Continuous web feeding system

A paper feeding system and roll paper technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of large energy consumption, increased production costs, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

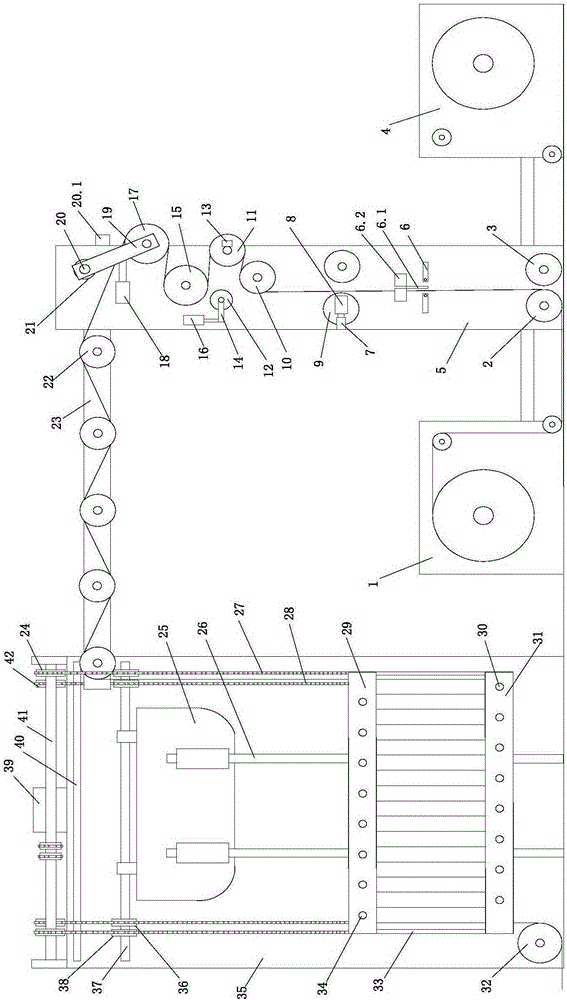

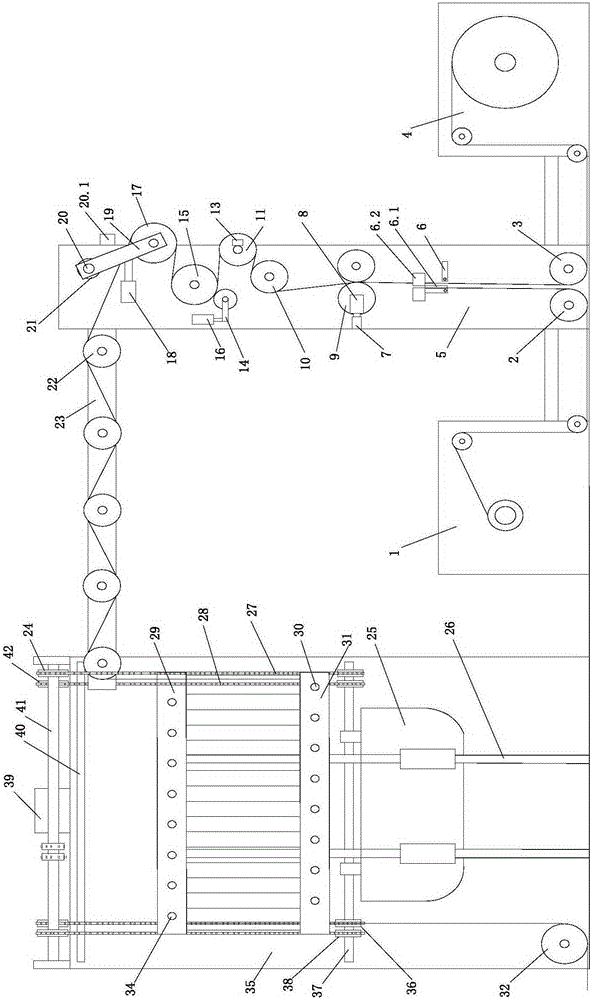

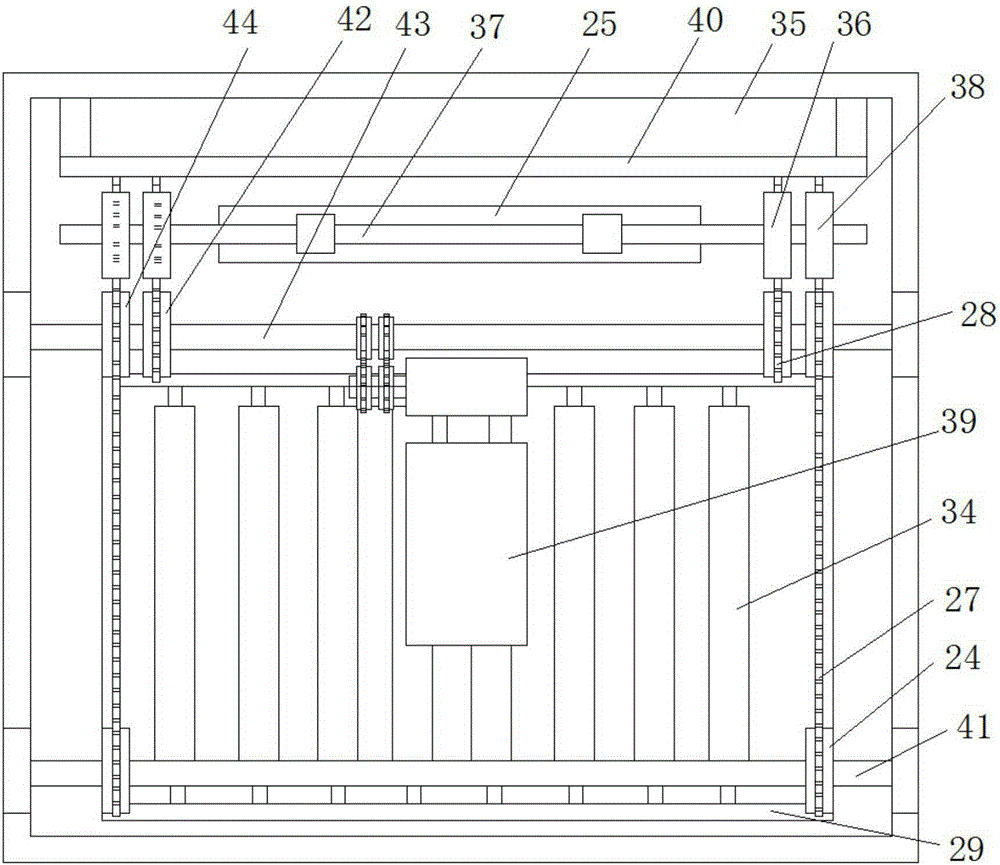

[0033] Such as figure 1 As shown, a continuous web feeding system includes a first paper feeder 1, a second paper feeder 4, a paper storage box 35, a first traction roller 15, a second traction roller 32, a paper gate 5, The central controller and the rectangular frame-shaped paper-passing suspension 23, the paper-passing door frame 5 are fixed vertically on the ground, and the first paper feeder 1 and the second paper feeder 4 are fixedly arranged on the paper-passing door frame 5 respectively. On the ground on the inner and outer sides, the first paper feeder 1 and the second paper feeder 4 are controlled by the central controller. The output end of the paper machine 4 is respectively rotatably connected with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com