Patents

Literature

95results about How to "Precise torque control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

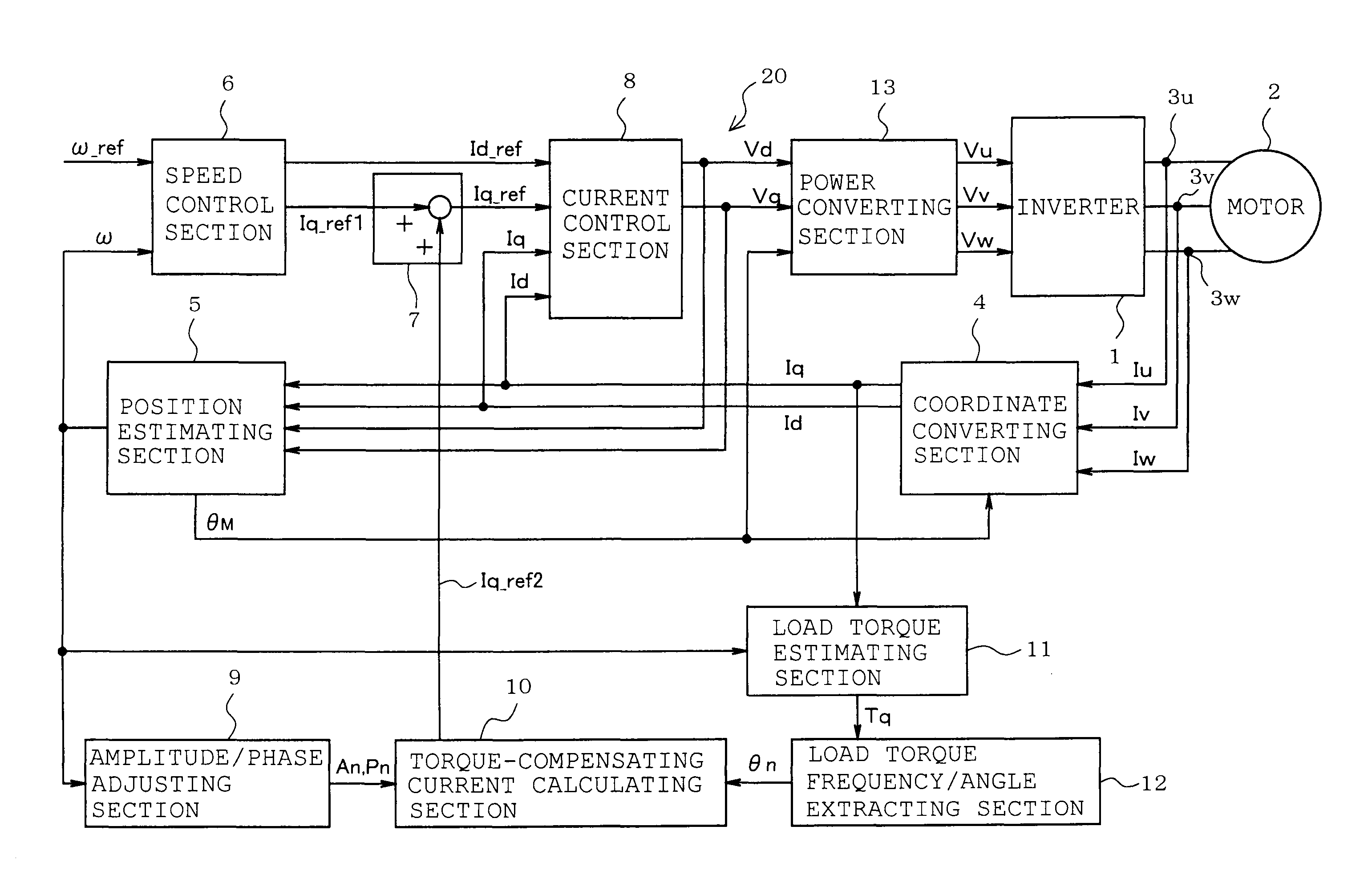

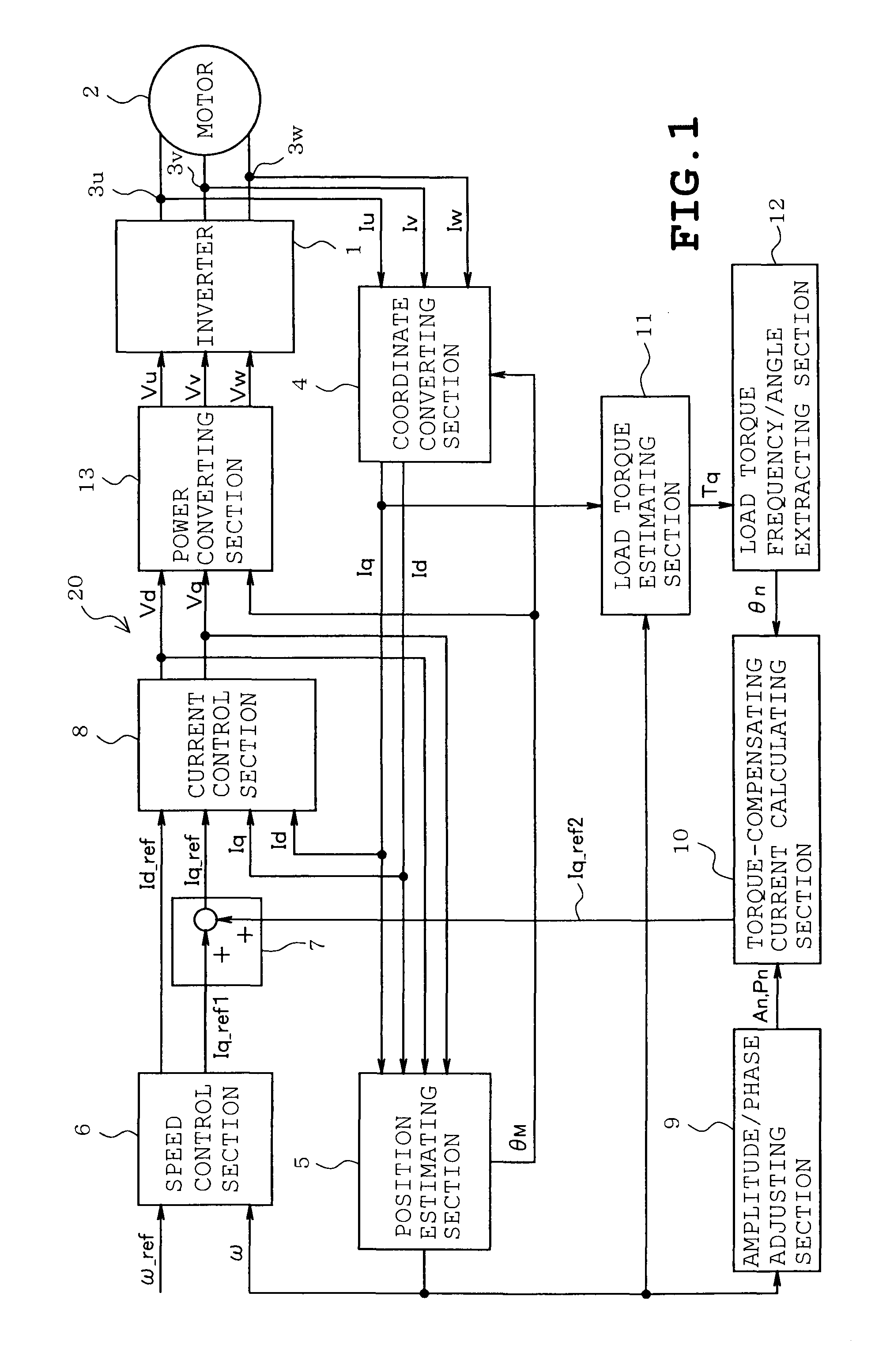

Motor control device and electrical equipment with motor controlled thereby

ActiveUS20110234144A1Precise torque controlSuppress fluctuationsTorque ripple controlCommutation monitoringPhysicsEngineering

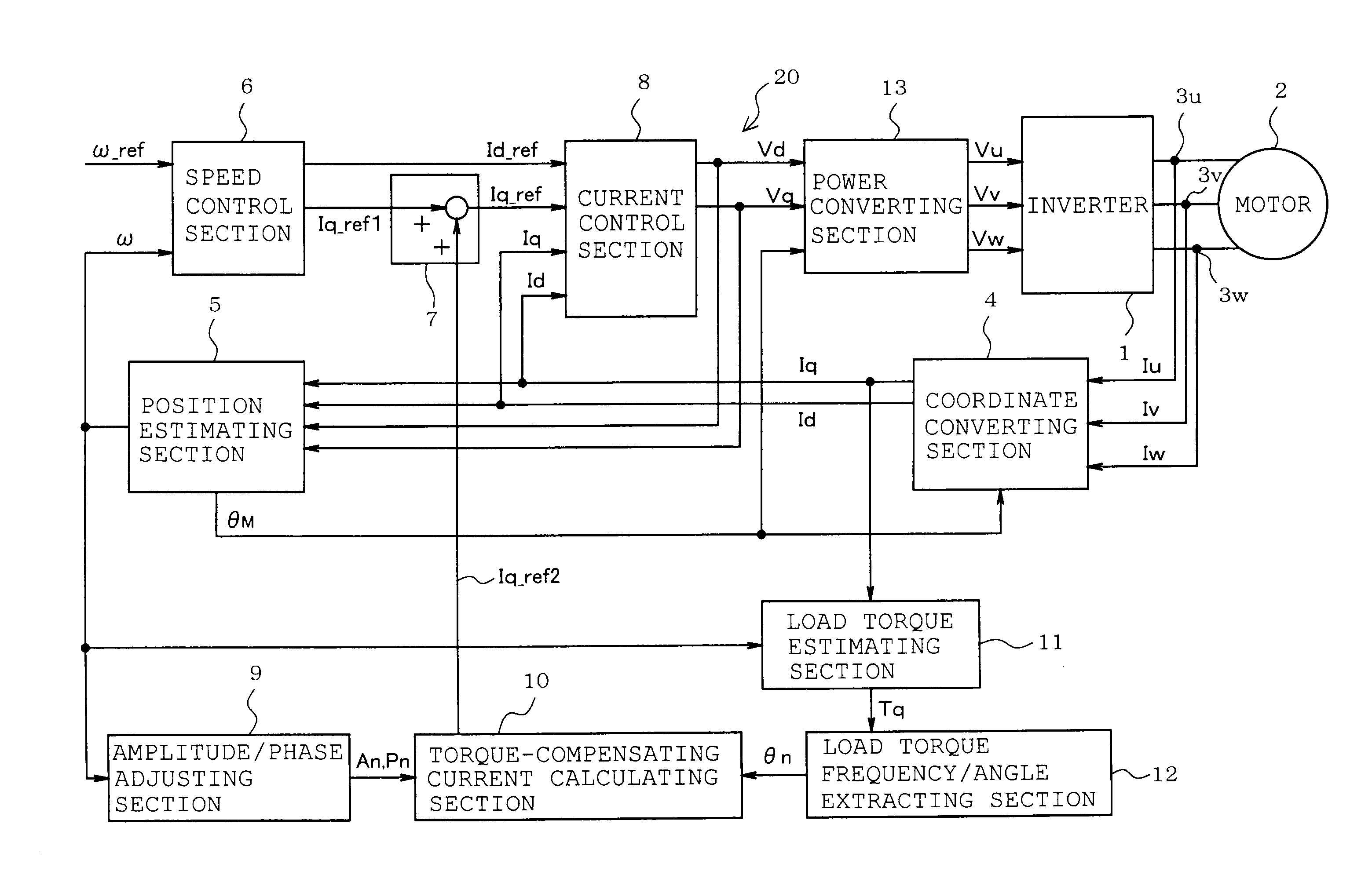

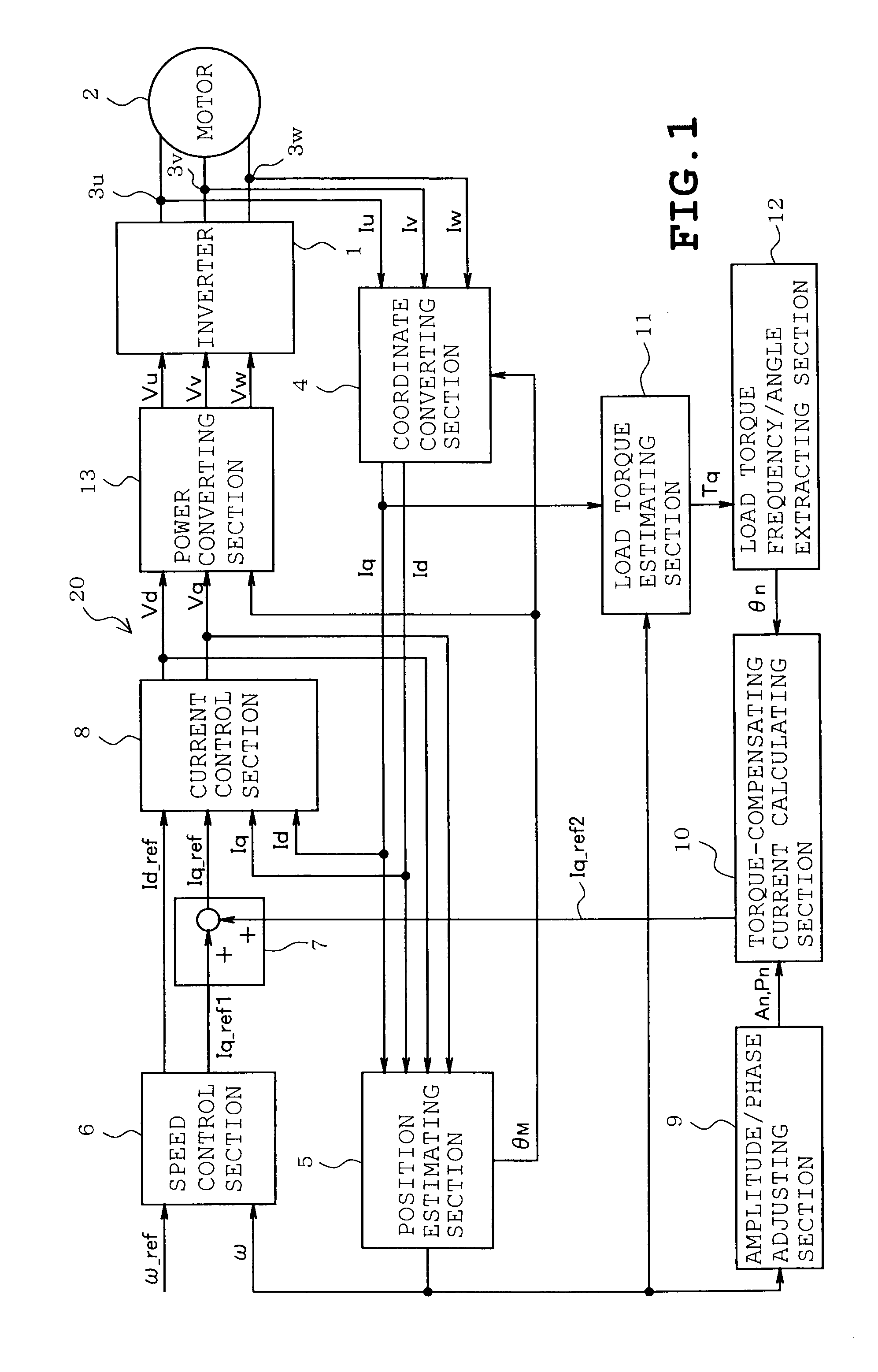

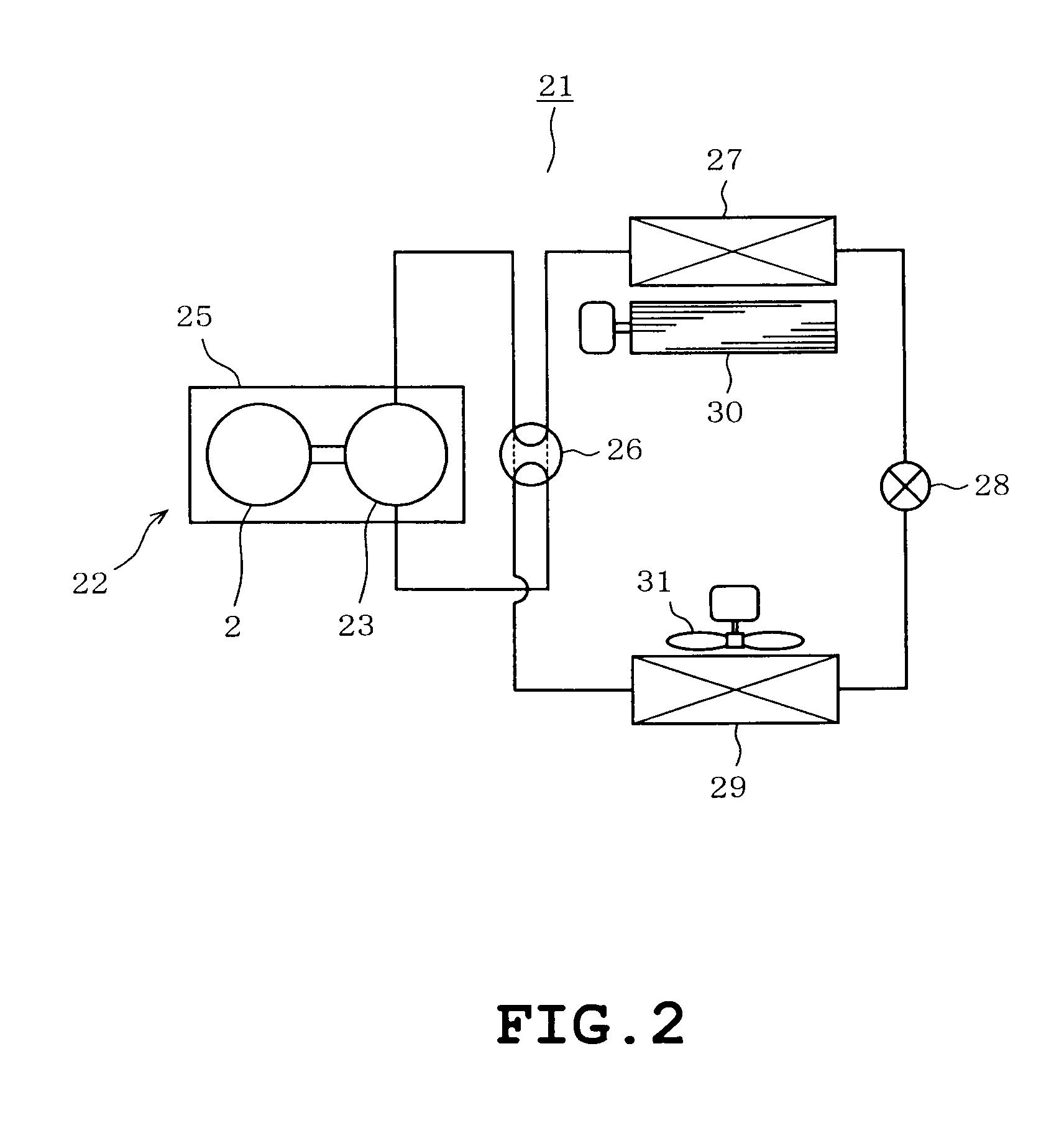

A motor control device includes a current detecting unit detecting current flowing into a motor winding, a speed / electrical angle estimating unit estimating a rotational speed and an electrical angle of the motor, based on the current, a load torque estimating unit estimating load torque to be developed by a load, from a torque current obtained based on the current and the electrical angle, a motor constant and inertia moment of the motor inclusive of the load, a load torque phase calculating unit calculating a phase of periodic fluctuation indicated by the load torque, a torque-compensating current determining unit determining a sinusoidal torque-compensating current, based on the load torque phase, and an amplitude / phase adjusting unit detecting speed fluctuation of the motor to adjust amplitude and phase of the torque compensating current by increasing or decreasing the amplitude and the phase so that the speed fluctuation is reduced.

Owner:KK TOSHIBA

Training apparatus, arrangement and method

ActiveUS10004945B2Avoid noiseFast response timePhysical therapies and activitiesElectronic commutation motor controlFrequency changerPower flow

Owner:EGYM

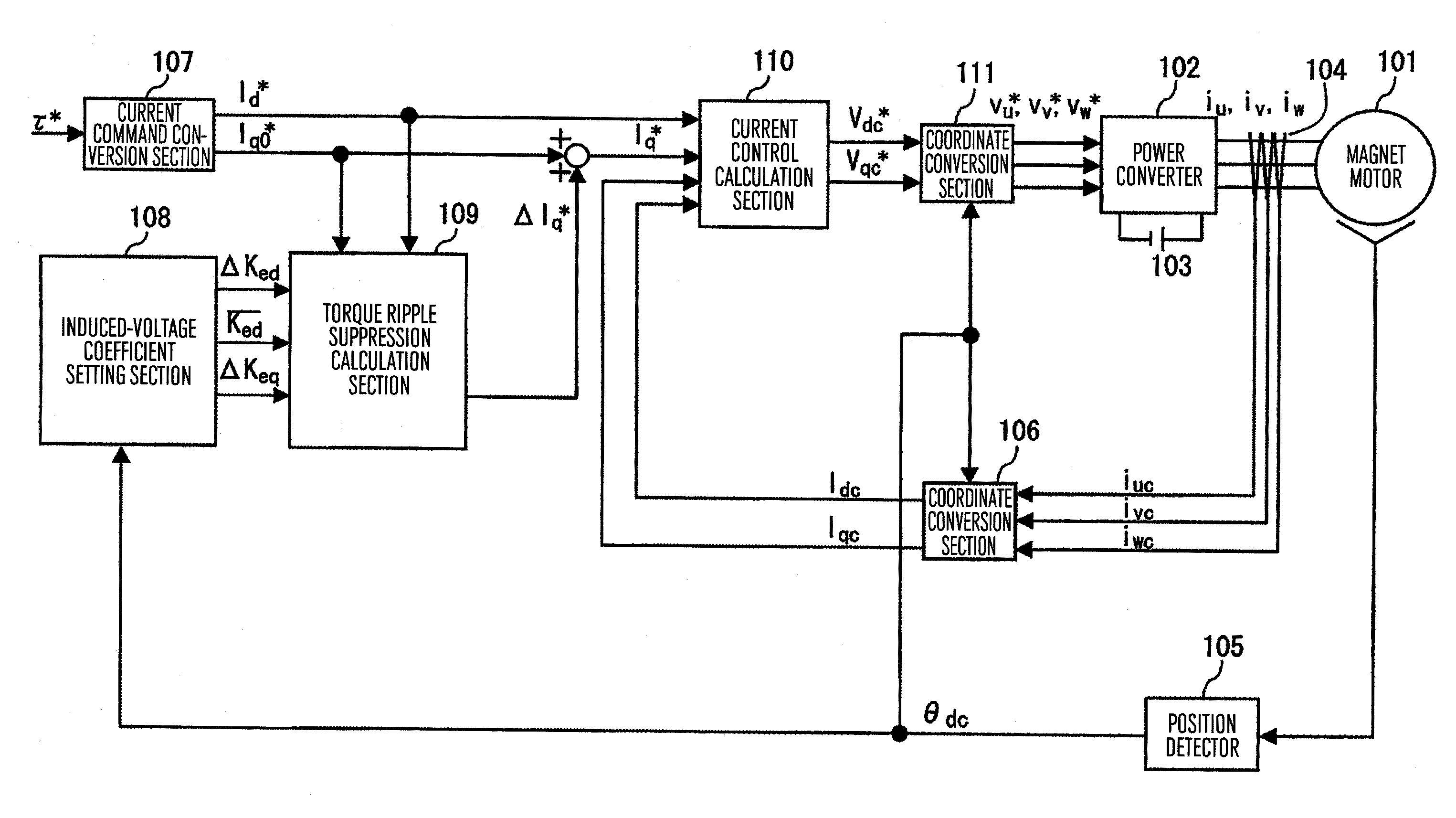

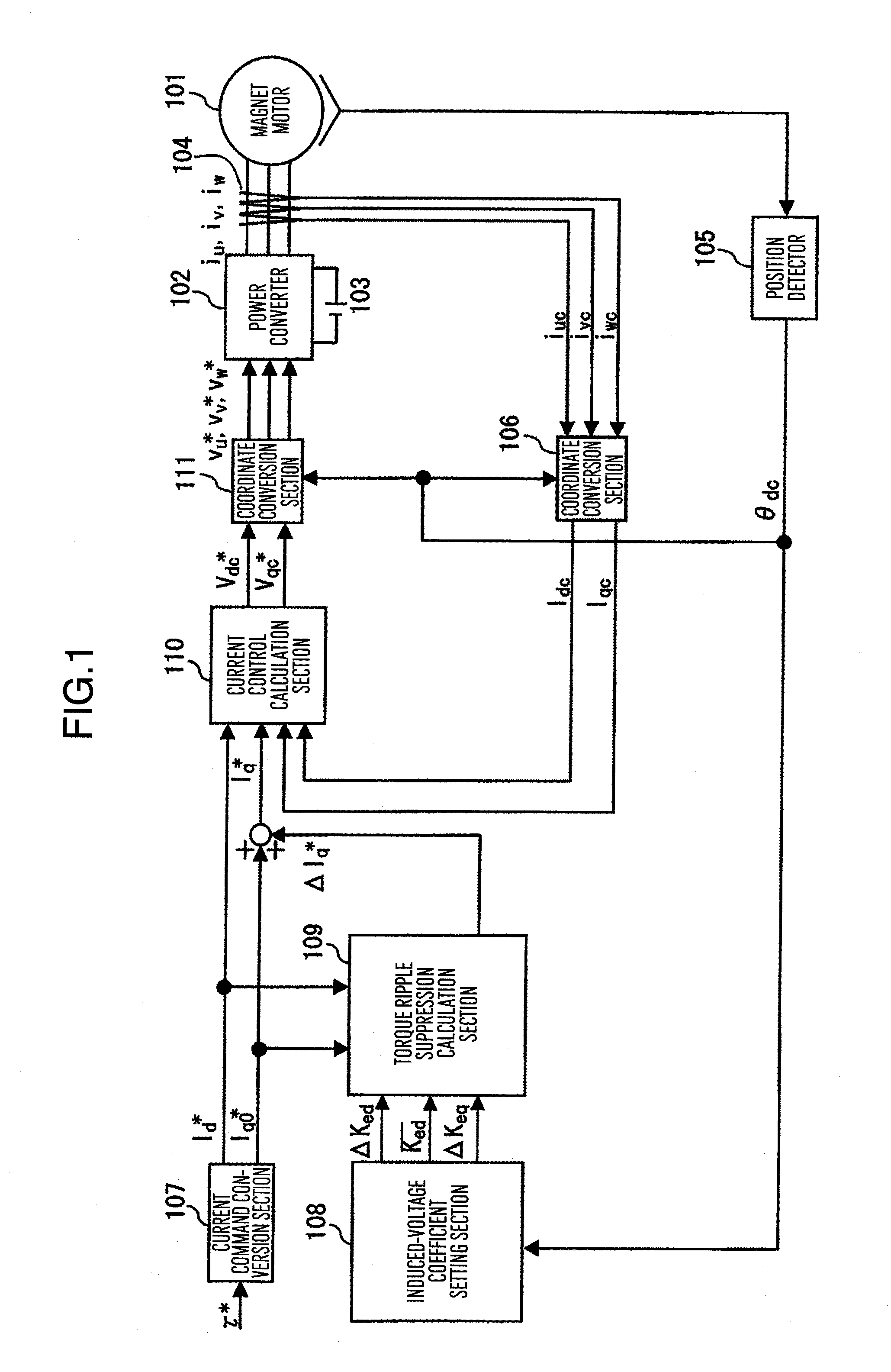

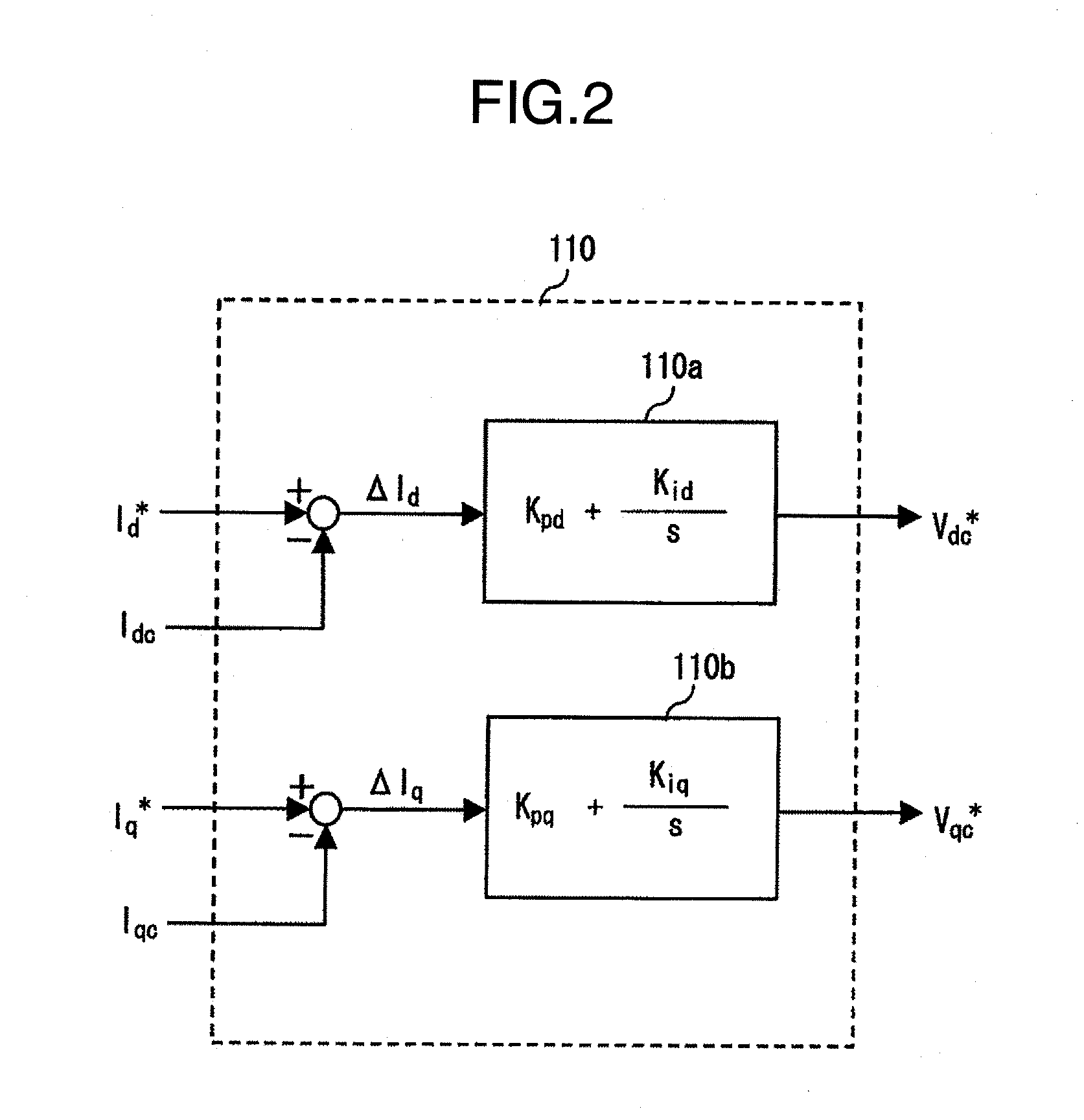

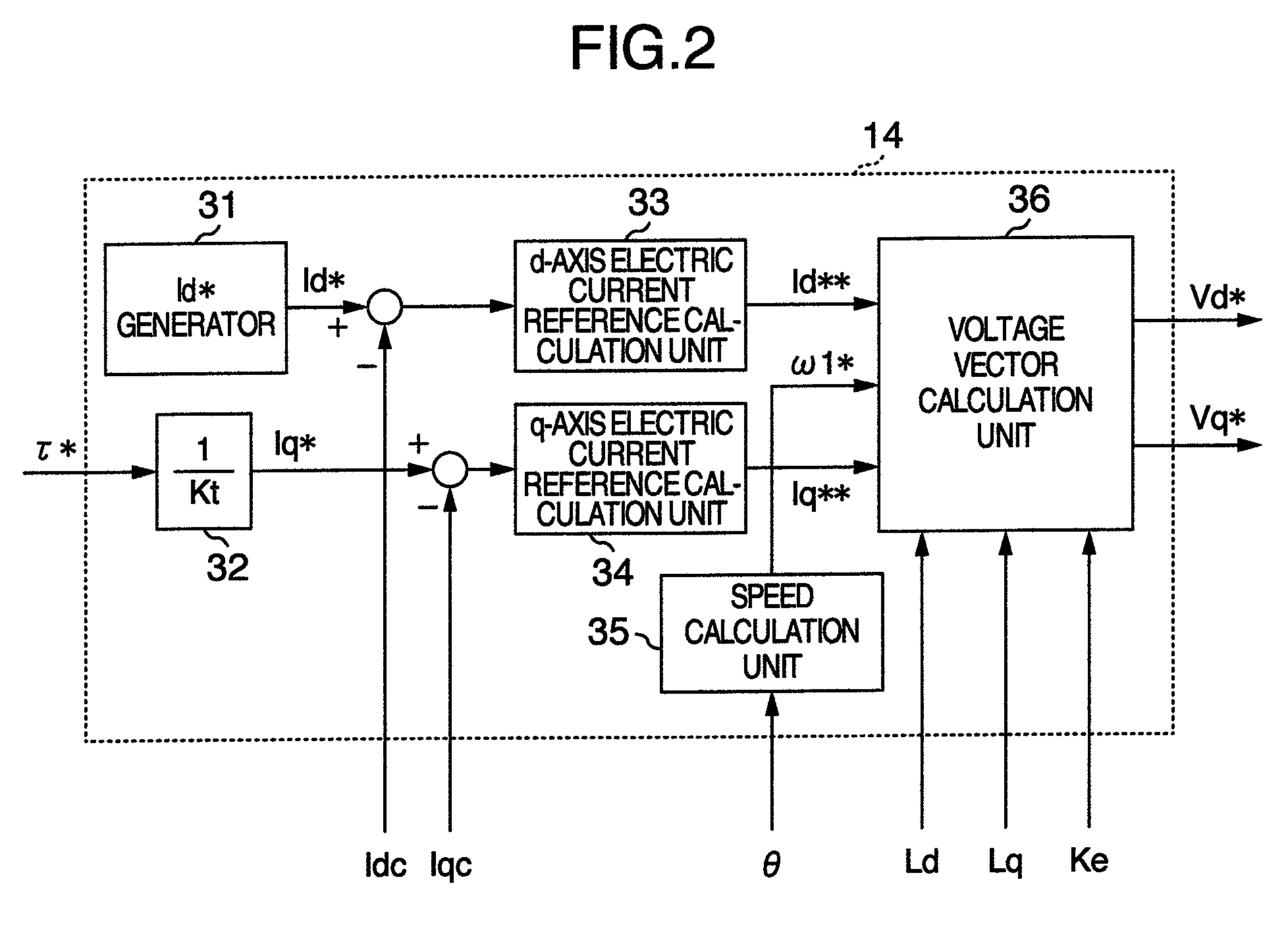

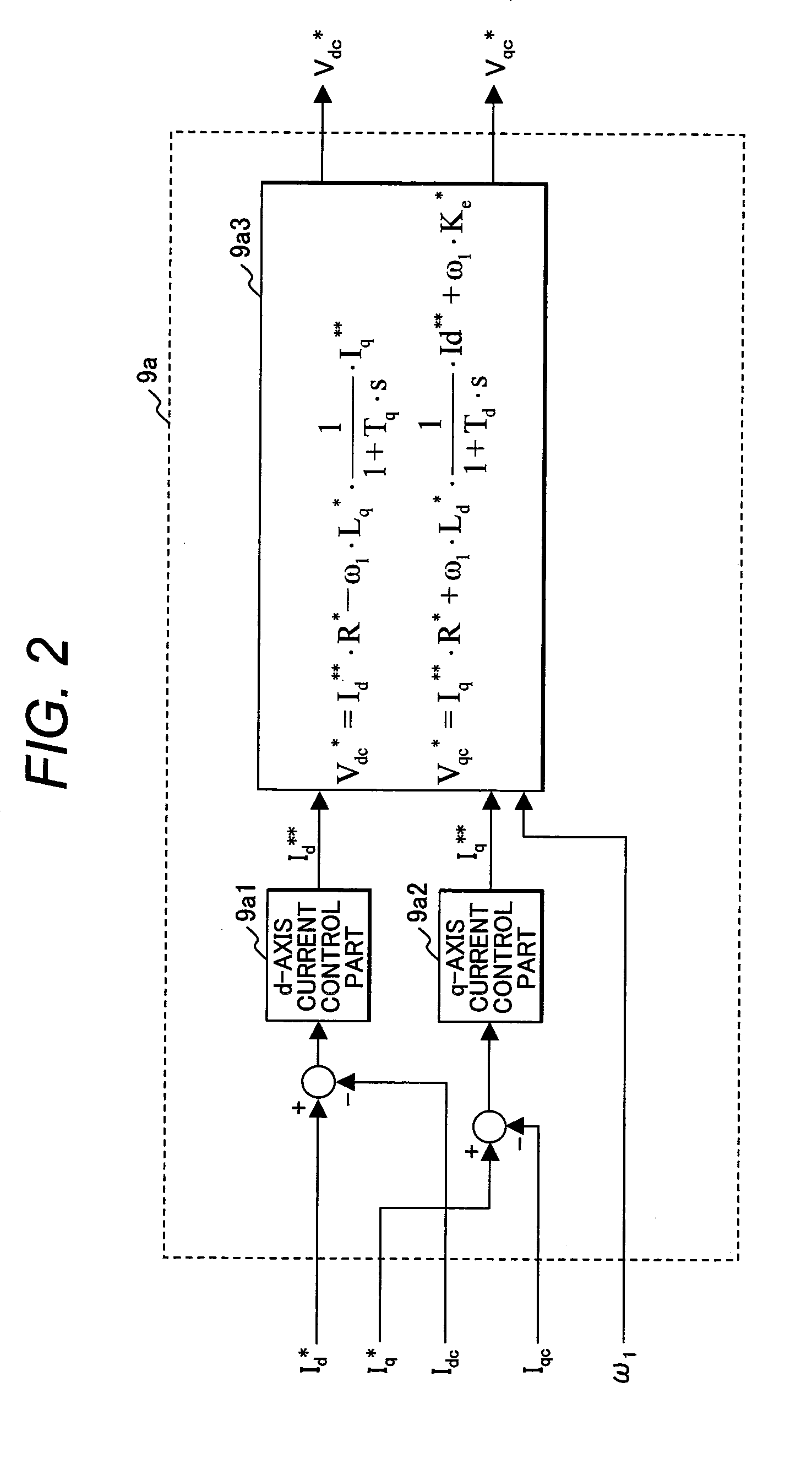

Control apparatus for permanent magnet motor

InactiveUS20110241586A1Precise torque controlTorque ripple controlSynchronous motors startersPermanent magnet motorEngineering

A sinusoidal signal is superimposed on a current command value of a q-axis (torque shaft) supplied from a host, and according to the resulting current command value, the output voltage of a power converter is controlled. For the calculation of the superimposed signal added to the current command value of the q-axis, with the use of the ripple component information of induced voltage coefficients of the d-axis and q-axis of the rotating coordinate system of a permanent magnet motor, the current command values of the d-axis and q-axis, an average value of induced voltage coefficients of the d-axis, and inductance values of the d-axis and q-axis, the sinusoidal superimposed signal is calculated and added to the above-described current command value of the q-axis.

Owner:KOKUSAN DENKI CO LTD

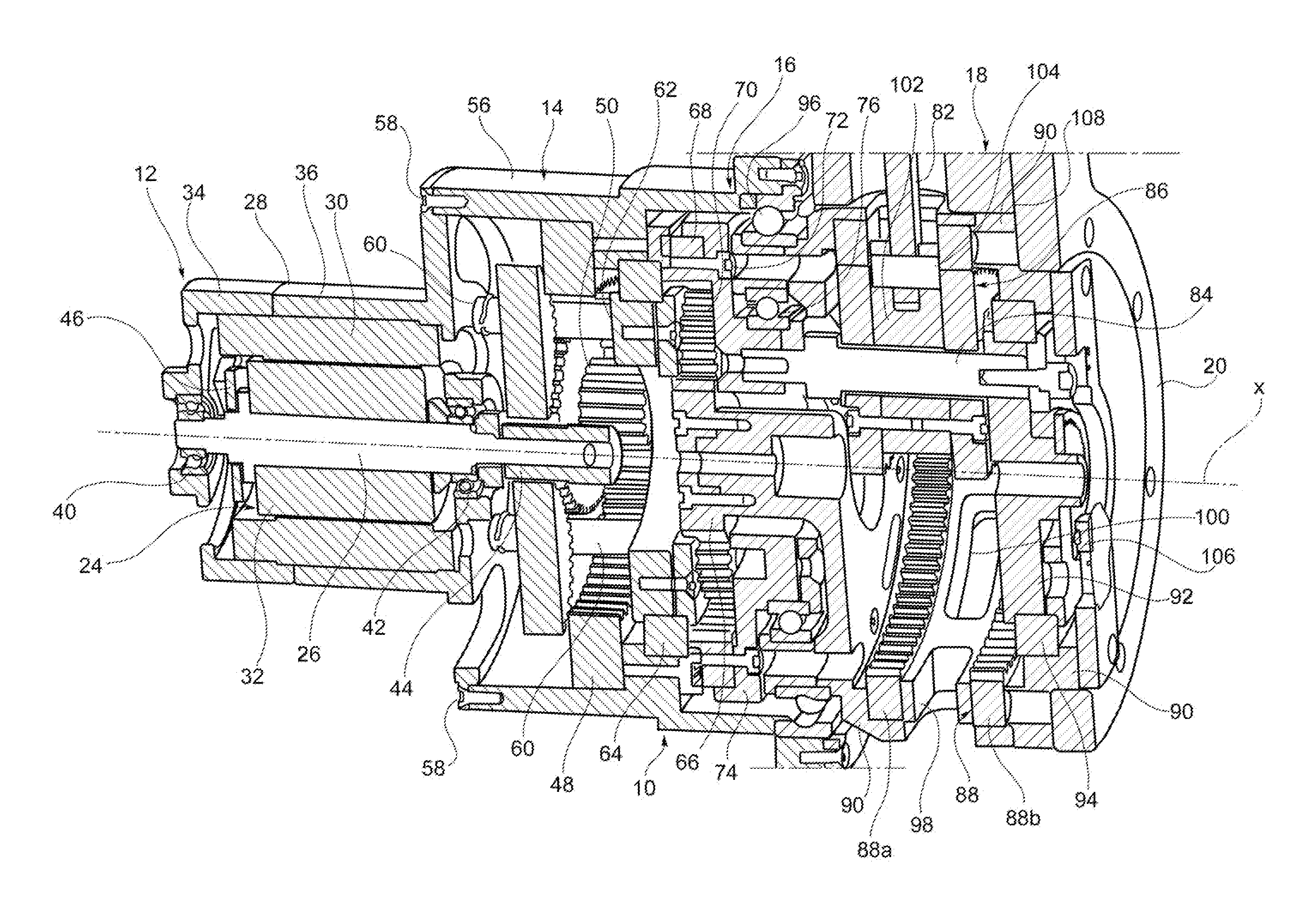

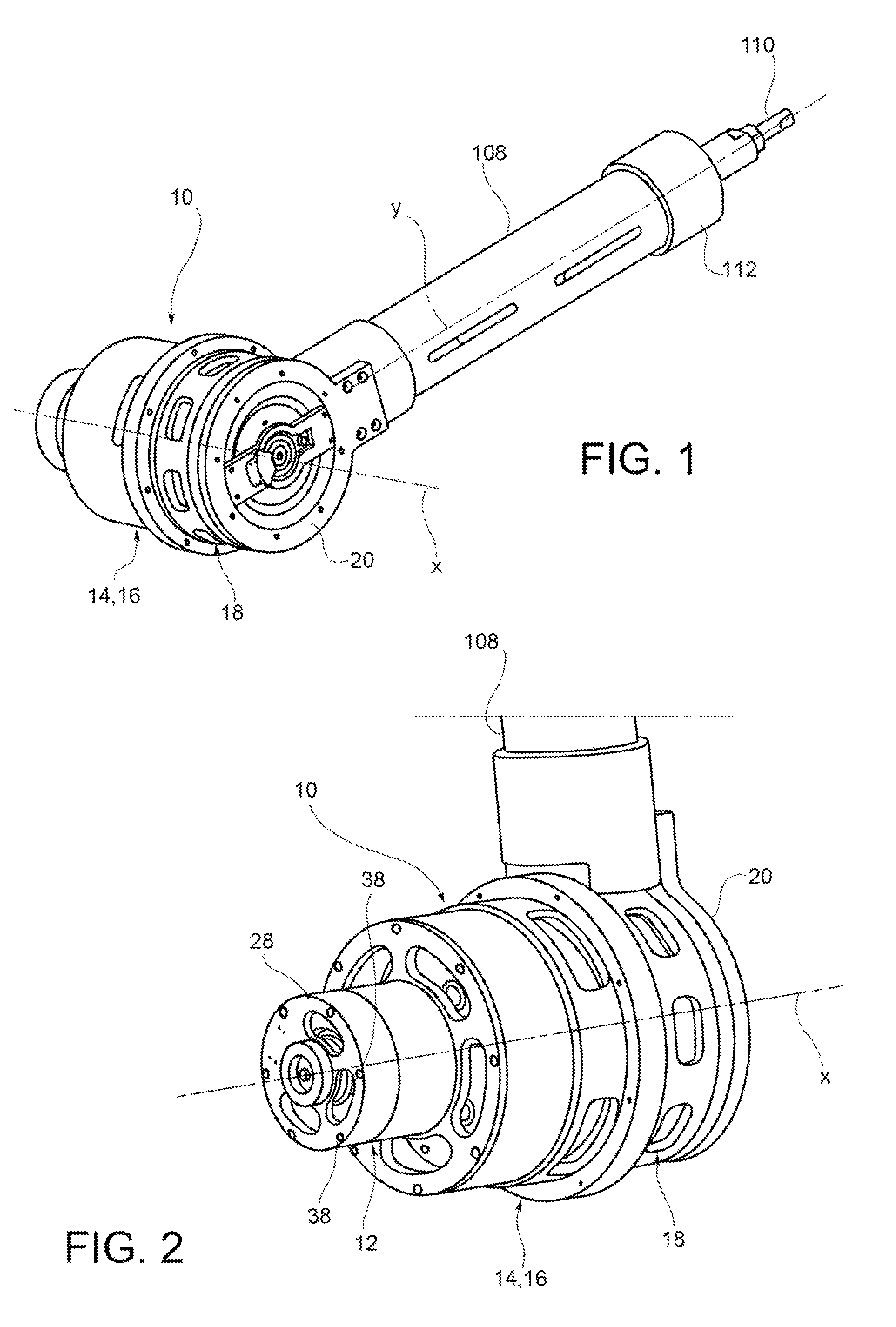

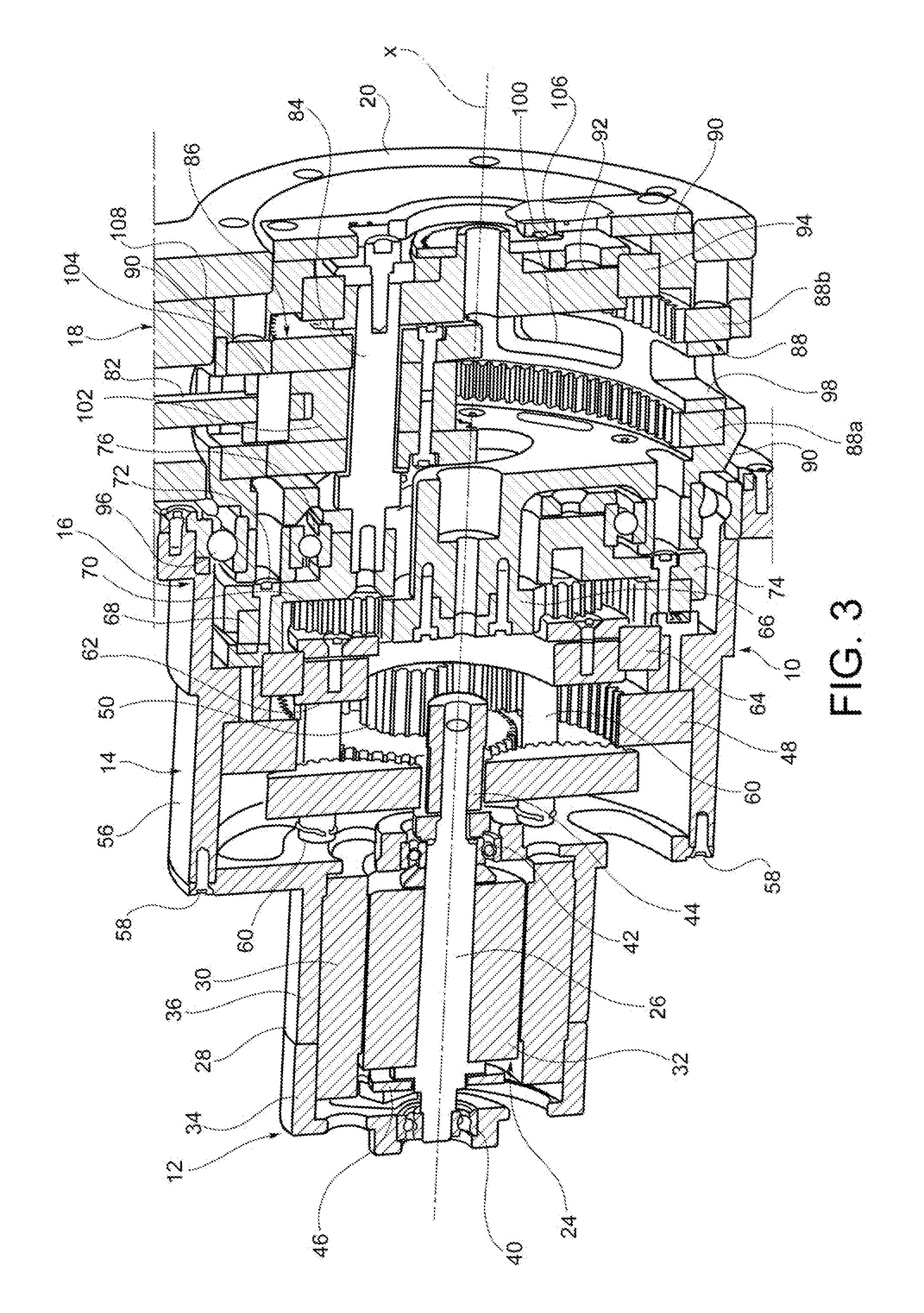

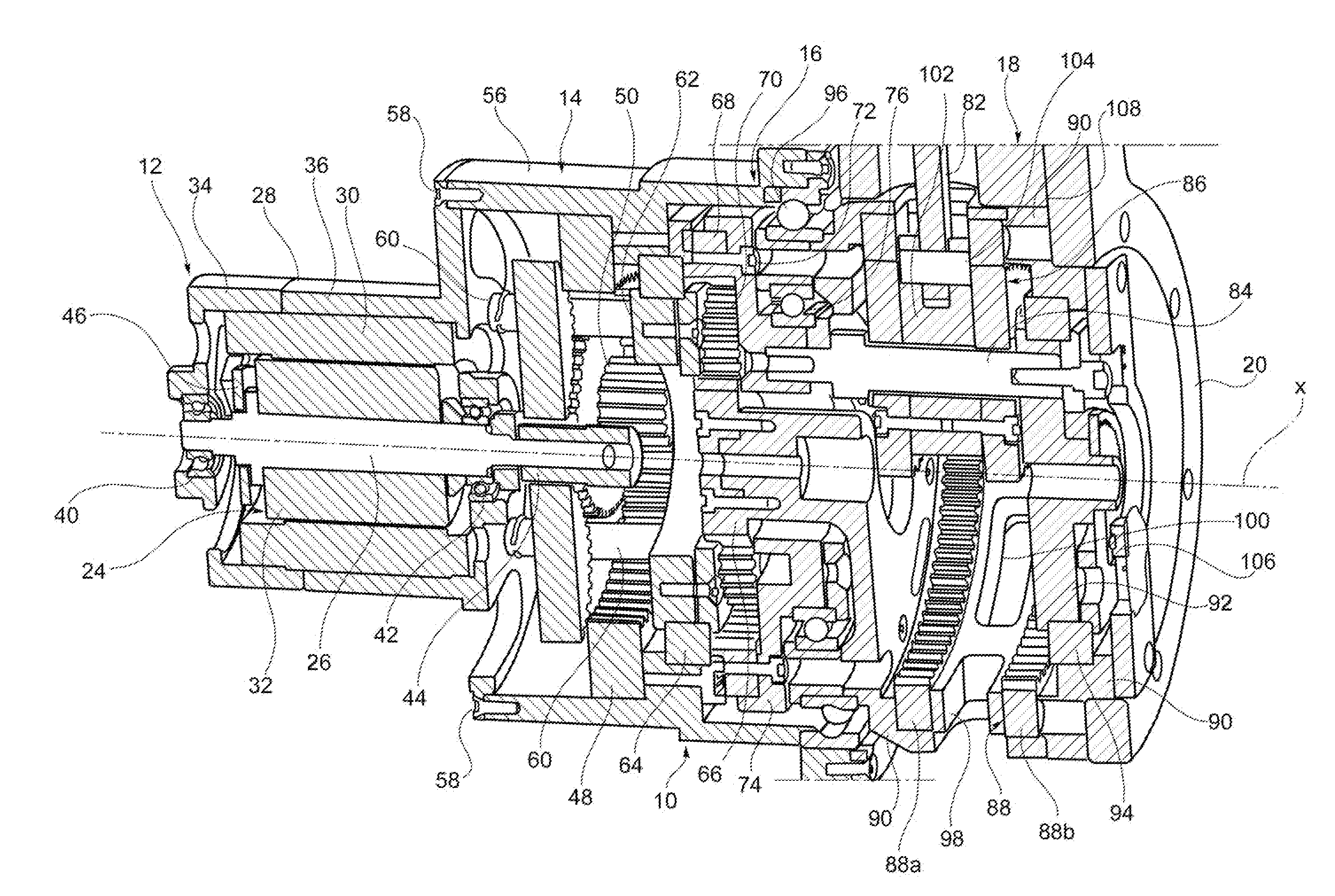

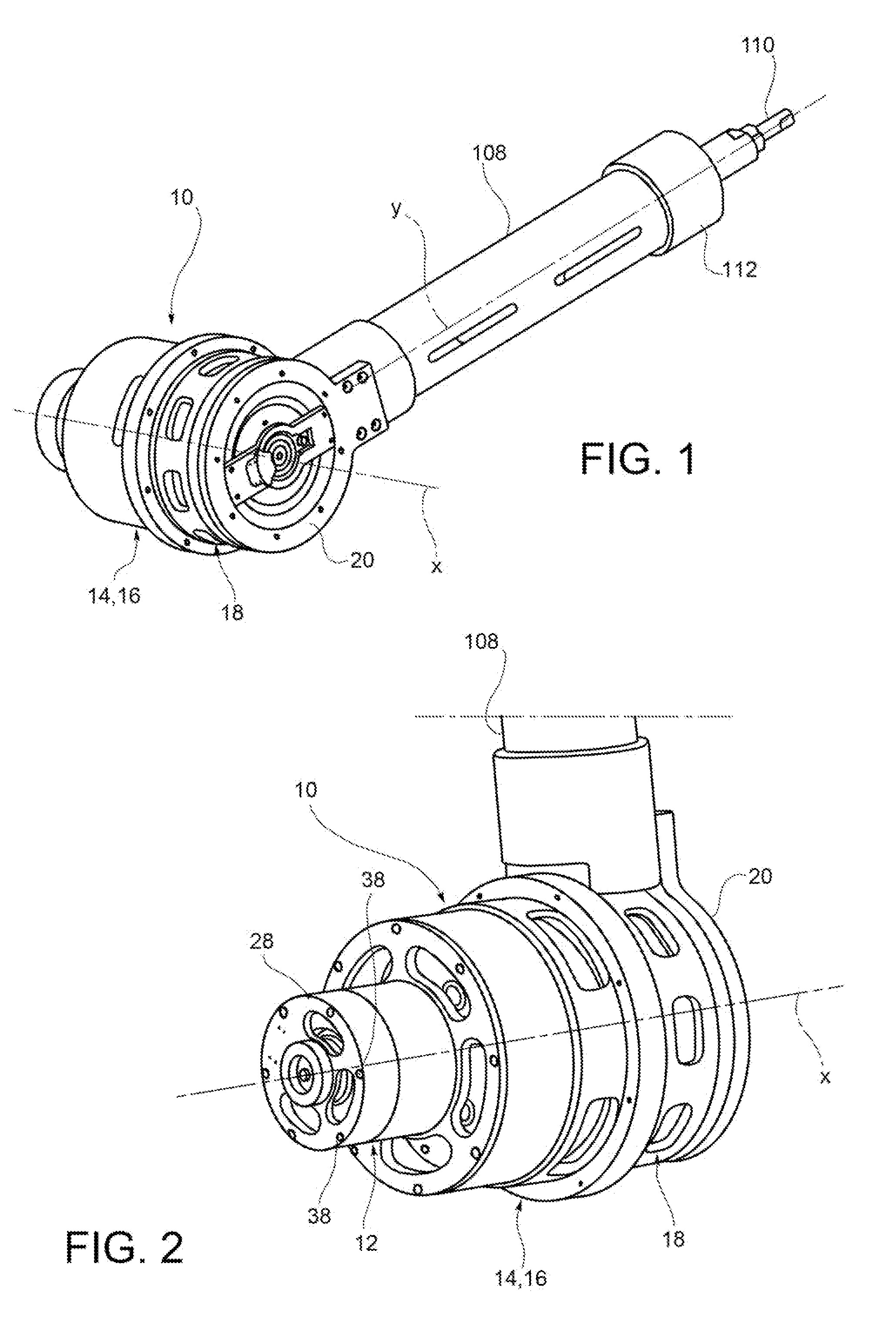

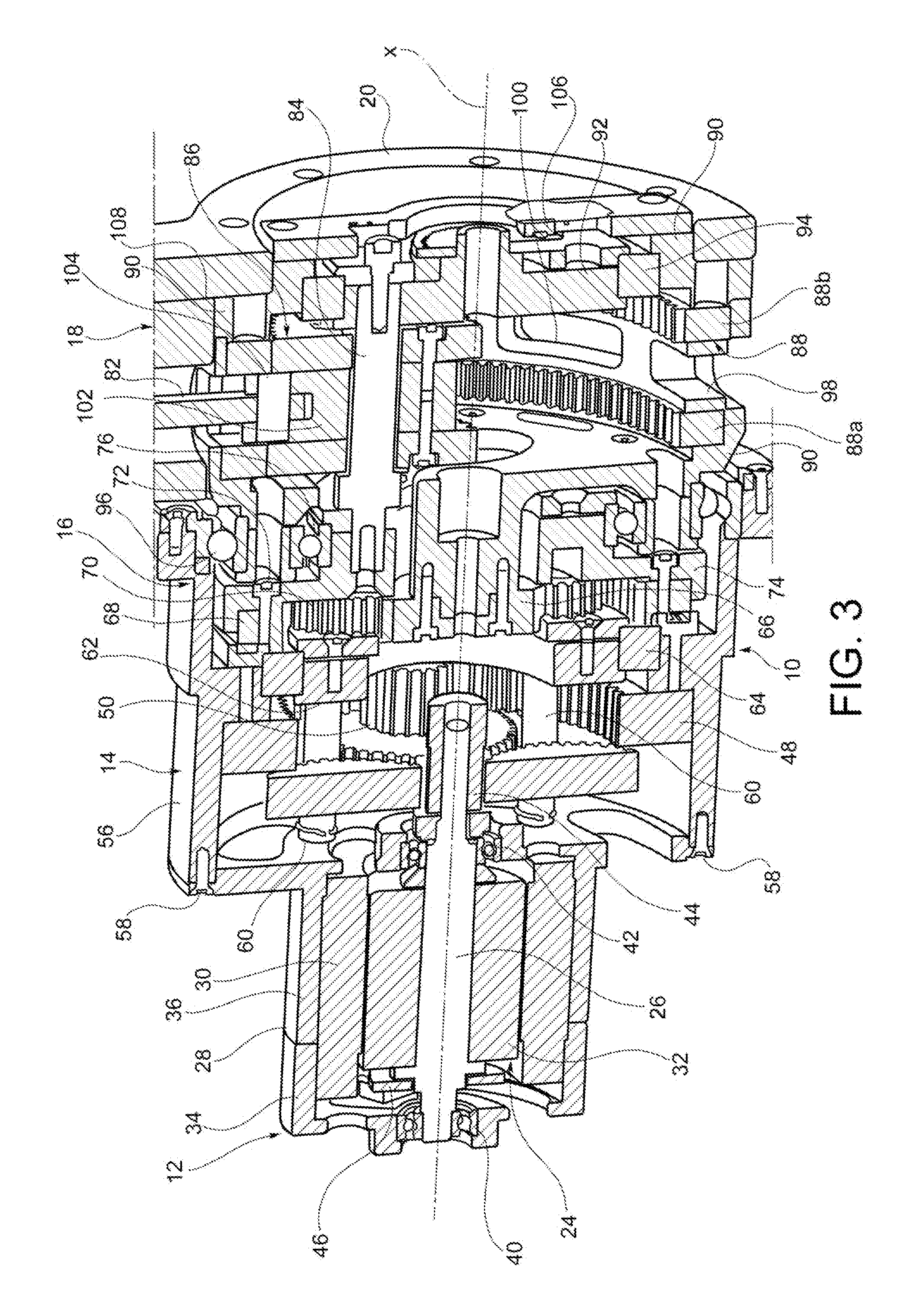

Elastic rotary actuator

InactiveUS8821338B2Improve performancePrecise torque controlProgramme-controlled manipulatorYielding couplingControl theoryRotary actuator

Rotary actuators having a final output member rotatable about an axis of rotation; a motor unit designed to drive the final output member for rotation about the axis of rotation; and an elastic unit arranged between the motor unit and the final output member and having an input member torsionally coupled to the motor unit and an output member rigidly connected for rotation with the final output member are provided.

Owner:FOND INST ITAL DI TECH

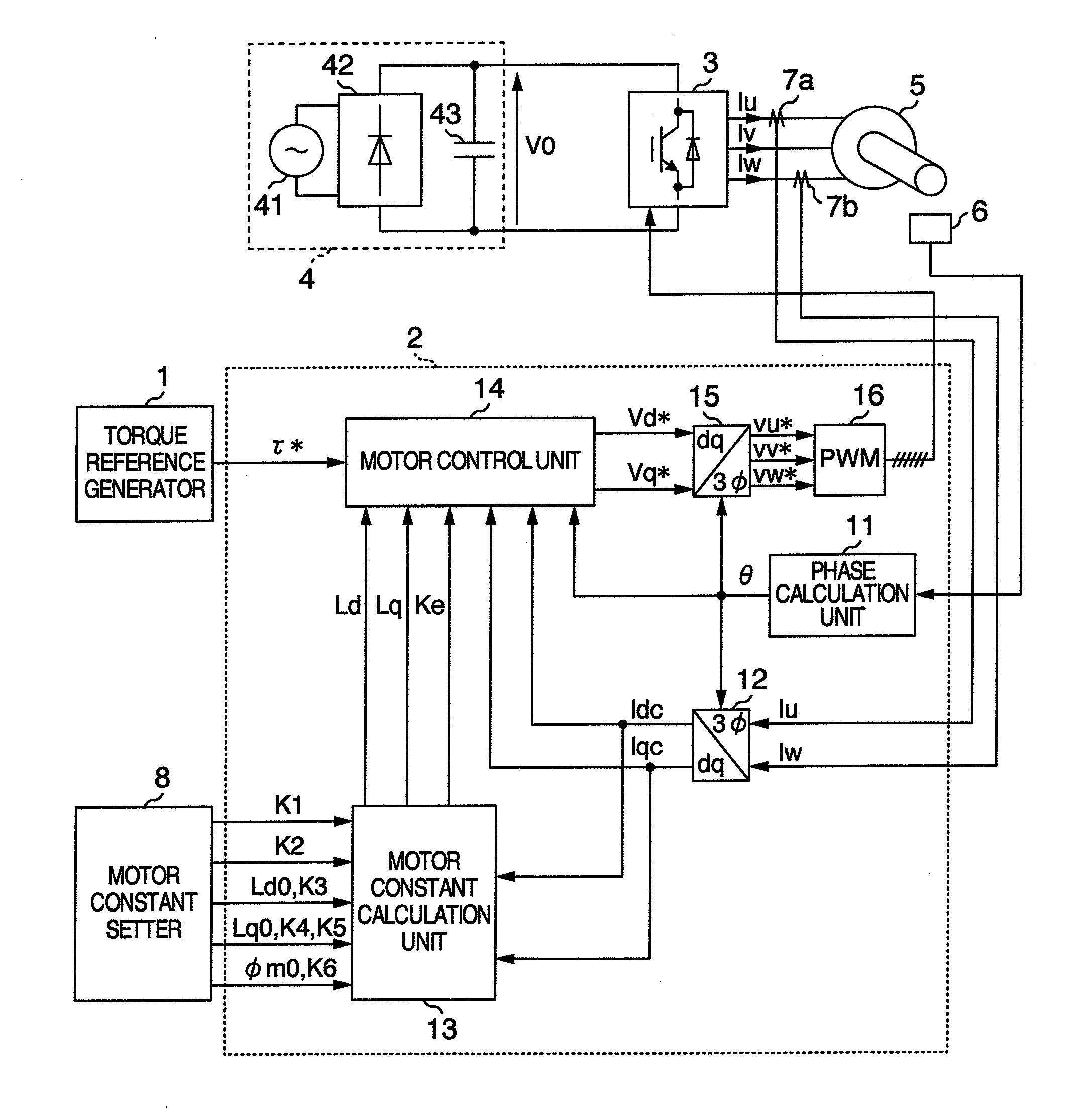

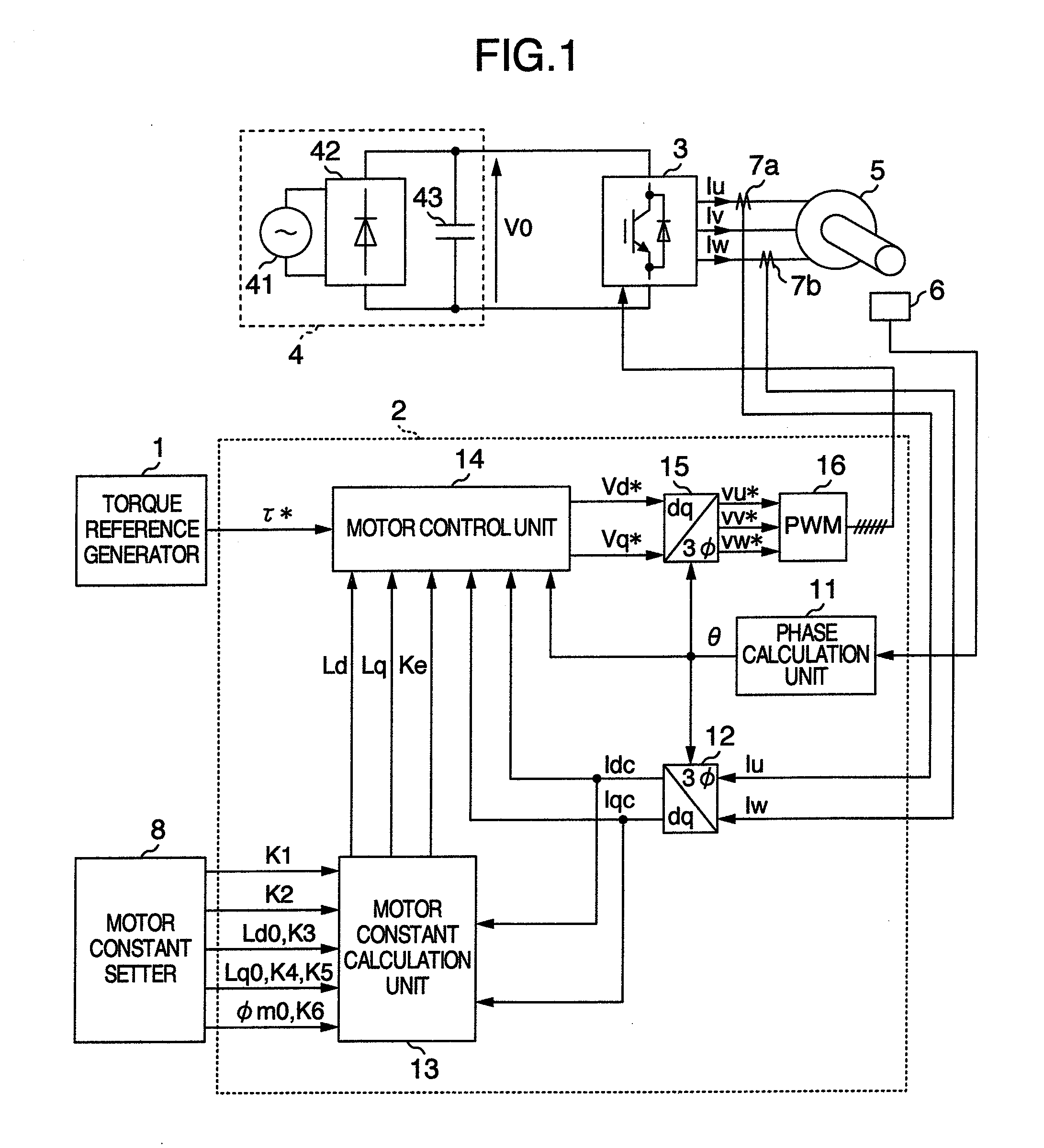

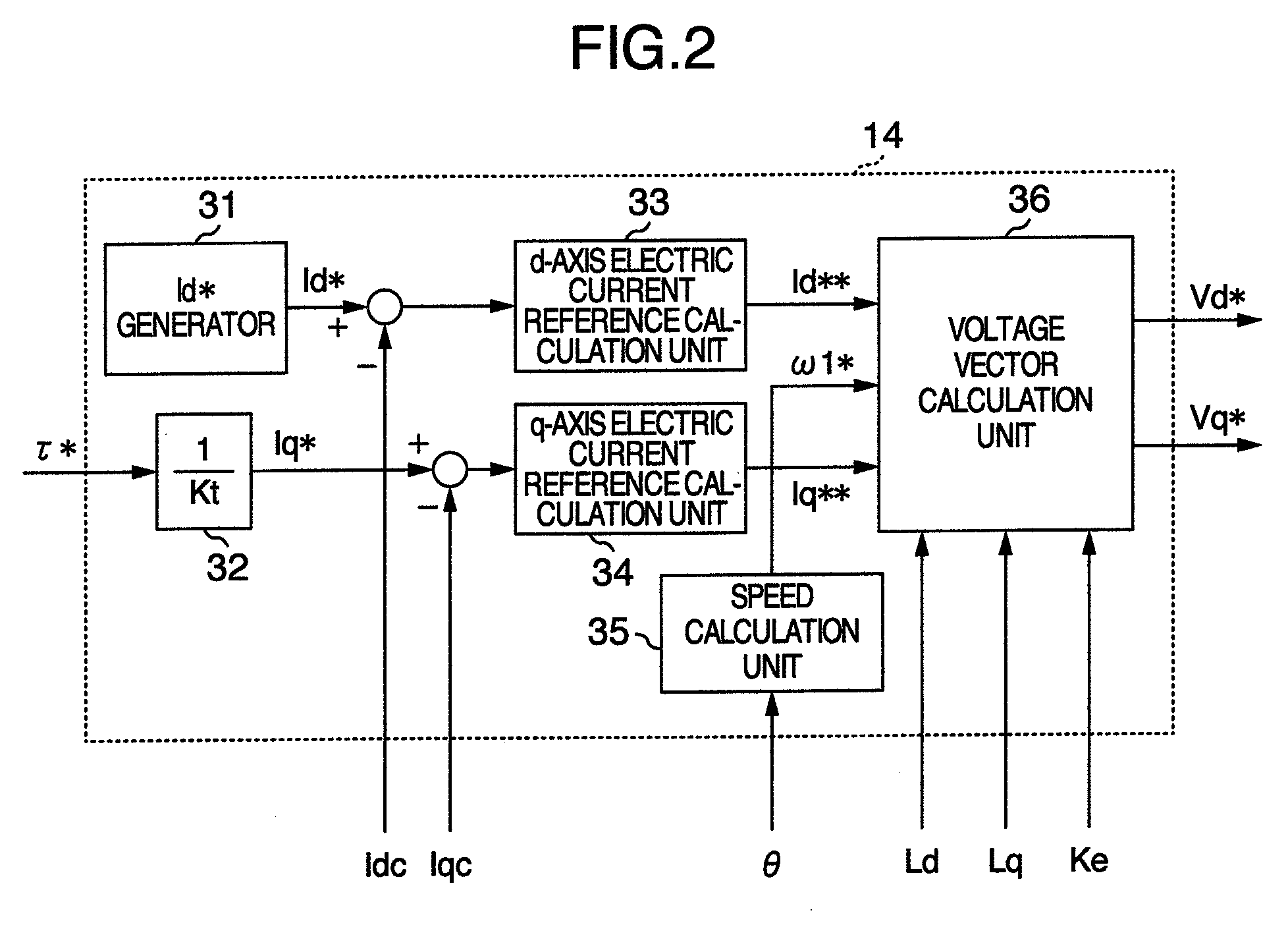

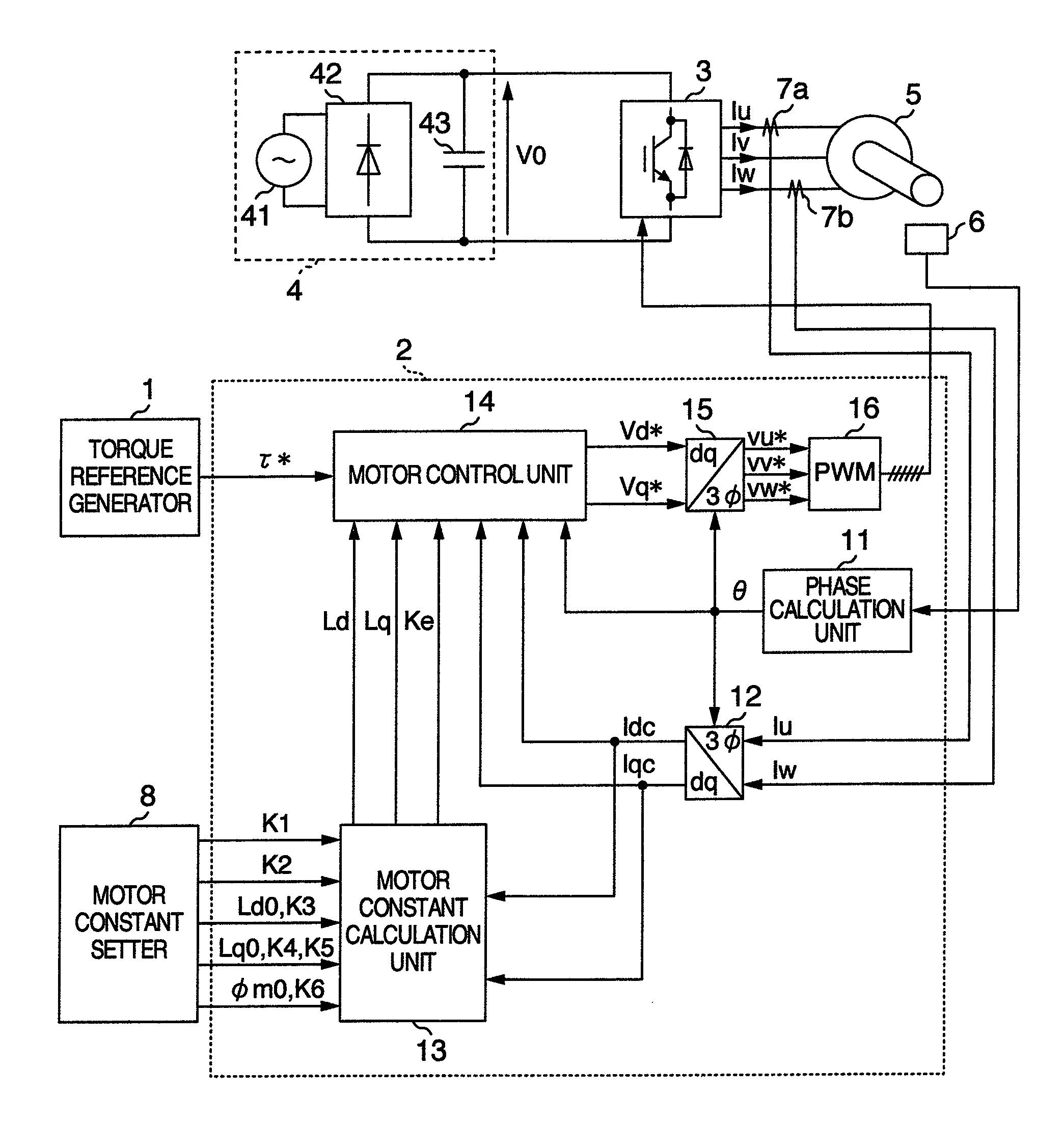

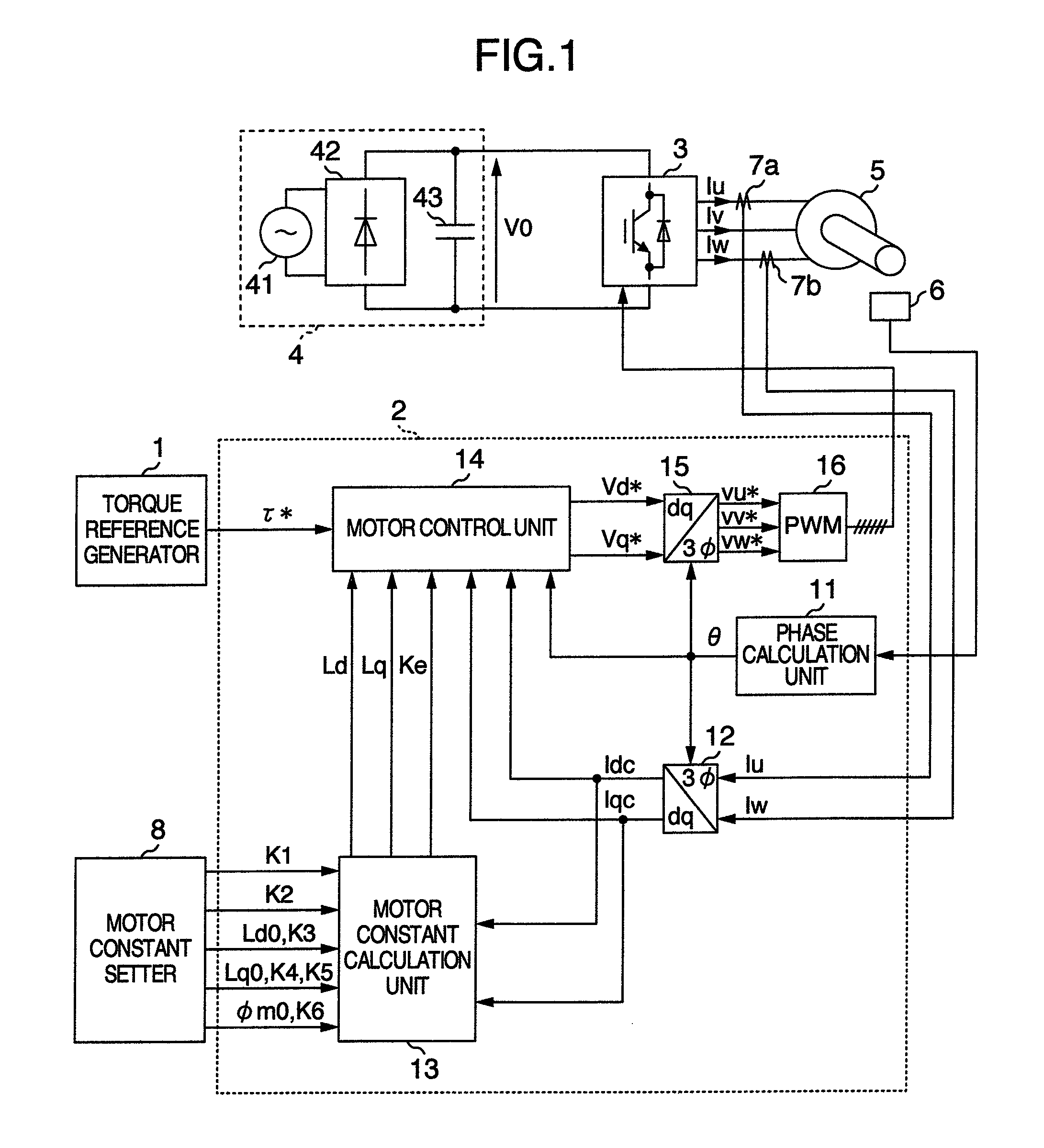

Control apparatus for ac motor

ActiveUS20090140674A1High-precision torque controlImprove responseSynchronous motors startersVector control systemsState variableOrthogonal basis

It is attained by being provided with a motor constant calculation unit for calculating electric constants of a motor, and by correcting setting values of electric constants defined on one of the axes of two orthogonal axes, by a functional expression using a state variable defined on the same axis, and by correcting them by a functional expression using a state variable defined on the other axis.

Owner:HITACHI LTD

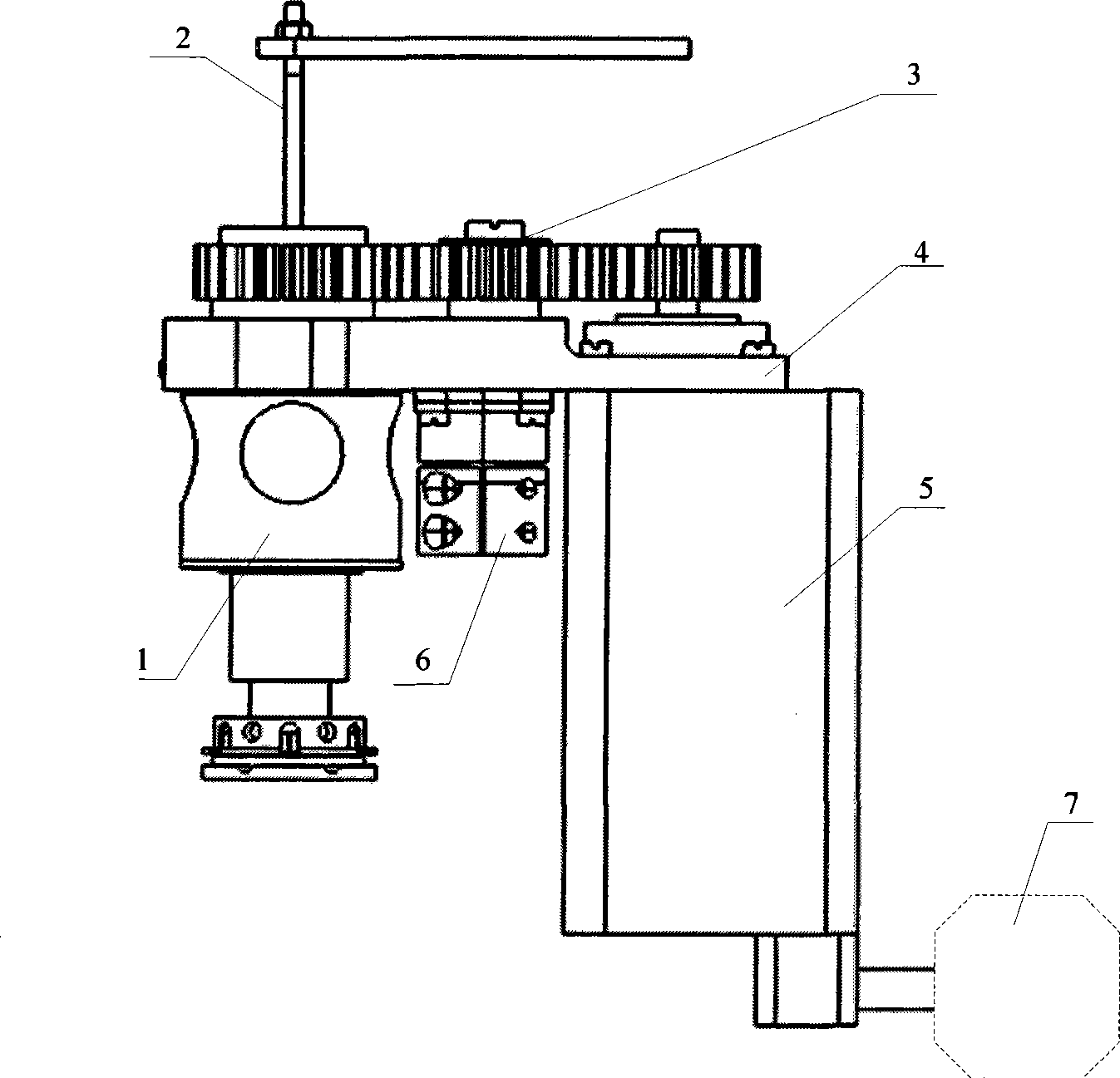

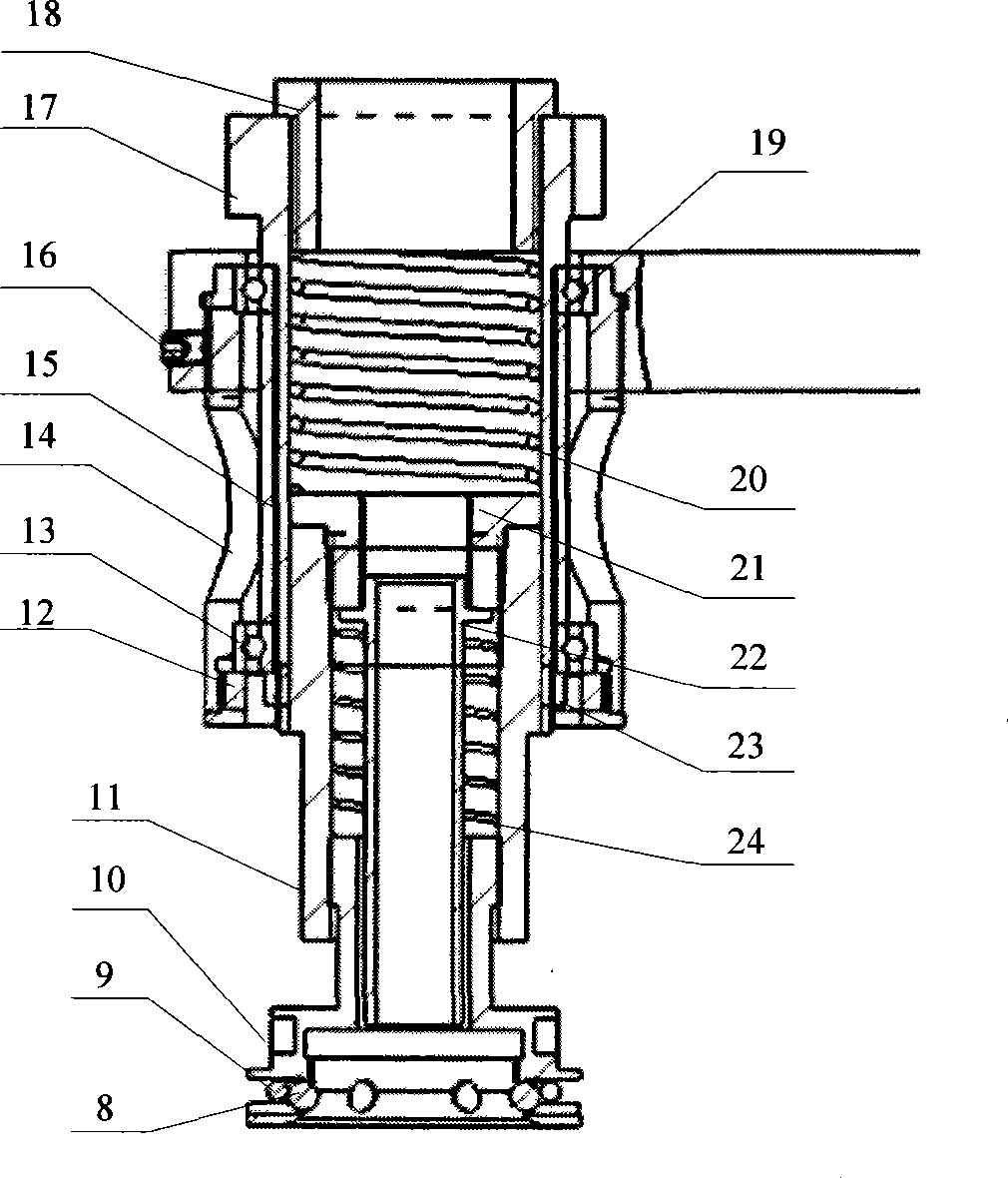

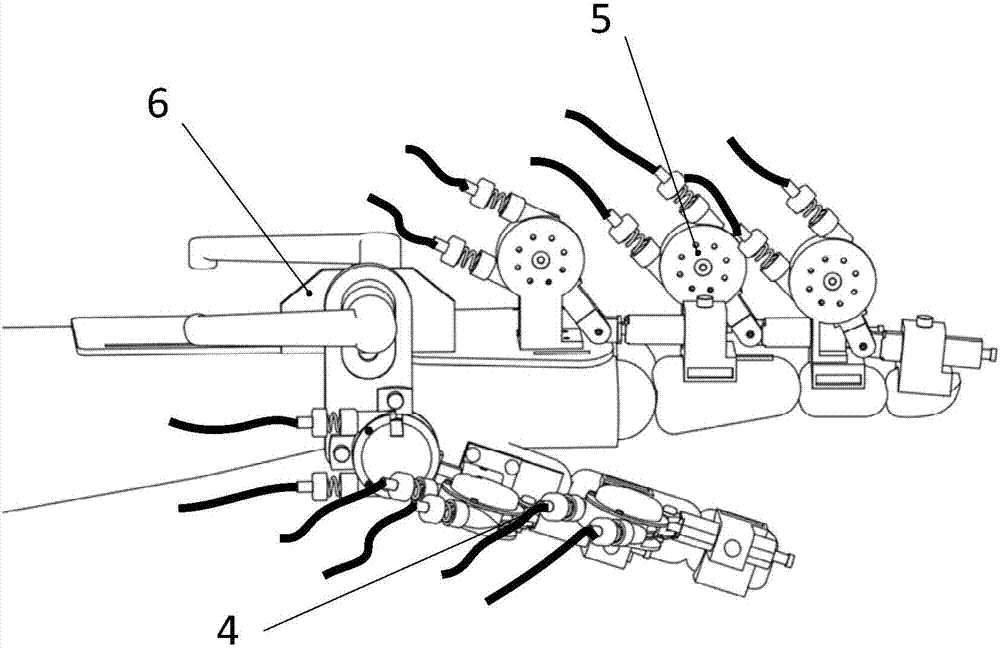

Servo bottle cap screwing mechanism

InactiveCN101386399APrevent crushingEffective screwingThreaded caps applicationPulp and paper industryServomotor

The invention relates to a servo bottle cap screwing mechanism in the technical field of packaging machinery, which comprises a cap screwing head, a waste cap withdrawing mechanism, an idler wheel mechanism, base blocks, a servomotor, a connecting support and a motor control system, wherein, the cap screwing head, the idler wheel mechanism, the servomotor and the connecting support are arranged on the base blocks, the motor control system controls the servomotor to rotate at certain rotating speed and torque, and the generated dynamic power is transferred to the cap screwing head by the idler wheel mechanism, so as to cause the cap screwing head to rotate along with the servomotor; the connecting support is connected with a lifting guide rod to drive the base blocks to raise and fall periodically, and the height of the waste cap withdrawing mechanism is unchanged, and the waste cap withdrawing mechanism is arranged at a cap screwing machine. Under the germfree condition, the entire bottle cap screwing mechanism is lubrication free, has no leakage, is convenient for frequent rinsing and disinfection; the cap screwing torque is controlled by computer, the cap screwing mechanism is driven by servomotor and has large adjustable range; and besides, the working torque, the cap screwing speed, and the like, of the single cap screwing mechanism can be displayed, and the cap screwing mechanism can automatically discharge waste or abnormal caps.

Owner:SHANGHAI JIAO TONG UNIV

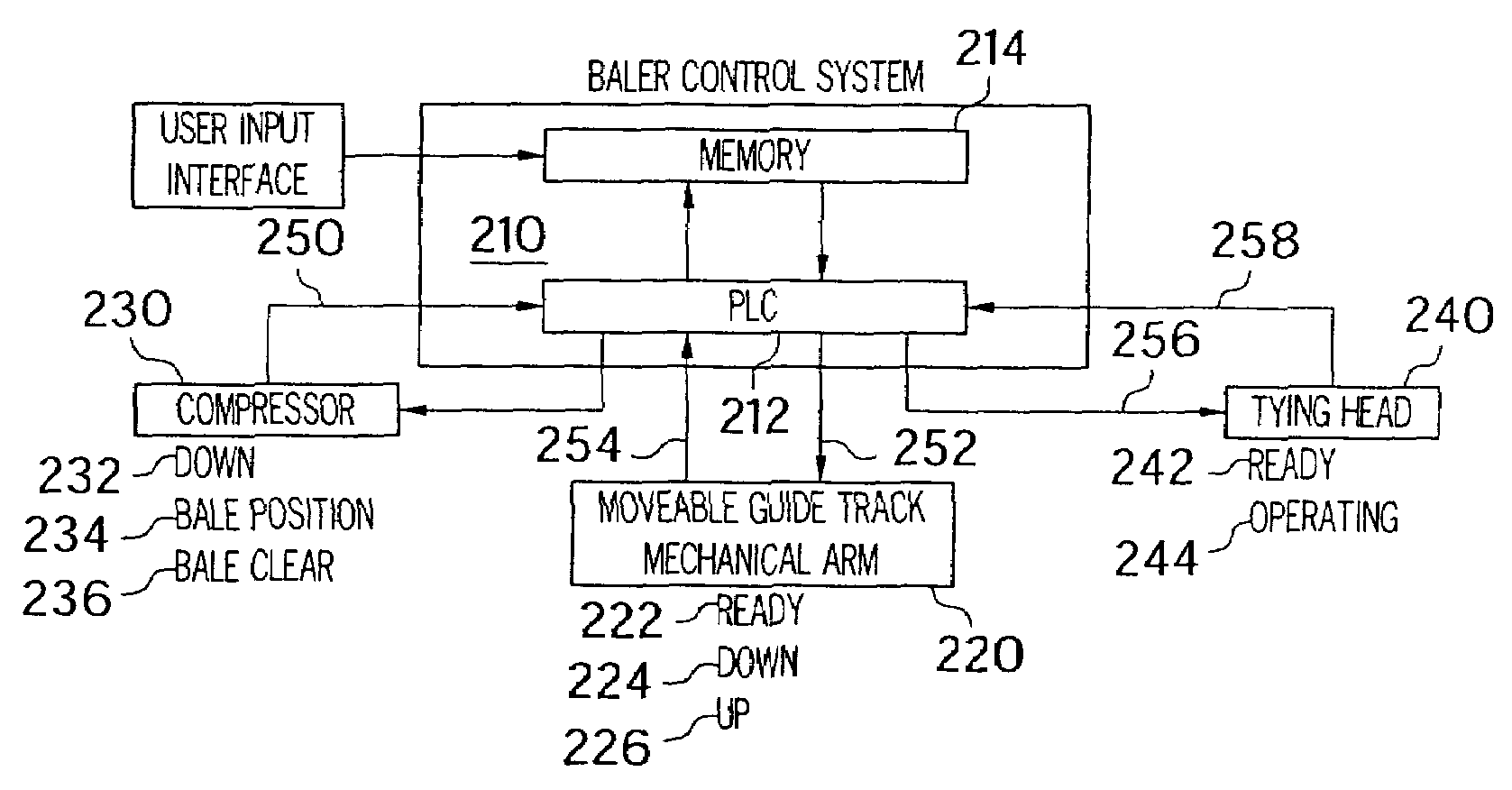

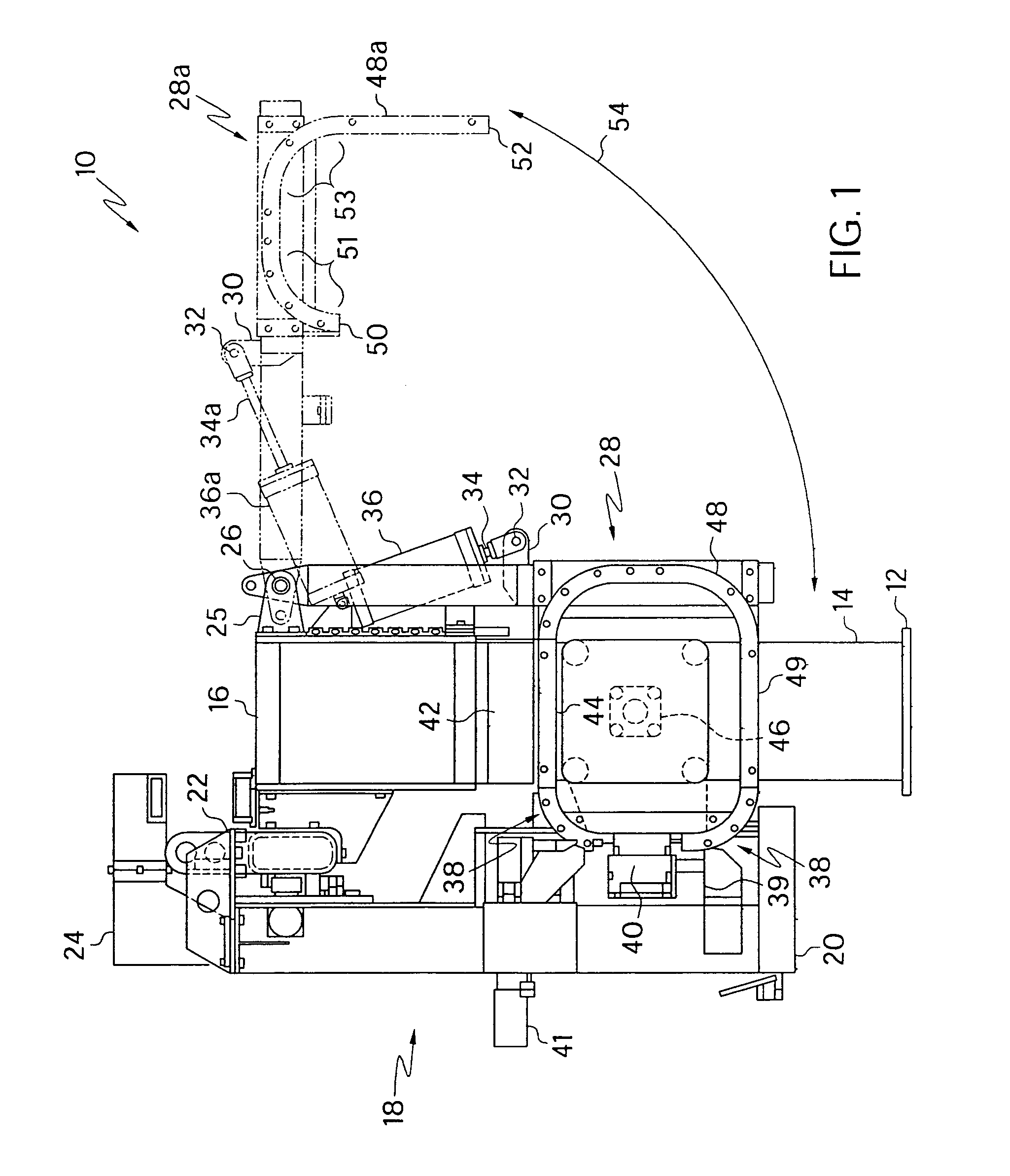

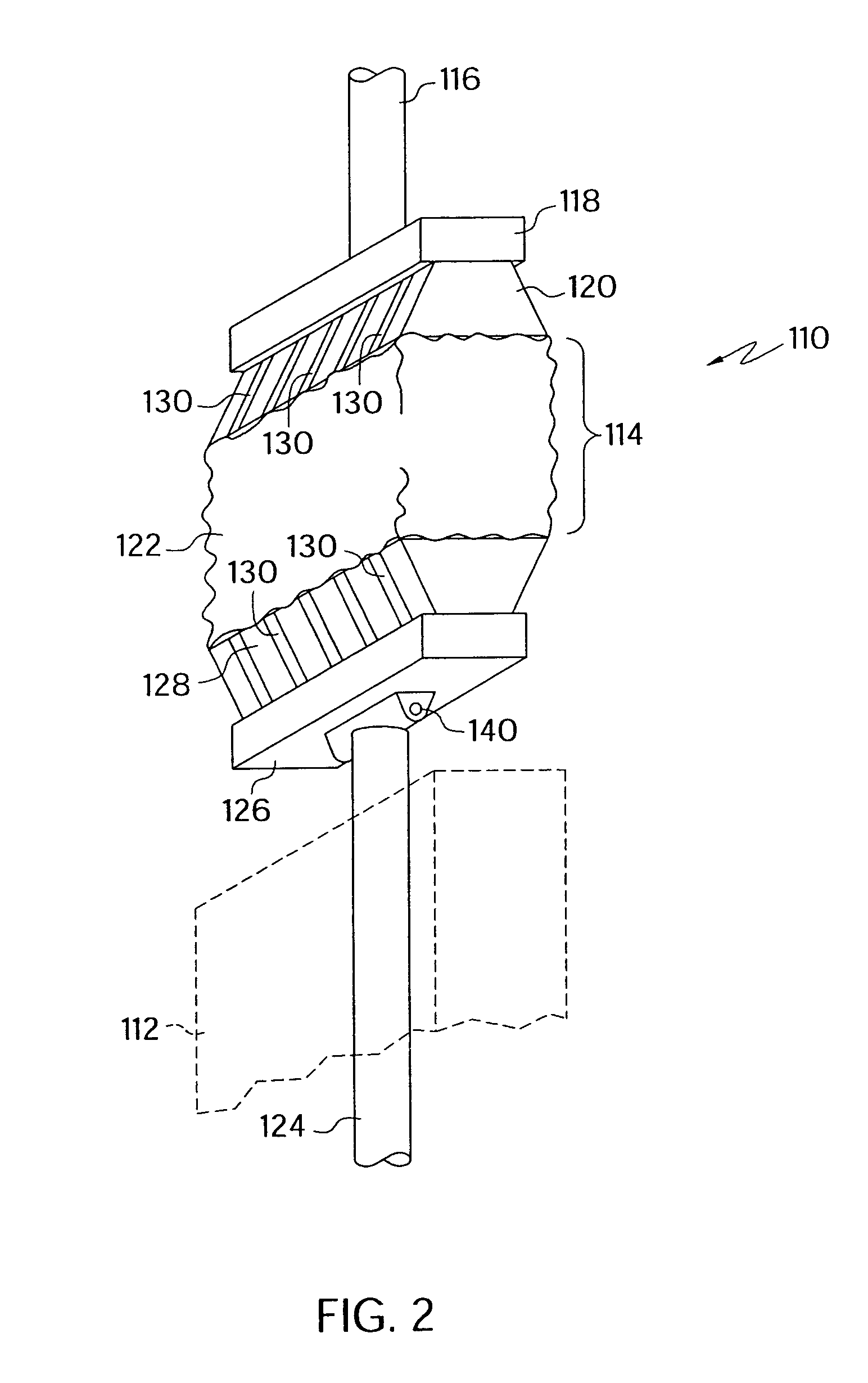

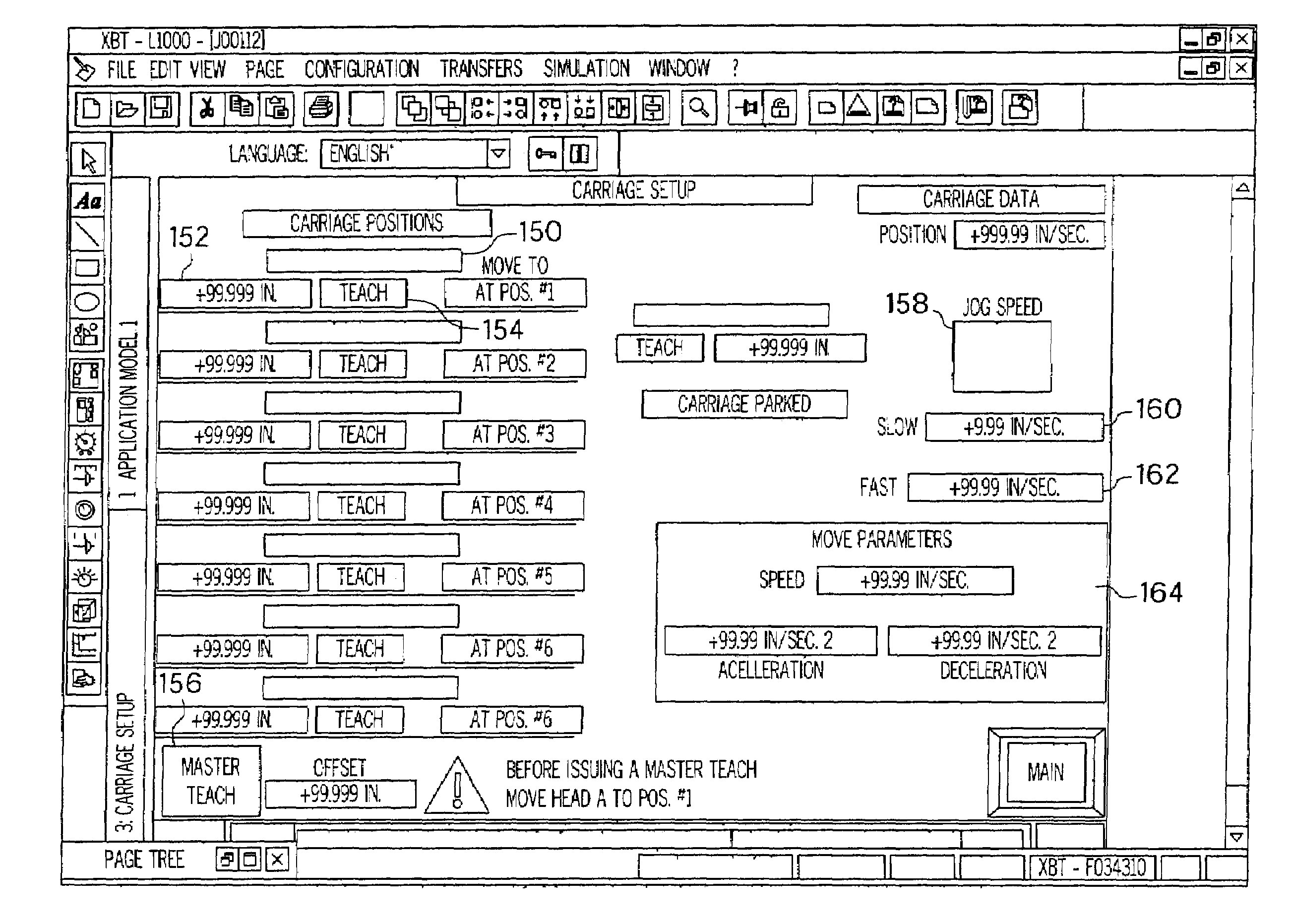

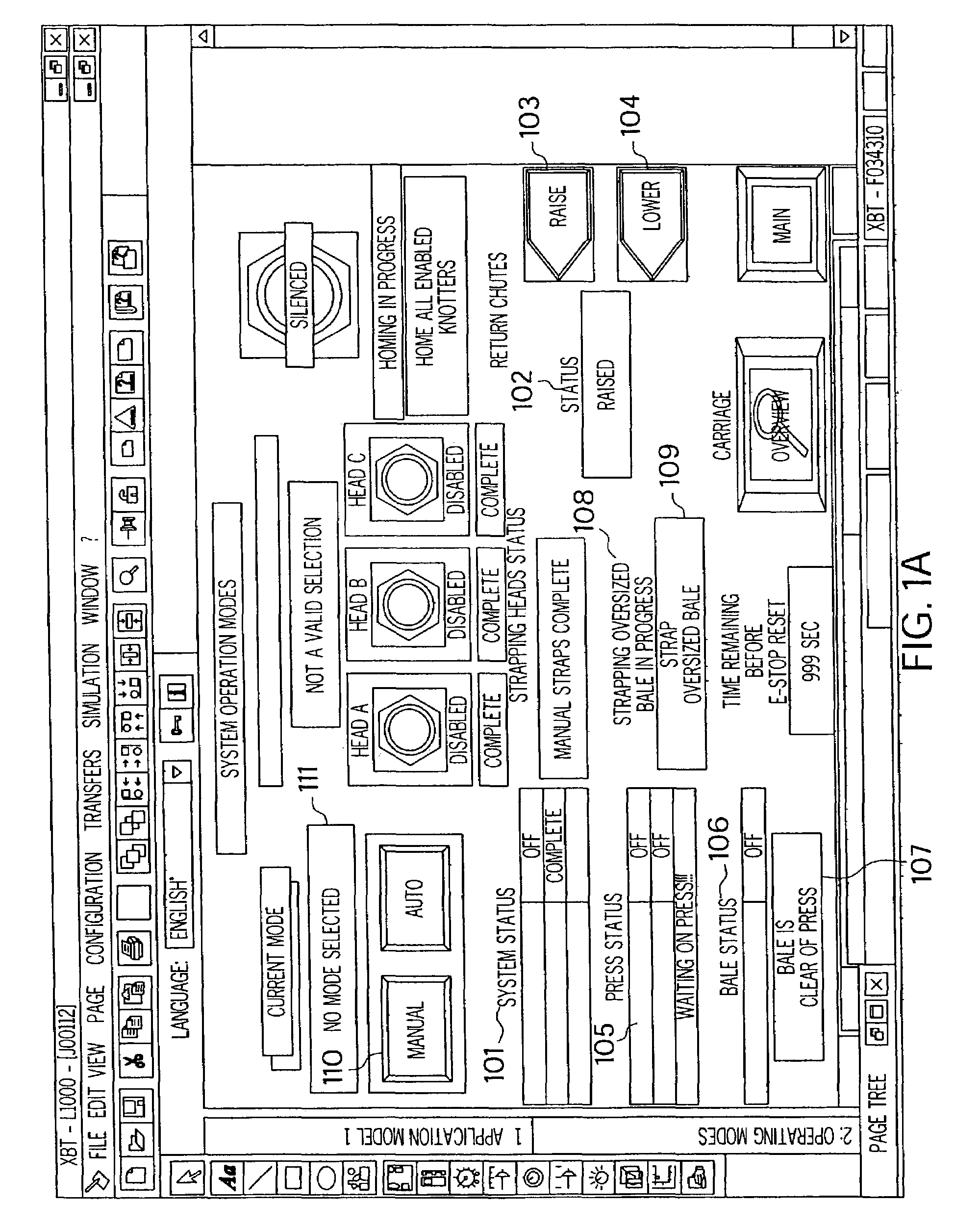

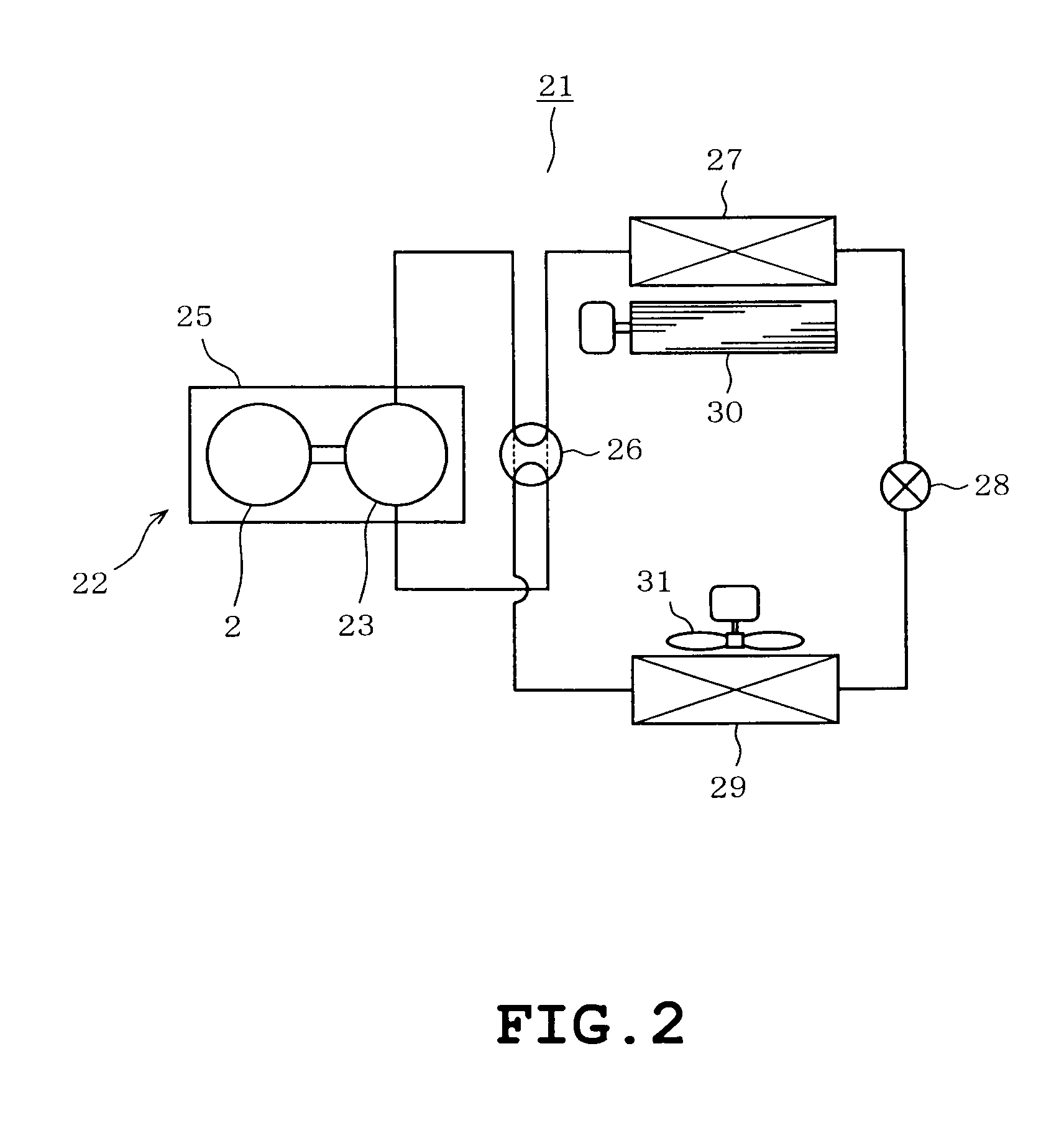

Control system for baling machine

InactiveUS7085625B2Precise torque controlAccurate measurementAnalogue computers for trafficTemperatue controlControl systemFeed drive

A control system for a bulk material baler embodied in a machine readable data structure and including an instruction to a moveable guide track to move from a removed position to a closed position to create a guide track loop around a volume of bulk material to be baled while that bulk material is under compression and also including in instruction to a bale strap feed drive to feed a pre-determined length of strapping around the guide track loop, and including an instruction to a cutter to cut the end of the bale strap and including an instruction to a strap fastener to fasten together the ends of the bale strap and including an instruction to remove the moveable guide track section from around the bale and an instruction to release compression and an instruction to eject a bound bale.

Owner:L P BROWN COMPANY INC DELAWARE

Elastic rotary actuator

InactiveUS20130074635A1Improve performancePrecise torque controlProgramme-controlled manipulatorYielding couplingEngineeringRotary actuator

Rotary actuators having a final output member rotatable about an axis of rotation; a motor unit designed to drive the final output member for rotation about the axis of rotation; and an elastic unit arranged between the motor unit and the final output member and having an input member torsionally coupled to the motor unit and an output member rigidly connected for rotation with the final output member are provided.

Owner:FOND INST ITAL DI TECH

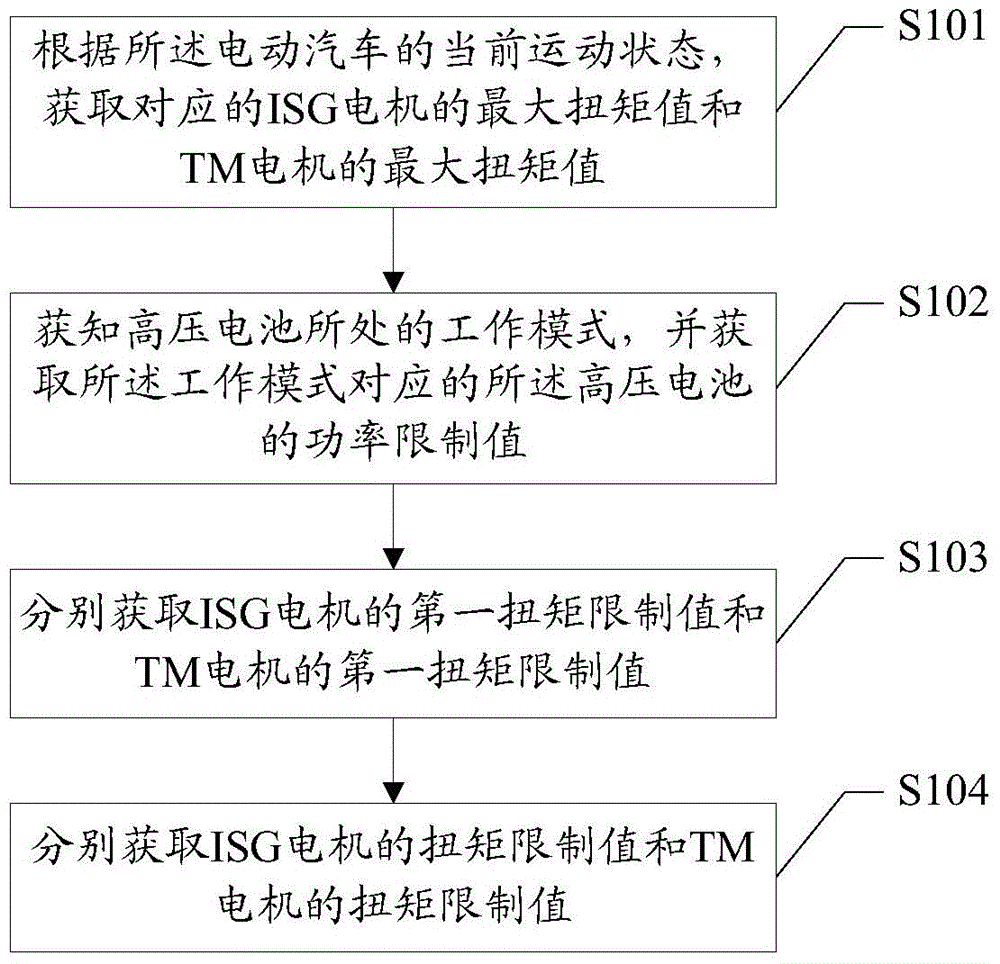

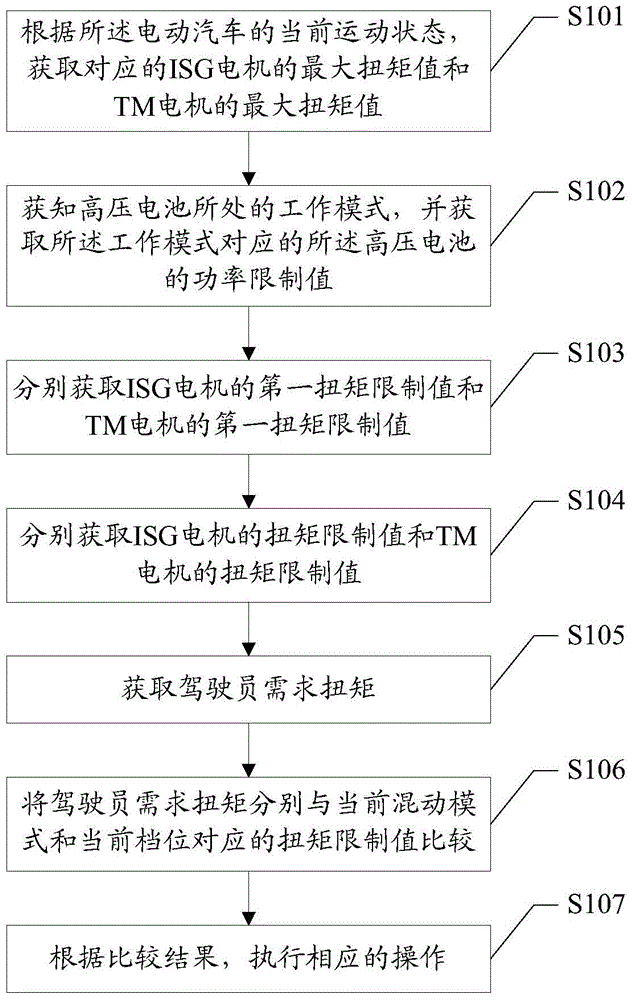

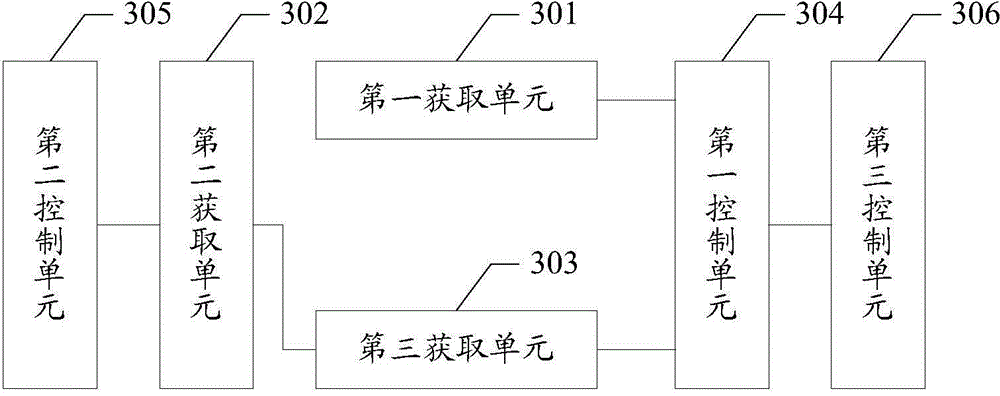

Electric automobile power system output torque control method and device

ActiveCN106314194APrecise torque controlPrevent overdischargeHybrid vehiclesSpeed controllerMaximum torqueElectric machine

The invention provides an electric automobile power system output torque control method and device. The electric automobile power system output torque control method comprises the steps that the corresponding maximum torque value of an ISG motor and the corresponding maximum torque value of a TM motor are obtained according to the current movement state of an electric automobile; the power limiting value corresponding to a working mode of a high-voltage battery is obtained; the first torque limiting value of the ISG motor and the first torque limiting value of the TM motor are obtained separately according to the power limiting value of the high-voltage battery and the power distribution relationship between the ISG motor and the TM motor under the current movement state of the electric automobile; the maximum torque value, the first torque limiting value and the preset second torque limiting value of the ISG motor are compared, and the minimum value is selected as the torque limiting value of the ISG motor; and the maximum torque value, the first torque limiting value and the preset second torque limiting value of the TM motor are compared, and the minimum value is selected as the torque limiting value of the TM motor. By adopting the electric automobile power system output torque control method and device, the torque limiting precision can be improved.

Owner:SAIC MOTOR

Control apparatus for AC motor

ActiveUS8044618B2Enabling useSet more correctly and more simply and convenientlySynchronous motors startersVector control systemsState variableOrthogonal basis

It is attained by being provided with a motor constant calculation unit for calculating electric constants of a motor, and by correcting setting values of electric constants defined on one of the axes of two orthogonal axes, by a functional expression using a state variable defined on the same axis, and by correcting them by a functional expression using a state variable defined on the other axis.

Owner:HITACHI LTD

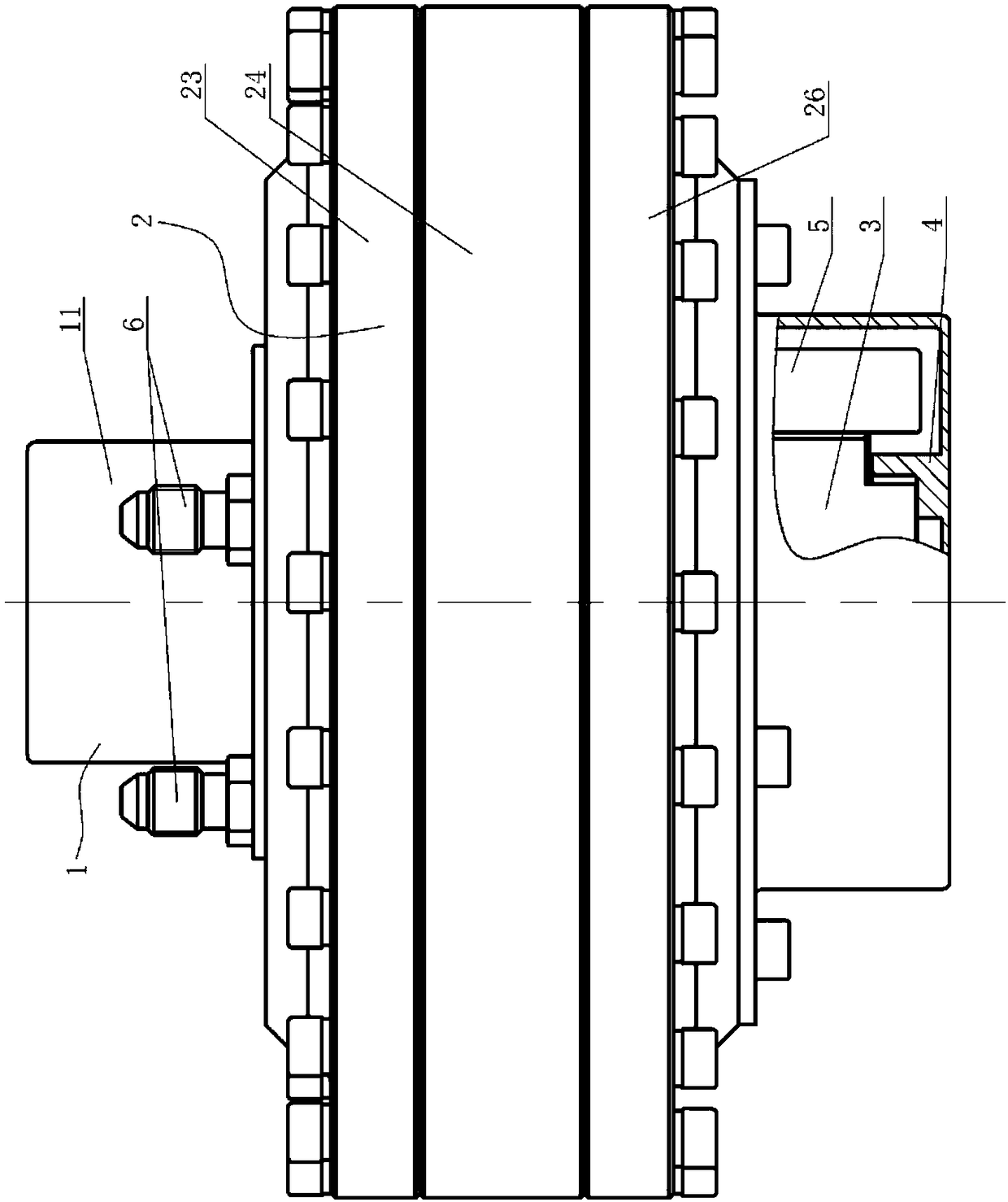

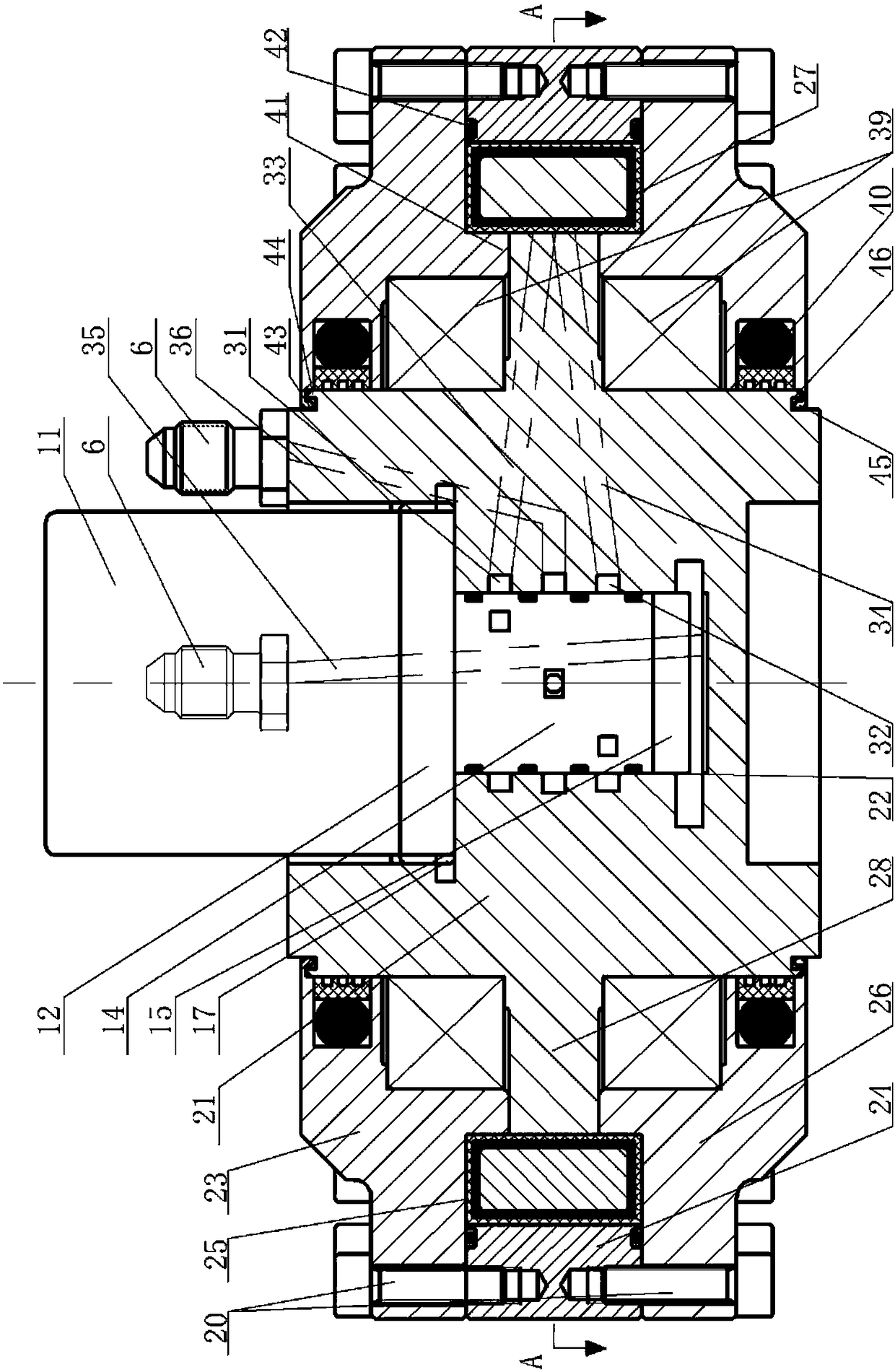

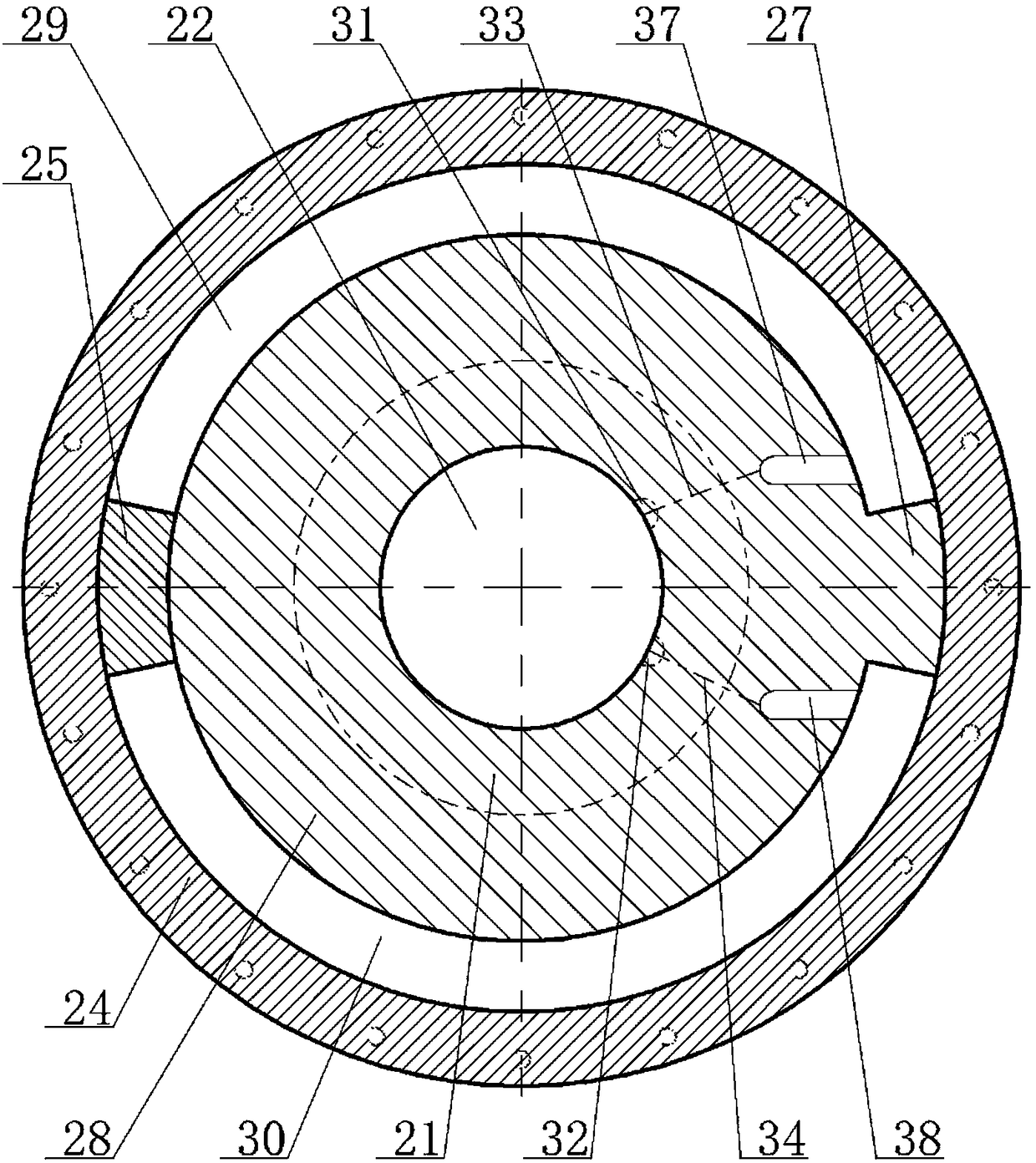

Hydraulic drive joint for robots

ActiveCN108608459AAccurate locationPrecise torque controlProgramme-controlled manipulatorJointsHydraulic cylinderActuator

The invention provides a hydraulic drive joint for robots, namely a robot joint based on the integration of a hydraulic plug-in rotary direct-drive valve and a blade rocking cylinder; a hydraulic actuator, an electrohydraulic servo valve, and detection elements, a position sensor and a pressure sensor, are modularly integrated and applied to the robot joint; the requirement for the development ofexisting robots can be met, and applicable range of the robots can also be widened. The hydraulic drive joint for robots comprises a threaded plug-in rotary direct-drive electrohydraulic servo valve,and a blade rocking hydraulic cylinder special for robot motion joints; the threaded plug-in rotary direct-drive electrohydraulic servo valve is abbreviated hereinafter as a hydraulic plug-in rotary direct-drive valve; the blade rocking hydraulic cylinder special for robot motion joints is abbreviated hereinafter as a blade rocking cylinder; a valve mounting cavity is pre-manufactured in one end of the center of a center spindle of the blade rocking cylinder; the shape of the valve mounting cavity is made according to the shape of an insert portion of the hydraulic plug-in rotary direct-drivevalve; the hydraulic plug-in rotary direct-drive valve is plugged in the valve mounting cavity.

Owner:JIANGSU DREAMWELL DYNAMICS TECH CO LTD

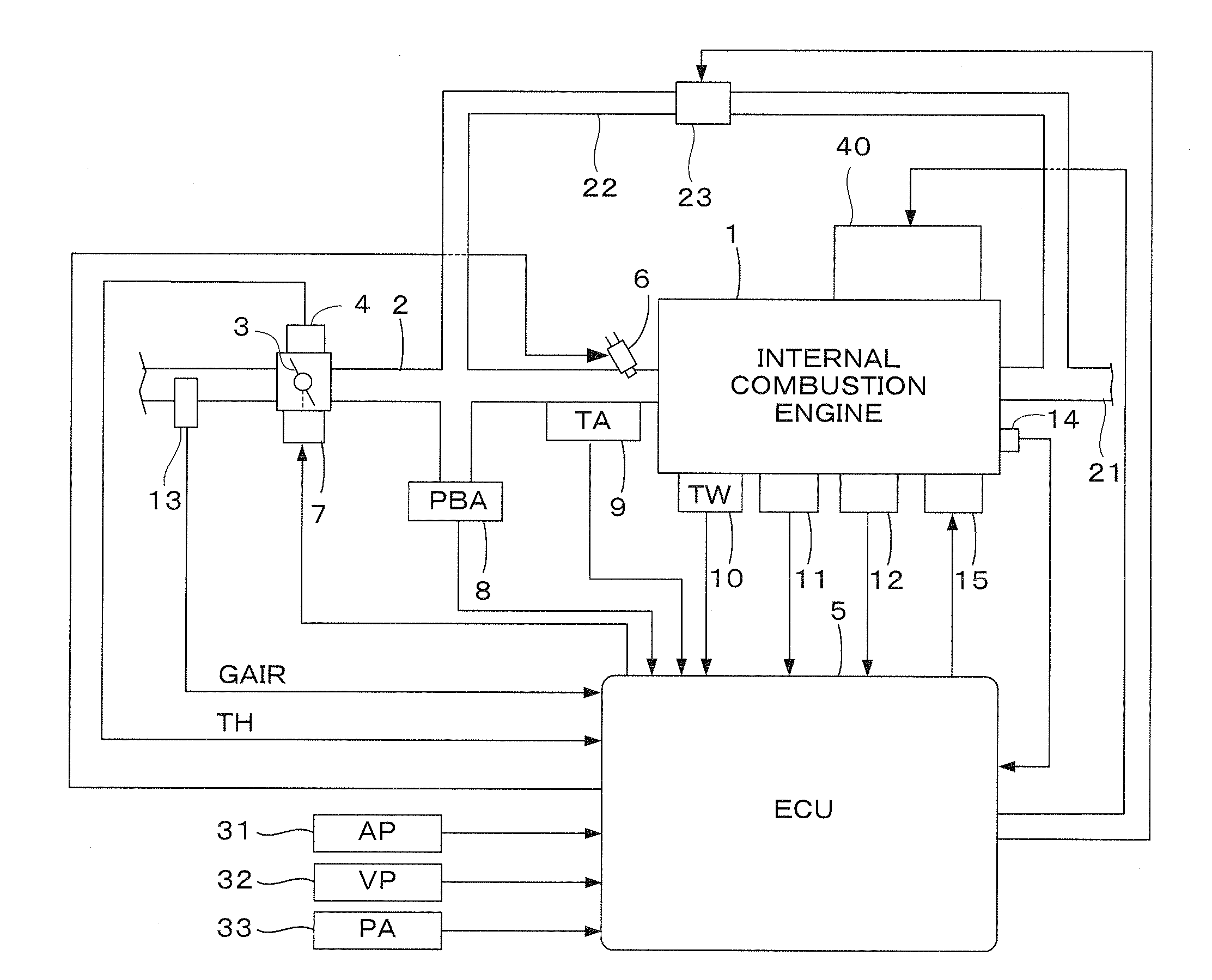

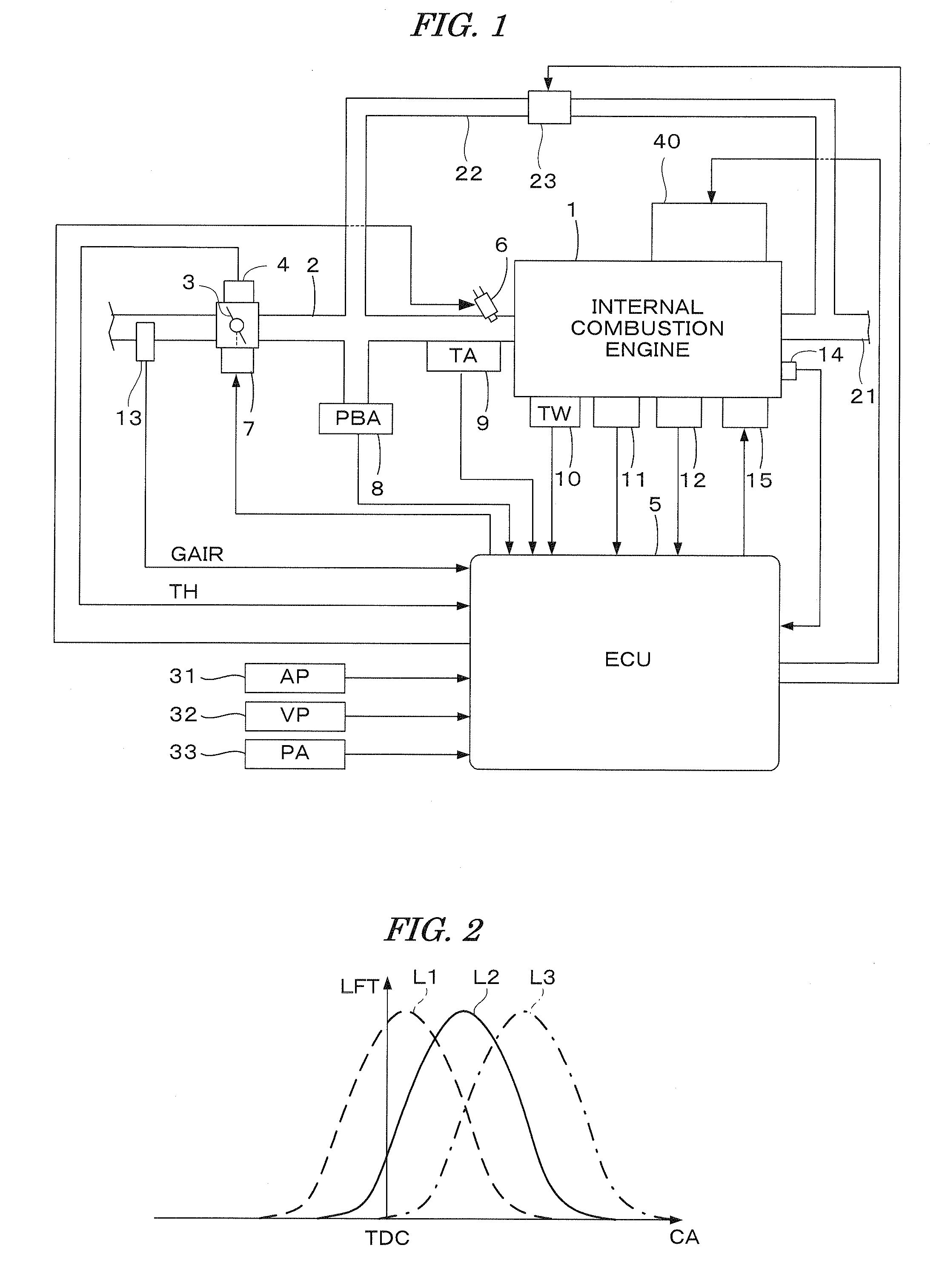

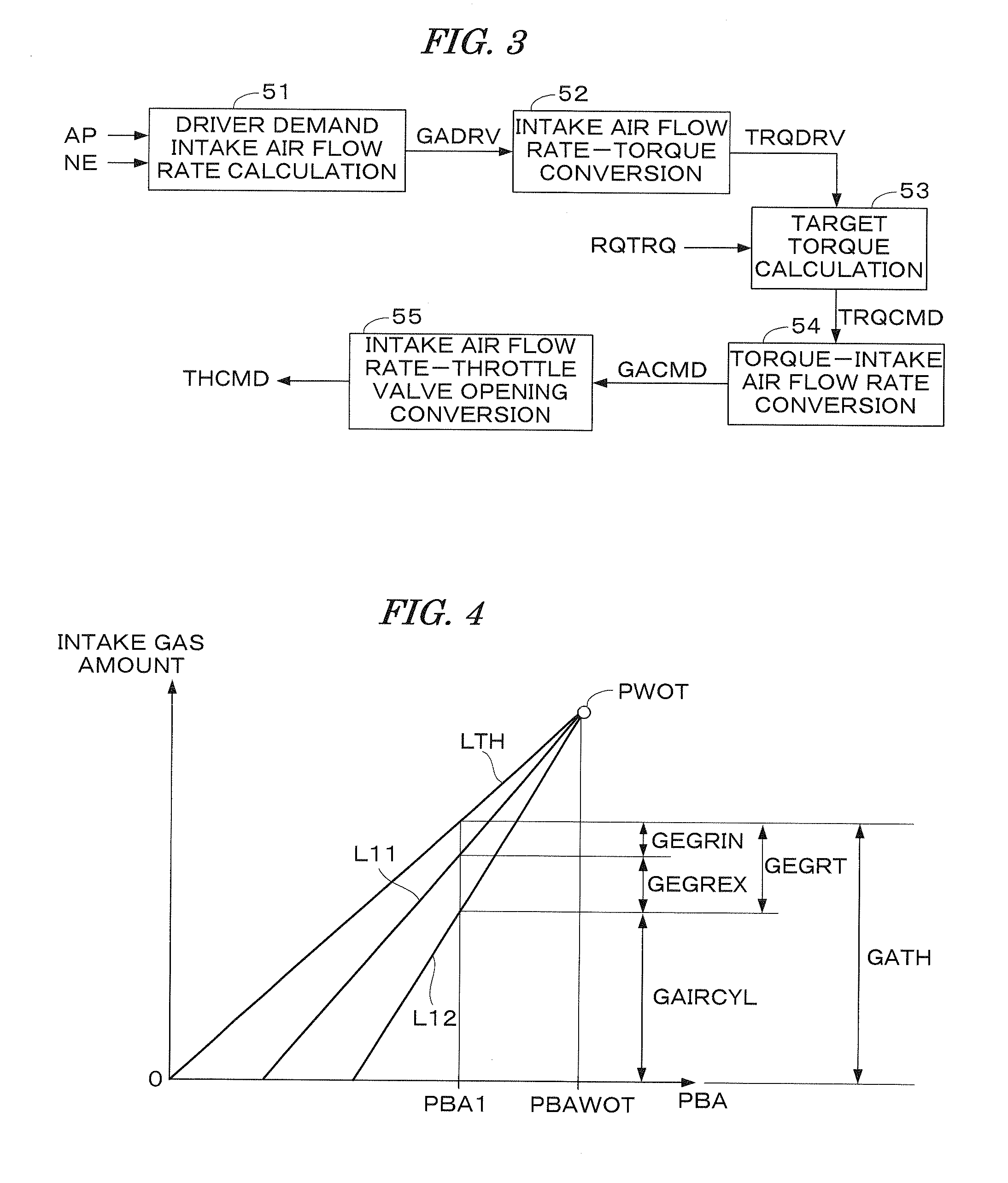

Control system for internal combustion engine

ActiveUS20120053822A1Accurate calculationSimple methodElectrical controlInternal combustion piston enginesExternal combustion engineControl system

A control system for an internal combustion engine having a throttle valve disposed in an intake passage of the engine. A target intake air amount of the engine is calculated, and an intake pressure of the engine is estimated. A wide-open intake air amount is calculated according to the engine rotational speed, and a theoretical intake air amount is calculated according to the wide-open intake air amount and the intake pressure. The wide-open intake air amount is an intake air amount corresponding to a state where the throttle valve is fully opened, and the theoretical intake air amount is an intake air amount corresponding to a state where no exhaust gas of the engine is recirculated to a combustion chamber of the engine. further, an exhaust gas recirculation ratio is calculated using the theoretical intake air amount and the target intake air amount, and a target output torque of the engine is calculated using the target intake air amount and the exhaust gas recirculation ratio. The engine is controlled using the target output torque.

Owner:HONDA MOTOR CO LTD

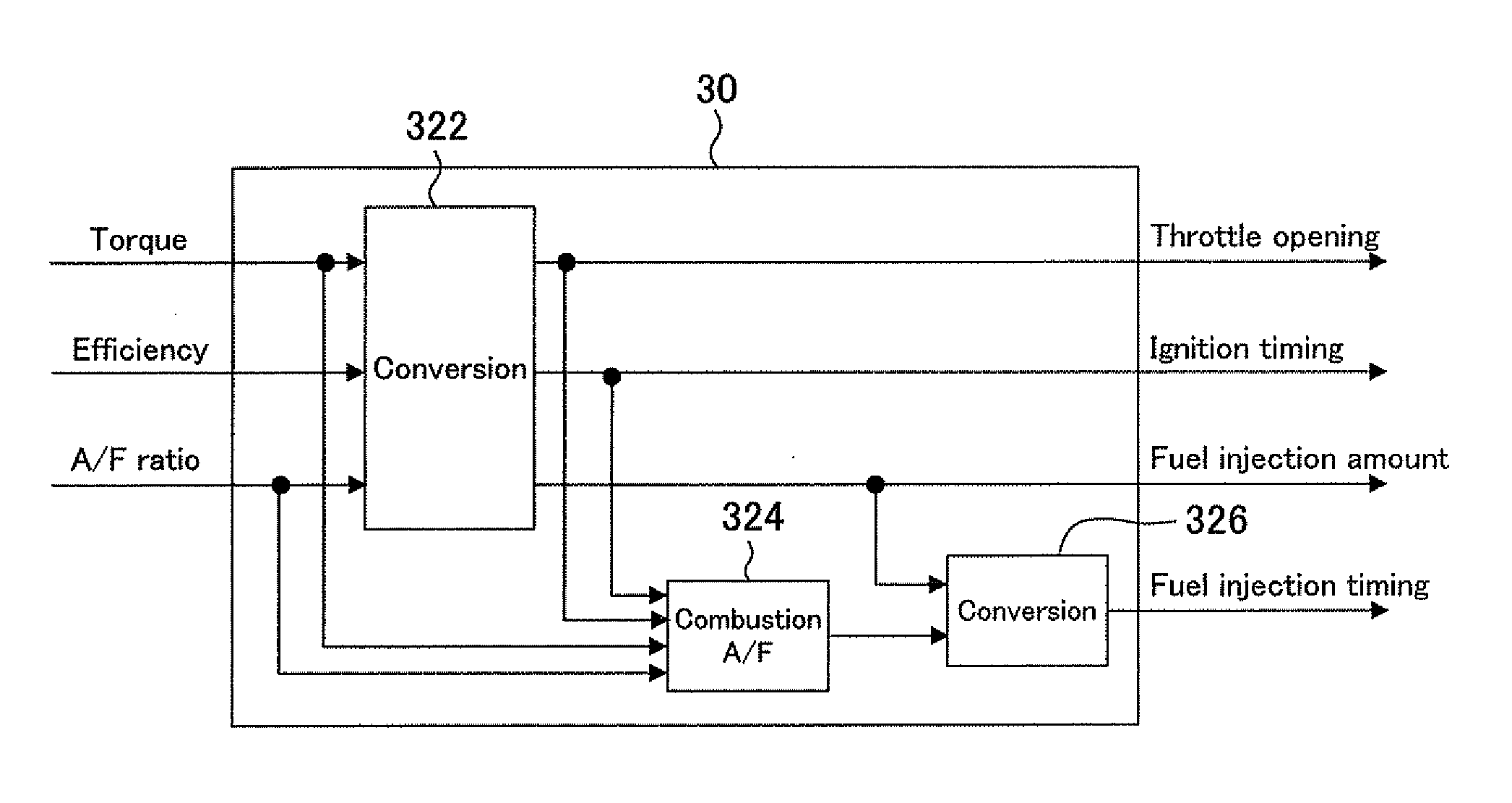

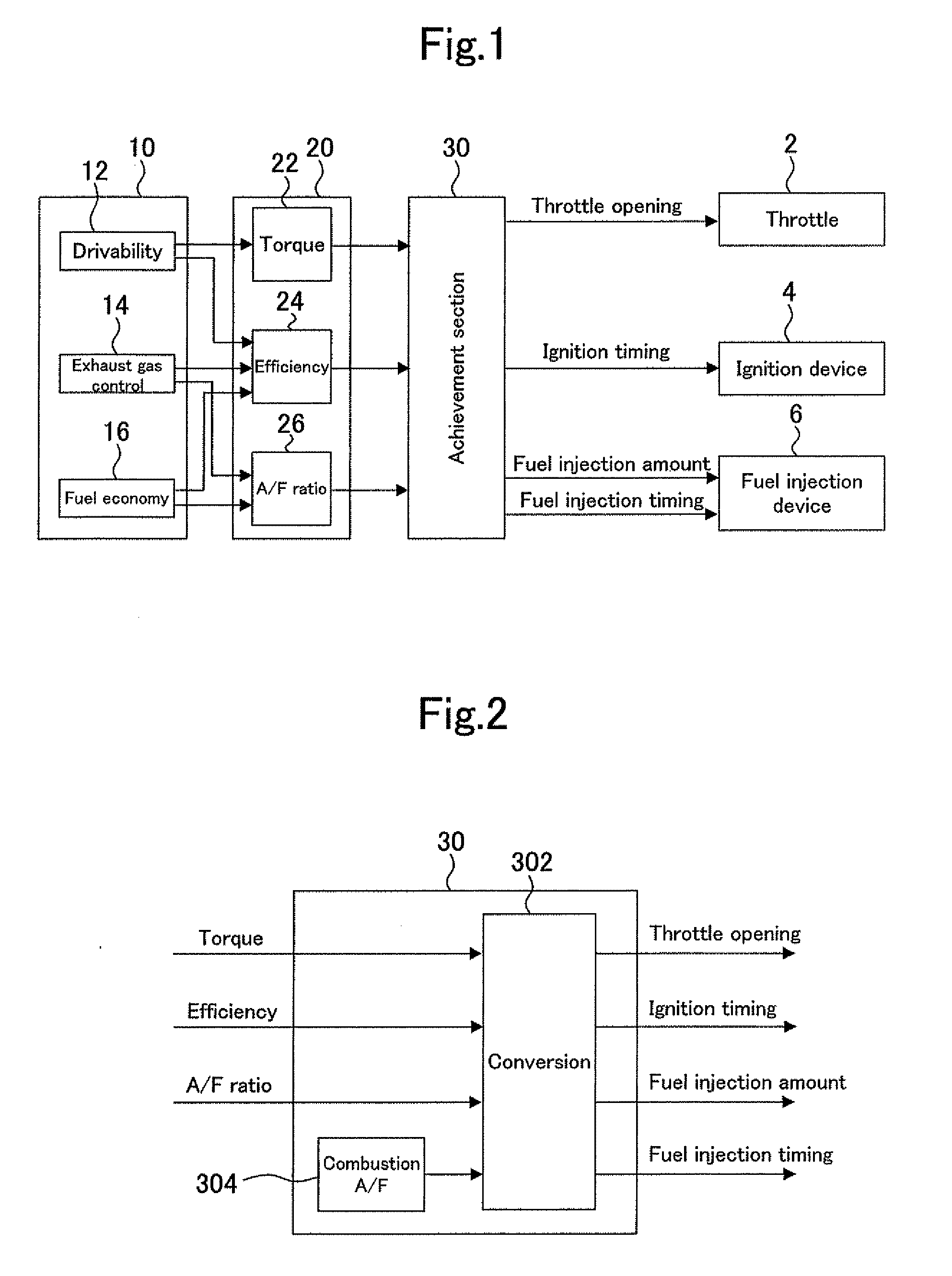

Control device for internal combustion engine

ActiveUS20110098905A1Accurately reflectAvoid complicationsAnalogue computers for vehiclesElectrical controlExternal combustion engineActuator

Disclosed are a control device and a control method that are used with an internal combustion engine in which the air-fuel ratio in the vicinity of an ignition plug differs from the overall air-fuel ratio in a cylinder, and capable of properly fulfilling demands concerning various capabilities of the internal combustion engine by accurately reflecting each of the demands in the operation of each actuator. Three physical quantities, namely, a torque, an efficiency, and an air-fuel ratio, are used as controlled variables for the internal combustion engine. Target values for the controlled variables are then set by integrating at least some of demands concerning a capability of the internal combustion engine into the three physical quantities. Further, in accordance with the target values for the three controlled variables, namely, the torque, the efficiency, and the air-fuel ratio, three operation amounts, namely, an intake air amount adjustment valve opening, an ignition timing, and a fuel injection amount are set, and a fourth operation amount for adjusting the air-fuel ratio distribution in the cylinder is set.

Owner:TOYOTA JIDOSHA KK

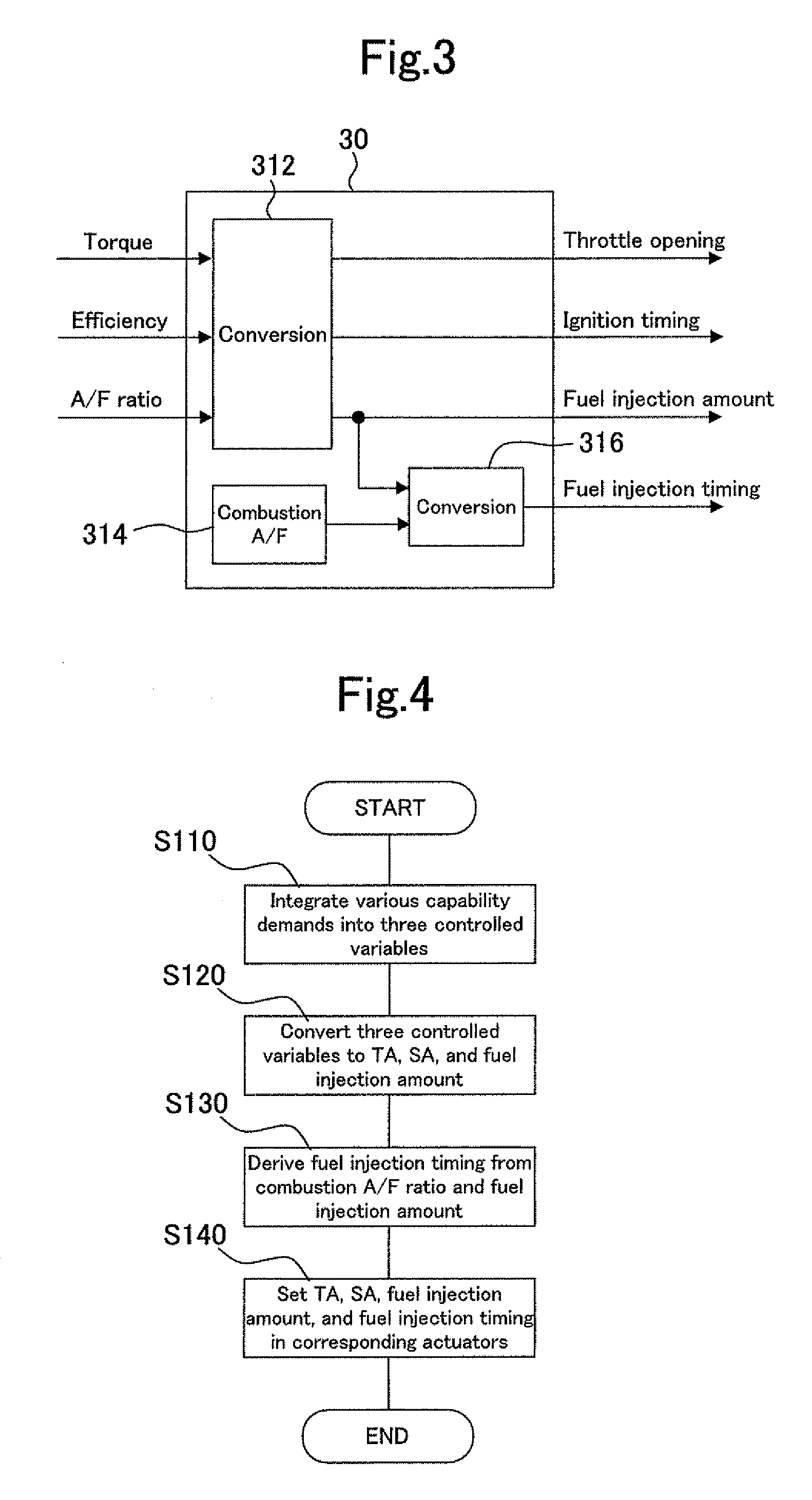

Operator input interface for baling machine

InactiveUS6975911B2Speed maximizationEffective controlProgramme controlComputer controlOperator interfaceControl system

An operator interface for a control system for a bulk material baler includes interface means such as a touch screen or keyboard for an operator to enter process parameters into a control system memory. A display shows process parameter fields into which an operator may enter desired control parameters. The display also displays data feedback from baler process sensors. The baler control system then controls baling parameters as the operator directs including: strap feed position, strap feed speed, strap feed torque, strap release tension, tying cylinder position, tying cylinder speed and tying cylinder torque. The operator may also control carriage movement, alarm limits, shut off limits and monitor on the display baler processing data both currently and historically. Other aspects of automated baling may be optionally monitored or controlled through the operator interface of the present invention.

Owner:L P BROWN COMPANY INC DELAWARE

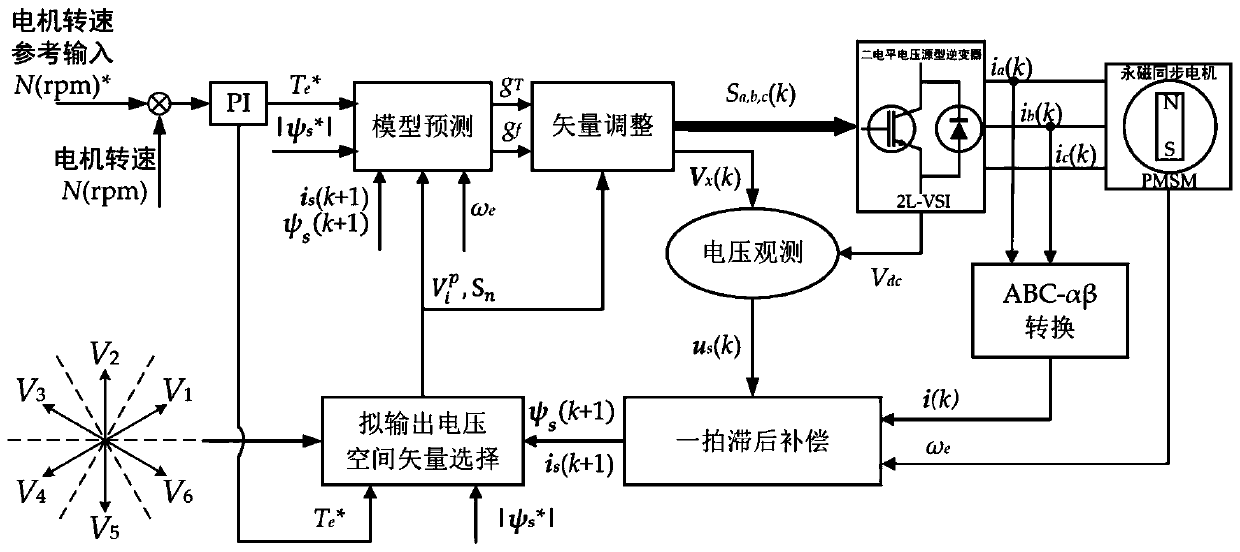

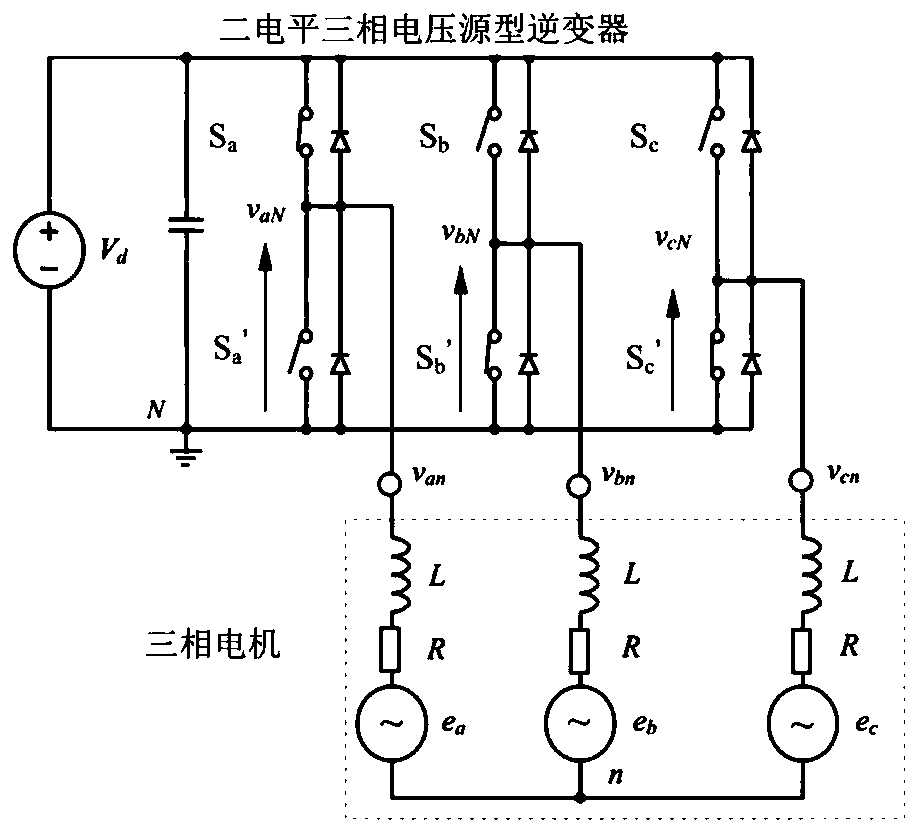

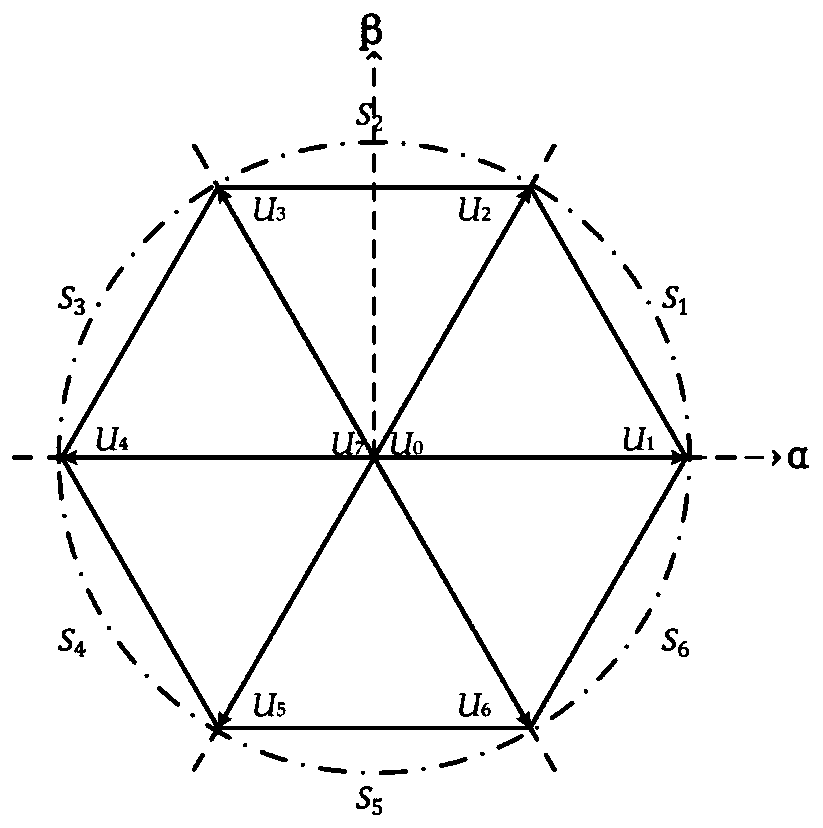

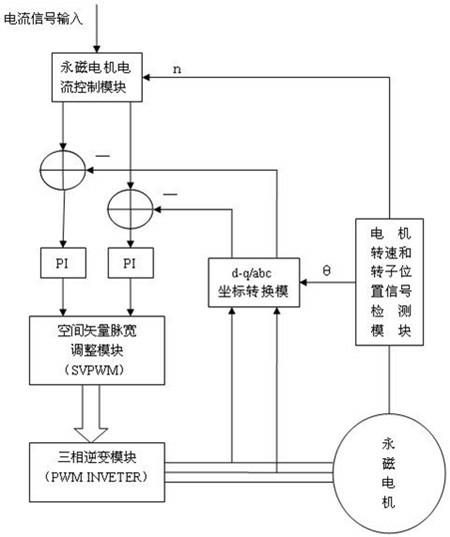

FCS-MPDTC control system and method for PMSM capable of expanding voltage space vector output

ActiveCN110601627AImprove controlIncrease the range that can be outputTorque ripple controlAC motor controlTotal harmonic distortionControl system

An FCS-MPDTC control system for a PMSM capable of expanding a voltage space vector output includes a proportional-integral (PI) controller, model prediction, vector adjustment, voltage observation, ABC-[alpha][beta] conversion, one-beat lag compensation, pseudo output voltage space vector selection, a two-level voltage source inverter and a permanent magnet synchronous motor. The control method, based on a torque control strategy capable of expanding an output voltage space vector range performed by two-step model prediction, can be developed on a comprehensive experimental platform of dSPACEand Typhoon HIL Q402. The system achieves good magnetic flux linkage and torque control performance, a small amount of calculation related to the algorithm, low current total harmonic distortion (THD), low development cost of the hardware requirements, and fast and real-time result monitoring, and is universal in development and test of power electronic drive systems.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Axial magnetic field printed circuit board permanent magnet brushless DC motor

InactiveCN105703510AIncrease powerFlexible designWindings conductor shape/form/constructionElectric machineEngineering

The invention discloses an axial magnetic field printed circuit board permanent magnet brushless DC motor. Including the rotating shaft, a pair of symmetrically arranged turntables installed on the rotating shaft; permanent magnets are fixed on the opposite surfaces of the two turntables; a printed circuit board is arranged in the middle of the two turntables, and there is a gap between the printed circuit board and the permanent magnets on both sides ; On the printed circuit board, there are many radial single wires evenly distributed around the center of the circle; the single wires are evenly divided into multiple groups, and each group of single wires includes a 3-phase coil; the single wire in each phase coil passes through the outer The outer ring connecting wire at the end and the inner ring connecting wire at the inner end are connected to form a winding loop. The invention uses printed circuit boards instead of traditional windings, so that the design of the motor stator is flexible and changeable, and high-precision wiring is realized; the circuit boards are arranged in multiple layers to increase the current carrying capacity, thereby increasing the power of the motor; no iron core is required, and eddy current loss is eliminated. The efficiency is improved, and the overall structure is simplified, which is beneficial to the assembly line and improves the production efficiency.

Owner:江苏河谷矿业科技发展有限公司

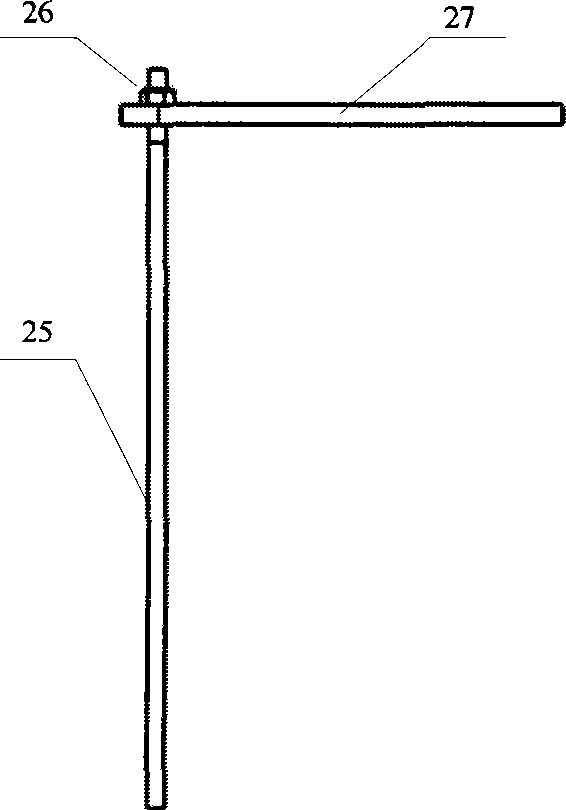

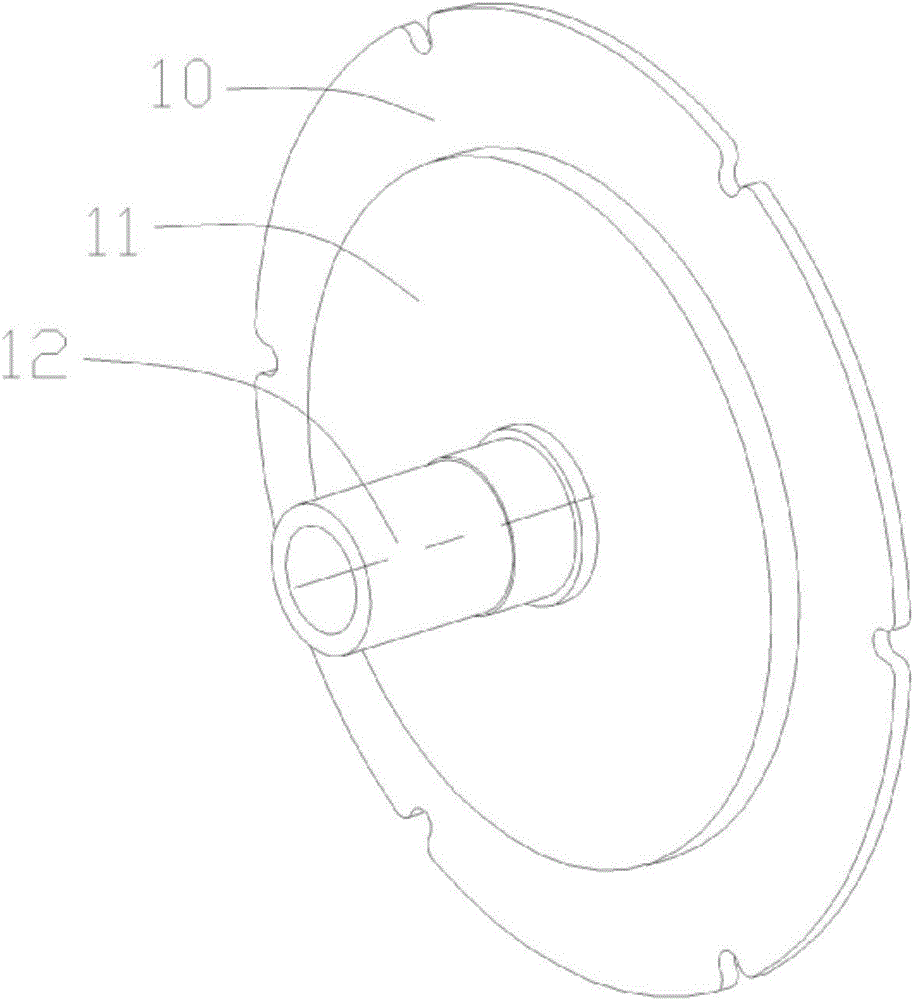

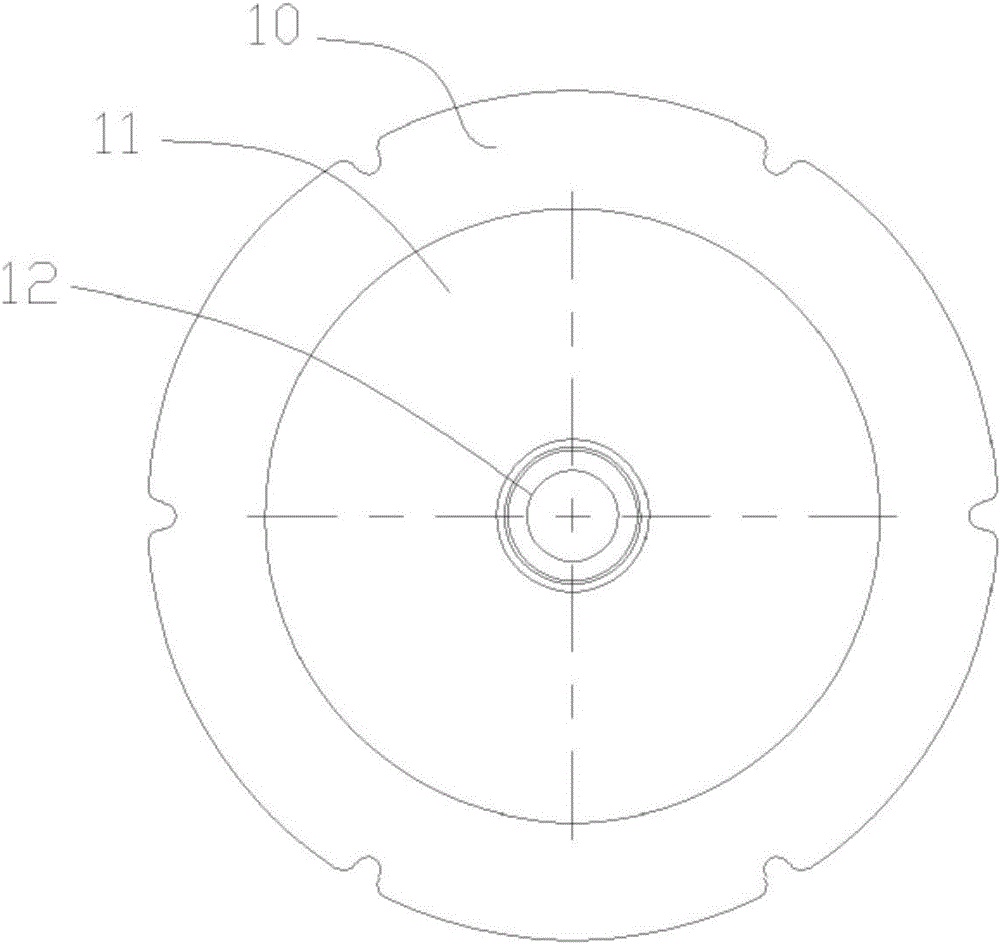

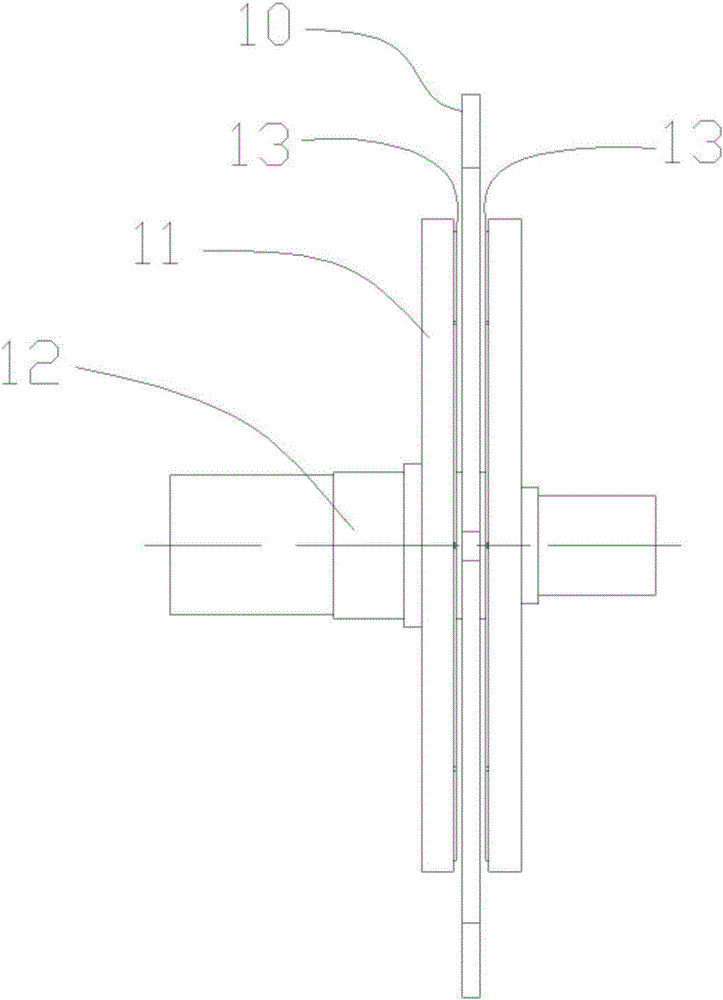

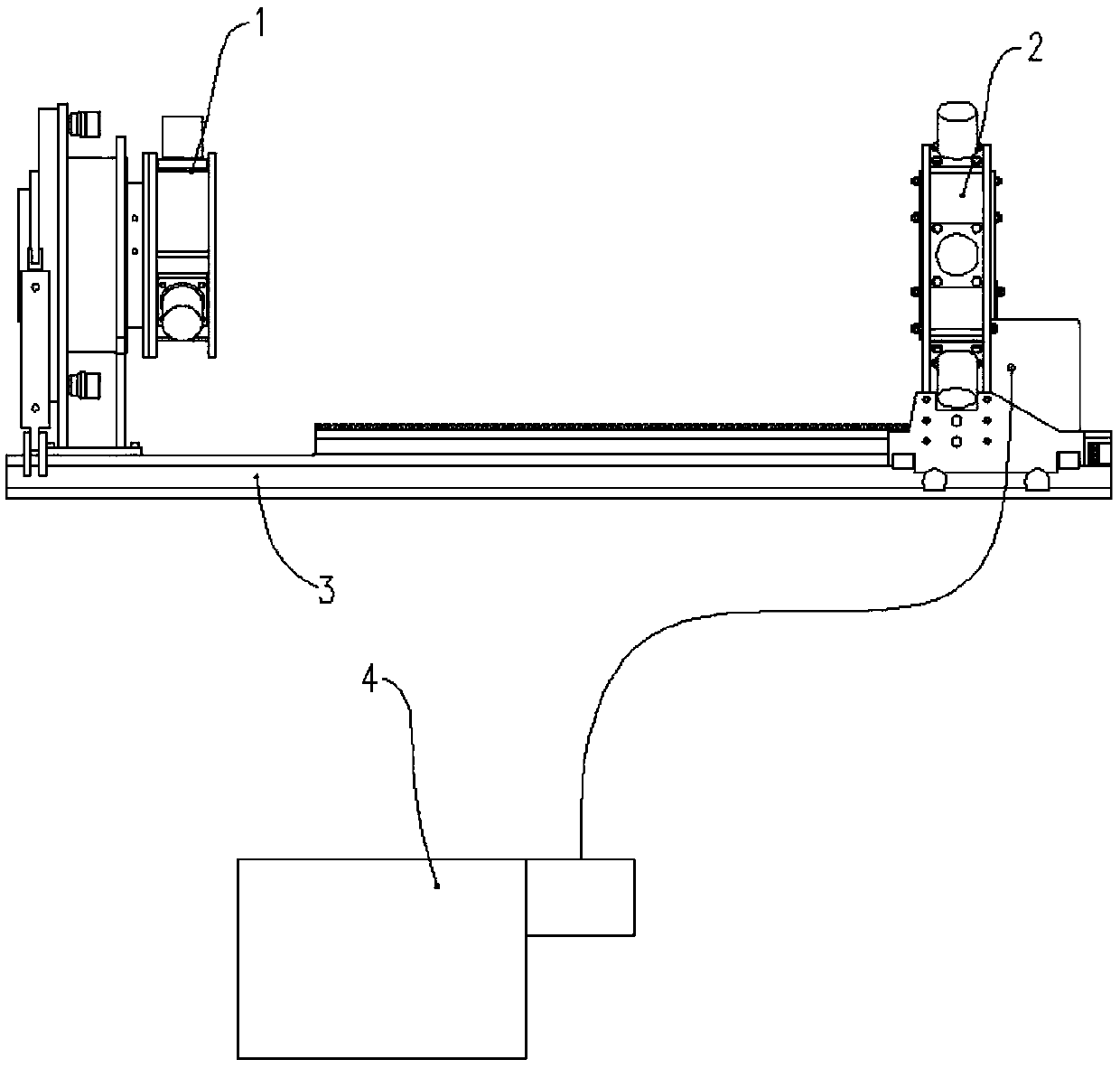

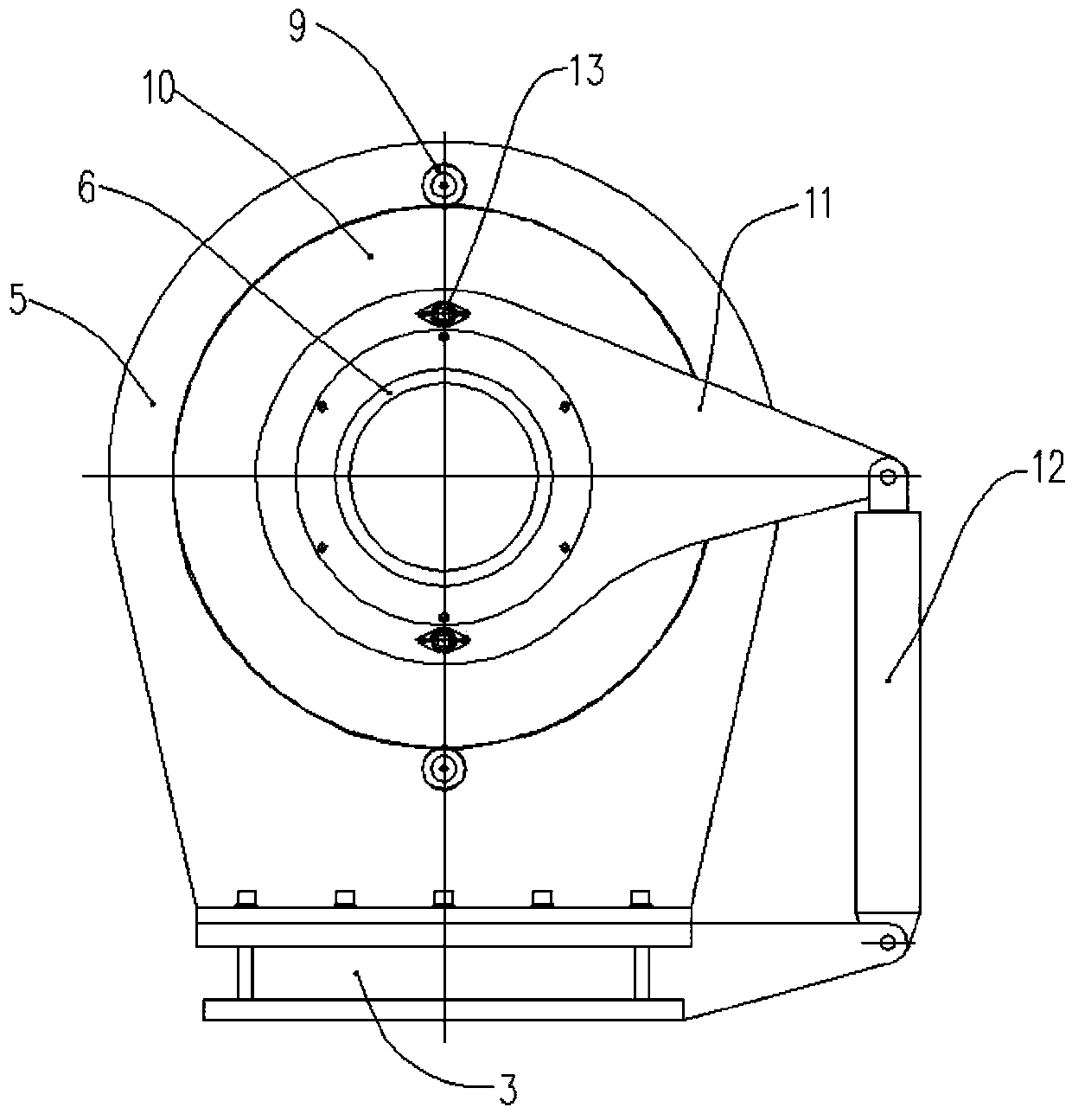

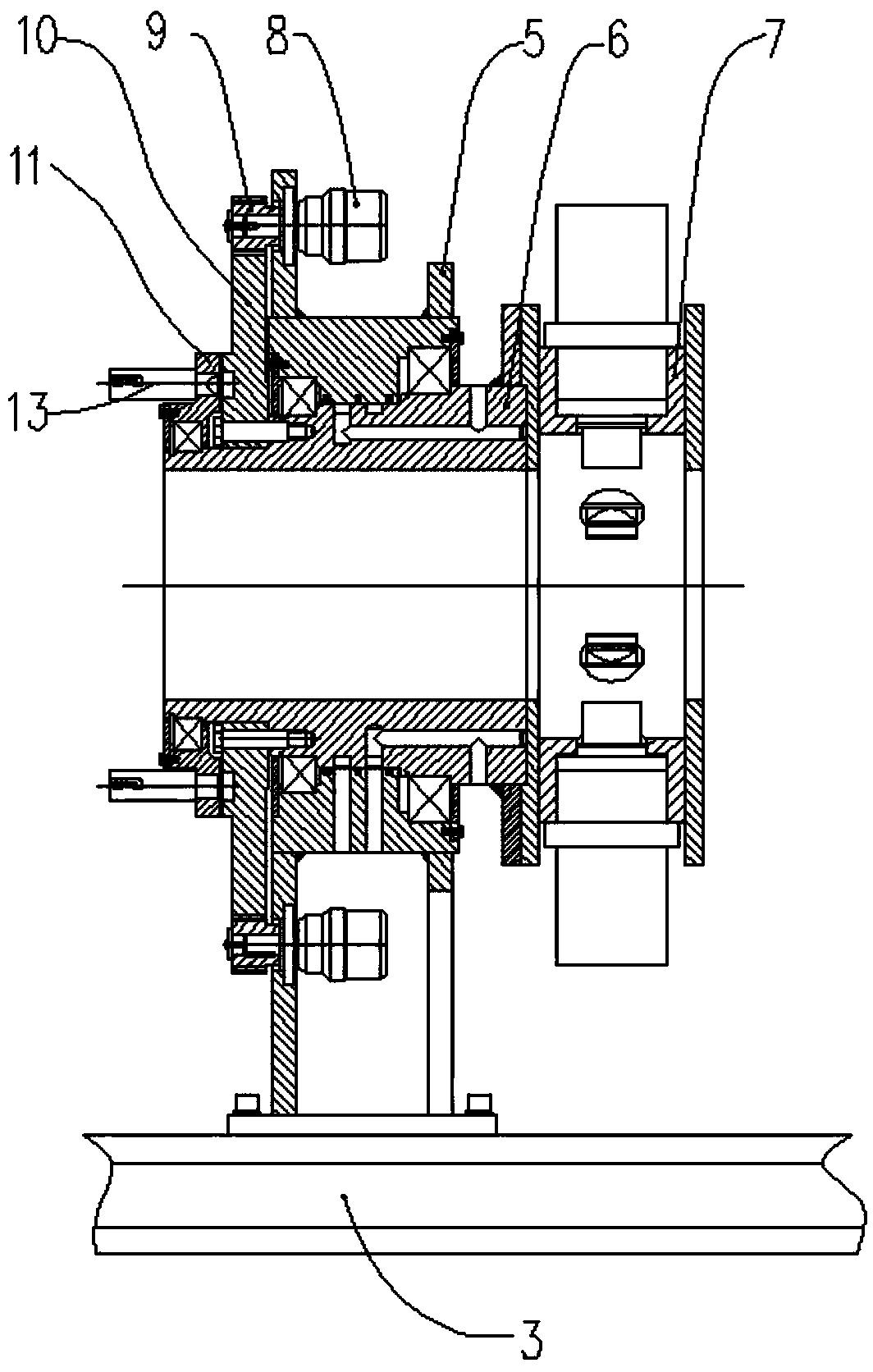

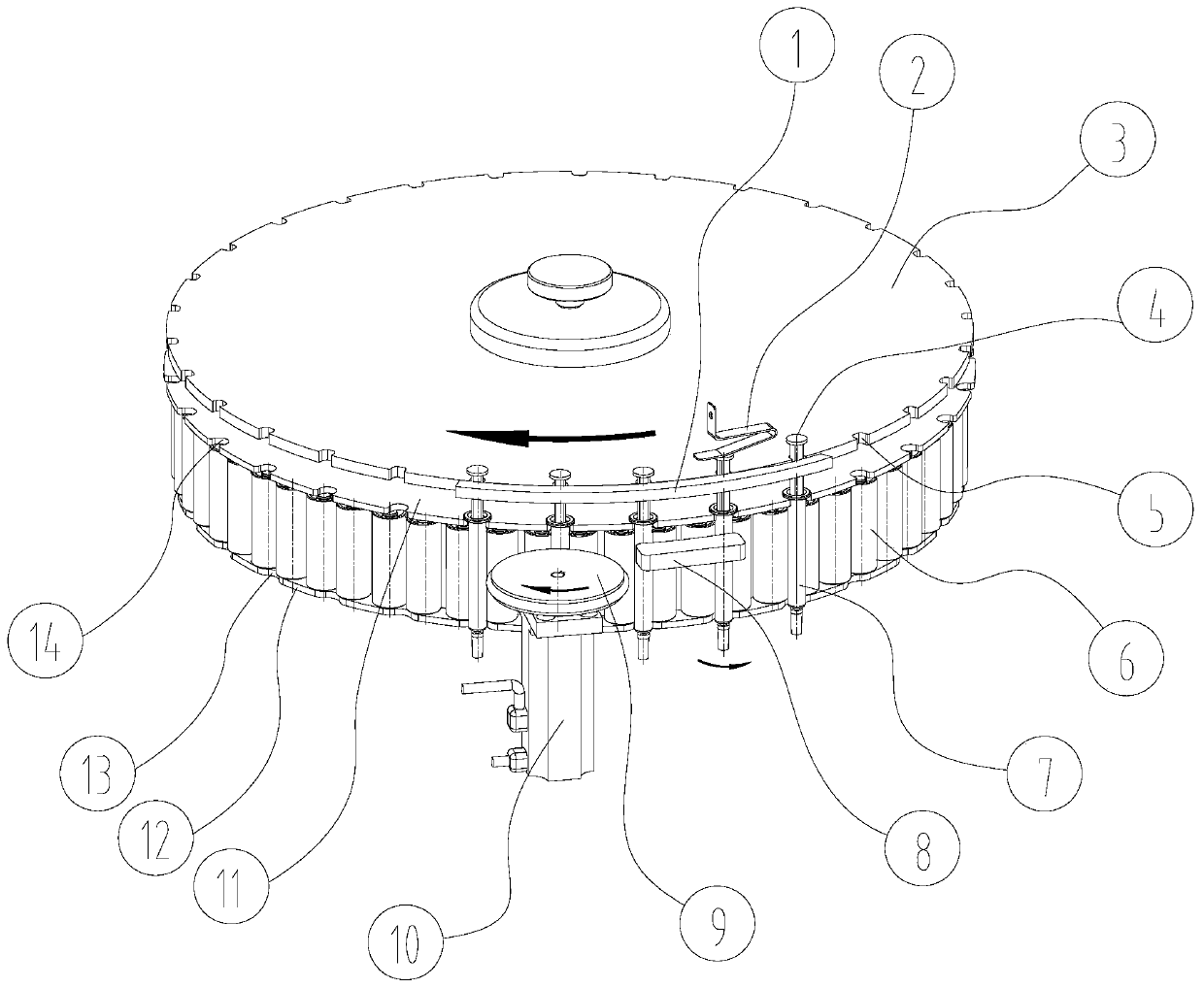

Continuous-spinning assembly and disassembly frame and torque and rotation speed control method

ActiveCN104196470AImprove work efficiencyAchieve relatively precise control of torqueDrilling rodsDrilling casingsMechanical engineeringControl engineering

The invention discloses a continuous-spinning assembly and disassembly frame and a torque and rotation speed control method. Through torque control, the requirements for torque of spinning at different stages are met, breakout is configured through separation and reunion, therefore, during continuous spinning and reciprocating punching, a workpiece does not need to be clamped repeatedly and makeup and breakout can be completed through one-time clamping. For most driving devices, due to the fact that the output power is fixed, when the speed is high, output torque is reduced correspondingly, therefore, the spinning speed can be automatically switched according to spinning torque by using the characteristic, the smaller the torque is, the higher the rotation speed is, and the working efficiency is effectively improved; when a set torque value is reached, unloading can be conducted automatically, and relatively accurate control over the torque is realized.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

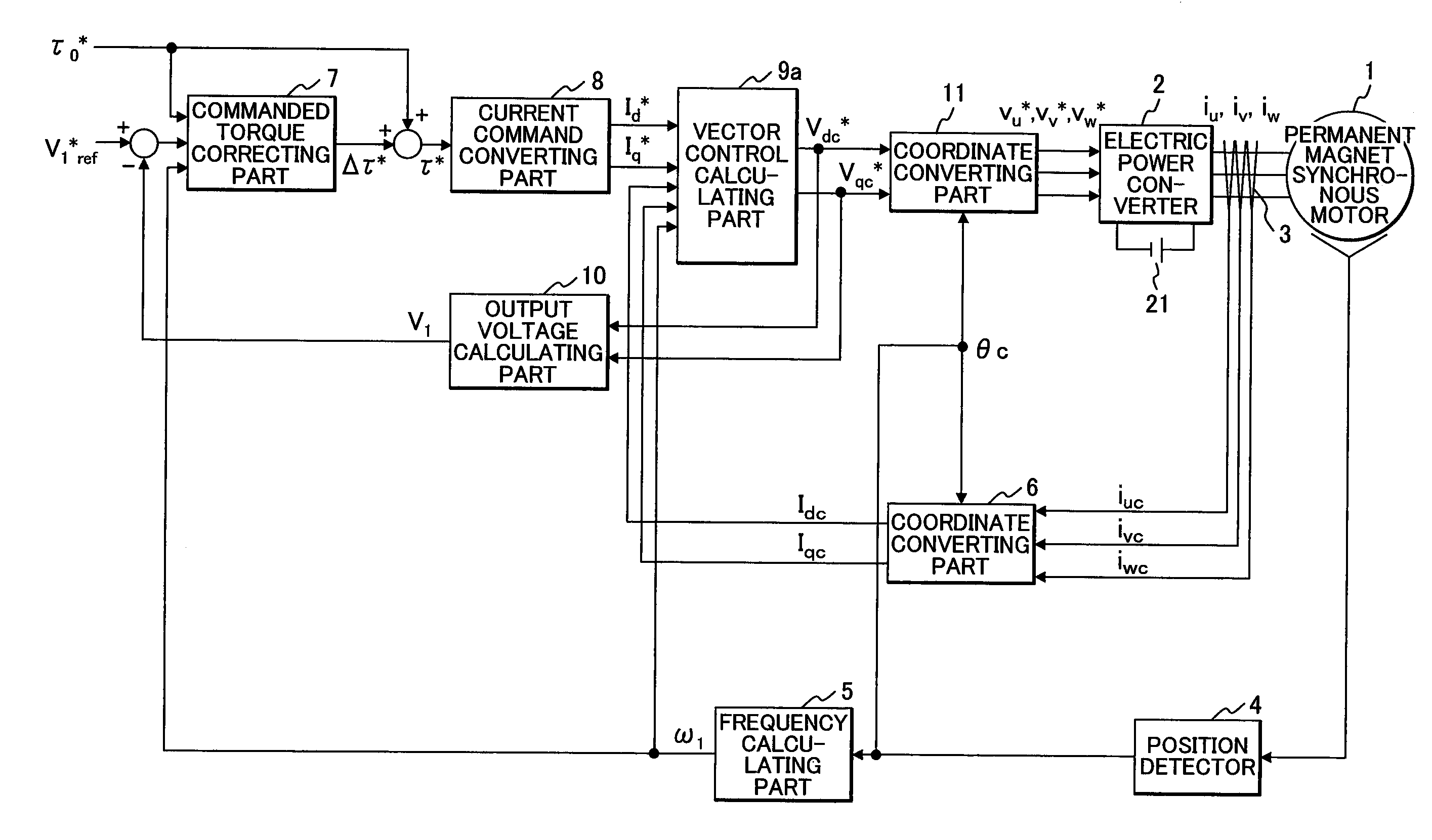

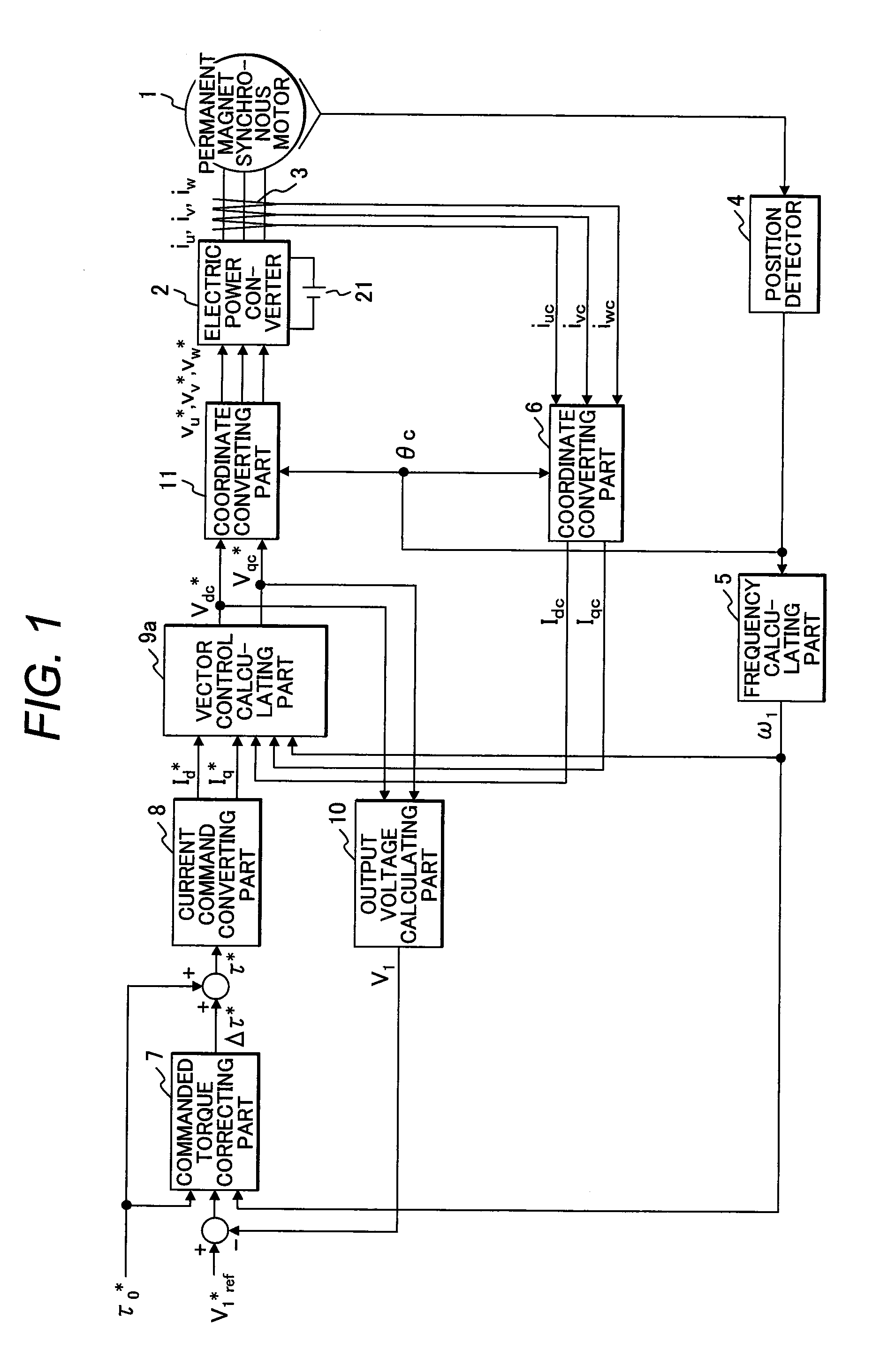

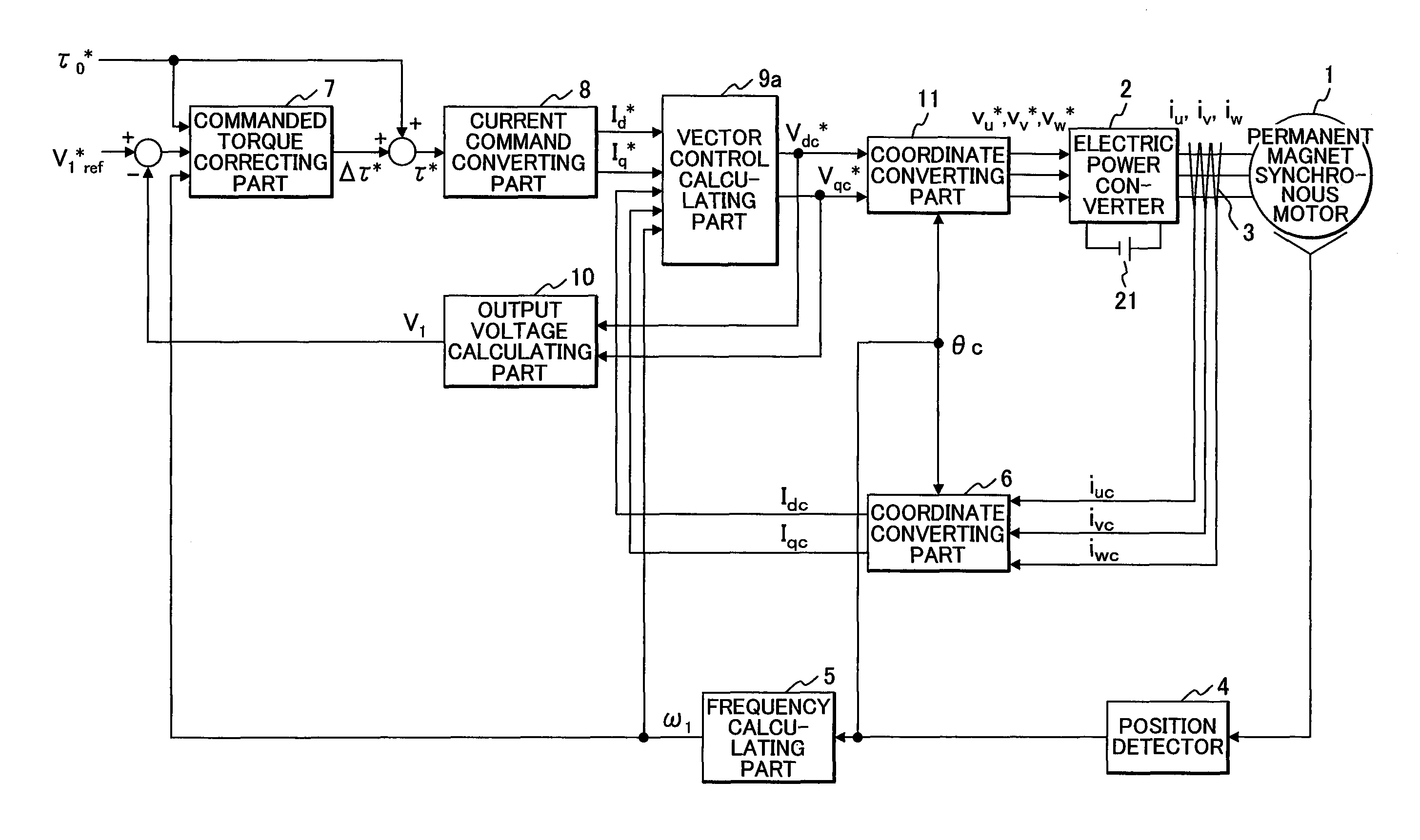

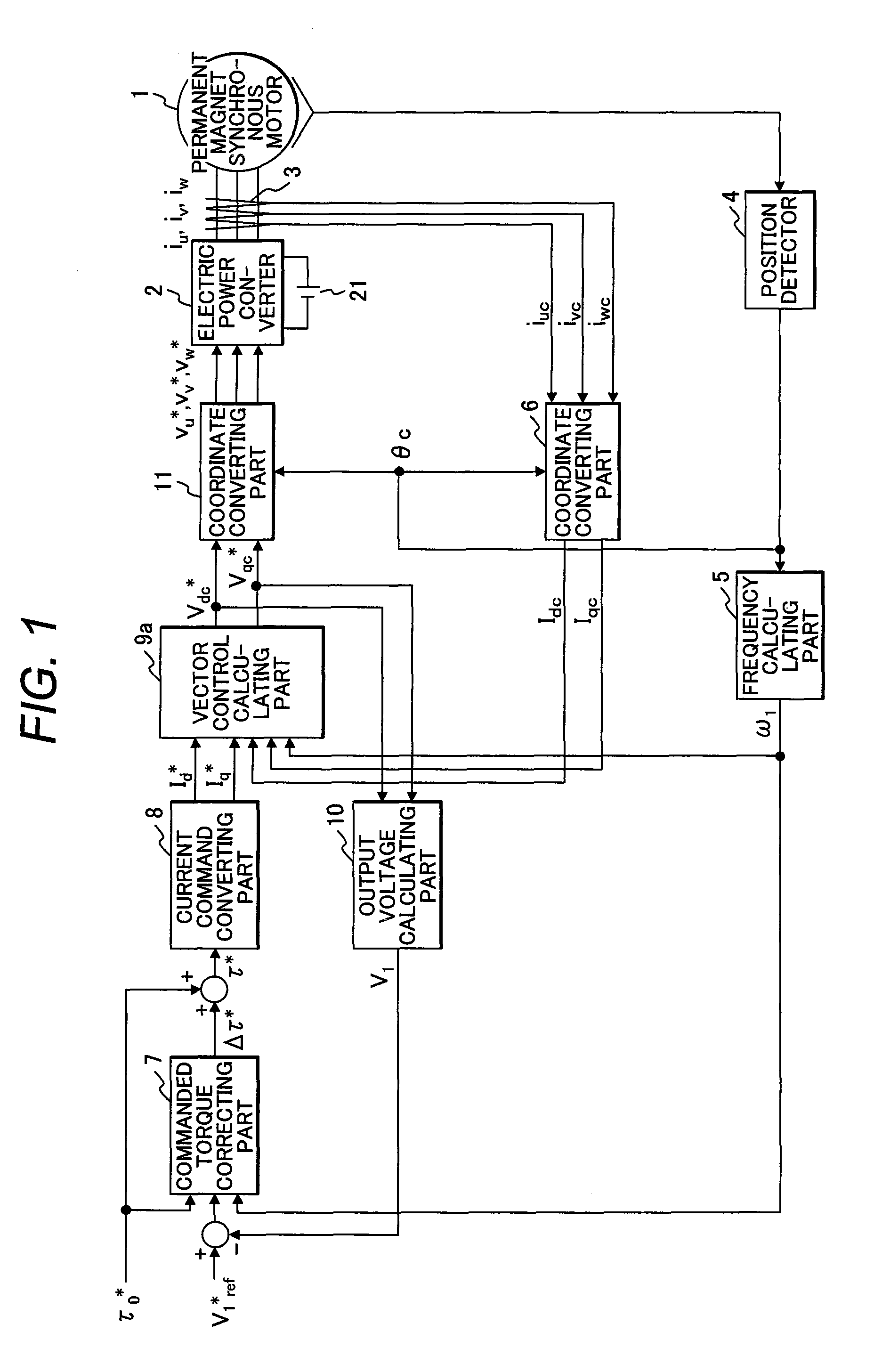

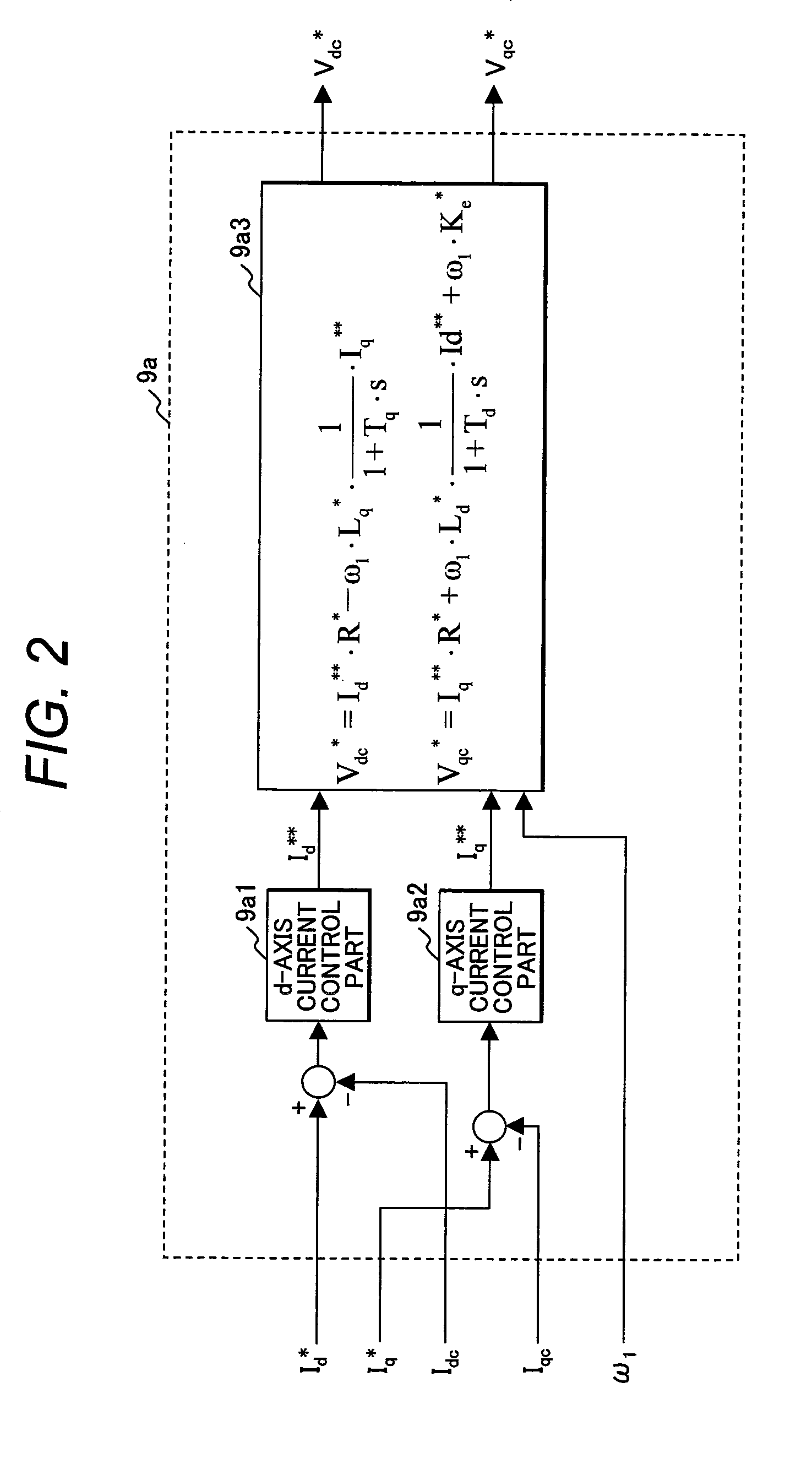

Torque Controller for Permanent Magnet Synchronous Motor

ActiveUS20100231148A1High-precision torque controlRapid responseSingle-phase induction motor startersDC motor speed/torque controlPermanent magnet synchronous motorPermanent magnet synchronous generator

When output voltage V1 of an electric power converter reaches a prescribed voltage V1*ref, a difference between V1 and V1*ref is integrated to correct a commanded torque to τo* (τ*=τo*+Δτ).

Owner:HITACHI CAR ENG CO LTD

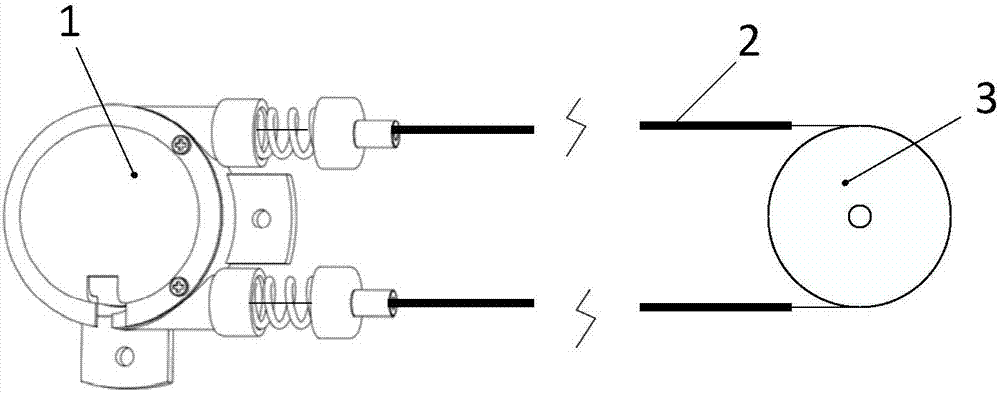

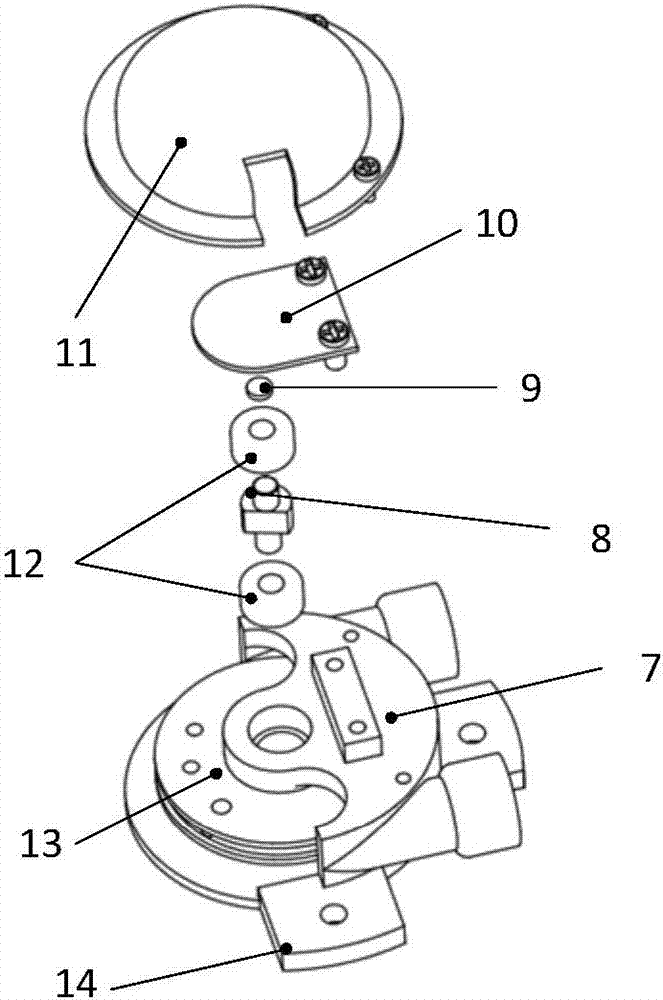

Joint torque measuring system for injured finger rehabilitation

ActiveCN107496139AHigh sensitivityHigh measurement accuracyMechanical oscillations controlChiropractic devicesBowden cableFinger joint

The invention discloses a joint torque measuring system for injured finger rehabilitation, and relates to a joint torque measuring system. By the aid of the joint torque measuring system, the problems of general deficiency of sensing functions of existing rehabilitation manipulators and incapability of measuring the magnitude of interaction force between finger joints and external skeletons by the existing rehabilitation manipulators can be solved. The joint torque measuring system is characterized in that motor output-end cable wheels are mounted on output shafts of driving motors, D-shaped shafts are penetratingly arranged on joint cable wheels, two ends of each D-shaped shaft are mounted on cable wheel carriers via two bearings, joint angle sensors are fixedly arranged on the upper end surfaces of the cable wheel carriers via screws, magnetic steel clings onto the upper end surfaces of the D-shaped shafts, the magnetic steel and the joint angle sensors are arranged in a directly facing manner, joint seat end covers are fastened on the upper end surfaces of the cable wheel carriers, joint seats are fixedly arranged on the side walls of the cable wheel carriers, each cable wheel carrier is provided with two threading pipes which are parallel to each other, an elastic element is arranged on each threading pipe, and Bowden cables are wound on external joint unit cable wheels and the motor output-end cable wheels. The joint torque measuring system has the advantage that the joint torque measuring system can be used for injured finger rehabilitation.

Owner:HARBIN INST OF TECH

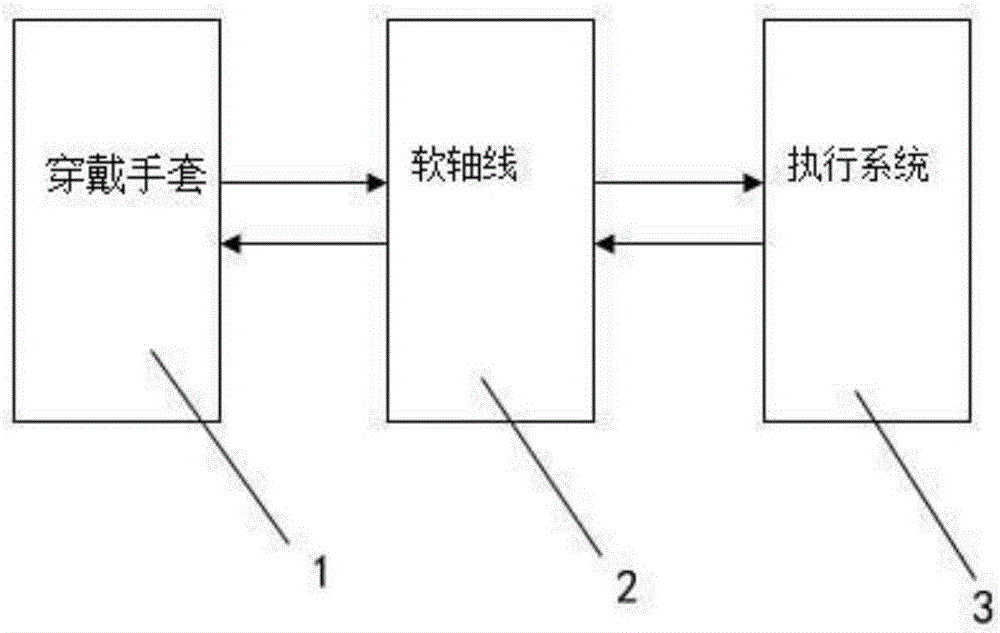

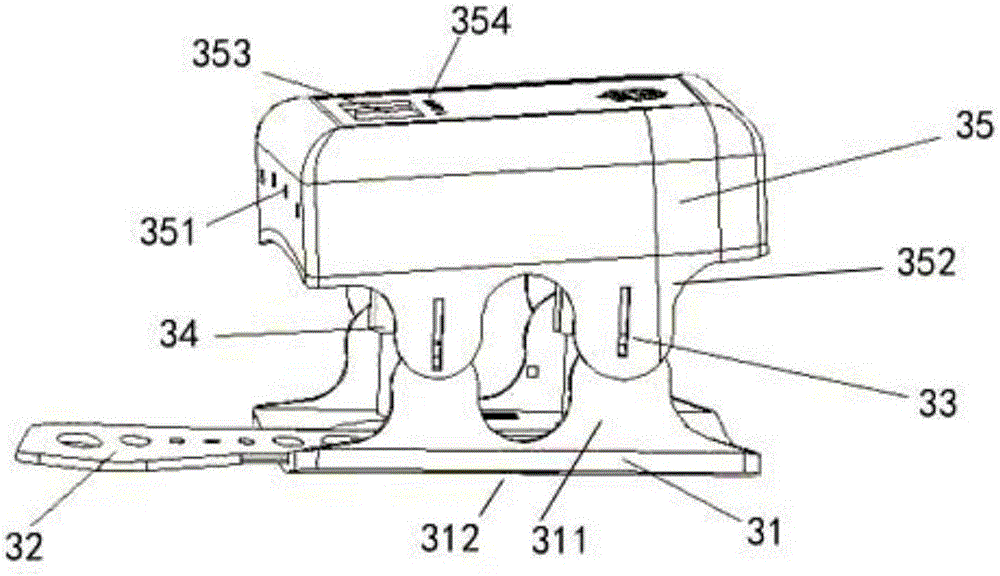

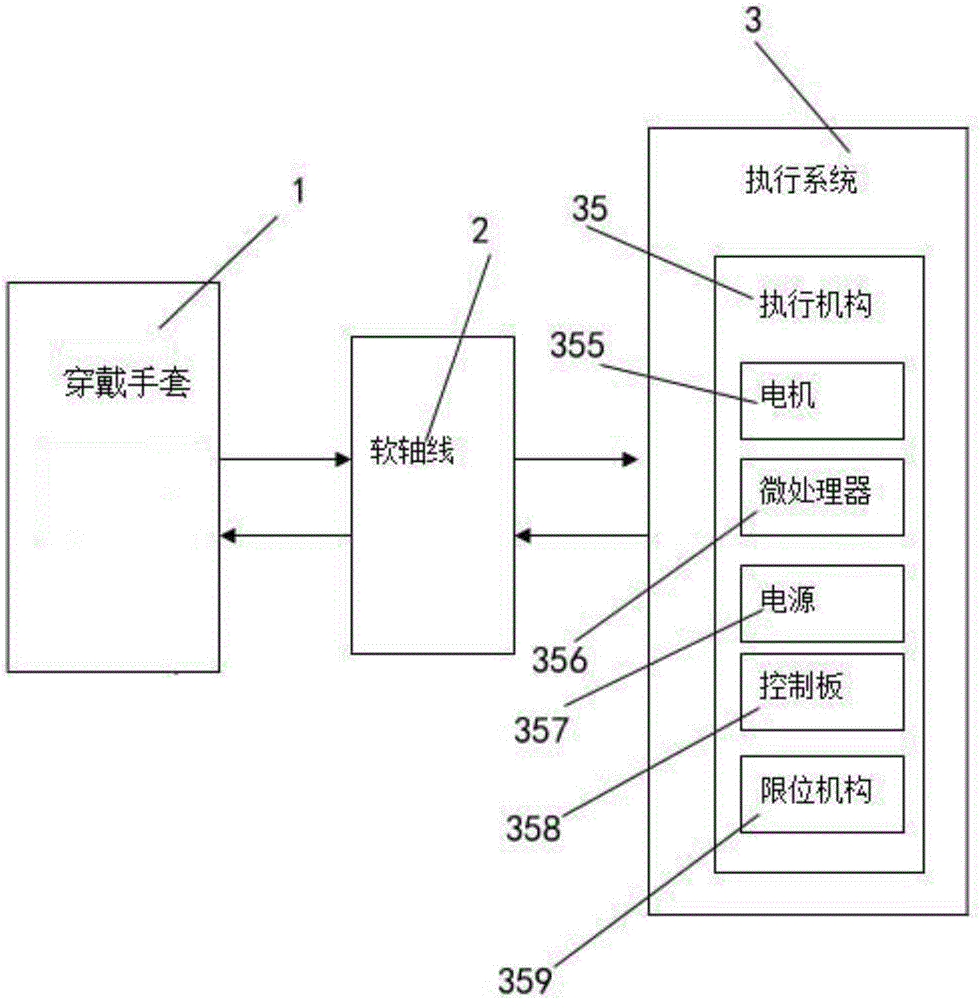

Multi-mode hand function training apparatus

The invention relates to a multi-mode hand function training apparatus. The training apparatus comprises a wearable glove, a soft axis line, and an execution system; the execution system comprises a base support, a palm rest, an elevating mechanism, a locking device, and an execution mechanism; the base support comprises a base plate and a first connection plate; the palm rest is connected with the axial direction of the inner wall of the base plate; a second connection plate is arranged on the execution mechanism, an elevating mechanism is arranged on the outer side of the second connection plate, and the locking device is arranged on the execution mechanism; a WiFi module is arranged on the inner side of the training apparatus, and a motor, a microprocessor, a power supply jack socket, a control plate and a position-limiting mechanism are arranged on the inner side of the execution mechanism. The training apparatus has the advantages that the hand part of a patient is moved by adopting the passive movement method to do the rehabilitation training, the movements of the motor are controlled and executed through the microprocessor, so that the hand part of the patient is moved to do passive movements. The patient can adjust single or multiple finger movement status according to the needs, and the data can be uploaded, so that the nursing staff can give instructional rehabilitation training advices.

Owner:康映科技(上海)有限公司

Torque controller for permanent magnet synchronous motor

ActiveUS8305019B2Precise torque controlRapid responseSingle-phase induction motor startersSynchronous motors startersPermanent magnet synchronous motorControl theory

When output voltage V1 of an electric power converter reaches a prescribed voltage V1*ref, a difference between V1 and V1*ref is integrated to correct a commanded torque to τo* (τ*=τo*+Δτ).

Owner:HITACHI CAR ENG CO LTD

Motor control device and electrical equipment with motor controlled thereby

ActiveUS8536812B2Precise torque controlSuppress fluctuationsTorque ripple controlCommutation monitoringElectricityLoad torque

A motor control device includes a current detecting unit detecting current flowing into a motor winding, a speed / electrical angle estimating unit estimating a rotational speed and an electrical angle of the motor, based on the current, a load torque estimating unit estimating load torque to be developed by a load, from a torque current obtained based on the current and the electrical angle, a motor constant and inertia moment of the motor inclusive of the load, a load torque phase calculating unit calculating a phase of periodic fluctuation indicated by the load torque, a torque-compensating current determining unit determining a sinusoidal torque-compensating current, based on the load torque phase, and an amplitude / phase adjusting unit detecting speed fluctuation of the motor to adjust amplitude and phase of the torque compensating current by increasing or decreasing the amplitude and the phase so that the speed fluctuation is reduced.

Owner:KK TOSHIBA

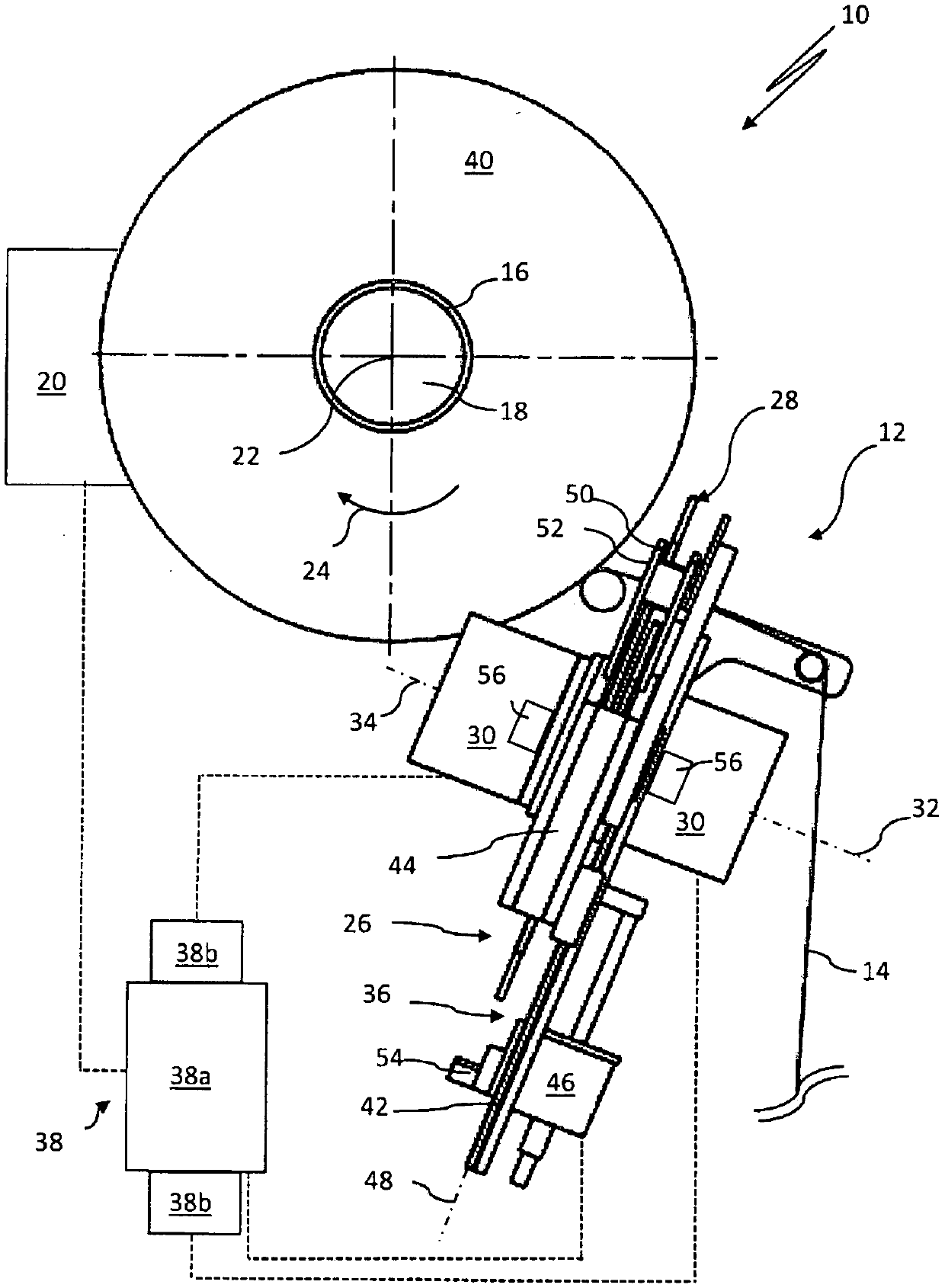

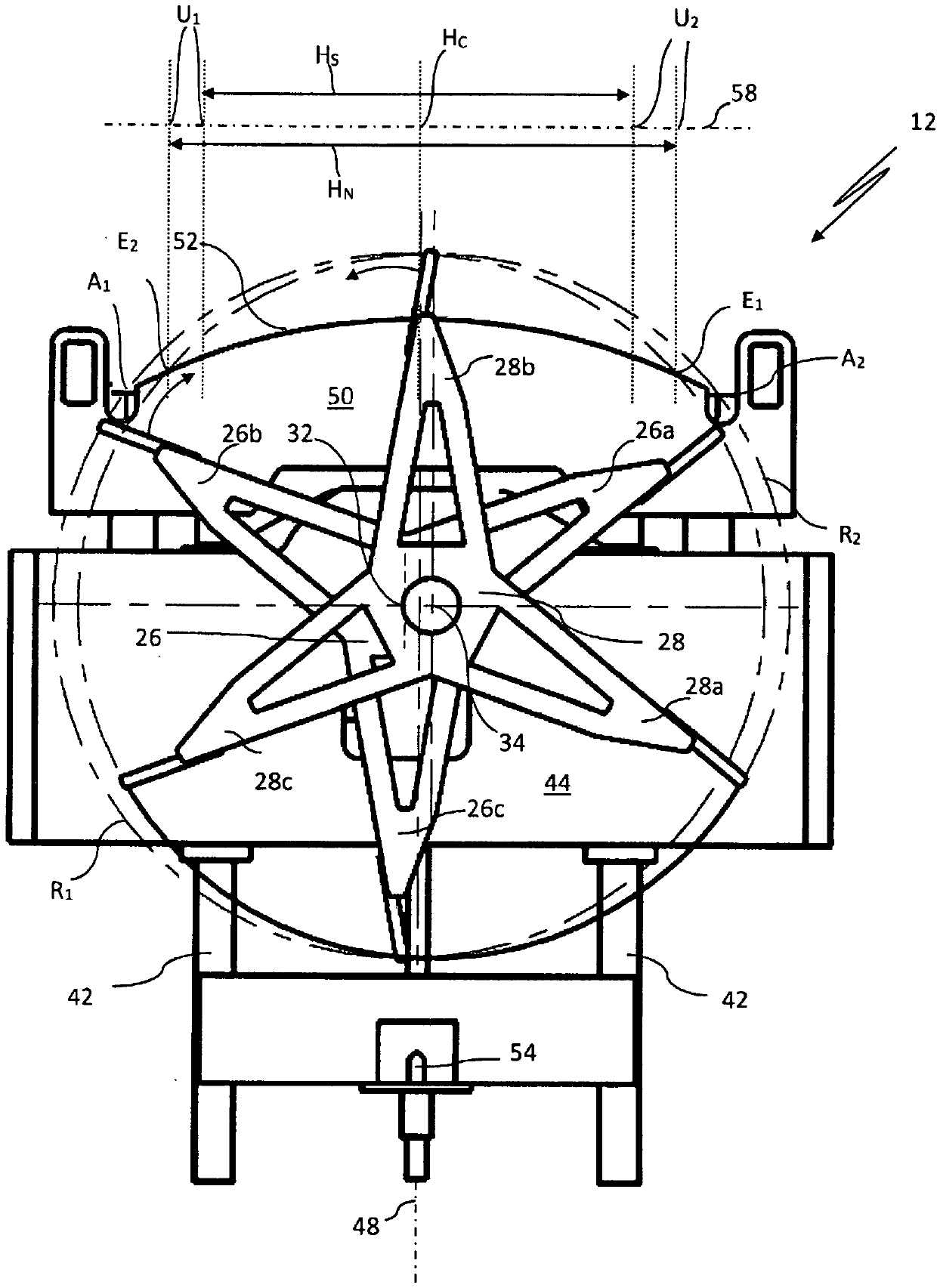

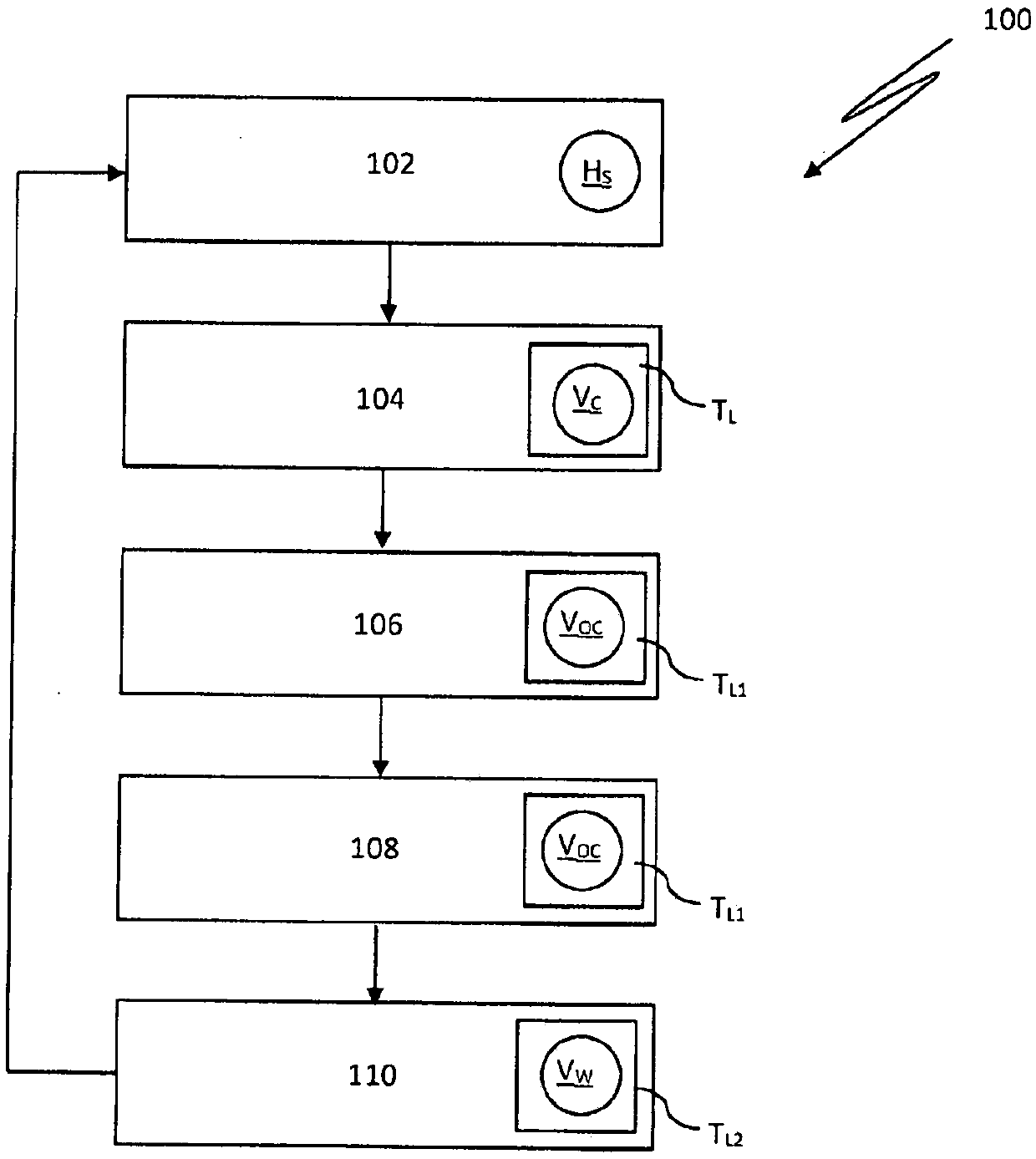

Method for controlling an impeller-type thread laying device, impeller-type thread laying device, and winding machine

The invention relates to a method (100) for controlling a thread laying device comprising two impellers (26, 28) which can be driven in opposite directions in order to move a thread to be wound on a rotating spool back and forth between two turning points (U1, U2) along the spool longitudinal axis by means of a traversing movement with a target traversing stroke width (Hs) of the thread laying device, said target traversing stroke width differing from a base traversing stroke width (HN). According to the invention, each impeller (26, 28) being moved in the idle traversing stroke, i.e. each idle traversing stroke impeller (26, 28), is first accelerated or braked to an overcompensation angular speed (Voc) in the idle traversing stroke interval (TL) of the impeller, said overcompensation angular speed being determined on the basis of a theoretical constant compensation angular speed (Vc) required to transfer the thread in the next turning point (U1, U2) of the traversing movement of the thread. The impeller is then moved at its specified operating angular speed (Vw) in order to receive the thread from the other impeller (26, 28) guiding the thread at the operating angular speed (Vw) in the next turning point (U1, U2) of the traversing movement of the thread. The invention further relates to a thread laying device and to a winding machine comprising such a thread laying device.

Owner:SSM萨罗瑞士麦特雷有限公司

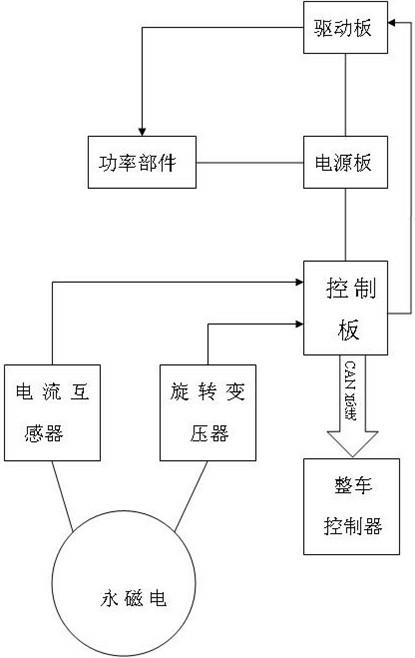

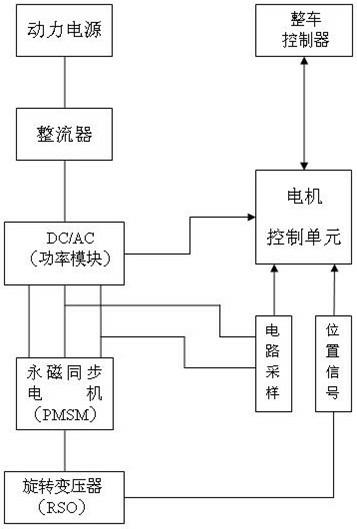

Permanent magnet motor controller applied to pure electric car and control method

InactiveCN102684576AGuaranteed uptimeImprove acceleration characteristicsElectronic commutation motor controlAC motor controlMotor speedElectric machine

The invention discloses a permanent magnet motor controller applied to a pure electric car and a control method. The controller is mainly composed of a power panel, a control board, a drive board and a power component; the power panel is connected with the control board, the drive board and the power component; the control board is connected with a vehicle controller through a CAN bus; the control output of the control board is connected with the drive board; the output of the drive board is connected with the power component; a group of analogue quantity inputs of the control board are respectively connected with a current transformer and a rotary transformer; the current transformer is connected with a power terminal of the permanent magnet motor, and the rotary transformer is connected with the rotating shaft of the permanent magnet motor. The permanent magnet motor controller applied to the pure electric car disclosed by the invention can precisely control the rotating speed of the motor, effectively reduces the switching loss and greatly improves the dynamic response speed of the system and the acceleration characteristics of the motor. The controller can meet the requirement of the pure electric car, of which the power requirement is less than 60KW, just by exchanging a cooler and the drive board as to the electric cars with different requirements, and saves the production cost and the production cycle for a manufacturing plant of the controller.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

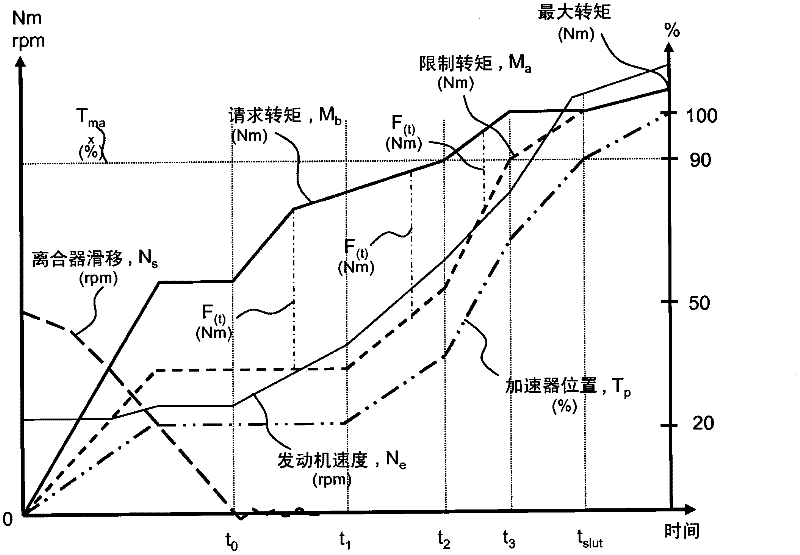

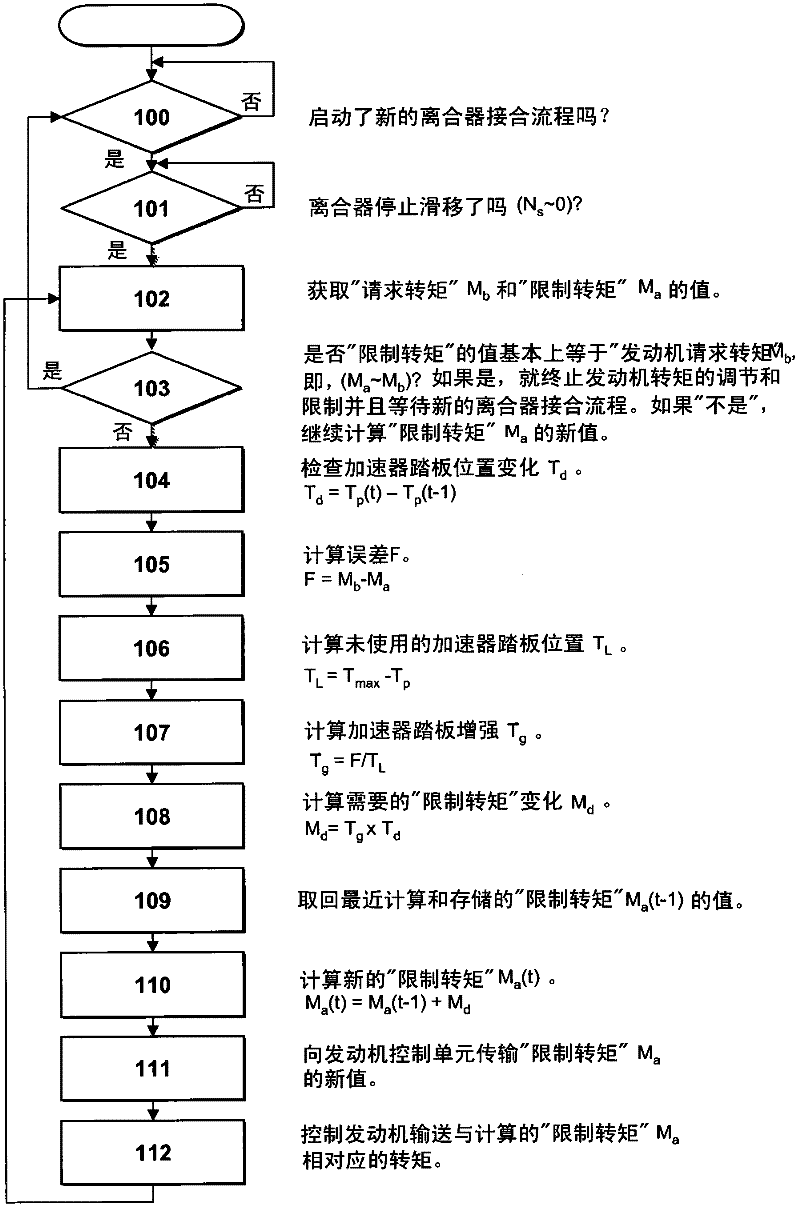

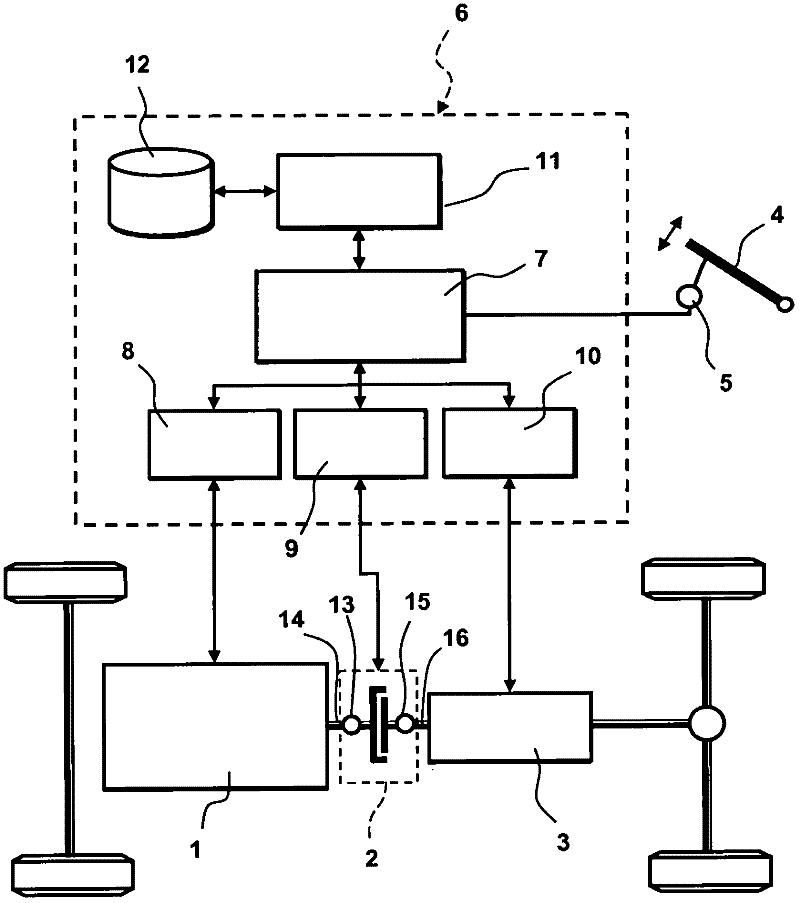

Method for bringing torque regulation back from a limited state to an unlimited state

The invention relates to a method for bringing the regulation of the engine's torque, in a vehicle which has an automatic clutch and in which the vehicle's control system automatically limits the "engine torque requested" (Mb) by the driver during a clutch engagement process, back from a state in which torque limitation is applied to a state in which the torque limitation decreases and totally ceases after the clutch engagement process has been completed. The invention is achieved by gradually bringing control back from torque limitation regulated by the engine control unit (8) to torque directly acted upon by the driver and the accelerator pedal (4) based on the difference between current values for "engine torque requested" (Mb) and "limited engine torque" (Ma) and on current accelerator pedal position (Tp).

Owner:SCANIA CV AB

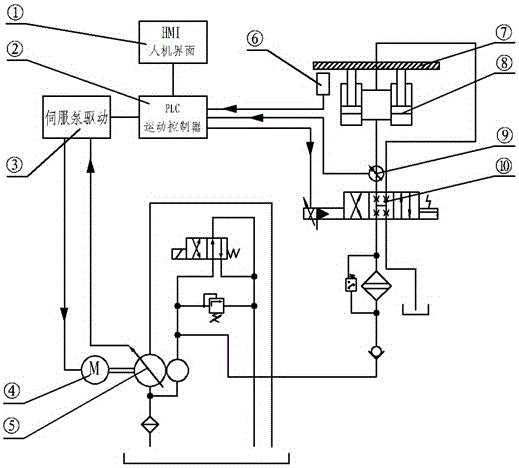

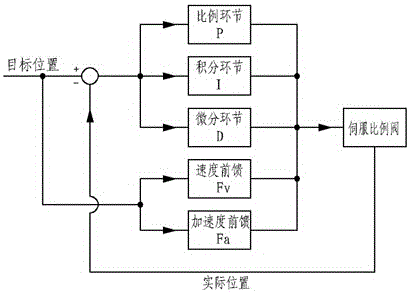

Stamping servo compensation system and working process thereof

PendingCN106640857APrecise torque controlAccurate speed controlFluid-pressure actuator componentsHydraulic cylinderControl system

The invention relates to a stamping servo compensation system and a working process thereof. The stamping servo compensation system is composed of a human-computer interaction interface, a PLC motion controller, a hydraulic servo pump system, a servo proportional valve, a position sensor, pressure sensors, an electric control element, a hydraulic cylinder body and a stamping fixing template. One way of the PLC motion controller is connected with a servo pump drive which is connected with the servo pump. The servo pump is connected with the first pressure sensor. The other way of the PLC motion controller is connected to the servo proportional valve controlled by the PLC motion controller. The other way of the PLC motion controller is connected with the second pressure sensor and a displacement sensor. The displacement sensor is used for detecting the position of the stamping fixing mould plate. The stamping servo compensation system has the beneficial effects that by the utilization of the servo hydraulic drive and a position sensor feedback position closed-loop control system, high-precision pressure, position and synchronous control can be achieved; the servo pump driven by a servo motor is utilized, during standby, the motor does not rotate, and the energy-saving effect is remarkable; and torque and rotating speed of the servo motor are controlled precisely, and high-precision pressure and flow control is achieved.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

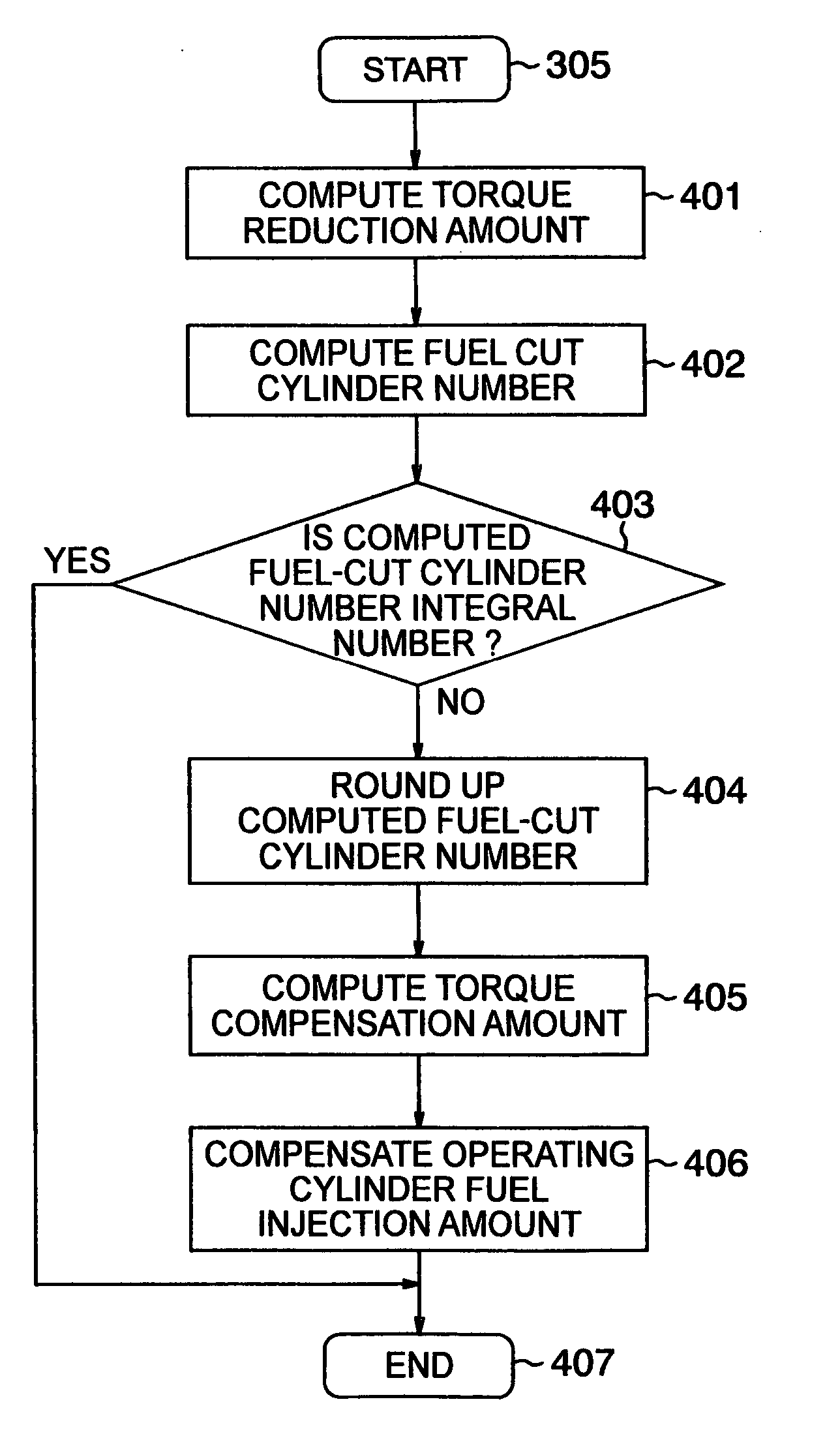

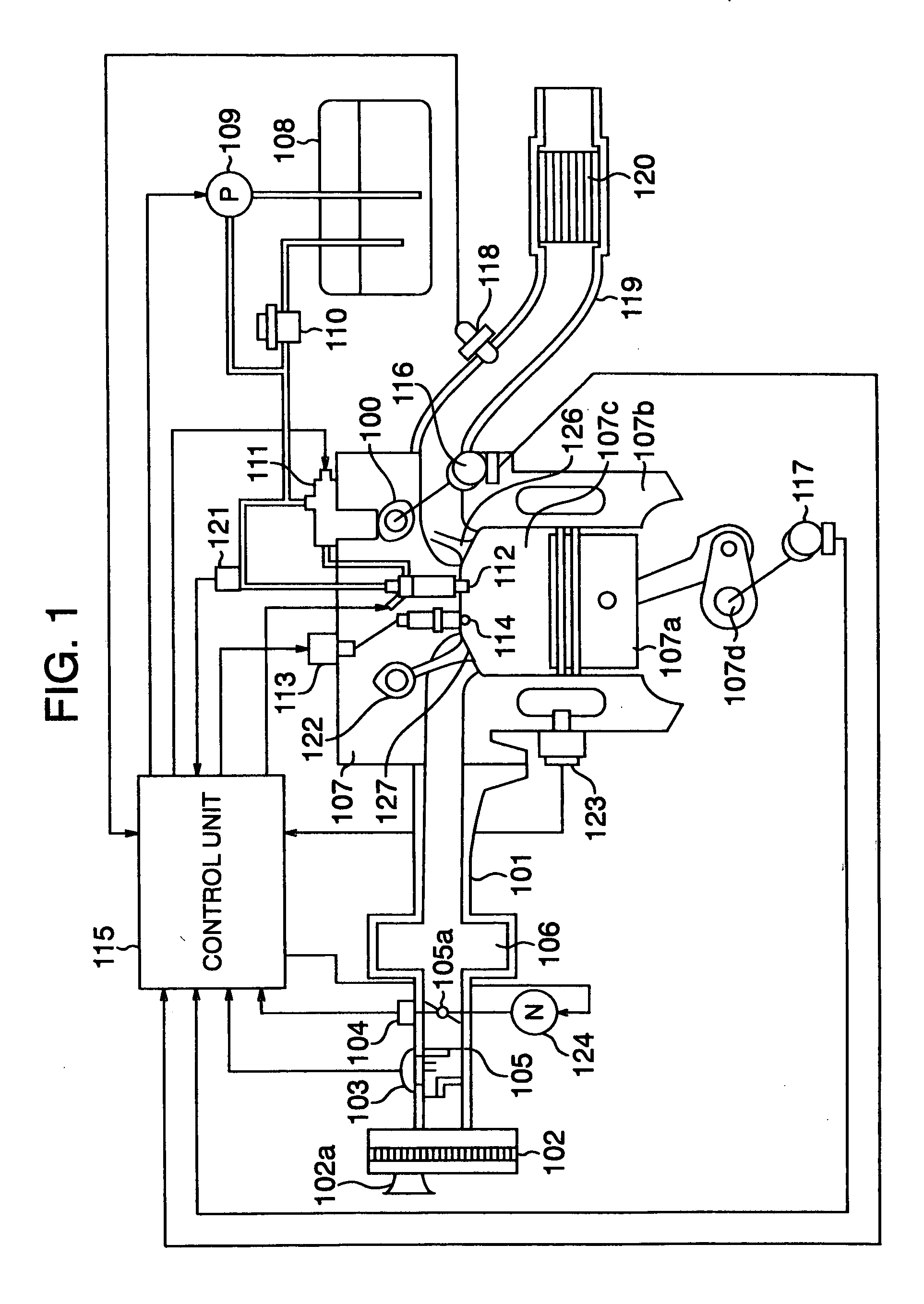

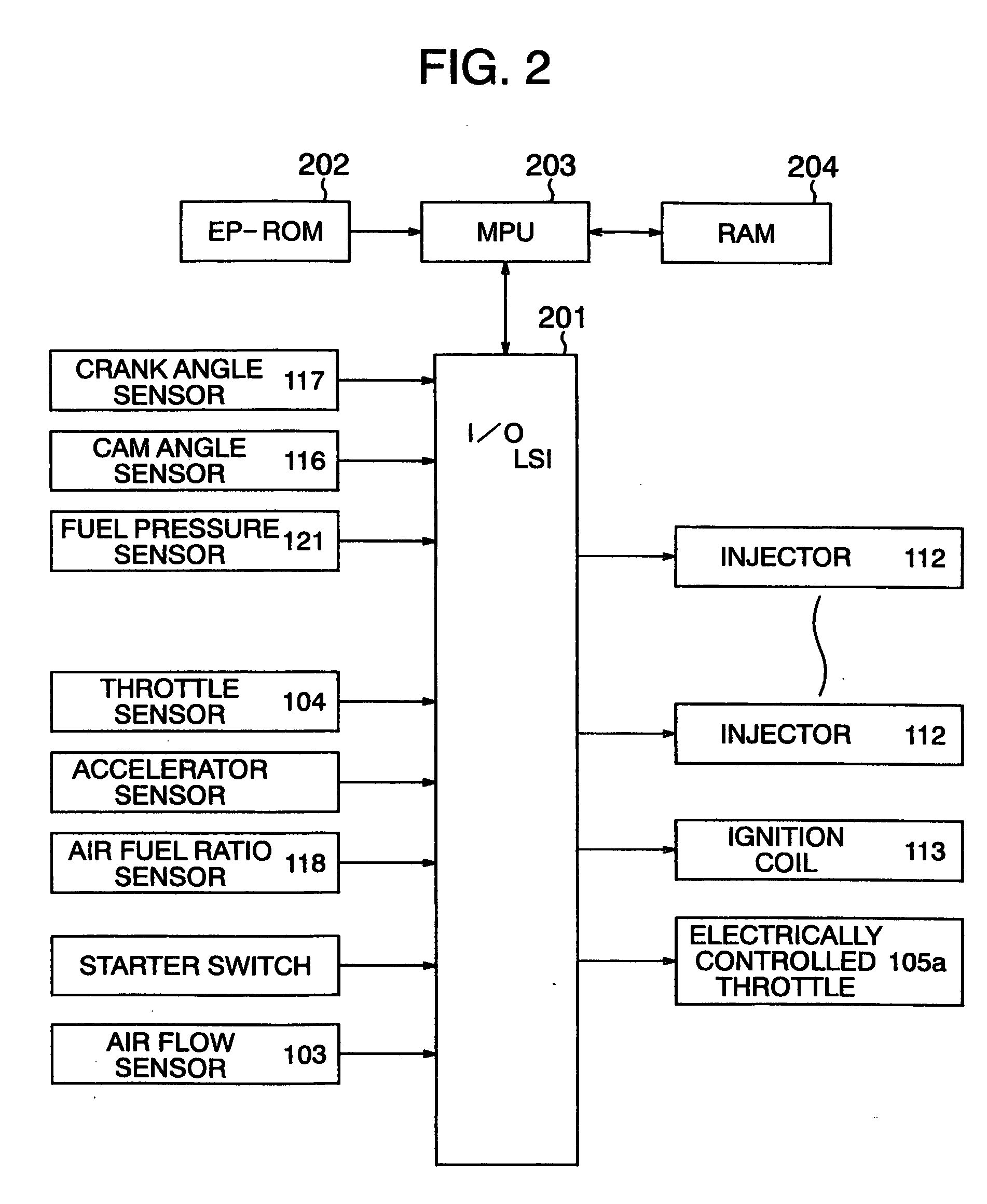

Control apparatus of internal combustion engine

InactiveUS20050005905A1Accurately and rapidly changingDeterioration can be suppressedElectrical controlFuel injection apparatusCombustionExternal combustion engine

The invention provides a control apparatus of a cylinder injection of fuel type internal combustion engine executing a dilute combustion, which can satisfy a requirement of rapidly changing an engine torque while restricting a deterioration of a driving property and an exhaust gas as much as possible. In a control apparatus of a multicylinder engine executing a dilute combustion, in the case that a requirement of reducing and changing an engine torque of the internal combustion engine is applied, the control apparatus executes a fuel cut of a predetermined number of cylinders, and controls so that a torque of operating cylinders except the cylinders executing the fuel cut becomes the required engine torque.

Owner:HITACHI LTD

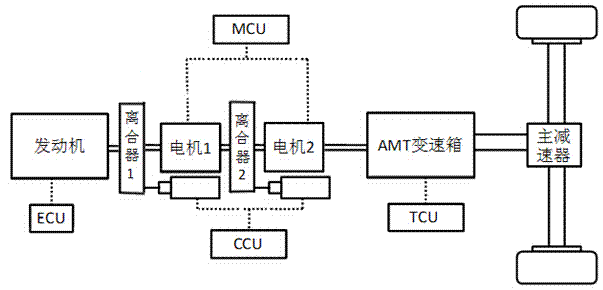

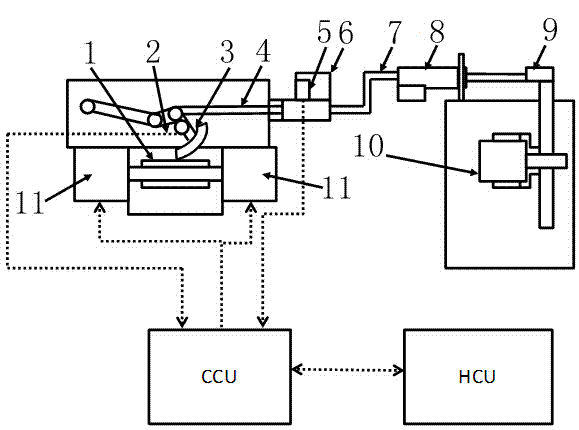

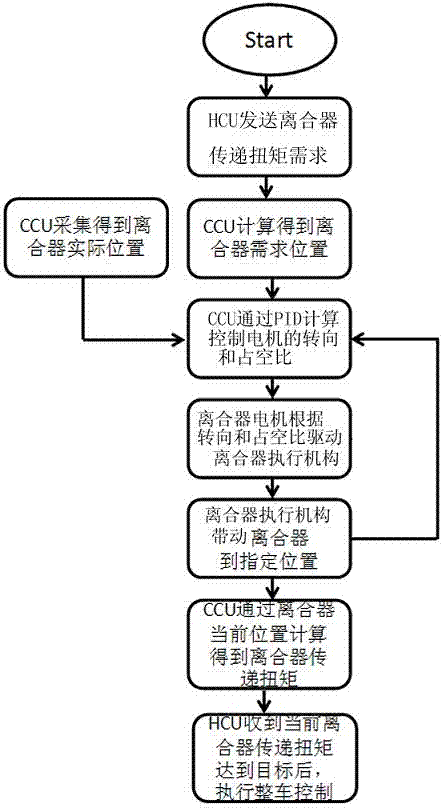

Control method of clutch for hybrid power vehicle

ActiveCN104847811APrecise torque controlReduce fuel consumptionClutchesHydraulic control unitEngineering

The invention discloses a control method of a clutch for a hybrid power vehicle, and belongs to the technical field of control of vehicle clutches. The control method mainly comprises the following steps: (1) a HCU (Hydraulic Control Unit) sends a clutch transfer torque demand to a CCU (Central Control Unit); (2) the CCU calculates and analyzes a received clutch transfer torque demand signal to obtain a clutch demanded position; (3) an actual clutch position is obtained through a clutch position sensor; and the clutch position is adjusted according to the difference between the demanded position and the actual position of the clutch, so that the clutch moves to the demanded position; and (4) the actual clutch position is obtained through the position sensor in real time, and the moving direction of the clutch is adjusted until the demanded position is reached. The control method solves such technical problems as easy motor damage, high processing precision requirement, low control precision and system unreliability. The control method realizes the mode switchover, the torque transfer, the starting / parking and the gear shifting separation of the hybrid power vehicle and the precise torque control of the clutch.

Owner:BEIQI FOTON MOTOR CO LTD

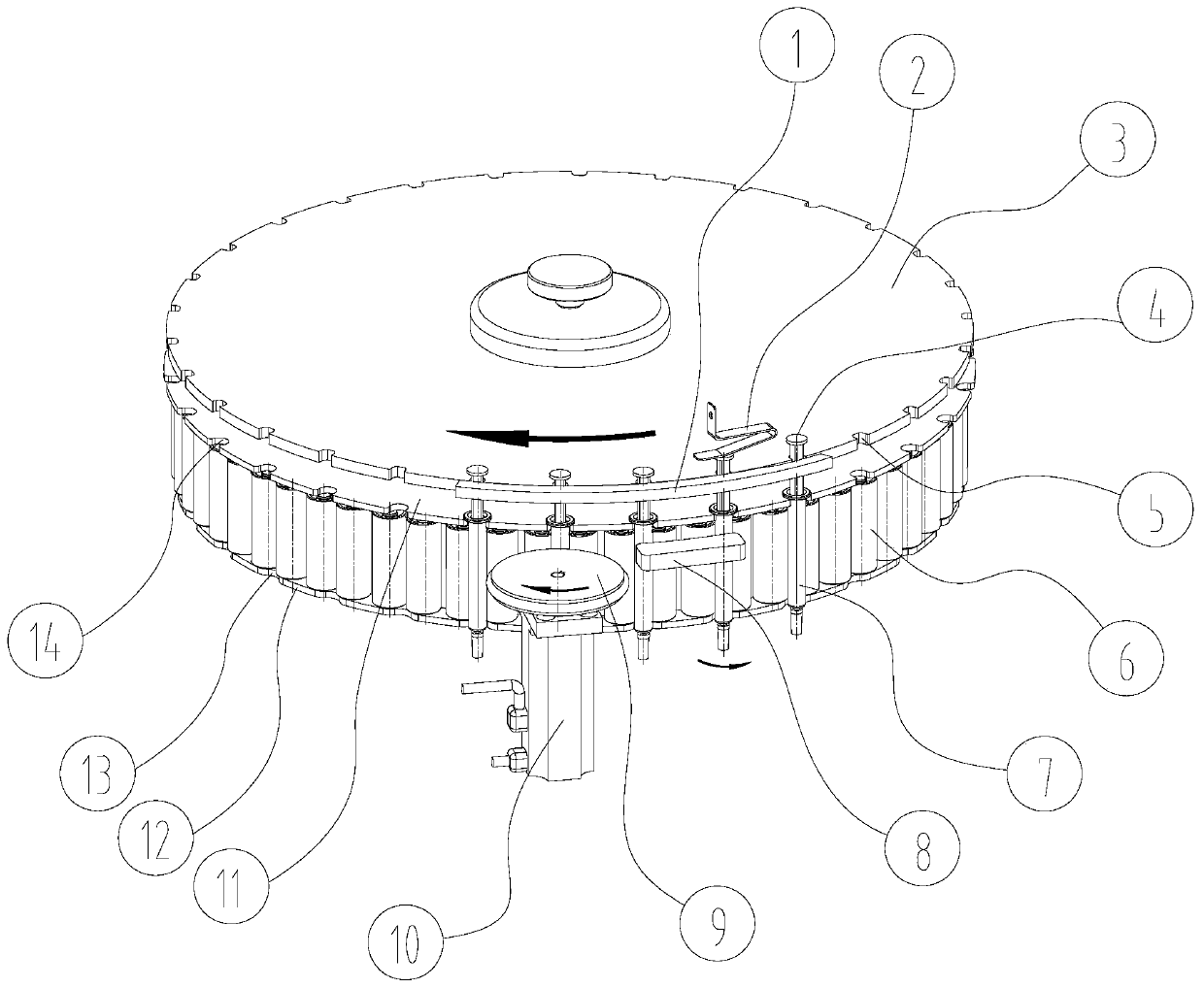

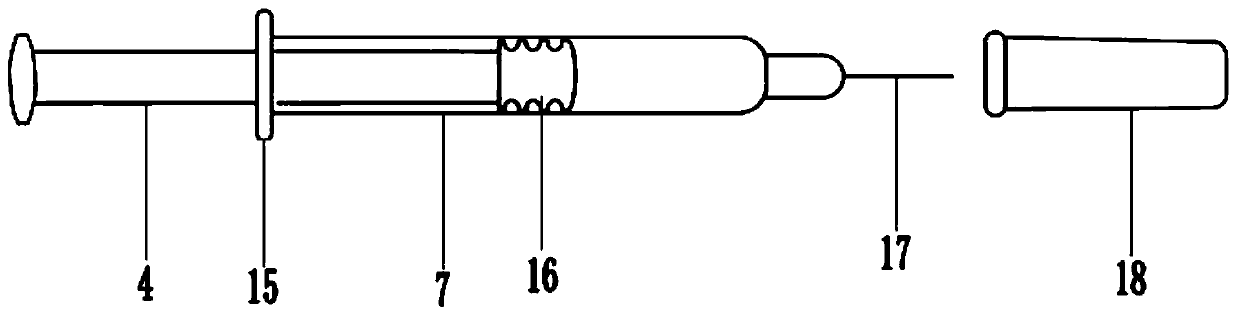

Pre-filled needle tube push rod precision assembly machine and assembly method thereof

ActiveCN106584081BEasy to controlAccurate torqueInfusion syringesMedical devicesEngineeringAssembly machine

The invention discloses a pre-filled needle tube push rod precision assembly machine and an assembly method thereof, comprising a turntable, the turntable includes an upper circular plate and a middle circular plate arranged coaxially from top to bottom, and a plurality of There is a U-shaped needle tube opening with an outward opening, a push rod bayonet on the upper circular plate, and a pair of rollers corresponding to the inner side of the U-shaped needle tube placement port; the axes of the rollers are parallel to the rotation axis of the turntable; Pre-twisted friction block, the inner side of the pre-twisted friction block is provided with an arc notch coaxial with the turntable, the rear side of the pre-twisted friction block is provided with a fine-twisted roller, and the fine-twisted roller is provided with a fine-twisted roller connected to the fine-twisted roller. Wheel drive mechanism. The present invention adopts the pre-twisted friction block and the push rod to be pre-tightened firstly, and then tightened tightly through the fine-twisted wheel, so that the push rod and the elastic rubber plug are connected in place, preventing the leakage of the injection during use. The assembly quality and production capacity of the push rod are improved, and the cost of the push rod assembly is reduced.

Owner:COLAMARK GUANGZHOU LABELING EQUIP

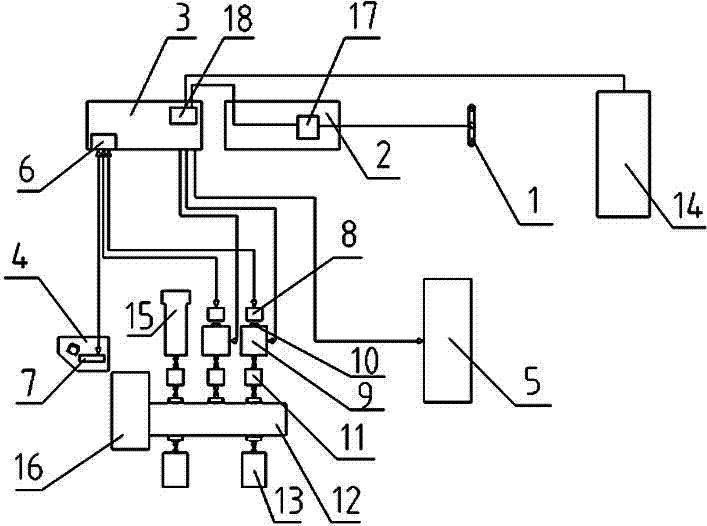

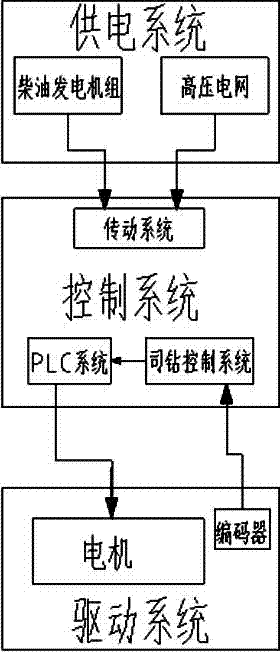

Telex control system for petroleum drilling equipment

ActiveCN102955445ADoes not affect drilling progressAccurate speed controlProgramme control in sequence/logic controllersAutomatic control for drillingFluid couplingClosed loop

The invention relates to a telex control system for petroleum drilling equipment. The telex control system comprises a power supply system, a control system and a driving system; the power supply system comprises a high-voltage power grid (1), a high-voltage room (2) and a diesel generating set (14) which is arranged in parallel to the high-voltage power grid (1); the control system comprises a control room (3), a driller control room (4), a motor operating cabinet (8) and an MCC (Mission Control Center) and electric control system (5); the driving system comprises a motor (9), a hydraulic coupler (11), a coder (10), a compound box (12), a winch (16) and a mud pump (13). The telex control system has the advantages that the diesel generating set is used as standby power supply equipment and used for supplying power for the control system and the driving system when the high-voltage power grid can not supply power; the transmission control adopts closed loop control, thereby ensuring the control accuractey control on the rotating speed and torque of the motor; and the variable frequency motor and the diesel engine unit of a machine room has complete exchange property, and the diesel engine unit can be changed as the variable frequency motor at any time, thereby being simple and fast to operate.

Owner:SICHUAN HONGHUA ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com