Filter panel screen tensioning tooling

A tooling and plate surface technology is applied in the field of filter plate surface mesh tensioning tooling, which can solve the problems of easy formation of wrinkles and difficulty in tensioning the filter surface mesh, and achieve the effects of improving friction, prolonging service life, and being flexible and convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

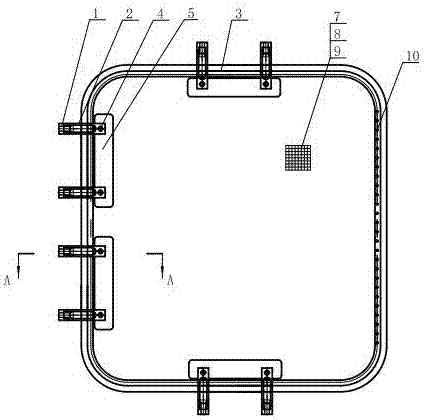

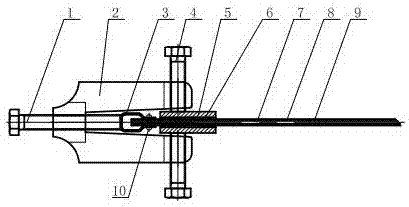

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 , figure 2 As shown, the tension seat 2 of the present invention is a jaw structure with one end fixed and the other end open, and a tension bolt 1 is horizontally arranged at the fixed end, and the external thread of the tension bolt 1 is connected to the horizontal screw hole at the fixed end of the tension seat 2. internal threads engage. A compression bolt 4 is vertically arranged at the opening end, and the external thread of the compression bolt 4 is engaged with the internal thread of the vertical screw hole at the opening end of the tension seat 2 . A pressing plate 5 and a liner 6 are arranged at the end of the hold-down bolt 4, the pressing plate 5 is preferably a metal plate, and the material of the liner 6 can be selected from materials such as cloth, fiber rubber plate, etc., which have relatively hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com