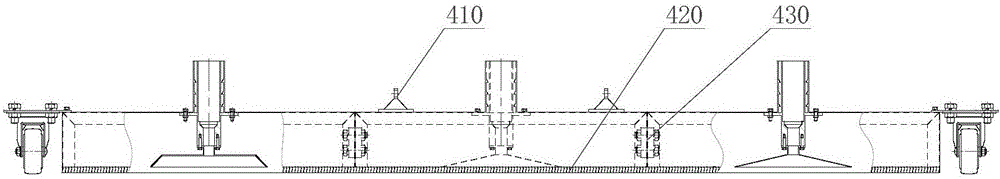

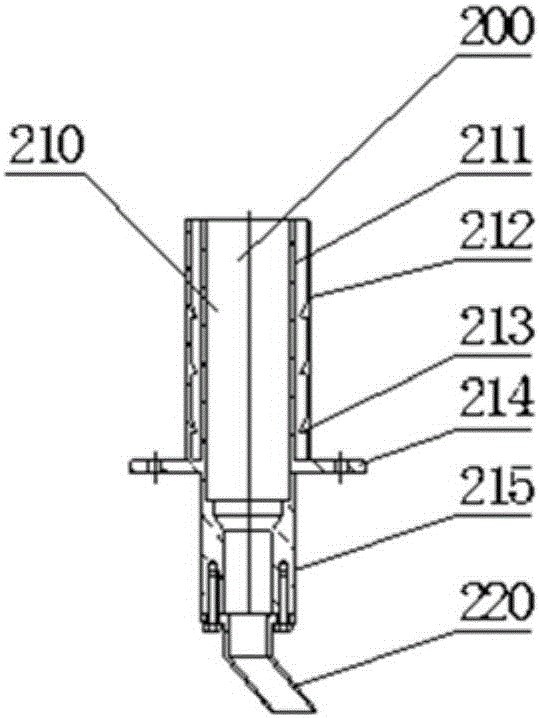

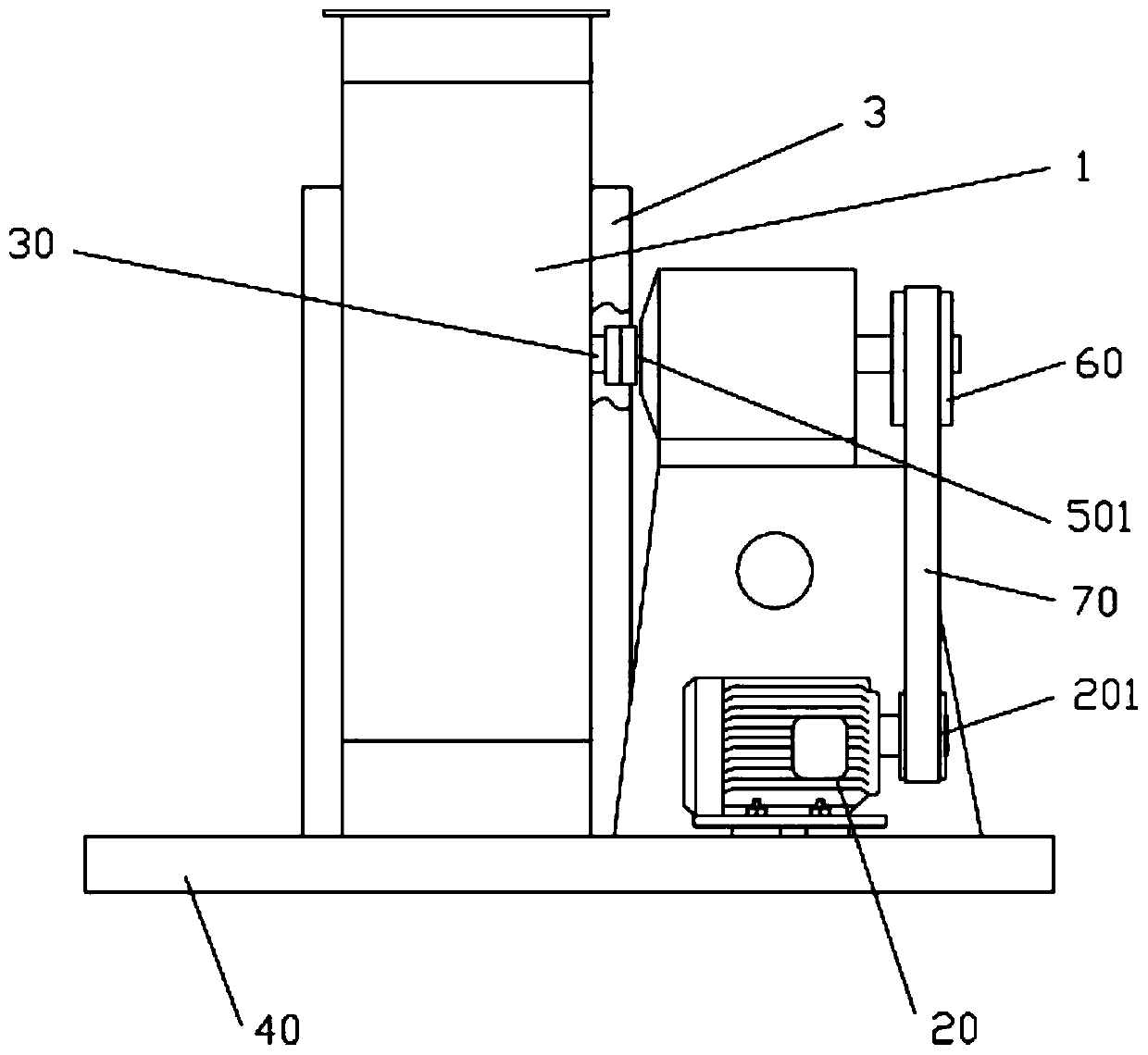

Suction sweeping device of special suction sweeping cart for pavement milling and planing

The invention discloses a suction sweeping device of a special suction sweeping cart for pavement milling and planing. A dragging device is hinged to a suction cover support through a pull rod, and a suction cover is divided into a plurality of rectangular spaces. Each rectangular space is internally provided with a suction device and reverse blowing devices. A dust removal and material collection device is connected with each suction device and an inlet of an air induction device through pipelines. An inlet of an air gathering chamber is connected with an outlet of the air induction device. The reverse blowing devices are connected with an outlet of the air gathering chamber. All the devices form a circulating air current flowing loop. Compared with a common sweeping cart, the suction sweeping device can effectively suck tiny dust generated during pavement milling and planing, the milled and planed pavement sweeping effect is good, and the bonding quality between layers during subsequent conduction is ensured. Through a four-bar mechanism, an adjusting spring and small supporting wheels, adjustment of the depth of parallelism of the suction sweeping device and the pavement is achieved, upward tension adjustment can also be achieved, the suction sweeping device is in a semi-floating balanced state with the swept pavement during working, the suction sweeping device ascends or descends freely in case of obstacles, and the suction sweeping device can adapt to the conditions of the pavement.

Owner:CHANGAN UNIV

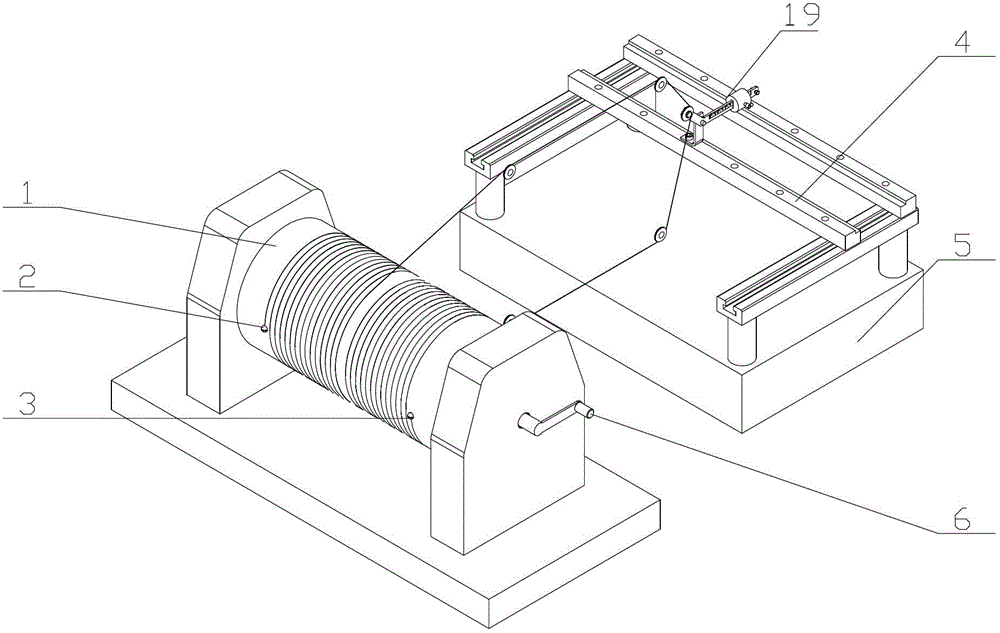

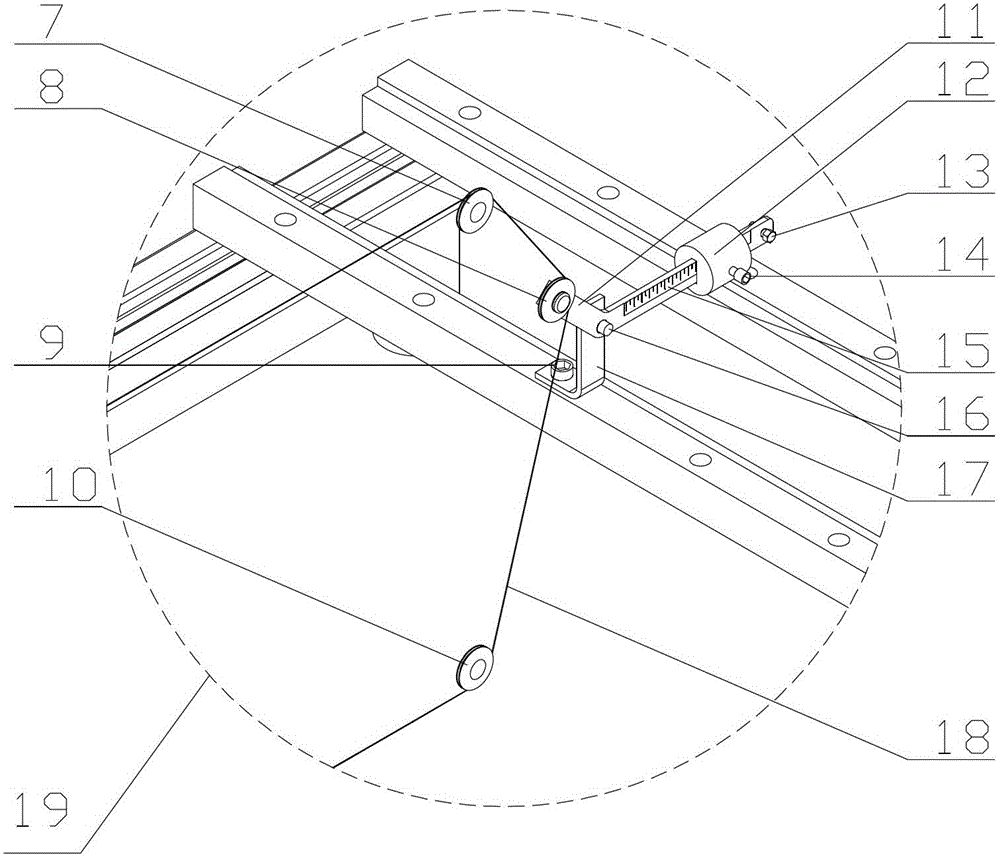

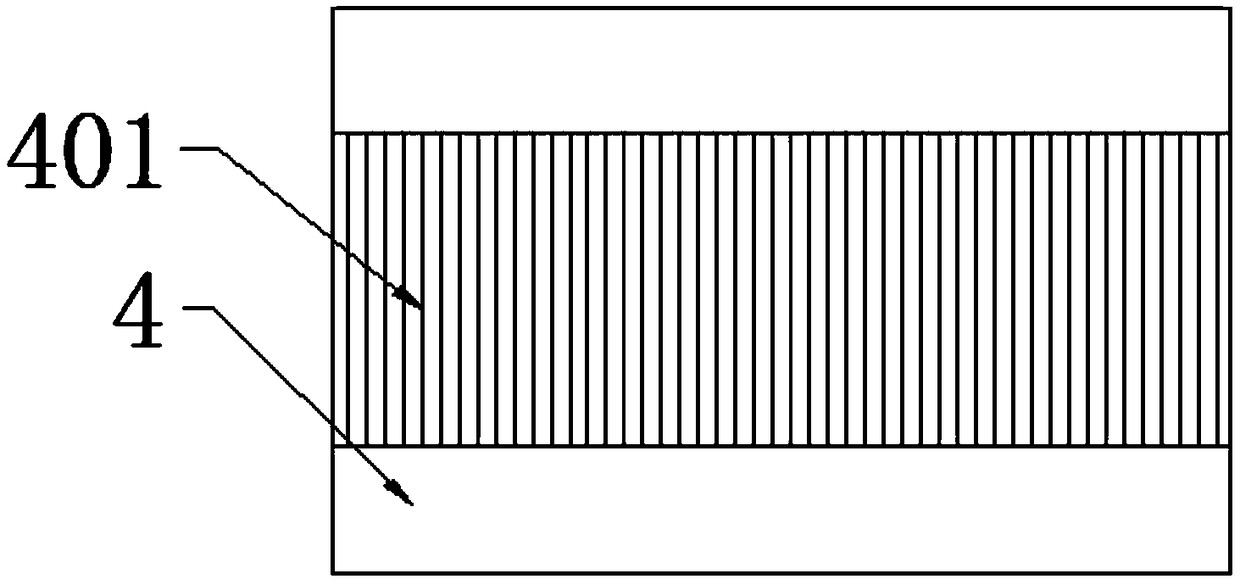

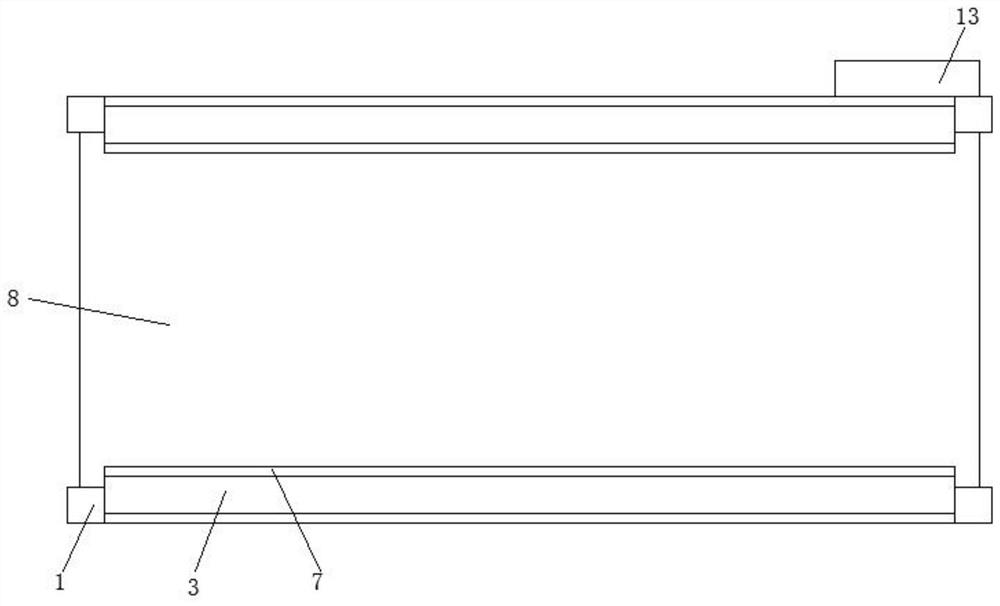

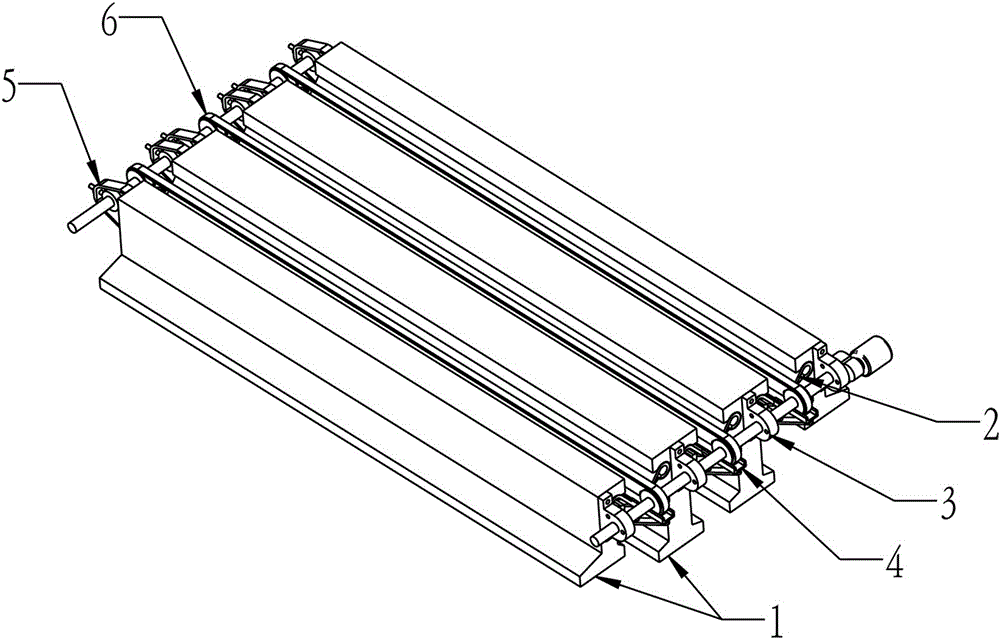

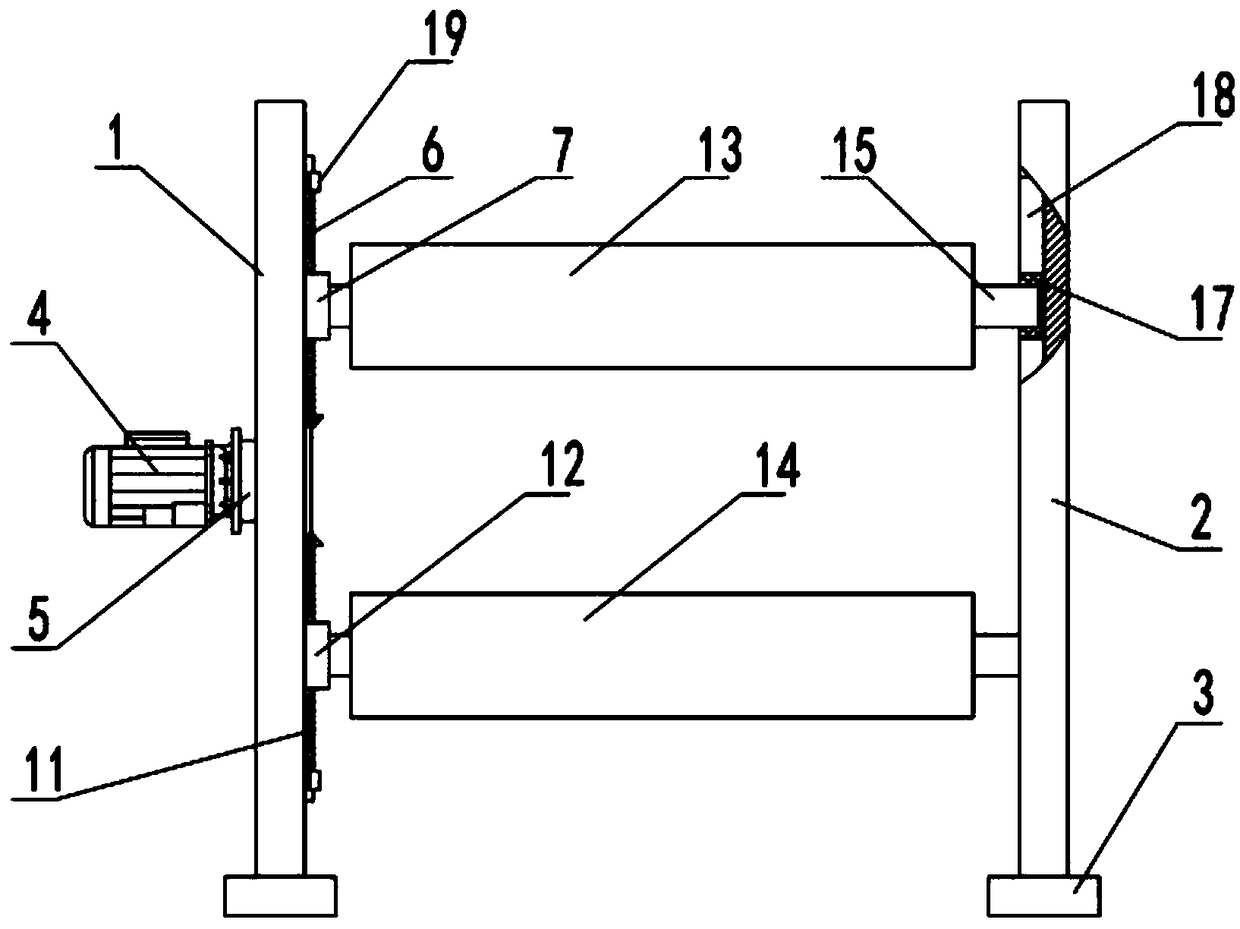

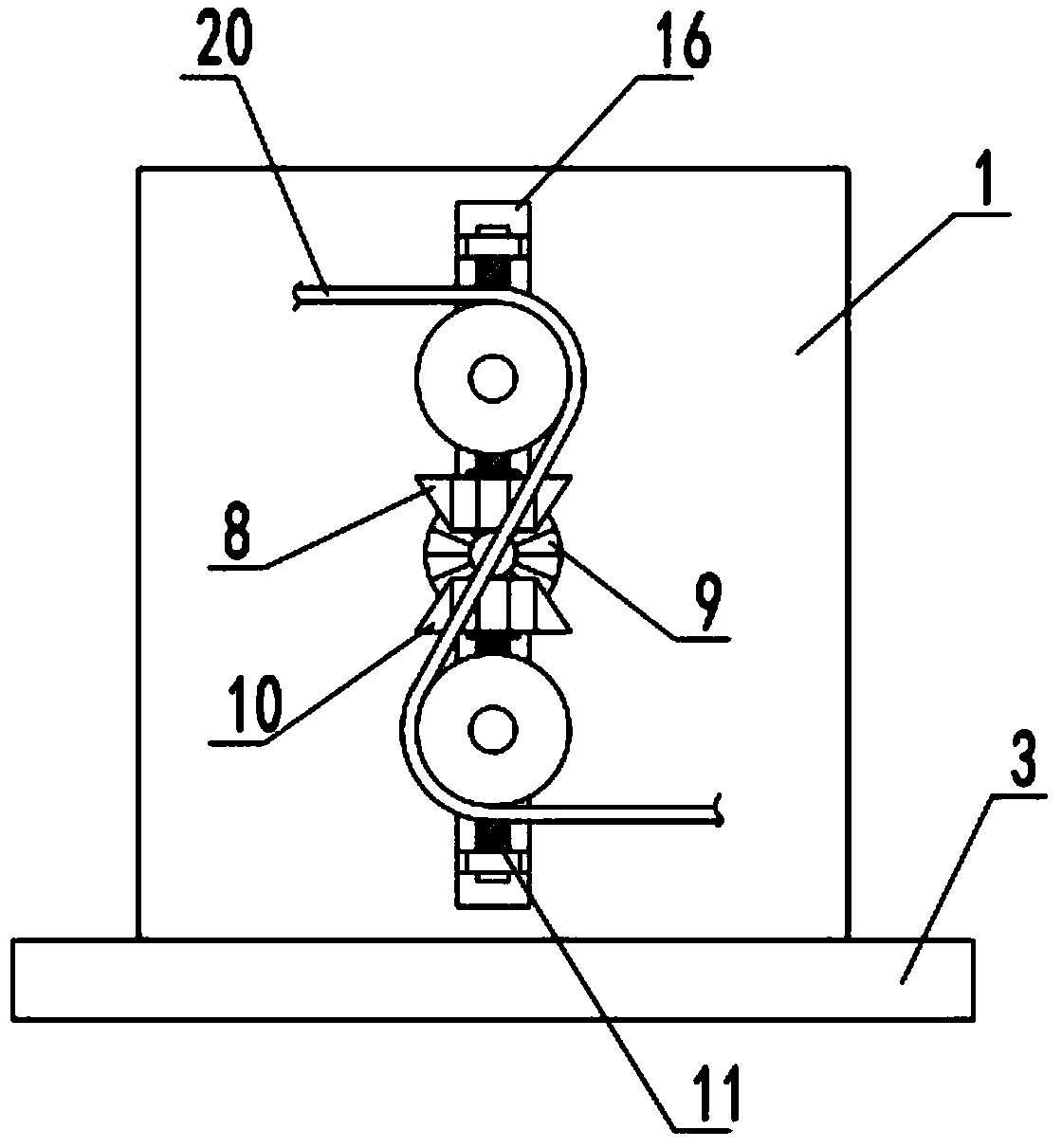

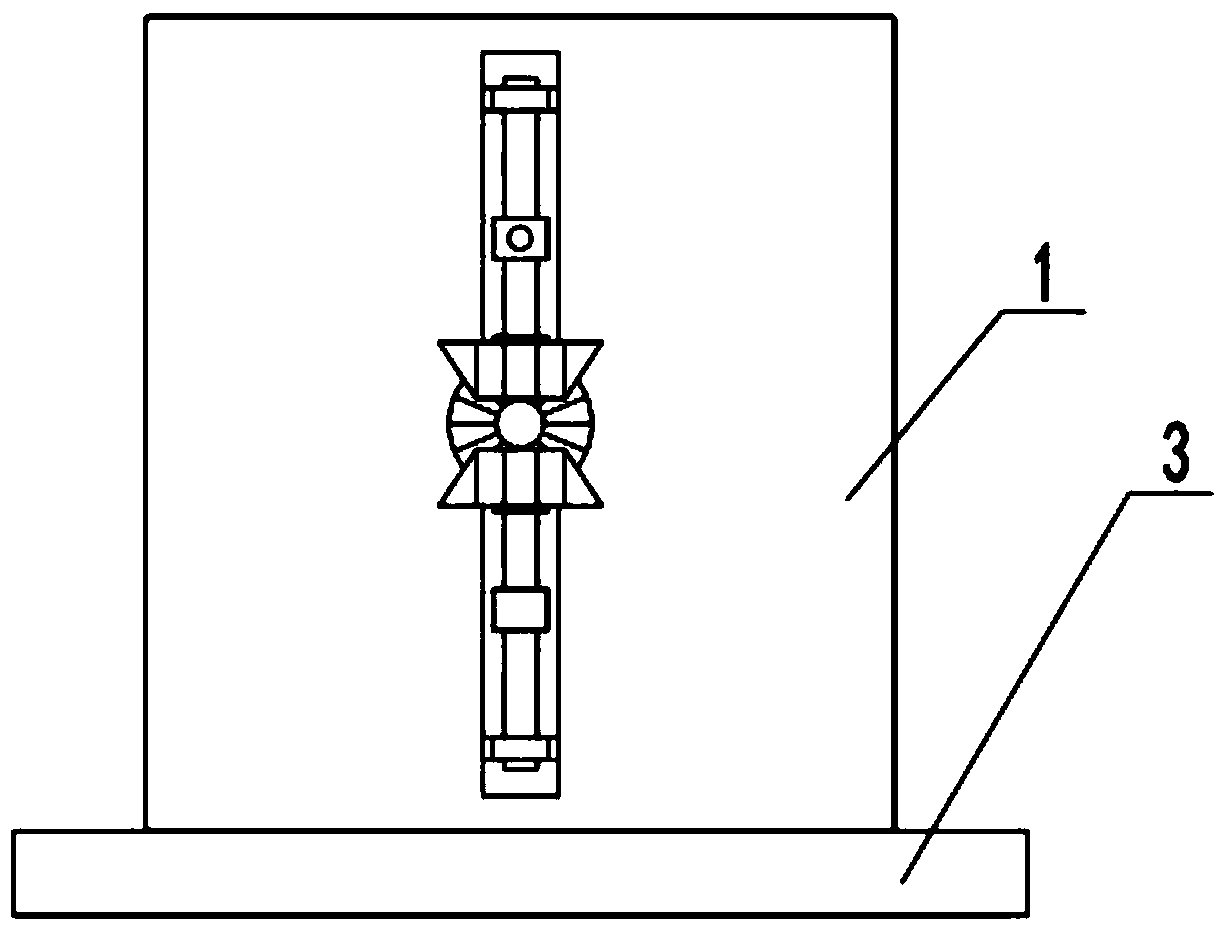

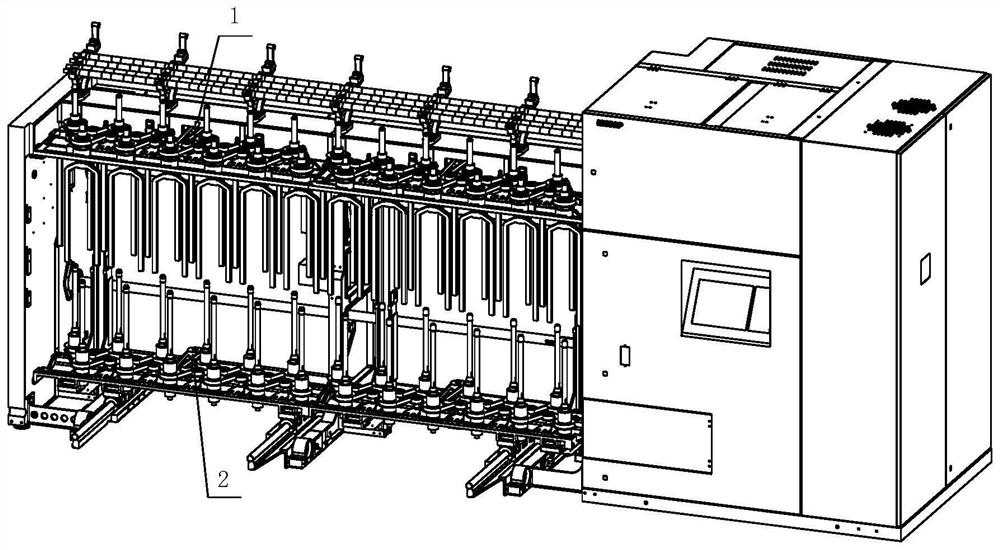

Upper and lower spindle rail tape transmission device for roving frames and roving frame

ActiveCN110629333AAchieving tension adjustmentAvoid wear and tearTextiles and paperBobbinEngineering

The invention provides an upper and lower spindle rail tape transmission device for roving frames and a roving frame, the upper and lower spindle rail tape transmission device comprises a plurality ofupper rail plate portions and a plurality of lower rail plate portions; each of the upper rail plate portions and the lower rail plate portions is provided with a transmission structure. Each transmission structure comprises a servo motor, a spindle tape, a friction disc mechanism and a tensioning wheel mechanism, wherein the spindle tape connects the servo motor, the friction disc mechanism andthe tensioning wheel mechanism in series. According to the upper and lower spindle rail tape transmission device herein, the servo motor is used for variable-speed driving, a flyer and a friction discon a bobbin are driven through tape serial driving, the problems of abrasion of gear transmission and damage of synchronous belt transmission are solved, and the spindle speed can reach 2000 r / min. The tensioning wheel mechanism is also provided such that tension adjustment of the spindle tape is achieved. The upper and lower spindle rail tape transmission device is simple in structure, high in transmission speed and convenient to install and maintain, and meets the trend that the spindle speed of the roving frame is developed to a high level.

Owner:CMT HICORP MACHINERY QINGDAO +1

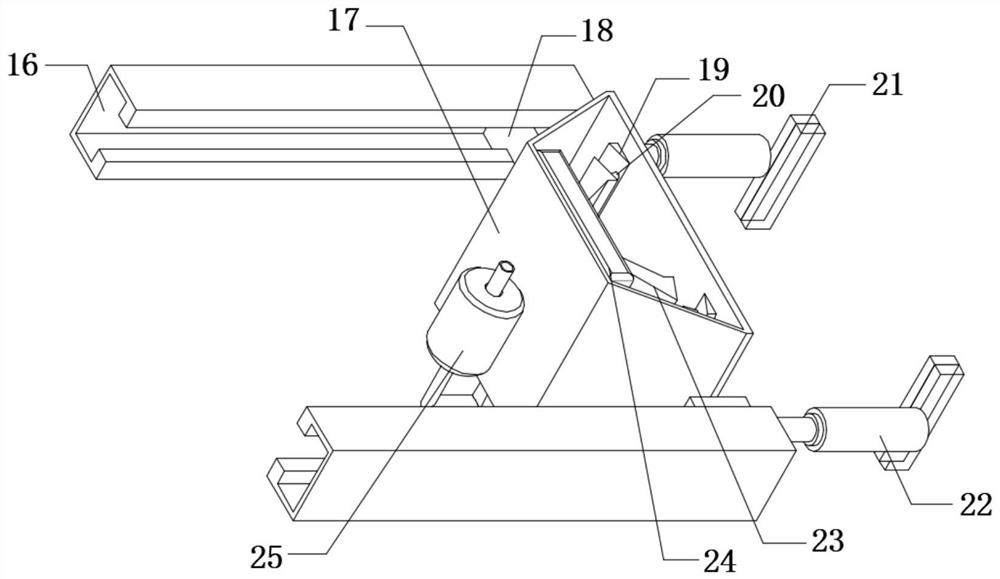

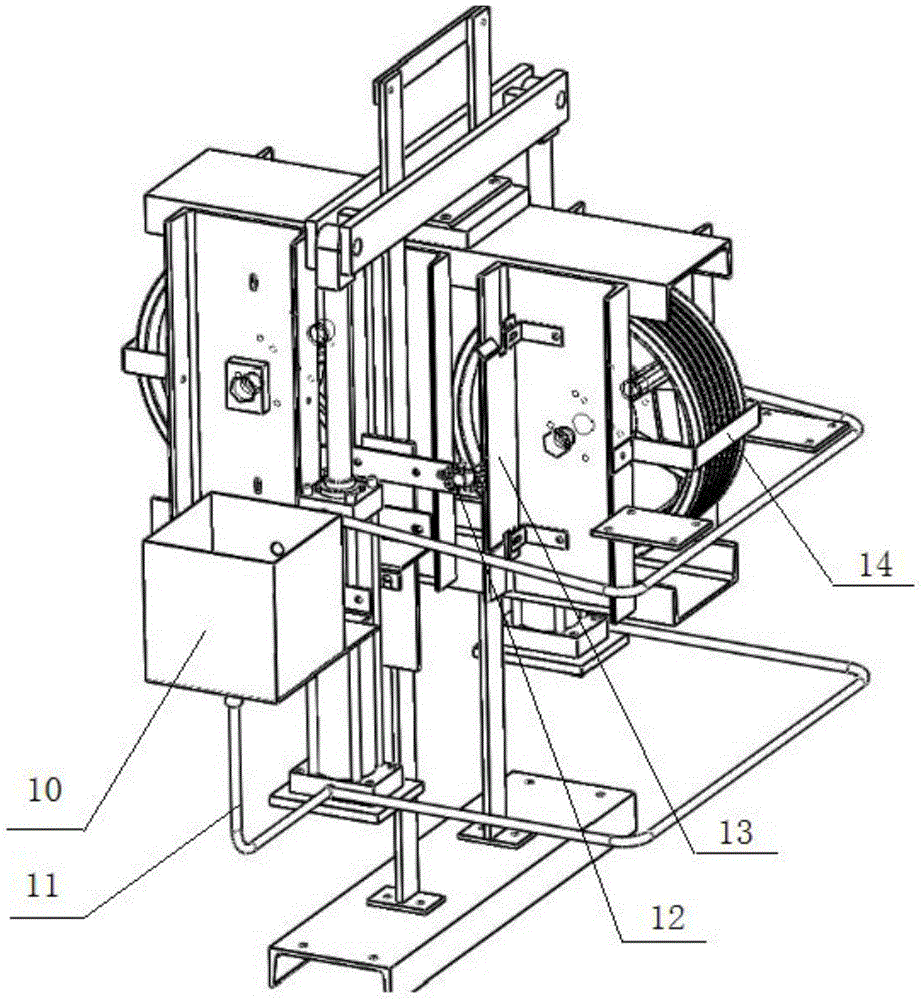

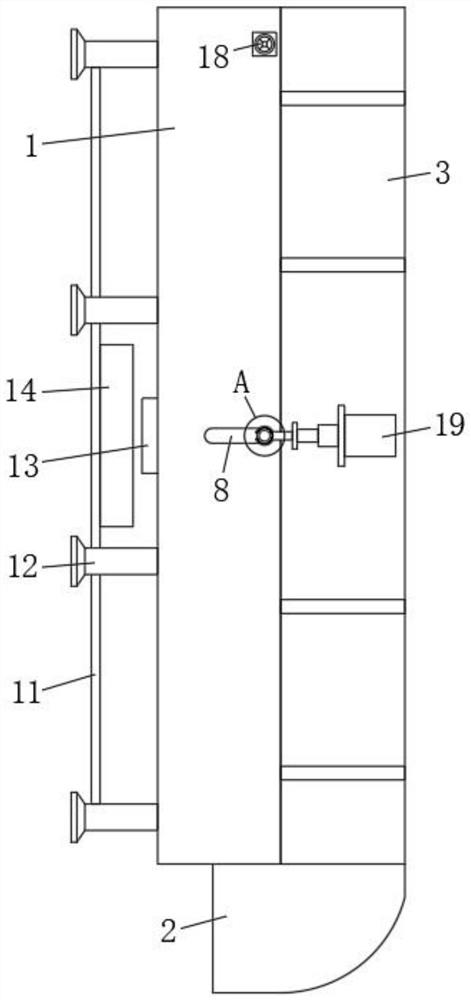

Tubular Stranding Machine for Wire Rope Production

ActiveCN113584915BAchieving tension adjustmentAchieve tractionRope making machinesBraced frameIndustrial engineering

The invention relates to the technical field related to the stranding machine, and discloses a tubular stranding machine for steel wire rope production, including a base of the tubular stranding machine and a supporting frame located on the base of the tubular stranding machine, the supporting frame The tension adjustment mechanism and the second traction assembly are respectively arranged on the top, and the second traction assembly includes a moving plate, a pressing block, a rope closing block and a vertical plate, and the vertical plate and the base of the tubular stranding machine pass through a third The sliding block is connected, the moving plate is arranged on the support frame, the moving plate is connected with the mounting plate through an electric push rod, and the mounting plate is slidably installed on the vertical plate through the sliding plate, the The rope closing block is rotatably connected to the vertical plate, and the pressing block is installed and fixed on the mounting plate; the present invention effectively solves the tension adjustment problem of the steel wire rope through the cooperation of the provided tension adjustment mechanism and the second traction assembly .

Owner:南通市海力钢绳有限公司

Bridge expansion joint with sweeping mechanism

ActiveCN106835968AExtended run timeAchieving tension adjustmentBridge structural detailsSurface layerBristle

Provided is a bridge expansion joint with a sweeping mechanism. A sweeping belt is arranged at the bottom of a V-shaped water stopping belt between beams, a driving shaft is arranged in a central hole of a belt wheel, one end of the driving shaft is connected to an output shaft of a gear box, and an input shaft of the gear box is connected to a motor. A screw is arranged on a movable bearing seat and is inserted into the top of a wheel support, the distance between the movable bearing seat and a shaft base can be adjusted by turning a nut on a screw, and tension adjustment of the sweeping belt is achieved. Two hinges are arranged at the bottom of a U-shaped shifting fork, the other end of each connecting rod on the same side is hinged to an installing base together to form a parallel four-connecting-rod mechanism, and the shifting fork can be pulled from a belt wheel or a driven belt wheel to the V-shaped water stopping belt regardless of any change of a separation distance of two side beams. The sweeping belt is provided with a bottom layer and a surface layer, the surface layer is provided with soft bristles arranged in an array mode, and a bristle brush belt is formed on the sweeping belt. Dust on the V-shaped water stopping belt can always reach an allowable range through cleaning of the sweeping belt, and the purposes of shortening maintenance time and increasing the operation time of the expansion joint are achieved.

Owner:铁木辛柯(浙江)金属结构有限公司

Auxiliary device for enameled wire winding

The invention belongs to the technical field of enameled wire production, and particularly relates to an auxiliary device for enameled wire winding. The auxiliary device is characterized in that the auxiliary device comprises a base and a winding roller, the outer wall of the top of the base is fixedly connected with two fixing plates, the outer walls of the opposite sides of the two fixing plates are fixedly connected with guide rails, and the inner walls of the two guide rails are slidably connected with sliding blocks. By arranging a first air cylinder, an extrusion plate, a limiting telescopic rod, an adaptive spring and a strip-shaped extrusion arc rod, when a motor drives a winding roller to conduct winding operation of an enameled wire, the first air cylinder is adjusted to drive the strip-shaped extrusion arc rod on the extrusion plate to make contact with the enameled wire, the adaptive spring drives the strip-shaped extrusion arc rod to extrude the enameled wire, so that all layers of the enameled wire are in perfect fit, the winding effect is improved, the adaptive spring drives the strip-shaped extrusion arc rod to extrude the enameled wire, so that the enameled wire is prevented from being damaged due to excessive extrusion, and the enameled wire is protected.

Owner:TONGLING JINGDA SPECIAL MAGNET WIRE CO LTD

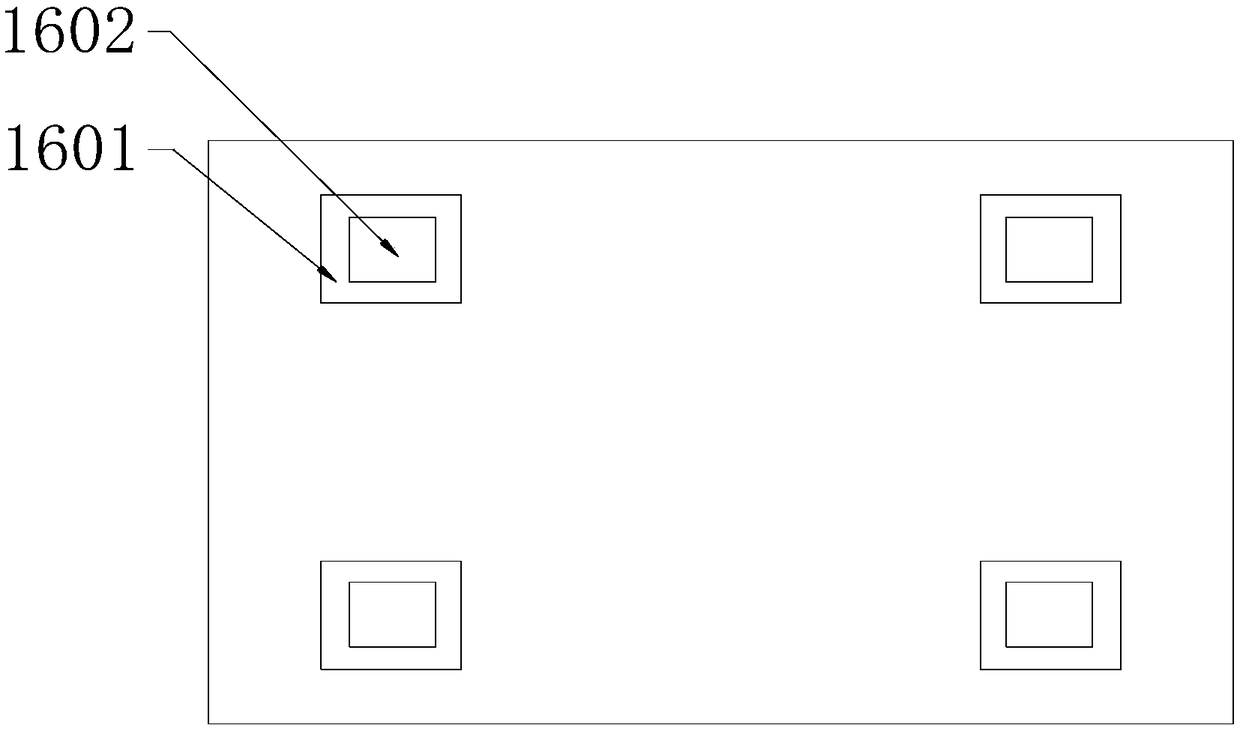

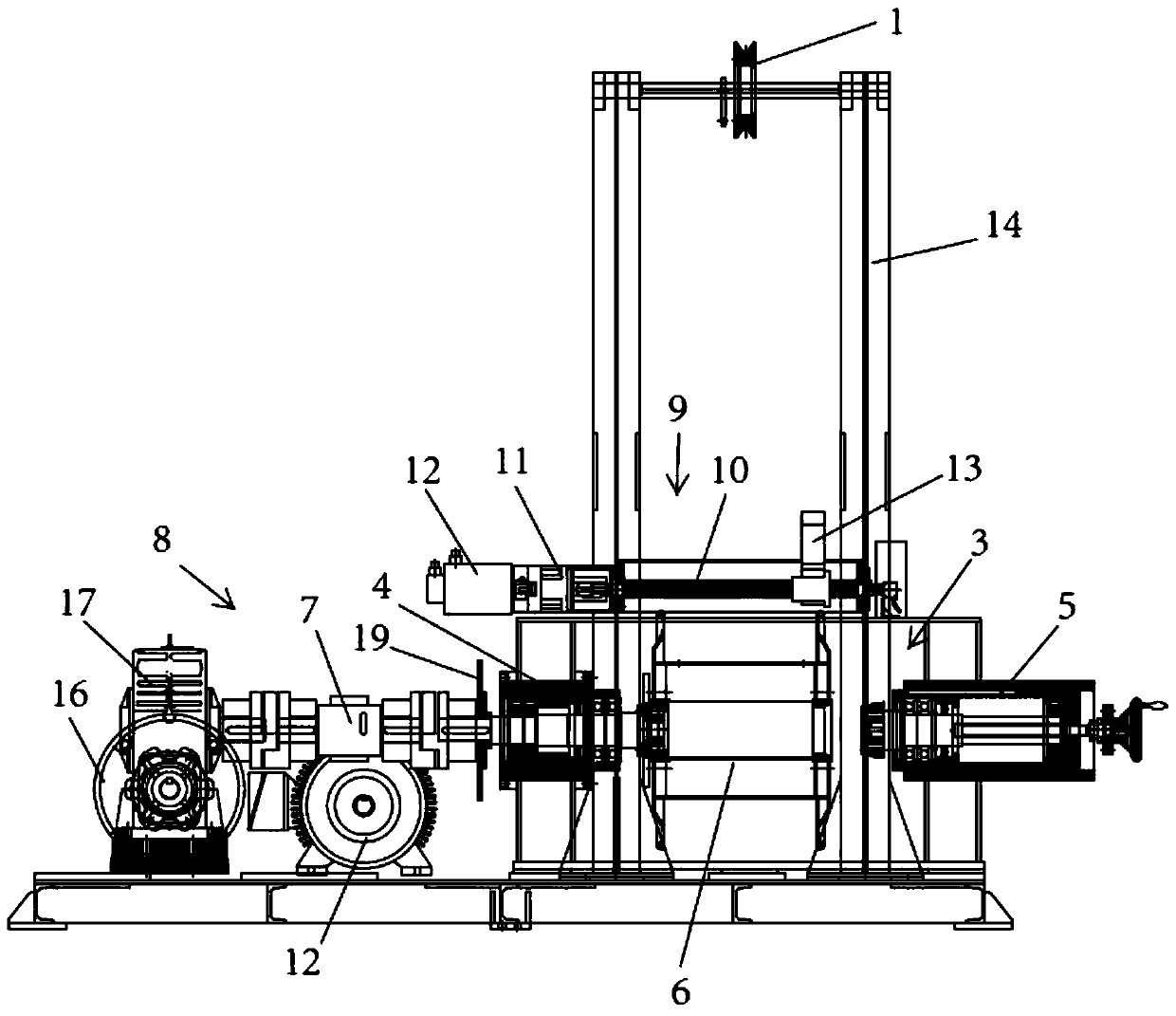

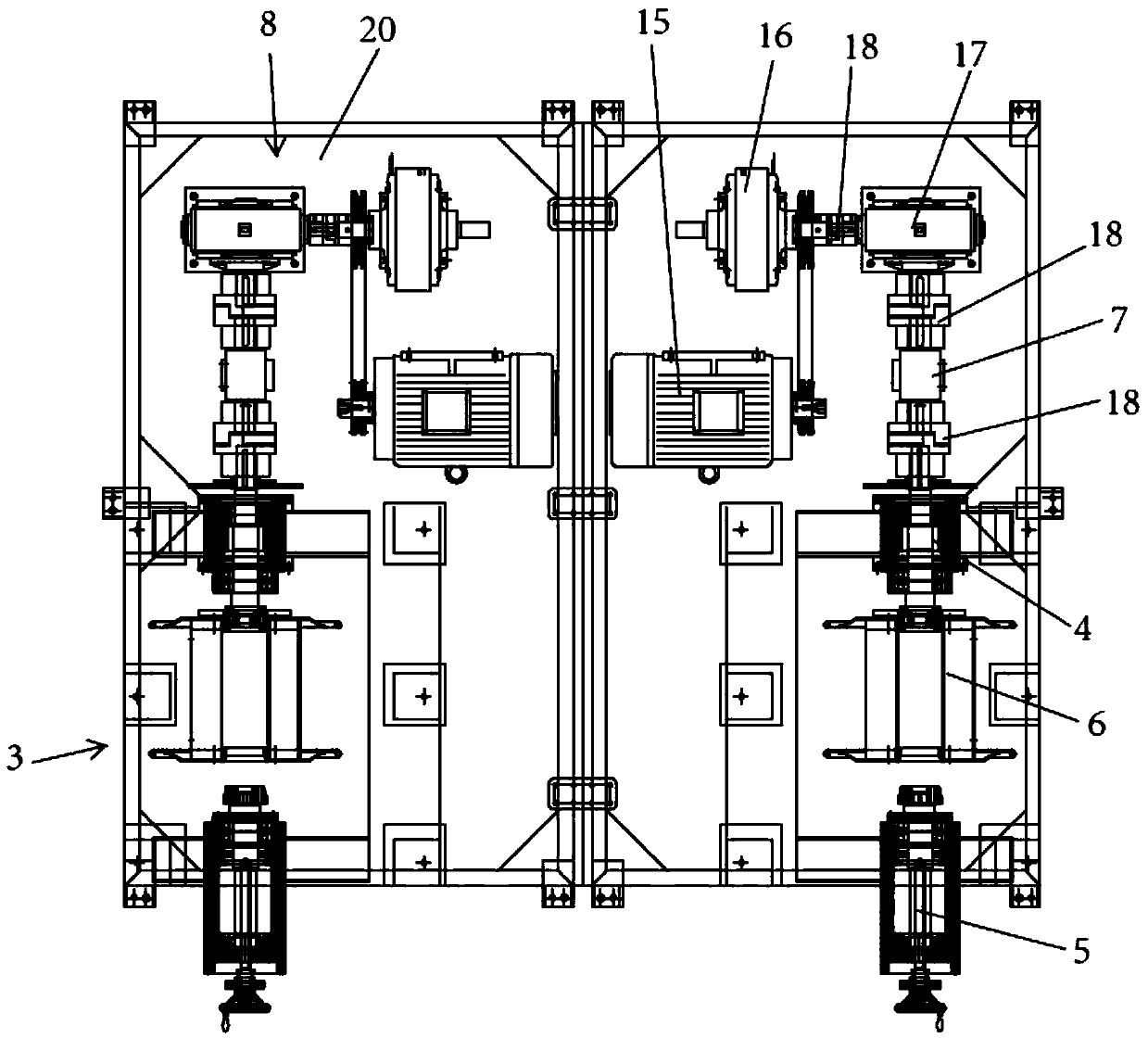

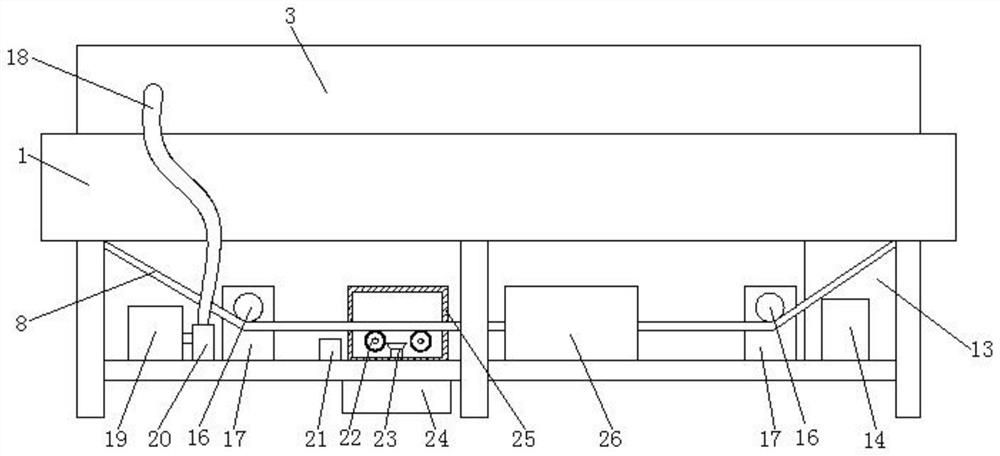

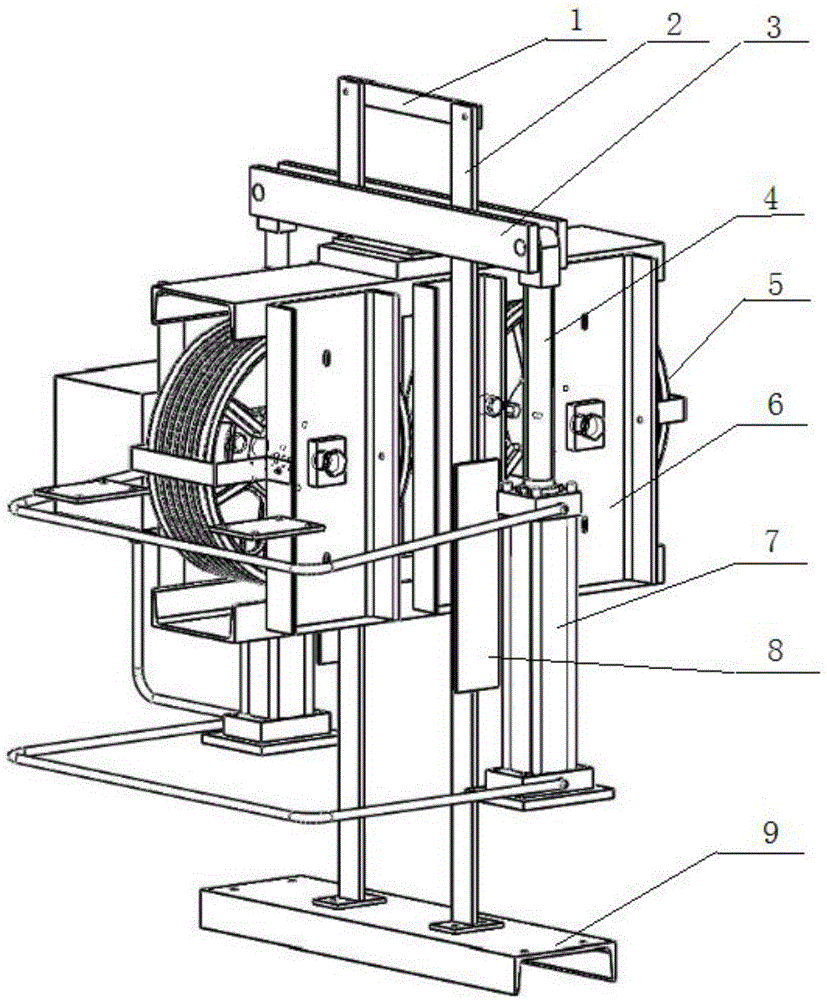

Double-tensioning-wheel tensioning device for compensating rope

InactiveCN106276490AAvoid swingingAchieving tension adjustmentElevatorsHydraulic cylinderEngineering

The invention relates to a double-tensioning-wheel tensioning device for a compensating rope. The double-tensioning-wheel tensioning device is characterized in that the double-tensioning-wheel tensioning device comprises a fixing rack, a lifting mechanism, compensating rope tensioning wheels and a tensioning wheel frame; the fixing rack comprises an installing base, guiding rail racks and a limiting rod, wherein the guiding rail racks are on the two sides of the fixing rack, and the limiting rod is on the top of the fixing rack; the lifting mechanism comprises a hydraulic cylinder installing base, symmetrical hydraulic cylinders and a lifting transverse beam driven by pushing rods of the hydraulic cylinders; the two compensating rope tensioning wheels are arranged in the tensioning wheel frames front and back; the top of the tensioning wheel frame is arranged below the lifting transverse beam; and guiding shoes on the two sides of the tensioning wheel frame are operationally installed on the guiding rail racks of the fixing rack correspondingly. The double-tensioning-wheel tensioning device for the compensating rope is scientific and reasonable in structure design, achieves jumping and swinging of the compensating rope, meanwhile, has a safety protection function, largely improves the operating safety of an elevator, and is the highly creative double-tensioning-wheel tensioning device for the compensating rope.

Owner:SIGNOR ELEVATOR

Flocking technology with anti-deviation structure

PendingCN111644350ASpread evenlyAchieving tension adjustmentLiquid surface applicatorsCoatingsElectric machineryDrive motor

The invention discloses a flocking technology with an anti-deviation structure. The flocking technology comprises a winding roller, a workbench, a base and a driving motor; the winding roller is arranged at the top end of the workbench; and the base is placed at the bottom end of one side of the workbench. According to the flocking technology, a driving motor is started, cloth is pulled out by thewinding roller and placed on a conveyor belt for a flocking process, the driving motor rotates to drive the conveyor belt to operate, the cloth moving on the conveyor belt is gummed firstly by a rubber roller; however, if the rubber roller is not completely contacted with the cloth, the gumming effect is poor, and a poor flocking effect is caused. Therefore, in order to avoid this, the rubber roller is designed flexibly. The rubber roller is placed on fixed seats by rotating shafts at the two ends, U-shaped guide rails are designed on the surfaces of the fixed seats, the rotating shafts are placed in the U-shaped guide rails, and height adjustment is carried out in cooperation with limiting springs at the bottoms of the rotating shafts, so that the flexibility of the rubber roller is higher, and then the stress area between the rubber roller and the cloth is adjusted.

Owner:昆山优杰工业设备有限公司

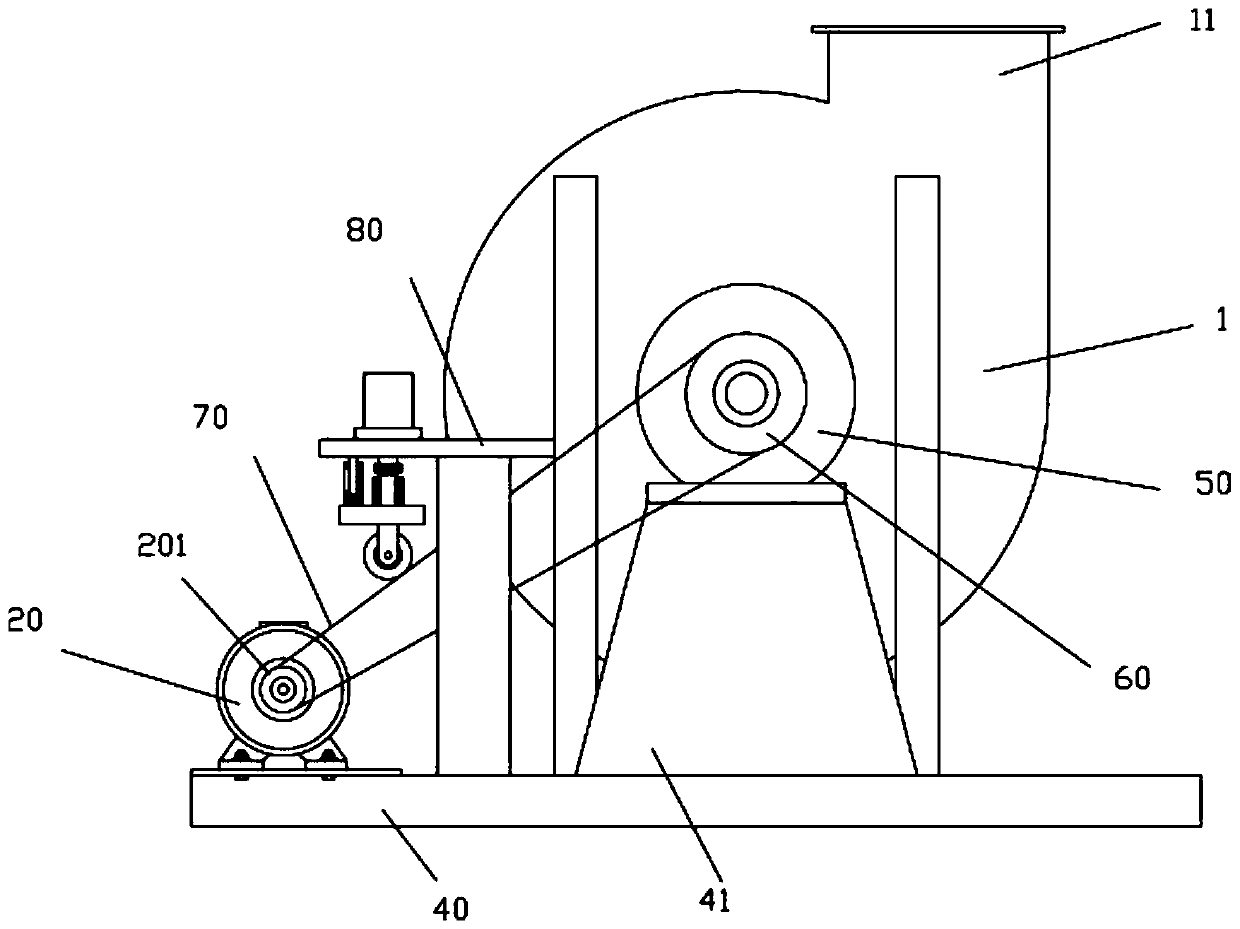

Passive hydraulic self-balancing adjusting and controlling device

ActiveCN101776134AAchieving tension adjustmentSimple structureConveyorsGearingCylinder blockControl theory

In order to solve the problem that a plurality of belts or chains are not evenly stressed at the same time in the tensioning process, the invention provides a passive hydraulic self-balancing adjusting and controlling device. The technical scheme adopted by the invention is as follows: (1) a group of cylinder tubes are arranged on the same cylinder body of the passive hydraulic self-balancing adjusting and controlling device, pistons and piston rods are arranged in the cylinder tubes; one end of each piston rod is connected with each piston inside the cylinder tube, and the other end of each piston rod is connected with an adjusting and controlling support outside the cylinder tube; (2) an adjusting and controlling wheel is arranged on the adjusting and controlling support; and (3) the other sides of the pistons for mounting the piston rods are communicated with each other among the group of cylinder tubes. The passive hydraulic self-balancing adjusting and controlling device of the invention has the advantages of simple structure and high practicability and provides guarantee for the continuous production of the follow-up station.

Owner:河北省机械科学研究设计院有限公司

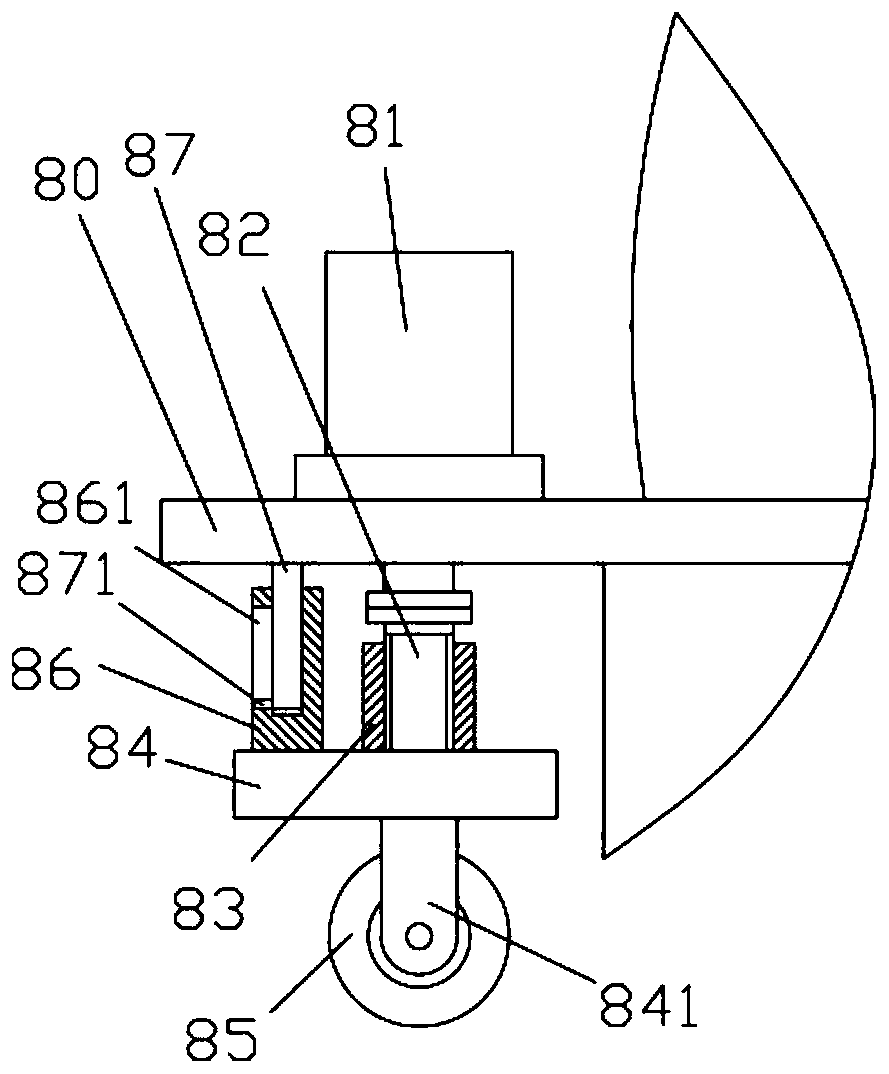

Dust discharge centrifugal ventilator with automatic adjusted tension

InactiveCN109931280AAchieving tension adjustmentEasy to adjustGearingPump installationsImpellerEngineering

The invention discloses a dust discharge centrifugal ventilator with automatic adjusted tension. The dust discharge centrifugal ventilator comprises a volute, a motor, a rotating shaft fixed with an impeller and a bottom support, wherein the volute is fixed on the bottom support, a gear box is fixed on the bottom support, one end of an output shaft of the gear box is connected with the rotating shaft through a coupler, an input shaft of the gear box is fixedly provided with a belt wheel, a transmission wheel is fixed on an output shaft of the motor, a belt is tensioned on the belt wheel and the transmission wheel, an adjusting support frame is fixed on the top surface of a main bottom plate of the bottom support, the top surface of a top plate of the adjusting support frame is fixedly provided with a pressing adjusting motor, an output shaft of the pressing adjusting motor penetrates through the bottom surface of a top plate of the adjusting support frame and is connected with a vertical adjusting screw rod through a coupler, a vertical adjusting screw sleeve is in threaded connection with the vertical adjusting screw rod, and a lifting plate is fixed at the bottom end of the vertical adjusting screw sleeve. According to the ventilator, the pressing adjusting motor operates to realize position adjustment of a pressing roller, then the tensioning degree of the belt can be adjusted, adjusting is convenient, and the effect is good.

Owner:SHENZHEN SENSELEADER TECH DEV CO LTD

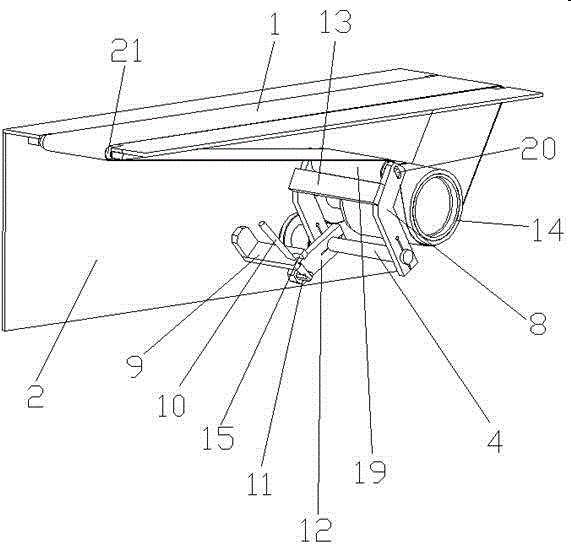

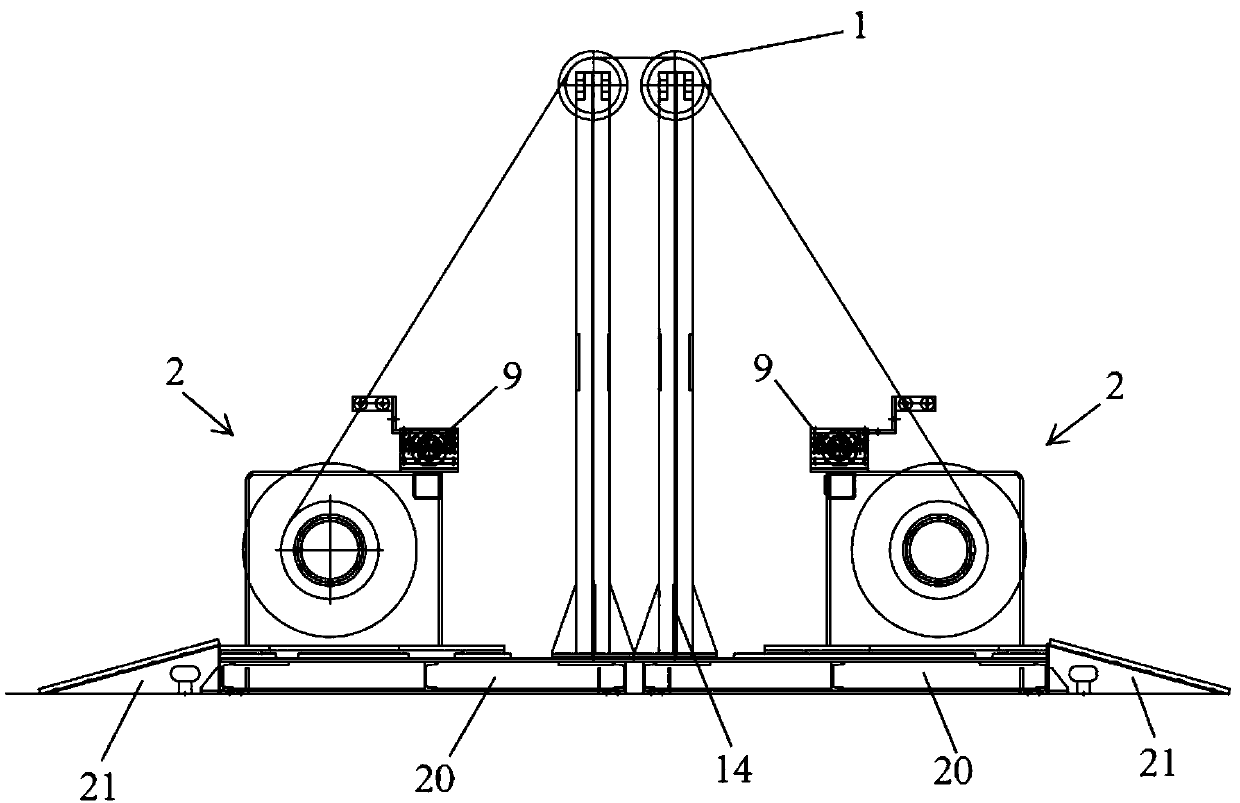

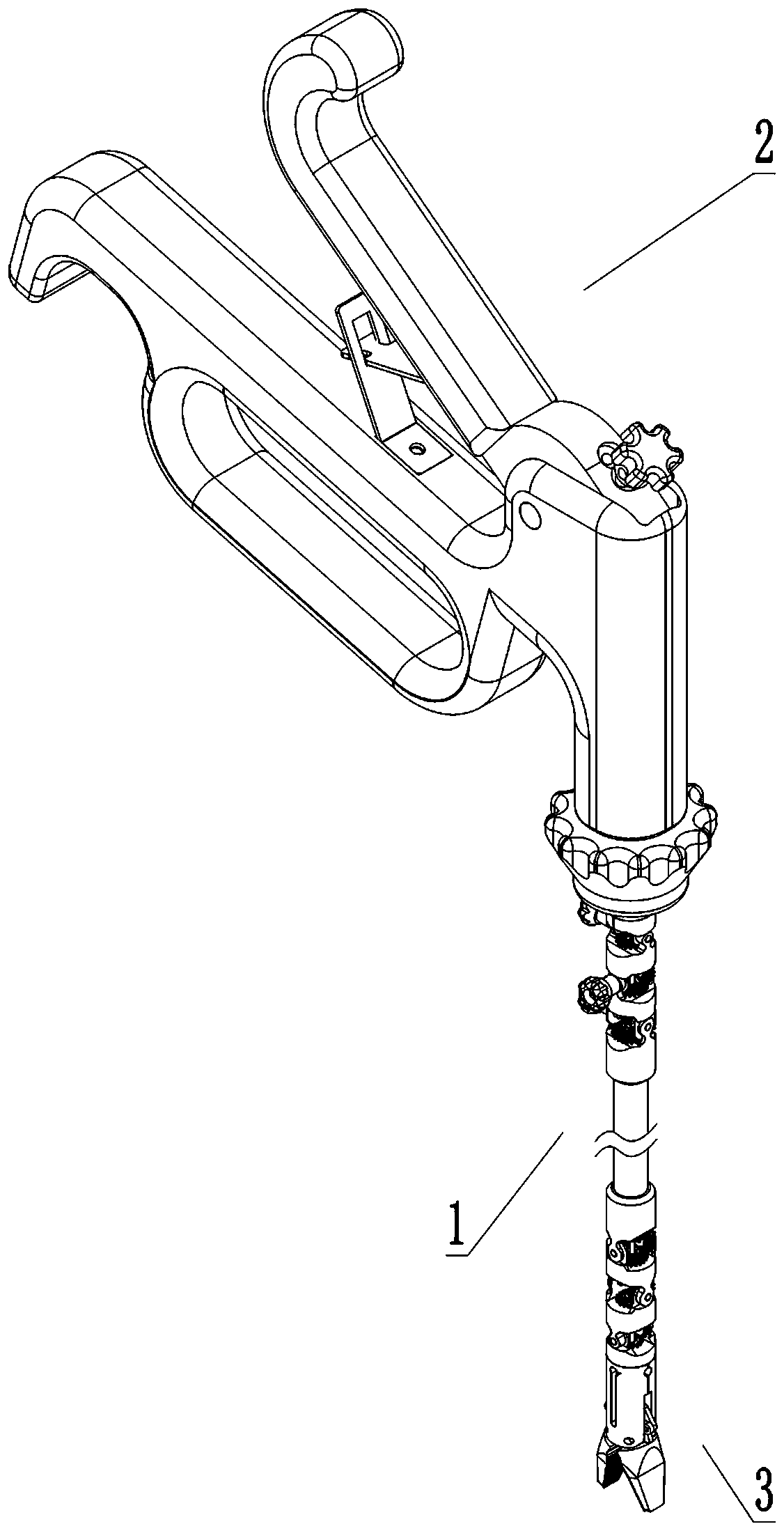

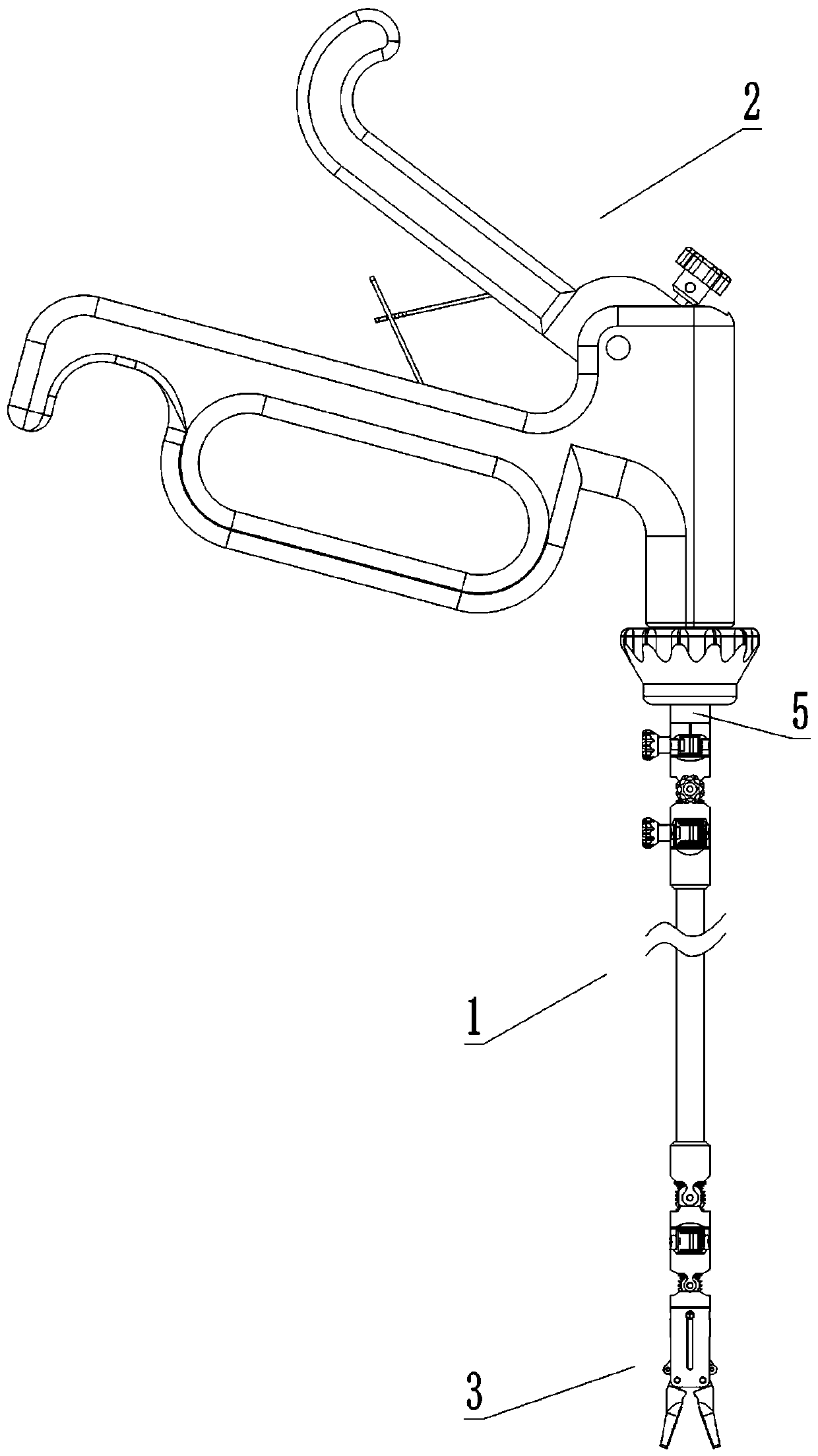

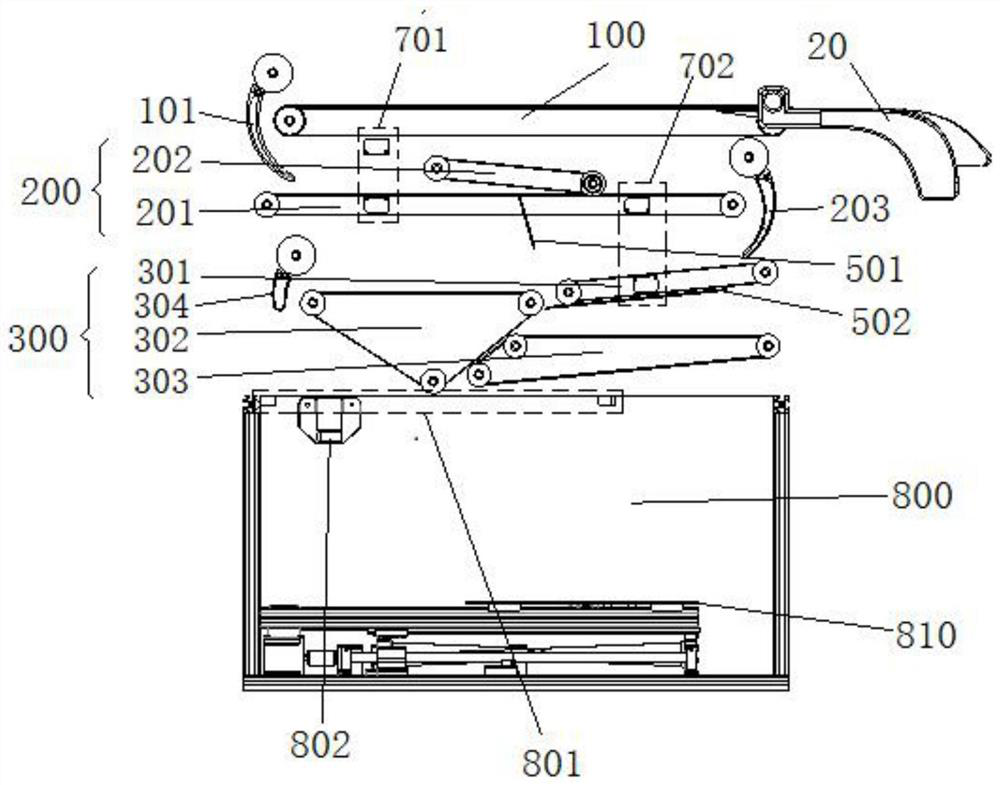

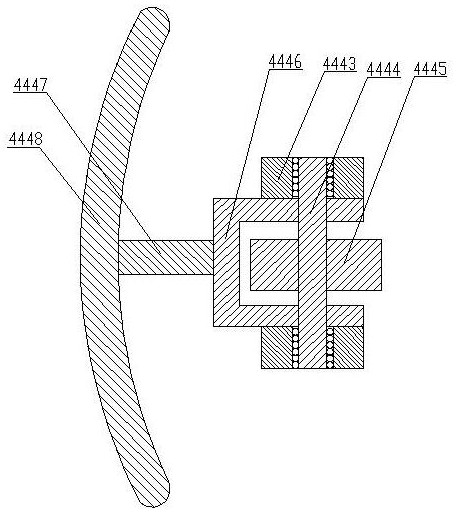

Handheld one-armed multi-degree-of-freedom laparoscope

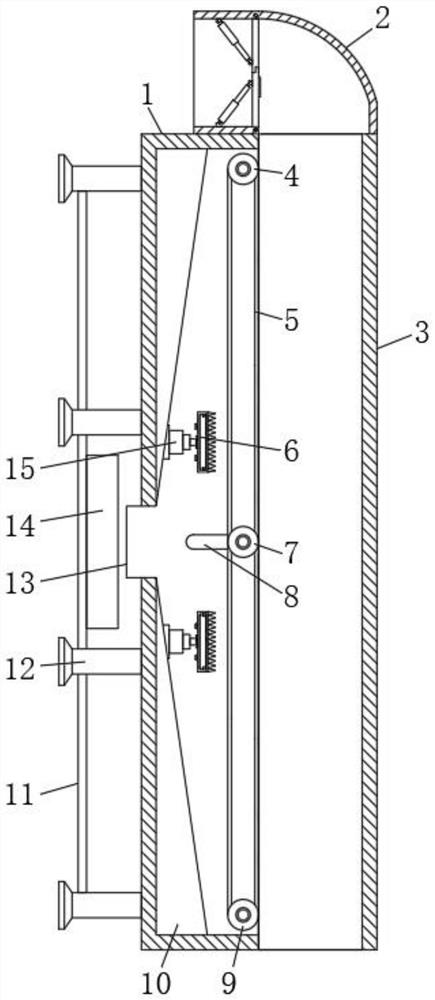

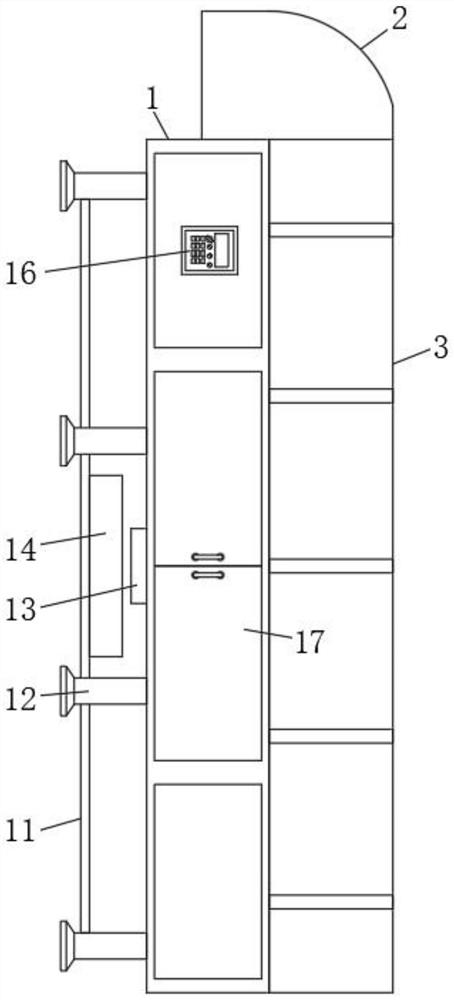

PendingCN110558929AReduce degrees of freedomReduced Locked Actuator Arm PoseLaproscopesForcepsSelf locking

The invention discloses a handheld one-armed multi-degree-of-freedom laparoscope. The laparoscope is characterized by comprising a pair of operating forceps, an operating mechanical arm and a handheldpart, wherein the operating mechanical arm comprises an executing arm and an operating arm. The handheld one-armed multi-degree-of-freedom laparoscope has the beneficial effects that each joint of the executing arm of the operating mechanical arm and each joint of the operating arm of the operating mechanical arm are in one-to-one correspondence, the operating arm and the executing arm are in running fit through a gear running mode. When the handheld one-armed multi-degree-of-freedom laparoscope is used, a user can manually operate the operating arm, the executing arm is synchronously drivenby the operating arm to act correspondingly, and manually direct copying operation can be realized; tension adjustment of a stay cord can be realized, so that stable and accurate control of the operating forceps can be favored; a worm gear has a self-locking function, and is reliable in tensioning; and the operating joints of the operating arm can be independently locked, and the degree-of-freedomof the executing arm or the executing arm locking posture can be reduced, so that subsequent operation of an operator can be facilitated, and the probability of misoperation of the operator can be greatly reduced.

Owner:BEIJING XIANJIN ROBOT CO LTD

Tension mechanism for hot galvanizing colorful coating plate production

The invention discloses a tension mechanism for hot galvanizing colorful coating plate production, comprising a left side plate, a right side plate, a base, a speed reducing motor, a guide roller I and a guide roller II; the left side plate is opposite to the right side plate; the bottoms of the left side plate and the right side plate are fixed on the base; an installing slot is formed on the left side plate; a driving bevel gear is installed in the middle of the installing slot; the driving bevel gear is connected with the speed reducing motor by a coupler; a bevel gear I and a bevel gear IIwhich are in engaging drive with the driving bevel gear are respectively arranged at the upper and lower positions of the driving bevel gear; the bevel gear I and the bevel gear II are respectively fixed and installed at the axial ends of a screw rod I and a screw rod II; and the screw rod I and the screw rod II are installed in the installing slot through a screw rod installing base. The tensionmechanism for hot galvanizing colorful coating plate production provided by the invention has the following beneficial effects: the opposite movement of the guide roller I and the guide roller II isrealized through the engaging effect of the gear and the drive effect of the screw rod pair so as to realize regulating of the tension of the galvanizing sheet strip; and the speed reducing motor is adopted for driving, so the tension regulation of the galvanizing sheet strip can be conveniently realized.

Owner:阜阳力佳门业有限公司

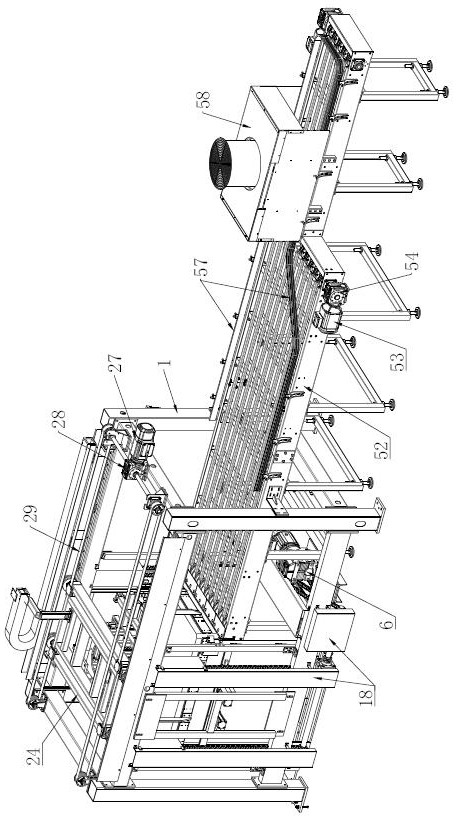

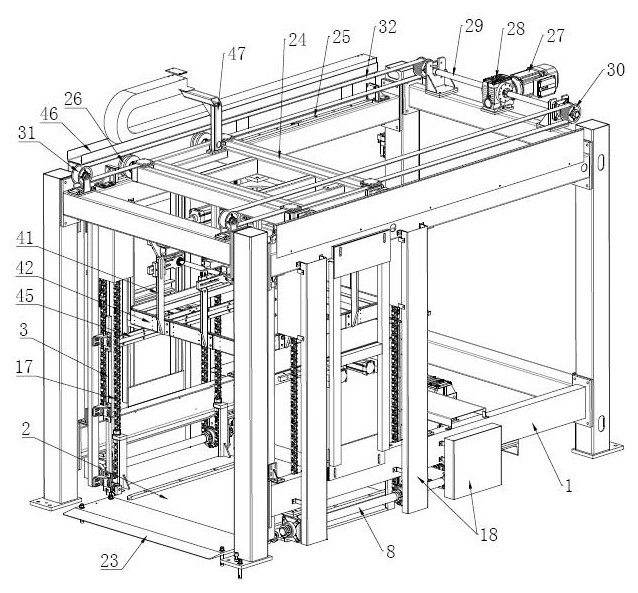

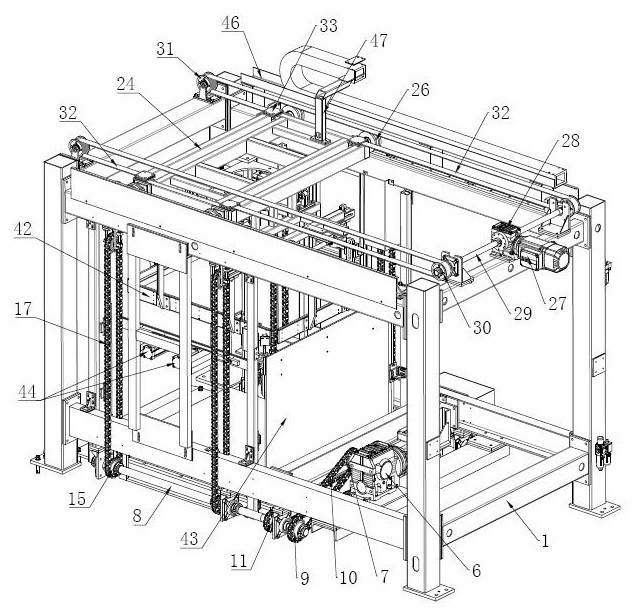

A horizontal push type automatic unstacking device

ActiveCN111559649BReduce labor costsReduce labor intensityConveyorsDe-stacking articlesBottleChain drive

The invention belongs to the technical field of glass bottle production, and provides a flat-push automatic depalletizing device, which includes a depalletizing machine and a bottle conveying machine; The supporting plate driven by the first driving device is slid and installed in the vertical direction, and the bottle pushing rack driven by the second driving device is slid and installed on the top of the unstacking frame along the horizontal direction. The position is fixed and the baffle plate is installed, and the two sides of the unstacking frame are respectively equipped with clamping mechanisms; the bottle conveyor includes a conveyor frame, and the conveyor frame is wound with a conveyor plate chain driven by a third drive device. One end of the rack is positioned against the baffle, flush with the top of the baffle. The horizontal pushing depalletizing method adopted by the present invention can directly push the entire layer of glass bottles to the bottle conveying machine for transportation. Compared with the traditional manual depalletizing method, it not only saves labor costs, but also greatly reduces labor intensity, and the work Efficiency is greatly improved.

Owner:山东三江智能装备有限公司

Clothes folding machine

PendingCN114056857AAchieving tension adjustmentExtended service lifeConveyorsFolding thin materialsEngineeringIndustrial engineering

The invention discloses a clothes folding machine. The clothes folding machine comprises conveying devices used for driving clothes to be folded to move and be folded, and tensioning adjusting mechanisms which are arranged on the conveying devices and used for adjusting the tensioning degree of conveying belts on the conveying devices. Compared with the prior art, the clothes folding machine has the following beneficial effects that the conveying devices are provided with the multiple conveying belts, tensioning adjustment of the conveying belts is achieved by arranging the tensioning adjusting mechanisms on the conveying devices, the structure is simple, operation is convenient, and the service lives of the belts can be prolonged.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

Intelligent conveying equipment for straw biogas engineering

InactiveCN113443392AAchieve cleanupAvoid damageConveyorsCleaningProcess engineeringIndustrial engineering

The invention discloses intelligent conveying equipment for straw biogas engineering, and relates to the technical field of biogas engineering, the intelligent conveying equipment for straw biogas engineering comprises a rack, a conveying mechanism and a brushing mechanism which are arranged in the rack, and an intelligent quantitative discharging mechanism and a controller which are arranged on the rack; the brushing mechanism comprises a brushing assembly, an adjusting assembly and a mounting assembly for connecting the brushing assembly with the adjusting assembly, the adjusting assembly is used for adjusting the position of the brushing assembly, and the brushing assembly is used for cleaning the conveying mechanism; and the conveying mechanism comprises a conveying assembly and a tension adjusting assembly, the conveying assembly can be cleaned, chippings can be prevented from remaining on the conveying assembly, the conveying assembly is prevented from being damaged, normal use of the conveying assembly is facilitated, rapid conveying of straw can be achieved, the service life of the conveying assembly can be prolonged, and the use cost of the intelligent conveying equipment is reduced.

Owner:张培全

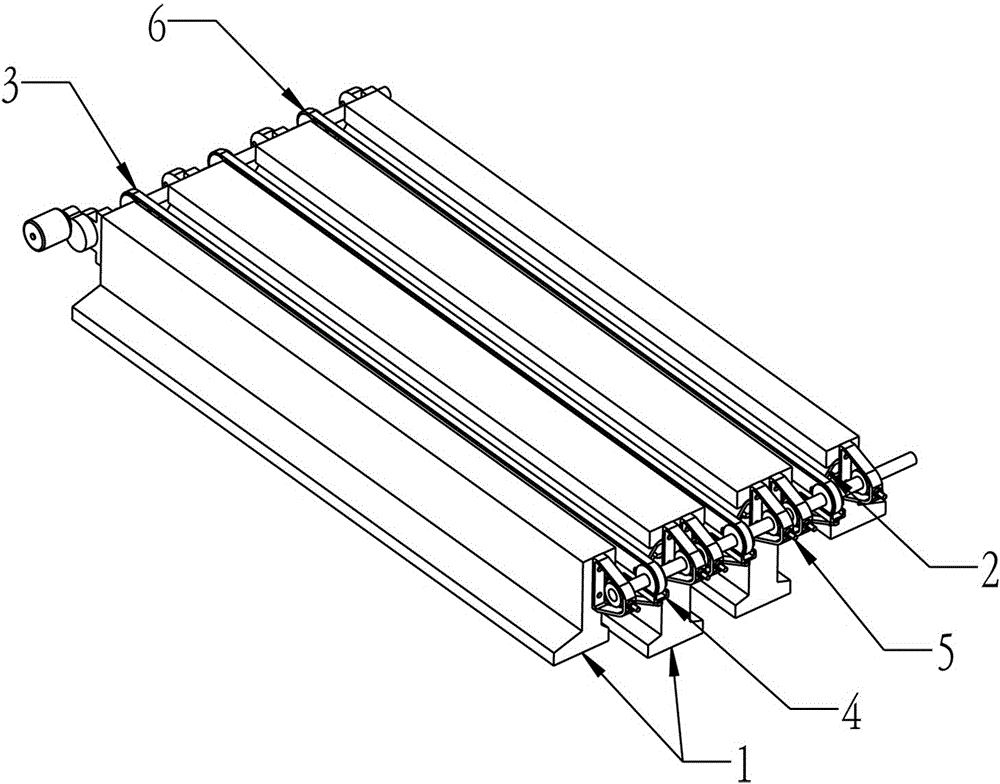

Roving frame upper and lower dragon rib spindle belt transmission device and roving frame

The invention provides an upper and lower spindle rail tape transmission device for roving frames and a roving frame, the upper and lower spindle rail tape transmission device comprises a plurality ofupper rail plate portions and a plurality of lower rail plate portions; each of the upper rail plate portions and the lower rail plate portions is provided with a transmission structure. Each transmission structure comprises a servo motor, a spindle tape, a friction disc mechanism and a tensioning wheel mechanism, wherein the spindle tape connects the servo motor, the friction disc mechanism andthe tensioning wheel mechanism in series. According to the upper and lower spindle rail tape transmission device herein, the servo motor is used for variable-speed driving, a flyer and a friction discon a bobbin are driven through tape serial driving, the problems of abrasion of gear transmission and damage of synchronous belt transmission are solved, and the spindle speed can reach 2000 r / min. The tensioning wheel mechanism is also provided such that tension adjustment of the spindle tape is achieved. The upper and lower spindle rail tape transmission device is simple in structure, high in transmission speed and convenient to install and maintain, and meets the trend that the spindle speed of the roving frame is developed to a high level.

Owner:CMT HICORP MACHINERY QINGDAO +1

timing belt tensioner

ActiveCN106352017BAchieving tension adjustmentSimple structureBelt fasteningsElectrical and Electronics engineering

The invention discloses a synchronous belt tensioning device. The synchronous belt tensioning device is formed by two clamping blocks, and the two clamping blocks are connected through bolts; the clamping blocks comprise first clamping plates and second clamping plates; the first clamping plates are in T shapes, bolt adjusting holes are formed in the two ends of transverse parts of the first clamping plates and used for containing the bolts; a plurality of installing holes are formed in the two ends of longitudinal parts of the first clamping plates respectively, the first clamping plates are fixedly connected with a carrying table through the installing holes, grooves for containing a synchronous belt are formed in the middles close to the side faces of the second clamping plates, and a plurality of first connecting holes are also formed in the two ends of the side faces respectively; a plurality of tooth grooves for containing synchronous-belt racks are arranged at the portions, close to the side faces of the first clamping plates, of the second clamping plates respectively, a plurality of second connecting holes are also formed in the two ends of the second clamping plates respectively and correspond to the first connecting holes. By means of the synchronous belt tensioning device, tensioning adjusting of the synchronous belt installed behind a lifting machine can be achieved, and tensioning adjusting of the synchronous belt installed after a lifting machine can also be achieved.

Owner:JIANGSU HUAZHANG LOGISTICS TECH CO LTD

Preparation method of release-paper-free adhesive film wall cloth

PendingCN114454589AImprove aestheticsMoisture-proofCovering/liningsPolyureas/polyurethane adhesivesWoven fabricPolymer chemistry

The invention relates to a preparation method of release-paper-free adhesive film wall cloth. The preparation method comprises the following steps: S1, preparing a hot melt adhesive film; s2, selecting a wall cloth base material: preparing figured cloth and spun-bonded non-woven fabric, taking the figured cloth as a wall cloth fabric, and taking the spun-bonded non-woven fabric as a wall cloth base; s3, positioning the wall cloth compounding device; s4, positioning a wall cloth base material; and S5, leveling treatment is carried out. The device has the following advantages that the production quality and the yield of the composite wall cloth are guaranteed, the composite defects of internal bulging, bar marks, wrinkles and the like of the composite wall cloth are avoided, tension adjustment of the wall cloth fabric, the wall cloth substrate and the hot melt adhesive film can be synchronously achieved, and the adjustment efficiency is improved.

Owner:江苏惠沣环保科技有限公司

Single-hand control device of hand-cranked wheelchair

ActiveCN104887411AAchieving tension adjustmentEasy to adjustWheelchairs/patient conveyanceWheelchairTransmission belt

The invention discloses a single-hand control device of hand-cranked wheelchair. The single-hand control device comprises a crank handle and a front wheel, and is characterized by further comprising a steering shaft, a front wheel frame, two threaded casings, two supporting screws, two driving belt pulleys, a driven belt pulley and two transmission belts assembled on the driving belt pulleys and the driven belt pulley in a surrounding manner, wherein the crank handle is a U-shaped crank handle; the steering shaft is arranged vertically, and the lower end of the steering shaft is fixedly connected with the front wheel frame; the driven belt pulley is rotationally supported on the front wheel frame, and rotates along with the front wheel coaxially and synchronously; the two threaded casings are vertically and symmetrically connected to the front wheel frame; the lower ends of the two supporting screws are in threaded connection with the threaded casings, respectively; supporting seats are arranged at the upper ends of the supporting screws, respectively; both ends of the U-shaped crank handle arranged inside the two threaded casings are transversely and rotationally supported in the supporting seats, respectively; the driving belt pulleys are assembled on the end parts of both ends of the U-shaped crank handle arranged outside the two threaded casings in a non-rotating manner, and rotate along with the U-shaped crank handle coaxially and synchronously. The single-hand control device is reasonable in structure, low in production cost and easy to control.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

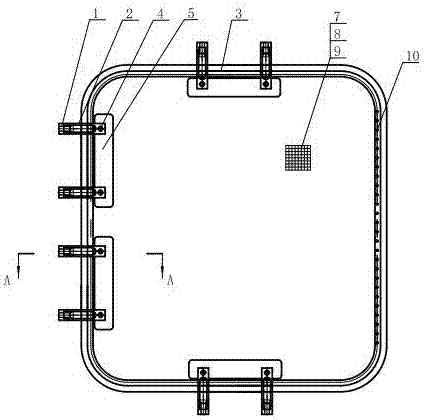

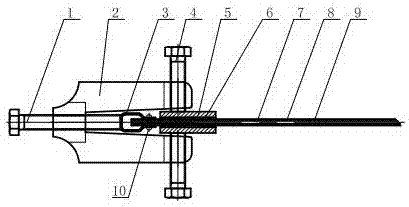

Filter panel screen tensioning tooling

ActiveCN105999820BPrevent crushingAchieving tension adjustmentMembrane filtersFiltration separationEngineeringFriction force

Owner:JIANGSU JUNENG MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com