Patents

Literature

353results about How to "Accurate speed control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

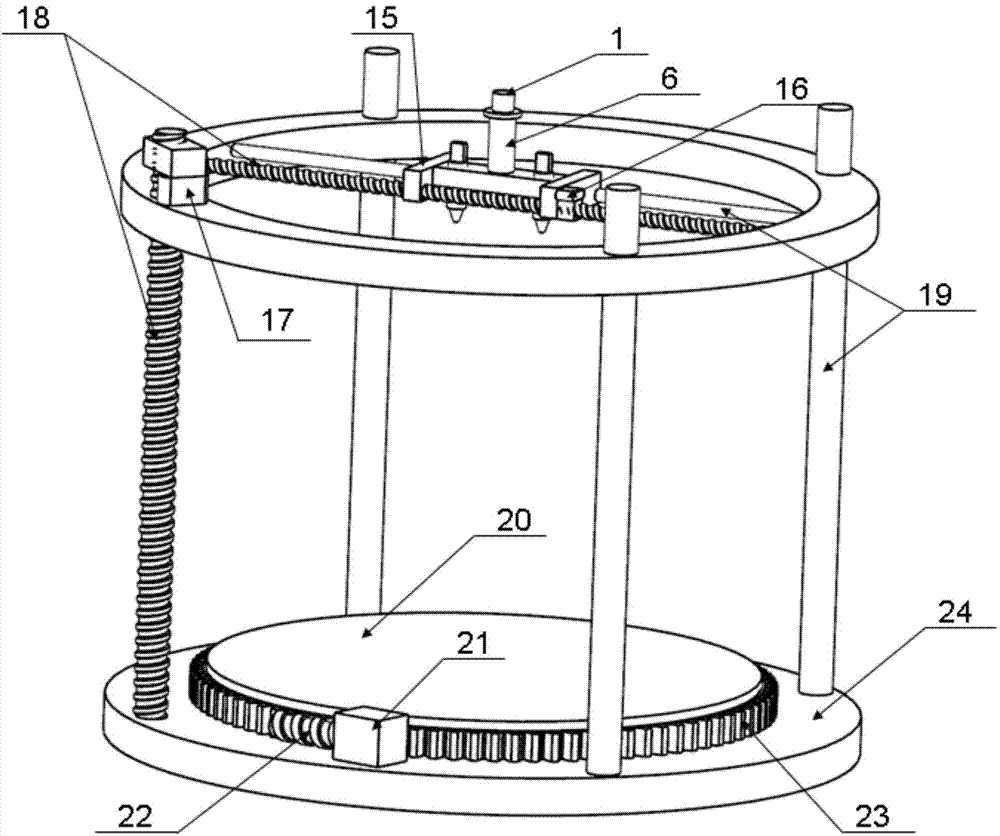

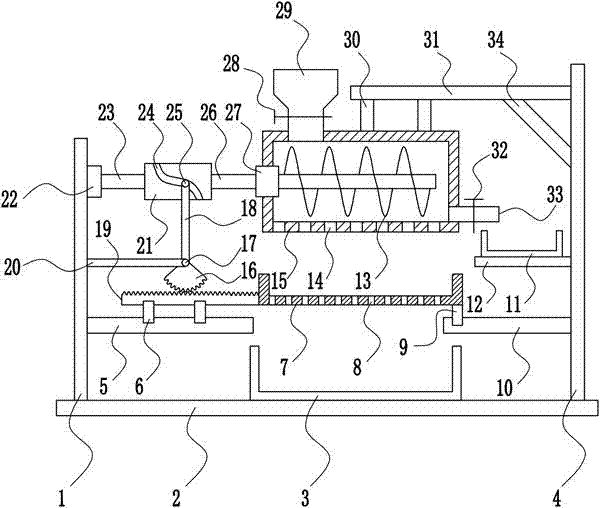

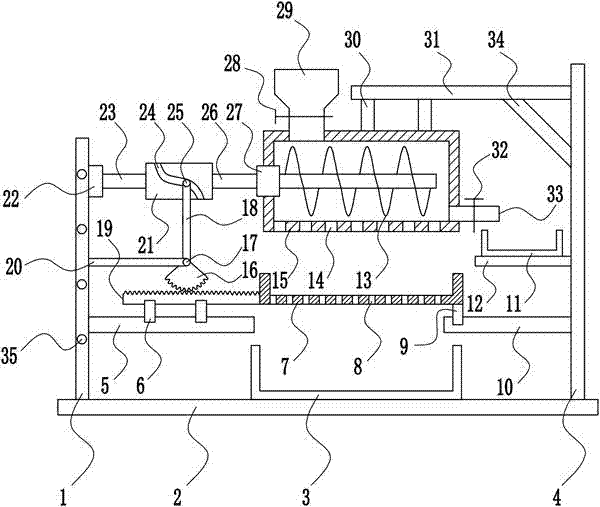

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

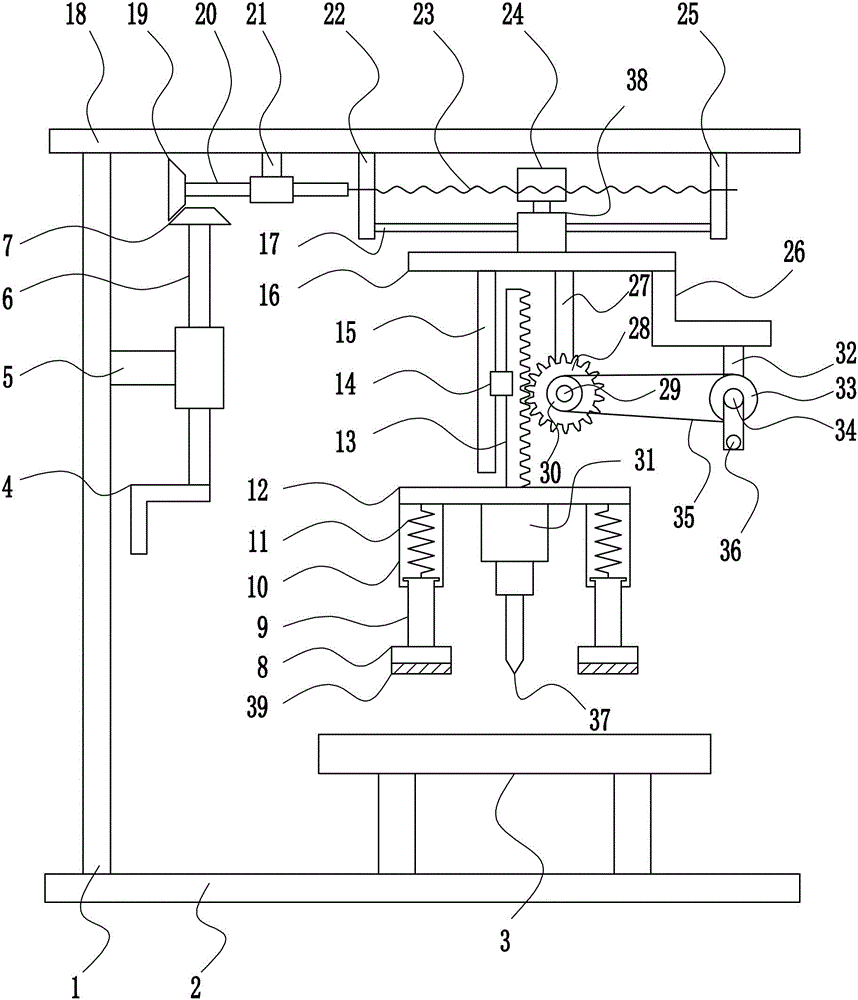

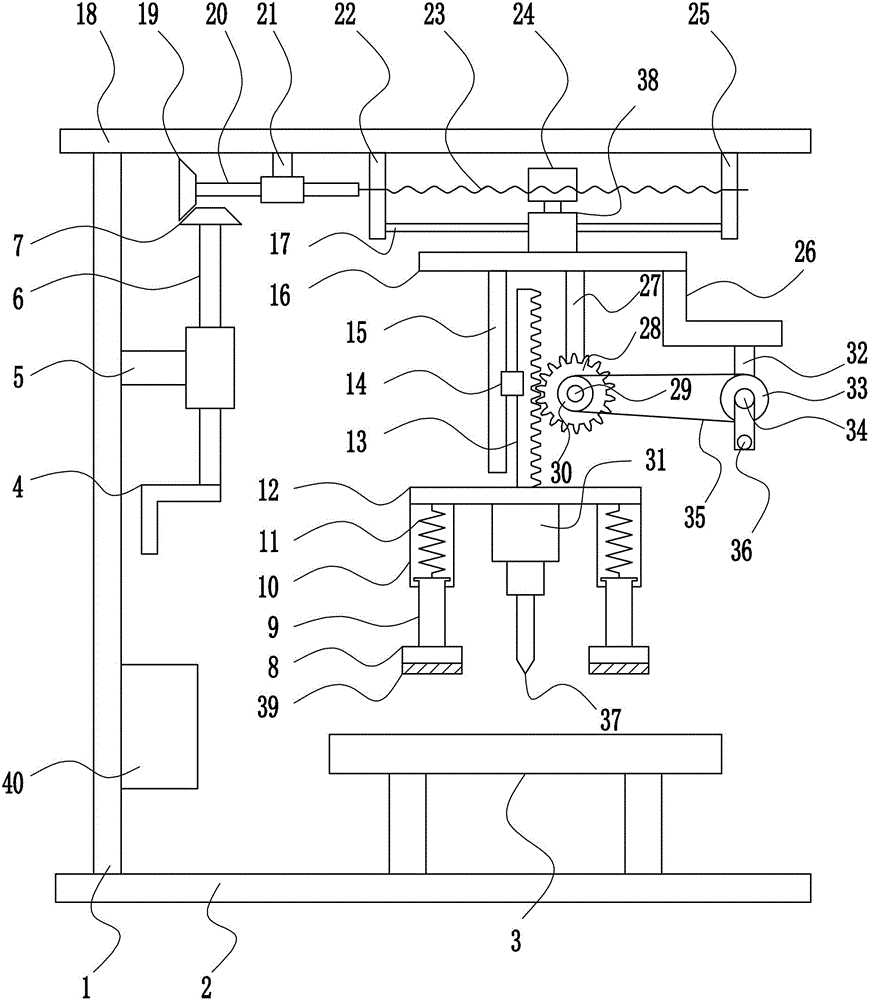

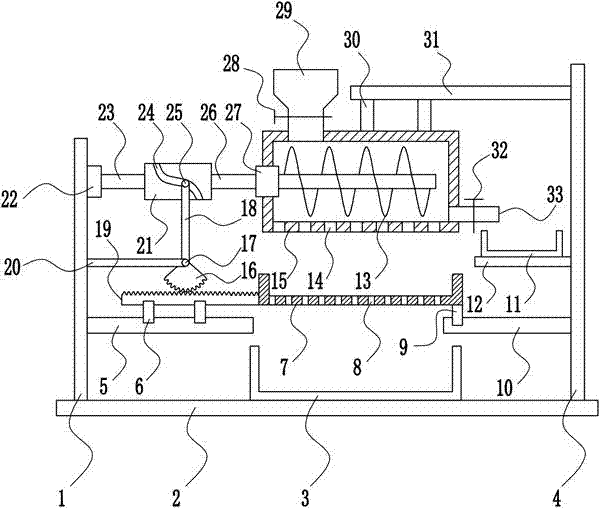

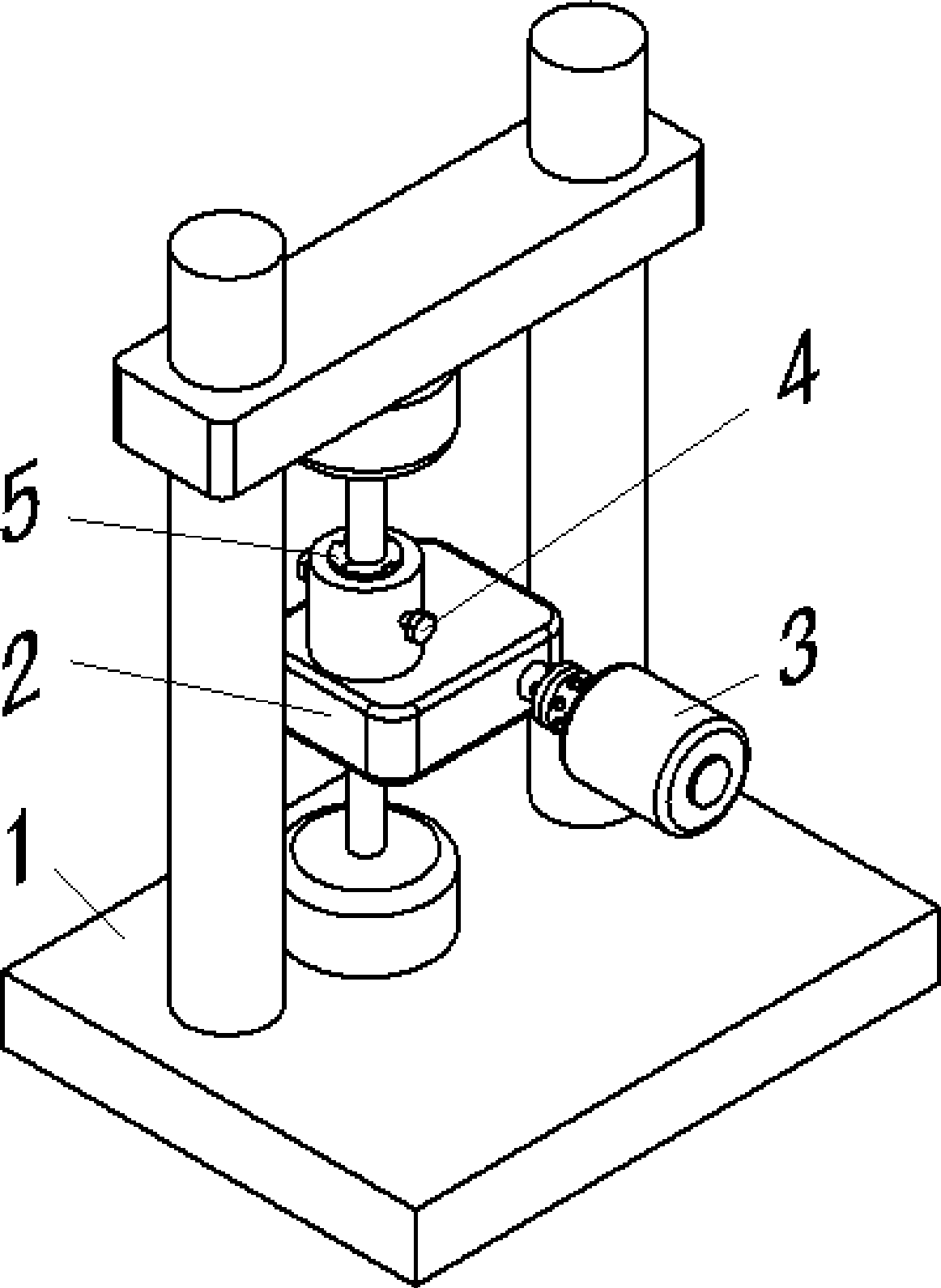

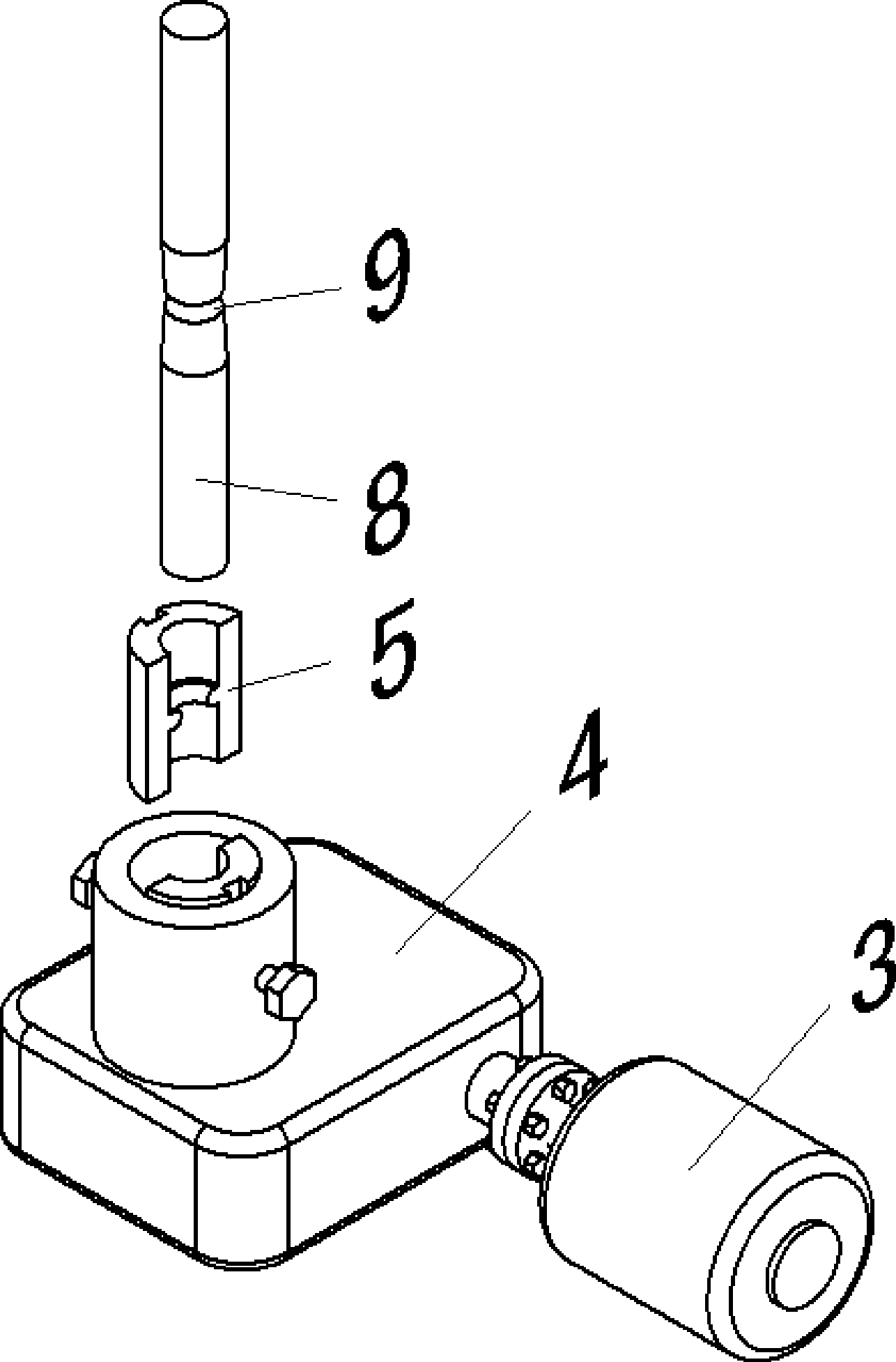

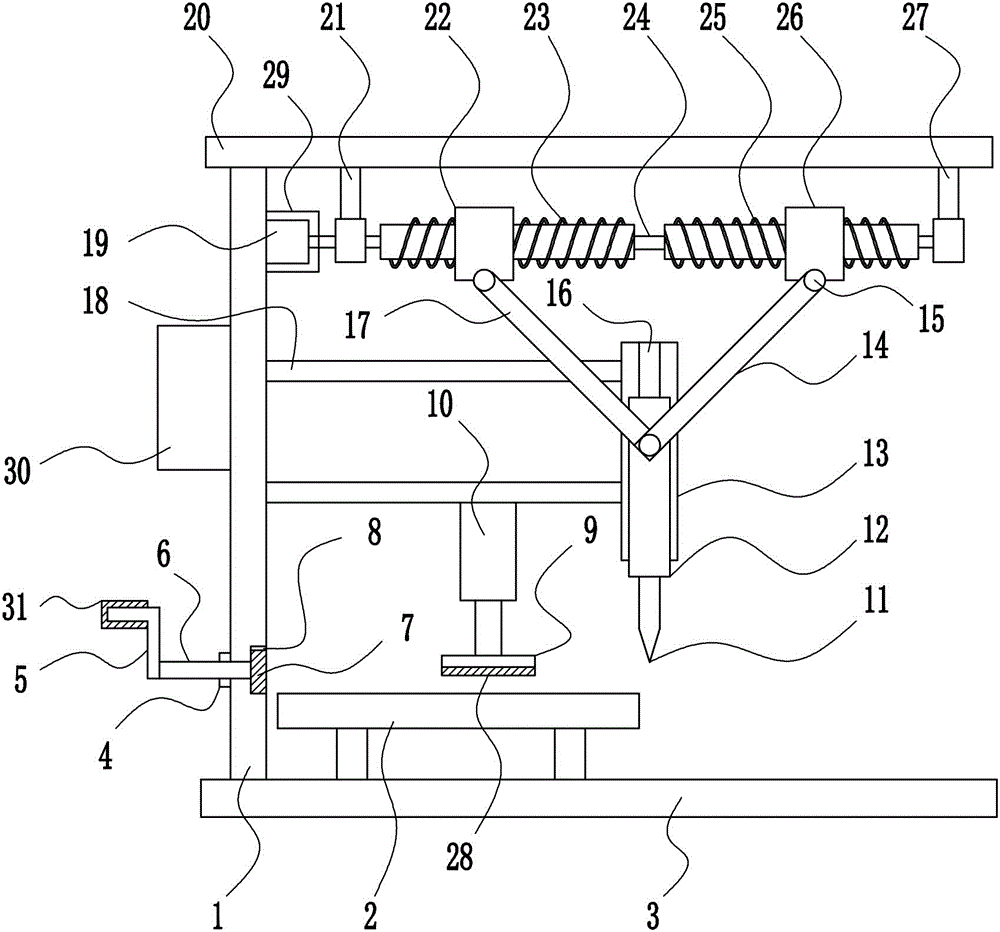

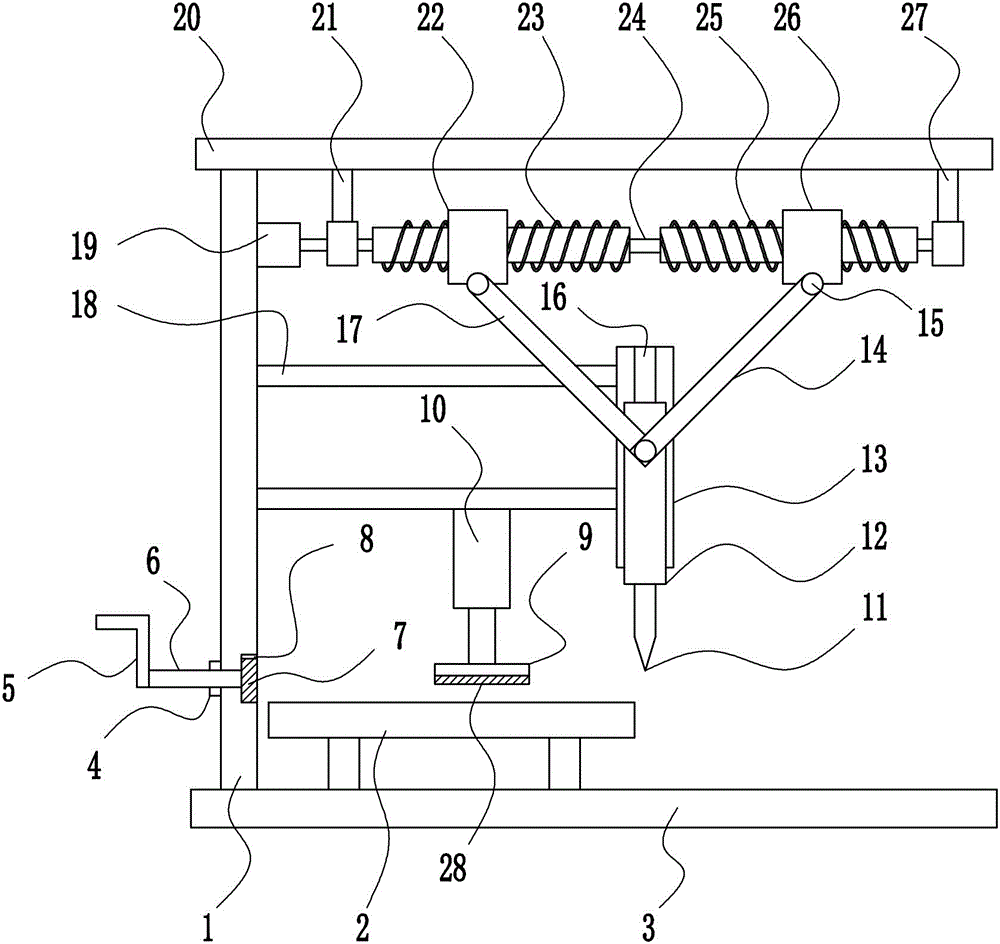

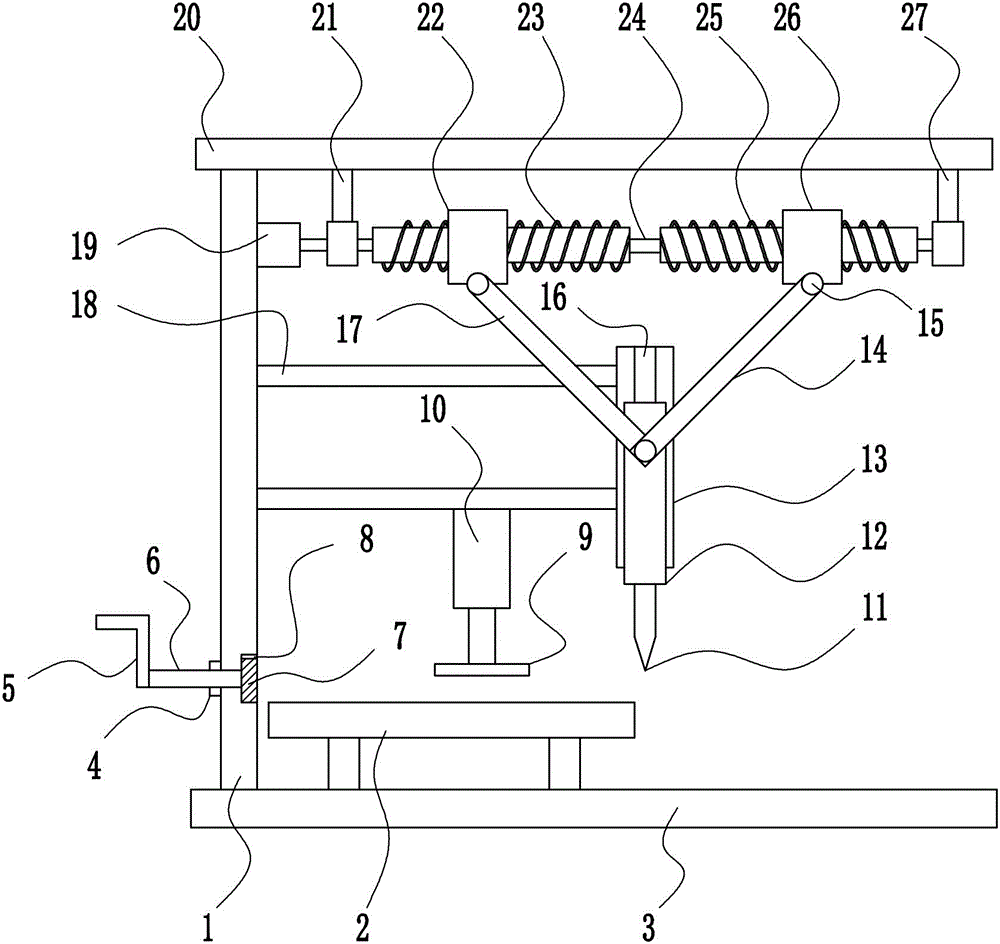

Novel drilling machine for carbon fiber composite plate

The invention relates to a drilling machine and particularly relates to a novel drilling machine for a carbon fiber composite plate. The technical problem to be solved by the invention is to provide the novel drilling machine for the carbon fiber composite plate, which is low in energy consumption, convenient to operate and high in drilling precision. In order to solve the technical problem, the invention provides such novel drilling machine for the carbon fiber composite plate, comprising a left frame, a bottom plate, a placing platform, a first rocking handle, a first bearing block, a first rotating shaft, a first bevel gear, a pressing block, a moving rod, a sleeve, an elastic element, a first fixed plate and the like; the left side of the top of the bottom plate is welded with the left frame; the middle of the top of the bottom plate is welded with the placing platform; and the upper end of the right side of the left frame is connected with the first bearing block in a bolt connection way. According to the novel drilling machine for the carbon fiber composite plate, the horizontal movement of a drill bit and the drilling operation for any position on the carbon fiber composite plate can be realized through rotating the first rocking handle, and the vertical movement of the drill bit can be realized through rotating a second rocking handle.

Owner:江苏吉神环卫设备有限公司

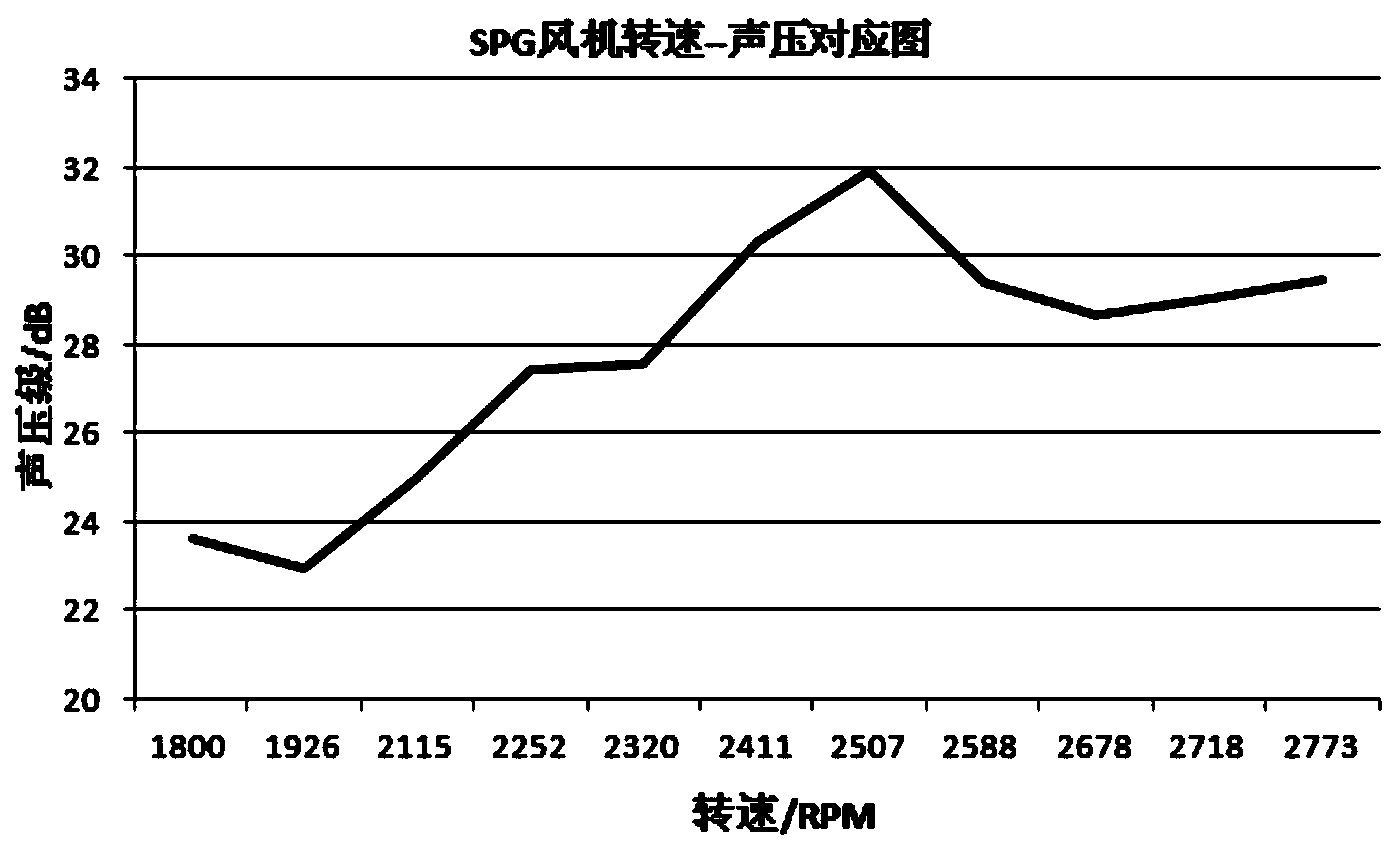

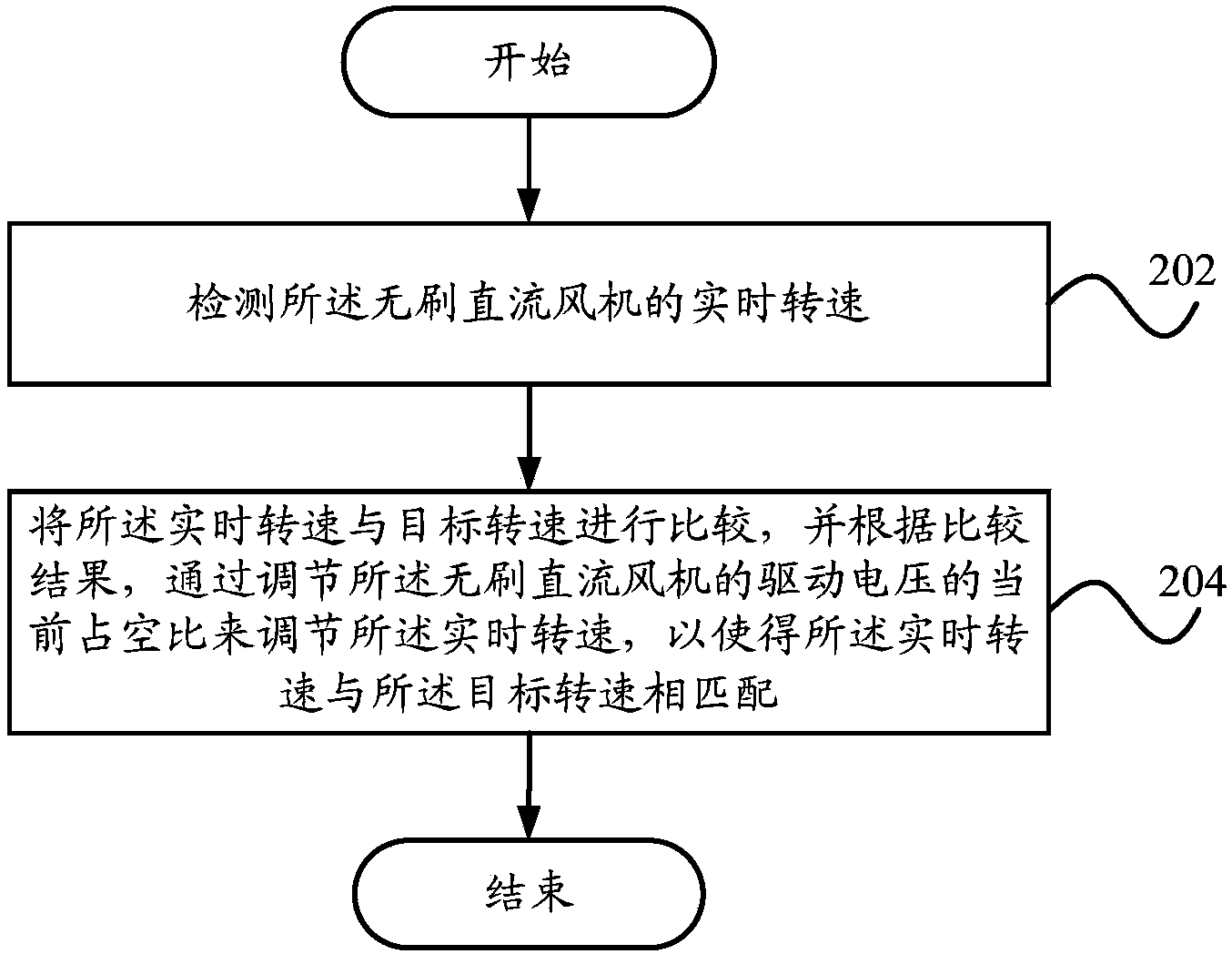

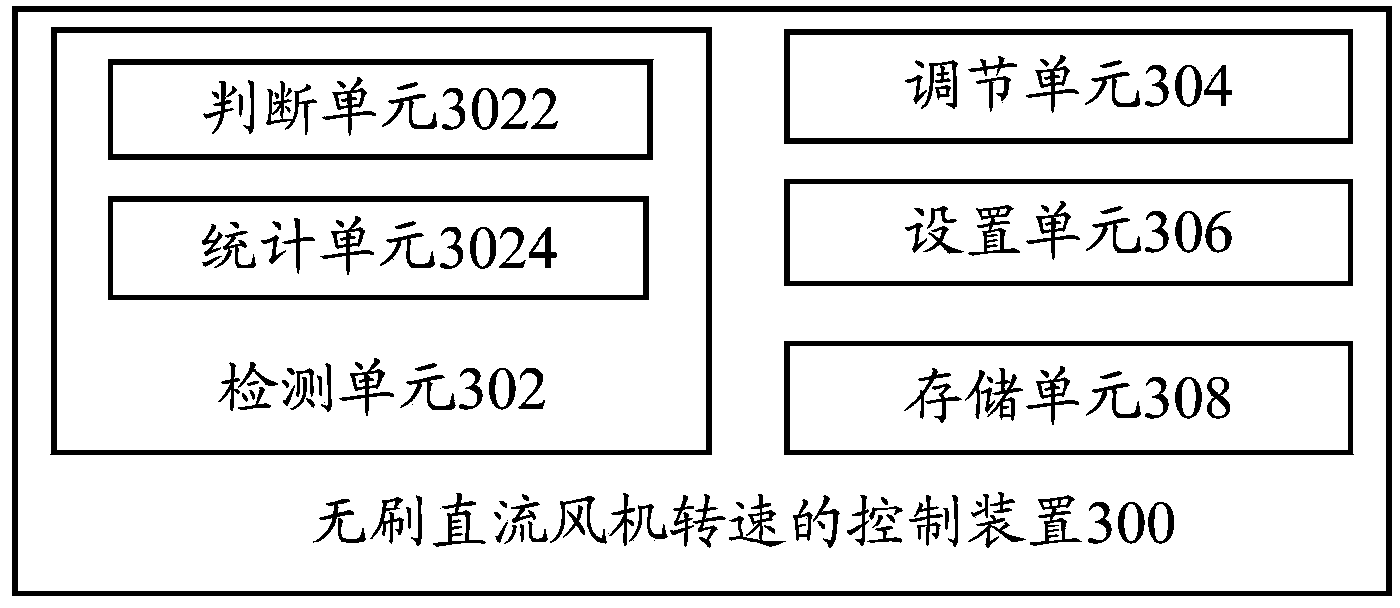

Rotating speed control method and device of brushless DC fan, fan and refrigerator

InactiveCN104265669AReduce noiseHigh control precisionPump controlNon-positive displacement fluid enginesRefrigerated temperatureDuty cycle

The invention provides a rotating speed control method and device of a brushless DC fan, the brushless DC fan and a refrigerator. The rotating speed control method of the brushless DC fan comprises the following steps: detecting the real-time rotating speed of the brushless DC fan; comparing the real-time rotating speed with a target rotating speed; adjusting the current duty ratio of the driving voltage of the brushless DC fan according to the comparison result, so as to adjust the real-time rotating speed to be matched with the target rotating speed. According to the technical scheme, the rotating speed control method of the brushless DC fan has the advantages that the duty ratio of the driving voltage of the fan can be accurately controlled, thus the output voltage of the fan can be accurately controlled, and as a result, the accurate control of the rotating sped of the fan is realized, and the noise of the refrigerator is minimized.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

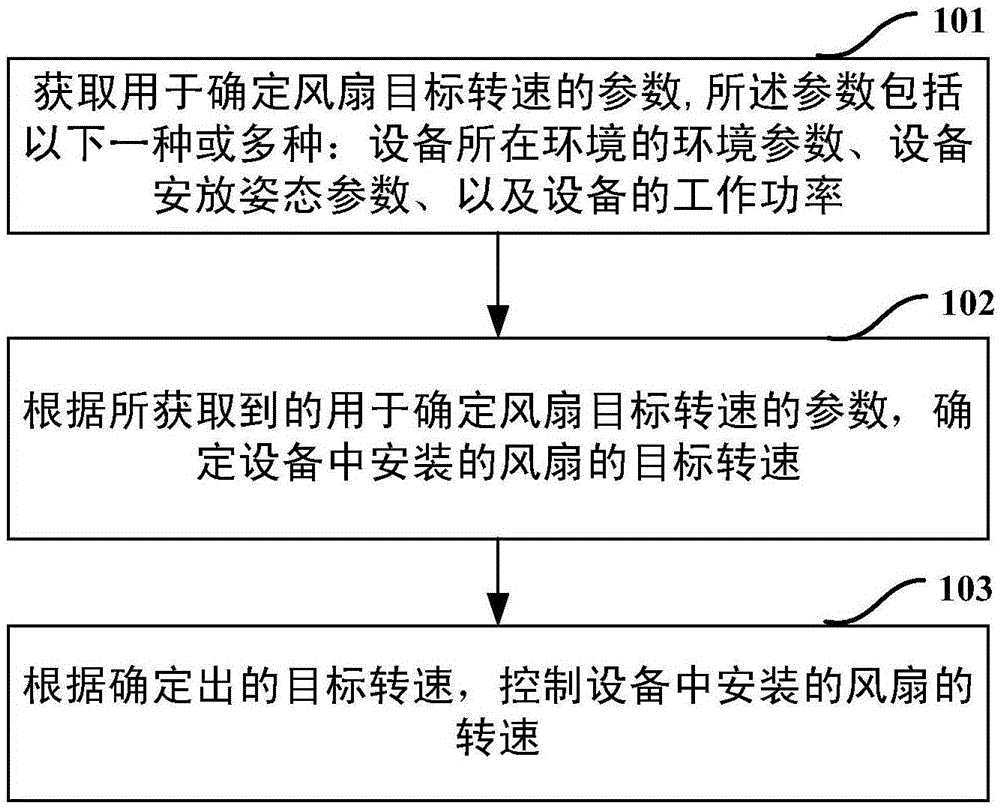

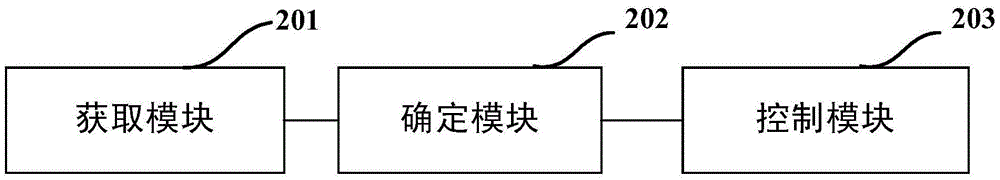

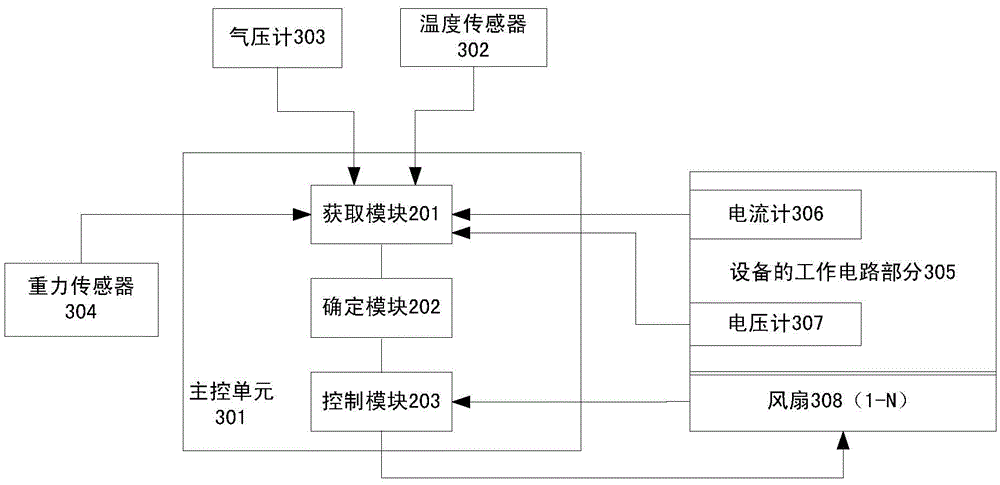

Fan rotation speed control method and device

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

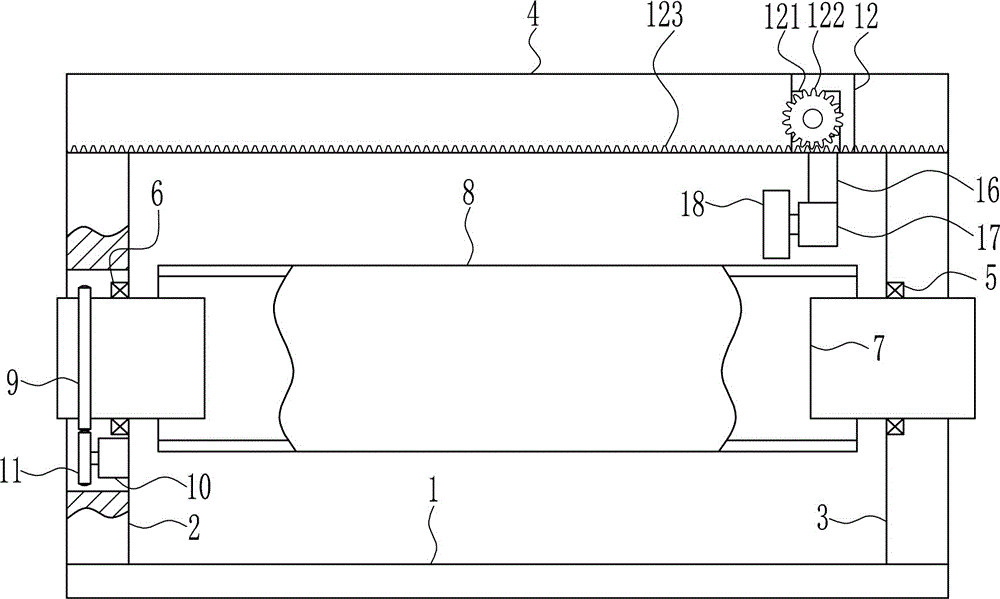

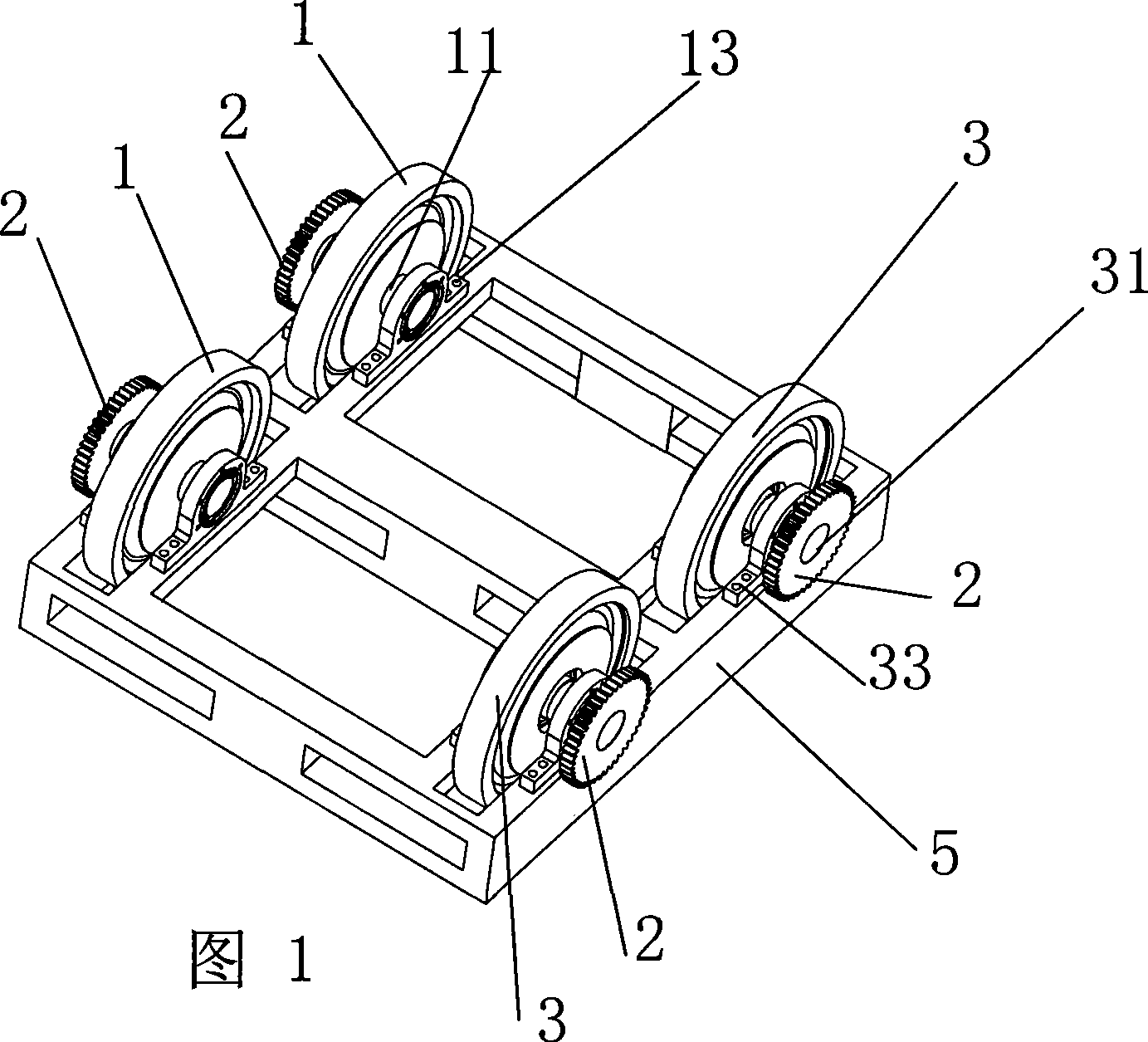

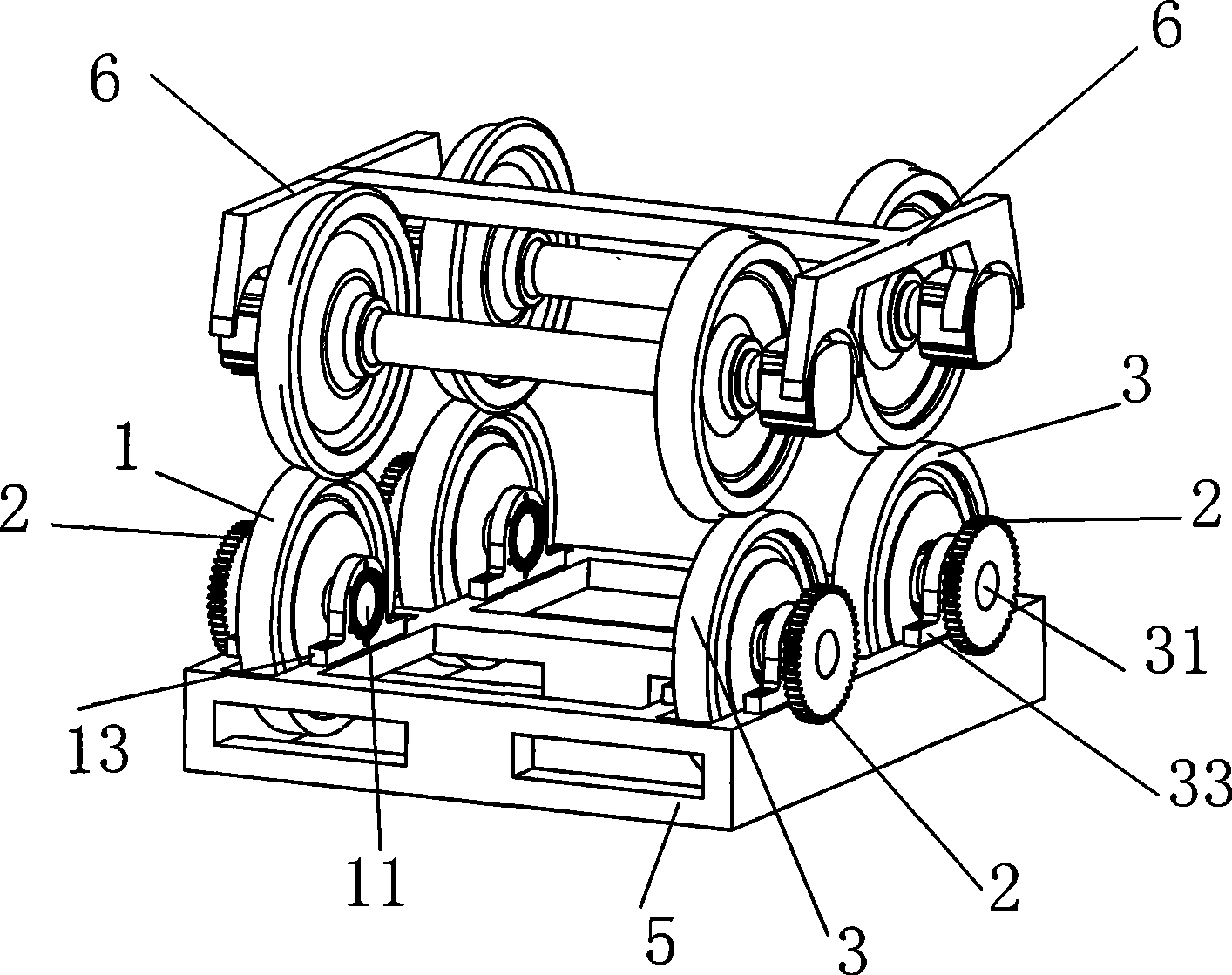

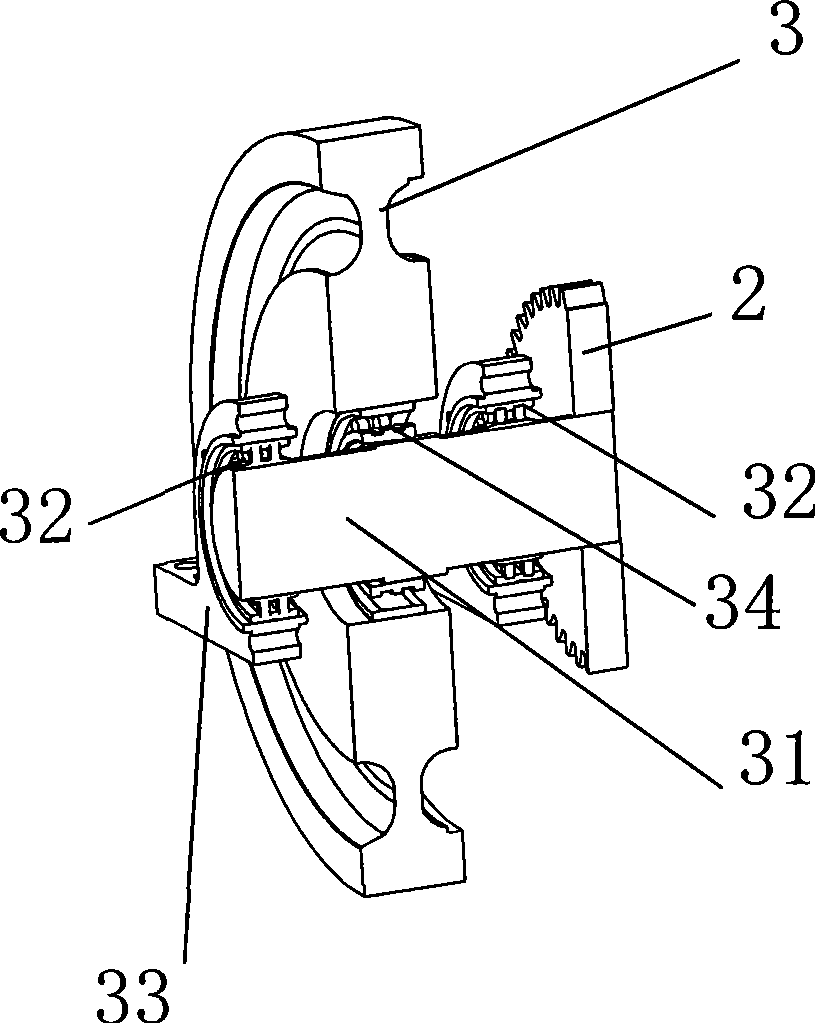

Polishing equipment for industrial steel pipe

InactiveCN106425818AHighly corrosiveStrong acid resistancePolishing machinesGrinding drivesIndustrial engineering

The invention relates to apolishingequipment, in particular to a polishing equipment for industrial steel pipes, and provides a polishing equipment for industrial steel pipes polishing uniformly, having less harm to people and saving both time and effort. In order to solve the technical problems, the invention provides the polishing equipment for industrial steel pipe. The polishing equipment for industrial steel pipes comprises a base plate, a first support plate, a second support plate, a first sliding rail, a first bearing pedestal, a second bearing pedestal, a positioning device, a steel pipe, a first gear and a first motor. The first support plate is welded at the left side of the base plate. The second support plate is welded at the right side of the base plate. The second support plate is arranged at the right of the first support plate. The polishing equipment for industrial steel pipes achieves the effect of uniform polishing, less harm to people and saving both time and labor during polishing through rotating steel pipes and moving polishing wheels.

Owner:南昌安润科技有限公司

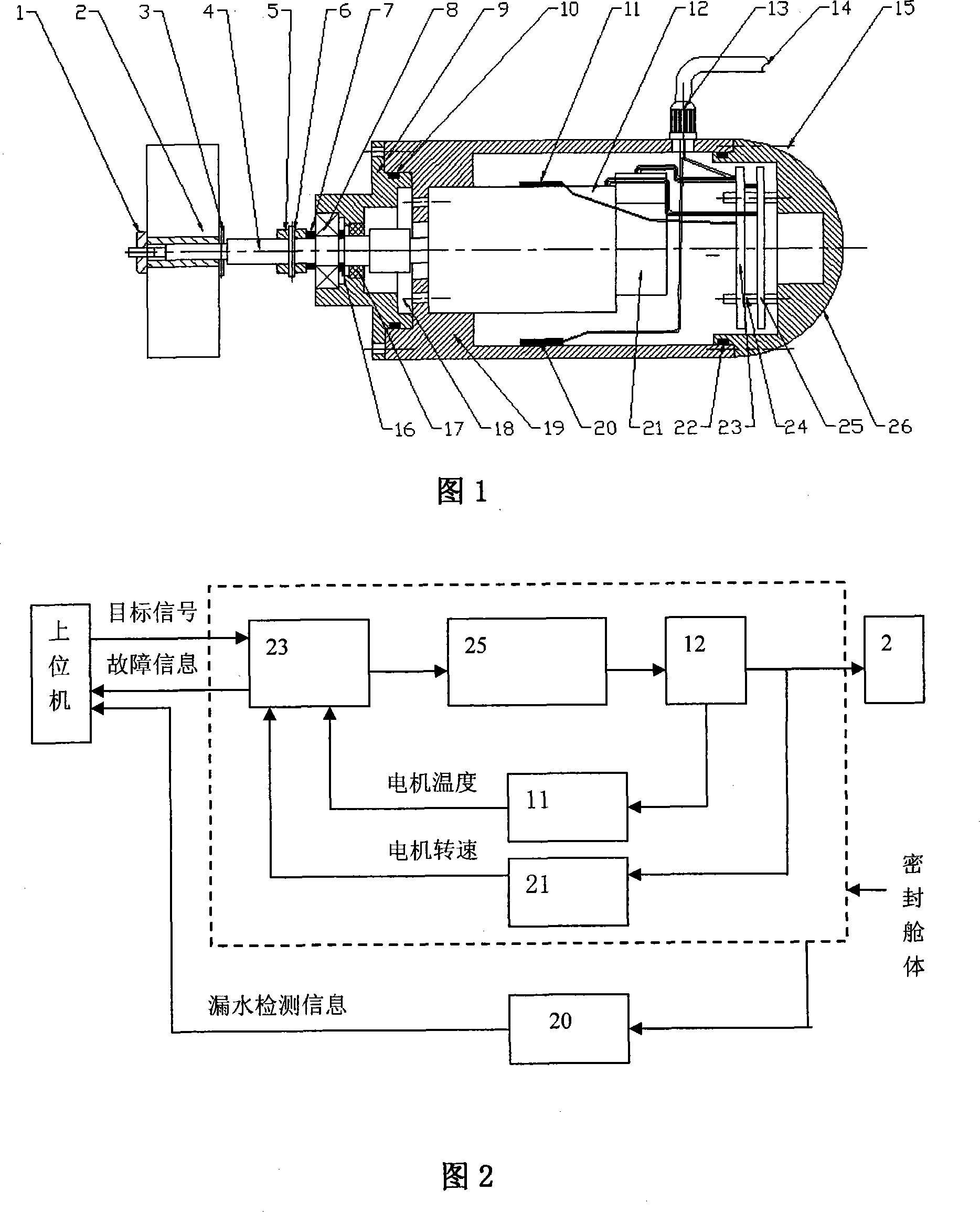

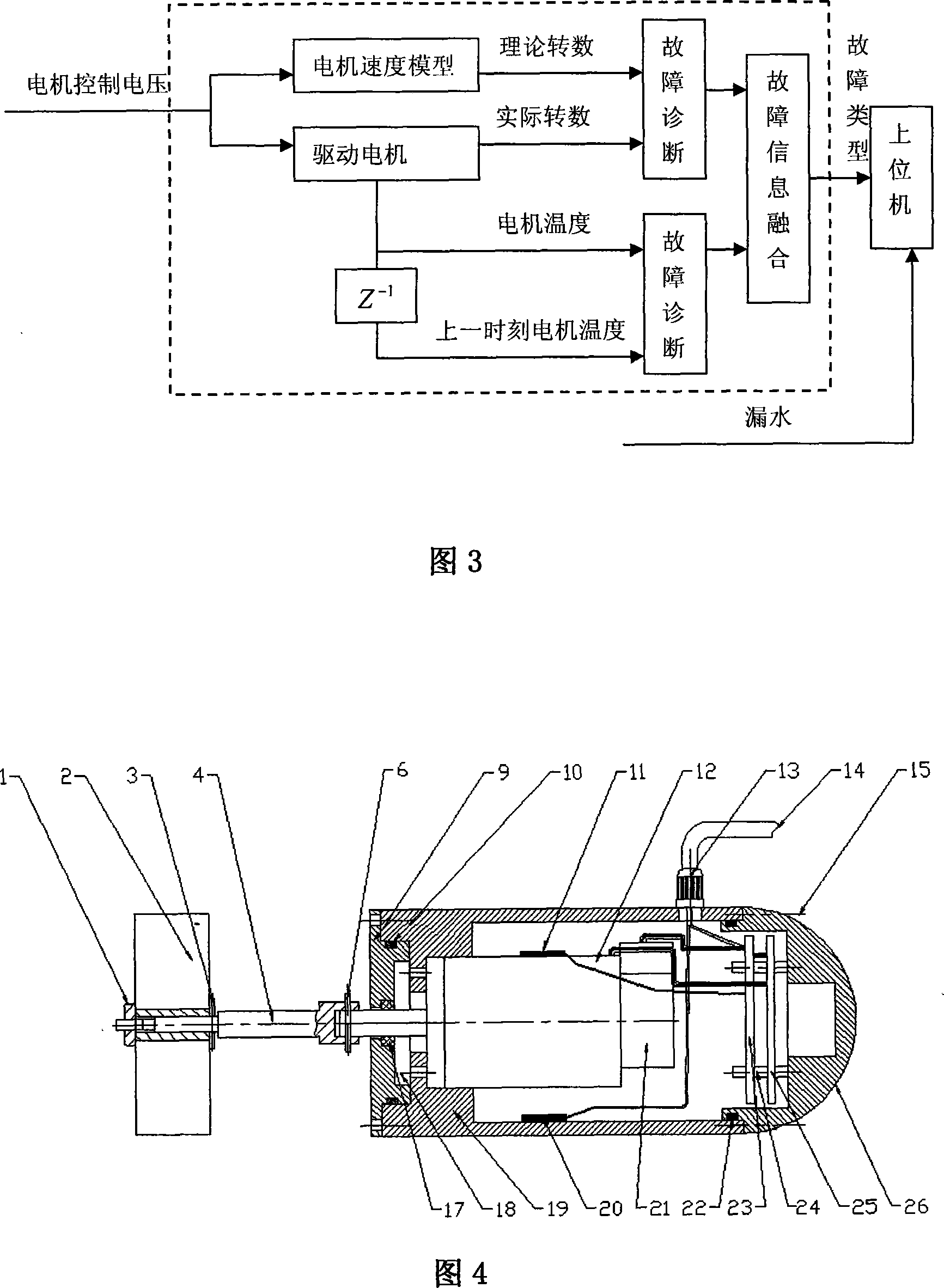

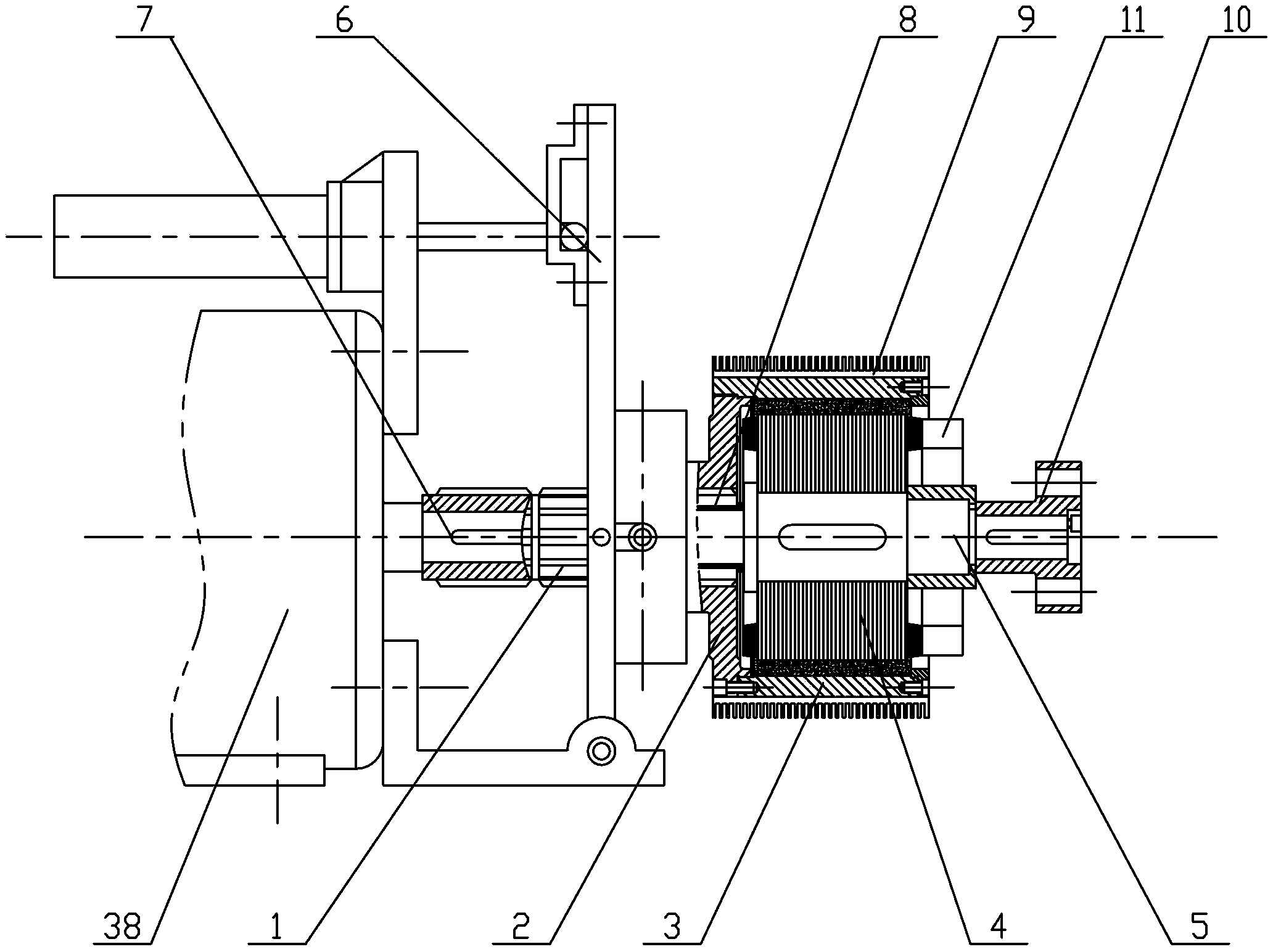

Underwater propeller thruster with self-diagnosing function

InactiveCN101125581AWith self-diagnostic abilityTimely emergency measuresPropulsion power plantsPropulsive elementsElectrical resistance and conductanceElectric machine

The present invention provides an underwater propeller pusher which has self diagnosing function and comprises a driving electrical motor, a propeller, an electrical motor driver, a DSP controller, a leaking detecting sensor, a platinum resistance temperature sensor and a coding device that is used for measuring the rotating speed of the electrical motor; wherein, the driving electrical motor, the electrical motor driver, the DSP controller, the leaking detecting sensor, the platinum resistance temperature sensor and the coding device are all encapsulated inside the sealed and dry inner boat; a cable screwing linker is arranged at the tail of the boat body and can fix and seal the waterproof cable on the crust, while the waterproof cable is connected with the controller and leaking detecting sensor inside the crust. The present invention integrates the driving device, the control circuit and the pusher driving electrical motor crust as a whole and has temperature sensor, leaking detecting sensor and speed sensor and also has self diagnosing function and is provided with a pushing shaft, while the structure is compact, high efficient and safe.

Owner:HARBIN ENG UNIV

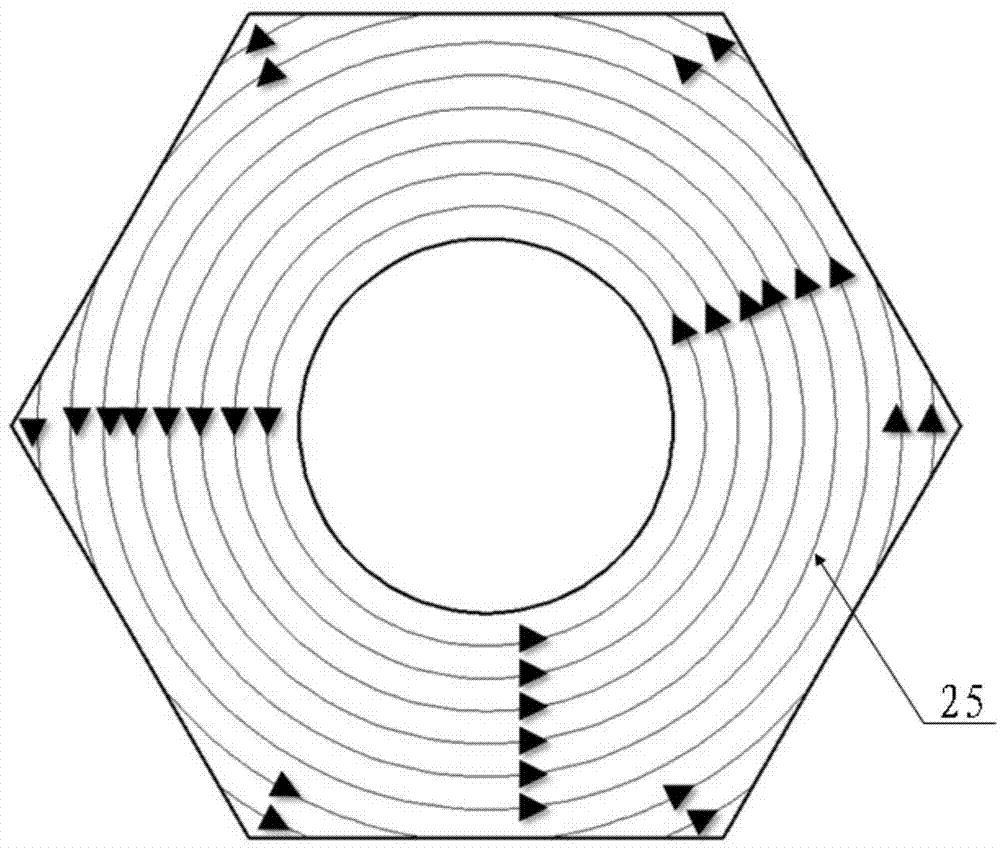

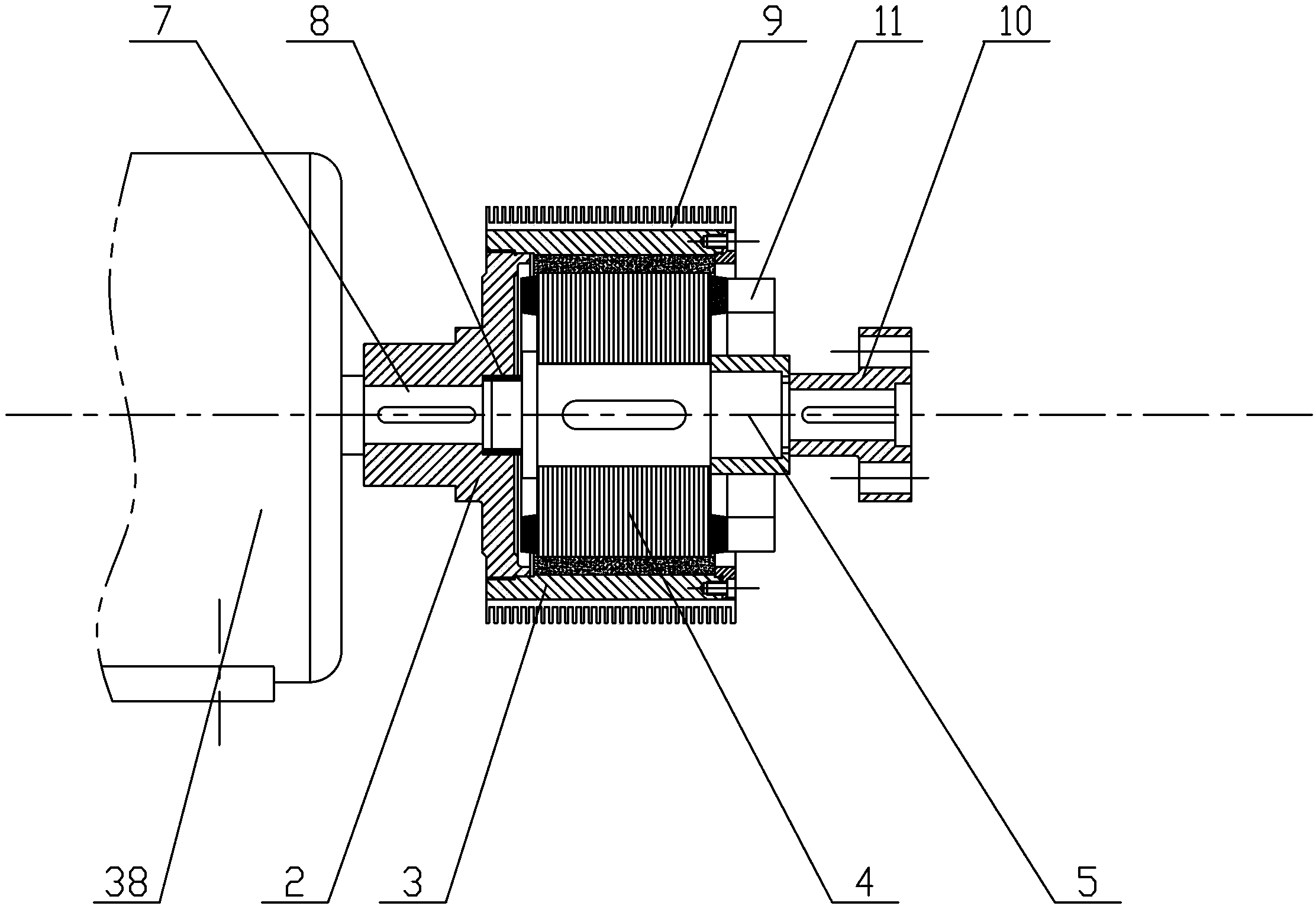

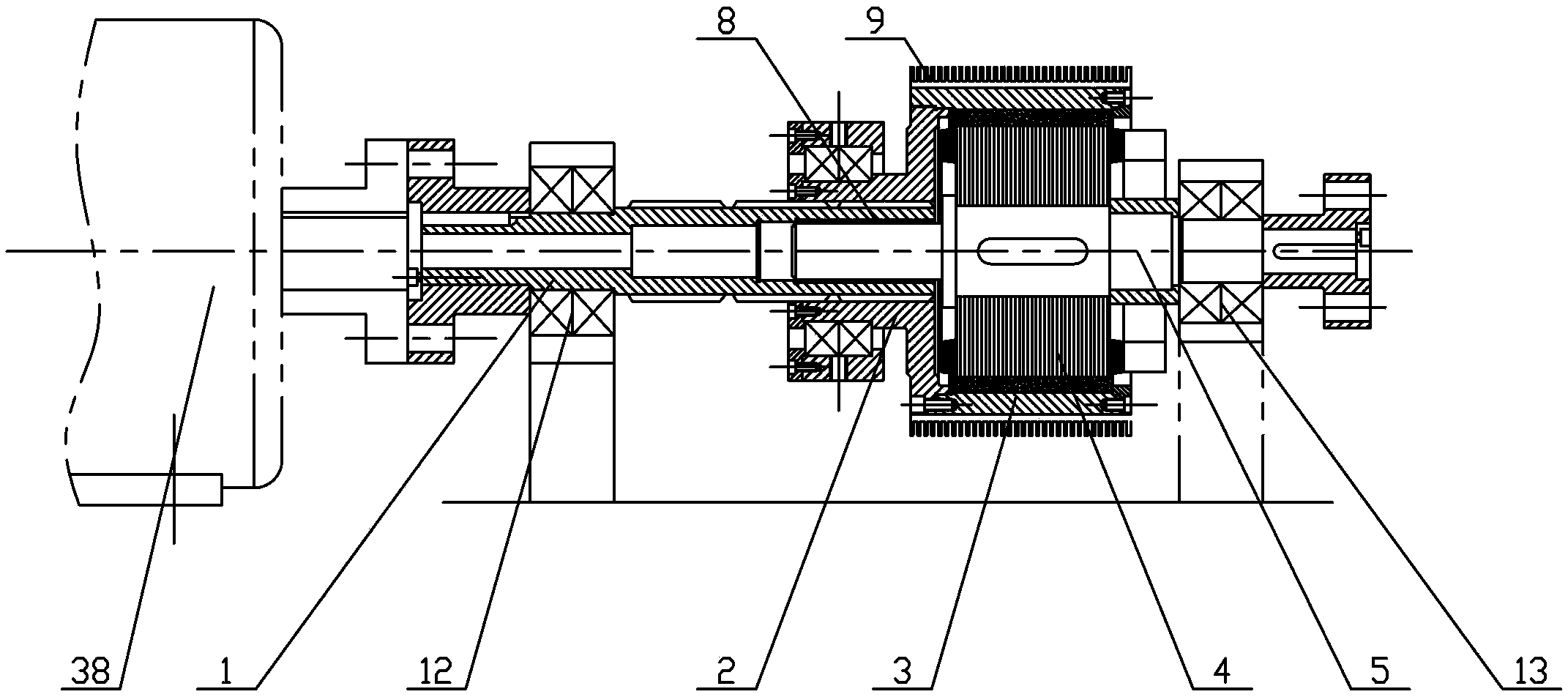

Magnetic coupler

ActiveCN103401398ASmall moment of inertiaImprove reliabilityDynamo-electric gearsElectric machineControl theory

The invention discloses a magnetic coupler which comprises a power input shaft, connecting flanges, permanent magnet outer rotor assemblies, cage type inner rotors, a power output shaft and a mechanical speed adjustment device, wherein the permanent magnet outer rotor assemblies have hollow cup-shaped structures, are sleeved outside the cage-type inner rotors and realize transmission of torque under the coupling action of an air gap magnetic field between the permanent magnet outer rotor assemblies and the cage-type inner rotors; the mechanical speed adjustment device can change axial air gap areas between the permanent magnet outer rotor assemblies and the cage-type inner rotors according to a lever theory, thus realizing stepless speed variation for load rotating speed. According to the magnetic coupler, a method for designing the number of pole pairs of the permanent magnet outer rotor assemblies is provided on the basis of a minimum torque ripple rule, so that the thickness of yokes and the rotating inertia of the coupler are reduced. The cage-type inner rotors can adopt structures which are the same as or similar to that of the conventional motor cage rotor iron core. The magnetic coupler disclosed by the invention can be coaxially connected with a load and can be used as a belt wheel adapter matched with a belt wheel.

Owner:DALIAN JIAOTONG UNIVERSITY

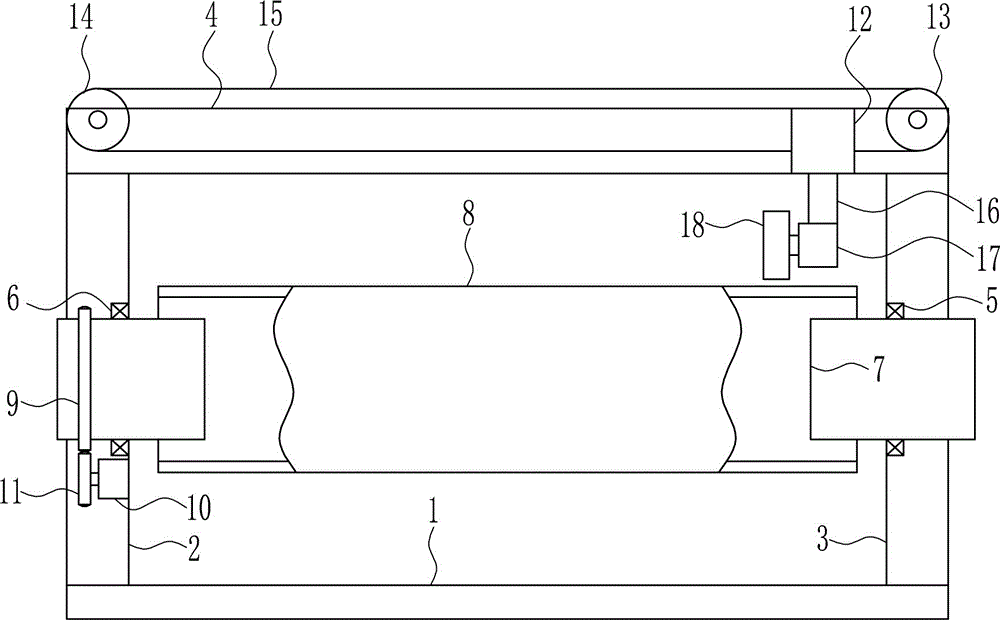

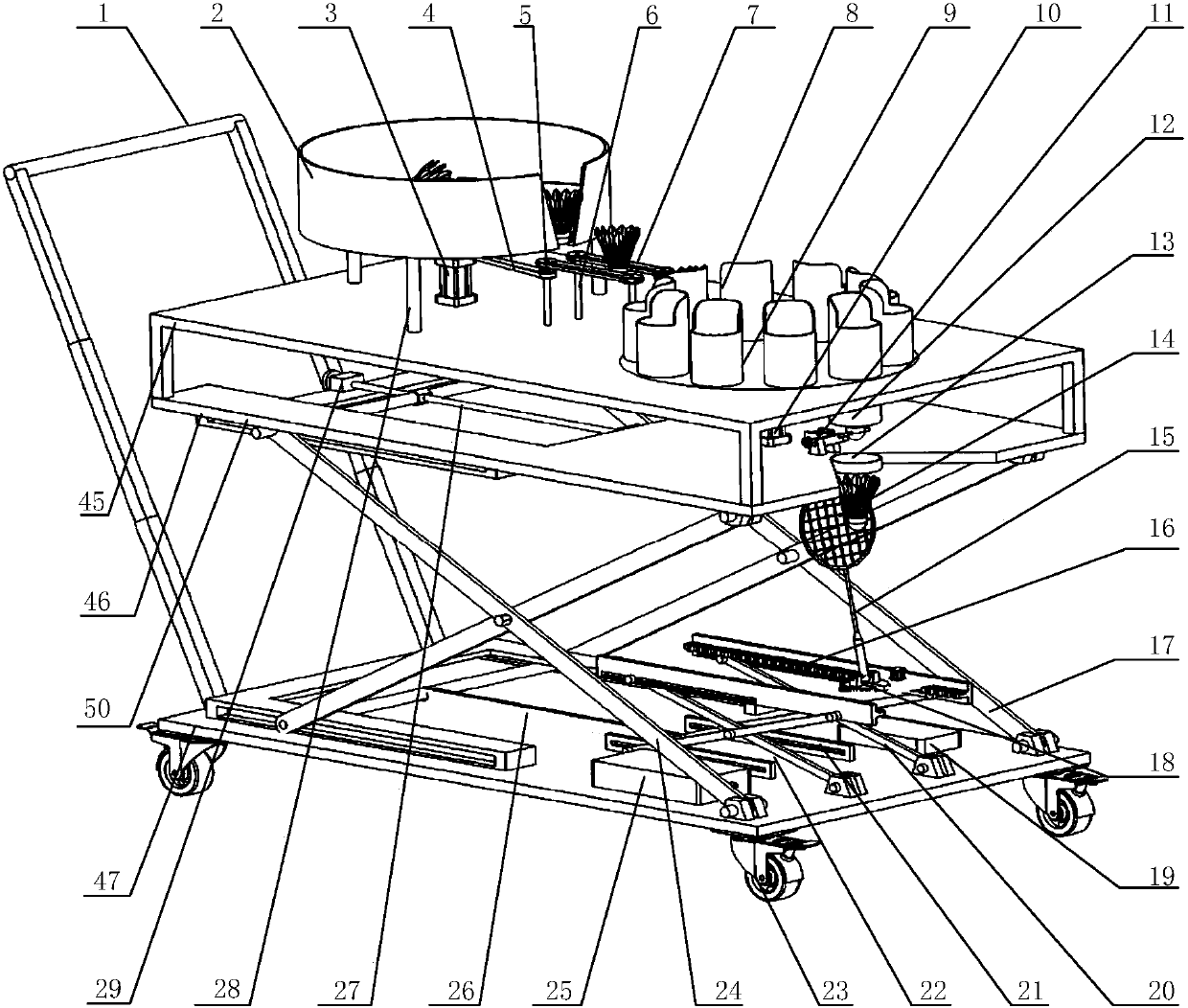

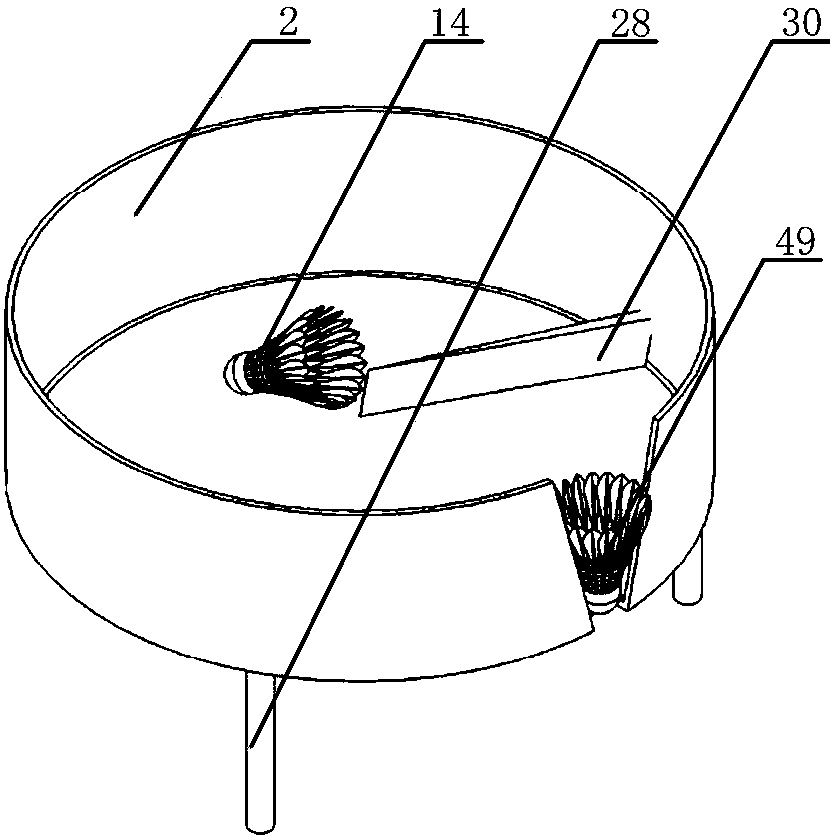

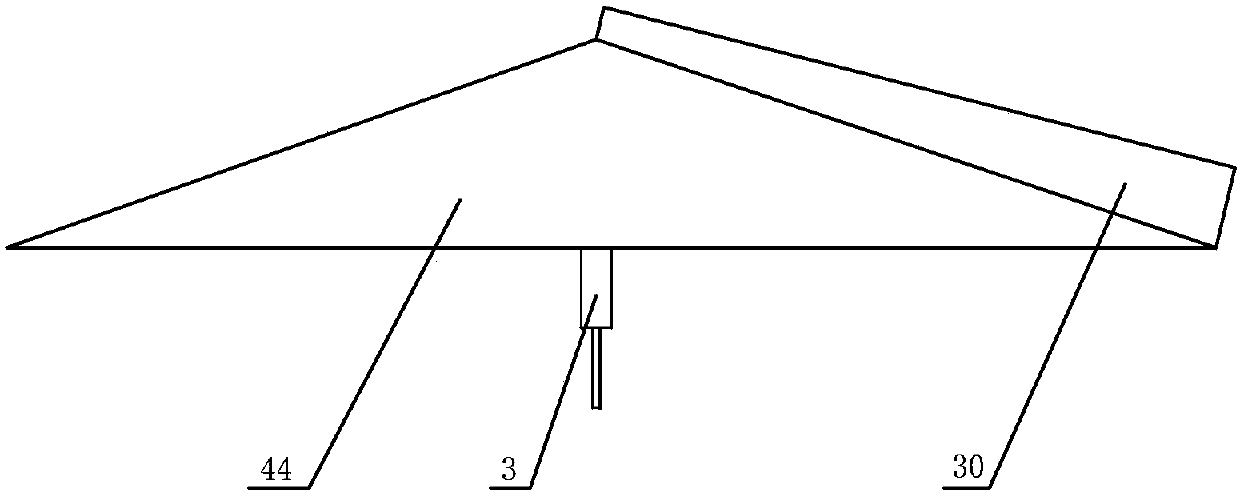

Badminton pitching machine with finishing function

PendingCN107596665AGuaranteed reliabilityImprove gripSport apparatusThree degrees of freedomEngineering

A badminton pitching machine with a finishing function comprises a finishing mechanism, a conveying mechanism, a pitching mechanism, a racket control latching mechanism and three supporting plates, wherein the badminton finishing mechanism includes a finishing cylinder, a conical disc, a baffle and a first motor. The conveying mechanism includes a transmission band, a ball-collecting cylinder, a turntable, a guiding cylinder and a guiding ring, and the badminton can be achieved from finishing mechanism to pitching mechanism. The pitching mechanism includes a ball-taking claw, a racket, a rack,a racket base, a first gear, a second gear, a second semicircle gear, a fourth motor, a fifth motor and a racket control latching mechanism. The badminton pitching machine with the finishing functionsolves the defects that the existing badminton pitching machine has simple structure but insufficient function or has complicated structure but no badminton finishing function, does not require manual works to conduct finishing, simultaneously can control the badminton to achieve the movement in vertical, longitudinal and rotary three degrees of freedom, increase the changes of pitching force, angle and track, and preferably simulate various complicated and changeable motion patterns in the badminton sport.

Owner:SOUTHWEST UNIVERSITY

Agricultural mechanical equipment for efficient screening of soybean seeds

InactiveCN106903049ASave materialEasy to carryGas current separationAgricultural engineeringMechanical equipment

The invention relates to agricultural mechanical equipment for efficient screening of soybean seeds. The agricultural mechanical equipment comprises a left frame, a bottom plate, a first collecting frame, a right frame, a first sliding rail, a first sliding block, a screening plate, a second sliding block, a second sliding rail, a second collecting box, a fixing plate and the like. The left frame is welded to the left side of the top of the bottom plate, the right frame is welded to the right side of the top of the bottom plate, and the first collecting frame is placed in the middle of the top of the bottom plate. The agricultural mechanical equipment has the beneficial effects that the structure is novel, the screening speed is high, and the soybean seeds are not damaged; and a worker can achieve efficient screening work on the soybean seeds through the equipment, operation is simple, and in addition, time and labor are saved.

Owner:六安市富民农用器材制造有限公司

Axial fatigue experimental approach and apparatus for stacking abrasion load

InactiveCN101368892AImproved strength designAvoid one-sidednessStrength propertiesFatigue loadingReduction drive

The invention discloses an axial fatigue test method with abrasion load superposition and a device thereof. The method is to impose the abrasion load on the specimen when an axial fatigue test machine carries out the axial fatigue experiment on the specimen; and the abrasion load is imposed through an abrasion load device sleeved on the specimen. The device comprises the axial fatigue test machine and the abrasion load device; the abrasion load device comprises a speed reducer; the input shaft of the speed reducer is connected with an adjustable speed motor; the output shaft of the speed reducer is a cylindrical structure; adjusting screws are symmetrically arranged at both sides of the output shaft of the speed reducer; and a friction plate is arranged inside the output shaft of the speed reducer. The invention enables the experimental results in the laboratory to truly reflect the actual service life of the component under various load effects and overcomes the one-sidedness of the existing experimental results. The invention helps finding out the fatigue fracture reasons and fatigue life prediction under the combined effect of simultaneous abrasion load and fatigue load bearing.

Owner:GUIZHOU UNIV

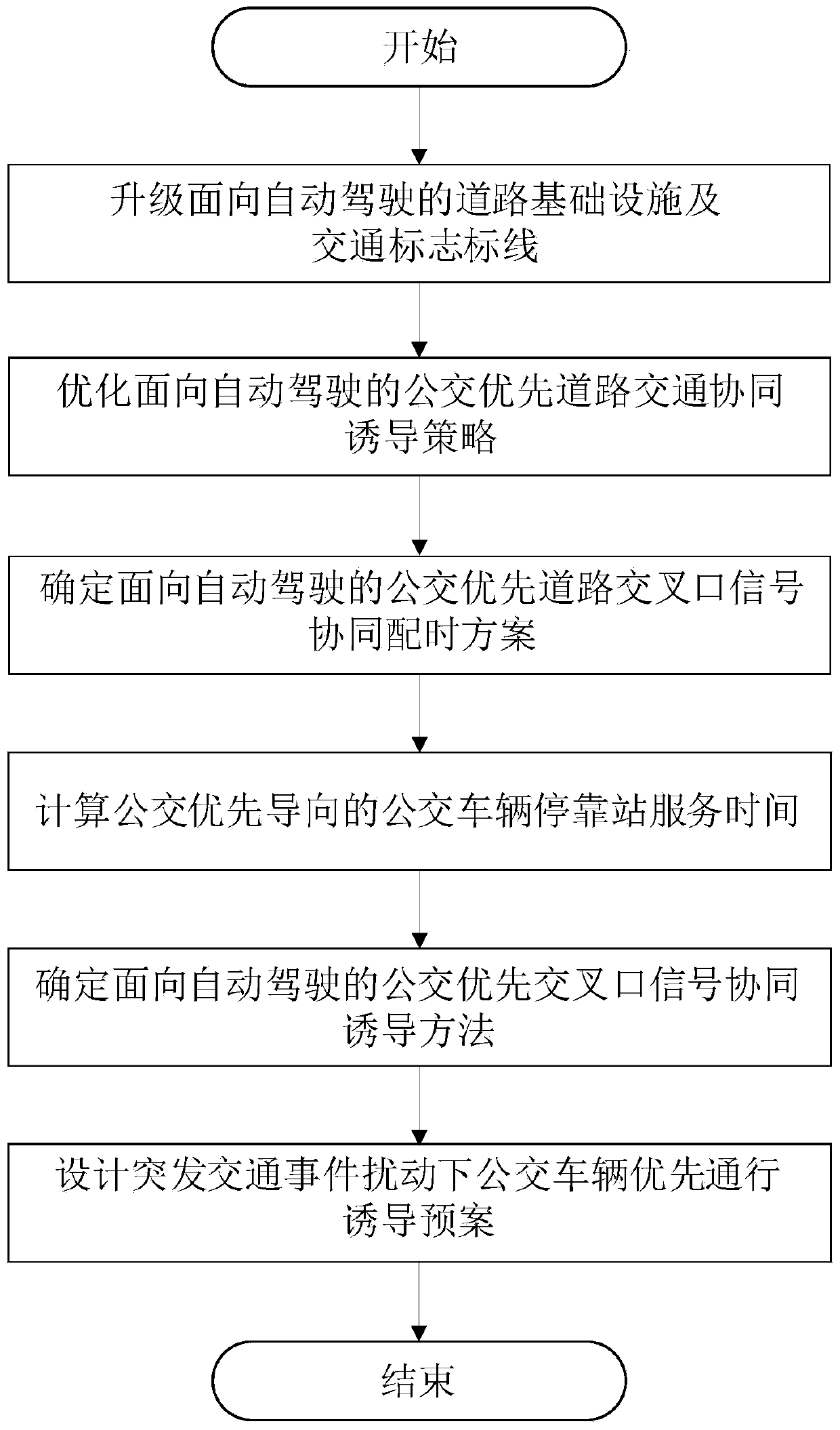

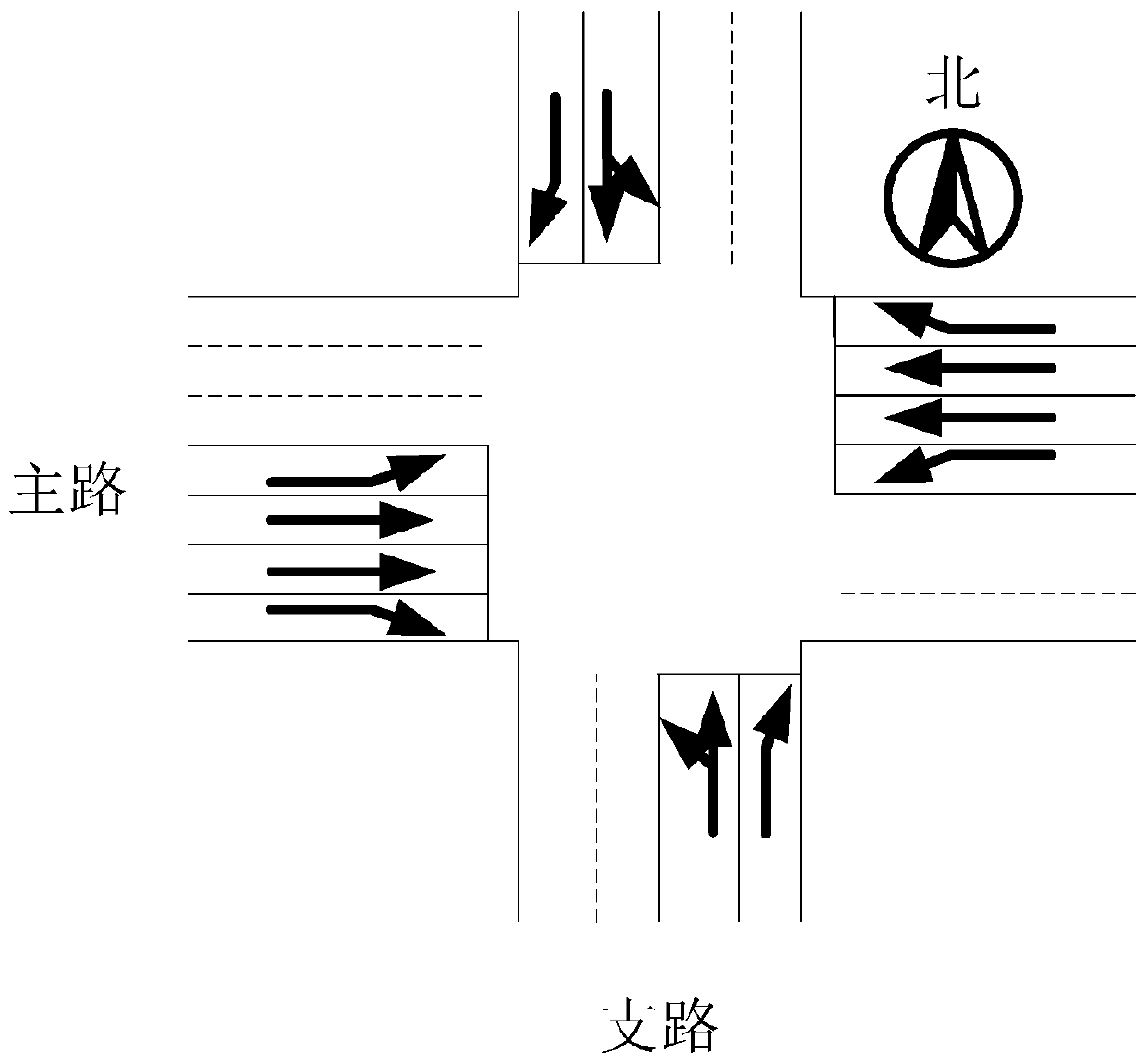

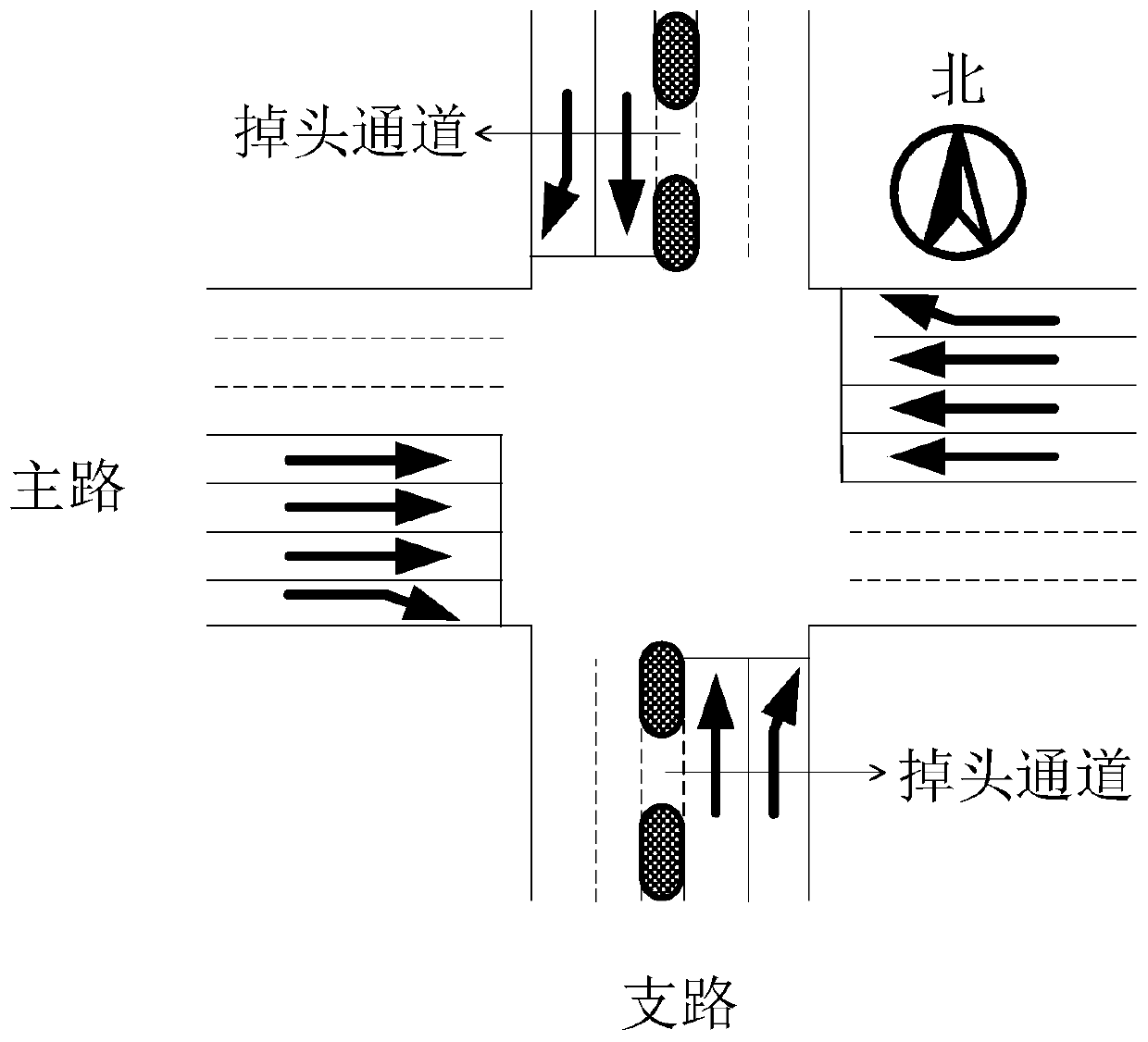

Bus priority road traffic cooperative induction method for automatic driving

ActiveCN111508247AImprove traffic efficiencyAccurate speed controlRoad vehicles traffic controlTraffic signalsSimulationTraffic flow

The invention discloses a bus priority road traffic cooperative induction method for automatic driving. The method comprises the steps of: upgrading road infrastructures and traffic sign marking linesfor automatic driving; optimizing a bus priority road traffic cooperative induction strategy for automatic driving; determining a bus priority road intersection signal cooperative timing scheme for automatic driving; calculating bus stop service time of bus priority guidance; determining a bus priority intersection signal cooperative induction method for automatic driving; and designing a publictransport vehicle priority passage induction plan under the disturbance of the emergency traffic incident. According to the invention, based on a traffic flow traffic operation process in an automaticdriving environment, accurate control and real-time adjustment and optimization of road speed can be realized; accurate and real-time two-way communication can be carried out between the bus and thesignal control machine, an intersection signal timing scheme can be adjusted in real time to enable the bus to pass within bus priority guarantee time, and the passing efficiency of the bus is greatlyimproved.

Owner:HOHAI UNIV

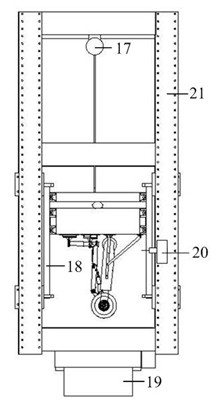

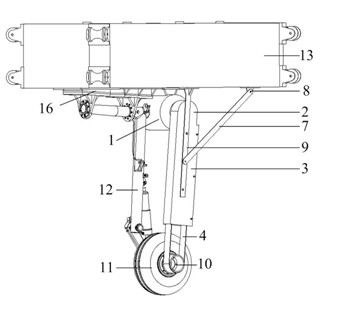

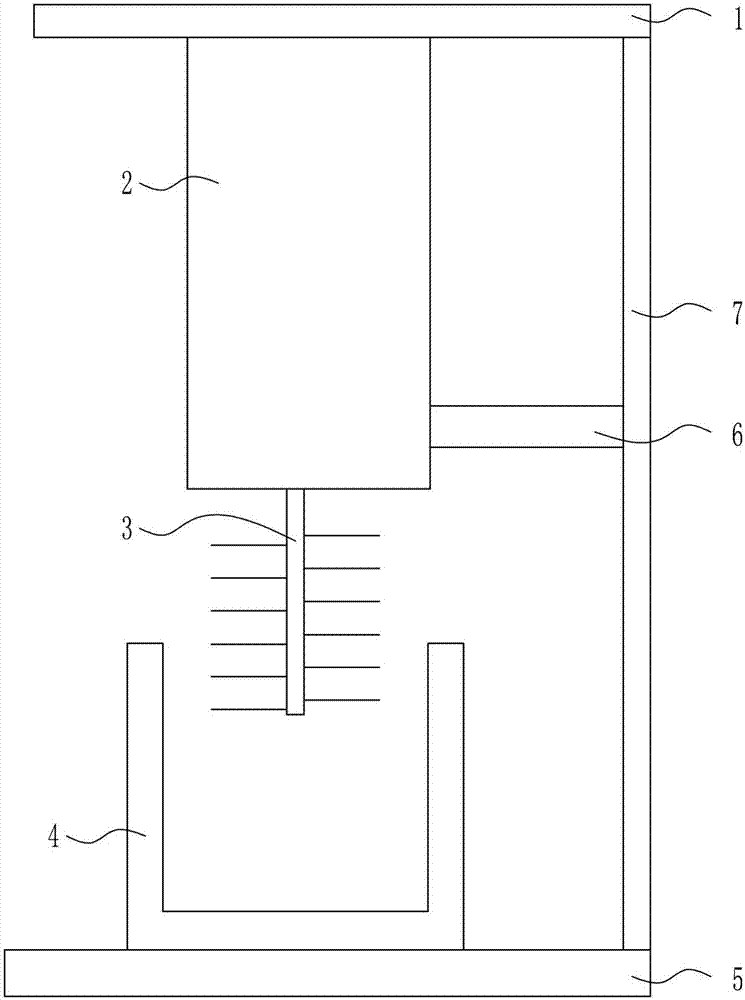

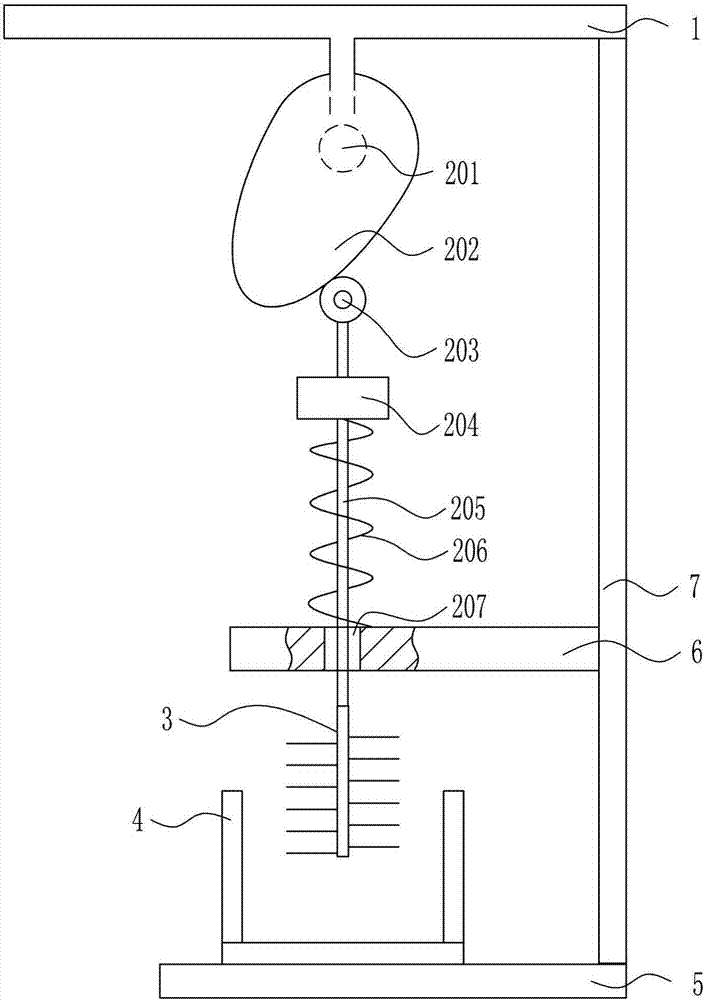

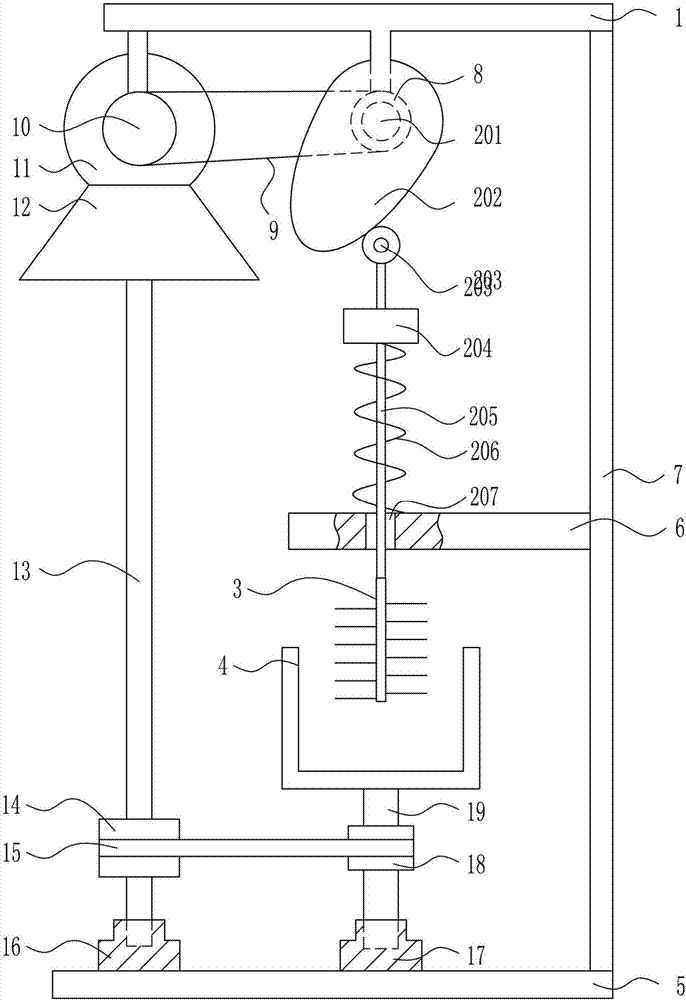

Drop test bed with speed controllable rotation driving mechanism

The invention discloses a drop test bed with a speed controllable rotation driving mechanism, which comprises a test bed rack, a hanging bracket and an undercarriage, wherein the hanging bracket is arranged in the test bed rack and can creep down along sliding ways of the test bed rack; and the undercarriage is fixed at the lower end of the hanging bracket. An electromotor is also arranged at the lower end of the hanging bracket. An electromotor belt pulley is connected to an output shaft of the electromotor. An airplane wheel belt pulley synchronous with an airplane wheel is arranged on the airplane wheel of the undercarriage, and is in transmission with the electromotor belt pulley through a belt. A travel switch is also arranged on the sliding way of the test bed rack, and controls the electromotor to stop when the airplane wheel is landed. The drop test bed with the speed controllable rotation driving mechanism has a light and compact structure, simple layout and reliable performance, and is convenient to operate.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

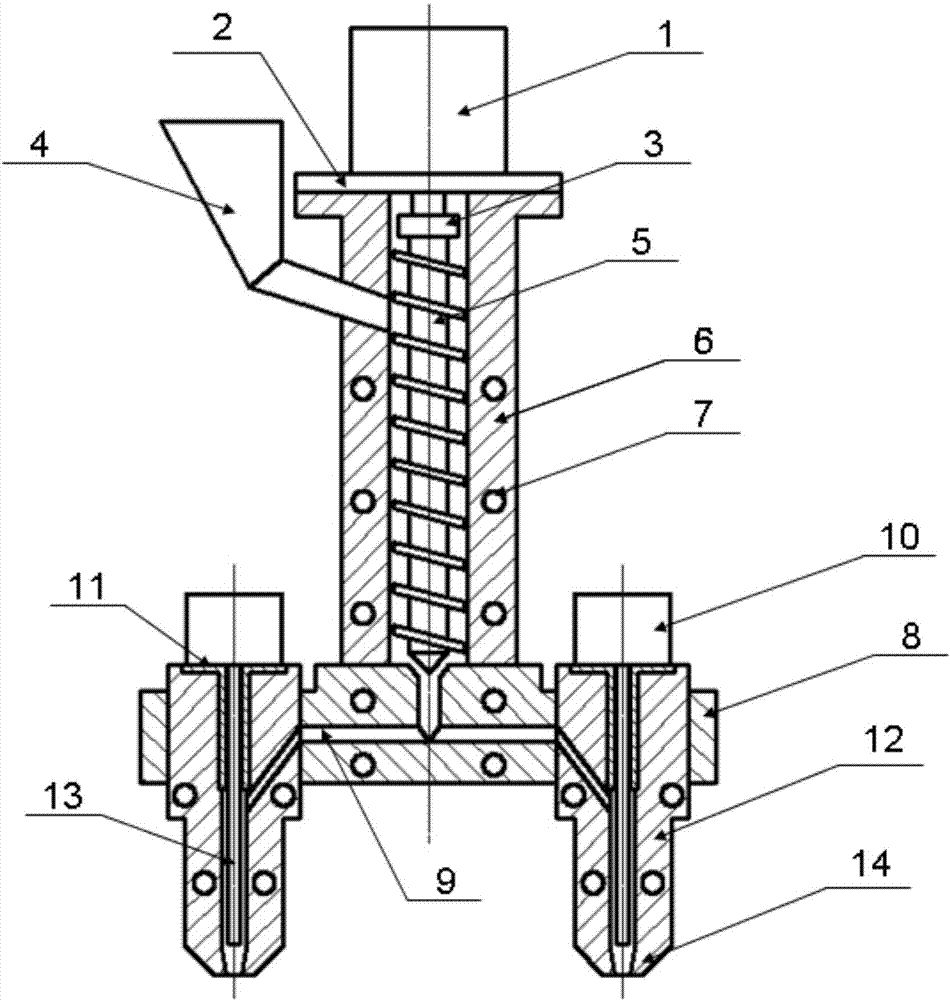

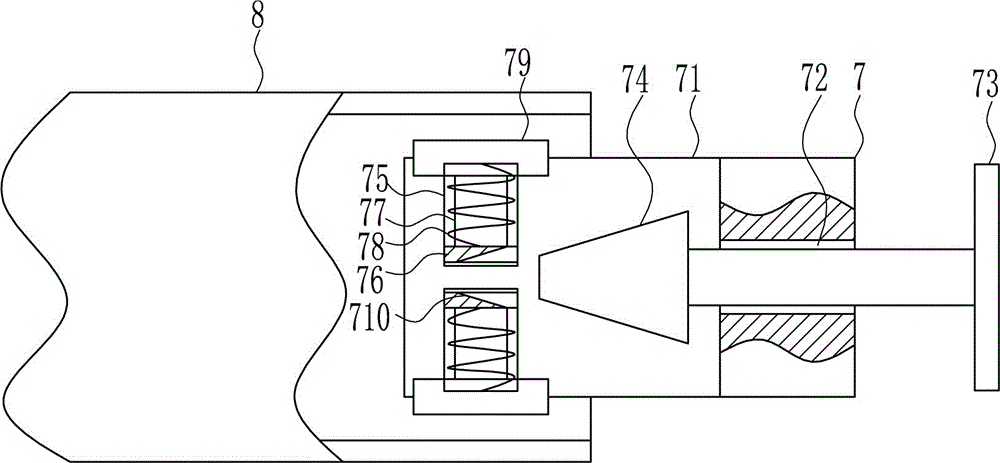

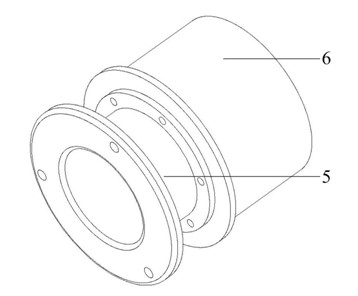

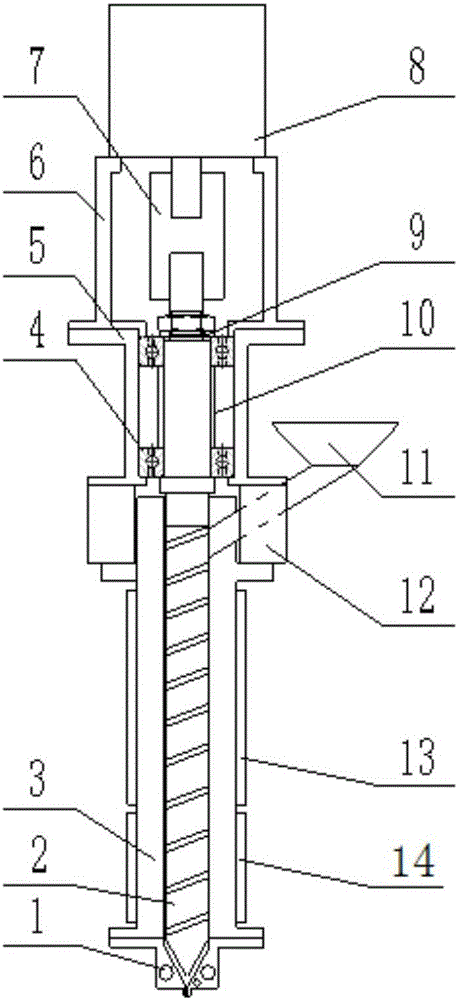

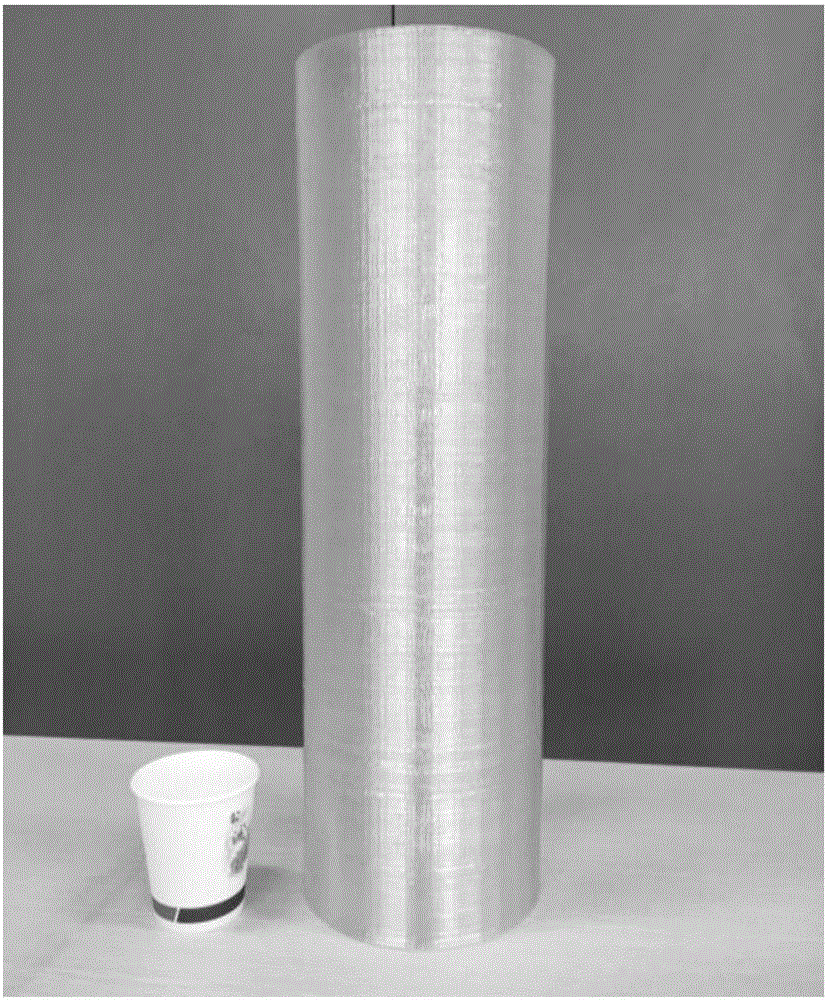

Screw type additive manufacturing spray head

InactiveCN106217867AEasy to useLow costAdditive manufacturing apparatusHeater RodPulp and paper industry

The invention discloses a screw type additive manufacturing spray head. Particles of the conventional size can be used as a raw material, the material extrusion process is stable, the extrusion force is large, and the forming efficiency is high. The screw type additive manufacturing spray head comprises a machine barrel, a nozzle fixed to the front end of the machine barrel, a screw arranged in the machine barrel and a drive motor fixed to the rear end of the machine barrel. The tail end of the screw is arranged in a cone shape. The front end of the screw is connected with the output end of the drive motor. The part, provided with a thread, of the screw is sequentially provided with a feeding segment, a compression segment and a metering segment from the front end to the tail end according to threaded groove depths. The groove depth of the feeding segment is the maximum, and the feeding segment is arranged in an equal groove depth manner. The groove depth of the metering segment is the minimum, and the metering segment is arranged in an equal groove depth manner. The groove depth of the compression segment is gradually changed into the minimum groove depth from the maximum groove depth. A feeding opening is formed in the position, corresponding to the feeding segment of the screw, of the machine barrel. A first heating ring is arranged at the position, corresponding to the compression segment, of the machine barrel, and a second heating ring is arranged at the position, corresponding to the metering segment, of the machine barrel. The interior of the nozzle is arranged in the manner of a conical face matched with the tail end of the screw. A set of heating bars is arranged on the nozzle in an inserted manner.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Testing table for fatigue strength of locomotive bogie

InactiveCN101363773ARealize full frequency bandDetermination of fatigue lifeVehicle testingBogieVertical vibration

A fatigue strength test stand of a locomotive bogie is as follows: drive eccentric shafts of a front drive eccentric wheel and a back drive eccentric wheel are fixed on one side of the bogie through a bearing and a bearing seat; driven eccentric shafts of a front driven eccentric wheel and a back driven eccentric wheel are fixed on the other side of the bogie through a bearing and a bearing seat; the front and the back drive eccentric shafts are respectively connected with a drive device. The test stand can simulate the vertical vibration, the transverse vibration, the nodding and the compound vibration of the bogie in full range so as to truly measure the fatigue life of the bogie, thereby determine the life cycle, and providing reliable guarantee for the safe operation of the locomotive. The test stand has the advantages of simple structure and convenient operation.

Owner:SOUTHWEST JIAOTONG UNIV

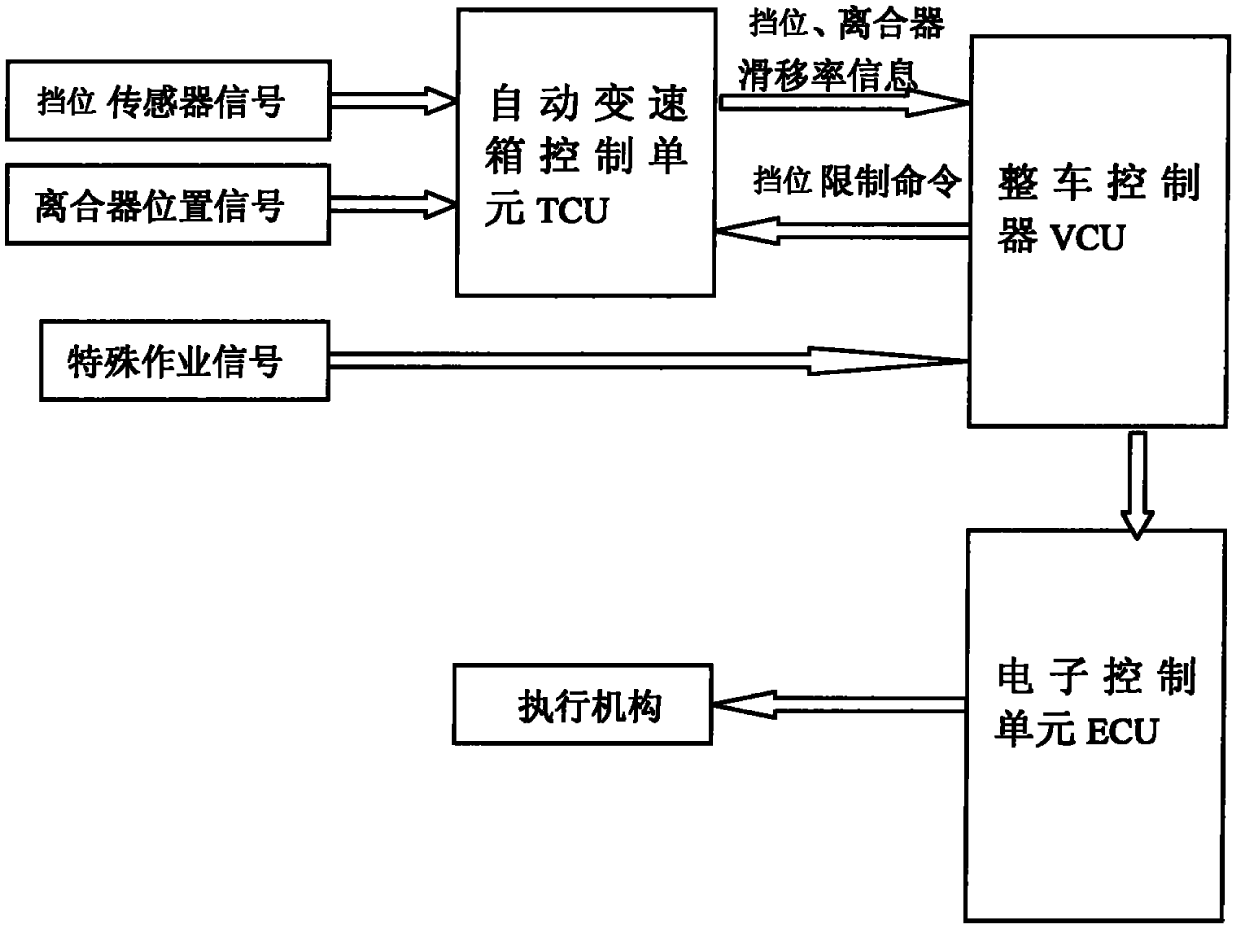

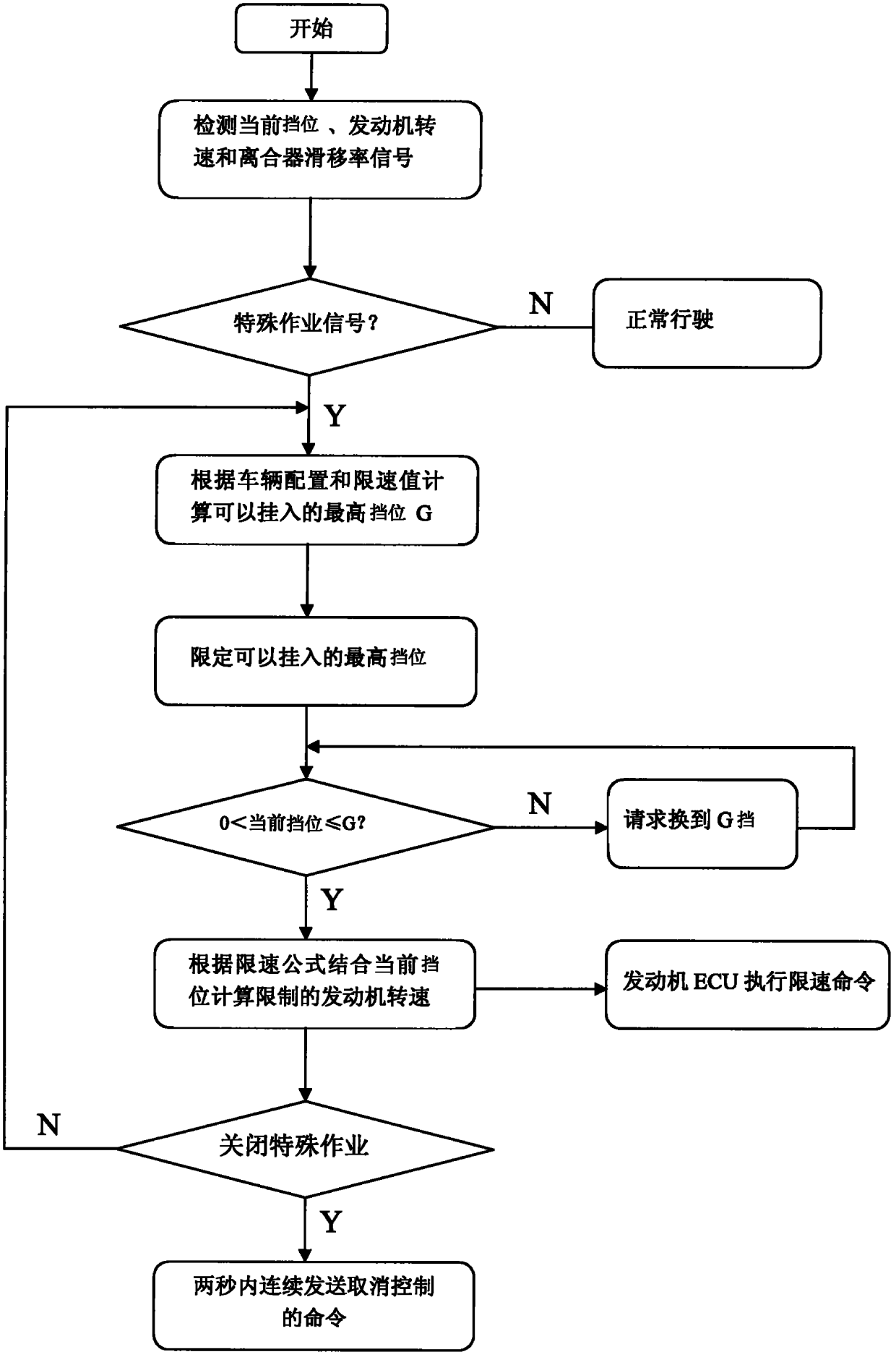

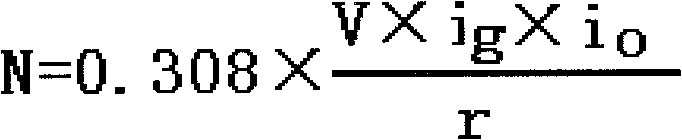

A method for controlling the speed limit of amt vehicles

The invention discloses a control method for speed limit of an AMT (Automatic Mechanical Transmission) type vehicle. The control method comprises the following steps that: a. an automatic TCU (Transmission Control Unit) receives a current gear signal, an engine revolution speed signal and a clutch slip ratio signal detected by a sensor, and transmits the signals and a determined driving chain combination state signal to a VCU (Vehicle Control Unit); b. the VCU calculates a maximum gear allowed to be switched and a maximum limit value of the engine revolution speed, real time transmits a command signal to an ECU (Electronic Control Unit) and detects whether the current gear is higher than the allowed maximum gear; c. the VCU transmits a gear-switching request command and reduces the current gear to be the allowed maximum gear; d. the ECU regulating a rail pressure and a fuel injection quantity according to the maximum limit value of the engine revolution speed so as to regulating the engine revolution speed to be lower than the maximum limit value; and e. a vehicle regularly runs. The invention has the beneficial effects of largely reducing the labor strength when effectively improving the safety of a driver.

Owner:SINO TRUK JINAN POWER

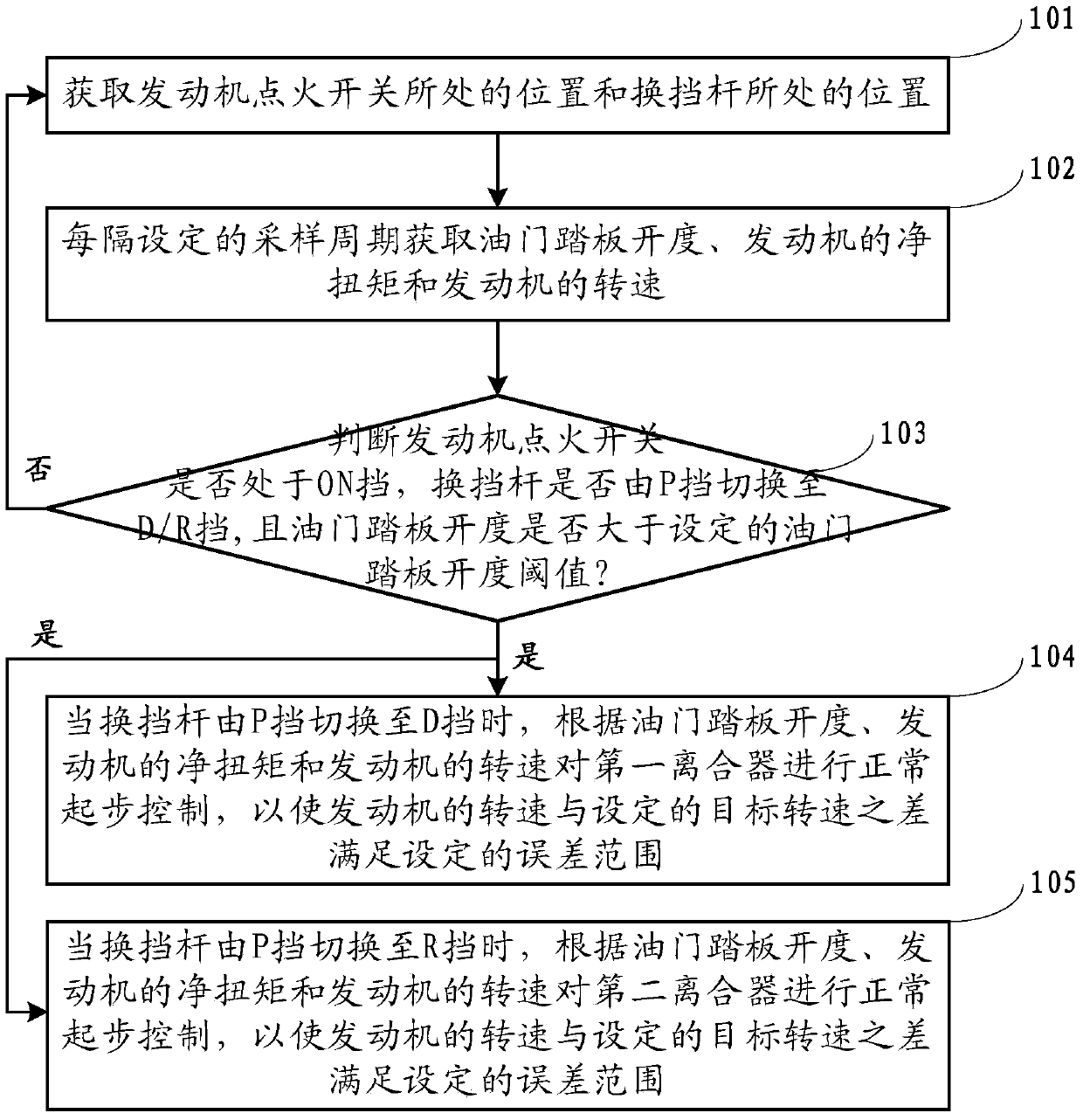

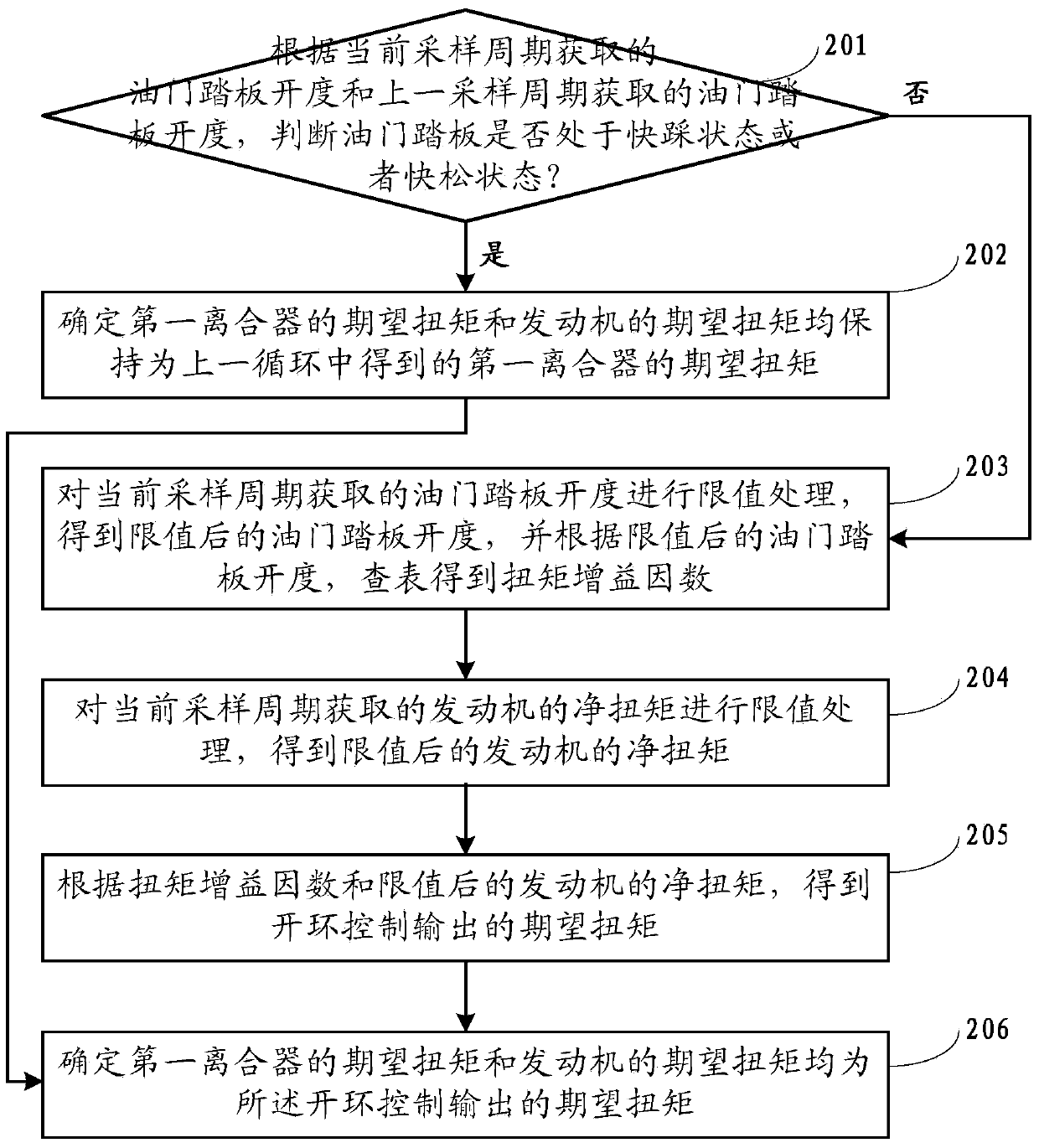

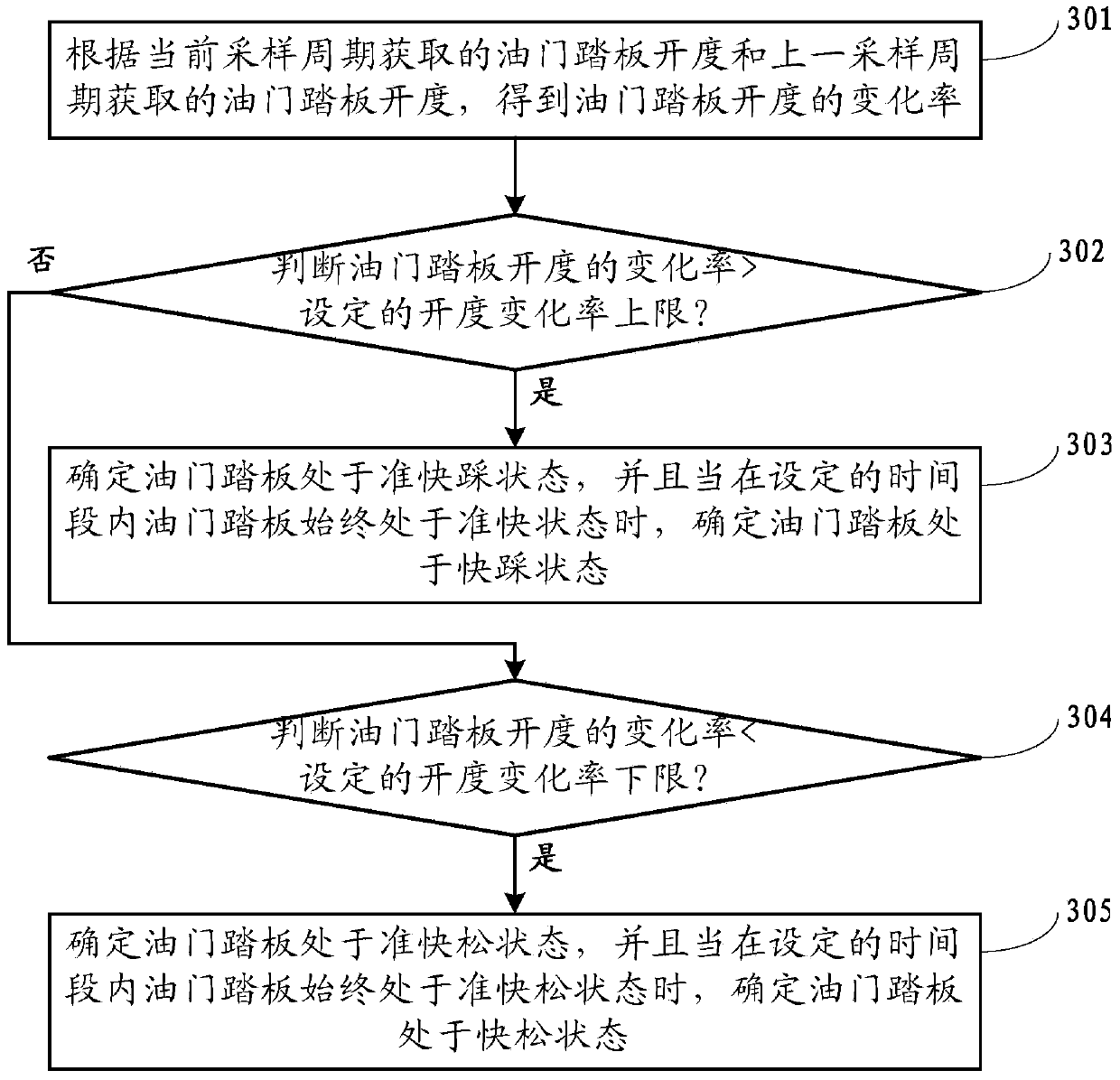

Method for controlling normal starting of dual-clutch automatic transmission

ActiveCN103807323AImprove securityImprove comfortClutchesGearing controlAutomatic transmissionEngineering

The invention discloses a method for controlling normal starting of a dual-clutch automatic transmission. The method comprises the steps of obtaining the position of an ignition lock of an engine and the position of a gear shifting rod; obtaining the opening of an accelerator pedal, the net torque of the engine and the rotating speed of the engine every a set sampling period; judging whether the ignition lock of the engine is in the ON gear, judging whether the gear shifting rod is switched to the D / R gear from the P gear, judging whether the opening of the accelerator pedal is larger than the set opening threshold value of the accelerator pedal; if the ignition lock of the engine is in the ON gear, the gear shifting rod is switched to the D / R gear from the P gear, and the opening of the accelerator pedal is larger than the set opening threshold value of the accelerator pedal, switching the gear shifting rod to the D gear from the P gear, conducting normal starting control over a first clutch so as to enable the difference between rotating speed of the engine and the set target rotating speed to meet the set error range; when the gear shifting rod is switched to the R gear from the P gear, conducting normal starting control over the second clutch so as to enable the difference between rotating speed of the engine and the set target rotating speed to meet the set error range. According to the method, in the normal starting process, switching between the two clutches is not required, and safety and comfort of a whole vehicle are facilitated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

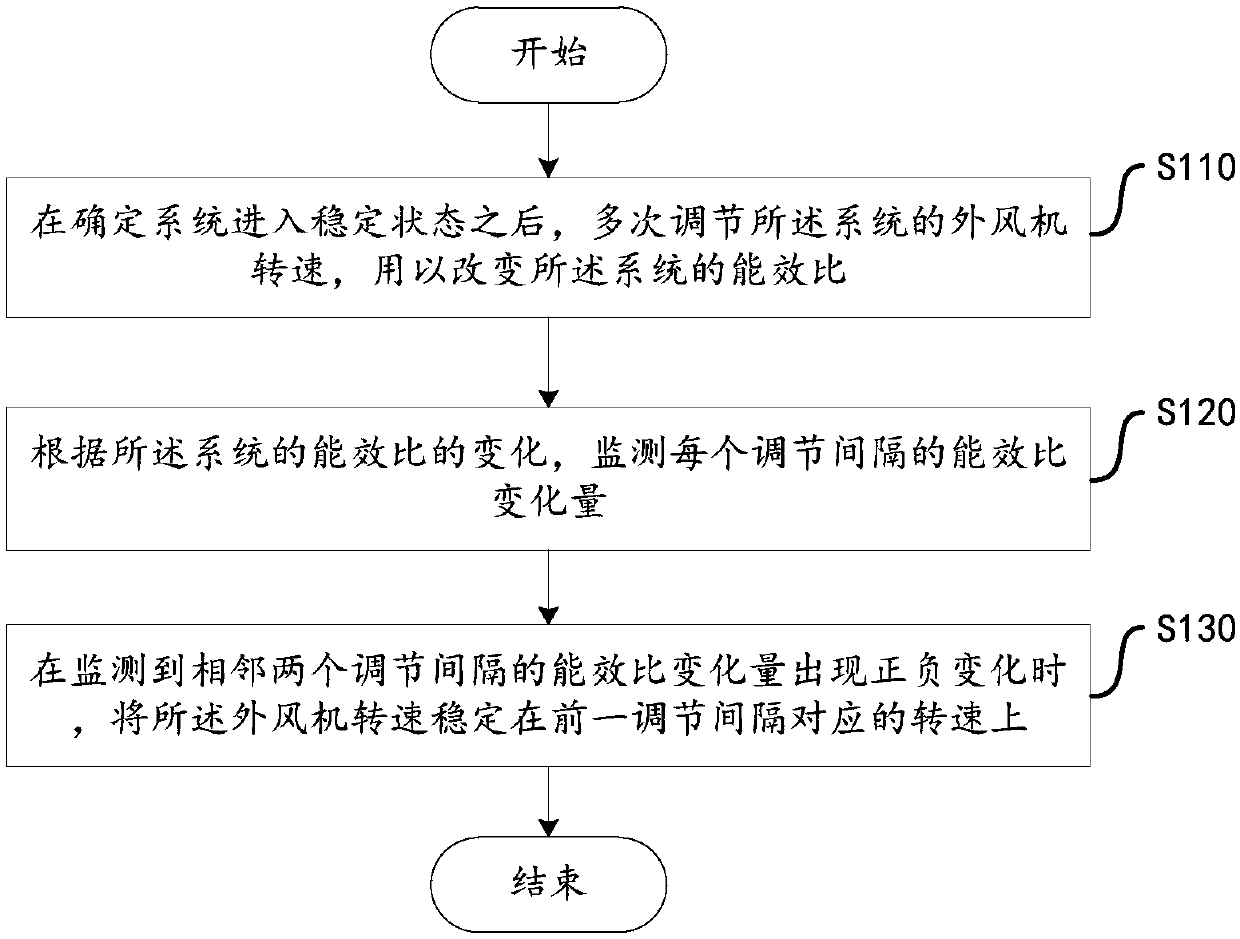

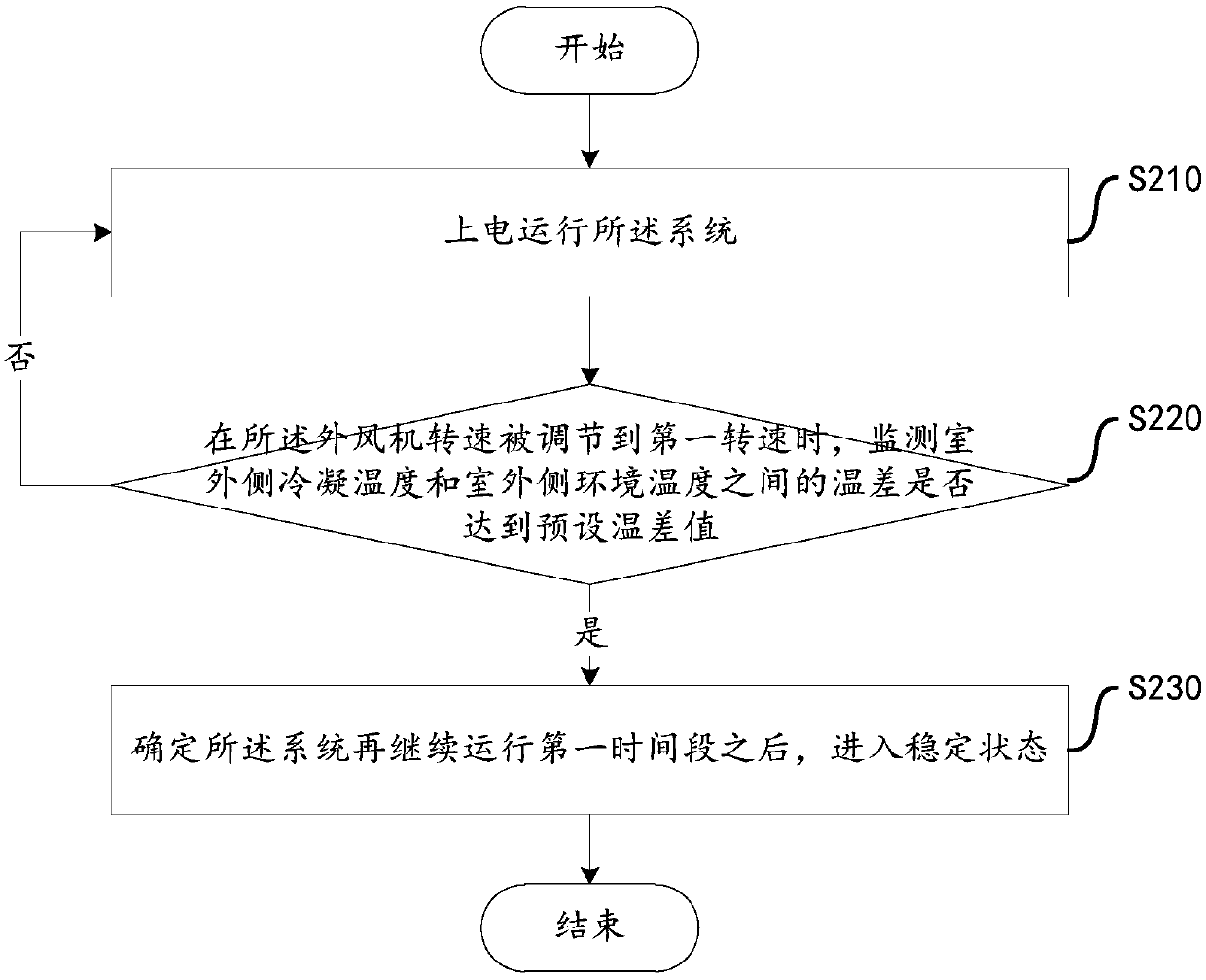

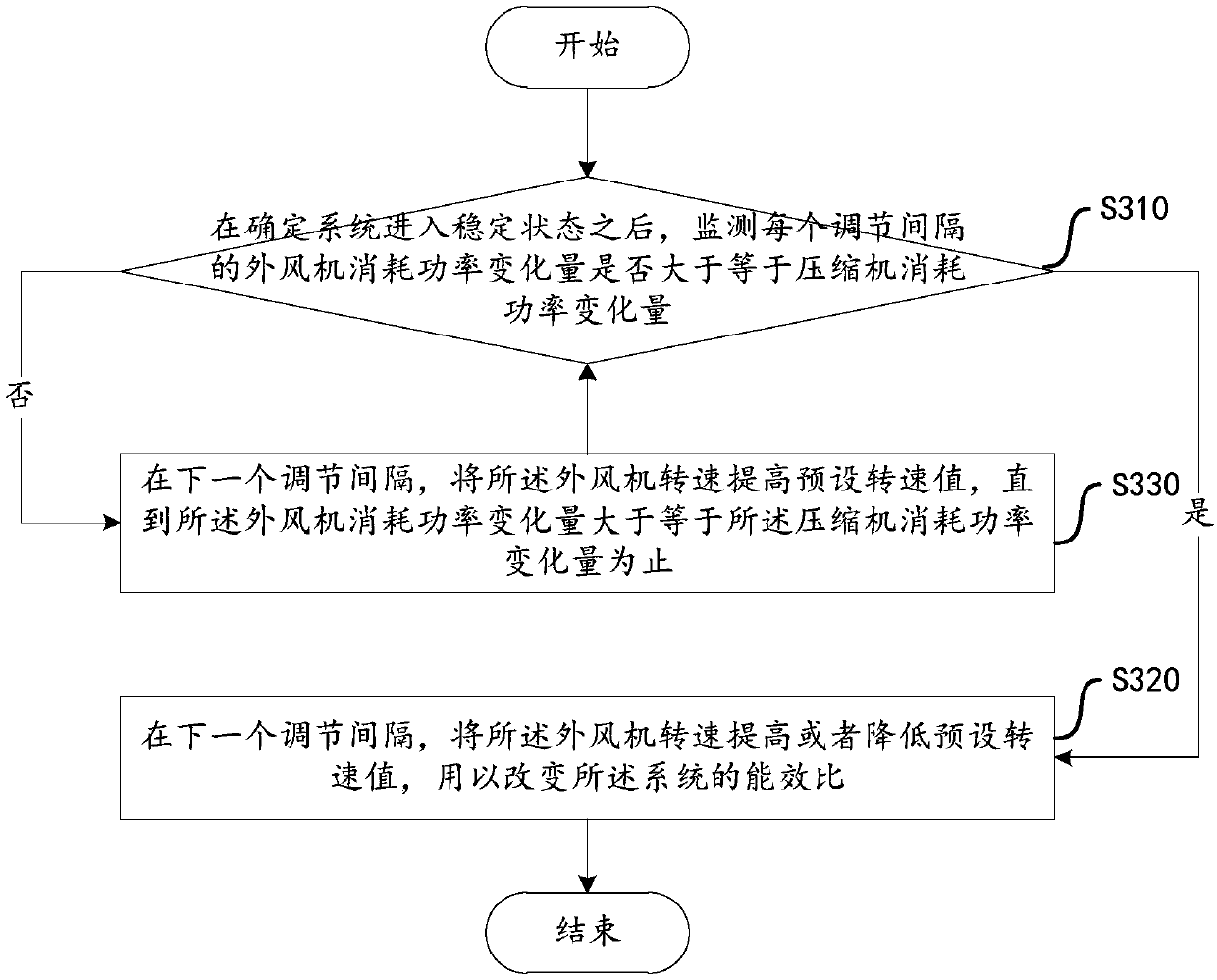

External fan rotating speed control method and device and computer storage medium

ActiveCN109253534AAccurate speed controlMechanical apparatusSpace heating and ventilation safety systemsStable stateBusiness efficiency

The invention discloses an external fan rotating speed control method and device and a computer storage medium. The method comprises the steps that after it is determined that the system enters a stable state, and the rotating speed of an external fan of the system is adjusted repeatedly, so that the energy efficiency ratio of the system is changed; according to the change of the energy efficiencyratio of the system, the energy efficiency ratio variable quantity of each adjusting interval is monitored; when it is monitored that the variable quantities of the energy efficiency ratios of everytwo adjacent adjusting intervals are in positive and negative change, the rotating speed of the external fan is stabilized at a rotating speed corresponding to the previous adjusting interval. The energy efficiency ratio of the system can be changed by adjusting the rotating speed of the external fan, and the energy efficiency change of the system can be monitored; the optimal rotating speed of the external fan is determined according to the energy efficiency change of the system, so that the rotating speed of the external fan is controlled more accurately, more rigorously and more scientific.

Owner:GREE ELECTRIC APPLIANCES INC

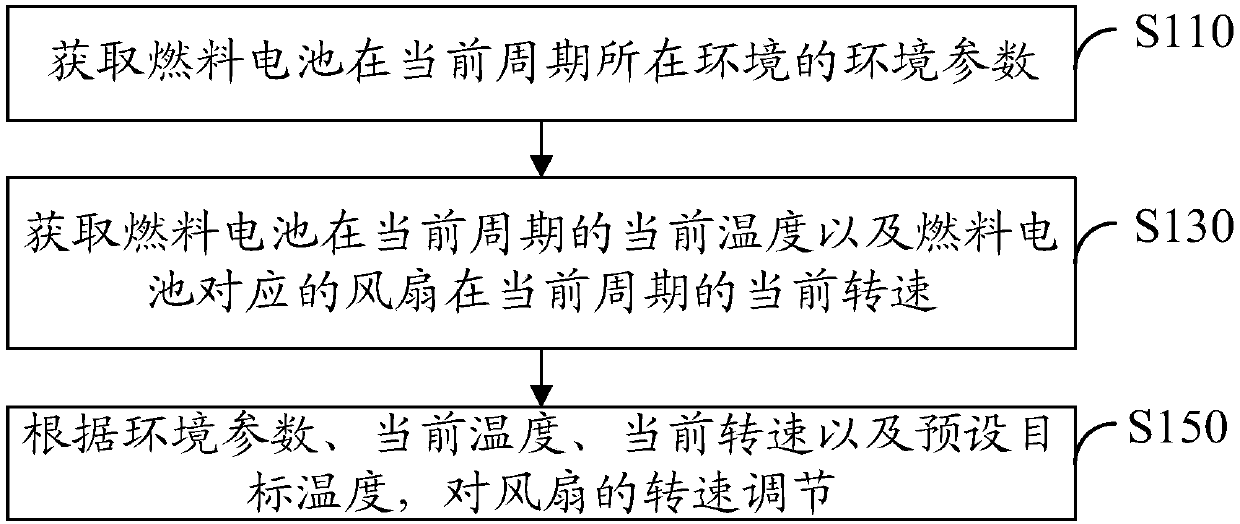

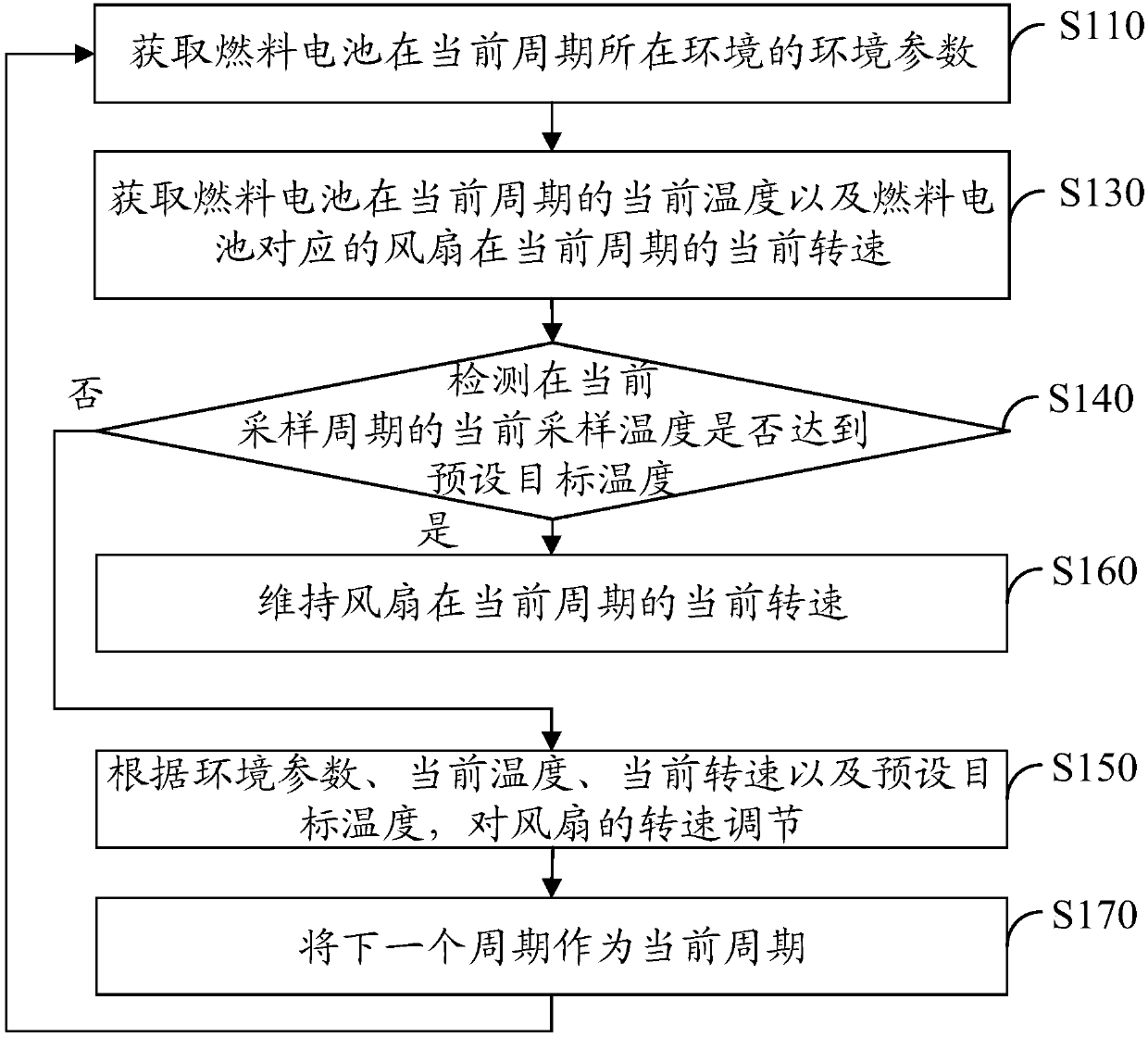

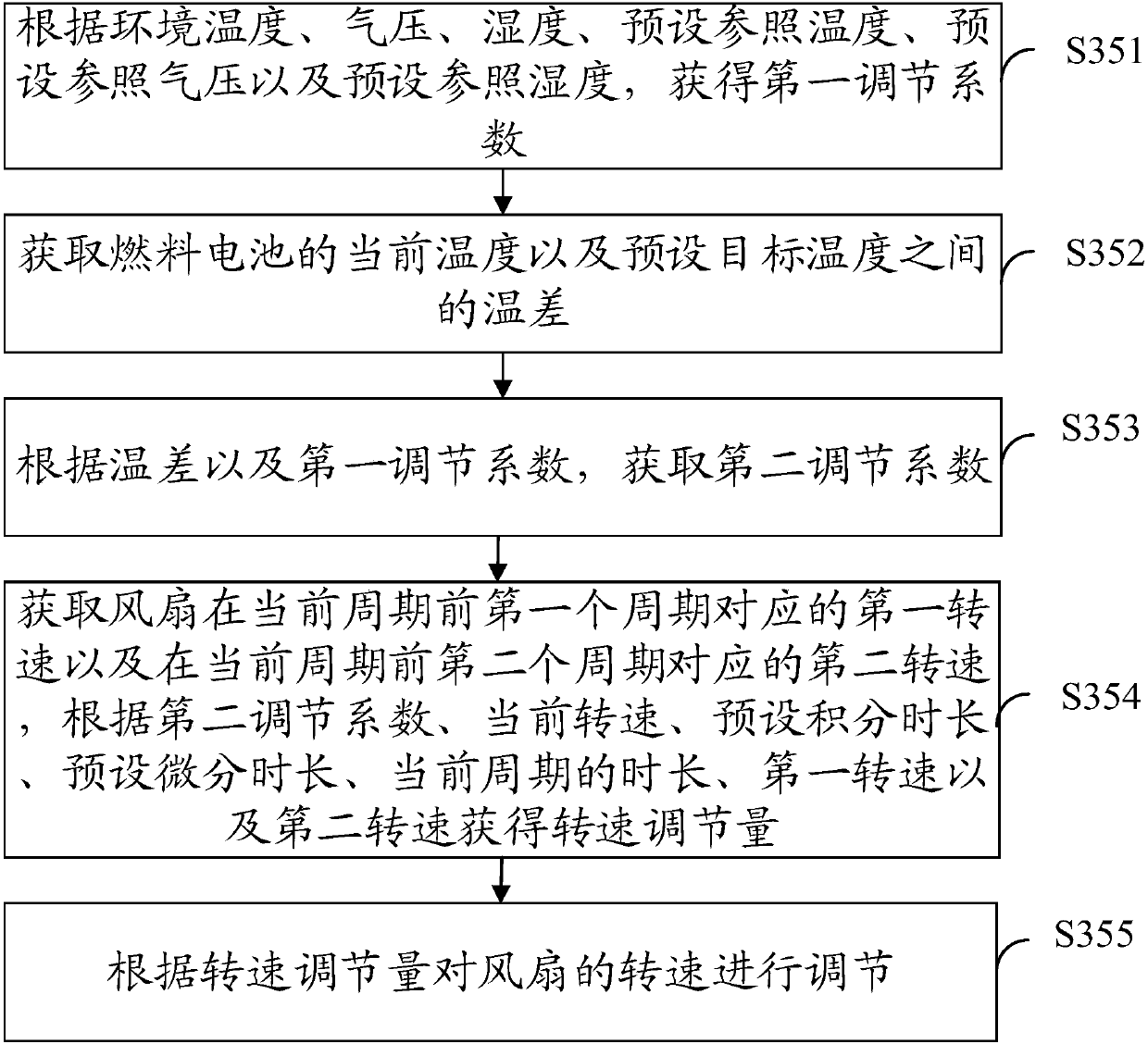

Method and device for adjusting rotating speed of fan of fuel cell, computer storage medium and computer equipment

ActiveCN108050092APrecise temperature controlAccurate speed controlEngine controlPump controlFuel cellsEngineering

The invention discloses a method and a device for adjusting the rotating speed of a fan of a fuel cell. The rotating speed of the fan is adjusted according to the environmental parameters of the environment where the fuel cell is located, the current temperature of the fuel cell, the current rotating speed of the fan and the preset target temperature, wherein the environment parameters of the environment where the fuel cell is located, the current temperature of the fuel cell and the current rotating speed of the fan are considered, and the preset target temperature is also considered so thatthe rotating speed of the fan can be more accurately controlled, moreover, the heat dissipation speed of the fuel cell can be influenced by the size of the rotating speed of the fan, and then the temperature of the fuel cell can be influenced so that the accurate control over the temperature of the fuel cell can be realized.

Owner:SHENZHEN MICROMULTICOPTER AERO TECH CO LTD

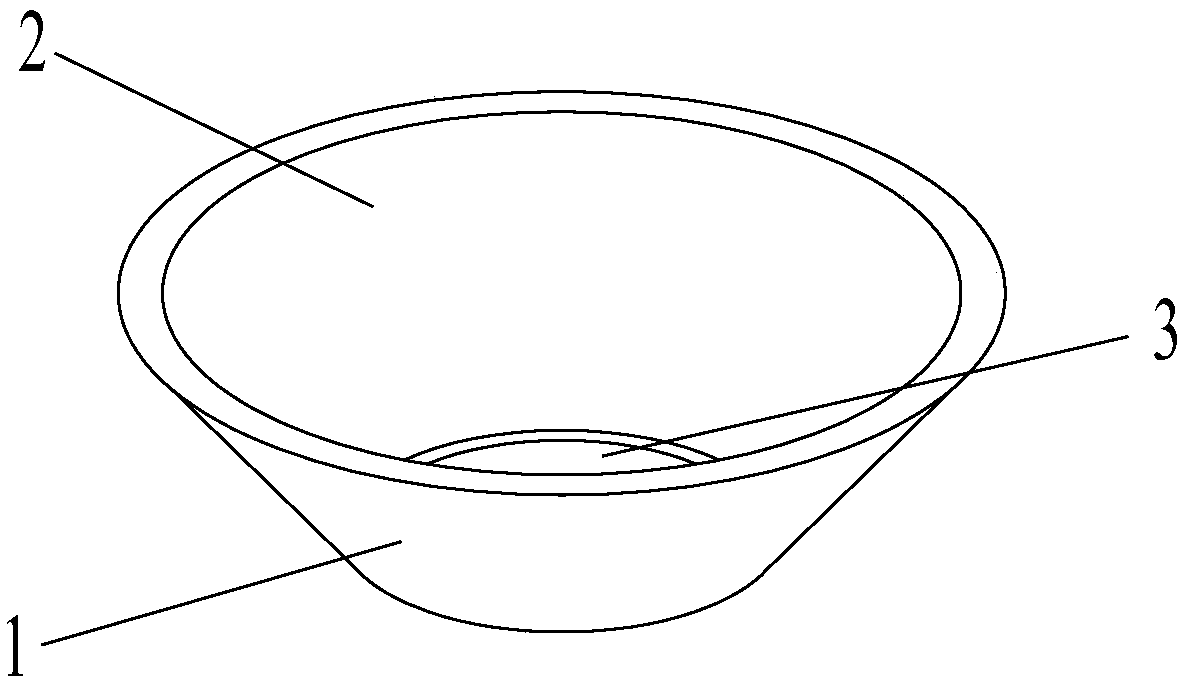

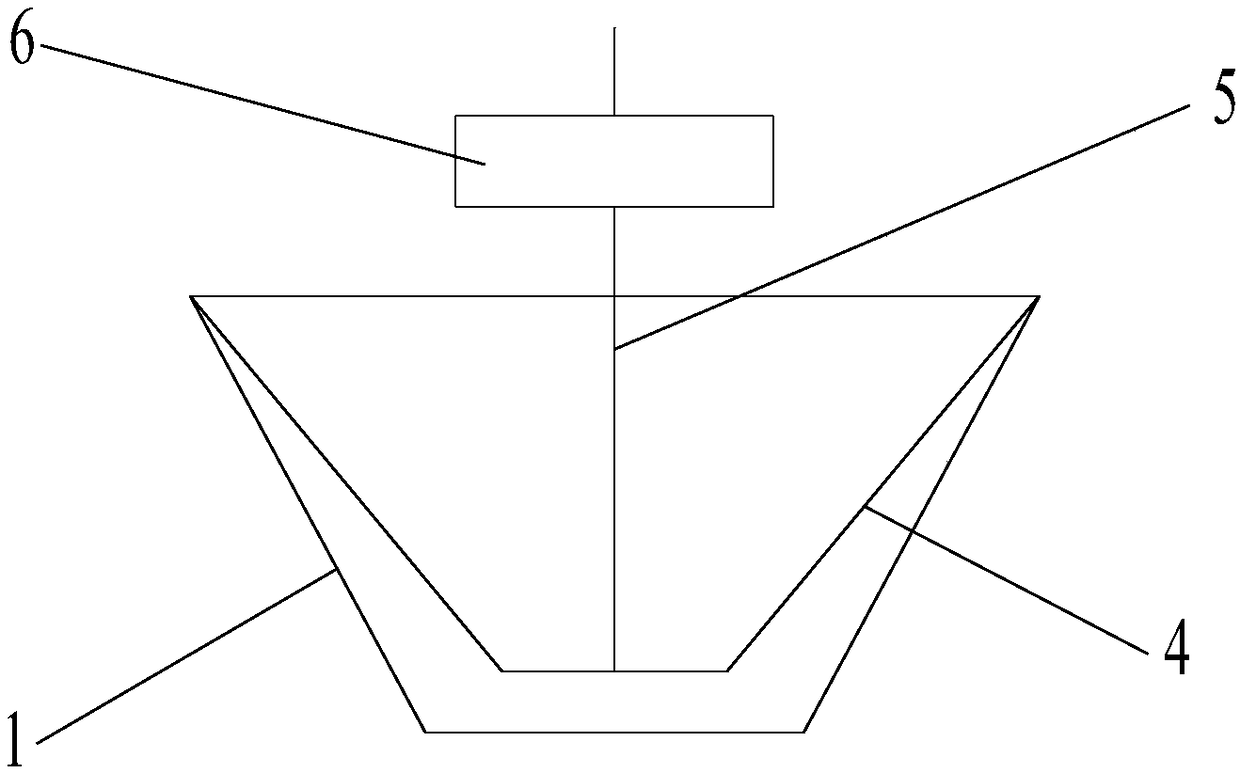

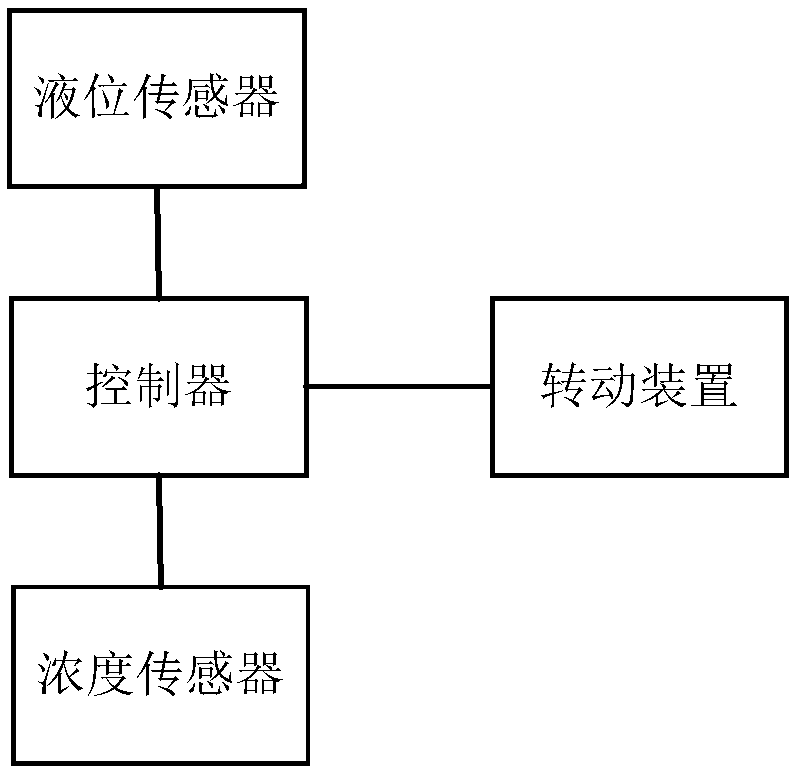

Extracted liquid filtering device

PendingCN108096873ASpeed up filteringReduce blockageSolid solvent extractionMoving filtering element filtersEngineeringLiquid level sensor

The invention relates to an extracted liquid filtering device. The extracted liquid filtering device comprises a circular truncated cone-shaped housing; the internal part of the circular truncated cone-shaped housing is hollow; the upper end and the lower end of the circular truncated cone-shaped housing are provided with openings; the opening on the upper end is an upper circular hole, and the opening on the lower end is a lower circular hole; a circular truncated cone-shaped filter screen is arranged in the circular truncated cone-shaped housing; the height of the circular truncated cone-shaped filter screen is smaller than or equal to that of the circular truncated cone-shaped housing; the upper end external edge of the circular truncated cone-shaped filter screen is pressed against theinternal edge of the upper circular hole; the center of the bottom wall of the circular truncated cone-shaped filter screen is detachably provided with a vertical rod; the vertical rod is connected with a transmission device; a liquid level sensor and a concentration sensor are arranged on the internal wall of the circular truncated cone-shaped filter screen; the transmission device, the liquid level sensor, and the concentration sensor are connected with a controller through electric connection respectively. The above design is capable of accelerating extracted liquid filtering speed; when the circular truncated cone-shaped filter screen is blocked, it is not necessary to pump out the unfiltered extracted liquid; and processing efficiency is increased.

Owner:荆州市宏达生物科技股份有限公司

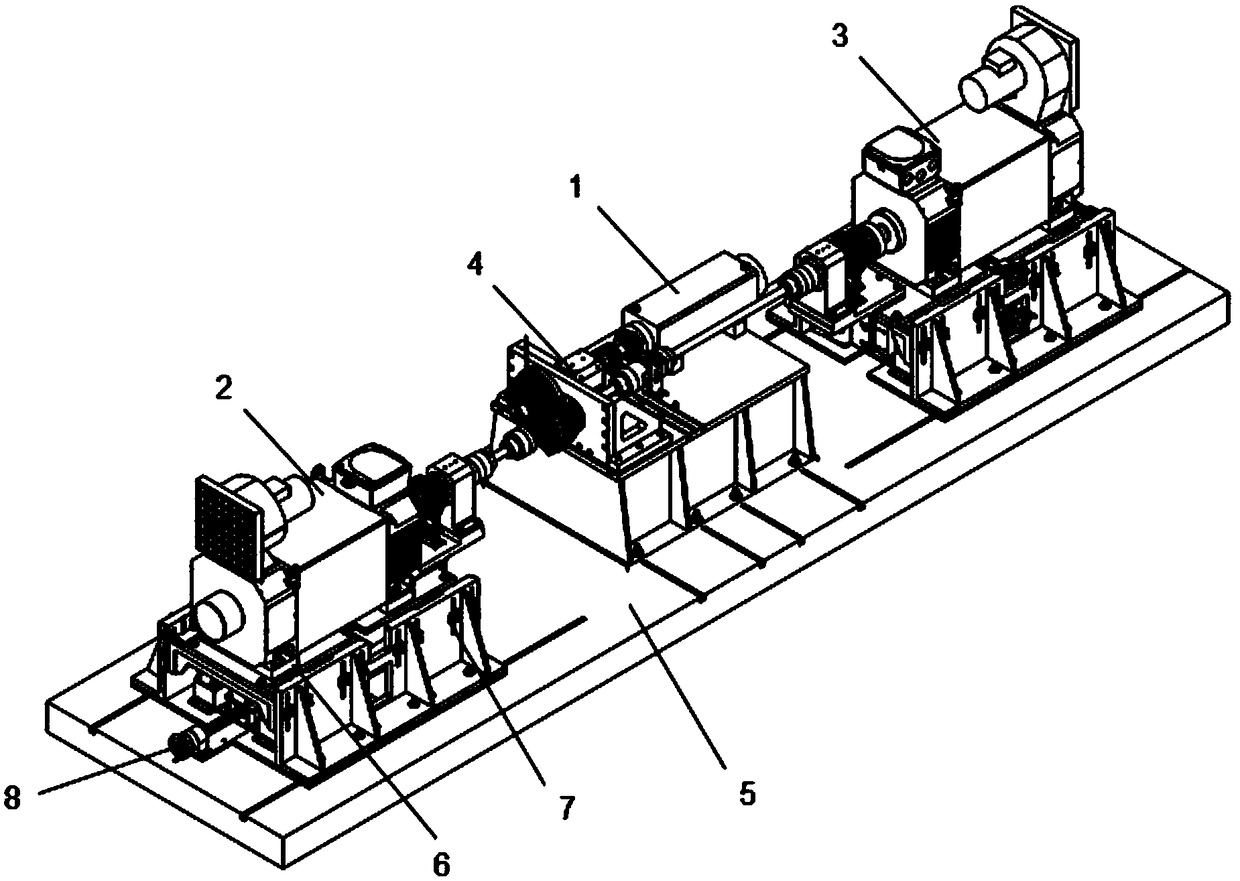

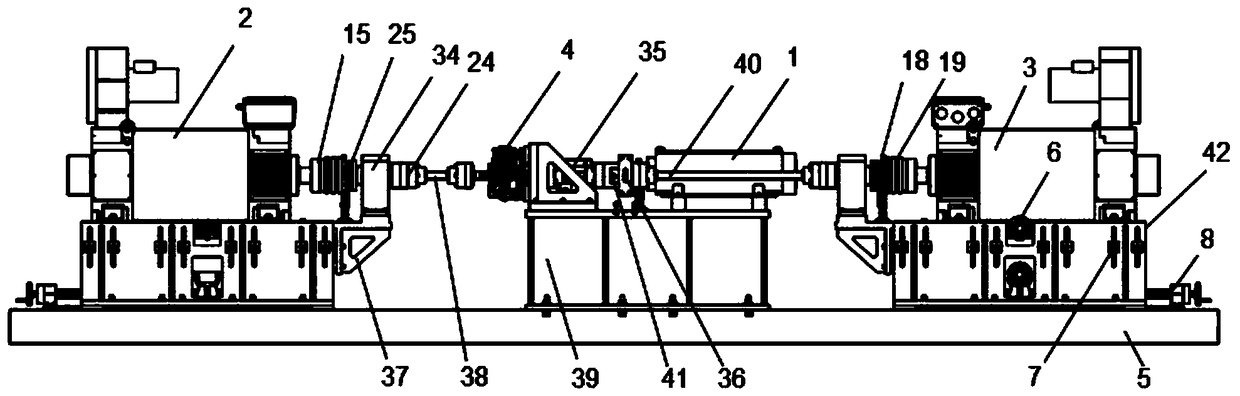

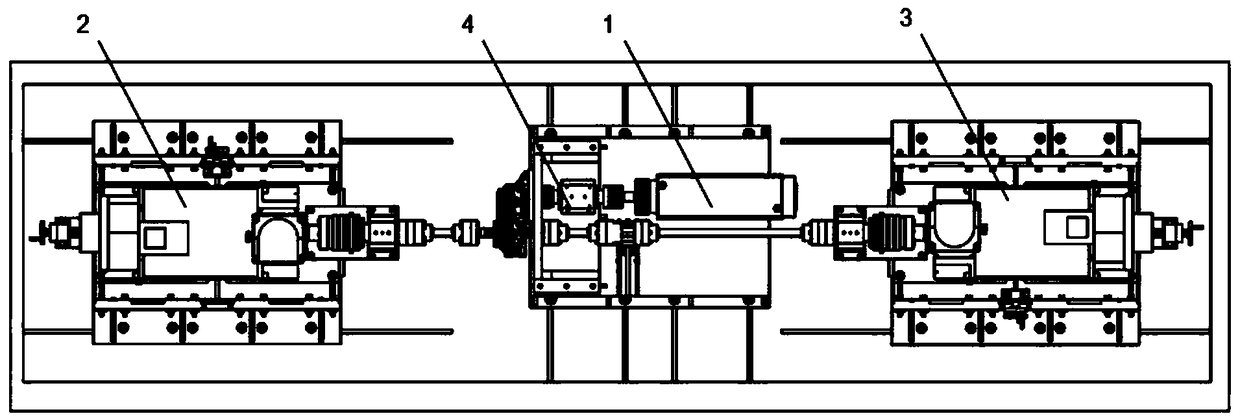

Multifunctional flexible gearbox testing system

PendingCN109029988AIncrease the speed of the first orderMeet the requirement of small center distanceMachine gearing/transmission testingElectric machineryMoment of inertia

The invention discloses a multifunctional flexible gearbox testing system, and solves a problem that a traditional testing system adopts a middle transition gearbox, the rotating inertia of a drivingsystem is increased, and the simulation is not facilitated; moreover, a front-engine front-wheel drive layout gearbox testing system for an automobile is mainly manually adjusted, the adjusting difficulty is large, and the coaxiality of 0.02 mm is difficult to achieve; meanwhile, a load motor can only achieve degree of freedom adjustment in two directions, the height direction is generally adjusted by adopting a cushion block mode, and adjustment is not convenient; and an efficiency test of the front-engine front-wheel drive layout gearbox testing system generally does not carry out oil temperature control, only the transmission efficiency at different rotating speeds is tested, and the oil temperature has a certain influence on transmission efficiency of a transmission gear. The multifunctional flexible gearbox testing system comprises a driving motor, a loading moto I, a loading motor II, a front-engine front-wheel drive layout gearbox and a detection system, wherein a driving motormounting platform is arranged at the bottom of the driving motor; and a testing machine mounting platform is arranged at the bottom of the loading motor I and the loading motor II.

Owner:安徽精科检测技术有限公司

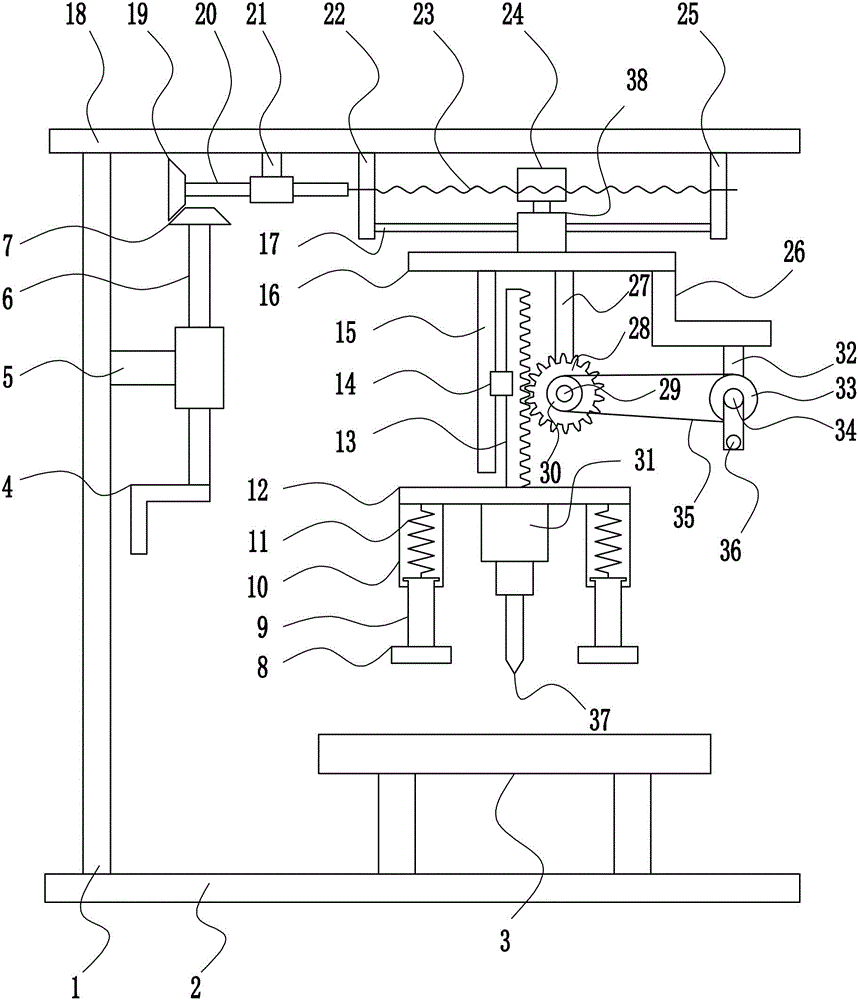

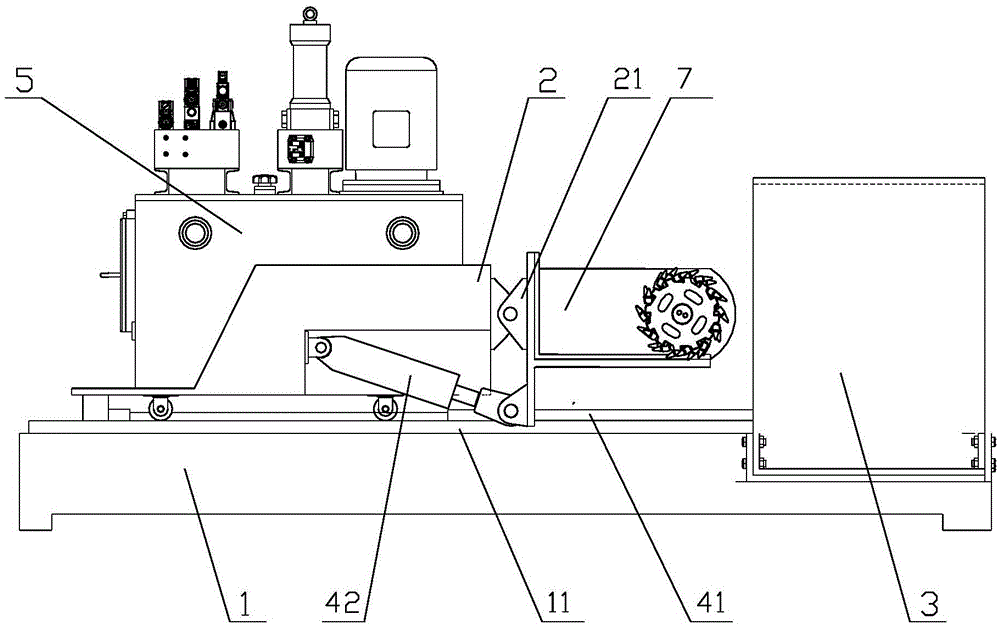

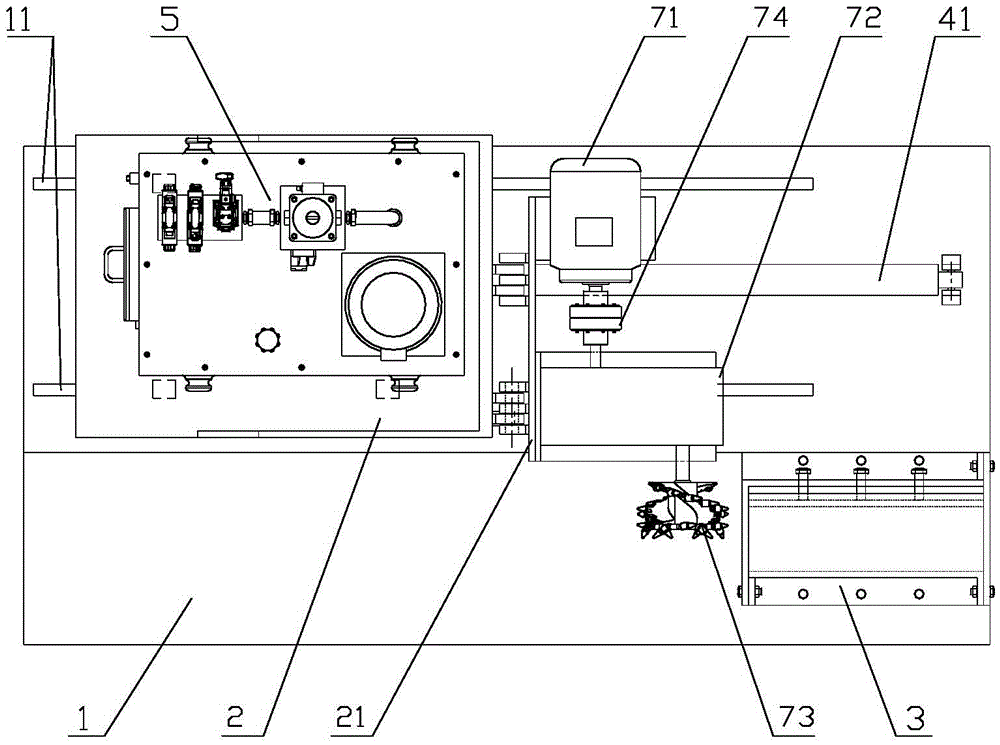

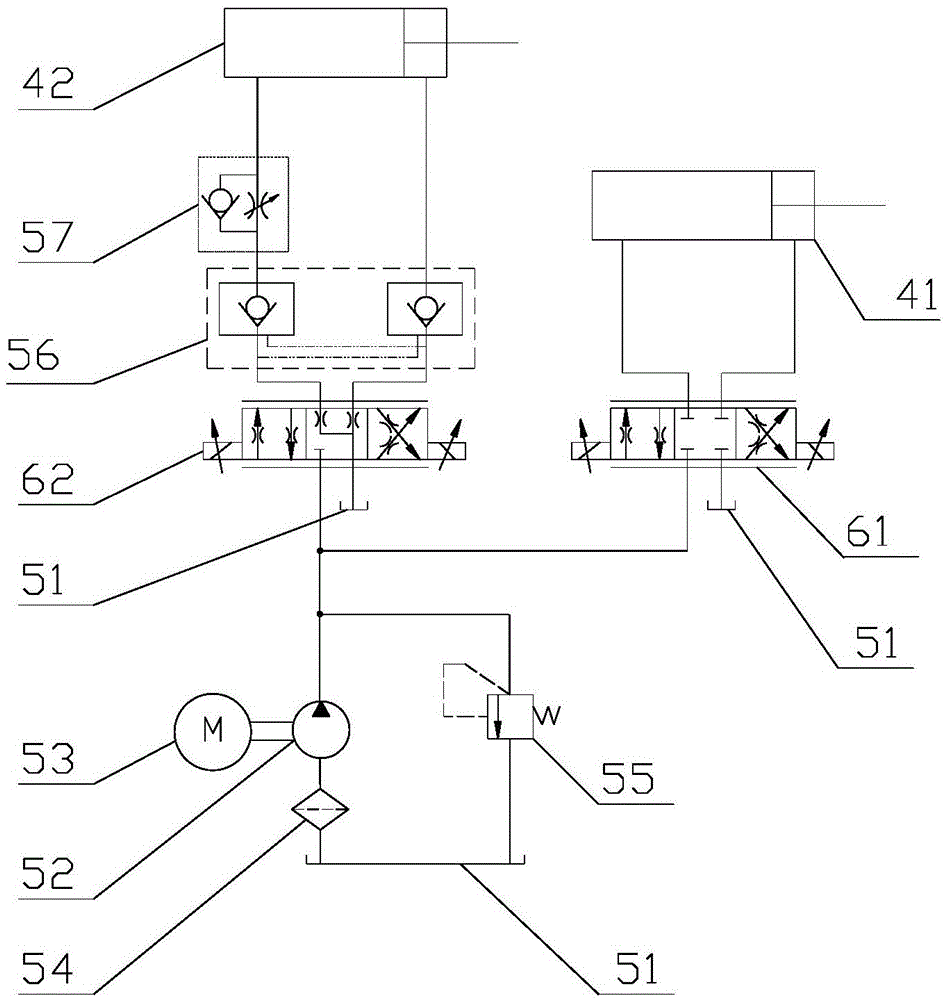

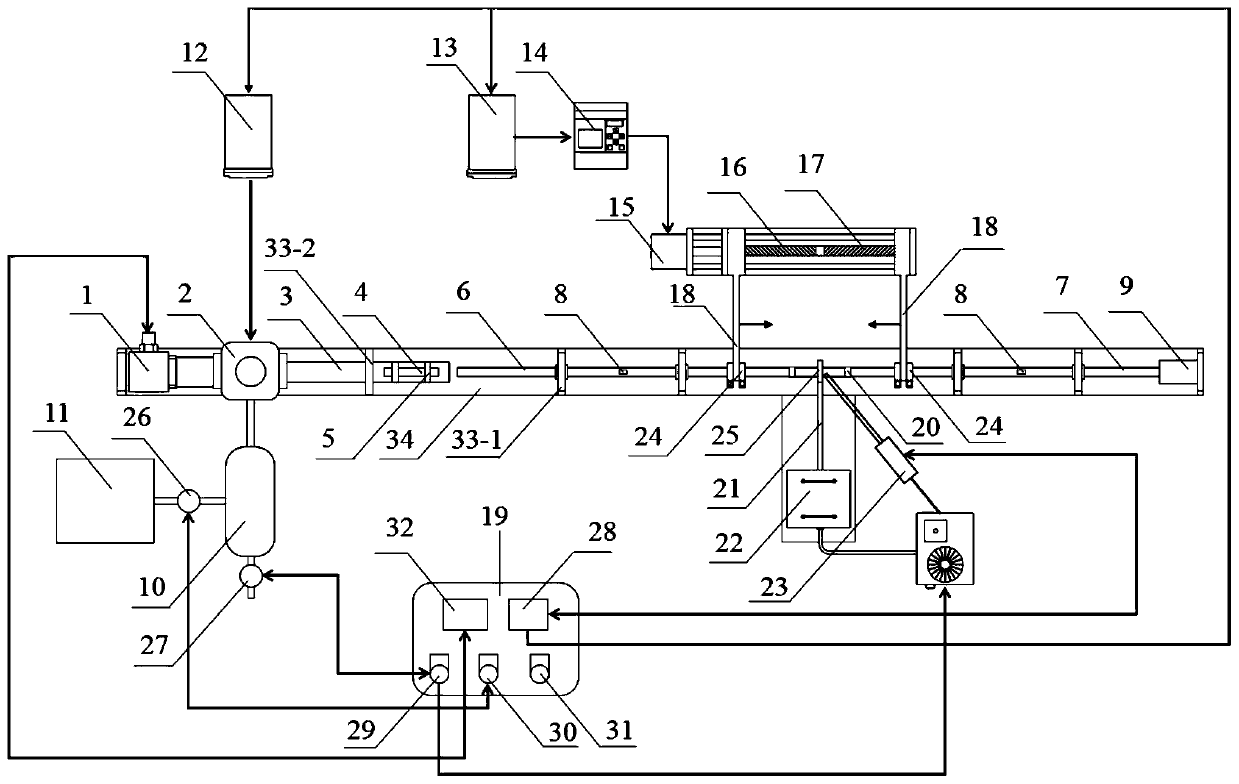

Simulative cutting experiment device for coal mining machine

ActiveCN105464657ARealize mock loadingAccurate speed controlCutting machinesCoal miningElectro hydraulic

The invention discloses a simulative cutting experiment device for a coal mining machine. The simulative cutting experiment device comprises a device body and a coal walling simulating mechanism; the device body is provided with a cutting mechanism, a first driving mechanism drives the cutting mechanism to move along a rail, and a second driving mechanism drives the cutting mechanism to vertically move. On one hand, the whole experiment device adopts the modular design, all the parts are integrated on the device body and a base, simulation on height adjusting motion, traction motion and coal rock cutting of the coal mining machine can be simultaneously achieved, and assembly and disassembly are convenient; on the other hand, the first driving mechanism and the second driving mechanism are both controlled by electro-hydraulic proportional valves, therefore, precise control cover the cutting drum height adjusting speed, the device body traction speed and the cutting drum height can be achieved, the working condition that the coal mining machine cuts coal rock underground can be simulated more truly, simulation loading on the electro-hydraulic proportional cutting mechanism in the experiment device is achieved, and an integrated platform is supplied to experimental study on simulative cutting of the coal mining machine and the electro-hydraulic proportional height adjusting system characteristics.

Owner:ANHUI UNIV OF SCI & TECH

Precision hardware punching device

The invention relates to a punching device, in particular to a precision hardware punching device and aims at achieving the technical purpose of providing the precision hardware punching device convenient to operate and capable of punching flat sections and reducing burrs. To achieve the above technical purpose, the precision hardware punching device is provided and comprises a left frame, a containing table, a bottom plate, a first nut, a rocking handle, a screw, a push block, a pressing block, an electric push rod, a cutter, a sliding block, a fixing plate, a first connecting rod and the like. The left frame is welded to the left side of the top of the bottom plate. The containing table is welded to the left side of the top of the bottom plate and located on the right side of the left frame. A groove is formed in the lower portion of the right side of the left frame. The first nut is welded to the lower portion of the left side of the left frame. A rotation motor is used for driving a first rotation shaft to rotate, the first rotation shaft drives a first bolt and a second bolt to rotate, and the first bolt and the second bolt drive a second nut and a third nut to move towards the middle from the two sides correspondingly.

Owner:渡边精密金属(珠海)有限公司

Quick stirring device for water purifier assembling

The invention relates to a stirring device, in particular to a quick stirring device for water purifier assembling. According to the stirring device for water purifying equipment assembling, time and labor are saved, uniform smearing is easy, and smearing is convenient. The quick stirring device for water purifier assembling comprises a top plate and the like. A lifting mechanism and a bracket are arranged at the bottom of the top plate; the lifting mechanism is located on the left portion of the bracket; a stirring rod is arranged at the bottom of the lifting mechanism; a supporting rod is arranged on the left side of the bracket and connected with the lifting mechanism; a bottom plate is arranged under the bottom of the top plate; a stirring box is arranged on the top of the bottom plate; and the right side of the top of the bottom plate is connected with the bracket. According to the quick stirring device, a sealing ring and Vaseline are more conveniently stirred, so that the Vaseline is smeared on the sealing ring more evenly, and the sealing ring and the Vaseline can be stirred more quickly.

Owner:施亮

High-temperature Hopkinson tensile bar test system by using two-way electromagnetically-driven synchronous assembly and method

ActiveCN110196199APrecise dynamic compression mechanical propertiesPrecise control of hot and cold contact timeMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesPilot systemDirect test

The invention relates to a high-temperature Hopkinson tensile bar test system by using two-way electromagnetically-driven synchronous assembly and method. A high-temperature Hopkinson tensile bar system and a high-temperature compression test method which use an accurate electromagnetically-driven two-way synchronous sliding assembly system and a high-frequency electromagnetic induction rapid heating method are built. According to the device in the invention, a set of electromagnetic control device, a set of electromagnetically-driven two-way synchronous assembly device and two high-precisiondelay devices are additionally arranged on the conventional Hopkinson tensile bar, the starting and ending time of each process including an impact process, a heating process and a loading rod synchronous assembly process during the high-temperature dynamic compression test can be accurately controlled, and the cold and hot contact time during the whole test process can be further accurately controlled. A control component is designed in an integrated module mode, the test accuracy is improved, and the dynamic compression mechanical properties of the material at a high temperature can be accurately and directly tested.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

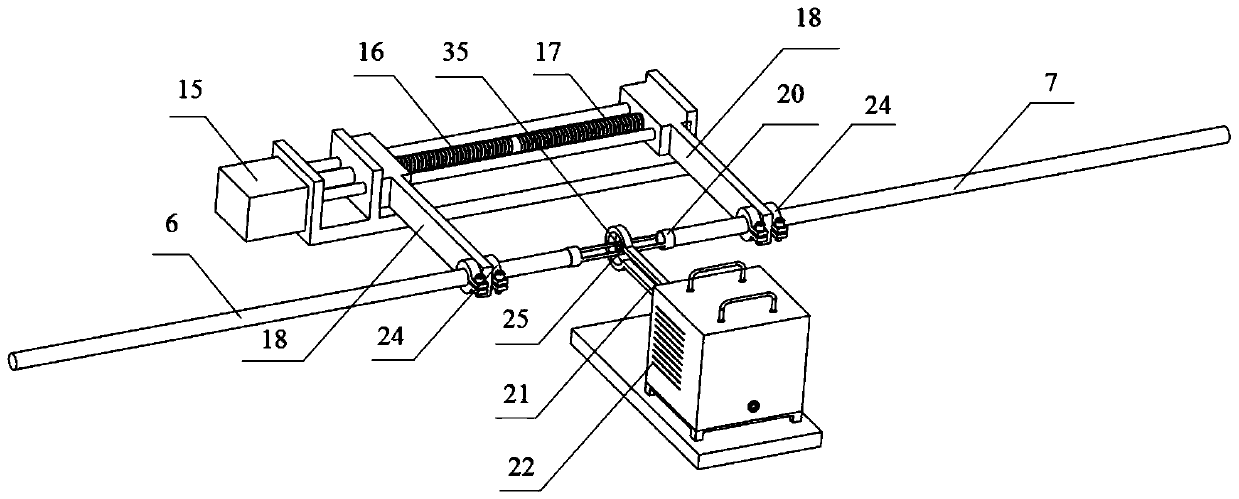

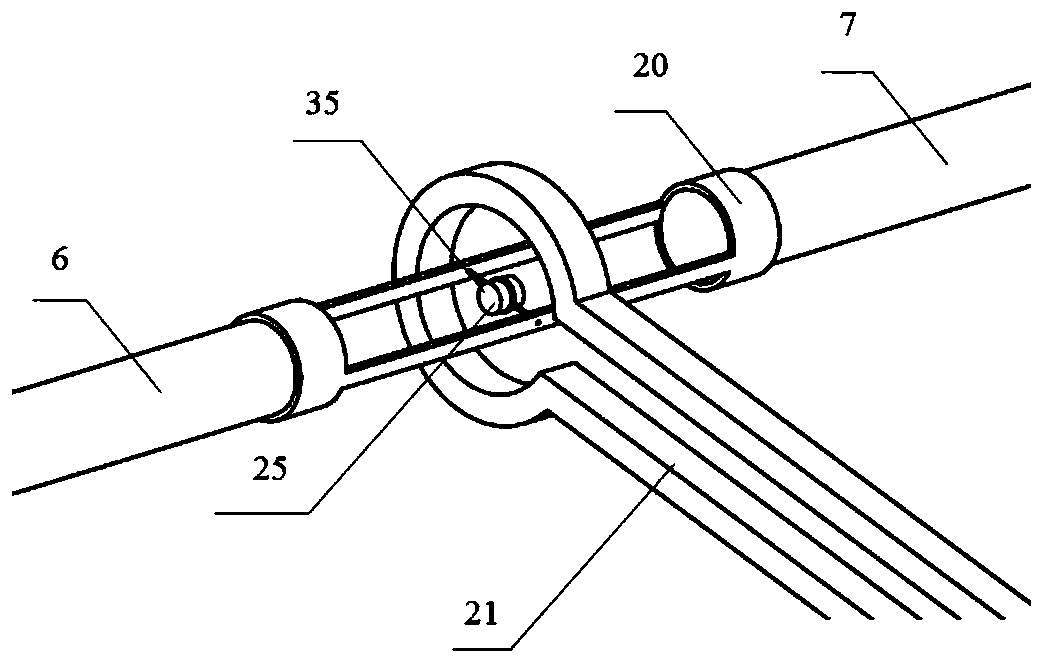

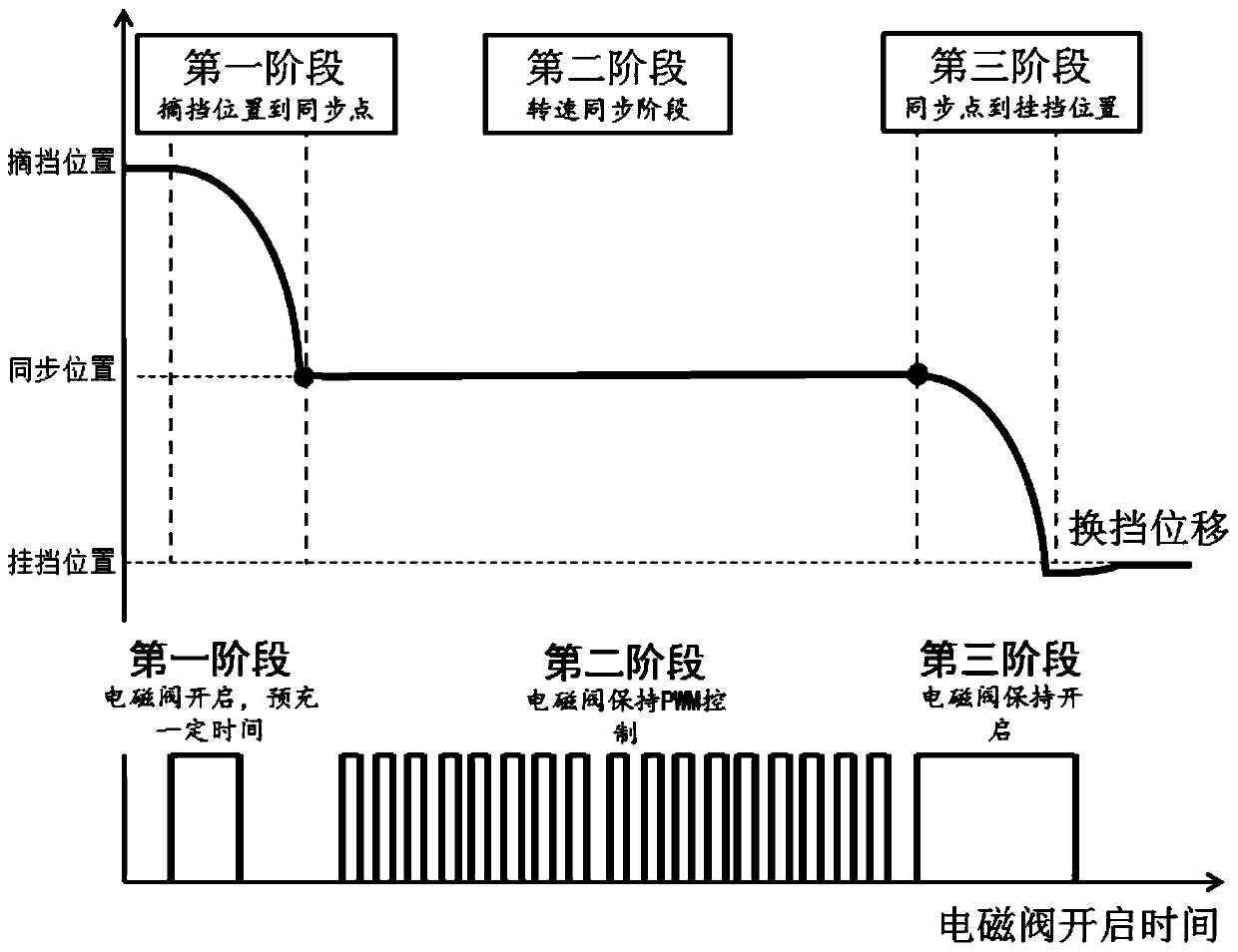

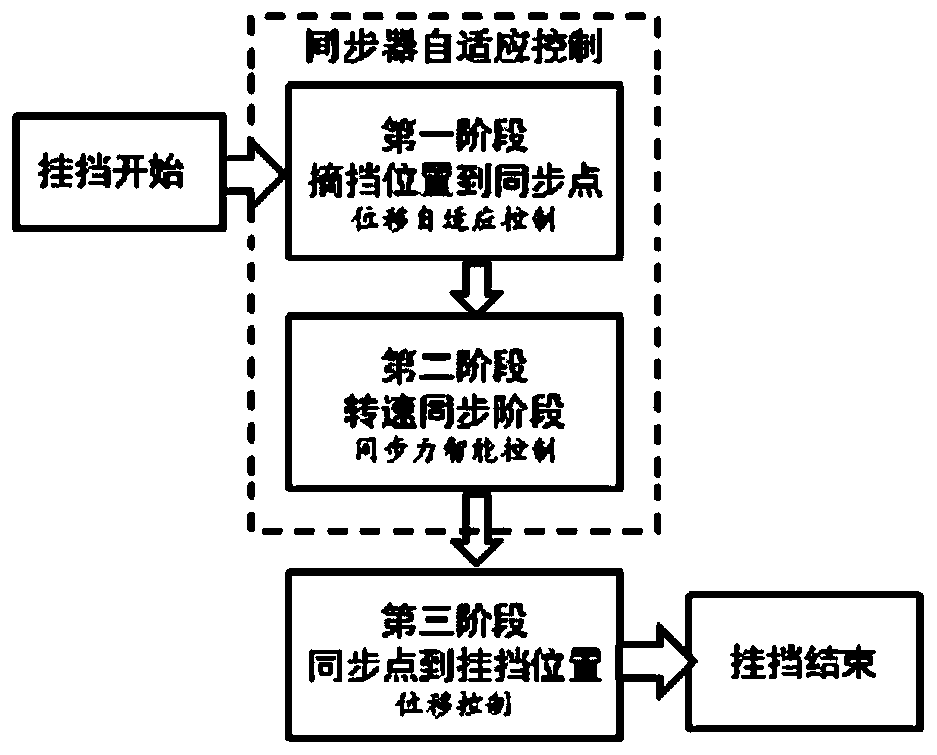

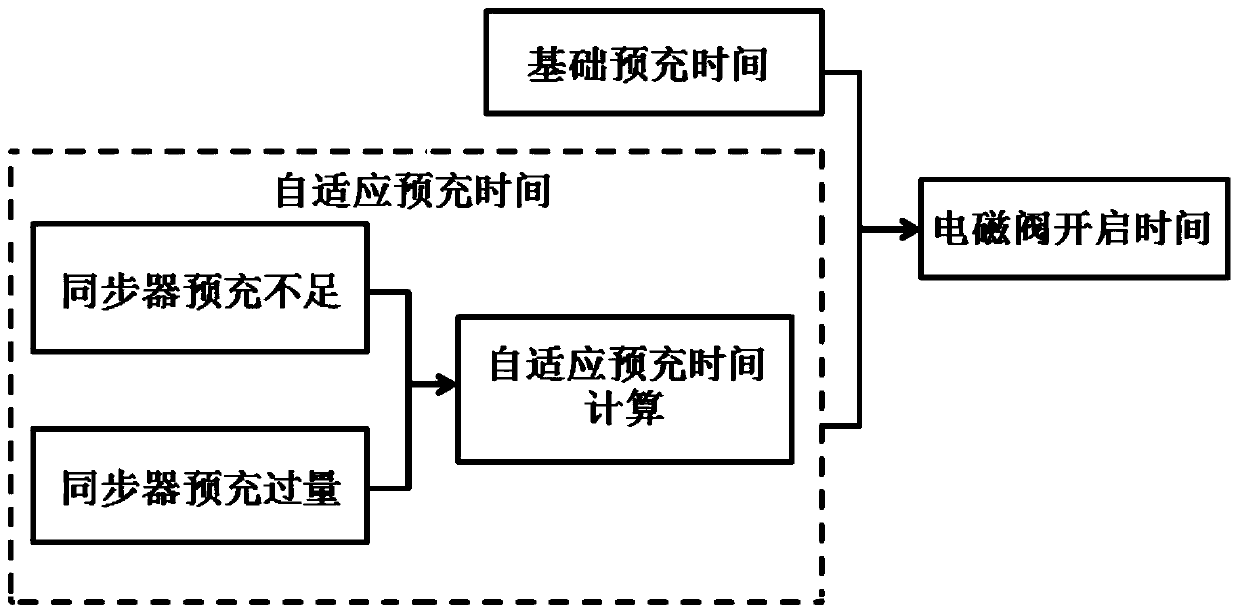

Self-adaptive control method of heavy-duty vehicle AMT synchronizer

ActiveCN110173560APrecise Control ArrivalAvoid affecting shift responsivenessGearing controlGear wheelEngineering

A self-adaptive control method of a heavy-duty vehicle AMT synchronizer comprises the following steps that firstly, the synchronizer moves from an idling position to a synchronization point, a gear shifting executing mechanism electromagnetic valve is kept full open and continuously kept for a preset time t2, and a gearbox gear shifting executing mechanism rapidly reaches the synchronization point; secondly, rotation speed synchronization is conducted, by means of PWM control of the gearbox executing mechanism electromagnetic valve, it is guaranteed that a front mesh gear and a back mesh gearreach synchronization, and the synchronous state of the synchronizer is calculated and judged; thirdly, the synchronizer moves from the synchronization point to the gear engaging position, the gear shifting executing mechanism electromagnetic valve is fully open, a gearbox gear shifting executing mechanism is made to enter the gear engaged position, and when gear engaging is up to end, through real-time judgment of the speed of shifting fork displacement change, a softstop function is selected. By the adoption of the self-adaptive control method of the heavy-duty vehicle AMT synchronizer, thesynchronizer can be accurately controlled to reach a synchronization point, insufficient synchronous displacement and excessive synchronous displacement are avoided, the output synchronizing force iscorrected in real time, and accurate control over the rotation speed synchronization of the synchronizer is achieved.

Owner:DONGFENG COMML VEHICLE CO LTD

Method for controlling primary powder apparent density accurately by utilizing ball mill

InactiveCN104148159APromote repairStable feeding and dischargingGrain treatmentsApparent densityPower flow

The invention discloses a method for controlling the primary powder apparent density accurately by utilizing a ball mill. The method comprises the following steps: (1) feeding, namely, carrying out flushing, crush breaking, hammer breaking or jaw breaking on qualified sponge iron, lifting powder with the particle size being 10-15mm to a ball milling front stock bin, conveying the powder into the ball mill by a vibration feeder, and grinding; (2) carrying out parameter control, namely adjusting the current of the vibration feeder arranged at the feeding end of the ball mill so as to control the feeding quantity, adjusting the current of the ball mill so as to control the rotation speed of the ball mill, thus controlling the grinding speed, adjusting dedusting air suction capacity so as to control the fine powder feeding quantity; (3) discharging through three parts; and (4) screening, namely after screen underflow conforming to the granularity need enters a magnetic separator at the lower part of a drum screen, carrying out magnetic separation, lifting the screen underflow to a storage bin, conveying oversized products not conforming to the granularity need to the ball milling front material feedback storage bin by a material returning belt, adding the oversized products into the ball mill quantitatively according the need of primary powder ingredients, and grinding. According to the method, the apparent density and the particle constitution can be effectively controlled, the production cost is lowered, and the yield is increased.

Owner:LAIWU TAIDONG POWDER TECH

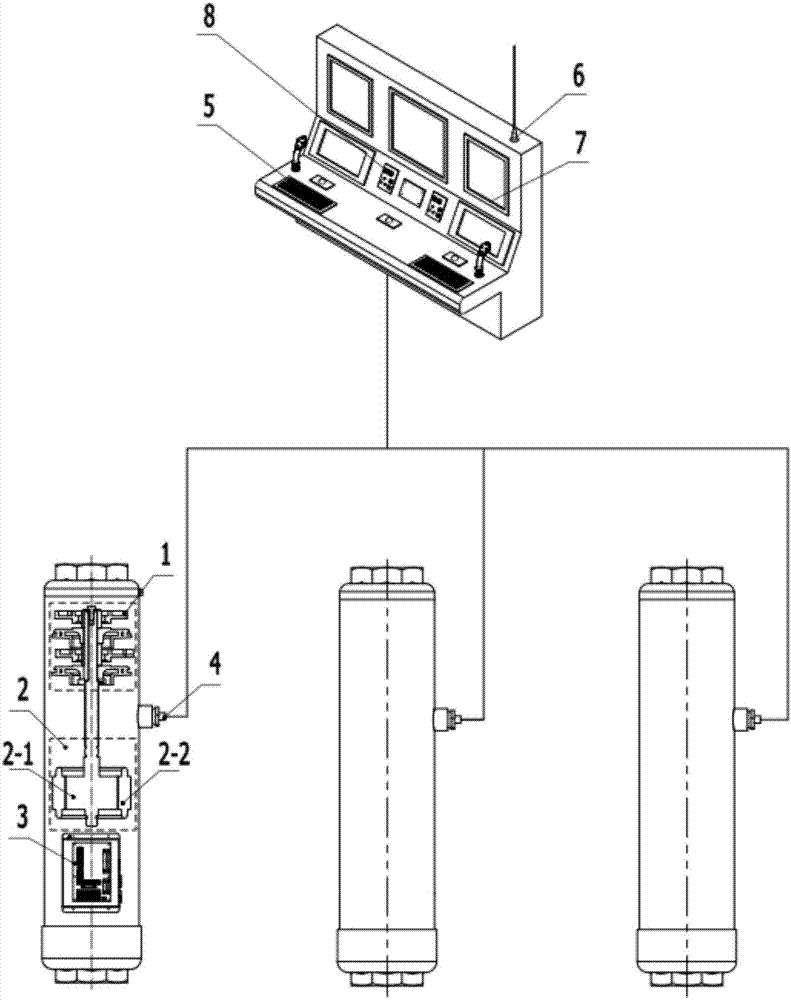

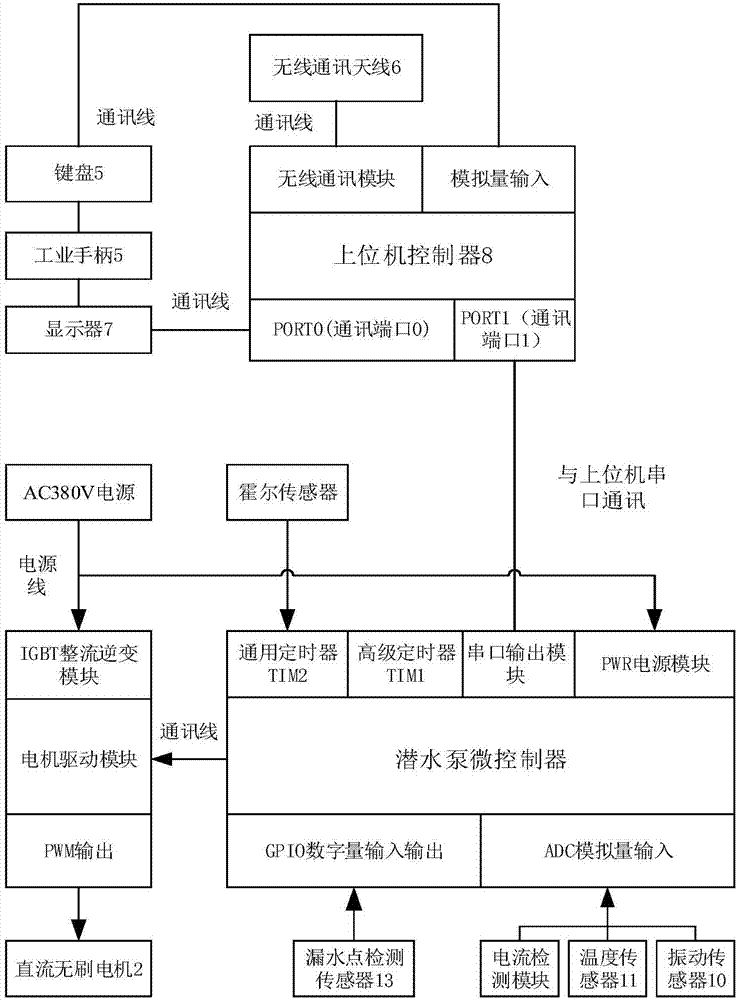

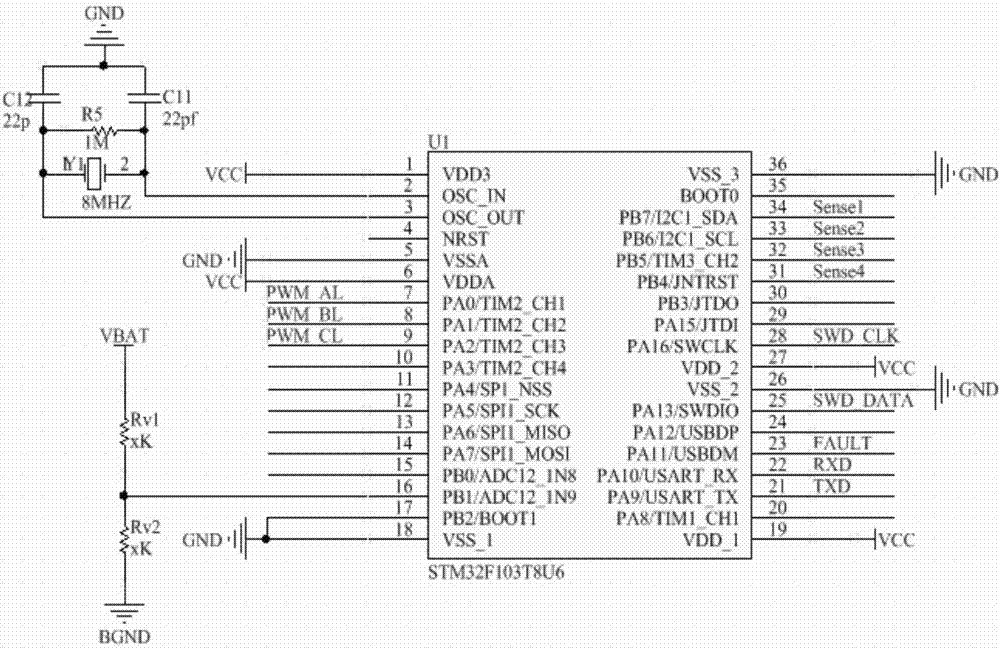

Intelligent integrated control system and intelligent integrated control method based on serial communication for submerged pump

InactiveCN107575401AWork reliablyReduce work injuriesMultiple motor speed/torque controlPump controlImpellerAutomatic control

The invention discloses an intelligent integrated control system and an intelligent integrated control method based on serial communication for a submerged pump, and belongs to the technical field ofintelligent control for submerged pumps. The control system comprises a shore-based upper computer system and underground submersible pump systems which are connected through serial communication wirecables. Each underground submersible pump system is composed of an impeller assembly, a motor and a printed circuit board, wherein the printed circuit board is integrated with an IGBT rectification-inversion module, a motor drive module, a sensor input module and a serial communication port. Each underground submersible pump system sends the internal vibration data, temperature and humidity dataand leakage-point detection sensor data to an upper computer controller in real time, and receives the instructions of the upper computer controller. The intelligent integrated control system is highin integration degree, convenient to install and automatic in control, thereby greatly lowering the labor intensity of personnel, and increasing the working efficiency. The intelligent integrated control method based on serial communication for the submerged pump is based on a multi-sensor fusion technology, and a PID control technology for the rotational speeds and the currents of the motors, thereby meeting the requirements of independent variable-frequency speed regulation and fault detection for the submerged pump.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

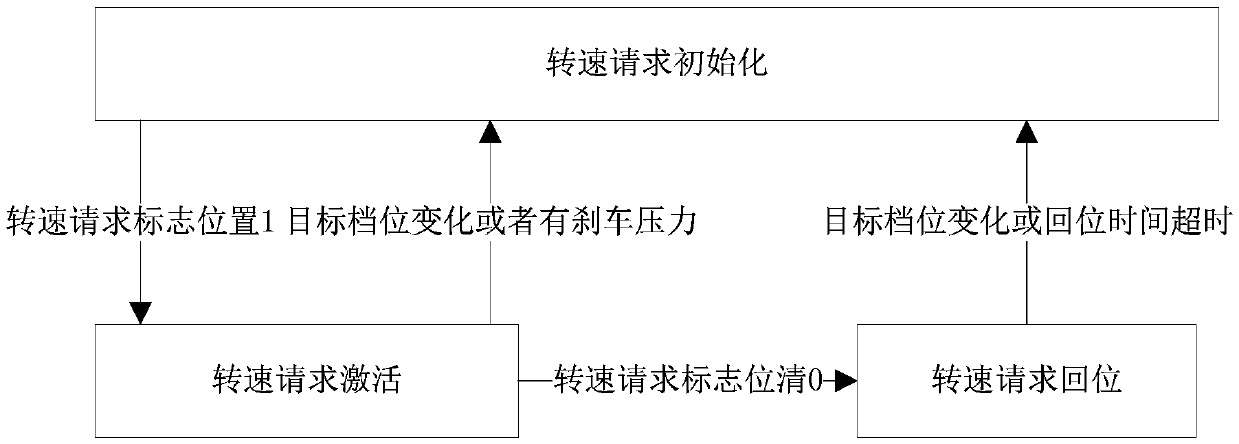

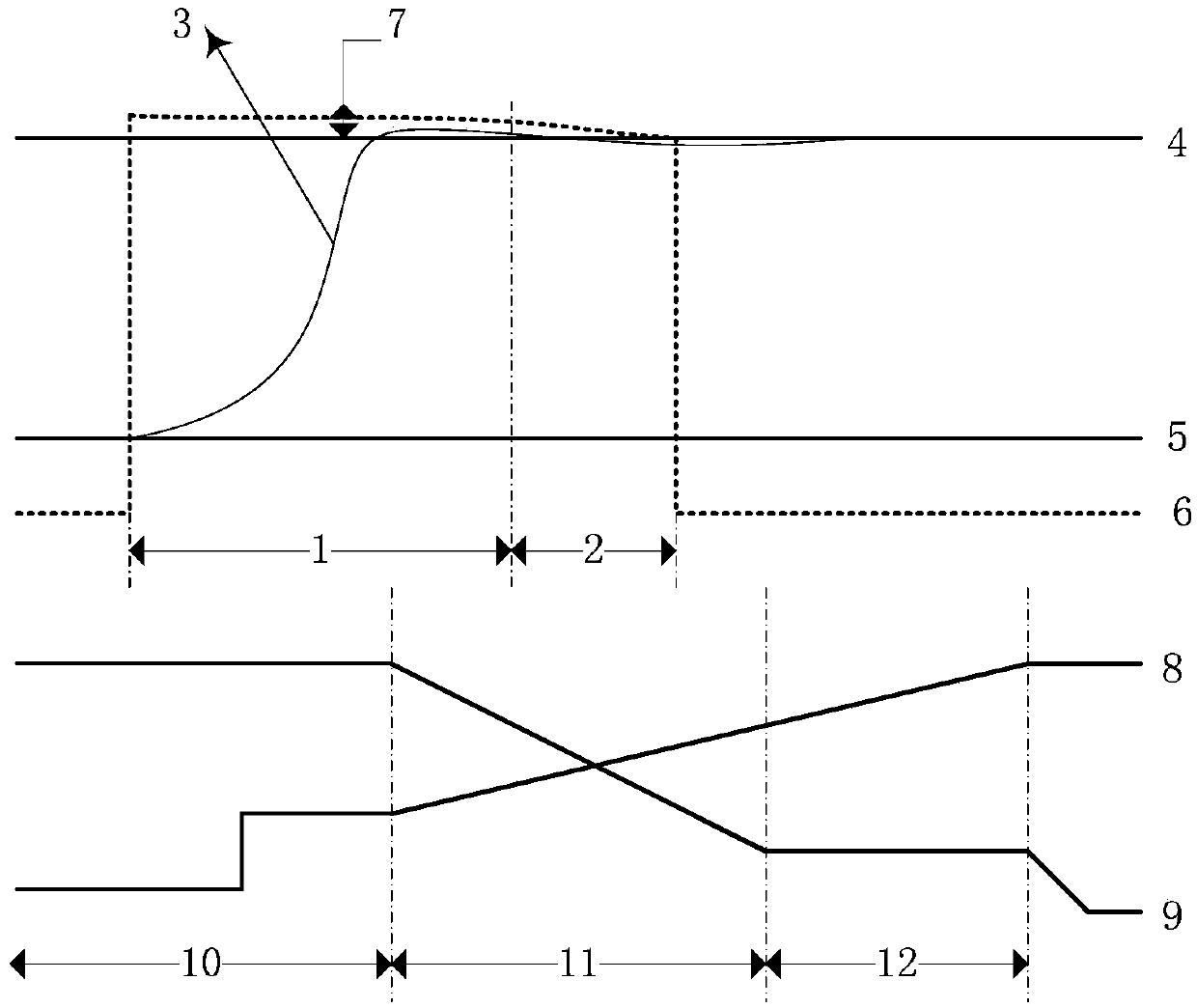

Achieving method for controlling gear selecting and shifting of double-clutch transmission through rotating speed request

The invention discloses an achieving method for controlling gear selecting and shifting of a double-clutch transmission through a rotating speed request. The method includes the steps that when a traveling working condition is changed, the speed of an engine is directly adjusted through the rotating speed request, and therefore rapid synchronizing between the rotating speed of the engine and the rotating speed of a shaft where a pre-combined gear is located is accurately controlled. A speed adjusting method specifically includes the steps of a rotating speed request initialization phase, a rotating speed request activating phase and a rotating speed returning section. By means of the achieving method, synchronous responses are faster while synchronizing between the rotating speed of the engine and the rotating speed of the pre-combined shaft can be accurately controlled.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

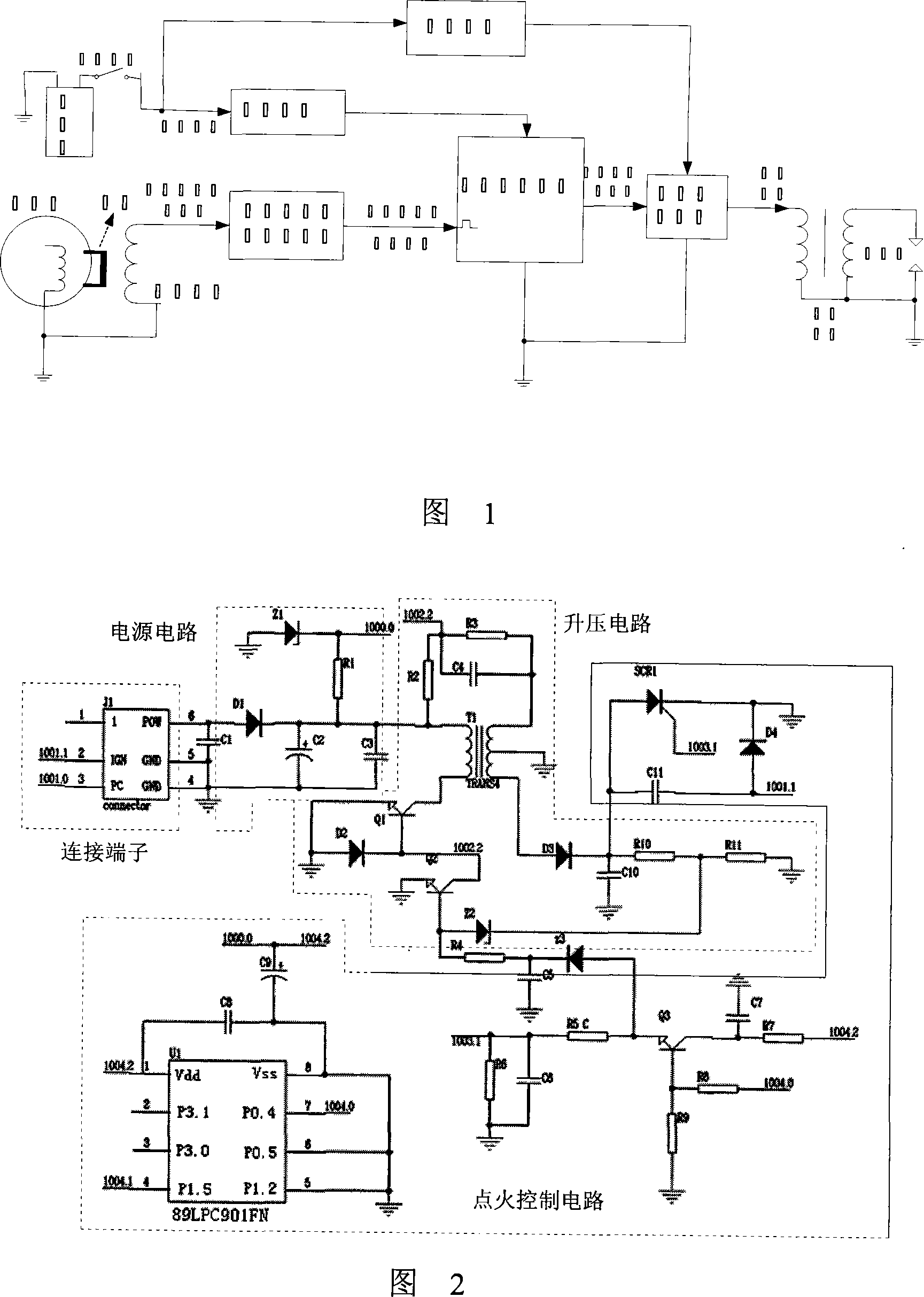

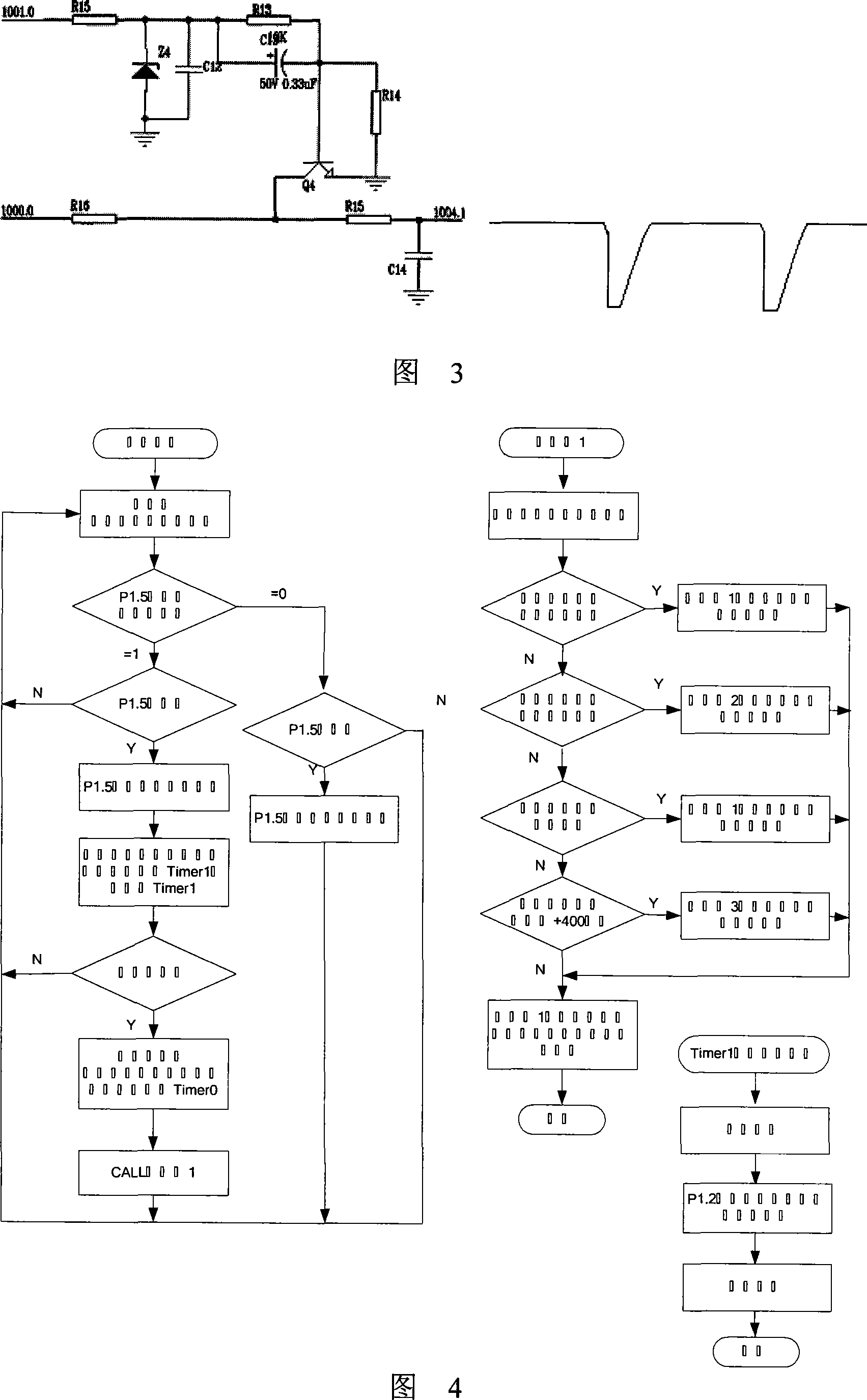

Motorcycle DC speed-governing igniter

InactiveCN101201037AEliminate input noiseTroubleshoot speed calculationsIgnition automatic controlInstallations with induction energy storagePower-on resetCam

A speed limiting igniter of a motorcycle introduces a microprocessor and an advanced control algorithm on the basis of the prior motorcycle igniter, which makes an engine work in an optimal condition. Centering on P89LPC901 microprocessor, a contactless digital igniter has the characteristics of simple circuit, single input and single output, power-on reset and no external clock circuit. Because of the direct current supply, the initial ignition speed of the invention is faster than that of an alternating igniter, which stabilifies the ignition voltage better. The principle is that a trigger signal generated by cutting a trigger loop with a magneto cam is transformed into an input signal. After being identified by the microprocessor, the input signal is transformed into the reference point signal of a speed and ignition signal. Compared with the predefined speed limit value, the optimal ignition moment can be obtained through fuzzy and intelligent control. The microprocessor controls an ignition circuit; consequently the ignition point can be controlled accurately. Compared with other igniters, the invention has the advantages of simple structure, low cost, accurate ignition point, high performance of the engine and accurate speed limit range.

Owner:JIANGNAN UNIV

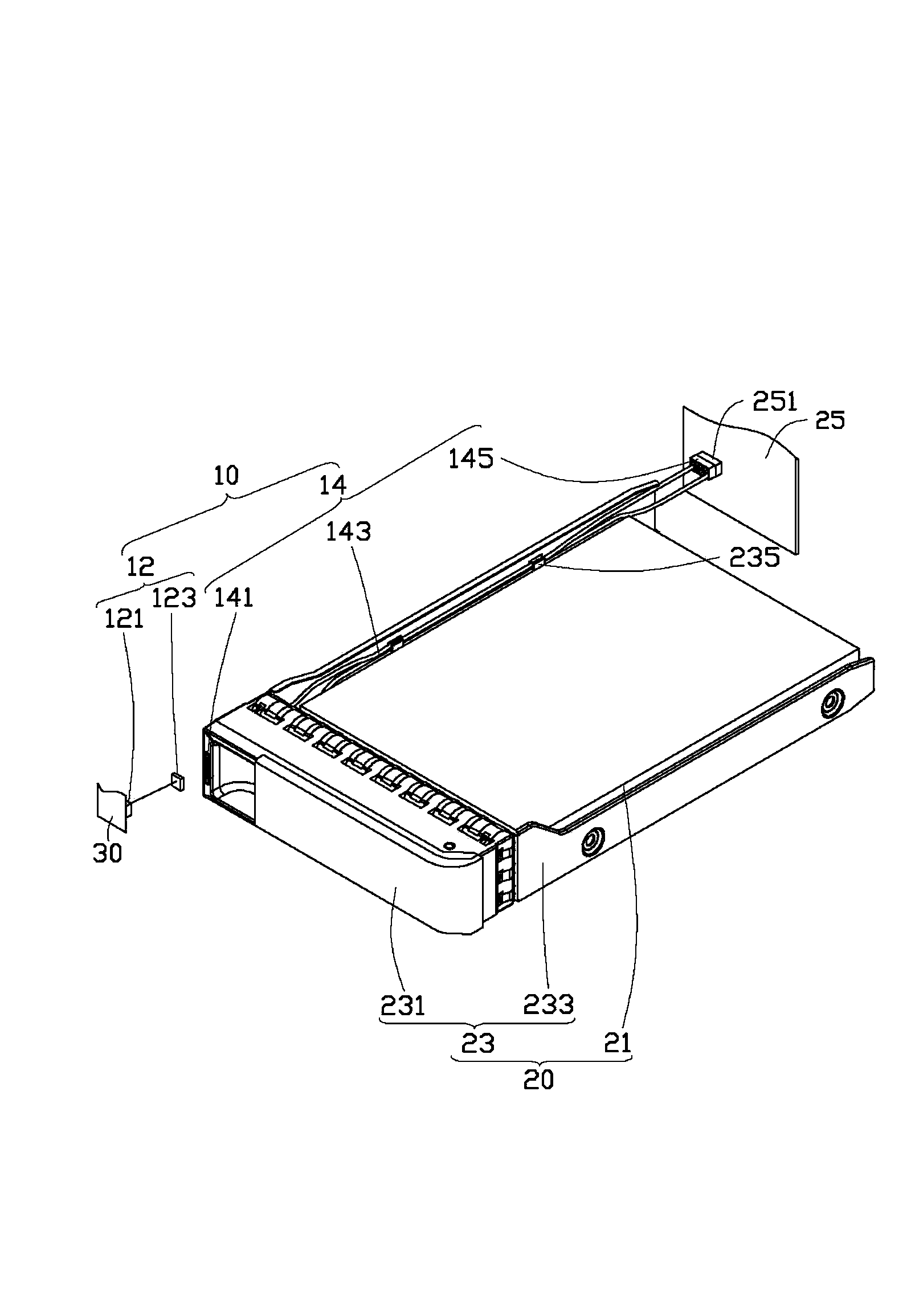

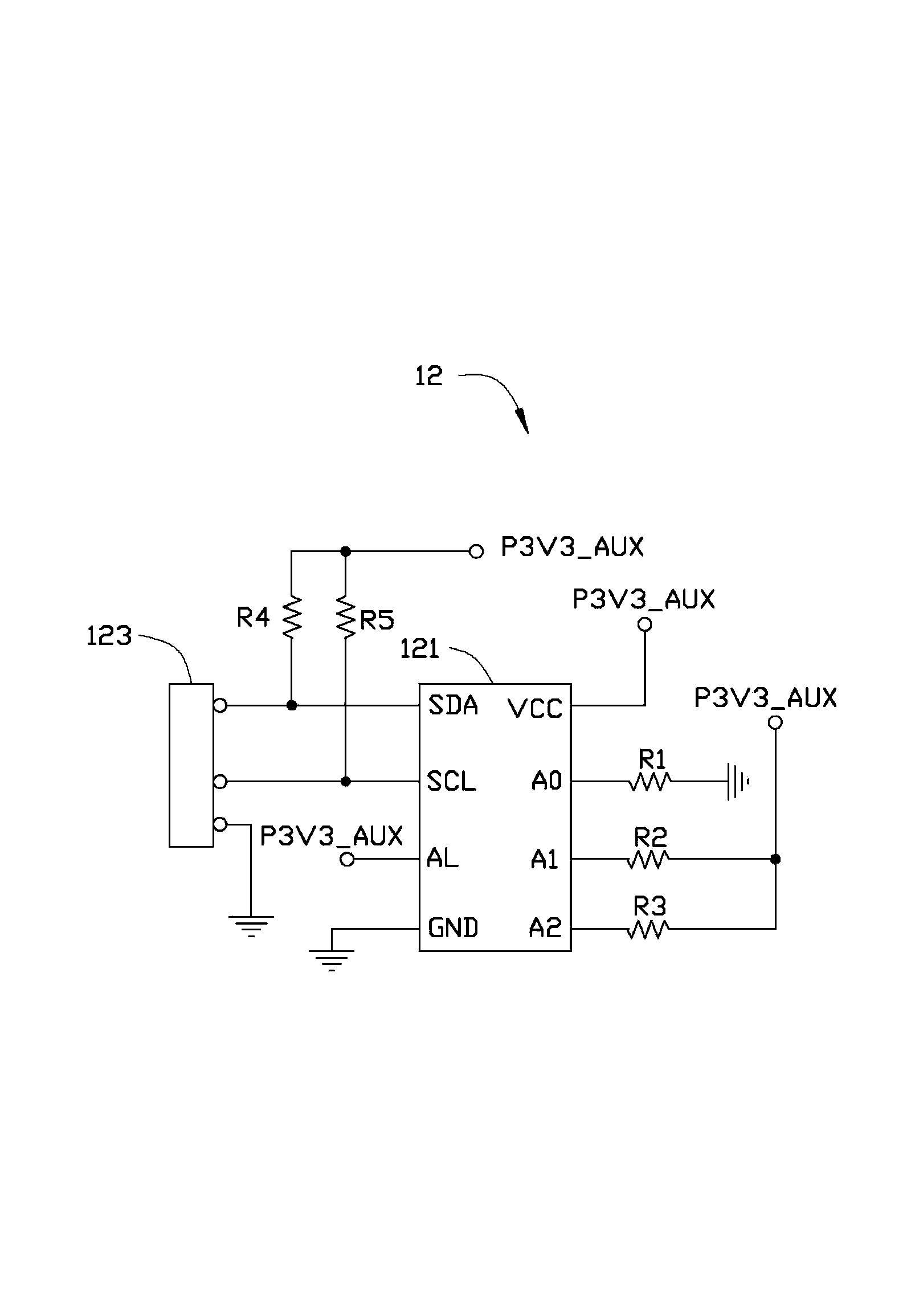

Temperature detecting system

InactiveCN103885870ASmall footprintAccurate speed controlThermometer detailsDigital data processing detailsControl systemTemperature difference

The invention provides a temperature detecting system used for detecting temperature of an air inlet of a heat radiating system. The temperature detecting system comprises a temperature detecting unit arranged to a cabinet shell, and a connecting unit arranged to a hard disk module, the hard disk module comprises a hard disk support and a hard disk mounted on the hard disk support, the temperature detecting unit is used for detecting the temperature of the air inlet of the heat radiating system in real time, and the connecting unit is arranged on the hard disk support and used for connecting the temperature detecting unit and a heat radiating control system. The temperature detecting system can detect the temperature of the air inlet of the heat radiating system in real time, so that the heat radiating system can accurately control rotating speed of a fan according to temperature difference of the air inlet and an air outlet, and space occupied by the temperature detecting system is saved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com