Testing table for fatigue strength of locomotive bogie

A locomotive bogie, fatigue strength technology, applied in the field of fatigue strength test bench, can solve problems such as inability to excite vibration, difficulty, stress amplitude rise, etc., and achieve the effect of wide vibration frequency range, easy maintenance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

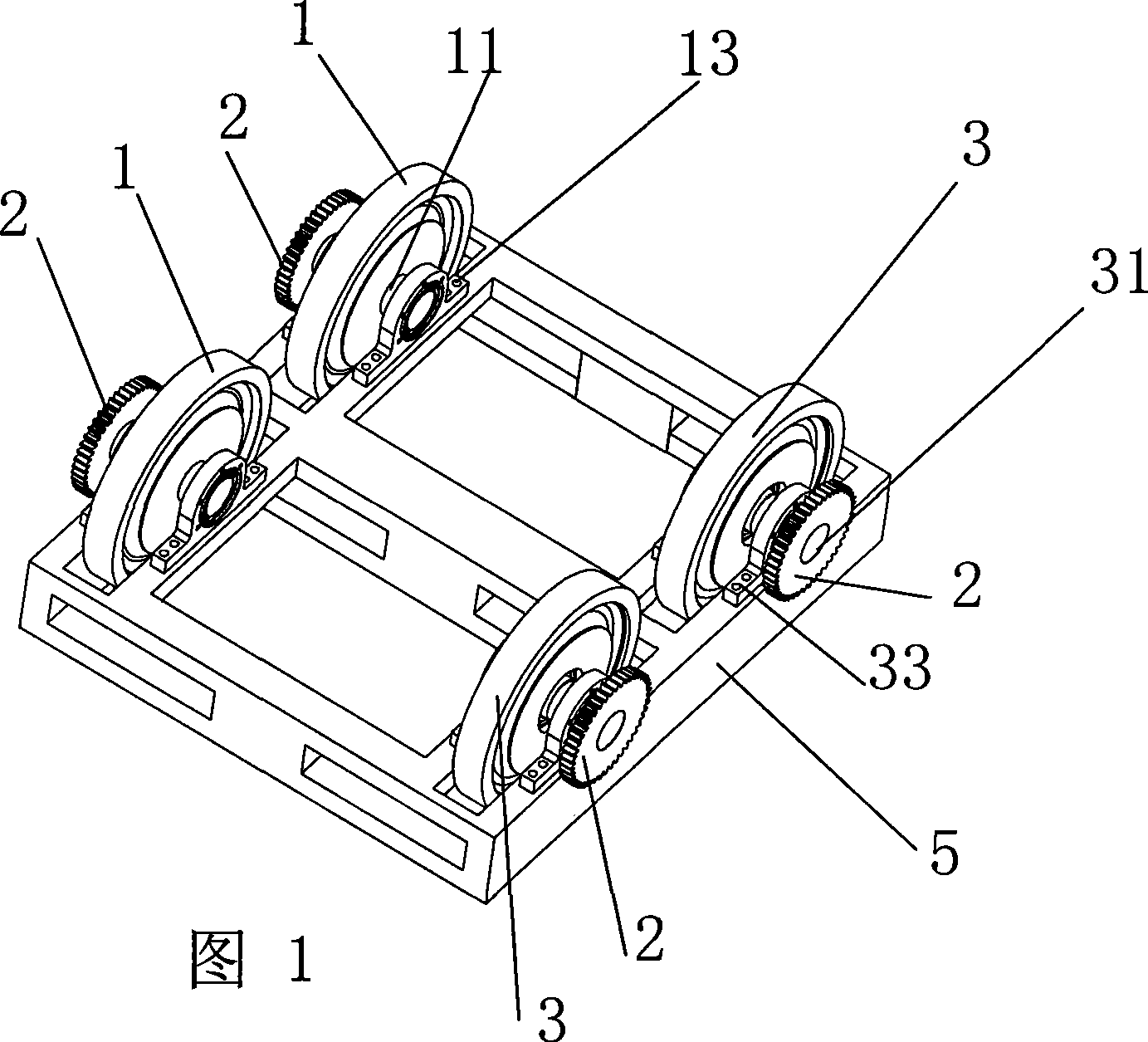

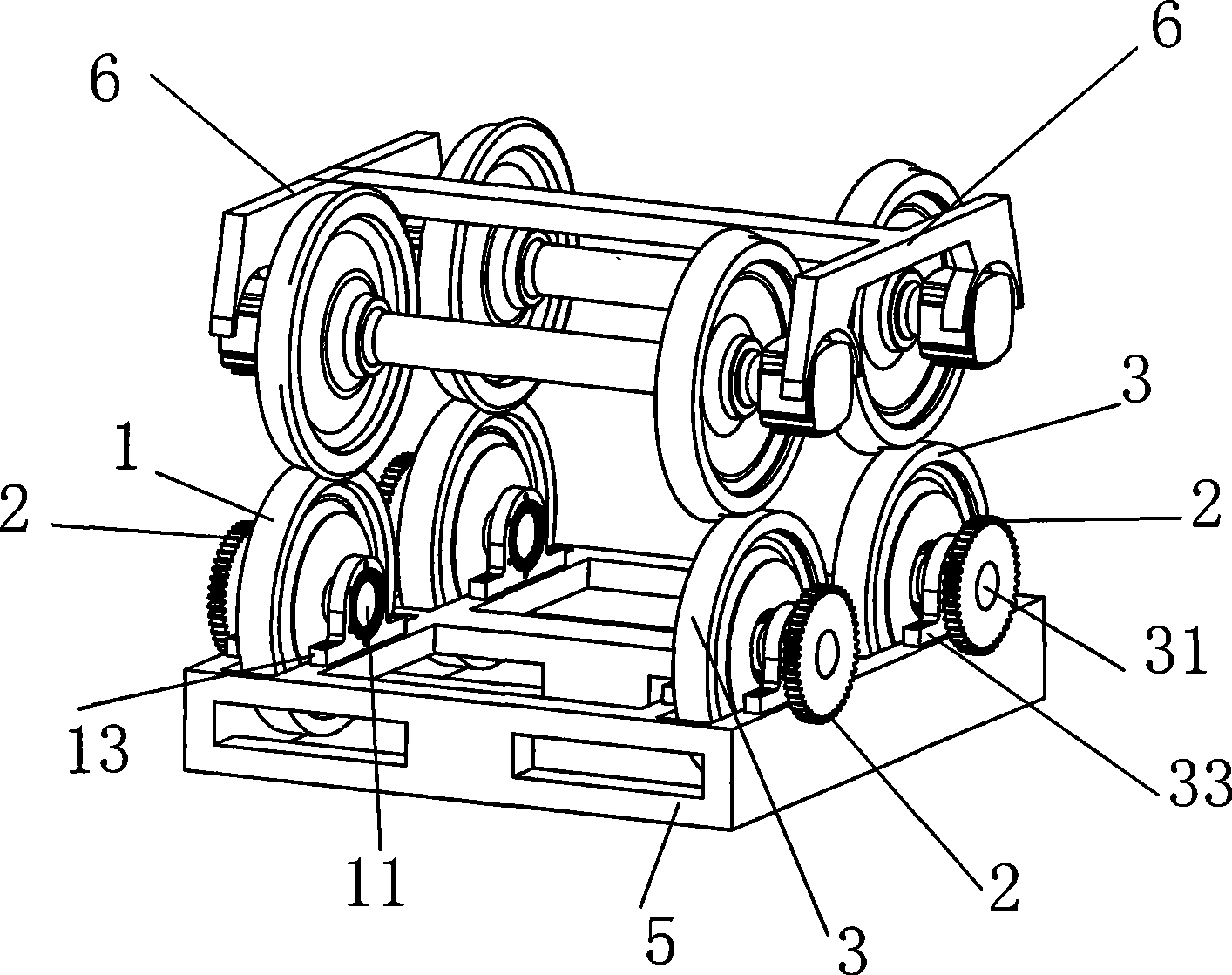

[0020] Fig. 1-4 shows, a kind of embodiment of the present invention is: a kind of locomotive bogie fatigue strength test bench, it is made up of: the active eccentric shaft 11 on the front and rear two active eccentric wheels 1 passes through bearing 12 and Its bearing seat 13 is fixed on one side of the platform 5; the eccentric shaft 31 of the front and rear two passive eccentric wheels 3 is fixed on the other side of the platform 5 through the bearing 32 and its bearing seat 33; The active eccentric shafts 11 are respectively connected with the driving device. Figure 4 It is also shown that the driving eccentric wheel 1 and the driving eccentric shaft 11 in this example are of an integrated structure.

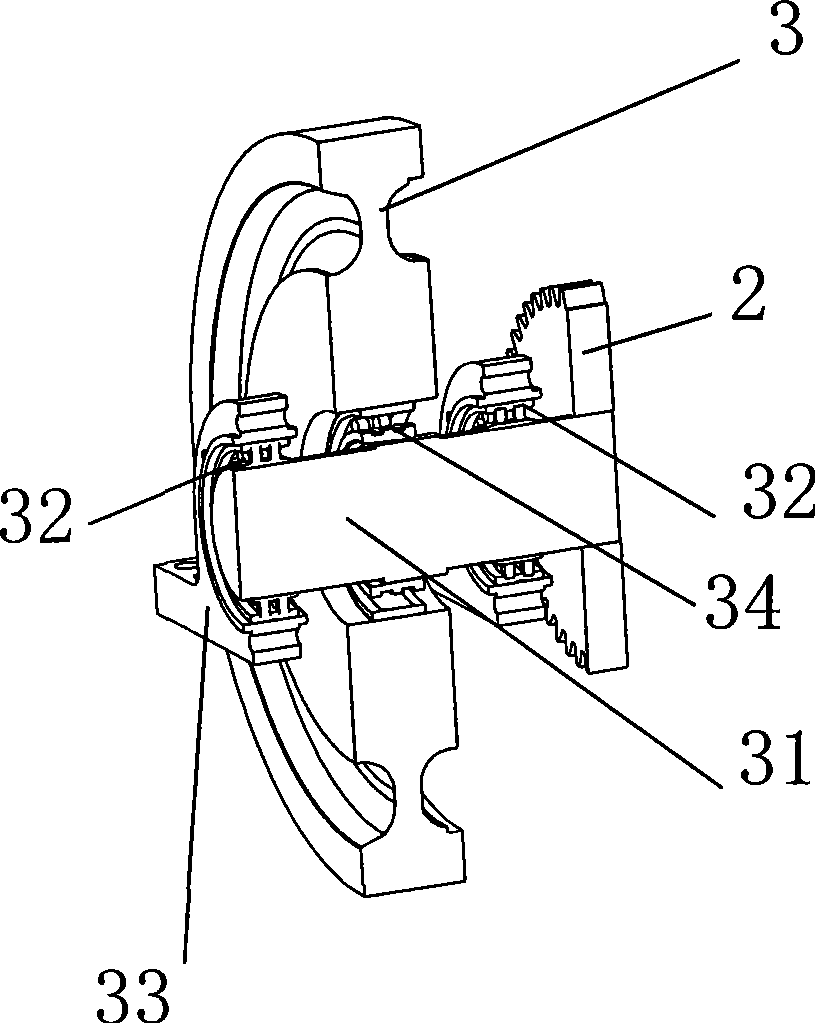

[0021] image 3 It is shown that the passive eccentric wheel 3 and the passive eccentric shaft 31 in this example are not integral structures, nor are they fixedly connected. Instead, the passive eccentric shaft 31 is tightly fitted on the inner ring of the differential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com