Servo bottle cap screwing mechanism

A servo-type, servo-motor technology, applied in the field of servo-type bottle cap tightening mechanism, can solve problems such as lubrication leakage, unfavorable sanitation and safety, and inability to remove, and achieve precise control of capping torque and speed, high degree of automation, and adjustable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

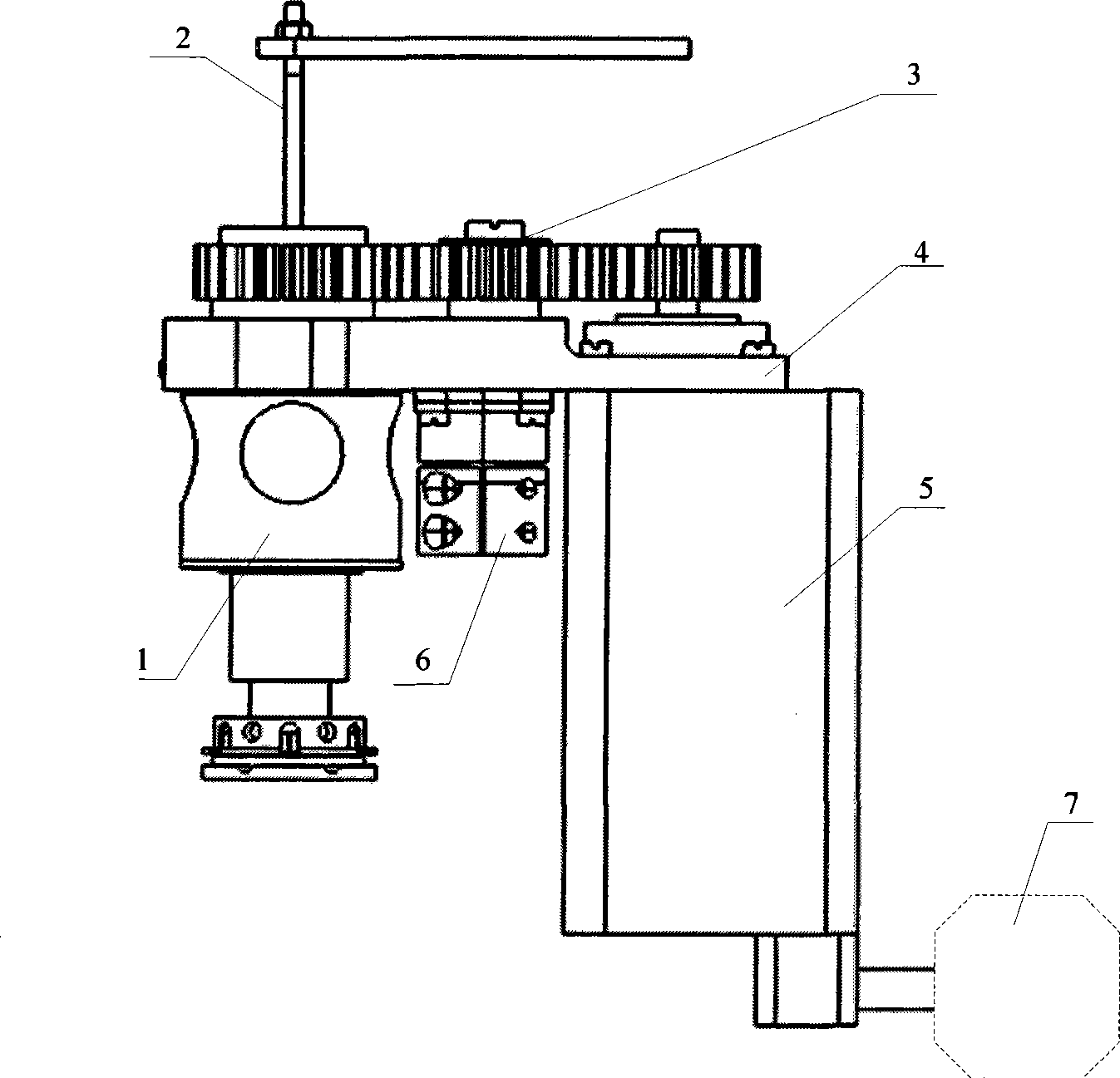

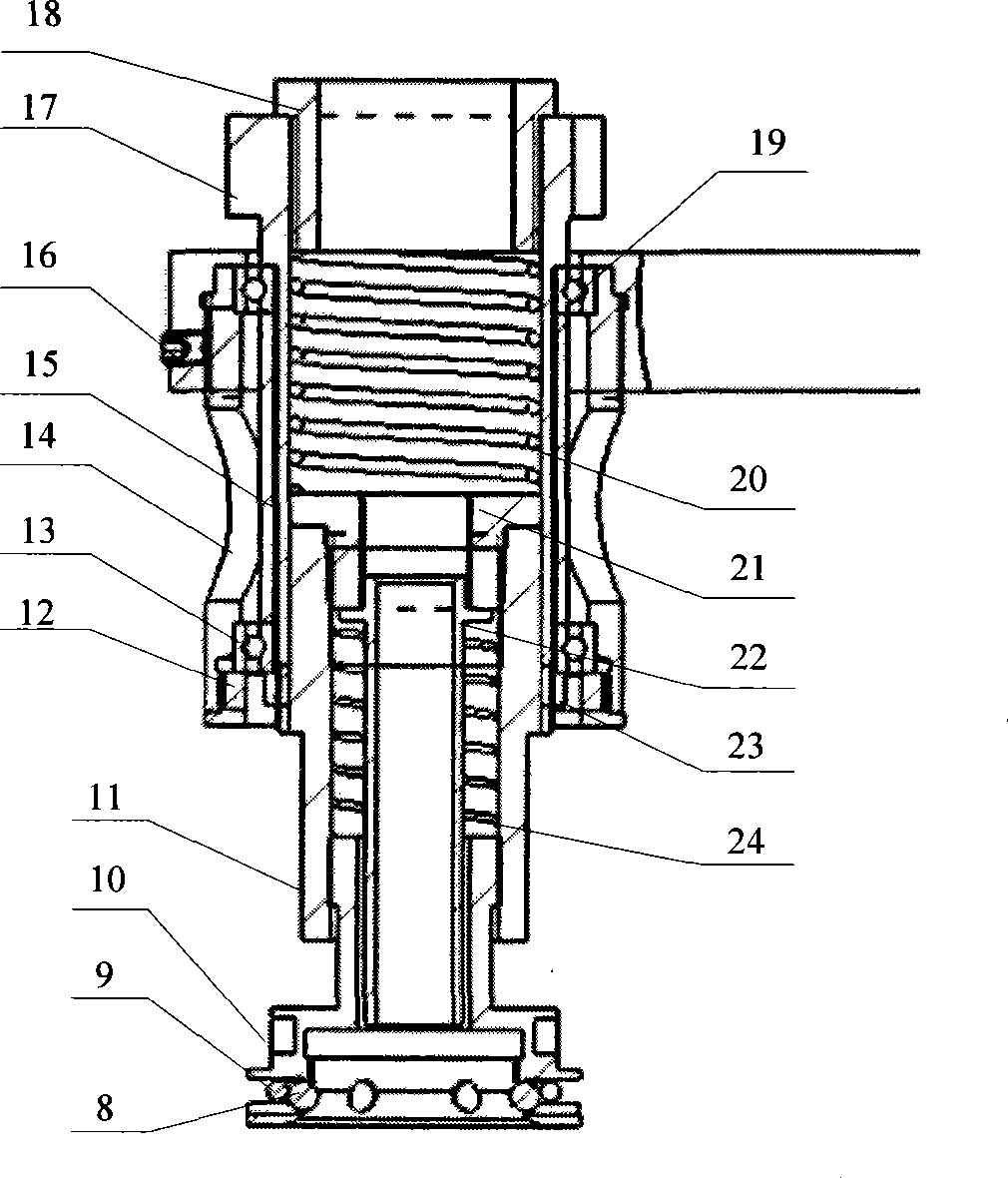

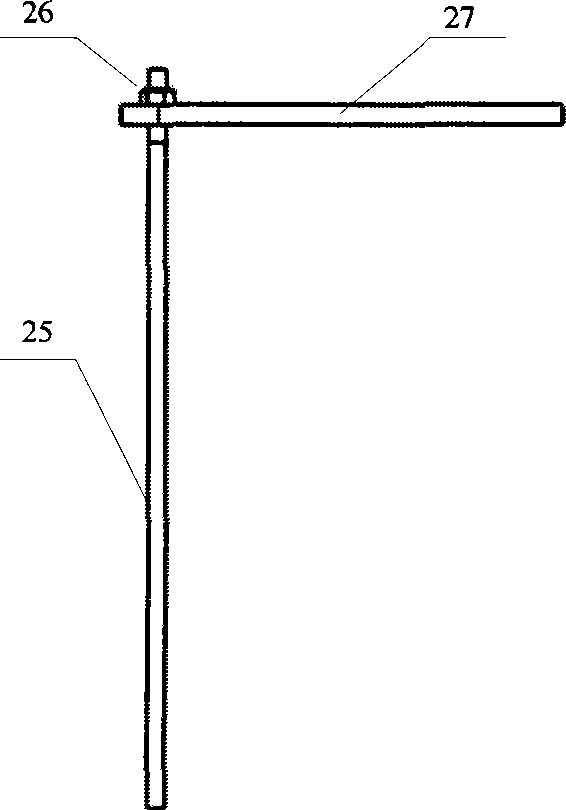

[0023] Such as figure 1 As shown, this embodiment includes: a capping head 1 , a waste cap removal mechanism 2 , an idler mechanism 3 , a base block 4 , a servo motor 5 , a connecting support 6 , and a motor control system 7 . The base block 4 is equipped with a capping head 1, an idler mechanism 3, a servo motor 5, and a connecting support 6, and the connecting support 6 is connected with a lifting guide rod on the capping machine; Waste cap mechanism 2 is installed on the capping machine, and the height is fixed. The capping head 1 is engaged with the idler mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com